Page 1

TG1010

Programmable 10 MHz

DDS Function Generator

User Manual

Manual Copyright © 1994 T T Instruments Ltd. All rights reserved.

Software Copyright © 1994 T T Instruments Ltd. All rights reserved.

Book Part Number 48591 - 0440 Issue 4

Page 2

Table of Contents

Introduction 2

Specifications 4

Safety 9

EMC 10

Installation 11

Connections 12

Front Panel Connections 12

Rear Panel Connections 12

General Operation 14

Main Generator Operation 17

Main Generator Parameters 17

Warning and Error Messages 20

Auxiliary Output 22

Waveform Generation Options 22

Sweep Operation 25

Triggered Burst and Gate 28

Triggered Burst 28

Gated Mode 30

Amplitude Modulation 31

FSK 33

Special Waveforms 34

Staircase 34

Arbitrary 34

Noise 36

HOP 37

System Operations 39

Storing and Recalling Set-ups 39

System Settings 39

Synchronising Generators 41

Calibration 43

Application Examples 45

DDS Operation and Further Waveform Considerations 49

Remote Operation 52

Remote Commands 62

Remote Command Summary 69

Appendix 1. Warning and Error Messages 72

Appendix 2. Factory System Defaults 74

Appendix 3. Instructions for using TG1010 with WaveForm DSP 74

Appendix 4. Application Information Notes 76

Appendix 5. Calibration Password 78

1

Page 3

This Programmable Function Generator uses direct digital synthesis to provide high performance

and extensive facilities at a breakthrough price. It can generate a variety of waveforms between

0.1mHz and 10MHz with a resolution of 7 digits and an accuracy better than 10ppm.

Direct digital synthesis for accuracy & stability

Direct digital synthesis (DDS) is a technique for generating waveforms digitally using a phase

accumulator, a look-up table and a DAC. The accuracy and stability of the resulting waveforms is

related to that of the crystal master clock.

The DDS generator offers not only exceptional accuracy and stability but also high spectral purity,

low phase noise and excellent frequency agility.

Introduction

A wide range of waveforms

High quality sine, square and pulse waveforms can be generated over the full frequency range of

0.1mHz to 10MHz.

Triangle waveforms, ramp waveforms and multi-level squarewaves can also be generated but

with limitations as to the maximum useable frequencies.

Variable symmetry/duty-cycle is available for all standard waveforms.

Arbitrary waveform capability

Arbitrary waveforms can be loaded via the digital interfaces and then used in a similar way to the

standard waveforms.

Up to five arbitrary waveforms of 1024 10-bit words can be stored in non-volatile memory. The

waveform clock is 27.48MHz maximum.

This facility considerably expands the versatility of the instrument making it suitable for the

generation of highly complex waveform patterns.

In addition, numerous “complex” waveforms are pre-defined in ROM, including commonly used

waveshapes such as sinex/x, exponentially decaying sinewave, etc. Further waveshapes will be

added to the library in response to customer requests.

Sweep

All waveforms can be swept over their full frequency range at a rate variable between 10

milliseconds and 15 minutes. The sweep is fully phase continuous.

Sweep can be linear or logarithmic, single or continuous. Single sweeps can be triggered from

the front panel, the trigger input, or the digital interfaces. Two sweep markers are provided.

AM

Amplitude Modulation is available for all waveforms and is variable in 1% steps up to 100%. An

internal AM source is incorporated. Alternatively modulation can be controlled from an external

generator.

FSK

Frequency Shift Keying provides phase coherent switching between two selected frequencies at

a rate defined by the switching signal source.

The rate can be set from dc to 50kHz internally, or dc to 1MHz externally.

Trigger/Burst & Gated

All waveforms are available as a triggered burst whereby each positive edge of the Trigger signal

will produce one burst of the carrier, starting and stopping at the phase angle specified by the

start-stop phase setting.

2

Page 4

The number of cycles in the burst can be set between 0.5 and 1023. The Gated mode turns the

output signal On when the gating signal is high and Off when it is low.

Both Triggered and Gated modes can be operated from the internal Trigger Generator (0.005Hz

to 50kHz) or from an external source (dc to 1MHz).

Waveform Hop & Noise

The generator can be set up to ‘hop’ between a number of different waveform set-ups either at a

pre-determined rate or in response to a manual trigger.

Up to 16 different hop waveforms can be defined in terms of frequency, amplitude, function, offset

and duration, which is variable in 1ms steps up to 60s. The generator can also be set to simulate

random noise within the bandwidth .03Hz to 700kHz with adjustable amplitude and offset.

Multiple phase-locked generators

The signals from the Clock In/Out socket and the Sync Out socket can be used to phase lock two

or more generators.

This can be used to generate multi-phase waveforms or locked waveforms of different

frequencies.

Easy and convenient to use

All of the main generator parameters are clearly displayed together on a backlit LCD with 4 rows

of 20 characters. Sub menus are used for the modulation modes and other complex functions.

All parameters can be entered directly from the numeric keypad. Alternatively most parameters

can be incremented or decremented using the rotary encoder.

This system combines quick and easy numeric data entry with quasi-analogue adjustment when

required.

Fully programmable

Addressable RS-232 standard, GPIB optional

The generator has an RS-232 interface as standard which can be used for remote control of all of

the instrument functions or for the down-loading of arbitrary waveforms.

As well as operating as a conventional RS-232 interface, it can also be used in addressable

mode whereby up to 32 instruments can be linked to one PC serial port as part of a TTi “ARC”

system.

Alternatively, a GPIB interface conforming to IEEE-488.2 is available as an option.

3

Page 5

Specifications

Specifications apply at 18°-28°C after one hour warm-up, at maximum output into 50Ω

FREQUENCY

Range:

Resolution:

Accuracy: Typically ± 10 ppm for 1 year, 18°C to 28°C

Temperature Stability: Typically <1 ppm/°C

SYMMETRY

Range: Sine, Triangle, Ramp - 1% to 99% at all frequencies

Resolution:

0.1 mHz to 10 MHz.

All waveforms are available up to 10 MHz. However, the purity of

triangle, ramp and multi-level squarewave waveforms is not

specified above the frequencies indicated in the appropriate

WAVEFORM section. In Arbitrary mode all waveform points are

continuously output up to approximately 27 kHz beyond which

they are sampled.

0.1mHz (7 digits)

Squarewave,Pulse -

0.1%

1% to 99% to 30kHz, 20% to 80% to 10MHz.

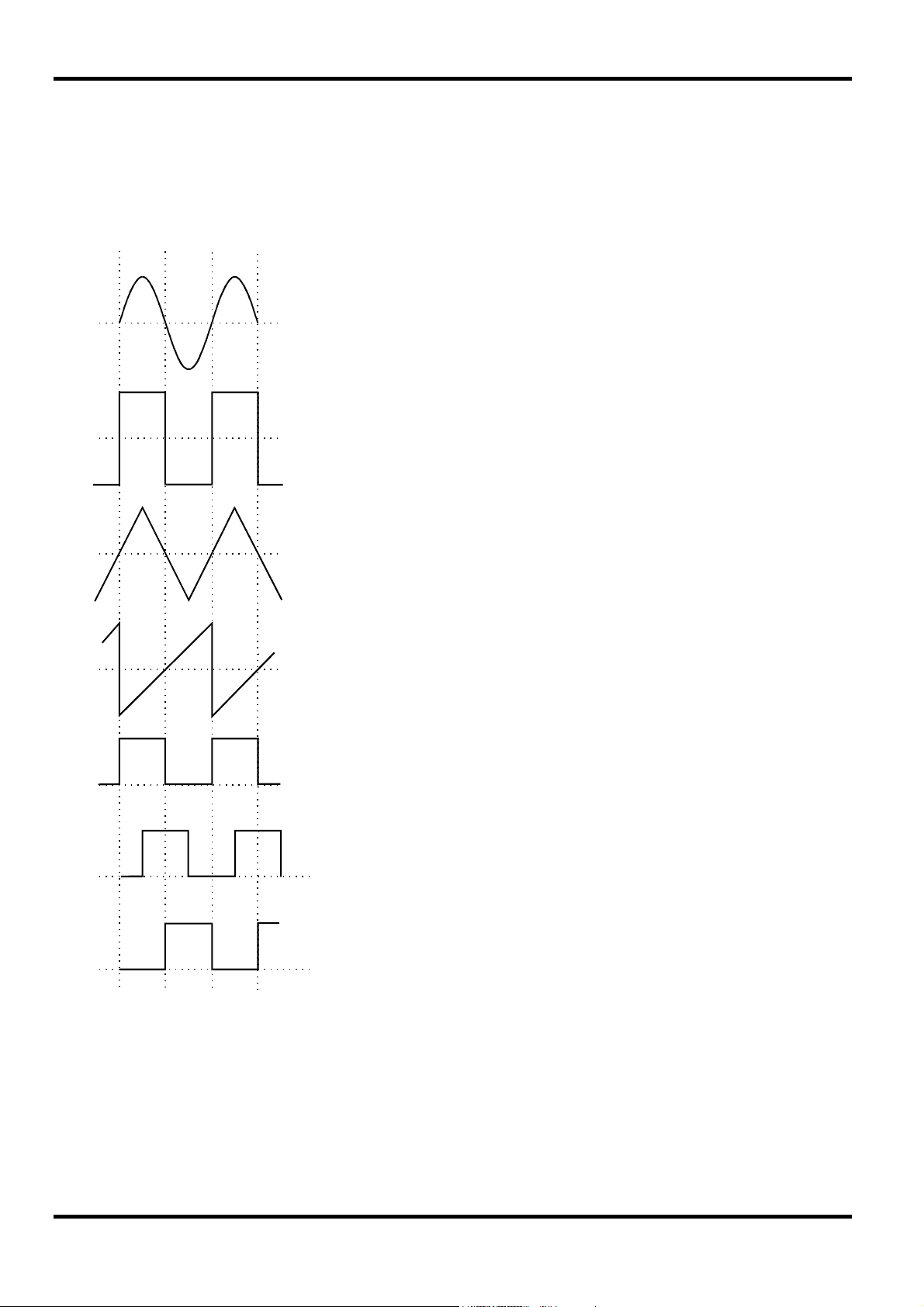

WAVEFORMS

Sine, square, positive pulse, negative pulse, multi-level squarewave, triangle, ramp up, ramp

down, DC, ARB and Noise.

Sinewave

Output level: 5mV to 20V p-p open circuit o/p.

Harmonic Distortion: <0.3% THD to 500kHz;

<-60dBc to 20kHz; <-50dBc to 1MHz; <-35dBc to 10MHz.

Non-harmonic Spurii: <-55dBc to 7MHz; <-50dBc to 10MHz.

Squarewave

Output level: 5mV to 20V p-p open circuit o/p.

Rise and Fall Times: <25ns

Triangle

Output level: 5mV to 20V p-p open circuit o/p.

Linearity error:

Positive and Negative Ramp

Output level: 5mV to 20V p-p open circuit o/p.

Linearity error:

Positive and Negative Pulse

Output level:

Rise and Fall Times: <25ns

Multi-Level Squarewave

<0.5% to 30 kHz

<0.5% to 30 kHz

2.5mV to 10V p-p open circuit o/p.

Up to 16 steps available per cycle, each step selectable for amplitude (10 bit resolution) and

duration (1 to 1024 samples). Allows generation of 3 level squarewave, staircase, multiplexed

LCD driver signals etc.

Frequency Range: All waveform points can be continuously output up to

approximately 27kHz, above which sampling will introduce a 1

clock edge uncertainty (1 clock = 36ns).

Output level: 5mV to 20V p-p open circuit o/p.

Rise and Fall Times: <25ns

4

Page 6

Arbitrary

A number of frequently required waveforms are pre-programmed in ROM. Alternatively,

waveforms can be downloaded via the generator’s RS232 or GPIB interfaces and stored in nonvolatile RAM.

Frequency range: All waveform points can be continuously output up to

approximately 27 kHz, above which they are sampled.

Output level: 5mV to 20V p-p open circuit o/p.

Number of samples: 1024

Sample levels: 1024 (10 bits)

HOP

Up to 16 different waveforms can be output in sequence at a rate determined by either the

internal timer, an external trigger a remote command, or from the keyboard. Each waveform can

be set to any waveshape (except noise), frequency, amplitude and offset. Frequency only

changes are phase-continuous.

Noise

White noise output with a typical -3dB bandwidth of 0.03Hz to 700kHz. Amplitude and offset

adjustable. Noise can only be used with Gated and AM modulation modes.

MODULATION MODES

Trigger/Burst

Phase coherent signal keying - each positive edge of the trigger signal will produce one burst of

the carrier, starting and stopping at the phase angle specified by the Start/Stop phase setting.

Carrier frequency:

0.1mHz to at least 1MHz

Carrier waveforms: All.

Number of cycles:

1 to 1023 (resolution 1 cycle) or 0.5 to 511.5 (resolution 0.5

cycle).

Trigger rep. rate: dc to 50 kHz internal, dc to 1MHz external.

Source: Internal from keyboard or trigger generator. External from EXT

TRIG input or remote interface.

Gated

Non-phase coherent signal keying - output carrier wave is on while Gate signal is high and off

while low.

Carrier frequency:

Carrier waveforms: All

Trigger rep. rate: dc to 50 kHz internal, dc to 1 MHz external.

Gate signal source: Internal from keyboard or trigger generator. External from EXT

From 0.1 mHz to 10 MHz.

TRIG input or remote interface.

Sweep

Carrier Waveforms: All

Sweep Mode: Linear or logarithmic, single or continuous.

Sweep Width:

From 0.1 mHz to 10 MHz in one range. Phase continuous.

Independent setting of the start and stop frequency.

Sweep Time: 10ms to 999s (3 digit resolution).

Markers: Two, variable during sweep. Available at the rear panel

TRIG/SWEEP OUT socket.

Sweep Trigger source: The sweep may be free run or triggered from any of the following

sources: Internal from keyboard. External from EXT TRIG input

or remote interface.

Amplitude Modulation

Carrier frequency:

5

From 0.1mHz to 10 MHz.

Page 7

Carrier waveforms: All.

Depth: Variable 0 to 100% typical, resolution 1%.

Internal source:

External: See VCA In

Frequency Shift Keying (FSK)

Phase coherent switching between two selected frequencies at a rate defined by the switching

signal source.

Carrier frequency:

Carrier waveforms: All.

Switch repetition rate: dc to 50 kHz internal, dc to 1 MHz external.

Switching signal source: Internal from keyboard or trigger generator. External from EXT

Start/Stop Phase

Carrier frequency:

Carrier waveforms: All.

Range: -360 to +360 degrees.

Resolution: 1 degree.

Accuracy: Typically 1 degree to 30 kHz.

1 kHz fixed sinewave or 0.005 Hz to 50 kHz squarewave.

From 0.1mHz to 10 MHz.

TRIG input or remote interface.

0.1 mHz to at least 1MHz.

Trigger Generator

Internal source 0.005 Hz to 50 kHz squarewave adjustable in 20µs steps. 3 digit resolution.

Available for external use from TRIG/SWEEP OUT socket.

OUTPUTS

Main Output

Output Impedance:

Amplitude:

Amplitude Accuracy:

Amplitude Flatness:

DC Offset Range:

DC Offset Accuracy: typically ±3% ±10mV, unattenuated.

Resolution: 3 digits for both Amplitude and DC Offset.

Pulse Aberrations: <5% + 2mV.

Aux Out

CMOS/TTL levels with symmetry and frequency of main output and phase of Start-Stop Phase

setting.

Trig/Sweep Out

50Ω or 600Ω

5mV to 20V pk-pk open circuit, (2.5mV to 10V pk-pk into

50Ω/600Ω). Output can be specified as EMF (open circuit value)

or P.D (potential difference) in pk-pk, r.m.s. or dBm.

typically ±3% ±1mV at 1kHz into 50Ω/600Ω.

±0.2dB to 200 kHz; ±1dB to 5 MHz; ±2.5dB to 10 MHz.

±10V. DC offset plus signal peak limited to ±10V from 50Ω/600Ω.

Multifunction output depending upon mode. Except in Sweep and HOP modes the output is that

of the Trigger Generator at CMOS/TTL levels from 1kΩ. In Sweep mode the output is a 3-level

waveform, changing from high (4V) to low (0V) at start of sweep, with narrow 1V pulses at each

marker point. In HOP mode the output goes low at the entry to each step, followed by a rising

edge after the frequency and waveshape have changed for the new step.

INPUTS

Ext Trig

Frequency Range: DC - 1 MHz.

Signal Range: Threshold nominally TTL level; maximum input ±10V.

6

Page 8

Minimum Pulse Width: 50ns, for Trigger, Gate and FSK modes; 1ms for Sweep and

HOP modes.

Input Impedance:

10kΩ

VCA In

Frequency Range: DC - 100 kHz.

Signal Range:

Input Impedance:

2.5V for 100% level change at maximum output.

typically 6kΩ.

PHASE LOCKING

The signals from these sockets are used to phase lock two or more generators.

Clock In/Out

TTL/CMOS threshold level as an input. Output logic levels nominally 1V and 4V from typically

50Ω as an output.

Sync Out

TTL/CMOS logic levels from typically 50Ω.

INTERFACES

Full remote control facilities are available through the RS232 (standard) or optional GPIB

interfaces.

RS232: Variable Baud rate, 9600 Baud maximum. 9-pin D-connector.

Fully compatible with Thurlby-Thandar ARC (Addressable

RS232 Chain) system.

IEEE-488: Conforming with IEEE488.1 and IEEE488.2

GENERAL

Display: 20 character x 4 row alphanumeric LCD.

Data Entry: Keyboard selection of mode, waveform etc.; value entry direct by

numeric keys or by rotary control.

Stored Settings: Up to 9 complete instrument set-ups may be stored and recalled

from battery-backed memory.

Size: 3U (130mm) height; half-rack (212mm) width; 330mm long.

Weight:

Power: 100V AC, 110-120V AC or 220V-240V AC ±10%, 50/60Hz,

4.1kg. (9lb.)

adjustable internally; 30VA max. Installation Category II.

Operating Range: +5°C to 40°C, 20-80% RH.

Storage Range: -20°C to + 60°C.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Options: IEEE-488 interface; 19 inch rack mounting kit.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

7

Page 9

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

TG1010 DDS Function Generator with GPIB Option

meets the intent of the EMC Directive 89/336/EEC and the Low Voltage Directive 73/23/EEC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326 (1998) Radiated, Class B

b) EN61326 (1998) Conducted, Class B

c) EN61326 (1998) Harmonics, referring to EN61000-3-2 (2000)

Immunity: EN61326 (1998) Immunity Table 1, Performance B, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (1997) Electromagnetic Field

c) EN61000-4-11 (1994) Voltage Interrupt

d) EN61000-4-4 (1995) Fast Transient

e) EN61000-4-5 (1995) Surge

f) EN61000-4-6 (1996) Conducted RF

Safety

EN61010-1 (1993) Installation Category II, Pollution Degree 2.

8

................................................................

CHRIS WILDING

TECHNICAL DIRECTOR

2 July 2001

Page 10

Safety

This function generator is a Safety Class I instrument according to IEC classification and has

been designed to meet the requirements of EN61010-1 (Safety Requirements for Electrical

Equipment for Measurement, Control and Laboratory Use). It is an Installation Category II

instrument intended for operation from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

This instrument uses a Lithium button cell for non-volatile memory battery back-up; typical life is 5

years. In the event of replacement becoming necessary, replace only with a cell of the correct

type, i.e. 3V Li/Mn0

in accordance with local regulations; do not cut open, incinerate, expose to temperatures above

60°C or attempt to recharge.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

LCD window. The following symbols are used on the instrument and in this manual:-

Caution -refer to the accompanying documentation, incorrect operation may

damage the instrument.

20mm button cell type 2032. Exhausted cells must be disposed of carefully

2

terminal connected to chassis ground.

mains supply OFF.

l

9

mains supply ON.

alternating current.

Page 11

This instrument has been designed to meet the requirements of the EMC Directive 89/336/EEC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2000) Class A; the instrument is Class A by product category.

Immunity

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved were:

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A.

b) EN61000-4-3 (1997) Electromagnetic Field, 3V/m, 80% AM at 1kHz, Performance A.

c) EN61000-4-11 (1994) Voltage Interrupt, 1 cycle, 100%, Performance B*.

d) EN61000-4-4 (1995) Fast Transient, 1kV peak (AC line), 0.5kV peak (signal lines and

e) EN61000-4-5 (1995) Surge, 0.5kV (line to line), 1kV (line to ground), Performance A.

f) EN61000-4-6 (1996) Conducted RF, 3V, 80% AM at 1kHz (AC line only; signal

EMC

RS232/GPIB ports), Performance A.

connections <3m not tested), Performance A.

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

*Note: To achieve Performance B it is necessary to set the instrument such that 'power down'

settings are restored at power up; set POWER UP = POWER DOWN on the SYStem settings

menu.

Cautions

To ensure continued compliance with the EMC directive the following precautions should be

observed:

a) connect the generator to other equipment using only high quality, double-screened cables.

b) after opening the case for any reason ensure that all signal and ground connections are

c) In the event of part replacement becoming necessary, only use components of an identical

remade correctly before replacing the cover. Always ensure all case screws are correctly

refitted and tightened.

type, see the Service Manual.

10

Page 12

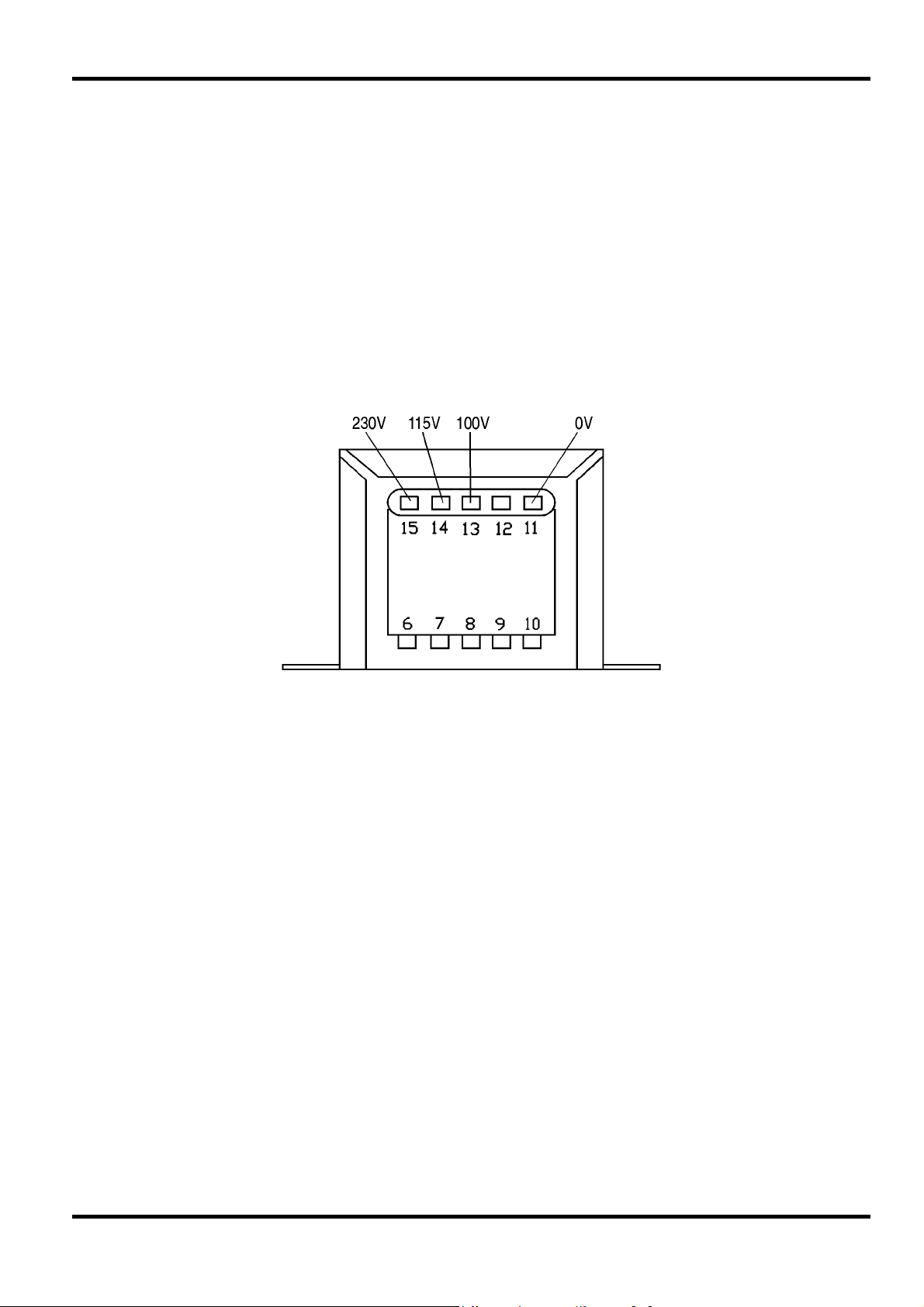

Check that the instrument operating voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Remove the screws which retain the top cover and lift off the cover.

3) Change the transformer connections as follows:

for 230V operation connect the live (brown) wire to pin 15

for 115V operation connect the live (brown) wire to pin 14

for 100V operation connect the live (brown) wire to pin 13

4) Refit the cover and the secure with the same screws.

5) To comply with safety standard requirements the operating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

6) Change the fuse to one of the correct rating, see below.

Installation

Fuse

Ensure that the correct mains fuse is fitted for the set operating voltage. The correct mains fuse

types are:

To replace the fuse, disconnect the mains lead from the inlet socket and release the fuse drawer

below the socket pins by depressing both clips together, with miniature screwdrivers, so that the

drawer can be eased open. Change the fuse and replace the drawer.

The use of makeshift fuses or the short-circuiting of the fuse holder is prohibited.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:-

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with feet for

bench mounting. The front feet include a tilt mechanism for optimal panel angle.

A rack kit for mounting one or two of these Half-width 3U high units in a 19” rack is available from

the Manufacturers or their overseas agents.

for 230V operation: 250 mA (T) 250 V HRC

for 100V or 115V operation: 500 mA (T) 250 V HRC

Brown - Mains Live

Blue - Mains Neutral

Green / Yellow - Mains Earth

WARNING! THIS INSTRUMENT MUST BE EARTHED

11

Page 13

Front Panel Connections

MAIN OUT

This is the 50Ω output from the main generator. It will provide up to 20V peak-to-peak e.m.f.

which will yield 10V peak-to-peak into a matched 50Ω load. It can tolerate a short circuit for 60

seconds.

Do not apply external voltages to this output.

AUX OUT

This is a TTL/CMOS level output synchronous with MAIN OUT. Symmetry is the same as that set

for the main output but the phase relationship between MAIN OUT and AUX OUT is determined

by the PHASE setting specified on the TRIGger menu.

AUX OUT logic levels are nominally 0V and 5V from typically 50Ω. AUX OUT will withstand a

short-circuit.

Do not apply external voltages to this output.

Connections

EXT TRIG

This is the external trigger input for Trigger, Gate, Sweep, FSK and HOP operating modes. It is

also the input used to synchronise the generator (as a slave) to another (which is the master).

Do not apply external voltages exceeding ±10 V.

Rear Panel Connections

CLOCK IN/OUT

The function of the CLOCK IN/OUT socket is set from the SYStem menu as follows:

INPUT The socket becomes an input for an external clock.

OUTPUT This is the default setting. The internal clock is made available at the

socket. When two or more generators are synchronised the ‘master’ is

set to OUTPUT and the signal is used to drive the CLOCK IN inputs of

the slaves.

PHASE LOCK When two or more generators are synchronised the slaves are set to

PHASE LOCK.

As an output the logic levels are nominally 1V and 4V from typically 50Ω. CLOCK OUT will

withstand a short-circuit. As an input the thresholds is TTL/CMOS compatible.

Do not apply external voltages to this output exceeding +7.5 V or -2.5 V.

VCA IN

This is the input socket for external voltage controlled amplitude (VCA). Input impedance is

nominally 6kΩ. Apply 2.5V for 100% level change at maximum output.

Do not apply external voltages exceeding ±10V.

12

Page 14

SYNC OUT

When two or more generators are synchronised the SYNC OUT socket on the master generator

is connected to the EXT TRIG inputs of slave generators.

SYNC OUT logic levels are nominally 0V and 5V from typically 50Ω. SYNC OUT will withstand a

short-circuit.

Do not apply external voltages to this output.

TRIG/SWEEP OUT

The function of this output is automatically determined by the generator operating mode.

Except in sweep and HOP modes the output is that of the internal trigger generator, a fixed

amplitude square-wave whose frequency is set on the TRIG or GATE menus. The rising edge of

the trigger generator initiates trigger, burst, gate, etc.

In sweep mode the output is a 3-level waveform, changing from high (4V) to low (0V) at start of

sweep, with narrow 1V pulses at each marker point.

In HOP mode the output goes low on entry to each waveform step and high after the new

frequency and waveshape of that step have been set.

Output levels are nominally 0V and 4V from 1kΩ. TRIG/SWEEP OUT will withstand a shortcircuit.

Do not apply external voltages to this output.

RS232

9-pin D-connector compatible with the Thurlby Thandar ARC (Addressable RS232 Chain)

system. The pin connections are shows below:

Pin 2, 3 and 5 may be used as a conventional RS232 interface with XON/XOFF handshaking.

Pins 7,8 and 9 are additionally used when the instrument is connected to the ARC interface.

Signal grounds are connected to instrument ground. The ARC address is set from the front panel

using the I/F menu.

GPIB (IEEE-488)

Pin Name Description

1 - No internal Connection

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 - No internal connection

5 GND Signal ground

6 - No internal connection

7 RXD2 Secondary received data

8 TXD2 Secondary transmitted data

9 GND Signal ground

The GPIB interface is an option. It is not isolated; the GPIB signal grounds are connected to the

instrument ground.

The implemented subsets are:

SH1 AH1 T6 TE0 L4 LE0 SR1 RL1 PP1 DC1 DT1 C0 E2

The GPIB address is set from the front panel using the I/F menu.

13

Page 15

This section is a general introduction to the features and organisation of the function generator

intended to be read before using the instrument for the first time. Detailed operation is covered in

later sections starting with Main Generator Operation.

DDS Principles

In this instrument waveforms are generated by Direct Digital Synthesis (DDS). One complete

cycle of the waveform is stored in RAM as 1024 10-bit amplitude values. As the RAM address is

incremented, the waveform values are output to a Digital-to-Analogue Converter (DAC) which

reconstructs the waveform. Sinewaves and triangles are subsequently filtered to smooth the

steps in the DAC output. The frequency of the waveform is determined by the rate at which the

RAM addresses are changed. Further details of how this rate is varied, i.e. how the frequency is

changed, are given later in the DDS Operation section; it is sufficient to know that at low

frequencies the addresses are output sequentially but at higher frequencies the addresses are

sampled. The major advantages of DDS over conventional analogue generation are:

General Operation

Frequency accuracy and stability is that of the crystal oscillator.

•

• Frequencies can be set with high resolution from mHz to MHz.

• Low phase noise and distortion.

• Very wide frequency sweeps are possible.

• Fast phase continuous frequency switching.

• Non-standard waveforms such as multi-level squarewaves are easily generated.

• Basic arbitrary waveform capability in the same instrument.

In addition, being a digital technique, it is easier to make every parameter programmable from the

keyboard, or remotely via RS232 or GPIB interfaces.

The fundamental limitation of the DDS technique is that, as the generator frequency is increased,

each waveform cycle is constituted from fewer samples. This is not a problem with sinewaves

which, because they are filtered, can be produced with low distortion up to the frequency limit of

the generator. With DDS squarewaves and pulse waveforms the 1 clock edge uncertainty sets a

practical limit to the upper frequency. However, on this instrument the generation technique

changes at 30kHz (but is overridable by the user) to use a comparator driven by the DDS

sinewave; this ensures jitter-free squarewaves and pulses up to the frequency limit of the

generator. Ramp and staircase waveforms are, by default, unfiltered (although filtering can be

selected) and therefore become degraded above the frequencies indicated in the Specification;

all waveforms are, however, available up to the maximum frequency of the generator.

Switching On

The power switch is located at the bottom left of the front panel.

At power up the generator displays the installed software revision whilst loading its RAM with

waveforms; if an error is encountered the message “SYSTEM RAM ERROR, BATTERY FLAT?”

will be displayed, see the Warnings and Error Messages section.

Loading takes a few seconds, after which the Main menu is displayed, showing the generator

parameters set to their default values, with the MAIN OUT set off. Refer to the System Menu

section for how to change the power up settings to either those at power down or to any one of

the stored settings.

Change the basic generator parameters as described in the Main Generator Operation section

and switch the MAIN OUT on with the OUTPUT key; the ON lamp will light to show that the

output is on. Note that AUX OUT, CLOCK OUT, etc. are always running and are not switched by

the OUTPUT key.

14

Page 16

Display Contrast

All parameter settings are displayed on the 20 character x 4 row backlit liquid crystal display

(LCD). The contrast may vary a little with changes of ambient temperature or viewing angle but

can be optimised for a particular environment by using the front panel contrast control. Insert a

small screwdriver or trimmer tool through the adjustment aperture marked LCD and rotate the

control for optimum contrast.

Keyboard

The keys can be considered in 7 groups:

• FUNCTION keys permit direct selection of the waveform function. Repeated presses of each

of the 3 keys steps the function selection through each of the 2 or 3 choices associated with

that key; the current selection is indicated by the illuminated lamp. Pressing a different key

selects the function last selected with that key. In this way it is therefore possible to select

between, for example, sine, square and triangle with single key presses, or between positive

pulses and negative pulses, etc.

• SET keys permit direct selection of the four main generator parameters shown on the Main

menu of the display, ready for value entries from the NUMERIC/UNIT keys.

• NUMERIC/UNIT keys permit direct entry of a value for the parameter currently selected;

parameter selection is either directly (by the SET keys) for the main parameters, or by moving

the cursor to the appropriate parameter in other menus. Thus to set a new frequency of

100kHz, for example press FREQ/PER, 1, 0, 0, kHz; or to change symmetry to 40%, press

SYMMETRY, 4, 0, %.

• FIELD and DIGIT keys are used, together with the ROTARY CONTROL, to edit parameters on

the current menu. Their use is explained more fully in the ‘Principles of Editing’ section below.

• MODE keys are used both to directly switch the respective mode (TRIG, GATE, AM, etc.) on

or off and to select the menus for setting up these special functions. Alternate presses of a

MODE key will turn the function on or off; when on the associated lamp is lit. Pressing the blue

EDIT key followed by a MODE key displays the edit menu for that mode; the associated lamp

flashes whilst the edit menu is displayed.

• UTILITIES keys give access to the STORE, RECALL and Interface parameter menus; the

MAN/SYNC key is used for manual triggering and synchronising two or more generators when

suitably connected together.

• Lastly, the CONFIRM, ESCAPE, and CE (Clear Entry) keys have self-explanatory functions.

Numeric entries are automatically confirmed when the appropriate unit key (Hz, kHz, MHz,

etc.) is pressed but CONFIRM can be used to enter a number in the parameter’s basic units or

to confirm entries with fixed units (e.g. phase) or no units (e.g. burst count). It is also used to

confirm certain options when prompted.

Pressing ESCAPE returns a setting being edited to its last value; a second press (when

appropriate) will return the display from an edit menu to the Main menu.

CE (Clear Entry) undoes a numeric entry digit by digit.

Further explanations will be found as appropriate in the detailed descriptions of the generator’s

functions.

15

Page 17

Principles of Editing

FIELD and DIGIT keys are used, together with the rotary control, to edit parameters shown on the

current menu. The Main menu shows all the basic generator parameters and is the one displayed

unless editing of a special function has been selected. These edit menus are accessed by

pressing the blue EDIT key, followed by the appropriate MODE key or a numeric key which has a

secondary function printed in blue.

FIELD keys move the flashing edit cursor forward or backwards from one editable field to the

next; all the digits of a numeric parameter value are treated as a single field. When the

parameters of a particular function occupy two or more pages of the display, e.g. the sweep mode

parameters, the further pages are indicated by MORE>>> shown in the display and the FIELD

keys are also used to step between the end of one page and the start of another, and vice-versa.

The attributes of the flashing edit cursor can be changed by the user if desired, see SYStem

Menu section.

DIGIT keys operate in more than one mode. When a numeric parameter value field is selected by

the FIELD keys, DIGIT keys step the edit cursor forward or backwards through the digits of the

field. When the edit cursor is positioned in a parameter name (e.g. FREQ) pressing either digit

key will step the parameter through each of the alternative forms in which a value may be entered

(e.g. FREQ is changed to PERiod); the parameter numeric value and units change accordingly.

Note that where there is no alternative form for the parameter (e.g. SYMMETRY) the edit cursor

cannot be stepped into that field. When the edit cursor is positioned in a parameter selection field

(e.g. SOURCE = on the TRIG menu), the DIGIT keys step through all possible choices for that

parameter (e.g. SOURCE = TGEN, SOURCE = EXT, etc.) Lastly, when the edit cursor is

positioned in the units field of a parameter value, the DIGIT keys increment or decrement the

numeric value of the parameter by a factor of 10 each press; the units change each time the

display autoranges.

The ROTARY CONTROL works as follows. With the cursor in any field other than a numeric

value field turning the control acts in exactly the same way as pressing the DIGIT keys. With the

edit cursor positioned anywhere in a parameter numeric field, turning the control will increment or

decrement the value; the step size is determined by the position of the edit cursor within the

numeric field.

Thus for FREQ = 1.000

display will auto-range up or down as the frequency is changed, provided that autoranging

permits the increment size to be maintained; this will in turn determine the lowest or highest

setting that can be achieved by turning the control. In the example above, the lowest frequency

that can be set by rotating the control is 1 kHz, shown on the display as

FREQ = 1.000000 kHz

This is the limit because to show a lower frequency the display would need to autorange below

1kHz to

FREQ = xxx.xxx Hz

in which the most significant digit represents 100Hz, i.e. the 1kHz increment would be lost. If,

however, the starting setting had been

FREQ = 1.0000

i.e. a 100 Hz increment, the display would have autoranged at 1kHz to

FREQ = 900.0000 Hz

00 MHz rotating the control will change the frequency in 1kHz steps. The

00 MHz

16

and could then be decremented further right down to

FREQ = 000.0000 Hz

without losing the 100 Hz increment.

Turning the control quickly will step numeric values in multiple increments.

Page 18

When first switched on, and at all subsequent power-ups unless specified otherwise on the

SYStem menu, the generator will be set to the factory defaults, with the output off. The basic

parameters can be set from the Main menu as described below.

Main Generator Parameters

Frequency

FREQ=10.00000kHz

EMF =+20.0 Vpp 50Ω

DC=+0.00mV (+0.00mV)

SYM=50.0% (50.0%)

With the flashing edit cursor anywhere on the first line of the Main menu the frequency can be

changed directly from the keyboard by entering the number and appropriate units only, e.g. 1kHz

can be set by entering 1,kHz or ., 0, 0, 1, MHz or 1, 0, 0, 0, Hz, etc. However, the display will

always show the entry in the most appropriate engineering units, in this case 1.000000 kHz. If

this cursor is not already in a top line field it is first necessary to press the FREQ/PER key before

making the number and unit entry. Note that this always returns the cursor to the parameter name

field which can then be alternated between FREQ and PERiod with successive presses of either

DIGIT key, or by turning the rotary control.

Main Generator Operation

PER =100.0000us

EMF =+20.0 Vpp 50

Ω

DC=+0.00mV (+0.00mV)

SYM=50.0% (50.0%)

When PER= shows in the display instead of FREQ=, the frequency can be set in terms of a

period; enter the number and units (ns, µs, ms or s) in the same way as for frequency. Note that

the precision of a period entry is restricted to 6 digits; 7 digits are displayed but the last significant

one is always zero. The hardware is always programmed in terms of frequency; when a period

entry is made the synthesised frequency is the nearest equivalent value that the frequency

resolution and a 6-digit conversion calculation gives. If the frequency is displayed after a period

entry the value may differ by a digit from the expected value because of these considerations.

Further, once the setting has been displayed as a frequency, converting back again to display

period will give an exact 6-digit equivalent of the 7-digit frequency, but this may differ, by a digit,

from the period value originally entered. If the edit cursor is moved to the numeric field, turning

the rotary control will increment or decrement the numeric value in steps determined by the edit

position within the field. The FIELD keys move the cursor to the field and the DIGIT keys move it

within the field; this is more fully explained in the Principles of Editing section. Lastly, with the edit

cursor in the units field, pressing the DIGIT keys or turning the rotary control will change the value

in decade increments; the decimal point will move and/or the units will change as appropriate.

Full 7-digit precision is maintained as the value is decremented until the 0.1mHz resolution limit of

the instrument is reached; values which would have had least significant bits <0.1mHz are

truncated with further decrements and the precision is consequently lost when the number is

incremented again.

Output Level

The second line of the Main menu permits the output level to be set in terms of EMF (open circuit

voltage) or PD (potential difference into a matched load) or dBm (referenced to the specified

source impedance). Both EMF and PD can be set in terms of peak-peak volts (Vpp) or r.m.s. volts

(Vrms). Note that in both cases the true peak-peak or r.m.s. values are shown for the selected

waveform, even an arbitrary waveform. However, in the case of Vrms the DC Offset (see next

17

Page 19

section) is ignored in the calculation and must be taken into consideration by the user if the DC

Offset is non-zero.

FREQ=10.00000kHz

EMF=+20.0 Vpp 50Ω

DC=+0.00mV (+0.00mV)

SYM=50.0% (50.0%)

The desired form of the output level display can be selected whilst the edit cursor is in the

parameter name field by stepping through all the options with the DIGIT keys or the rotary control;

bring the cursor to the parameter name field first, if necessary, by pressing EMF/PD, or by using

the FIELD keys.

With the appropriate parameter form selected, the value is entered as a number followed by units,

e.g. 100mV can be entered as 1, 0, 0, mV or ., 1, V etc. The software acts intelligently in certain

situations; for example, even if EMF or PD is the selected parameter form, entering a number

followed by the dBm key will cause the number to be entered as dBm. Similarly, with dBm as the

selected parameter form, entering a number followed by V or mV will cause the number to be

entered as PD=Vrms. 0dBm is 1mW into the specified impedance; low signal levels are specified

by using the +/- key to enter negative dBm. See also the last paragraph of this section for the use

of the +/- key for output inversion.

Moving the edit cursor to the numeric field permits the set value to be varied by the rotary control

in steps determined by the cursor position within the field. The FIELD keys move the cursor to the

field and the DIGIT keys move it within the field; this is explained more fully in the Principles of

Editing section.

Moving the edit cursor to the units field permits the numeric value to be changed in decade steps

by the DIGIT keys or rotary control; the decimal point will move and/or the units will change as

appropriate. Further increments are inhibited if the next decade step would take the value above

the maximum level or below the minimum level. Decade stepping with the DIGIT keys or rotary

control is also inhibited when the level is displayed in dBm.

Wherever the cursor is positioned on the second line of the display, alternate presses of the +/key will invert the MAIN OUT output; if DC OFFSET is non-zero, the signal is inverted about the

offset. The one exception to this is if the output level is specified in dBm; since low signals are

specified in -dBm, the - sign is interpreted as part of a new output level entry and not as a

command to invert the signal. The output level must be shown as an EMF or PD value for the +/key to operate as a signal invert key.

If an amplitude change is made which involves switching the attenuator, the output is switched off

for 45ms whilst the change is made to prevent any transients appearing at the output.

Output Impedance

The impedance of the MAIN OUT output is selected in the last field of the second line. Move the

edit cursor to this field and use the DIGIT keys or rotary control to toggle between 50Ω and

600Ω. The output level is unchanged but the displayed value in dBm will change because the

0dBm reference level (1mW into the specified impedance) changes with the impedance.

DC Offset

The DC Offset is set on the third line of the Main menu. With the cursor anywhere in the third line

the DC offset can be changed directly from the keyboard by entering the number and appropriate

units, e.g. 100mV can be set by entering 1, 0, 0, mV or ., 1, V, etc. If the cursor is not already in

the third line of the display it is first necessary to press the DC OFFSET key, to position the

cursor, before making the number and unit entry. Note that, unlike the FREQ= or EMF=

parameter fields, the cursor does not move into the DC OFFSET name because it has no

alternative.

18

With the edit cursor in the numeric field, turning the rotary control will increment or decrement the

numeric value in steps determined by the edit cursor position within the field. The DC OFFSET or

Page 20

FIELD keys move the cursor to the field and the DIGIT keys move it within the field; this is more

fully explained in the Principles of Editing section. Because DC offset can have negative values,

the rotary control can take the value below zero; although the display may autorange to a higher

resolution if a step takes the value close to zero, the increment size is maintained correctly as the

offset is stepped negative. For example, if the display shows

DC = +2

with the cursor in the most significant digit, the rotary control will decrement the offset in 100mV

steps as follows:

DC = +205.mV

DC = +105.mV

DC = +5

DC = -9

DC = -1

The +/- key can also be used at any time to set the offset value negative; alternative presses

toggle the sign between + and -. Alternatively the sign of the offset can be changed as part of the

entry of a new value, e.g. if the offset is +2.00V it can be changed to -100mV by pressing

+/-, 1, 0, 0, mV.

The actual DC offset at the MAIN OUT socket is attenuated by the fixed-step output attenuator

when this is in use. Since it is not obvious when the signal is being attenuated the actual offset is

shown in brackets as a non-editable field to the right of the set value.

For example, in the display below, the pk-pk output is not attenuated by the fixed attenuator and

the actual DC offset (in brackets) is the same as that set.

05. mV

.00 mV

5.0 mV

95. mV

FREQ=10.00000kHz

EMF=+2.50 Vpp 50Ω

DC=+150.mV (+150.mV)

SYM=50.0% (50.0%)

If the output level is now reduced to 250mV pk-pk, which introduces the attenuator, the actual DC

offset changes by the appropriate factor:

The above display shows that the set DC offset is +150mV but the actual offset is +15.1mV. Note

that the actual offset value also takes into account the true attenuation provided by the fixed

attenuator, using the values determined during the calibration procedure. In the example

displayed the output signal is 250mV pk-pk exactly and takes account of the small error in the

-20dB fixed attenuator; the offset is 15.1mV exactly, taking account of the effect of the known

attenuation (slightly less than the nominal -20dB) on the set offset of 150mV.

Whenever the set DC offset is modified by a change in output level in this way a warning

message that this has happened will be displayed. Similarly, because the DC offset plus signal

peak is limited to ± 10V to avoid waveform clipping, a warning message will be displayed. This is

explained more fully in the Warnings and Error Messages section.

DC Output

The DC Offset control can be used to provide an adjustable DC output level if the waveform is off;

the recommended set-up is as follows:

FREQ=10.00000kHz

EMF=+250.mVpp 50Ω

DC=+150.mV (+15.1mV)

SYM=50.0% (50.0%)

19

Page 21

Select GATE edit mode and set the SOURCE to MAN/REMOTE. Exit edit mode and turn on

GATE mode with the GATE key. Provided that GATE mode is not triggered, the MAIN OUT will

now remain at the level set by the DC Offset control.

On the main menu set the output level to 1Vpp; this ensures that the software does not warn of

clipping (output level too high) and that the output attenuator is not switched in (which would also

attenuate the DC Offset). With the cursor in the DC Offset field the MAIN OUT can now be

adjusted over the range ±10V EMF.

Symmetry

Pressing the SYMMETRY key moves the flashing edit cursor directly to the symmetry numeric

field on the bottom line of the display. This is the only field that can be edited; the bracketed field

on the right-hand side shows the actual symmetry which might differ from that set if the set value

is outside that permitted for the selected frequency and waveform combination, see Specification

section. For example, in the display below the frequency is set to 100kHz and a squareware is

selected.

FREQ=100.0000kHz

EMF=+20.0 Vpp 50Ω

DC=+0.00mV (+0.00mV)

SYM=90.0% (80.0%)

The symmetry is set to 90% but the actual symmetry is 80%, the limit for squarewaves and pulse

waveforms above 30kHz.

The flashing cursor can be moved within the field using the DIGIT keys; turning the rotary control

will then increment or decrement the setting in steps determined by the position of the cursor in

the field.

Should the symmetry be set outside the permitted range for the selected frequency and waveform

combination a warning message will be shown on the display, see Warnings and Error Messages

section below.

Warning and Error Messages

Two classes of message are displayed on the screen when an illegal combination of parameters

is attempted.

WARNING messages are shown when the entered setting causes some change which the user

might not necessarily expect. Examples are:

1. Changing the EMF from 2.5Volts pk-pk to 250mV pk-pk brings in the step attenuator; if a nonzero offset has been set then this will now be attenuated too. The message ‘DC OFFSET

CHANGE BY OUTPUT LEVEL’ will be shown temporarily on the screen but the setting will be

accepted; in this case the actual, attenuated, offset will be shown in brackets to the right of the

set value.

2. With the output level set to 10V pk-pk, increasing the DC offset beyond ± 5V will cause the

message ‘DC OFFSET + LEVEL MAY CAUSE CLIPPING’. The offset change will be accepted

(producing a clipped waveform) and the user may then choose to change the output level or

the offset to produce a signal which is not clipped.

20

3. With 100kHz squarewave selected, increasing symmetry beyond 80% will cause the message

‘SYMMETRY TOO WIDE FOR FUNC/FREQ’ to be displayed. The setting will be accepted but

the actual symmetry will be limited to 80% as shown in the bracketed field beside the setting. If

this out-of-specification setting is changed by reducing the frequency below 30kHz or by

changing the waveform then the warning ‘SYMMETRY CHANGED BY FUNC/FREQ’ is

displayed.

Page 22

ERROR messages are shown when an illegal setting is attempted, most generally a number

outside the range of values permitted. In this case the entry is rejected and the parameter setting

is left unchanged. Examples are:

1. Entering a frequency of 100 MHz. The error message ‘FREQUENCY/PERIOD VAL OUT OF

RANGE’ is shown.

2. Entering an EMF of 25V pk-pk. The error message ‘MAX OUTPUT LEVEL EXCEEDED’ is

shown.

3. Entering a DC offset of 20V. The error message ‘MAX DC OFFSET EXCEEDED’ is shown.

The messages are shown on the display for approximately two seconds. The last two messages

can be viewed again by pressing the blue EDIT key followed by MSG (the 0 number key). Each

message has a number and the full list appears in Appendix 1, together with some further

explanation where the message is not entirely self-explanatory.

The default set-up is for all warning and error messages to be displayed and for a beep to sound

with each message. This set-up can be changed on the ERRor menu, accessed by pressing the

blue EDIT key followed by ERRor key (the 2 number key). The ERRor menu is shown below:

ERROR BEEP=ON

ERROR MESSAGE=ON

WARNING BEEP=ON

WARNING MESSAGE=ON

The flashing cursor can be moved through each of the four editable fields in turn using the FIELD

keys. The field can then be toggled between ON and OFF, using the DIGIT keys or rotary control,

to create the desired setting. If the new setting is required for future use it should be saved by

changing the POWER UP= setting on the SYStem menu to POWER UP=POWER DOWN, see

System Menu section.

21

Page 23

Auxiliary Output

AUX OUT is a TTL/CMOS level output synchronous with MAIN OUT and with the same

symmetry. However, the phase of the AUX OUT can be varied with respect to the MAIN OUT by

changing the PHASE setting on the TRIGger edit menu.

Auxiliary Output Phase

Sine

Square

Triangle

Ramp

AUX 0º

AUX 90º

The convention adopted for phase in this instrument is

illustrated in the diagram. 0° is always the first data point in

waveform memory. On symmetrical waveforms 0° is the

rising edge ‘zero-crossing’ point for sine, square, triangle

and pulse waveforms; 0° is the start point of ramps,

staircase and arbitrary waves. When the phase is set to 0°

the rising edge of the AUX OUT squarewave is at 0° too.

When the phase is set to a positive value, e.g. +90°, the

AUX OUT squarewave follows MAIN OUT by 90°, when the

phase is set to a negative value AUX OUT leads MAIN

OUT.

The phase is set by pressing the blue EDIT key followed by

TRIG to select the trigger edit menu; the edit cursor is then

moved to the PHASE field using the FIELD keys. PHASE

can be entered directly from the keyboard, using the +/- key

to change the sign if necessary, or by rotary control.

Above 30kHz the AUX OUT accompanying sine, triangle,

square and pulse waveforms is automatically switched such

that it is derived from the comparator (driven by the DDS

sinewave) used to generate higher frequency MAIN OUT

squarewaves and pulses; see the DDS Principles section

for further information. This ensures a jitter-free AUX OUT

signal up to the maximum frequency of the generator but

means that phase shifting between MAIN OUT and AUX

OUT is not then possible. However, this constraint can be

removed by changing the setting on the OPTions menu

from AUX OUTPUT=AUTO to AUX OUTPUT=LOW FREQ;

the AUX OUT signal then continues to be generated

independently, with phase adjustable with respect to the

MAIN output, although the 1 clock (36ns) jitter will become

increasingly significant at higher frequencies. Changing

AUTO settings is described more fully in the next section,

Waveform Generator Options.

22

The AUX OUT signal accompanying ramp, staircase and

AUX 180º

0º 180º 360º

arbitrary waveforms is, by default, always generated

independently; phase shift is adjustable across the

frequency range but again clock jitter becomes increasingly

significant at higher frequencies.

Waveform Generation Options

A number of parameters are, by default, switched automatically either when the frequency is set

above 30kHz or when the operating mode is changed such that the best overall performance is

achieved across the whole generator frequency range; see the DDS Principles section for further

details of the 30kHz changeover. In addition, triangle, ramp, staircase and arbitrary waveforms

can be inhibited from being set above 100kHz, to ensure that they are not used accidentally at

frequencies where the waveshape is noticeably deteriorating. In all cases, however the default

choice can be overridden by the user by changing the setting on the OPTions menu.

Page 24

The OPTions edit menu shown above is selected by pressing the blue EDIT key followed by

OPTN (the shifted function of 1). The following descriptions, grouped together in this section for

reference convenience, should be read in conjunction with the main explanations of the

appropriate parameter elsewhere in this manual. Each parameter is altered by moving the edit

cursor to the appropriate field with the FIELD keys and using the DIGIT keys or rotary control to

change the setting.

Squarewave Generation

In LOW FREQency mode the squarewave and pulse waves are generated digitally; in this way

precision squarewaves can be generated down to very low frequencies without the edge

uncertainty that would be associated with conventional ramp-and-comparator techniques. Above

approximately 27kHz (clock frequency, 27.487MHz, ÷1024) the waveforms are sampled and the

1 clock (36ns) uncertainty introduces edge jitter which becomes increasingly significant at higher

frequencies. In HIGH FREQuency mode the squarewave and pulses are derived from the output

of a comparator driven by the DDS generated sinewave. The sinewave is, by default, filtered and

jitter-free; the high frequency squareware and pulse waveforms are thus jitter free too.

SQWAVE GEN=AUTO

FILTER=AUTO

AUX=AUTO FSTOP=ON

SWEEP TGEN OUT=AUTO

In AUTO mode (the default) the generation of squarewave and pulse waveforms is automatically

switched from low to high frequency mode when the frequency exceeds 30kHz. However, when

these waveforms are used in sweep and FSK modes, over a frequency range which includes the

30kHz changeover point, the generation mode will not change even though AUTO is selected.

Instead, the mode in use before sweep or FSK are turned on is maintained across the frequency

range; this can of course be overridden by selecting either high or low frequency mode on the

Options menu, as described above.

Filter

The generator contains a 7-stage elliptical filter which exhibits a sharp cut-off beyond the

maximum generator frequency, reducing intermodulation spurii and clock harmonics to a very low

level. With the default condition of FILTER=AUTO set on the Option menu, the filter is switched in

automatically for sine, triangle, high frequency squarewave and high frequency pulse waveforms

(although the squarewave and pulse waveforms themselves do not pass through the filter); the

filter is automatically switched out for low frequency squarewave and pulses, ramp, staircase and

arbitrary waveforms because of the degrading effect it has on fast transitions in the waveform.

However, for all these waveforms the filter can be set to be always on (FILTER=ON) or always off

(FILTER=OFF); this has the advantage that, for example, an arbitrary waveform with an

essentially sinusoidal content can be output with the filter on.

When Noise is selected, see Special Waveforms section, this 7-stage filter is always off, whatever

the FILTER = setting, and a simple 700kHz low pass RC filter is switched in instead.

Auxiliary Output

When sine, triangle, squarewave or pulse waveforms are selected and with AUX

OUTPUT=AUTO the auxiliary output squarewave generation switches automatically at 30kHz

from DDS generation to a signal derived from a comparator driven by the DDS sinewave; the

advantages of this approach are the same as those detailed previously in the Squarewave

Generation section. However, as detailed in the Auxiliary Output Phase section, the high

frequency generation mode has the disadvantage that a phase difference can no longer be set

between AUX OUT and MAIN OUT. The automatic switchover at 30kHz can therefore be

overridden by setting AUX OUTPUT=LOW FREQuency, to maintain it in true DDS mode, or AUX

OUTPUT=HIGH FREQuency to lock it in high frequency mode. With AUX OUTPUT=AUTO there

is no automatic mode changeover if ramp, staircase or arbitrary waveforms are selected; high

frequency mode can however be forced by setting AUX OUTPUT=HIGH FREQ.

23

Page 25

Note that there is some second order interaction between the Squarewave Generation, Filter and

Auxiliary Output settings which demand a little thought before deviations from the default

conditions are defined. For example, if SQWAVE GEN and AUX OUTPUT options are set to

AUTO but FILTER is set to OFF the edges of both the MAIN OUT and AUX OUT squarewaves

will exhibit some jitter at high frequencies (e.g. 1MHz) because the sinewave driving the

comparator from which both are derived will itself be jittery.

Frequency Stop

In the default mode of FSTOP=OFF there are no frequency limits on any waveform and the

frequency and waveform can be set as described in the Main Generator section; waveform

quality will however deteriorate progressively as the frequency increases for certain waveforms,

as discussed in the DDS Principles section. With FSTOP=ON the maximum settable frequency

for triangle, ramp, staircase and arbitrary is limited to 100kHz. Error messages will be shown if

either an attempt is made to enter a frequency above 100kHz whilst one of these waveforms is

selected, or if an attempt is made to select one of these waveforms with the frequency already set

above 100kHz. This mode is useful in ensuring that frequencies are not accidentally set too high

for waveforms whose quality will deteriorate above 100kHz.

Trigger/Sweep Output

With SWEEP/TGEN=AUTO the function of the rear panel TRIG/SWEEP OUT socket changes

automatically when the operating mode is changed between Sweep, HOP and any other mode;

the two functions of this output are described in the Connections section.

When SWEEP/TGEN=SWEEP is set the TRIG/SWEEP OUTput is always in the Sweep mode, if

sweep is operational, or HOP mode if HOP is on; when SWEEP/TGEN=TRIG the TRIG/SWEEP

OUTput always outputs the internal trigger generator signal. Note that, except when using the

internal trigger generator in Trigger, Gate, FSK or AM modes, this signal is not synchronised with

the main generator.

24

Page 26

General

Sweep Operation

DDS operation gives the significant advantage over conventional function generators of phasecontinuous sweeps over very wide frequency ranges, up to 10

remembered that the frequency is actually stepped, not truly linearly swept, and thought needs to

be given as to what the instrument is actually doing when using extreme combinations of sweep

time and frequency span, see Frequency Stepping Resolution section.

Sweep mode is turned on and off with alternate presses of the SWEEP key; the lamp beside the

key lights when sweep mode is on. The sweep parameters (begin, end and marker frequencies,

sweep direction, law, ramp time and source) are all set from the sweep edit menu which is

selected by pressing the blue EDIT key followed by the SWEEP key. When sweep edit is selected

the lamp beside the SWEEP key flashes to show edit mode regardless of whether sweep

operation is selected to be on or off. The sweep mode parameters are set up on two pages of the

display; the flashing edit cursor is moved around each page, and between pages, by the FIELD

and DIGIT keys as described in the Principles of Editing section.

Return to the Main menu from either page of the edit menu is achieved by pressing the ESCAPE

key.

See also the Squarewave Generation section for information concerning the use of sweep with

squarewaves.

Connections for Sweep Operation

Sweeps are usually used with an oscilloscope or hard-copy device to investigate the frequency

response of a circuit. The MAIN OUT is connected to the circuit input and the circuit output is

connected to an oscilloscope or, for slow sweeps, a recorder.

10

:1. However, it must be

To show the markers on the display instrument the rear panel TRIG/SWEEP OUT socket should

be connected to a second channel; an oscilloscope should be triggered off this channel (negative

edge) or the TRIG/SWEEP OUT can be connected directly to the external trigger of the

oscilloscope if no marker display is required.

The TRIG/SWEEP OUT socket provides a 3-level waveform in sweep mode. The output changes

from high (4V) to low (0V) at start of sweep and goes high again at end of sweep; it can therefore

be used as a pen-lift signal (inverted by the user if necessary) if the display device is a chart

recorder. Additionally the output provides narrow 1V pulses at each marker frequency, see

Setting Sweep Span and Markers section.

For externally triggered sweeps, a trigger signal must be provided at the front panel EXT TRIG

socket. A sweep is initiated by the rising edge of the trigger signal.

The generator does not provide a ramp output for use with X-Y displays or recorders.

Setting Sweep Span and Markers

Pressing the blue EDIT key followed by the SWEEP key displays the first page of the sweep

parameters with values set to factory defaults.

BEG FRQ=100.0000kHz

END FRQ=10.00000MHz

MARK FRQ=5.000000MHz

MORE->>>

The BEGin, END, and MARKER frequencies can all be set or modified in exactly the same way

as described for the setting of the frequency in the Main Generator section. In summary, with the

cursor in the first field of any line, the DIGIT keys or rotary control will alternate the display

between FRQ= and PER=; with the cursor in the numeric field the DIGIT keys will move the

cursor within the field and the rotary control will change the value in increments determined by the

25

Page 27

cursor position; with the cursor in the units field, the DIGIT keys or rotary control will change the

value in decade increments. Direct keyboard entries (number plus units) will be accepted with the

cursor anywhere in the line of the display. Note that if sweep mode is actually on (selected by

alternate presses of the SWEEP key) and the ramp time is set to 200ms or less, then changing

the BEGin or END frequency causes the current sweep to be aborted, the frequency steps to be

recalculated, and a new sweep started at each frequency change; it is therefore faster to make

changes with the sweep off. The MARKER frequency, however, can be changed without

interrupting the sweep.

A second marker is also displayed at the frequency set on the main menu, i.e. at the frequency

set for the generator in non-sweep mode. This offers the advantage of a marker adjustable from

the same menu used to control amplitude, offset, etc.

The marker signal is output from the rear panel TRIG/SWEEP OUT socket, see Connections for

Sweep Operation section. The output is low (0V) for the duration of the sweep, with narrow 1V

pulses at the marker frequency. Note that the marker pulse width is that of the duration of the

frequency step with the closest value to the marker frequency. This means that sweeps with few

steps will have wider markers than those with many steps, see Frequency Stepping Resolution

section.

Setting Sweep Mode, Ramp Time and Source

Pressing the FIELD keys to move the cursor through each editable field of the first page of the

sweep menu eventually steps the cursor onto the second page shown below.

MODE=BEG-END LAW=LOG

RAMP TIME=0.05 S

TRIG SRC=CONTINUOUS

MORE->>>

Pressing the left FIELD key with the cursor in the first (MODE) field will return the edit cursor to

the last field on the first page of the sweep menu. Pressing the right FIELD key will step the

cursor through all the editable fields up to TRIGger SouRCe; one more press returns the cursor to

the first field of the first page. Pressing ESCAPE always exits the edit menu and returns to the

Main menu.

With the edit cursor in the MODE field, alternate presses of the DIGIT keys, or turning the rotary

control, will set the sweep direction to BEGin-END or END-BEGin. There are no restrictions on

the BEGin and END frequencies, e.g. the BEGin frequency can be higher than the END

frequency, so the MODE field simply provides an easy way to reverse the sweep direction.

With the edit cursor in the LAW field the sweep can be changed from LINear to LOGarithmic.

With LAW=LIN set, the frequency changes linearly with time across the sweep; with LAW=LOG

set, the frequency changes exponentially with time across the sweep. The term ‘log sweep’ is a

convention; with the start frequency lower than the stop frequency (the usual mode of operation)

the mathematical relationship of frequency to time is actually anti-log.

The sweep rate is set with the cursor in the RAMP TIME field; ramp time can be set with 3 digit

resolution from 0.01s (10ms) to 999s. The choice of ramp time affects the number of discrete

frequency steps in the sweep; faster sweeps will have fewer steps, see Frequency Stepping

Resolution section.

26

The trigger mode of the sweep is set with the cursor in the TRIGger SouRCe field; the options are

CONTINUOUS, EXTernal and MAN/REMOTE. In CONTINUOUS mode the sweep starts

simultaneously with the high-to-low transition of the TRIG/SWEEP OUT signal; the sweep starts

with the phase at 0° and at the output level set by the DC offset. At the end of the sweep the

signal returns to this DC offset level and the TRIG/SWEEP OUT signal simultaneously goes high

again. After a delay long enough for an oscilloscope to retrace, for example, the cycle repeats.

In EXTernal mode a trigger signal is connected to the front panel EXT TRIG socket. A sweep

starts typically 200-800µs after the rising edge of the trigger signal; the sweep is completed

Page 28

before another trigger edge is recognised and a new sweep initiated. The minimum trigger pulse

width is 1ms and the repetition rate should be >(1.1 x sweep time +5)ms.

In MAN/REMOTE mode a single sweep is initiated by each press of the MAN/SYNC key or by

each remote command. If the MAN/SYNC key is pressed during a sweep (continuous or single

sweep) the sweep will be paused at the instantaneous sweep frequency until MAN/SYNC is

pressed again to allow the sweep to continue.

Frequency Stepping Resolution

The generator frequency is stepped, not truly swept, between the BEGin and END frequencies.

The number of discrete frequency steps in a sweep is determined by the ramp time selected on

the sweep edit menu; the size of each step, i.e. the frequency stepping resolution, is determined

by the number of steps and the sweep span. For the fastest sweeps, 10ms to 200ms, the

frequency steps are pre-calculated and output at 125us intervals; this means that there are 80

discrete steps in a 10ms sweep, 160 in a 20ms sweep, and so on up to 1600 steps in a 200ms

sweep. For slow sweeps, from >200ms up to 999s, each frequency step is calculated on-the-fly

and output every 5ms; this means that there are 100 steps in a 500ms sweep, 200 in a 1s sweep,

and so on up to nearly 200,000 steps in a 999s sweep.

Note that at the fastest sweep rates, with fewest frequency steps (e.g. 10ms sweep) two effects

can occur at extremes of frequency span which are not experienced with conventional

generators. Firstly, if the scan is very wide the frequency changes will be quite large at each step;

if the output is applied to a filter, for example, the response will be a succession of step-change

levels with (at higher frequencies) many cycles of the same frequency at each step. Secondly, if

the begin frequency is less than 800Hz (the ramp rate for fast sweeps), one or more of the low

frequency steps will contain incomplete cycles. In part, of course, these effects can only be

created because of the very wide sweeps that can be achieved with DDS techniques; analogue

generators usually have more restricted capabilities.

Note also that because the marker pulse duration (from the rear panel TRIG/SWEEP OUT

socket) is that of the nearest frequency step, fast sweep rates with few steps will have wider

marker pulses.

27

Page 29

In Burst mode a defined number of cycles are generated following each trigger event. This mode

is edge triggered.

In Gated mode the generator runs whenever the gating signal is high. This mode is level

sensitive.

Both Burst and Gated modes can be controlled by either the internal trigger generator, an

external trigger input, by the front panel MAN/SYNC key or by remote control.

Internal Trigger Generator

The internal trigger generator divides down a crystal oscillator to produce a 1:1 square-wave with

a period from 0.02ms (50kHz) to 200s (.005Hz). Generator period entries that cannot be exactly

set are accepted and rounded up to the nearest available value, e.g. .109ms is rounded to .12ms.

The generator output is available as a TTL level signal at the rear panel TRIG/SWEEP OUT

socket.

In Burst most the rising edge of each cycle of the trigger generator is used to initiate a burst; the

interval between bursts is therefore 0.02ms to 200s as set by the generator period.

In Gated mode the output of the main generator is gated on whilst the trigger generator output is

high; the duration of the gate is therefore .01ms to 100s in step with trigger generator periods of

.02ms to 200s.

Triggered Burst and Gate

External Trigger Input

External trigger or gate signals are applied to the front panel EXT TRIG input which has a TTL

level (1.5V) threshold. In Triggered Burst mode the input is edge sensitive; the rising edge of

each external trigger initiates the specified burst. In Gated mode the input is level sensitive; the

output of the main generator is on whilst the gate signal is high (>1.5V).

The minimum pulse width that can be used with the EXT TRIG input is 50ns and the maximum

repetition rate is 1MHz. The maximum signal level that can be applied without damage is ±10V.

Triggered Burst

Triggered Burst mode is turned on and off with alternate presses of the TRIG key; the lamp

beside the key lights when triggered mode is on. The triggered mode parameters (trigger source,

internal trigger generator, burst count and start/stop phase) are all set from the trigger edit menu