Page 1

THURLBY THANDAR INSTRUMENTS

TA320S

32-CHANNEL LOGIC ANALYSER

INSTRUCTION MANUAL

Page 2

Table of Contents

Introduction 1

Section 1 - Specification 2

Section 2 - Safety, Installation and EMC 4

Section 3 - Initial Operation 7

Section 4 - Configuration Menu 10

Section 5 - Trigger Words Menu 14

Section 6 - Trigger Sequence Menu 17

Section 7 - Timing Display 20

Section 8 - List Display 25

Section 9 - Utilities Menu 29

Section 10 - Making an Acquisition 32

Section 11 - ARC Remote Control 33

Introduction

The TA320 is a high performance, very low-cost, portable logic analyser for development, production and

field-service applications. It can capture data across 32 channels (at 25MHz) at up to 100MHz (8

channels) and display it in both Timing and List formats on the built-in supertwist LCD or on a PC screen.

The TA320 features multi-level triggering with event counting and restart. Glitch capture and glitch

triggering are also available with the appropriate input pods. The three external clocks have independent

qualifiers and both data and clock pod inputs can be fixed (TTL) or variable threshold depending on pod

choice.

All functions are accessed through easy to follow soft-key controlled displays. The use of soft-keys

guides the user and minimises the number of keystrokes required to achieve the desired function.

Alternatively the TA320 can be fully remote-controlled via its RS232 serial interface from a PC which

offers an enhanced soft-key orientated user interface and more sophisticated data displays.

An ARC (Addressable RS232 Chain) compatible RS-232 interface is standard, as is non-volatile storage

of data and set-ups (battery-backed CMOS RAM). Disassemblers for popular microprocessors are

optional.

1

Page 3

Section 1 - Specification

SIGNAL INPUTS

Number of Data Channels: 32

Number of Clock Inputs: 3 Independent clock inputs; active edge can be independently selected

for each to be either positive, negative or off.

Number of Clock Qualifiers: 3, 1 for each clock. Selectable to be active high, low or don't care.

Input Characteristics: Determined by the type of pod fitted. All data and clock inputs on the

standard AP01 (25MHz) pod are fixed TTL threshold with an impedance

of typically 100kOhm//10pF. AP03 and AP04 are high speed (100MHz)

TTL threshold data and clock pods respectively, and AP03V/AP04V are

versions with the threshold variable from 2.5V to +7.3V in 100mV steps.

Input impedance for all high speed pods is typically 100kOhm//6pF.

Activity Indicator: Shows whether the channel input is high, low or switching

MEMORY ORGANISATION

Data Memory Size: 32 bits x 2k

Reference Memory Size: 32 bits x 2k

Non-Volatile Memory: Non-volatile storage for 10 acquisitions and 10 set-ups. Data retention

by Lithium cell; typical life 5 years.

EXTERNAL CLOCK

Frequency Range: DC to 25MHz

Minimum Clock Pulse Width: 20ns

Organisation 3 clocks, individually qualified and ORed together.

Set-up and Hold Times: 18ns set-up, 0ns hold for both data and clock qualifiers.

INTERNAL CLOCK

Clock Rate: Selectable 40ns to 100ms (25MHz to 10Hz) in a l:2:4 sequence with all

pods. 10ns (100MHz) with high speed pods in high speed mode.

TRIGGERING

Trigger Sequencer Words: 4 words of up to 32 bits.

Trigger Sequencer Terms: The actual trigger term searched for in a sequencer step each consist

of up to 4 trigger sequencer words ORed together.

Trigger Sequencer Steps: Each of up to 4 sequencer steps consists of a search for the trigger

term specified in that step. Each step has an event count of 1 to 128

occurrences of the trigger term.

Trigger Position: Selectable to be from 0 to 5k clocks before the start, centre or end of

store, in 1k steps.

Trigger Output: TTL level signal at rear panel BNC

GLITCH (Only available when high speed pods are fitted)

Number of Channels: 16 (8 per pod)

Minimum Detectable Pulse: 5ns

Glitch Triggering: A glitch word can be specified which can be ORed with any trigger word

within a trigger term.

2

Page 4

TIMING DISPLAY

Number of Channels: Any 6 channels may be displayed; channels may be repeated.

Channel Labelling: A user-defined name can be given for each group of channels and each

channel will be uniquely numbered within the group.

Number of Samples: A maximum of 1152 samples can be shown in the display window, with

expansions of x2, x4, x8, and x16. The window can be scrolled

throughout the store and a window indicator shows the position of the

window within the store.

Cursors: A movable cursor and a moveable marker, with direct readout of

absolute and relative store positions and the data values at those locations. The marker will default to the trigger location following each

acquisition.

Glitch: Glitches are shown by markers on the appropriate data channels.

Search: A search can be made for any word; the search word may include

glitches on the glitch channels.

LIST DISPLAY

Channel Groups: Up to 32 channels can be grouped together under a single character

label and given the corresponding name defined on the Timing display.

Up to 16 groups can be specified.

Display Format: Binary, Octal, Hex, Decimal or ASCII individually selectable for each

channel group. Each group is listed underneath its label or name.

Cursors: A movable cursor and a fixed marker are provided.

Search & Compare: Differences between data and reference can be shown and a search

made for any word and any difference. Automatic comparisons between

data and reference memories can be performed on a user specified area

of the data and acquisitions stopped on an equality or inequality.

Print Output: Any specified portion of the List display can be printed out via the RS232

interface to a serial or parallel (with PC02 serial-to-parallel converter)

printer.

SYSTEM DATA

Display: 240 x 64 pixel graphic LCD giving 40 characters x 8 lines.

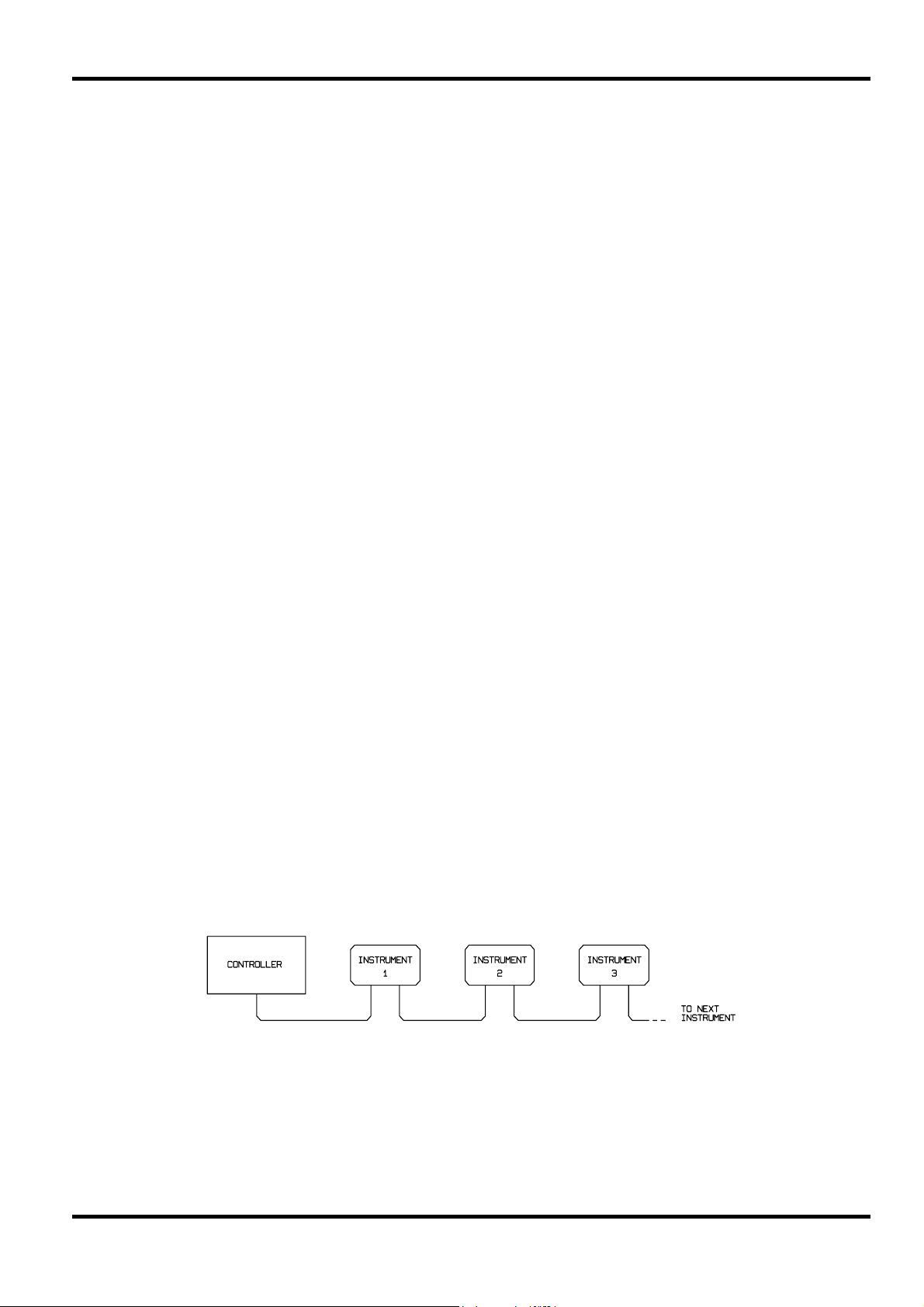

Interface: Addressable RS232 interface, for remote control and data transfer,

complying with the ARC standard.

Audible Warning Signal: Buzzer.

GENERAL

Size: 260(W) x 88(H) x 235(D)mm (10.2 x 3.4 x 9.2").

Weight: 1.9 kg (4.2lb)

Power: 110-120V AC or 220V-240V AC ±10%, 50/60Hz, by rear panel

adjustment. 25VA max. Installation Category II.

Operating Range: +5°C to 40°C, 20-80% RH.

Storage Range:

–20°C to + 60°C.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2

Safety: Complies with EN61010-1.

3

Page 5

Safety

This instrument is Safety Class I according to IEC classification and has been designed to meet

the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use). It is an Installation Category II instrument intended for operation

from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5° and -10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range. In particular excessive moisture may impair safety.

Section 2 - Safety, Installation and EMC

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

This instrument uses a Lithium button cell for non-volatile memory battery back-up; typical life is 5

years. In the event of replacement becoming necessary, replace only with a cell of the correct

type, i.e. 3V Li/Mn0

in accordance with local regulations; do not cut open, incinerate, expose to temperatures above

60°C or attempt to recharge.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

LCD window. The following symbols are used on the instrument and in this manual:-

20mm button cell type 2032. Exhausted cells must be disposed of carefully

2

4

Caution - refer to the accompanying documentation, incorrect operation may

damage the instrument.

alternating current.

Page 6

Mains Operating Voltage

The TA320 is a safety class 1 instrument, installation category II by IEC classification.

Before making connections to the AC line source ensure that the operating voltage of the

instrument is correctly set.

The operating voltage is indicated by the orientation of the fuseholder. When the 230V marking is

upwards the unit is set for operation over the range 198V to 264V. When the 115V marking is

upwards the unit is set for operation over the range 99V to 132V. To change the operating voltage

range, remove the AC line plug, pull out the fuse holder, replace the fuse with one of the appropriate rating (see below) and rotate the fuse holder before pushing it firmly back into place.

Fuse

The correct fuse must be fitted after an operating voltage change. Only a time-lag fuse should be

fitted.

For 230V operation use 125mA 250V time-lag.

For 115V operation use 250mA 250V time-lag.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short circuiting of fuse holders is prohibited.

Mains Lead

When a three core mains lead with bare ends is provided this should be connected as follows:

Any interruption of the protective conductor inside or outside the instrument or disconnection of

the protective earth terminal is likely to make the apparatus dangerous. Intentional interruption is

prohibited.

Maintenance

Cleaning

If the instrument requires cleaning use a cloth that is only lightly dampened with water or a mild

detergent. Polish the display with a soft dry cloth.

WARNING! To avoid electric shock, or damage to the instrument, never allow water to get inside

the case. To avoid damage to the case or display never clean with solvents.

BROWN - MAINS LIVE

BLUE - MAINS NEUTRAL

GREEN/YELLOW - EARTH

WARNING! - THIS INSTRUMENT MUST BE EARTHED

5

Page 7

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

TA320S and TA320PC Logic Analysers

i. meets the intent of the Low Voltage Directive 73/23/EEC by conformance with EN61010-1

(1993) Installation Category II.

and

ii. meets the intent of the EMC Directive 89/336/EEC by conforming with the protection

requirements of the U.K. EMC Regulations SI 1992/2372 under the provisions made for

Education and Training Equipment (Regulation 8).

Use of the apparatus outside the classroom, laboratory, study area or similar such place

invalidates conformity with the protection requirements of the Electromagnetic

Compatibility Directive (89/336/EEC) and could lead to prosecution.

The apparatus when operated will not cause electromagnetic disturbance to apparatus

situated outside its immediate electromagnetic environment.

CHRIS WILDING

TECHNICAL DIRECTOR

1 December 1996

6

Page 8

3.1 Introduction

This section describes how the TA320 is made operational and introduces the user to the

keyboard, the menus and the data displays.

3.2 Power

Having checked that the instrument's operating voltage has been correctly set for the local supply

(see section 2), plug the power cord into the rear panel inlet and switch the instrument on using

the POWER switch beside the inlet.

The analyser will 'beep' and the main Select Menu will be displayed below the instrument

designation and firmware revision shown in the top line, see fig. 3.1. The displays accessible via

this menu are described below together with the keyboard operation.

Section 3 - Initial Operation

3.3 Keyboard

The keys on the front panel can be divided into soft-keys, cursor keys and alpha-numeric keys.

Soft-keys

The 6 keys under the LCD each take the function shown immediately above them on the display;

see, for example, fig 3.1. As the cursors move the edit zone around the editable fields of the

display, the functions shown in the boxes change and hence the functions of the keys change; for

this reason they are known as soft-keys.

The six soft-keys of the Select Menu give access to the six menus and data displays through

which the instrument is controlled and results are presented.

The menus and data displays can also be accessed by pressing the appropriate numeric key

shown beside each display name, e.g. 4 for TIMING display. To move from one such menu or

display to another it is always necessary to return to the Select Menu by pressing the MENU key

in the alpha-numeric group, and to then select the new display with the appropriate soft-key.

The operations accessible through each display are presented in detail in sections 4 to 9. Briefly

the features accessed by each key are:

CONFIG CONFIGuration MENU. Selection of the instrument configuration including pod type,

fig 3.1.

clock parameters, and acquisition modes.

WORDS Trigger WORDS MENU. Specification of the channel groups and the trigger words.

SEQ Trigger SEQuence MENU. Specification of the trigger sequence.

TIMING TIMING DISPLAY. Presentation of the acquired data as a waveform display with

magnify, find, etc. features.

LIST LIST DISPLAY. Presentation of the acquired data as a state list display in the

selected bases (binary, octal, hex, decimal, ASCII and microprocessor mnemonics)

with find, compare etc. features.

UTIL UTILities MENU. Primarily for the saving of data and set-ups to non-volatile memory

and for specifying the RS232 inter-face parameters.

7

Page 9

Cursor Keys

The cluster of 4 arrowed cursor keys have 2 basic modes of operation, i.e. moving the edit zone

around menu displays (and data displays if DIT is switched on) or moving the cursor in the

TIMING and LIST data displays.

When used to move the edit zone in menu displays (and data displays when EDIT is switched

ON) the RIGHT and LEFT cursor keys move the edit zone along the line of the display to the next

editable parameter field, and the UP and DOWN keys move the edit zone up or down to the next

line containing an editable parameter field. Note that, when the edit zone is in the rightmost

editable field of a particular line, a further press of the RIGHT cursor key will take the edit zone to

the leftmost editable field of the line below; similarly if the edit zone is in the leftmost editable field

of a particular line, a further press of the LEFT key will take the edit zone to the rightmost editable

field of the line above. It is therefore always possible to move the edit zone through all the

editable parameter fields of a menu using the RIGHT and LEFT cursor keys only. On some lines

of some menus all the editable fields can be accessed at the same time, using the appropriate

soft-keys, without extra cursor moves and the cursor consequently moves from line to line with

each press of the LEFT or RIGHT cursor key.

When the edit zone is in the bottom line of the display a further press of the DOWN key will bring

it to the top line of the display; similarly if the edit zone is in the top line of display a further press

of the UP key will bring the edit zone to the bottom line of the display, i.e. the display 'wrapsround' as far as the cursor is concerned.

In the TIMING data display the LEFT and RIGHT cursor keys are used to move the cursor or

marker through the acquired data and the UP and DOWN keys can be used to scroll any 6 of the

32 channels or scale into view. In the LIST data display the UP and DOWN cursor keys can be

used to scroll through the complete store and the LEFT and RIGHT keys can be used to bring all

specified channel groups into view. In both data displays, when EDIT is turned ON the cursor

keys move the edit zone around the editable fields as in MENU displays.

Alpha-numeric Keys

The majority of parameters are set using the soft-keys. However, several are more easily set with

direct alpha-numeric entries, such as event and delay counts, character labels for channel

groups, etc. The alpha-numeric keypad provides direct entry of all hex characters plus X (don't

care) and the shift key allows all the other alpha characters to be used for labels, etc.

Note that SHIFT remains operational until it is pressed a second time. Shift mode is always

indicated by the message <SHIFT> at the top right-hand corner of the display.

Also grouped with these keys are the RUN and STOP keys, whose functions are fully described

in section 10, and the MENU and EDIT keys. MENU always selects the main Select Menu and

EDIT selects the edit mode within the TIMING or LIST data displays.

3.4 Pods, Cables and Probes

Pod Types

The standard AP01 32-channel combination data and clock pod provides high impedance

buffering of the signal inputs, over-voltage protection, and line drivers to drive the cables which

connect the pod to the analyser. AP01 has a maximum clock rate of 25MHz and no glitch capture

capability. The input threshold is fixed (TTL).

High Speed AP03 data pods provide 16 data inputs without glitch or 8 data inputs with glitch

capture at clock frequencies up to 25MHz, or 4 data inputs at 100MHz clock (asynchronous only).

Two AP03 data pods are needed for the TA320, together with an AP04 clock pod for synchronous

data acquisition. AP04 provides 3 clocks and 3 qualifiers at up to 25MHz. AP03 and AP04 input

thresholds are fixed (TTL).

High speed AP03V and AP04V data and clock pods are variable threshold versions of AP03 and

AP04. Note that fixed and variable threshold pods must not be mixed on the same analyser.

Disassembler pods are special versions of AP01 containing the disassembler software which

connect directly to the processor via a test clip. Full instructions for use are provided with each

disassembler pod.

8

Page 10

Connecting the Pods to the Analyser

To connect a pod, proceed as follows:

i) Open out the latching levers of the connector, see fig 3.2.(a)

ii) Insert the socket at the end of the pod's cable into the corresponding connector on the rear

panel (TA320S) or front panel (TA320PC). The socket moulding is polarized with a 'bump' so

that it can only be inserted one way round, see fig 3.2.(b)

iii) Press the socket fully home and lock it in position by closing the latching levers, see fig

3.2.(c). The pod can be disconnected again by opening out the latching levers until the socket

is ejected.

fig 3.2

Connecting the Test Leads and Grabber Probes to the Pods

All pods are provided with colour-coded connecting leads which have a multi-pin socket at one

end (for connection to the pod) and which are individually terminated at the other end with

sockets that will connect to the pin of the optional grabber probes or to any other standard .025"

(0.64mm) square or 0.25" diameter pin, e.g. a wire-wrap post. Note that the socket may become

permanently deformed and loose-fitting if it is forced over a larger pin such as those of some IC

test clips (.030" or more).

For microprocessor disassembly a special test lead is provided which is terminated with a testclip for direct connection to the processor.

When connecting the input pods to the target system at least one ground lead on each pod must

be connected to the target to ensure signal integrity.

3.5 Activity Indication

Pressing <EDIT> whilst the main Select Menu is being displayed changes the display to that

shown in fig. 3.3.

The display is a representation of all 32 input channels, numbered according to the hardware

groupings used for the pod inputs.

When an input channel is below the pod threshold the indicator arrow points down, when it is

above the threshold it points up. The indicators track the input state for low frequencies but for

higher frequency signals the indicators will toggle at the rate at which the data is asynchronously

sampled by the CPU, i.e. a few Hertz.

3.6 Display Contrast

Use the CONTRAST control on the case lower to adjust for best LCD contrast with the analyser

set in its working position.

fig. 3.3

9

Page 11

4.1 Introduction

The Configuration menu, accessed by pressing the CONFIG soft-key on the Select Menu has

three principle functions. The first is the selection of the basic configuration of the instrument, i.e.

pod type and glitch on or off. The second is the clock selection including, if external clock is

selected, the specification of the active edges and qualifiers. Thirdly, the menu is used to specify

the acquisition mode, including the comparison ranges if automatic modes are selected.

Fig 4.1. shows the default Configuration menu immediately after selection from the Select Menu.

Section 4 - Configuration Menu

fig 4.1

The first 7 lines contain the parameters which are editable in this display. At the right-hand side of

the top line is the menu title (CONFIG); this area is used to display the status of the current

acquisition (e.g. <RUNNING>) or editing prompts and warnings (e.g. <SHIFT> when the shift

function is selected).

At the bottom are the soft-keys used when editing the display. In this menu all the parameters on

the same line can be edited at the same time so both the LEFT/RIGHT and UP/DOWN cursor

keys move the edit zone one line with each press and the soft-keys change accordingly.

Acquisitions can be initiated and stopped from the Configuration menu but no parameters can be

edited on the menu while the acquisition is running.

4.2 Pod Selection

-POD------------------------------------

Pressing the <POD> soft-key cycles the pod selection through AP01, AP03, AP03V and

DISSassembler in turn. When AP03 or AP03V is selected additional soft-keys are shown to

enable glitch to be selected, and when AP03V is selected further soft-keys permit threshold

selection, see sections 4.3 and 4.4.

4.3 Glitch Selection (APO3 and AP03V only)

POD----ON----OFF------------------------

Soft-key representation

Soft-key representation

10

With AP03 or AP03V selected in the Pod field (see 4.2) the soft-keys change to permit glitch

selection.

<ON> selects glitch on and <OFF> selects glitch off. In the top line of the display <glitch>

indicates that glitch is off and <GLITCH> (i.e. capitals) indicates that glitch is on.

If INTernal clock had already been set to 10ns (100MHz), selecting glitch on will force it to 40ns

(25MHz), the fastest clock rate compatible with glitch selection, see 4.5.

Page 12

With glitch on, the trigger WORDS and SEQuence menus will change to the glitch default settings

to permit only those set-ups compatible with glitch operation. This will happen immediately glitch

is set on (without accessing the other menus) which means that the channel groupings used in

the non-glitch mode will be lost and will not be restored when glitch is set off again.

However, if no acquisition has been run in the new configuration, the 'Last Run Set-up' can be

reloaded from the Utilities menu to restore the previous channel groupings, etc.

4.4 Pod Threshold Selection (AP03V only)

-POD----ON----OFF----TTL----INC----DEC—

With AP03V selected in the Pod field (see 4.2) the soft-keys change as shown above.

The thresholds are INCreased or DECreased from the default TTL (1.4V) level in 100mV steps

using the <INC> and <DEC> soft-keys. The TTL compatible threshold can be reset directly using

the <TTL> soft-key.

The range of values 'wraps-round' such that decreasing -2.5V by a further step sets the threshold

to 7.3V and increasing 7.3V by a further step sets the value to -2.5V. The set threshold is used

universally for the inputs of all data (AP03V) and clock (AP04V) pods.

4.5 Clock Specification

Soft-key representation

Internal Clock

At power-up the clock is defaulted to INTernal clock and 40ns period (25MHz); the soft-keys are

as shown above. With INT clock selected the clock period can be INCreased or DECreased in a

1:2:4 sequence using the <INC> or <DEC> soft-keys. For information only (i.e. it is not an

editable field) the equivalent clock frequency is shown in brackets after the clock period field.

The INTernal clock period can be set from 40ms (25MHz) to 40ns (25MHz) plus 10ns (100MHz)if

APO3 or AP03V have been selected. Note that the range of values 'wraps-round' such that

INCreasing the period when it is already at maximum (40ms) sets the clock to 40ns (10ns if

AP03/AP03V selected) and DECreasing the period when it is already at minimum sets the period

to 40ms.

Selecting 10ns (100MHz) whilst AP03 or AP03V are selected immediately sets the trigger

WORDS and SEQuence menus to the 100MHz default settings to permit only those entries

compatible with 100MHz operation. This means that channel groupings used in sub-100MHz

mode will be lost and will not be restored when 100MHz mode is deselected. If 10ns (100MHz)

has been selected with AP03 or AP03V, reselection of AP01 or DISSassembler pods will

automatically reset the clock to 40ns (25MHz) and any channel groupings set for 100MHz mode

will again be immediately lost. However, if no acquisition has been run in the new configuration,

the 'Last Run Set-up' can be reloaded from the Utilities menu to store the previous channel

groupings, etc. Even with AP03 or AP03V selected the maximum clock reverts to 25MHz if glitch

mode is selected.

INT/EXT-INC----DEC----------------------

Soft-key representation

External Clock

Alternate presses of the <INT/EXT> soft-key select between INTernal and EXTernal. At power-up

the clock is defaulted to INTernal and the first press of <INT/EXT> changes the clock to EXTernal.

With EXTernal clock selected the INTernal clock parameters are suppressed on the display and

the EXTernal clock operates in the way defined by the clock parameters on the next three lines of

the display. Maximum external clock frequency is 25MHz (minimum clock pulse width 20ns).

11

Page 13

External Clock Active Edge

Moving the edit zone into the <Clk 1>, <Clk 2> or <Clk 3> lines of the display changes the softkeys to those shown above. The active clock edge can be set to <+ve>, <-ve>, or <off> with

repetitive presses of the <CLK> soft-key. The active edge can be independently set for the 3

separate clock inputs. Setting the active edge to <off> disables that clock and its associated

qualifier.

External Clock Qualifiers

Pressing the <QUAL> soft-key increments the setting of the qualifier field through the possible

values of 1, 0 or X (don't care). The threshold value used for the qualifiers is the same as that set

for the data and clock inputs.

4.6 Acquisition Mode

Manual Mode

MANUAL--AUTO--=ref---=#ref--aborted------

-CLK----QUAL----------------------------

Soft-key representation

-CLK----QUAL----------------------------

Soft-key representation

Soft-key representation

When the edit zone is in the <Acq Mode> parameter field and <manual> is selected (the powerup default setting), the soft-keys are as above. The <=ref>, <=#ref> and <aborted> soft-keys

names are lower-case because they are inactive in <manual> mode. Pressing <AUTO> will

cause these 3 soft-keys to be made active, see Auto-repeat mode section. Pressing <MANUAL>

will return the instrument to manual mode.

In manual mode, a single acquisition is initiated by pressing the RUN key. Whilst the acquisition is

in progress the message <RUNNING> will be shown on the right-hand side of the top line of the

display. This message may change to a warning message <no clk> if RUN is pressed with

EXTernal clock selected but no clock signal connected. The <compare from to> field is

inoperative in <manual> mode.

Auto-repeat Mode

Pressing the <AUTO> soft-key whilst in manual mode changes the <Acq mode> parameter field

from <manual> to <repeat until> and makes the <=REF>, <=#REF> and <ABORTED> soft-keys

active. This is indicated by a change from lower-case to capitals for the soft-keys names. Now

when the RUN button is pressed acquisitions will be initiated, completed and re-initiated as

specified by the <repeat until> field. The message <RUNNING> will be shown on the right-hand

side of the top line of the display whilst the acquisition is running, but not between one acquisition

and the next. Auto acquisitions can be stopped at any time by pressing the STOP key which

operates as follows in auto-repeat modes. The first press of STOP during an auto acquisition

effectively changes the acquisition to manual mode; no further acquisitions are initiated when the

present one is completed. If STOP is pressed a second time before the acquisition is completed

then the acquisition is immediately terminated; no further acquisitions are initiated until RUN is

pressed again. However, between acquisitions, i.e. when <RUNNING> is not shown in the top

line of the display, only one press of STOP is required to inhibit further acquisitions.

MANUAL--AUTO--=REF---=#REF--ABORTED------

Soft-key representation

12

Page 14

Auto-repeat Conditions

Pressing <=REF> sets the condition that, when RUN is pressed, acquisitions will be repeated

until the acquired data matches the data held in reference memory for the specified store

locations and channels.

Pressing <=#REF> sets the condition that, when RUN is pressed, acquisitions will be repeated

until the acquired data does not match the data held in reference memory for the specified store

locations and channels.

Pressing <ABORTED> sets the condition that, when RUN is pressed, acquisitions will continue

until halted by pressing the STOP key as described previously. In each case, the number of

acquisitions made is shown in the <count=nnn> field. The maximum count is 999.

Compare Memory Range

Moving the edit zone down to the last line of the menu changes the soft-keys as shown above.

Alternate presses of the <FROM/TO> soft-key changes the field into which entries can be made

from <FROM nnnn> to <TO nnn>; the active field is the one in capitals into which numeric entries

can be made.

Keyboard entries are made 'calculator-style', i.e. store location 1000 is entered as 1,0,0,0; each

entry appears in the least significant position and increments the previous entry to the next

significant digit on the left. Four key entries fill the field; the next entry will be interpreted as the

first digit of a new store location and will therefore be shown in the least significant position with

all other digits shown as zeroes. A low-numbered location can be entered either as, for example,

0,0,2,1, or as 2,1,X where X terminates the entry; moving the edit zone out of the field also

terminates the entry. Both the start and stop store locations are included in the comparison. If the

start location is greater than the stop location, no comparison will be made. The default values of

the start and stop compare locations are 0000 and 2047 respectively. Comparisons will be made

only across those channels which have been given a label in the WORDS menu, i.e. channels

that have been switched off are masked from the comparison.

FROM/TO---------------------------------

Soft-key representation

13

Page 15

5.1 Introduction

The Trigger WORDS menu, accessed by pressing the WORDS soft-key on the main Select

Menu, is used to create the channel groups and to define up to 4 trigger words.

Fig 5.1. shows the WORDS menu with its power-up default values (assuming the Configuration

menu also has its default values).

Section 5 - Trigger Words Menu

The Trigger menu is edited by moving the edit zone to the parameter field of interest. The edit zone is

moved around the editable parameter fields by the

Acquisitions can be initiated and stopped from the Trigger menu but no parameters can be edited

on the menu while the acquisition is running.

5.2 Channel Group Labels

DEFAULT-CLEAR--OFF----------------------

A channel group is any block of contiguous channels grouped together under one channel group

label letter. A channel group may be from 1 to 32 channels wide and up to 16 different groups

may be specified and labelled with the letters <a> through <p>. A channel group may not be split,

i.e. all channels used in the group must be adjacent. If a label is split whilst labelling the channels,

the warning message <LABEL!> will be shown on the right-hand side of the top line of the display.

The label will be accepted (and labelling can continue) but the warning will continue to be

displayed and it will not be possible to move the edit zone from this line, or run an acquisition,

until the split label has been corrected.

Any letter <a> through <p> can be entered from the keyboard, using the SHIFT key for letters

<g> through <p>. As each letter is entered, the 'flashing' cursor automatically moves right to the

next channel so that its label can be edited. The 'flashing' edit cursor can also be moved to a

particular position using the LEFT and RIGHT cursor keys without disturbing the labelling of the

channels the cursor moves through.

The <CLEAR> soft-key can be used to clear all the channel groupings. Since clearing the labels

in this way may cause a complex set-up to be lost, two presses of the <CLEAR> soft-key are

required; after the first press the message <CONFIRM> is displayed on the right-hand side of the

top line of the display and a second press is required to actually implement the clear. Pressing

any other key instead of the <CLEAR> soft-key a second time will maintain the existing label

status and clear the warning message.

Pressing the <DEFAULT> soft-key sets the channel groupings to those shown in fig 5.1. Two

presses of the <DEFAULT> soft-key are necessary to implement the change, as for <CLEAR>.

Note that changing to and from 100MHz and glitch modes on the Configuration menu

immediately changes the WORDS menu to the appropriate default state. The channel grouping

used in the previous configuration is lost and not restored when the configuration is changed

back. However, if no acquisition has been run in the new configuration, the 'Last Run Set-up' can

be reloaded from the Utilities menu to restore the previous channel groupings, etc.

fig 5.1

cursor keys as described in section 3.

Soft-key representation

14

Page 16

5.3 Trigger Word Radix Selection

--BIN---OCT----HEX----------------------

Having grouped and labelled the data channels as required (section 5.2), the edit zone can be

moved to the radix field; the soft-keys change as shown above.

The base for each channel group can be independently set to be BINary, OCTal or HEXadecimal

using the appropriate soft-key. The RIGHT and LEFT cursor keys are used to move the edit zone

to each channel group in turn.

The base can also be changed with the edit zone in the trigger word fields, see section 5.4; this

section also explains how 'don't care' trigger word entries are handled by the software when the

base is changed.

5.4 Trigger Word Specification

--BIN---OCT----HEX-----------------FIND-

The trigger words themselves can be specified by moving the edit zone into each channel group

parameter field of the four trigger words in turn. The trigger words are defined by entering

characters from the keyboard consistent with the selected base of each channel group, viz. 0 and

1 for binary, 0 through 7 for octal and 0 through 9 plus A through F for hexadecimal. An X can be

used to denote a 'don't care' in any of the three bases. If there is not an exact multiple of 3

channels in an octal group, or an exact multiple of 4 channels in a hex group then the 'incomplete'

group will be the most significant bit in the appropriate base and the entries accepted in that bit

will be restricted accordingly. Thus an 8-channel group can have a trigger word specified in hex

between 00 and FF, but a 7-channel group with a hex base is restricted to entries between 00

and 7F.

Soft-key representation

Soft-key representation

As each bit is specified in the appropriate base, the 'flashing' cursor automatically moves right to

the next trigger bit. The 'flashing' cursor can also be moved to a particular position using the

RIGHT and LEFT cursor keys without disturbing the trigger bits that the cursor moves through.

As indicated by the available soft-keys, it is possible to also change the radix of the channel

groups whilst in the trigger word fields; the three soft-keys can be used to select the required

base for the channel group within which the edit cursor is currently positioned. If X (don't care) is

present in a trigger word when a radix change is made then the corresponding bit or bits in the

new base will be shown in one of the two following ways. Firstly, if an exact correspondence can

be shown in the new radix then X will appear in the appropriate bit(s); for example

1111XXXX(binary) will change to FX (hex) and vice-versa. However, if there is no exact

correspondence then an asterisk (*) will be displayed instead of an X; for example 1111111X

(binary) will be shown as F* (hex) to indicate that at least 1, but not all, of the 4 least significant

channels are don't care(s). Note that the original trigger word entry is always remembered in its

original base; it is always used in that form within the analyser and can be displayed again by reselecting that base. Thus 1111111X ( b i n a r y ) b e c o m e s F * ( h e x ) b e c o mes 1111111X (binary);

however, if F* (hex) is edited to FX (hex) then this becomes 1111XXXX (binary).

In 100MHz mode (AP03 and AP03V only) only the active channels (a0-a3 and b0-b3) are shown

and may be edited. The disabled channels are suppressed on the display and both the label and

trigger bit entries are replaced by <.>.

Similarly when glitch is on only the 8 active channels of each pod (a0-a7 and b0-b7) are shown.

Channels disabled for these reasons are also suppressed on the Timing and List displays.

15

Page 17

5.5 Find Word Specification

--BIN---OCT----HEX-----------------FIND-

Any one of the trigger words can additionally be specified as a FIND word for use in a search of

the LIST display. The default FIND word is Word 1 and this is indicated by an <F> next to the

<Wd1> name. To make another trigger word the FIND word, move the edit cursor to any bit within

that word with the cursor keys and press the <FIND> soft-key. The <F> marker will move to that

word.

5.6 Glitch Triggering (AP03 and AP03V only)

If glitch has been selected on in the Configuration menu then the Trigger WORD menu changes

from showing Word 4 to the glitch trigger word <GLT> in the last line above the soft-keys,

see fig. 5.2.

Soft-key representation

fig 5.2

With the edit cursor in this field the soft-keys change to:

--OFF---ON------------------------------

Soft-key representation

Pressing the <ON> key enters a <G> on the glitch channel where the 'flashing' edit cursor is

positioned and automatically steps the cursor to the next channel; pressing <OFF> enters an X

(don't care); G and X can also be entered directly from the keyboard. The RIGHT and LEFT

cursor keys can be used to move the edit cursor through the field without affecting the bits

already set.

The glitch trigger word (<GLT>) is the ORed combination of any glitches specified. This glitch

word can then be used in the sequencer specification in the usual way, see section 6. The glitch

word cannot be used as a <FIND> word.

16

Page 18

6.1 Introduction

The Trigger Sequence menu, accessed by pressing the SEQ soft-key in the main Select Menu is

devoted entirely to the trigger sequence itself. For clarity, the full trigger sequence construction is

always shown even if it is not fully utilised or, as in the case of 100MHz operation, is not fully

available. Fig 6.1. shows the default sequencer menu at power-up, assuming the Configuration

menu also has its default values set.

The sequencer has four steps followed by the trigger position specification. Each step consists of

specifying the trigger term to be found, the number of times it must be found, and the restart term

which will cause the sequence to be restarted; the trigger position field allows the trigger to be

positioned up to 5,000 clocks before the start, centre or end of store. These parameters are

explained fully in the following sections.

Section 6 - Trigger Sequence Menu

fig. 6.1

6.2 The Find Term

With the edit zone in the <find> term field of any of the 4 sequence steps, the soft-keys are as

shown above.

The <find> term is any ORed combination of the 4 trigger words. Trigger words are added or

deleted from the <find> term with alternate presses of the corresponding <Wd1> through <Wd4>

soft-keys; the keyboard keys <1> through <4> can also be used. The trigger words will always be

shown in numerical order in the <find> term, regardless of the order in which they have been

entered.

The <X> soft-key can be used to make the whole term 'don't care'. Note that, to ensure a valid

sequence is always constructed, <x> default don't cares are automatically inserted into 'empty'

sequence steps followed by an active step. The use of a lower-case <x> differentiates the 'don't

care' from one deliberately inserted (<X>) but the sequence operates in the same way in both

cases.

The <CLEAR> soft-key is an alternative, quicker, way of clearing all words from the term.

When glitch is selected on (AP03 and AP03V pods only) a glitch trigger word can be set up in the

Trigger Words menu, see section 5, and on the sequencer menu soft-key <Wd4> is replaced by

<GLT> the glitch trigger word. Alternate presses of <GLT> insert the glitch trigger word in the

<find> term in the same way as for trigger words <Wd1> through <Wd3> and the <find> term

becomes the OR'ed combination of the specified words.

--Wd1----Wd2----Wd3---Wd4---CLEAR---X---

Soft-key representation

In 100MHz mode the sequence is restricted to a single <find> term.

17

Page 19

6.3 Trigger Event Delay

Moving the edit zone to the <n clks> field in any of the sequence steps gives the soft-key display

shown above. The number of times that the trigger term must be found (before the sequencer is

incremented to the next step) is set in this field.

Up to 128 counts of the trigger term can be specified, either by using the <INC> and <DEC> softkeys or (more quickly for larger counts) by direct decimal entries from the keyboard. If a count of

0 is entered from the keyboard, a warning message <illegal value> is displayed at the right-hand

side of the top line of the display; the count will default to 001 when the field is exited. If a count of

greater than 128 is entered from the keyboard, the entry defaults to 128. Keyboard entries are

made 'calculator-style' as described more fully in section 4.

The count can always be returned to its minimum value 001) by pressing the <N=1> soft-key.

No event count is available in 100MHz mode.

6.4 The Restart Term

--Wd1----Wd2----Wd3---Wd4---CLEAR---X---

INC----DEC----N=1----------------------

Soft-key representation

Soft-key representation

With the edit zone in the <restart if> field of any of the 4 sequence steps, the soft-keys are as

shown above.

The restart feature adds a conditional capability to the trigger sequencer which resets the

sequencer to the step 1 <find> term if the specified <restart if> term is found. The <restart if> term

is any ORed combination of the 4 trigger words. Trigger words are added or deleted from the

<restart if> term with alternate presses of the corresponding soft-keys <Wd1> through <Wd4>;

the keyboard keys <1> through <4> can also be used. The words will always be shown in

numerical order in the <restart if> term, regardless of the order in which they have been entered.

The <X> soft-key can be used to make the whole term 'don't care'. The <CLEAR> soft-key is an

alternative, quicker, way of clearing all words from the term.

No restart capability is available in 100MHz mode since it is meaningless in a single-step

sequence.

6.5 Trigger Position

Moving the edit zone down from sequence step 4 into the trigger position fields enables both the

clock count and the reference position to be entered using the soft-keys shown above.

The power-up default condition is <0k> clocks before the start of store; the trigger word is put in

store location 0000 and the store is filled with the samples following the trigger word. This set-up

ensure that a complete store full of data is acquired even if the trigger words are all don't care.

--INC---DEC----N=0---END---START---50%--

Soft-key representation

18

If the trigger position is selected to be <0k> clocks before the end of store by pressing the <END>

soft-key then the trigger word is positioned at the end of the stored data. Note that if the trigger

word is recognised within the specified store depth then the store will not be completely filled; the

first store location will contain the first sample of data acquired after pressing RUN and the last

stored sample will be the trigger word. An extreme example of this is if the trigger is recognised

immediately the acquisition is initialised; the store will be empty except for the trigger word

positioned at the first location.

Page 20

Similarly, if the trigger position is selected to be <0k> clocks before the centre of store by pressing

the <50%> soft-key then the trigger word is positioned half the store before the last stored

sample; if the trigger is recognised within half the store of initiating the acquisition then the

second half of the store will be correspondingly partly empty.

It is possible to position the trigger elsewhere in the store, or before the start of store, in steps of

1k clocks using the <trigger nk clks before> field.

The trigger delay clock count is INCreased or DECreased in 1k steps using the <INC> or <DEC>

soft-keys; it can also be specified by direct decimal entries from the keyboard in the range 0 to 5.

The count can always be returned to its default value of <0k> by pressing the <N=0> soft-key.

6.6 Trigger Output

The <TRIGGER OUT> signal at the rear panel BNC connector is a TTL level signal which goes

high when the last trigger term in the sequence is found, i.e. before the delay by clocks (if used).

19

Page 21

7.1 Introduction

The Timing display is accessed by pressing the TIMING soft-key in the main Select Menu.

Section 7 - Timing Display

fig 7.1

The top line of the display is an information line giving the current magnification, a graphical

representation of the part of the store currently being displayed, plus cursor, marker and

difference location readouts.

Below the information line are 6 lines for the display of data; channels can be displayed and

repeated in any order. Any channel can be brought into view, either by scrolling it into the display

with the UP and DOWN cursor keys, or by direct editing. To the left of each displayed line is the

name of the channel; this is either the default channel group label, or a channel group name that

can be given to it in the edit mode of this display.

At power up the data displayed is that from the last acquisition but the channels will be in default

order, see 7.8.Striking vertically through the lines of data are a movable cursor and marker; the

cursor and marker are themselves marked <c> and <m> respectively at the top of the vertical

lines, above the first line of timing data. Either the cursor or marker may be designated active at

any one time, i.e. made movable by the arrowed RIGHT and LEFT cursor keys. Magnification of

the data by up to x16 is possible; magnification is always about the cursor, <c>. A graphical

representation of the store area currently being displayed is shown in the information line above

the data area.

Down the right-hand side of the data area is a column of characters, one character for each line

of waveform data. This column can be selected to give a readout of the cursor or marker

positions, or can be used to specify a FIND word used in a search of the Timing display.

There are no soft-keys until edit mode is entered by pressing the <EDIT> key; in edit mode the

last line of channel data is replaced by soft-keys which change with the position of the edit zone,

as in the menu displays.

Acquisitions can be initiated and stopped from the Timing display and the display can be

manipulated while the acquisition is running although the speed of operation will generally be

slower.

7.2 Active Cursor Marker Selection and Move

-MAG>---MAG<-CUR/mar-ACQ/ref-----EX-FIND

Either the cursor or the marker is selected to be active at any one time. The one currently active

is indicated by displaying it as a capital letter in the <C=nnnn> or <M=nnnn> position field in the

information line at the top of the display; the inactive one is displayed with a lower-case <c> or

<m>. In fig 7.1 the cursor is active. Only the one currently active can be moved by the RIGHT and

LEFT cursor keys or by direct entries from the keyboard. Moving the cursor and marker on the

Timing display also moves them on the List display.

20

Soft-key representation

Page 22

To change which one is active it is necessary to enter edit mode by pressing the <EDIT> key. The

bottom line of the display shown in fig. 7.1. is replaced by the soft-keys shown above if the cursor

is in its default position.

Marker or cursor are set active with alternate presses of the <CUR/mar> soft-key; as well as

showing <C=nnnn> or <M=nnnn> in capitals, the active one is shown by using capitals for

<CUR> or <MAR> in the soft-key itself.

The information line at the top of the display gives the cursor and marker absolute store locations

in the fields <C=nnnn> and <M=nnnn> respectively.

Each location corresponds to a clock sample, either internal or external as defined on the

Configuration menu; the interval of the internal clock, if used, is only shown on the Configuration

menu. The one currently active is indicated with a capital <C> or <M> and, having exited edit

mode, direct numeric entries can be made to that field to move the cursor/marker quickly.

Keyboard entries are made 'calculator-style', i.e. store location 1000 is entered as 1,0,0,0; each

entry appears in the least significant position and increments the previous entry to the next

significant digit on the left. Four key entries fill the field and on the fourth entry the cursor/marker

is moved to the specified location; the next entry is then interpreted as the first digit of a new

location. To move to a low-numbered location the entry can either be made as, for example,

0,0,2,1, so that the move is made on the fourth (1) entry key press, or it can be entered by

pressing 2,1,X, where X terminates the entry and causes the cursor/marker to move. High

numbers, outside the range of the currently selected store depth, are accepted but the cursor will

only move to the highest location in the store. Note that, when the active cursor/marker is being

moved with the RIGHT and LEFT cursor keys, the cursor/marker initially moves slowly but then

speeds up if the key is kept depressed; releasing the key and pressing again (as the

cursor/marker approaches the desired location) moves it slowly once more.

7.3 Acquisition Reference Memory Selection

-MAG>---MAG<-CUR/mar-ACQ/ref-----EX-FIND

With edit mode selected by pressing the <EDIT> key, the soft-keys are as shown above. The

memory whose contents are to be displayed is selected with alternate presses of the <ACQ/ref>

soft-key; the currently active memory is shown in capitals within the soft-key itself, the inactive

one in lower-case letters. The acquisition memory is the memory in which the most recently

acquired data is stored.

The reference memory may have been loaded from the previous acquisition or any earlier

acquisitions saved in non-volatile memory, see section 9.

7.4 Glitch Display

-MAG>---MAG<-CUR/mar-ACQ/REF-glt-EX-FIND

With edit mode selected by pressing the <EDIT> key, the soft-keys are as shown above. If the

data being displayed was acquired with glitch mode selected on the Configuration menu (AP03,

AP03V only), then an additional <glt> (glitch) soft-key will show to the right of the ACQ/ref key.

Alternate presses of the <glt> soft-key will then turn the display of glitches on or off; the current

status of the glitch display is shown by displaying <GLT> in capitals for glitch on and <glt> (lowercase) for glitch off.

Soft-key representation

Soft-key representation

Glitches are shown on the display as vertical lines extending both above the logical '1' level and

below the logical '0' level. As a reminder that only channels 0 through 7 of each pod are active

when glitch is selected, they are marked with a lower-case <g> following their channel group

name at the left-hand side of the data line.

21

Page 23

7.5 Display Magnification

-MAG>---MAG<-CUR/mar-ACQ/ref-----EX-FIND

With edit mode selected by pressing the <EDIT> key, the soft-keys are as shown above. The

display magnification can be increased and decreased from x1 to x16 in multiples of 2 using the

<MAG>> and <MAG<> soft-keys respectively.. The range of values 'wraps-round' so that

INCreasing the magnification by a further step when it is already at x16 will set it to x1, and

DECreasing the magnification by a further step when it is already at x1 will set it to x16; this can

be used to get from minimum to maximum magnification very quickly, and vice-versa. The current

magnification factor is always shown in the <mag => field in the information line at the top of the

display.

In the information line there is also a graphical representation of the area and 'depth' of the

currently displayed data. The whole store is defined by the single line below the <M=> and <CM=> fields and the extent and position of the currently displayed data is shown by the shorter line

on top of the full line. Note that, since less than 2k samples can be displayed at once, the line

indicates that only about 1/2 of the store is currently being displayed with the magnification at x1.

7.6 Data Searching in the Timing Display

-MAG>---MAG<-CUR/mar-ACQ/ref-----EX-FIND

Soft-key representation

Soft-key representation

With edit mode selected by pressing the <EDIT> key, the soft-keys are as shown above. A search

for the specified <FIND> word can be made at any time by pressing the <EX-FIND> soft-key. If

the word is found, the cursor will move to that store location; subsequent presses of the <EXFIND> soft-key will move the cursor to the next higher store location at which the word is found,

and so on until the end of the store is reached.

To set up the <FIND> word the edit zone must first be moved to the right-hand 'readout' column

by one press of the RIGHT cursor key (from the default position); the soft-keys then change to

those shown below:

--------FIND--CURSOR--MARK-------EX-FIND

Soft-key representation

The <FIND>, <CURSOR> and <MARK> soft-keys are then used to select the function of this

column:

<FIND> : column becomes the <FIND> word and binary entries can be specified from the

keyboard; as each entry is made the edit cursor automatically moves down to the

next line. The edit cursor can also be moved up and down the column by the

arrowed UP and DOWN cursor keys. If glitch display is on (see section 7.4) then

the <FIND> can also be specified to search for glitches by entering G instead of

0, 1 or X in the <FIND> bits of the glitch channels.

The search is made across all channels currently turned on in the Timing display

(see section 7.8), not just those currently view. When the channel order is edited

the <FIND> bit moves with its associated channel. A search can be initiated

without the <FIND> being displayed.

22

<CURSOR> : column becomes the readout, in binary, of the store contents at the location of the

cursor <c>.

<MARK> : column become the readout, in binary, of the store contents at the location of the

marker <m>.

Page 24

7.7 Channel Group Names

-------SPACE----/-----*------?-----CLEAR

Moving the edit cursor down with the DOWN cursor key from its default position (when edit mode

is first selected) changes the soft-keys to those shown above.

Each of the 16 possible channel groups can be given a 4-character channel group name in place

of the <A...>, <B...>, <C...>, etc, default "names" which correspond to the labels <a>, <b>, <c>,

etc., allocated in the trigger <WORDS> menu. With the edit cursor positioned over the first

character of any default channel name within the group to be changed, a new name can be

entered from the keyboard. Any number or character can be used in the channel group name,

including the four special characters available on the soft-keys, i.e. <SPACE>, </>, <*> AND <?>.

As each character is entered the 'flashing' cursor automatically moves to the next character to be

edited; it can also be moved to a particular position using the LEFT and RIGHT cursor keys. The

<CLEAR> soft-key blanks the whole name, and moves the edit cursor to the first position to allow

a new name to be entered.

When there is more than 1 channel in a group changing the name of any channel in the group

renames all the channels in that group. However, each channel in the group is automatically

uniquely numbered. For example, if there are 4 channels grouped under a label and given the

name <DATA>, the Timing display will show the 4 channels labelled as <DATA0> through

DATA3>. Note that because the channel name is restricted to 5 characters including the

automatically added numbers, 4-character names are truncated to 3 characters for groups with

channel numbers greater than 9. For example, a channel group of 16 channels with a channel

name <DATA> will have the channels named on the Timing display as <DATA0> through DATA9>

and <DAT10> through <DAT15>.

Soft-key representation

7.8 Editing the Timing Display

INSERT-DELETE--NEXT--PREV-DEFAULT-------

Soft-key representation

Moving the edit cursor to the right of any channel name with the RIGHT cursor key changes the

soft-keys to those shown above. The default order in which the data channels are displayed at

power up is channel 0 through channel 15 of DATA A followed by channel 0 through 15 of DATA

B, where DATA A and DATA B are the hardware channel groupings defined by the analyser input

connectors and the pods themselves. The data channels can, however, be repeated and

displayed in any order using the 5 soft-keys.

With the edit zone positioned to the right of any channel name, the five soft-keys have the

following functions:

<DEFAULT> returns the channel order to the default setting. Pressing <DEFAULT> once causes

the warning message <CONFIRM> to be displayed at the right-hand side of the top

line of the display; it is necessary to press it a second <DEFAULT>. Pressing any

other key instead of a second press of <DEFAULT> will prevent the default from being

implemented.

<DELETE> deletes the data channel over which the edit zone is positioned; all the channels below

that line are immediately scrolled up one position and the edit zone therefore

effectively becomes positioned over what was the next data channel.

<NEXT> changes the data channel displayed at the edit zone position to the next data channel

as defined by the hardware, e.g. if the edit zone is at channel 14 of DATA A, the data

channel will change to channel 15 of DATA A, then channel 0 of DATA B etc.

23

Page 25

<PREV> changes the data channel displayed at the edit zone position to the previous data

channel as defined by the hardware, e.g. if the edit zone is at channel 14 of

DATA A, the data channel will change to channel 13 of DATA A, then channel 12 of

DATA A, etc.

<INSERT> scrolls all the data channels below the edit zone down 1 line with each press. The line is

left blank until a data channel is inserted using the <NEXT> and <PREV> keys. If the

<NEXT> key is the first key pressed after <INSERT> then channel 0 of DATA A will be

inserted and further presses of <NEXT> will increment the line forward through all the

channels in their hardware order as described for <NEXT> above. If the <PREV> key is

the first key pressed after <INSERT> then a blank will be inserted and further presses of

the <PREV> key will decrement the line back through all the channels in their reverse

hardware order as described for <PREV> above.

Note that there is effectively a 33rd line which is a 'blank'; if the line is incremented with the

<NEXT> key through all possible channels, a further press of <NEXT> will make the line blank;

one more press will bring channel 0 of DATA A into view, etc. Similarly, pressing <PREV> with the

edit zone over channel 0 of DATA A will make the line go blank and another press will bring

channel 15 of DATA B into view, etc. In 100MHz or glitch modes (APO3/APO3V only) the

unavailable channels are automatically suppressed on the Timing display. When standard 32channel mode is reselected (no 100MHz or glitch) the channels remain suppressed, if an

acquisition had been made in 100MHz or glitch mode, until a new acquisition is taken. The

channels that are available when a configuration is changed will be shown in whatever position in

the Timing display they were last edited into.

24

Page 26

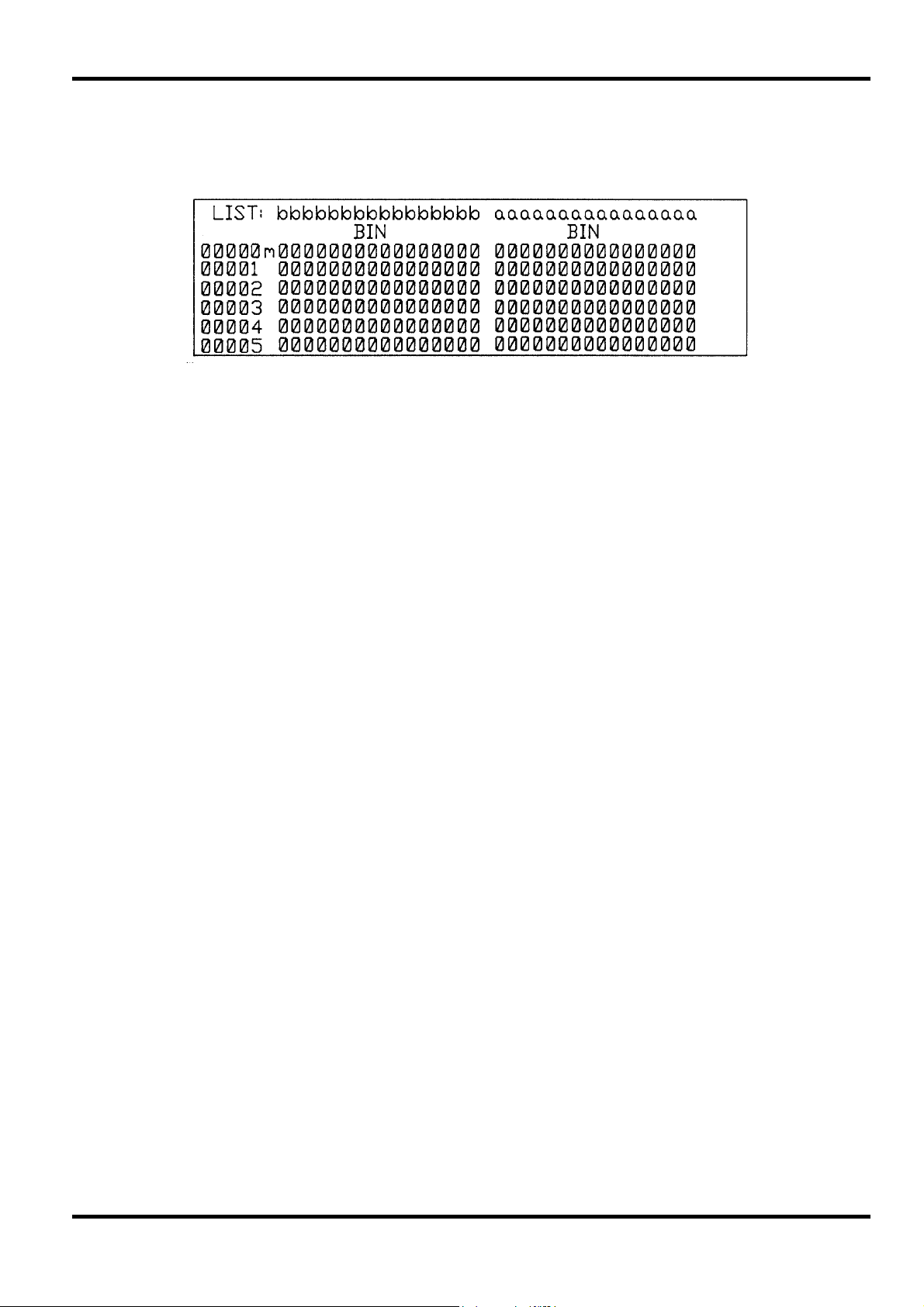

8.1 Introduction

The List display is accessed by pressing the LIST soft-key in the main Select Menu.

Data from 6 consecutive store locations and the numbers of the locations are listed in channel

groups headed by the channel group label and group base. The cursor is always positioned in the

top line of the display and is not marked; the marker position is indicated by an <m> immediately

to the right of the store location column. At power-up the data displayed is that from the last

acquisition but only the default channel groups <a> and <b> will be listed.

There are no soft-keys until edit mode is entered by pressing the <EDIT> key; in edit mode the

last line of data is replaced by soft-keys which change with the position of the edit zone, as in the

menu displays. Acquisitions can be initiated and stopped from the List display and the display can

be manipulated while the acquisition is running although the speed of operation will generally be

slower.

Section 8 - List Display

fig 8.1

8.2 Cursor Move

The data at the store location at which the cursor is present is always displayed on the top line,

i.e. the cursor is always at the top line of the data display. The UP cursor key moves the cursor to

the next higher store location (auto-repeating if kept pressed); since the cursor is always

positioned on the top line of the display, this has the effect of scrolling the data up the display. The

data can be scrolled up the display until the last valid store location is brought into the display.

Similarly, the DOWN cursor key moves the cursor to the next lower store location; ie. scrolls the

data down the display. The data can be scrolled down the display until the first valid store location

is in the top line of data.

Fast cursor moves can be achieved using the <P>UP> and <P>DOWN> soft-keys available in

edit mode which respectively scroll the data up and down by 6 locations at each key press.

The cursor can also be moved with a direct keyboard entry. Keyboard entries are made

'calculator-style', i.e. store location 1000 is entered as 1,0,0,0. The first entry enters the number in

the least significant position; each subsequent entry appears in the least significant position and

increments the previous entry to the next significant digit on the left. Four key entries fill the field

and on the fourth entry the cursor is moved to the specified location.

To move to a low-numbered location the entry can either be made as, for example, 0,0,2,1, so

that the move is made on the fourth (1) key press, or it can be entered by pressing 2,1,X, where X

terminates the entry and causes the cursor to move. High numbers, outside the range of the

currently selected store depth, are accepted but the cursor will only move to the highest location

in the store. Moving the cursor in List display also moves it to the same store location in Timing

display.

The LEFT and RIGHT cursor keys are used to scroll all the channel groups into view if they

cannot be viewed simultaneously; this situation can arise if channel groups with a large number of

channels are repeated several times in a 'wide' base, e.g. binary, see section 8.6. Additional

channel groups to the right are indicated by the > symbol on the far right of the group label line;

these groups can be brought into view by pressing the RIGHT cursor key. Similarly, groups to the

left of the channels in view are indicated by the < symbol and can be brought into view by

pressing the LEFT cursor key.

25

Page 27

8.3 Acquisition Reference Memory Selection

-FND1-compare-diff-ACQ/ref-P>DOWN--P>UP-

With edit mode selected by pressing the <EDIT> key and the edit zone moved to the bottom line

of the display with 2 DOWN cursor presses, the soft-keys are as shown above. The memory

whose contents are to be displayed is selected with alternate presses of the <ACQ/ref> soft-key;

the currently active memory is shown in capitals within the soft-key itself, the inactive one in

lower-case letters.

The acquisition memory is the memory in which the most recently acquired data is stored. The

reference memory may have been loaded from the previous acquisition or any earlier acquisitions

saved in non-volatile memory, see section 9.

8.4 Data Searching in the List Display

-FND1-Compare-diff-ACQ/ref-P>DOWN--P>UP-

A search for a particular word can be made at any time by pressing the <FIND> soft-key. If the

word is found, the cursor will move to that store location; subsequent presses of the <FIND> softkey will move the cursor to the next higher store location at which the word is found, and so on

until the end of the store is reached. The word to be found is the trigger word marked with an

<F> in the WORDS menu, see section 5.5; if <WD1> was marked as the <FIND> word then the

soft-key is shown as <FND1> in the List display, if <Wd2> then it is shown as <FND2> etc.

Soft-key representation

Soft-key representation

Any number of words can be searched for by editing the trigger word(s) specified as a <FIND>

word and re-running <FIND n> on the same data, i.e. a search is not restricted to the words used

in the trigger sequence of the acquisition itself. The search for a specified word is made across

the full width of the data, not just the channels displayed, and ignores the order and base of the

displayed channels. If a search is to be restricted to a certain group of channels then 'don't cares'

must be specified in the remaining channels on the trigger WORDS menu, see 5.4, or the

unwanted channels must be turned off, see 5.2.

8.5 Compare and Find Difference in the List Display

-FND1-Compare-diff-ACQ/ref-P>DOWN--P>UP-

Soft-key representation

A comparison between the acquisition and reference memories can be switched on and off with

alternate presses of the <compare> soft-key; the current ON condition is indicated within the softkey itself by showing <COMPARE> in capitals. Differences are shown with an asterisk (*). When

COMPARE is ON, the <DIFF> soft-key becomes active, indicated by showing <DIFF> in capitals.

A search for a difference can be made by pressing the <DIFF> soft-key whilst the COMPARE is

ON. If a difference is found, the cursor will move to that store location; i.e. the difference will move

to the top line of the display. Subsequent presses of <DIFF> will move the cursor to next higher

store location at which a difference is found, and so on until the end of the store is reached. A

search for a difference applies only to those channel groups currently being viewed, i.e. the

search ignores channels not displayed and channels that have 'overflowed' the display to the left

and/or right.

26

Comparisons with the reference memory are possible even if the reference memory contains data

acquired under different conditions, eg. 100MHz configuration or glitch on. However, such

comparisons will be meaningless and it is left to the user to ensure that comparisons are only

made between memories that have data acquired under identical conditions.

Page 28

8.6 Editing the List Display

Fig 8.1. shows the 'default' List display after running an acquisition with the default parameters of

the Configuration and Words menus; the data is listed in binary in the 2 default channel groups

(group <a> for the DATA A channels, etc.). Note that at switch-on the data displayed will always

be that from the last acquisition but it will be displayed in the default format; to display it in the

correct format it is necessary to recall the last run set-up from non-volatile memory, see section 9

By entering edit mode using the <EDIT> key, the channel groups displayed, and the base they

are displayed in, can be edited.

Editing Channel Groups in List Display

INSERT-DELETE--NEXT--PREV--DEFAULT-NAME-

With the edit mode selected by pressing the <EDIT> key, the soft-keys are as shown above with

the edit zone in the label line. The RIGHT and LEFT cursor keys move the edit zone along the

label line from one channel group to an adjacent one.

The only channel groups which can be displayed are those which have already been defined in

the trigger WORDS menu, see section 5.2. In 100MHz or glitch modes, the groups displayed are

further restricted to those of the channels which are operational in such configurations. When

standard 32-channel mode is reselected (no 100MHz or glitch) the channels remain suppressed,

if an acquisition had been made in 100MHz or glitch mode, until a new acquisition is taken. The

channel groups can be displayed in any base (not necessarily the base used for that group in the

Trigger menu), any number of times and in any order, within the overall constraint of a maximum

of 16 channel groups. If channel groups containing a large number of channels are repeated a

number of times such that they cannot all be shown on the screen at once then it will be

necessary to scroll the groups into the display using the LEFT and RIGHT cursor keys, see

section 8.2.

Soft-key representation

With the edit zone positioned in the channel label line the soft-keys have the following functions:

<DELETE> deletes the channel group over which the edit zone is positioned; all the channel groups on

the right of the deleted group are immediately scrolled to the left and the edit zone

therefore effectively becomes positioned over what was the next group to the right.

<NEXT> changes the channel group displayed at the edit zone position to the next channel group (in

alphabetical order), of those channel groups specified on the trigger WORDS menu.

<PREV> changes the channel group displayed at the edit zone position to the previous channel

group (in reverse alphabetical order) of those channel groups specified on the Trigger

WORDS menu.

<INSERT> scrolls the channel group at which the edit zone is positioned, and all channels to its right,

over to the right; the edit zone is blank until the channel group to be inserted is specified

using the <NEXT> and <PREV> keys or direct entries from the keyboard. If the <NEXT>

key is the first key pressed after <INSERT> then the channel group which is first in

alphabetical order will be inserted and further presses of <NEXT> will increment the

channel group forward through all possible choices as described for <NEXT> above. If the

<PREV> key is the first key pressed after <INSERT> then the channel group which is last

in alphabetical order will be inserted and further presses of <PREV> will decrement the

channel group backward through all possible choices as described for <PREV> above.

The channel group label to be inserted can also be entered directly from the keyboard by

pressing the appropriate key (and using SHIFT for characters g through p) after <INSERT>;

only labels for those channel groups already specified on the trigger WORDS menu will be

accepted from the keyboard.

When channel groups are inserted they are listed in the default base of binary; see the next

section for changing the channel group base.

27

Page 29

With the edit zone positioned over a channel group the label can also be edited by a direct entry

from the keyboard (using SHIFT for labels g through p). The <DEFAULT> soft-key can be used to

display the default groups (<a> and <b>) provided they were specified on the trigger WORDS

menu. Since defaulting the channel groups in this way may cause a complex arrangement to be

lost, two presses of the soft-key are required; after the first press the message <CONFIRM> is

displayed on the right-hand side of the top line of the display and a second press is required to

actually implement the default. Pressing any other key instead of <DEFAULT> a second time will