Page 1

THURLBY THANDAR INSTRUMENTS

LD300 300W DC ELECTRONIC LOAD

INSTRUCTION MANUAL

Page 2

Table of Contents

Introduction 2

Specification 3

EMC 8

Safety 9

Installation 10

Connections 11

Operating Controls 13

Operation 16

Application Notes 22

Remote Control 27

Maintenance 28

Instructions en Francais 29

Bedienungsanleitung auf Deutsch 49

Istruzioni in Italiano 71

Instrucciones en Español 91

1

Page 3

Introduction

This DC electronic load is intended for use in investigating the behaviour of many different types

of DC power sources such as batteries, solar cells, fuel cells or wind generators, as well as

electronic power supply units.

It operates over the current range 0 to 80 Amps and voltage range 0 to 80 Volts with a power

dissipation capability of up to 300 Watts. It is designed to have very low internal resistance to

allow operation at high currents with low voltage drop. The voltage of the source can be sensed

either internally for convenience or externally for better accuracy.

A low voltage dropout facility is provided to protect sources such as batteries from damaging

levels of discharge by reducing the load current when the source voltage falls below the dropout

threshold.

The unit provides five different operating modes: constant current, constant voltage, constant

power, constant resistance and constant conductance. The value of the chosen constant

parameter is set by 10-turn controls on the front panel.

An internal transient generator can repeatedly switch the load between two different operating

levels set on separate 10-turn controls. The frequency and duty cycle of the transients can be set

over a wide range. The transients can also be initiated by an external logic signal. The transitions

between the levels have a true linear slewing characteristic in all modes; the slew-rate is

adjustable over a wide range.

An external control voltage can also be used to set the level of the load. Any desired waveform

can be applied; the internal slew rate control circuit remains active.

Two 4-digit meters can be switched to display either the level settings, the transient generator

parameters, the measured values of Volts & Amps or the equivalent Watts & Ohms. A monitor

output providing a voltage proportional to the current flowing allows the behaviour of a source to

be viewed on an oscilloscope or external meter.

The unit is fully protected against excessive current, power dissipation or internal temperature,

and minimises audible noise by automatically controlling the fan speed according to the power

dissipation.

2

Page 4

Accuracy specifications apply for 18°C – 28ºC. Setting accuracies apply with slew rate control at

mid position and at 50W load power; regulation specifies variation at other powers.

INPUT

Maximum Input Ratings

Current: 80 Amps max. at rear panel terminals.

Voltage: 80 Volts max. while conducting current.

Power: 320 Watts max. up to 28ºC, derating to 300 watts at 40ºC.

Reverse Polarity: Diode will conduct; 80 Amps max.

Specification

30 Amps max. at front panel terminals

Surge suppressors start to conduct at 120V (nominal),

Max. non-repetitive surge energy: 80 Joules.

Off State Leakage:

Minimum Operating Voltage: 2V at 80A; typically 1V @ 40A, 0·5V @ 10A.

Isolation Voltage: ± 300Vdc max, either load input to chassis ground.

Input Terminals

Rear Panel Input: Safety terminals accepting 6mm diameter wire, 6mm plugs or 8mm

Front Panel Input: Safety terminals accepting 4mm diameter wire, 4mm plugs or 6·5mm

External Voltage Sense

Connection: Terminal block on rear panel. Slide switch to select between Internal

Input Impedance:

Max. Sense Voltage Drop: 6V.

OPERATING MODES

Constant Current Mode (CI)

Current Ranges: 0 to 8 A (1 mA resolution) and 0 to 80 A (10 mA resolution).

Setting Accuracy: ± (0·2% + 30 mA).

<10 mA, plus 680kΩ sensing resistance.

spades at 80 Amps max or 4mm plugs at 30 Amps max.

spades. 30 Amps max.

and External Voltage Sense.

680kΩ each input to load negative.

Regulation: < 30 mA for 90% load power change (V > 2 Volts).

Temperature Coefficient: < (0·02% + 5 mA) per ºC.

Slew Rate Ranges: 8 A range: <2·5 Amp per s to >250 Amp per ms.

80 A range: <25 Amp per s to >2500 Amp per ms.

Minimum transition time: 32 µs.

Constant Resistance Mode (CR)

Resistance Ranges:

Setting Accuracy: ± (0·5% + 2 digits + 30 mA).

Regulation: < 2% for 90% load power change (V > 2 Volts, using remote sense).

Temperature Coefficient: < (0·04% + 5 mA ) per ºC.

Slew Rate Ranges:

Minimum transition time: 100 µs.

3

0·04 to 10 Ω (0·01 Ω resolution); 2 to 400 Ω (0·1 Ω resolution).

10 Ω range: <1 Ω per s to 100 Ω per ms.

400 Ω range: <400 Ω per s to 4000 Ω per ms.

Page 5

Constant Conductance Mode (CG)

Conductance Ranges: <0·01 to 1 A/V (1 mA/V resolution); <0·2 to 40 A/V (0·01 A/V

resolution).

Setting Accuracy: ± (0·5% + 2 digits + 30 mA).

Regulation: < 2% for 90% load power change (V > 2 Volts, using remote sense).

Temperature Coefficient: < (0·04% + 5 mA) per ºC.

Slew Rate Ranges: 1 A/V range: <0·1 A/V per s to >10 A/V per ms.

40 A/V range: <4 A/V per s to >400 A/V per ms.

Minimum transition time: 100 µs.

Constant Voltage Mode (CV)

Voltage Ranges:

Setting Accuracy: ± (0·2% + 2 digits).

Regulation: < 30 mV for 90% load power change (using remote sense).

Temperature Coefficient: < (0·02% + 1 mV) per ºC.

Slew Rate Ranges: 8 V range: <0·8 V per s to >80 V per ms.

Minimum transition time: 100 µs.

Constant Power Mode (CP)

Power Range: 0 to 320 Watts.

Setting Accuracy: ± (0·5% + 2 W).

Regulation: < 2% over 5 V to 75 V source voltage change (using remote sense).

Temperature Coefficient: < 0·1% per ºC.

Slew Rate Ranges: <32 W per s to >3200 W ms.

Minimum transition time: 100 µs.

TRANSIENT CONTROL

to 8 V (1 mV resolution) and V

V

min

depends on current: typically <2V at 80A

V

min

to 80 V (10 mV resolution).

min

80 V range: <8 V per s to >800 V per ms.

Transient Generator

Pulse Repetition Rate: Adjustable from 0·1Hz to 10kHz in 3 overlapping ranges.

Pulse Duty Cycle: 1% to 99% (percentage of period at Level B).

Setting Accuracy: Frequency: ± 2% of range; Duty Cycle: +2%

Slew Rate Control

The slew rate control applies to all changes of level whether caused by manual selection, remote

control or the transient generator.

The level change is a linear slew between the two level settings with a slope determined by a

three-position range switch and a single turn control. Read-out is in the units of the mode

selected; the range available in each mode is shown above.

Setting Accuracy: ± 10% ± minimum transition time (levels within 10% to 90% or range).

Level Variation: ± 5 digits

4

Page 6

Oscillator Sync Output

Connection: Terminal block on rear panel. Opto-isolated open collector output

Max Off State Voltage: 30V.

Collector Current: 2mA (typical).

DROPOUT VOLTAGE

The load will cease to conduct if the applied voltage falls below the Dropout Voltage setting;

active in all modes except Constant Voltage. The Dropout Voltage setting is also the threshold for

the Slow Start facility and acts as an offset voltage in Constant Resistance mode.

Setting Accuracy: ± 1% + 2 digits.

Slow Start

If the Slow Start switch is engaged, the load will not conduct any current until the source voltage

reaches the Dropout Voltage setting; it will then ramp up to the Level setting at a rate determined

by the settings of the Slew Rate controls.

METER SPECIFICATIONS

Display Type: Two 4-digit 14mm LED displays showing combinations of measured or

conducts during Level B phase of internal transient generator.

set-up values selected by a 5-position switch.

Illuminated annunciators display the measurement units.

Measured Values

Volts & Amps: Measured values of current through and voltage across the load.

Watt & Ohms: Power and equivalent load resistance, calculated from Volts and Amps.

Voltage Accuracy: ± 0·1% + 2 digits.

Current Accuracy: ± 0·2% + 3 digits.

Set-up Values

Level A & Level B: The two levels set by the front panel controls.

Frequency & Duty Cycle: The settings of the oscillator in the transient generator.

Slew Rate & Dropout V: Displays the slew rate setting and the value of the dropout voltage.

CURRENT MONITOR OUTPUT

Output Terminals: 4mm safety sockets on front panel or terminal block on rear panel.

Output Impedance:

Scaling: 50mV per Amp (4 Volts full scale).

Accuracy: ± 0·5%.

Common Mode Range: ± 3Vdc max. to input negative.

600Ω.

REMOTE CONTROL

External Control Input Characteristics

Connection: Terminal block on rear panel.

Input Impedance:

Common Mode Range: ± 100V to load negative.

5

400kΩ each input to load negative.

Page 7

External Voltage Control

Operating Mode: The applied voltage determines the operating level within the selected

Scaling: 4 Volts full scale.

Accuracy: ± 0·3% ± accuracy of selected range.

Common mode rejection: Better than –66dB.

External TTL Control

Operating Mode: The applied signal selects between Level A and Level B settings.

Threshold: + 1·5V nominal. A logic high selects Level B.

Remote Disable Input

Connection: Terminal block on rear panel.

Threshold: Apply +3 to +5 V to disable load input.

PROTECTION

Excess Current: The unit will trip into the fault state at nominally 92 Amps.

range.

Excess Power: The unit will attempt to limit the power to approx 335 Watts; if this fails

Excess Voltage: The unit will conduct a current pulse (to absorb inductively generated

Temperature: The unit will trip into the fault state if the heatsink temperature exceeds

Sense Error: The unit will trip into the fault state if the external voltage sense is more

Mode Switching: The unit will trip into the fault state if the mode is changed while the input

General

AC Input: 110V–120V or 220V–240V AC ±10%, 50/60Hz. Installation Category II.

Power Consumption: 30VA max.

Operating Range: + 5ºC to + 40ºC, 20% to 80% RH.

Storage Range: – 40ºC to + 70ºC.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

the unit will trip into the fault state at about 360 Watts.

spikes) for 1ms at 90V.

The unit will trip into the fault state at nominally 95V.

Surge suppressors will start to conduct above 120V.

safe levels.

than 6V below the internal sense.

is enabled.

6

Cooling: Dual 2-speed fans. Air exit at rear.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

Size: 130mm H (3U) x 212mm W (½ rack) x 435mm L.

Weight: 6 kg.

Option: 19-inch rack mount kit.

Page 8

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

LD300 DC Electronic Load

meets the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class B

b) EN61326-1 (2006) Conducted, Class B

c) EN61326-1 (2006) Harmonics, referring to EN61000-3-2 (2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2007) Conducted RF

Performance levels achieved are detailed in the user manual.

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

CHRIS WILDING

TECHNICAL DIRECTOR

2 May 2009

7

Page 9

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A (B).

EMC

b) EN61000-4-3 (2006) Electromagnetic Field:

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle and 1 cycle, 0%: Performance A (B);

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line), 0·5kV peak (Load connections),

Performance A (B).

e) EN61000-4-5 (2006) Surge, 0·5kV (line to line), 1kV (line to ground), Performance A (B).

f) EN61000-4-6 (2007) Conducted RF, 3V, 80% AM at 1kHz (AC line only; Load

connections <3m, therefore not tested), Performance B

According to EN61326-1 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

†

Note: In high RF fields (radiated or conducted) the actual load current may deviate beyond the

set current accuracy at certain frequencies up to 200MHz. Such deviations will be small and

infrequent and are unlikely to be a problem in practice. In all other respects the LD300 will

perform normally (Performance A) in RF fields up to 3V/m.

Cautions

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance B

Performance A (A); 1V/m, 2.0GHz to 2.7GHz: Performance A (A).

25 cycles, 70%: Performance A (C); 250 cycles, 0%: Performance B (C).

†

(A) and 1.4GHz to 2GHz:

†

(A).

8

To ensure continued compliance with the EMC directive observe the following precautions:

a) after opening the case for any reason ensure that all signal and ground connections are

remade correctly and that case screws are correctly refitted and tightened.

b) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

Page 10

Safety

This instrument is Safety Class I according to IEC classification and has been designed to meet

the requirements of EN61010−1 (Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use). It is an Installation Category II instrument intended for operation

from a normal single phase supply.

This instrument has been tested in accordance with EN61010−1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% −80% RH (non−condensing). It may occasionally be

subjected to temperatures between +5° and −10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. The unit does not have a fuse in the load circuit: ensure that the

maximum prospective fault current is limited to a safe level.

Do not operate the instrument outside its rated supply voltages or environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

The instrument contains both encapsulated fuses and a non-resetting thermal fuse; these are not

replaceable by the user. The short-circuiting of these protective devices is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:−

Caution −refer to the accompanying documentation,

incorrect operation may damage the instrument.

Alternating Current.

mains supply OFF.

l

9

mains supply ON.

Page 11

Mains Operating Voltage

The operating voltage of the instrument is shown on the rear panel. Should it be necessary to

change the operating voltage from 230V to 115V or vice-versa, proceed as follows:

1. Disconnect the instrument from all voltage sources.

2. Remove the screws which hold the case upper to the chassis and lift off.

3. Turn the unit over and support the weight of the power supply PCB while removing the six

screws which hold it to the chassis. Leave the pillars attached to the PCB.

4. Fit the soldered links (alongside the transformer) for the required operating voltage: For 230V fit only LK1

For 115V fit LK2 and LK3 and not LK1

These links may be either tinned copper wire or zero-ohm resistors.

5. Refit the power supply PCB to the chassis, ensuring that no wires are trapped. Check that

all cables are correctly connected.

6. Refit the case upper.

Installation

7. To comply with safety standard requirements the operating voltage marked on the rear

Fuses

There are no user replaceable fuses in the instrument.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited.

Mounting

This instrument is suitable both for bench use and rack mounting. It is delivered with feet for

bench mounting. The front feet include a tilt mechanism for optimal panel angle.

panel must be changed to clearly show the new voltage setting.

Brown - Mains live

Blue - Mains Neutral

Green/Yellow - Earth

WARNING! THIS INSTRUMENT MUST BE EARTHED

A rack kit for mounting one or two of these half-width 3U high units is available from the

Manufacturers or their overseas agents; a blanking piece is also available for unused positions in

the rack.

Ventilation

The unit is cooled by two 2-speed fans which vent at the rear. Take care not to restrict the air

inlets at the top, side and bottom panels or the exit at the rear. In rack-mounted situations allow

adequate space around the instrument and/or use a fan tray for forced cooling.

If ducting is applied to the air outlet, additional extraction is required.

10

Page 12

Front Panel Connections

Load Input

The INPUT terminals for the load circuit on the front panel accept 4mm plugs into the end, 4mm

diameter wire or plugs into the cross hole, or ¼ inch spade connections (with a maximum blade

width of ½ inch). Their maximum current rating is 30 Amps. For higher currents (or lower circuit

resistance) use the rear panel terminals; do not use both simultaneously.

The load circuit is isolated from ground, and potentials up to ± 300 Volts to ground are allowed,

but it is essential to observe safe insulation practice.

Ensure that the source is connected with the correct polarity.

The maximum current through these terminals is 30 Amps.

The maximum voltage allowed across the load is 80 Volts.

The unit does not have a fuse in the load circuit: ensure that the maximum

prospective fault current is limited to a safe level.

Current Monitor Output

The Current Monitor terminals provide a voltage proportional to the load current flowing with a

scaling factor of 50 mV per Amp (4 Volts for 80 Amps full scale). The output impedance is 600Ω

and the calibration assumes a high impedance load.

Connections

A differential driver allows a common mode range of ± 3 Volts between the negative

monitor terminal and the negative load terminal. The output will be inaccurate (and the

unit may be damaged) if voltages exceeding this are applied.

Rear Panel Connections

Load Input

The INPUT terminals for the load circuit on the rear panel accept 4mm plugs into the end (4mm

plugs will only support 32 Amps), 6mm diameter wire or plugs into the cross hole or 8mm spade

connections (with a maximum blade width of 16mm).

The wiring and connection arrangement must be capable of supporting the current required; for

80 Amps, 16mm

The load circuit is isolated from ground, and potentials up to ± 300 Volts to ground are allowed,

but it is essential to observe safe insulation practice.

Ensure that the source is connected with the correct polarity.

The maximum current through these terminals is 80 Amps.

The maximum voltage allowed across the load is 80 Volts.

The unit does not have a fuse in the load circuit: ensure that the maximum

prospective fault current is limited to a safe level.

Terminal Blocks

2

cable is needed.

All other rear panel connections are made via the screw-less terminal blocks. To make

connections to the terminal blocks, use a flat screwdriver to press the spring-loaded orange

actuator inwards to open the wire clamp; insert the wire end fully into the hole and release the

actuator. Ensure the wire is properly gripped. Take care to observe the marked polarity.

Current Monitor Output

The top pair of terminals, marked CURRENT MONITOR, provide the current monitor output. They

are wired in parallel with the front panel sockets (see above).

11

Page 13

Remote Control Input

The CONTROL VOLTAGE terminals are used in two operating modes of the instrument (as

selected by the front panel LEVEL CONTROL switch):

In EXTERNAL VOLTAGE mode an analogue signal applied here sets the level of the load;

the scaling is 4 Volts full scale.

In EXTERNAL TTL mode, a logic signal applied here selects either the LEVEL A setting

(logic low) or the LEVEL B setting (logic high). The switching threshold is nominally +1·5V.

These terminals will tolerate a common mode voltage of up to ±100 Volts relative to

the negative terminal of the load input. The input impedance is 400kΩ from each

terminal to the load negative, so a common mode current will flow.

External Voltage Sense Input

To avoid errors in sensing the voltage of the source caused by voltage drops in the high current

wiring, connect the EXTERNAL SENSE terminals to the external circuit at the point where the

voltage needs to be measured (normally at the output terminals of the source under test). Move

the VOLTAGE SENSE SELECT slide switch to the EXT position.

Ensure that the source is connected with the correct polarity.

These terminals must not be connected to any voltage other than the source that is

connected to the load input.

Remote Disable Input

Apply +3V to +5V to the DISABLE INPUT terminals to disable the load input; they are the input to

an opto-coupler and are galvanically isolated from all other terminals. The input current is less

than 2·5mA at 5V. The INPUT ENABLE switch on the front panel must also be depressed for the

unit to operate.

Oscillator Sync Output

The SYNC OUTPUT is an open collector output of an opto-coupler driven by the signal from the

internal oscillator; it is galvanically isolated from all other terminals. A suitable pull-up resistor and

power supply (e.g. 4·7kΩ to +5V) are needed to generate a usable signal, which could be used to

trigger an oscilloscope. There is a 1kΩ series protection resistor.

12

Page 14

This section of the manual is a brief introduction to the controls of the instrument and is intended

to be read before using the load for the first time.

In this manual, front panel controls and connections are shown in capitals, e.g. LEVEL

CONTROL.

Switching On, Load Enable On/Off

The line POWER ( ) switch is at the bottom left of the front panel. Before switching on ( l ),

check that the line operating voltage of the unit (marked on the rear panel) is suitable for the local

supply and that the INPUT ENABLE switch is in the released (Off) position.

Operating Controls

Switch the power on (

Caution: If, while the load is enabled (the INPUT ENABLE switch is depressed), the line power

is disconnected and then re-connected, the instrument will restart and conduct load current

(unless a transient condition causes the fault latch to trip).

Metering

The two 4-digit meters have multiple functions depending on the setting of the METERS switch at

top right of the panel. The following combinations are available:

WATTS & OHMS

The load power and the equivalent resistance are displayed. These values are calculated from

the present measured values of voltage and current.

VOLTS & AMPS

The present measured values of voltage and current are displayed.

LEVEL A & LEVEL B

The settings of the two LEVEL controls are displayed. The measurement units, which depend

upon the selected operating mode, are indicated above the readout.

FREQUENCY & DUTY CYCLE

The left meter displays the frequency of the internal oscillator (in Hz or kHz) and the right meter

shows the percentage of each cycle that LEVEL B is active.

l ) ; the fan should be heard to start and the meter displays should light.

SLEW RATE & DROPOUT VOLTAGE

The left meter shows the slew rate setting. The measurement unit, which depends on the

selected operating mode, is indicated above the readout and is either per-millisecond or

per-second as indicated by a second annunciator.

The right meter shows the dropout voltage setting (below which the load will cease to conduct).

This will always be zero in Constant Voltage mode.

Load Mode Switch

The LOAD MODE switch selects the operating mode and range.

Level A and Level B Controls

The two 10-turn controls marked LEVEL A and LEVEL B set the two operating levels, which can

be selected by the LEVEL CONTROL switch or the transient signal.

13

Page 15

Level Control Switch

The LEVEL CONTROL switch selects the level setting mode.

The LEVEL A and LEVEL B settings select constant operation at the value set on the

corresponding LEVEL control.

The TRANSIENT setting enables the internal transient generator. Operation alternates between

the LEVEL A and LEVEL B settings at a rate determined by the settings of the FREQUENCY and

DUTY (%B) controls. The signal passes through the slew rate generator.

The EXTERNAL TTL setting enables the use of an external oscillator or logic signal (connected to

the terminal block on the rear panel) to select the operating level. Operation alternates between

the LEVEL A and LEVEL B settings depending on the level of the external signal (logic high

selects LEVEL B). Following the selection gate the signal passes through the slew rate generator.

The EXTERNAL VOLTAGE setting enables external analogue voltage control of the load. The

signal applied to the rear panel terminal block determines the level setting, with a scaling factor of

4 Volts full scale. The signal passes through the slew rate circuit.

Dropout Voltage

The DROPOUT control sets the voltage level below which the load will cease to conduct current.

It does not operate in Constant Voltage mode and has a special effect in Constant Resistance

mode.

This setting is also the threshold for the slow start circuit.

Input Enable Switch

Pressing the latching INPUT ENABLE switch enables the load input.

There is also a remote DISABLE INPUT facility available at the terminal block on the rear panel;

applying +3 to +5 Volts here will disable the input.

The INPUT ENABLE switch must be released to reset the fault latch if it is tripped.

Input Indicator Lamp

A multi colour lamp indicates the operating state of the unit. It is off when the input is disabled. It

shows green in normal operation, or orange if the input is enabled but the power stage is

saturated (because there is insufficient voltage for the required current to flow). It shows red if a

fault condition exists; the INPUT ENABLE switch must be released to reset this condition.

Slow Start

The setting of the SLOW START switch determines the behaviour of the unit when it starts to

conduct, either because the INPUT ENABLE switch is pressed while the source voltage is

already present, or because the source is switched on after the load is already enabled. If the

SLOW START switch is not engaged, the load will conduct the full current immediately (without

the control of the slew-rate circuit). If the SLOW START switch is engaged, the load will not

conduct any current until the source voltage reaches the dropout voltage setting; it will then ramp

up to the LEVEL setting at a rate determined by the settings of the SLEW RATE controls.

Transient Frequency

The FREQUENCY control and the associated three-position range switch set the frequency of the

internal oscillator.

Duty Cycle

The setting of the DUTY (% B) control determines the percentage of the oscillator period that the

load is at the LEVEL B setting. The duration of the slewing time from the LEVEL A state to the

LEVEL B state is included in this value.

14

Page 16

Slew Rate

The SLEW RATE control and its associated three-position range switch determine the slope of

the transitions from one level setting to the other.

Voltage Sense Select (Rear Panel)

The rear panel VOLTAGE SENSE SELECT switch selects between INT (internal) and EXT

(external) sensing of the effective voltage across the load. Note that internal sensing is always

used for the power and voltage protection circuits.

Caution: The unit is designed to permit up to 6 Volts difference between internal and external

sensing; if this switch is in the EXT sense position, but the terminals are not connected, the unit

will not detect the fault condition until the source voltage exceeds this value. This can result in

unexpected operation.

15

Page 17

This instrument provides a controllable DC load (a power sink) intended for testing all forms of

DC power supply including batteries, photo-voltaic cells, turbines and generators as well as

electronic power supply units.

New users should first read the Operating Controls section, which gives an overview of the

instrument’s controls. This section gives detailed information on setting up and using the unit.

Application hints and cautions, particularly concerning stability and dynamic behaviour, are given

in the Application Notes section later.

Connecting the Load to the Source

The INPUT terminals of the load must be connected to the source to be tested using sufficiently

low resistance and low inductance connections. The wiring should be as short and as thick as

possible. The front panel terminals may be used for currents up to 30 Amps; for higher currents

the rear panel terminals should be used.

The load terminals of the instrument are floating from ground, and may be used at potentials of

up to ± 300 Volts from ground. Ensure that all wiring is safely insulated for the working voltage

involved.

Voltage Sensing

Operation

If the load is to be operated in Constant Current (CI) mode, then external voltage sensing will only

be needed if accurate readings are required on the voltage, power or equivalent resistance

meters. In all other modes the conductivity of the load depends on the applied voltage, so

external sensing is needed for proper accuracy of the load characteristics.

In the interests of stability, high frequency feedback is always taken from the internal sense

circuit; this minimises the possibility of phase shifts due to the external wiring affecting the unit.

Nevertheless, to avoid impact on the stability margin do not add phase shift in the sensing circuit;

in particular, the use of decoupling capacitors should be avoided. If the sensing connections are

likely to be subject to RF or magnetic fields, use twisted pair cable with an overall shield. The

shield should be grounded or connected to load negative.

Principles of Operation

The normal sequence of operation is to select the LOAD MODE and LEVEL CONTROL mode,

set the required operating level and dropout voltage, and then enable the input. If transient

operation is required, the second level setting and the slew rate parameters must be set, as well

as the frequency and duty cycle of the internal oscillator if it is to be used.

The meters can be used to view the settings before the INPUT is enabled; once the load is

conducting the actual Voltage and Current, or the Watts and Ohms calculated from those values,

can be read.

All controls except LOAD MODE can be adjusted as required while the input is enabled.

Attempting to change the LOAD MODE while the input is enabled will trip the fault latch and

cause the input to be disabled until reset.

Load Operating Modes

There are five possible operating modes, selected by the switch marked LOAD MODE; there are

two ranges for all modes except Constant Power. The INPUT ENABLE switch should be released

before changing modes; if the LOAD MODE switch is moved with the load enabled the fault latch

will be tripped.

16

Page 18

Constant Current (CI)

In this mode, the LEVEL setting defines a required current and the load seeks to sink this current

regardless of the voltage of the source. This mode is not suitable for use with constant current

sources as the load will either saturate (if the load setting is greater than the supply setting) or

switch off.

If the source cannot supply the current level set then the load will saturate, conducting as much

current as possible with a low voltage across its terminals; the front panel lamp will show orange.

This condition also occurs while the source is switched off. If the current capability of the source

is increased, normal operation will resume.

If the combination of the load current setting and the actual supply voltage exceeds the power

dissipation capability of the load, the current value will be reduced in an attempt to keep the

power at the permitted limit. If this is not possible, or if the maximum rated voltage is exceeded,

the unit will enter the fault state. While the power limiting circuit is active the front panel lamp will

show orange.

The dropout voltage capability is active in this mode; if it is not required set the control to 0V. As

the voltage falls below the dropout threshold the current reduces rapidly to zero. In this state the

front panel lamp shows orange. There is a possibility of instability in the transition region.

Constant Voltage (CV)

In this mode, the LEVEL setting defines a required voltage and the load attempts to sink whatever

current is needed to maintain this voltage. If the applied voltage rises, the resistance of the load

will fall in attempt to sink more current and pull the voltage down to the required level. This

behaviour is that of a shunt regulator (it might be considered as an adjustable Zener diode) and

requires the source to have a high impedance. Because of the active feedback within the load the

slope resistance is extremely low, and this mode is best used with a true current source.

If the source impedance is too low, the current will rise until the maximum power dissipation limit

is reached and the unit will enter the fault state.

The slow start capability can be used, but will result in the load starting to conduct at zero volts;

this is the highest current condition, which is probably not the action required. It may be

necessary, with some sources, to enable the load with the voltage level set above the output

voltage of the source (so no current flows), and then manually decrease the setting until the

required voltage is reached.

Constant Power (CP)

In this mode, the load implements the equation I = W / V. The LEVEL setting defines the required

power, and the unit continuously monitors the source voltage and calculates the current required

to obtain the set power dissipation. As the source voltage falls, the demanded current will rise.

This action simulates the behaviour of many switch-mode power supplies; it is also useful in

checking the characteristics of photovoltaic cells. However, the load is acting as a negative

resistance, which can give rise to stability difficulties with some sources.

If the source enters a current limit, the load will saturate with a low terminal voltage while

attempting to reach the required power setting by increasing the current. This condition is not

recoverable without disabling the load and allowing the source to recover. With most sources this

current limited condition will occur at switch-on, so it will normally be necessary to use the slow

start facility in constant power mode.

The dropout voltage capability is active in this mode; if it is not required set the control to 0V.

Constant Conductance (CG)

In this mode, the load implements the equation: I = V * G. The unit continuously measures the

source voltage and calculates the current required to simulate the required conductance. For any

given conductance setting, the load current is directly proportional to the applied voltage.

17

Page 19

Because the LEVEL controls set conductance, it is easy to get fine adjustment of the setting of

low resistance (high conductance) values in this mode. Conversely, Constant Resistance (CR)

mode is more convenient for high resistances. When the load is conducting, the WATTS & OHMS

position of the METERS switch can be used to view the equivalent resistance value of the load.

The dropout voltage capability is active in this mode; if it is not required set the control to 0V.

Constant Resistance (CR)

In this mode, the load implements the equation I = (V – V

has a special effect in this mode: it acts as an offset to the start of the resistance characteristic.

Below the dropout setting, no current passes; above that voltage level, the current rises linearly

with a slope defined by the resistance setting. At low resistance settings, the action is similar to a

Zener diode with the threshold voltage set by the DROPOUT control and the slope resistance

defined by the LEVEL setting.

If the dropout voltage is set to 0V, this mode acts as a normal resistor with the load current

directly proportional to the applied voltage.

If the slow start circuit is used in this mode, the load will start at (nearly) zero Ohms and ramp up

to the set resistance value. This means that the initial current is higher than the final current,

which is probably not the effect required. For this reason the slow start circuit is of little use in this

mode; if slow start is required, use Constant Conductance (CG) mode.

Note that high resistance settings on the 400Ω range are primarily intended for use with higher

voltage sources (even at 80V the dissipation is only 16W). Small errors in current produce

relatively large errors in the effective resistance. The resistance can be adjusted to the required

value by using the WATTS & OHMS position of the METERS switch to view the actual effective

resistance.

Level Setting

The LEVEL A and LEVEL B controls set the two operating levels, which can be selected by the

LEVEL CONTROL switch, the transient generator or an external TTL signal. If only a constant

level is required, either may be used. The values can be read by setting the METERS switch to

the LEVEL A & LEVEL B position. The measurement units of these readings depend on the

operating mode, and are indicated at the top of the display.

) / R. The dropout voltage setting

dropout

Level Control

The LEVEL CONTROL switch provides the options of constant operation at either the LEVEL A or

LEVEL B setting, TRANSIENT operation (alternating between the two levels at a rate determined

by the internal transient generator), EXTERNAL TTL (alternating between the two levels under

the control of a logic signal applied to the rear panel terminals) or EXTERNAL VOLTAGE control

(when the operating level is set proportional to a voltage applied to the rear panel terminals). The

remote control facilities are described in a later chapter in this manual.

Dropout Voltage

The primary purpose of the DROPOUT Voltage setting is to protect batteries from total discharge.

It provides a voltage threshold below which the load will cease to conduct current. The same

voltage is also used as the threshold for the slow start circuit. When discharging batteries, set the

dropout voltage to the manufacturer’s recommended end-of-discharge voltage. If the dropout

facility is not required, set the control to 0V (fully counter-clockwise).

Note that if there is any wiring resistance between the source and the voltage sensing point of the

load then there will be a soft entry into the dropout condition – as the current starts to fall the

series voltage drop reduces, so raising the terminal voltage measured at the load. There is a

possibility of instability in this operating condition.

18

Page 20

The front panel lamp will show orange when the dropout limit circuit becomes active. A detector

on the current monitor output might also be used to detect the operation of the dropout voltage

circuit and trigger an external timer.

The dropout voltage facility is not active in Constant Voltage (CV) mode as it is not necessary – if

the source voltage falls below the LEVEL setting then the load does not conduct any current. As

described above, the Dropout voltage setting has a special effect in Constant Resistance mode.

Slow Start

The purpose of the slow start circuit is to detect the initiation of voltage from the attached source

and to ramp the demand of the load up from zero to the final value. The rate of rise is determined

by the settings of the SLEW RATE controls. The reference voltage for the voltage detection

comparator is the setting of the DROPOUT voltage control.

Note that in Constant Resistance (CR) mode the load will start at (nearly) zero Ohms and ramp

up to the final Ohms value. This means that the load initially conducts maximum current; this is

often not the effect required, in which case Constant Conductance (CG) mode will be more

appropriate.

In Constant Power (CP) mode the slow start facility will usually be needed because of the lock-up

condition that can occur at low voltages, if the source does not have sufficient current capability to

reach the power level demanded. Calculate the voltage at which the supply has sufficient current

capability to achieve the power level setting, and set the dropout voltage to a little above that

level.

Input Enable

Once the required operating mode and level settings are established, depress the INPUT

ENABLE switch.

Input Enable Indicator

The multi-colour lamp above the INPUT ENABLE switch indicates one of four conditions:

Lamp Off Input not enabled.

Green Input enabled and operating normally.

Orange Input enabled, but the power stages are saturated. Occurs if the source is

switched off. Also indicates if the current is below the expected value because of

operation of the Voltage Dropout or Power Limit circuits.

Red A fault condition has occurred and the input has been disabled. This condition will

latch until the Input Enable switch is released. The lamp will continue to show red,

even with the input disabled, if the fault condition persists.

Power Limit

The unit continuously monitors the internal power dissipation and switches the fans to a higher

speed above about 230 Watts.

If the dissipation rises above about 335 Watts, a power limit circuit will come into operation and

attempt to reduce the load current to control the dissipation. The unit is then effectively operating

in constant power mode, which will change the stability conditions. If the power limit circuit fails to

keep the power at a reasonable level (because the source voltage rises as the current falls, for

example), the fault latch will be tripped and the load will cease to conduct.

19

Page 21

Fault Conditions

The unit detects the following fault conditions:

• Current above about 92 Amps.

• Voltage above about 95 Volts.

• Power in excess of about 350 Watts (that the power limit circuit has not succeeded in

controlling).

• Excess Heatsink temperature.

• Excess difference between external and internal voltage sense values.

When any such fault condition occurs, the input is disabled, so the unit will cease to conduct

current, and the INPUT lamp on the front panel turns red. This condition is latched until the

INPUT ENABLE switch is released, when the lamp will turn off, if the fault condition has been

cleared. If the lamp remains red, then the fault is still present and must be either excessive

voltage, high heatsink temperature or incorrect sense connections.

The fault detectors for excess current and power have filter networks with a time-constant of a

few milliseconds to allow brief transients to be handled.

Transient Operation

The unit includes the capability of generating load transients, which are intended to help in testing

the transient response of a source. A transient is a change from one load setting to another, with

a defined slew rate between them. The two load settings are defined by the LEVEL A and

LEVEL B controls - there is no limitation on which of these levels is the larger. Note that the

transient is specified as the two absolute levels, not the difference between them (as is the case

with some electronic loads).

Transient operation is available in all operating modes. The load is designed so that the transition

between the two levels is a straight line whose slope is determined by the setting of the slew rate

controls.

Transients can be timed either by the internal oscillator or by an external TTL signal. It is also

possible to use EXTERNAL VOLTAGE mode to generate transients of any required shape by

making the external generator produce the required waveform. Note that the external signal still

passes through the internal slew rate generator, so appropriate settings need to be made on its

front panel controls.

Transient Frequency and Duty Cycle

The frequency of the internal oscillator is set by a three-position range switch and a single-turn

variable control, which covers a 100:1 range. The duty cycle can be varied over the range 1% to

99% by a second single-turn control. This percentage is the portion of each repetition spent at the

LEVEL B setting, including the transition from LEVEL A to LEVEL B; the transition back to LEVEL

A and the time stable at that setting occupy the remainder of the cycle.

20

These settings can be read on the meters by switching the METERS switch to the FREQ & DUTY

% position. The frequency reading (on the left hand meter) may be in Hz or kHz as indicated; the

DUTY % reading is always in percent.

Transient operation always starts with the LEVEL A setting. The oscillator starts on the last of

three possible events: either the LEVEL CONTROL switch is moved to the TRANSIENT position,

or the input is enabled or (if the slow start circuit is active) the source voltage rises above the

DROPOUT threshold. The duration of the first LEVEL A condition will be about 3% longer than the

normal value.

Note that the time interval represented by the shortest portion of the cycle must be sufficient for

the transition defined by the slew rate and level setting controls to occur, otherwise the load will

never reach the steady state at the set value. This error condition is discussed below.

Page 22

Slew Rate

The SLEW RATE control and its associated three-position range switch set the slope of the

transitions between the two level settings. When the METERS switch is set to the SLEW &

DROPOUT position, the left hand meter indicates the slew rate: the measurement unit of the

presently selected mode is indicated above the display, with either the /ms (per millisecond) or /s

(per second) annunciator also lit.

The circuit provides a linear transition in the control value of the active mode, so, for example, in

Constant Power (CP) mode the slew rate is expressed in Watts per millisecond (or Watts per

second at very slow rates). The shape of the current transition is therefore not necessarily linear.

The slew rate setting is applied to all changes in level whether caused by manual adjustment, the

transient generator or external voltage control. It is also used to determine the rate of rise when

the slow start circuit is triggered.

The bandwidth of the power stages of the load is reduced whenever the slew rate range switch is

in the Lo position, even if the transient facilities are not being used. This changes the dynamic

behaviour of the unit and may improve stability with some difficult combinations of source and

load characteristics.

Slew Rate Error Conditions

There is an upper and a lower limit to the slew rate value that can be used in combination with

the settings of the other controls. In the top right hand corner of the display area there is an

indicator which lights, showing ERR, if either of the circumstances described below arise.

The lower limit is determined by the relationship of level settings, slew rate, frequency and duty

cycle. If the transition time (which is the difference in the level settings divided by the slew rate) is

longer than the oscillator period times the duty factor, then there is insufficient time for the

transition to complete before the oscillator initiates a return to the other level, so the desired level

will never be reached. In this case, the indicator flashes ERR.

The upper limit is determined by the minimum transition time of the power stages of the load

(which depends on the operating mode – see the specification). If a combination of a fast slew

rate and a small change in level imply a transition time shorter than this, then the settling time of

the power stage will dominate. In this case the ERR indicator is lit continuously. Note that this

indicator assumes an ideal source and optimum interconnections. Further limits on slew rate can

be imposed by the output impedance and dynamic characteristics of the source, and by

inductance in the connections.

In practice, the dynamic behaviour of a source and load combination at high slew rates depends

on many factors, particularly interconnection inductance and the damping factor of feedback

loops. In addition, the response of the power stages of the load is slower when operated at very

low or high currents, or at low voltages. In many circumstances, a lower slew rate setting will be

needed to avoid aberrations.

In Constant Resistance mode, where the current is inversely related to the resistance transition, it

is particularly difficult to predict the maximum useful slew rate setting.

21

Page 23

This chapter is intended to give helpful information concerning practical applications of the unit.

All electronic loads are subject to the impact of source characteristics, interconnection inductance

and feedback loop characteristics, and the following sections will assist in understanding the

factors involved.

Sources

Batteries are a low impedance source; apart from the possibility of inductance in the

interconnecting leads, they are generally easy to use in conjunction with an electronic load. The

dropout facility should be used with batteries that can be damaged by total discharge.

Electronic supplies have active feedback networks whose dynamic characteristics often interact

with the load. When that load is itself an active network whose dynamic characteristics depend on

the nature of the source, it will be apparent that the behaviour of the resulting system can be

impossible to predict.

Some common problems:

Constant Power mode has an inherent negative resistance characteristic that can result in

oscillation with some source impedances.

Many “constant current” sources based on feedback circuits are only high output impedance at

low frequencies. As the frequency increases, the output impedance falls. In fact, such units often

have a significant capacitor across the output terminals.

Application Notes

Many supplies have L-C output filters to reduce noise; these introduce extra phase shift into the

overall source – load combination and can give rise to instability. If there is no damping across

the inductor, a resonant circuit can be formed which allows oscillations to build up to significant

amplitude.

When using transient frequencies of a few kHz, it is often possible to excite the natural frequency

of the feedback circuit in the supply. This can have unexpected results, in extreme cases leading

to destruction.

Sources with asymmetrical characteristics can cause instability; many electronic power supplies

can source current to increase their terminal voltage rapidly, but cannot sink current and so can

only reduce their terminal voltage slowly. Equally, the load can only sink current and reduce the

voltage across its terminals; it relies on the source to pull the voltage up.

Simple supplies have just a transformer, rectifier and a large reservoir capacitor across the output

terminals. When fed from standard 50 or 60 Hz mains supplies this capacitor will not be

recharged until the peak of the next mains cycle. Such a supply has no pull-up capability between

mains cycles.

Wound machines have substantial inductance and slow response times. Transient response

testing of such sources should only be attempted at low slew rates.

Inductive sources

If a source has significant inductance, then, whenever the load current falls, a voltage transient

will be generated which might exceed the voltage rating of the load. The unit is fitted with

varistors designed to absorb non-repetitive transients up to 80 Joules, but repetitive energy up to

only 2 watts. If the energy is likely to exceed either limit then some form of external protection

must be added, perhaps a catching diode across the inductor itself.

22

When operating in Constant Power, Conductance or Resistance modes, the conductivity of the

load changes as the applied voltage changes; this magnifies the effect of any voltage transients

caused by inductance.

Inductive sources also increase the possibility of instability, as discussed below.

Page 24

Grounding

A scope will often be used to view the voltage and current waveforms, particularly when using the

transient capabilities of the load to investigate the behaviour of a source. Take care to select a

suitable point to connect the scope ground, as voltage drops on the interconnecting cables

(particularly transients caused by inductance) can give misleading results. The Current Monitor

Output from the load can be used to avoid multiple grounds, as it provides common mode

rejection (as long as the voltage is kept within a few volts of the load negative terminal). If

possible, the best ground point is usually the negative terminal of the source.

Note that if the load is used with a source having the positive terminal grounded, then any

instrument attached to the Current Monitor output must be fully floating.

Stability

This load is optimised for accuracy under constant load conditions and has high internal

feedback. Because of this, the possibility exists for combinations of source, interconnection and

load characteristics to give rise to instability. There are three major potential causes: inductance

in the wiring between source and load (or an inductive output impedance of the source),

capacitance in parallel with the connection between source and load (including an output

capacitor within the source) and the characteristics of active feedback circuits within the source.

In Constant Power, Conductance and Resistance modes, the system includes an analogue

multiplier used by the load to derive the current requirement from the instantaneous voltage. This

adds additional phase shift into the loop. In general, Constant Current mode is the most likely to

be stable, but in some cases instability can be avoided by using a different mode. The conditions

that affect the dynamic behaviour of the load in transient operation also lead to instability, and

some of the suggestions in the sections below may be found helpful.

Remedial Actions

The compensation networks of the power stages in the load are changed when the SLEW RATE

RANGE switch is put in the Lo position. Even if the transient facilities are not being used, this

change in compensation may make the load stable.

If instability arises, observe the voltage waveform across the load with a scope: if at any point the

voltage rises above the open circuit emf of the source, then there must be an inductive element

present to form a resonant circuit. Some means must be found to insert damping into this circuit.

One technique is to use a snubber network (consisting of a capacitor and a resistor in series),

across the input terminals of the load. Many electronic loads have such a network built-in; it is

omitted from this load to maximise its versatility by offering the minimum possible input

capacitance. It can be added externally: values around 2·2µF and 5Ω are common; note that this

must be a power resistor (capable of handling a few watts) constructed with non-inductive

technology – a flat film type is best.

Dynamic Behaviour in Transient Operation

When the transient capabilities of the load are used, the dynamic behaviour of the source and

load combination during the transitions depends on similar considerations to those affecting

stability: series inductance, shunt capacitance and feedback loop characteristics. Proper

operation depends on the load neither saturating nor cutting off at any point in the cycle. The

faster the slew rate sought, the more likely it is that aberrations will occur on the transitions.

Because of changes in the transconductance of the FETs, the dynamic behaviour of the power

stages changes at both low and high currents, and also at low voltages when the inter-electrode

capacitance increases considerably. In general, behaviour is optimum in the middle of the current

range (5 to 60 Amps) and at voltages between about 3 volts and 3 volts below the open circuit

voltage of the source.

Attempting to achieve a slew rate beyond the capabilities of a source and load combination will

result in substantial overshoot and ringing. Reducing the slew rate, sometimes by just a small

amount, will improve the response considerably.

23

Page 25

Source inductance

Source and interconnection inductance has a major impact on the behaviour of the load: the

fundamental characteristic of an inductance is that it resists any change in current. As the current

rises, the inductance generates an emf that reduces the voltage across the load, often to the

point where the load saturates. Whenever the voltage falls below about 3V the transconductance

of the power stage changes considerably, changing the damping factor of the feedback loop, and

the dynamic behaviour changes markedly. As the current falls, the inductance generates an emf

that increases the voltage across the load terminals; this in turn affects the conductivity of the

load in operating modes that are voltage dependent.

Shunt capacitance

The load can only sink current, and can only pull the voltage at its terminals down. The source

must pull the voltage up, including providing charging current to any capacitance across the

terminals. If the total current available is more than sufficient to charge this capacitance at the

slew rate required, then the load will continue to conduct the excess current during the transition.

However, if the source cannot charge the capacitor at the required slew rate, then the load will

cut-off until the final voltage is reached. There will then be an overshoot before it starts to

conduct, followed by a ringing as the source responds.

Source Characteristics

The purpose of transient testing is to examine the behaviour of any feedback loops within the

source. If the response of the source is under-damped, then in general the use of an active load

will accentuate the effect. This is particularly true in the modes where the load responds to

changes in voltage. At particular transient frequencies the load may excite resonances in L-C

filters or match the natural frequency of a feedback loop. This can result in considerable reaction

from the source.

Implementation

The following sections give a brief description of the way each mode operates, and give some

guidance of the effect that has on the application of the load.

Constant Current Mode

The load has two power stages (each a large FET) in parallel; each stage has local current

feedback to ensure equal power sharing. Overall current feedback to an earlier stage is used to

enhance accuracy. The sensed voltage signal is only used for the meters. Ideally, the operation

of the power stages would be independent of the applied voltage, but in practice, both the gain

and the inter-electrode capacitance of the FETs vary with operating point, particularly at low

voltages (below about 3V) and at low and high currents. This results in slower response and

different stability conditions and dynamic behaviour in these regions.

Constant current mode is normally used in conjunction with low impedance power supplies, and

is normally quite stable unless there is significant inductance in either the interconnections or the

source. The load is designed to support higher current slew rates in Constant Current mode than

in all the other modes; this makes it particularly critical to have low inductance connections.

Constant Voltage Mode

Because the power stages of the load are fundamentally a current sink, Constant Voltage mode

operates in an entirely different manner to all other modes. The difference between the sensed

voltage and the required voltage is applied to an integrator with a short time constant. The output

of this integrator (which is, in effect, a guess at the current required) drives the power stages. The

operation of this mode depends entirely on feedback action. The transconductance of the load

(the change in load current caused by a small change in sensed voltage) is very high, resulting in

very high system gain.

24

Page 26

Constant Voltage mode is intended for use with true high impedance current sources. The

presence of shunt capacitance can form a relaxation oscillator, where the load takes a pulse of

current and then cuts off until the source recovers. Asymmetrical sources (those which can only

pull up, not down) make this problem worse. Electronic supplies operating in constant current

mode often have high impedance only within the bandwidth of a feedback loop. At higher

frequencies, a shunt capacitor reduces the output impedance considerably; a combination of this

load and such a source is often unstable.

If Constant Voltage mode cannot be made stable, it is possible to use the offsetting capability of

Constant Resistance mode. The DROPOUT control is set to the required voltage and the

resistance level setting is used to define the slope resistance. Increasing this setting will reduce

the gain and perhaps allow stable operation to be obtained.

Constant Power Mode

Constant Power mode is implemented by using an analogue divider to divide the required power

by the sensed voltage to calculate the necessary current. The effect of this is to attempt to satisfy

a demand for more power by increasing the conductivity of the load and raising the current.

Because of source (and wiring) resistance, the terminal voltage will fall as the current rises;

provided the power (the product of terminal voltage and current) rises as the current increases

then the load will function as expected.

The maximum load power that can be drawn from a given source occurs when its terminal

voltage has fallen to half the open circuit voltage. As the current increases beyond this point, the

fall in voltage outweighs the increase in current and the power falls. The load then latches into a

condition of hard conduction, with maximum current and almost zero voltage: it is attempting to

increase the power level by increasing the current, but as the supply is already delivering its

maximum current this attempt fails. The only way to recover from this situation is to disable the

load input or the source output.

Constant Power mode has the characteristics of a negative resistance (the current increases as

the voltage falls) and the possibility always exists of forming a negative resistance oscillator in

combination with the output impedance of the source. In practice, constant power mode normally

operates well in conjunction with sources designed to supply such a load.

In transient operation, if the source is constant voltage (with low source impedance), then the

current will follow the changes in power demand and the response will be very similar to constant

current mode. If the source voltage falls as the power demand increases, then the current has to

increase more than proportionally and the current slew rate rises; this will limit the maximum

useful power slew rate to a setting below the point at which the ERR indicator lights.

Constant Conductance and Resistance Modes

In both these modes, an analogue multiplier-divider is used to derive the current required from the

sensed voltage. In Conductance mode the current required is calculated by multiplying the

sensed voltage by the required conductance; in Resistance mode the current required is

calculated by dividing the difference between the sensed voltage and the dropout voltage setting

by the required resistance.

In both cases, the current rises as the applied voltage rises. At equivalent resistance and

conductance settings, the path from the voltage sense input through to the power stage is the

same, so the two modes will exhibit similar stability characteristics.

In transient operation, the two modes are very different. In Conductance mode, the current

required linearly follows the changing conductance value and the behaviour is fundamentally

similar to constant current mode. In Resistance mode, the required current is inversely

proportional to the linearly changing resistance value, so the resulting current waveform is very

non-linear, rising rapidly at the low resistance part of the cycle. This rapid rise accentuates the

effect of inductance in the interconnecting leads and can easily lead to bottoming and overshoots.

Resistance mode is best used at higher voltages and modest currents.

25

Page 27

Zero Volt Operation

Although this unit is designed with very low internal resistance (less than 25mΩ) to enable

operation down to low voltages at high currents, there are occasions when a load is needed

capable of conducting the full current down to zero voltage. This can be achieved by connecting

an external offsetting supply in series with the load (with the opposite polarity). External voltage

sensing must be used, with the sense leads connected to the supply under test, outside the

series combination of the load and the offsetting supply.

An offset voltage of at least the operating voltage of the load plus any voltage drop in the interconnections is needed; the maximum permissible voltage is 6 Volts. The offset supply must be

capable of providing the full load current and must have a dynamic performance that does not

impair the stability of the combination; it should be protected against reverse voltages. If possible,

the use of batteries is recommended, but care must be taken to avoid full discharge or reverse

current.

Note that the combination of the offsetting supply and the load can apply a reverse voltage to the

source under test, so appropriate protection should be provided. It is strongly recommended that

a switch, capable of disconnecting the full load current, should be included in the circuit.

The load has a diode across the input terminals that will conduct current if reverse

polarity is applied, even if the INPUT ENABLE switch is released.

Multiple Unit Operation

It is possible to operate multiple loads in parallel in Constant Current mode. This will increase

both the current handling and power dissipation capability beyond that of a single unit. The

connections to the source should be matched as well as possible. Note that, because of the

additional feedback loops and inter-connections, stability issues are likely to be more

troublesome.

It may also possible to operate two units in series in Constant Voltage mode, but this should only

be used to increase the power dissipation capability, not the voltage handling. The open circuit

voltage of the source must not exceed the 80V rating of a single unit. It is, however, very likely

that instability will be a problem.

It is not recommended that multiple unit operation be attempted in Constant Power, Resistance or

Conductance modes.

26

Page 28

Two forms of voltage controlled remote operation are available: EXTERNAL VOLTAGE control,

where an analogue voltage defines the demanded level of the chosen operating mode, and

EXTERNAL TTL control where an external voltage selects between the level settings of the

LEVEL A and LEVEL B front panel controls.

The controlling voltage is applied to the two CONTROL VOLTAGE terminals on the rear panel.

Each terminal has an input impedance of nominally 400kΩ to the load negative terminal. A

differential line receiver allows common mode voltages up to ±100 Volts. The common mode

rejection is better than –66dB (50mV at 100V); although it is typically much better than this

(-80dB), the effect on the programmed level can be significant. Consideration should also be

given to the return path for the input currents.

Remote Voltage Control

Set the LEVEL MODE switch to EXTERNAL VOLTAGE position. The front panel LEVEL A and

LEVEL B controls have no effect. The LOAD MODE switch selects the required operating mode

and full scale range. The front panel DROPOUT voltage control setting remains active.

The CONTROL VOLTAGE input has a scaling factor of 4 Volts full-scale. The conversion factors

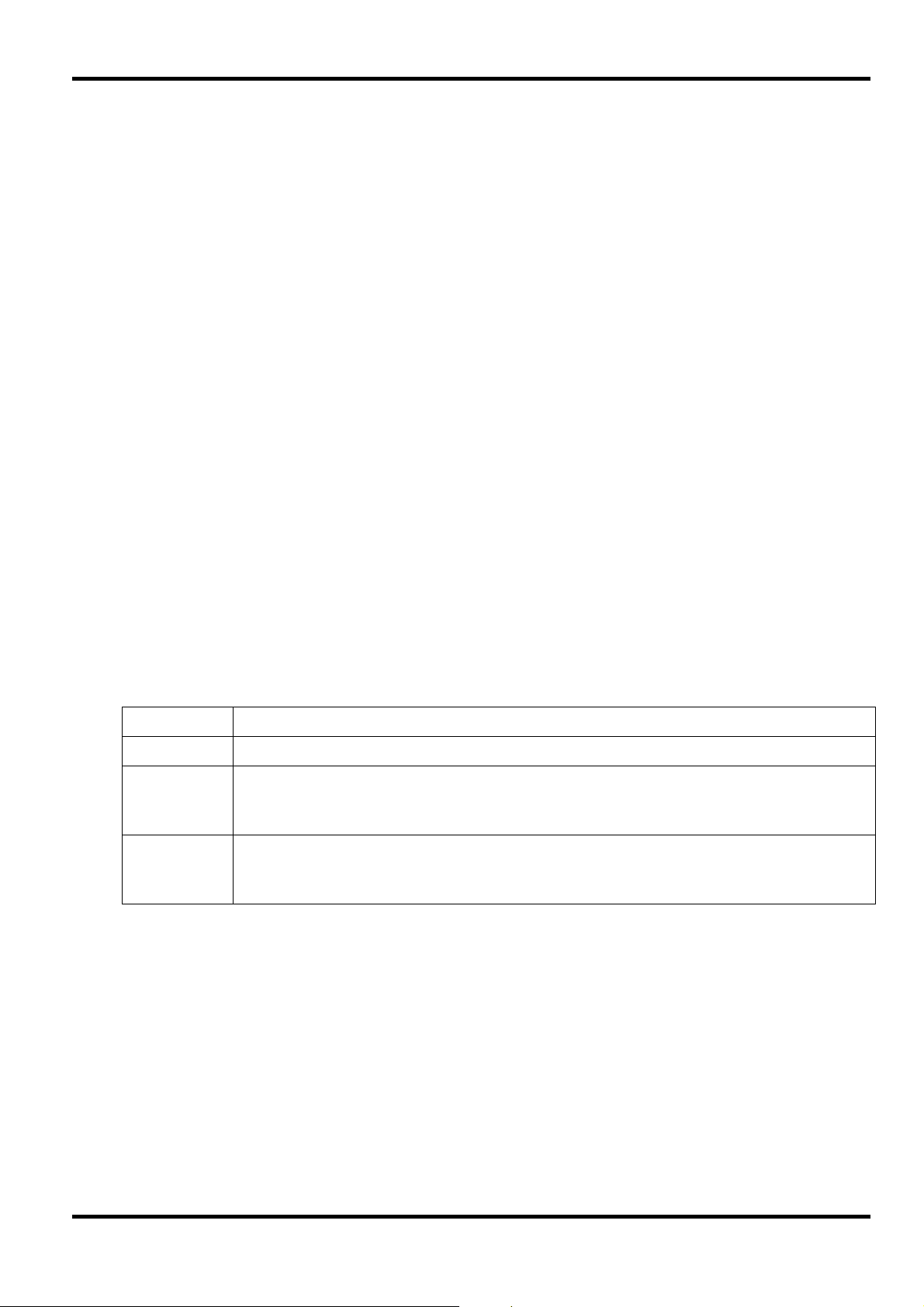

for each mode and range are:

Remote Control

The slew rate circuit and its front panel controls remains in circuit and the required transient

waveshape can be obtained by adjusting these settings in combination with the shape of the

signal applied to the remote input, subject to the transition time limitations of the load circuit.

Remote Level Select

Set the LEVEL CONTROL switch to the EXTERNAL TTL position. If the external signal applied to

the CONTROL VOLTAGE input is below the logic threshold (nominally + 1·5 V) then the level set

by the LEVEL A control is active; if the signal is above the threshold then the level set by the

LEVEL B control applies. The transitions are defined by the setting of the SLEW RATE controls

on the front panel.

Operating Range Scale Factor

80 Amps 20 Amps per Volt

8 Amps 2 Amps per Volt

80 Volts 20 Volts per Volt

8 Volts 2 Volts per Volt

320 Watts 80 Watts per Volt

400 Ohms 100 Ohms per Volt

10 Ohms 2·5 Ohms per Volt

1 A/V (Siemens) 0·25 A/V (Siemens) per Volt

40 A/V (Siemens) 10 A/V (Siemens) per Volt

Remote Input Disable

This input is provided for remote override of the INPUT ENABLE function of the load. It is

available in all operating modes of the instrument. It is a fully floating input to an opto-isolator:

apply 3 to 12 volts (observing polarity) to disable the load. The load is only enabled if this signal is

absent and the front panel INPUT ENABLE switch is depressed.

27

Page 29

The Manufacturers or their agents overseas will provide a repair service for any unit developing a

fault. Where owners wish to undertake their own maintenance work, this should only be done by

skilled personnel in conjunction with the service manual, which may be purchased directly from

the Manufacturers or their agents overseas.

Cleaning

If the instrument requires cleaning use a cloth that is only lightly dampened with water or a mild

detergent.

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE INSTRUMENT, NEVER

ALLOW WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE NEVER

CLEAN WITH SOLVENTS.

Calibration

To ensure that the accuracy of the instrument remains within specification the calibration must be

checked (and if necessary adjusted) annually. The calibration adjustment procedure is detailed in

the service manual.

Fuses

Maintenance

The transformer primary is protected by a non-resetting thermal fuse inside the windings. It can

only be replaced by fitting a new transformer.

The secondary circuits are protected by encapsulated fuses soldered to the PSU PCB. Consult

the service manual for replacement details.

28

Page 30

Sécurité

Cet instrument est de classe de sécurité 1 conforme à la classification IEC et il a été conçu pour

satisfaire aux exigences de la norme EN61010-1 (Exigences de sécurité pour les équipements

électriques de mesure, de contrôle et d'utilisation en laboratoire). Il s'agit d'un instrument de

Catégorie II d'installation devant être exploité depuis une alimentation monophasée standard.

Cet instrument a été testé conformément à la norme EN61010-1 et il a été fourni en tout état de

sécurité. Ce manuel d'instructions contient des informations et des avertissements qui doivent