Page 1

INSTRUCTION MANUAL

LCR400

Precision LCR Bridge

Page 2

Table of Contents

Introduction 2

Specification 3

EMC 6

Safety 7

Installation 8

Connections 9

Operation 10

Measurement Principles 12

Component Sorting 16

Remote Operation 20

Remote Commands 21

Maintenance 24

Instructions en Francais 25

Bedienungsanleitung auf Deutsch 45

Istruzioni in Italiano 65

Instrucciones en Español 85

1

Page 3

Introduction

The LCR 400 Precision Bridge provides a fast, convenient and accurate means of measuring the

inductance, capacitance, resistance, D and Q of components with a basic accuracy of 0.1%. The

major and minor parameters of the component are displayed simultaneously.

The microprocessor controlled unit provides fully automatic mode and range selection for a wide

range of components. Control is by front panel keyboard or by RS232 link to a PC which can be

used to set up all measurement functions.

The LCR400 can be programmed to sort a range of components into bins according to value.

Multiple bins can be set to sort different tolerances of the same value or different values.

Up to nine measurement set-ups can be stored in the instrument in non-volatile memory and

called up for re-use with a few keystrokes.

Connections to the components are made via the built in four–terminal test fixture or plug–in axial

adaptor providing true contact resistance free measurements for low impedance components.

The capacitance (up to 100pf) introduced by an external test fixture can be cancelled out

permitting high impedance measurements to be made with confidence.

2

Page 4

Specification

Specifications apply for 18ºC − 28ºC ambient after 30 minute warm-up.

Functions

Parameters Measured: R, L, C, D & Q.

Measurement Modes: Series or parallel equivalent circuit.

Measurement Functions: Fully autoranging including selection between L, C and R. The Zero C

function nulls out up to 100pF of stray capacitance in the test fixture.

Measurement Frequency: User selectable to be 100Hz, 1kHz or 10kHz; frequency accuracy

± 0.01%. 120Hz instead of 100Hz by factory option for 60Hz operation.

Measurement Ranges

and Resolution:

R

L

C

D

Q

Measurement Accuracy:

R (Q<0·1) 0.1% ± 1 digit

0.5% ± 1 digit

2% ± 1 digit

L (Q>10) 0.1% ± 1 digit

0.5% ± 1 digit

2% ± 1 digit

C (D<0.1) 0.1% ± 1 digit

0.5% ± 1 digit

2% ± 1 digit

Parameter

100/120Hz 1kHz 10kHz

2Ω − 1MΩ

0.4Ω − 5MΩ

0.1Ω − 20MΩ

4mH – 500H

800µH – 2500H

200µH − 9900H

10nF − 1000µF

2nF − 5000µF

500pF − 20000µF

Range

0.1mΩ − 990MΩ

0.001µH − 9900H

0.001pF − 99000µF

0.001 − 999

0.001 − 999

2Ω − 500kΩ

0.4Ω − 2MΩ

0.1Ω − 10MΩ

400µH − 50H

80µH – 250H

20µH − 1000H

1nF − 100µF

200pF − 500µF

50pF − 2000µF

2Ω − 50kΩ

0.4Ω − 200kΩ

0.1Ω – 500kΩ

40µH − 5H

8µH – 25H

2µH − 100H

100pF − 10µF

20pF − 50µF

5pF − 200µF

Q & D 0.25% ± 1 digit

Capacitance accuracies apply after null.

Measurement Update Rate: 2.5 readings per second.

0.25 − 4.0

for C = 40nF – 100µF

or L = 10mH – 50H

0.25 − 4.0

for C = 10nF – 10µF

or L = 1mH – 2.5H

0.25 − 4.0

for C = 1nF – 1µF

or L = 100µH – 250mH

Limits Comparator (Sort Mode)

Type: Comparison with multiple limits set up from the keyboard or PC via RS232 interface.

Binning: Up to 8 Pass bins for the major parameter, plus minor parameter Fail and general Fail bins.

3

Page 5

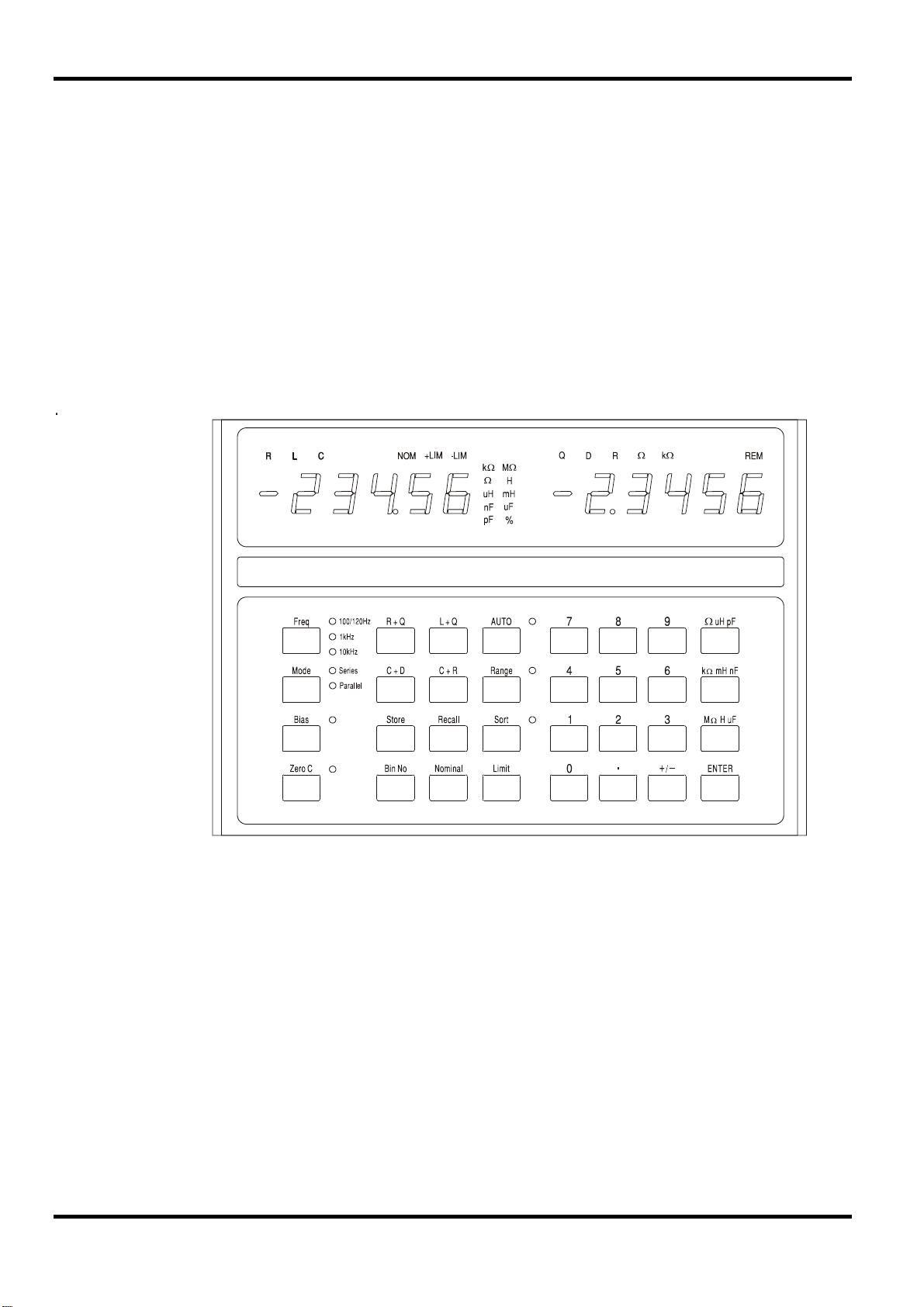

Display

Display Type: Dual 5-digit 0·56” LEDs with range and function indication.

Maximum display count 50,000.

Display Functions: Simultaneous display of R + Q, L + Q, C + D, or C + R in normal

measurement modes.

Prompts to change frequency or mode to improve accuracy.

Simultaneous display of Pass/Fail status with Bin No. in Sort mode.

Inputs

Component Connection: 4-terminal connection for both radial and axial devices.

Maximum Voltage on

Component:

Bias Voltage: Switchable 2V polarising voltage for measuring electrolytic capacitors.

Input Protection: The instrument has been designed to withstand direct connection of

0·3Vrms.

capacitors charged up to 50V DC with up to 1 Joule ( ½ CV

energy.

2

) of stored

Interfaces

RS232: Serial link to PC permitting range/function control, limits setting and

results data-logging on the PC.

General

Keyboard: Full numeric keyboard for entry of limits data.

Non-Volatile Memory: Up to 9 complete set ups stored in non-volatile memory.

Power: 220V-240V AC or 110V-120V AC ±10%, 50/60Hz, adjustable internally;

25VA max. Installation Category II.

Operating Range: +5ºC to 40ºC, 20-80% RH.

Storage Range: –40ºC to 70ºC.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

Size: 365 x 240 x 95 mm, including feet.

Weight: 2.9 kg.

Options: Remote 4–terminal measurement interface.

4–terminal surface mount tweezers.

Kelvin Clip set.

PC logging software.

4

Page 6

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

meets the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

LCR400 LCR Bridge

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class B

b) EN61326-1 (2006) Conducted, Class B

c) EN61326-1 (2006) Harmonics, referring to EN61000-3-2 (2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2007) Conducted RF

Performance levels achieved are detailed in the user manual.

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

CHRIS WILDING

TECHNICAL DIRECTOR

1 May 2009

5

Page 7

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A (B).

EMC

b) EN61000-4-3 (2006) Electromagnetic Field:

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance B

Performance B

†

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle and 1 cycle, 0%: Performance A (B);

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line), 0·5kV peak (signal connections),

e) EN61000-4-5 (2006) Surge, 0·5kV (line to line), 1kV (line to ground), Performance A (B).

f) EN61000-4-6 (2007) Conducted RF, 3V, 80% AM at 1kHz (AC line only), Performance A (A).

According to EN61326-1 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

The LCR400 is a sensitive measuring instrument and may show minor deviations in

measurement readings if subjected to RF fields greater than 1V/m and a modulation

frequency exactly that selected for the LCR400 measurement. Under all other conditions

the instrument will operate within specification (Performance A).

25 cycles, 70% and 250 cycles, 0%: Performance B (C).

Performance A (B).

†

(A); 1V/m, 2.0GHz to 2.7GHz: Performance A (A).

†

(A) and 1.4GHz to 2GHz:

Cautions

To ensure continued compliance with the EMC directive observe the following precautions:

a) after opening the case for any reason ensure that all signal and ground connections are

b) In the event of part replacement becoming necessary, only use components of an identical

6

remade correctly and that case screws are correctly refitted and tightened.

type, see the Service Manual.

Page 8

Safety

This instrument is Safety Class I according to IEC classification and has been designed to meet

the requirements of EN61010−1 (Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use). It is an Installation Category II instrument intended for operation

from a normal single phase supply.

This instrument has been tested in accordance with EN61010−1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% −80% RH (non−condensing). It may occasionally be

subjected to temperatures between +5° and −10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short−circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:−

Caution −refer to the accompanying documentation,

incorrect operation may damage the instrument.

alternating current.

7

Page 9

Mains Operating Voltage

The operating voltage of the instrument is shown on the rear panel. Should it be necessary to

change the operating voltage from 230V to 115V or vice-versa, proceed as follows:

1. Disconnect the instrument from all voltage sources.

2. Remove the 6 screws which hold the case upper to the chassis and lift off, noting the flat

cable connector positions.

3. Remove the 4 screws securing the power supply pcb to the chassis and lift the pcb free.

4. Change the appropriate zero-ohm links beside the transformer on the pcb:

Link LK4 only for 230V operation

Link LK3 and LK5 only for 115V operation

Note that, if the change of operating voltage is accompanied by a change of supply

frequency, optimum common mode rejection of the mains will be achieved by setting the

internal 100/120Hz selection to 100Hz for 50Hz supply and 120Hz for a 60Hz supply.

This is set by the status of link LK2 which is situated immediately below the oscillator

module on the main circuit board. With no shorting link fitted to the pins the frequency is

set to 100Hz; if a shorting link is fitted it is set to 120Hz. The factory setting for 230V

operation is 100Hz and for 115V operation is 120Hz. If LK2 is changed from the factory

setting the unit will need to be recalibrated at the new frequency setting (calibration

settings for 100Hz and 120Hz cannot be held simultaneously).

Installation

5. Refit the pcb to the chassis, ensuring all connections (especially safety earth) are remade

6. To comply with safety standard requirements the operating voltage marked on the rear

7. Change the fuse to suit the new operating voltage, see below.

Fuse

The correct time-lag fuse must be fitted for the selected operating voltage.

For 230V operation use 125mA (T) 250V HBC.

For 115V operation use 250mA (T) 250V HBC.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders are prohibited.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:

Brown - Mains live

Blue - Mains Neutral

Green/Yellow - Earth

as before, and refit the case upper.

panel must be changed to clearly show the new voltage setting.

8

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited.

Page 10

Component Connections

The leads of the Device Under Test (DUT) are inserted in the Kelvin connectors on the top of the

instrument. Axial components can be inserted into the adaptors supplied, which themselves are

inserted into the Kelvin connectors. Both forms of connection provide true four–terminal contact

to the DUT to ensure accurate measurement of low impedance components.

The leads of radial components can be pushed directly into the spring–loaded connectors.

Alternatively, for delicate leads, the connectors can be opened by pressing down on the

connector actuators.

Similarly, the axial adaptors can be inserted by pushing directly into the main connectors; adjust

the position of the adaptors to suit the lead and body length of the axial DUT.

Ensure the contact surfaces of the Kelvin connectors are free from contamination. If in doubt,

refer to the Maintenance section.

Surface Mount Components

Plug the interface module of the optional surface mount tweezers into the Kelvin connectors.

True four–terminal connection is maintained at the tweezers.

Connections

Remote Connections

A remote test jig can be connected via the BNC connectors on the optional interface module

which inserts into the Kelvin connectors on the top of the instrument. The connectors are labelled

High Drive, High Sense, Low Sense and Low Drive. The screens of the Drive coax cables should

be connected together at the remote end and connected to the screen and case of the external

jig. The screens of the Sense leads should be isolated both from each other and from the jig

screen.

Whilst leads of up to 1 metre are unlikely to present problems, the leads to an external jig should

be kept as short as possible and the accuracy of measurements checked at all test frequencies

and over the range of values being measured before being relied upon.

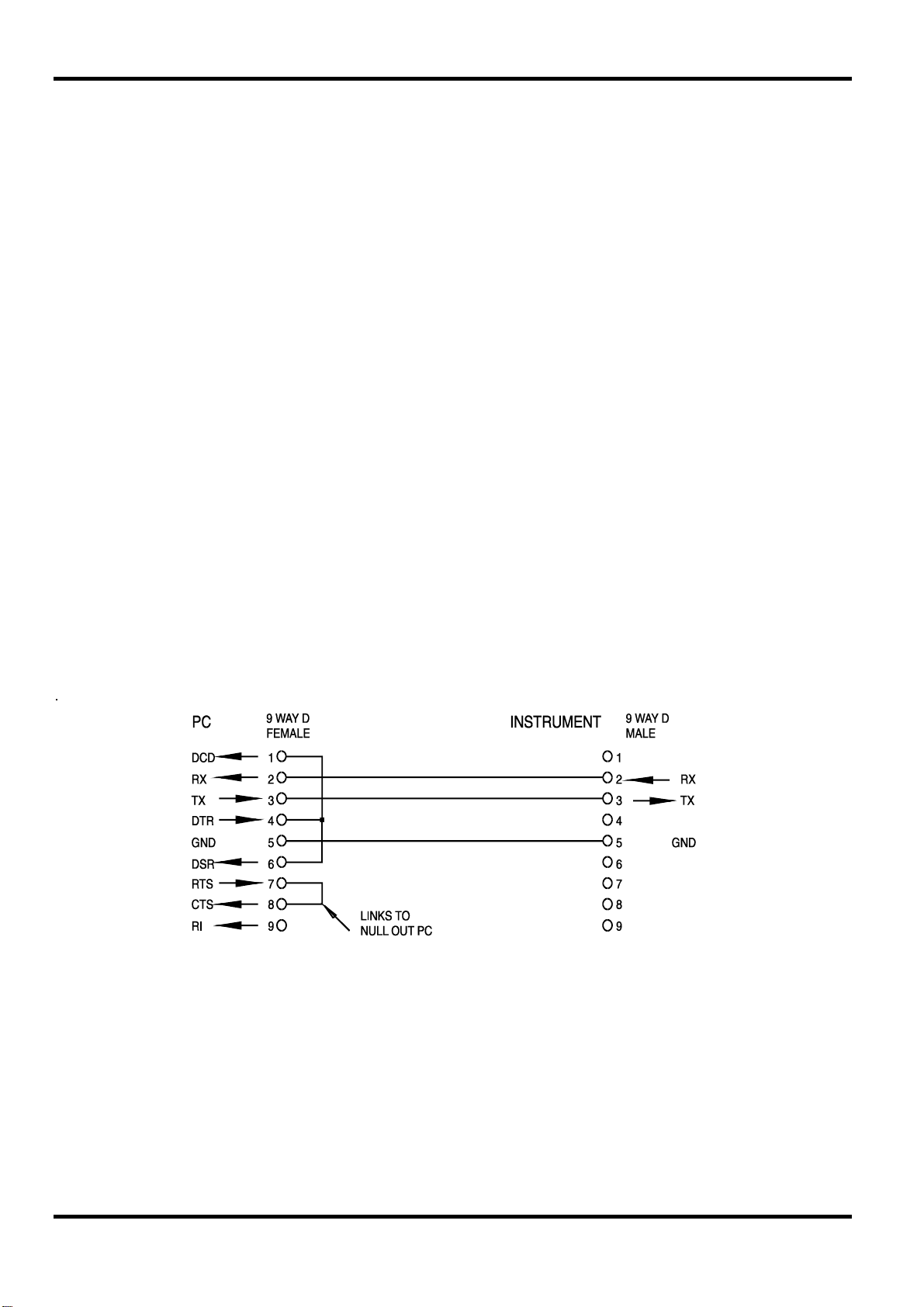

RS232

9–pin D–connector for PC remote control with the following connections:

Pin Name Description

1 DCD Linked to pins 4 and 6

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 DTR Linked to pins 1 and 6

5 GND Signal ground

6 DSR Linked to pins 1 and 4

7 RTS Linked to pin 8

8 CTS Linked to pin 7

9 – No internal connection

Connect to a PC with a cable which has pins 2, 3 and 5 wired plus pins 1, 4 & 6 and pins 7 & 8

linked at the PC end. Alternatively, since the links are made within the instrument, a fully–wired 1–

to–1 cable may be used.

9

Page 11

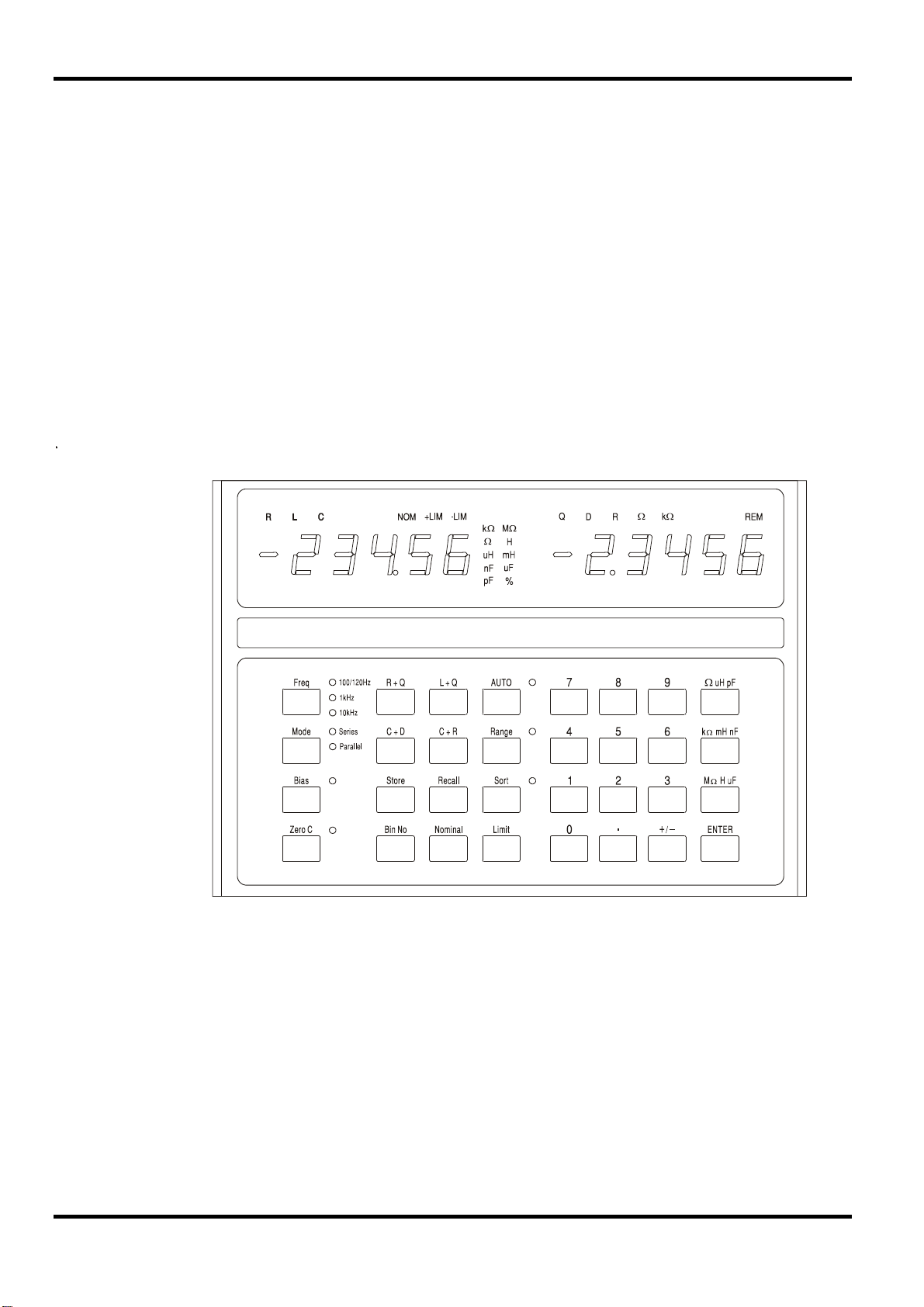

This section covers general use of the instrument. Although the basic capabilities are largely

obvious from the keypad functions, users requiring full performance and accuracy are advised to

read this and the Measurement Principles sections in full.

Switching On

Switch on the instrument using the ON/OFF switch on the rear panel.

At switch on the instrument runs a short internal self test procedure, displays the software

version, and then waits in Auto mode for a component to measure. If it is switched on with a

component connected it will automatically detect and measure that component.

To fully disconnect from the AC supply unplug the mains cord from the back of the instrument or

switch off at the AC supply outlet; make sure that the means of disconnection is readily

accessible. Disconnect from the AC supply when not in use.

Display

Operation

10

In normal use the left–hand 5–digit display shows the value of the major parameter (L, C or R)

and the right–hand display shows the value of the minor parameter (Q, D or R). The parameters

being displayed are indicated above their respective numeric values and the units of the

parameter are shown to the right of the value itself. A display test which lights all the indicators

can be carried out by holding down any key while the instrument is switched on.

Basic measurement accuracy is 0.1% and, for the impedance range for which this accuracy is

guaranteed (see Specification) the instrument will autorange to give typically between 5,000 and

50,000 counts of display resolution. If the measured value is outside the range within which 0.1%

accuracy is guaranteed (at the measurement frequency selected) the units indicator (kΩ, pF, etc.)

will flash to show this. If the frequency indicator is also flashing, changing the frequency range

may bring the component being measured within the range of the instruments 0.1% accuracy

specification. For example, measuring 680pF at the default Auto frequency of 1kHz will cause

both the units indicator (pF) and frequency range lamp to flash; changing the frequency to 10kHz

brings 680pF within the instrument’s 0.1% specification and both lamps will stop flashing.

During the set–up and use of the sort facility the displays have other uses; these are fully

explained in the Component Sorting section.

Page 12

Measurement Keys and Indicators

Frequency

Pressing the Freq key sets the test frequency for the measurement to 100/120Hz, 1kHz or

10kHz.

Note: For a 50Hz supply the lowest test frequency will generally be 100Hz, for a 60Hz supply it

will generally be 120Hz, see Installation section.

Pressing the key changes the frequency from 100/120Hz to 1kHz to 10kHz and back to

100/120Hz. The lamp indicates the setting being used. If the lamp flashes it is a warning that

another frequency may give a more accurate measurement for a component of that type and

value.

Mode

Selects either series or parallel mode equivalent circuit values to be displayed, see Measurement

Principles section. If the lamp flashes it is a warning that the other mode is the more usual

selection for a component of that type and value. If Auto mode has been selected the Mode

cannot be changed without first selecting L, C or R mode.

Bias

This applies 2 Volts DC across the test terminals to polarise electrolytic capacitors according to

the polarity marked on the Kelvin connectors. Note that applying bias to resistors or inductors

may cause a measurement error because of internal overload. Bias voltages up to 50V DC can

be applied externally, see the External Bias section of the Measurement Principles chapter.

Zero C

When measuring capacitors, pressing this button prior to inserting the component under test

zeroes the capacitance reading thereby eliminating the capacitance of the test jig. Up to 100pF of

stray capacitance may be zeroed out in this way. The correction factor is lost when the bridge is

turned off. Zero C can only be used when capacitance is being measured; if any other function is

selected the display will show

not C for 2 seconds and the command will be ignored.

R+Q, L+Q, C+D, C+R

Sets the instrument to show the major parameter in the left–hand display and the corresponding

minor parameter on the right.

Auto

In Auto mode the instrument automatically detects whether the component being measured is a

resistor, capacitor or inductor and sets the instrument to display the parameters of the test

component automatically. Note that ‘imperfect’ components, e.g. inductors with a high series

resistance, may be incorrectly detected in Auto mode and will need to have the correct function

set manually. In Auto mode the measurement frequency can be changed (by pressing the Freq

key) but the Series/Parallel mode selection is held at the default selection for that component

type, see Measurement Principles section. To change from series to parallel mode, or

vice–versa, it is first necessary to exit Auto mode by selecting the appropriate function

(R+Q, L+Q, etc.); the mode can then be changed with the Mode key.

Range Hold

Holds the measurement range at that in use when the button is pressed. This disables the auto–

ranging and minimises the settling time between measurements of similar value components.

Note that DUT voltage and current measurement are individually auto–ranged for optimum

accuracy and resolution; the processor then determines the measurement uncertainty and sets

an appropriate display resolution. Range Hold fixes all of these ranges. If a component with a

significantly different value is measured, causing any of these ranges to be exceeded, the display

will show

or (out of range) and Range Hold will need to be turned off to get a true reading.

Sorting Keys and Store/Recall Keys

The keys used to set up sorting and binning, and to store and recall complete sorting set–ups,

are described in the Component Sorting section.

11

Page 13

RsZ

ω

ω

ω

ω

=

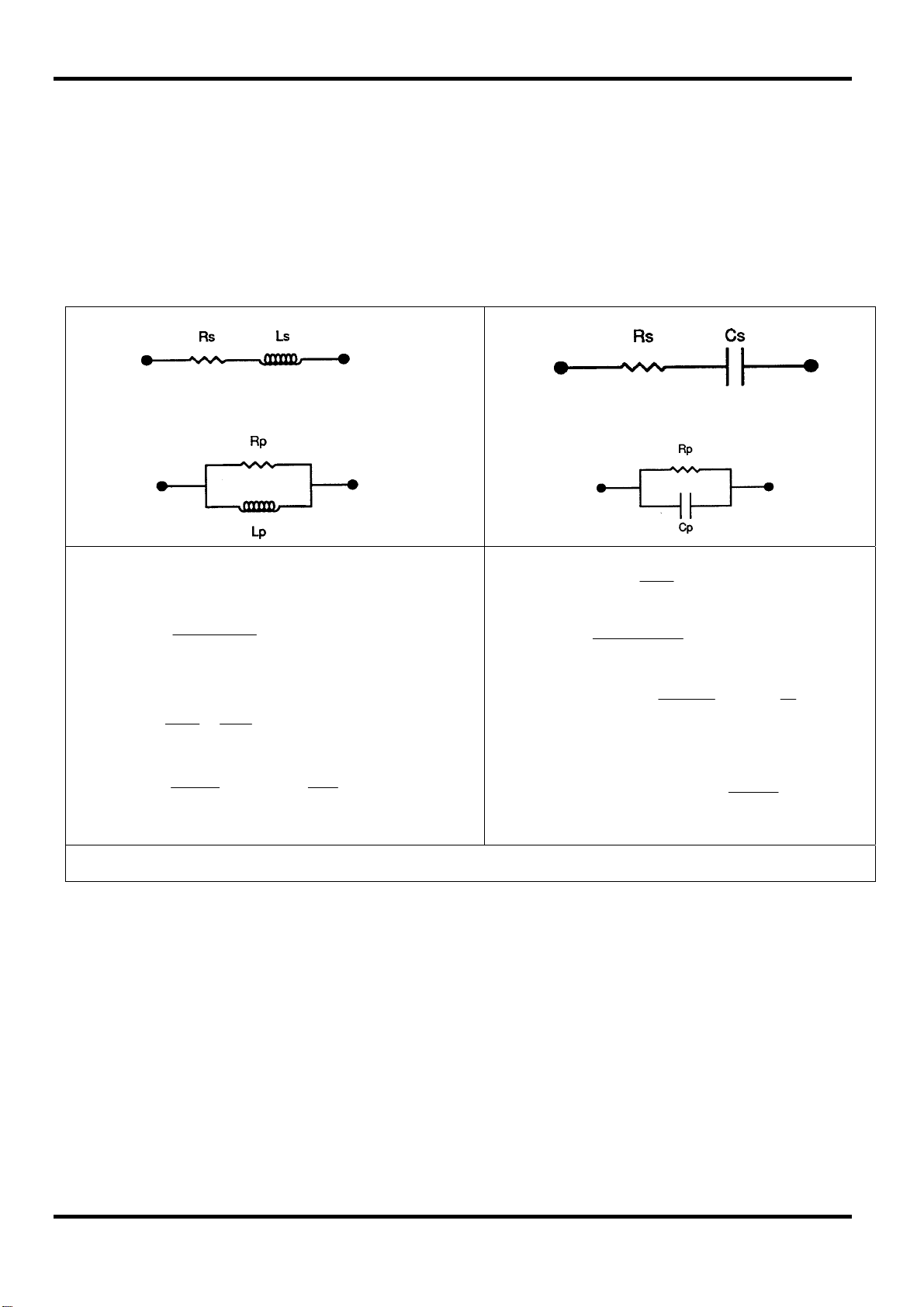

Circuit models

Resistors, capacitors and inductors can all be represented at a given frequency by a simple

series or parallel equivalent circuit. It must be stressed that this is a simple equivalent circuit and

as such will only be representative over a limited frequency range. The effects of a wide

frequency range are discussed later.

The Models used by the LCR400 are as follows:

Measurement Principles

s

Zp

+=

ω

=

+

Rp

Q

Lp

ω

2

Q

=

Ls

1+

Q

Lsj

ω

LpjRp

Ls

LpRpj

==

Rs

Rs

Lp

2

L

s

= LpQRp

Q

(D is also known as tanδ)

CpDCs )1(

Zp

jRsZs

−=

Rp

RpCpj

ω

+=1

RsCsD

ω

2

+= Rp

1

Cs

ω

1

==

RpCp

ω

=

Rs

1+

D

D

=

2

2

D

1

Q

Resistors

All resistors have parasitic impedances, both inductance and capacitance and distributed effects

of both. Fortunately, however, in normal use these parasitic effects are usually very small

compared with the resistance.

The LCR 400 provides the opportunity to evaluate the series and parallel components of resistors

at 100Hz and 1kHz and 10kHz.

Some types of resistor have more prominent parasitic effects than others. Wire wound resistors,

unless they are specially wound, have more inductance than their carbon and metal film

equivalents. Even carbon film resistors have inductance due to the inductance of the leads and

the spiral cut used to trim the resistance. There is also always capacitance between the end cap

connections - on metal film resistors it is typically around 0.25pF. This usually only becomes

significant on high value resistors or/and at high frequencies. Bifilar wound resistors may have

low inductance but the close proximity of the windings can introduce significant capacitance –

distributed along the resistance. To predict the performance of such a component at high

12

where

ω =

2πf

Page 14

frequencies requires a more complex equivalent circuit than the simple two component series or

parallel circuits discussed here. In practice the solution is to select component types to match the

frequency range of the application.

For the majority of resistors, where inductive and capacitive parasitics are minimal, both series

and parallel circuits will give identical results for resistance.

For resistors where inductance is the significant parasitic, the series equivalent circuit will give the

value which matches the manufacturer’s data-sheet. For high value devices, capacitance can

start to be significant and the parallel equivalent circuit may be more appropriate.

Normally R+Q should be selected for resistors; the Q of a resistor will usually be very low –

especially at the low measurement frequencies used. However if the series and parallel

resistances at 10kHz differ significantly to those at 100Hz or 1kHz, the Q will be significant. Either

the inductance or capacitance of the resistor is producing an effect. Selecting either C+R or L+Q

will quantify the parasitic capacitance or inductance.

Low value resistors can be measured at any of the three LCR400 test frequencies but high value

resistors (>100kΩ) are best measured on the 100Hz range. The instrument warns if a

measurement is outside its maximum accuracy range by flashing the units annunciator; if

accuracy can be improved by changing the measurement frequency the frequency annunciator

will also flash, see Display section.

Capacitors

All capacitors have parasitic inductance and resistance in addition to their intended capacitance.

The leads of a capacitor can add significant inductance at high frequencies. Spiral wound metal

film capacitors can have significant parasitic inductance, which is why they are not used for

decoupling high frequencies. Some types of ceramic capacitors can provide excellent decoupling, i.e. have high capacitance with low series resistance and inductance, but can be very

lossy. Large value electrolytic capacitors can have significant inductance – this inductance can

even resonate with the capacitance at the measurement frequencies of the LCR400. This has the

effect of showing a known high value capacitor to have either negative capacitance or inductance.

Capacitors have two main types of parasitic resistance. Firstly there is the physical resistance of

the dielectric and dielectric losses; this is normally specified in terms of the Dissipation Factor ‘D’

or loss tangent and is frequency dependent. Secondly, there is the physical resistance of the

leads and the connections to the electrodes on the dielectric. The lead and connection resistance

are usually negligible, but on high value electrolytics, used to smooth power supplies, it can be

very important. The series resistance of such devices is often a manufacturers specified

parameter.

For most capacitors, other than high value electrolytics, the parallel equivalent circuit will give the

capacitance that matches the manufacturers data sheet. For low loss capacitors the series and

parallel equivalent capacitances will be the same.

Electrolytic capacitors are polarity sensitive and should be connected to the instrument correctly

and bias applied. For very high value electrolytics, for which the manufacturer specifies

Equivalent Series Resistance (ESR) the series equivalent circuit should be used.

The LCR 400 provides the means to investigate the losses of capacitors either in terms of

dissipation factor (C+D) or in terms of equivalent series or parallel resistance (C+R).

To get maximum resolution and accuracy, low values of capacitance, (<4nF) are best measured

on the LCR 400 at 10kHz after zeroing the capacitance with no component connected. Higher

values, (>10µF) should be measured at 100Hz. The instrument warns if a measurement is

outside its maximum accuracy range by flashing the units annunciator; if accuracy can be

improved by changing the measurement frequency the frequency annunciator will also flash, see

Display section.

13

Page 15

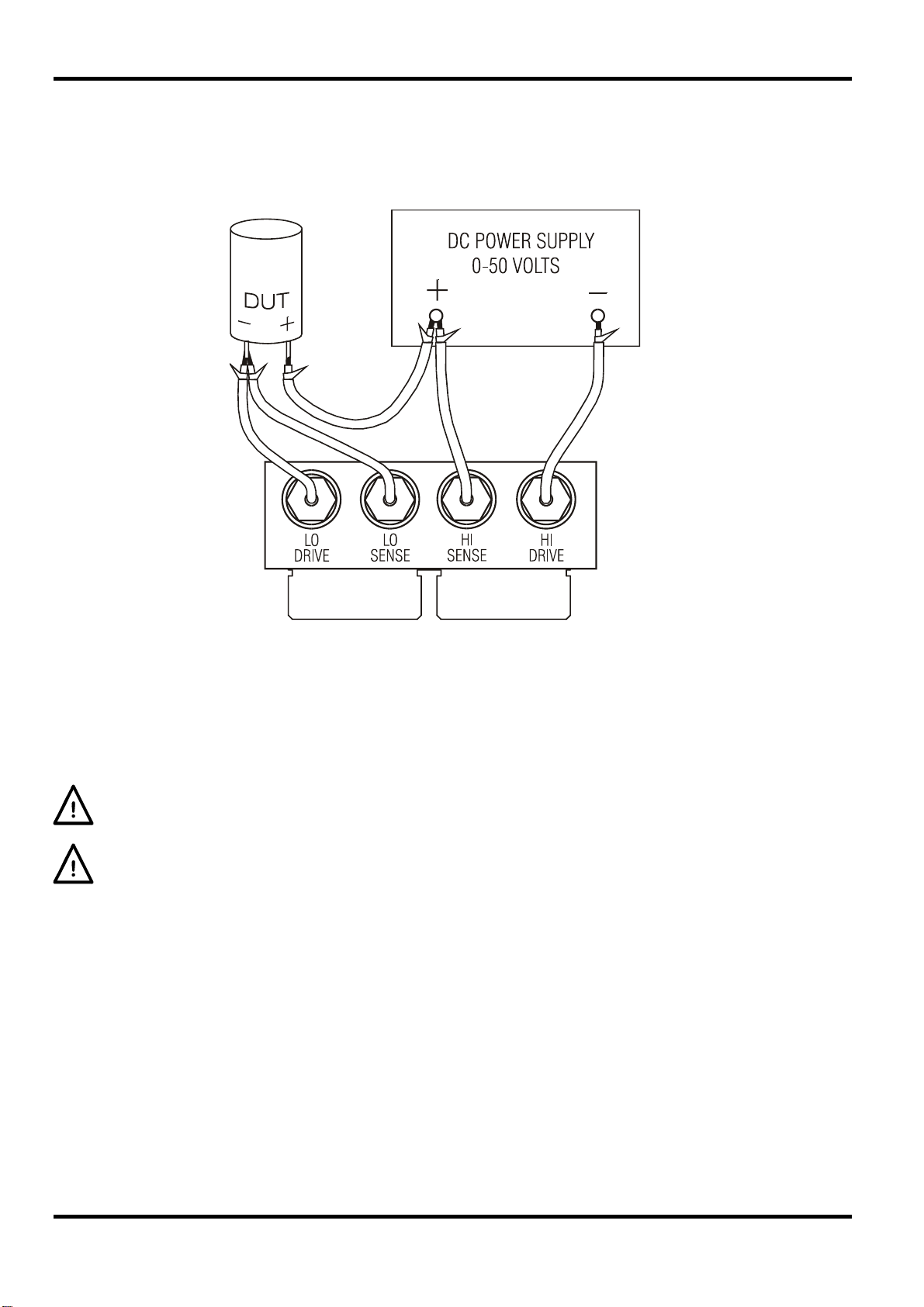

External Bias

The 2 Volt DC bias available internally (see the Measurement Keys and Indicators section) is

usually adequate for polarizing electrolytic capacitors. However, it is possible to externally

connect a fully floating power supply (or battery) to give a bias voltage of up to 50 Volts DC.

The external DC bias must be connected to the LCR400 and DUT as shown in the diagram. The

High Drive, High Sense, Low Drive and Low Sense connections to the LCR400 are made using

the optional interface module which inserts into the Kelvin connectors on the top of the

instrument.

The BNC connectors on the interface module are marked with the signal names. Connect to the

power supply and DUT using screened cables, e.g. miniature coaxial cable, but leave the screens

unconnected at the remote end.

CAUTION. Always observe the correct polarity when connecting capacitors; failure to do so

may result in damage to the DUT and possible user injury.

Always discharge capacitors after making measurements with a DC bias, especially at high bias

voltages; failure to do so may result in possible user injury and damage to the LCR400 if the

charged capacitor is subsequently connected directly to the Kelvin connectors. The LCR400

has been designed to withstand the direct connection of capacitors charged up to 50V DC with

up to 1 Joule of stored energy ( ½ CV

such capacitors. Higher voltage or higher energy may result in damage to the instrument.

Inductors

All inductors have resistive losses, parasitic capacitance and an external coupled magnetic field.

The resistive losses are the resistance equivalent to losses in the core and the resistance of the

conductive wire making up the turns of the inductor. There is capacitance between each turn of

conductor and every other turn. The magnetic field of an inductor can extend outside the physical

package of the component.

2

); it should not, however, be used to routinely discharge

14

In its simplest form the resistance can be represented as a resistor in series with the inductance,

and the capacitance as a capacitor in parallel. The effect of an inductor’s self capacitance and

inductance at any given frequency combine to produce net inductance below the resonant

frequency or capacitance above the resonant frequency.

Page 16

On high value inductors, such as transformers designed to work at 50/60Hz, the self resonant

frequency can be below the higher test frequencies of the LCR 400. Above the self-resonant

frequency these inductors will appear as a lossy capacitor. Due to the distributed nature of these

parasitics, the equivalent values of the resistance and capacitance change with frequency.

The leaked magnetic field, whilst usually negligible in the case of torroids, laminated core

inductors and pot core inductors, can be significant with axial inductors like RF chokes and ferrite

rod antennae. This means that the inductance of a device with a ‘leaky’ magnetic field can vary

considerably depending upon the characteristics of any conducting or magnetic material close to

the device. Any conductive material within the device’s field will contain induced currents that can

in turn have the effect of reducing the apparent inductance of the component. Conversely any

ferro-magnetic material in the immediate area of the component can have the effect of increasing

the apparent inductance. In extreme cases the inductance of a component can appear to vary

depending upon its distance above the connectors and steel case of the LCR400.

Low value inductors (<100uH) are best measured at 10kHz whilst high values >25H should be

measured at 100Hz. The instrument warns if a measurement is outside its maximum accuracy

range by flashing the units annunciator; if accuracy can be improved by changing the

measurement frequency the frequency annunciator will also flash, see Display section.

Series / Parallel connection

The LCR400 provides the capability of measuring the series or parallel equivalent circuit

parameters of resistors, capacitors and inductors.

In Auto mode the bridge uses the following models.

Resistor Series

Inductor Series

Capacitor <1µF

Capacitor >1µF

These will provide the parameters that will match data sheet values for most components.

Parallel

Series

15

Page 17

The LCR 400 provides comprehensive facilities for sorting components into ‘bins’ according to

value. The parameters for each bin can be defined from the keyboard or from a PC via the RS232

interface. Binning parameters are stored with the instrument set–up; up to 9 complete set–ups

can be stored.

Bin limits are set up as percentages around nominal values and can be overlapping or sequential

(with the same nominal) or can be percentages around quite different nominals; the bins must,

however, apply to the same parameter (R, L or C).

If only one bin is set up, all components outside the range are fails. Up to 8 bins (0–7) can be

used to sort on the basis of the major parameter; bin 8 can be used to set limits for the minor

parameter only (D, Q or R) and bin 9 is the general fail bin.

Sorting Keys

The following keys are associated with sorting; they are described more fully in the sections that

follow.

Sort

Turns the sorting function on and off.

Bin No.

Component Sorting

Used for setting each of up to eight bin values.

Nominal

Used to set the nominal value for a bin and the limit for minor parameter (bin 8).

Limit

Used to set the limits for a bin, in percentages.

Numeric keys 0-9, • and ±

Used to enter the bin numbers, program store numbers, nominal values and percentage limits.

Ω µH pF

Used when entering nominal component values to set the appropriate multiplier.

kΩ mH nF

Used when entering nominal component values to set the appropriate multiplier.

MΩ H µF

Used when entering nominal component values to set the appropriate multiplier.

Enter

Used to confirm a numerical entry (value, bin number or program store number).

Store/Recall Keys

The following keys are used to store and recall set–ups:

Store

Stores the complete set–up, including the set binning values, in non volatile memory.

Recall

Recalls up to nine previously stored set–ups.

16

Page 18

Simple Pass / Fail Sorting

To set up simple pass/fail sorting, first select the measurement type to be made, i.e. R+Q, L+Q,

C+D or C+R. Set the measurement frequency and select series or parallel measurement as

required.

Note: Binning cannot be set with the bridge in Auto mode.

Bin Selection

Press the Bin No. key to enter set–up mode. Successive presses of the Bin No. key will step the

display through the options of

selected bin),

press of Bin No. will enter the option sequence where it was last exited; it may be necessary to

press the key several times to get to the desired option.

CLEAR ALL? (clear all bins) and End? (exit bin set–up mode). The first

binX (where X is the bin number), CLEAr? (clear the

If any previous binning information needs to be cleared select

and press Enter; the display should show the message

the right–hand display, ready for the next step. If all bins are to be cleared select

and follow a similar procedure.

For simple pass/fail sorting, bin 0 must be used. The other bins (1 to 7 inclusive) should be

‘closed’ by setting their limits to zero; alternatively, and easier, all the bins can be cleared by using

CLEAr ALL? before bin 0 is set. Bin 8 can be used to set limits for the minor parameter (Q, D,

or R); parts that fail these limits fall into bin 8. Parts that fall into neither bin 0 nor bin 8 fall into

bin 9, the general fail bin.

Press Bin No. until

the right–hand display.

Setting Nominal Value

With bin0 displayed, press the Nominal key; the left–hand display now shows six dashes and

NOM above them.

Enter the nominal value required, followed by the appropriate units key (kΩ, µF, etc.). Press

Enter to save the value; the left–hand display now shows the value entered.

To edit an entered value simply enter a new value and press Enter again.

Setting Limits

CLEAr? with the Bin No. key

CLEAr donE and then binX in

CLEAr ALL?

binX shows in the display. Press 0 to select bin 0; bin0 should show in

With bin0 displayed, press the Limit key; the left–hand display now shows six dashes and

+LIM above them. The units indicator changes to %.

Enter the upper limit of deviation from the nominal allowed for a pass component, as a

percentage, and press Enter. Note that the minimum value that can be entered is 0.1% and the

resolution is 0.1%. The left–hand display again shows the value entered. To change an entered

value simply enter a new value and press Enter again.

Press the Limit key again; the left–hand display shows six dashes but now with

them. Enter the lower limit of deviation from the nominal allowed for a pass component, as a

percentage, and press Enter. Note that for a limit below the nominal value it is necessary to

enter a minus value using the

even both be above the nominal or both below the nominal. If no –LIM limit is entered the limits

are assumed to be symmetrical about the nominal value, i.e. if the upper limit has been set to

+0.5%, the lower limit automatically defaults to –0.5%.

The lower limit (

selecting Sort will give

17

–LIM) can be set above the upper limit (+LIM) but exiting set–up mode and

Err bin0.

± key. Note also that the limits need not be symmetrical and can

–LIM above

Page 19

Minor Parameter Limits

To set the minor parameter limit (Q, D or R) select bin 8; do this by using the Bin No. key until

BinX is shown, then enter 8. bin8 will now show in the left–hand side of the display.

To enter the limit press Nominal; the minor parameter indicator (Q, D or R) will show in the

right–hand side of the display and the limit value should then be entered from the keyboard.

Press Enter to confirm the limit.

Parts that fail the minor parameter limit of bin 8 will fall into bin 8 regardless of whether the major

parameter passes the bin 0 limits. Use of bin 8 is optional; it is not necessary to set a limit and if

the limit is left ‘closed’ (the default state, indicated by dashes) bin 8 will be ignored.

Fail Bin

Parts that do not fall into bin 0 or bin 8 are assigned to bin 9, the general fail bin.

Using Sort

Having set up bin 0, press Bin No. until End? is shown in the display then press Enter to exit

the set–up mode.

Press Sort to turn on the sort facility. Parts that pass the major parameter percentage limits will

be indicated by

will be indicated by

by FAIL bin9.

PASS bin0 in the display; parts that fail the minor term limits of bin 8 (if set)

FAIL bin8, parts that do not fall into either bin 0 or bin 8 will be indicated

Storing Sort Set–ups

To store a Sort set–up press the Store key; the display shows StorE?. Press a key 1 to 9

followed by Enter; after a few seconds the right–hand display shows

set–up has been stored. The binning nominal and limits are stored, together with the Function,

Frequency, Mode, etc. used for the Sort set–up.

To recall a Sort set–up press Recall, the store number (1 to 9), and Enter. The display shows

rcl donE when the set–up has been reloaded from non–volatile memory.

Note that memory 0 contains the factory default settings; these can be loaded by pressing,

Recall, 0, Enter. Memory 0 cannot be overwritten by pressing Store, 0, Enter and cannot

therefore be used to store binning information.

Multiple Bin Sorting

The LCR400 supports two different schemes for multiple bin sorting, overlap and sequential.

Overlapping (or nested) bins have one nominal value and progressively larger symmetrical limits.

Sequential bins can also have one nominal value but asymmetric limits (e.g. –5% to –2%, –2% to

+2%, +2% to 5%) or can have different nominal values, each with their own percentage limits.

As with simple pass/fail sorting, bin 8 is the failure bin for the appropriate minor parameter and

bin 9 is the general fail bin.

Multiple bin sort schemes can be quite complicated; it is therefore a good idea to write down the

binning set–up before programming is started and to save the set–up once programming is

complete.

donE to indicate that the

18

Page 20

Overlap Sorting

Overlap sorting is used when components are to be sorted into bins according to their deviation

from a nominal value, for example sorting a particular resistor value into ± 0.1%, ± 0.5% and

± 1% selections.

To set up this type of binning first select the measurement type to be made, e.g. R + Q, set the

measurement frequency and select series or parallel mode as required.

Select bin 0 and set the nominal value and tightest tolerance to be selected (i.e. 0.1% in the case

of the example) using the Nominal and Limit keys exactly as described for simple pass/fail

testing. Note that, since the limits are symmetrical, it is only necessary to set

–LIM is ‘closed’ (dashes shown in the display) the lower limit is automatically –0.1%.

Next select bin 1 in a similar way to bin 0 and set its limits to the next tightest tolerance (i.e. 0.5%

for the example). In the same way as for bin 0 it is only necessary to set

–LIM will default to –0.5% if no limit is set. Also note that it is not necessary to set a nominal for

bin 1 (and any successive bins that use the same nominal); if the nominal is left ‘closed’ (dashes

shown in the display) the nominal of the next lower bin, in this case bin 0, is automatically used.

Note that if bin 0 does not have a nominal value and limits, selecting Sort will cause the display to

show the message

+LIM to 0.1%; if

+LIM to 0.5%;

Err bin0.

Set the

Set the minor term limit (Q in the case of R + Q measurements) in bin 8 if required; bin 8 is

ignored if the limit is ‘closed’ (dashes shown in the display).

Parts that fall into more than one bin are assigned to the lower numbered bin, Thus the tightest

tolerances should be assigned to the lowest bin number, as in the example.

Unused bins should be ‘closed’ (indicated by dashes) by using the clear bin function.

Parts that do not fall into the pass bins or bin 8 are assigned to bin 9, the general fail bin.

+LIM limit of bin 2 to 1% to complete the example given.

Sequential Sorting

Sequential sorting with the same nominal can be set up in essentially the same way as for

overlap sorting, with a nominal value only defined for bin 0. However, every bin will need both

upper (

the bands –2% to –1%, ± 1%, and +1% to +2%, bin 0 has its

value,

set to +1% and its

+LIM) and lower (–LIM) limits defined. For example, to sort a particular resistor into

+LIM set to –1% and –LIM set to –2%; bin 1 has no NOM value and its +LIM is

–LIM is set to +1%.

Sequential sorting with different nominals can again be set up in essentially the same way but this

time every bin has

are symmetric then only

need to be set.

NOM set to the nominal resistor

–LIM to –1%; bin 2 has no NOM either, its +LIM is set to +2% and its

NOM set to its respective nominal. If the limits associated with each nominal

+LIM need be set, but if they are asymmetric then –LIM will also

In both schemes bin 8 can be set with the limit for the minor term, if required, exactly as

described previously.

Any parts that do not fall into the pass bins or bin 8, including any ‘gaps’ between the limits of the

sequential bins are assigned to bin 9, the general failure bin.

Storing and Recalling Sort Set–ups

Set–ups for multi–bin sorting are stored and recalled from non–volatile memory exactly as

described for simple pass/fail sorting.

19

Page 21

General

The instrument can be remotely controlled via its RS232 interface.

At power-on the instrument will be in the local state with the REMote indicator off. When a

command is received the remote state will be entered and the REMote indicator will be turned on.

The keyboard is not locked out and the instrument may be returned to the local state by pressing

any key; however, the effect of this action will only remain until the instrument receives another

character from the interface, when the remote state will once again be entered.

Remote command format and the remote commands themselves are detailed in the Remote

Commands chapter.

RS232 Connector

The 9-way D-type serial interface connector is located on the instrument rear panel. The pin

connections are as shown below:

Pin Name Description

1 DCD Linked to pins 4 and 6

2 TXD Transmitted data from instrument

3 RXD Received data to instrument

4 DTR Linked to pins 1 and 6

5 GND Signal ground

6 DSR Linked to pins 1 and 4

7 RTS Linked to pin 8

8 CTS Linked to pin 7

9 - No internal connection

Remote Operation

Connect to a PC with a cable which has pins 2, 3, 5, wired plus pins 1, 4, 6 and pins 7 and 8,

linked at the PC end, see diagram. Alternatively, since the links are also made at the instrument

end, a fully-wired 1-to-1 cable may be used.

The interface parameters are fixed as follows:

RS232 Character Set

Any ASCII code can be used. Bit 7 of ASCII codes is ignored, i.e. assumed to be low. No

distinction is made between upper and lower case characters in command mnemonics and they

may be freely mixed. The ASCII control codes between 00H and 31H are ignored, except for 0AH

(Line Feed, LF) which is used as a command terminator.

Baud Rate: 9600

Start Bits: 1 Parity: None

Data Bits: 8 Stop Bits: 1

20

Page 22

RS232 Remote Command Formats

Serial input to the instrument is buffered in an input queue which is filled, under interrupt, in a

manner transparent to all other instrument operations. This queue contains raw (un-parsed)

command data which is taken, by the parser, as required. Commands (and queries) are executed

in order and the parser will not start a new command until any previous command or query is

complete.

Commands (and queries) must be sent as specified in the command list and must be terminated

with the command terminator code 0AH (Line Feed, LF). Note that parameters are separated

from the command header by one space (20H) and multiple parameters are separated by

commas (2CH).

Responses to commands or queries are sent immediately; there is no output queue. The

controller must wait for the response to a command or query before the next command or query

is sent.

The instrument responds to the controller after every command either with ‘OK’ if the command

was completed successfully, or with ‘ERRnn’ if the command was not accepted; nn is the error

number, see list at the end of this section. The instrument responds to the controller after every

query as specified in the commands list. In all cases each response is terminated by 0DH

(Carriage Return, CR) followed by 0AH (Line Feed, LF).

Remote Commands

<WHITE SPACE> is defined as character codes 00H to 20H inclusive. <WHITE SPACE> is ignored

except in command identifiers. e.g. '*C LS' is not equivalent to '*CLS'.

The high bit of all characters is ignored.

The commands are case insensitive.

Command List

This section lists all commands and queries implemented in this instrument. The commands are

listed in alphabetical order within the function groups.

The following nomenclature is used:

<rmt> <RESPONSE MESSAGE TERMINATOR>, CR followed by LF

<nrf> A number in any format. e.g. 12, 12·00, 1·2 e1 and 120 e-1 are all

accepted as the number 12. Any number, when received, is converted to

the required precision consistent with the use then rounded up to obtain

the value of the command.

<nr1> A number with no fractional part, i.e. an integer.

Measurement Set-up Commands

BIASOFF Sets internal bias off.

BIASON Sets internal bias on.

FREQ <nr1> Sets the frequency as follows:

<1> sets 100Hz or 120Hz as determined by internal hardware link.

<2> sets 1kHz.

<3> sets 10kHz.

FUNC <nr1> Sets the measurement function as follows:

<0> sets Auto

<1> sets R + Q

<2> sets L + Q

<3> sets C + D

<4> sets C + R

21

Page 23

HOLDOFF Sets Range Hold off.

HOLDON Sets Range Hold on.

MODE <nr1> Sets the equivalent circuit mode as follows:

<1> sets Series mode.

<2> sets Parallel mode.

ZEROCON ‘Nulls out’ residual capacitance (up to 100pF) at the measurement

terminals; the measured value is subtracted from all subsequent C + D or

C + R readings until Zero C is turned off. Can only be used with a

capacitance function already selected.

ZEROCOFF Turns off Zero C function.

Measurement Reading Commands

READALL? Returns the values of the major parameter, minor parameter and bin

number of the reading completed immediately after the command has been

passed.

The syntax of the response is <ASCII data><rmt>, where <ASCII data>

consists of the three values separated by commas.

The major and minor values are returned as a character string of the form

X=n.nnnnE±nn where X = R, L, C, Q or D and n is a decimal number. The

units are Ohms for R, Henrys for L and Farads for C.

For example:

L=1.5000E-6 is 1.5µH

C=18.000E-12 is 18pF

Q=2.56 is Q = 2.56

D=0.015 is D = 0.015

The bin number is returned in the form BIN=n, where n is a decimal

READMAJ? Returns the value of the major parameter only, in the format described

READMIN? Returns the value of the minor parameter only, in the format described

R=2.0000E+3 is 2kΩ

number. When binning is not active, NOBIN is returned.

Examples of complete responses are:

L=1.5000E-6,Q=2.18,NOBIN<rmt>

C=186.97E-6,R=0.2015,BIN=2<rmt>

R=384.30E-3,Q=0.0004,BIN=1<rmt>

above for READALL?

above for READALL?

READBIN? Returns the value of the bin number only in the format described above for

READALL?

22

Page 24

Binning Commands

BINCLEAR Clears the nominal values and limits of all the bins; this has the effect of also

turning off Sort, should it be selected.

BINNOM <nr1>,<nrf> Sets the nominal of Bin <nr1> to value <nrf>; <nr1> can be 0 to 8 (9 is the

general fail bin). Note that Bin 8 is always the minor term bin (Q, D or R)

The nominal value <nrf> relates to the function selected at the time the first bin

is defined; further bins defined relate to the same function. Selecting Sort will

force that selected function.

If no nominal value is set for a bin, the nominal value for the next lowest bin will

automatically be used. The lowest numbered active bin must have its nominal

value set; Bin 0 must always be set for binning to be enabled.

BINNOM? <nr1> Returns the nominal value of bin <nr1> in the form <nrf><rmt>.

LIMHI <nr1>,<nrf> Sets the upper limit of Bin <nr1> to <nrf>%. The upper limit must be set before

the lower limit.

LIMHI? <nr1> Returns the upper limit of Bin <nr1>.

LIMLO <nr1>,<nrf> Sets the lower limit of Bin <nr1> to <nrf>%. The lower limit must be set below

the upper limit (which must have been set first). If no lower limit is set the

instrument will use the negative of the upper limit, i.e. the limits will be

symmetrical about the nominal.

LIMLO? <nr1> Returns the lower limit of Bin <nr1>.

Note: Limits may be set for bins with no nominal value; the nominal used will

be that of the next lowest bin which has a nominal set.

SORTON Enables binning (sort). Enabling sort forces the measurement function

associated with the binning set-up. Sort can only be enabled if at least one bin

has been defined.

SORTOFF Disables binning (sort).

System Commands

RST Resets the instrument to the power-up default settings.

RCL<nr1> Recalls the instrument set–up contained in store number <nr1>. Valid store

numbers are 0 - 9. Recalling store 0 sets all parameters to the power-up

default settings. An attempt to recall from a store which has not been

previously loaded with a set–up will cause an error.

SAV<nr1> Saves the complete instrument set–up in store number <nr1>. Valid store

numbers are 1 – 9.

Status Commands

*LRN?

Returns the complete set up of the instrument as a hexadecimal character data

block. The syntax of the response is LRN <data><rmt>.

To re-install the set–up return the block exactly as received, including the LRN

header at the beginning of the block, see below. The settings in the instrument

are not affected by execution of the *LRN? command.

LRN

<character data>

Install data from a previous *LRN? command. Note that the LRN header is

provided by the *LRN? response block.

Miscellaneous Commands

*IDN

?

23

Returns the instrument identification. The exact response is determined by the

instrument configuration and is of the form <NAME>,<model>, 0,<version><rmt>

where <NAME> is the manufacturer's name, <model> defines the type of

instrument and <version> is the revision level of the software installed.

Page 25

Calibration Specific Commands

See Service Manual for details of calibration specific commands.

Error Numbers

The instrument responds to the controller after every command with 'OK' if the command was

completed successfully or with 'ERRnn' if the command was not accepted. Commands will not

be accepted if the command is correct but the parameters are out of range (e.g. 'FREQ 5' will

return 'ERR1') or if the command is correct but cannot be implemented (e.g. ZEROCON with

resistance selected). In the case of '?' commands the error is returned if there is nothing set up to

return, e.g. 'ERR8' if no Hi limits have been set for the selected bin. Neither 'OK' nor 'ERRnn' are

returned if the command cannot be recognised.

Error Code List

The commands associated with the various error numbers are as follows:

Error No. Command

1 FREQ <nr1>

2 FUNC <nr1>

3 MODE <nr1>

4 ZEROCON

5 ZEROCOFF

6 BINNOM <nr1>,<nrf>

7 BINNOM? <nr1>

8 LIMHI? <nr1>

9 LIMLO? <nr1>

Error 18 is returned in response to READALL? if there is no valid measurement, e.g. display

shows overrange.

Error No. Command

10 LIMHI <nr1>,<nrf>

11 LIMLO <nr1>,<nrf>

12 SORTON

13 RCL <nr1>

14 RST

15 SAV <nr1>

16 *LRN?

17 LRN <data>

18 READALL?

Maintenance

The Manufacturers or their agents overseas will provide a repair service for any unit developing a

fault. Where owners wish to undertake their own maintenance work, this should only be done by

skilled personnel in conjunction with the service manual which may be purchased directly from

the Manufacturers or their agents overseas.

Cleaning

If the instrument requires cleaning use a cloth that is only lightly dampened with water or a mild

detergent.

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE INSTRUMENT, NEVER

ALLOW WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE NEVER

CLEAN WITH SOLVENTS.

Connector Contact Cleaning

Ensure the contact surfaces of the Kelvin connectors are free from contamination. The contacts

of both the built–in connectors and the axial adaptors are made of high quality stainless steel but

they can pick up contamination from the environment or from component leads inserted into the

connector. Occasionally clean the connectors by inserting a piece of clean stiff card between

them and lightly pushing back and forth. In extreme cases the card may be moistened with a little

suitable cleaning solution.

24

Page 26

Sécurité

Cet instrument est de Classe de sécurité 1 suivant la classification IEC et il a été construit pour

satisfaire aux impératifs EN61010-1 (impératifs de sécurité pour le matériel électrique en vue de

mesure, commande et utilisation en laboratoire). Il s'agit d'un instrument d'installation Catégorie II

devant être exploité depuis une alimentation monophasée habituelle.

Cet instrument a été soumis à des essais conformément à EN61010-1 et il a été fourni en tout

état de sécurité. Ce manuel d'instructions contient des informations et avertissements qui doivent

être suivis par l'utilisateur afin d'assurer un fonctionnement en toute sécurité et de conserver

l'instrument dans un état de bonne sécurité.

Cet instrument a été conçu pour être utilisé en interne dans un environnement de pollution

Degré 2, plage de températures 5°C à 40°C, 20% - 80% HR (sans condensation). Il peut être

soumis de temps à autre à des températures comprises entre +5°C et −10°C sans dégradation

de sa sécurité. Ne pas l'utiliser lorsqu'il y a de la condensation.

Toute utilisation de cet instrument de manière non spécifiée par ces instructions risque d'affecter

la protection de sécurité conférée. Ne pas utiliser l'instrument à l'extérieur des tensions

d'alimentation nominales ou de la gamme des conditions ambiantes spécifiées.

AVERTISSEMENT! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Il est absolument interdit d'effectuer une interruption à dessein. Ne

pas utiliser de cordon de prolongation sans conducteur de protection, car ceci annulerait sa

capacité de protection.

Lorsque l'instrument est relié au secteur, il est possible que les bornes soient sous tension et par

suite, l'ouverture des couvercles ou la dépose de pièces (à l'exception de celles auxquelles on

peut accéder manuellement) risque de mettre à découvert des pièces sous tension. Il faut

débrancher ke cordon secteur de l'appareil avant de l'ouvrir pour effectuer des réglages,

remplacements, travaux d'entretien ou de réparation.

Eviter dans la mesure du possible d'effectuer des réglages, travaux de réparation ou d'entretien

lorsque l'instrument ouvert est branché au secteur, mais si c'est absolument nécessaire, seul un

technicien compétent au courant des risques encourus doit effectuer ce genre de travaux.

S'il est évident que l'instrument est défectueux, qu'il a été soumis à des dégâts mécaniques, à

une humidité excessive ou à une corrosion chimique, la protection de sécurité sera amoindrie et il

faut retirer l'appareil, afin qu'il ne soit pas utilisé, et le renvoyer en vue de vérifications et de

réparations.

Remplacer les fusibles uniquement par des fusibles d'intensité nominale requise et de type

spécifié. Il est interdit d'utiliser des fusibles bricolés et de court-circuiter des porte-fusibles.

Eviter de mouiller l'instrument lors de son nettoyage.

Les symboles suivants se trouvent sur l'instrument, ainsi que dans ce manuel.

ATTENTION - se référer à la documentation ci-jointe; toute utilisation

incorrecte risque d'endommager l'appareil.

Courant alternatif (c.a.)

25

Page 27

Tension d'alimentation secteur

La tension dalimentation de l'instrument est indiquée à l'arrière. S'il est nécessaire de la modifier

de 230V à 115V ou vice-versa, procéder comme suit :

1. Débrancher l'instrument du secteur d'alimentation.

2. Retirer les 6 vis qui maintiennent le couvercle supérieur et soulever ce couvercle en

notant la position du connecteur du câble plat.

3. Retirer les 4 vis qui maintiennent la carte à circuits imprimés sur le châssis et libérer la

carte.

4. Changer les liaisons zéro ohm appropriées à côté du transformateur de la carte :

LK4 uniquement pour le fonctionnement à 230V

LK3 et LK5 uniquement pour le fonctionnement à 115V

Noter que si le changement de tension de fonctionnement s'accompagne d'un

changement de fréquence de la tension, le rejet du mode commun optimum de la tension

du secteur peut être réalisé en définissant la sélection interne de 100/120Hz sur 100Hz

pour une alimentation à 50Hz et sur 120Hz pour une alimentation à 60Hz. Cette opération

se réalise en agissant sur l'état de la liaison LK2 située immédiatement sous le module

oscillateur de la carte de circuit principale. Sans liaison de court-circuit sur les broches, la

fréquence est fixée à 100Hz ; avec cette liaison, elle est de 120Hz. Le réglage en usine

de 230V est de 100Hz, et en 115V, il est de 120Hz. Si le réglage en usine de LK2 est

modifié, l'instrument doit être recalibré à la nouvelle fréquence (le calibrage simultané à

100Hz et 120Hz est impossible).

Installation

5. Remonter la carte sur le châssis en s'assurant que toutes les connexions

(particulièrement la terre) sont rétablies et remonter le couvercle supérieur.

6. Pour satisfaire aux exigences de sécurité, la tension d'alimentation secteur indiquée à

l'arrière de l'instrument doit être modifiée pour indiquer la nouvelle tension opérationnelle.

7. Changer le fusible afin qu'il corresponde à la nouvelle tension de fonctionnement (voir ciaprès).

Fusible

Le fusible approprié doit être installé en fonction de la tension de fonctionnement sélectionnée.

Pour le fonctionnement à 230V, utiliser un HBC 125mA (T) 250V.

Pour le fonctionnement à 115V, utiliser un HBC 250mA (T) 250V.

S'assurer que seuls les fusibles de la tension nominale et du type requis soient utilisés.

L'utilisation de fusibles «maison» et le court-circuitage des porte-fusibles est strictement interdit.

Cordon d'alimentation

Lorsqu'un cordon d'alimentation de rallonge à trois conducteurs est fourni, il doit être utilisé

comme suit :

Marron - Phase

Bleu - Retour

Vert/Jaune - Terre

26

AVERTISSEMENT ! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Toute interruption intentionnelle est absolument interdite.

Page 28

Connexion des composants

Les fils du composant sous test sont branchés aux connecteurs Kelvin sur le dessus de

l'instrument. Les composants à sorties axiales doivent être insérés dans les adaptateurs fournis,

lesquels sont eux-mêmes branchés aux connecteurs Kelvin. Les deux formes de connexion

permettent le contact véritable à quatre bornes du composant, pour garantir la mesure précise

des composants de faible impédance.

Les fils des composants à sorties radiales peuvent être insérés directement dans les connecteurs

à ressort. Pour les fils fragiles, ouvrir les connecteurs en appuyant sur leur actionneur.

De la même manière, les adaptateurs axiaux peuvent être insérés directement dans les

connecteurs principaux ; régler la position des adaptateurs en fonction de la longueur des fils et

de celle du corps du composant.

Vérifier que les surfaces de contact des connecteurs Kelvin soient exemptes de contamination.

En cas de doute, consulter la section Maintenance.

Composants montés en surface

Branchez le module d'interface des pinces de montage en surface optionnelles dans les

connecteurs Kelvin. Un véritable contact quatre bornes est assuré au niveau des pinces.

Connexions distantes

Un gabarit de test à distance peut être connecté via les connecteurs BNC au module externe

d'interface optionnel qui s'insère dans les connecteurs Kelvin sur le dessus de l'instrument. Les

connecteurs sont nommés High Drive, High Sense, Low Sense et Low Drive. Les blindages des

câbles coaxiaux Drive doivent être branchés ensemble à l'extrémité distante et reliés à l'écran et

au boîtier du gabarit externe. Les blindages des câbles Sense doivent être isolés à la fois l'un de

l'autre et aussi de l'écran du gabarit de test.

Connexions

RS232

Les câbles jusqu'à un mètre de longueur sont peu susceptibles de poser des problèmes, mais les

câbles reliés à un gabarit externe doivent être aussi courts que possible et la précision des

mesures doit être vérifiée à toutes les fréquences de test ainsi que sur la plage de valeurs

mesurée avant d'être considérées comme fiables.

Connecteur D à 9 broches pour contrôle à distance par ordinateur individuel :

Broche Nom Description

1 DCD Reliée aux broches 4 et 6

2 TXD Données transmises depuis l'instrument

3 RXD Données reçues par l'instrument

4 DTR Reliée aux broches 1 et 6

5 GND Terre

6 DSR Reliée aux broches 1 et 4

7 RTS Reliée à la broche 8

8 CTS Reliée à la broche 7

9 – Aucune connexion interne

Relier ce connecteur à un PC à l'aide d'un câble dont les broches 2, 3 et 5 sont câblées entre les

deux extrémités alors que, côté PC, les broches 1, 4, 6 sont reliées entre elles, de même que 7 à

8. Ces liaisons entre broches existant déjà dans l'instrument, un câble blindé fil par fil peut être

utilisé.

27

Page 29

Cette section présente l'utilisation générale de l'instrument. Bien que ses fonctions de base

soient évidentes à l'aperçu du clavier, les utilisateurs souhaitant avoir recours à toutes les

performances et à un degré maximal de précision sont invités à lire ce manuel et les sections

Principes de mesure attentivement.

Mise en marche

Mettre en marche l'instrument à l'aide de l'interrupteur ON/OFF à l'arrière.

A l'allumage, l'instrument exécute une courte procédure d'autotest, affiche la version du logiciel et

attend en mode Auto qu'un composant soit mesuré. S'il est allumé alors qu'un composant lui est

connecté, il le détecte automatiquement et le mesure.

Pour couper entièrement l'instrument du secteur, débrancher le cordon d'alimentation à l'arrière

de l'instrument ; s'assurer que la déconnexion est facilement accessible. Débrancher l'instrument

du secteur lorsqu'il est inutilisé.

Affichage

Fonctionnement

28

En utilisation normale, l'instrument affiche le paramètre majeur (L, C ou R) à l'aide des 5 chiffres

de gauche, et le paramètre mineur (Q, D ou R) à l'aide des 5 chiffres de droite. Les paramètres

affichés sont indiqués au-dessus de leurs valeurs numériques respectives et les unités du

paramètre s'affichent sur la droite de la valeur elle-même. Un test d'affichage qui allume tous les

chiffres peut être effectué : pour ce faire, maintenir enfoncée une touche quelconque du clavier

au moment de la mise sous tension.

La précision de base est de 0,1% et, pour la plage d'impédance pour laquelle cette précision est

garantie (voir Spécifications), l'instrument distingue la plage automatiquement pour fournir

typiquement entre 5 000 et 50 000 décomptes de résolution d'affichage. Si la valeur mesurée se

trouve en dehors de la plage pour laquelle la précision de 0,1% est garantie (à la fréquence de

mesure sélectionnée) l'indicateur d'unités (kΩ, pF, etc.) clignote pour le signaler. Si l'indicateur de

fréquence clignote également, le fait de modifier la fréquence peut ramener le composant mesuré

dans la plage de 0,1% de précision. Le fait, par exemple, de mesurer 680pF à la fréquence Auto

Page 30

par défaut de 1kHz fait clignoter à la fois l'indicateur d'unité (pF) et de fréquence ; changer la

fréquence à 10kHz ramène la valeur de 680pF dans la plage de précision de 0,1% de

l'instrument, et les voyants cessent de clignoter.

Pendant la configuration et la fonction de tri, l'affichage a d'autres fonctions qui sont expliquées à

la section Tri des composants.

Touches et indicateurs de mesure

Fréquence

Le fait d'appuyer sur la touche Freq (Fréquence) règle la fréquence de mesure sur 100/120Hz,

1kHz ou 10kHz.

Remarque : pour une alimentation à 50Hz, la fréquence de test la plus basse est généralement

de 100Hz ; à 60Hz d'alimentation elle est généralement de 120Hz, voir la section Installation.

Le fait d'appuyer sur cette touche fait passer la fréquence de 100/120Hz à 1kHz puis à 10kHz et

de retour à 100/120Hz. Le voyant indique le réglage utilisé. S'il clignote, il indique qu'une autre

fréquence pourrait donner une mesure plus précise du composant du type et de la valeur en

cours.

Mode

Cette touche sélectionne le mode circuit série ou circuit parallèle équivalent à afficher. Voir la

section Principes de mesure. Si l'un des voyants clignote, il indique que l'autre mode de

fonctionnement convient mieux au composant du type et de la valeur en cours de mesure. Si le

mode Auto (automatique ) a été sélectionné, le Mode ne peut être modifié sans sélectionner

préalablement L, C ou R.

Bias

Cette fonction applique 2 Volts CC aux bornes de test pour polariser les capacités électrolytiques

conformément à la polarité indiquée sur les connecteurs Kelvin. Notez que l'application d'une

polarisation aux résistances ou aux inductances peut entraîner une erreur de mesure du fait

d'une surcharge interne. Les tensions de polarisation jusqu’à 50 V CC peuvent être appliquées

de manière externe : consulter la section Polarisation externe du chapitre Principes de mesure.

Zero C

Lorsque des capacités sont mesurées, le fait d'appuyer sur cette touche avant d'insérer le

composant à tester met l'affichage de capacité à zéro et élimine ainsi la capacité du gabarit de

test. Jusqu'à 100pF de capacité résiduelle peut être ainsi éliminée. Le facteur de correction est

perdu lorsque le pont est éteint. La fonction Zero C ne peut être utilisée que lorsqu'une capacité

est mesurée ; si une autre fonction est sélectionnée, l'instrument affiche

secondes et la commande est ignorée.

not C pendant 2

R+Q, L+Q, C+D, C+R

Règle l'instrument pour afficher le paramètre majeur à gauche et le paramètre mineur à droite.

Auto

En mode Auto, l'instrument détecte automatiquement si le composant en cours de mesure est

une résistance, une capacité ou une inductance, et règle l'instrument pour afficher les paramètres

de test du composant automatiquement. Il convient de noter que les composants "imparfaits" tels

que les inductances à résistance élevée en série peuvent être détectés de manière incorrecte en

mode Auto : il est alors nécessaire de régler manuellement la fonction appropriée. En mode Auto,

la fréquence de mesure peut être modifiée (en appuyant sur la touche Freq) mais la sélection de

mode Series/Parallel est maintenue à sa valeur par défaut pour le type de composant en cours.

Voir la section Principes de mesure. Pour passer du mode série au mode parallèle, ou vice–

versa, il est d'abord nécessaire de quitter le mode Auto en sélectionnant la fonction appropriée

(R+Q, L+Q, etc.) ; le mode peut alors être modifié à l'aide de la touche Mode.

29

Page 31

Range Hold

Cette fonction maintient la gamme de mesure en cours d'utilisation lorsque la touche est

enfoncée. Ceci désactive le changement de gamme automatique et minimise le temps

d'établissement entre mesures de composants d'une valeur similaire.

Il convient de noter que la gamme de la mesure de la tension et du courant du composant sous

test se définit manuellement, pour une précision et une résolution optimales ; le processeur

détermine alors l'incertitude de mesure et fixe une résolution d'affichage appropriée. La fonction

Range Hold (maintien de la gamme) fixe toutes ces gammes. Si un composant d'une valeur très

différente est mesuré et cause le dépassement de l'une quelconque de ces gammes, l'écran

affiche

affichage exact.

or (hors gamme) et la fonction Range Hold doit être alors désactivée pour obtenir un

Touches de tri, de sauvegarde et de rappel

Les touches utilisées pour configurer le tri et l'établissement de casiers de mémoire, pour

sauvegarder et rappeler des configurations, sont décrites à la section Tri des composants.

30

Page 32

RsZ

ω

ω

ω

ω

=

Modèles de circuits

Résistances, capacités et inductances peuvent tous être représentés à une certaine fréquence

par un simple circuit série ou parallèle équivalent. Il convient de noter qu'il s'agit d'un simple

circuit équivalent qui, en tant que tel, ne représente qu'une plage de fréquences limitée. Les

effets d'une vaste plage de fréquences sont abordés plus avant.

Les modèles utilisés par le LCR400 sont les suivants :

Principes de mesure

Zp

Q

Ls

Lsj

s

+=

ω

Rs

Lp

LpjRp

Ls

Rs

= LpQRp

Q

L

s

LpRpj

ω

=

+

Rp

==

Lp

ω

2

Q

=

1+

Q

2

Zp

=

1

(D également : tg δ)

CpDCs )1(

RsCsD

ω

+= Rp

+

1

−=

jRsZs

Cs

ω

Rp

RpCpj

ω

==

RpCp

ω

2

1

Rs

1

D

=

Q

2

D

=

1+

D

2

où

ω =

2πf

Résistances

Toutes les résistances ont des impédances parasitaires, à la fois au niveau inductance et

capacité et les effets des deux combinés. Heureusement, en conditions normales d'utilisation,

ces effets parasitaires sont très faibles comparés à la résistance.

Le LCR 400 permet d'évaluer les composants série et parallèle des résistances à 100Hz, 1kHz et

10kHz.

Certains types de résistances présentent des effets parasitaires plus marqués que d'autres. Les

résistances bobinées, à moins qu'elles ne soient spécialement bobinées, présentent une

inductance plus élevée que leurs équivalents à couche de carbone ou de métal. Même les

résistances à couche de carbone présentent une inductance du fait de l'inductance des fils et de

la coupe en spirale utilisée pour finir la résistance. Une capacité existe toujours entre les

connexions d'extrémités : sur les résistances à film métallique, elle se situe typiquement autour

de 0,25pF. Ceci ne devient important que sur les résistances de valeur élevée ou/et aux hautes

fréquences. Les résistances à enroulement bifilaire peuvent présenter une faible inductance,

mais la proximité de l'enroulement peut induire une capacité importante répartie le long de la