Page 1

THURLBY THANDAR INSTRUMENTS

HA1600

POWER AND HARMONICS ANALYSER WITH FLICKERMETER

INSTRUCTION MANUAL

Page 2

Table of Contents

Introduction 2

Specification 3

Safety 5

EMC 7

Installation 8

Connections 9

Front Panel Connections 9

Rear Panel Connections 9

Initial Operation 10

Power Meter View 12

Power Meter Set-up 14

Waveform Graph View 15

Waveform Graph Set-up 16

Harmonics View 19

Harmonics Set-up 20

Display Format - Histogram 20

Display Format – Tables 23

Test Control View 25

Test Control Set-up (Harmonics) 26

EN61000-3-3 Flicker and Fluctuations 31

Test Control Set-up (Flicker) 33

Meter View (Flicker) 35

Flicker Meter Page 35

Voltage Variation Page 36

Peak Inrush Current Measurement 38

Test Control Set-up (Peak Inrush Current) 40

Report View 41

Report Formats 42

Report Set-up 45

Compliance Measurements with the HA1600 47

Harmonics Measurements 47

Taking Harmonics Measurements 48

Taking Flicker and Fluctuation Measurements 49

HA-PC Link Plus Software 50

Software Installation 50

Operation of the HA-PC Link Plus Software 50

Installation of USB drivers 53

Maintenance & Calibration 54

Software Updates 55

1

Page 3

High performance power analyser

The HA1600 is a high speed, high accuracy AC power analyser for single phase supplies of up to

16 Amps rms.

The supply to be measured is connected via a dedicated input cable independently of the supply

to the instrument. The output to the load is via a front panel mounted 'standard' mains connector.

A wide range of power connectors is available including most European national types.

The HA1600 can measure Watts, VA, Volts rms, Volts peak, Amps rms, Amps peak, Crest factors,

THD, Power factor, Frequency and Inrush current.

The large display can show multiple parameters simultaneously along with graphical

representations of voltage and current waveforms.

Dual 16 bit Analog to Digital converters continuously sample both voltage and current and give a

wide dynamic range. A fast Digital Signal Processor gives the performance needed for continuous

real-time analysis of the data. Advanced algorithms yield accurate results, using extended

precision or floating point arithmetic wherever necessary.

Compliance-quality harmonics analyser

Introduction

The HA1600 has been designed to make harmonics measurements both quick and simple.

It measures harmonics from the 1

It is suitable for pre-compliance measurements using a normal mains supply and is capable of full

compliance measurements to EN61000-3-2 in conjunction with a suitable power source (such as

the AC1000).

Capabilities include continuous monitoring of the supply voltage, continuous comparison to

harmonic limits and timed test sequences with analysis of fluctuating harmonics.

Compliance-quality flicker meter

The HA1600 has the capability to operate as a compliance quality voltage variation and flicker

meter in conformance with EN61000-3-3 and EN61000-4-15.

Flicker severity can be measured in terms of P

analysis of voltage variations, including the calculation of the maximum value d

between steady states d

and the change characteristic d(t).

c

For pre-compliance testing, a current measurement method can be used, rather than voltage

measurement, to eliminate the need for a clean power generator and a reference impedance.

A full range of interfaces

A parallel printer interface is included, for record keeping and archiving, and also a high speed

RS-232 interface is provided for use with either a printer or remote control software running on a

PC. The HA1600A also has a USB port for use with the HA-PC Link Plus software.

st

to the 40th and updates the display in real time.

and P

st

while simultaneously performing full

lt

max

, the difference

The internal software of the instrument is stored in flash memory and can be updated through the

serial port as the requirements of the measurement standards evolve.

HA1600 and HA1600A

The two versions of the instrument are in different cases, with slightly different front panel layouts.

The HA1600A has a USB port. In all other respects the operation and performance of the two

types is identical. Both use the same firmware, and this manual applies to either type if fitted with

firmware version 2.60 or later.

2

Page 4

Specification

MAINS ANALYSER

Measurement Circuit: Single Phase with standard mains connector.

Current Rating: 16A rms continuous, or national connector rating if lower.

Voltage Ranges: 115V (± 200V pk) and 230V (± 400V pk).

Current Ranges: ± 24mA pk to ± 400A pk in fifteen 2:1 ranges.

Frequency Range: 43 – 67 Hz.

Shunt Resistance:

Sampling Rate: 300 points per cycle.

Basic Accuracy: Better than 0.2% ±1mA, up to 16A.

Measured Parameters: Vrms, Vpk, Arms, Apk, Crest factors, THD, W, VA, Power factor, Frequency,

Display Modes: Tabular display of all parameters including latest and highest inrush current.

Waveform Graph display of Voltage and Current with normal, Max hold,

Monitor Outputs: Re-constructed Voltage and Current Signals.

3mΩ.

Peak Inrush current.

accumulate and multiple cycle display modes.

HARMONICS ANALYSER

Measurements: 1st harmonic to 40th harmonic.

Measurement processing to EN61000-3-2. and EN61000–4–7

Continuous calculation, analysis and assessment of unfiltered, filtered,

average, minimum and maximum current harmonic levels and limits.

Continuous measurement and assessment of supply waveform and

harmonics.

Current Rating: 16A rms continuous, or national connector rating if lower.

Voltage Ranges: 115 (± 200V pk) and 230V (± 400V pk).

Current Ranges: ± 24mA pk to ± 400A pk in fifteen 2:1 ranges.

Frequency Range: 43 – 67 Hz.

Shunt Resistance:

Transform Windows: Continuous 4, 10, 12 or 16 cycle Discrete Fourier Transforms.

Basic Accuracy: Better than 5% of limit or 0.2% of selected range (whichever is the greater)

Display Modes: Display of load supply assessment for voltage, harmonics, crest limits and

Histogram or tabular display of supply voltage harmonics.

Histogram display of current harmonics with limits (calculated from EN61000-

Tabular display of current harmonics showing present values, limits, average

3

3mΩ (less than 150mV across shunt up to 50 Amp peak).

±1mA.

frequency against requirements defined in EN61000-3-2.

3-2), with Min. hold, Max. hold and percentage of limit display options.

values, average as percent of limit, maximum values, maximum as percent of

limit and pass or fail assessment for each harmonic.

Page 5

Test Control: Untimed, manually timed or automatically timed tests; user-defined test time.

Declaration of load class. Limits automatically determined from EN61000-3-2

for appropriate class; Class C and Class D limits can be automatically

calculated from power measurements or from ratings declared by the user.

Minimum and maximum power thresholds for limits can be changed by the

user.

Facility for declaring supply voltages other than 230V and deriving

appropriate limits. Facility for insetting test limits.

Report Printing: Direct printer connection for hard-copy report with user-entered narrative,

supply voltage assessment and current harmonic analysis and assessment.

VOLTAGE FLUCTUATIONS & FLICKER METER

Measurements:

Voltage fluctuations d

, d(t) and d

c

and flicker P

max

and P

st

lt

to EN61000-3-3 and EN61000-4-15.

Current Rating: 16A rms continuous, or national connector rating if lower.

Voltage Ranges: 115V (± 200V pk) and 230V (± 400V pk).

Fluctuation Range: 25% max (relative to nominal voltage).

Flickermeter Range: Voltage change up to 20% (sinewave change) or 10% (low repetition rate

rectangular change) relative to AGC level.

Equivalent to 6400 pu on 8.8 Hz sinewave.

Flickermeter AGC: Up to ±5%.

Flickermeter Accuracy: Better than 5% for P

range 0·7 to 10·0.

st

Frequency Range: 50 or 60 Hz (operates over 43 – 67 Hz).

Report Printing:

Tabular listing of voltage variations, P

classifier and P

st

in each Plt interval.

st

GENERAL

Display: 320 x 240 pixel backlit LCD.

Clock:

Interfaces: Parallel Printer, RS-232 (for printer or PC); also USB (for PC) on HA1600A.

Instrument Supply: 220V–240V or 110V–120V ±10%, 48 to 65Hz. Installation Category II.

Real−time clock for time and date−stamping of Report data.

Maximum instrument power 25VA. The instrument can be operated at a

different supply voltage and/or frequency from that used to supply the load.

Operating Range: +5°C to 40°C, 20-80% RH.

Storage Range: –10°C to +60°C.

Environmental: Indoor use at altitudes up to 2000m, Pollution Degree 2.

Safety: Complies with EN61010-1.

EMC: Complies with EN61326.

Dimensions (WxHxD): HA1600A: 357 x 132 x 235mm; HA1600: 305 x 148 x 220mm.

Weight: HA1600A: 4.4kg; HA1600: 4.2kg.

4

Page 6

Safety

This instrument is Safety Class I according to IEC classification and has been designed to meet

the requirements of EN61010-1 (Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use). It is an Installation Category II instrument intended for operation

from a normal single phase supply.

This instrument has been tested in accordance with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5° and -10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to either supply, terminals may be live and opening the covers

or removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

This instrument uses a Lithium button cell for the real-time clock and non-volatile memory battery

back-up; typical life is 3 years. In the event of replacement becoming necessary, replace only with

a cell of the correct type, i.e. 3V Li/Mn0

disposed of carefully in accordance with local regulations; do not cut open, incinerate, expose to

temperatures above 60°C or attempt to recharge.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

LCD window. The following symbols are used on the instrument and in this manual:-

Caution -refer to the accompanying documentation, incorrect

operation may damage the instrument.

20mm button cell type 2032. Exhausted cells must be

2

Terminal connected to chassis ground.

Alternating current.

5

Page 7

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

HA1600A Power and Harmonics Analyser

meets the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: EN61326 (1998) Radiated, Class B

a) EN61326 (1998) Conducted, Class B

b) EN61326 (1998) Harmonics, referring to EN61000-3-2 (2000)

Immunity: EN61326 (1998) Immunity Table 1, Performance B, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (1997) Electromagnetic Field

c) EN61000-4-11 (1994) Voltage Interrupt

d) EN61000-4-4 (1995) Fast Transient

e) EN61000-4-5 (1995) Surge

f) EN61000-4-6 (1996) Conducted RF

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

6

CHRIS WILDING

TECHNICAL DIRECTOR

2 February 2007

Page 8

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2000) Class A; the instrument is Class A by product category.

Immunity

EN61326 (1998) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved were:

a) EN61000-4-2 (1995) Electrostatic Discharge, 4kV air, 4kV contact, Performance B.

b) EN61000-4-3 (1997) Electromagnetic Field, 3V/m, 80% AM at 1kHz, Performance B.

EMC

c) EN61000-4-11 (1994) Voltage Interrupt, 1 cycle, 100%, Performance A.

d) EN61000-4-4 (1995) Fast Transient, 1kV peak (AC line), 0.5kV peak (signal lines and

e) EN61000-4-5 (1995) Surge, 0.5kV (line to line), 1kV (line to ground), Performance A.

f) EN61000-4-6 (1996) Conducted RF, 3V, 80% AM at 1kHz (AC line only; signal

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

Cautions

To ensure continued compliance with the EMC directive the following precautions should be

observed:

a) After opening the case for any reason ensure that all signal and ground connections

I/O ports), Performance A.

connections <3m, therefore not tested), Performance A.

are remade correctly before replacing the cover. Always ensure all case screws are

correctly refitted and tightened.

b) In the event of part replacement becoming necessary, only use components of an

identical type, see the Service Manual.

Note that the conducted emissions measured on the LOAD POWER connection of the

HA1600 will be those of the load itself since the HA1600 contains no filtering on this

connection. When making measurements on non-compliant loads, therefore, care must be

taken to ensure that its emissions do not interfere with other equipment.

7

Page 9

Mains Operating Voltage – Instrument Power

Before making connections to the AC line source ensure that the operating voltage of the

instrument is correctly set. The operating voltage is indicated by the orientation of the fuseholder.

When the 230V marking is upwards, the unit is set for operation over the range 198V to 264V.

When the 115V marking is upwards, the unit is set for operation over the range 99V to 132V. To

change the operating voltage range, remove the AC line plug, pull out the fuse holder, replace the

fuse with one of the appropriate rating (see below) and rotate the fuse holder before pushing it

firmly back into place.

Safety Note: To fully disconnect the Instrument Power from the AC supply, unplug the mains

cord from the INSTRUMENT POWER inlet or from the AC supply outlet.

Mains Operating Voltage – Load Power

The fixed LOAD POWER mains lead is an independent connection, which provides power to the

appliance connector on the front panel; it can be at a different voltage and frequency from the

instrument power. The maximum permitted load power voltage is 264Vrms and the frequency

range is 43 - 67Hz.

For full compliance measurements to EN61000-3-2 the load power lead should be connected to

an AC supply that meets the voltage, frequency and harmonics requirements defined in the

standard; the AC1000 low distortion power source can be used for this purpose.

Installation

Safety Note: To fully disconnect the Load Power from the AC supply unplug the mains cord

from the AC supply outlet.

Fuse – Instrument Power

The correct time-lag fuse must be fitted for the selected operating voltage.

For 230V operation use 250mA (T) 250V time-lag HBC

For 115V operation use 500mA (T) 250V time-lag HBC

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders are prohibited.

Fuse – Load Power

A high voltage, high breaking current, fuse is fitted internally in the load power circuit. The correct

fuse type is: 20A 500V HBC Type aM or gL.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders are prohibited.

Mains Lead

When a three core mains lead with bare ends is provided this should be connected as follows:

BROWN - MAINS LIVE

BLUE - MAINS NEUTRAL

GREEN/YELLOW - EARTH

8

WARNING ! - THIS INSTRUMENT MUST BE EARTHED

Any interruption of the protective conductor inside or outside the instrument will make the instrument

dangerous. Intentional interruption is prohibited

.

Page 10

Front Panel Connections

Appliance Connector

The load under test should be plugged into the front panel appliance connector. Power to the

connector is supplied from the fixed

which is controlled by the

instrument power (e.g. the

from the appliance socket.

A wide choice of national appliance connectors is available but the connector is factory fitted and

cannot be changed by the user. The maximum load current that can be supplied is the rating of

the connector, or 16Arms, whichever is lower.

Voltage and Current Monitor

The Voltage Monitor and Current Monitor BNC sockets output reconstructed, scaled versions of

the load power voltage and current waveforms referenced to instrument ground, permitting direct

connection to other instruments such as an oscilloscope. The output voltage is approximately

2.5V pk-pk for a full-scale signal on any current or voltage range.

LOAD switch. If the LOAD switch is in the OFF position, or if there is no

POWER switch is OFF) then the load power supply is disconnected

Connections

LOAD POWER cable via an internal 20A fuse and a relay

Rear Panel Connections

Instrument Power and Load Power

The IEC inlet supplies power for the instrument only; the fixed lead supplies the load power to the

front panel appliance connector. Refer to the Installation section.

USB

The USB interface is intended for communication with a PC running the HA-PC Link Plus

software. See software installation section for information about device driver requirements.

RS232

The RS232 interface should be connected to a standard PC port using a fully wired 1-1 malefemale cable without any crossover connections. It may also be used with a serial printer.

The 9-pin female D-connector has the following pin-out:

Pin Name Direction Description

1 DCD O

2 TXD O Transmitted data to computer

3 RXD I Received data from computer

4 DTR I Computer can receive

5 GND Signal ground

6 DSR O

7 RTS ( I ) Assumed asserted

8 CTS O Computer may send

9 RI No connection

Passively asserted (+10V through 10kΩ)

Passively asserted (+10V through 10kΩ)

The signal ground is connected to instrument ground. The Baud rate is fixed at 115,200.

Printer

25-way female D-connector configured as a standard parallel (Centronics) printer port. Connect

directly to a suitable printer using a standard shielded cable.

9

Page 11

Initial Operation

This section is a general introduction to the organisation of the instrument and is intended to be

read before using it for the first time. Detailed descriptions of each function are given in later

sections, starting with Power Meter.

In this manual front panel keys and connectors are shown in capitals, e.g.

MONITOR; all soft-key labels, messages and data values displayed on the LCD are shown in a

different type font, e.g. Setup Range, Load Declared Class A.

Switching On

With both the POWER and LOAD switches in the OFF position connect the INSTRUMENT POWER

lead to the standard AC supply and connect the

source as described in the Installation section.

Switch the POWER switch to ON to turn the instrument power on; the display will show the

Initialisation screen for a few seconds followed by the Select screen. A 20 second time-out is

started, with a count down shown on the display. If no key is pressed during this time out, or if the

Resume Operation soft-key (F5) is pressed, the instrument will continue operation using the

Test and Report parameters automatically stored at the last power−down; the parameter settings

stored are given in the table at the end of this chapter. The instrument will start up with the LCD

showing the Waveform Graph display. The display will show the load voltage waveform, which will

appear to be unstable for 4 to 5 seconds or more until the sampling clock synchronises exactly

with the incoming supply; the display will then show a single cycle of the voltage waveform with

the rising zero-crossing point at the left edge.

The second soft-key option on the Select screen is Restore Defaults; this continues

operation with all parameters defaulted to their original factory setting. The stored parameters and

their default settings are listed in the table at the end of this chapter.

METER, VOLTAGE

LOAD POWER lead to a suitable low distortion AC

The final soft-key option is Setup, which gives access to a further screen where the soft-keys

are Restart and Update Software. Restart returns the instrument to the Initialisation

screen. Update Software selects the mode in which the instrument’s software can be

updated from a PC via its RS232 port; see the section of the Maintenance chapter for details.

If the load is now connected and the

will also show in the display; the instrument will auto-range to show the current waveform at the

best resolution achievable. Load power is disconnected, even if the LOAD switch is ON, when

INSTRUMENT POWER is turned off.

Safety Note: Neither the POWER switch, nor the LOAD switch, fully disconnect their respective

AC supplies when switched to the OFF position. To fully disconnect from the AC supply unplug

the mains cords from the AC supply outlets; make sure that the means of disconnection are

readily accessible. Disconnect from the AC supplies when not in use.

Display Contrast

The contrast of the LCD may vary a little with changes of ambient temperature or viewing angle

but can be optimised for a particular environment by using the front panel contrast control. Insert

a small screwdriver or trimmer tool through the adjustment aperture marked LCD and rotate the

control for optimum contrast.

Keyboard

The keys on the front panel can be considered in the following groups:

LOAD switch also turned to ON the load current waveform

10

• The five keys beneath the LCD. When the green VIEW lamp is lit these are used to directly

call each of the five main display views (METER for Power Meter, WAVE for Waveform Graph,

etc.). In addition, when the set-up screen for each of these views is displayed (by pressing the

SET-UP / VIEW key to light the red SET-UP lamp) they become 'soft-keys' which take the

functions shown immediately above them in boxes on the LCD.

Page 12

• The four cursor keys marked and are used to move the edit zone (shown as an

outline box) around the editable fields of a set-up display. For each position of the edit zone

the keys below the display have the functions shown immediately above them in boxes on the

LCD; the functions change as the edit zone is moved which is why they are called 'soft' keys.

The cursor keys auto-repeat when held down.

• Numeric keys permit direct entry of values in certain set-up displays. ENTER confirms a

numeric entry and

CANCEL terminates the entry without changing the parameter to the new

value.

• START TEST and STOP TEST have specific functions determined by the type of test selected

on the Test Control set-up display; full details are given in the Test Control section.

• The

LOCAL key switches the instrument between remote and local (keyboard) control.

Stored Settings and their Factory Defaults

The following parameters have their current setting stored at power−down; these are recalled at

power−up if Resume Operation is selected. If Restore Defaults is selected instead, the

settings are those shown in the Defaults Setting column.

Parameter Default Setting

Nominal Voltage and tolerance 230V ± 2%

Nominal Frequency and tolerance 50Hz ± 0.5%

Test Duration Standard value for each mode.

Assessment inset 1.00

Operating Mode EN61000-3-2:2000 Harmonics (Edition 2)

Load Classification Class A

Class C Limit basis, current and PF Automatic (maximum fundamental current)

Class D Limit basis and power Automatic (maximum power)

Class D minimum power 75W

Class D − A cross−over power (1995)

600W

Flicker sensing method Voltage

Simulated Flicker Reference Impedance

limit

d

max

0.4 + j 0.25 Ω

4 %

d(t) limit * < 500 ms above 3.3%

d

c

limit

* 3.3 %

Steady State Definition * > 1000 ms within ±0.32%

Switching sequence On and Off time 1000 cycles

Switching sequence On and Off phase 0 degrees

Left Margin (of Report) 5 characters

Report No. 1

* These values reflect the 2001 Amendment to EN 61000-3-3.

Note that the Report’s Header, Title and Footer text is not restored to the original form by the

Restore Defaults choice; the text can only be changed by entering new characters.

11

Page 13

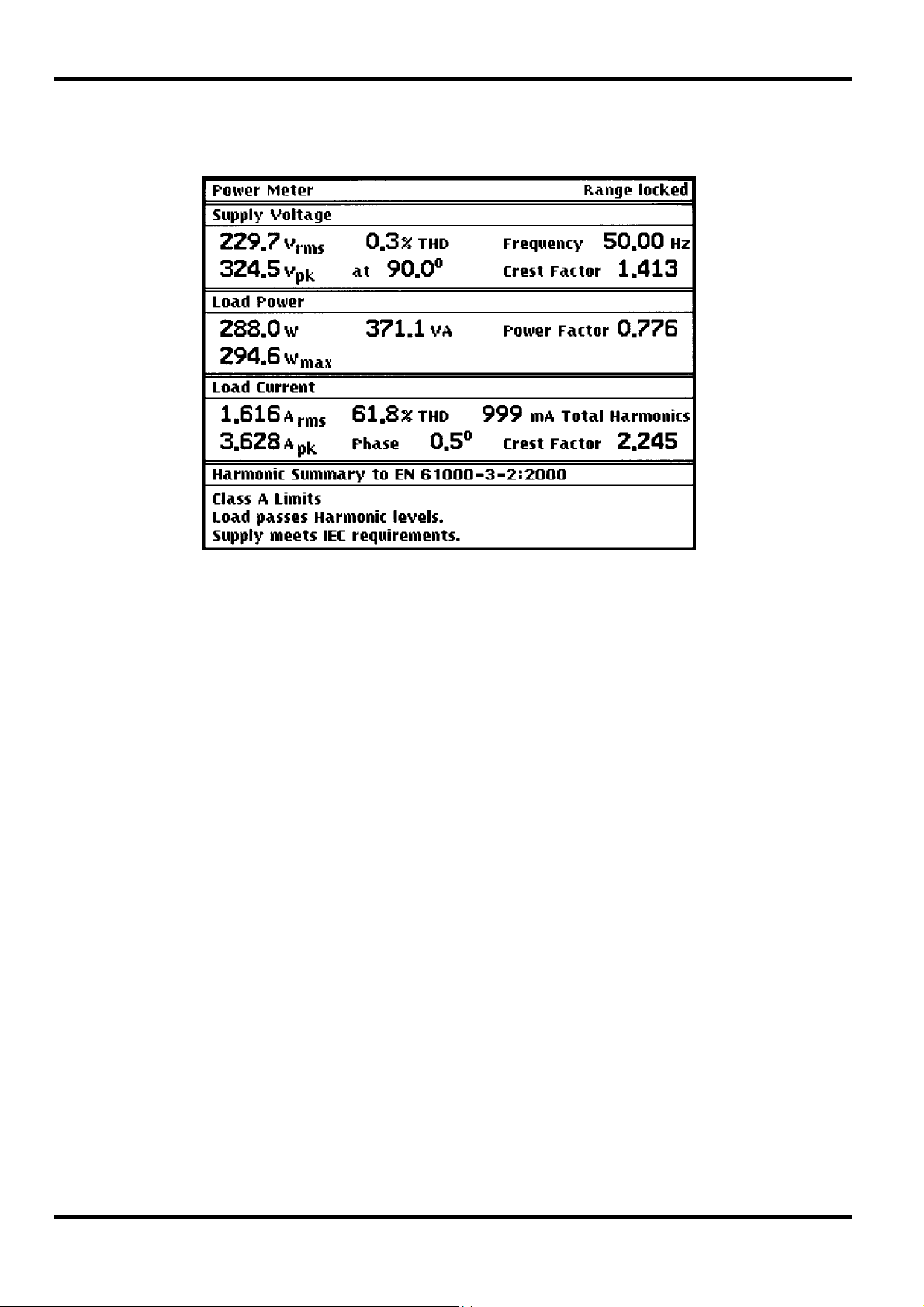

Power Meter View

With the green VIEW lamp lit, press the METER key to display the Power Meter view.

The Power Meter view gives a continuously updated display of the major parameters of the

supply voltage and load current, together with an instantaneous summary of whether the supply

and load meet the limits of the harmonics standard.

The Supply Voltage group shows the Vrms and frequency of the load power supply, together

with its total harmonic distortion (THD), peak voltage (Vpk), the phase of the peak with respect to

the zero-crossing point and the calculated crest factor (Vpk/Vrms).

For compliance quality measurements, the load power supply must meet the following

requirements:

Harmonics (max % of fundamental) 0.9% : 3

0.4% : 5

0.3% : 7

0.2% : 9

0.1% : even 2

0.1% : all 11

rd

th

th

th

nd

– 10th

th

– 40th

Voltage 230 Vrms ± 2%

Frequency 50Hz ± 0.5%

Crest Factor (Vpk/Vrms) Between 1.40 and 1.42

Phase of Vpk Between 87° and 93° after zero crossing

All the above parameters are continuously monitored. All supply parameters are compared

against the limits and a pass or fail indication is given in the Harmonic Summary section of the

display.

12

The Load Power group shows the true power (Watts), apparent power (V.A) and power factor

(W/V.A). The maximum value of the true power is also shown.

The Load Current group shows the rms and peak load currents, together with the total

harmonic distortion (THD), the phase of the current peak, the calculated crest factor (Ipk / Irms)

and the total harmonic current (this is the rms sum of all the harmonics between 2 and 40 and

can be used to find a worst case operating condition of the load under test).

Page 14

The Harmonic Summary group gives a simple overview of the supply and load harmonic

status. It states whether the supply passes or fails the specified requirements; compliance quality

measurements can obviously only be made with a supply that meets the harmonics, voltage,

frequency, crest factor and phase requirements described earlier. It also states the load class as

declared by the user and any power related exclusions detected by the analyser; refer to the Test

Control section. Lastly the display states whether the load current passes or fails the harmonics

limits of the Class shown.

When the instrument is operated in Inrush or Flicker mode the region at the bottom of the screen

is used to display a summary of those measurements instead of the Harmonic Summary. In

Flicker mode two further display pages are available: one showing Voltage Variations and the

second Flicker Results. For full details, see the relevant chapters in this manual.

13

Page 15

With the Power Meter view displayed, pressing SET-UP shows the Power Meter set-up screen,

which gives access to the Setup Range soft-key. In Flicker mode, it also gives access to the

Flicker and Voltage Variations result pages. See the Flicker Meter chapter for details.

Set-up Range

Pressing the Setup Range soft-key (on either the Meter or Waveform Graph views) changes

the display to a graphical view of the current waveform with three further soft-keys: Up, Down

and Lock Range. Pressing any of these turns off auto-ranging; the Lock Range key keeps

the present measurement range, while the Up and Down keys change the range in x2 and ÷2

steps respectively. The scaling of the waveform display changes to reflect the peak capability of

the new range and the maximum current is shown in the bottom left-hand corner of the display;

for example, 1500mA peak means that the top of the display represents +1500mA and the

bottom represents –1500mA with respect to the centre zero line.

The range can be set from 24mA peak to 400A peak in 2:1 steps. The waveform display on this

set-up screen is always updated every cycle, regardless of the mode set up for the Waveform

Graph view.

Important Note: To take compliance quality measurements the range must not change during the

Power Meter Set-up

test. The user must select a range that will accommodate the highest waveform

peak that will be encountered during the load’s operating cycle. It is therefore

recommended that a preliminary assessment of the load should be made, with

the instrument in auto-range mode, to determine the highest peak current

operating condition. The instrument should then be locked on this range to

ensure that harmonics measurements are correct and that the derived values

(Average, Max Hold and Min Hold etc.) are meaningful.

If too low a range is chosen, no damage will be done, but all the measurement

results will be invalid and the message Overload will show in the status line at

the top of the Meter View display. It is more important to maintain adequate

‘headroom’ for the measurement, i.e. to avoid overload, than it is to maximise

the vertical resolution on the Waveform Graph view; measurement accuracy is

maintained even when the vertical scaling of the display is well below optimum.

Once the range is locked, the Lock Range soft-key label becomes Auto Range; pressing

this key releases the lock and allows the instrument to auto-range on the present waveform.

Several other soft-keys 'toggle' between alternate choices in this way; it is only necessary to

remember that at any time the soft-key box shows what will happen when the key is pressed.

Having set the range (or selected auto-range), the previous view can be recalled by pressing the

VIEW key.

Auto-ranging is only available in Harmonics operating mode (see the Test Control section). Note

that auto-ranging is disabled while the LOAD switch is OFF to prevent the instrument autoranging to the most sensitive range when there is no load current. At switch-on the default range

is 3A peak if the LOAD switch is OFF; at other times, switching the LOAD to OFF locks the range

at the setting currently in use.

In Flicker mode with voltage sensing, the range can be manually changed, but should be left at a

setting that avoids overload at any time during the test. When current sensing is selected, the

range is fixed to suit the requirements of the calculations and cannot be changed.

On selecting Peak Inrush mode, the highest current range is initially set; it can be manually

changed as required.

14

Page 16

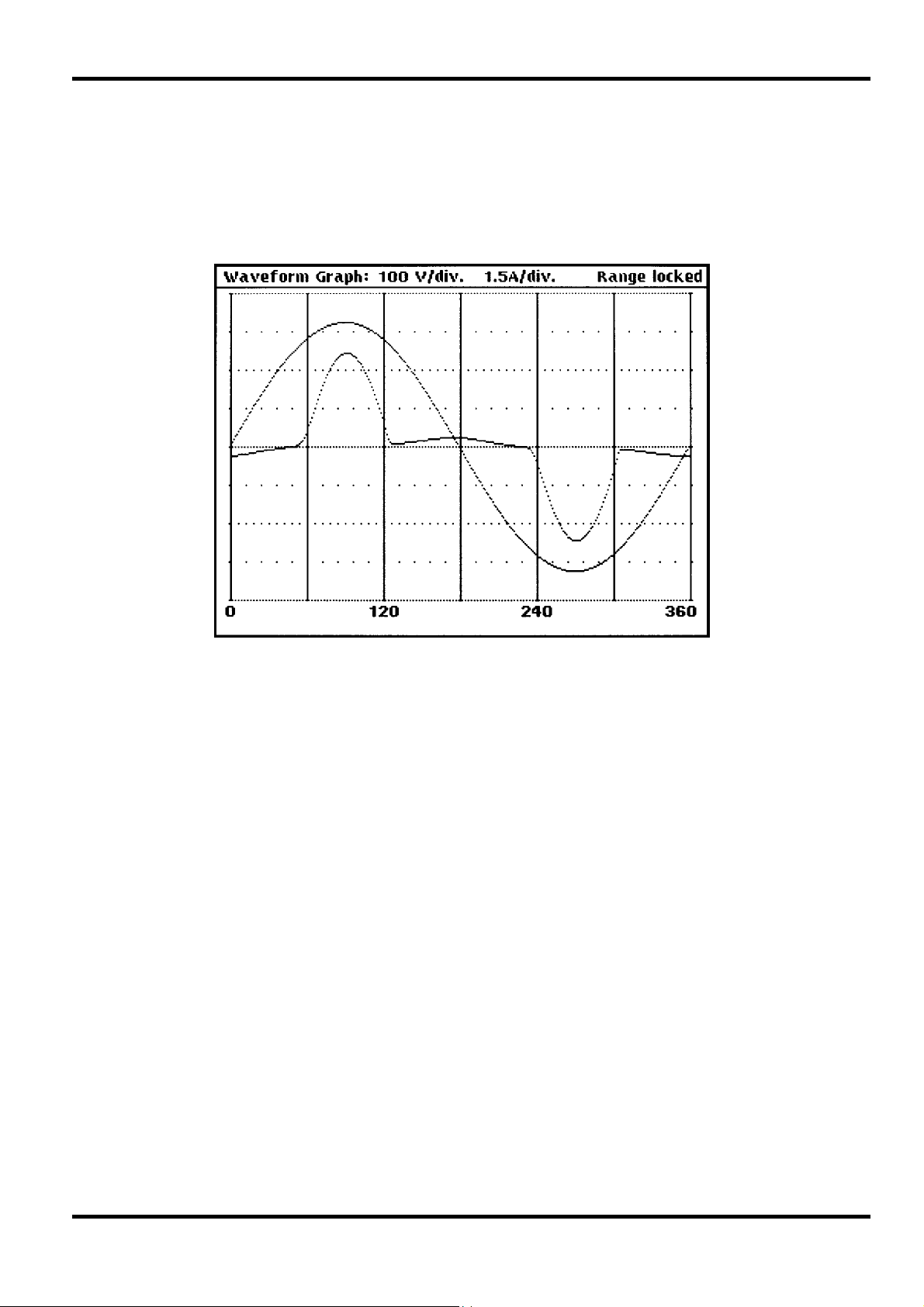

Waveform Graph View

The Waveform Graph display (which is the default display at instrument switch on) can be

selected by pressing the WAVE key whenever the green VIEW lamp is lit. The default format of

the display is a full-screen view of both the voltage and current waveforms. The format of the

display can be changed in various ways as described in the Waveform Graph Set-up section

below.

At the top of the display the scaling for both voltage and current are given. There are 8 divisions

vertically, thus 100mA/div is the scaling shown if the ± 400mA peak range has been selected

on the set-up screen. In auto-range mode (the default condition) the most sensitive range that

gives an in-range display is automatically selected. To avoid excessive range changes when the

measurement is near a range boundary the instrument auto-ranges up at full-scale and autoranges down at about 0.44 times full-scale.

The voltage display has two ranges only: 100V/div, for nominal 230V supplies, and 50V/div for

nominal 115V supplies; the voltage range is set by declaring the nominal voltage on the Test

Control set-up display.

The X-axis of the single cycle display is divided into 6 divisions, each representing 60° of phase.

The rising zero-crossing point of the single voltage waveform cycle displayed is positioned at the

left edge of the display for the default selection of voltage as the Trigger Source; this will change if

alternative Trigger Sources are selected, see Trigger Source section.

The X-axis is marked every 180º of the 2 cycle display and every cycle of the 4 and 10 cycle

displays.

15

Page 17

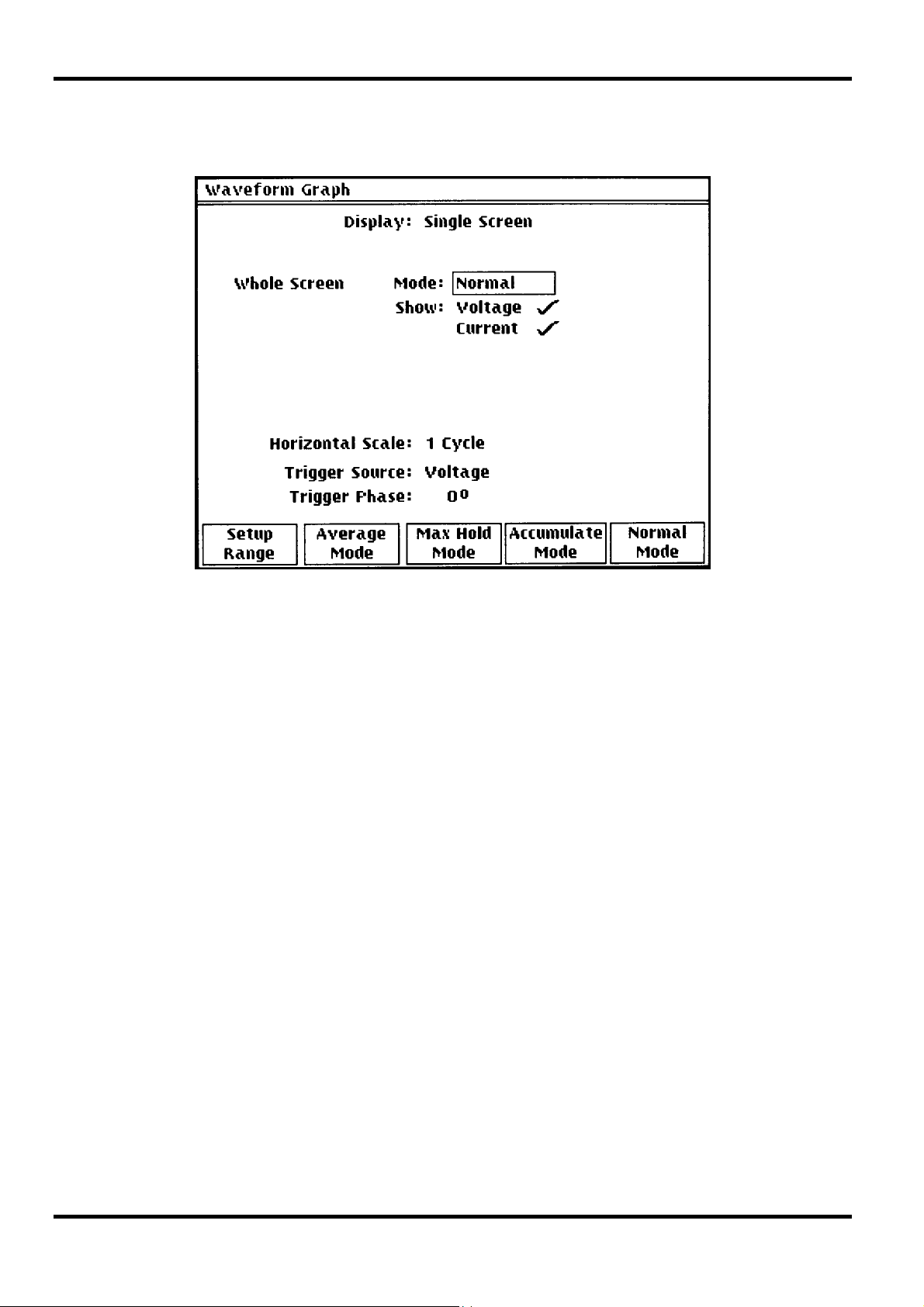

Waveform Graph Set-up

With the Waveform Graph view displayed, pressing SET-UP shows the Waveform Graph set-up

screen.

With the exception of the Setup Range key, the functions of the soft-keys change as the edit

zone is moved through the editable fields of the display using the

described below. Pressing the VIEW key returns the display to the Waveform Graph view.

Set-up Range

Pressing the Setup Range soft-key (on either the Meter or Waveform Graph views) changes

the display to a graphical view of the current waveform with three further soft-keys: Up, Down

and Lock Range. Pressing any of these turns off auto-ranging; the Lock Range key keeps

the present measurement range, while the Up and Down keys change the range in x2 and ÷2

steps respectively. The scaling of the waveform display changes to reflect the peak capability of

the new range and the maximum current is shown in the bottom left-hand corner of the display;

for example, 1500mA peak means that the top of the display represents +1500mA and the

bottom represents –1500mA with respect to the centre zero line. The range can be set from 24mA

peak to 400A peak in 2:1 steps. The waveform display on this set-up screen is always updated

every cycle, regardless of the mode set up for the Waveform Graph view.

Important Note: To take compliance quality measurements the range must not change during the

keys; each field is

test. The user must select a range that will accommodate the highest waveform

peak that will be encountered during the load’s operating cycle. It is therefore

recommended that a preliminary assessment of the load should be made, with

the instrument in auto-range mode, to determine the highest peak current

operating condition. The instrument should then be locked on this range to

ensure that harmonics measurements are correct and that the derived values

(Average, Max Hold and Min Hold etc.) are meaningful.

If too low a range is chosen, no damage will be done but all the measurement

results will be invalid and the message Overload will show in the status line at

the top of the Meter View display. It is more important to maintain adequate

‘headroom’ for the measurement, i.e. to avoid overload, than it is to maximise

the vertical resolution on the Waveform Graph view; measurement accuracy is

maintained even when the vertical scaling of the display is well below optimum.

16

Page 18

Screen

Once the range is locked, the Lock Range soft-key label becomes Auto Range; pressing

this key releases the lock and allows the instrument to auto-range on the present waveform.

Several other soft-keys 'toggle' between alternate choices in this way; it is only necessary to

remember that at any time the soft-key box shows what will happen when the key is pressed.

Auto-ranging is only available in Harmonics operating mode (see the Test Control section). Note

that auto-ranging is disabled while the LOAD switch is OFF to prevent the instrument autoranging to the most sensitive range when there is no load current. At switch-on the default range

is 3A peak if the LOAD switch is OFF; at other times, switching the LOAD to OFF locks the range

at the setting currently in use.

In Flicker mode with voltage sensing, the range can be manually changed, but should be left at a

setting that avoids overload at any time during the test. When current sensing is selected, the

range is fixed to suit the requirements of the calculations and cannot be changed.

On selecting Peak Inrush mode, the highest current range is initially set; it can be manually

changed as required.

Having set the range (or selected auto-range), the Waveform Graph view can be recalled by

pressing the VIEW key.

With the edit zone in the Screen field, the soft-key choices are Single Screen and

Split Screen. The default mode is Single Screen, which uses the whole display with

8 vertical divisions. Split Screen changes the screen into 2 separate displays, each with

4 vertical divisions; this is particularly useful when the current waveform is essentially in phase

with the voltage and displaying both together would cause confusion. At the same time the

Waveform Graph set-up display changes to add extra editable fields (mode and Traces) for the

second display, see below.

Mode

With the edit zone in the mode field the soft-key choices are as follows:

Normal:

Accumulate:

Max Hold:

The display is updated every waveform cycle. This is the default mode.

The display is written to every waveform cycle without erasing the previous

data. A history of the waveform is built on the screen, which means that shortterm aberrations can be captured.

The Accumulated display is lost when the view is changed, and can be

manually cleared at any time by pressing the VIEW key twice. Since it is also

automatically cleared at every range change it may be necessary to lock the

current range, see Set-up Range section above. For clarity, it is recommended

that only one waveform be accumulated, by selecting either Voltage or Current

(see Traces section below).

The display is updated every waveform cycle with the greater of the new and

existing value at every point on the display.

The Max Hold algorithm keeps the largest amplitude (positive or negative) for

each pixel. This often results in an apparent small discontinuity in the

maximum hold waveform at the zero-crossing point.

The Max Hold data can be manually reset at any time by pressing the START

key. It is also automatically reset at every range change, so it may be

necessary to lock the current range, see Set-up Range section above.

Average:

When split screen is selected, the modes for the upper and lower screens can be set

independently. Changing between single screen and split screen will also change the modes to

those last used for that screen set-up. The modes are maintained when the view is changed.

17

The display is updated every waveform cycle with a rolling average of the last

8 cycles. This mode offers a degree of noise reduction.

Page 19

Traces

With the edit zone in the Show Traces field the soft-keys are Voltage and Current.

Alternate presses of each key will turn that trace on and off; confirmation is given by a or X

against the corresponding trace name in the Show Traces edit zone.

The default setting for single screen is both traces selected. If split screen is selected, the default

is Voltage only on the upper screen and Current only on the lower screen. However, any

combination of traces can be set on either screen.

Horizontal Scale

With the edit zone in the Horizontal Scale field, the soft-keys allow the choice of 1, 2, 4 or

10 cycles of the waveform across the width of the screen. When split screen is selected, both

graphs have the same horizontal scale. There are some restrictions on the facilities available in

the multi-cycle displays: the Max Hold and Average modes are only available for a 1 cycle display.

The 10 cycle display can only show Current and is not available in all modes (it is mainly used in

Peak Inrush mode). No action is required from the user; the soft-keys only offer available options

and any conflicting selections are automatically ignored. The set-up display changes to describe

the graphs that will actually be shown.

Trigger Source

With the edit zone in the Trigger Source field the signal source for the display

synchronisation can be selected. Note that this is the trigger source for the display only and does

not affect the measurement synchronisation. The soft-key choices are:

Voltage

Current

Internal

Inrush

When split screen is selected, both graphs have the same trigger point and are exactly

synchronised.

Trigger Phase

This field defines the phase of the waveform (relative to its rising zero crossing) to be set at the

left hand edge of the display. The required value may be entered using the number keys followed

by ENTER. Values between –999 and 999 are accepted and converted into the range 0 to 359

degrees.

The default condition: the rising zero-crossing point of the voltage waveform is

set at the left hand edge of the display.

Sets the rising zero-crossing point of the current waveform at the left hand edge

of the display.

Synchronises the display with the internal data buffers; this can be useful under

some circumstances when asynchronous components in a voltage or current

waveform cause display jitter. The actual synchronisation point is arbitrary; it is

determined at instrument switch-on and will be different if the instrument is

switched off and then on again. The trigger phase setting can be used to move

the waveform if desired.

Provides a single shot display refreshed whenever there is an Inrush event. The

trigger occurs whenever the peak current in a cycle is more than twice the peak

current in the previous cycle.

18

Page 20

Harmonics View

With the green VIEW lamp lit, press the HARMONICS key to display the Harmonics view. The

default display is a current harmonics histogram.

The harmonics histogram can be set to show either absolute harmonic levels or levels as a

percentage of individual limits; it can also be modified to show, for example, odd harmonics only.

The histogram bar for each harmonic is made up of two parts: an inner section, which is normally

used to show the presently measured value, and an outer section which by default shows the EN

specification limit for that harmonic. Other combinations may be selected.

The harmonics can also be listed in a table, with limits. The table has two forms: a compact form

showing all 40 harmonics and a detailed form, separated into two pages, showing full results on

either all the even or all the odd harmonics. Additionally, the harmonics of the supply voltage can

also be displayed in histogram and table form.

All the above view options are set from the Harmonics set-up screen; full descriptions of each are

given in the Harmonics Set-up Section. The measurement parameters and the classification of

the unit under test are made on the Test Set-up screen and are described in that section of this

manual.

19

Page 21

Harmonics Set-up

With the Harmonics view displayed, pressing SET-UP shows the Harmonics set-up screen.

The soft-key functions change as the edit zone is moved through the editable fields of the display

using the

to the Harmonics view. The selections made for each of the display formats are stored until the

instrument is switched off.

keys; each field is described below. Pressing the VIEW key returns the display

Waveform Selection

With the edit zone in the Display Harmonics of field, the soft-key choices are Current

Waveform and Voltage Waveform. Current harmonics are the default choice, for which the

full range of display and measurement mode options described previously are available. When

Voltage harmonics are selected, a restricted choice of display and measurement modes applies

as explained in the appropriate sections.

Display Format - Histogram

With the edit zone in the Display Format field, the soft-key choices are Histogram, Odd

Table, Even Table and Combined Table.

With Histogram selected as the Display Format the further editable fields of Vertical

Scale, Data Selection and Show are available; these can be used to optimise the form of

the histogram for particular measurement. In the power-up default form shown in the Harmonic

View section, for example, the histogram shows all harmonics and limits as absolute values.

All histograms are of the same general form as the default version. The horizontal scale is

marked with the harmonic number, odd harmonics & limits are shown as wide bars and even

harmonics & limits are shown as narrow bars. The fundamental is shown to the left of the second

harmonic as a wide bar and the DC component is shown to the left of the fundamental as a

narrow bar. More information about what combinations of data can be shown in the display is

given in the Data Selection and Show sections below.

20

Page 22

Vertical Scale

With the edit zone in the Vertical Scale field the soft-key choices are Absolute or

Percent Limit. With the default condition of Absolute, the initial scaling is determined by the

instrument’s measurement range. However, the scaling can be changed easily using the

and keys; the key increases the resolution, permitting a ‘zoom’ view of low level

harmonics, and the

view. In this way any harmonic can be observed with optimum display resolution. Changing this

display resolution does not affect the hardware measurement range, which, for correct operation

of the transform processing, must always be chosen so the waveform peak is in-range; see the

Important Note in the Power Meter Set-up section.

Measuring and reporting absolute harmonic levels is necessary during development and type

approval exercises but a quicker pass or fail assessment can be made by viewing harmonics as a

percentage of their individual limits; this is more appropriate in a Q.A. situation, for example. With

the edit cursor in the Vertical Scale field, selecting Percent Limit and returning to the

key reduces resolution, bringing off-screen harmonics and limits into

Harmonics View gives the following display.

The horizontal scale is marked with the harmonic number as before but now the vertical scale is

0 to 200% of limit. The value of each harmonic is shown as a percentage of its individual limit;

where the limit changes with the power level, e.g. Class D products, the harmonic level is shown

as a percentage of its instantaneous limit corresponding to that measurement. The Percent Limit

display thus gives an instant view of harmonic performance, even as absolute levels change,

without having to adjust display scaling.

Note that when Percent Limit is selected as the display mode the Data Selection field (see

next section) is forced to Normal & Max Hold, so the inner (solid) bars represent the

instantaneous harmonic values and the tops of the outer bars mark the maximum value reached

by each harmonic. The Max Hold can be reset at any time by pressing the START key and is

automatically reset when the measurement range is changed or auto-ranges. Only those

harmonics that are subject to a limit are shown.

21

Page 23

When Absolute is selected for the Vertical Scale, moving the edit zone to Data Selection,

changes the soft-key choices to Normal & Limit (the default), Max Hold & Limit,

Normal & Max Hold and Min & Max Hold. These keys determine which parameters the

inner (solid) bars and outer (open) bars of the histogram represent. For example, with the default

selection of Normal & Limit the individual limits are shown by the open outer bars while the

normal (instantaneous) values of the harmonics are shown by the solid inner bars, ‘thermometer’

style. Note that, in this example, the limits might also be changing dynamically (e.g. for a Class D

device whose power is increasing) and that the solid inner bar may extend beyond the open outer

bar if the limit is exceeded.

The full list of display options is described below; only the first of these (Normal & Limit) is

available for Voltage Harmonics Histograms.

Normal & Limit:

Max Hold & Limit:

Normal & Max Hold:

The default selection for Absolute scaling. The solid inner bars

represent the normal (instantaneous) harmonic value (the choice of

filtered or unfiltered is made below) and the open outer bars show the

instantaneous limit for each harmonic.

The histogram is updated with the values from every transform. The

limits are also calculated dynamically where appropriate (e.g. Class D).

The open outer bars show the limits for each harmonic, as above, but

the solid inner bars now mark the maximum harmonic level; the

histogram is updated after every transform with the greater of the new

and existing value for every harmonic. The actual (100%) limits are

shown; it may be permissible for the maximum harmonic level to be up

to 150% of the limit, see the standard.

Note that if the range changes then the previous Max Hold data is lost.

The range should be locked when making measurements of this nature;

use the Set-up screen of either the Power Meter or Waveform Graph

displays. This must be done with care, see the Important Note in those

Set-up sections.

The Max Hold can be manually reset at any time by pressing the

START key.

The solid inner bars represent the instantaneous harmonic values from

every transform and the open outer bars mark the maximum value

reached by each harmonic since Max Hold was last reset by pressing

START or changing range (see notes above).

22

This is the only Data Selection mode available if Vertical Scale is set to

Percent Limit but, since the vertical scale represents the normalised

limits (0 to 200%), limits information is always available.

Min & Max Hold:

The above represent all combinations of data and limits that might be displayed; any of the

parameters may also be completely suppressed using the Show facility, see below.

In this display mode, the open outer bars show the Max Hold value as

described above but the solid inner bars now represent the Min Hold,

i.e. the lesser of the new and existing value after each transform. The

display therefore shows the range of individual harmonics over a period

of time or as operating conditions are varied.

Note that Min Hold and Max Hold are both automatically reset when the

instrument changes range (see above), and can be manually reset at

any time by pressing the START key.

Page 24

Show

With the edit zone in the Show field there are four soft-keys which permit the parameters of the

chosen Data Selection mode to be turned on and off in the display. For example, for the default

condition of Normal & Limit, the four soft-keys are Odd Harmonics, Even Harmonics,

Normal and Limits. For clarity, the list changes to confirm the present usage of the inner and

outer bars of the histogram. Alternate presses of each key will turn that item on and off in the

display; confirmation is given by a or X against the corresponding parameter in the Show edit

zone. Note that when the odd harmonics are turned off the fundamental is also turned off and

when the even harmonics are turned off the DC component is also turned off.

Filter

With the edit zone in the Filter field, the soft-key choices are Unfiltered and Filtered.

The standard requires the transform results to be passed through a 1st order filter with a 1.5s time

constant before assessment. When Filtered is selected these values are displayed; the raw

values from the transforms can be viewed if required by selecting Unfiltered. This Filter

option is also available when tables are displayed.

Display Format – Tables

With the edit zone in the Display Format field, the soft-key choices are Histogram, Odd

Table, Even Table and Combined Table.

The Table displays have two distinct forms – one shows limited data for all 40 harmonics on a

single page; the other shows more columns of data but is separated into Even and Odd harmonic

pages. This second form is available for current harmonics only. The alternatives are reflected in

the Show field of the setup display; the soft-key choices available when the edit zone is in that

field offer another way to choose the table format.

Selecting Combined Table (which sets the show field to All Harmonics) and returning

to the Harmonics view by pressing the VIEW key gives a display of the following form:

This table lists all odd and even harmonics up to the 40

hand group has the fundamental and all the odd harmonics up to the 39

lists the even harmonics 2

nd

to 40th. The format is the same for both groups; for each numbered

th

in two groups on a single page: the left-

th

, the right-hand group

harmonic, the measured harmonic value is shown together with the limit for that harmonic and the

measured value expressed as a percentage of that limit. The harmonic value can be filtered or

unfiltered depending on the selection in the Filter field (as described above); the column heading

changes to indicate the selection made. A '—' is shown in the table when no limit applies, (e.g. for

the fundamental, or for loads below the minimum power limit for their class).

23

Page 25

The assessment of current harmonics against the limits requires the use of the average and

maximum values, which are not shown in this combined table. To display this information, return

to the Harmonics set-up, by pressing SET-UP, and select either Even Table or Odd Table

(alternatively, move the edit zone to the Show field and choose Even Harmonics, or Odd

Harmonics). These tables have additional columns of data, but list only the even or only the odd

harmonics respectively.

These tables show the present measured value (normally the filtered value should be chosen),

the limit, the average of the filtered value since the test started, that average as a percentage of

the limit, the maximum filtered value and that maximum as a percentage of the limit. Finally the

right-hand column gives a pass or fail assessment for that harmonic indicated by a or X

respectively. This assessment includes a comparison of the average value against 100% of the

limit, the maximum value against 150% of the limit and (where relevant) the Partial Odd Harmonic

current against its limit. The bottom line of the Odd Harmonic page is marked P: and shows the

present Partial Odd Harmonic Current and its limit. Note that the percentage of limit figures are

shown for information only, and may be subject to small calculation errors. The Pass or Fail

assessment is made more accurately by a subtractive comparison.

24

Page 26

Test Control View

With the green VIEW lamp lit, press the TEST key to display the Test Control view. This display

sets the operating mode of the instrument to Harmonics, Voltage Variations & Flicker, or Peak

Inrush Current and allows the details of all the measurements to be configured.

The contents of the Test Control view change depending on which mode is selected; the following

paragraphs describe the Test Control facilities available in the Harmonics mode. The other modes

are described in their own chapters.

The Harmonics mode Test Control view has three sections. The top section shows the nominal

voltage and frequency parameters of the test supply. The middle section contains the declaration

of the class of the item being tested, and other parameters of the measurement to be performed.

The lower section summarises the time element of test control (i.e. whether timed or continuous)

and shows the current test status. There are two lines of help text at the bottom of the screen.

The associated selections are made on the Test Control Set-up screen and a full explanation of

the options available is given in the Test Control Set-up section below. Tests are controlled by the

START and STOP keys as prompted on this view.

The measurement requirements for current harmonics are given in EN61000-3-2; there have

been two editions of this standard. The original edition, which was published in 1995, was later

changed by an amendment (known as A14), which introduced changes that were so substantial

that a revised version was published, known as EN61000-3-2 Edition 2 : 2000.

EN61000-3-2:1995 is now obsolete. Older versions of the software for this instrument supported

both sets of requirements, in which case this view will be different, with additional soft-key

selections not described here. Such software should be upgraded, as it does not implement the

current requirements.

EN61000-3-2:2000 in turn refers to EN61000-4-7for measurement methods; there are now two

versions of this standard: 1993 and 2002. The present issue of the instrument software supports

both; the choice is made on the Test Set-up view. The presentation of the results appears the

same, but the internal signal processing requirements differ substantially and may give different

results, especially if the waveform contains non-harmonic components (known as inter-harmonics

in the standard).

25

Page 27

With Test Control view displayed, pressing SET-UP shows the Test Control set-up screen. This is

essentially the same as the view screen but with soft-keys at the bottom of the display that

change as the edit zone is moved through the editable fields of the display with the

Operating Mode

With the edit zone in the Operating Mode field, the soft-keys are used to select the operating

mode. The default is EN61000-3-2:2000 Harmonics; the alternatives are Voltage

Variations & Flicker and Peak Inrush Current. Old versions of the instrument

software also offered IEC61000-3-2:1995 Harmonics; this is no longer used and any

instrument with that software should be upgraded to the current version.

The Inrush Current and Flickermeter facilities are described in separate chapters; the editable

fields of the Harmonics mode are described below.

Nominal Voltage

With the edit zone in the Nominal Voltage field the nominal supply voltage and its voltage

tolerance, against which the load supply will be monitored, can be set using the Set Voltage

and Set tolerance soft-keys. When either key is pressed, an appropriate message is

displayed at the bottom of the display (in place of the soft-keys) with a flashing cursor, e.g.

Test Control Set-up (Harmonics)

keys.

The new value is entered from the keyboard and confirmed with the ENTER key; pressing

CANCEL instead of ENTER returns the voltage (or tolerance) to the previous value.

Important note: The hardware voltage measurement range is automatically set according to the

Nominal Frequency

With the edit zone in the Nominal Frequency field the nominal supply frequency and its

frequency tolerance, against which the load supply will be monitored, can be set using the Set

Frequency and Set tolerance soft-keys. The numeric entry procedure is the same as

described for Nominal Voltage above.

Important note: The transform length and the filter time constants used in the measurements are

Load Class

EN61000–3–2 defines different harmonic current limits for different classes of equipment; users

must refer to the standard to determine the class of the equipment being tested. The class must

be declared to the analyser so that the correct limits are used for the pass or fail assessments.

With the edit zone in the Declare Load Class field, the soft-key options include Class A,

Class B, Class C, and Class D; a Professional Equipment modifier is also offered.

For Class A the limits are absolute values for all harmonics, as given in Table 1 of

EN61000-3-2.

Nominal Voltage: _ Volts.

value entered here, so for optimum accuracy the correct entry must be made.

determined by this value, so for proper operation the correct value of the actual

frequency of the load supply must be entered.

26

For Class B the limits are absolute values for all harmonics and are the class A limits multiplied

by a factor of 1.5.

For Class C the limits depend on the fundamental current and power factor of the load and are

calculated according to the percentage factors in Table 2 of EN61000-3-2. Limits apply to all odd

harmonics and to the second harmonic; there are no limits for the other even harmonics.

For Class D the limits depend on the power consumption of the load and are calculated

according to the milliamps per Watt factors in Table 3 of EN61000-3-2, subject to the maximum

values also listed in that table (which are equal to the class A limits). There are limits for the odd

harmonics only.

Page 28

The additional soft-key option determines whether the equipment under test is considered to be

Professional Equipment or not. No limits are applied to Professional Equipment with rated power

consumption over 1000 Watts. This soft-key acts as a toggle, displaying either Professional

Equipment or Standard Equipment to reverse the setting currently active.

A number of subsidiary configuration lines appear on the Test Control screen depending on the

class declared.

Basis of limits

If either Class C or D is selected then the limits depend on the behaviour of the unit being tested

and an additional line becomes available to control the way the limits are calculated. With the edit

zone in the Basis of Limits field, the soft-key choices are Automatic, Declare Value

and Store Present.

When Automatic is selected, the limits are continuously calculated from the measured

consumption of the equipment under test. For class C the maximum fundamental current and the

simultaneous power factor are used; for class D the maximum power consumption in Watts is

used.

When Store Present is pressed, the actual power consumption (or, for class C, the

fundamental current and power factor) of the load at the moment the key is pressed is stored and

used thereafter as the basis for calculating the limits. The values measured are displayed on the

Basis of Limits line, followed by the word Condition. The limits then remain fixed until the

basis of limits is changed.

This method is used, for example, when testing discharge lamp luminaires with built-in dimming

devices when the standard requires the limits to be calculated from the fundamental current and

power factor measured at the maximum load condition. After setting up the maximum condition

press Store Present to set the basis of limits. As the dimmer setting is varied, the harmonic

currents are assessed against the limits derived from the stored setting.

When Declare Value is pressed the user is prompted to enter the rated consumption of the

equipment being tested using the keyboard.

For a Class D load, pressing the Declare Value soft-key brings up a message at the bottom

of the display (in place of the soft-keys) with a flashing cursor.

Rated Power: _Watts

The rated value is entered from the keyboard and confirmed with the ENTER key; the entered

value is shown in the Basis of Limits field following by the term Rating to indicate that it is a

declared rating. Pressing CANCEL instead of ENTER returns the Basis of Limits to the previous

state.

For a Class C load both Declare Current (for the fundamental current) and Declare PF

(for the power factor) must be entered in a similar manner. If the value given for the current is 16

or less then it will be taken as Amps, otherwise it will be taken as mA. The power factor will

default to 1.0 if not explicitly entered.

In general, the present edition of the standard requires the manufacturer’s declared rating to be

entered as the basis of the limits, rather than using the automatic detection.

Class D-A Crossover Power

Class D is only defined for equipments with power consumption up to 600 Watts; above that

power class A limits apply. If the consumption of a particular equipment varies around the

crossover value, the applicable limits change rapidly, resulting in measurements that are hard to

interpret. If this is the case, the standard now suggests that the declared power (rather than the

crossover point) should be changed slightly to clearly define whether the equipment is in class A

or class D. Therefore the use of this edit field is now unlikely, but it makes it possible to change

the crossover power setting slightly and take one set of measurements in class D and a second

set in class A.

27

Page 29

Note that each individual harmonic limit in class D (when calculated by the appropriate mA/W

formula) is also subject to a maximum value equal to the class A limit for that harmonic. The

power level at which this occurs is around 600 watts, but varies slightly between harmonics

(because of the coefficients of the various equations). Changing the crossover power setting does

not alter these calculations.

With the edit zone in the Class A-D Crossover field, the default class crossover point can

be changed using the Set Power soft-key exactly as described above.

Minimum Power (No limits below)

The standard specifies that no harmonic current limits apply to equipments (other than class C)

below a power consumption of 75 watts. This figure might change in a future edition of the

standard.

Class C lighting equipment with an active input power ≤ 25W must meet the power–related

harmonics limits of Class D (i.e. Table 3 of EN61000-3-2). The analyser can be set up to do this

by declaring Class D and setting the Minimum Power to zero, so that limits are calculated and

displayed for all load power levels. Note that the user must monitor the actual power level (using

the Meter view); if the load exceeds 25W then conventional Class C limits apply and the class

declaration must be changed accordingly.

With the edit zone in the No Limits below field, the default minimum power limit can be

changed using the Set Power soft-key. Pressing this key brings up a message at the bottom of

the display (in place of the soft-keys) with a flashing cursor:

The new value is entered from the keyboard and confirmed with the ENTER key; pressing

CANCEL instead of ENTER returns the limit to its previous value. When the load power is below

this power, no limits are applied.

Maximum Power (No limits above)

If the equipment under test is defined as Professional Equipment then no limits apply above 1000

Watts. This power threshold can be changed if required (perhaps to allow testing with some

margin beyond the exemption level).

With the edit zone in the No limits above field, the default Professional exemption power

can be changed using the Set Power soft-key exactly as described above.

This line only appears if the equipment has been declared Professional in the Declare Load Class

field.

Adjust Limits

The Limits field provides the user with the opportunity to scale the current limits defined in the

standard (which strictly only apply to 230V ±2% operation) to a different operating voltage, e.g.

100V, to give the same harmonic power. Users should check carefully the details of the national

adaptation of the standard to determine the requirements.

With the edit zone in the Limits field the soft-key choice is Standard or Voltage Ratio.

With Standard selected (the default), the limits defined in the EN standard apply; if Voltage

Ratio is selected, the limits are scaled by the ratio between 230V and the nominal voltage set in

the Nominal Voltage field. In Voltage Ratio mode the set-up display reads:

Minimum power _ Watts.

28

Limits: Adjust by 230V/Nominal

This adjustment is reflected both in the limit current values shown in the results and in the

assessments.

Page 30

Measurement Method

With the edit zone in the Measurement Method field, the soft-keys offer the choice of

EN61000–4–7:1993, EN61000–4–7:2002 or 4 Cycle transforms as measurement

methods. This selection affects both the length of the data window for each Discrete Fourier

Transform and the post-transform data processing.

EN61000–4–7:2002 (the present method) requires transform windows nominally 200ms long:

10 cycles at 50Hz, or 12 cycles at 60Hz. This instrument makes the choice depending on whether

the nominal frequency declared is above or below 55Hz. The amplitudes of any signal

components that fall between two harmonic frequencies (called inter-harmonics) are rms summed

into the nearest harmonic value before subsequent processing. This procedure is known as

grouping.

EN61000–4–7:1993 uses 16 cycle transforms, with only the results at harmonic frequencies

used; there is no grouping of inter-harmonic values. At present, it is still permissible to use this

method, provided that this fact is recorded in the report.

This instrument also offers the option of 4 cycle transforms. These give a faster response on

screen and may be useful for development purposes, but they should not be used for compliance

measurements.

All three methods use transforms with contiguous rectangular windows; the data processing is

continuous with no gap or overlap between successive transforms.

Assessment Inset

With the edit zone in the Assessment inset field, the Set Level soft-key allows the actual

limit to be set as a decimal fraction or multiple of the limits automatically defined by the choice of

Operating mode and load Class. Setting the inset to 0.95, for example, gives a 5% 'safety margin'

between the measurement limits used and the limits defined by the standards. Note that this inset

only affects the Pass or Fail assessment on the Harmonics View and in the printed reports; the

numerical data and limit values shown in the tables are not affected.

Pressing the Set Level soft-key the message:

Assessment inset: _ of limit

is shown at the bottom of the display (in place of the soft-keys) with a flashing cursor. The new

value is entered from the keyboard and confirmed with the ENTER key; pressing CANCEL

instead of ENTER leaves the previous multiplier value unchanged.

Test Timing, Measurement Hold and Load Power Control

The lower section of the Test Control set-up has two further editable fields, Test type and

Load Power, for which the soft-key choices are inter-dependent. In addition, the Test status

field (non-editable) immediately above the soft-keys provides the same information about a timed

test as the Test Control view display.

Important note: When making compliance measurements it is essential to set up and execute a

proper timed test after locking the current range. This is especially the case if

the harmonic levels vary during the operating cycle of the equipment being

tested. Requirements for test duration are given in the standard for some types

of equipment and some general guidance has been added to the 2000 edition. If

the equipment being tested has an obvious operating cycle over a period of

some minutes then a test should be taken over a full cycle. If the cycle is

quicker, the test should cover multiple cycles. In any event, the test should last

at least 150 seconds.

With the edit zone in the Test type field, the soft-key choices are as follows; the

corresponding Load Power options are detailed with each test type choice.

29

Page 31

Untimed:

This state is entered at power-up, to allow initial investigation of the equipment

under test. Measurement is continuous; consequently load power is Always On.

The test status is Normal (i.e. continuous measurement) unless STOP is pressed.

When STOP is pressed, the measurement is interrupted and the displayed values

are held; test status changes to Hold. The TEST lamp flashes to show that the

measurement is held; pressing STOP again restarts the measurement and turns the

TEST lamp off. STOP can be used with the instrument set to any view. Thus, it can

be used to “freeze” the values in the Power Meter view or the histogram or tabular

displays of the Harmonics view; however, STOP does not hold the Waveform Graph

view.

Manual:

Timed:

The test is manually controlled using the START and STOP keys. With the edit

zone moved into the Load Power field there is now the option to have the load

power Always On or just on During Test. With Always On selected, when

the test is started with the START key the Test status field changes to show