Page 1

EL302P

Bench Power Supply

INSTRUCTION MANUAL

Page 2

Table of Contents

Introduction 1

Specification 2

EMC 5

Safety 6

Installation 7

Connections 8

Operation 8

Remote Operation 9

Remote Commands 11

Maintenance 12

Instructions en Francais 13

Bedienungsanleitung auf Deutsch 21

Istruzioni in Italiano 29

Instrucciones en Español 37

Introduction

The EL302P is a digitally controlled version of the standard EL302 linear power supply with an

isolated RS-232 interface.

It offers a low-cost solution for a bas ic programmable PSU, and will be sufficient for many

applications where the sophistication and complexity of GPIB is not needed.

A simple command set allows remote control of voltage, current and output enable together with

read-back of meter ing values and operat ional status.

Local control is via three rotary encoders providing rapid and accurate setting of voltage and

current during bench use.

Excellent line and load regulation is matched by very low noise and good transient response.

Improved power efficiency ensures that the units require no fan cooling.

The EL series has been designed to meet the stringent requirements of relevant IEC standards

for safety and EMC. All outputs are intrinsically short circuit proof and are protected ag ainst

external voltages and reverse currents.

1

Page 3

Voltage Range:

0V to 30V minimum.

Current Range:

0.01A to 2A minimum.

Resolution 10mV. Sett ing accuracy 0.3% ± 20mV (for V >0.1V)

Resolution 10mA. Setting accuracy 0.6% ± 20mV ( for I >0.1A)

cross-over.

Output Switch:

Electronic. Preset voltage and current displayed when off.

3A.

Load Regulation:

<0.01% of maximum output for 90% load change.

Line Regulation:

<0.01% of maximum output for 10% line change.

(20MHz bandwidth)

Transient Load Response:

<20µs to within 50mV of set level for a 5% to 95% load change.

Temperature Coeff icient :

Typically < 100ppm /°C

Status Indication:

Output on lamp. CC mode lamp.

14mm (0.56") LED displays. Reading rate 4/sec.

100mV and when in CC mode the last digit will be set to zero.

Current (CV mode) 0.6% ± 20mA.

Specification

General specifications apply for the tem per ature range 5°C to 40°C. Accuracy specifications

apply for the temperature range 18°C to 28°C after 1 hour warm-up with no load and calibration

at 23°C. Typical specifications are determined by design and are not guaranteed.

OUTPUT

Voltage Setting: By coarse and fine rotary encoders or RS-232 interface.

Current Setting: By single rotary encoder or RS-232 interface.

Operating Mode: Constant voltage (CV) or constant current (CC) with automatic

Output Protection: Outputs will withstand forward voltages of up to 20V above the rated

output voltage. Reverse protection by diode clamp for currents up t o

Ripple & Noise:

Typically < 1m Vrms (CV mode).

METER SPECIFICATIONS

Meter Types: Separate 4 digit meter for voltage and 3 digit m et er for current with

Meter Resolutions: 100mV, 10mA

Note that in constant voltage mode the meter will show the set voltage

to resolution of 10mV. However the metering resolution is limited to

Meter Accuracies: Voltage (CC mode) 0.3% ± 100mV.

MEMORY

The power supply saves the voltage, current and output-enable status at power down and restores

the settings at power up.

2

Page 4

9-pin D connector.

Baud Rate:

Variable from 600 baud to 9,600 baud.

Read Current, Read On/Off, Read Mode (CV or CC).

Current 0.6% ± 20mA (for I >0.1A).

Setting Resolution:

Voltage 10mV. Curr ent 10mA.

Readback Accuracy:

Voltage 0.3% ± 100mV. Current 0.6% ± 20mA.

Readback Resolution:

Voltage 100mV. Curr ent 10mA.

Output T erminals:

Universal 4mm safety binding posts on 19m m ( 0. 75”) pitch.

AC Input:

230V AC or 115VAC ± 10%, 50/60Hz. Installation Category II.

Power Consumption:

160VA max.

Operating Range:

+5ºC to +40ºC, 20% to 80% RH.

Storage Range:

−40ºC to +70ºC.

Environmental:

Indoor use at altitudes up to 2000m, Pollution Degree 2.

Safety:

Complies with EN61010-1.

EMC:

Complies with EN61326.

Size:

140 x 160 x 295 mm (WxHxD)

Weight:

4.1kg.

RS-232 CONTROL

Interface: RS-232 interface, fully opto-isolat ed from power supply output.

Remote Functions: Set Voltage, Set Current, Set O utput On/Off, Read Voltage,

Setting Accuracy: Voltage 0.3% ± 20mV (for V >0.1V).

GENERAL

3

Page 5

Performance levels achieved are detailed in the user manual.

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

EL302P Bench Power Supply

meets the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Comm unit ies.

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class B

b) EN61326-1 (2006) Conducted, Class B

c) EN61326-1 (2006) Harmonics, referring t o EN61000-3-2 (2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring t o:

a) EN61000-4-2 (2009) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2009) Conducted RF

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

CHRIS W ILDING

TECHNICAL DIRECTOR

2 January 2013

4

Page 6

This instrument has been designed to meet the requirements of t he EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of t he following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harm onics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and per formance achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (2009) Electrostatic Discharge : 4k V air, 4kV contact, Perfor m anc e A (B).

EMC

b) EN61000-4-3 (2006) Electromagnetic Fie ld:

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance A ( A) and 1.4GHz to 2GHz:

Performance A (A) ; 1V/ m , 2.0GHz to 2.7GHz: Performance A ( A) .

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle and 1 cycle, 0%: Performance B (B);

25 cycles, 70% and 250 cycles, 0%: Performance B (C) .

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line), 0·5kV peak ( DC Out puts) ,

Performance B (B).

e) EN61000-4-5 (2006) Surge, 0·5kV (line t o line), 1kV (line to ground), Perform ance A (B).

f) EN61000-4-6 (2009) Conducted RF, 3V, 80% AM at 1kHz (AC line only; DC Output

connections <3m, therefor e not tested), Performance A (A).

According to EN61326-1 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specificat io n limits.’

Performance criterion B: ‘During t est , temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During t est, temporary degradation, or loss of function or

performance which requires operat or int er vention or s ystem r eset occurs.’

Where Performance B is stated it is because DC Output regulation, or V & I measurement

accuracy, m ay deviate beyond Specification limits under the test conditions. However, the

possible deviations are still small and unlikely to be a problem in practice.

Note that if operation in a high RF f ield is unavoidable it is good pract ice t o c onnect the PSU to

the target system using screened leads which have been passed (together) through an absorbing

ferrite sleeve fitted close to the PSU terminals.

Cautions

To ensure continued compliance with the EMC directive observe the following precautions:

a) after opening the case for any reason ensure that all signal and ground connect ions ar e

remade correctly and that case screws are corr ect ly refitted and tightened.

b) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

5

Page 7

l

Safety

This power supply is a Safety Class I instrument according to IEC classification and has been

designed to meet the requirem ents of EN61010-1 (Safety Requirements for Elect r ical Eq uipment

for Measurement, Control and Laborator y Use). It is an Installation Category II instrument

intended for operation from a normal single phase supply.

This instrument has been tested in accordanc e with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to r etain the inst r um ent in a safe condition.

This instrument has been designed f or indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% - 80% RH (non-condensing). It may occasionally be

subjected to temperatures between +5°C and –10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not spec ified by these instructions may impair the safety

protection provided. Do not operate the instrum ent outside its rat ed supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conduct or inside or outside t he inst r um ent will make the

instrument dangerous. Int entional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, t er minals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, m aint enance or repair. Capacitors inside the power supply may still be

charged even if the power supply has been disconnected from all voltage sources but will be

safely discharged about 1 minute after switching off power.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be

avoided as far as possible and, if inevitable, shall be carried out only by a skilled person who is

aware of the hazard involved.

If the instrument is clearly def ec t ive, has been subj ec t t o mechanical damage, excessive

moisture or chemical corrosion the safety protection may be impaired and the apparatus should

be withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used f or

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it. The following symbols are used on the instrument

and in this manual:-

Earth (ground) terminal.

mains supply OFF

mains supply ON

alternating current (ac)

direct current (dc)

6

Page 8

Mains Operating Voltage

Check that the instrument oper ating voltage marked on the rear panel is suitable for the local

supply. Should it be necessary to change the operating voltage, proceed as follows:

1. Ensure that the instrument is disconnect ed from the AC supply.

2. Remove the screws holding the case upper and handle and lift off the case upper.

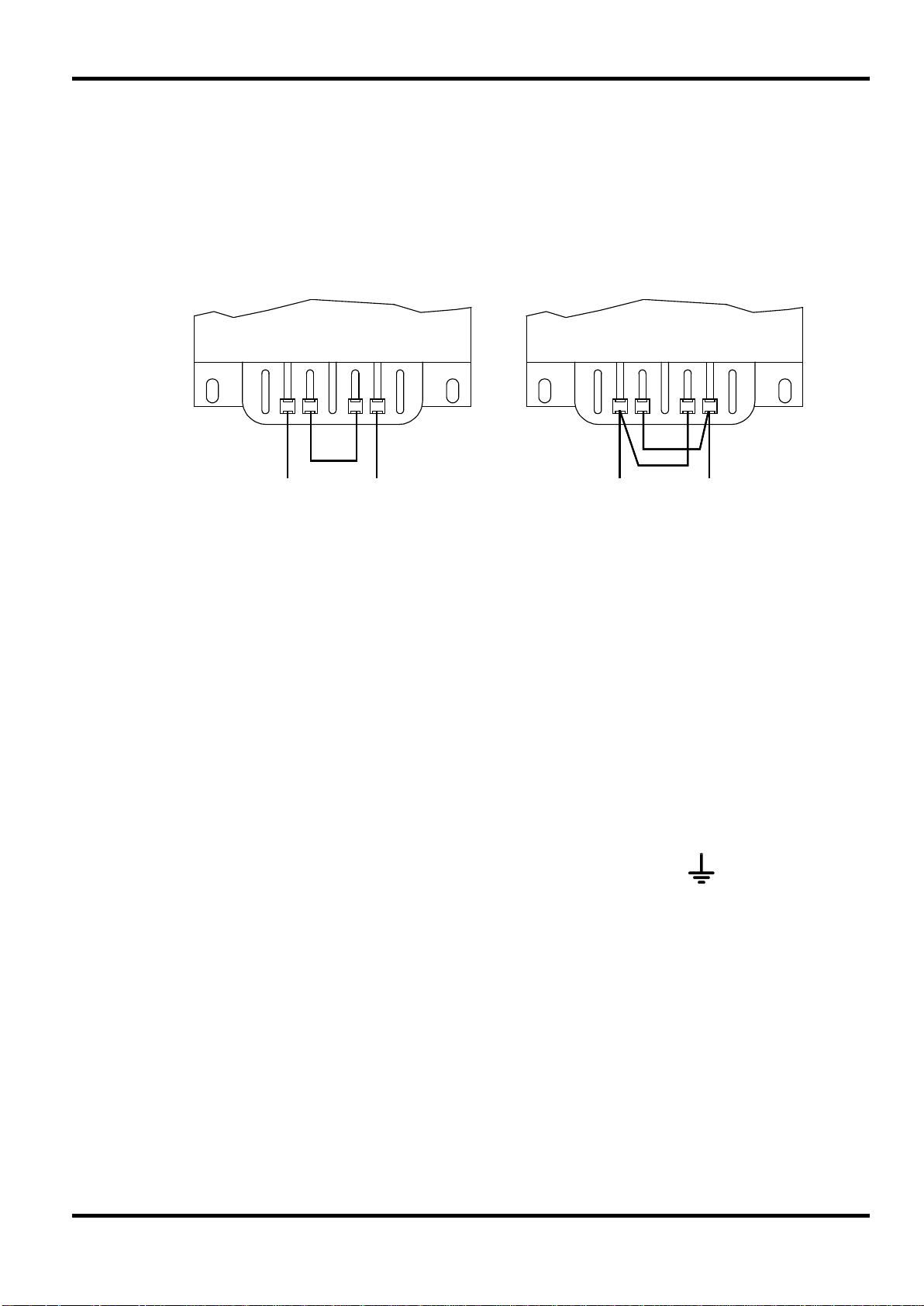

3. Change the transformer c onnections following the diagram below:

230V Operation 115V Operati on

BLUE BROWN BLUE BROWN

Installation

4. Re-assemble in the reverse order.

5. To comply with safety standard requirem ents t he oper at ing voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

Fuse

The AC fuse is located in the fuse drawer in the lower part of the IEC inlet connector. To change

the fuse remove the line cord and open the f use dr awer with a suitable tool.

The correct fuse type is 20 x 5mm 250V HBC time-lag with the following rating:

Make sure that only fuses with the required current rating and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuseholders are prohibited.

Mains Lead

When a three c or e m ains lead with bare ends is provided this should be connect ed as follows:

As the colours of the wires in the mains lead of this apparatus m ay not cor r es pond with the

coloured markings identifying the terminals in your plug proceed as follows:

230V operation : 1.6A (T)

115V operat ion: 3.15A (T)

BROWN - MAINS LIVE

BLUE - MAINS NEUTRAL

GREEN/YELLOW - EARTH Safety Earth Symbol

The wire which is coloured green-and-yellow must be connected to the terminal in the plug which

is marked by the letter E or by the safety earth symbol shown above or coloured green or greenand-yellow.

The wire which is coloured blue must be connected to the terminal which is marked with the letter

N or coloured black.

The wire which is coloured brown must be connected to the terminal which is marked with the

letter L or coloured red.

WARNING! THIS INSTRUMENT MUST BE EARTHED.

Any interruption of the mains earth conduct or inside or outside t he inst r um ent will make the

instrument dangerous. Int entional interruption is prohibited.

7

Page 9

Pin

Name

Description

1

DCD

Linked to pins 4 and 6

2

TXD

Transmitted data from instrument

3

RXD

Received data to instrument

4

DTR

Linked to pins 1 and 6

5

GND

Signal ground

6

DSR

Linked to pins 1 and 4

7

RTS

Linked to pin 8

8

CTS

Linked to pin 7

9

–

No internal connection

Output Terminals

All power connections are made from the fr ont panel.

The load should be connected to the positive (red) and negat ive (black ) terminals marked

OUTPUT. Both are fully floating and either can be connected to ground.

Connections

The terminal marked

is connected to the chassis and safety eart h ground.

RS232

9–pin D–connector for PC remote control with the following connections:

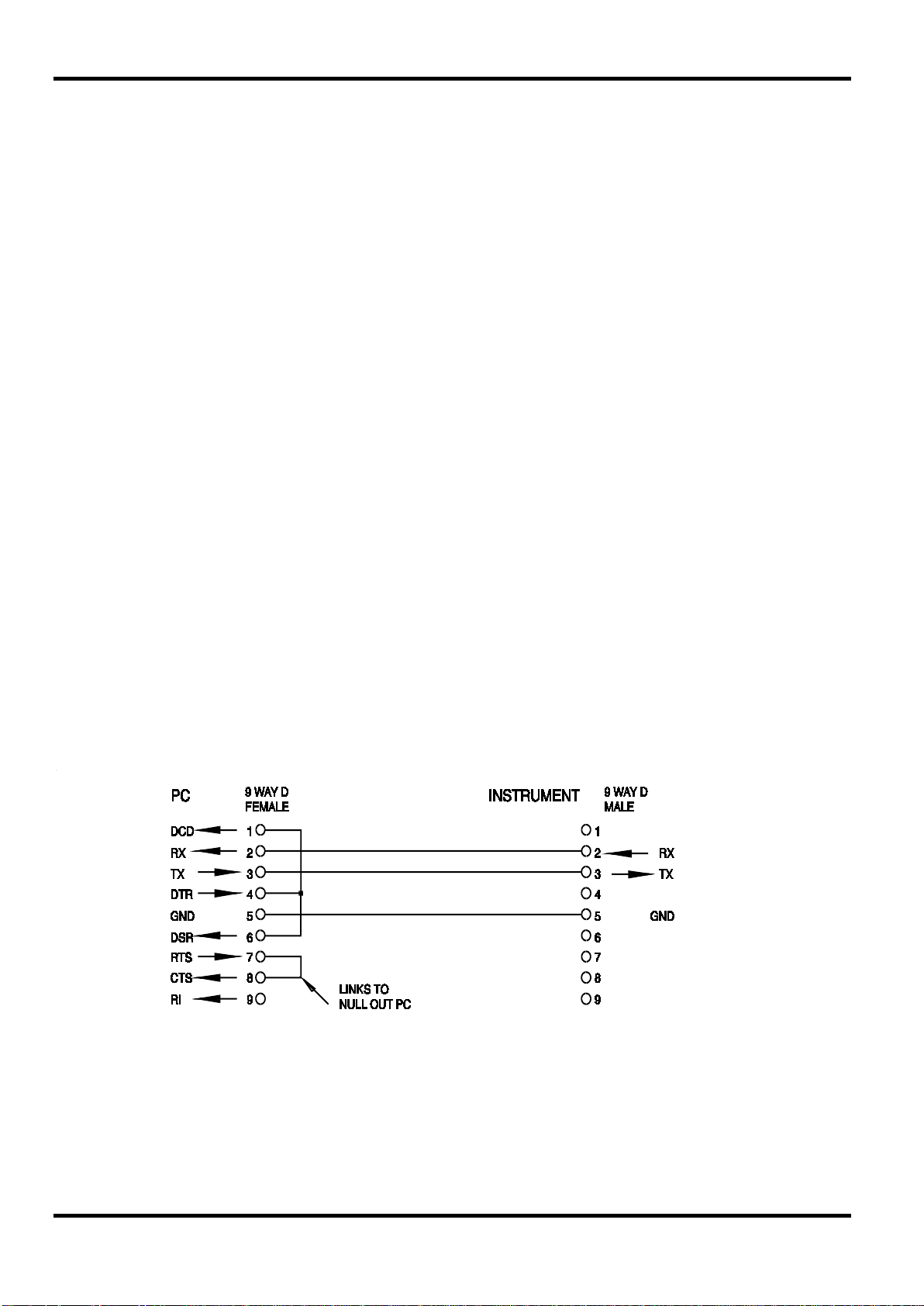

Connect to a PC with a cable which has pins 2, 3 and 5 wired plus pins 1, 4 & 6 and pins 7 & 8

linked at the PC end.

Setting Up the Output

With the PO WER switch on (l) and the output off the out put voltage and cur r ent limit can be

accurately preset using the VOLTAGE and CURRENT controls; the left-hand met er shows the set

voltage and the right-hand meter shows the set maximum c ur r ent.

When the output switch is switched on, the ON lamp lig hts; the left-hand meter still shows the

preset voltage but the right-hand met er now shows the actual load current.

Constant Voltage

The output voltage is adjusted using the coar se and fine VOLTAGE controls; the coarse control

changes the voltage in 100mV steps and the fine control in 10mV steps. The CURRENT control

sets the maximum current that can be supplied; the c ont r ol changes the current limit in 10mA

steps.

Constant Current

If the load resistance is low enough such that, at t he output voltage set, a current greater than

the current limit setting would flow, the power supply will automatically move into constant current

operation. The current output is adjusted by the CURRENT control and the VOLTAGE controls

set the maximum voltage that can be generated.

The CC lamp lights to show constant current mode.

Instantaneous Current Output

The current limit control can be set t o limit the continuous output current to levels down to 10mA.

However, in com m on with all precision bench power supplies, a capacitor is connected acr os s

the output to maintain stability and good transient response. This capacitor charges to the output

voltage and short-circuiting of the output will produce a current pulse as the capacitor discharges

which is independent of the current limit set ting.

Operation

8

Page 10

Efficiency

To improve efficiency at low output levels the overhead voltage to the output regulators is

automatically switched by a relay to a lower voltage; hysteresis at the threshold point prevents

unnecessary switching when the output voltage is set at about that level. Apart from an audible

‘click’ the user will be unaware that the relay has switched; there will be no disturbance on the

output.

Protection

The output has intrinsic short-cir cuit pr ot ec t ion and is pr ot ec t ed from reverse voltages by a diode;

the continuous reverse current must not exceed 3 Amps, although transients can be much higher.

In common with all series regulated single-ended power supplies, the unit is not c apable of

sinking current provided fr om an exter nal sour ce.

If a voltage greater than t he set output voltage of the unit is applied from an external source, the

internal regulator will turn off, no current will flow, and the voltage met er will read the applied

voltage. No damage will result providing the applied voltage does not exceed the maximum

output voltage of the power supply by more than 20 Volts. Application of a voltage g reater than

this is prohibited.

Series or Parallel Connection with Other Outputs

The outputs of the power supply are fully floating and m ay be used in series with other power

supply units to generate high DC voltages up to 300V DC.

The maximum permissible voltage between any terminal and earth ground (

maximum permissible voltage between either terminal of one output and any term inal of another

output on the same supply is also 300VDC.

WARNING! Such voltages are exceedingly hazardous and great care should be taken to shield

the output terminals for s uch use. On no account should the output terminals be touched when

the unit is switched on under such use. All connections to the terminals must be made with the

power switched off on all units.

It should be noted that the unit can only source current and cannot sink it, thus units cannot be

series connected in anti-phase.

The unit can be connected in parallel with others to produce higher currents. Where several units

are connected in parallel, the output voltage will be equal to that of the unit with the hig hest

output voltage setting until the current dr awn exceeds its current limit setting, upon which the

output will fall to that of the next highest setting, and so on. In constant current m ode, units can

be connected in parallel to provide a current equal to the sum of t he c ur r ent limit s et t ings.

Ventilation

The power supply can generate significant heat at full power. The supply relies on convection

cooling only and it is therefore important that ventilation is never restricted if performance and

safety are to be maintained.

) is 300VDC; the

Remote Operation

Remote command format and the remote commands themselves are detailed in the Remote

Commands chapter.

Baud Rate Selection

The Baud rate is set by pressing the OPT I ON SELECT/OK button until bAUd appears in the

left-hand display; the right-hand display shows the current setting in the form of

Baud etc. Change the Baud rate by pressing the CHANGE butt on to step the rate through all the

possible options. When t he required rate is displayed press OPTION SELECT/OK ag ain t o

confirm and exit the rate change m ode.

9

960 for 9600

Page 11

1

DCD

Linked to pins 4 and 6

2

TXD

Transmitted data from instrument

3

RXD

Received data to instrument

8

CTS

Linked to pin 7

9 - No internal connection

Start Bits: 1

Parity: None

Data Bits: 8

Stop Bits: 1

Remote/Local Operation

At power on the instrument will be in the local state with the Rem (remote) lamp off. When a

command is received the remote state will be entered and the Rem lamp will be turned on. The

rotary Controls are not locked out by this action and the instr um ent will be returned t o t he local

state if they are used; however, if the instrument receives another character f rom the interface,

the remote state will again be entered.

Local operation of the rotary controls, output On/Off switch and CHANGE button can be disabled

by pressing the OPTION SELECT/OK but t on until

right-hand display shows the current sett ing ,

button selects

again to confirm and exit the change m ode.

Local operation can be restored at any time by pressing the O PTION SELECT/OK button; if

on or oFF ; when the required setting is displayed press OPT I ON SELECT/OK

LoCL has been set to oFF the first press of OPTION SELECT/OK returns the instrument to

local control and subsequent presses select the ot her modes as described above.

RS232 Connector

The 9-way D-type serial interface connector is located on the instrument r ear panel. The pin

connections are as shown below:

Pin Name Description

LoCL appears in the left-hand display; the

on or oFF . Alternate presses of the CHANGE

4 DTR Linked to pins 1 and 6

5 GND Signal ground

6 DSR Linked to pins 1 and 4

7 RTS Linked to pin 8

Connect to a PC with a cable which has pins 2, 3, 5, wired plus pins 1, 4, 6 and pins 7 and 8,

linked at the PC end, see diagram.

Baud rate is set as described above; the other interface parameters are fixed as follows:

RS232 Character Set

Any ASCII code can be used. Bit 7 of ASCII codes is ignored, i.e. assumed to be low. No

distinction is made between upper and lower case characters in command mnemonics and t hey

may be freely mixed. The ASCII control codes between 00H and 31H are ignored, except for 0AH

(Line Feed, LF) which is used as a command terminator.

10

Page 12

<rmt>

<RESPONSE MESSAGE TERMINATOR>, CR followed by LF.

<nr1>

A number with no fractional part, i.e. an integer.

<nr2>

A number in a fixed point format, e.g. 11.52, 3.61, etc.

outside the range of the output an er r or will be generat ed.

outside the range of the output an er r or will be generat ed.

ON

Sets the DC output on.

OFF

Sets the DC output off.

V<nr2><rmt>

the command V? will be V 12.55<rmt>.

I<nr2><rmt>

command I? will be I 1.00<rmt>.

RS232 Remote Com m and Formats

The instrument's input buff er acc epts a sing le com mand (or query) at a time, under interr upt, in a

manner transparent to other instr um ent oper ations. Commands and queries must be sent as

specified in the command list and must be ter m inat ed with the com m and terminator code 0AH

(Line Feed, LF). Note that parameters ar e separat ed from the command header by one space

(20H).

After a command has been sent the contr oller must wait at least 10ms from the command

terminator before the next com mand (or query) is started, to allow the instrument to clear t he

input buffer.

Responses to queries are sent immediately. The controller must wait for the response to a query

before the next command or quer y is sent. The instrument responds to the controller after every

query as specified in the commands list. I n every case a response is t erminated by 0DH

(Carriage Return, CR) followed by 0AH (Line Feed, LF).

<WHITE SPACE> is defined as character codes 00H to 20H inclusive. <WHITE SPACE> is ignor ed

except in command identifiers. e.g. '*I DN?' is not equivalent to '*IDN?'.

The high bit of all characters is ignored.

The commands are case insensitive.

Remote Commands

Command List

This section lists all commands and queries implemented in this instrument. The commands are

listed in alphabetical order within the function groups.

The following nomenclature is used:

Set-up Commands

V <nr2> Set the voltage to <nr2>. The value of <nr2> must be in Volts; no

I <nr2> Set current limit to <nr2>. The value of <nr 2> m us t be in Amps; no

Readback Commands

V? Returns the set output voltage in Volts in <nr2> numeric format.

multipliers are allowed. If the value of <nr2>, af t er rounding, is

multipliers are allowed. If the value of <nr2> , after rounding, is

The syntax of the response is

Example: If the set output voltage is 12.55 Volts the response to

I? Returns the output current limit in Amps in <nr2> numeric format.

The syntax of the response is

Example: If the current limit is 1.00 Amps the response to the

11

Page 13

<nr2>V<rmt>

response to the command VO? will be V12.55<rmt>.

<nr2>A<rmt>

the command IO? will be A0.93<rmt>.

or OUT OFF<rmt>

or M CC<rmt>

2 = command value outside instrument limits.

(1.00V, 1. 00A, output off).

<version> is the revision level of the software installed.

VO? Reads and returns the actual output voltage in Volts in <nr2>

numeric format. The syntax of the response is

Example: If the actual output voltage is 12.55 Volts the

IO? Reads and returns the actual output curr ent in Amps in the <nr2>

numeric format. The syntax of the response is

Example: If the output current is 0. 93 Amps the response to

OUT? Returns status of the output as

OUT ON<rmt>

M? Returns output mode status as

M CV<rmt>

ERR? Returns the value in the error register in t he form ERR <nr1><rmt>

Miscellaneous Commands

*RST Resets the instrument to the default power-up settings

*IDN? Returns the instrument identification. The exact response is

The Manufacturers or their ag ents overseas will provide repair for any unit developing a fault.

Where owners wish to undertake t heir own maintenance work , this should only be done by skilled

personnel in conjunction with the service manual which may be purchased directly from the

Manufacturers or their agents overseas.

0 = no errors.

1 = command not recognised.

determined by the instrument configuration and is of the form

<NAME>,<model>, 0, <version><rmt> where <NAME> is the

manufacturer's name, <model> defines the type of instrument and

Maintenance

Cleaning

If the PSU requires cleaning use a clot h t hat is only lightly dampened with water or a mild

detergent. Polish the display window with a soft dry cloth.

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE PSU, NEV ER ALLOW

WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE OR DISPLAY

WINDOW NEVER CLEAN WITH SOLVENTS.

12

Page 14

courant alternatif (c.a.)

Sécurité

Cet instrument est de Classe de sécurité 1 suivant la classif icat ion I EC et il a été c onst ruit pour

satisfaire aux impératifs EN61010-1 ( impér atifs de sécurité pour le matériel électrique en vue de

mesure, commande et utilisation en laboratoire) . Il s'agit d'un instrument d'installation Catég orie

II devant être exploité depuis une alimentation monophasée habituelle.

Cet instrument a été soumis à des essais conformément à EN61010-1 et il a été fourni en tout

état de sécurité. Ce manuel d'instructions contient des informations et avertissements qui doivent

être suivis par l'utilisateur afin d'assurer un fonctionnement de toute sécurité et de conserver

l'instrument dans un état de bonne sécurité.

Cet instrument a été conçu pour être ut ilisé en inter ne dans un environnement de pollution

Degré 2, plage de températur es 5°C à 40°C, 20% - 80% HR (sans condensation). Il peut être

soumis de temps à autre à des températures c om pr ises entre +5°C et -10°C sans dégradation

de sa sécurité. Ne pas l'utiliser lorsqu'il y a de la condensation.

Toute utilisation de cet instr um ent de m anièr e non spéc ifiée par ces instructions risque d'affecter

la protection de sécurité conférée. Ne pas utiliser l'instrument à l'extérieur des tensions

d'alimentation nominales ou de la gamme des conditions ambiantes spécifiées.

AVERTISSEMENT! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l' inst r ument

rendra l'instrument dangereux. I l est abs olument interdit d'effectuer une interrupt ion à dessein.

Ne pas utiliser de cordon de prolongation sans conducteur de protect i on, c ar cec i annulerait sa

capacité de protection.

Lorsque l'instrument est r elié au sect eur, il est possible que les bornes soient sous tension et par

suite, l'ouverture des couvercles ou la dépose de pièces (à l'exception de celles auxquelles on

peut accéder manuellement) risque de mettre à découvert des pièces sous tension. Il faut

débrancher ke cordon secteur de l'appareil avant de l'ouvrir pour effectuer des réglages,

remplacements, travaux d'entretien ou de réparations. Les condens at eur s qui se trouvent dans le

bloc d'alimentation risquent de rester chargés, même si le bloc d'alimentation a été déconnecté

de toutes les sources de tension, mais ils se décharg er ont en toute sécurité environ 10 minutes

après extinction de l'alimentation.

Eviter dans la mesure du possible d'effectuer des rég lages, travaux de réparations ou d'entretien

lorsque l'instrument ouvert est br anc hé au secteur, mais si c'est absolument nécessaire, seul un

technicien compétent au courant des risques encour us doit effectuer ce genre de travaux.

S'il est évident que l'instrument est défectueux, qu'il a été soumis à des dégâts mécaniques, à

une humidité excessive ou à une corrosion chimique, la protection de sécurité ser a am oindr ie et

il faut retirer l'appareil, afin q u'il ne soit pas utilisé, et le renvoyer en vue de vérifications et de

réparations.

Remplacer les fusibles uniquement par des fusibles d' int ensit é nom inale requise et de type

spécifié. Il est interdit d'ut iliser des fusibles bricolés et de court-circuiter des port e-fusibles.

Eviter de mouiller l'instrument lors de son nettoyage.

Les symboles suivants se trouvent sur l'instrument, ainsi que dans ce m anuel.

Borne de terre (masse)

l

13

alimentation secteur ON (allumée)

alimentation secteur OFF (éteinte)

courant continu (c.c.)

Page 15

Tens ion d’utilisation secteur

Vérifier que la tension opérationnelle de l'instrum ent indiq uée sur le panneau arrière est

appropriée pour l'alimentation locale. S'il s'avère nécessaire de modifier la t ension opérationnelle,

procéder de la manière décrite ci-dessous:

1. S'as sur er que l'instrument est débranché de l'alimentation c.a.

2. Enlever les vis de retenue de la partie supérieure du boîtier et de la m anet t e et soulever

la partie supérieure du boîtier.

3. Chang er les connexions du tr ansformateur conformém ent au s chém a c i -dessous.

Fonctionnement 230 V Fonctionnement 115 V

BLEU MARRON BLEU MARRON

Installation

4. Effecteur le remontage dans l'ordre inverse.

5. Afin de respecter les impératifs des normes de s écur it é, il faut changer la tension de

fonctionnement marquée s ur le panneau arrière pour indiq uer c lairem ent le nouveau

réglage de tension.

Fusible

Le fusible c.a. se trouve dans le tiroir de f us ibles dans la partie inf ér ieur e du connec t eur d'entrée

IEC. Pour remplacer le fusible, enlever le cordon de ligne et ouvrir le t iroir de fusibles en utilisant

un outil approprié.

Le type de fusible correct est 20 x 5 mm HBC temporisé de r égime suivant:

Fonctionnement 230V : 1,6A (T)

Fonctionnement 115V : 3,15A (T)

Veiller à remplacer les fusibles uniquement par des fusibles de courant nominal correct et de

type spécifié. Il est interdit d'utiliser des fusibles bricolés et de court-circuiter des port e-fusibles.

Câble secteur

Relier de la manière suivante tout câble secteur à trois conducteur s à fils nus:

MARRON - SECTEUR SOUS TENSION

BLEU - SECTEUR NEUTRE

VERT/JAUNE - TERRE Symbole Terre de pr otection

Lors du montage d'une fiche à fus ible, m ettre un fusible de 5 A à l'intérieur de la f iche. I l est

possible que les couleurs des fils du câble secteur de cet appareil ne correspondent pas aux

marques de couleur d'identificat ion des bor nes de la fiche, et par suite, il est recommandé de

procéder de la manière suivante:

Relier le fil vert et jaune à la borne de la fiche désignée par la lettre E ou par le symbole Terr e

de protection indiqué ci-dessus, ou qui est en vert, ou en vert et jaune.

Relier le fil bleu à la borne désignée par la lettre N, ou qui est en noir.

Relier le fil marron à la borne désignée par la lettre L, ou q ui est en r ouge.

AVERTISSEMENT! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l' inst rument

rendra l'instrument dangereux. I l est abs olument interdit d'effectuer une interruption à dessein.

14

Page 16

Broche

Nom

Description

1

DCD

Reliée aux broches 4 et 6

2

TXD

Données transmises depuis l'instrument

3

RXD

Données reçues par l'instrument

4

DTR

Reliée aux broches 1 et 6

5

GND

Terre

6

DSR

Reliée aux broches 1 et 4

7

RTS

Reliée à la broche 8

8

CTS

Reliée à la broche 7

9

–

Aucune connexion interne

Bornes de sortie

Toutes les connexions d’alimentation s’effectuent à partir du panneau avant.

Relier la charge aux bornes positive (rouge) et négative (noire) m ar quées OUTPUT (Sortie). Les

deux sont entièrement flottantes et l'une ou l' aut re peut être connectée à la masse.

Connexions

La borne désignée

RS232

Connecteur D à 9 broches pour contrôle à distance par ordinateur individuel :

Relier ce connecteur à un PC à l'aide d'un câble dont les broches 2, 3 et 5 sont câblées ent r e les

deux extrémités alors que, côté PC, les broches 1, 4, 6 s ont r eliées ent r e elles, de m êm e que 7 à

8.

Réglage de la sortie

est reliée au châssis et à la terre de protect ion.

Fonctionnement

L’interrupteur POWER (alimentation) sur (l) et la sor tie éteinte, il est possible de régler avec

précision la limite de tension et de courant de sortie au moyen des commandes VO LTAGE

(Tension) et CURRENT (Courant); l’appareil de mesure gauche indiq ue la t ension r églée et

l’appareil droit le courant maximum réglé.

Lorsque le commutateur de sortie

de gauche montre toujours la tens ion prér églée mais le compteur de droite montre maintenant

l'intensité réelle de la charge.

Constant Voltage

Les commandes VOLTAGE de réglage grossier et de précision permettent d’ajuster la tension de

sortie ; la commande de réglage grossier change la tension par pas de 100mV et la commande

de réglage fin par pas de 10mV. La commande CURRENT règle le courant maximum qui peut

être fourni ; la commande chang e l' int ensit é par pas de 10mA.

Tens ion constante

Les commandes VOLTAGE de réglage grossier et de précision permettent d’ajuster la tension de

sortie; la commande CURRENT règle le courant maximum qui peut êt r e fourni.

Courant constant

Si la résistance de charge est suffisamment bass e qu’un courant supérieur au réglage de limite

de courant puisse passer pour la tension de sortie réglée, l’alimentation passera

automatiquement en mode de f onc t ionnem ent de courant constant. La commande CURRENT

ajuste le courant de sortie et les commandes VO LTAGE règ lent la tens ion maximale q ui peut êt r e

engendrée. Le témoin CC s’allume pour indiquer le mode de courant constant .

est mis sous tension, le témoin ON s'allume ; le com pt eur

15

Page 17

Sortie de courant instantanée

Il est possible de régler la commande de limite de courant pour limiter le courant de sortie

continu à des niveaux aussi bas que 10 mA. Toutefois, ainsi que c’est le cas de toutes les

alimentations de précision sur banc, un condensateur est relié aux bornes de la sort ie, afin de

maintenir la stabilité, ainsi qu’une bonne réponse transitoire. Ce condensat eur se c har ge jusqu’à

la tension de sortie, et le court-circuitage de la sor t ie pr oduir a une impulsion de cour ant , lors du

déchargement du condensateur indépendamment du réglage de limite de courant.

Protection

La sortie dispose d’une protection intrinsèque contr e les cour ts-circuits et elle est protégée contre

la tension inverse par une diode; le courant inverse continu ne doit pas dépasser 3 A, bien qu’il

soit possible que l’intensité des transitoires soit nett ement supérieure.

Connexion à la charge

Relier la charge aux bornes de sortie positive (rouge) et nég at ive (noire) . Les deux bornes sont

entièrement flottantes et il est poss ible de relier chacune à la terre.

Connexion en série ou en parallèle avec d’autres sorties

Les sorties de l’alimentation sont entièrement flot tant es et elles peuvent être utilisées en série

avec d’autres blocs d’alimentation, afin de produire des tensions c.c . jusqu’à 300 V c.c.

La tension maximale admissible entre une borne et la terre (

AVERTISSEMENT! Des tensions de ce genre sont extrêmement dangereuses et il faut prendre

toutes les précautions d’usage pour protéger les bornes de sortie en conséquence. Ne jamais

toucher les bornes de sortie lorsque le bloc est allumé pour ces applicat ions. Toutes les

connexions des bornes doivent être effectuées lorsque tous les blocs s ont ét eints.

Il faut noter que le bloc peut uniq uem ent recevoir du courant, mais non le consommer, de sorte

qu’il n’est pas possible de mettre en opposition de phase les blocs reliés en série.

Il est possible de relier le bloc en parallèle avec d’autres, afin de produire des courants de haute

intensité. Lorsque plusieurs blocs sont reliés en parallèle, la tension de sortie doit être égale à

celle du bloc de réglage de tension de sortie le plus élevé, jusqu’à ce que le cour ant consommé

dépasse le réglage de limite de courant, auquel cas la sort ie descend à c elle du réglage le plus

haut suivant, etc. En mode de courant constant, les blocs peuvent êt re reliés en parallèle, afin

de donner un courant égal à la somme des réglages de limite de courant.

Il faut noter que la tension nom inale maximale des bornes de sor tie est de 15 A; si plusieurs

sorties sont utilisées en parallèle avec la source avec des courants plus élevés, effecteur une

jonction à un point séparé, et non à des bornes.

Ventilation

L’alimentation est très perform ante, mais elle peut toutefois générer beaucoup de chaleur à

puissance maximale. L’alimentation a besoin d’un refroidissement par convection uniquement et

il est donc important que la ventilation ne soit jamais réduite, afin d’assurer une bonne

performance et sécurité.

) est de 300 V c.c.

16

Page 18

Broche

Nom

Description

1

DCD

Reliée aux broches 4 et 6

2

TXD

Données transmises à partir de l'instrument

3

RXD

Données reçues à l'instrument

4

DTR

Reliée aux broches 1 et 6

5

GND

Masse du signal

Fonctionnement à distance

Le format des commandes à distance et les com mandes à distance elles-mêmes sont détaillés

dans le chapitre Commandes à distance.

Sélection de la vitesse de transmission

Appuyer sur le bouton OPTION SELECT/OK jusqu'à ce que bAUd apparaisse dans l'affichage

de gauche permet de régler la vitesse de tr ans m ission ; l' affichage de droite montre le réglage

actuel sous la forme

appuyant sur le bouton CHANGE pour faire défiler tout es les opt ions poss ibles pour c e r églage.

Une fois la vitesse voulue affichée, appuyer sur OPTION SELECT/O K de nouveau pour

confirmer et quitt er le m ode de changement de vitesse.

Fonctionnement distant/local

A la mise sous tension, l'instrument est en état local avec le témoin Rem (à distance) éteint.

Lorsqu'une commande est reçue, l' inst r ument entre en état distant et le témoin Rem s'allume.

Les commandes rotatives ne sont pas condamnées par cette action et l'instr ument sera renvoyé

à l'état local si on les utilise ; cependant, si l'instrument r eçoit un aut r e c ar actère de l'interface, il

entrera de nouveau en état distant.

L'utilisation locale des commandes rotatives, du commutateur Marche/Arr êt de s or t ie et du

bouton CHANGE peut être désactivée en appuyant sur le bouton OPTION SELECT /OK jusqu'à

ce que

actuel,

LoCL apparaisse dans l'affichage de gauche ; l'aff ichage de droite montre le réglage

on ou oFF . Des appuis successifs sur le bouton CHANGE sélectionnent on ou

oFF ; lorsque le réglage voulu est affiché, appuyer sur OPTION SELECT/OK de nouveau pour

confirmer et quitt er le m ode de changement.

960 pour 9600 Bauds etc. Modifier la vitesse de transmission en

Le fonctionnement local peut être rétabli à tout m om ent en appuyant sur le bouton OPTION

SELECT/OK ; si

SELECT/OK renvoie l'instrument en c ont r ôle local et les appuis suivants sélectionnent les aut r es

modes, comme décrit ci-dessus.

Connecteur RS232

Le connecteur d'interface sér ie 9 voies type D est situé sur le panneau arrière de l' inst r um ent.

Les brochages sont indiqués ci-dessous :

6 DSR Reliée aux broches 1 et 4

7 RTS Reliée à la broche 8

8 CTS Reliée à la broche 7

9 - Pas de connexion interne

LoCL a été réglé sur oFF le premier appui sur le bouton OPT ION

Connecter à un PC avec un câble comportant les broches 2, 3, 5 câblées plus les broches 1, 4, 6

et les broches 7 et 8, reliées côté PC, voir le schéma.

17

Page 19

Bits de départ : 1

Parité : Aucune

Bits de données : 8

Bits d'arrêt : 1

La vitesse de transmission est réglée comme décr it plus haut ; les autres paramètres de

l'interface sont fixés comm e suit :

Jeu de caractères RS232

N'importe quel code ASCII peut être utilisé. Le bit 7 des codes ASCII est ignoré, c'est à dire

supposé bas. Aucune distinction n'est faite entre les caractères majuscules et m inusc ules dans

les mnémoniques de commandes et ils peuvent être librement m élangés. Les codes de contrôle

ASCII entre 00H et 31H sont ignorés, excepté 0AH (saut de lig ne, LF) qui est utilisé comme fin

de commande.

18

Page 20

<rmt>

<RESPONSE MESSAGE TERMINATOR>, fin de message réponse, CR suivi de LF.

<nr1>

Un nombre sans partie décimale, c’est à dire un entier.

<nr2>

Un nombre dans un format décimal f ixe, par ex. 11,52, 3,61, etc.

erreur est générée.

la sortie, une erreur est générée.

ON

Active la sortie CC.

OFF

Désactive la sortie CC.

V<nr2><rmt>

commande V? sera V 12.55<rmt>.

Commandes à distance

Formats des commandes à distances RS232

Le tampon d'entrée de l'instrument accept e une seule com m ande (ou interrogation) à la fois,

sous interruption, d'une manière trans parente pour les autres opérations de l'instrument. Les

commandes et interrogations doivent êtr e envoyées comme spécifié dans la liste des

commandes et doivent se terminer par le code de fin de comm ande 0AH (s aut de lig ne, LF).

Noter que les paramètres sont séparés de l’entête de com mande par un espace (20H).

Après qu’une commande a été envoyée, le contrôleur doit attendr e au m oins 10m s à partir de la

fin de commande avant de démarrer la comm ande ( ou int er r ogation) suivante, pour permettre à

l’instrument de vider le tampon d’entrée.

Les réponses aux interrogations sont envoyées immédiatement. Le contrôleur doit attendre la

réponse à une interrogation avant d’envoyer la commande ou l’interrogat ion suivante.

L’instrument répond au contrôleur après chaque interrogation comm e spéc ifié dans la liste des

commandes. Dans chaque cas, une réponse se t er m ine par 0DH (ret our chariot, CR) suivie de

0AH (saut de ligne, LF).

L’espace blanc

est ignoré excepté dans les identifiants de commande. Par ex. ' *I DN?' n’est pas équivalent à

'*IDN?'.

Le bit haut de tous les caractères est ig nor é.

Les commandes sont insensibles à la casse (majuscule/minusc ule).

<WHITE SPACE> désigne les codes car act ères 00H à 20H inclus. <WHITE SPACE>

Liste des commandes

Cette section énumère toutes les commandes et int er r ogations mises en œuvre dans cet

instrument. Les commandes sont énum érées dans l’ordre alphabétique au sein des groupes de

fonctions.

La nomenclature suivante est utilisée :

Commandes de configuration

V <nr2> Règle la tension à <nr2>. La valeur de <nr2> doit être en Volts ; aucun multiplicateur

n’est permis. Si la valeur de <nr2>, après arrondi, sor t de la plage de la sortie, une

I <nr2> Règle la limite d’intensité à <nr2>. La valeur de <nr2> doit êt r e en A ; aucun

multiplicateur n’est permis. Si la valeur de <nr2>, apr ès arrondi, sort de la plage de

Commandes de collationnement

V? Renvoie la tension de sortie réglée en Volts sous le format numérique <nr2>. La

syntaxe de la réponse est

Exemple : Si la tension de sortie réglée est de 12,55 Volts, la réponse à la

19

Page 21

I<nr2><rmt>

commande I? sera I 1.00<rmt>.

<nr2>V<rmt>

commande VO? sera V12.55<rmt> .

<nr2>A<rmt>

sera A0.93<rmt>.

ou OUT OFF<rmt>

ou M CC<rmt>

2 = valeur de commande hors des limites de l’instrument.

(1,00V, 1, 00A, s or t ie coupée) .

d’instrument et <version> est le niveau de révision du logiciel installé.

I? Renvoie la limite d’intensité de sortie réglée en A sous le form at numérique <nr2>.

La syntaxe de la réponse est

Exemple : Si la limite d’intensité de s or t ie r églée est de 1,00 A, la réponse à la

VO? Lit et renvoie la tension réelle de sort ie en Volts sous le format numérique <nr 2> .

La syntaxe de la réponse est

Exemple : Si la tension réelle de sor t ie est de 12,55 Volts, la répons e à la

IO? Lit et renvoie l’intensité réelle de sortie en A sous le for mat numérique <nr2>.

La syntaxe de la réponse est

Exemple : Si l’intensité de sor t ie est de 0,93 A, la réponse à la commande IO?

OUT? Renvoie le statut de la sortie comme

OUT ON<rmt>

M? Renvoie le statut du mode de sortie comme

M CV<rmt>

ERR? Renvoie la valeur dans le registre d’erreur sous la forme ERR <nr1>< r m t >

0 = pas d’erreurs.

1 = commande non reconnue.

Commandes diverses

*RST Réinitialise l’instrument aux réglages par défaut à la mise sous t ens ion

*IDN? Renvoie l’identification de l’instrument. La réponse exacte est déter m inée par la

configuration de l’instrument et est de la forme <NAME>,<model>, 0,

<version><rmt> où <NAME> est le nom du fabricant, <model> définit le type

Le Constructeur ou ses agents à l'étranger répareront tout bloc qui tombe en panne. Si le

propriétaire de l'appareil décide d'effectuer lui-même la maintenanc e, c eci doit uniquement être

effectué par un personnel spécialisé qui doit se référ er au m anuel d’entretien que l'on peut se

procurer directement auprès du Constr uc t eur ou de s es agents à l'étranger.

Maintenance

Nettoyage

S'il faut nettoyer le bloc d'alimentat ion, ut iliser un chiffon légèrement imbibé d'eau ou d'un

détergent doux. Nettoyer le cadran d'aff ichage au moyen d'un chiffon sec et doux.

AVERTISSEMENT! EMPECHER TOUTE INTRODUCTION D'EAU DANS LE BOITIER AF IN

D'EVITER TOUT CHOC ELECTRIQUE ET DEGATS AU BLOC D'ALIMENTATION. NE JAMAIS

UTILISER DE DISSOLVANTS POUR NETTOYER LE BLOC, AFIN D'EVITER

D'ENDOMMAGER LE BOITIER OU LE CADRAN D’AFFICHAGE.

20

Page 22

l

Sicherheit

Dieses Gerät wurde nach der Sicherheitsklasse (Schutzart) I der IEC-Klassifikation und g em äß

den europäischen Vorschriften EN61010-1 (Sicherheitsvorschriften für elektrische Meß-, Steuer,

Regel- und Laboranlagen) entwickelt. Es handelt sich um ein G er ät der Installationskategorie II,

das für den Betrieb von einer normalen einphasigen Versorgung vorgesehen ist.

Das Gerät wurde gemäß den Vorschriften EN61010-1 geprüft und wurde in sicherem Zustand

geliefert. Die vorliegende Anleitung enthält vom Benutzer zu beachtende Informationen und

Warnungen, die den sicheren Betrieb und den sicheren Zustand des G er ätes gewährleisten.

Dieses Gerät ist für den Betrieb in Innenr äumen der Umgebungsklass 2 , für einen

Temperaturbereich von 5° C bis 40° C und 20 −80 % relative Feuchtigkeit (nicht kondensierend)

vorgesehen. Gelegentlich kann es Temperaturen zwischen +5° und −10°C ausgesetzt sein, ohne

daß seine Sicherheit dadurch beeinträchtigt wird. Betreiben Sie das Gerät jedoch auf keinen Fall,

solange Kondensation vorhanden ist.

Ein Einsatz dieses Geräts in einer Weise, die für diese Anlage nicht vorgesehen ist, kann die

vorgesehene Sicherheit beeinträchtigen. Auf keinen Fall das Gerät außerhalb der angegebenen

Nennversorgungsspannungen oder Umgebungs beding ungen betreiben.

WARNUNG! - DIESES GERÄT MUSS GEERDET WERDEN!

Jede Unterbrechung des Netzschutzleiters innerhalb oder außerhalb des Ger äts m acht das

Gerät gefährlich. Eine absichtliche Unterbrechung ist verboten. Die Schutzwirkung darf durc h

Verwendung eines Verlängerungskabels ohne Schutzleiter nicht aufgehoben werden.

Ist das Gerät an die elektrische Versorgung angeschlossen, so können die Klemmen unter

Spannung stehen, was bedeutet, daß beim Entfernen von Verkleidungs- oder sonstigen Teilen

(mit Ausnahme der Teile, zu denen Zugang mit der Hand möglich ist) höchstwahrscheinlich

spannungsführende Teile bloßgelegt weden. Vor jeglichem Öffnen des Geräts zu Nachstell-,

Auswechsel-, Wartungs- oder Reparatur zwecken, G er ät s t ets von sämt lichen Spannungsquellen

abklemmen. Kondensatoren in der Stromversorgung können auc h noch nach Abschalten

sämtlicher Stromversorgung Spannung führen, sie entladen sich jedoch innerhalb von etwa 10

Minuten nach Spannungsabschaltung.

Jegliche Nachstellung, Wartung und Reparatur am geöffneten, unter Spannung stehenden

Gerät, ist nach Möglichkeit zu vermeiden. Falls unvermeidlich, sollten solche Arbeiten nur von

qualifiziertem Personal ausgeführ t werden, das sich der Gefahren bewußt ist.

Ist das Gerät eindeutig fehlerbehaftet, bzw. wurde es mechanisch beschädigt, übermäßig er

Feuchtigkeit oder chemischer Korr os ion ausgesetzt, so können die Schutzeinrichtungen

beeinträchtigt sein, weshalb das Gerät aus dem Verkehr zurückgezogen und zur Überprüfung

und Reparatur eingesandt werden sollte.

Sicherstellen, daß nur Sicherungen der vorgeschriebenen Stromstärke und des vorg es ehenen

Typs als Ersatz verwendet werden. Provisorische “Sicherungen” und der Kurzschluß von

Sicherungshaltern ist verboten.

Beim Reinigen darauf achten, daß das Gerät nicht naß wird.

Am Gerät werden folgende Symbole verwendet:

Erdungsklemme

Netz ON (ein)

21

Netz OFF (aus)

Gleichstrom

Wechselstrom

Page 23

Installation

Netzbetriebsspannung

Sicherstellen, daß die auf der Geräterüc kwand angegebene Betriebsspannung mit der

Versorgungsspannung am Ort übereinstimmt. Falls es erforderlich ist, die Betriebsspannung zu

ändern, wie folgt vorgehen:

1. Sicherstellen, daß das Gerät vom Wechselstromnet z g et r ennt ist.

2. Schrauben entfernen, mit denen die obere Gehäusehälfte und der Handgriff befestigt sind

und obere Gehäusehälfte abheben.

3. Transfor m atoranschlüsse entsprechend dem nachstehenden Diagramm ändern.

230 V-Betrieb 115 V-Betrieb

BLAU BRAUN BLAU BRAUN

4. G er ät in um gekehrter Reihenfolge wieder zusammenbauen.

5. Die Sicherheitsvorschriften werden nur dann erfüllt, wenn auch die Angabe der

Betriebsspannung auf der Geräter ückwand geändert wird, so daß die neue

Spannungseinstellung deutlich angezeigt ist.

Sicherung

Die Wechselst r omsicherung befindet sich im schubladenförm ig en Sicher ungshalter im unteren

Teil der des IEC Steckanschlusses. Zum Auswechseln der Sicherung, Netzkabel entfernen und

Sicherungshalter mit geeignet em Werkzeug öffnen.

Vorgeschriebene Sicherungsart: 20 x 5 mm 250 V träg e Hochleist ungssicherung für folgende

Stromstärken:

230 V Betrieb : 1,6 A (T)

115 V Betrieb: 3,15 A (T)

Stellen Sie sicher, daß beim Auswechseln der Sicherungen nur Sicherungen der er forderlichen

Stromstärke und der angegebenen Art verwendet werden. Die Verwendung von

Behelfssicherungen und das Kurzschließen von Sicherungshaltern ist unzulässig.

Netzkabel

Steht nur ein Netzkabel ohne St ec ker zur Verfügung, so ist es wie folgt anzuschließen:

BRAUN - STROMFÜHRENDER LEITER

BLAU - NULLEITER

GRÜN/GELB - SCHUTZLEITER Schutzleitersymbol

22

Bei Steckern mit eingebauten Sicherungen sollte eine 5 Ampere-Sicherung verwendet werden.

Da die Farben der Netzkabeladern nicht unbedingt mit den Farbmarkierungen der Klemmen

Ihres Steckers übereinstimmen, ist wie folgt vorzugehen:

Die grün/gelbfarbene Ader ist an die mit E oder mit dem oben abgebildeten Schutzleitersymbol

markierte oder grün bzw. Grün-gelbfarbene Steckerklemme anzuschließen.

Die blaue Ader ist an die mit N markierte oder schwarzfar bene Klemm e anzuschließen.

Die braune Ader ist an die mit L m ar kierte oder rotfarbene Klemme anzuschließen.

WARNUNG! DIESES GERÄT MUSS GEERDET WERDEN!

Jede Unterbrechung des Netzschutzleiters innerhalb oder außerhalb des Ger äts m acht das

Gerät gefährlich. Eine absichtliche Unterbrechung ist verboten.

Page 24

Stift

Bezeichnung

Beschreibung

1

DCD

Mit Stift 4 und 6 verbunden

2

TXD

Vom Gerät übertragene Daten

3

RXD

Vom Gerät empfangene Daten

4

DTR

Mit Stift 1 und 6 verbunden

5

GND

Betriebserde

6

DSR

Mit Stift 1 und 4 verbunden

7

RTS

Mit Stift 8 verbunden

8

CTS

Mit Stift 7 verbunden

9

–

Keine interne Verbindung

Ausgangsklemmen

Alle Anschlüsse werden auf der Vorderseite hergestellt.

Der Verbraucher sollte an die mit AUSGANG (OUTPUT) markierte positive (rot) und negative

(schwarz) markierte Klemme angeschlossen werden. Beide sind g alvanisch get r ennt und

können beliebig geerdet werden.

Anschlüsse

RS232

Die mit dem Symbol

verbunden.

9-poliger Steckverbinder (Typ D) für die PC-Fernsteuerung mit folgender Stiftbelegung:

Anschluss an einen PC mit einem Kabel, bei dem die Stifte 2, 3 und 5 verdrahtet und die Stifte 1,

4 und 6 und die Stifte 7 und 8 am PC-Ende angeschlossen sind.

gekennzeichnete Klemme ist mit dem Chassis und der Schutzerde

Einstellung des Ausgangs

Bei eingeschaltetem POWER-Schalter (Netz I) und ausgeschaltetem Ausgang

Ausgangsspannung und Strombegrenzung mit Hilfe der Knöpfe VO LTAGE (Spannung) und

CURRENT (Strom) genau voreinstellen. Die linke Anzeige zeigt die eingestellte Spannung und

die rechte den eingestellten Maximalstrom an.

Bei eingeschaltetem Ausgang

die voreingestellte Spannung an, während die rechte Anzeige nun den tatsächlich abgegebenen

Strom darstellt.

Konstantspannung

Die Ausgangsspannung wird mit den Grob- und Feinreglern (VOLTAGE) eingestellt. Dabei

beträgt die Schrittgr öße für den Grobregler 100 mV und für den Feinr egler 10 mV. Der

Stromregler (CURRENT) regelt den maximal zur Verfügung stehenden Strom in Schritten von 10

mA.

Konstantstrom

Ist der Belastungswiderstand ausreichend niedrig, daß bei der eing estellten Ausgangsspannung

ein Strom fließen würde, der größer wäre als die eingestellte Strombegrenzung, so schaltet die

Stromversorgung automatisch auf konstanten Strombetrieb. Der Stromausgang wird mit dem

Knopf CURRENT eingestellt und die maximal generierbare Spannung mit dem Knopf VOLTAGE.

Die CC-Leuchte leuchtet bei eingeschaltetem Konstantstr om m odus auf.

Betrieb

läßt sich die

leuchtet die ON Lampe auf. Die linke Anzeige zeigt weiterhin

23

Page 25

Augenblickstromausgang

Mit der Strombegrenzung kann der kontinuierliche Ausgangsstrom bis auf 10 mA begrenzt

werden. Wie bei allen Präzisions-Stromversorgungs-Tischgeräten ist der Ausgang zur

Aufrechterhaltung der Stabilität und zwecks gutem Einschwingverhalten mit einem Kondensator

versehen. Der Kondensator wird bis zur Höhe der Ausgangsspannung aufgeladen. Ein

Kurzschließen des Ausgangs bewirkt beim Entladen des Kondensators einen Stromimpuls, der

von der Strombegrenzungseinstellung unabhängig erfolgt.

Schutzvorrichtungen

Der Ausgang ist mit einem eigenen Kurzschlußschutz versehen und mittels Diode vor

Umkehrspannungen geschützt. Kontinuierlicher Um kehrstrom darf 3 Amp nicht überschreiten.

Transiente Ströme können jedoch wesentlich höher liegen.

Verbraucheranschluß

Der Verbraucher ist an die positive (rote) und negative (schwarze) Ausgangsklemme

anzuschließen. Bei beiden Ansc hlüssen handelt es sich um vollkom m en potentialfreie, die jeweils

geerdet werden können.

Reihen- und Parallelschaltung mit anderen Ausgängen

Da der Ausgang des Netzteils vollständig potentialfrei ist, kann er mit anderen Netzgeräten zur

Erzeugung hoher Gleichspannungen bis maximal 300V in Reihe geschaltet werden.

Die maximal zulässige Spannung zwischen einer beliebigen Klemme und Erde (

V Gleichspannung.

WARNUNG! Spannungen in dieser Größenordnung sind überaus gef ährlich. Bei einer solchen

Einsatzweise sollten die Ausg angsklemmen mit größter Sor gfalt abgeschirmt werden. Unter

diesen Bedingungen dürfen die Ausgangsklemmen keinesfalls berühr t werden, wenn das Gerät

eingeschaltet ist. Wann immer Verbindungen mit den Klemmen hergest ellt werden, m üss en

sämtliche Geräte ausgeschaltet sein.

Zu beachten ist dabei, daß das Gerät ausschließlich stromliefernd, nicht aber stromziehend

arbeiten kann, und daß die Geräte daher nicht gegenphasig in Reihe geschaltet werden können.

Das Gerät kann zur Erzeugung einer höheren Stromabgabe mit anderen G er ät en parallel zu

diesen geschaltet werden. Wenn mehr er e G er äte parallel geschaltet werden, entspricht die

Ausgangsspannung der Ausgangsspannung des Geräts, bei dem der Einstellwert für die

Ausgangsspannung am höchsten ist, bis die Stromaufnahme den bei diesem Gerät eingestellten

Grenzwert überschreitet, woraufhin der Ausgang auf die zweilhöchste Einstellung abfällt, und so

weiter. Im Konstantstrombetrieb können Geräte parallel geschaltet werden, wodurch sich eine

Stromabgabe erreichen läßt, die der Summe der Einstellwerte für die Strombegrenzung

entspricht.

Zu beachten ist, daß die Ausgangsklemmen für maximal 15 A vorgesehen sind. Werden mehrere

Ausgänge parallel betrieben, um höhere Ströme als diesen zu liefern, so sollte die Verbindung an

einer getrennten Stelle vorgenommen werden, nicht an einer der Klemmen.

Ventilation

Obwohl die Stromversorgung äußerst effizient arbeitet kann sie bei voller Leistung ein

beträchtliches Maß an Wärm e er zeug en. Die Kühlung der Stromversorgung erfolgt

ausschließlich durch Konvektion, weshalb es wichtig ist, daß die Ventilation niemals

eingeschränkt wird, wenn Leistung und Sicherheit auf r echt erhalten werden sollen.

) beträgt 300

24

Page 26

1

DCD

Mit Pin 4 und 6 verbunden

2

TXD

Vom Gerät übertragene Daten

4

DTR

Mit Pin 1 und 6 verbunden

5

GND

Betriebserde

6

DSR

Mit Pin 1 und 4 verbunden

7

RTS

Mit Pin 8 verbunden

8

CTS

Mit Pin 7 verbunden

Format und Inhalt der Fernbedienungsbefehle sind im Kapitel “Fernbedienungsbefehle”

aufgeführt.

Wahl der Baudrate

Die Einstellung der Baudrate erfolgt dur c h Drüc ken der Taste OPTION SELECT/OK bis bAUd

auf der linken Anzeige erscheint. Die rechte Anzeige zeigt nun die aktuelle Einstellung an, z. B

960 bei einer Baudrate von 9600 Baud usw. Die Baudrate kann durch wiederholtes Drücken

der Taste CHANGE geändert werden. Sobald die gewünschte Rate im Display erscheint, die

Taste OPTI O N SELECT/ OK erneut drücken, um den Vorgang zu bestätigen und den

Einstellmodus zu verlassen.

Fern-/Lokalbetrieb

Nach dem Einschalten befindet sich das Gerät im Lokalbetrieb, die REM (Remote) Anzeige

leuchtet nicht auf. Wird ein Befehl empfangen schaltet das Gerät auf Fernbedienung und die

REM Anzeige leuchtet auf. Die Drehregler sind weiter funktionsfähig, jedoch schaltet das Gerät

bei deren Bedienung wieder auf Lokalbetrieb. Bei Erhalt eines weiteren Befehls über die

Schnittstelle schaltet das Gerät dann erneut auf Fernbetrieb.

Der Lokalbetrieb für die Drehreg ler, den Ein/Aus-Schalter für den Ausgang und die Taste

CHANGE kann durch Drücken der Tast e O PTION SELECT/OK deaktiviert werden. Wenn

auf der linken Anzeige erscheint, zeigt die rechte Anzeige den aktuellen Status in Form von

oFF an. Durch wiederholtes Drücken auf die Taste CHANGE k ann zwischen on und oFF

oder

umgeschaltet werden. Sobald die gewünschte Einstellung im Display erscheint, die Tast e

OPTION SELECT/OK erneut drüc ken um den Vorgang zu bestätigen und den Einstellmodus zu

verlassen.

Fernbedienung

LoCL

on

Der Lokalbetrieb kann durch Drück en der Taste OPTION SELECT/OK jeder zeit wieder

hergestellt werden. Wurde

der Taste OPTION SELECT/O K wieder auf Lokalbetrieb zurück. Durch erneutes Drücken dieser

Taste können dann wieder die anderen Betriebsarten angewählt werden (siehe oben).

RS232 Anschlu ss

Der 9-polige Steckverbinder (Typ D) für die serielle Schnittstelle befindet sich auf der

Geräterückseite. Stiftbelegung:

Pin Bez. Beschreibung

3 RXD Vom Gerät empfangene Daten

9 - Keine Verbindung

LoCL auf oFF gestellt, so kehrt das Gerät beim ersten Drücken

Zum Anschluss an einen PC werden lediglich die Stifte 2, 3 und 5 benötigt. Die Stifte 1, 4, 6

sowie 7 und 8 müssen am PC-seitigen Steckverbinder verbunden sein (siehe Zeichnung).

25

Page 27

Startbits: 1

Parität: Keine

Datenbits: 8

Stopbits: 1

Die Baudrate wird wie bereits beschrieben eingestellt. Die übrigen Parameter sind wie folgt

festgelegt:

RS232 Zeichensatz

Es kann jeder beliebige ASCII-Code gesendet werden. ASCII-Bit 7 bleibt unberücksichtigt, bzw.

es wird angenommen, dass es 0 ist. Zwischen Groß- und Kleinbuchstaben in Befehlskürzeln wird

nicht unterschieden, sie können also beliebig benutzt werden. ASCII Steuerzeichen zwischen

00H und 31H werden ignoriert, mit Ausnahme von 0AH (Line Feed, LF) das als Befehlsabschlusszeichen dient.

26

Page 28

<rmt>

<RESPONSE MESSAGE TERMINATOR>, CR gefolgt von LF.

<nr1>

Eine Nummer ohne Bruchteil, d.h. eine Ganzzahl.

<nr2>

Eine Nummer mit Festkomma, z. B. 11.52, 3.61, usw.

V <nr2>

Spannung auf <nr2> setzen. Der Wert für < nr 2> muss in Volt angegeben werden,

außerhalb des gültigen Bereichs wird eine Fehlermeldung erzeugt.

(nach Rundung) außerhalb des gültigen Bereichs wird eine Fehlermeldung er zeug t .

ON

DC Ausgang Ein.

OFF

DC Ausgang Aus.

V<nr2><rmt>

auf den Befehl V? V 12.55<rmt> .

Fernbedienungsbefehle

RS232 Format der Fernbedienungsbe fehle

Der Eingabepuffer des Geräts akzeptiert jeweils einen einzelnen Befehl (bzw. Abfrage). Dies

erfolgt unter Verwendung eines Interrupts, quasi im Hintergr und und unabhängig zu allen

anderen Gerätefunkt ionen. Befehle und Abfragen müssen entsprechend der Befehlsliste

gesendet und mit dem Befehlsschlusszeichen „0AH“ (Line Feed, LF) abgeschlossen werden. Die

Parameter müssen durch ein Leerzeichen (20H) vom eigentlichen Befehl getrennt werden.

Nach Senden des Befehls muss der Controller ab Erhalt des Schlusszeichens mindestens 10 m S

mit dem nächsten Befehl (bzw. Abfrage) warten, damit das Gerät den Eingabepuffer löschen

kann.

Antworten auf Abfragen werden sofort gesandt. Der Controller muss auf die Antwort auf eine

Abfrage warten bevor der nächste Bef ehl (bzw. Abfrage) gesandt wird. Das Gerät antwortet nach

jeder Abfrage entsprechend der Befehlsliste. Jede Antwort wird mit dem Zeichen 0DH (Carriage

Return, CR) und anschließendem 0AH (Line Feed, LF) abgeschlossen.

<WHITE SPACE> wird mit den Zeichen 00H bis 20H (einschließlich) definiert . <WHITE SPACE> bleibt

unberücksichtigt, ausg enom men bei Befehlskennzeichen. So entspricht z. B. '*I DN?' nicht

'*IDN?'.

Das hochwertige Bit der gesendeten Zeichen bleibt immer unberücksichtigt.

Bei den Befehlen brauchen Groß- und Kleinbuchstaben nicht beachtet zu werden.

Befehlsliste

In diesem Abschnitt sind sämtliche Befehle und Abfragen aufgeführt, die in diesem Gerät

implementiert sind. Innerhalb ihrer Funk t ionsgruppen sind die Befehle alphabetisch geordnet.

Folgende Nomenklatur wurde verwendet:

Setup Befehle

I <nr2> Strombegrenzung auf <nr2> set zen. Der Wert für <nr2> m uss in Ampere

Multiplikatoren sind nicht erlaubt. Liegt der Wert von <nr2> (nach Rundung)

angegeben werden, Multiplikatoren sind nicht erlaubt. Lieg t der Wert von <nr2>

Rückmeldungsbefehle

V? Rückmeldung der gesetzten Ausgangsspannung in <nr2> Volt (numerisches

Format). Die Antwort ist

Beispiel: Wurde die Ausgangsspannung auf 12,55 Volt gesetzt so lautet die Antwort

27

Page 29

I<nr2><rmt>

Antwort auf den Befehl I? I 1.00<r mt>.

<nr2>V<rmt>

Antwort auf den Befehl VO? V12.55<rmt>.

<nr2>A<rmt>

Befehl IO? A0.93<rmt>.

oder OUT OFF<rmt>

oder M CC<rmt>

2 = Befehlswert liegt außerhalb des gültigen Ber eichs.

(1,00 V, 1, 00 A, Ausgang aus).

Revisionsnummer der installierten Software bezeichnet.

I? Rückmeldung der Ausgangsstrombegrenzung in <nr2> Ampere (numerisches

Format). Die Antwort ist

Beispiel: Wurde die Strombegrenzung auf 1,00 Ampere gesetzt, so lautet die

VO? Rückmeldung der tatsächlichen Ausgangsspannung in <nr2> Volt (numerisches

Format). Die Antwort ist

Beispiel: Beträgt die tatsächliche Ausgangsspannung 12,55 Volt, so lautet die

IO? Rückmeldung des tatsächlichen Ausgangsstroms in <nr2> Ampere (numerisches

Format). Die Antwort ist

Beispiel: Beträgt der Ausgangsstrom 0,93 Ampere, so lautet die Antwort auf den

OUT? Rückmeldung des Status für den Ausgang mit:

OUT ON<rmt>

M? Rückm eldung der Betriebsart für den Ausgang mit:

ERR? Rückmeldung des Werts im Fehler r egister im Format ERR <nr1><rmt>

Diverse Befehle

*RST Setzt das Gerät auf die Standardeinstellung beim Einschalten zurück

*IDN? Rückmeldung der Gerätebezeichnung. Die g enaue Antwort hängt von der

Die Hersteller bzw. der en Vertretungen im Ausland bieten die Reparatur von Geräten an, bei

denen eine Störung aufgetreten ist. W enn der Eig ent üm er die Wartungsarbeiten selbst

durchführen möchte, hat er dafür Sorge zu tragen, daß diese Arbeiten ausschließlich von

entsprechend qualifiziertem Personal und gemäß Wartungshandbuch ausgeführt werden, das

direkt von den Herstellern oder deren Vertretungen im Ausland bezogen werden kann.

Reinigung

M CV<rmt>

0 = keine Fehler.

1 = Befehl nicht erkannt.

Gerätekonfigur ation ab und hat das Format <NAME>,<model>, 0, <version><rmt > ,

wobei <NAME> den Herstellernamen, <model> den Gerätetyp und <version> die

Wartung

Falls die Stromversorgung der Reinigung bedarf, einen mit W ass er oder einem m ilden Deter gens

angefeuchteten Lappen benutzen. Anzeigefenster mit einem weichen, trockenen Lappen

polieren.

WARNUNG! ZUR VERMEIDUNG EINES ELEKTRISCHEN SCHLAGS BZW. BESCHÄDIGUNG DER

STROMVERSORGUNGSEINHEIT, DAFÜR SORGEN, DASS KEIN WASSER INS GEHÄUSE EINDRINGT.

UM SCHADEN AM GEHÄUSE BZW. AM ANZEIGEFENSTER ZU VERMEIDEN, KEINE

LÖSUNGSMITTEL ZUR REINIGUNG VERWENDEN!

28

Page 30

l

Sicurezza

Questo strumento appartiene alla Categoria di Sicurezza 1, secondo la classif ica I EC, ed è s tato

progettato in modo da soddisfare i crit er i EN61010-1 (requisiti di Sicurezza per Apparecchiature

di misura, controllo e per uso in laboratorio). È uno st r um ento di Categoria d’installazione II ed è

inteso per il funzionamento con un’alimentazione normale monofase.

Questo strumento ha superato le pr ove previste da EN61010-1 e viene fornito in uno stato di

sicurezza normale. Questo manuale contiene informazioni e avvertenze che devono essere

seguite per assicurare un funzionamento sicur o e m antenere lo strumento in condizioni di

sicurezza.

Questo strumento è prog et tat o per uso all’interno e in un am bient e d’inq uinamento Grado 2,

entro la gamma di temperatur a da 5° C a 40C°, con um idità relativa (non condensante) di

20% - 80%. Può occasionalmente essere assoggettato a temperature fr a + 5° C e -10°C senza

comprometterne la sicurezza. Non usare in presenza di condensazione.

L’uso dello strumento in maniera non conforme a quanto specificato in queste istruzioni potrebbe

pregiudicare la protezione di cui è dotato. Non usare lo strumento per m isur are tensioni al di

sopra dei valori nominali o in condizioni ambientali al di fuori di quelle specificate.

ATTENZIONE: QUESTO STRUMENTO DEVE ESSERE COLLEGATO A TERRA

Una qualsiasi interruzione sia interna che esterna del collegamento a ter ra rende pericoloso

questo strumento. È proibito int er rompere questo collegamento deliberatamente. L’azione

protettiva non deve essere negata dall’uso di una prolunga priva conduttore di prot ezione.

Quando lo strumento è collegato all’alimentazione, alcuni morsetti sono sotto tensione e

l’apertura dei coperchi o la rimozione di parti (eccetto quei componenti accessibili senza l’uso di

attrezzi) può lasciare scoperti i morsetti sott o t ensione. Pr ima di apr irla per eseguire regolazioni,

manutenzione o riparazioni, l’apparecchiatura deve essere staccata da tutte le sorgenti di

tensione. I condensatori collegati all’alimentazione interna possono essere carichi anche dopo

aver staccato l’alimentazione ma si scaricano in circa 10 minuti dopo aver staccato la corrente.

Per quanto possibile, si consiglia di evitare qualsiasi operazione di regolazione e riparazione

quando lo strumento è sotto tens ione e, qualora fosse inevitabile, dette operazioni devono

essere eseguite da una persona specializzata in materia, che sia pienamente conscia del

pericolo presente.

Quando sia chiaro che lo strumento è difettoso, o che ha subito un danno meccanico, un

eccesso di umidità, o corrosione a mezzo di agenti chimici, la sicurezza potrebbe essere stata

compromessa e lo strumento deve essere ritir at o dall’uso e rim andat o indietro per le prove e le

riparazioni del caso.

Assicurarsi di usare solo fusibili della portata giusta e del tipo corretto durant e eventuali

sostituzioni. Sono proibiti sia l’uso di fusibili improvvisati che il corto circuito deliberat o dei

portafusibili.

Evitare di bagnare lo strumento quando lo si pulisce.

Sullo strumento e in questo manuale si fa uso dei seguenti simboli.

Terminale di terra

Corrente Continua

alimentazione ON (accesa)

29

alimentazione OFF (spenta)

Corrente Alternata

Page 31

1.

Controllare che lo strumento sia scollegato dall'alimentazione a c.a.

2.

Togliere le viti che fissano il coperchio superior e e la maniglia e sollevare il coperchio superiore.

3.

Modificare le connessioni del trasformatore riferendosi al diagramma seguente:

4.

Riassemblare invertendo la procedura di smontaggio.

essere opportunamente modificata per m ostrare chiaramente la nuova impostazione di tensione.

Installazione

Tensione d’esercizio

Controllare che la tensione d’esercizio dello strumento segnata sul pannello posteriore sia uguale

a quella della rete elettrica locale. Se dovesse rendersi necessario cambiare la t ensione

d'esercizio, osservare il seguente procedimento:

Funzionamento a 230V Funzionamento a 115V

BLU MARRONE BLU MARRONE

5. Per soddisfare le norme di antinfor t unist ica, la t ens ione segnata sul pannello posteriore deve

Fusibile

Il fusibile c.a. è situato nel portafusibili nella parte infer ior e del connet t or e d'ingresso IEC. Per

sostituire il fusibile, rimuovere il cavo di linea ed aprire il portafusibili con uno strumento adat t o.

Il tipo di fusibile corretto è: 20 x 5mm 250V HBC con dispositivo di regolazione del tempo e con

le seguenti portate nominali:

per esercizio alla tensione di 230 V: 1,6 A (T)

per esercizio alla tensione di 115V: 3,15 A (T)

Accertarsi che per la sostituzione vengano utilizzati esclusivamente fusibili con la corrente

nominale richiesta e del tipo specificato. Sono vietati l'uso di fusibili di ripiego e la

cortocircuitazione dei portafusibili.

Cavo d’alimentazione

Quando viene fornito un cavo a tre fili con le estremità nude, collegare come segue:

MARRONE LINEA

BLU NEUTRO

VERDE/GIALLO TERRA Simbolo di sicurezza - TERRA.

Quando si collega una spina dotata di portafusibile, in essa bisogna inserire un fusibile da 5A. Se

il colore dei fili del cavo non corrisponde ai contrassegni colorati dei contatt i della spina,

procedere come segue:

Il filo verde e giallo deve essere collegato al morsetto della spina contr ass egnato con la lettera E

oppure con il simbolo di sicurezza che rappresenta la terra, o di colore verde o verde/giallo.

Il filo blu deve essere collegato al morsetto cont r ass egnato con la lettera N o di colore nero.

Il filo marrone deve essere collegato al morsetto contrassegnato con la lettera L o di colore

rosso.

ATTENZIONE! QUESTO STRUMENTO DEVE ESSERE COLLEGATO A TERRA

Una qualsiasi interruzione sia interna che esterna del collegamento a ter r a r ende pericoloso

questo strumento. È proibito int er rompere questo collegamento deliberatamente.

30

Page 32

Pin

Nome

Descrizione

1

DCD

Collegato ai pin 4 e 6

2

TXD

Dati trasmessi dallo strumento

3

RXD

Dati ricevuti allo strumento

4

DTR

Collegato ai pin 1 e 6

5

GND

Segnale terra

6

DSR

Collegato ai pin 1 e 4

7

RTS

Collegato al pin 8

8

CTS

Collegato al pin 7

9

–

Nessun collegamento interno

Morsetti di uscita

Tutti i collegamenti elettrici si realizzano dal quadro anteriore.

Il carico va collegato ai morsetti positivo (rosso) e neg ativo (nero) contrassegnati OUTPUT

(uscita). Entrambe le uscite sono a tensione variabile e possono essere collegate a terra.

Collegamenti

Il morsetto segnato

RS232

Connettore D a 9 pin per controllo remoto da PC con i seguenti colleg am enti:

Collegare ad un PC con un cavo che ha i pin 2, 3 e 5 collegati più i pin 1, 4 e 6 e i pin 7 e 8

collegati al lato del PC.

Impostazione dell’uscita

è collegato allo chassis e al terminale di sicurezza di terra.

Funzionamento