Page 1

THURLBY THANDAR INSTRUMENTS

BS407

PRECISION MILLI/MICRO OHMMETER

INSTRUCTION MANUAL

Page 2

Table of Contents

Introduction 2

Specification 3

EMC 5

Safety 6

Installation 7

Connections 8

Front Panel Controls 9

Operation 10

Maintenance 13

Instructions en Francais

Sécurité 14

Installation 15

Connexions 16

Commandes du panneau frontal 17

Fonctionnement 18

Maintenance 22

Bedienungsanleitung auf Deutsch

Sicherheit 23

Installation 24

Anschlüsse 25

Frontplatten-Bedienungseinrichtungen 26

Betrieb 27

Reparatur 31

Istruzioni in Italiano

Sicurezza 32

Installazione 33

Collegamenti 34

Controlli sul pannello frontale 35

Operazione 36

Manutenzione 39

Instrucciones en Español

Seguridad 40

Instalación 41

Conexiones 42

Controles del panel frontal 43

Funcionamiento 44

Mantenimiento 48

1

Page 3

Introduction

The BS407 is fully optimised for accurate measurement of low resistances with a best resolution

of 1µΩ. It has applications beyond the testing of components such as measuring the resistance of

motor or transformer windings, the properties of materials, the thickness of plates, the security of

pipework joints or wiring installations and many others.

It uses a Direct Current technique to measure true resistance, rather than the resistive

component of impedance which is shown by AC excited RLC bridges. The test current for each

range has been carefully chosen to minimise heating of the sample under test while being

sufficient to minimise the effects of thermal emf and noise. This gives much greater accuracy at

low resistances than can be obtained from the very low test currents used by general purpose

high resolution multimeters. The low-noise low-drift bipolar amplifiers employed need much less

noise filtering than alternative chopper stabilised technologies resulting in faster settling to the

correct reading.

The BS407 uses a four terminal measurement system and is supplied with a set of high quality

Kelvin clip leads. For speed and convenience front panel switches are provided for current

diversion (allowing in-situ zero adjustment) and current reversal (for identifying thermal emf

effects). An indicator lamp confirms correct flow of the measuring current thus preventing

spurious results from being recorded.

The BS407 has eight push-button selected decade measurement ranges from 1999µΩ up to

19.99kΩ. A front panel operated ‘clamp’ switch is available to limit the maximum voltage across

the unknown to 20mV. This is a requirement for the measurement of switch contact resistances to

international standards. With a lowest range of 1999µΩ the BS407 can resolve 1µΩ. Precision

analogue circuitry ensures high measurement accuracy of up to 0.1% of reading ±1 digit.

The BS407 is a fully portable instrument which operates from NiMH rechargeable batteries.

Stabilised internal operating conditions ensure that readings do not vary with the state of the

battery charge. The battery charger is built into the instrument and can be operated while

measurements continue.

2

Page 4

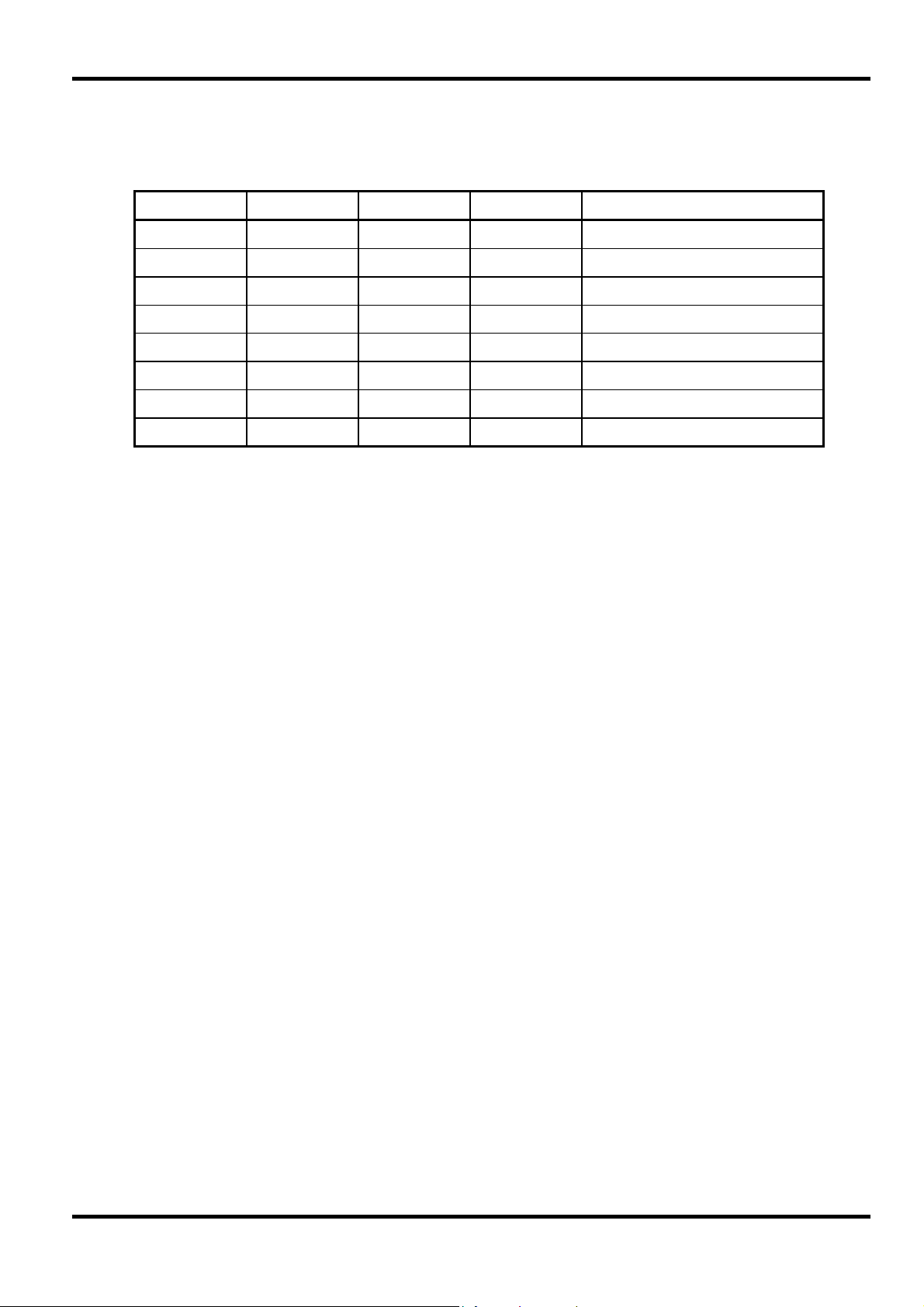

Ranges and Accuracy

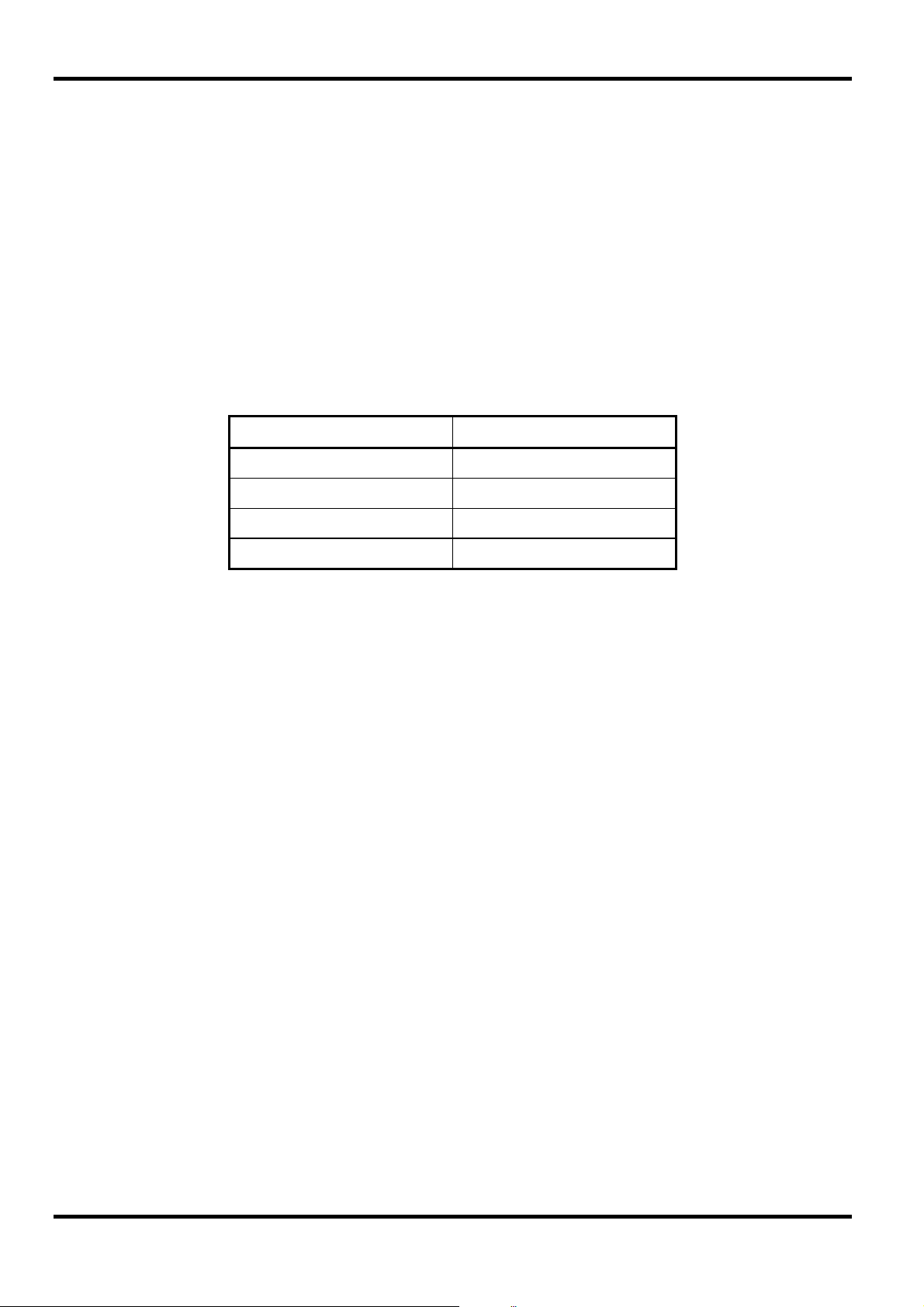

The 3½ digit display has a 1999 count full scale. Eight ranges are provided:

Range Resolution Test Current F.S. voltage Accuracy

Specification

Accuracies apply for a calibration interval of 1 year at 23º ±5ºC after 5 minutes warm-up, with the

instrument and test connections in thermal equilibrium and the zero correctly set.

Temperature coefficient outside the stated range is < ±45 ppm/ºC.

Facilities

Set zero by front panel control with switch to divert test current from unknown.

Test current polarity reversal for thermal emf detection.

Front panel lamp indicates correct force circuit measurement conditions.

20mV source emf clamp to limit open circuit voltage across the unknown to 20mV maximum for

"dry circuit" testing of switch and relay contacts. (Not available on 2kΩ and 20kΩ ranges.)

1999 µΩ 1 µΩ

19.99 mΩ 10 µΩ

199.9 mΩ 100 µΩ

1999 mΩ 1 mΩ

19.99 Ω 10 mΩ

199.9 Ω 100 mΩ

1999 Ω 1 Ω

19.99 kΩ 10 Ω

250 mA 500 µV 0.1% reading + 0.4% range

50 mA 1 mV 0.1% reading + 0.2% range

10 mA 2 mV 0.1% reading + 0.1% range

5 mA 10 mV 0.1% reading + 0.1% range

500 µA 10 mV 0.1% reading + 0.1% range

50 µA 10 mV 0.1% reading + 0.1% range

10 µA 100 mV 0.1% reading + 0.1% range

10 µA 200 mV 0.1% reading + 0.2% range

Built-in battery charger allows instrument operation while re-charging.

Measurement circuit

Source emf: 18 mV (±2mV) with clamp active, < 6 V otherwise.

Compliance:

Protection: The meter is protected against the back-emf of its own test current from any

General

Battery: 4 internal non-removable Ni-MH cells. Low battery indication in display.

Operating time: Typically > 150 hours with no test current flowing, > 8 hours continuous

Power: 110V–120V or 220V–240V AC (internal setting) ±10%, 50/60 Hz, 20VA max.

Recharge time: Nominally 12 hours with instrument not in use.

Operating Range: Indoor use +5ºC to +40ºC, 20% to 80% RH, up to 2000m, Pollution Degree 1.

Storage Range:

Safety and EMC: Complies with EN61010–1 (safety) and EN61326 (EMC).

Size and Weight: 220 mm (w) x 102 mm (h) x 235 mm (d), 1.5 kg.

> 0.5 V on 1999µΩ range, > 1.0 V on all other ranges.

inductance and against accidental short-term connection to external voltage

sources up to 50 V.

measurement on lowest range.

−40ºC to +50ºC.

Accessories: Supplied with Kelvin clip leads.

3

Page 5

EC Declaration of Conformity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

BS407 Micro/milli Ohmmeter

meets the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Communities.

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class B

b) EN61326-1 (2006) Conducted, Class B

c) EN61326-1 (2006) Harmonics, referring to EN61000-3-2 (2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring to:

a) EN61000-4-2 (1995) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2007) Conducted RF

Performance levels achieved are detailed in the user manual.

Safety

EN61010-1 Installation Category II, Pollution Degree 2.

4

CHRIS WILDING

TECHNICAL DIRECTOR

2 May 2009

Page 6

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of the following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Harmonics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test methods, limits and performance achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (1995) Electrostatic Discharge : 4kV air, 4kV contact, Performance A (B).

EMC

b) EN61000-4-3 (2006) Electromagnetic Field:

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance B

Performance A (A); 1V/m, 2.0GHz to 2.7GHz: Performance A (A).

†

Note: The BS407 is a sensitive measuring instrument and, if subjected to sufficiently

large RF fields, measurements may deviate beyond the accuracy specification at certain

frequencies up to 600MHz. However, possible deviations will be small and are not

deemed to be a problem in practice.

c) EN61000-4-11 (2004) Voltage Interrupt: ½ cycle and 1 cycle, 0%: Performance A (B);

25 cycles, 70%: Performance A (C); 250 cycles, 0%: Performance A (C).

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line), 0·5kV peak (signal connections),

Performance A (B).

e) EN61000-4-5 (2006) Surge, 0·5kV (line to line), 1kV (line to ground), Performance A (B).

f) EN61000-4-6 (2007) Conducted RF, 3V, 80% AM at 1kHz (AC line only; signal

connections <3m, therefore not tested), Performance A (A).

According to EN61326 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During test, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During test, temporary degradation, or loss of function or

performance which requires operator intervention or system reset occurs.’

†

(A) and 1.4GHz to 2GHz:

Cautions

To ensure continued compliance with the EMC directive the following precautions should be

observed:

a) After opening the case for any reason ensure that all signal and ground connections are

remade correctly before replacing the cover. Always ensure all case screws are correctly

refitted and tightened.

b) In the event of part replacement becoming necessary, only use components of an identical

type, see the Service Manual.

5

Page 7

Safety

This instrument is Safety Class I according to IEC classification and has been designed to meet

the requirements of EN61010−1 (Safety Requirements for Electrical Equipment for Measurement,

Control and Laboratory Use). It is an Installation Category II instrument intended for operation

from a normal single phase supply.

This instrument has been tested in accordance with EN61010−1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to retain the instrument in a safe condition.

This instrument has been designed for indoor use in a Pollution Degree 2 environment in the

temperature range 5°C to 40°C, 20% −80% RH (non−condensing). It may occasionally be

subjected to temperatures between +5° and −10°C without degradation of its safety. Do not

operate while condensation is present.

Use of this instrument in a manner not specified by these instructions may impair the safety

protection provided. Do not operate the instrument outside its rated supply voltages or

environmental range.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

When the instrument is connected to its supply, terminals may be live and opening the covers or

removal of parts (except those to which access can be gained by hand) is likely to expose live

parts. The apparatus shall be disconnected from all voltage sources before it is opened for any

adjustment, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of

the hazard involved.

If the instrument is clearly defective, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protection may be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

The instrument contains both non-resetting and self-resetting thermal fuses which are not

replaceable by the user. The short-circuiting of these protective devices is prohibited.

The instrument contains Nickel Metal Hydride batteries. Do not open, puncture, incinerate or

short circuit these cells. These batteries must be disposed of in accordance with local regulations

and should be removed from the instrument before its final disposal.

Do not wet the instrument when cleaning it.

The following symbols are used on the instrument and in this manual:−

Caution −refer to the accompanying documentation,

incorrect operation may damage the instrument.

6

alternating current.

Page 8

Mains Operating Voltage

The operating voltage of the instrument is shown on the rear panel. Should it be necessary to

change the operating voltage from 230V to 115V or vice-versa, proceed as follows:

1. Disconnect the instrument from all voltage sources.

2. Remove the screws which hold the case upper to the case lower and lift off.

3. Disconnect the 3 way cable from the power supply PCB, remove the six screws and lift

the PCB from the case. The Power Supply PCB has an insulator attached to its underside

to ensure that the batteries are not accidentally short circuited. The centre pin of the

retaining rivets can be carefully pushed out allowing them to be re-used. Replace the

insulator immediately after servicing is complete.

4. Fit the soldered links for the required operating voltage: For 230V fit only LK2

For 115V fit LK1 and LK3 and not LK2

These links may be either tinned copper wire or zero-ohm resistors.

5. Refit the power supply PCB to the case lower and reconnect the 3 way cable.

Installation

6. Refit the case upper taking care not to overtighten the screws.

7. To comply with safety standard requirements the operating voltage marked on the rear

Fuses

There are no user replaceable fuses in the instrument.

Mains Lead

When a three core mains lead with bare ends is provided it should be connected as follows:

Any interruption of the mains earth conductor inside or outside the instrument will make the

instrument dangerous. Intentional interruption is prohibited.

panel must be changed to clearly show the new voltage setting.

Brown - Mains live

Blue - Mains Neutral

Green/Yellow - Earth

WARNING! THIS INSTRUMENT MUST BE EARTHED

7

Page 9

Input Terminals

Connections are provided on the front panel for standard 4-terminal resistance measurements.

The test current flows between the terminals marked FORCE + and – and the voltage across the

unknown resistance is measured between the terminals marked SENSE + and –. To obtain

correct readings the entire measurement circuit should be connected only to the resistance being

measured.

The instrument is supplied with a Kelvin lead set consisting of two special crocodile clips

connected to four 4mm plugs. The upper and lower jaws of each crocodile clip are not electrically

connected: the grey jaws are used as the force terminals and the coloured jaws (red and black)

as the sense terminals. The grey jaws are connected to the plugs which have a grey collar.

Connect these leads to the instrument as follows:

Connections

Plug Connection

All red Sense +

Red with grey collar Force +

The instrument can be used with any other 4 terminal connection arrangement as required by the

physical size of the resistance being measured.

The measurement circuit is not grounded (even when the battery is charging) but for the safety of

the operator the connections should be within ±30 volts from earth. It is permissible for the circuit

to be externally connected to earth at one point only.

The maximum voltage emitted from the instrument is 6V DC.

Protection

When measuring the resistance of large iron-cored inductors the test current builds a magnetic

field within the core. When this current is removed a back-emf is generated as the field collapses.

Take care when disconnecting the test leads from inductors not to touch the terminals as the

back-emf can give a noticeable electric shock. It is better to depress the Set Zero switch and

allow the instrument to absorb the stored energy before disconnecting the inductor.

Protection circuits within the instrument ensure that it will not be damaged by the back-emf of its

own test current from any inductance.

It is not intended that any external voltage be applied to the input terminals. However, there are

circuits designed to protect the instrument against brief accidental connections. In the case of

more severe misuse fusible resistors protect the internal circuits. These resistors are not

replaceable by the user.

All black Sense –

Black with grey collar Force –

8

Page 10

Front Panel Controls

The following paragraphs give a brief description of the controls. Fuller details of the operation of

the instrument are given in later sections.

Operate

The Operate switch connects the measurement circuits to the battery; it does not control the

battery charger which operates whenever the unit is connected to the supply mains.

Set Zero

Depressing the Set Zero switch diverts the test current away from the Force terminals so there is

no voltage drop across the resistance being measured. The reading can then be set to zero

taking account of the effect of external thermal emfs.

20mV Clamp

Depressing the 20mV Clamp switch limits the open circuit voltage of the force terminals to 20mV.

This is used when measuring the contact resistance of switches or relays as this low voltage does

not break down oxide films.

Polarity

Depressing the Polarity switch reverses the direction of the test current through the unknown. If

there are no thermal emfs in the measurement circuit the two readings should be the same (apart

from the minus sign). If a thermal emf is present it will add to one reading and subtract from the

other; the true resistance value is obtained by taking the numerical average.

Range switches

The legend above the range switches shows the display units (µΩ, mΩ, Ω or kΩ). The nominal

measurement current is shown below the switches for reference.

Charge lamp (red)

The Charge lamp will light while the unit is connected to the mains supply which causes the

battery to be charged. The unit should be disconnected from the supply when the battery is fully

charged.

Force On lamp (green)

The Force On lamp lights when the test current is flowing correctly. If the 20mV clamp is in use

the lamp will only light when the external voltage drop is less than the clamp threshold.

Display

The 3½ digit display shows the measurement result. It should only be taken as valid when the

Force On lamp is lit and the BAT indicator is off. When the resistance is too large for the range

selected (or the sense leads are open circuit) the overscale indication consists of a 1 and three

blank digits. A negative sign will show when reverse polarity readings are being taken. The zero

setting is signed; the display will alternate between –000 and +000 at true zero.

The signal BAT in the lower left corner of the display shows when the battery is nearly

discharged. At this point readings are still accurate, but there is no further indication when the

battery voltage falls to the point that errors arise; therefore when the BAT indication is displayed

the charger should be connected to the supply.

9

Page 11

Switching On

Switch on the instrument using the Operate switch on the front panel. If there are no digits shown

in the display then the batteries may be completely discharged. Connect the unit to the supply

mains; the Charge lamp should light to show that charging is taking place. If display operation

does not resume after a few minutes charging time the unit may be faulty; switch off, disconnect

from the supply and seek service.

Battery Charging

When the unit is connected to the supply mains the red Charge lamp will be illuminated and the

battery will be charging. Resistance measurements may continue while charging with some small

reduction in accuracy because of the temperature rise within the unit. Charging normally takes

about 12 hours but if the 2000µΩ range is used the 250mA test current considerably reduces the

charging current and it will take longer to fully charge the battery. A taper charge characteristic is

employed to quickly raise the charge level of a completely discharged battery and reduce the

current once fully charged; nevertheless, the unit should not be left on continuous float charge as

this will reduce battery life.

The Ni-MH cells used do not suffer from any memory effect and are not harmed by either

complete discharge or partial re-charge.

While the unit is not in use the batteries will self-discharge. This effect is greatly increased at

higher temperatures. If the unit has been stored for so long that the batteries have become

completely discharged it may require two or three charge–discharge cycles for full capacity to be

restored.

The batteries are not replaceable by the user. If the capacity becomes noticeably low then the

unit should be sent to a qualified service facility for the batteries to be replaced. The cells must be

handled and disposed of in accordance with local safety and environmental requirements.

Operation

Principles of Operation

This instrument measures resistance using the ratiometric method: a test current is passed

through both a precise internal reference resistance and the unknown resistance. The magnitude

of the test current is chosen according to the range selected; it is a compromise between

sensitivity to noise and thermal emfs and minimising self-heating of the unknown. The voltages

developed across the two resistances are compared using a ratiometric Analogue to Digital

converter which calculates the result for the display.

The accuracy of this method depends on the accuracy of the reference resistors and on sensing

the exact voltage drop across the unknown, not on the magnitude of the test current. The two

main sources of error are voltage drops in the connections and thermal emfs.

The problem of voltage drops is overcome by the 4 terminal connection. The current flows in the

force leads and the instrument can tolerate any voltage drop in these leads up to its compliance

limit. There is no voltage drop in the sense leads because of the very high input impedance of the

voltage measuring circuit in the unit. The resistance is measured between the physical points

where the sense leads connect to the unknown.

An emf is produced at any junction between dissimilar metals. The magnitude of this emf

depends on the materials and the temperature. In any closed circuit which starts and ends on the

same metal (as in the sockets of the instrument) there will be a equal number of junctions

between dissimilar metals. If all the pairs of junctions are at the same temperature then the net

emf around the circuit is zero, but if there are temperature differences then the sum of the emfs is

not zero - this difference is the thermal emf of the circuit. It is often of the order of a few tens of

microvolts which is sufficient to influence the reading on low resistance ranges.

10

The instrument cannot distinguish between this emf and the voltage drop across the test sample

caused by the measuring current. However if the direction of the test current is reversed then the

thermal emf will add to one reading and subtract from the other; the true resistance can be

calculated as the average of the two readings. This is the purpose of the Polarity switch.

Page 12

The most effective way to remove thermal emfs is by removing the temperature differences; take

care when connecting samples not to hold the connections points in the fingers - do not touch

plug contacts when connecting the leads. Wait until thermal equilibrium is established - it can take

many minutes for the effect of even the most brief contact with the fingers to dissipate.

The effect of thermal emfs could also be eliminated by the use of an AC measurement technique

but this results in measuring the resistive component of impedance (including the effect of any

core losses etc.) rather than the true resistance value obtained by the DC method used in this

instrument.

Setting Zero

To set the zero reading it is necessary that the force current is flowing (so the reference

resistance is experiencing normal conditions) and that there is no voltage between the sense

terminals. The ZERO ADJUST control can then be set for a reading of zero to compensate for the

internal offset voltages of the instrument.

The most direct way to do this is to use one cable to connect FORCE + to FORCE – and a

second cable to join SENSE + to SENSE –, select the range required and use the ZERO

ADJUST control to obtain a reading of zero. Note that this reading is signed: the exact zero is at

the point where the minus sign in the display appears on alternate readings. These cables are

then removed and the test sample connected as required. This method zeros the internal offsets

within the instrument.

The zero adjustment can also be used to remove the effect of small external thermal emfs from

the measurement. Connect the test cables to the unknown ready to take a measurement and

select the required range. Depress the Set Zero button and set the reading to zero. Release the

Set Zero button and allow the reading to settle at the resistance value. This is the most

convenient method in normal use.

Note that the zero cannot be set with the sense terminals open circuit.

Connecting the Unknown Resistance

The Kelvin clips supplied with the instrument make the force and sense connections on opposite

sides of the conductor. This suits wire-ended components and long thin objects.

When measuring low resistance physically large samples, separate wires and clips may be

needed for the two sets of connections which must be made in a way that reflects the required

measurement. The sense terminals should be connected to the sample at the exact points

between which the resistance is to be measured; the force terminals should be connected to the

sample outside the sense terminals. They should be sufficiently far from the sense connections to

allow for the region where the current spreads out across the cross-section of the sample.

When measuring components the test connections should match the application connections as

closely as possible; when measuring the properties of material samples, consistency of

connection is the most important thing. This may require the construction of a suitable jig.

The green Force On lamp lights when the test current flowing through the unknown produces a

voltage drop within the compliance specification of the instrument. A valid reading can then be

obtained provided that the sense connections are properly made (if they are not then the display

will normally show the overrange indication). Note that when measuring very large inductances

(such as high voltage transformers) there may be a delay before the lamp lights as it takes some

time for the test current to rise to the full value (the rate of rise of the current depends on the

inductance and the source emf of the instrument). Similarly it takes time for the current to reverse

when the Polarity selection is switched.

It is very important when attaching connections to avoid touching any metallic part of the circuit,

because the heat conducted from the fingers will generate thermal emfs that take a significant

time to decay.

11

Page 13

Taking the Reading

After setting zero, release the Set Zero switch and allow the reading to settle at the resistance

value. Note this reading and depress the Polarity switch; ideally (if there are no external thermal

emfs) this reading will be the same as the first. If it is not, take the numerical average of the two

(ignore the sign); this value is the true resistance. Note that if the sample is not in thermal

equilibrium the reading will be changing because of both thermal emfs and the temperature

coefficient of the unknown.

It is possible to check the results by depressing the Set Zero button, noting the zero reading and

then computing the two differences between this value and the reading of each polarity (taking

the signs into account). These two values should agree within a digit; if they do not, then the

thermal emfs are changing too rapidly for a reliable measurement to be made.

Contact Resistance Measurements

The contacts of relays, switches etc. are often covered by oxides or corrosion products. If the

voltage in the circuit being switched is not high enough to break down this insulating film the

contact resistance measured will be much higher than that measured in a high power conditions.

In order to obtain a reading that reflects the operation of the component in these “dry circuit”

conditions it is necessary to ensure that the test equipment does not subject the sample to a high

open circuit voltage. International standards define the “dry circuit” measurement voltage as being

not more than 20mV.

This instrument contains a suitable clamp circuit activated by the front panel 20mV Clamp push

button. This places an internal electronic shunt across the force terminals and controls the

resistance of this circuit to maintain a voltage of 18mV (±2mV) between these terminals. When

the contact being measured closes, its resistance must be sufficiently low for the voltage drop

across it (at the measuring current of the range selected) to be less than the clamp voltage. The

internal shunt then switches off, the green Force On lamp lights and the correct resistance

reading is displayed.

Note that battery drain is higher when the clamp is engaged as the measurement current is

always flowing, either through the internal clamp or the external contact.

The 20mV clamp facility does not operate with the 2kΩ or 20kΩ ranges as the maximum

measurement voltage on these ranges is greater than 20mV.

Applications

To measure the temperature rise of the windings of a transformer or motor first measure the

resistance with the item cold. Then disconnect the meter and operate the device for the required

period of time. Disconnect all supplies and re-connect the meter and measure the winding

resistance in the hot condition. Knowing the temperature coefficient of the winding material these

two resistance readings can be used to calculate the temperature change.

Measurement Notes

If the reading drifts continuously this may indicate either a change in a thermal emf caused by a

change in temperature or a real change in the resistance of the item being measured. If the

sample is physically small this may be caused by the heating effect of the test current. Using a

higher range reduces the test current but also reduces the measurement resolution.

Random fluctuations in the reading of more than a digit may indicate poor connections to the

sample under test, particularly the sense leads. It can also be caused by magnetic fields

intersecting the test circuit; move the leads to keep them close together and away from any

transformers or motors.

If the three readings (zero, normal and reverse polarity) do not correlate then either there is a

poor connection, or a thermal emf is changing rapidly or the actual value being measured is

changing rapidly.

12

Semiconductor junctions will appear open circuit in both directions because the measurement

voltage of this instrument is too small to cause any noticeable conduction.

Page 14

The Manufacturers or their agents overseas will provide a repair service for any unit developing a

fault. Where owners wish to undertake their own maintenance work, this should only be done by

skilled personnel in conjunction with the service manual which may be purchased directly from

the Manufacturers or their agents overseas.

Cleaning

If the instrument requires cleaning use a cloth that is only lightly dampened with water or a mild

detergent.

WARNING! TO AVOID ELECTRIC SHOCK, OR DAMAGE TO THE INSTRUMENT, NEVER

ALLOW WATER TO GET INSIDE THE CASE. TO AVOID DAMAGE TO THE CASE NEVER

CLEAN WITH SOLVENTS.

Calibration

To ensure that the accuracy of the instrument remains within specification the calibration must be

checked (and if necessary adjusted) annually. This requires access to accurately known standard

resistors; the instrument is adjusted to obtain the correct readings from these resistors. This

instrument has independent calibration for each range.

Maintenance

Fuses

The transformer primary is protected by a non-resetting thermal fuse inside the windings. It can

only be replaced by fitting a new transformer.

The battery charge and discharge circuits are protected by self-resetting devices. If it is

suspected that one of these has tripped, disconnect the unit from the mains supply, switch it off

and wait ten minutes. It is likely that any such tripping indicates an internal fault and the unit

should be serviced by a competent repair facility.

13

Page 15

Sécurité

Cet instrument est de classe de sécurité 1 conforme à la classification IEC et il a été conçu pour

satisfaire aux exigences de la norme EN61010-1 (Exigences de sécurité pour les équipements

électriques de mesure, de contrôle et d'utilisation en laboratoire). Il s'agit d'un instrument de

Catégorie II d'installation devant être exploité depuis une alimentation monophasée standard.

Cet instrument a été testé conformément à la norme EN61010-1 et il a été fourni en tout état de

sécurité. Ce manuel d'instructions contient des informations et des avertissements qui doivent

être suivis par l'utilisateur afin d'assurer un fonctionnement et un état en toute sécurité.

Cet instrument a été conçu pour être utilisé en intérieur, en environnement de pollution de

deuxième degré (Pollution degree 2) à des plages de températures de 5°C à 40°C, et à des taux

d'humidité compris entre 20% et 80% (sans condensation). Il peut être soumis de temps à autre à

des températures comprises entre +5°C et –10°C sans dégradation de sa sécurité. Ne pas

l'utiliser en conditions de condensation.

Toute utilisation de cet instrument de manière non spécifiée par ces instructions risque d'affecter

sa protection de sécurité. Ne pas utiliser l'instrument hors des plages de tension d'alimentation

nominale recommandées ni hors de ses tolérances d'environnement.

AVERTISSEMENT ! CET INSTRUMENT DOIT ETRE RELIE A LA TERRE

Toute interruption du conducteur de la terre du secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Il est absolument interdit de priver intentionnellement l'instrument

de son branchement à la terre. La sécurité de l'instrument ne doit pas être annulée par l'utilisation

de rallonge sans conducteur de protection.

Lorsque l'instrument est relié au secteur, il est possible que les bornes soient sous tension :

l'ouverture des couvercles ou la dépose de pièces (à l'exception des pièces accessibles

manuellement) risque de mettre à découvert des pièces sous tension. L'instrument doit être

débranché du secteur et de toute source d'alimentationavant tout réglage, remplacement, travaux

d'entretien ou de réparations.

Eviter dans la mesure du possible d'effectuer des réglages, travaux de réparations ou d'entretien

lorsque l'instrument ouvert est branché au secteur. Si cela s'avère toutefois indispensable, seul

un technicien compétent connaissant les risques encourus doit effectuer ce genre de travaux.

S'il est évident que l'instrument est défectueux, qu'il a été soumis à des dégâts mécaniques, à

une humidité excessive ou à une corrosion chimique, la protection de sécurité est affaiblie :

l'instrument doit être retiré de l'exploitation et renvoyé vérifications et de réparations.

Cet instrument contient à la fois des fusibles thermiques non rajustables et auto-réglables ne

pouvant faire l'objet d'un remplacement par l'utilisateur. Il est strictement interdit de court-circuiter

ces fusibles de protection.

Cet instrument contient des piles au nickel-hydrure de métal. Ne pas ouvrir, percer, incinérer ni

court-circuiter ces piles. Ces piles doivent être jetées conformément aux lois et règlements locaux

en vigueur et doivent être retirées de l'instrument avant d'en disposer.

Ne jamais humidifier l'instrument lors du nettoyage.

Les symboles suivants se trouvent sur l'instrument, ainsi que dans ce manuel.

14

ATTENTION - se référer à la documentation ci-jointe; toute utilisation

incorrecte risque d'endommager l'appareil.

Courant alternatif (c.a.)

Page 16

Tension de fonctionnement secteur

La tension de fonctionnement de l'instrument est indiquée à l'arrière. S'il est nécessaire de la

modifier de 230V à 115V ou vice-versa, procéder comme suit :

1. Débrancher l'instrument de toutes les sources d'alimentation.

2. Retirer les vis qui maintiennent le couvercle supérieur et soulever ce couvercle.

3. Débrancher le câble trois voies de la carte à circuits imprimés d'alimentation, retirer les 6

vis et soulever la carte du boîtier. La carte d'alimentation porte un isolateur sur sa face

inférieure pour éviter tout court-circuit accidentel de la batterie. La goupille centrale des

rivets de fixation peut être soigneusement poussée vers l’extérieur pour réutiliser les

rivets. Remettre l’isolateur en place immédiatement après la révision.

4. Établir les connexions selon la tension appropriée: 230V: LK2 uniquement

115V: LK1 et LK3 et non LK2

Il peut s'agir de fil de cuivre étamé ou de résistances zéro ohm.

5. Rebrancher la carte d'alimentation dans le boîtier et rebrancher le câble trois voies.

Installation

6. Remettre le couvercle en place en prenant soin de ne pas trop serrer les vis.

7. Pour satisfaire aux exigences en matière de sécurité, la tension de fonctionnement

indiquée à l'arrière de l'instrument doit être modifiée pour indiquer la nouvelle tension

opérationnelle.

Fusibles

Cet instrument ne contient aucun fusible remplaçable par l'utilisateur.

Cordon d'alimentation

Lorsqu'un cordon d'alimentation de rallonge à trois conducteurs est fourni, il doit être utilisé

comme suit :

Marron - Tension secteur

Bleu - Neutre

Vert/Jaune - Terre

AVERTISSEMENT ! CET INSTRUMENT DOIT ÊTRE RELIÉ À LA TERRE

Toute interruption du conducteur de terre secteur à l'intérieur ou à l'extérieur de l'instrument

rendra l'instrument dangereux. Toute interruption intentionnelle est absolument interdite.

15

Page 17

Bornes d'entrée

Le panneau frontal permet de brancher les appareils de mesure standard à 4 bornes. Le courant

de test circule entre les bornes FORCE + (force +) et - et la tension sur la résistance inconnue est

mesurée entre les bornes SENSE + (détection +) et -. Pour obtenir les valeurs correctes, le circuit

de mesure tout entier ne doit être branché qu'à la résistance mesurée.

Cet instrument est fourni avec un jeu de câbles Kelvin consistant en deux prises crocodile

spéciales, branchées à quatre prises de 4 mm. Les mâchoires supérieure et inférieure de chaque

prise crocodile ne sont pas connectées mécaniquement : les mâchoires grises servent de bornes

de forces et les mâchoires de couleur (rouge et noire) servent de bornes de détection. Les

mâchoires grises se branchent aux prises à col gris.

Branchez les câbles à l'instrument comme suit :

Connexions

Prise Branchement

Toute rouge Sense +

Rouge à col gris Force +

Cet instrument peut être utilisé avec n'importe quelle combinaison à 4 bornes, requise par la taille

physique de la résistance mesurée.

Le circuit de mesure n'est pas relié à la terre (même lorsque la batterie se recharge) mais, pour la

sécurité de l'utilisateur, les connexions devraient se trouver à ±30 volts de la terre. Il est permis

de relier le circuit à la terre par voie externe et en un point uniquement.

La tension maximale émise par l'instrument est de 6V CC.

Protection

Lorsque vous mesurez la résistance de gros inducteurs à noyau de fer, le courant de test établit

un champ magnétique dans le noyau. Une fois ce courant supprimé, une force électromotrice en

retour est générée par la chute du champ magnétique. Nous conseillons la prudence aux

utilisateurs lorsqu'ils débranchent les câbles des inducteurs : ne pas toucher les bornes - la f.é.m.

peut donner un choc électrique notable. Il est préférable d'appuyer sur le bouton Set Zero (remise

à zéro) et permettre à l'instrument d'absorber l'énergie emmagasinée, avant de débrancher

l'inducteur.

Les circuits de protection intégrés à l'instrument préviennent tout dommage éventuel pouvant être

causé par le retour de f.é.m. de son propre courant de test.

Toute noire Sense –

Noire à col gris Force –

16

Il n'est pas prévu d'appliquer quelque tension externe que ce soit aux bornes en entrée.

L'instrument contient, toutefois, des circuits conçus pour le protéger des branchements

accidentels de courte durée. Dans l'éventualité d'une utilisation erronée plus grave, des

résistances à fusible protègent les circuits internes. Ces résistances ne peuvent être remplacées

par l'utilisateur.

Page 18

Commandes du panneau frontal

Les paragraphes qui suivent décrivent brièvement les commandes de l'instrument. Les sections

qui suivent donnent une description plus détaillée du fonctionnement de l'instrument.

Operate

Le bouton Operate (fonctionnement) connecte les circuits de mesure de la batterie ; il ne

commande pas le chargeur de la batterie, qui fonctionne dès que l'unité est branchée au secteur.

Set Zero

Le fait d'appuyer sur le bouton Set Zero (remise à zéro) dérive le courant de test des bornes

Force pour qu'aucune chute de tension ne se produise sur la résistance en cours de test. La

lecture peut alors être remise à zéro en prenant en compte l'effet des f.é.m. thermiques externes.

20mV Clamp

Le fait d'appuyer sur le bouton 20mV Clamp (limiteur 20 mV ) limite la tension du circuit ouvert

sur les bornes Force à 20 mV. Cette fonctionnalité est particulièrement utile lorsque l'on mesure

la résistance de contact des commutateurs ou des relais : cette basse tension ne décompose pas

les couches d'oxyde.

Polarity

Le fait d'appuyer sur le bouton Polarity (Polarité) inverse le sens du courant de test dans la

résistance inconnue. Si le circuit de mesure ne présente aucune f.é.m. les deux valeurs devraient

être identiques (à part le signe moins). Si une f.é.m. thermique est présente, elle vient s'ajouter à

l'une des valeurs et se soustrait de l'autre ; pour obtenir la véritable valeur de la résistance,

calculer la moyenne numérique.

Boutons de plages

Les légendes au-dessus des boutons de plages indiquent les unités d'affichage (µΩ, mΩ, Ω ou

kΩ). L'intensité du courant nominal de mesure est indiquée sous les boutons pour référence.

Voyant Charge (rouge)

Le voyant Charge (chargement) s'allume lorsque l'instrument est relié au secteur : la batterie se

recharge. L'instrument doit être débranché du secteur une fois la batterie rechargée.

Voyant Force On (vert)

Le voyant Force On (force appliquée) s'allume lorsque le courant de test circule correctement. Si

le limiteur de 20 mV est utilisé, le voyant ne s'allume que lorsque la chute de tension externe est

inférieure au seuil du limiteur.

Affichage

L'écran de 3 pouces ½ affiche le résultat de la mesure. Il ne peut être considéré comme valable

que lorsque le voyant Force On est allumé et que le voyant de batterie (BAT à l'écran) est éteint.

Lorsque la résistance est trop importante pour la plage sélectionnée (ou dans le cas d'un circuit

ouvert) l'écran affiche un 1 suivi de trois blancs. Un signe négatif s'affiche lorsque les mesures de

polarité inverse sont effectuées. Le réglage du zéro est signé ; l'écran alterne entre –000 et +000

au zéro véritable.

L'écran affiche le mot BAT dans l'angle inférieur gauche lorsque la batterie est pratiquement

déchargée. L'affichage est toujours exact, mais il faut savoir que les erreurs surviennent lorsque

la tension de la batterie tombe sous un certain niveau, et l'utilisateur ne reçoit aucune indication

de ce niveau ; par conséquent, dès que les lettres BAT s'affichent, le chargeur doit être branché

au secteur.

17

Page 19

Mise en marche

Allumez l'instrument à l'aide du bouton Operate à l'avant. Si aucun chiffre ne s'affiche, cela

signifie probablement que la batterie est totalement déchargée. Branchez l'instrument au

secteur ; le voyant Charge devrait s'allumer, indiquant ainsi que le chargement a lieu. Si

l'affichage ne se rétablit pas au bout de quelques minutes de chargement, l'instrument a

probablement un défaut ; éteignez-le, débranchez-le du secteur et contactez le service de

réparation.

Chargement de la batterie

Lorsque l'instrument est branché au secteur, le voyant rouge Charge s'allume et la batterie se

recharge. L'utilisateur peut poursuivre les mesures de résistance pendant le chargement, en

sachant qu'une petite baisse de précision intervient du fait de la température en hausse de

l'instrument. Le chargement prend normalement 12 heures, mais si la plage 2000 µΩ est utilisée,

le courant de test de 250 mA réduit considérablement le courant et la batterie peut mettre

beaucoup plus longtemps à se recharger. Une fonction de charge à tension constante est utilisée

pour faire monter rapidement le niveau d'une batterie totalement déchargée et réduire le courant

une fois le chargement complet, mais l'instrument ne doit pas rester en chargement permanent,

car cela réduit la durée de vie de la batterie.

Les piles Ni-MH utilisées ne souffrent d'aucun effet de mémoire et ne peuvent être

endommagées par un chargement total ni un chargement partiel.

Fonctionnement

Lorsque l'instrument n'est pas utilisé, la batterie s'autodécharge. Cet effet s'accroît

considérablement à hautes températures. Si l'instrument a été rangé pendant un certain temps et

que la batterie est totalement déchargée, deux ou trois cycles de chargement complets sont

nécessaires pour que l'instrument retrouve sa pleine capacité.

La batterie ne peut être remplacée par l'utilisateur. Si l'utilisateur constate que la capacité devient

faible, l'instrument doit être envoyé à un site qualifié de maintenance et capable de remplacer la

batterie. Les piles doivent être manipulées et jetées conformément aux lois sur la sécurité et

l'environnement en vigueur.

Principes de fonctionnement

Cet instrument mesure la résistance à l'aide de la méthode logométrique : un courant de test

circule à la fois dans une résistance de référence interne précise et dans la résistance inconnue.

L'intensité du courant de test est choisie en fonction de la plage sélectionnée ; il s'agit d'un

compromis entre la sensibilité au bruit et aux f.é.m. thermiques et la réduction maximale de

l'autochauffe de la résistance inconnue. Les tensions sur les deux résistances sont comparées à

l'aide d'un convertisseur logométrique analogique à numérique, qui calcule le résultat et le

transmet à l'affichage.

L'exactitude de cette méthode dépend de la précision des résistances de référence et de la

détection de la chute exacte de tension sur l'inconnue, et non de l'intensité du courant de test.

Les deux sources principales d'erreur sont les chutes de tension dans les connexions et les

f.é.m. thermiques.

Le problème des chutes de potentiel est résolu par la connexion à quatre bornes. Le courant

circule dans les câbles de force et l'instrument peut tolérer n'importe quelle chute de potentiel

dans ces câbles, jusqu'à sa limite. Aucune chute de tension ne se produit dans les câbles de

détection du fait de la très haute impédance du circuit de mesure de la tension dans l'unité. La

résistance est mesurée entre les points physiques où les câbles de détection se connectent à

l'inconnue.

18

Une force électromagnétique se produit à toute connexion entre métaux différents. L'intensité de

cette f.é.m. dépend des matériaux utilisés et de la température. Dans un circuit fermé

commençant et se terminant par un métal identique (comme dans les prises de l'instrument) le

nombre de jonctions entre métaux différents est égal. Si toutes les paires sont à la même

température, la f.é.m. autour du circuit est égale à zéro, mais si des différences de températures

sont observées, la somme des forces n'est pas zéro : la différence constitue la f.é.m. du circuit.

Page 20

La force est souvent de l'ordre des dixièmes de microvolts, ce qui suffit pour influencer la lecture

sur les plages de faible résistance.

L'instrument n'est pas capable de distinguer entre cette f.é.m. et la chute de tension sur

l'échantillon de test, causée par le courant de mesure. Si, toutefois, la direction du courant de test

est inversée, la f.é.m. s'ajoute à une valeur et se soustrait de l'autre ; la valeur véritable de la

résistance se calcule alors en établissant la moyenne entre les deux valeurs affichées. C'est le

but du bouton Polarity.

La manière la plus efficace de supprimer les f.é.m. thermiques consiste à supprimer les

différences de température ; nous conseillons à l'utilisateur de faire attention lorsqu'il branche les

échantillons : ne pas tenir les points de connexion avec les doigts - ne jamais toucher les

contacts de branchement lorsque les câbles sont branchés. Attendre que l'équilibre thermique

soit établi - l'effet du moindre contact avec les doigts peut prendre de longues minutes pour

s'effacer.

L'effet des f.é.m. thermiques peut également être éliminé par l'utilisation d'une technique de

mesure CA, mais ceci revient à mesurer le composant résistif de l'impédance (y compris l'effet

sur les pertes du noyau, etc) plutôt que la vraie valeur de résistance obtenue par la méthode CC

utilisée par cet instrument.

Définition du zéro

Pour définir l'affichage zéro, le courant de force doit circuler (pour que la résistance de référence

se trouve en conditions normales) et aucune tension ne doit être présente entre les bornes de

détection. La commande ZERO ADJUST (réglage du zéro) peut alors être réglée pour lire le zéro

et compenser les déséquilibres internes de tension de l'instrument.

La manière la plus directe de ce faire consiste à utiliser un câble pour relier la borne FORCE + à

la borne FORCE – et un second câble pour relier les bornes SENSE + et SENSE – ; sélectionner

la plage désirée et utiliser la commande ZERO ADJUST pour obtenir un affichage de zéro. Noter

que cette lecture est signée : le zéro exact se trouve au point où le signe moins de l'affichage

apparaît alternativement. Ensuite, retirer les câbles et brancher l'échantillon. Cette méthode

annule les déséquilibres internes de l'instrument.

Le réglage du zéro peut également être utilisé pour supprimer l'effet de petites f.é.m. externes de

la mesure. Brancher les câbles de test à l'inconnue pour prendre une mesure et sélectionnez la

plage requise. Appuyer sur le bouton Set Zero et régler l'affichage sur zéro. Relâcher le bouton

Set Zero et attendre que l'affichage se stabilise à la valeur de résistance. Cette méthode est la

plus pratique en conditions normales d'utilisation.

Noter que le zéro ne peut être réglé en condition de circuit ouvert des bornes de détection.

Connexion de la résistance inconnue

Les attaches Kelvin fournies avec l'instrument se chargent des connexions de force et de

détection des deux côtés du conducteur. Elles conviennent aux composants à embout métallique

et aux objets longs et fins.

Lorsque l'utilisateur mesure la faible résistance de gros échantillons, des câbles et des clips

séparés peuvent être nécessaires pour les deux jeux de connexions qui doivent être effectuées

de manière à refléter la mesure requise. Les bornes de détection doivent être branchées à

l'échantillon aux points exacts entre lesquels la résistance doit être mesurée ; les bornes de force

doivent être branchées à l'échantillon hors des bornes de détection. Les branchements de force

doivent se trouver assez loin des branchements de détection pour donner la place au courant de

se répandre sur la section croisée de l'échantillon.

Lorsque l'utilisateur mesure les composants, les branchements tests doivent correspondre aux

branchements de l'application autant que faire se peut ; lorsque l'on mesure les propriétés de

matériaux échantillons, l'homogénéité du branchement est alors le facteur le plus important. Ceci

peut nécessiter la construction d'un gabarit approprié.

19

Page 21

Le voyant vert Force On s'allume lorsque le courant de test circulant dans la résistance inconnue

produit une chute de tension dans les limites de conformité des spécifications de l'instrument.

Une lecture valide peut alors être obtenue, à condition que les connexions de détection soient

correctement effectuées (dans le cas contraire, l'écran affiche normalement les valeurs hors

plage). Noter que lorsque de fortes valeurs d'induction sont mesurées (comme c'est le cas pour

les transformateurs haute tension) un temps d'attente peut survenir avant que le voyant ne

s'allume, puisque le courant de test prend un certain temps pour monter à la valeur totale (la

vitesse de montée du courant dépend de l'induction et de la f.é.m. source de l'instrument). De la

même manière, le courant prend un certain temps pour s'inverser lorsque le bouton Polarity est

enfoncé.

Il est très important, lorsque l'on effectue les branchements, d'éviter de toucher les parties

métalliques du circuit, parce que la chaleur induite des doigts peut générer des f.é.m. thermiques

pouvant prendre un certain temps avant de s'éliminer.

Prise de mesure

Après le réglage du zéro, relâcher le bouton Set Zero et attendre que l'affichage se stabilise à la

valeur de résistance. Noter l'affichage et relâcher le bouton Polarity ; dans l'idéal (en l'absence de

toute f.é.m. thermique externe) la nouvelle valeur est identique à la première. Dans le cas

contraire, calculer la moyenne numérique des deux valeurs (ignorer le signe) ; cette moyenne est

la valeur véritable de résistance. Noter que si l'échantillon n'est pas équilibré au plan thermique,

l'affichage change à cause des f.é.m. thermiques et du coefficient de température de la

résistance inconnue.

Il est possible de vérifier les résultats en appuyant sur le bouton Set Zero, notant la lecture du

zéro, puis de calculer les deux différences entre cette valeur et la valeur de chaque polarité (en

prenant les signes en compte). Ces deux valeurs devraient être identique à l'unité près ; dans le

cas contraire, les f.é.m. thermiques changent trop vite pour qu'une mesure fiable puisse être

effectuée.

Mesures des résistances de contact

Les contacts des relais, des commutateurs, etc, sont souvent recouverts d'oxydes ou de produits

de corrosion. Si la tension dans le circuit en cours de commutation n'est pas assez élevée pour

décomposer le film isolant, la résistance de contact mesurée est beaucoup plus importante que

celle qui est mesurée dans des conditions de tension plus élevée. Pour obtenir une mesure

reflétant le fonctionnement du composant dans ces conditions de "circuit sec", il est nécessaire

de faire en sorte que l'équipement de test ne soumette pas l'échantillon à une tension élevée de

circuit ouvert. Les normes internationales définissent la tension de mesure d'un "circuit sec" égale

ou inférieure à 20 mV.

Cet instrument contient un circuit limiteur qui peut être actionné à l'aide du bouton 20mV Clamp

situé sur le panneau frontal. Ce bouton a pour effet de shunter les bornes de force

électroniquement, en interne, et de commander la résistance de ce circuit pour qu'elle maintienne

une tension de 18 mV (±2 mV) entre ces bornes. Lorsque le contact mesuré se ferme, sa

résistance doit être suffisamment basse pour que la chute de tension qu'elle subit (chute de la

tension du courant de mesure sur la plage sélectionnée) soit inférieure à la tension du limiteur. Le

shunt interne s'éteint, le voyant vert Force On s'allume et la résistance correcte s'affiche.

20

Noter que la batterie se vide plus vite lorsque le limiteur fonctionne : le courant de mesure circule

continuellement, soit par le limiteur interne, soit par le contact externe.

La fonctionnalité de limiteur 20 mV ne fonctionne pas sur les plages de 2 kΩ ni 20 kΩ car la

tension maximale de mesure sur ces plages est supérieure à 20 mV.

Page 22

Applications

Pour mesurer la hausse de température sur les enroulements d'un transformateur ou d'un

moteur, commencer par mesurer la résistance de l'élément à froid. Débrancher ensuite

l'instrument de mesure et faire fonctionner le dispositif pendant la période requise. Débrancher

toutes les alimentations et rebrancher l'instrument de mesure : mesurer la résistance des

enroulements à chaud. En connaissant ainsi le coefficient de température de l'enroulement, les

deux valeurs de résistance peuvent être utilisées pour calculer le changement de température.

Notation des mesures

Si les valeurs affichées fluctuent continuellement, cela peut indiquer soit un changement de f.é.m.

thermique entraîné par un changement de température, soit un changement réel de la résistance

de l'élément mesuré. Si l'échantillon est de petite taille, ceci peut être causé par l'effet de chauffe

du courant de test. En utilisant une plage plus élevée, on réduit le courant de test mais on réduit

également la résolution de la mesure.

Les fluctuations aléatoires de plus d'une unité peuvent indiquer de mauvais branchements aux

échantillons, particulièrement au niveau des câbles de détection. Ces fluctuations peuvent être

également causées par des champs magnétiques interférant sur le circuit de test ; déplacer les

câbles pour les rapprocher entre eux mais les éloigner de tout transformateur ou moteur.

Si les trois valeurs (polarité zéro, normale et inverse) ne se corrèlent pas, soit le branchement est

mauvais, soit une f.é.m. thermique change rapidement, ou la valeur réelle mesurée se modifie

très vite.

Les jonctions de semi-conducteurs apparaissent comme des circuits ouverts dans les deux sens

parce que la tension de mesure de cet instrument est trop basse pour causer une conduction

notable.

21

Page 23

Les constructeurs ou leurs agents à l'étranger fourniront un service de réparation pour tout

appareil qui deviendrait défectueux. Lorsque le propriétaire de l'instrument désire effectuer ses

propres travaux de maintenance, cette intervention ne doit être effectuée que par un personnel

expérimenté utilisant le manuel d'entretien disponible auprès du constructeur ou de ses agents à

l'étranger.

Nettoyage

Si l'instrument requiert d'être nettoyé, utiliser un chiffon légèrement humidifié ou légèrement

imbibé d'un détergent doux.

AVERTISSEMENT ! AFIN D'EVITER TOUT CHOC ELECTRIQUE OU D'ENDOMMAGER

L'INSTRUMENT, NE JAMAIS LAISSER L'EAU PENETRER A L'INTERIEUR DU BOITIER.

POUR EVITER D'ENDOMMAGER LE BOITIER, NE JAMAIS EMPLOYER DE SOLVANTS.

Étalonnage

Pour garantir que la précision de cet instrument reste conforme à ses spécifications, l'étalonnage

doit être vérifié (et réglé, le cas échéant) tous les ans. Cette procédure requiert l'accès à des

résistances standard connues avec précision ; l'instrument est réglé en obtenant et en affichant la

mesure exacte de ces résistances. Cet instrument s'étalonne différemment selon les plages de

valeurs.

Maintenance

Fusibles

Le circuit principal du transformateur est protégé par fusible thermique non ajustable à l'intérieur

des enroulements. Il ne peut être remplacé que si un nouveau transformateur est installé.

Le chargement de la batterie et les circuits de décharge sont protégés par des dispositifs à

autoréglage.

Si l'utilisateur soupçonne que l'un d'eux a disjoncté, il lui est conseillé de débrancher l'unité du

secteur, de l'éteindre complètement et d'attendre dix minutes.

Si l'un des composants disjoncte, cela indique très probablement que l'instrument doit faire l'objet

d'une révision ; toute maintenance doit être effectuée par un service de réparation compétent.

22

Page 24

Sicherheit

Dieses Gerät wurde nach der Sicherheitsklasse (Schutzart) I der IEC-Klassifikation und gemäß

den europäischen Vorschriften EN61010-1 (Sicherheitsvorschriften für elektrische Mess-, Steue-,

Regel- und Laboranlagen) entwickelt. Es handelt sich um ein Gerät der Installationskategorie II,

das für den Betrieb von einer normalen einphasigen Versorgung vorgesehen ist.

Das Gerät wurde gemäß den Vorschriften EN61010-1 geprüft und in sicherem Zustand geliefert.

Die vorliegende Anleitung enthält vom Benutzer zu beachtende Informationen und Warnungen,

die den sicheren Betrieb und den sicheren Zustand des Gerätes gewährleisten.

Dieses Gerät ist für den Betrieb in Innenräumen der Umgebungsklasse 2 , für einen

Temperaturbereich von +5°C bis +40°C und 20 - 80 % relative Feuchtigkeit (nicht kondensierend)

vorgesehen. Gelegentlich kann es Temperaturen zwischen −10°C und +5°C ausgesetzt sein,

ohne dass seine Sicherheit dadurch beeinträchtigt wird. Betreiben Sie das Gerät jedoch auf

keinen Fall, solange Kondensation vorhanden ist.

Ein Einsatz dieses Gerätes in einer Weise, die für diese Anlage nicht vorgesehen ist, kann die

vorgesehene Sicherheit beeinträchtigen. Auf keinen Fall das Gerät außerhalb der angegebenen

Nennversorgungsspannungen oder Umgebungsbedingungen betreiben.

WARNUNG! - DIESES GERÄT MUSS GEERDET WERDEN!

Jede Unterbrechung des Netzschutzleiters innerhalb oder außerhalb des Gerätes macht das

Gerät gefährlich. Eine absichtliche Unterbrechung ist verboten. Die Schutzwirkung darf durch

Verwendung eines Verlängerungskabels ohne Schutzleiter nicht aufgehoben werden.

Ist das Gerät an die elektrische Versorgung angeschlossen, so können die Klemmen unter

Spannung stehen, was bedeutet, daß beim Entfernen von Verkleidungs- oder sonstigen Teilen

(mit Ausnahme der Teile, zu denen Zugang mit der Hand möglich ist) höchstwahrscheinlich

spannungsführende Teile bloßgelegt weden. Vor jeglichem Öffnen des Gerätes zu Nachstell-,

Auswechsel-, Wartungs- oder Reparaturzwecken, dieses stets von sämtlichen Spannungsquellen

abklemmen.

Jegliche Nachstellung, Wartung und Reparatur am geöffneten, unter Spannung stehenden Gerät,

ist nach Möglichkeit zu vermeiden. Falls unvermeidlich, sollten solche Arbeiten nur von

qualifiziertem Personal ausgeführt werden, das sich der Gefahren bewusst ist.

Ist das Gerät eindeutig fehlerbehaftet bzw. wurde es mechanisch beschädigt, übermäßiger

Feuchtigkeit oder chemischer Korrosion ausgesetzt, so können die Schutzeinrichtungen

beeinträchtigt sein, weshalb das Gerät aus dem Verkehr zurückgezogen und zur Überprüfung

und Reparatur eingesandt werden sollte.

Das Gerät enthält nicht rückstellbare und selbstrückstellende thermische Sicherungen, die nicht

vom Benutzer erneuert werden können. Das Kurzschließen dieser Schutzeinrichtungen ist

verboten.

Das Gerät enthält Nickelhybrid-Batterien. Diese Zellen nicht öffnen, durchbohren, verbrennen

oder kurzschließen. Diese Batterien müssen gemäß den vor Ort geltenden Regelungen entsorgt

werden und sind vor der Entsorgung des Geräts daraus zu entfernen.

Beim Reinigen darauf achten, dass das Gerät nicht nass wird.

Am Gerät werden folgende Symbole verwendet:

Vorsicht! Bitte beachten Sie die beigefügten Unterlagen. Falsche

23

Bedienung kann Schaden am Gerät verursachen!

Wechselstrom

Page 25

Netzbetriebsspannung

Die Betriebsspannung des Gerätes ist auf der Rückseite vermerkt. Wenn die Betriebsspannung

von 230V auf 115V umgestellt werden muss oder umgekehrt, ist folgendermaßen vorzugehen:

1. Das Gerät von allen Spannungsquellen trennen.

2. Die 4 Schrauben entfernen, mit denen die obere mit der unteren Gehäusehälfte

verbunden ist, und das Oberteil des Gehäuses hochheben.

3. Das 3-polige Kabel von der Stromversorgungs-SPS abnehmen, die sechs Schrauben

entfernen und die SPS aus dem Gehäuse heben. An der Unterseite der

Stromversorgungs-SPS ist ein Isolator angebracht der sicherstellt, dass die Batterien nicht

zufällig kurzgeschlossen werden. Der mittlere Haltebolzen kann vorsichtig

herausgeschoben und wiederverwendet werden. Setzen Sie den Isolator nach den

Servicemaßnahmen sofort wieder ein.

4. Die gelöteten Verbindungen für die gewünschte Arbeitsspannung einsetzen:

Für 230V nur LK2 einsetzen.

Für 115V LK1 und LK3 einsetzen und LK2 nicht einsetzen.

Diese Verbindungen können verzinnte Kupferdrähte oder Null-Ohm-Widerstände sein.

Installation

5. Die Stromversorgungs-SPS wieder in das untere Gehäuse einbauen und das 3-polige

Kabel wieder anschließen.

6. Das obere Gehäuse wieder anbringen und darauf achten, dass die Schrauben nicht

überdreht werden.

7. Zur Einhaltung der Anforderungen der Sicherheitsstandards muss die auf der Rückseite

angegebene Betriebsspannung geändert werden, so dass die neue Spannungseinstellung

deutlich zu erkennen ist.

Sicherungen

In diesem Gerät befinden sich keine austauschbaren Sicherungen.

Netzanschlussleitung

Wenn eine dreiadrige Netzanschlussleitung mit blanken Kabelenden zur Verfügung steht sollte

das Gerät folgendermaßen angeschlossen werden:

Braun - Phase

Blau - Nullleiter

Grün/Gelb - Erde

VORSICHT! DIESES GERÄT MUSS GEERDET WERDEN

24

Jegliche Unterbrechung des Netzschutzleiters innerhalb oder außerhalb des Gerätes macht das

Gerät gefährlich. Eine absichtliche Unterbrechung ist verboten.

Page 26

Eingangsanschlüsse

Auf der Frontplatte stehen Anschlussmöglichkeiten für standardmäßige Widerstandsmessungen

mit 4 Anschlüssen zur Verfügung. Der Prüfstrom fließt zwischen den Anschlüssen, die mit

FORCE + (KRAFT) und – beschriftet sind, und die Spannung, die am unbekannten Widerstand

anliegt, wird zwischen den Anschlüssen gemessen , die mit SENSE + (ABTASTUNG) und –

beschriftet sind. Um korrekte Ergebnisse zu erhalten, sollte der gesamte Messkreis nur an den zu

messenden Widerstand angeschlossen sein.

Das Gerät wird mit einem Kelvin Anschlussleitungssatz geliefert, der aus zwei SpezialKrokodilklemmen besteht, die mit vier 4mm-Stöpseln verbunden sind. Die oberen und unteren

Klemmbacken haben bei beiden Krokodilklemmen keine elektrische Verbindung: Die grauen

Klemmbacken dienen als Force-Anschlussklemmen und die farbigen Klemmbacken (rot und

schwarz) als Sense-Anschlussklemmen. Die grauen Klemmbacken sind mit den Stöpseln

verbunden, die einen grauen Bund haben.

Diese Anschlussleitungen sind folgendermaßen an das Gerät anzuschließen:

Anschlüsse

Stöpsel Anschluss

Schutz

ganz rot Sense +

rot mit grauem Bund Force +

ganz schwarz Sense –

schwarz mit grauem Bund Force –

Das Gerät kann mit einer beliebigen anderen Verbindungsanordnung mit 4 Anschlüssen

verwendet werden, wenn die physische Größe des gemessenen Widerstands dies erforderlich

macht.

Der Messkreis ist nicht geerdet (selbst während die Batterie geladen wird), aber zum Schutz des

Bedienpersonals sollten die Anschlüsse innerhalb von ±30 Volt von Erde liegen. Extern darf der

Stromkreis nur an einem Punkt an Erde angeschlossen werden.

Die höchste Spannung, die vom Gerät abgegeben wird, beträgt 6V DC.

Bei der Widerstandsmessung an großen Induktionsspulen mit Eisenkern baut der Prüfstrom im

Eisenkern ein magnetisches Feld auf. Wenn der Strom abgestellt wird, wird mit dem

Zusammenbruch des Felds eine Gegen-EMK erzeugt. Beim Abnehmen der PrüfAnschlussleitungen von den Induktionsspulen nicht die Anschlüsse berühren, da die Gegen-EMK

einen spürbaren elektrischen Schlag verursachen kann. Am besten den Tastenschalter Set Zero

(Nullstellung) drücken und das Gerät die gespeicherte Energie aufnehmen lassen, bevor die

Induktionsspule von den Anschlüssen getrennt wird.

Schutzschaltungen im Gerät gewährleisten, dass es nicht von der Gegen-EMK einer Induktanz

seines eigenen Prüfstroms beschädigt wird.

Es ist nicht vorgesehen, dass eine externe Spannung an die Eingangs-Anschlüsse angelegt wird.

Es sind allerdings Schaltungen zum Schutz des Geräts vor kurzen unbeabsichtigten

Verbindungen vorhanden. Im Falle eines schwerwiegenderen Missbrauchs schützen

Schmelzwiderstände die internen Stromkreise. Diese Widerstände können nicht vom Benutzer

ersetzt werden.

25

Page 27

Frontplatten-Bedienungseinrichtungen

Die folgenden Absätze enthalten eine Kurzbeschreibung der Bedienungseinrichtungen.

Genauere Angaben zum Betrieb des Geräts sind in späteren Kapiteln zu finden.

Operate

Der Tastenschalter Operate (Einschalten) verbindet die Messkreise mit der Batterie; er steuert

nicht die Batterieladevorrichtung, die immer in Betrieb ist, wenn das Gerät an die Netzversorgung

angeschlossen ist.

Set Zero

Durch Drücken des Tastenschalters Set Zero (Nullstellung) wird der Prüfstrom von den ForceAnschlüssen weggeleitet, so dass es am gemessenen Widerstand keinen Spannungsabfall gibt.

Die Anzeige kann dann auf Null gesetzt werden, wobei die Auswirkung externer thermischer EMK

berücksichtigt wird.

20mV Clamp

Durch Drücken des Tastenschalters 20mV Clamp (20mV Begrenzung) wird die Leerlaufspannung

der Force-Anschlüsse auf 20mV begrenzt. Diese Funktion wird bei der Messung des

Kontaktwiderstands von Schaltern oder Relais verwendet, da durch diese niedrige Spannung

keine Oxidschichten durchbrochen werden.

Polarity

Durch Drücken des Tastenschalters Polarity (Polarität) wird die Richtung des Prüfstroms durch

den unbekannten Widerstand umgekehrt. Wenn keine thermischen EMK im Messkreis vorhanden

sind, sollten die beiden Messergebnisse übereinstimmen (abgesehen vom Minuszeichen). Wenn

eine thermische EMK vorhanden ist, verfälscht sie das eine Messergebnis nach oben und das

anderen nach unten; der wirkliche Widerstandswert ist der numerische Mittelwert aus den beiden.

Messbereich-Tastenschalter

Die Messbereich-Tastenschalter sind mit den Anzeige-Einheiten beschriftet (µΩ, mΩ, Ω und kΩ).

Der Nenn-Mess-Strom ist als Zusatzinformation unter den Tastenschaltern angegeben.

Charge-Leuchte (rot)

Die Leuchte Charge (Ladung) leuchtet, während das Gerät an die Netzversorgung

angeschlossen ist, was bedeutet, dass die Batterie geladen wird. Das Gerät ist von der

Versorgung zu trennen, wenn die Batterie vollständig geladen ist.

Force On-Leuchte (grün)

Die Leuchte Force On (Force Ein) leuchtet, wenn der Prüfstrom korrekt fließt. Wenn die 20mVKlemme verwendet wird, leuchtet sie nur, falls der externe Spannungsabfall unter der

Klemmengrenze liegt.

Anzeige

Die 3½-stellige Anzeige gibt das Messergebnis an. Es ist nur dann als gültiges Messergebnis

aufzufassen, wenn die Leuchte Force On leuchtet und die BAT-Anzeige aus ist. Wenn der

Widerstand zu hoch für den gewählten Messbereich ist (oder die Sense-Anschlussleitungen

einen offenen Stromkreis bilden) wird die Messbereichsüberschreitung durch eine 1 und drei

Leerzeichen angezeigt. Ein Minuszeichen erscheint, wenn mit umgekehrter Polarität gemessen

wird. Die Nullstellung hat ein Vorzeichen; in der echten Nullposition wechselt die Anzeige

zwischen –000 und +000.

Das BAT-Signal in der linken unteren Ecke des Anzeigefensters zeigt an, dass die Batterie fast

entladen ist. Zu diesem Zeitpunkt sind die Messergebnisse noch genau, aber es gibt kein

weiteres Zeichen, wenn die Batteriespannung auf den Punkt fällt, an dem Fehler auftreten.

Daher ist die Ladevorrichtung an die Versorgung anzuschließen, wenn die BAT -Anzeige

erscheint.

26

Page 28

Einschalten

Das Gerät wird an der Frontplatte mit dem Tastenschalter Operate eingeschaltet. Wenn im

Anzeigefenster keine Ziffern erscheinen, sind die Batterien wahrscheinlich vollständig entladen.

Schließen Sie das Gerät an die Netzversorgung an; die Charge-Leuchte sollte aufleuchten, um

anzuzeigen, dass die Batterien geladen werden. Wenn das Anzeigefenster nach ein paar Minuten

Ladezeit nicht den Betrieb aufnimmt, kann das Gerät defekt sein. Gerät ausschalten, von der

Versorgung trennen und zur Reparatur geben.

Ladung der Batterie

Wenn das Gerät an die Netzversorgung angeschlossen ist, leuchtet die rote Charge-Leuchte und

die Batterie wird geladen. Widerstandsmessungen können mit einer kleinen Genauigkeitseinbuße

aufgrund des Temperaturanstiegs im Gerät weiter durchgeführt werden. Der Ladevorgang dauert

gewöhnlich etwa 12 Stunden, aber wenn der 2000µΩ-Messbereich verwendet wird, verringert der

Prüfstrom von 250mA den Ladestrom beträchtlich und es dauert länger, bis die Batterie

vollständig geladen ist. Ein konisches Ladungsmuster wird angewandt, damit das Ladungsniveau

einer voll entladenen Batterie schnell erhöht und der Strom verringert wird, wenn die Batterie voll

geladen ist; dennoch sollte das Gerät nicht kontinuierlich nachgeladen werden, da dies die

Lebensdauer der Batterie verringern würde.

Die Ni-MH-Zellen haben keinen Nachklingeffekt und nehmen durch eine vollständige Entladung

oder eine teilweise Aufladung keinen Schaden.

Betrieb

Wenn das Gerät nicht verwendet wird, entladen sich die Batterien selbst. Dieser Effekt wird durch

höhere Temperaturen wesentlich verstärkt. Wenn das Gerät so lange gelagert wurde, dass die

Batterien vollständig entladen sind, können zwei bis drei Lade/Entlade-Zyklen nötig sein, bis die

volle Kapazität wiederhergestellt ist.

Die Batterien können nicht vom Benutzer ausgetauscht werden. Wenn die Kapazität merklich

abnimmt, sollte das Gerät an eine qualifizierte Reparaturwerkstatt geschickt werden, um dort die

Batterien austauschen zu lassen. Die Zellen müssen entsprechend der örtlich geltenden

Arbeitssicherheits- und Umweltanforderungen gehandhabt und entsorgt werden.

Betriebsgrundsätze

Dieses Gerät verwendet das ratiometrische Verfahren zur Messung des Widerstands: Ein

Prüfstrom wird durch einen präzisen internen Bezugswiderstand und durch den unbekannten

Widerstand geleitet. Die Höhe des Prüfstroms wird je nach eingestelltem Messbereich gewählt.

Sie stellt einen Kompromiss zwischen Rauschempfindlichkeit und thermischen EMK und einer

Minimierung der Selbsterwärmung des unbekannten Widerstands dar. Die Spannungen, die sich

an den beiden Widerständen entwickeln, werden mit einem ratiometrischen Analog-DigitalWandler verglichen, der das Ergebnis für die Anzeige errechnet.

Die Genauigkeit dieses Verfahrens hängt von der Genauigkeit des Bezugswiderstands ab und

davon, ob der Spannungsabfall am unbekannten Widerstand exakt gemessen wird, nicht von der

Höhe des Prüfstroms. Die beiden Hauptfehlerquellen sind Spannungsabfälle an den

Verbindungsstellen und thermische EMK.

Das Problem der Spannungsabfälle wird durch die 4-Anschluss-Verbindung gelöst. Der Strom

fließt durch die Force-Anschlussleitungen und das Gerät kann jeden Spannungsabfall in diesen

Leitungen bis zu seiner Nachgiebigkeitsgrenze tolerieren. In den Sense-Anschlussleitungen gibt

es aufgrund der sehr hohen Eingangsimpedanz des Spannungsmesskreises im Gerät keinen