Page 1

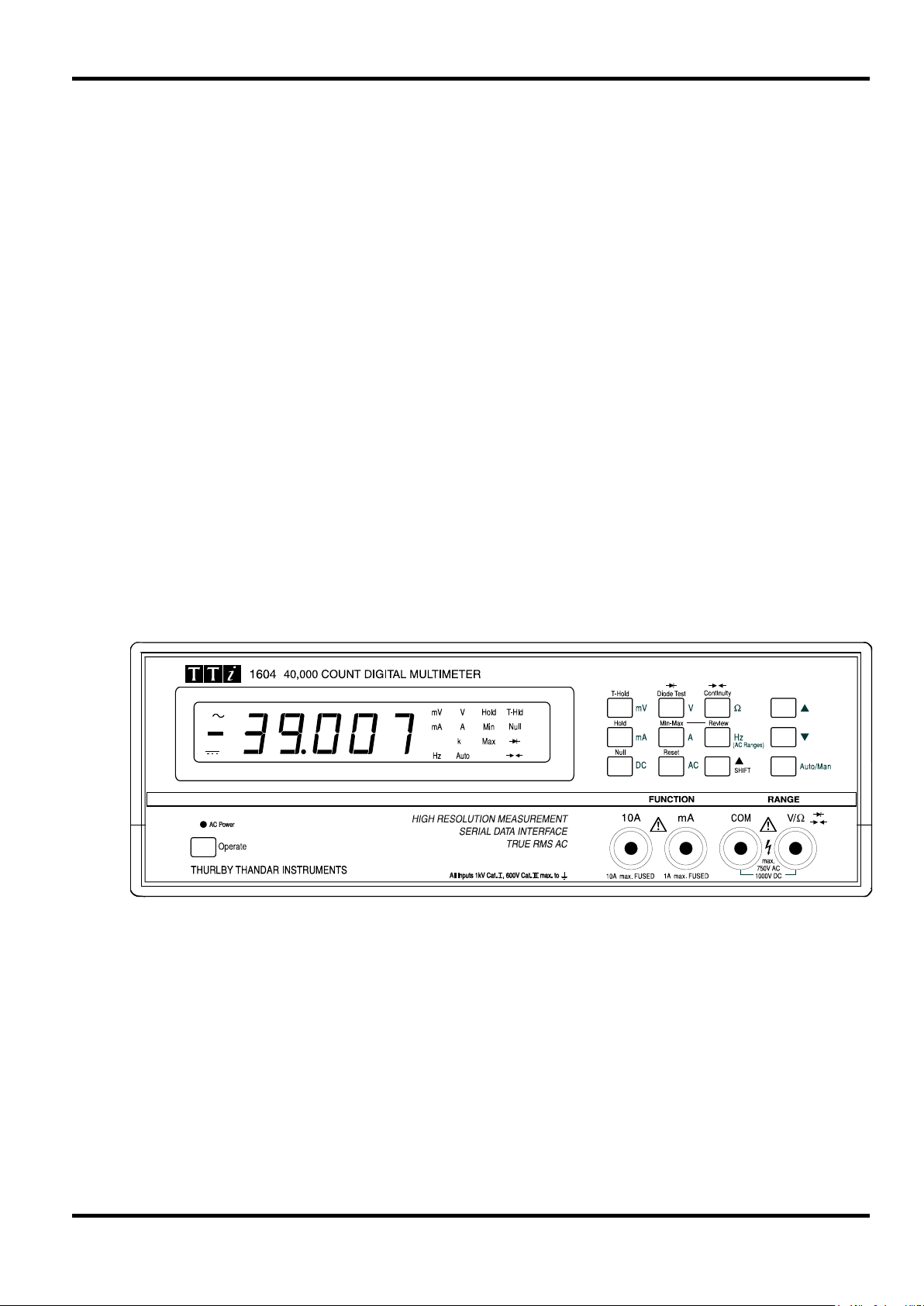

1604

40,000 Count Digital Multimeter

Page 2

Table of Contents

Introduction 2

Specifications 3

Safety 7

EMC 8

Installation 9

General Operation 10

Making Measurements 12

Further Functions 14

Maintenance & Calibration 15

Remote Operation 15

Instructions en Francais 16

Bedienungsanleitung auf Deutsch 25

Istruzioni in Italiano 34

Instrucciones en Español 43

1

Page 3

Introduction

This true RMS multimete r is a low-cost manual/autoranging bench-top instrument with a large,

bright LED display. It offers 4¾ digit ( 40,000 count) scale length and a resolution of 10µV and

10mΩ.

The key features are:

• 0.56” (14mm) high brightness LED display.

• 0.08% basic accuracy, 40,000 counts.

• Manual or autoranging.

• DC and AC Volts, DC and AC current, Resistance and Frequency measurement; Continuity

and Diode checks.

• True RMS AC measurem ent , 4,000 counts.

• Display nulling.

• Touch hold mode - holds ont o a stable reading until updated.

• Remote control and data-logging to disk using optional W indows software.

• Fully compliant with EN61010-1 Safety and EN61326 EMC standards.

TEST EQUIPMENT RISK ASSESSMENT

Recommendation from the U.K. Health and Safety Executive

Users of this equipment and or their employers are reminded that Health and

Safety Legislation require them to carry out valid risk asses sments of all electrical

work so as to identify potential sources of electrical danger and risk of electrical

injury such as from inadvertent short circuits. Where the assessments show that

the risk is significant then the use of fused test leads constructed in accordance

with the HSE guidance note GS38 ‘Electrical Test Equipment’ for use by

electricians’ should be used.

2

Page 4

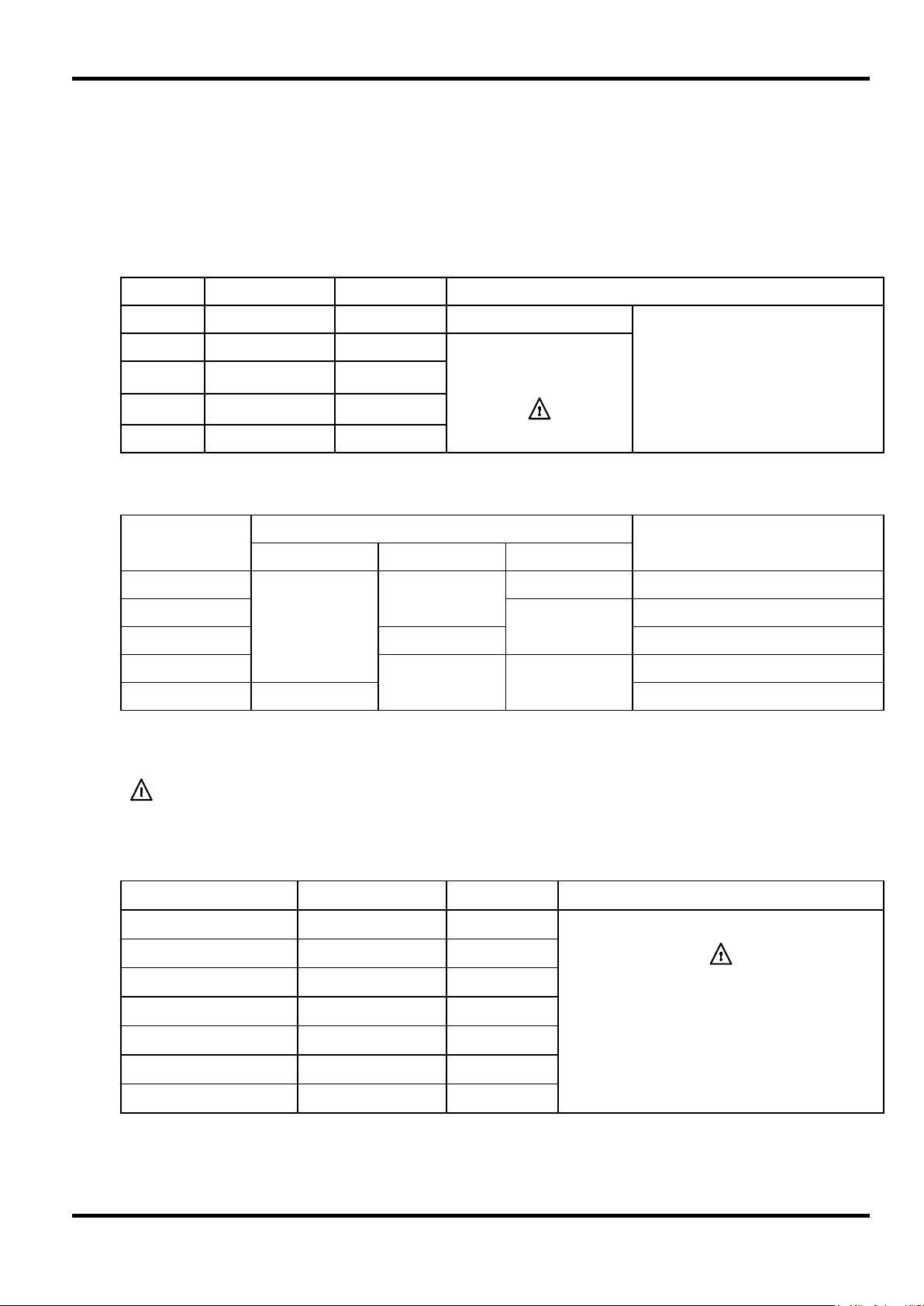

Range

Accuracy

Resolution

Notes

Max input 1000V

†

Range

Accuracy

Resolution

ACCURACY

Accuracies apply for 1 year 19°C to 25°C. Temper at ure coefficient outside these limits is

<0.1 x quoted range accuracy per °C.

DC Volts

Specifications

400mV 0.08% ± 4 dig. 10µV

4V 0.08% ± 4 dig. 100µV

40V 0.08% ± 4 dig. 1mV DC/AC pk.

400V 0.08% ± 4 dig. 10mV

1000V 0.09% ± 4 dig. 100mV

AC Volts (True RMS)

45Hz - 400Hz 400Hz - 4kHz 4kHz - 20kHz

400mV 1% ± 4 dig. 2% ± 4 dig. 100µV

4V 1mV

40V 0.5% ± 4 dig 2% ± 4 dig 5% ± 4 dig. 10mV

400V - - 100mV

750V 1% ± 4 dig. - - 1V

Accuracies apply for readings between 400 and 4,000 counts. Additional error at crest

factor = 3 is typically 1%. Input impedance = 10MΩ nominal.

1kΩ unbalanced CMR = >60dB at DC/50Hz/60Hz

265V DC/AC rms max

†

.

Input impedance 10MΩ nominal

NMR:>60dB @ 50/60Hz

CMR:>90dB @ DC/50Hz/60Hz†

Max. input = 750V rms, 1kV pk. (265Vrms on 400mV range).

Resistance

Range Accuracy Resolution Notes

400Ω 0.15% ± 6 dig.∗ 10mΩ

4kΩ

40kΩ

400kΩ

4MΩ

40MΩ (up to 20MΩ)

40MΩ (up to 40MΩ)

0.1% ± 4 dig.

0.1% ± 4 dig.

0.15% ± 4 dig.

0.3% ± 6 dig.

1.0% ± 10 dig.

2.0% ± 10 dig

∗ after Null

100mΩ

1Ω

10Ω

100Ω

1kΩ

1kΩ

3

Max. input 265V DC or ACrms any r ange.

Max. open circuit voltage 4V.

†

60Hz rejection is a factory option.

Page 5

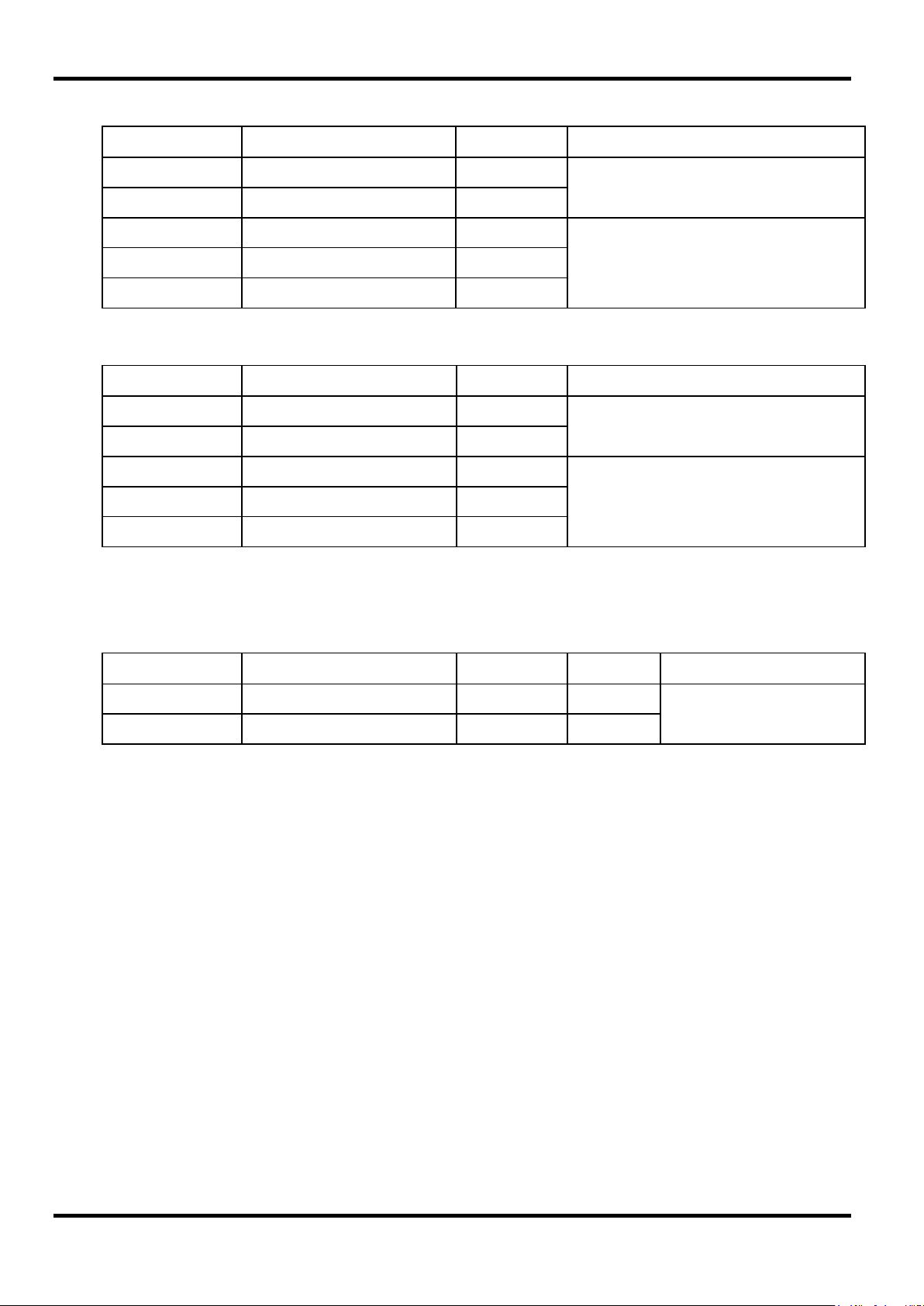

Range

Accuracy

Resolution

Notes

4mA

0.1% ± 4 dig.

0.1µA

Max. input 1A, 250V, f use pr otected

400mA

0.1% ± 4 dig.

10µA

Voltage burden <500mV

10A (up to 1A)

0.3% ± 4 dig.

1mA

10A (up to 5A)

1.0% ± 4 dig.

1mA

Max. input 10A, 250V, f us e pr ot ec t ed

10A (up to 10A)

3% ± 10 dig

1mA

Voltage burden <500mV

Range

Accuracy (45Hz - 10kHz)

Resolution

Notes

4mA

0.5% ± 4 dig.

1µA

Max. input 1A, 250V, f use pr otected

400mA

0.5% ± 4 dig.

100µA

Voltage burden <500mV

10A (up to 1A)

0.8% ± 4 dig.

10mA

10A (up to 5A)

1.5% ± 4 dig

10mA

Max. input 10A, 250V, f us e pr ot ec t ed

10A (up to 10A)

3% ± 4 dig.

10mA

Voltage burden <500mV

Range

Accuracy

Resolution

Gate

Notes

4kHz

0.01% ± 1 dig.

0.01Hz

1s

Sensitivity set by

40kHz

0.01% ± 1 dig.

0.1Hz

10s

AC range setting

Continuity:

4kΩ range select ed; audible t one sounds for impedance <10Ω.

Diode Test:

Test curr ent approximately 1mA at 1V; displays voltages up to 3V.

Voltage:

4V

Maximum Input:

265V DC or AC rms.

Hold:

Reading is frozen

T-Hold (Touch & Hold):

Reading is frozen when stable.

Min/Max:

Minimum and maximum readings stored.

shows in the display when the measurement range is exceeded.

DC Current

AC Current (True RMS)

Accuracies apply for readings between 400 and 4,000 counts. Additional error at crest factor = 3

is typically 1%.

Frequency

Continuity and Diode Test

Maximum Open Circuit

FURTHER FUNCTIONS

Null (Relative): Stores current reading and subtracts it from future readings. Up to

±1,000 counts can be nulled without restricting the measur em ent

range. Counts greater than ± 1,000 can be nulled to give a Relative

reading but the measurement range is correspondingly reduced; OFL

4

Page 6

Display Ty pe:

High brightness LED. Height 0.56” ( 14m m ) .

Scale Length:

4¾ digits (40,000 counts); AC ranges 4,000 counts.

Annunciators:

For all ranges, functions and program modes.

Reading Rate:

2.5 readings/sec.

Overrange:

Display shows OFL if input too great for range.

3VA max. Installation Category II. 60Hz operation is a factory option.

optional Windows software.

Operating Range:

+5°C to + 40°C, 20% to 80% RH.

Storage Range:

−40°C to + 70°C.

Environmental:

Indoor use at altitudes up to 2000m, Pollution Degr ee 1.

Safety:

Complies with EN61010-1.

EMC:

Complies with EN61326.

Size:

260(W) x 88(H) x 235(D)m m, excluding handle and feet.

Weight:

2.0kg.

DISPLAY

GENERAL

Power: 110V-120V or 220V-240V AC ±10%, 50/60Hz, adjustable internally;

RS232 Interface: Baud Rate 9600. Permits remot e c ont r ol and data-logging to disk using

5

Page 7

Performance levels achieved are detailed in the user manual.

EC Declaration of Conf ormity

We Thurlby Thandar Instruments Ltd

Glebe Road

Huntingdon

Cambridgeshire PE29 7DR

England

declare that the

Model 1604 Digital Multimeter

meets the intent of the EMC Directive 2004/108/EC and the Low Voltage Directive 2006/95/EC.

Compliance was demonstrated by conformance to the following specifications which have been

listed in the Official Journal of the European Comm unit ies.

EMC

Emissions: a) EN61326-1 (2006) Radiated, Class B

b) EN61326-1 (2006) Conducted, Class B

c) EN61326-1 (2006) Har m onics, referring to EN61000-3-2 ( 2006)

Immunity: EN61326-1 (2006) Immunity Table 1, referring to:

a) EN61000-4-2 (2009) Electrostatic Discharge

b) EN61000-4-3 (2006) Electromagnetic Field

c) EN61000-4-11 (2004) Voltage Interrupt

d) EN61000-4-4 (2004) Fast Transient

e) EN61000-4-5 (2006) Surge

f) EN61000-4-6 (2009) Conducted RF

Safety

Multimeter: EN61010-1

Installation Category I measurements to 1000V,

Installation Category II measurements to 600V,

Pollution Degree 1.

Probes: IEC1010-2-031

Rated to 1000V, Installation Category III.

CHRIS W ILDING

TECHNICAL DIRECTOR

2 January 2013

6

Page 8

incorrect operation may damage the met er.

Safety

This multimeter is a Safety Class I instr um ent according to IEC classification and has been

designed to meet the requirem ents of EN61010-1 (Safety Requirements f or Elect r ical Eq uipment

for Measurement, Control and Laborator y Use). It is an Installation Category II instrument int ended

for operation from a nor m al single phase supply.

WARNING! THIS INSTRUMENT MUST BE EARTHED

Any interruption of the mains earth conduct or inside or outside t he inst r um ent will make the

instrument dangerous. Int entional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protect ive conductor.

The test leads supplied with this instrument meet t he r equirements of IEC1010-2-031 and are rated

to 1000V Category III; use only these test leads with the m et er or a set of equivalent perfor m anc e.

This instrument has been tested in accordanc e with EN61010-1 and has been supplied in a safe

condition. This instruction manual contains some information and warnings which have to be

followed by the user to ensure safe operation and to r etain the inst r um ent in a safe condition.

This instrument has been designed f or indoor use in a Pollution Degree 1 environment (no

pollution, or only dry non-conductive pollution) in the temperature range 5°C to 40°C, 20% - 80%

RH (non-condensing). It m ay occasionally be subjected t o t emperatures between +5° and −10°C

without degradation of its safety. It has been designed for Installation Category II m easur em ent use

to 600VDC/ACrms and Installation Category I measurement us e t o 1000VDC/750VACrms. The full

definitions of Categories I and I I can be found in IEC664, but the f ollowing can be taken as a guide:

Installation Category I is signal level e.g. telecommunicat ion, elect r onic equipment, with smaller

transient overvoltages than Installation Category II.

Installation Category II is local domestic supply level, e.g. portable equipment and appliances. In

particular, Category II does not include distribution level supplies, e.g. three phase installations

which are classified as Installation Category III.

For this equipment 2500V is the maximum peak transient overvoltage that can be tolerated by any

terminal with respect to earth ground without impairing s afety.

Use of this instrument in a manner not spec ified by these instructions may impair the safety

protection provided. Do not operate the instrum ent outside its rat ed supply voltages or

environmental range. In particular excessive moisture may impair safety.

When the instrument is connected to its supply or its inputs are connected to live voltages,

terminals may be live and opening the covers or removal of parts (except those t o which access

can be gained by hand) is likely to expose live parts. The apparatus shall be disconnected from all

voltage sources before it is opened for any adjust m ent, replacement, maintenance or repair.

Any adjustment, maintenance and repair of the opened instrument under voltage shall be avoided

as far as possible and, if inevitable, shall be carried out only by a skilled person who is aware of the

hazard involved.

If the instrument is clearly def ec t ive, has been subject to mechanical damage, excessive moisture

or chemical corrosion the safety protec t ion m ay be impaired and the apparatus should be

withdrawn from use and returned for checking and repair.

Make sure that only fuses with the required rated current and of the specified type are used for

replacement. The use of makeshift fuses and the short-circuiting of fuse holders is prohibited.

Do not wet the instrument when cleaning it and in particular use only a soft dry cloth to clean the

display window. The following symbols are used on the instrument and in this manual:

WARNING - risk of electric shock.

CAUTION - refer to accompanying documentation;

7

mains earth (ground)

direct current

alternating current

Page 9

This instrument has been designed to meet the requirements of the EMC Directive 2004/108/EC.

Compliance was demonstrated by meeting the test limits of t he following standards:

Emissions

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use. Test limits used were:

a) Radiated: Class B

b) Conducted: Class B

c) Har m onics: EN61000-3-2 (2006) Class A; the instrument is Class A by product category.

Immunity

EN61326-1 (2006) EMC product standard for Electrical Equipment for Measurement, Control and

Laboratory Use.

Test met hods, limits and performance achieved are shown below (requirement shown in

brackets):

a) EN61000-4-2 (2009) Electrostatic Discharge : 4kV air, 4kV contact, Performance B (B).

EMC

b) EN61000-4-3 (2006) Electromagnetic Field:

c) EN61000-4-11 ( 2004) Voltage Interrupt: ½ cycle and 1 cycle, 0% : Performance A (B);

d) EN61000-4-4 (2004) Fast Transient, 1kV peak (AC line), 0·5kV peak (signal connections),

Performance B (B).

e) EN61000-4-5 (2006) Surge, 0·5k V ( line to line), 1kV (line to ground), Performance A (B).

f) EN61000-4-6 (2009) Conducted RF, 3V, 80% AM at 1kHz (AC line only; signal

connections <3m, therefor e not tested), Perform ance A (A).

According to EN61326-1 the definitions of performance criteria are:

Performance criterion A: ‘During test normal performance within the specification limits.’

Performance criterion B: ‘During t est, temporary degradation, or loss of function or

performance which is self-recovering’.

Performance criterion C: ‘During t est, temporary degradation, or loss of function or

performance which requires operator int er vention or s ystem r eset occurs.’

†

Note: The 1604 is a sensitive measuring instrument and, if s ubj ec t ed to a sufficiently large

radiated RF field, measurements may deviate beyond the accuracy specification at c er t ain

frequencies up to 1GHz. However, possible deviations will be small and infrequent and are not

deemed to be a problem in practice. In all other res pects t he inst r ument will operate normally

(Performance A) in fields up to 3V/m.

Cautions

To ensure continued com pliance with the EMC directive the following precautions should be

observed:

a) Only use screened cables and connectors to connect between the mult im et er’s RS232

interface and other equipment .

b) After opening the case f or any reason ensur e that all signal and ground connections are

remade correctly before replacing the cover. Always ensure all case screws are correctly

refitted and tightened.

c) In the event of part replacement becoming neces sar y, only use components of an

identical type, see the Service manual.

†

3V/m, 80% AM at 1kHz, 80MHz – 1GHz: Performance B

Performance A (A); 1V/m, 2.0GHz to 2.7GHz: Performance A (A).

25 cycles, 70% : Performance B (C); 250 cycles, 0% : Per formance C(C).

(A) and 1.4GHz to 2GHz:

8

Page 10

Mains Operating Voltage

Check that the instrument oper ating voltage marked on the rear panel is suitable for the local

supply. Should it be neces sar y to change the operating voltage, proceed as follows:

1) Disconnect the instrument from all voltage sources.

2) Unclip the front bezel by gently pulling the centre of each long edg e up and forward.

The case halves are held together by 4 plastic push-rivets. Use the blade of a s m all

screwdriver in the slot beside each rivet to first ease out t he r ivet head and t hen fully remove

the rivet body. Separate the case halves. Visit www.tti-test.com for further details.

3) Remove the 3 scr ews securing the pcb to the case lower and lift out the pcb with front and

rear panels attached.

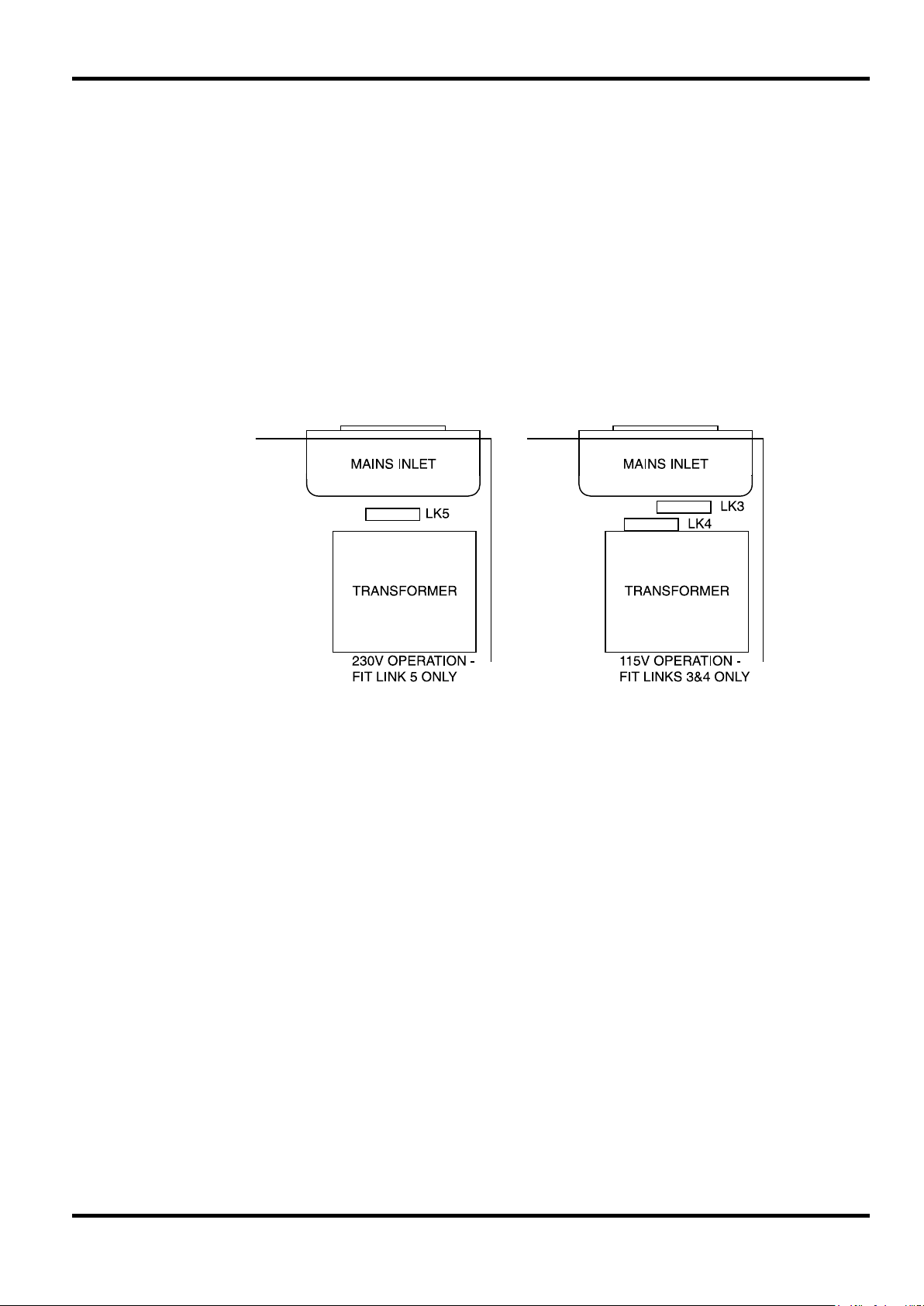

4) Change the voltage settings by changing the soldered links as shown below:

Installation

5) Reassemble in the reverse order.

6) To comply with safety standard requirements t he oper ating voltage marked on the rear panel

must be changed to clearly show the new voltage setting.

Note: The transfor mer primary is protected by an integral thermal fuse which remains unchanged

when the operating voltage is altered.

Mains Lead

When a three c or e m ains lead with bare ends is provided it should be connected as follows:-

WARNING! THIS INSTRUMENT MUST BE EARTHED WHEN OPERATED FROM AN AC LINE SUPPLY

Any interruption of the mains earth conduct or inside or outside t he inst r ument will make the

instrument dangerous. Int entional interruption is prohibited. The protective action must not be

negated by the use of an extension cord without a protective conductor.

Brown - Mains Live

Blue - Mains Neutral

Green / Yellow - Mains Earth

9

Page 11

600V (Category II) and 10A current capability.

Pin

Name

Description

1

DCD

Linked to DTR

2

TXD

Transmitted data from instrument

3

RXD

Received data to instrument

4

DTR

DTR from host PC must be set t o + 9V ( logic 0)

5

GND

Signal ground

6

DSR

Linked to DTR

7

RTS

RTS from host PC must be set to -9V (log ic 1)

8

CTS

Linked to RTS

This section is a general introduction to t he features and organisation of t he multimeter intended

to be read before using the instr ument for the first time. Detailed operation is covered in the

Making Measurements section.

Connections

Input Sockets

The input sockets are 4mm safety sockets on a 19mm pitch designed to accept 4m m safety

plugs with fixed or retractable shrouds. The sockets are all rated t o 1000V ( Cat egory I)/600V

(Category II) with respect to eart h ground.

The input impedance between V/Ω and COM is nominally 10MΩ. The black COM socket is

considered less positive than the red socket.

The mA/10A current sockets are low impedance; the voltage burden between mA/10A and COM

at full scale is <500mV. The black COM socket is considered less positive than the white mA/10A

sockets.

Multimeter Test Leads

General Operation

RS232

The test leads supplied meet the requir em ents of IEC1010-2-031 and are rated to 1000V

Category III. Use only the test leads provided, or a set of similar performance, to ensure safe

operation. Alternative test leads should be rated to at least 1000V (Category I),

The RS232 interface permits remot e cont r ol and data-logging to disk using optional Windows

software. The interface is fully opto-isolated from the measurement system; t he hos t computer

provides power (via the DTR and RTS lines) to the TXD opto output and drives the RXD opto

input directly. The 9-way D-type on the meter m ust be connected to the 9-way D-type of the PC’s

serial port via a 9-way cable (all connections made); the PC is nulled out at the multimeter

interface as shown below:

9 GND Signal ground

Signal grounds are connected to instrum ent safety ground.

To ensure compliance with EMC legislation use only screened cable assemblies with screened

connectors when connecting to other equipment .

10

Page 12

Switching On

Power Switch

The multimeter is switched on and off with alternate press es of the Operate key. This key only

switches the DC power to the measurement circuits; it does not switch the AC power which

means that the isolated RS232 circuit continues to be powered. Disconnect from the AC supply

by unplugging the mains cord from the back of the instrum ent or by switching off at the AC supply

outlet; make sure that the means of disconnection is readily accessible. Disconnect f r om t he AC

supply when not in use.

Power-up Settings

At power-up using the Operate key the default action is to restore power-down settings; t he

power-down settings are not retained if AC power is removed.

To restor e t he default settings (Volts, DC, Autorange) press SHIFT then Reset.

Turning the meter on at the AC supply whilst any key is held down initiates a buzzer and display

test (all segments and annunciators should be lit); when the key is released the revision of the

installed firmware is shown in the display as x.x. Pressing the Operate key switches on the meter

as normal.

Buzzer

A short beep is sounded whenever an invalid key is pressed, e.g. pressing Hz when an AC range

is not selected; such keystrokes ar e not accepted. The buzzer is also used to indicate a

resistance <10Ω in Continuity mode.

Keyboard

Selection of the primary function is made dir ectly by pressing the appropriate keys e.g. V and DC

for DC Volts; the primary function is showing beside the key. The meter is switched between

autoranging and manual with alternate presses of the Auto/Man key; alternatively using the

arrowed up and down keys changes the range and sets manual ranging.

The further f unc t ions ( Null, Hold, Min-Max etc.) are all selected by pressing SHI FT f ollowed by

the appropriate key; the shifted function is shown in blue above the key. When SHIFT is pressed

the annunciators for all the shifted functions are lit; when the function is selected with the

appropriate key only the associated annunciator remains lit.

11

Page 13

is exceeded.

Scale Length

The scale length is always ± 40,000 counts, except AC ranges which are ± 4,000.

Function Selection

All functions are directly selected by pressing the appropriat e function keys (e.g. V followed by

DC to set DC Volts). Changing function sets autorange when there is more than one range;

providing the appropriate function has been selected ( e.g. Ω f or r esistance m easurement) and

the parameter to be measured is within the range of the meter, a valid reading should always be

shown.

Making Measurements

The units and function are shown in the display (e.g.

to indicate autorange.

Continuity and Diode Test and selected by pressing SHIFT followed by the appropriate key. The

associated annunciator confirms the s elect ion. Continuit y sets the meter to the 4kΩ r ange and

buzzes for values below approximately 10Ω.

Range Selection

Selecting a new function always sets autorange to ensure an in-range reading is made with

maximum resolution whenever possible; the meter ranges up at 40, 000 counts ( 4, 000 on AC

ranges) and ranges down at 3,840 counts (V and Ω) or 255 counts (mA); AC ranges range down

at 384 counts and 25 counts respectively.

There are, however, situations when it is desirable to lock the range; for example, to stop the

meter autoranging to t he 40MΩ range and back between successive resistance measurements

of lower resistance values, or to set a lower resolution range when an unstable parameter is

being monitored. To lock t he r ange, change from auto to manual ranging, see below.

Manual range changing is selected either by alternate presses of the Auto/Man key, which locks

the meter in its present range, or by using the arrowed up/down keys which both change the

range and lock the meter in that new range. The Auto annunciator is off in Manual mode.

Overrange is indicated by OFL in the display; overrange is shown when the count exceeds

40,000 in a manually locked range (1024V/768V on the 1000VDC/750VAC ranges respectively).

Autoranging can be restored by pressing t he Auto/Man key again.

and V for DC Volts) together with Auto

Making Voltage Measurements

Voltage measurements are made using t he r ed V/Ω socket and the black CO M socket having

selected the appropriate function and range as described above.

The meter will show a minus sign (on dc measurements) when the voltage applied to the red

socket is more negative than that applied to t he black socket.

Note that when AC voltage ranges are selected with the meter inputs open circuit a non-zero

reading will usually show because stray AC sig nals couple into the meter’s high impedance input.

This is perfectly normal and will not affect the accur acy of practical voltage measurements where

source impedance is generally low.

The maximum voltage that can be applied between V/Ω and COM is 1000V DC or 750V AC

(265V DC/AC rms on 400mV range), Categ or y I; dam age to the instrument may result if this limit

WARNING! The maximum input voltage to ground must not exceed 1000V (Category I) or 600V

(Category II) dc or ac rms . Safety will be impaired if these ratings are exceeded, see Safety

section at the beginning of t he m anual.

12

Page 14

Making Current Measurements

Having selected the appropriate current function (mA for 4mA and 400mA range, A for 10A

range), current measur ements up to 400mA are made using the white mA socket and the black

COM socket; current measurements up t o 10A are made using the 10A and COM socket. The

meter will show a minus sign (on dc measurements) when the polarity of the current is out of the

mA or 10A sockets.

Current measurements using the mA socket can be autoranged between the 4mA and 400mA

ranges; measurements up to 10A can be made using the 10A socket having selected the 10A

range with the A key.

The 4mA and 400mA ranges, using the mA socket, are protected by a 1A (F) HBC fuse and the

10A range, using the 10A socket, is protected by a 10A (F) HBC fuse. Both fuses are fitted inside

the instrument and replacement is described in the Maintenance sect ion later in t he m anual.

Note: After measuring high current using the 10A input, thermal voltages are generated that may

create errors when making measur em ents on t he m ost sensitive dc voltage, current or Ohms

ranges immediately afterwards. To ensure that the specified accuracy is maintained, allow 10

minutes for the therm al effects to fade before mak ing sensitive measurements.

Making Resistance Measurements

Resistance measurements are made using the V/Ω and COM sockets.

Null can be used to null out residual test lead resistance, see Further Functions sec t ion.

Making Continuity and Diode Checks

Continuity and diode checks are made using the V/Ω and COM sockets.

Select Continuity mode by pressing SHIFT followed by Continuity; the continuity indicator is

shown in the display. The 4kΩ range is selected and readings below approximately 10Ω sound

the continuity buzzer.

Select Diode Test by pressing SHIFT followed by Diode Test; the diode annunciator is shown in

the display. The 4V rang e is select ed and the diode voltage at approximately 1mA is shown

(3V maximum). Reverse diode connection will show overload (OFL).

Making Frequency Measurements

Frequency measurements are made using either the V/Ω and COM sockets (f or AC voltages) or

mA/10A and COM (for AC curr ents) .

First set the input sensitivity by selecting the appropriate AC volts or current range to give an inrange measurement of at least 2,000 counts; then press the Hz key to select frequency mode.

Two ranges (4kHz and 40kHz) are available giving resolutions of .1Hz and 1Hz respectively over

an operating frequency rang e of 10Hz to 40kHz.

The default frequency range is 40kHz which has a 1s gate time. To select the 4kHz range (10s

gate time) use the arrowed down key; the Hz annunciator flashes slowly to indicate that the 4kHz

range has been selected. The 40kHz range can be reselected with the arr owed up key.

At low signal levels use a screened lead and an adaptor (BNC to 4mm plugs, 19mm pitch) t o

preserve signal quality and avoid spurious readings from st ray pick-up.

Note that the further functions of Null, Hold, T-Hold and Min-Max (next section) do not operate

with frequency measurement.

13

Page 15

Null

Hold

Further Functions

The further f unc t ions of Null, Hold, T-Hold and Min-Max are all selected by pressing SHIFT

followed by the appropriate key; the shifted func t ion is shown in blue above the key.

Selecting Null stores the current reading and subtracts it from all the following readings. The

meter range is locked and Null shows in the display. Hold, T-Hold and Min-Max can all be

subsequently selected but changing f unction or range (or selecting Auto) will automatically cancel

Null. Null can also be cancelled by pressing SHIFT followed by Null.

Null can be used to null out the effect of r esidual t est lead r esistance on t he lower Ohm s r anges.

Select the appropriate Ohms range us ing the arrowed up/down keys. Connect the test leads

together, wait for the reading to settle and select Null. Make the Ohm s m eas ur em ents in the

usual way but note that if Auto is reselected or if the range is changed then Null will be cancelled.

Null cannot be used with Hz.

Selecting Hold freezes the reading in the display and flashes the Hold annunciator. Hold can be

used with the Null already selected but Null and Min-Max cannot be selected once Hold is set.

Selecting any other function (including range change, Auto/Man and T-Hold) will set that function

and cancel Hold. Hold cannot be used with Hz.

T-Hold

In T-Hold (Touch and Hold) mode the meter will hold a reading until a new non-zero

measurement has been detected; this allows the user to touch-probe the measurement point,

remove the probes and read the meter aft er wards. Care s hould be tak en, however, when using

T-Hold with the most sensitive voltage ranges; when the probes ar e lift ed from the circuit being

measured their high impedance means that s t r ay pick-up might generate another ‘valid’ reading

and the true T-Hold reading may be lost. Selecting T-Hold locks the meter range and shows the

T-Hold annunciator in the display. When T-Hold is initially selected it is automatically ‘armed’ and

the first valid (non-zero) reading will cause the display to update with a beep and the T-Hold

annunciator to flash.

The meter will re-arm (2 beeps) when it subsequently sees a near-zero reading ( bec ause, for

example, the probes have been removed from the measurement) but the original reading is held

in the display. After the 2 beeps the T-Hold annunciator stops flashing to confirm that the m et er is

armed and a new reading is taken when the probes next make a non-zero measurement. Wit h

Ohms and continuity measurements, overflow, associated with the probes being open-circuit, rearms the meter. For all functions a measurement change of more than 1000 counts will also

initiate a re-arm/new measurement cycle. T-Hold can be used with Null already selected but Null

and Min-Max cannot be selected once T-Hold is set . Select ing any other function (including range

change, Auto and Hold) will set that function and cancel T-Hold.

T-Hold cannot be used with Hz.

Min-Max

While Min-Max is selected the minimum (m os t negative) and maximum (most positive) readings

are stored. The Min and Max readings can be displayed, while Min-Max is running, by using the

Review function (SHIFT followed by Review). The first SHIFT/Review displays the Minimum,

indicated by flashing the Min annunciator; the second SHIFT/Review displays the Maximum (Max

flashes); the third SHIFT/Review returns the display to normal with Min-Max still running.

Min-Max can be turned off by pressing SHIFT/Min-Max again. Selecting another function or

range or Auto also cancels Min-Max. Null, Hold and T-Hold cannot be selected with Min-Max

running. Min-max cannot be used with Hz. Review cannot be used with Min-Max turned off.

14

Page 16

Routine maintenance is limited to re-calibration and cleaning. The only repair maintenance that

can be carried out by the user is current rang e fuse replacement.

Calibration

Calibration is guaranteed as in the specification. The manufacturers provide a re-calibration

service, as do most of their agents overseas. Where owners wish to carry out re-calibration

themselves, this should only be done by skilled personnel with access to precision equipment

working in conjunction with the service manual which may be purchased directly from the

manufacturers or their agents overseas.

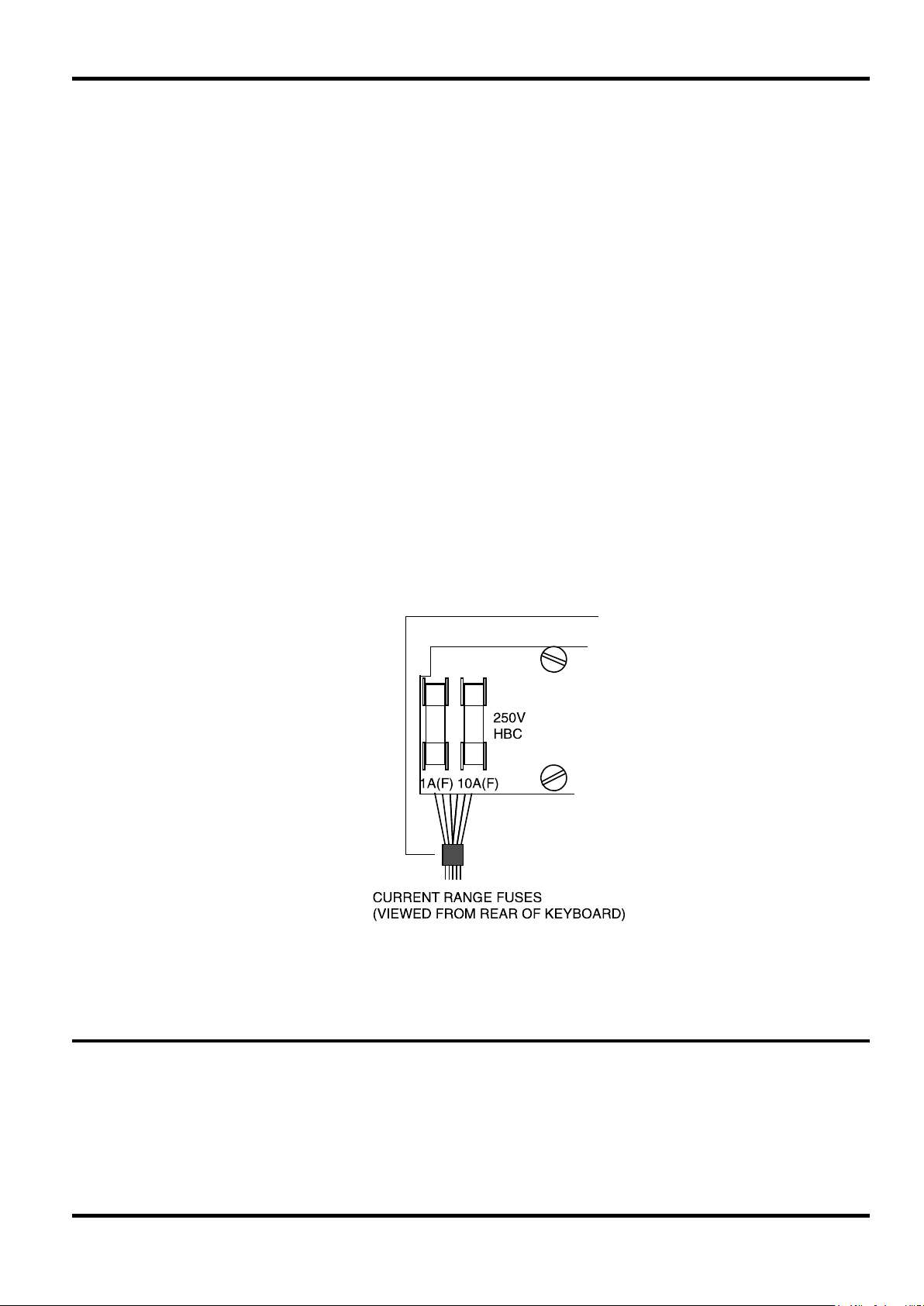

Current Range Fuses

The mA socket is protected by a 1A (F) HBC fuse and the 10A socket by a 10A (F) HBC fuse,

both mounted internally. To replace a fus e, proceed as follows:

1. Disconnect the instrument fr om all voltage sources.

2. Unclip the front bezel by gently pulling the centre of each long edge up and forward.

The case halves are held together by 4 plastic push-rivets. Use the blade of a s m all

screwdriver in the slot beside each rivet to first ease out t he r ivet head and then fully

remove the rivet body. Separate the case halves. Visit www.tti-test.com for further

details.

Maintenance & Calibration

3. Replace the fuse with one of an identical rating using t he diagram below as a guide.

4. Reassemble in the reverse order.

Mains Fuse

The transformer pr imary is protected by an integral thermal fuse which is not user replaceable.

Should a fault develop which causes the thermal fuse to blow, the meter must be returned to t he

manufacturer or ag ent for service.

Remote Operation

The RS232 interface permits remot e cont r ol and data-logging to disk using optional Windows

software; operation is controlled by clicking with the mouse on the keys of the virtual front panel

displayed on the PC.

Connection between the RS232 port and the PC’s serial port is made using a 9-way D -type to

D-type cable with all connections made, see Connections section under General Operation.

15

Page 17

Sécurité

Ce multimètre est un appareil de sécurité Classe I selon la classification de la CEI. Sa

conception est conforme aux normes EN61010-1 ( Règles de sécurité pour les appareils

électriques de mesurage, de régulation ou de laboratoire). Cet appareil à installation Catégorie II

est conçu pour courant normal monophasé.

ATTENTION ! CET APPAREIL DOIT ETRE RELIE A LA TERRE

Toute interr upt ion du conduc t eur à la t er r e à l’intér ieur ou à l’extérieur de l’appareil rendra

l’appareil dangereux. Toute interruption intentionnelle est inter dit e. Ne pas utiliser de rallonge

sans fil neutre qui annulerait la protect ion de l’appareil.

Les fils d’essai fournis avec cet appareil sont conformes aux exigences IEC1010-2-031 et leur

tension assignée est de 1000V Catégorie III . Seuls ces fils d’essai ou des fils de perf or m ance

identique doivent être utilisés avec ce multimètre.

Cet instrusment a été testé selon EN61010-1 et a ét é fourni en bon état. Ce manuel fournit des

informations et des notices de sécurit é que l’utilisateur devra suivre pour garantir le

fonctionnement en toute sécurit é de l’appareil et le conserver en bon état.

Cet appareil doit être utilisé à l’intérieur dans un milieu de Pollution Degré 1 (aucune pollution ou

pollution sèche non-conductrice) entre une tempér ature de 5°C à 40°C, 20% - 80% d’Humidit é

Relative (sans condensation). Il peut de temps en temps être soumis à des t em pér atures entre

+5° et -10°C sans être endommag é.

Cet appareil a été conçu pour un mesurage d’installation Catégorie II j us qu’à 600V DC/CCrms et

un mesurage d’Installation Catégorie I j usqu’à 1000V DC/750V CCrms. Les définitions complètes

des Catégories I et II se tr ouvent dans IEC664. Les informations suivantes peuvent cependant

servir de guide :

L’installation Catégorie I s’applique aux appareils de niveau de signal comme par exemple les

appareils de télécommunication et les appareils électroniques avec des surtensions transit oires

plus petites que pour l’Installation Catégorie II.

L’installation Catégorie II s’applique aux appareils de niveau de courant domestique l ocal t els que

les appareils et équipement portables. Catégorie II n’inclut pas les installations tels que les

installations à trois phases, classées sous les Installations Catégorie II I .

Pour cet équipement, 2500V est la surtens ion transitoire maximale qui peut être tolérée par les

bornes pour la mise à la terre, sans créer de pr oblèm es de séc ur it é.

Une utilisation non conforme aux instructions fournies pourra entraîner l’endommagement du

dispositif de sécurité. Ne pas faire f onc t ionner cet appareil au-delà de ses voltages assignés ou

dand un environnement autre que l’environnement spécifié. Un excès d’humidité pourr a

endommager la sécurité de l’appareil.

Lorsque l’appareil est connecté à son courant ou que ses connexions sont sous tension, il se

peut que les bornes soient également sous t ension ; l’ouvertur e du boîtier ou le ret r ait des pièces

(sauf celles pouvant être accédées à la main) mettra à nu des pièces sous tension. Avant de

l’ouvrir pour effectuer tout travail de réglag e, de remplacement, d’entretien ou de réparation,

l’appareil doit être déconnecté de toutes les sources de tension.

Il est recommandé, dans la mesure du possible, d’éviter d’entr eprendre tout réglage, tr avail

d’entretien et de réparation de l’appareil lorsq’u’il est ouvert et sous tension. Si ces tr avaux sont

inévitables, ils doivent être effectués par une personne compétente connaissant les risq ues .

Si l’appareil est défectueux, a subi des dommages mécaniques ou a ét é exposé à une humidité

excessive ou à une corrosion chimique, il se peut que la protection de sécurit é soit endom m agée

; l’appareil devra être mis hors service et renvoyé afin être vérifié et réparé.

Pour le remplacement des fusibles, vérifier que seuls des fusibles du type spécifié et

correspondant au courant assigné sont utilisés. L’utilisation d’autre fusibles et la mise en courtcircuit des douilles des fusibles est interdite.

16

Page 18

n’est pas utilisé correctement.

Ne pas mouiller l’appareil lors de son nettoyage ; utiliser un chiffon doux pour nettoyer l’écran

d’affichage.

Les symboles suivants figurent sur l’appareil et dans ce manuel :

ATTENTION - risque d’électrocution.

AVERTISSEMENT - se rapporte à la documentation; l’appareil sera endommagé s’il

- terre

- courant continu

- courant alternatif

17

Page 19

Tension sect eur assi gnée

Vérifier que la tension assignée indiquée à l’arrièr e du paneau corres pond au cour ant local. Si la

tension assignée doit être modifiée, r es pect er les instructions suivantes :

1) Déconnecter l’appareil de toutes les sources de voltage.

2) Décrocher le panneau avant en tirant doucement vers le haut puis en avant au milieu de

chaque long.

Les deux parties du boîtier sont attachées par 4 rivets-poussoir en plastique. Utilisez la

lame d’un petit tournevis dans la fente à coté de chaq ue rivet pour faire sortir la tête du

rivet puis enlevez complètement le rivet. Séparez les deux parties du boîtier. Visitez le site

www.tti-test.com

3) Enlever les 3 vis fixant la carte à circuits imprimés au bas du boîtier et soulever la carte à

circuits imprimés avec les panneaux avant et arrière.

4) Changer le voltage en changeant les liens brasés comme montré ci-dessous :

Installation

pour de plus amples informations.

5) Assembler de nouveau en utilisant la procédure inverse.

6) Pour rester conform e aux norm es de s écur it é, la t ens ion assig née indiq uée à l’arrière du

A Noter : Le côté primaire du transformateur es t pr otégé par un fusible thermique intég ral qui

reste inchangé lorsque la tension assignée est modifiée.

Fil de secteur

Lorsqu’un fil secteur à trois br ins est fourni il doit être connecté de la façon suivante :

ATTENTION ! CET APPAREIL DOIT ETRE RELIE A LA TERRE LORSQU’IL EST UTILISE

Toute interr upt ion du conduc t eur à la t er r e à l’intér ieur ou à l’extérieur de l’appareil rendra

l’appareil dangereux. Toute interruption intentionnelle est inter dit e. Ne pas utiliser de rallonge

sans fil neutre qui annulerait la protect ion de l’appareil.

panneau doit être modifiée pour indiquer clairement le nouveau voltage.

Brun - Sous tension

Bleu - Neutre

Vert / Jaune - Terre

EN COURANT ALTERNA TIF

18

Page 20

de courant de 10A.

Broche

Nom

Description

1

DCD

Relié au DTR

2

TXD

Données transmises par l’appareil

3

RXD

Donnée reçues par l’appareil

4

DTR

DTR du serveur doit être sur +9V (logique 0)

5

GND

Prise de terre

6

DSR

Relié au DTR

7

RTS

RTS du serveur doit être sur -9V (logique 1)

8

CTS

Relié au RTS

9

GND

Prise de terre

Ce chapitre est une introduction générale sur les car actérisitiques et les fonctions du multim èt re

et doit être lue attentivement avant d’utiliser l’appareil pour la première f ois. De plus amples

informations sur le fonct ionnem ent de l’appareil se trouvent dans le chapitr e Pr ise de Mesures

Connexions

Prises d’entrée

Les prises d’entrée sont des prises de sécurité de 4mm sur un pas de 19mm conçu pour les

prises de sécurité de 4mm avec des protecteurs de c ontact coquille fixes ou rétractables. Leur

tension assignée est de 1000V (Catégorie I) / 600V ( Cat égorie II).

L’impédance d’entrée entre V/Ω et COM est 10MΩ. La borne noire COM est moins positive que

la rouge.

Les bornes mA/10A ont une impédance basse; La charge de tension entre mA/10A et COM à

échelle véritable est <500mV. La bor ne noir e CO M est moins posit ive que les blanches mA/ 10A.

Fils d’essai du multimètre

Fonctionnement Général

RS232

Les fils d’essai fournis sont conf or m es aux exigences IEC1010-2-031 et leur tension assignée

est de 1000V Catégorie III. Pour un fonctionnement en toute sécurité, n’utiliser que les fils

d’essais fournis ou un jeu de perform anc e ident iq ue. La tension assignée des fils d’essai de

rechange doivent être d’au moins 1000V (Catégorie I) , 600V (Catégorie II) et avoir un potentiel

L’interface RS232 permet le contrôle à distance de l’appareil et la saisie des données sur

disquette en utilisant un logiciel optionnel pour Windows. L’interface est totalement opto-isolée du

système de mesure, le serveur alimente (par l’intermédiaire des lignes DT R et RTS ) le débit final

opto TXD et conduit le débit d’entrée opto du RXD directement. Le D-type à 9 voies doit être

connecté au D-type à 9 voies du port de série du PC par un câble à 9 voies (toutes autres

connexions faites); le PC passe par zéro à l’interface du multimètre com m e m ontré ci-dessous :

Les prises de terre sont connectées à la terr e de s écur it é de l’appareil.

Pour que l’appareil soit conforme à la législation EMC, n’utiliser, lors de la connexion à d’autres

appareil, que des câbles déparasités avec des connecteurs déparasités.

19

Page 21

Mise en Marche

Sectionneur de puissance

Le multimètre s’allume et s’éteint en appuyant sur la touche “ O per ate”. Cette touche alimente en

courant continu les circuits de mesurage ; elle ne distribue pas de courant alt er nat if, le circuit

isolé RS232 continue donc à être alimenté. Déconnecter du courant alter natif en débranchant le

fil secteur à l’arrière de l’appareil ou en éteignant le courant alter natif; Vérifier que les moyens de

déconnexions sont accessibles. Lorsque l’appareil n’est pas utilisé, le débrancher du secteur à

courant alternatif.

Réglage de puissance

En mode haute puissance l’action par défaut de la touche “Operat e” sera de rétablir les valeurs

de basse puissance; les réglages de basse puissance ne sont pas conservés si le courant

alternatif est éteint.

Pour retrouver les valeurs par défaut (Volts, CC, champ automatique) appuyer sur SHIFT puis

Reset.

Allumer le multimètre au secteur CA lorsqu’une touche est appuyée déclenchera un signal

sonore et un test d’affichage (t ous les segments et les annonciateurs devraient être allumés);

lorsque la touche est relachée la révision du microprogramme est affichée (x.x). La touche

“Operate” mettra en m ar c he le mult im èt r e.

Signal sonore

Un court bip est émis lorsqu’une mauvaise touche est utilisée, par exemple, appuyer sur Hz

lorsqu’une zone CA n’a pas été sélectionnée ne sera pas accepté. Ce signal sonore indique

également une résistance <10Ω en m ode de cont inuit é.

Clavier

Les fonctions primaires sont sélectionnées en appuyant sur les t ouches appr opr iées, par

exemple V et DC pour CC Volts; les fonctions primaires s ont indiq uées à côt é de la t ouc he. Pour

mettre le multimètre en mode m anuel ou automatique appuyer sur la touche Auto/Man ; les

flèches peuvent aussi être utilisées; elles changent la zone de mesure et m ettent l’appareil en

mode manuel.

Pour sélectionner les autres fonct ions ( Null, Hold, Min-Max etc.) appuyer sur la touche SHIFT

puis sur la touche appropriée; les fonctions secondaires “ shif t” sont indiquées en bleu au-dessus

des touches. Lorsque SHIFT est utilisé les annonciateurs de toutes les fonctions”SHIFT”

s’allument; lorsque SHIFT est sélectionné avec la touche appropriée, seul l’annonciateur

concerné reste allumé.

20

Page 22

(Catégorie I) ; si cette limit e est dépassée, l’appareil risque d’être endommagé.

Longueur du champs de mesure

La longueur du champs de mesure est toujours ± 40,000 comptes, sauf pour les zones CA qui

sont de ± 4,000.

Sélection des fonctions

Toutes les f onc t ions sont obtenues directement en appuyant sur la touche appropriée ( par

expemple V suivi de DC pour régler les Volts CC). Lorsqu’il y a plus d’un champs de mesure, le

fait de changer de fonction déclenche le mode automatique; si la bonne fonction a ét é

sélectionnée (par exemple. Ω pour mesurag e de la rés itance) et le paramèt r e à mesurer figure

dans le champ de mesure du multimètre, le relevé affiché devrait t oujours être valable. Les

unités et fonctions sont affichées sur l’écr an ( par exemple.

indique le champ de mesure automatique.

Les tests de continuité et de diode sont sélectionnés en appuyant sur SHIFT suivi de la touche

appropriée. L’annonciateur confirme la sélection. La touche “Continuity” règle le multimèt r e s ur le

champ 4kΩ et émet un signal sonore pour les valeurs inférieures à environ10Ω.

Sélection du champ de mesure

La sélection d’une nouvelle fonction déclenche le mode automatique pour assurer, dans la

mesure du possible, un mesurage à haute résolut ion à l’intérieur du cham p; la valeur maximum

du champ de mesure du multimètre est 40, 000 comptes (4,000 dans les champs CA) et sa

valeur minimum est 3,840 comptes (V et Ω) ou 255 comptes (mA); pour le CA les comptes

minimum sont 384 comptes et 25 comptes r espec t ivement.

Prise de mesure

et V pour Volts CC) avec Auto qui

Dans certains cas il est souhaitable de verrouiller le champ de mesure; par exemple, pour

empêcher le multimètre de se remett re automatiquement sur la zone 40MΩ entre c haque

mesure de résistance de valeur inférieure ou pour fixer un champ à résolution inférieure

lorsqu’un paramètre instable est observé. Pour verrouiller le champ de mesure, s élect ionner le

mode manuel de la manière expliquée ci-dessous.

Pour sélectionner le mode manuel, appuyer sur la touche Auto/Man qui verrouillera le multimètre

sur le champ sélectionné ou utiliser les flèches; elles changer ont le cham p de mesure et

verrouilleront le multimètre sur ce nouveau champ. En mode Manuel l’annonciateur est éteint. Le

hors champ est indiqué sur l’écran par OFL; il est indiqué lorsque le compte dépasse 40,000

dans un champ verrouillé manuellement (1024V/768V sur les champs 1000VCC/750VCA

respectivement). Pour remett r e l’appareil en mode automatique appuyer à nouveau sur la touche

Auto/Man.

Mesure de la tension

Les mesurages de tensions sont effec t ués en utilisant la borne rouge V/Ω et noir e CO M et en

sélectionnant la fonction appropriée et le champ de mesure de la manière décrite ci-dessus.

Le multimètre affichera un signe moins ( mesurages en cc) lorsque le voltage de la borne rouge

est plus négatif que celui de la noire.

Lorsque les champs de voltage CC sont sélectionnés avec le circuit ouvert des débits d’entrée,

un relevé différent de zéro sera indiqué parce que les signaux CA de fuite s’accouplent dans le

débit d’entrée à haute impédance du multimètre. Ce phénom ène est normal et n’affectera pas

l’exactitude des mesures de tension où l’impédance de source est généralement bas se.

Le voltage maximum pouvant être utilisé entre V/Ω et COM est 1000V CC ou 750V CA

ATTENTION ! le voltage maximum d’entrée à la terre ne doit pas dépasser 1000V (Catég or ie I )

ou 600V (Catégorie II) cc ou ca rms . Si ces valeurs sont dépassées l’appareil deviendra

dangereux, voir chapitre Sécurité au début de ce manuel.

21

Page 23

Mesurage du courant

En sélectionnant la touche de courant appropriée (mA pour 4mA et 400mA, A pour 10A), les

mesures de courant jusqu’à 400mA sont effectuées en utilisant la borne blanche mA et la borne

noire COM; les mesures de courant jusqu’à 10A sont effectuées en utilisant la borne 10A et la

borne COM. Le multimètre affichera un signe m oins ( m esur ages en cc) lorsque la polarité du

courant est en dehors des bornes mA ou 10A.

Les mesures de courant effectuées avec la borne mA peuvent être effectuées en mode

automatique entre 4mA et 400mA ; les mesures jusqu’à 10A peuvent être effectuées en

sélectionnant 10A avec la touche A et en utilisant la borne 10A.

Les champs 4mA et 400mA q ui ut ilisent la borne m A sont protégés par un fusible 1A (F) HBC et

le champ 10A qui utilise la borne 10A est prot égé par un fusible 10A (F) HBC. Ces deux fusibles

sont à l’intérieur de l’appareil. Les procédures de remplacement sont décr it es dans le chapt ir e

“Entretien” de ce manuel.

A Noter : Après avoir mesuré un courant élevé en utilisant la borne 10A, des tensions

thermiques sont produites et pour r ont causer des erreurs lors de mesures sur les c ham ps de

voltage cc, de courant ou Ohms les plus sensibles. Pour conserver l’exactitude spécifiée,

attendre 10 minutes avant de reprendre des mesur es sensibles pour que les effets thermiques

s’atténuent.

Mesure de la résistance

Les mesures de résistance sont effectuées en ut ilisant les bor nes V/Ω et COM.

Null peut être utilisé pour annuler la résistance résiduelle du fil d’essai, voir Autres Fonctions.

Vérification de continuité et de la diode

Les vérifications de Continuité et de Diode sont effectuées en ut ilisant les bor nes V/Ω et COM.

Sélectionner le mode Continuité en appuyant sur SHIFT suivi de “Continuity”; l’indicateur de

continuité s’affichera. Le champ 4kΩ est sélectionné et les mesures inf ér ieures à environ 10Ω

déclencheront le signal sonore de continuité.

Sélectionner le test de Diode en appuyant sur SHIFT suivi de “Diode Test”; l’annonciateur de

diode s’affichera. Le champ 4V est sélectionné et le voltage de la diode d’environ 1mA est affiché

(3V maximum). La connexion inverse de la diode montrera une surcharge ( O FL) .

Mesure de fréquence

Les mesures de fréquence sont effectuées en utilisant les bornes V/Ω et COM (tensions CC) ou

mA/10A et COM (CA).

Régler tout d’abord la sensibilité de débit d’entrée en sélectionnant les volts CA ou le champ de

courant appropriés afin d’obtenir une mesur e dans un champ d’au moins 2,000 comptes ;

appuyer ensuite sur la touche Hz pour sélectionner le mode de fréquenc e. Deux champs (4k Hz

et 40kHz) sont disponibles et donnent des résolutions de.1Hz et 1Hz respectivement sur un

champ de fréquence assignée de 10Hz à 40kHz.

La fréquence par défaut est 40kHz et son temps de comptage est 1s. Pour sélectionner 4kHz

(temps de comptage 10s) utiliser la flèche vers le bas; Hz clignoter a lent em ent pour indiquer que

4kHz a été sélectionné. 40kHz peut être resélectionné en appuyant sur la flèche vers le haut.

A des niveaux bas de signal utiliser un fil déparasité et un adapteur (BNC prises de 4mm , pas de

19mm) pour conserver la qualité de signal et éviter des m esures fictives provenant de

perturbations de fuite.

Noter que les fonctions Null, Hold, T-Hold et Min-Max (chapitre suivant) ne fonctionnent pas avec

la fonction de mesure de fréquence.

22

Page 24

Null

Hold

Autres Fonctions

Les fonctions Null, Hold, T-Hold et Min-Max se sélectionnent en appuyant sur SHIFT suivi de la

touche appropriée ; les fonctions secondaires “ shif t” sont indiquées en bleu au-dessus des

touches.

La fonction Null enregistre la mesure act uelle et la soustrait de toutes les mesures suivantes. Le

champ de mesure est verrouillé et Null est affiché. Hold, T-Hold et Min-Max peuvent alors être

sélectionnés mais le fait de changer la f onction ou le champ (ou sélectionner Auto) annulera

automatiquement Null. Null peut également êt re annulé en appuyant sur SHIFT suivi de Null. Null

peut être utilisé pour annuler les effets de résistance résiduelle de fil d’essai sur les c ham ps

Ohms inférieurs. En utilisant les flèches, sélectionner le champ Ohms approprié. Connect er les

fils d’essai l’un à l’autre, attendre que le relevé se stabilise et sélectionner Null. Mesurer les

Ohms de la façon ordinaire ; noter cependant que si Auto est resélectionné ou si le champ est

modifié, Null sera annulé. Null ne peut pas être utilisé avec Hz.

La fonction Hold figera l’affichag e et l’annonciateur Hold clignotera. Hold peut être utilisé lorsque

Null est déjà sélectionné mais Null et Min-Max ne peuvent pas être sélectionnés une fois que

Hold est utilisé. La sélection de toute autre fonc t ion ( y compr is le chang ement du champ de

mesure, Auto/Man et T-Hold) annulera Hold. Hold ne peut pas être utilisé avec Hz.

T-Hold

La fonction T-Hold (Touch and Hold) figera le relevé jusqu’à ce qu’une mesure diff ér ent e de zéro

soit détectée ; cela permet à l’utilisateur de sonder le point de m esure, d’enlever les sondes et de

lire le multimètre par la suite. Il faut cependant faire attention lorsque T-Hold est utilisé avec les

champs de voltages les plus sensibles. En effet lorsque les sondes sont ret irées du cir cuit

mesuré, leur haute impédance signifie que des perturbations de fuite peuvent produire une aut r e

mesure valable et la véritable mesure pourra se perdre. T-Hold verrouille le champ du multimètre

et affiche l’annonciateur de T-Hold. Lorsque T-Hold est sélectionné il s’arme automatiquement et

le premier relevé valable (différent de zéro) entraînera la mise à jour de l’affichage ac com pagné

d’un bip sonore et le T-Hold clignotera.

Le multimètre se réarmera (2 bips) lorsqu’il recevra un relevé proche de zéro (lorsque par

exemple, les sondes ont été enlevées) mais le relevé d’origine restera affiché. Après 2 bips, THold s’arrêtera de clignoter pour conf ir m er que le multimètre est armé. Le prochain relevé sera

pris lorsque les sondes détecteront une mes ur e différente de zéro. Avec les mesures Ohms et de

continuité, le courant de surface, ass ocié aux sondes à circuit ouvert, réarme le multimètre. Pour

toutes les fonctions, un chang em ent de mesure de plus de 1000 comptes déclenchera un cycle

de réarmement/nouvelle mesure. T-Hold peut être utilisé avec Null déjà sélectionné mais Null et

Min-Max ne peuvent pas être sélectionnés une fois que T-Hold est choisi. Sélectionner toute

autre fonction (y compris la modif icat ion du cham p mesure, Auto et Hold) annulera T-Hold.

T-Hold ne peut pas être utilisé avec Hz.

Min-Max

Lorsque Min-Max est sélectionné, les relevés minimum (le plus négatif) et m aximum ( le plus

positif) sont enregistr és . Les relevés Min et Max peuvent être affichés lorsque la fonction MinMax est en opération, en utilisant la fonction Review (SHIFT suivi de Review). Le premier

SHIFT/Review affiche le Minimum et l’annonciateur Min clignote ; le second SHIFT/Review

affiche le Maximum (Max clignote) ; le troisième SHIFT/Review affichera l’écran normal, Min-Max

étant toujours en opération. Min-Max se désélectionne en appuyant sur SHIFT/Min-Max. La

sélection d’une autre fonction, d’un champ de mesur e ou d’Aut o annule ég alem ent Min-Max.

Null, Hold et T-Hold ne peuvent pas être sélectionnés lorsque Min-Max est en opération. Min-max

ne peut pas être utilisé avec Hz. Review ne peut pas être utilisé lorsque Min-Max est éteint.

23

Page 25

L’entretien de routine se limite au recalibrage et au nettoyage de l’appareil. Le remplacement du

fusible du champ de mesure du courant est la seule réparat ion pouvant êtr e effectuée par

l’utilisateur.

Calibrage

Comme stipulé dans les spécifications, le calibrage est garanti. Les fabricants, ainsi q ue la

plupart des agents à l’étranger, offrent un service de recalibrage. Si les propriétaires de l’appareil

souhaitent recalibrer eux-mêmes l’appareil, ce travail devra être effect ué par des pers onnes

compétentes munies du matériel de précision adéquat et les instructions du manuel d’entretien,

disponible directement chez les fabricants ou leurs agents à l’étranger, devront être respectées.

Fusibles de courant

La borne mA est protégée par un fusible 1A (F) HBC et la borne 10A par un fusible 10A (F) HBC ;

tous deux se trouvent à l’intérieur de l’appareil. Pour remplacer le fusible, procéder de la façon

suivante :

1. Déconnecter l’appareil de toutes les sources de tension.

2. Décrocher le panneau avant en tirant doucement vers le haut puis en avant au milieu de

chaque long.

Entretien et Calibrage

Les deux parties du boîtier sont attachées par 4 rivets-poussoir en plastique. Utilisez la

lame d’un petit tournevis dans la fente à coté de chaque r ivet pour faire sortir la tête du

rivet puis enlevez complètement le rivet. Séparez les deux parties du boîtier. Visitez le site

www.tti-test.com pour de plus amples informations.

3. Remplacer le fusible avec un fusible identique en respectant le shéma ci-dessous.

4. Assembler de nouveau en utilisant la procédure inverse.

Fusible du secteur

Le côté primaire du transform ateur est protégé par un fusible thermique intégral qui n’est pas

remplaçable par l’utilisateur. Si, à la suite d’une faute, les fusibles thermiques sautent, le

multimètre devra être envoyé au fabricant ou à l’agent.

Fonctionnement à Distance

L’interface RS232 permet le fonctionnement à distance et la saisie de données sur disquette en

utilisant un logiciel optionnel pour W indows. Le fonctionnement est contrôlé en cliquant avec la

souris sur les touches du panneau virtuel affiché sur l’écran du PC.

Le port RS232 et le port de série du PC sont connectés à l’aide d’un câble D-Type à D-Type à 9

voies avec toutes les connexions ; voir Connexion dans le chapitre Fonctionnement général.

24

Page 26

Sicherheit

Dieses Multimeter (Mehrfunktionenzähler) ist nach der Klassifikation des IEC-Normenausschusses

ein Sicherheits Klasse-1- Gerät und ist so angelegt, dass es den Vorschriften der EN61010-1

(Sicherheits-ansprüche für elektrische Geräte für Messung, Kontrolle und Laborbedarf). Es handelt

sich um ein Kategorie II Installationsigerät, welches zum Betrieb einer normalen

Einzelphasenversorgung gedacht ist.

WARNUNG! DIESES GERÄT MUSS GEERDET SEIN

Jede Unterbrechung des Erdungsleiters der Hauptleitung innerhalb oder ausserhalb des Geräts

macht das Gerät gefährlich. Absichtliche Unterbrechung ist verboten. Die Absicherungsvorrichtung

darf nicht durch die Benutzung eines Verlängerungskabels ohne Sicherungs-leitung ausser Kraft

gesetzt werden.

Die mit diesem Gerät mitgelieferten Testkabel erfüllen die Vorschriften der IEC 1010-2-031 und sind

als 1000V Kategorie III eingestuft; ausschliess-lich die zu dem Messgerät gehörigenTestkabel oder

einen Satz Kabel mit equivalenter Leistung benutzen!

Dieses Gerät ist in Übereinstimmung mit EN61010 -1geprüft und in einwandfreiem Zustand geliefert

worden. Diese Anleitung ent hält einige Informationen und Warnungen, die vom Benutzer befolgt

werden müssen, damit ein sicherer Betrieb gewährleistet werden kann, und das Sicherheitsniveau

des Geräts erhalten bleibt.

Das Gerät ist für eine Benutzung in geschlossenen Räumen mit Ver unr einigungsgrad 1 ( keine

Verunreinigung, oder nur t r ockene nichtleitende Verunreinigung) bei einer Temperaturspanne von 5°C

bis 40°C, 20% - 80% RH (nichtkondensierend). Es kann gelegentlich auch Temperaturen zwischen

+5° und -10°C ausgesetzt werden, ohne dass ene Sicherungsverminderung eintritt.

Das Gerät ist für Messungen der Installationskategorie II bei 600V DC/ACrms und Messungen der

Installationskategorie I bei 1000V DC/750V ACrms gedacht. Die vollständigen Definitionen für die

Categorien I und II können im IEC664 eingesehen werden, aber die folgenden Aussagen können als

Anleitung verstanden werden:

Installationskategorie I ist die Signalebene, z.B.: Telekommunikation, elektronisches Gerät mit

kleineren transienten Überspannungen als Kategorie II.

Installationskategorie II ist die lokale häusliche Vers or gungsebene, z.B.:tragbare Geräte und

Vorricht ungen. I ns besonder e ent hält Kat egor ie II nicht die Versorgung auf der Ver t eilungsebene, z.B.:

drei-Phasen-Installationen, die als Installationskategorie III klassifiziert sind.

Bei diesem Gerät sind 2500 V die maximale Stoßspannung, die von einer Klemme in Bezug auf

Erde ohne Beeinträchtigung der Sicherheit toler ier t werden kann.

Die Benutzung dieses Geräts in einer Form, die nicht in dieser Gebrauchsanleitung niedergelegt ist,

kann die Sicherungvorrichtung beinträchtigen. Das Gerät darf nicht ausserhalb seiner Versorgungsspannungs- oder Umgebungseinstufung betrieben werden.

Insbesondere übermässige Feuchtigkeit kann die Sicherheit beinträch-tigen. Wenn das Gerät an

seiner Versor gung angeschlossen ist oder seine Inputs mit elektrischer Spannung geladen sind,

können die Pole unter Spannung stehen. Das Öffnen des Gehäuses oder die Entfernung von Teilen

(ausser denen die mit der Hand erreicht werden können) würde wahrscheinlich unter Spanung

stehende Teile blosslegen. Das Gerät sollte daher von nur unter Ausschluss jeder Quelle elektrischer

Spannung geöffnet werden, um Wartung, Einstellung, Ersatzteileinbau und Reparaturen

durchzuführen. Jegliche Einstellung, Wartung und Reparatur am offenen Gerät sollte sow eit wie

möglich vermieden werden, und, falls absolut nötig, nur von einer qualifizierten Kraft ausgeführt

werden, die sich der Sicherheitsrisiken bewusst ist.

Wenn das Gerät offensichtlich defekt ist- durch mechanische Beschädigung, übermässige

Feuchtigkeit oder chemische Korrosion, ist es möglich, dass die Sicherungsvorrichtung nicht mehr

intakt ist.In diesem Fall sollte das Gerät nicht mehr benutzt und zur Überpr üfung und Repar at ur

eingesandt werden. Es dürfen ausschliesslich Sicherungen mit der vorgeschriebenen

Stromeinstufung und des angegebenen Typs als Ersatz verwendet werden. Das Benutzen von

provisorischen Sicherungen und das Kurzschliessen von Sicherungsfassungen ist verboten.

25

Page 27

Bei der Reinigung darf das Gerät nicht nass werden; insbesondere zur Reinigung des

Anzeigefensters nur ein weiches, trockenes Tuch verwenden.

Die folgenden Symbole werden auf dem Gerät und in dieser Anleitung ver w endet:

WARNUNG - Gefahr eines elektrischen Schlags

VORSICHT – begleitende Dokumentation z u Rate ziehen; inkorrekter Betrieb kann den

Zähler beschädigen.

- Hauptleitungserdung

- Gleichstrom

- Wechselstrom

26

Page 28

Betriebsspannung der Hauptleitung

Versichern Sie sich, dass die Betr iebsspannung des Geräts, die an der hinteren Platte markiert ist, für

die örtliche Stromversor gung geeignet ist. Sollte es nöt ig sein, die Betr iebsspannung zu ändern,

gehen Sie vor wie folgt:

1) Alle Stromquellen zum Gerät unt er br echen.

2) Die vordere Blende durch vorsichtiges Ziehen der Mitte jeder langen Kante nach vorne oben

abklemmen.

Die beiden Gehäusehälften sind durch 4 Plastikdrucknieten zusamm engehalten. Die

Klinge eines kleinen Schraubendrehers in den Schlitz neben jedem Niet einstecken, um

zuerst den Nietkopf und anschließend den gesamten Nietk ör per zu entfernen. Die beiden

Gehäusehälten voneinander trennen. Weiter e Einzelheiten sind auf www.tti-test.com

finden.

3) Die 3 Schrauben, die die Leiterplatte am unteren Teil des Gehäuses befestigen, abschrauben

und den pcb (Leiterplatte) mitsamt Vorder-und Hinterplatte herausheben.

4) Die Spannungseinstellung lässt sich durch eine Änderung der Löt-verbindungen verändern.

Installation

zu

5) Zusammenbau in umgekehrter Reihenfolge.

6) Um den Sicherheitsvorschriften gerecht zu werden, muss die Angabe der Bet r iebsspannung,

Man beachte: Die Tr ansformator haupt leitung w ird von einer integralen Thermalsicherung geschützt,

die unverändert bleibt, wenn die Spannung geändert wird.

Hauptleitung

Wenn eine Dreiwegleitung mit abisolierten Enden geliefert wird, sollten diese wie folgt verbunden

werden:

Jede Unterbrechung des Erdungsleiters der Hauptleitung innerhalb oder ausserhalb des Geräts

macht das Gerät gefährlich. Absichtliche Unterbrechung ist verboten. Die Absicherungsvorrichtung

darf nicht durch die Benutzung eines Verlängerungskabels ohne Sicherungs-leitung ausser Kraft

gesetzt werden.

die an der hinteren Platte markiert ist, so geändert werden, dass die neue

Spannungseinstellung deutlich erkennbar ist.

Braun - Stromführende Hauptleitung

Blau - Neutrale Hauptleitung

Grün/Gelb - Erdungshauptleitung

WARNUNG! DIESES GERÄT MUSS GEERDET SEIN, WENN ES VON EINER

WECHSELSTROMVERSORGUNGSLEI TUNG BETRIEBEN WIRD.

27

Page 29

Pin

Name

Beschreibung

1

DCD

Mit DTR verbunden

2

TXD

Vom Gerät über mittelte Dat en

3

RXD

Vom Gerät emp fangene Daten

4

DTR

DTR vom Wirts-PC muss die Einstellung +9V (Logik 0) haben

5

GND

Signalerde

6

DSR

Mit DTR verbunden

7

RTS

RTS vom Wirts-PC muss die Einstellung-9V (Logik 1) haben

8

CTS

Mit RTS verbunden

9

GND

Signalerde

Dieser Abschnitt ent hält eine generelle Einführung in die Charakteristika und Organisation des

Multimeters, die vor der ersten Benutzung des G er äts gelesen werden sollte. Eine detaillierte Bedienungsanleitung ist im Abschnitt 'Messungen machen' enthalten.

Verbindungen

Input- Steckdosen

Die Input- Steckdosen sind 4mm Sicherheitssteckdosen auf einem 19mm Abstand, was für 4mm

Sicherheitssteckdosen mit einziehbarer Umhüllung vorgesehen ist. In Bezug auf die Erdung sind die

Steckdosen alle als 1000V (Kategorie I)/600V (Kategor ie II ) eingest uf t .

Der Input-Widerstand zwischen V/ Ω und COM ist nominell 10m Ω. Die schwarze COM- Steckdose

wird als weniger positiv angesehen als die rote Steckdose.

Die mA/10A Stromsteckdosen haben niedrige Widerstände; die Spannungsladung zwischen mA/10A

und COM bei vollem Einsatz ist <500mV. Die schwarze COM- Steckdose wird als weniger positiv

angesehen als die weissen mA/10A Steckdosen.

Multimeter Testkabel

Die mitgelieferten Testkabel erfüllen die Ansprüche der IEC1010-2-031 und sind 1000V Kategorie Il

zugeordnet. Nur die mitgelieferten Testkabel, oder einen Kabelsatz mit ähnlicher Leistung, verwenden,

um sicheren Betrieb zu garantieren. Alternative Testkabel sollten wenigstens mit 1000V (Kategorie I)

eingestuft sein, 600V (Kategorie lI) und 10A Strompotential.

Generelle Bedienung

RS232

Das RS232 Interface ermöglicht Ferngesteuerte Kontroll- und Datenaufzeichnung auf Diskette durch

wahlweise Windows Software. Das Interface ist vollständig v om Messsystem opto-isoliert; der

Wirtscomputer versorgt den TXD opto-output mit Strom (via den DTR und RTS Leitungen) und

betreibt den RXD opto- input direkt. der 9-Weg D-Typ auf dem Meter muss mit dem 9- Weg D-Typ

des Serien-ports des PC via einem 9 - Wegkabel (alle Verbindungen hergestellt) ; der PC wird aus

dem Multimeter-Interface ausgenullt, siehe unten:

Signalerde ist mit mit der Sicherheitserde des Geräts verbunden.

Um Übereinstimmung mit EMC- Gesetzen-zu gewährleisten, für die Verbindung mit anderem Gerät

nur abgeschirmte Kabelassem-blierungen mit abgeschirmten Anschlussbuchsen v er wenden.

28

Page 30

Einschalten

Elektroschalter

Das Multimeter wird durch abwechselndes drücken der Operate (Betriebs)-Taste ein-und

ausgeschaltet. Diese Taste schaltet ausschliesslich den Gleichstrom zu den Messschaltkreisen, er

schaltet nicht den Wechselstrom, was bedeutet, dass der isolierte RS232 Schaltkreis weiterhin unter

Strom steht. Unterbrechen Sie die Wechselstrom-versorgung , indem Sie das Haupstromkabel am

Gerät hinten herausziehen, oder am Wechselstromversorgungsauslass ausschalten; sorgen Sie

dafür, dass die Unterbr echungs möglichkeiten gut zugänglich sind. Die Wechselstromversorgung

immer unter-brechen, wenn das Gerät nicht benutzt wird.

Starteinstellungen

Beim Starten, indem man die Operate-Taste drückt, die Default-aktion ist zur Wiederherstellung der

Stillstandseinstellungen; die Stillstandseinstellungen bleiben nicht erhalten, wenn der Wechsel-strom

abgestellt wird. Um die Defaulteinstellungen wiederherzustellen (Volt, Gleichstrom, Autorange (autoBereich)), SHIFT drücken, dann Reset.

Wenn man das Meter bei Wechselstromversorgung einschaltet während eine Taste heruntergedrückt

ist, wird ein Summer und Anzeigetest aktiv iert ( alle Segmente und Anzeiger sollten erleuchtet sein);

wenn die Taste losgelassen wird, erscheint die Revision der installierten Firmware als xx auf der

Anzeige. Wenn man die Operate-Taste drückt, wird der Zähler normal eingeschaltet.

Summer

Ein kurzer Summton erklingt wenn eine ungültige Taste gedrückt wird, z.B.: wenn man Hz drückt und

keine AC (Wechselstrom) -Wahl ist getroffen worden; solche Tastendrucke werden nicht anerkannt.

Der Summton wird auch zum Anzeigen eines Widerstands <10 Ω in Continuity Mode

(Kontinuitätsmodus) verwendet.

Tastatur

Die Auswahl der Primärfunktion wird direkt gemacht, indem die ent-sprechenden Tasten gedrückt

werden, z.B.: V (Volt) und DC (Gleichstrom) für DC Volt; die Primärfunktion wird neben der Taste

angezeigt. Der Meter ist zwischen auto-Bereich und manuell geschaltet und das wechselweise

Benutzen der Tasten mit Pfeil nach unten und Pfeil nach oben verändert den Bereich und stellt auf

manuelle Bereichausrichtung.

Die weiteren Funktionen (Null, Hold, Min-Max etc.) werden alle durch das Drücken von SHIFT und

dem anschliessenden Drücken der entsprechenden Taste ausgewählt; die verschobene Funktion wird

in blau über der Taste angezeigt; Wenn SHIFT gedrückt wird, leuchten die Anzeiger aller

verschobenen Funktionen auf; wenn die Funktion mit der entsprechenden Taste gewählt worden ist,

bleibt nur der damit verbundene Anzeiger erleuchtet.

29

Page 31

werden.

Skalenlänge

Die Länge der Skala ist immer ± 40.000 Zählungen, ausser Wechselstromreichweiten, die ± 4.000

betragen.

Auswahl der Funktionen

Alle Funktionen werden direkt durch Drücken der entsprechenden Funktionstasten gewählt (z.B. : V

(Volt) , gefolgt von DC (Gleichstrom) um Gleichstromspannungen einzustellen).Wechselnde

Funktionen stellen auto-Bereichausrichtung ein, wenn es mehr als einen Bereich gibt; vorausgesetzt

dass die richtige Funktion gewählt worden ist (z.B.: Ω um Widerstand zu messen) und der zu

messende Parameter innerhalb der Reichweite des Zählers ist, sollte immer ein gültiger Messwert

erscheinen. Die Einheiten und Funktionen erscheinen auf der Anzeige (z.B.: und V für

Gleichstromspannungen) zusammen mit Auto, um auto-Bereich anzuzeigen.

Continuity und Diode Test werden durch das Drücken von SHIFT gewählt, gefolgt v on der

entsprechenden Taste. Der mit ihnen verbundene Anzeiger bestätigt die Wahl. Continuity stellt das

Meter auf die 4k Ω -Reichweite ein und erreicht Werte von ungefähr unterhalb 10 Ω.

Auswahl des Bereichs

Die Wahl einer neuen Funktion stellt immer auto-Bereich ein um sicherzugehen das eine

Innerbereichs-Ablesung mit der maximal möglichen Auflösung gemacht wird.; Der Zähler hat eine

obere Reichweite von 40.000 Zählungen (4.000 auf Wechselstrom)) und eine untere Reichweite von

3.840 Zählungen. (V und Ω) oder 255 Zählun-gen (mA); Wechselstromreichweiten reichen unten bis

384 Zählungen und 25 Zählungen respektive.

Durchführung von Messungen

Es gibt jedoch Situationen in denen es wünschenswert ist, den Bereich festeinzustellen; Zum Beispiel

um den Zähler daran zu hindern, zwischen aufeinanderfolgenden Widerstandsmessungen niedrigerer

Widerstandswerte in die 40 Ω Reichweite und zurück auto- auszurichten, oder einen niedrigeren

Auflösungsbereich einzustellen, wenn ein unstabiler Bereich übrewacht werden soll. Um den Bereich

festeinzustellen, wechsele man von auto - zu manueller Ausrichtung, siehe unten.

Manueller Bereichwechsel wird entweder durch abwechselndes Drücken der Auto/Man-Taste

gewählt, welche den Zähler in seinem gegenwärtigen Bereich feststellt, oder indem man die Pfeiloben/ unten-Tasten benutzt, die beides tun, Bereich wechseln und den Zähler in der neuen

Reichweite feststellen. Der Auto-Anzeiger ist auf Manuellen Modus eingestellt.

Messbereichsüberschreitung ist auf der Anzeige durch OFL gekennzeichnet;

Messbereichsüberschreitung wird angezeigt, wenn die Zählung in einem manuell festeingestellten

Bereich 40.000 überschreitet.(1024V/768V auf den 1000V-Gleichstrom-/750VWechselstromreichweite respektive). Auto-Ausrichtung kann durch Drücken der Auto/Man-Taste

wiederherge-stellt werden.

Durchführung von Spannungsmessungen

Für Voltmessungen wer den, nach Auswahl der entsprechenden Funktion und Bereich, die rote

V/ Ω -und der schwarze COM-Steckdose benutzt. Das Meter zeigt ein Minusz eichen (bei

Gleichstrommessungen) wenn die Spannung, die in die rote Steckdose gegeben wird, negativer ist,

als die in die schwarze Steckdose gegebene. Man beachte dass bei der Wahl der

Wechselstromvoltberreiche bei einem offenen Meterinputstromkreis, eine Anzeige, die nicht null ist,

meist deswegen erscheint, weil Wechselstromsstöraufnahmen sich an das Hochwiderstands-Input

anpaaren. Dies ist völlig normal und beinträchtigt die Genauigkeit praktischer S pannungsmessungen,

bei denen Widerstand an der Quelle generell niedrig ist, nicht.

30

Die maximale Spannung, die zwischen V/ Ω und COM verwendet w er den kann, bet rägt 1000V

Gleichstrom oder 750V Wechselstrom (Kategorie I); bei Überschreitung kann das Gerät beschädigt

WARNUNG! Die maximale Input Voltstärke zur Erde darf 1000V (Kategorie I) oder 600V (Kategorie II)

Gleich-oder Wechselstrom rms nicht überschreiten. Die Sicherheit wird beeinträchtigt, w enn diese

Werte überschritten werden, siehe Abschnitt über Sicherheit am Anfang der Bedienungsanleitung.

Page 32

Durchführung von Strommessungen

Nachdem die angemessenen Stromfunktionen (mA für4mA-Bereich und A für 10A-Bereich),

Strommessungen bis zu 400mA werden durch die Benutzung der weissen mA-Steckdose und der

schwarzen COM-Steckdose erzielt; S t r ommessungen bis zu 10A werden durch die Benutzung der

10A- und COM-St eckdosen erz ielt. Auf dem Zähler erscheint ein Minuszeichen (bei

Gleichstrommessungen), wenn die Polarität des S t r oms aus den mA- oder10A-Steckdosen kommt.

Strommessungen, die die mA-Steckdose verwenden, können zwischen den 4mA und 400mABereichen auto-ausgerichtet werden; Messungen bis z u10A können mittels Benutzung der 10ASteckdose durchgeführt wer den, nachdem der10A-Bereich mit der A-Taste ausgewählt wurde. Die