Page 1

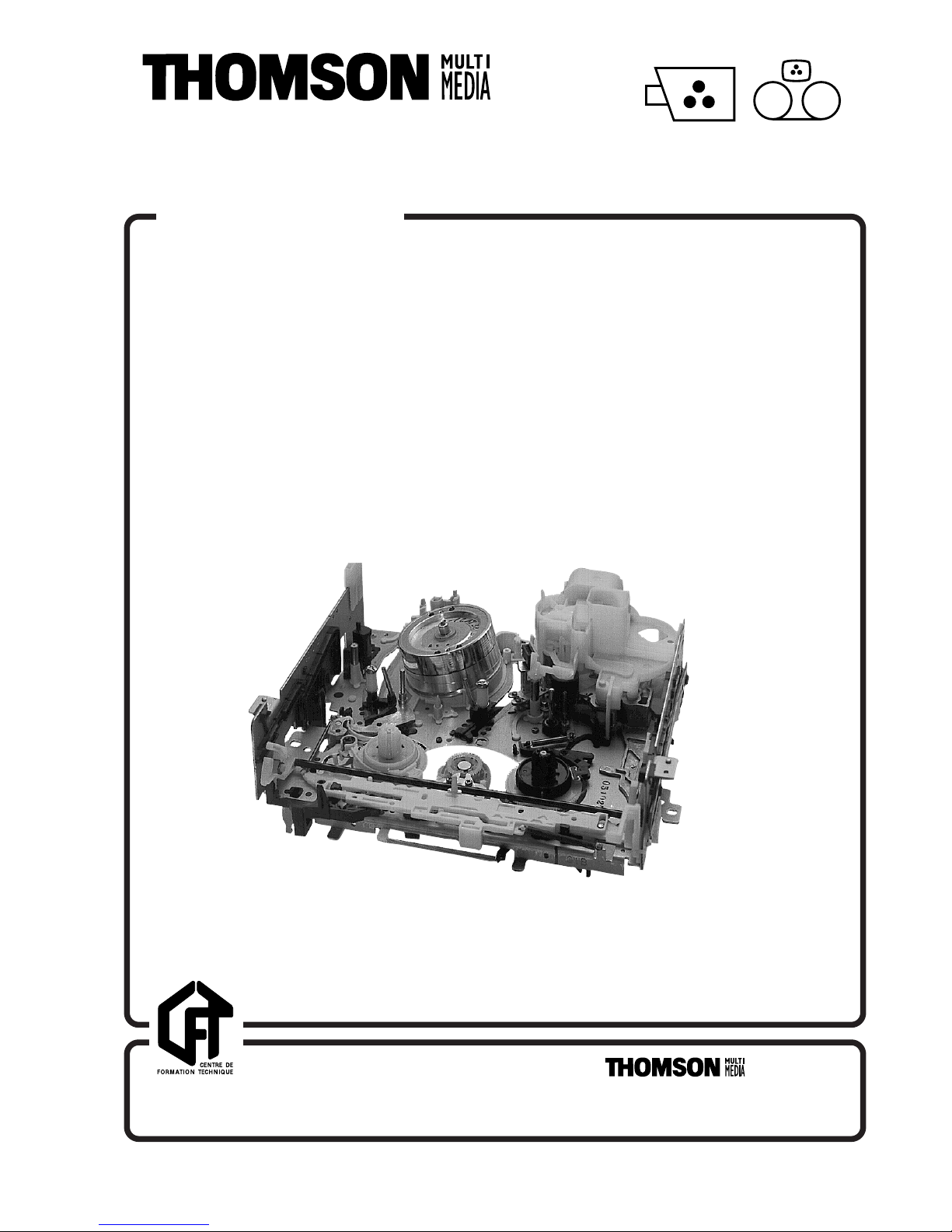

R6000 CAT. 1 CHASSIS

VIDEO RECORDERS

19, AVENUE DUBONNET - B.P.25

92403 COURBEVOIE CEDEX

TEL.(1) 46 91 36 00 -

TELEX : 610 081 F - TELECOPIE : (1) 46 91 01 80

Code : 350 543 90 - 1295/00 M - 000 000 - Imp.

Tous droits de reproduction, de traduction, d'adaptation Les descriptions et caractéristiques figurant sur ce document sont données à titre d'information

et d'exécution réservés pour tous les pays. et non d'engagement. En effet, soucieux de la qualité de nos produits, nous nous réservons

le droit d'effectuer, sans préavis, toute modification ou amélioration.

S.A. AU CAPITAL DE 200 000 000 F

SIEGE SOCIAL : 9, Place des Vosges - La Défense 5

92400 COURBEVOIE

RCS NANTERRE B 322 019 464

TECHNICAL GUIDE

Page 2

R6000 MONO

CHASSIS VIDEO

RECORDERS

TECHNICAL GUIDE

Centre de formation

46 Quai Alphonse Le Gallo

92648 BOULOGNE CEDEX

Tél :0141865000

N° de déclaration d'existence :

1 1 92 052 87 92

Tous droits de reproduction, de traduction, d'adaptation Les descriptions et caractéristiques figurant sur ce document sont données à titre d'information

et d'exécution réservés pour tous les pays. et non d'engagement. En effet, soucieux de la qualité de nos produits, nous nous réservons

le droit d'effectuer, sans préavis, toute modification ou amélioration.

Siège Social

46 Quai Alphonse Le Gallo

92648 BOULOGNE CEDEX

S.A. au capital de 200.000.000 francs

R.C.S Nanterre B 322 019 464

Code :000000000 - 01/97 M - 000 000 - Imp.

Page 3

R6000

CAT. 1

CHASSIS VIDEO

RECORDERS

Page 4

Page 5

1

CONTENTS

INTRODUCTION 3

SETUP MORE 11

POWER SUPPLY 17

MECANISM 31

SERVO CONTROL 37

PROGRAMMIG OSD 51

SERVO CONTROL 61

SWITCHING 79

VIDEO PROCESSING 85

Page 6

2

Page 7

3

INTRODUCTION

Page 8

4

Page 9

5

The chassis and commercial model numbers of 6000 Series video recorders are as follows:

CHASSIS MODEL NO.

R6015CE

R6045CE

R6048CE

R6414CE

R6444CE

R6704PS

R6744PS

COMMERCIAL MODEL

VP2750

VP4750

VP4780

VR8027

VR8047

VK231PS

VK431PS

THOMSON

SABA

BRANDT

EXPLANA TION OF CHASSIS MODEL NUMBERS

R: Video recorder

First digit: Series to which device belongs (in this

case, 6 = 6000 Series)

Second digit: Brand of device

0: Thomson

4: Saba

7: Brandt

Third digit: Product type

0: Two video heads, basic

1: Two video heads

4: Four video heads

Fourth digit:

4/5: ShowView

8: ShowView, Jog Shuttle

CE: Central Europe (BG, DK, L)

PS: PAL/SECAM

BRAND

Page 10

6

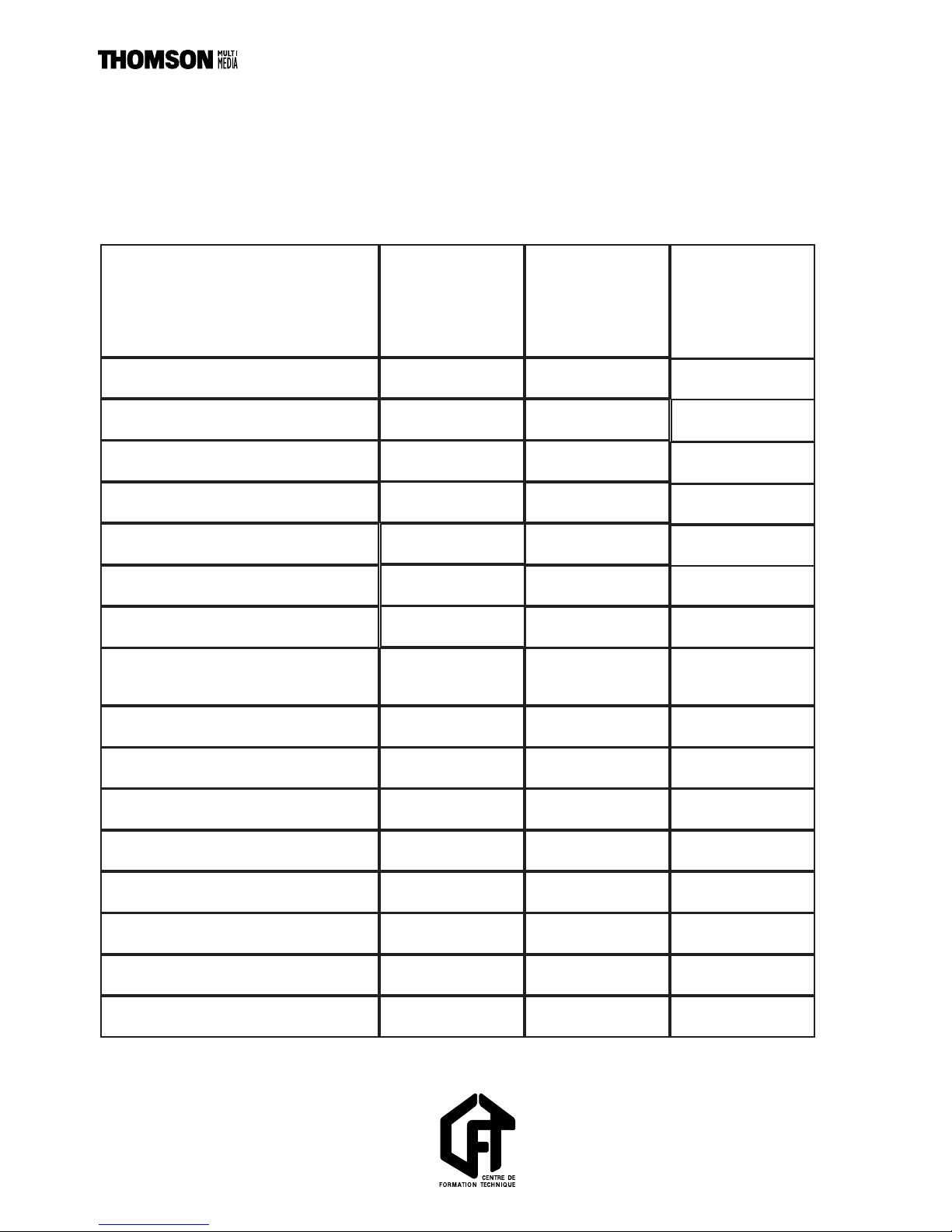

NO

NO

YES

CHARACTERISTICS

NUMBER OF VIDEO HEADS

H. Q.

CASSETTE TIME AND "TAPE

REMAINING" COUNTER

REAL-TIME TAPE

COUNTER

DIRECT ACCESS

INDEX: MARKING/SEARCH

FWD/REW VISUAL SEARCH

5 speeds

IMAGE PAUSE, FRAME-BY-FRAME,

SLOW MOTION

OPEN-ENDED

RECORD/PLAY

AUTOMATIC AV

RECORDING

COLLISION MESSAGE

PICTURE PEAK ADJUSTMENT

SATELLITE RECEIVER CONTROL

PLAY NTSC ON PAL TV

Automatic channel name memory

VP2750

VR8027

VK231

VP4750

VR8047

VK431

2

YES

WH. C/DE/YNR

YES

NO

YES

NO

NO

NO

YES

NO

4

WH. C/DE/YNR

YES

YES

NO

NO

YES

YESYES

NO

YES

NO

NO

NO

YES

NO

LONG PLAY NO YES

VP4780

4

WH. C/DE/YNR

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

Page 11

7

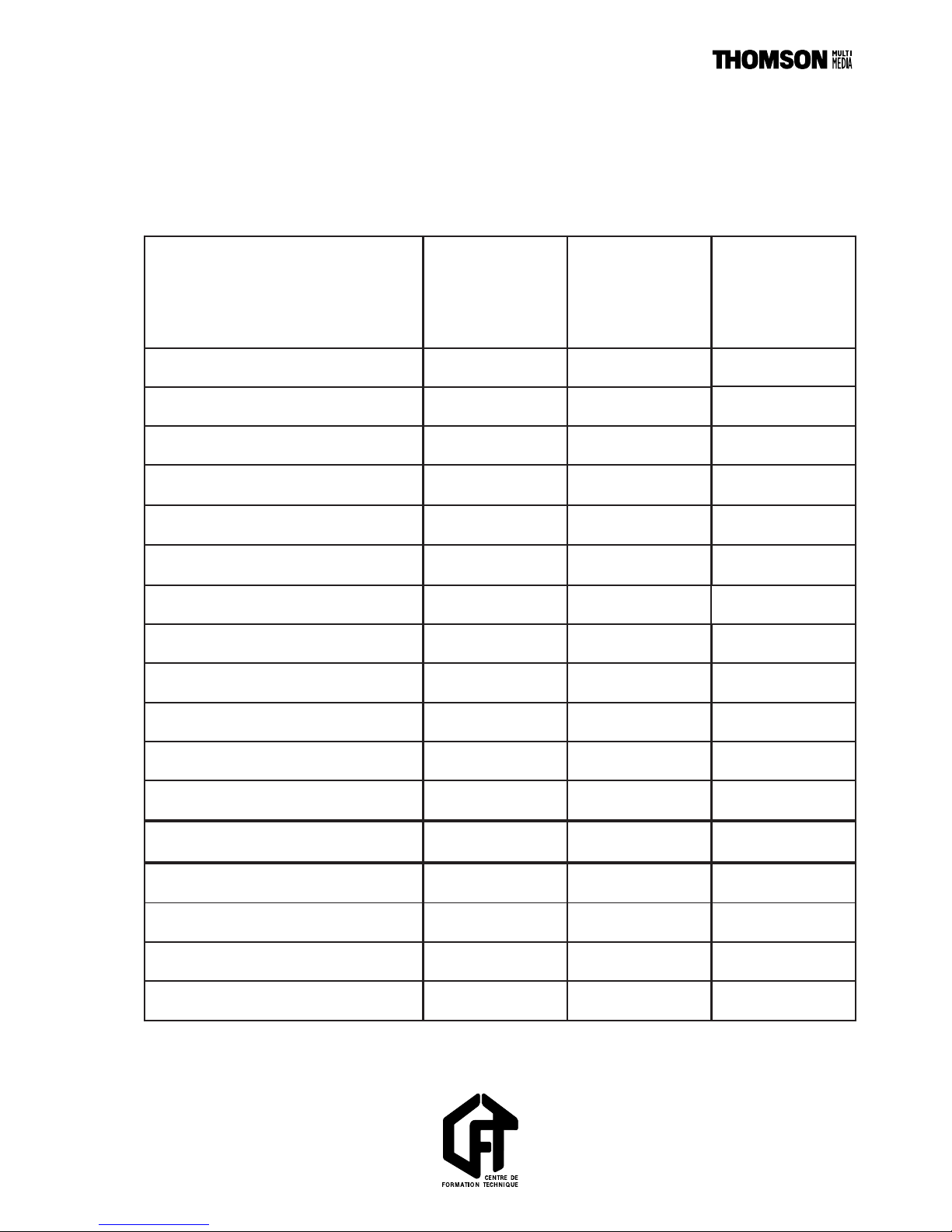

CHARACTERISTICS

UHF MODULATOR

VK231

VK431

VR8027

VR8047

VP2750

VP4750

VP4780

L

51 through 67

L ,G, K

51 through 67

L ,G , K

51 through 67

WIDE BAND TUNER YES YES

YES

CHANNEL SEARCH

SYNTH. FREQ.

99 PRG.

SYNTH. FREQ.

99 PRG.

SYNTH. FREQ.

99 PRG.

STANDARDS LL’BG LL’BGDKK’ LL’BGDKK’

COLOUR STANDARD

PAL SECAM

MESECAM

PAL SECAM

MESECAM

PAL SECAM

MESECAM

AUTO CHANNEL MEMORY

YES YES YES

CHANNEL CLASSIFICATION NO YES YES

OSD ON TV YES YES YES

AUTO TIME SET NO YES YES

PROGRAMMING 8 progs. over 1 year 8 progs. over 1 year 8 progs. over 1 year

VPS / PDC NO YES YES

SHOWVIEW YES YES YES

VIDEO CAMERA SYNCHRO MOUNTING NO NO YES

MAINS POWER CUT BACKUP 30 mn 30 mn 30 mn

FRONT PANEL AV CONNECTORS NO NO YES

TV Universal REMOTE CONTROL UNIT NO NO YES

A/B CODE NO NO YES

Page 12

8

Page 13

9

LANGUAGE SELECTION

Press and hold the EXIT/STATUS key on the remote control unit for a few seconds. "French"

and "English" are displayed in turn. Release the key to make your selection.

UHF MODULATOR CHANNEL ADJUSTMENT

Connect the antenna cable to the antenna system.

Press and hold the A menu key until SYS appears on the video recorder display.

Use the AV key to select the system.

SYS 1 France (L standard)

SYS 2 Western Europe (BG standard)

SYS 3 Eastern Europe (DK standard)

Press <A> to continue.

After a few seconds, the video recorder shows the channel number. You can change it using

the + and - keys on the remote control.

OPERATING TIME

Press and hold the 0000 or ERASE key on the remote control for ten seconds. A menu

appears on the screen, and shows the number of hours of operating time in Play Mode and

Record Mode.

Page 14

10

Page 15

11

SETUP MODE

AND

SELF DIAGNOSIS

Page 16

12

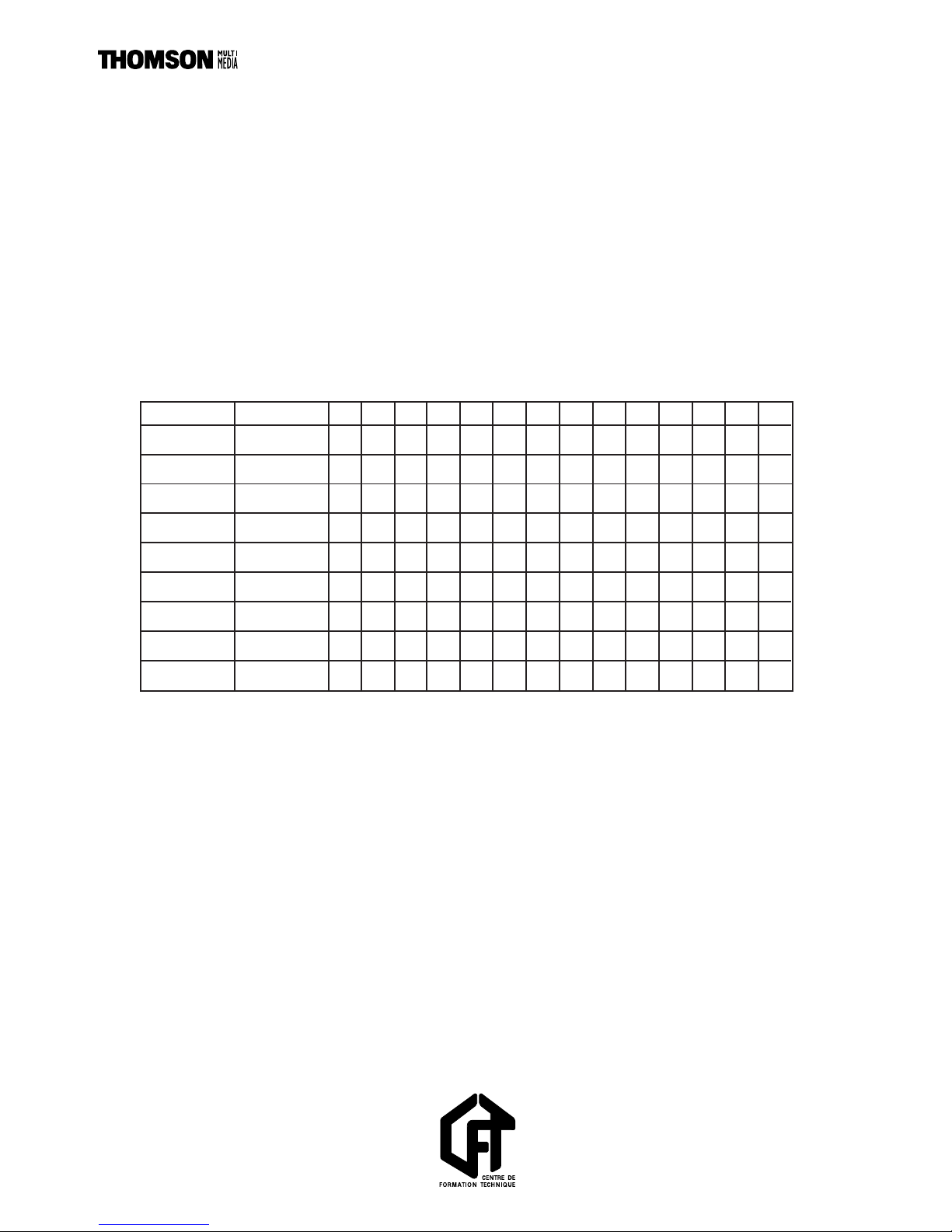

Com. Ref.

VP2750

VP4750

VP4780

VR8027

VR8047

VK231PS

VK431PS

1

0

0

0

0

0

0

0

3

1

1

2

1

1

0

0

4

0

0

0

0

0

0

0

5

8

8

8

8

8

8

8

6

4

E

E

4

E

4

E

7

4

4

4

0

0

0

0

8

4

4

5

4

4

4

4

9

B

B

B

B

B

4

4

10

0

0

0

0

0

0

0

11

9

9

B

9

9

1

1

12

1

1

3

1

1

1

1

13

0

8

A

0

8

0

8

14

3

3

3

3

3

B

B

Model

R6015CE

R6045CE

R6048CE

R6414CE

R6444CE

R6704PS

R6744PS

2

2

2

2

2

2

1

1

TABLE OF R6000 SETUP MODE CODES

Page 17

13

SETUP MODE

GENERAL RESET

- Disconnect the video recorder from the power supply.

- Press <P+> and <P-> on the keypad. For a machine without these keys, press

<Stop>, <Play>, and <Standby> on the keypad.

- Reconnect the video recorder to the power supply, and release the keys.

The Setup consists of 14 digits corresponding to the Setup mode values.

In Setup mode, certain values can be entered according to the characteristics of the device

(see summary table).

DATA ENTRY

The digit to be confirmed flashes on screen. Use the number keys on the remote control to

make entries or changes.

Press <2> to go to the next digit. Press another number key to change the value from 0 to F.

Note: Before storing the parameters in memory, it is essential to go back to the first digit.

MEMORY

Press <Stop> on the remote control or keypad.

You can quit the menu without entering anything in the memory by pressing <Exit> or <Off>.

SETUP

0 2 1 0 8 4 4 4 B 0 9 1 0 3

STOP

store

Page 18

14

Digit Number Meaning Value

1 and 2 Function requested and position 1 - Fast FWD or REW

of mechanism at the time of the 2 - Stop

incident 3 - Stanby

3 - Play

4 - Reverse play

5 - Load/Unload

6 - Arrêt (unload at limit stop)

7 - Eject.

F - Initialisation

3 and 4 Function performed by the 00 - Stop

microprocessor (Servo control/ 01 - Fast rewind

Automatic control) 02 - Fast forward

04 - Play

11 - Reverse play

12 - Search/Play

44 - Record

84 - Image pause

C4 - Record pause

40 - Record/Record pause

10 - Search

5,6,7 and 8 Function in progress before error bit 0

Normal 0 0 0 0

Record 0 0 0 1

FRAME-BY-FRAME 0 0 0 4

Stop (unload at limit stop) 0 0 0 8

Eject. 0 0 1 0

Stop 0 0 2 0

Capstan lock 0 0 4 0

Initialisation 0 0 8 0

Record loop 0 2 0 0

Play loop 0 4 0 0

Record or play loop 0 8 0 0

Fast FWD or REW 1 0 0 0

Search 2 0 0 0

Image pause 4 0 0 0

Play 8 0 0 0

9 and 10 Error message 81 - Drum

82 - Left reel stand

84 - Right reel stand

88 - Function incomplete

Page 19

15

SELF DIAGNOSIS

STOP

EXIT

clear number

exit

00 00 00 00 00

SELF DIAGNOSIS

When a mechanical incident occurs, or following an operator error, a 10-digit number

representing the error is stored in the EEPROM. This number can be displayed on screen so

that the problem can be investigated and solved.

ERROR MESSAGE DISPLAY

There are two ways to do this:

Via Setup mode, when the Service Setup page is displayed on screen, press the Fast

Forward key on the remote control.

In Stop or Standby Mode, when nothing is displayed on the television screen, press

<ERASE/0000> for at least ten seconds.

Use the table opposite to interpret the message.

ERASE THE TEN DIGITS OF THE ERROR MESSAGE

Press <Stop> on the remote control.

EXIT SETUP MODE WITHOUT STORING IN MEMORY

Press <Exit> on the remote control.

SERVICE COUNTER

Page 20

16

Page 21

17

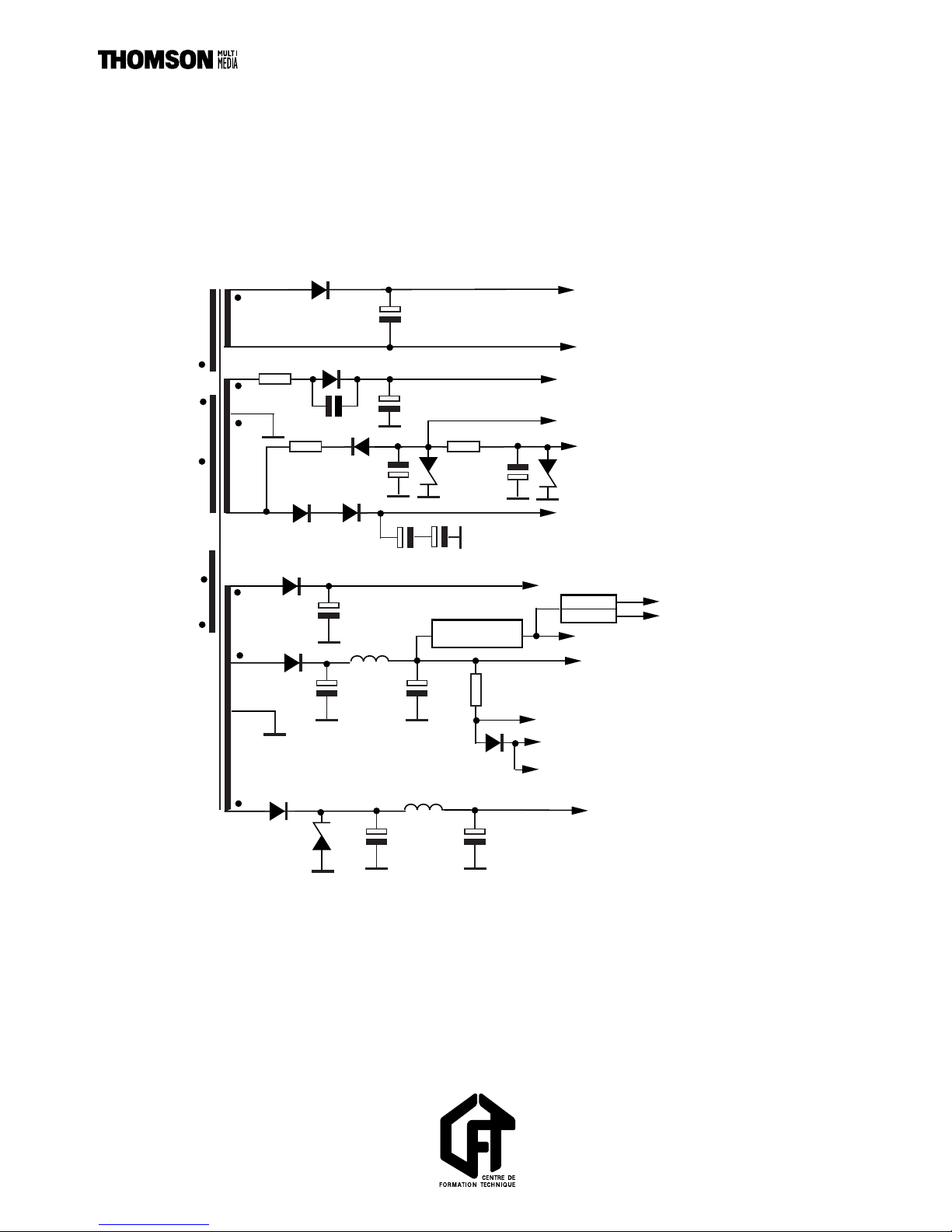

POWER SUPPLY

Page 22

18

CP023

RP024

CP024

RP019 DP019

RP021

RP022

RP029

TP023

TP020

CP021

RP026

TP022

CP022

RP020

RP027

RP025

CP025

DP025

RP037

DP037/ 038

RP038

CP038

DP023

RP023

RP004/005/006

007/008/009

FP44

CP010

DP002

DP003

DP001

DP004

300V

4

6

5

8

3

9

1

RP028

7

RP012

DP012

DP041

DP040RP041 RP040

CP040

SECONDARY

REGULATION

IP 050

5 VE

14 VE

DP033

CPO31/ 032

DP034

DP031

RP033

RP034

RP011

DP005

DP044

DP020

LP050

3,9 V

33 V

22 V

6,8 V

Page 23

19

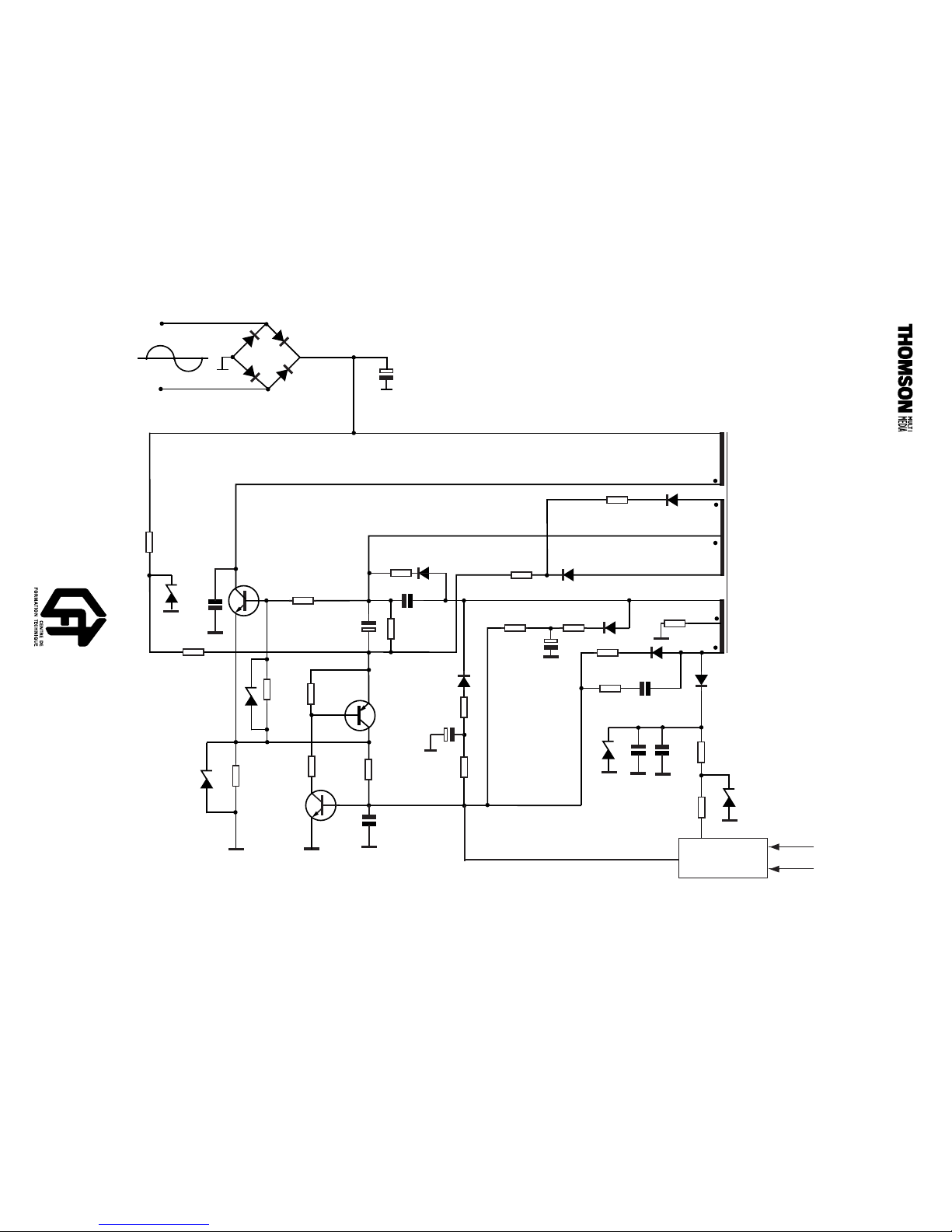

GENERAL INFORMATION

Self-oscillating switching power supply called FROSIN (FRee Oscillating Safe INtelligent).

In operation, the switching frequency varies from 42 kHz to 45 kHz for a power of 17 W . In

Standby Mode, the switching frequency is close to 56 kHz for a power of 9 W . In Standby there

is a Power-Saving Mode, where the frequency is 23 kHz and consumption is 4.8 W .

CONDUCTION OF SWITCHING DEVICE TP20

The 300 V dc voltage, rectified and filtered by DP01 through DP04 and CP10, is used as a

source for start-up. It supplies the base current for TP20 via RP04/05/06/07/08/09/1 1,

CP23/RP24 and RP21.

The current induced in winding 4-6 of LP050 via DP19/RP19 maintains conduction in TP20.

CP24 accelerates the conduction of TP20.

While TP20 is conducting, CP23 is charged by winding 8-3 of LP050 via DP23 and RP23.

LOCKING OF SWITCHING DEVICE TP20

When the voltage at the terminals of RP20 is suf ficiently high, TP22 conducts, followed by

TP23. CP23 is then connected between the base and emitter of TP20, and leads to its

discharging and locking. A polarity reversal at the terminals of LP050 achieves the following:

- Improved discharging by CP24

- Recovery of the energy in the secondaries

- Putting into service of the regulation

- Charging of CP25 via DP25 (soft start circuit)

- Maintaining conduction of TP22/23 via DP37/38 and RP37 (FROSIN circuit)

- Maintaining the charging of CP023 by 7 of LP050, DP12, RP12, and 3 of LP050.

SOFT START

The negative voltage, rectified by DP25 and filtered by CP25, delays the instant of conduction

of TP22/23, and then the instant at which TP20 locks. At first, this negative voltage is 0. TP22

commands come from RP20. This negative voltage then appears and increases, and then

delays control of TP22/23. The conduction time of TP20 is therefore increasingly long.

Page 24

20

CP023

RP024

CP024

RP019 DP019

RP021

RP022

RP029

TP023

TP020

CP021

RP026

TP022

CP022

RP020

RP027

RP025

CP025

DP025

RP037

DP037/ 038

RP038

CP038

DP023

RP023

RP004/005/006

007/008/009

FP44

CP010

DP002

DP003

DP001

DP004

300V

4

6

5

8

3

9

1

RP028

7

RP012

DP012

DP041

DP040RP041 RP040

CP040

SECONDARY

REGULATION

IP 050

5 VE

14 VE

DP033

CPO31/ 032

DP034

DP031

RP033

RP034

RP011

DP005

DP044

DP020

LP050

3,9 V

33 V

22 V

6,8 V

Page 25

21

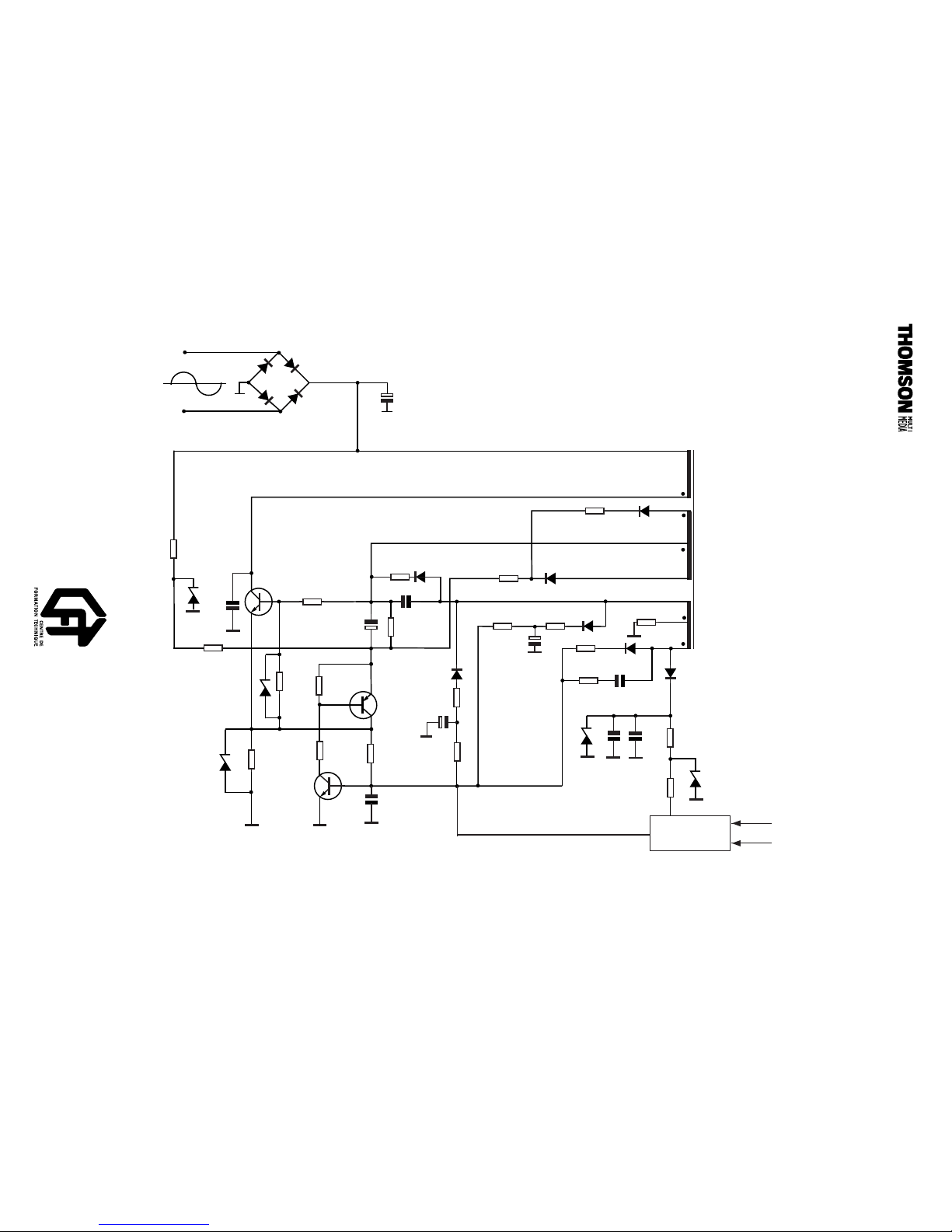

FROSIN CIRCUIT

During the energy restoration phase, Transistors TP22/23, maintained in their conduction

phase by Network 5 of LP050, DP37/38, and RP37, block TP20. At the end of

demagnetisation, the voltage induced on the collector of TP20 is reduced, and the charging of

CP21 triggers an oscillation cycle with the primary of LP050. Because of this, the collector

voltage of TP20 continues to fall when it reaches 300 V.

The new saturation control of TP20 becomes involved when the collector voltage of TP20 is

close to 0. This effect is obtained by placing a time delay on the action of the positive voltage

induced at 4 of LP050. This limits power losses due to the switching of TP20. The efficiency of

this power supply is therefore above 81% in operation (38% in Standby Mode).

This time delay is caused by the time taken to discharge TP22/23 (related to the FROSIN

circuit: DP37/38, RP37 by controlling the saturation current).

POWER SUPPLY BEHAVIOUR IN STAND-BY MODE

Because the secondaries require little energy in Stand-by Mode, the saturation time of TP20

tends to fall to 0.2 µs (frequency on the order of 200 kHz). This value is too low, and would

affect power supply efficiency in this mode. A minimum conduction time circuit (Ton min =

0.5 µs) for TP20 has therefore been added, using components CP38/RP38.

In steady state, regulation phototransistor IP050 cannot handle the saturation of TP22 and

TP23 (and then the blocking of TP20) alone. The following must assist:

• Positive voltage produced at RP20 terminals during the Storage Phase,

• Positive voltage supplied by the FROSIN circuit (DP37/38) in Restoration Phase.

In Standby Mode, the stored energy becomes greater than the small requirements of the

secondaries. Because of this, the secondary voltages, and in particular the 14 V, increase

during the energy restoration phases. The conduction time of TP20 is shortened to 3 µs by the

secondary regulation effect. This limits the energy stored in LP050.

Ton min is a result of the negative pulse obtained from the voltage induced in 5 of LP050

(negative when TP20 is conducting) and the charging of CP38 via RP38. This negative pulse

keeps TP22 blocked for a minimum of 0.5 µs.

Page 26

22

CP023

RP024

CP024

RP019 DP019

RP021

RP022

RP029

TP023

TP020

CP021

RP026

TP022

CP022

RP020

RP027

RP025

CP025

DP025

RP037

DP037/ 038

RP038

CP038

CP071

CP041

DP023

RP023

RP004/005/006

007/008/009

FP44

CP051

DP051

DP056

CP057

CP056

DP061 CP061

CP010

DP002

DP003

DP001

DP004

300V

4

6

5

11

8

14

7

10

9

1

RP028

3

RP012

DP012

DP041

DP040RP041 RP040

CP040

DP033

CPO31/ 032

DP034

DP031

RP033

RP034

RP073

RP035

RP073

RP067

RP065

RP011

DP005

DP044

DP020

16

17

+ UH

- UH

RP056

+ 33 VE

18

CP054

DP053

RP053

- 30 VE

DP081/ 082

CP081/ 082

+ 36 VE

VM + 20VE

15

1

6

2

5

4

14VE

13

5VE

DP067

CP064

CP068

CP066

CP067

CP065

CP064

DP064

DP066

DP071

TP071

DP073

4V3

IP050

DP067

LP066

12

13,6 VEDM

13 VECM

13 VELM

RW085

DW086

DP054

DW010

CW004

RW005

- 5 VE

LP050

22V

6,8V

3,9V

33V

Page 27

23

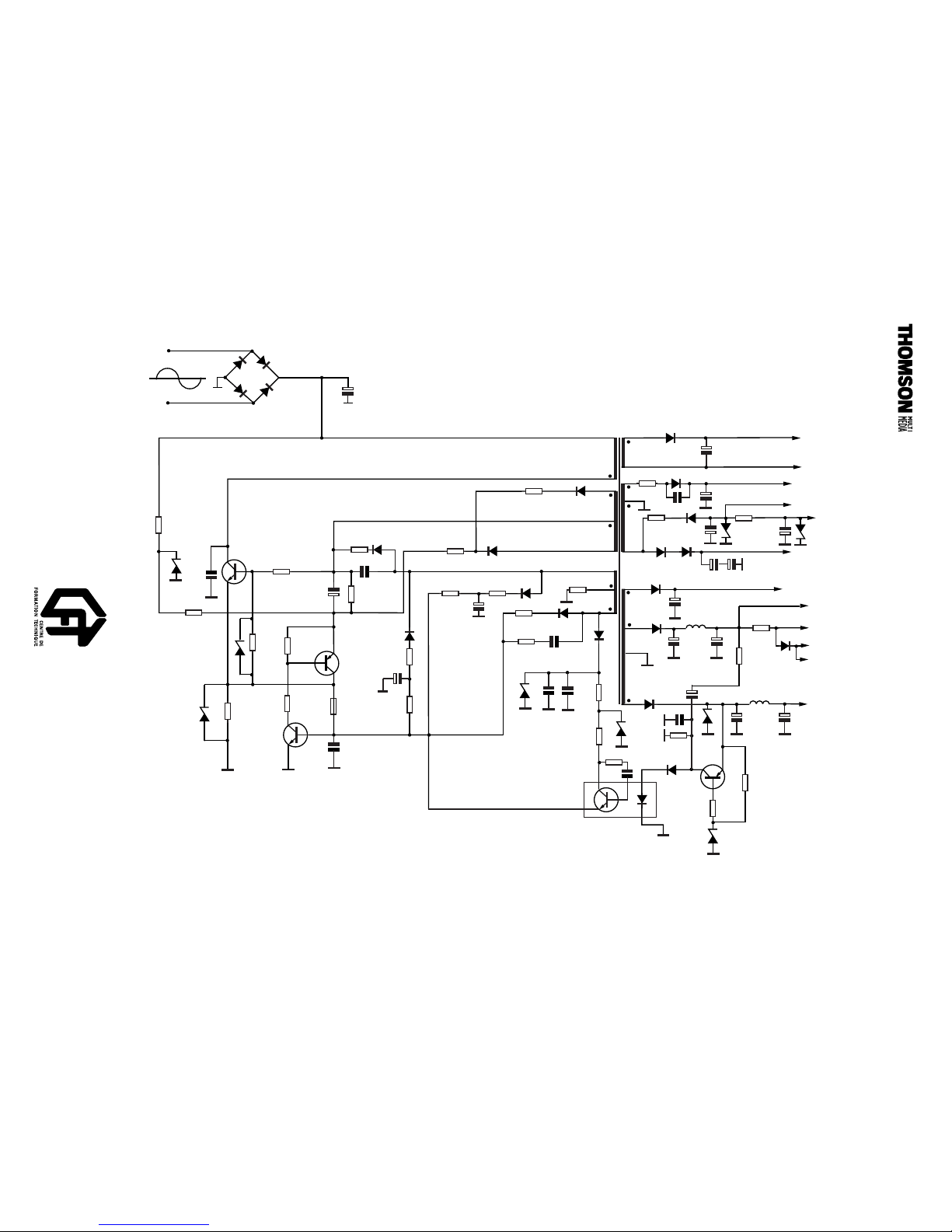

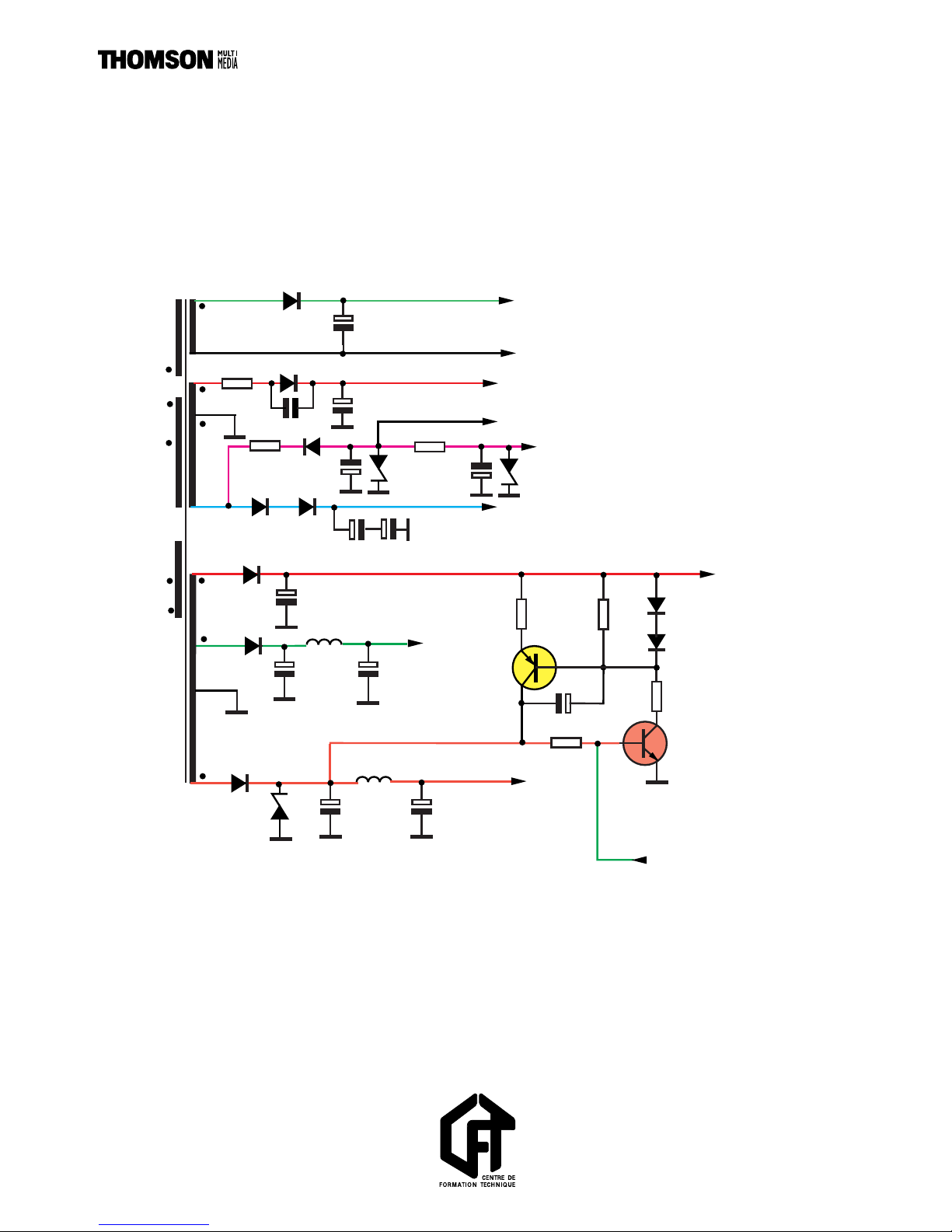

SECONDARY REGULATION

Transistor TP071 and optocoupler IP050 are used in conjunction for secondary regulation. The

current in the optocoupler diode is controlled by the regulation error voltage from the collector

of TP071. (This error voltage is obtained by comparing a reference voltage on the base of the

transistor and the 5VE image).

This current sets the value of the internal resistor in the optocoupler transistor. The switching

transistor is blocked according to the addition of the voltage obtained at the terminals of

Resistor RP020 and the voltage brought back by the internal resistor of the optocoupler

transistor. These two voltages polarise the base of TP022.

CP068 allows IP050 to handle abrupt variations of 14VE (motor start-up).

SECURITY

To avoid security problems, a new component called Protector Module (e.g. FP044) has

replaced classic fuses in several positions.

The advantage of the Protector Module is the ratio between its maximum current and the

current that destroys it. This ratio is 3, whereas the ratio is greater than 15 for a classic fuse.

In the event of an excessive increase in the conduction time of Transistor TP20 (overload of a

secondary), the voltage induced on winding 4-6 of LP050 during this phase increases and

charges Capacitor CP040. From a certain threshold, this will saturate TP022, block TP020,

and therefore shut off the power supply until CP040 discharges and allows TP022 to be

become blocked to re-start the power supply.

Page 28

24

CP051

DP051

DP056

CP057

CP056

DP061 CP061

4

6

5

11

8

14

3

10

9

1

7

16

17

+ UH

- UH

RP056

+ 33 VE

18

CP054

DP053

RP053

- 32 VE

DP081/ 082

CP081/ 082

+ 36 VE

VM + 20VE

15

14 VE

13

5VE

DP067

CP064

CP066

CP067

CP065

CP064

DP064

DP066

LP066

12

DP054

DW010

CW004

RW005

- 5 VE

ON / OFF

FROM PIN

24 IR001

ECO

CP095

DP096

DP097

RP096

RP094

RP095

RP098

TP095

TP096

_____

Page 29

25

ECO CIRCUIT

This circuit reduces consumption in Standby Mode from 9 W to 4.8 W by shutting off the display

and replacing it with a red LED on the front panel. Two transistors (TP095 and TP096) are

used to perform this function. In classic Standby Mode, these two transistors are blocked.

This function is enabled by Line 7 of the main menu, which supplies a Level 1 to Pin 24 of the

control microprocessor during the changeover to Standby Mode. This saturates the two

transistors.

The saturation of these transistors damps Transformer LP050, leading to a reduction in

frequency, to 23 kHz, and a reduction of the energy storage time. Because of this, all the

voltages fall, which limits consumption by eliminating the display.

Only the 5VE voltage remains at its nominal value because of the regulation.

Page 30

26

CP051

DP051

DP056

CP057

CP056

DP061 CP061

11

14

10

16

17

+ UH

- UH

RP056

+ 33 VE

18

CP054

DP053

RP053

- 30 VE

DP081/ 082

CP081/ 082

+ 36 VE

VM + 20VE

15

14VE

13

5VE

DP067

CP064

CP066

CP067

CP065

LP064

DP064

DP066

LP066

12

13,6 VEDM

13 VECM

13 VELM

RW

085

DW086

DP054

DW010

CW004

RW005

- 5 VE

LP050

12 VS

5 VS

5 VS

TW 083

DT 067

TW001 -TW002

TW003 - DW006

( SERVO CONTROL)

Page 31

27

SECONDARY VOLTAGES

The energy exchange caused at the primary induces several secondary voltages.

Pin 16/17 via DP051, CP051: two voltages, +UH and -UH, to supply power to the display

filament.

Pin 10 via RP056, DP056, CP057: a 33VE voltage used to obtain the Varicap voltage for the

tuner.

Pin 18 via RP053, DP053, CP054, stabilised by DP054: -30 V for the display grid, and then

stabilised by DW010: a -5VE voltage used to power the switching stages.

Pin 18 via DP081, DP082, CP081, CP082: a +36VE voltage used for the POWER GOOD

function.

Pin 11 via DP061, CP061: a +20VE VM voltage used to over-supply the capstan motor for the

REWIND function.

Pin 15 via DP064, CP064, LP064, CP065: a 14 VE voltage. This voltage is used to obtain

three voltages to supply power to the motors:

-13.6 VEDM for the drum motor,

-13 VELM for the function control motor and slow switching of AV1

-13 VECM for the capstan motor.

This voltage also obtains the 12VS switched voltages via TW001, TW002, TW003, and DW006

for the tuner and the IF, and two 5VS voltages. The first polarises Pin 80 of IT001 via Zener

diode DT067. The second powers the HF and IF stages, video processing, audio processing,

and switching via TX083.

Pin 12 via DP066, CP066, LP066, CP067, stabilised by DP067: a 5VE voltage supplying

power to the control and programming stages, the tuner, and the switching.

Page 32

28

140 V

120 V

0

0,9V

-6 V

0,17 V

-0,25 V

1 V

-0,2 V

0

0

0

10 s

46 s

63 s

TP20

COLLECTOR

TP20

BASE

TP20

EMITTER

TP22

BASE

-6 V

1,3 V

Page 33

29

POWER SUPPLY TROUBLESHOOTING METHOD

POWER SUPPLY CHECK USING THE LOW-VOLTAGE METHOD

• Discharge Capacitor CP10

• Shunt Resistors RP004 through RP011 using a 10kΩ resistor.

• Power the video recorder with 12 V dc via the mains connector.

In this configuration, the following measurements are obtained on the secondaries:

DP056 cathode (33 V) : 11 V

DP053 anode (-32 V) : -10 V

DP061 cathode (20 V) : 7 V

DP064 cathode (14 V) : 5.4 V

DP066 cathode (5 V) : 2.1 V

Page 34

30

Page 35

31

MECHANISM

Page 36

32

The mechanism has three motors:

Drum motor (three-phase ac).

- The stator of this motor is secured to the chassis.

- Capstan motor

- Function control motor.

Functions of the Capstan Motor:

- Sets the tape winding speed,

- Drives the reel stands via a belt and a free wheel.

Functions of the Function Control Motor:

- Cassette loading and ejection,

- Loading and unloading of tape,

- Positioning of the mechanism parts.

Page 37

33

CASSETTE LOADING

Microcontactor ST001 on the Main Board handles cassette detection. This microcontactor is

actuated by the front left cam of the cassette holder, and closes when a cassette is inserted.

The function control motor is powered, and drives the cassette holder drive axle via the

cassette holder control slide and control cam.

When cassette loading is complete, and after an analysis of drum motor and capstan motor

rotation, the function control motor loads the tape using its control cam.

NOTE: If the drum position and speed signal is absent, the tape is not loaded. Loading does

take place, however, if the Stop function is requested. If signals FGA and FGB are absent, the

tape is not loaded, and the cassette is ejected.

The tape start and tape end phototransistors and the mechanism position switch indicated

whether or not a cassette is present in the device.

- Tape start phototransistor blocked: 5 V at 50 of IT001

- Tape end phototransistor blocked: 5 V at 52 of IT001

- Cams A, B, and C must not indicate the EJECTION code (0 on Pins 9, 10, and 11 of

IT001).

TAPE LOADING AND POSITIONING OF MECHANISM PARTS

The control cam and its associated mechanisms load the tape and position the parts of the

mechanism.

In addition, a switch analyses control cam movement, and then informs the servo control of the

mechanism's position via the Cam A, B, and C signals.

OPERATION OF MECHANISM WITHOUT CASSETTE HOLDER

- Remove the cassette holder

- Apply power to the video recorder

- Mask the tape start and tape end phototransistors

- Tip the cassette holder drive axle towards the rear (drum).

Page 38

REPLACEMENT OF CONTROL CAM

The part references shown come from the mechanism manual.

DISASSEMBLY

- Remove the function control motor assembly by releasing the four clips (mechanism manual,

Page 10).

- Remove the cassette holder drive axle (14).

- Remove the right gear of the drive axle (14) by pressing A.

- Remove the drive axle (14) by pulling upwards.

- Remove slide (40) as follows:

- Remove the spring (39),

- Release the levers on each side of the take-up reel stand from the slide (take-up reel

secondary brake lever, and end-of-unloading tape tension lever), and then push the slide

to the right,

- Remove the slide (40).

- Remove the lever (25),

- Remove the capstan idler (1),

- Remove the control cam.

34

A

Marking hole H2

Right gear

shaft 14

Arm 24

Align

Mark

Page 39

35

REASSEMBLY

- Place the loading arm and tape tensioning arm in unloaded tape position.

- Align Guide Hole H2 of Rod 24 with the hole in the chassis.

- Install the control cam by aligning its guide hole (H1) with the hole in the chassis.

- Reinstall the capstan idler by inserting its control tappet in the first cam groove from the axle.

- Reinstall the lever (25) by inserting its tappet in the second cam groove from the axle.

- Reinstall the slide (40). Pay attention to the tape tensioning arm return lever; place its control

tappet in the slot in the slide. Bring the slide over to the left.

- Reinstall the spring (39).

- Reinstall the drive axle (14), and tilt forward.

- Reinstall the drive axle (14) gear, and align as shown below.

A

Marking hole H2

Right gear

shaft 14

Arm 24

Align

Mark

Page 40

36

Page 41

37

SERVO CONTROL

Page 42

38

Page 43

39

GENERAL INFORMATION

The servo control system consists mainly of microcontroller IT001: TMP90PR74.

Keypad function data are generated by programming microcontroller IK01.

The servo control microcontroller is continually informed about mechanism operation by the

static and dynamic status data. These data allow the microcontroller to decide whether to

execute or reject an order.

The servo control microcontroller controls the following via interfaces:

- Capstan motor,

- Function control motor,

- Switching.

In addition, the servo control microcontroller/IT001 automatic control informs programming

microcontroller IK01 to inform the user of the following:

- Cassette presence,

- Cassette type,

- Tape remaining,

- Tape counter reading.

Page 44

40

IT001

IT005

5 V

14VE

33VE

RT072

CT049

TW003

TW002

TW001

RW003

DW006

12 V

DW007

DTO67

5 V

60

64

45

59

80

30

61

13

QT003

16MHz

12 VS

5 VS

ON: 5 V

RESET

AVCC2

1

2

3

1,5Vcc

LT001

RT073

AVCC1

5 VD

TW005

RW009

RW010

TW004

CW002

RW012

RW030

RW006

RT017

RT018

RW002

RW007

RT067

CT049

CW003

33 VE

CT053

DT013

RT081

0,1F

CT032

14

DVCC1

DVCC2

RT072

RT075

TW006

DW015

RW004

RW083

RW084

+ 5VE

5 VS

TW083

CW020

IF, RF

Vid o, Audio,

Switching

Tuner, IF

5 VE

Page 45

41

POWER SUPPLY, CLOCK, RESET, POWER SUPPLY BACK-UP

Power supplies to IT001 are obtained from the 33VE and 5 V from the power supply. A pseudothyristor assembly, TW005, TW004, and a transistor, TW006, allow IT001 to be powered at 5 V.

- 5 VD, Pin 13

- DVCC1, Pin 14

- DVCC2, Pin 64

- AVCC1, Pin 45

Pin 80 of IT001 also receives a switched 5 V voltage (AVCC2). This voltage is present in ON

Mode only.

If one of the power supply tensions of IT001 is missing, Diode DW005 blocks the pseudothyristor assembly, and all power supplies to IT001 disappear.

The signal shaping circuit, IT005, and the time constant of RT072/CT049 reset IT001. The

trigger threshold is 3.2 V.

A 16-MHz clock, 1.5 Vpp, is present at 60 of IT001.

Page 46

42

IK01

C

TIMER

IT001

C

SERVO CONTROL

KEYBOARD

FUNCTIONS

IR/RECEPT.

71

72

73

67

70

21

19

95

97

48

KEYBOARD CTL BUS

CK

K DATAS

REMOTE CONTROL CODE

IK01

C

TIMER

IT001

C

SERVO CONTROL

KEYBOARD

FUNCTIONS

IR/RECEPT.

18

19

9

12

25

26

95

97

48

KEYBOARD CTL BUS

CK

K DATAS

REMOTE CONTROL CODE

VERSION 1

VERSION 2

Page 47

43

FUNCTION DATA

KEYBOARD

The KEYBOARD FUNCTION keys are located between the sweep outputs of IK01 (Pins 71/72

or 18/19) and the function inputs of IK01 (Pins 67 through 70 or 9 through 12).

The keyboard function data are sent to servo control microcontroller IT001 via Output 21 or 25

of IK01. The serial transfer clock is present at 19 or 26 of IK01. This clock consists of 8-bit

bursts. The clock period is 16 µs.

REMOTE CONTROL

The remote control function code is a 12-bit serial word. It arrives at 48 of IT001.

It has the following composition:

A3 through A0 = 4 address bits

A3 A2 A1 A0

0 0 0 0

T0 = 1 bit. This bit changes state each time a key is pressed.

It makes it possible to distinguish between a continuous command and a

new command.

D6 through D0 = 7 function bits

READING FUNCTION CODE

5ms

2,5ms

640µs

A3

A2 A1 A0 T0 D6

D5 D4 D3

D2 D1 D0

Page 48

44

47

RT027

GT004

GT003

DRUM FG/PG

TU REEL FG

SUPPLY REEL FG

CAM C

82

52

50

81

10

GT006

GT005

TAPE END

TAPE START

30

TT 003

ON : 5V

7

12,6VE

CASSETTE DETECT.

LED

CASSETTE

5VE

RT012

ST001

5Vpp

5Vpp

11

1

2

16

15

314

2

RT001

5VE

IT003

GT001

GT002

H+ 0,5Vpp

H- 0,5Vpp

CAM B

CAM A

41

33

32

REG. SAVE

CTL HEAD

CAPSTAN

MOTOR

MR

MR

CTL PULSES

CAPSTAN FG

RT048

IT001

0

5V

5V with cassette tab in

0 with cassette tab off

cassette detection

end cassette loading

7 IT001

0,8s

0

47 IT001

25Hz / 200Hz

9

Page 49

STATUS DATA

- STATIC

- DYNAMIC

DATA

CASSETTE AND RECORDING

PROTECTIO MICROCONT ACT

TAPE START

TAPE END

CAM A

CAM B

CAM C

IT001

PINS

7

52

50

11

10

9

COMMENTS

5 V without cassette

0 V cassette loading

0 V with cassette tab off

0 V at tape start

0 V at tape end

Indicate

cassette

presence

Indicate position of mechanism

DATA

DRUM POSITION SENSOR

TAKE-UP REEL STAND

POSITION SENSOR

TAKE-UP REEL STAND POSITION

SENSOR

SUPPLY REEL STAND POSITION SENSOR

CAPSTAN SPEED SENSOR

SUPPLY REEL STAND

POSITION SENSOR

CAPSTAN SPEED SENSOR

CAPSTAN SPEED

SENSOR

CONTROL PULSES

IT001

PINS

47

82

82

81

41

81

41

41

33

COMMENTS

Monitors drum rotation

Monitors position of reel stand

Calculates cassette type

(Number of capstan speed pulses for one revolution

of each reel stand, and then comparison to a constant)

Calculates tape remaining (Number of capstan speed

pulses for one revolution of the supply reel stand)

Automatic VN/LD switching in Play Mode.

Automatic NTSC switching in Play Mode (number of

capstan speed pulses between two control pulses).

45

Page 50

46

CAM C

52

50

10

GT006

GT005

TAPE END

TAPE START

30

TT 003

ON: 5V

7

CASSETTE DETECT.

LED

CASSETTE

5VE

RT012

ST001

11

GT002

CAM B

CAM A

REC. SAVE

12,6VE

IT002

MOTOR

INTERFACE

26

25

1

9

3

7

6/8

2

5

5VE

M

7

0

14V

0

3

0

0

14V

9

5V

0

5V

1

5V

5V

0

STOP

FORWARD

REVERSE

STATES TABLE IT002

IT001

9

LM

Page 51

47

FUNCTION CONTROL MOTOR

The function control motor performs the following functions:

- Cassette loading and ejection,

- Tape loading and unloading,

- Positioning of the mechanism parts.

CASSETTE LOADING

Cassette insertion leads to the following actions:

- Closure of ST001 (cassette microcontactor),

- Pin 7 of IT001 goes to 0,

- Function control motor rotates forwards.

Pins 52 and/or 50 of IT001 indicate when cassette loading is complete.

TAPE LOADING AND POSITIONING OF MECHANISM PARTS

Signals CAM A, B, and C tell IT001 the position of the mechanism, and make servo control of

the function control motor possible.

MECHANICAL FUNCTION TIMING DIAGRAM

5V

CAM C

CAM B

CAM A

EJECTION

AV. RAP.

RET. RAP.

BREF

CHARG.

DECHARG.

BANDE

LECTURE

ENREG.

A/ I - RAL. AV.

RECH. AV.

STOP 1

RECH.ARR.

RAL. ARR.

STOP 2

après 5 minutes

de stop 1

AV. RAP.

RET. RAP.

5V

5V

0

0

0

Page 52

21

19

17

15

13

11

9

7

5

3

20

18

16

14

12

10

8

6

4

2

1

TX352

12,6 VE-LM

TX351

RX353

1 Kohm

RX358

1 Kohm

TX350

51

23

SCART

ACT : 5 V

16/9 :5 V

CTL

PULSE

33

IT001

24 ms 16 ms

-2,5%

+2,5%

NORMAL CTL PULSE

16/9 CTL PULSE "N"

16/9 CTL PULSE "N+1"

48

Page 53

49

AUTOMATIC 16/9 SWITCHING

Certain products in this video recorder series can record and play cassettes in 16/9 format.

To do this, the duty ratio of the recording and control pulses must be altered. The falling edge of

the control pulses is shifted by ±2.5% in alternation.

In Play Mode, the servo control/control circuit (IT001) detects this change, and enables Output

23.

This leads to the saturation of Transistor TGX352, and then a voltage of 6 V at 8 of the TV

SCART.

Page 54

50

Page 55

51

PROGRAMMING

OSD

Page 56

52

3

19

20

21

12

13

14

IK 01

13-45-80

14-64

59

1-12-31-56-71

IT 001

48

54

95

96

97

55

86

87

6

5

8

10

83

84

64

63

11

TUNER

(MODULATOR

according

to the version)

IT 004

IV001

EEPROM

IR

Z

39

64

71

72

33

67

70

9/10/15

32

Display

Keyboard

CK

CK

Data S/K

Data K/S

Reset

Strobe

SDA

SDA

VIDEO- PROCESSOR

SCL

QK 01

8MHz

QT 002

32KHz

QT003

16MHz

Reset

5 Volts

5 Volts

+ 5 VE

+ 5 Volts

60

61 57 58

Page 57

53

PROGRAMMING AND DISPLAY

The programming circuit includes the following elements:

- Microcontroller IT001 used for programming,

- EEPROM IT004,

- Infrared receiver,

- Programming keyboard,

- Microcontroller IK001, which sends the signals from the keyboard and controls the display.

Microcontroller IT001

Remote control signals are sent via the infrared receiver to Pin 48 of IT001.

The SERVO data are output from Pin 96 and sent to display control microcontroller IK001.

At Pin 95, the clock supplies Pin 19 or 26 of IK001.

Bus I2C carries signals output from Pins 86 and 87 to the EEPROM, IT004, the tuner, and the

modulator.

IT001 RESETS IK001 from Pin 55.

An enable command at IT001 Pin 54 is sent to Pin 3 or 22 of IK01.

EEPROM IT004

This memory contains the switching points, Setup Mode, error signals from the self diagnosis,

the number of each program stored in memory, and any programming.

It is powered by the 5VE.

IK001

Microcontroller IK001 is used to control the display, and relays the keyboard commands to

IT001. It also handles control of the satellite demodulators via the infrared LEDs

(GK202/203/204) via signals output from Pin 80.

The KEY data, available on Pin 21 of IK01, are sent to Pin 97 of IT001.

Page 58

54

28 29 30 31 32 33 34 35 36 37 38 39 40 41

G1 G2 G3 G4 G5 G6 G7 G8 G9 G10 G11 G12 G13 G14

DISPLAY GK01

IK001 MCU DISPLAY CTL

56789101112131415

16

171819

a b c d e f g h i j k l m n o

50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

49 48 47 46 45 44 43 42 41 40 39 38 37 36

UH +

UH -

1

2

46

47

38

41

42 7

43 44 1 2 3 4 5 6 8

41

42

27 28 29 30 31

32

33 34

35

36 37

* Different outline according to the display

Page 59

55

KEY DISPLAY BOARD (KDB)

DISPLAY CONTROL CIRCUIT

This front-panel control circuit consists of:

a- Control microcontroller IK001F. This issues display commands, and relays the front-

panel keyboard commands to the servo control microcontroller.

Note: The control microcontroller is also the satellite receiver on certain models.

b- Display GK01 BJ446GK.

c- Front panel control keyboard.

d- Camera video/audio input socket circuit AV3, on the front panel on certain models.

e- Satellite receiver control circuit (on certain models).

DISPLAY

The control MCU (IK001) issues the display grid control signals from its outputs 36 through 49

and 27 through 37.

At outputs 50 through 64 or 38, or 41 through 44, 1 through 8, it generates display segment

commands.

For a segment to be lit (anode), there must be a high level (5 V) simultaneously on a grid

control and a segment control.

Filament heating is obtained from LP050 winding 16/17 and DP051.

Page 60

56

QT002

32KHz

QT003

16MHz

Power ON

14 D.Vcc 1

64 D. Vcc 2

57

58

60

61

30

IT 001

CP081

/082

12

DP081

13

18

14

RP085

+ 5 VE.

LP081

CP082

1000uF

CP081

1000uF

CT053

0,1F

Halt

49

LP20

TW004

TW005

TW006

RT061

DT013

DP082 / 081

+ 36 VE

RP084

RP083

RP086

RP087

TPO82

TPO86

Page 61

57

MAINS POWER CUT

In the event of a mains power cut, the video recorder continues to power the clock for

30 minutes.

When a mains power cut occurs, Transistors TP082 and TP086 become saturated, and

impose a low level on the collector of TP086. This signal is transmitted to Pin 49 of servo

control microcontroller IT001 (POWER GOOD or microcontroller halt).

0.1-F Battery CT053 powers VCC1 Pin 14 and servo control microcontroller IT001 VCC2

Pin 64.

During this phase, the microcontroller powers the clock function stage only, using its 32kHz

oscillator.

The 16MHz oscillator is stopped.

Page 62

58

TV402

EF

TT013

TV401

EF

TV020

EF

CLAMP

AMPLI

AMPLI

L

E

92

2

4

5

1

3

10

9

10 1

2

15

12

14

11

4

5

3

9

LV401

CV404

4,4

28

34

38

CV083

IV500

SYNCHRO

SEPARATEUR

IX101

SW

IT001

C

IV001

IV401

HD

QT001

17,73Mhz

H+V from 3 IV500

AV1

AV2

FI

FCB

SEL 1

SEL 2

h

l

l

l

h

67

75

70

69

5V FULL SCREEN

5Vcc MIX SCREEN

OSD VIDEO

¥SYNCHRO

¥BLUE BACKDROP 1Vcc Full Screen

¥CHARACTERS

¥SYNCHRO

¥CHARACTERS

1Vcc Mix Screen

H+V to 70 IT001

4

AGC

AMPLI

35

AGC

DETECT

CV087

22

3

h

l

7

1

2

IX 004

VIDEO AV2

MONITOR

FROM 29 IT 001

TO MODULATOR

AND

PIN 19/AV1

OSD MIX L

74

LOW LEVEL

EE MIX SCREEN

SECAM

78

79

h

PH 1

PH

RT

110

Page 63

59

ON-SCREEN DISPLAY (OSD)

The servo control microcontroller provides the on-screen display. It is controlled via the

STATUS key on the remote control unit.

There are two possible display modes:

- FULL SCREEN Mode,

- MIX SCREEN Mode (OSD + video composite).

The servo control microcontroller receives the HD horizontal synchronisation signal from Pin 9

of IV500 on Pin 69, and the composite synchronisation signal on Pin 70. 17.73-MHz oscillator

QT001 (i.e. 4 x 4.43 MHz) supplies the clock to Pins 79 and 78 of IT001.

FULL SCREEN MODE

Servo control microcontroller IT001 supplies a signal of amplitude 1 Vpp from its Output 75.

This signal consists of a blue backdrop (on the 4.43-MHz PAL carrier), white characters, and

the L +T synchronisation signal.

This signal is sent to switching circuit IV401 via TV401. It enters at 3 of this circuit, and leaves

via Pin 4. It is then applied to switching circuit IX004 (Pin 3), and then to the modulator.

MIX SCREEN MODE

Servo control microcontroller IT001 supplies a signal of amplitude 1 Vpp from its Output 75.

This signal consists of white characters and the L +T synchronisation signal.

From its Output 67, it supplies a fast switching signal PH1. When applied to IV401 Pin 9, this

signal inlays characters on the video.

The video signal arrives at IV401 Pin 5.

Page 64

60

Page 65

61

SERVO CONTROL

Page 66

62

DRUM

MOTOR

CAPSTAN

MOTOR

CTL

HEAD

CAPSTAN

FG

DRIVER

OUTPUT

AMPLIFIER

DRUM

FG / PG

SIGNALS

GENERAT.

CTL

DRUM

START

OSC.

IT001

SERVO.

QT003

SYNCHRO

VM

VM

CAPSTAN ROT. / FWD / REV.

600Hz

7Hz

16MHz

60 61

47

100

70

53

99

41

NORMAL SPEED : 758Hz

SEARCH (9) :6,8KHz

FAST FORWARD/

REWIND :1,5 12KHz

3

DRUM

MOTOR

CTL

33

1

15,16

7,8,9

11

IT003

25Hz/

200Hz

H

GT001

Page 67

63

Speed and phase servo control must be applied to the capstan and video head drum motors.

FUNCTION OF DRUM SERVO CONTROL

RECORDING:

- 1500 rpm rotation,

- Position one of the video heads at the start of a track when a frame time signal appears.

Moreover, when Head 1 records the frame time signal, a reference mark is written to the servo

control track to indicate the position of Video Track 1.

PLAY:

- 1500 rpm rotation.

FUNCTION OF CAPSTAN SERVO CONTROL

RECORDING:

- The capstan must simply wind the tape at an exact, stable speed of 2.339 cm/s (SP), and

1.17 cm/s (LP).

PLAY:

- The capstan must also move the tape at the same speed but, in addition, it must place the

video track immediately opposite the corresponding head, according to the information

provided by the servo control time signals.

NOTE:

Drum speed is 1800 rpm in NTSC.

Capstan speed is:

- 3.335 cm/s (SP)

- 1.667 cm/s (LP)

- 1.111 cm/s (EP).

Page 68

64

Page 69

65

FUNCTION

DRUM CABESTAN

SPEED

PHASE

REFERENCE

MEASUREMENT

SPEED

PHASE

REFERENCE

MEASUREMENT

RECORD

PLAY

SPEED

SENSOR

GT001

// OSC. // // //

25 Hz

CONTROL

PULSES

OSCILLATOR

RESET BY

SYNCHRO V

POSITION

SENSOR

GT001

SPEED

SENSOR

OSCILLATOR

SPEED

SENSOR

PAUSE //*

// // CAPSTAN MOTOR STOP

SEARCH

F FWD

F REW

//* // //

SPEED

SENSOR

//

OSCILLATOR

CONTROL

PULSES

* The signal from the capstan speed sensor provides compensation for the relative speed.

Page 70

66

61

60

47

89

100

70

4

drum

FG / PG

IV500

IT001

FLIP FLOP 25Hz

RT014/015

CT014/015

VM

DRUM

QT003

16MHz

HEAD

1

1,5Vc/c

SYNC.

H+V

4V

0

2

16

15

12

4

3

1

RT001

5VD

GT001

IT003

H+

H-

25Hz/600Hz

25Hz/200Hz

0,4Vcc

0

5V

pin15: same signal

with opposite phase

Page 71

67

DRUM CONTROL

SIGNALS REQUIRED

- 16-MHz OSC., Pins 60 and 61 of IT001,

- Speed and position sensor, Pin 47 of IT001,

- Recording frame synch, Pin 70 of IT001.

GENERATION OF DRUM VM

A PWM (5 Vpp) signal is present on Output 100 of IT001. Its period is 24 µs. This signal is

integrated by network RT014/CT014 and RT015/CT015. It then informs drum motor control

integrated circuit IT003.

5V

2,7V

0,7s

11 of

IT003

start

Page 72

68

DRUM MOTOR CONTROL CIRCUIT

11

14 6,10

7

8 9

600Hz

7Hz

OUTPUT

AMPLIFIER

OUTPUT

AMPLIFIER

OUTPUT

AMPLIFIER

START

OSC.

COUNTER

DECODER

CK

VM

SIGNAL

GENERATOR

CTL MOTOR

DRUM

MOTOR

START

STOP

CT016

RT008

RT009

IT003

4 Vcc /10 Hz

0,1V

13V

7V

IT003 pins 7,8,9

T=10ms

Page 73

69

RECORDING CONTROL PULSES

When Head 1 records the frame time signal, a reference mark is written on the control track.

This picture-frequency (25 Hz) reference mark is obtained from the frame synch (50 Hz) at 70

of IT001.

It is available on Output 33 of IT001.

INDEX MARKING (IS)

The duty cycle of these control pulses is modified at the start of each recording (STOP to

RECORD), and when the INDEX key is pressed.

This marking lasts approximately 2.5 s (63 ±3 control pulses).

70

61

60

33

32

2,4V

CTL

HEAD

QT003

16MHz

SYNC.

IT001

24 ms

16 ms

10 ms

30 ms

START REC.

or press on INDEX

0

4V

0

0

4V

4V

REC.

REF.

VOLTAGE

Page 74

70

NOTES

Page 75

71

CAPSTAN CONTROL

The signals required for capstan control are as follows:

- 16-MHz oscillator, IT001 Pins 60 and 61,

- Speed sensor (magnetoresistive element),

- PLAY control pulses.

RECORDING PHASE AND SPEED CIRCUIT

The FGA signal from a magnetoresistive element is used. It is amplified and shaped by IT001.

Note: Two magnetoresistive elements are used. They react in a similar way to Hall elements.

These two elements are located in the same box, and are mechanically positioned to

supply two signals, FGA and FGB, that are 90° out of phase.

These two signals make it possible to obtain the tape COUNTER/COUNTDOWN

information. This information takes capstan motor inertia into account.

60

61

QT003

16MHz

M.R.

+V

FGA

FGB

RT049

IT001

1,5Vc/c

2,5V

80mVc/c

2,5V

( REC/BP )

+

+

-

41

43

40

RT048

758Hz

RT046

RT047

44

Page 76

72

33

IT001

CTL

HEAD

RT043

16ms

24ms

24ms

16ms

3Vc/c

PB

5V

0

QT003

16 MHz

+

-

TRIGGER

32

34

37 36 38 39

46

RT042

RT041

CT026

CT025

BW006

60

61

35

PEAK

DETECT.+

U. REF.

FF/

REWIND

E

L

PEAK

DETECT. -

4V(PB) 1V(PB)

2,4V

CT023

Page 77

73

PLAY PHASE CIRCUIT

The oscillator and control pulses are used.

The control pulses are read by the head, and then amplified and shaped by IT001.

During the FAST REWIND and FORWARD functions, amplifier gain is reduced to avoid signal

deformation through amplifier saturation or blockage, which would lead to errors in INDEX

searching.

The voltages at the terminals of Capacitors CT025 and CT026 indicate the minimum and

maximum respectively of the signal peaks. These voltages determine the trigger thresholds

(50% of the peaks).

2,5V

V1

V2

16ms 24ms

seuil du trigger à V1-2,5v

2

seuil du trigger à 2,5v-V2

2

V1

V2

Lect.VN Lect.LD Rech.VN

4V

1V

3,2V

1,8V

5V

0V

Page 78

74

GENERATION OF CAPSTAN MOTOR V

A 5 Vpp PWM signal is present on Output 99 of IT001. After integration by RT006, CT003, and

RT005, CT004, this signal is sent to the capstan motor control circuit. In this circuit, it is

compared to the reference voltage from Output 42 of IT001.

Capstan motor V at 9 of BT001, for all functions, is in the region of 2.6 V.

Output 98 of IT001 supplies a 2.5 Vpp PWM signal with a period of 48 µs. After integration by

RT004, CT002, this signal limits the current in the capstan motor. The voltage obtained after

integration is in the region of 2.4 V. During the FAST REW/FWD and SEARCH X7/X9

functions, this voltage becomes 2 V. Because of this, the current limitation is reduced.

42

98

99

IT001

RT005 /006

CT003 /004

RT004

CT002

REFERENCE:2,4V

T = 24 s

T = 48 s

0

5V

2,5V

0

VM

CAPSTAN

MOTOR

CIRCUIT

53

FWD:0V / REV:5V

LIMITOR

BT001

6

9

8

7

1

28

TT005

TT006

VMC

DW087

20VE

14 VE

H: FF / Rewind

Search : x7 / x9

L : (PB / REC)

Search : x3 / x5

12,6 VE CM

Page 79

75

AUTOMATIC TRACKING

This is based on the 25-Hz flip flop and the MF envelope. It consists of putting the maximum of

the MF signal in phase with the centre of Video Track 1 (middle of the low level of the 25-Hz flip

flop). The MF envelope is sampled and blocked every 40 ms.

During Track 1 and in LP Mode, the level of the MF envelope is increased by the disconnection

of RV187.

This tracking adjustment comes into operation when:

- A new cassette is loaded,

- The FM envelope falls by more than 30%,

- The user requests it.

CAP

MOTOR

IT001

CV051

RV032

3

99

VM

1V

3V

ENV. MF

3 de IT001

BISTABLE

25Hz

89 de IT001

ENV.

MF

CENTER

TRACK 1

40 ms

89

RV098

TV019

FLIP FLOP 25Hz

BV001

Heads preamplifier connector

6

RV031

5 VS

TV018

HA Sel

RV099

Page 80

76

PAUSE, FRAME-BY-FRAME, AND SLOW MOTION

During these functions, Video Heads 2 are in operation. They read only Tracks 2 (-6°).

PAUSE

When this function is requested, Microcontroller IT001 stops the capstan. A braking pulse

(5 Vpp) is sent to the capstan motor. 150 ms later, the capstan motor is placed in forward

rotation mode for 20 ms. At the end of this cycle, Microcontroller IT001 seeks a control signal

rising edge (reference Track 1). A few milliseconds after this rising edge (the exact time

depends on the phase control), capstan motor braking is performed.

LD1 ( +6° )

LD2 ( -6° )

N1 ( +6° )

N2 ( -6° )

2L

TRACK 1

T

2,6V

46 IT001

CTL PULSE

9 BT001

VM CAP.

53 IT001

FWD. / REV.

5V

5V

0

PAUSE

PULSE

5ms

20ms

5V

0

0

2,6V

5V

4V

5V

Page 81

77

FRAME-BY-FRAME AND SLOW MOTION

When one of these functions is requested, Microcontroller IT001 places the capstan motor in

Forward Rotation Mode for approximately 20 ms. In the next phase, Microcontroller IT001

seeks a control signal rising edge (reference Track 1). A few milliseconds after this rising edge

(the exact time depends on the phase control), capstan motor braking is performed.

LONG PLAY

In Long Play Mode, tape speed is halved. This function is incorporated in RECORD mode by a

Standard Play/Long Play switch.

This function is automatically incorporated in PLAY mode by counting the capstan speed pulses

between two control pulses.

These video recorders have no circuit for Long Play special effect corrections (chroma and

horizontal correlation).

Because of this, during LP SEARCH functions, the picture becomes desynchronised, and the

colour is removed. In Pause Mode and SECAM LP SLOW, the colour is removed.

TRACK 1

T

2,6V

5V

0

46 IT001

CTL PULSE

9 BT006

VM CAB.

53 IT001

AV. / ARR.

5V

4V

0

0

20ms

5ms

20ms

5V

Page 82

78

Page 83

79

SWITCHING

Page 84

80

AV1

AV2

21

17

19

15

13

20

18

16

14

12

11

9

10

8

7

5

3

1

6

4

2

21

17

19

15

13

20

18

16

14

12

11

9

10

8

7

5

3

1

6

4

2

51

6

IT 001

6

9

10

3

1

2

4

5

TX 350

TX351

COMMUT.

94

22

21

INSEL 1 INSEL 2 PB ON

PB ON INSEL 2 INSEL 1

IN frontal

AU

IV001

IX 004

IX 003

28

38

V EE REC

VIDEO OUT

V IF

3

1

3

1

V EE PB

AV1

AV2

TV020

IV401

TV402

2

7

7

2

MONITOR

from 29 IT001

DECODER

27 de IT001

H

H

L

L

to 19 AV2

V EE PB MD

IF

VISION

IX 001

MONITOR

DECODER

27

29

Page 85

81

VIDEO SWITCHING

The Audio and V ideo switching circuit consists of two SCAR T connectors, A V1 (black

connector), and A V2 (blue connector), and four integrated circuits.

VIDEO SWITCHES

An integrated circuit, IX001, MC14052, handles video switching. At Inputs 1, 2, 4', and 5, it

receives the composite video signal from Connectors A V2, AV1, from the IF V output of the

video recorder , and from front panel connector A V3. This circuit is controlled by servo control

Microcontroller IT001, INSEL 1 (21), and INSEL 2 (22).

An integrated circuit IX003, MM1226 handles decoder switching. It is controlled by servo

control Microcontroller IT001, Pin 27.

An integrated circuit IX004, MM1226 handles monitor switching. It is controlled by servo

control Microcontroller IT001, Pin 29.

IX001 IX003 IX004

9 10 6 2 2

RECTUNER 5V 5V 0 4V 4V

RECAV1 5V 0 0 4V 4V

REC AV2 0 0 0 4V 4V

REC AV3 0 5V 0 4V 4V

REC TUNER 5V 5V 0 4V 0

PLAY C+

REC C+ 0 0 0 04V

PLAY. X X 5V 4V 4V

STANDBY X X X 4V 0

Page 86

82

21

17

19

15

13

20

18

16

14

12

11

9

10

8

7

5

3

1

6

4

2

21

17

19

15

13

20

18

16

14

12

11

9

10

8

7

5

3

1

6

4

2

Audio EE/REC.

6

10

IX 001

IX 002

IX 002

4

3

H

H

L

L

5

9

12

14

13

11

Audio IF

Audio Front AV ( AV3 )

Audio EE/PB

ES

TX204

TX214

AV1

AV2

ES

DECODER

from 27 IT001

MONITOR

from 29 IT001

15

14

12

11

9

94

22

21

INSEL 2

PB ON

INSEL 1

13

IT001

Page 87

83

AUDIO SWITCHES

Audio Switches IX001 and IX002 are created using Integrated Circuits MC14052 and

MC14053, controlled via IT001.

The audio switching table is identical to the video switching table.

The microprocessor controls IX002 on Pin 9 and Pin 11.

Page 88

84

Page 89

85

VIDEO PROCESSING

Page 90

86

DETECT

AGC

SYNC.

SEP.

AMPLI

L

E

L

E

CCD

DELAY

1 LINE

YNR

REC

PB

TV005

EF

CV011/019

RV010/011

3,9

CLAMP

vers 4

de BV001

DETECT.

CHROMA

TV013

EF

1

2

4

5

3

28

34

38

CV037

37

42

40

5

7

10

39

59

25

26

62

CV023

IV001

IX001

COMMUT.

IV100

KIL DET

AV1

AV2

FI

FCB

1Vcc

1,5V

4Vcc

0,35Vcc

0,3Vcc

0,5Vcc

Vid o out

to

TV020

to details

enhancer circuit

Clamp

35

22

CV083

to pin 13

BV003

AMPLI

AGC

60

QV001

4,43MHz

Page 91

87

LUMINANCE PROCESSING DURING RECORDING

In R6000 Series video recorders, luminance processing is performed by circuit IV001,

LA71500M.

Pin 28 of this circuit receives the composite video signal from Pin 3 of input selector IX001. At

the output of a clamp stage, the video signal is applied to Pin 35, at a stage of the AGC that

reacts only to the amplitude of the synchronisation time signals. This allows the video signal to

return to its original amplitude.

The video signal is sent to:

• Pin 38 of IV001 and impedance adapter TV020. This output is used for the control

channel.

• A 3-MHz cutoff frequency low-pass filter.

The purpose of this filter is to eliminate the chroma component of the composite signal, and

keep only the luminance component. The signal Y thus selected is applied to the vertical preemphasis circuit, and is then available on Output 25 of IV001.

The signal is sent to the 3.9 MHz trap, which removes the remaining chroma component of the

luminance signal.

The signal returns on Pin 26 IV001 via Transistor TV005, and is sent to the detail enhancing

stages via a clamp stage.

A PAL/SECAM chroma detection circuit is used to issue the standard command from Output

62.

Page 92

88

CLAMP

DETAILS

ENHANCER

WHITE CLIP

DARK CLIP

NON LINEAR.

PREEMPHASIS

MAIN

PREEMPHASIS

SHIFT

1/2 FH

MF

MODULAT.

COL ROT

IT001

C

26

64

63

CV008

66

18

LV014/134

CV134/140

RV134

2

5

RV038

RV039

4

SYNC

from 37 from IV001

BV001

93

89

92

to

REC.

AMPLI

DFF HASEL

5Vcc

0,3cc

0

1,6V

3,2V

5V

LD

VN

100mVcc

CHROMA

from 3 from BV003

from TV005

0,5Vcc

IV001

TV014

EF

83

84

DATA

CLOCK

BUS

Decoder

CV013

24

TV008

EF

Page 93

89

DETAIL ENHANCEMENT, PRE-EMPHASIS

The luminance signal applied to Pin 26 is sent to the detail enhancement circuit. This circuit

amplifies high-frequency, low-level signals. This circuit is active in Record Mode only.

It then arrives at the non-linear pre-emphasis circuit. Pre-emphasis also increases highfrequency, low-level signals.

Signal Y then arrives at the main pre-emphasis stage. This pre-emphasis amplifies highfrequency signals whatever their level. Excessively large transients created by the preemphasis circuits are clipped by the white and dark clipping stages. This prevents any

excessively large variations at the FM modulator output.

Page 94

90

CLAMP

DETAILS

ENHANCER

WHITE CLIP

DARK CLIP

NON LINEAR.

PREEMPHASIS

MAIN

PREEMPHASIS

SHIFT

1/2 FH

MF

MODULAT.

COL ROT

IT001

C

26

64

63

CV008

66

18

LV014/134

CV134/140

RV134

2

5

RV038

RV039

4

SYNC

from 37 from IV001

BV001

93

89

92

to

REC.

AMPLI

DFF HASEL

5Vcc

0,3cc

0

1,6V

3,2V

5V

LD

VN

100mVcc

CHROMA

from 3 from BV003

from TV005

0,5Vcc

IV001

TV014

EF

83

84

DATA

CLOCK

BUS

Decoder

CV013

24

TV008

EF

Page 95

91

FM MODULATION

The luminance signal from the main pre-emphasis stage is sent to the FM modulator. The FM

modulator generates a 3.8-MHz frequency for a synchronisation time signal backdrop, and a

4.8-MHz frequency for a 100% white.

The colour rotation signal, applied at 66 of IV001, causes a continuous shift of the luminance

signal leading to a 1/2-Fh shift of alternate tracks at the FM modulator output. This shift

eliminates the coinciding of energy lines of the FM carriers of two adjacent tracks.

Signal Y, FM modulated in this way, is available on IV001 Pin 18.

It then goes through a high-pass filter with a cutoff frequency of 1.5-MHz. This filter eliminates

part of the lower side band of the luminance signal, to avoid any overlap with the chrominance

signal.

The luminance signal is adapted and added to the PAL, SECAM, or MESECAM chrominance

signal.

The signal passes through TV008, and is output at 2 of BV001. It is then sent to the recording

amplifier.

RECORDING AMPLIFIER

The recording amplifier is built into the fixed part of the drum motor.

It receives the following signals:

• BV001 Pin 2: Y FM and chroma to be recorded,

• BV001 Pin 4: synch enabling the AGC acting of the FM level during recording,

• BV001 Pin 5: DFF signal, and selection of Standard Play heads and LP, HA SEL heads.

Page 96

92

E

L

LIMIT.

: 4

5V PB

DETECT.

CHROMA

15

21

LC004

CC019

2

127

18

CC017

8

BC100

7

12

5VS

5 22

12

TC015

EF

BC100

62

IC100

COL OFF

KIL DET

1,1

4,4

MODULE SECAM

to

Y/C

mixer

SYNC

37 de IV001

CHROMA

PAL/MESEC

14 IV001

IV001

VIDEO

from 3 IX001

LC001

CC005

MUTE

ENR

11

TC009

EF

E

L

DET

CONTR

logi.

mode

CTL

DET

contr

logi.

mode

CTL

Adj Filtres

CAF

16

4,43 MHz

from TV044

TC014

EF

TC001

INV

COL OFF

11 BC100

KIL DET

13 BC100

IC101

14

13

12

9/10/11

15

1

2

C SYN

12 BC100

E / L

2

16

13

3

4

to

27 de IC100

PB ON

11

to

TC001

4,28

1,07

ERASE

ANTI

BELL

FILTER

BELL

FILTER

REG

4,2V

ERASE

GENE

fo

ADJ

fo

ADJ

VCO

6 8

5VS

CC008

4,43 MHz

V EE REC

LC006/007

CC015/016

H

L

S/P

Page 97

93

SECAM CHROMINANCE PROCESSING DURING RECORDING

The SECAM chrominance processing of R6000 Series video recorders is handled by IC100, a

specialised integrated circuit.

The composite video signal, output from Pin 3 of IX001, is applied to Pin 15 of IC100. The

chrominance component of this signal is taken by a 4.4-MHz band pass filter.

The SECAM chroma, thus selected, is sent to a bell filter with central frequency 4.28 MHz.

This filter shapes the chroma signal to obtain a constant level whatever the signal frequency

deviation. The bell filter consists of LC004 and CC019.

The chroma signal is sent to a limiter stage. This circuit clips the signal, thus transforming the

input sinusoidal signal into a square signal. This creates good conditions for entering the fourway divider.

At the divider output, the SECAM chroma signal is transposed to 1.07 MHz. The band pass

filter, with a central frequency of 1.1 MHz, isolates the fundamental of the square signal, and

thereby returns the chroma signal to sinusoidal form.

The signal is sent to an anti-bell filter with central frequency 1.07 MHz, consisting of LC001 and

CC005.

The SECAM chrominance signal is output at 11 of IC100 via a mute circuit.

The chroma signal is then mixed with the Y FM signal via TC015, IC101, and TC009.

CHROMA ERASURE

Line erasure is performed by the line synchronisation time signals at 27 of IC100.

Frame erasure is performed by a VCO locked by the frame sync present at 27 of IC100.

Page 98

94

DETECT

CAG

AMPLI

CAG

SEP.

SYNC.

PB

R

1

2

4

5

3

35

22

CV037

59 60

QV001

4,43MHz

IX001

COMMUT.

AV1

AV2

FI

FCB

4,3

R

PB

SUPP

1/2 FH

ACC

DET

ACC

BURST

GATE

PREACC

BURST

CONVERT

1

5,06

BALANCE

E

L

PAL CHROMA

DETECT

VCO

COMPAR

8

CONVERT

2

VXO

MESECAM

90ß

PULSE

GENE

BURST

GATE

2

FH

FH

SHIFT

90ß

MESECAM

RV015

CV032

CV

031

RV

016

CV

033

CV

061

36/765VS

2/27/5766

COL ROT

from 92 from IT001

51

54

vers 4 de BV003

IV001

14

10 from IV100,

base from TV044

5Vcc

NTSC: 320FH

PAL/MESEC: 321FH

28

34

Data

Clock

63

64

CLAMP

Page 99

95

PAL CHROMINANCE PROCESSING DURING RECORDING

The PAL chrominance processing of R6000 video recorders is handled by Integrated Circuit

IV001.

The block diagram opposite describes this processing.

The input signal from switching circuit IX001 is applied to a clamp circuit on Pin 28 of IV001.

The signal returns on Pin 35, and is sent to an AGC stage and a band pass filter with central

frequency 4.3 MHz.

This filter selects the PAL chrominance component. The signal is then sent to the ACC stage.

ACC STAGE

The ACC (Automatic Color Control) is an AGC chrominance stage with the special feature that

it reacts only to the amplitude of bursts.

The output from the ACC is sent to a burst detection circuit. The circuit is enabled by the burst

gate pulses.

At the ACC output, a PAL chroma signal with bursts of constant amplitude is obtained.

The PAL chroma signal is sent to Converter 1.

Page 100

96

DETECT

CAG

AMPLI

CAG

SEP.

SYNC.

P

R

1

2

4

5

3

35

22

CV037

59 60

QV001

4,43MHz

IX001

COMMUT.

AV1

AV2

FI

FCB

4,3

R

P

SUPP

1/2 FH

ACC

DET

ACC

BURST

GATE

PREACC

BURST

CONVERT

1

5,06

BALANCE

E

L

PAL CHROMA

DETECT

VCO

COMPAR

8

CONVERT

2

VXO

MESECAM

90ß

PULSE

GENE

BURST

GATE

2

FH

FH

SHIFT

90ß

MESECAM

RV015

CV032

CV

031

RV

016

CV

033

CV

061

36/765VS

2/27/5766

COL ROT

from 92 from IT001

51

54

vers 4 de BV003

IV001

14

10 from IV100,

base from TV044

5Vcc

NTSC: 320FH

PAL/MESEC: 321FH

28

34

Data

Clock

63

64

CLAMP

Loading...

Loading...