Page 1

SERVICE MANUAL

DOCUMENTATION TECHNIQUE

TECHNISCHE DOKUMENTATION

DOCUMENTAZIONE TECNICA

DOCUMENTACION TECNICA

No copying, translation, modification on other use authorized. All rights reserved worldwide. • Tous droits de reproduction, de traduction, d'adaptation et d'exécution réservés pour tous les pays. • Sämtliche Urheberrechte an diesen Texten und Zeichnungen stehen uns zu. Nachdrucke,

Vervielfältigungen - auch auszugsweise - nur mit unserer vorherigen Zustimmung zulässig. Alle Rechte vorbehalten. • I diritti di riproduzione, di traduzione, e esecuzione sono riservati per tutti i paesi. • Derechos de reproduccion, de traduccion, de adaptacion y de ejecucion reservados para todos los paises.

WARNING : Before servicing this chassis please read the safety recommendations.

ATTENTION : Avant toute intervention sur ce châssis, lire les recommandations de sécurité.

ACHTUNG : Vor jedem Eingriff auf diesem Chassis, die Sicherheitsvorschriften lesen.

ATTENZIONE : Prima di intervenire sullo chassis, leggere le norme di sicurezza.

IMPORTANTE : Antes de cualquier intervención, leer las recomendaciones de seguridad.

Code : 35841010 - 0205 / 4,8M - DTH6300 Print.

VIDEO

DTH6300

DTH6300E

DTH6300F

DTH6300R

DTH6300U

Page 2

Indicates critical safety components, and identical components should be used for replacement. Only then can the

operational safety be garanteed.

Le remplacement des éléments de sécurité (repérés avec le symbole ) par des composants non homologués selon la

Norme CEI 65 entraine la non-conformité de l'appareil. Dans ce cas, la responsabilité du fabricant n'est plus engagée.

Wenn Sicherheitsteile (mit dem Symbol gekennzeichnet) nicht durch Original - Ersatzteile ersetzt werden, erlischt die

Haftung des Herstellers.

La sostituzione dei componenti di sicurezza (evidenziati con il segno ) con componenti non omologati secondo la

norma CEI 65 comporta la non conformitá dell'apparecchio. In tal caso è "esclusa la responsabilità " del costruttore.

La sustitución de elementos de seguridad (marcados con el simbolo ) por componentes no homologados segun la

norma CEI 65, provoca la no conformidad del aparato. En ese caso, el fabricante cesa de ser responsable.

MEASUREMENT CONDITIONS - CONDITIONS DE MESURES - MESSBEDINGUNGEN

CONDIZIONI DI MISURA - CONDICIONES DE MEDIDAS

RICEVITORE :

In UHF, livello d'entrata 1 mV, monoscopio barre :

- PAL, norma G. bianco 100%.

Via SCART, livello d'entrata 1 Vpp, monoscopio barre :

Colore, Contrasto, Luminositá media, Suono minimo.

Programma selezionato PR 01.

Tensioni continue rilevate rispetto alla massa con un voltmetro digitale.

RECEIVER :

On UHF,input level : 1 mV, bar test pattern :

- PAL, I standard, 100% white.

Via the scart socket, input level : 1 Vpp, bar test pattern :

Colour, contrast and brightness at mid-position, sound at minimum.

Programme selected : PR 01.

DC voltages measured between the point and earth using a digital

voltmeter.

EMPFÄNGER :

Bei UHF Eingangspegel 1 mV, Farbbalken :

- PAL, Norm G, Weiss 100%.

Über die Scartbuchse : Eingangspegel 1 Vss, Farbbalken :

Farbe, Kontrast, Helligkeit in der Mitte des Bereichs, Ton auf Minimum.

Zugeordnetes Programm PR 01.

Gleichspannungen mit einem digitalen Voltmeter zur Masse gemessen.

RECEPTEUR :

En UHF, niveau d'entrée 1 mV mire de barres

- SECAM, Norm L, Blanc 100%.

Par la prise Péritélévision, niveau d'entrée 1 Vcc, mire de barres .

Couleur, contraste, lumière à mi-course, son minimum.

Programme affecté PR 01.

Tensions continues relevées par rapport à la masse avec un

voltmètre numérique.

RECEPTOR :

En UHF, nivel de entrada 1 mV, mira de barras :

- PAL, norma G, blanco 100%.

Por la toma Peritelevision, nivel de entrada 1 Vpp mira de barra.

Color, Contraste, luz a mitad de carrera, Sonido minimo.

Programa afectado PR 01.

Tensiones continuas marcadas en relacion a la masa con un voltimetro digital.

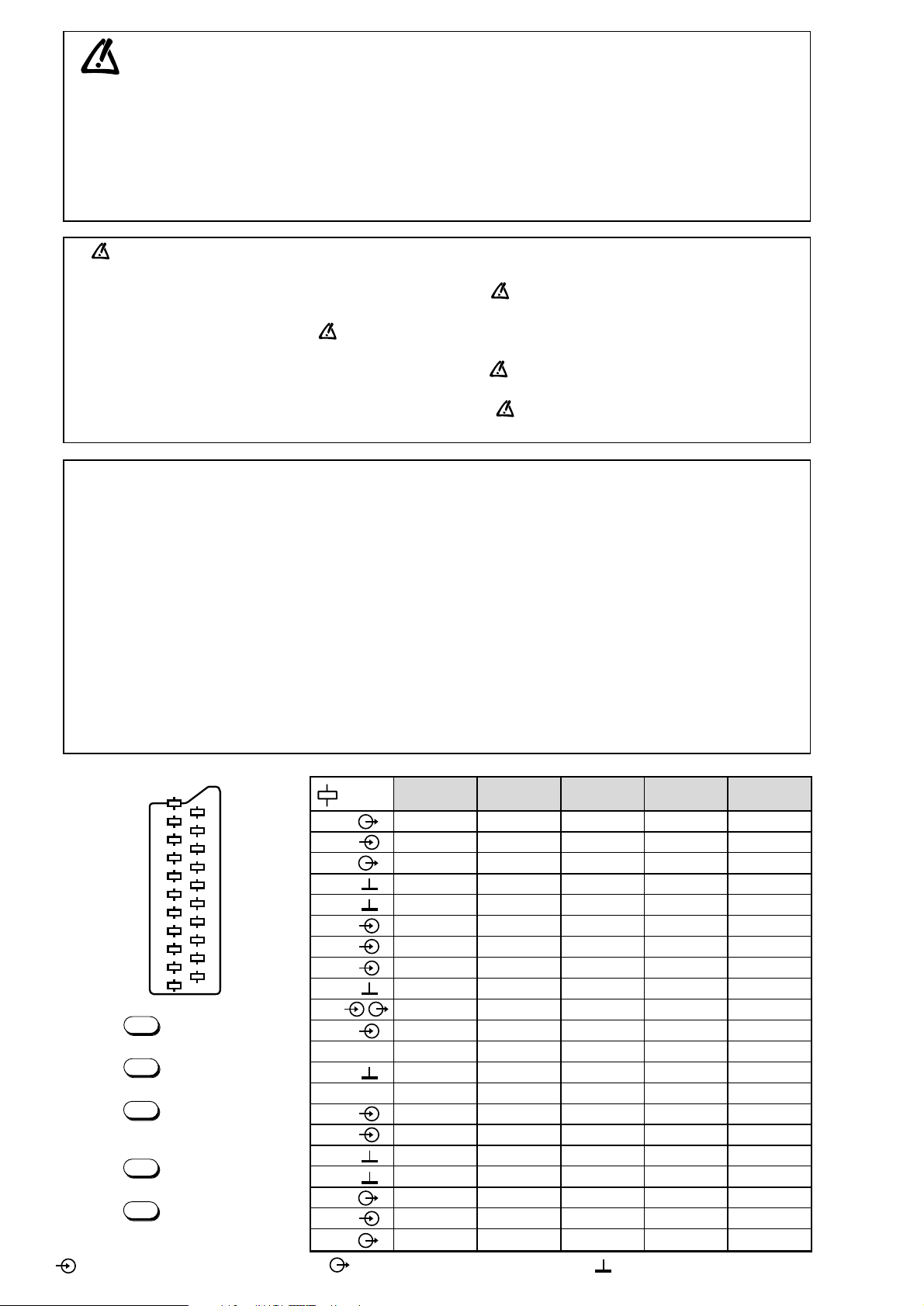

MAIN

FRANÇAIS ESPAÑOLDEUTSCHENGLISH ITALIANO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

NC

21

17

19

15

13

20

18

16

14

12

11

9

10

8

7

5

3

1

6

4

2

NC

AUDIO "R"

AUDIO "R"

AUDIO "L"

NOTE :

... etc. identifies each

pcb module.

AUDIO "D"

AUDIO "D"

AUDIO "G"

AUDIO

"BLEU"

AUDIO "G" MONO

"BLEU"

COMMUT. LENTE

"VERT"

"VERT"

"ROUGE"

COMMUT. RAPIDE

COMMUT. RAPIDE

VIDEO

VIDEO SYNCHRO

BLINDAGE PRISE

AUDIO "R"

AUDIO "R"

AUDIO "L"

AUDIO

"BLAU"

AUDIO "L" MONO

"BLAU"

AV

UMSCHALTUNG

"GRÜN"

"GRÜN"

"ROT"

AUSTASTUNG

AUSTASTUNG

VIDEO

VIDEO ODER

SYNCHRO

ABSCHIRMUNG

DES STECKERS

AUDIO "D"

AUDIO "D"

AUDIO "I"

AUDIO

"AZUL"

AUDIO "I" MONO

AZUL

"CONMUTACION

LENTA"

"VERDE"

"VERDE"

"ROJA"

"CONMUTACION

RAPIDA"

"CONMUTACION

RAPIDA"

VIDEO

VIDEO O SINCRO

BLINDAJE

DEL ENCHUFE

AUDIO "D"

AUDIO "D"

AUDIO "S"

AUDIO

"BLU"

AUDIO "S" MONO

BLU

"COMMUTAZIONE

LENTA"

"VERDE"

"VERDE"

"ROSSO"

"COMMUTAZIONE

RAPIDA"

"COMMUTAZIONE

RAPIDA"

VIDEO

VIDEO O SINCRO

INVOLUCRO METAL-

LICO DELLA PRESA

AUDIO "L" MONO

"BLUE"

"GREEN"

AV LINK AV LINK AV LINK AV LINK AV LINK

"GREEN"

"RED"

"ROUGE" "ROT" "ROJA""ROSSO""RED"

SLOW SWITCH

FAST SWITCH

VIDEO

VIDEO VIDEO VIDEOVIDEOVIDEO

PLUG SCREEN

BOX

VIDEO OR "SYNC"

FAST SWITCH

AUDIO

"BLUE"

: OUTPUT - SORTIE - AUSGANG - USCITA - SALIDA •

: EARTH - MASSE - MASSE - MASSA - MASA

MAIN

NOTE :

... etc. repères des

platines constituant l'appareil.

MAIN

NOTA :

... etc. marcas de las

placas que constituyen el

aparato.

MAIN

NOTA :

... ecc. sigla delle

piastre dell' apparecchio.

MAIN

HINWEIS :

... usw. Kennzeichnung

der Platinen, aus denen das

Gerät zusammengesetzt ist.

: INPUT - ENTRÉE - EINGANG - ENTRATA - ENTRADA •

Do not disconnect modules when they are energized!

Repairs on power supply section are to be carried out only with isolating transformer.

Ne pas retirer les modules lorsqu' ils sont sous tension. N'effectuer les travaux de maintenance sur la partie reliée

au secteur (Switch Mode) qu'au travers d'un transformateur d'isolement.

Module nicht bei eingeschaltetem Gerät entfernen!

Servicearbeiten am Netzteil nur unter Verwendung eines Regeltrenntrafos durchführen.

Non scollegare le piastre quando sono alimentate!

Per le riparazioni sulla sezione alimentatore, utilizzare un trasformatore isolatore.

No desconectar los módulos cuando están activados. Las reparaciones en la sección de alimentación de energía

deben ser ejecutadas solamente con un transformador de separación.

Page 3

DTH6300

First issue 03 / 05 3

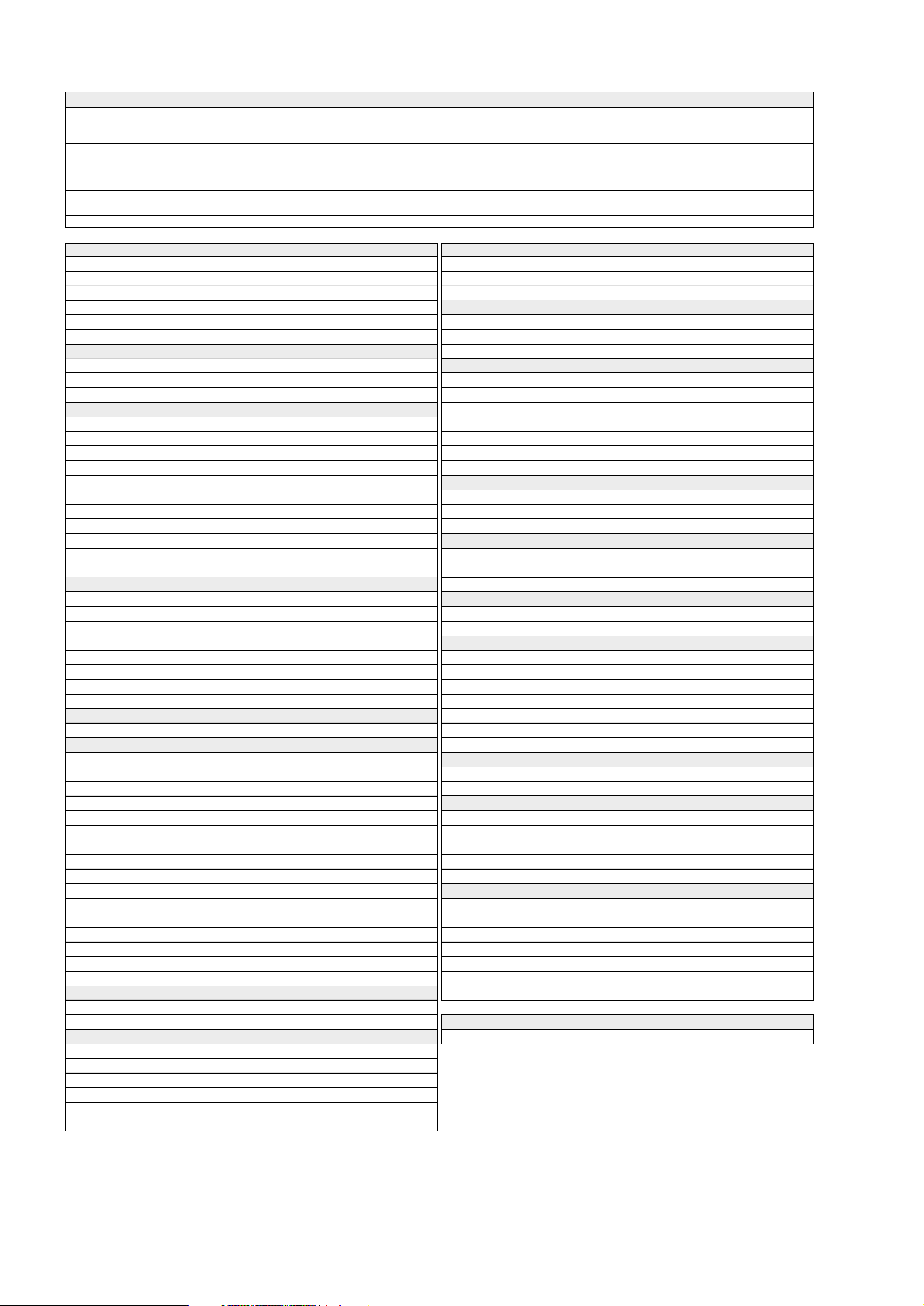

SOMMAIRE

Page

CARACTERISTIQUES TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . .4

PREVENTION CONTRE LES DECHARGES ELECTRIQUE . . . . . .5 / 6

MANIPULATION DU BLOC OPTIQUE . . . . . . . . . . . . . . . . . . . . .7 / 8

SCHEMA D' INTERCONNEXION / REGLAGE . . . . . . . . . . . . . . . . .9

SCHEMA SYNOPTIQUE (VCR) . . . . . . . . . . . . . . . . . . . . . . . . . . .10

SCHEMA DES CIRCUITS D’ALIMENTATIONS . . . . . . . . . . . .11/14

SCHEMA DE LA PLATINE PRINCIPALE . . . . . . . . . . . . . . . .15 / 34

Page

SCHEMA DES CIRCUITS COMMANDES . . . . . . . . . . . . . . . .31/32*

SCHEMA SYNOPTIQUE (DVD) . . . . . . . . . . . . . . . . . . . . . . . .35 / 36

SCHEMA DE LA PLATINE PRINCIPALE . . . . . . . . . . . . . . . .37 / 44

CIRCUIT IMPRIME PLATINE ALIMANTATION . . . . . . . . . . . . . . .45

CIRCUIT IMPRIME PLATINE COMMANDES / AFFICHEUR . . . .46*

CIRCUIT IMPRIME PLATINE PRINCIPALE . . . . . . . . . . . . . . .47/52

REGLAGE MECANIQUE - DEMONTAGE / REMONTAGE . . . . .53/78

CONTENTS

Page

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

PREVENTION OF ELECTRO STATIC DISCHARGE . . . . . . . . . .5 / 6

HANLING THE OPTICAL PICKUP . . . . . . . . . . . . . . . . . . . . . . . .7 / 8

WIRING DIAGRAM / ADJUSMENTS . . . . . . . . . . . . . . . . . . . . . . . .9

SCHEMA SYNOPTIQUE (VCR) . . . . . . . . . . . . . . . . . . . . . . . . . . .10

POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11/14

MAIN SCHEMATIC DIAGRAM (VCR ) . . . . . . . . . . . . . . . . . .15 / 34

Page

CONTROL SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . .31/32*

BLOCK DIAGRAM (DVD) . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 / 34

MAIN SCHEMATIC DIAGRAM (DVD ) . . . . . . . . . . . . . . . . . .37 / 44

POWER SUPPLY P.C.B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

KEYBOARD /DISPLAY /CLOCK . . . . . . . . . . . . . . . . . . . . . . . . . .46*

MAIN P.C.B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47 / 52

MECHANICAL ADJUSTMENT-DISASSEMBLY/ASSEMBLY . .53/78

SUMARIO

Página

DATOS TECNICOS ............................................................................4

PREVENCIÓN CONTRA DESCARGAS ELECTRO-STATICA ........5 / 6

MANEJO DEL OPTICO .................................................................7 / 8

ESQUEMA DE INTERCONEXIONES / AJUSTES............................9

SCHEMA SYNOPTIQUE (VCR) .......................................................10

ESQUEMA DE LOS CIRCUITOS DE ALIMENTACIÓN..............11/14

ESQUEMA DE LA PLATINA PRINCIPAL ...............................15 / 34

Página

ESQUEMA DE LOS CIRCUITOS MANDOS ............................31/32*

ESQUEMA DE BLOQUES (DVD).............................................35 / 36

ESQUEMA DE LA PLATINA PRINCIPAL................................37 / 44

PLATINA ALIMANTACIÓN .............................................................45

PLATINA MANDOS / INDICADOR / RELOJ..................................46*

PLATINA PRINCIPAL.................................................................47/52

AJUSTES MECANICOS - DESMONTAR/VOLVER A MONTAR .....53/78

SOMMARIO

Pagina

DATI TECNICI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

AZIONI PREVENTIVE CONTRO LE SCARICHE ELETTROSTATICHE 5 /6

MANEGGIAMENTO OTTICA PICKUP . . . . . . . . . . . . . . . . . . . . . .7 / 8

DIAGRAMMA DELLE INTERCONNESSIONI /REGOLAZIONI . . . . .9

SCHEMA A BLOCCHI (VCR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

ALIMENTAZIONE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11/14

SCHEMA DELLA PIASTRA PRINCIPALE . . . . . . . . . . . . . . .15 / 34

Pagina

SCHEMA DEI CIRCUITI TASTIERA . . . . . . . . . . . . . . . . . . . .31/32*

SCHEMA A BLOCCHI (DVD) . . . . . . . . . . . . . . . . . . . . . . . . .35 / 36

SCHEMA DELLA PIASTRA PRINCIPALE . . . . . . . . . . . . . . .37 / 44

PIASTRA DEI CIRCUITI DI ALIMENTAZIONE . . . . . . . . . . . . . . . . .45

PIASTRA TASTIERA / INDICATORE / OROLOGIO . . . . . . . . . . . .46*

PIASTRA PRINCIPALE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47/52

ISTRUZIONI PER LA MANUTENZIONE MECCANICA . . . . . . . .53/78

INHALT

Seite

TECHNISCHE DATEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

VERMEIDUNG VON ELEKTROSTATISCHER ENTLADUNG (ESD)5 / 6

HANDHABUNG DER OPTISCHEN EINHEIT . . . . . . . . . . . . . . . .7 / 8

VERDRAHTUNGSPLAN / EINSTELLLUNGEN . . . . . . . . . . . . . . . .9

SCHEMA SYNOPTIQUE (VCR) . . . . . . . . . . . . . . . . . . . . . . . . . . .10

NETZTEIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11/14

SCHALTBILD HAUPTPLATINE . . . . . . . . . . . . . . . . . . . . . . . .15 / 34

Seite

SCHALTBILD BEDIENTEIL/ ANZEIGE . . . . . . . . . . . . . . . . . .31/32*

BLOCKSCHALBILD (DVD) . . . . . . . . . . . . . . . . . . . . . . . . . . .35 / 36

SCHALTBILD HAUPTPLATINE . . . . . . . . . . . . . . . . . . . . . . . .37 / 44

LEITERPLATTE NETZTEIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

LEITERPLATTE BEDIENTEIL/ ANZEIGE . . . . . . . . . . . . . . . . . . .46*

GRUNDPLATTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47/52

MECHANISCHE EINSTELLUNGEN-DEMONTAGE/MONTAGE . . .53/78

Some Models*

Page 4

DTH6300

4 First issue 03 / 05

TECHNICAL DATA - CARACTERISTIQUES TECHNIQUES TECHNISCHE DATEN - DATI TECNICI - DATOS TECNICOS

• THOMSON Multimedia reserves the right to change the specifications without notice

• Tous droits de modification des spécifications réservés.

• Änderungen der technischen Daten sind ohne Ankündigung möglich.

• Con riserva di modifica dei dati tecnici senza preavviso.

• Nos reservamos el derecho de modificar los datos técnicos sin previo aviso.

PLAYABLE DISK TYPE DVD

Video DVD+R/+RW/-R/-RW+VCD/S-VCD

audio CD audio + most of CD-R/CD-RW

MODULATOR

Video (2) jpeg

System PLL I (DTH6300F) / - (DTH6300E)

DiviX "Home cinema certified" yes

Channel range 21-69 (DTH6300F) / - (DTH6300E)

Regional code 2

Auto channel select Yes (DTH6300F) / - (DTH6300E)

Disk sizes 8 + 12 cm

AUTO MODES

VIDEO DVD

Auto power on Yes

Output signal PAL / PAL 60 Hz / NTSC

Auto playback Yes

Digital to analog converter 10 Bit / 27 MHz

Auto rewind Yes

Progressive video processor Yes (DTH6300F) / - (DTH6300E)

VIDEO VCR

TIMER

Colour System Pal / Secam (DTH6300F / Pal (DTH6300E)

Timer capacity 7 events / 1 month

MESECAM Yes

Daily / weekly repeat Mo-Fr/Yes

NTSC playback (PB) on PAL TV Yes

Power back-up EEPROM

Yes (DTH6300F) / - (DTH6300E)

Heads (Video+Audio+FEH) 4+2

PDC decoder

VPS decoder

Yes

Tape speed SP / LP / SLP (NTSC)

Easy programming ShowView (DTH6300F) / Video Plus + (DTH6300E)

Still Picture Noiseless (SP)

Slow Motion Noiseless (SP)

Frame advance Noiseless (SP)

Tracking Digital Auto

Instant recording Yes

Assemble Yes

CLOCK

16:9 identif. REC./PB Auto

System Quartz

AUDIO DVD

Clock setting Auto(TXT/UTC)

Digital to analog converter 96 kHz / 24 bits

Power back-up (min) 3 sec

Signal to Noise ratio 100 dB

DISPLAY

Dolby Digital 5.1 Passthrough

Graphical user interface Yes

DTS Passthrough

OSD langages GB,D,F,I,E,NL

MPEG 2 audio Passthrough

Front display technology LED

FRONT CONNECTORS

MP3 decoder built in Yes

RCA Audio IN 2

Virtual surround Yes

RCA video IN 1

Voice enhancing effect NA

AUDIO VCR

HIFI Stereo Yes

REAR CONNECTORS

Number of scart sockets 2

… of which Y/C 1

PLAYBACK FEATURES DVD

…of which RGB 1

Still picture Yes

Scart with RGB loop 1

Frame advance Yes

RCA video out 1

Repeat function DVD Tittle/Chapter/AB

Repeat function CD Disk / track / Program

Digital audio out Coaxial & Optical

YPrPb (component) RCA Yes

Program play Yes (CD/mp3)

REMOTE CONTROL

Random play Yes (CD/mp3)

Model Multiproduct (DTH6300F) / RCT311DA1(DTH6300E)

Dealers mode Yes

Type 3 in 1 : TH TV / TH VCR / TH DVD

Parental lock Yes

SUPPLIED ACCESSORIES

Zoom Yes

RCU battery 2 x AAA

Power cable / Plug FIXED / CEE (DTH6300F) / UK fuse (DTH6300E)

Variable search speed Yes x 4 speed/SCAN/Slow

Scart cable Yes

Resume memory 1 disc

RCA A/V cable Yes

Introscan Yes (CD)

Scene again Yes

IB languages (1) F/D/I/NL/GB (DTH6300F) / GB (DTH6300E)

jpeg photos playback Yes (Slideshow)

jpeg combination playback jpeg & mp3

GENERAL DATA

Kodak Picture CD Playback Yes

Product size (W x H x D in mm) 430 x 79 x 255

TAPE ACCESS

Packaging size (W x H x D in mm) TBD

Counter Real time

Weight : Net / Gross (Kg) 4/ 5,4

EAN code 3244480148518

Power supply 230 V - 50 Hz

Power consumption 21 W (DTH6300F) / 23W (DTH6300E)

Standby Power Consumption <3 W (DTH6300F) / 6,3W (DTH6300E)

NOTE*

Auto Power / Rewind / Eject Yes

Most CD-R / CD-RWs Total compatibility not guaranteed

Tuning system PLL

Standard LL', BG, DKK'(DTH6300F) / BG,DKK' (DTH6300E)

Programme Number 88

NICAM / FM Stereo Sound I / - (DTH6300F) // L,BG, DK/ BG, DK (DTH6300E)

Auto installation Yes

Auto sorting Yes

RECEPTION

FEATURES BENEFITS

Combines all features of a DVD player and HiFi VHS videorecorder Easy connection and upgrade to DVD in one compact unit

Built-in mp3 decoder, CD-R, CD-RW & S-VCD playback Allows playback of DVD discs, CD audio and most CD-R / CD-RW* as well as listening to

your own MP3 CDs* & S-VCD discs

DivX playback (DivX®5, DivX®4, DivX®3 and DivX®VOD) "Home Theatre Certified" Plays videos and movies downloaded from internet.

Ready for future DivX formats

VPS and PDC function Don't miss the recording if the program starts late (on VPS and PDC channels)

Showview For easy and quick recording thanks to the showview code

2 scarts with loop-through (among them 1 RGB) For an easier installation of your DVD / VCR with other Audio and Video equipment.

RGB to enhance picture quality transmitted to your TV

Front A-V connectors For easy recording from external equipment like camcorders

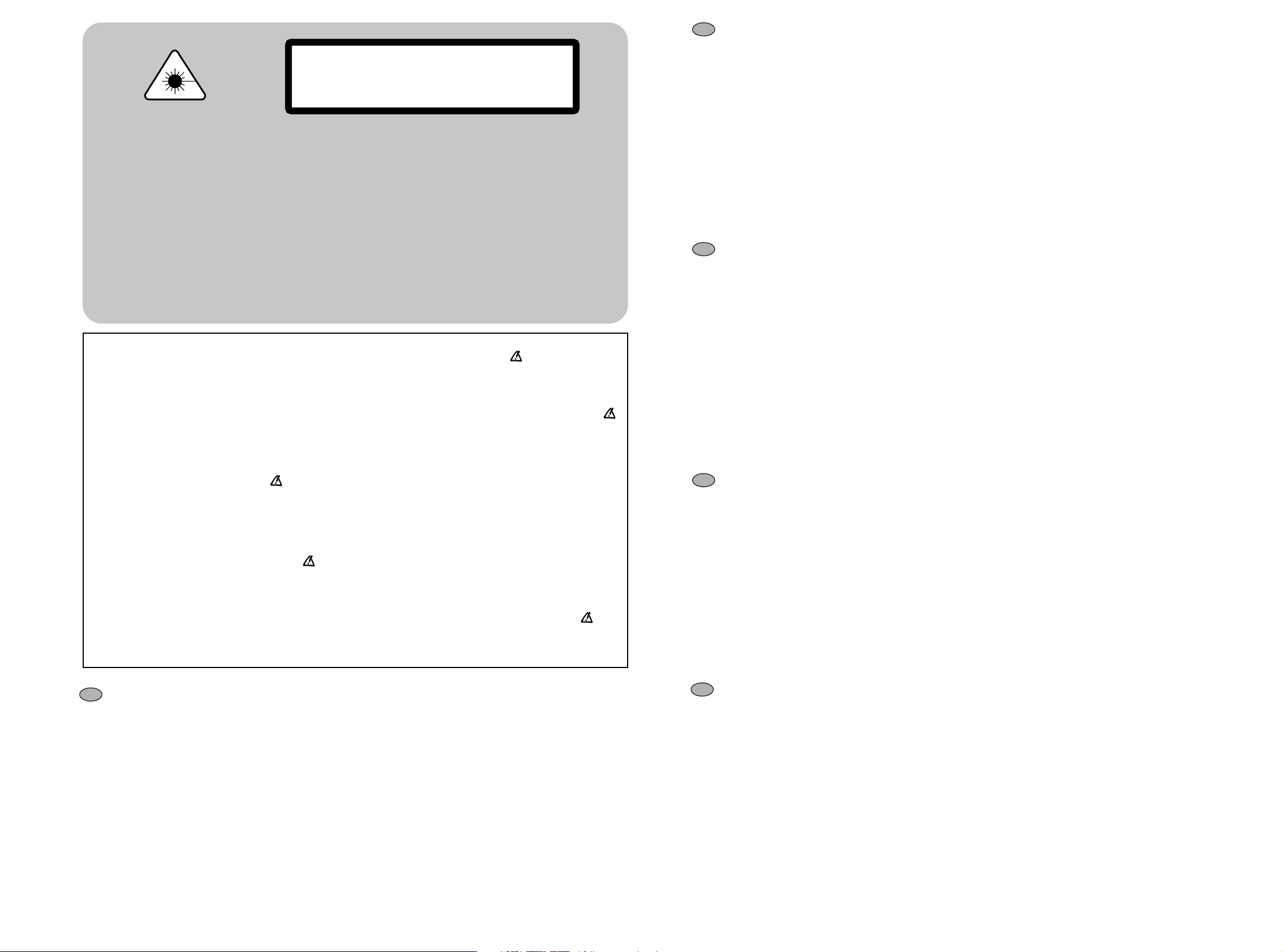

Page 5

6

DTH6300

First issue 03 / 05 5

Invisible laser radiation when open and interlock

failed or defeated. Avoid direct exposure to beam.

Le rayon laser est invisible. Eviter l'exposition directe

lors de la maintenance.

Bei geöffneter Schublade und Defekt der Sicherheitsvorrichtungen besteht die Gefahr unsichtbaren

Laserlichts. Niemals direkt in den Laserstrahl sehen.

Il raggio laser è invisible. Evitare l'esposizione diretta

durante la manutenzione.

El rayo laser es invisible. Evitar la exposición directa

en el momento del mantenimiento.

DANGER :

ATTENTION :

VORSICHT BEI

REPARATUREN :

ATTENZIONE :

IMPORTANTE :

CLASS 2 LASER PRODUCT

APPAREIL A LASER DE CLASSE 2

LASER KLASSE 2

APPARECCHIO CON LASER DI CLASSE 2

APARATO CON LASER DE CLASE 2

IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are imporant for safety. These part are marked by symbol on the schematic

circuit diagrams and replacement part list. It is essential that these safety critical components are replaced with the manufacture’s specified

parts to prevent electric shock, fire, or other hazards. do not attempt to modify the original design without permission of the manufacturer.

REMARQUES DE SECURITE IMPORTANTE

Il y a des composants spéciaux utilise dans cet appareil qui sont important pour la sécurité. Ces pièces sont repérées par un symbole

sur les schémas de principes et la liste de pièces détachées. Il est essentiel que ces composants de sécurité soient remplacés par les

pièces spécifiques du constructeur pour éviter les chocs électriques, feux ou autres risques. Ne tentez pas de modifier la conception

originale sans autorisation du constructeur.

WICHTIGER SICHERHEITSHINWEIS

In diesem Gerät wurden sicherheitsrelevante Komponenten verwendet. Diese Teile sind im Schaltbild und in der Ersatzteilliste mit

einem Symbol markiert. Es ist wichtig, dass diese kritischen Komponenten ausschließlich durch solche ersetzt werden, die den

Spezifikationen des Herstellers entsprechen. Die Produkthaftung des Herstellers erlischt bei Einsatz von nicht den Spezifikationen

entsprechenden Sicherheitsbauteilen und bei eigenmächtigen Schaltungsänderungen.

IMPORTANTE INFORMAZIONE DI SICUREZZA

Ci sono speciali componenti usati in questa apparecchiatura che sono importanti per la sicurezza. queste parti sono facilmente identificabili,

sullo schema e sulla lista parti, da un apposito simbolo . E’ indispensabile che questi componenti di sicurezza, nel caso di alterazioni o

guasti, vengano sostituiti con specifici ricambi originali per evitare shock elettrici, fuoco o altri rischi. Non modificare mai il circuito senza

autorizzazione della casa costruttrice.

AVISO IMPORTANTE SOBRE SEGURIDAD

En este equipo se utilizan componentes especiales que son muy importantes para la seguridad. están marcados con el símbolo en los

esquemas eléctricos y en las listas de repuestos. Es fundamental que estos componentes críticos de seguridad, sean reemplazados por las

piezas originales indicadas por el fabricante para evitar los peligros de electrocución, de fuego, etc. y no modificar el diseño original sin

autorización del fabricante.

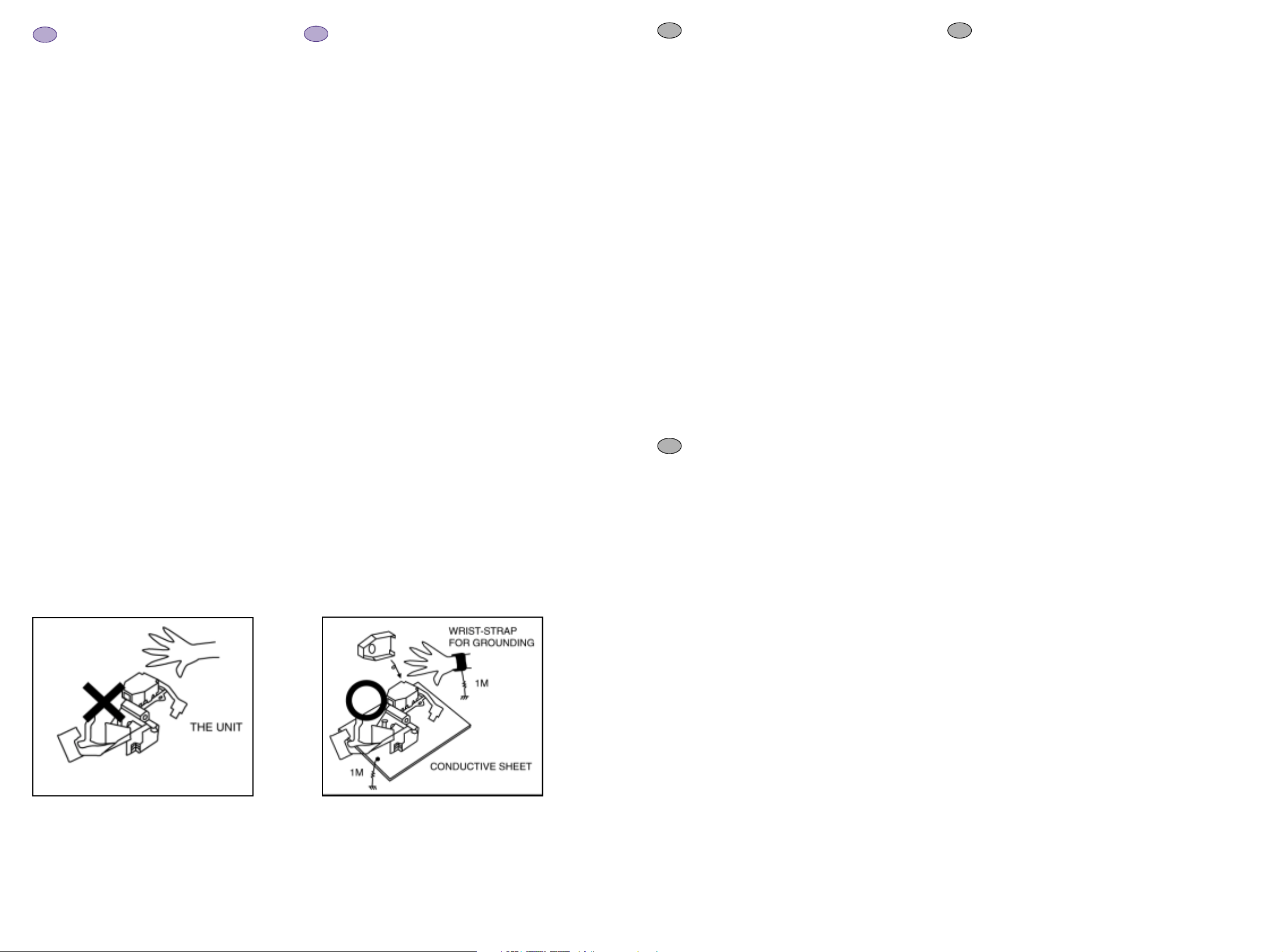

EN Prevention of electro static discharge (esd) to Electrostatically Sensitive Devices (ESD)

Some semiconductor devices can be damaged easily by static electricity (integrated circuits, some field-effect transistors and

semiconductor chip components. The following techniques should be used to help reduce the incidence of component damage caused

by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge

on your body by touching a known earth ground or wear a discharging wrist strap device, which should be removed for potential

shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface such as aluminum

foil.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal devices.

5. Do not use freon-propelled chemicals.

6. Do not remove a replacement ESD device from its protective package until immediately before your are ready to install it.

7. Immediately before removing the protective materials from the leads of a replacement ESD device, touch the protective material to

the chassis or circuit assembly into which the device will be installed.

CAUTION : Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ESD devices

FR Prévention des composants et sous-ensembles contre les ESD ( Décharge d'Electricité Statique )

Certains semi-conducteurs peuvent être facilement endommagés par l’électricité statique (les circuits intégrés et certains transistors à

effet de champs, les composants semi-conducteurs de type chip ainsi que les diodes à émission laser équipant les lecteurs optiques ).

Les précautions suivantes doivent être utilisées pour réduire l’incidence des dommages causés par l’électricité statique.

1. Immédiatement avant de manipuler tout composant semi-conducteur ou ensemble équipé de semi-conducteurs, éliminez toute charge

électrostatique de votre corps en touchant une terre connue. Ou bien, mettez un bracelet antistatique, qui doit être retiré, pour des

raisons de choc électrique, avant de mettre l’appareil sous tension.

2. Après démontage d’un ensemble électrique équipé d’éléments sensibles aux ESD, Placez l’ensemble sur une surface conductrice telle

qu’une feuille d’aluminium.

3. N’utilisez qu’un fer à souder relier à la masse pour souder ou dessouder ces composants.

4. Pour dessouder, n’utilisez que du matériel antistatique

5. N’utilisez pas de produits chimiques à propulsion de fréon.

6. Ne retirez pas ces composants de leur emballage de protection jusqu’à ce que vous soyez prêt à l’installer.

7. Juste avant de retirer la protection des broches de ces composants, touchez la protection sur le châssis ou le circuit dans lequel le

composant va être installé.

ATTENTION : Assurez-vous que le châssis ou le circuit n’est pas sous tension, et observez toutes les autres précautions de sécurité.

8. Minimisez les déplacements corporels lorsque vous manipulez un de ces composants de remplacement déballé.

DE Vermeidung von Elektrostatischer Entladung (ESD)

Manche elektronische Komponenten wie Transistoren, Integrierte Schaltkreise oder Chipelemente können leicht durch ESD beschädigt

oder zerstört werden. Die folgenden Richtlinien helfen Schäden durch ESD zu vermeiden.

1. Unmittelbar vor dem Hantieren Halbleitern oder Baugruppen mit Halbleitern leiten Sie die statische Aufladung Ihres Körpers durch

Berühren einen geerdeten Gegenstandes ab. Beschaffen Sie sich ein leitendes Hansgelenkband. Dieses müssen Sie allerdings vor dem

Einschalten des zu prüfenden Gerätes ablegen.

2. Nach dem Ausbau einer empfindlichen elektronischen Baugruppe legen Sie diese auf einen leitende Unterlage wie Aluminium-Folie um

eine elektrostatische Entladung zu vermeiden.

3. Benutzen Sie für Lotarbeiten an empfindlichen Komponenten einen geerdeten Lötkolben.

4. Benutzen Sie antistatisches Entlötwergzeug.

5. Verwenden Sie keine Sprays, die Freon als Treibmittel enthalten. Diese können ausreichend elektrostatische Ladung erzeugen, um

empfindliche Komponenten zu schädigen.

6.

Entfernen Sie die Antistatik-Schutzverpackung (Alu-Folie, Leitgummi, Leitfolie, ..) von Komponenten und Baugruppen erst wenn Sie diese benötigen.

7. Unmittelbar vor dem Entfernen der Schutzverpackung führen Sie ein Potentialausgleich durch Berühren des Gerätes mit der

Komponente/Baugruppe durch. ACHTUNG: Stellen Sie Sicher, Dass das Gerät nicht unter Spannung steht und beachten Sie alle

einschlägigen Sicherheitsvorschriften.

8. Bewegen Sie sich beim Hantieren mit empfindlichen Komponenten/Bausteinen möglichst wenig, da die Reibung Ihrer Kleidung oder

der Füße auf dem Bodenbelag elektrostatische Ladung erzeugen kann.

IT

Azioni preventive contro le scariche elettrostatiche (esd) sui Dispositivi Sensibili Elettrostaticamente (ESD)

Alcuni semiconduttoripossono essere facilmente danneggiati da elettricità statica (circuiti integrati, alcuni transistor ad effetto di campo e

componenti chip semiconduttori). Al fine di ridurre l’incidenza dei componenti danneggiati a causa di elettricità statica si dovrebbero

osservare le seguenti precauzioni.

1.

Immediatamente prima di maneggiare qualsiasi tipo di componente semiconduttore o di apparecchio che impiega semiconduttori, scaricare le

possibili cariche elettrostatiche del proprio corpo toccando un punto sicuramente collegato a terra. In alternativa, indossare un apposito braccialetto

antistatico che dovrebbe però essere tolto, per possibili potenziali shock, immediatamente prima di alimentare l’apparecchiatura sotto test.

2. Dopo il disimballo porre l’apparecchiatura equipaggiata con dispositivi ESD su una superficie conduttiva tipo foglio di alluminio.

3. Usare saldatori con punta a massa per saldare o dissaldare dispositivi ESD.

4. Usare solo saldatorI antistatici.

5. Non usare prodotti chimici tipo freon.

6. Rimuovere il dispositivo ESD dal suo imballo protettivo solo immediatamente prima del suo utilizzo.

7. Immediatamente prima della rimozione del materiale protettivo dai piedini del dispositivo ESD di ricambio, toccare con il materiale

protettivo il telaio o la massa del circuito stampato dove il dispositivo deve essere inserito.

ATTENZIONE : Assicurarsi che il circuito o il telaio non sia alimentato, e osservare tutte le altre precauzioni di sicurezza.

8. Limitare gli spostamenti quando si maneggia un dispositivo ESD disimballato.

ES Prevención contra descargas electro-státicas (esd) para los DISPOSITIVOS SENSIBLES electrostáticamente (ESD)

Algunos dispositivos semiconductores, pueden ser dañados fácilmente por la electricidad estática (los circuitos integrados, algunos

transistores de Efecto de Campo y los semiconductores "chip"). Las siguientes técnicas pueden ser utilizadas para ayudar a reducir la

destrucción de los componentes causada por la electricidad estática.

1. Inmediatamente antes de manejar cualquier componente semiconductor o conjunto equipado con semiconductores, elimine la carga

electrostática de su cuerpo tocando alguna toma de tierra conocida o utilizar una correa conductora conectada a una toma de tierra que

se pone en la muñeca la cual debe ser quitada (por razones de seguridad) antes de conectar la alimentación al equipo bajo prueba.

2. Después de quitar un conjunto equipado con componentes ESD, coloque el conjunto sobre una superficie conductora, como papel aluminio.

3. Utilizar únicamente soldadores con la punta conectada a la toma de tierra para soldar o desoldar componentes ESD.

4. Utilizar solamente soldadores antiestáticos para quitar componentes.

5. No utilizar productos químicos con gas freón como propelente.

6. No sacar de su embalaje protector el nuevo componente ESD hasta inmediatamente antes de estar todo preparado para montarlo.

7. Inmediatamente antes de quitar los materiales de protección de las patillas del componente, tocar el material protector al chasis del

conjunto donde se vaya a montar el componente.

CUIDADO : Asegúrese de que la alimentación no esté aplicada al chasis o circuito, y cumpla todas las precauciones de seguridad.

8. Maneje sin movimientos bruscos el componente ESD una vez desempaquetado.

Page 6

7

DTH6300

8 First issue 03 / 05

HANDLING THE OPTICAL PICKUP

The laser diode used in the optical pickup may break down

due to potential differences caused by electricity produced

by clothing or the human body, care should therefore be

taken to prevent electrostatic discharge whilst repairing the

optical pickup.

The following method is recommended.

1) Place a conductive sheet on the work bench (The black

sheet used for wrapping repair parts.)

2) Place the set on the conductive sheet so that the

chassis is grounded to the sheet.

3) Place your hands on the conductive sheet (doing this

gives them the same ground as the sheet.

4) Remove the optical pickup block

5) Perform work on top of the conductive sheet. Be careful

not to let your clothes or any other static sources to

touch the unit.

* Grounding the Human Body, use an antistatic wrist

strap to discharge static electricity from your body.

* Grounding the work place, use either an antistatic matt

or a sheet of steel on the area where the optical pickup

is to be placed and ground the matt/sheet.

6) Short the short terminal on the PCB, which is inside the

Pickup Assembly, before deconnecting the flexible

cable for replacing the Pickup. (The short terminal is

shorted when the Pickup Assembly is being lifted or

moved.)

7) After replacing the Pickup, open the short terminal on

the PCB.

MANIPULATION DU BLOC OPTIQUE

La diode laser utilisée dans le bloc optique peut se

détériorer à cause d’une différence de potentiel causé par

l’électricité produite par les vêtements ou le corps humain,

par conséquent des précautions doivent être prise pour

éviter les décharges électrostatiques pendant la réparation

du bloc optique.

Il est recommandé de suivre la méthode suivante.

1) Placez une feuille conductrice sur le banc de travail (la

feuille noire utilisée pour envelopper les pièces

détachées).

2) Placez l’ensemble sur la feuille conductrice pour que le

châssis soit mis à la masse par la feuille.

3) Mettez vos mains sur la feuille conductrice (en faisant

ceci, vous leur donnez la même masse que la feuille)

4) Retirez le bloc optique

5) Travaillez en haut de la feuille conductrice. Prenez soin

de ne pas laisser vos vêtements ou autre source

statique toucher le bloc optique.

* Mise à la terre du corps humain : utilisez un bracelet

antistatique pour décharger l’électricité statique de

votre corps.

* Mise à la terre du poste de travail : placez soit un tapis

antistatique, soit

une feuille d’acier sur le banc de travail où vous

poserez le bloc optique après avoir relier le tapis ou la

feuille à la masse.

6) Pour remplacer le bloc optique, soudez le court-circuit

sur le circuit imprimé qui se trouve sur l’ensemble

optique, avant de déconnecter le câble flexible (le

court-circuit est soudé lorsque l’ensemble optique est

levé ou déplacé).

7) Après le remplacement du bloc optique, dessoudez le

court-circuit sur le circuit imprimé.

EN

FR

Fig. 1

Fig. 2

DE IT

ES

HANDHABUNG DER OPTISCHEN EINHEIT

Die verwendete Laser-Diode kann unter Umständen zerstört

werden, wenn sie mit statischer Spannung aufgeladene Teile in

Berührung kommt . Deshalb ist unbedingt zu beachten, daß vor

der Reparatur alle Teile potentialfrei sind.

Empfehlenswert ist folgende Methode.

1) Eine leitende Unterlage auf den Werktisch legen (über

1MOhm Widerstand geerdete Leitgummi-Matte, Metallplatte

oder ggf. die schwarze Folie der Ersatzteilverpackung).

2) Das Gerät auf diese Fläche stellen, damit ein

Potenzialausgleich stattfinden kann.

3) Bringen Sie Ihren Körper auf das gleiche Potenzial wie die

Unterlage (z.B. mit Handgelenkband über 1 MOhm

geerdet).

4) Jetzt kann das DVD-Laufwerk bzw. die optische Einheit

ausgebaut werden .

5) Führen sie alle Arbeiten auf der Leitgummi-Matte aus.

6) Zum Schutz des Lasers verbinden vor dem Ausbau der

optischen Einheit (Lösen der Flachbandleitung) die beiden

Lötpunkte auf der Leiterplatte der optischen Einheit

miteinander. Die Leiterplatte befindet sich in der optischen

Einheit.

7) Nach dem Einbau der (neuen) optischen Einheit den

Kurzschluß wieder beseitigen !

MANEGGIAMENTO OTTICA PICKUP

Il diodo laser usato nelle ottiche pickup si può danneggiare a

causa di differenze di potenziale causate da elettricità prodotta

da vestiti o dal corpo umano, particolari attenzioni devono

essere prese, durante la riparazione di apparecchiature con

pickup ottici, per prevenire scariche elettrostatiche.

Si raccomanda di seguire le seguenti indicazioni.

1) Mettere un foglio conduttivo sul banco di lavoro (tipo foglio

nero utilizzato per avvolgere le parti di ricambio).

2) Posizionare l’apparecchiatura sul foglio conduttivo per

collegare la massa del telaio al foglio conduttivo.

3) Toccare con le mani il foglio conduttivo per avere lo stesso

potenziale di massa del foglio conduttivo.

4) Rimuovere l’assieme ottica pickup.

5) Lavorare sopra il foglio conduttivo. Evitare di far toccare i

propri vestiti o qualsiasi altra sorgente statica

all’apparecchiatura.

* Per scaricare a massa l’elettricità statica del proprio corpo

utilizzare l’apposito braccialetto antistatico.

* Per mettere a terra il proprio posto di lavoro utilizzare un

tappetino antistatico o un foglio di acciaio collegati a massa,

sull’area dove deve essere sostituita l’ottica.

6) In caso di sostituzione del pick up, cortocircuitare prima gli

appositi punti della piastrina dell’assieme pickup, poi

scollegare il cavo di collegamento flessibile.

7) Aprire il cortocircuito dei terminali solo dopo la sostituzione

del Pickup.

MANEJO DEL CONJUNTO OPTICO

El diodo láser utilizado en el lector óptico puede resultar

averiado a causa de las diferencias de potencial eléctrico

producidas por el roce con la ropa o con el cuerpo humano,

también hay que tener cuidado de que no se produzcan

descargas electrostáticas mientras se repara el lector óptico.

Se recomienda el siguiente método.

1) Colocar una hoja conductora en el banco de trabajo (Vale la

hoja negra que se utiliza para envolver los repuestos).

2) Colocar el aparato en la hoja conductora de forma que el

chasis haga contacto con la hoja.

3) Poner las manos sobre la hoja conductora (haciendo esto

se da la misma toma de tierra que a la hoja).

4) Retirar el conjunto óptico.

5) Realice el trabajo encima de la hoja conductora. Tenga

cuidado para no permitir que su ropa o cualquier otra fuente

de electricidad estática pueda tocar a la unidad.

* Conecte a tierra el cuerpo humano, utilizando una

muñequera antiestática para descargar la electricidad

estática del cuerpo.

* Conectar a tierra el lugar de trabajo, utilizando una

alfombrilla antiestática o una hoja de papel de aluminio en

el área donde

se coloque el lector óptico y conectándola a la toma de

tierra.

6) Poner en cortocircuito los terminales de los diodos

(soldaduras en la cinta del conjunto óptico) antes de

desconectar el cable flexible para remplazar el lector óptico.

7) Después de cambiar el lector óptico, quitar los

cortocircuitos anteriores.

Page 7

DTH6300

First issue 03 / 05 9

ELECTRICAL ADJUSTMENTS - REGLAGES ELECTRIQUES

ELEKTRISCHE EINSTELLUNGEN - REGOLAZIONI ELETTRICHE

AJUSTES ELECTRICOS

WIRING DIAGRAM - SCHEMA D’INTERCONNEXIONS - VERDRAHTUNGSPLAN

DIAGRAMMA DELLE INTERCONNESSIONI - ESQUEMA DE INTERCONEXIONES

OVERALL WIRING DIAGRAM

DECK MDSMPS

BOARD

123456789

CF G

I-limit

5.2VA

PMC0 1

12VA(CAP)

CAP REV’H’

123456789

GND

MOT OR GND

CAP CT L

12VA(DRUM)

101112

LD IN

DFG/FG

101112

12345

6

1

2

GND

A.PB

A/E(-)

A/E(+)

CTL(-)

A.REC

P3D0 2

CTL(+ )

DRUM CT L

12345

P3D0 3

FUL L ERASE

6

1

2

123456789

24VA(28V A)

12PIN PPM0 1

123456789

101112

4VA

GND

GND

GND

14VA

33VA

5.3VA

101112

123456789

PMD01

RF_OUT

HFM_VCC

FROM P/UP

123456789

LD_DVD

MD_DVD

10111213141516171819202122

F

E

A

VCC

VREF

VR_DVD

GND_PD

10111213141516171819202122

B

D

C

FOCUS+

TRACKING-

MAIN PCB

Head switching point

Mode & Signal Test Point Description

• Adjustment Procedure

a) Insert the SP Test Tape and play.

6.5H(416us)

Note - Adjust the distance of X, ( See deck mechanism adjustment page 69 )

b) Connect the CH1 of the oscilloscope to the H/SW(TP) and CH2 to the Video Out for the VCR.

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW(TP), and then check

the distance (time difference), which is from the selected A(B) Head point of the H/SW(TP)

signal to the starting point of the vertical synchronized signal, to 6.5H ± 0.5H (412µs, 1H=63µs).

PB (SP)

Dual trace

Oscilloscope

SCART PIN19

Video

H/SW

Composite

VIDEO

CH1

CH2

FOCUS-

SW_PDI C

TRACKING+

LD_C D

GND_LD

MD_CD

23

VR_CD

23

123456789

SPM -

SPM +

PMD02

FROM MD

123456789

11

10

LM -

FM -

GNDSWGND

LM +

FM +

OPEN

CLOSE

11

10

VCR PCB

H/SW

H/SW

Composite

VIDEO

6.5H(416us)

• PG Adjustment Method

a-1) Payback the SP standard tape

b-2) Press the “1” key on the Remote controller and the “PLAY” key on the Front Panel the same time, then

it goes in to Tracking initial mode.

c-3) Repeat the above step(No.b-2), then it finishes the PG adjusting automatically. "off" then "on" is displayed

d-4) Stop the playback, then it goes out to PG adjusting mode after memory the PG data.

Page 8

DTH6300

10 First issue 03 / ,05

2fsc

R524, R514, R518,

R516, R589, C577,

C576, L501, Q504

LD(+)

LD(-)

L/M CONTROL

R525, R526

IC501

HD6432197A

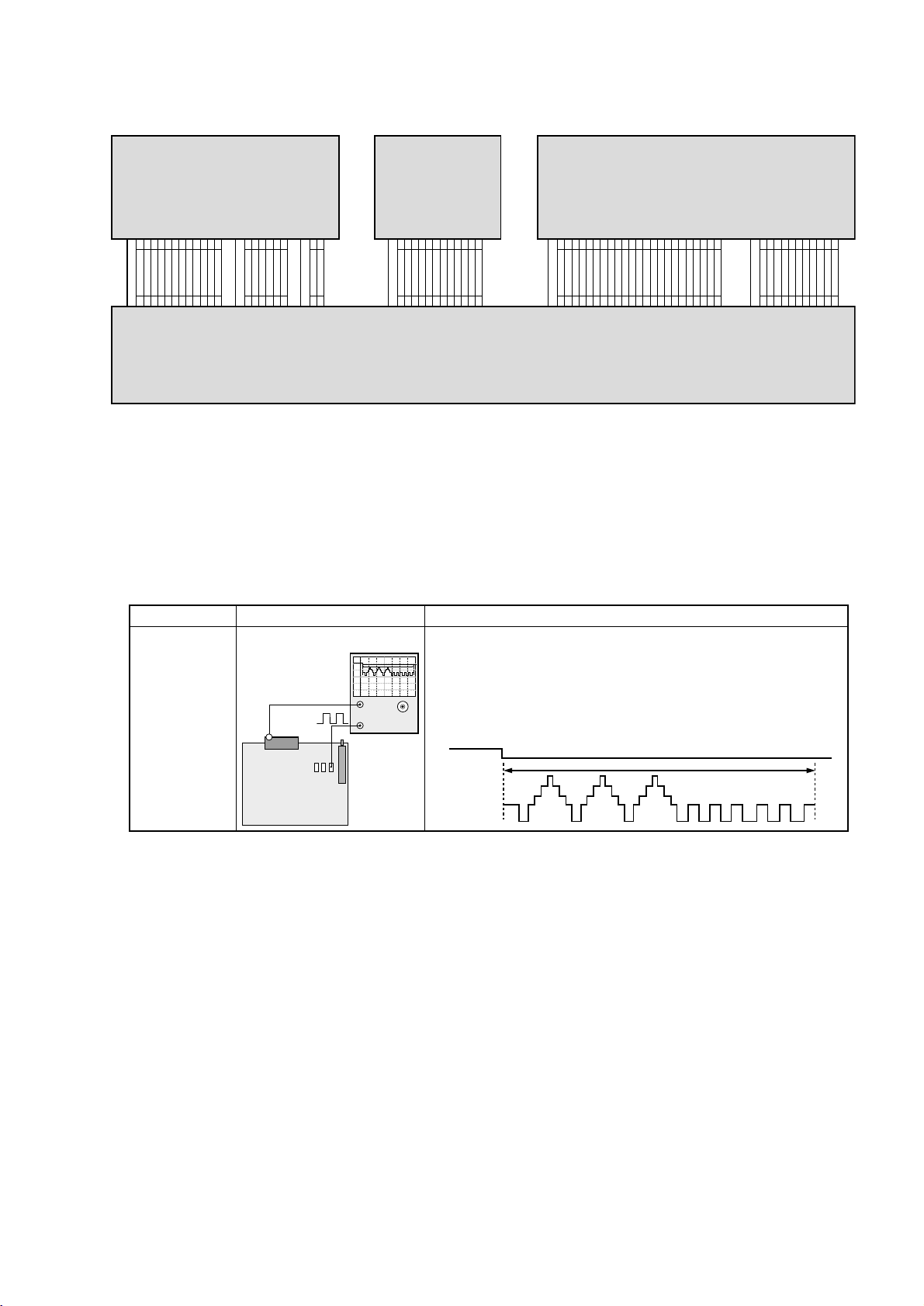

BLOCK DIAGRAM - SCHEMA SYNOPTIQUE - BLOCKSCHALTBILD - SCHEMA A BLOCCHI ESQUEMA DE BLOQUES

Page 9

12

DTH6300

First issue 03 / 05 11

BLOCK DIAGRAMS

POWER(SMPS) BLOCK DIAGRAMS

BD101

T101

TRANS

R101

+

BR BL

(BK)(WH)

C103

!

FUSE

(F101)

NOISE FILTER

BLOCK

(C101,L102,

C102)

PHOTO COUPLER

(IC102)

ERROR

AMP

(IC103)

SNUBBER

BLOCK

(D101,C105

C106,R104)

DRIVE & S/W BLOCK

(IC101, D102, R105,

C104, C109 , C135)

Y-CAP

C111

Y-CAP

C110

FEED-BACK

BLOCK

R112,R113,

C133,R114.

R115.R116

R117)

< HSR OPTION>

24V S/W BLOCK

(Q153,R151,R152,

D122,Q154,R110,

D116,R181,R182)

< HSR OPTION>

RECTIFIER&

SMOOTING BLOCK

(D106,C117,R130)

RECTIFIER&

SMOOTING BLOCK

(D110,C123,C163,

R133,L122,C126)

RECTIFIER&

SMOOTING BLOCK

(D118,D112,C129,

C131,L124,L125)

RECTIFIER&

SMOOTING BLOCK

(D111,C127,L123,

C128)

RECTIFIER&

SMOOTING BLOCK

(D113,C132,R119)

CAP VCC

13VA/24V

HSR’H ’

D117

D115

DRUM VCC

13VA

12VT

8V

5.3VA

5.0V

3.3V

D111

2.5V

33VT

TIMER’H ’

12V REG BLOCK

(Q156,ZD103,C151,

R150,R153,C152)

8V REG BLOCK

(D114,IC151,R170,

C154)

5V S/W BLOCK

(Q150,C155,D121,

R157,R158,R159,R160

Q162,R164,R172,C161)

3.3V REG BLOCK

(IC152,C153,R156)

33VT S/W BLOCK

(Q161,R154,R155

Q173,R174,R177)

5VT S/W BLOCK

(Q163,C162,R173,

R176,R175,Q164)

PWR CTL’H'

5.0VT

!

!

!

!

!

6578

2

31

BLOCK DIAGRAM - SCHEMA SYNOPTIQUE - BLOCKSCHALTBILD - SCHEMA A BLOCCHI - ESQUEMA DE BLOQUES

( SMPS )

Page 10

13

DTH6300

14 First issue 03 / 05

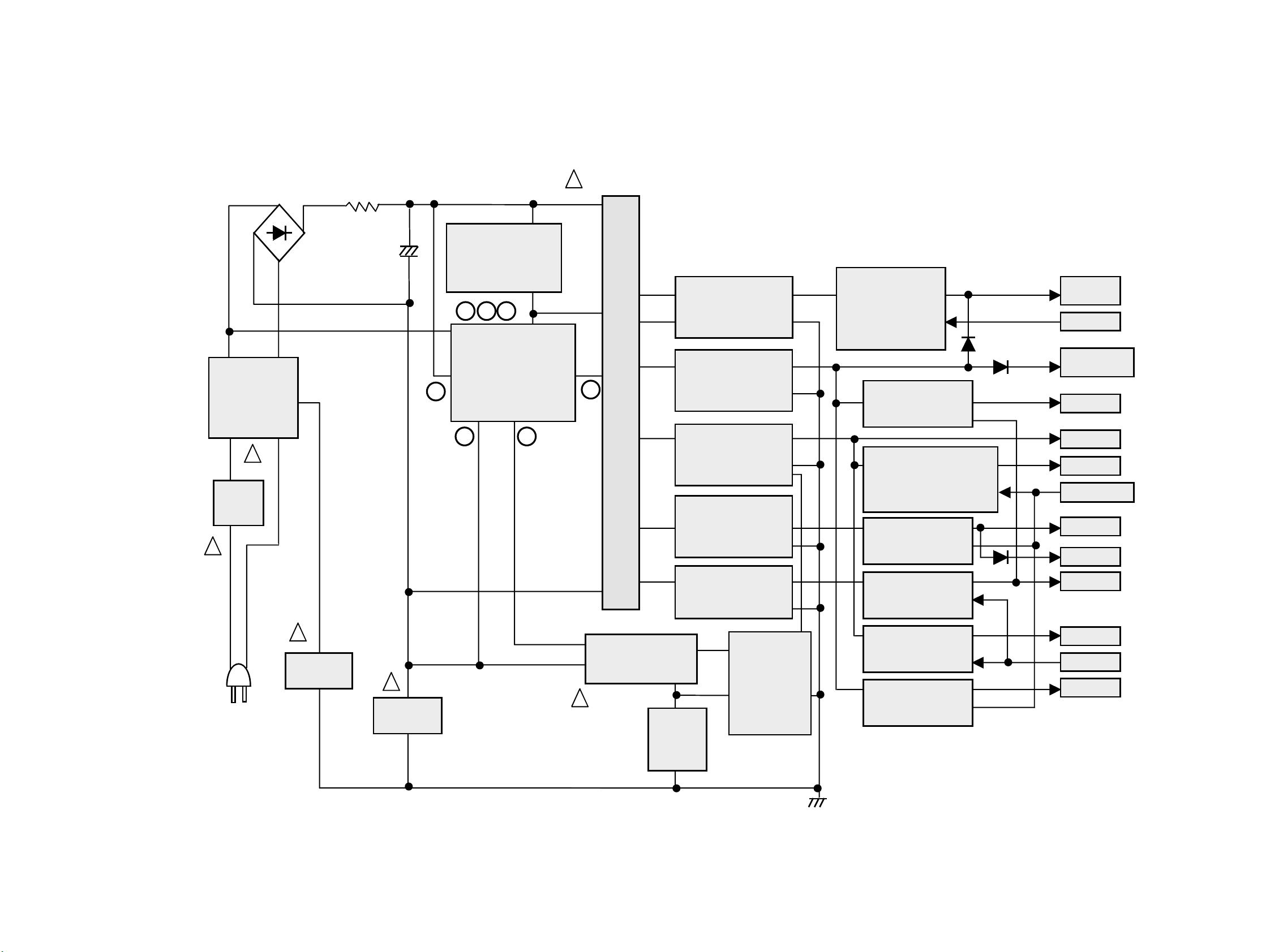

POWER SUPPLY - ALIMENTATION - NETZTEIL - ALIMENTAZIONE - ALIMENTACIÓN

SCHEMATIC DIAGRAM - SCHEMA DE PRINCIPE - SCHALTBILD - SCHEMA - ESQUEMA

POWE

315

(315)

T=20uS

600Vpp-H

0V

100V

(351,5)

352

5,3

(5,3)

28

(26)

14

(13)

5,3

(5,3)

14,2

(13)

Note :

Power Supply primary circuit measurements.

- Use only ( ) connection point.

Achtung :

Bei Messungen im Primärnetzteil

- Primärnetzteilmasse verwenden ( ).

Cuidado :

Medida en el bloque de alimentacion

- Utilizar la masa del bloque de alimentacion ( ).

* According to Models

315

(315)

0,8

(0,5)

Attention :

Mesure dans la partie primaire de l'alimentation

- Utiliser la masse du bloc alimentation ( ).

Attenzione :

misure nell'alimentatore primario

- usare massa alimentazione primario ( ).

Part of board connected to mains supply.

Partie du châssis reliée au secteur.

Primärseite des Netzteils.

Parte dello châssis collegata alla rete.

Parte del chassis conectar a la red.

*

3,9

(4,2)

33,9

(30)

5

(5)

4

(4)

(30) = Standby

Safety Part

When repairing, use original part only

Pièce de securité

N'utilisez que les pièces d'origine

Sicherheitsbauteil

Bei Ersatz nur Originalteil verwenden

Componenti di sicurezza

Per la riparazione utilizzare solo componenti originali

Utilice solo piezas originales

Pieza de seguridad

Use isolating mains transformer.

Utiliser un transformateur isolateur du secteur.

Einen Trenntrafo verwenden.

Utilizar un transformador aislador de red.

Utilizzare un transformatore per isolarvi dalla rete.

Page 11

16

DTH6300

First issue 03 / 05 15

POWER SUPPLY - ALIMENTATION - NETZTEIL - ALIMENTAZIONE - ALIMENTACIÓN

SCHEMATIC DIAGRAM - SCHEMA DE PRINCIPE - SCHALTBILD - SCHEMA - ESQUEMA

POWER(SMPS) CIRCUIT DIAGRAM 2

MAIN

13,4

28,3

28

33,9 33,7

33,1

13,9

5,3

4,4

13,4

11,9

12,3

5,2

5,3

4,4

5

Page 12

17

DTH6300

18 First issue 03 / 05

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

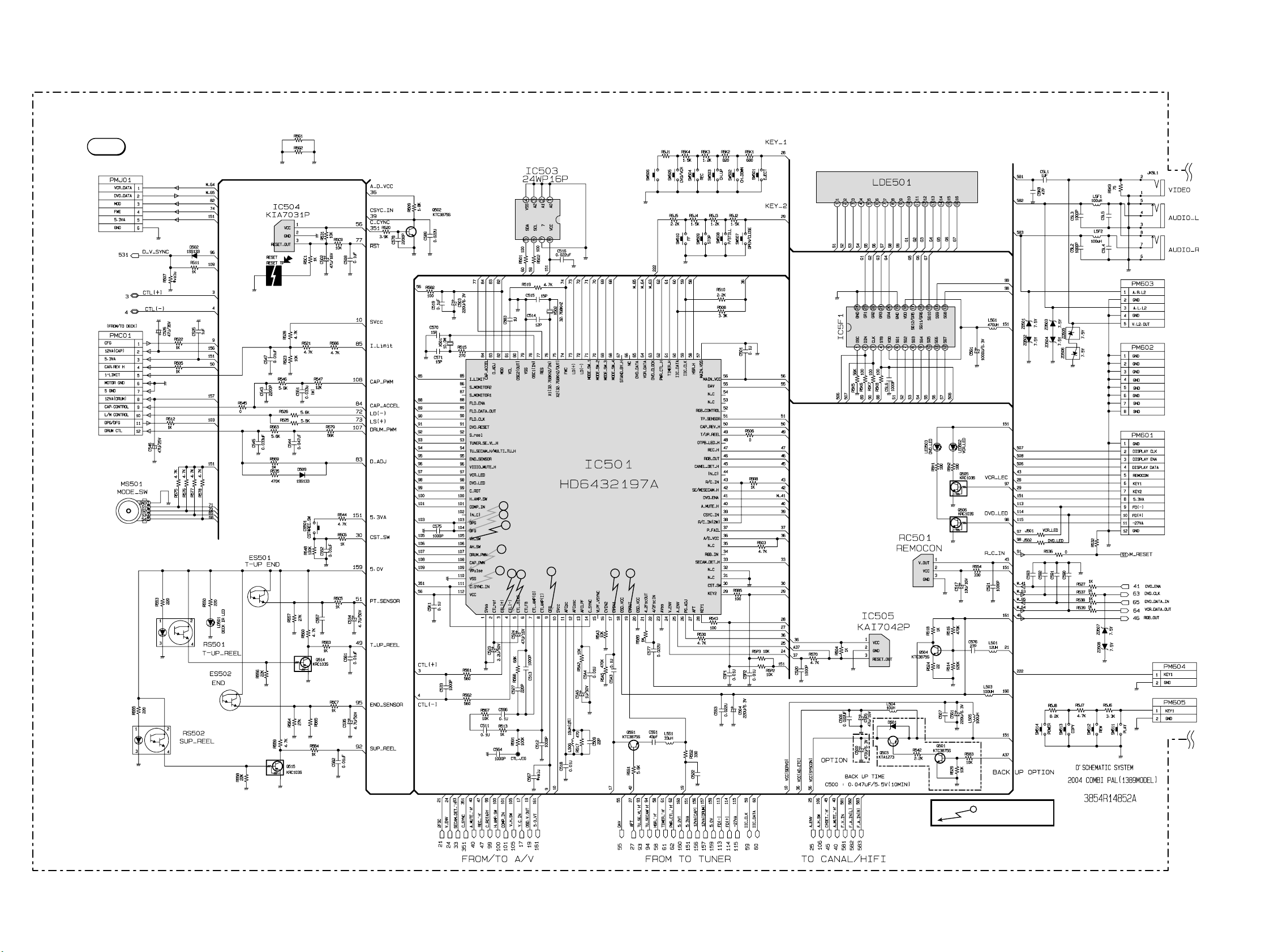

SYSTEM CIRCUIT DIAGRAM

MAIN

5

5

1

2

9

3

6

4

8

7

WAVEFORM

Page 13

20

DTH6300

First issue 03 / 05 19

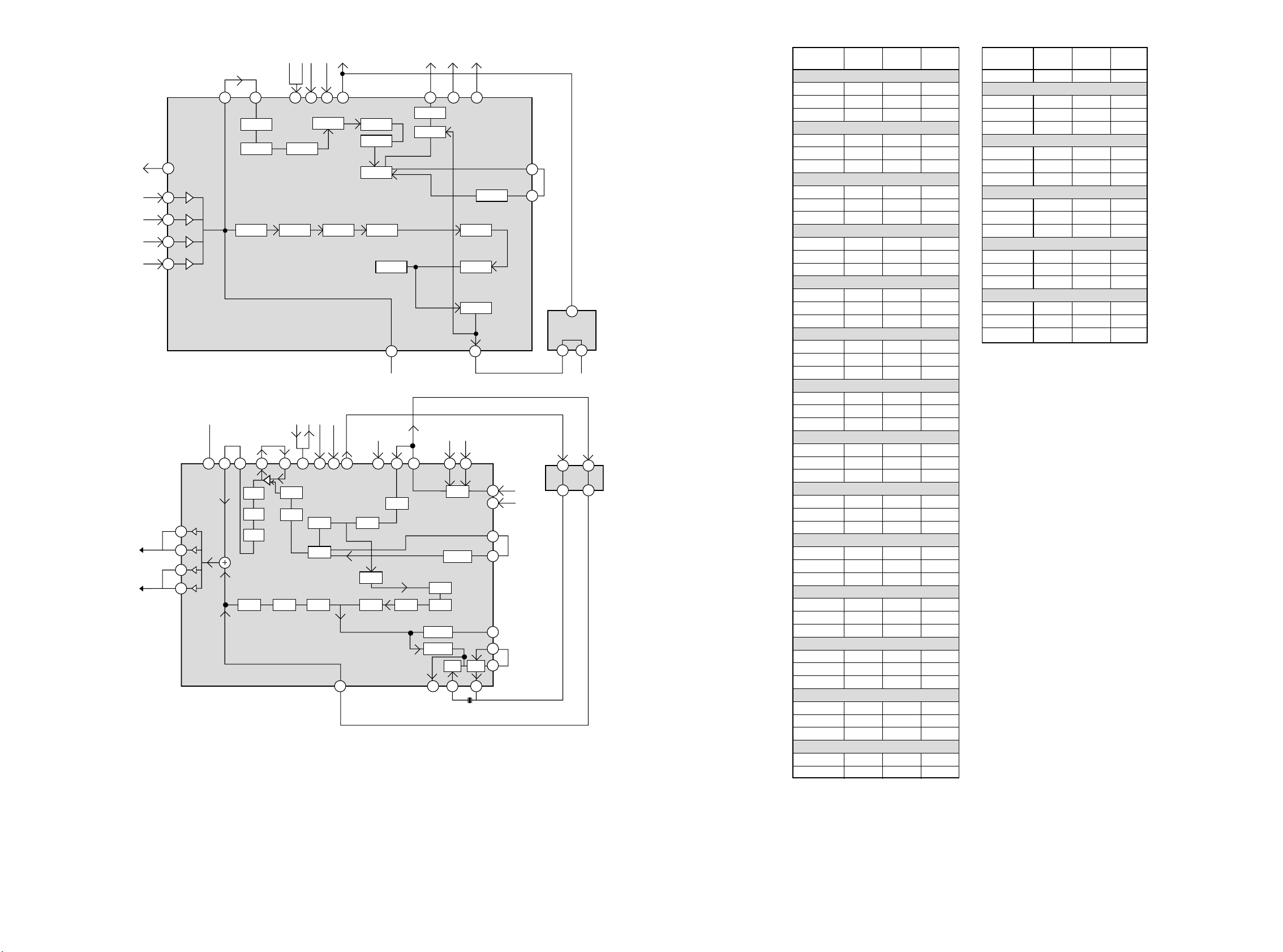

Y/C BLOCK DIAGRAM

MEASUREMENTS - MESURES - MESSUNGEN - MISURE ELABORAZIONE - MEDIDAS - TRATAMIENTO

(PB MODE)

84V.ENV

87

90

93

96

(REC MODE)

88

(To Drum )

(To Drum )

LP REC

SP REC

89

94

95

V.H.SW

C.ROT AR Y

D ATA

CLOCK

C.SYNC

79 78

PB FM

AGC

PB FM EQ FM OEM

IC301

LA71750M

REC’H’

80

79 78 76 75 70 69 68 67 65 59 58 54 52

W/D

CLIP

W/D

CLIP

REC

FM EQ

IC301

LA71750M

Killer C-LP F ACC

70

ACCC LP F

NL

EMPHA

DET AI L

ENH

V.H.SW

69 68 67

SUB LP F

MAI N

CONV

C.ROT AR Y

D ATA

CLOCK

C SYNC

Y-LP F FBC

YNR

Main

Conv

MAI N

DE EMP

Y-LP F

YNR

V.OUT

BPF

BPF

ACC

DET

MICOM

AGC

Main

Conv

65 63 61

60dB AMP

Y/C MI X

KILL DEC

REC APC

V.OUT

1H/2H

DEL AY

COMP

AMP

2721

(MICOM)

S2 V.OUT

C-Delay

(1H/2H )

CCD

LP F

CNC

2521

V.IN4

FRONT

V.IN3

DEC

SW

Y-DEL AY

VX0 2 VX0 2

2928

4.43MHz

S1 V.OUT

Y-Delay

50 V.IN2 S1

48

46

43

33

32

31

46

43

V.IN1 TUNER

CLK-IN

SYNC IN

29

IC201

LA70100M

18 14

29 16

IC201 LA70100M

212

EEPIN PB REC EEPIN PB REC

Q301

BASE 0.01 V 0.013 V 0.79 V

EMITER 0.003 V 0.004 V 0.005 V

COLECTOR

4.83 V 4.82 V 1.02 V

Q302

BASE 4.85 V 4.18 V 4.75 V

EMITER 0.002 V 4.85 V 4.75 V

COLECTOR

(-)2.79 V 4.8 V (-)25.5 V

Q303

BASE (-)2.76 V 0.7 V (-)25.6 V

EMITER (-)0.8 V 0.007 V (-)19.13 V

COLECTOR

0.002 V 0.012 V 0.004 V

Q304

BASE (-)2.62 V 0.72 V (-)25.4 V

EMITER 0.002 V 0.002 V (-)19.4 V

COLECTOR

0.002 V 0.004 V 0.004 V

Q305

BASE 1.71 V 1.41 V 1.7 V

EMITER 2.41 V 2.1 V 2.39 V

COLECTOR

0.003 V 0.004 V 0.005 V

Q309

BASE 2.18 V 2.01 V 2.33 V

EMITER 2.87 V 2.7V 3V

COLECTOR

0.012 V 0.005 V 0.012 V

Q501

BASE 0.69 V 0.69 V 0.69 V

EMITER 0.002 V 0.003 V 0.003 V

COLECTOR

0.02 V 0.012 V 0.023 V

Q502

BASE 0.31 V 0.38 V 0.33 V

EMITER 0.004 V 0.004 V 0.004 V

COLECTOR

2.65 V 1.93 V 2.4 V

Q504

BASE 0.59 V 0.51 V 0.50 V

EMITER 0.03 V 0.03 V 0.03 V

COLECTOR

3.78 V 3.75 V 3.71 V

Q5S1

BASE 0.006 V 0.005 V 0.003 V

EMITER 1.77 V 1.8 V 1.89 V

COLECTOR

2.41 V 2.1 V 2.4 V

Q515

BASE 4.94 V 0.5~4.3 V 0.4~4.9 V

EMITER 0.002 V 0.003 V 0.005 V

COLECTOR

0.02 V 0.2~3.5 V 0.4~4.9 V

Q514

BASE 4.96 V 0.8~4.2 V 0.2~4.3 V

EMITER 0.002 V 0.002 V 0.003 V

COLECTOR

0.02 V 0.01~4.8V 0.011 V

Q7S1

BASE 0.007 V 0.007 V 0.008 V

EMITER 0.001 V 0.001 V 0.001 V

COLECTOR

3.7

3.5 V0.057

V

Q801

BASE 0.7 V (-)0.1 V 0.01 V

EMITER 0.001 V 0.003 V 0.001 V

0.004V 0.006 V

Q802

BASE 0.7 V (-)0.12 V 0.7 V

EMITER 0.001 V 0.001 V 0.001 V

COLECTOR

0.004 V0.02 V0.005

Q804

BASE 1.81 V 2.5 V 1.79 V

EMITER 2.5 V 3.20V 2.48 V

COLECTOR

0.002V 0V0V

Q901

BASE 0.005 V 0.005 V 0.006 V

EMITER 0.003 V 2.04 V 1.9 V

COLECTOR

0.003 V 0.004 V 0.005 V

Q902

BASE (-)1.64 V (-)1.69 V (-)1.79 V

EMITER 0.003 V 0.004 V 0.004 V

COLECTOR

0.004 V 0.004 V 0.005 V

Q903

BASE (-)1.74 V (-)1.63 V (-)1.8 V

EMITER 0.003 V 0.003 V 0.005 V

COLECTOR

0.003 V 0.004 V 0.005 V

V

~

V

Page 14

21

DTH6300

22 First issue 03 / 05

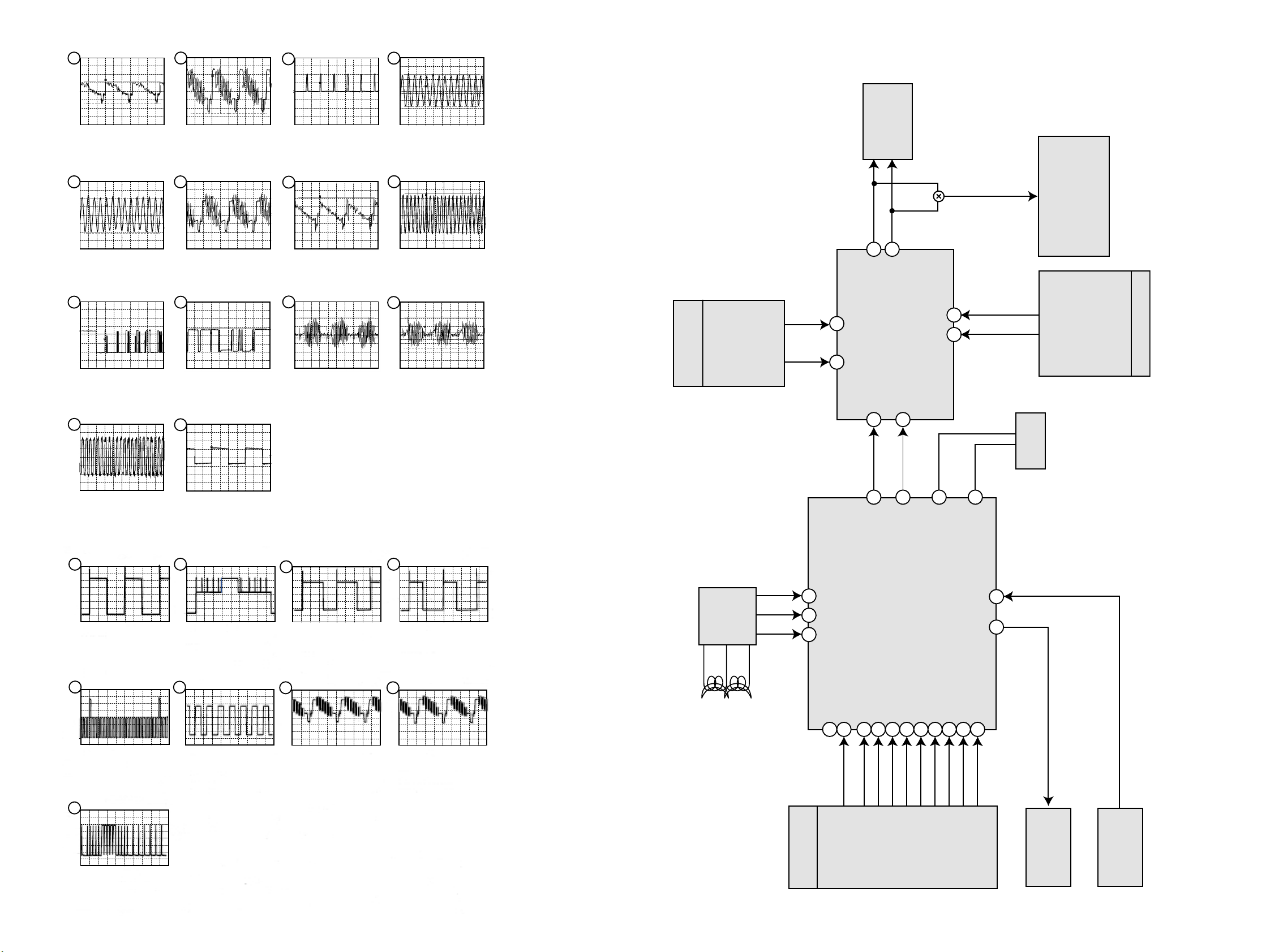

V. HS W

( IC501 Pin 105)

1V/10ms

REC/PB MODE

1

DV.SYNC

( IC501 Pin 109)

1V/100µs

QUE/REV MODE

2

CTL(+)

( IC501 Pin 3)

1V/10ms

3

CTL(-)

( IC501 Pin 4)

1V/10ms

4

DPG/DFG

( IC501 Pin 103,104)

1V/10ms

REC/PB MODE

5

CFG

( IC501 Pin 9)

1V/10ms

6

V. IN

( IC501 Pin 17)

500mv/20µs

7

V. OU T

( IC501 Pin 19)

500mv/20µs

EE/PB MODE

8

C.SYNC

( IC501 Pin 111)

1V/100µs

EE/PB MODE

9

MEASUREMENTS - MESURES - MESSUNGEN - MISURE ELABORAZIONE - MEDIDAS - TRATAMIENTO

( VCR )

BLOCK DIAGRAM - SCHEMA SYNOPTIQUE - BLOCKSCHALTBILD - SCHEMA A BLOCCHI ESQUEMA DE BLOQUES

1

2

3

4

Hi-Fi BLOCK DIAGRAM

( IC301 Pin 75 )

PB mode PB / REC mode REC mode

500mv PP

5

( IC301 Pin 3)

REC mode PB mode PB mode

2,0 V pp

9

( IC301 Pin 68 )

PB / REC mode REC mode PB mode

5,0 V pp

13

( IC301 Pins 48, 50, 52

54, 56 )

Video in 1,0V pp

6

( IC301 Pin 65 )

PB mode

2,02 V ppp

10

( IC301 Pin 69 )

PB / REC mode

5,0 V pp

14

( IC301 Pin 67)

4,0 V pp

7

( IC301 Pin 43 )

400m V pp

11

( IC301 Pin 21 )

340m V pp

( IC301 Pin 100 )

1,1 V pp

8

( IC301 Pin 28 )

400m V pp

12

( IC301 Pin 25 )

300m V pp

BLOCK

VIDEO INPUT

DVD/R V.IN

OSD V.IN

128

A.OUT

10 22

To JACK

26

IC802

16

A.OUT

(To Tu)

MODULA TO R

20

24

DVD A.IN ’R ’

DVD A.IN ’L’

AUDIO INPUT BLOCK

SCA RT 2

( IC301 Pin 29 )

PB mode

400mv PP

( IC301 Pin 70 )

PB mode

3,6V pp

Hi-Fi/

A

REC

B

Hi-Fi PB ’A’

Hi-Fi REC

36 35

Hi-Fi PB ’B’

37

1

A.OUT ’L’

A.OUT ’R ’

16

EU2.A.OUT.L

17

EU2.A.OUT.R

19

20

21 22

IC801

2

3

4

5

6

7

8

9

11

10

Tu A.IN ’L ’

BLOCK

AUDIO INPUT

Tu A.IN ’R ’

EU1 A.IN ’L ’

DVD A.IN ’L ’

EU1 A.IN ’R ’

DVD A.IN ’R ’

AV2 A.IN ’L ’

EU2 A.IN ’L ’

AV2 A.IN ’R ’

EU2 A.IN ’R ’

OUT(T o AVCP)

NORMAL AUDIO

IN(From AVCP)

NORMAL AUDIO

Page 15

24

DTH6300

First issue 03 / 05 23

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

A/V CIRCUIT DIAGRAM

MAIN

9

3

6

1

14

10

2

2

2

7

4

WAVEFORM

5

13

11

12

8

PB Y+ C

PB Y

PB C

PB SECAM COLOR

REC AUDI O

PB AUDIO(MONO)

REC Y+ C

REC Y

REC C

REC SECAM COLOR

Page 16

25

DTH6300

26 First issue 03 / 05

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

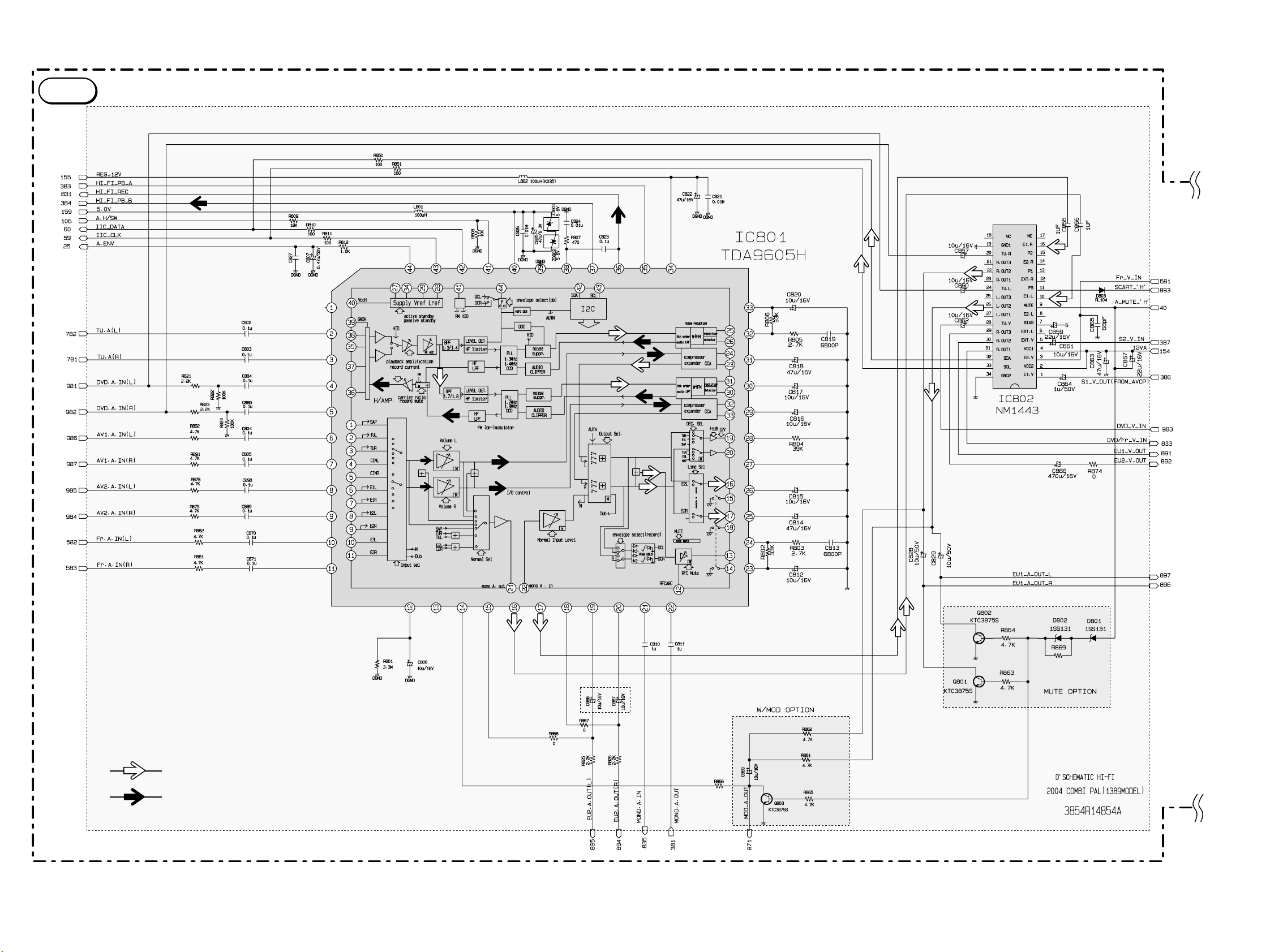

MAIN Hi-Fi CIRCUIT DIAGRAM

PB

REC

Page 17

28

DTH6300

First issue 03 / 05 27

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

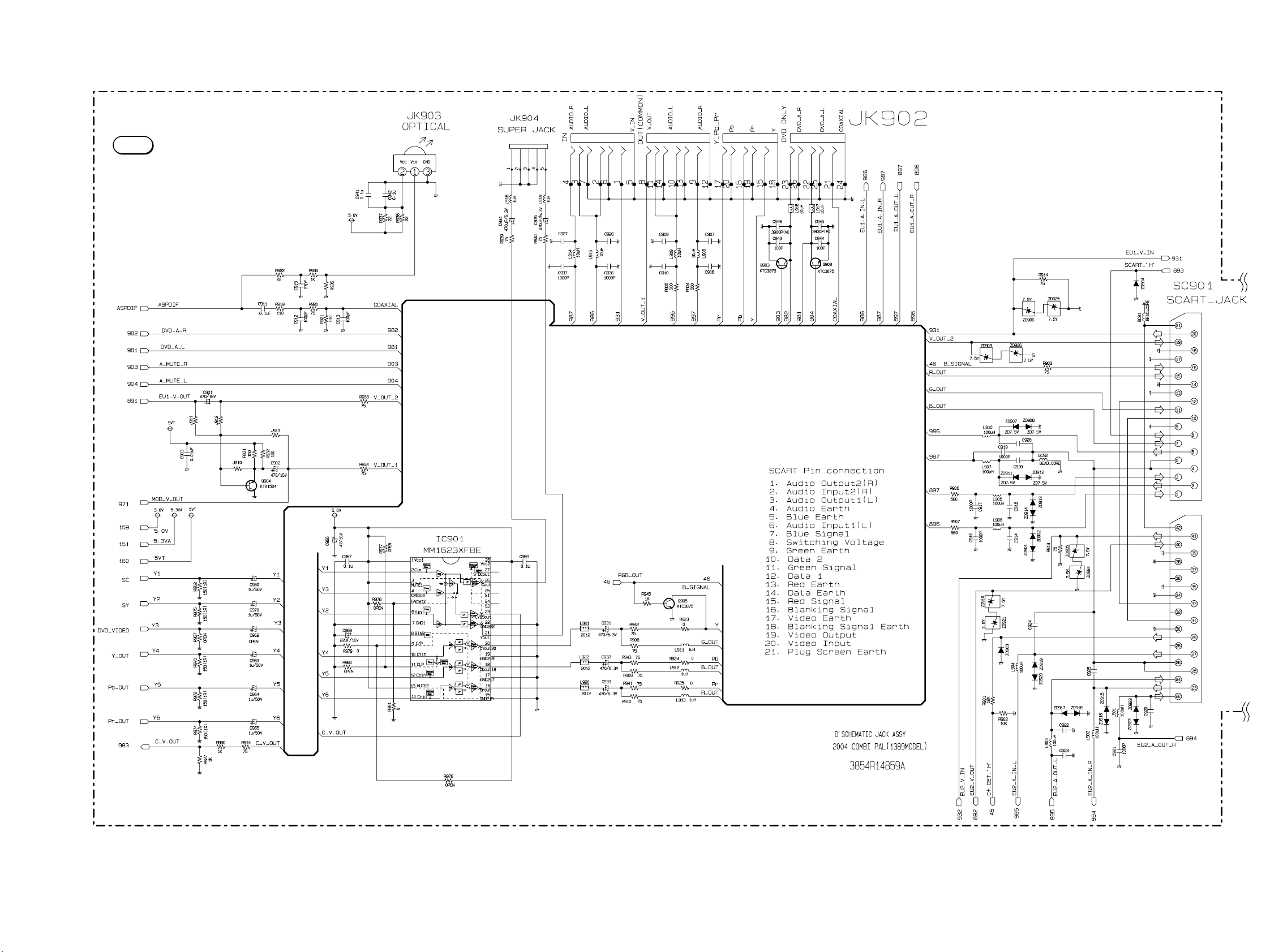

SCART (JACK) CIRCUIT DIAGRAM

MAIN

Page 18

29

DTH6300

30 First issue 03 / 05

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

TU/IF, NICAM & A2 CIRCUIT DIAGRAM

MAIN

EE MODE(VIDEO)

TU MODE (AUDIO)

Page 19

32

DTH6300

First issue 03 / 05 31

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

Some Models*

KEYBOARD

TIMER CIRCUIT DIAGRAM*

Page 20

33

DTH6300

34 First issue 03 / 05

MEASUREMENTS - MESURES - MESSUNGEN - MISURE ELABORAZIONE - MEDIDAS - TRATAMIENTO

( VCR )

CIRCUIT VOLTAGE CHART

MODE

PIN NO .

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

EE PB REC

IC201

2.36 V

2.4 V

3.5 V

2.43 V

0.002 V

0.4 V

0.003 V

0.003 V

2.87 V

2.36 V

3.16 V

2.3 V

2.98 V

3.2 V

0.15 V

0.124 V

2.23 V

1.84 V

4.71 V

4.72 V

4.72 V

2.37 V

2.37 V

0.182 V

0.46 V

1.95 V

3 V

4 V

3 V

3 V

2.35 V

2.35 V

3.49 V

2.41 V

0.005 V

3.7 V

0.003 V

0.003 V

2.85 V

2.35V

3.13 V

1.7 V

4 V

2.3 V

1.78 V

3.2 V

3.86 V

3.38 V

2.23 V

3.3 V

2.34 V

0.002 V

4.69 V

4.69 V

2.26 V

2.25 V

2.86 V

0.187 V

0.62 V

1.94 V

IC301

4.8 V

0.11 V

2.16 V

0.69 V

2.15 V

2.16 V

2.15 V

2.15 V

2.14 V

2.16 V

2.23 V

1.56 V

2.14 V

0.022 V

2.14 V

4.85 V

2.14 V

4.8 V

3.88 V

2.31 V

3.2 V

3.2 V

3 V

4.84 V

0.014 V

2.16 V

0.63 V

2.15 V

2.15 V

2.15 V

2.15 V

2.14 V

2.16 V

2.27 V

0.002 V

2.14 V

0.022 V

2.14 V

0.146 V

2.14 V

4.86 V

3.92 V

0.003 V

1.68 V

2.62 V

2.55 V

2.32 V

2.4 V

3.5 V

2.38 V

0.006 V

0.39 V

0.003 V

0.003 V

2.81 V

2.32 V

3 V

3.03 V

4 V

2.25 V

2.93 V

3.2 V

0.017 V

0.127 V

2.23 V

3.3 V

2.35 V

0.007 V

4.64 V

4.63 V

2.37 V

2.36 V

3 V

0.182 V

0.85 V

1.91 V

0.99 V

0.81 V

2.03 V

1.73 V

2.26 V

2.06 V

2.1 V

2.1 V

2.73 V

2.66 V

2.8 V

2.0 V

0.095 V

2.05 V

2.08 V

4.68 V

2.09 V

4.73 V

2.72 V

0.006 V

3.02 V

3.2 V

3.2 V

MODE

PIN NO .

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

EE PB REC

4.85 V

0.121 V

1.65 V

2.16 V

3.75 V

2.43 V

0.002 V

4.76 V

4.68 V

2.88 V

0.061 V

3.02 V

3.5 V

1.7 V

8.65 V

0.002 V

0.002 V

4.8 V

2.4 V

13.8 mV

2.5 V

2.6 V

4.14 V

3.3 V

2.97 V

1.93 V

0.002 V

1.93 V

2.33 V

1.93 V

5.14 V

2.24 V

1.95 V

2.9 V

1.47 V

1.8 V

0.087 V

1.8 V

0.002 V

1.71 V

0.002 V

0.005 V

4.8 V

4.7 V

7.75 V

5.55 V

4.84 V

2.21 V

2.45 V

2.38 V

2.4 V

1.58 V

2.44 V

2 V

3 V

4.85 V

3.4 V

1.25 V

2.1 V

3.7 V

2.46 V

0.002 V

4.58 V

4.58 V

2.86 V

0.06 V

2.34 V

2.84 V

1.76V

2.05 V

8.6 V

0.003 V

0.003 V

4.8 V

2.67 V

3.86 V

2.52 V

2.78 V

4.14 V

3.09 V

2.93 V

1.92 V

0.003 V

1.93 V

2.33 V

1.92 V

5.14 V

2.57 V

2.28 V

2.55 V

2.93 V

1.54 V

2.44 V

0.09 V

2.55 V

0.003 V

0.002 V

0.003 V

0.07 V

4.8 V

4.7 V

2.55 V

0.008 V

4.8 V

2.2 V

2.6 V

0.72 V

0.81 V

1.6 V

3.35 V

4.75 V

0.19 V

1.6 V

2.14 V

3.66 V

2.34 V

0.005 V

4.72 V

4.71 V

2.8 V

0.061 V

2.99 V

3.4 V

1.61 V

1.94 V

8.38 V

0.006 V

0.006 V

4.68 V

2.17 V

0.03 V

2.55 V

2.64 V

4.14 V

3.30 V

3.69 V

1.92 V

0.005 V

1.92 V

2.34 V

1.92 V

5.13 V

2.22 V

0.006 V

3.01 V

2.92 V

1.48 V

1.79 V

0.088 V

1.78 V

0.006 V

1.69 V

0.006 V

0.44 V

4.78 V

4.7 V

5.55 V

0.008 V

4.72 V

2.24 V

2.43 V

2.38 V

2.39 V

1.48 V

2.33 V

MODE

PIN NO.

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

EE PB REC

1.73 V

0.98 V

1.1 V

0.003 V

1.65 V

0.258 V

0.002 V

0.251 V

0.77 V

0.77 V

0.77 V

0.77 V

4.85 V

2.1 mV

1.7 V

1.7 V

1.7 V

1.7 V

0.002 V

2.16 V

2.16V

2.16 V

1.67 V

0.98 V

1.13 V

0.004 V

1.03 V

2.5 V

0.003 V

0.014 V

0.78 V

0.78 V

0.78 V

0.78 V

4.83 V

0.004 V

1.72 V

1.71 V

1.71 V

1.71 V

0.005 V

2.16 V

2.16 V

2.16 V

IC5F1

2.33 V

4.98 V

4.96 V

4.89 V

0.64 V

0.64 V

0.64 V

0.73 V

0.72 V

1.83 V

0.73 V

1.26 V

1.26 V

1.65 V

1.58 V

4.89 V

0.002 V

1.75 V

1.7 V

1.78 V

1.73 V

0.002 V

5 V

1 V

2.31 V

4.9 V

5 V

4.9 V

4.85 V

0.59 V

0.59 V

0.61 V

0.93 V

0.92 V

0.63 V

1.84 V

0.75 V

1.22 V

1.23 V

1.63 V

1.58 V

4.8 V

0.003 V

1.63 V

1.7 V

1.71 V

1.6 V

0.003 V

IC751

5.1 V

1.5 V

1.5 V

0.002 V

2.5 V

2.44 V

1.84 V

5.1 V

1.5 V

1.5 V

0.003 V

2.46 V

2. 44 V

1.89 V

2.51 V

4.46 V

1.15 V

0.006 V

1.41 V

0.014 V

1.38 V

1.98 V

0.78 V

0.77 V

0.77 V

0.77 V

4.74 V

0.006 V

3.94 V

3.93 V

3.92 V

3.94 V

0.006 V

2.21 V

2.25 V

2.31 V

2.3 V

4.9 V

5 V

4.9 V

4.8 V

0.6 V

0.6 V

0.6 V

0.96 V

0.91 V

0.92 V

1.8 V

0.72 V

1.2 V

1.1 V

1.54 V

1.42 V

4.8 V

0.003 V

1.5 V

1.5 V

1.5 V

1.41 V

0.003 V

5.08 V

1.51 V

1.5 V

0.003 V

2.46 V

2.43 V

2.06 V

MODE

PIN NO.

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

EE PB REC

1.86 V

1.86 V

0.002 V

5.12 V

1.75V

1.77 V

1.77 V

1.75 V

1.75 V

0.003 V

1.88 V

0.002 V

0.002 V

0.002 V

0.05 V

0.05 V

0.002 V

0.002 V

2.78 V

2.78 V

0.002 V

4.06 V

0.003 V

2.77 V

0.002 V

0.002 V

0.002 V

2.76 V

2.76 V

2.59 V

2.35 V

0.003 V

4.8 V

4.7 V

5 V

5.1 V

5.1 V

0.004 V

0.004 V

0.003 V

5.12 V

4.75 V

0.003 V

1.58 V

0.005 V

0.005 V

0.003 V

0.051 V

0.05 V

0.003 V

0.003 V

2.77 V

0.003 V

5.09 V

4.08 V

0.003 V

2.76 V

0.002 V

0.003 V

0.003 V

2.75 V

2.75 V

2.59 V

2.35 V

0.003 V

IC501

0.002 V

2.56 V

2.56 V

2.56 V

2.56 V

2.56 V

2.64 V

2.54 V

0.064 V

5.13 V

1.69 V

2.32 V

0.48 V

1.28 V

1.84 V

2.32 V

0.002 V

2.55 V

2.55 V

2.55 V

2.55 V

2.56 V

2.63 V

2.53 V

2.27 V

5.12 V

1.68 V

1.7 V

0.08 V

1.29 V

1.83 V

4.8 V

2.6 V

2.6 V

5 V

1.5 V

1.5 V

5 V

5.1 V

1.9 V

1.7 V

2 V

3 V

0.004 V

0.004 V

0.003 V

5.11 V

4.8 V

4.7 V

2.59 V

2.6 V

5 V

2.06 V

2 V

5 V

0.003 V

2 V

5.11 V

0.004 V

0.005 V

0.003 V

0.051 V

0.05 V

0.005 V

0.003 V

2.76 V

2.76 V

0.005 V

5.08 V

4.06 V

0.003 V

2.76 V

0.002 V

0.002 V

0.002 V

2.75 V

2.75 V

2.6 V

2.35 V

0.003 V

0.002 V

2.55 V

2.9 V

2 V

2.55 V

2.55 V

2.6 V

2.52 V

2.26 V

5.11 V

1.66 V

1.67 V

2.3 V

0.53 V

1.36 V

1,8 V

2.26 V

MODE

PIN NO .

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

EE PB REC

4.7 V

2.19 V

0.01 V

2.2 V

2.32 V

0.01 V

0.3 V

0.08 V

5.14 V

4.2 V

5.13 V

5.13 V

0.004 V

0.002 V

0.002 V

0.18 V

1.37 V

5.14 V

5.14 V

4.74 V

4.74 V

2.45 V

5 V

2.28 V

0.003 V

4.76 V

0.003 V

(-)0.001 V

0.003 V

0.003 V

0.003 V

5.14 V

5.1 V

4.38 V

0.031 V

0.003 V

5.1 V

5.1 V

5.1 V

0.002 V

0.003 V

4.8 V

4.7 V

4.7 V

5 V

1.8 V

5.1 V

1.78 V

5.1 V

0.004 V

0.001 V

0.001 V

5.14 V

5.14 V

0.028 V

4,7 V

3 V

0.009 V

2.2 V

2.3 V

0.009 V

2.84 V

3.4 V

5.13 V

4.16 v

5.13 V

5.13 V

0.002 V

0.002 V

0.002 V

0.18 V

1.3 V

5.13 V

5.13 V

4.73 V

4.75 V

4.9 V

0.003 V

1.55 V

0.003 V

4.75 V

0.003 V

(-)0.001 V

0.003 V

0.003 V

0.003 V

0~5 V

0.003 V

0.03 V

5.06 V

0.003 V

5 V

5.13 V

5,1 V

0.002 V

0.004 V

4.8 V

4.7 V

5 V

5 V

1.3 V

5 V

5.1 V

5.1 V

4.4 V

5.1 V

5.1 V

5.1 V

0.001 V

0.028 V

4.6 V

2.13 V

0.01 V

2.16 V

2.26 V

0.01 V

0.012 V

0.068 V

5.12 V

3.93 V

5.11 V

5.11 V

0.003 V

0.002 V

0.002 V

0.18 V

1.42 V

5.1 V

5.1 V

4.7 V

4.7 V

2.33V

4.96 V

1.42 V

0.004 V

4.73 V

0.004 V

(-)0.001 V

0.004 V

5 V

0.004 V

0.005~5 V

0.004 V

0.035 V

0.038 V

0.004 V

5 V

5.11 V

5.1 V

0.002 V

0.004 V

4.8 V

4.9 V

5 V

5 V

1.68 V

5 V

1.66 V

5.08 V

5.08 V

0.005 V

5.12 V

5.12 V

0.001 V

0.029 V

MODE

PIN NO .

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

1

2

3

4

5

6

7

8

9

10

11

12

13

14

EE PB REC

5 V

0.001 V

1.5 V

1.7 V

5.1 V

2.5 V

0.001 V

2.53 V

3.2 V

5.12 V

0.172 V

0.004 V

0.019 V

2.55 V

5.11 V

5.11 V

5.11 V

5.11 V

5.11 V

5.12 V

0.005 V

0.005 V

4.38 V

0.005 V

5.11 V

0.005 V

5.11 V

0.005 V

1.51 V

0.005 V

0.099 V

0.099 V

5.11 V

0.005 V

0.005 V

0.005 V

0.049 V

0.002 V

0.48 V

5.12 V

5.1 V

0.001 V

1.93 V

2.02 V

5.1 V

2.51 V

0.002 V

2.5 V

3.2 V

5.1 V

2.68 V

2.4 V

3.4 V

2.55 V

3.1 V

4.95 V

4.97 V

5 V

5.1 V

0.008~0.05 V

0.005 V

0.005 V

0.05 V

0.005 V

5.1 V

5.3 V

2.55 V

0.005 V

2.6 V

0.006 V

1.36 V

1.36 V

2.55 V

2.54 V

2.75 V

2.81 V

50.6 V

0.002 V

0.6 V

5.11 V

IC801

3.8 V

3.8 V

3.8 V

3.8 V

3.8 V

3.8 V

3.8 V

3.8 V

3.8 V

3.8 V

3.8 V

0.054 V

3.87 V

0.008 V

3.81 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

~

3.8 V

0.003 V

5.04 V

0.002 V

1.48 V

1.44 V

5.08 V

2.52 V

0.002 V

2.5 V

3.19 V

5.1 V

2.55 V

2.69 V

3.44 V

2.56 V

2.29 V

4.9 V

4.9 V

4.98 V

5.09 V

0.006 V

0.006 V

0.013 V

0.012 V

0.006 V

5.09 V

0.006 V

2.52 V

0.006 V

1.31 V

0.006 V

1.38 V

1.36 V

2.53 V

2.53 V

2.75 V

2.79 V

0.05 V

0.002 V

0.55 V

5.1 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

3.82 V

0.048 V

3.99 V

0.011 V

MODE

PIN NO .

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

EE PB REC

0.008 V

4.58 V

3.82 V

3.86 V

3.87 V

3.87 V

0.76 V

0.001 V

3.84 V

3.86 V

0.77 V

3.87 V

3.86 V

3.86 V

11.84 V

0.64 V

0.64 V

0.64 V

0.005 V

0.002 V

0.005 V

0.078 V

6 V

6 V

7 V

6 V

6 V

5 V

4.7 V

4.8 V

0.006 V

6.07 V

6.07 V

6.07 V

6.06 V

6.07 V

4.57 V

3.82 V

3.84 V

3.84 V

3.9 V

0.003 V

0.003 V

3.83 V

3.86 V

0.76V

3.87 V

3.87 V

3.86 V

11.76 V

0.44 V

0.62 V

0.63 V

0.008 V

0.005 V

5.07 V

0.92 V

4.7 V

4.8 V

3.3 V

IC802

3 V

2.93 V

11.8 V

2.74 V

11.8 V

2.74 V

11.23 V

0.008 V

5.54 V

0.008 V

0.002 V

0.002 V

(-)0.001 V

5.54 V

5.5V

5.6 V

5.5 V

5 V

5.5 V

5.5 V

5.5 V

5.5 V

5.6 V

5.6 V

5.6 V

11.76 V

2.74 V

11.75 V

2.75 V

5.5 V

5.56 V

5.5 V

0.006 V

5.5 V

11.15 V

5.5 V

0.01 V

5.5 V

0.009 V

5.5 V

0.003 V

0.005 V

0.001 V

5.5 V

5.59 V

5.59 V

5.51 V

5.5 V

0.01 V

6.07 V

6.08 V

0.11 V

0.028V

6.07 V

5.9 V

3.82 V

3.86 V

3.87 V

3.87 V

0.76 V

0.005 V

3.83 V

3.86 V

0.76 V

3.86 V

3.87 V

3.86 V

11.77 V

4.3 V

4.3 V

4.28 V

4.32 V

0.006 V

5.05 V

0.92 V

4.7 V

4.8 V

0.068 V

3.05 V

11.76 V

2.74 V

11.76 V

2.75 V

5.5 V

5.57 V

5.49 V

4.97 V

5.5 V

11.16 V

5.5 V

0.009 V

5.5 V

0.009 V

5.51 V

0.005 V

0.004 V

0.001 V

5.51 V

5.59 V

5.59 V

5.52 V

5.5 V

MODE

PIN NO.

25

26

27

28

29

30

31

32

33

34

EE PB REC

5.6 V

5.6 V

5.54 V

4.16 V

1.46 V

2.1 V

1.35 V

4.7 V

4.8 V

(-) 0.002 V

5.58 V

5.58 V

5.5 V

4.32 V

1.46 V

1.99 V

1.35 V

4.7 V

4.8 V

0.001 V

5.59 V

5.59 V

5.5 V

4.51 V

1.46 V

2.07 V

1.35 V

4.7 V

4.8 V

0.000 V

Page 21

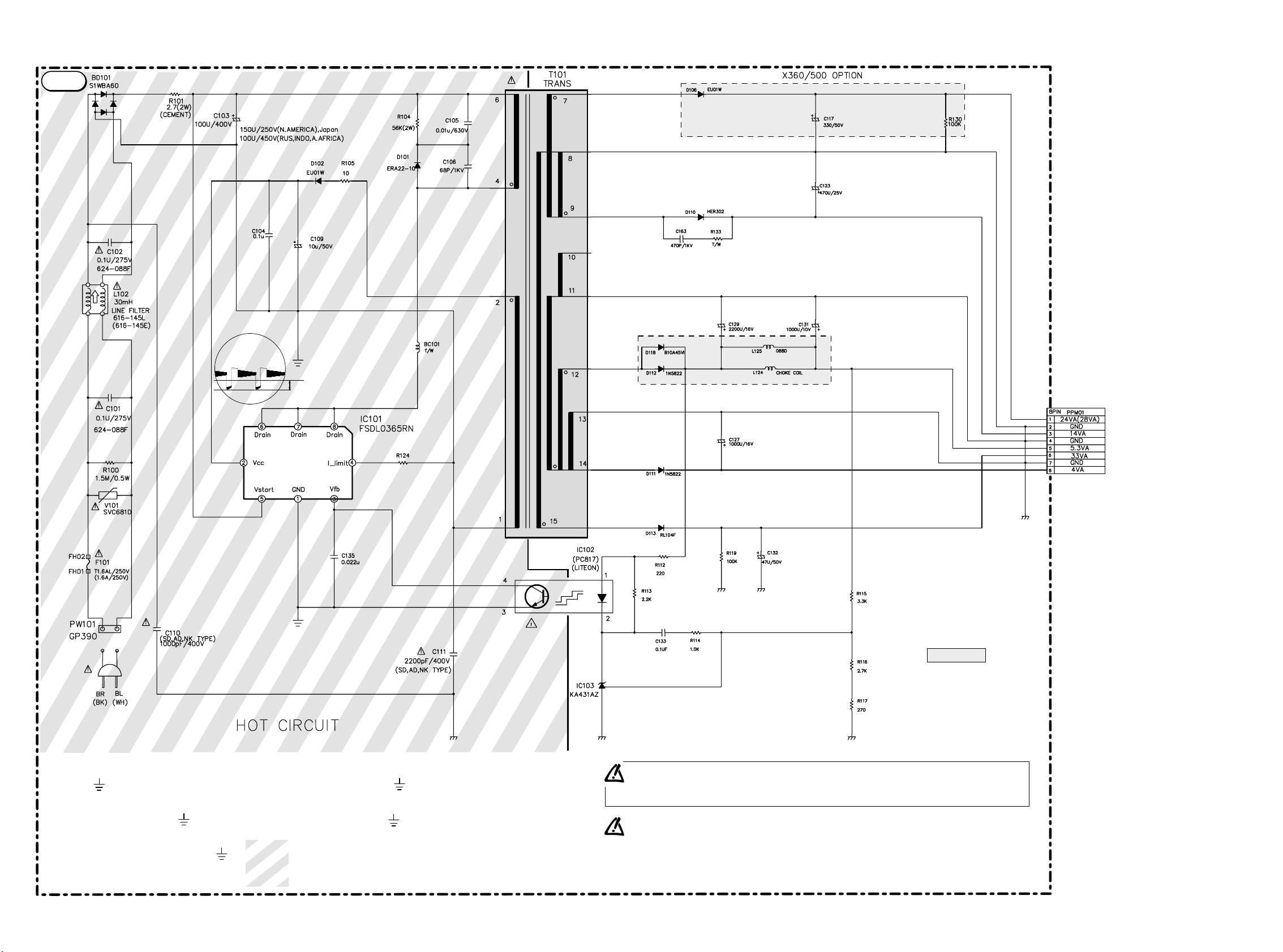

36

DTH6300

First issue 03 / 05 35

BLOCK DIAGRAM - SCHEMA SYNOPTIQUE - BLOCKSCHALTBILD - SCHEMA A BLOCCHI - ESQUEMA DE BLOQUES

DVD PRINCIPAL

Overall Block Diagram

LOADING

5V/8V

SPINDLE

MOTOR

M

MOTOR

(FEEDING)

LOAD[+,-]

SLED

MOTOR

M

SL ED[+,-]

DISC

M

SP INDLE[+,-]

FOCUS[+,-]

PICK

UP

Pick-up

TRACK[+,-]

DV D : A,B,C,D,RF0

CD : A, B,C,D, E,F,RF0

CDMDI,DVDMDI

CDLD,DVDLD,SVREF21

XSFGN,XSFGP

HOMESW

INSW,OUTS W

CD_D VD, VR_CD,VR_DVD

OPU_SEL

CD_D VD_CT

VD33 D

VD18/VD33

IC602

MX29LV160T

2/4M

16/32BIT

FLASH ROM

19]

ROMAD[0:

ROMRD

ROMWR

ROMDAT A[0:7]

VD33 D

MA[00:11 ]

DMCL K

DQM

CA SJ

RA SJ

IC601

MTK MT1389

CS J

BA 0

BA 1

WE J

IC603

4M

16BIT

4BanK

SDRAM

RF+

MD[00:15]

CN603

RS232

Download

RS 232_R XD

IIC/VFD/ DA C_ SCK

IIC/VFD/ DA C_TX D

BCLK

LRCL K

DA CCLK

SER3,DAC_ML0

VD33D

IC606

S524A40X21

EEPROM

VD33D/5V

IC401

CS4392

2DAC

3V3M

DAC_RST

IC201

IP4504A

Motor Drive

AC 90V~240V

50HZ/60Hz

OPEN,C LO SE ,SLE GP ,SPINDLE,FOC US ,TRACK, SVREF

DR VS B

VF +

VF -

-27V A

5.2V A

5V

POWER

BOARD

12V

3.3V-M1

3.3V

3.3V- M

8V

U7

+12V

VD18

VD33,VD33D

3V3M

5.3VA

LED501

CLK DISPLAY

PWRCTL

5.2VA

M-RESET

VFD_RXD

IC501

KEY Input

5.2VA

74HCT244

S_ REQ

IC607

6MHz

M_REQ

27MHz

VIDE O_SW

IC505

RESET IC

RC601

R/C

TRIGGER

MPEG IC

D2_T [1:3]

SCART_16:9

RGB_SEL

JACK

5V

IC901

MM162 3XFBE

VIDEO BUFFER

CVBS

R/Pr G/ Y

B/Pb

YC_MIX

Y

C

TV_D AC[0:3]

IECDAOUT

COAXIAL

SPDIF

RS 232_TXD

L/R

+12V

IC602

MC4580

OP-AMP

L/R

Page 22

37

DTH6300

38 First issue 03 / 05

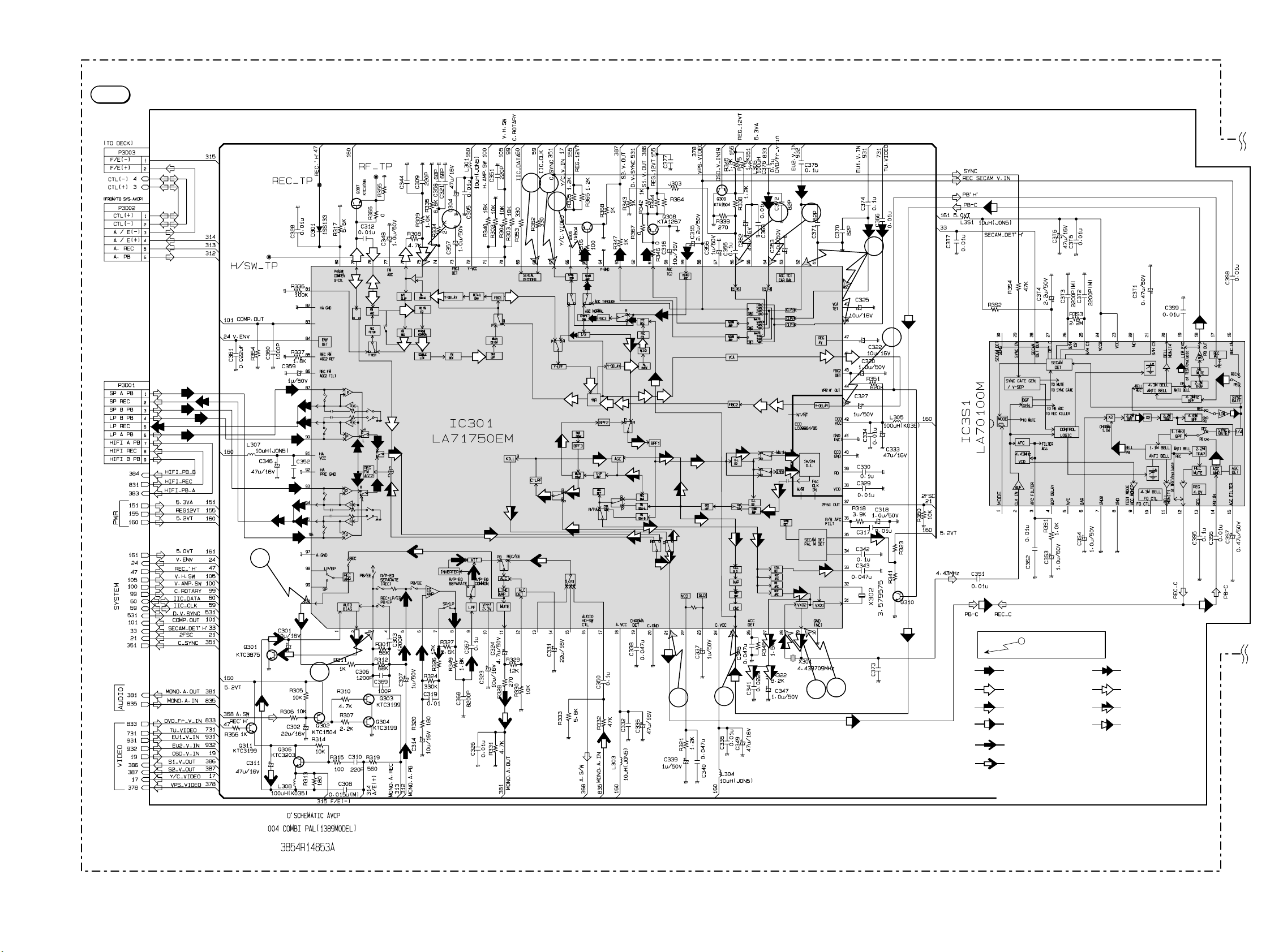

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

DVD PART

MAIN SERVO

Page 23

40

DTH6300

First issue 03 / 05 39

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

DVD PART

MAIN DVD AUDIO

Page 24

41

DTH6300

42 First issue 03 / 05

MAIN

1. SYSTEM CIRCUIT DIAGRAM

MAIN SCHEMATIC DIAGRAM - SCHEMA DE LA PLATINE PRINCIPALE - SCHALTBILD HAUPTPLATINE - SCHEMA DELLA PIASTRA PRINCIPALE- ESQUEMA DE LA PLATINA PRINCIPAL

DVD PART

Page 25