Page 1

Build-In Cooking Hob

SHB353XXZ Series Hobs

SCU353XXXZ Series Combination Hobs

For use with Universal LPG

INS 1024Z – Issue 0 - English

User and installation instructions

Please read and keep for future reference

For use in Australia

Original Instructions

THETFORD AUSTRALIA PTY LTD

41 LARA WAY CAMPBELLFIELD VIC

TEL: 03 9358 0700 FAX: 03 9357 7060

www.thetford-europe.com

Page 2

2

CAUTION

• Appliance and accessible parts become hot during use. Avoid

touching the heating elements or pan supports.

• The use of a gas cooking appliance results in the production of

heat, moisture and products of combustion in the room in which

it is installed. Ensure that the kitchen is well ventilated especially

when the appliance is in use. Keep natural ventilation holes open

or install a mechanical ventilation device (mechanical extractor

hood).

• Prolonged intensive use of the appliance may call for additional

ventilation, for example opening of a window or more effective

ventilation, for example increasing the level of mechanical

ventilation where present.

• Do not use or store flammable materials in the appliance storage

drawer or near this appliance.

• Do not spray aerosols in the vicinity of this appliance whilst it is in

operation.

• Children less than 8 years of age shall be kept away from the

appliance unless continuously supervised.

• Children shall not play with the appliance.

• Cleaning and user maintenance shall not be made by children

without supervision.

• Unattended cooking on a hob with fat or oil can be dangerous

and may result in fire. Do not leave the appliance unattended

when in use.

• Never extinguish a cooking fire with water, switch off the

appliance and cover the flames with a lid or fire blanket.

• Danger of Fire: Do not store any items on the cooking surface.

• The use of inappropriate hob guards can cause accidents and

may affect safe combustion of the appliance.

• Do not modify this appliance or make any adjustments unless

such work is carried out by authorized personnel, the

manufacturer or their representative. No parts other than those

supplied by the manufacturer shall be used on this appliance.

Page 3

3

CAUTION

• Do not allow cooking vessels to overlap the edges of the

appliance – use the correct sizes of pans and position them

centrally over the burners.

• Do not use harsh abrasive cleaners or sharp metal scrapers to

clean the glass since they can scratch the surface, which may

result in shattering of the glass.

• Do not use steam cleaners or pressure washers to clean the

appliance. Refer to cleaning and maintenance instructions.

• This appliance is for cooking purposes only. Where this

appliance is installed in marine craft or in caravans, it shall not

be used as a space heater.

• Do not allow oil or fat to build up on the appliance – clean the

appliance after each use.

• GLASS LID SYMBOL – Do not shut lid when burners are

alight. Printed on the underside of the glass lid.

• Always make sure the control knobs are in the off position when

you have finished using the hotplate burners and before closing

the glass lid.

Page 4

4

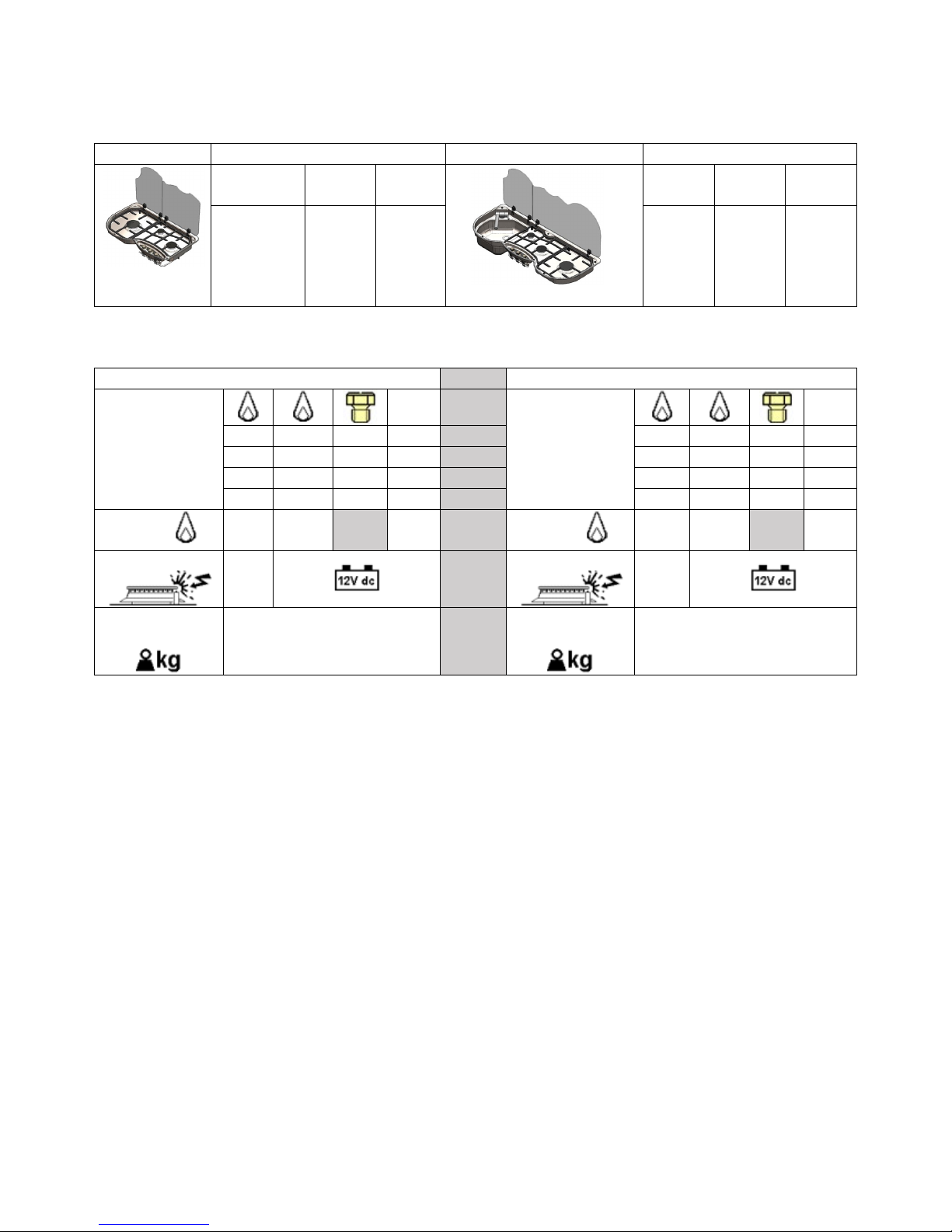

APPLIANCE DIMENSIONS AND SPECIFICATIONS

APPLIANCE

SHB353XXZ SERIES

APPLIANCE

SCU353XXXZ SERIES

H

(mm)

W

(mm)

D

(mm)

H

(mm)

W

(mm)

D

(mm)

101 660 410 160 980 410

Gas category – Universal LPG Only

Universal LPG 2.75 kPa / 27.5 mbar

Gas Input & Injector Size

Gas Input & Injector Size

SHB353XXZ

SERIES

SCU353XXXZ

SERIES

kW

MJ/hr

mm

kW

MJ/hr

mm

1.0

3.6

0.52

1.0

3.6

0.52

1.75

6.3

0.67

1.75

6.3

0.67

2.5

9.0

0.82

2.5

9.0

0.82

∑ Qn

5.25 18.9

∑ Qn

5..25 18.9

Spark ignition

Spark ignition

Appliance

Weight

8.5 kg

Appliance

Weight

10.7 kg

Page 5

5

Fig. 1 - WORKTOP CUTOUT – SHB353XXZ Series

Page 6

6

Fig. 2 – WORKTOP CUTOUT – SCU353XXXZ Series

Page 7

7

Fig. 3 - SURFACE MOUNT FIXING – SHB & SCU 353 SERIES EDGE DETAIL

Fix the hob centrally in the cut-out to maintain a 2-3mm air gap to the worktop.

1

Surface mounting bezel

2

Pressing

3

Glass Lid

4

Screw fixing cap

5

Bump Stop

6

Wood Screw

7

Worktop

Fig. 4 – MINIMUM DISTANCE TO COMBUSTIBLE MATERIALS

For SHB353 & SCU353 Series, the minimum permitted distances to combustible

materials are as shown below.

A= 200mm minimum unless protected by a non-combustible heat barrier.

B = 500mm minimum from burner ports to fitment above appliance.

Page 8

8

Fig. 5 – Air Gap and Gas Dispersal Hole

A = 58mm Air gap beneath hob pressing.

B = Gas dispersal hole. Min Ø 12mm, max Ø 25mm, with baffle & grille, venting to outside.

Fig. 6 – Control Positions

OFF FULL RATE LOW RATE

Fig. 7 – Minimum and Maximum Pan Sizes

• The minimum permitted pan sizes are Ø100mm for the auxiliary burner, Ø120mm for the

semi-rapid burner and Ø150mm for the rapid burner.

• The maximum recommended pan sizes are as shown below.

• Avoid old or misshapen pans as these may reduce efficiency and can cause instability.

• Using larger than recommended pan sizes may reduce performance or cause damage.

Page 9

9

INTRODUCTION

This appliance is designed for cooking foods and any other use is incorrect and may be

dangerous. Failure to install the appliance correctly or improper use will invalidate any warranty

or liability claims.

This appliance must only be installed by an approved and competent person, in accordance

with the local Regulations in force. Particular attention shall be given to the requirements

regarding air supply and ventilation. Read the instructions and warnings fully before installing or

using the appliance.

Data label.

The data label is located on the underside of the appliance and a duplicate label is supplied to

adhere to a visible accessible area next to the appliance.

Gas type.

This appliance should only be used with Universal LPG (ULPG). Use only the gas type and

pressure specified on the data label and in these instructions.

BURNER OPERATION

The burners on the appliance have fixed aeration and no adjustment is required. The burners

should normally flame as follows:

• With Universal LPG, on initial lighting, flames may have yellow tips, this increases slightly

as the burners heat up.

The burners are controlled individually and each is monitored by a thermocouple probe. In the

event that the burner flames are accidentally extinguished, turn off the burner control and do not

attempt to re-ignite the burner for at least one minute.

As a safety feature, this appliance is fitted with a glass lid shut-off switch which shuts off the gas

supply to the burners if the lid is closed. The lid must be opened fully before attempting to use

the burners. Ensure the burners are shut off and allowed to cool before closing the lid, do not

rely on the automatic shut-off switch.

Before using the appliance for the first time, remove any surface protection film,

ie plastic coating. Clean all surfaces with hot soapy water and a sponge, to

remove any residual protective covering of oil, then rinse and dry carefully with a

soft cloth.

Page 10

10

OPERATION

Hob burners

1. Ensure gas supply is connected and turned on and the glass lid to the hob is fully open

before using the appliance. For combination units the separate glass lid to the sink bowl

may be left closed whilst the hob is in use.

2. Push in the control knob and turn anticlockwise to full rate – large flame ( ), see Fig 6.

3. Continue depressing the knob whilst holding a lighted match or taper to the burner.

For models fitted with’Auto Spark’ the procedure is similar except burner ignition is

automatic whilst knob depressed.

For models fitted with spark ignition the procedure is similar except that burner is ignited

by depressing the ignition button located on the fascia.

4. After the burner is lit continue depressing the knob for approximately 10 - 15 seconds.

5. Release knob and turn to required heat setting.

6. If burner has not lit within 15 seconds, release knob and wait at least 1 minute before

repeating operations (2) to (5).

7. To turn off, rotate the control knob until the line on the knob is aligned with dot on the

control panel.

Do's and Don'ts

DO Read the user instructions fully and carefully before first use of appliance.

DO Allow the burners to heat before using for the first time, in order to expel

any fumes or odour before the introduction of food.

DO Clean the appliance regularly with warm water and soap solution.

DO Remove any spills as soon as possible.

DO Check that controls are in the off position when finished using the appliance.

DO Turn pan handles away from the front so that they cannot be caught accidentally.

DO NOT Allow small children near the appliance when in use.

DO NOT Allow oils, fats or food residue to build up on the appliance base.

DO NOT Use abrasive cleaners or powders that will scratch the surfaces of the

appliance.

DO NOT Under any circumstances use the appliance as a space heater.

Leaks

If a smell of gas becomes apparent, the gas supply should be turned off at the cylinder

IMMEDIATELY. Extinguish naked lights including cigarettes and pipes and do not operate

electrical switches. Open all doors and windows to permit any gas to escape. ULP gas is

heavier than air; any gas escaping will therefore collect at low level. The strong unpleasant

smell of gas will enable the general area of the leak to be detected. Check that the gas is not

escaping from an unlit burner. Never check for leaks with a naked flame; leak investigation on

the appliance should be carried out using a leak detector spray.

MAINTENANCE

We recommend an annual inspection and service by an authorised service agent to maintain

the efficient performance of the appliance. In between annual service the appliance needs little

maintenance other than cleaning. All parts should be cleaned using warm soapy water and a

soft cloth or sponge, then carefully wiped dry. Do not use abrasive cleaners, metal scourers, or

wire brushes on the hob and pan rests as they can cause damage. When cleaning the burner

rings it is essential to ensure that the holes do not become blocked. The control knobs are a

push fit and can be removed for cleaning. They are interchangeable without affecting the sense

of operation. If any replacement parts are required they must be obtained by contacting Thetford

Ltd at the address or telephone number shown in this manual.

Page 11

11

INSTALLATION

Regulations and Standards

Read the instructions before installing this appliance and comply with the cautions and warnings

section on Page 2 & 3 of this manual. Gas appliances must only be installed and serviced by an

approved and competent person. Failure to install the appliance correctly could invalidate any

warranty or liability claims and may lead to prosecution.

Prior to connection ensure the local conditions for gas type and gas pressure match the

appliance specification. The adjustment conditions for this appliance are printed on the data

badge located on the base of the appliance.

This appliance is not connected to a combustion products evacuation device. It shall be installed

and connected in accordance with current installation regulations in force in the country of use.

Particular attention shall be given to the requirements regarding ventilation.

Ventilation

The installation must be in accordance with AS/NZS 5601.2: “LP Gas installations in caravans

and boats for non-propulsive purposes”. This appliance is suitable for installation into Holiday

Homes, Touring Caravans, Motor-Homes and Boats. The requirements for ventilation for the

particular vehicle into which the appliance is to be installed must be followed.

A gas dispersal hole is recommended beneath the appliance, venting to the outside, with

minimum size Ø12mm, maximum Ø25mm, which should be screened and baffled to prevent

direct draughts to the appliance, see Fig 5, Item B.

Location of Appliance

This appliance maybe installed in a kitchen/kitchen diner but NOT in a room containing a bath or

a shower. LP gas appliances must not be fitted below ground level, e.g. in a basement

Position

The appliance should be installed onto a suitable worktop. A cut-out should be prepared in the

worktop as shown in Fig 1 or Fig 2, depending on the Series type.

We recommend the underside of the hob be shielded – see Fig. 5 - particularly if the area

beneath is to be used for storage or the installation of another appliance. The shield should be

fabricated from non-combustible material, but if the enclosure is manufactured from combustible

material there should be a minimum air gap of 58mm between the underside of the hob

pressing and the shield. THIS AIR SPACE MUST BE WELL VENTILATED.

A horizontal distance of 200mm must be maintained between the edge of the burners and any

combustible material, unless this is protected by a layer of non-combustible material. See Fig 4.

Due to protection from the glass lid, the distance from the edge of the burner to the rear wall can

be reduced to 130mm.

All combustible materials such as curtains and shelves must be kept well clear of the appliance.

Any fitments such as a cupboard above the appliance must have a minimum clearance of

500mm between the fitment and the top of the burner ports – see Fig. 4.

Page 12

12

INSTALLATION

Care should be taken to position the appliance centrally in the worktop cut-out to ensure an air

gap is maintained between the edges of the appliance and the sides of the cut-out. The

appliance may then be fixed in position with screws - see Fig. 3. Make sure the appliance is

level and correctly positioned in the aperture before fixing in place.

This appliance must be positioned free from draughts, which may affect the combustion, and in

a manner that will prevent the accumulation of unburned gas. When in use ensure that air vents

are not inadvertently blocked or shut off. Ensure all combustible materials such as curtains,

blinds and shelves are well clear of the appliance.

If other appliance/s are located below the hob we recommend conducting a temperature

verification test to confirm any rise in temperature of the cabinet materials are within allowable

limits and meet requirements specified in standards AS 4551-2008 and AS/NZS 5601.2 Section

6.5 Clearances.

After installation the appliance must be tested for gas soundness and satisfactory ignition of all

burners both individually and combined.

The gas supply pressure to which this appliance is connected must not rise or fall by more than

0.25 kPa (2.5mbar) from nominal, when all appliances connected to the supply are operated

simultaneously.

The performance of this appliance meets the requirements of AS 4551-2008 which specifies a

maximum temperature rise for the furniture into which the appliance is installed of 65oC above

the ambient temperature. It is important the installer verifies the furniture construction material

and that it is suitable for the application - i.e. plastic materials or adhesives used in the

construction may have a softening point lower than the maximum allowable temperature rise

specified in the appliance standard.

We recommend the installation follows the minimum dimensions shown in this manual as any

deviation could result in excessive temperature rise. If minimum dimensions must be reduced,

due to design constraints, a temperature rise test of all furniture fitted around the unit MUST be

performed. The design is deemed permissible providing the results of this test comply with the

allowable temperature rise specified above and with all standards in force. In addition comply

with all requirements detailed within the furniture manufacturer’s material specification. Where

minimum dimensions are reduced we recommend protecting with non combustible material.

Connection - Gas

A ¼” BSP taper gas inlet connection and pressure test point is provided underneath the

appliance. It is recommended that the appliance is connected by steel or copper tubing, a

rubber or hose connection should not be used. The gas inlet must be accessible with the

appliance installed to ensure installation in accordance with AS/NZS 5601.2. After connection

the appliance must be tested for gas soundness.

This appliance is suitable for use with UNIVERSAL LPG ONLY at 2.75 kPa pressure.

It is important that the regulator should be set to the correct pressure for the type of gas being

used. Excessive pressure must not be permitted.

If the flame on any burner should show a tendency to lift, it is possible that the line pressure is

too great. Should there be excessive yellow tips (resulting in sooting), then it is possible that the

line pressure is too low. In either case the burners should not be used until the line pressure has

been confirmed.

The burners on this appliance have fixed aeration and no adjustment is necessary.

Page 13

13

INSTALLATION

Electrical Connection

The spark ignition generator must only be connected to a suitable 12V DC battery. Sheathed

spade connectors should be used to connect the spark generator to the power supply.

SERVICING

Do not modify this appliance. All servicing must be carried out by an approved and competent

person. Before any service work is started the appliance must be left to cool and be

disconnected from both the gas and electrical supplies. After each service the appliance must

be checked for gas soundness.

Details of the injector orifice size are provided within the specification table on page 4. To verify

the system is operating at the correct pressure, a pressure test point is provided on the gas

manifold, located below the control panel. The pressure is measured with the Semi Rapid

burner on a high flame and with an inlet pressure of 2.75 kPa (Universal LPG).

To remove the hob.

Isolate the gas supply and disconnect inlet pipe

Disconnect 12v power wires to spark generator.

Lift the glass lid and unscrew the appliance from the worktop - see Fig. 3 on page 7 for fixing

details. Lift and place the hob onto a suitably protected surface.

Hob burner gas valve removal/replacement.

Shut off gas supply and disconnect gas supply pipe from the unit.

Remove the hob from the worktop as above.

Remove the appropriate control knob by pulling up on the knob.

From underside of hob disconnect the appropriate thermocouple at the gas valve.

Unscrew the appropriate gas supply pipe nut.

Remove the appropriate gas valve clamp by unscrewing the two screws.

Unscrew the gas valve retaining nut.

Remove the gas valve.

Replace the valve and gasket. Refit using the reverse of the above procedure.

To ensure correct operation observe the following installation requirements:

• Build the appliance into a self-contained cabinet which is not connected

to externally vented chambers in adjacent furniture, other than the

correct size gas dispersal hole.

• Holes for cables & pipes should have minimum clearances.

• A gas dispersal hole should be fitted, this must not exceed Ø25mm

• Cupboards below appliance must not allow gas to enter the living area.

• Air vents and gas dispersal holes must be kept clear

• If this appliance is not installed in accordance with the instructions and

tolerances detailed herein, we the manufacturer can not be held

responsible for any problems that occur, or poor performance that is

perceived/witnessed

Page 14

14

Hob burner injector removal/replacement.

Lift off the appropriate pan rest to release it from the rubber bushes.

Remove the screw in the burner cap and lift off the burner cap and skirt / flame spreader.

With a 7mm A/F socket, unscrew the injector from the bottom of the burner mixing tube.

Replace/refit using the reverse of the above procedure.

Thermocouple removal/replacement

Shut off gas supply and disconnect gas supply pipe from the unit.

Remove the hob from the worktop as above.

From the underside of the hob, disconnect the appropriate thermocouple at the gas valve and at

the shut-off switch attached to the hinge for the glass lid.

Remove the spring clip retaining the thermocouple at the burner.

Remove the thermocouple.

Replace/refit using reverse of the above procedure.

Spark ignition.

Disconnect from gas supply.

Disconnect 12v power wires to spark generator.

Remove appliance from worktop as above.

12v Spark Generator replacement

Located on the underside of appliance.

Remove all electrode wires.

Unscrew and/or unclip the spark generator and lift off the unit.

Replace/refit using reverse procedure.

Spark Ignition Wires.

Pull off the fixing clip on the burner and remove electrode from the burner cup.

Trace the electrode wire back to the generator and pull off the connector.

Replace/refit using reverse procedure.

Glass Lid and Glass Lid Safety Shut-Off Switch.

The glass shut-down lid may be removed with the appliance in-situ. Open the glass lid fully and

use a screwdriver to loosen the clamping screws in the upper leaves of the hinges. The glass

should be carefully lifted from the hinges when the screws are loose enough. Place the glass lid

in a protected area to avoid breakage.

To remove the safety shut-off switch the glass lid must first be removed and the appliance

disconnected from gas and electricity and removed from the cabinet. Disconnect the

thermocouple wires from the switch terminals by pulling straight down, away from the switch

without bending the connecting tabs.

Remove the two hinge-mounting screws from the hinge which carries the shut-off switch and

remove the switch from the hinge. A switch actuating pin is mounted in a hole located on the

underside of the hinge - catch the pin as it will fall out of the hinge as the switch is removed and

retain it for refitting. Refitting is the reverse of removal, including replacing the pin in the hole

underneath the hinge.

.

Page 15

15

FAULT DIAGNOSIS

FAULT

CAUSE

SOLUTION

Burner will not adjust

(continuous on low or high

flame).

Gas pressure

Blocked jet

Control tap

Check gas pressure correct

Clear blockage from jet.

Check jet size correct

Inspect/test control tap

Burner sooting. Gas pressure

Check pressure, low pressure is the cause of

sooting.

Burner – no Spark Ignition

Power supply

Poor connection

Spark generator

Check power supply

Check all connections

Test spark generator

Earth leakage due to damaged wire

Burner will not remain lit

Thermocouple

failure.

Blocked jet

Test & replace thermocouple if required

Check thermocouple in flame path

Clear jet blockage

In the event that this appliance cannot be adjusted to perform correctly and for any service

assistance, please contact your authorised local Service Agent giving details of the model and

serial number from the data badge on the underside of the appliance, plus the date of purchase.

In accordance with our policy of ongoing product development, specifications may change

without prior notice.

THETFORD AUSTRALIA PTY LTD

41 LARA WAY CAMPBELLFIELD VIC

TEL: 03 9358 0700 FAX: 03 9357 7060

Loading...

Loading...