Texas Instruments UCC39422PWTR, UCC39422PW, UCC39422N, UCC39421PWTR, UCC39421PW Datasheet

...

UCC29421/2

T

UCC39421/2

Multimode High Frequency PWM Controller

FEATURES

Operation Down to an Input Voltage

•

of 1.8V

High Efficiency Boost or Flyback

•

(Buck-Boost) Topologies

Drives External FETs for High Current

•

Applications

Up to 2MHz Oscillator

•

Synchronizable Fixed Frequency

•

Operation

High Efficiency Low Power Mode

•

High Efficiency at Very Low Power

•

with Programmable Variable

Frequency Mode

• Pulse by Pulse Current Limit

• 5µA Supply Current in Shutdown

• 150µA Supply Current in Sleep Mode

• Selectable NMOS or PMOS

Rectification

• Built-in Power on Reset

(UCC39422 Only)

• Built-in Low Voltage Detect

(UCC39422 Only)

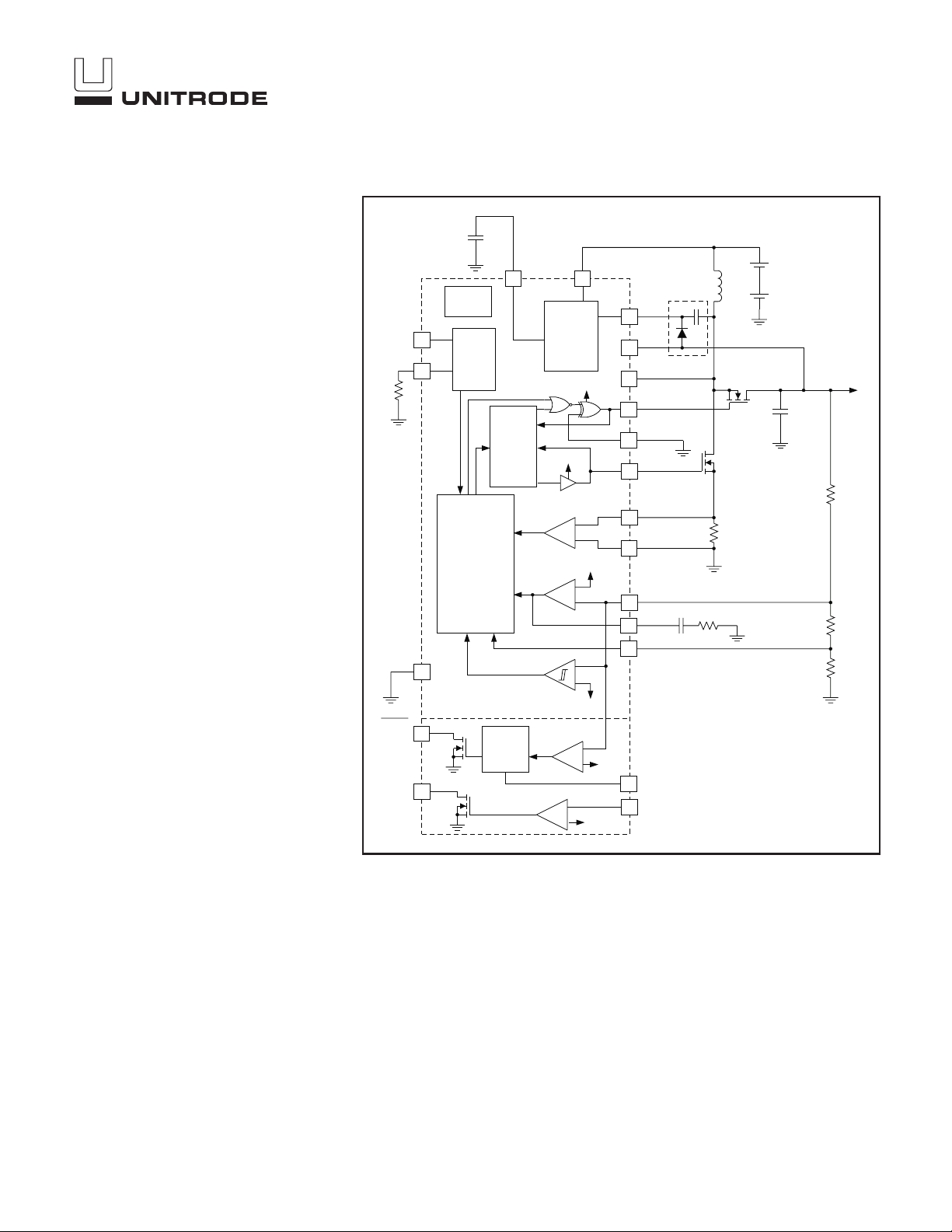

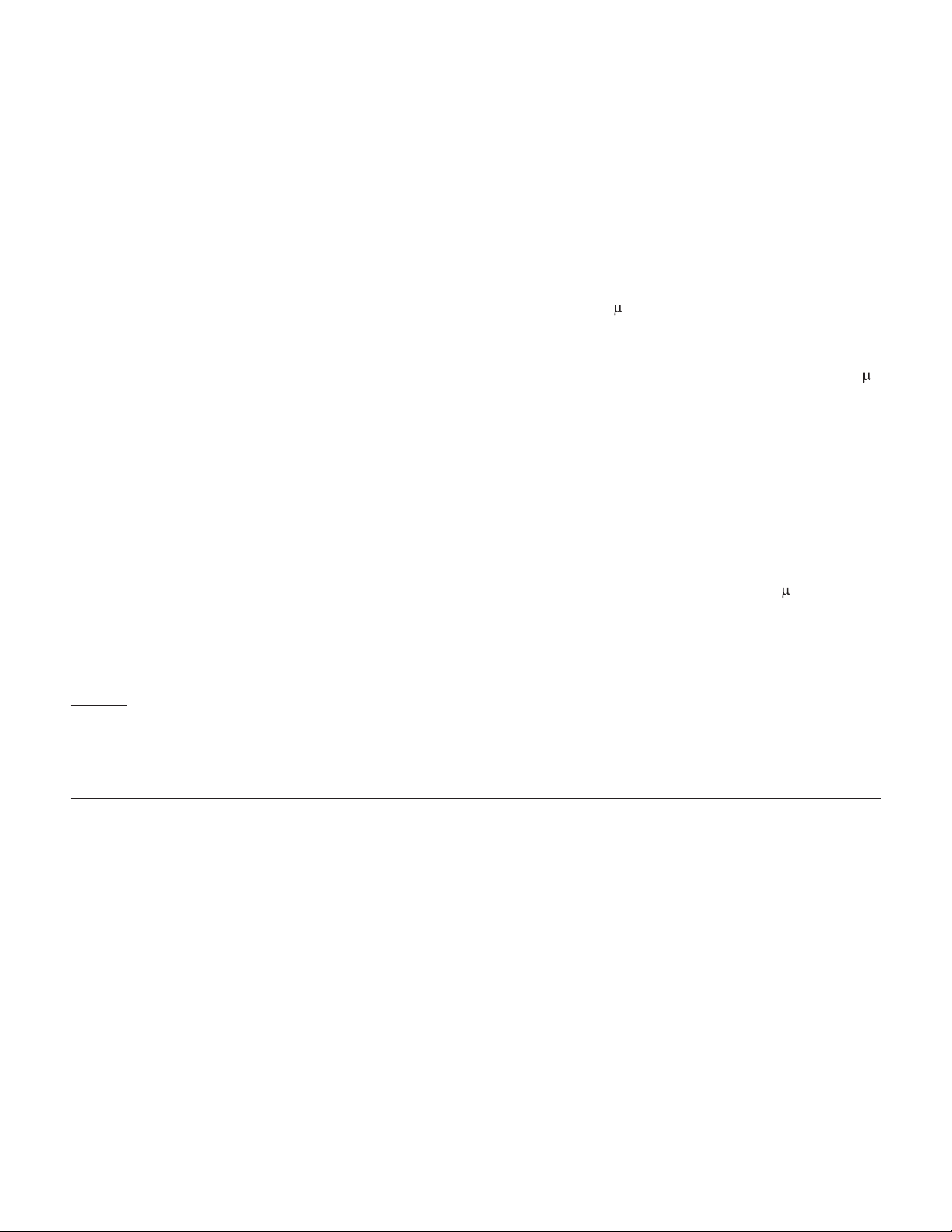

SIMPLIFIED BLOCK DIAGRAM AND APPLICATION CIRCUIT

1.8VMIN

97

1.25V

VREF

SYNC/SD

RT

GND

RESET

LOWBAT

13

14

PWM CIRCUITRY

CURRENT LIMIT

LOW POWER

COMPENSATION

15

1

10

PWM

OSC

MODE

SLOPE

PFM MODE

CONTROL

LP_MODE

ANTI-

CROSS

COND.

200mS

RESET/

POR

CHARGE

PUMP

VGD

X10

ERROR

AMP

1.23/1.25V

UCC39422

ONLY

+

–

VPUMP

+

–

1.25V

+

–

–

+

–

+

1.25V

VINVPUMP

1.18V

19

12

17

18

16

20

11

8

3

2

4

6

5

CP

VOUT

RSEN

RECT

RSEL

CHRG

ISENSE

PGND

FB

COMP

PFM

RSADJ

VDET

PRELIMINARY

+

2CELL

ALKALINE/

NiCd OR

+

1 LI-ION

50mV TYP

VOU

UDG-98122

DESCRIPTION

The UCC39421 family of synchronous PWM controllers

is optimized to operate from dual Alkaline/NiCd cells or a

single Lithium-Ion (Li-Ion) cell, and convert to adjustable

output voltages from 2.5V to 8V. For applications where

the input voltage does not exceed the output, a standard

boost configuration is utilized. For other applications

where the input voltage can swing above and below the

output, a 1:1 coupled-inductor (Flyback or SEPIC) is

used in place of the single inductor. Fixed frequency op

eration can be programmed, or synchronized to an exter

nal clock source. In applications where at light loads

variable frequency mode is acceptable, the IC can be

programmed to automatically enter PFM (Pulse Fre

quency Modulation) mode for an additional efficiency

benefit.

SLUS246A - OCTOBER 1999

Synchronous rectification provides excellent efficiency at

high power levels, where N or P type MOSFETs can be

used. At lower power levels (10-20% of full load) where

fixed frequency operation is required, Low Power Mode

is entered. This mode optimizes efficiency by cutting

back on the gate drive of the charging FET. At very low

power levels, the IC enters a variable frequency mode

(PFM). PFM can be disabled by the user.

-

Other features include pulse by pulse current limiting,

-

and a low 5µA quiescent current during shutdown. The

UCC39422 incorporates programmable Power on Reset

circuitry and an uncommitted comparator for low voltage

-

detection. The available packages are 20 pin TSSOP, or

20 pin N for the UCC39422, and 16 pin TSSOP, or 16

pin N for the UCC39421.

UCC29421/2

UCC39421/2

ABSOLUTE MAXIMUM RATINGS

Supply Voltage (VIN, VOUT,VPUMP) . . . . . . . . . . . . . . . . . . 8V

CP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8V

RSEN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to 12V

SYNC/SD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to 5V

ISENSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3 to 1V

Storage Temperature . . . . . . . . . . . . . . . . . . . –65°C to +150°C

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . . +300°C

All voltages are with respect to GND. Currents are positive

into, negative out of the specified terminal. Consult Packaging

Section of Databook for thermal limitations and considerations

of packages.

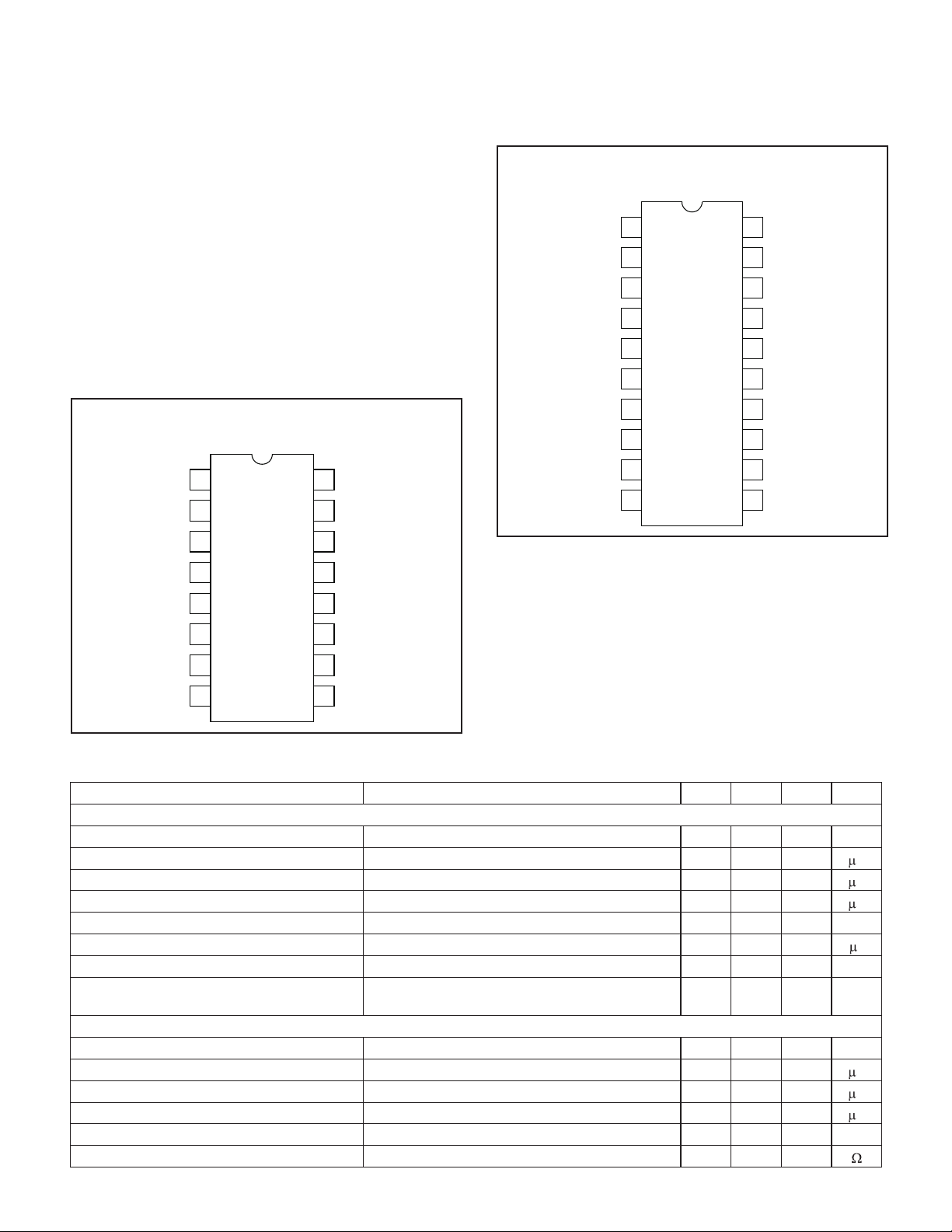

TSSOP-16, DIL-16 (TOP VIEW)

N, PW Packages

RSEN

VOUT

RECT

PGND

1

2

3

4

RSEL16

15

COMP

FB

14

PFM

13

CONNECTION DIAGRAMS

TSSOP-20, DIL-20 (TOP VIEW)

N, PW Packages

RESETB

RSEN

VOUT

RECT

PGND

CHRG

VPUMP

LOWBAT

1

2

3

4

5

6

7

8

CP

VIN ISENSE

9

10 VDET

20

19

18

17

16

15

14

13

12

11

RSADJ

RSEL

COMP

FB

PFM

GND

RT

SYNC/SD

CHRG

VPUMP

CP

VIN

5

6

7

8

ELECTRICAL CHARACTERISTICS: Unless otherwise stated these specifications apply for T

UCC29421/2, 0°C to +70°C for UCC39421/2; R

12

11

10

9

GND

RT

SYNC/SD

ISENSE

=100K, V

T

VPUMP

=6V, V

VIN

=3V

= –40°C to +85°C for

A

PARAMETER TEST CONDITIONS MIN MAX UNITS

VIN Section

Minimum Start-up Voltage 1.5 1.8 V

Operating Current Not in PFM Mode, No Load 35 60

Sleep Mode Current PFM Mode, No Load 35 60

Shutdown Supply Current SYNC/SD = High 1.5 4

Startup Frequency V

Startup Off Time V

Startup CS Threshold V

Minimum PUMP or VOUT Voltage to Exit

= 1.8V 60 120 190 kHz

IN

= 1.8V 2 5 s

IN

= 1.8V 36 56 mV

IN

2.2 2.5 2.8 V

Startup

VPUMP Section

Regulation Voltage V

=3.3V 5.5 6.6 V

VOUT

Operating Current Outputs OFF 100 275

Sleep Mode Current 515

Shutdown Supply Current SYNC/SD = High, V

CP Voltage to Turn On Pump Switch V

Pump Switch RDS

ON

= 5V 5.3 5.5 V

VPUMP

OUT

= 3V, V

= 3V 2 15 A

VPUMP

4

A

A

A

A

A

2

UCC29421/2

UCC39421/2

ELECTRICAL CHARACTERISTICS:

UCC29421/2, 0°C to +70°C for UCC39421/2; R

Unless otherwise stated these specifications apply for TA= –40°C to +85°C for

=100K, V

T

VPUMP

=6V, V

VIN

=3V

PARAMETER TEST CONDITIONS MIN MAX UNITS

VOUT Section

Operating Current 500 650

Sleep Mode Current 50 100 150

Shutdown Supply Current SYNC/SD = High 1 2.2

V

PUMP

to V

Threshold to Enable

OUT

V

= 3.3V 1.4 1.7 2.0 V

OUT

N-Channel Rectifier

Error Amp Section

Regulation Voltage 2V < VIN < 5V 1.21 1.24 1.27 V

FB Input Current V

Max Sinking Current, I

Max Sourcing Current, I

OL

OH

Transconductance V

Unity Gain Bandwidth C

Max Output Voltage V

= 1.25V 100 350 nA

FB

V

= 1V, VFB= Regulation Voltage +50mV 6.5 13 20 A

COMP

V

= 0V, VFB= Regulation Voltage –50mV –20 –13 –6.5 A

COMP

= Regulation Voltage ±4mV 150 270 370 S

FB

= 330pF 100 kHz

C

= 0V 1.9 2.3 V

FB

Oscillator Section

Frequency Stability R

= 350k 100 150 190 kHz

T

= 100k 375 475 575 kHz

R

T

= 35k 0.9 1.2 1.4 MHz

R

T

RT Voltage 0.600 0.625 0.650 V

SYNC Threshold 0.9 1.2 1.6 V

SYNC Input Current SYNC/SD = 2.5V 200 nA

Max SYNC High Time To Avoid Shutdown 11 20 29

SYNC Range R

= 100k 1.1ƒo 1.5ƒo kHz

T

Current Sense Section

Gain 8 10 11 V/V

Overcurrent Limit Threshold 150 200 mV

Unity Gain Bandwidth 25 MHz

COMP Voltage to I

Accuracy I

SENSE

= 70mV 0.8 1.0 1.2 V

SENSE

PWM Section

Maximum Duty Cycle V

Minimum Duty Cycle V

Low Power Mode V

Threshold At COMP pin 0.5 0.6 0.7 V

COMP

Slope Compensation Accuracy R

= 0V, VFB = 0V 80 88 %

ISENSE

= 1.5V 0 %

FB

= 350k, R

T

= 20k 1.4 2.8 4.0 A/s

SLOPE

Rectifier Zero Current Threshold RSEL = GND –2 15 28 mV

RSEL = VIN –28 –15 2 mV

RSEL Threshold 0.5 0.9 1.3 V

PFM Section

PFM Disable Threshold 0.17 0.22 0.27 V

Comp Hold During Sleep V

Startup Delay After Sleep V

= 0.4 0.45 V

PFM

< 1.23V 4 9 s

FB

FB Voltage to Sleep Off 1.19 1.22 1.25 V

FB Voltage to Sleep On 1.22 1.25 1.28 V

Low Power Mode Timer After Sleep 250 450 µs

A

A

A

s

3

UCC29421/2

UCC39421/2

ELECTRICAL CHARACTERISTICS:

UCC29421/2, 0°C to +70°C for UCC39421/2; R

PARAMETER TEST CONDITIONS MIN MAX UNITS

VGSW Drive Section

Rise Time C

Fall Time C

Output High I

Output Low I

Charge Off to Rectifier On Delay 10 30 50 ns

RECT Drive Section

Rise Time C

Fall Time C

Output High I

Output Low Rectifier I

Rectifier Off to Charge On Delay 10 20 50 ns

RESET Section (UCC39422 Only)

Reset Timeout C

Reset Threshold % Below Regulation Voltage –7 –5.5 –4 %

Output Low Voltage Reset Condition, I = 5mA 0.1 0.25 V

Output Leakage RESET = 8V 0.05 0.2

Voltage Detection Section (UCC39422 Only)

Threshold Voltage 1.18 1.26 1.34 V

Output Low Voltage I = 5mA 0.15 0.3 V

Output Leakage LOWBAT = 8V 0.05 0.25

Unless otherwise stated these specifications apply for TA= –40°C to +85°C for

=100K, V

T

= 1nF 18 35 ns

O

= 1nF 14 30 ns

O

= –100mA, Respect to VPUMP 0.4 0.65 V

OUT

= –1mA, Respect to VPUMP 4 10 mV

I

OUT

= 100mA 0.2 0.35 V

OUT

= 1mA 2 6 mV

I

OUT

= 1nF 20 40 ns

O

= 1nF 14 30 ns

O

= –100mA, Respect to VPUMP 0.2 0.5 V

OUT

= –1mA, Respect to VPUMP 5 10 mV

I

OUT

= 100mA 0.2 0.35 V

OUT

= 1mA 2 6 mV

I

OUT

= 0.33 F 100 250 400 ms

RSADJ

VPUMP

=6V, V

VIN

=3V

A

A

PIN DESCRIPTIONS

COMP: This is the output of the transconductance error

amplifier. Connect the compensation components from

this pin to ground.

CHRG: This is the gate drive output for the N-channel

charge MOSFET. Connect it to the gate directly, or

through a low value gate resistor.

CP: This is the input for the charge pump. For

applications requiring a charge pump, connect this pin to

the charge pump diode and flying capacitor, as shown in

the applications diagram of Fig 5. For applications where

no charge pump is required, this pin should be grounded.

FB: The feedback input is the inverting input to the tran

sconductance error amplifier. Connect this pin to a

resistive divider between V

voltage will be regulated to:

and ground. The output

OUT

R

V

OUT

=•

125

.

1

RR

+

12

()

where R1 goes to GND and R2 goes to VOUT.

GND: This is the signal ground pin for the device. It

should be tied to the local ground plane.

ISENSE: This is the input to the X10 wide bandwidth

current sense amplifier. Connect this pin to the high side

of the current sense resistor. An internal current is

sourced out this pin for slope compensation. For

applications requiring slope compensation (or filtering of

the current sense signal), use a resistor in series with

this pin.

LOWBAT: This is the open drain output of the

uncommitted comparator. (UCC39422 only). This output

is low when the VDET pin is above 1.25V.

4

PIN DESCRIPTIONS (cont.)

PFM: This is the programming pin for the PFM (Pulse

Frequency Modulation) Mode threshold. Connect this pin

to a resistive divider off of the FB pin (or VOUT) to set the

PFM threshold. To disable PFM Mode, connect this pin to

ground (below 0.2V).

PGND: This is the power ground pin for the device.

Connect it directly to the ground return of the current

sense resistor.

RECT: This is the gate drive output for the synchronous

rectifier. Connect it to the gate of the P or N channel

MOSFET directly, or through a low value gate resistor.

RECTSEN: This pin is used to sense the voltage across

the synchronous rectifier for commutation. In boost

configurations, connect this pin through a 1K resistor to

the junction of the two MOSFETs and the inductor. In

flyback and SEPIC configurations, connect this pin

through a 1K resistor to the junction of the drain of the

synchronous rectifier and the secondary side winding of

the coupled inductor.

RSADJ: A capacitor from this pin to ground sets the

reset delay. (UCC39422 only)

RSEL: This pin programs the device for N channel or P

channel synchronous rectifiers by inverting the phase of

the RECT gate drive output. Connect this pin to ground

for N-channel MOSFETs, connect it to V

MOSFETs.

RESET:

This is the open drain output of the Reset

comparator. (UCC39422 only) and is active low.

for P-channel

IN

UCC29421/2

UCC39421/2

RT: A resistor from this pin to ground programs the

frequency of the pulse width modulator.

SYNC/SD: This dual function pin is the SYNC and

Shutdown input. To synchronize the internal clock to an

external source, this pin must be driven above 2.0V. The

clock syncs to the rising edge of the input. To shutdown

the converter, this pin must be held high (above 2.0V) for

a minimum of 20

grounded.

VPUMP: This is the output of the charge pump. For

applications requiring a charge pump, connect a 1

capacitor from this pin to ground. Otherwise, connect

this pin to the higher of V

0.1µF capacitor.

VOUT: Connect this pin to the output voltage. This input

is used for sensing the voltage across the synchronous

rectifier and for bootstrapping the gate drive to the

charge FET and should be decoupled with a 0.1µF

capacitor.

VIN: This is the input power pin of the device. Connect

this pin to the input voltage source. A 0.1

capacitor should be connected between this pin and

ground.

VDET: This is the non-inverting input to an uncommitted

comparator. This input may be used for detecting a low

battery condition. (UCC39422 only)

sec. If not used, this pin should be

or V

IN

, and decouple with a

OUT

F decoupling

F

APPLICATION INFORMATION

The UCC39421 is a high frequency, synchronous PWM

controller optimized for portable, battery powered appli

cations where size and efficiency are of critical impor

tance. It includes high speed, high current FET drivers

for those converter applications requiring low RDS

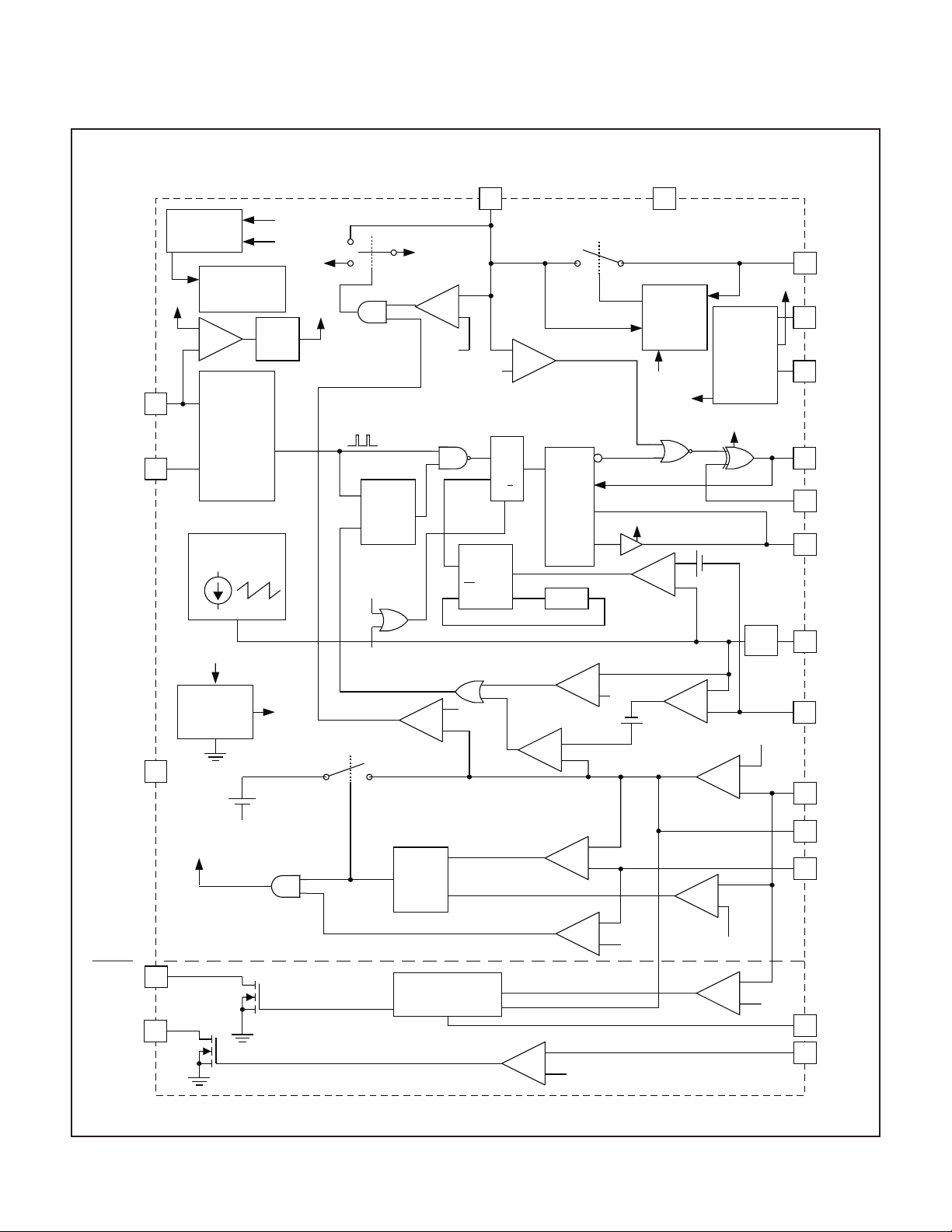

ternal MOSFETs. A detailed block diagram is shown in

Fig 1.

Optimizing Efficiency

The UCC39421 optimizes efficiency, extending battery

life, by its low quiescent current and its synchronous rec

tifier topology. The additional features of Low Power

Mode and PFM Mode maintain high efficiency over a

wide range of load current. These features will be dis

cussed in detail.

ON

ex

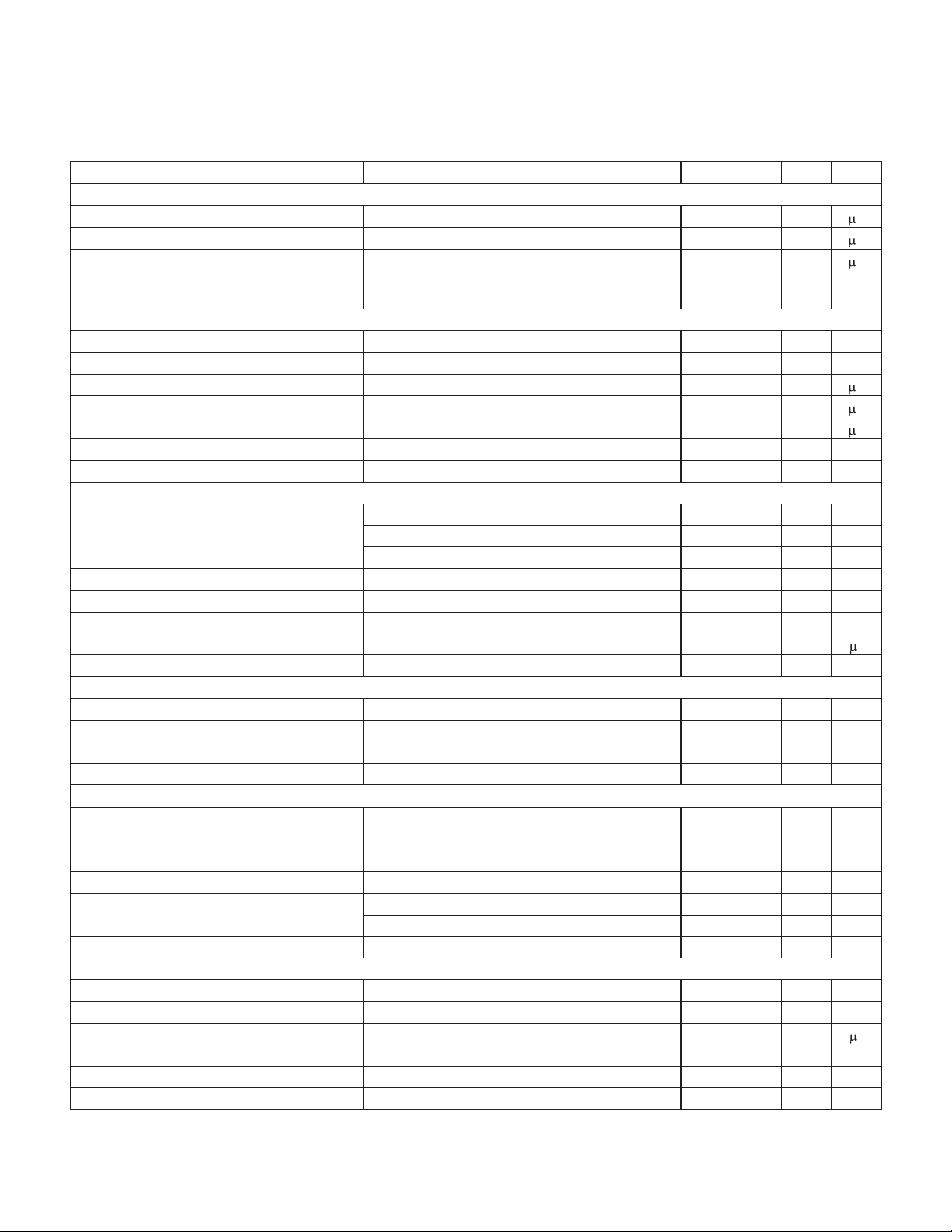

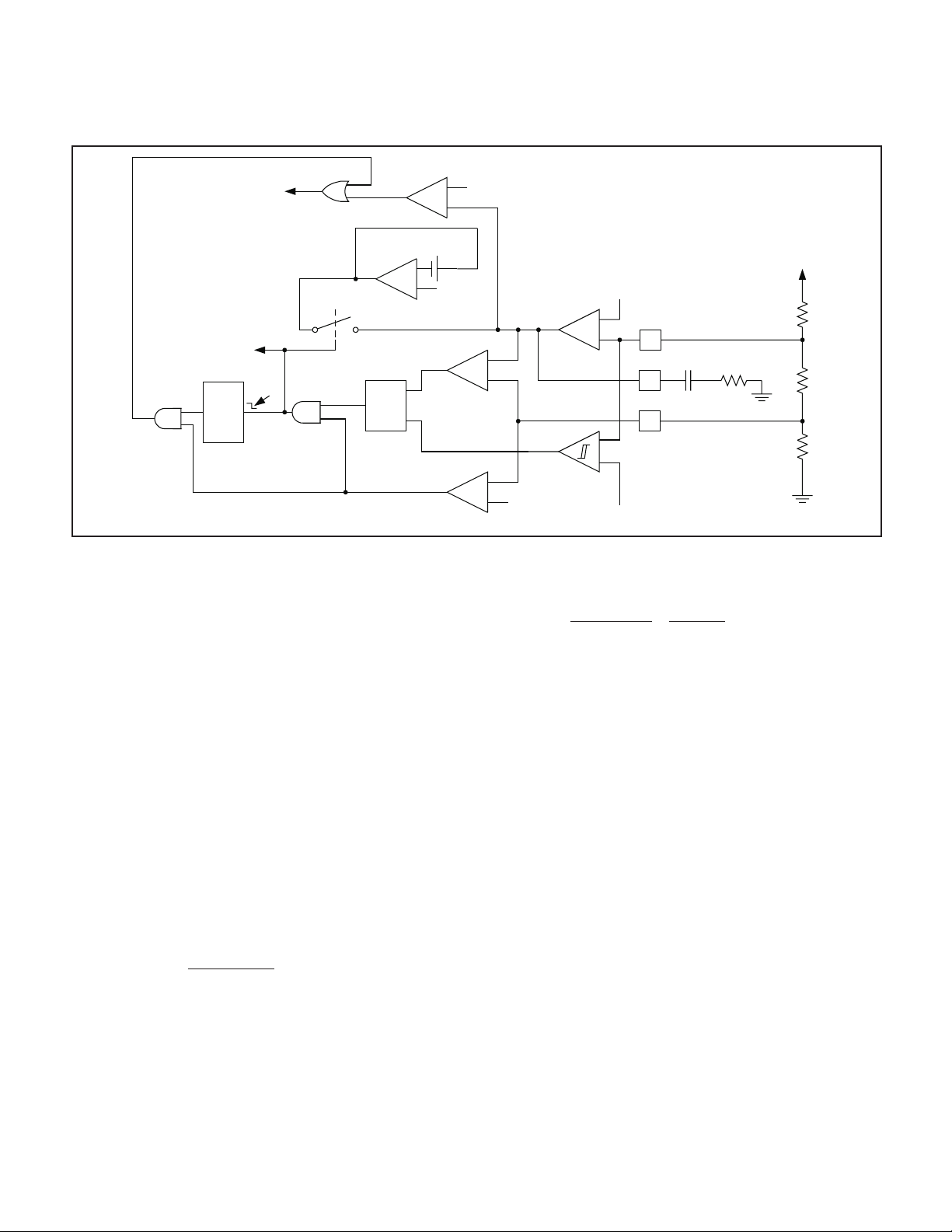

Power Saving Modes

Since this is a peak current mode controller, the error

amplifier output voltage sets the peak inductor current re

quired to sustain the load. The UCC39421 incorporates

two special modes of operation designed to optimize effi

ciency over a wide range of load current. This is done by

comparing the error amplifier output voltage (on the

COMP pin) to two fixed thresholds (one of which is user

programmable). If the error amplifier output voltage drops

below the first threshold, Low Power (LP) mode will be

entered. If the error amplifier output voltage drops even

further, below a second user programmable threshold,

PFM Mode will be entered. These modes of operation

are designed to maintain high efficiency at light load, and

are described in detail below. Refer to the simplified

block diagram of Fig. 2 for the control logic.

5

-

-

APPLICATION INFORMATION (cont.)

VPUMP

VOUT

VIN

1=SD

20uS

DELAY

85%

DMAX

CLK

VPUMP >2.5V

SYNC/SD

RT

1.25V

13

14

VDD

CONTROL

VDD

VDD BIAS

CONTROL

AND UVLO

–

+

SLOPECOMP

PWM

OSC

UCC29421/2

UCC39421/2

VINVPUMP

7 9

VGD

+

–

VIN

VOUT+2V

R

Q

S

QQR

QQR

MUX

A

B

A/B

S

S

–

+

ANTI-

CROSS

COND.

START-UP

2.5µS

CONTROL

VGD

PUMP

SWITCH

VIN

IZERO

–

+

ADAPTIVE

CURRENT

SENSING

VPUMP

36mV

+

PGND

ZERO

19

CP

8

VOUT

3

RSEN

2

RECT

4

RSEL

CHRG

6

GND

RESET

LOWBAT

V

IN

1.25V

VREF

15

1=SLEEP

SLEEP=

POWER DOWN ALL

BUTVOUTCOMP

1

10

+

PFM

10-20% OF FULL

LOAD=LP_MODE

50mV

UCC29422

ONLY

VOUT>2.5V

LP_MODE

Q

+

0.5V

–

S

R

RESET/POR

ILIM COMP

PWM

COMP

+

–

PFM DISABLE

COMP

+

–

+

–

–

+

+

–

1.25V

0.15V

+

ERROR AMP

0.2V

30MHz AMP

+

X10

0.3V

–

+

–

+

–

1.23/1.25

–

+

LEB

1.25V

1.18V

12

17

18

16

20

11

5

ISENSE

PGND

FB

COMP

PFM

RSADJ

VDET

Figure 1. Detailed block diagram.

UDG-98107

6

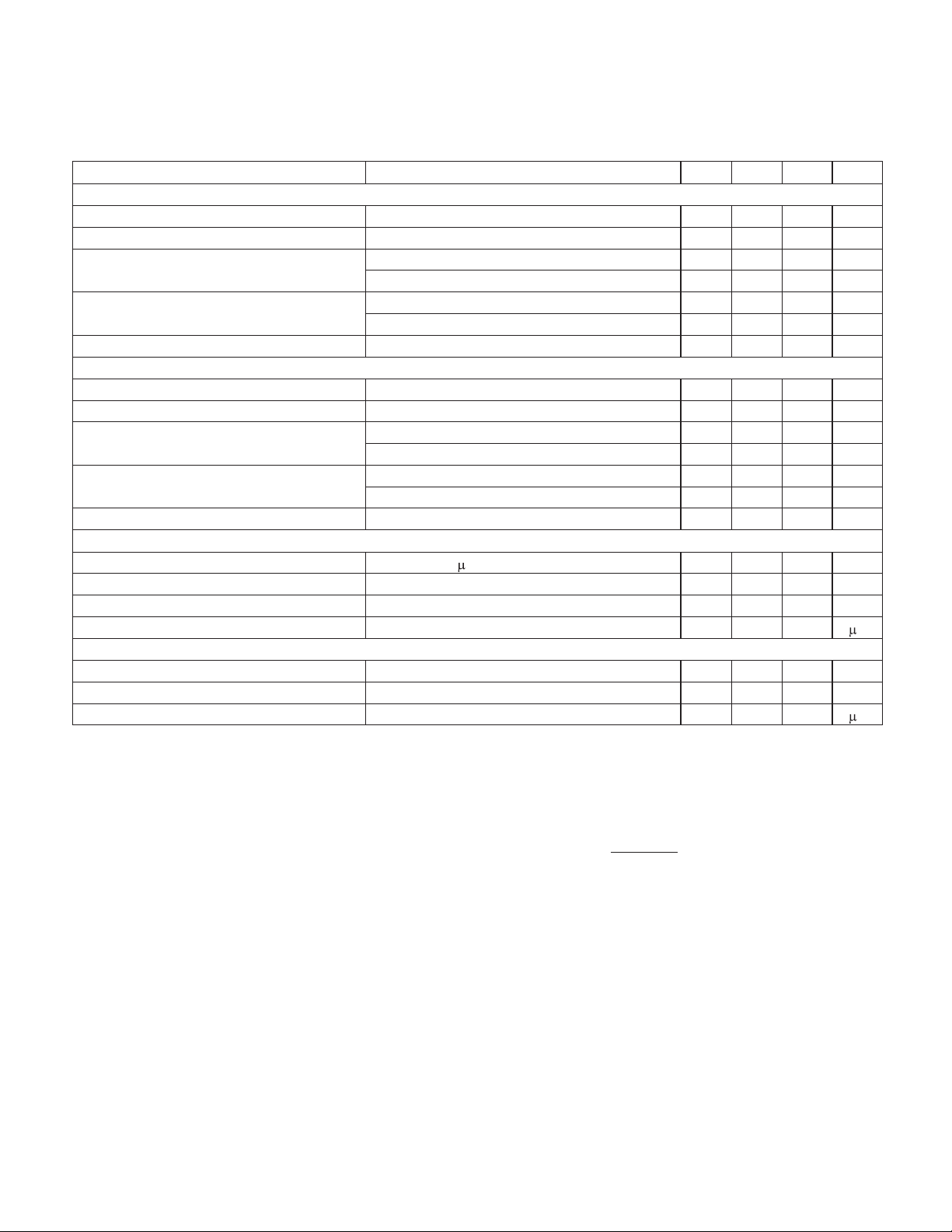

APPLICATION INFORMATION (cont.)

LP_MODE

LPM COMP

+

–

UCC29421/2

UCC39421/2

0.5V

50mV

+

–

+

1=SLEEP

200µs

ONE

SHOT

HOLD AMP

PFM

PFM COMP

S

Q

R

PFM DISABLE COMP

–

+

+

–

ERROR AMP

0.2V

+

–

–

+

1.25V

FB

COMP

PFM

1.23/1.25

Figure 2. Simplified block diagram of Low Power and Pulse Mode control logic.

−

05 03

..

Low Power Mode

During normal operation, at medium to high load cur-

I

PEAK

()

=

KR R

•

SENSE SENSE

=

rents, the switching frequency remains fixed, programmed by the resistor on the RT pin. At these higher

loads, the gate drive output on the CHRG pin (for the N

channel charge FET) will be the higher of V

or V

IN

PUMP

When the load current drops (sensed by a drop in the er

ror amp voltage), the UCC39421 will automatically enter

LP mode, and the gate drive voltage on the CHRG pin

will be reduced to lower gate drive losses. This helps to

maintain high efficiency at light loads where the gate

drive losses begin to dominate and the lowest possible

Rdson is not required. If the load increases, normal or

“High Power” mode will resume. The expression for gate

drive power loss is given by equation 1. It can be seen

that the power varies as a function of the applied gate

voltage squared.

2

••

GG

V

S

P

GATELOSS

QV f

=

Where 0.5V is the threshold for LP mode, 0.3V is the internal offset and K is the nominal current sense amplifier

gain of 10 and R

.

resistor. If the peak inductor current is below this value,

-

SENSE

is the value of the current sense

the UCC39421 will enter LP mode and the gate drive

voltage on the CHRG pin will be equal to V

currents higher than this, the gate drive voltage will be

the higher of V

or VPUMP.

IN

PFM Mode

At very light loads, the UCC39421 will enter PFM Mode.

In this mode, when the error amplifier output voltage

drops below the PFM threshold, the controller goes into

sleep mode until V

has dropped slightly (20mV mea

OUT

sured at the feedback pin). At this time, the controller will

(1)

turn back on and operate at fixed frequency for a short

duration (typically a few hundred microseconds) until the

output voltage has increased and the error amplifier out

put voltage has dropped below the PFM threshold once

Where Q

is the total gate charge and Vsis the gate volt

g

age specified in the MOSFET manufacturer’s data sheet,

is the applied gate drive voltage, and f is the switching

V

g

frequency.

The nominal COMP voltage where LP mode will be en

tered is 0.5V. Given the internal offset and gain of the

current sense amplifier, this corresponds to a peak

again. Then the converter will turn off and the cycle will

repeat. This results in a very low duty cycle of operation,

reducing all losses and greatly improving light load effi

ciency. During sleep mode, most of the circuitry internal

to the UCC39421 is powered down, reducing quiescent

current and maximizing efficiency.

switch current of:

002

.

VOUT

SENSE

in

UDG-98108

(2)

. At peak

-

-

-

7

APPLICATION INFORMATION (cont.)

The peak inductor current at which this mode will be en

tered is user programmable, by setting the voltage on the

PFM pin. This can be done with a single resistor in series

with the feedback divider, as shown in the application di

agrams. The nominal peak current threshold for PM

mode will be defined by:

(3)

is the

I

PEAK

125 1

12

RR

()

≅

KR

+

•

R

•

SENSE

−

03..

Where 0.3V is the internal offset and K is the nominal

current sense amplifier gain of 10 and R

SENSE

value of the current sense resistor. Note that in this case,

the PFM pin voltage is set by the R1/R2 resistive divider

off of the FB pin, which is regulated to 1.25V.

To further increase efficiency in Pulse mode, the gate

drive on the CHRG pin will be held in the LP mode for

sec each time the controller comes on. This keeps

200

gate drive losses low, even though the error amplifier

output voltage may overshoot slightly when coming out

of PFM. During sleep mode, the COMP pin is forced to

50mV above the PFM pin voltage. This minimizes error

amplifier overshoot when coming out of sleep mode, and

prevents erroneously tripping the PFM comparator.

Disabling PFM Mode

The user may disable PFM mode by pulling the PFM pin

below 0.2V. In this case, the UCC39421 will remain on,

in fixed frequency operation at all load currents. The

PFM pin can also be driven, through a resistive divider,

off of an output from the system controller. This allows

the system controller to prepare for an expected step in

crease in load, improving the converter’s large signal

transient response. An example of this is shown in Fig 3.

Choosing a Topology and Optimal Synchronous

Rectifier

The UCC39421 is designed to be very flexible, and can

be used in Boost, Flyback and SEPIC topologies. It can

operate from input voltages between 1.8 and 8.0V. Out

put voltages can be between 2.5V and 8.0V. (Note that

at higher input voltages, such as from four or five Alka

line or Nickel cells or two Li-ion cells, a buck regulator

UCC29421/2

UCC39421/2

-

UCC39421

-

PFM

Figure 3. Driving the PFM pin from a controller

output.

would usually be employed.) It will also drive either

N-channel or P-channel MOSFET synchronous rectifiers.

Table 1 can be used to select the appropriate topology

for a given combination of input and output voltage re

quirements. Although it is designed to operate as a peak

current mode controller, it can also be configured for volt

age mode control. This will be discussed in a later section.

The user can program the gate drive output on the RECT

pin for N-channel MOSFETs by grounding the RSEL pin,

or for P-channel MOSFETs by connecting the RESEL

pin to VIN. Table 2 is used to determine whether an N or

P channel synchronous rectifier should be used.

Note: In all cases, low voltage logic MOSFETs should be

used to achieve the lowest possible on-resistance for the

highest efficiency

.

The application diagrams in Figs 4-8 illustrate the use of

the UCC39421 in all the topologies, using N and P chan

nel rectifiers. They will be discussed in detail in the next

section.

Note that the higher the frequency of operation, the more

critical the MOSFET gate charge becomes for efficiency,

particularly at light loads. However, high load currents

demand lower RDS

, which will tend to increase gate

ON

charge. These two parameters should be balanced. At

lower frequencies, the gate charge will become less im

portant, at 1MHz or more, it is critical.

-

-

ENABLE OUTPUT

FROM CONTROLLER

R2

7

R1

-

-

-

-

Table I. Selecting Topology Based on Input and Output Voltage Requirements

Cell Type No. of Cells VINRange V

Alkaline or NiCd, NiMH 2 1.8V -3.0V 3.0 < V < 8.0 Boost

3 2.7V - 4.5V 2.5 < V < 3.9 Flyback or SEPIC

4.5 < V < 8.0 Boost

Li-Ion 1 2.3V - 4.2V 2.5 < V < 3.6 Flyback or SEPIC

4.2 < V < 8.0 Boost

OUT

Topology

8

APPLICATION INFORMATION (cont.)

Boost Topology

The boost topology is simple and efficient, and should be

used whenever the desired output voltage is greater than

the maximum input voltage.

Boost Using Two N-Channel MOSFETs

A boost converter using two N-channel MOSFETs is

shown in Fig 4. This configuration is optimal for output

voltages below 4V, where the output voltage may not be

high enough to provide optimal gate drive for a

P-channel MOSFET. Note that in this case, a charge

pump is required to provide proper gate drive levels. This

Table II. Selecting Synchronous Rectifier Based on Topology and Output Voltage

Topology VOUT Synchronous Rectifier

Boost 3.0 < V < 8.0 P-channel (low voltage logic)

V < 4.0 N-channel (low voltage logic)

Note: Requires a diode and a capacitor for the charge pump

Flyback 2.5 < V < 3.0 N-channel (low voltage logic)

Note: Requires a diode and a capacitor for the charge pump

3.0 < V < 8.0 N-channel (low voltage logic)

SEPIC 3.0 < V < 8.0 P-channel (low voltage logic)

is easily accomplished by adding an external diode and a

capacitor, as shown. The diode connects from the output

voltage to the CP pin. It should be an ultrafast or a

Schottky diode. A 0.1µF ceramic capacitor is connected

from the drain of the charge FET to the CP pin. This is

the “flying” cap that will be charged to (V

every time the charge FET is on. A charge pump reser

voir cap is connected from the VPUMP pin to ground. It

should be at least 1µF. A high speed active rectifier in

side the UCC39421 charges the pump capacitor from the

CP pin. The charge pump voltage will be:

UCC29421/2

UCC39421/2

–V

OUT

DIODE

)

-

-

+V

IN

+1.8–3.2V

V

OUT

+3.3V

+C

100µF

10V

C

OUT

IN

Q2 (N)

D

PUMP

1N4148

C

0.1µF

FLY

L1

COILTRONICS

CTX5-2

1k

0.1µF

Q1

(N)

R

SENSE

0.025

+V

IN

RG2 4.7

RG1

4.7

C

PUMP

1µF

C5

0.1µF

1

2

3

4

5

6

7

8

UCC39421

RSEN

VOUT

VGRECT

PGND

CHRG

VPUMP

CP

VIN

R

SLOPE

1.5k

RSEL

COMP

FB

PFM

GND

RT

SYNC/SD

ISENSE

16

15

14

13

12

11

10

C

POLE

R

COMP

RT

100k

9

C

COMP

R3

100k

1%

R2

41k

1%

R1

20k

1%

UDG-98116

Figure 4. Application diagram for the boost topology using an N-channel synchronous rectifier.

9

k

k

k

APPLICATION INFORMATION (cont.)

VV

≅•2

PUMP OUT

For a block diagram of the charge pump logic, refer to

Fig 12.

Note: A charge pump should not be used at output volt

ages over 4.0V to avoid pump voltages exceeding 8V

For other applications, where the charge pump is not re

quired, the CP pin should be grounded and the pin

should be connected to either V

or VIN, whichever is

OUT

greater.

Boost Using N & P Channel MOSFETs

For output voltages greater than the input and greater

than about 3.0V, a P-channel may be used for the syn

chronous rectifier. This configuration is shown in Fig 5. In

this case, the VPUMP pin should be connected to V

This configuration can be used for a 3.3V output if a low

voltage logic MOSFET is used.

(4)

.

OUT

UCC29421/2

UCC39421/2

Relating Peak Inductor Current to Average Output

Current for the Boost Converter

For a continuous mode boost converter, the average out

put current is related to the peak inductor current by the

-

following:

-

I

PEAK

=

()

where D is the duty cycle and the inductor ripple current,

dI, is defined as:

tVLDV

•

ON IN IN

di

=

where f is the switching frequency and L is the inductor

.

value. The duty cycle is defined as:

VV

−

OIN

D

=

V

O

I

OUT

1

di

+

=

•

fL

•

2

D

−

-

(5)

(6)

(7)

+1.8V –4.8V

V

+5V

0A-1A

C

IN1

10µF

IN

C

10µF

16V

OUT2

16V

C

OUT1

10µF

16V

Q1B

Si6803

(P)

+V

IN

2.2µH

R7

Q1A

Si6803

(N)

R

S

0.025

1k

L1

C6

0.1µF

C4

0.1µF

C5

0.1µF

1

2

3

4

5

6

7

8

RSEN

VOUT

VGRECT

PGND

CHRG

VPUMP

CP

VIN

R6

1.5k

UCC39421

SYNC/SD

RSEL

COMP

FB

PFM

GND

RT

ISENSE

16

15

14

13

12

11

10

C1

10pF

R5

1M

C2

470pF

SHUDOWN

R4

100k

R4

100k

9

R1

15

1%

R2

15

1%

R3

15

1%

SYNC/

INPUT

UDG-98117

Figure 5. Application diagram for the boost topology using a P-channel synchronous rectifier.

10

APPLICATION INFORMATION (cont.)

V

IN

+2.5–8.0V

+

C

IN

100µF

V

OUT

+3.3V

10V

C

OUT

+

10

L1B

10

470pF

470pF

Si9802

Q1B

(N)

L1A

COILTRONICS

CTX5-2

Q1A

Si9802

(N)

R

SENSE

0.05Ω

0.1µF

RG2 4.7

RG1

4.7

UCC29421/2

UCC39421/2

UCC39421

1k

1

2

3

4

5

6

RSEN

VOUT

VGRECT

PGND

CHRG

VPUMP

COMP

RSEL

FB

PFM

GND

RT

16

15

14

13

12

11

RT

100k

R

COMP

C

POLE

C

COMP

R3

100k

1%

R2

41k

1%

R1

20k

1%

10

9

0.1µF

+V

SYNC/SD

CP

7

ISENSE

VIN

IN

0.1µF

C5

8

R

SLOPE

1.5k

Figure 6. Application diagram for the flyback topology using an N-channel synchronous rectifier.

Substituting equations (6) and (7) into equation (5)

yields:

I

PEAK

I

=

VV

−

1

O

−

OIN

V

O

V

IN O IN

+

fL

••

2

VV

−

•

V

O

with a 1:1 turns ratio. The advantage of this topology is

that the output voltage can be greater or less than the in

put voltage, as shown in Table 1. For example, this is

(8)

ideal for generating 3.3V from a Lithium-Ion cell. Note

that RC snubbers are placed across the primary and sec

ondary windings to reduce ringing due to leakage induc

tance. These are optional, and may not be required in

Note: In these equations, the voltage drop across the rectifier

has been neglected.

Flyback Topology Using N-Channel MOSFETs

A flyback converter using the UCC39421 is shown in

Fig 6. It uses a standard two-winding coupled inductor

the application.

Note that for converters where V

IN

and V

be below 3V, a charge pump is needed to provide ade

quate gate drive. This is illustrated in the example if Fig.

7.

OUT

UDG-98113

-

-

-

may both

-

11

APPLICATION INFORMATION (cont.)

V

IN

+1.8–4.2V

+

C

IN

100µF

V

OUT

+2.5V

10V

L1B

470pF

10

C

OUT

+

Q1B

D1

1N4148

Si9802

(N)

L1A

COILTRONICS

CTX5-2

Q1A

Si9802

(N)

RG1

4.7

1k

0.1µF

RG2 4.7

1

2

3

4

5

6

UCC39421

RSEN

VOUT

VGRECT

PGND

CHRG

VPUMP

RSEL

COMP

FB

PFM

GND

RT

16

15

14

13

12

11

RT

100k

R

COMP

C

UCC29421/2

UCC39421/2

POLE

C

COMP

R3

100k

1%

R2

41k

1%

R1

20k

1%

R

SENSE

0.05Ω

0.1µF

+V

7

CP

VIN

IN

R

BIAS

8

0.1µF

R

180k

SLOPE

SYNC/SD

ISENSE

1.5k

10

9

Figure 7. Flyback converter using charge pump input for low voltage operation.

Relating Peak Inductor Current to Average Output

Current for the Flyback Converter

For a continuous mode flyback converter, the average

output current is related to the peak inductor current by

the following:

I

PEAK

I

OUT

=

−

12

di

+

D

Where D is the duty cycle and the inductor ripple current,

dI, is defined as:

tVLDV

•

ON IN IN

di

=

=

•

fL

•

(10)

Where f is the switching frequency and L is the inductor

value. The duty cycle is defined as:

D

=

VV

V

O

+

IN O

(11)

Substituting equations (10) and (11) into equation (9)

yields:

I

I

PEAK

=

1

O

V

O

−

VV

+

IN O

(9)

Figure 7 shows an example of a converter where both

and Vout may be quite low in voltage. In this case, a

V

IN

diode has been added to peak detect the voltage on the

drain of the charge FET and use it for the pump input

voltage. This is used to drive the gates of the FETs. To

assure that the pump voltage will be used (rather than

, which may be low), resistor R

V

IN

added to the ISENSE input to inhibit LP mode. This tech

nique is discussed further in the section about Changing

the Low Power Threshold.

UDG-98211

V

+

••

2

IN O

•

fLVV

IN

has also been

BIAS

+

(12)

V

O

-

12

APPLICATION INFORMATION (cont.)

V

IN

+1.8–6.0V

+

C

V

OUT

+3.3V

+

10µF

10V

100µF

Q2

(P)

IN

10V

10µF 16V

L1B

Q1

Si9802

(N)

R

SENSE

0.05Ω

L1A

+V

UCC29421/2

UCC39421/2

UCC39421

1k

0.1µF

0.1µF

IN

0.1µF

1

2

3

4

5

6

7

8

RSEN

VOUT

VGRECT

PGND

CHRG

VPUMP

CP

VIN

COMP

SYNC/SD

ISENSE

RSEL

PFM

GND

RT

FB

16

15

14

13

12

11

10

C

POLE

1M

C

COMP

R

COMP

RT

47k

9

R3

100k

1%

R2

41k

1%

R1

20k

1%

SYNC

INPUT

R

1.5k

SLOPE

Figure 8. Application diagram for the SEPIC topology using a P-channel synchronous rectifier.

SEPIC Topology Using N & P Channel MOSFETs

The UCC39421 may also be used in the SEPIC (Single

Ended Primary Inductance Converter) topology. This to

pology, which is similar to the flyback, uses a capacitor to

aid in energy transfer from input to output. This configu

ration is shown in Fig 8. The N-channel synchronous rec

tifier has been changed to a P-channel and moved to the

other end of the inductor’s secondary winding, and a new

capacitor has been placed across the dotted ends of the

two windings. The SEPIC topology offers the same ad

vantage of the flyback in that it can generate an output

However it also offers improved efficiency. Although it re

quires an additional capacitor in the power stage, it

greatly reduces ripple current in the input capacitor and

improves efficiency by transferring the energy in the leak

age inductance of the coupled inductor to the output.

This also provides snubbing for the primary and second

ary windings, eliminating the need for RC snubbers. Note

that the capacitor must have low ESR, with sufficient rip

ple current rating for the application. Another advantage

of the SEPIC is that the inductors don’t have to be on the

same core.

voltage that is greater or less than the input voltage.

UDG-98214

-

-

-

-

13

APPLICATION INFORMATION (cont.)

PWM Duty Cycle and Slope Compensation

All boost and flyback converters using peak current

mode control are susceptible to a phenomenon known

as sub-harmonic oscillation when operated in the contin

uous conduction mode beyond 50% duty cycle. Continu

ous conduction mode (CCM) means that the inductor

current never goes to zero during the switching cycle.

For a CCM boost converter, the required duty cycle for a

given input and output voltage (neglecting voltage drops

across the MOSFET switches) is given by equation (7).

This is shown graphically for a number of common output

voltages in Fig 9. For example, it can be seen that for a

3.3V output (using the boost topology) slope compensa

tion will not be required because the duty cycle will never

exceed 50%.

For the flyback topology, using a coupled inductor with a

1:1 turns ratio, the duty cycle is defined by equation (11).

This is shown graphically for a number of common output

voltages in Fig. 10.

To prevent sub-harmonic oscillation beyond 50% duty

cycle, a technique called slope compensation is used,

which modifies the slope of the current ramp. This is accomplished by adding a part of the timing ramp to the

current sense input. In the UCC39421 this can be done

by simply adding a resistor in series with the ISENSE input. A current is sourced within the IC which is proportional to the internal timing ramp voltage. The value of

the resistor will determine the amount of slope compensation added.

UCC29421/2

UCC39421/2

The slope compensation output current at the ISENSE

pin is equal to:

I

-

SLOPE

where R

slope compensation resistor for a boost configuration is

given by:

R

SLOPE

where is the current sense resistor value in Ohms (Ω)

and L is the inductor value in microHenries (µH), For a

flyback topology, using a 1:1 turns ratio, the equation be

comes:

R

SLOPE

If the converter is operated in the discontinuous conduction mode (inductor current drops to zero), no slope compensation is required. The point at which this mode

boundary occurs is a function of switching frequency, input voltage, output voltage, load current and inductor

value. However, in general the converter will be more efficient when operated in the continuous conduction mode

due to the lower peak currents.

1

A

=

is the timing resister in Ohms (Ω), The required

T

=

=

/secµ

R

T

VVRR

()

−• • •2

OUT IN SENSE T

(min)

L

VV R R

()

−••

OUT IN SENSE T

(min)

L

(13)

(14)

-

(15)

Figure 9. Duty cycle of CCM boost converter as a

function of input and output voltage.

V

OUT=

80%

70%

60%

50%

DUTY CYCLE

40%

30%

2.0 2.5 3.0 3.5 4.0 4.5

2.5 3.0 3.3 5.0

V

IN

Figure 10. Duty cycle of CCM flyback converter as a

function of input and output voltage.

14

APPLICATION INFORMATION (cont.)

V

IN

+1.8–4.5V

+

C

IN

100µF

10V

UCC29421/2

UCC39421/2

L1

V

OUT

+5.0V

0.1µF

10V

1k

+

C

OUT

Q2

(P)

0.1µF

Q1

(N)

+V

0.1µF

RG2

4.7

RG1

4.7

IN

1

2

3

4

5

6

7

8

0.1µF

UCC39421

RSEN

VOUT

VGRECT

PGND

CHRG

VPUMP

SYNC/SD

CP

VIN

Figure 11. Typical boost configuration using voltage mode control

RSEL

COMP

FB

PFM

GND

RT

ISENSE

16

15

14

13

12

11

10

C

POLE

R

COMP

RT

100k

9

R

SLOPE

5.6k

C

COMP

R3

100k

1%

R2

41k

1%

R1

20k

1%

UDG-98215

Voltage Mode Control

The UCC39421 can be operated as a voltage mode con

troller by connecting a 5.6k resistor from the ISENSE pin

to ground. The internal current source will generate an

artificial ramp voltage on this input. In this case, no slope

compensation is required, and no current sense resistor

is required in series with the source of the N-channel

MOSFET. A typical application diagram is shown in Fig

11. However, in this configuration there will be no

overcurrent protection. In addition, the Pulse and Low

Power modes, designed to increase efficiency at light

loads, will operate at different load currents. This is be

cause the internal error amplifier’s output voltage is no

longer a direct function of load current, but rather of duty

cycle. When operating in CCM, the duty cycle is largely a

function of input and output voltage, not load current. At

light enough loads however, the converter will go into

discontinuous mode and the error amplifier voltage will

drop low enough to activate the Low Power and Pulse

modes.

Start Up

-

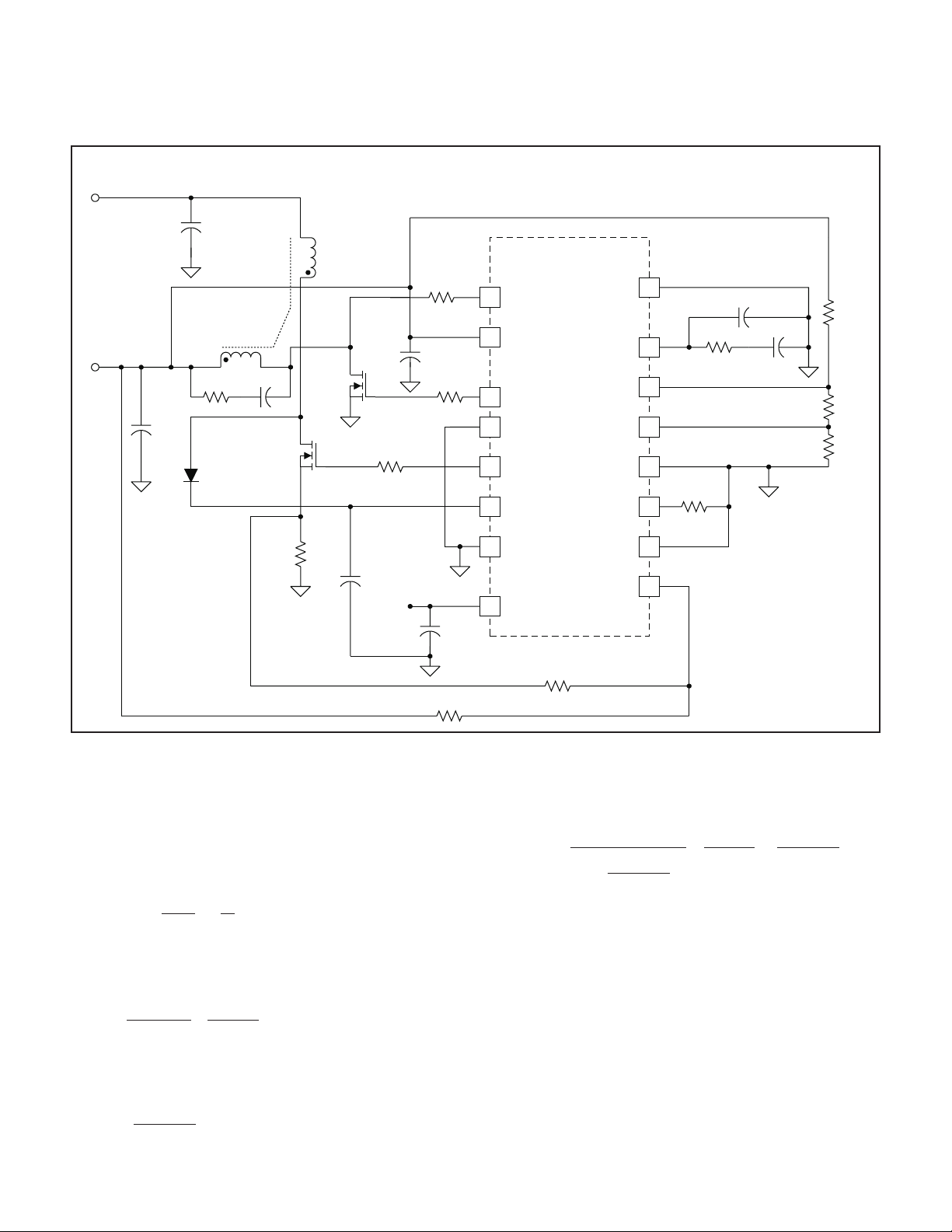

The UCC39421 incorporates a unique feature to help it

start-up at low input voltages. If the input voltage is be

low 2.5V at start-up, a separate control circuit takes over

until V

OUT

or V

gets above 2.5V. In this mode, the

PUMP

charge MOSFET is turned on for 5µsec, or until the volt

age on the ISENSE pin reaches 36mV, whichever occurs

first. The charge MOSFET then remains off for a fixed

time of 2.5µsec, and the body diode of the synchronous

rectifier MOSFET is used to supply current to the output.

This cycle repeats until either V

-

2.5V. This results in constant off time control, with a mini

OUT

or V

PUMP

mum switching frequency of approximately 120kHz. Dur

ing this low voltage start-up mode, all other internal

circuitry is off, including the synchronous rectifier drive

and the slope compensation current source. The peak in

ductor current during this mode is limited to:

=

.036

R

SENSE

I

PEAK

15

-

-

exceeds

-

-

-

(13)

APPLICATION INFORMATION (cont.)

UCC29421/2

UCC39421/2

V

IN

R

SENSE

L

V

PUMP

C

PUMP

2.5V < V

PUMP

2.5V < V

NORMAL PWM

OUT

A

B

UCC39421

MUX

A/B

–

+

2.5V < V

LPM < V

5µsec

DELAY

Q

Q

2.5µsec

DELAY

PUMP

COMP

S

R

V

IN

DRIVER

+

–

36mV

V

+

PUMP

Figure 12. Simplified diagram of low voltage start-up and charge pump control logic.

C

FLY

D

BODY

V

OUT

C

OUT

UDG-98121

If input voltages below 2.5V are expected, it is important

to use a low voltage logic N-channel MOSFET (with a

threshold voltage around 1V or less) to guarantee

start-up at full load.

A block diagram of the low voltage start-up logic is

shown in Fig 12.

Anti Cross-Conduction and Adaptive Synchronous

Rectifier Commutation Logic

When operating in the continuous conduction mode

(CCM), the charge MOSFET and the synchronous recti

fier MOSFET are simply driven out of phase, so that

when one is on the other is off. There is a built-in time

delay of about 30nsec to prevent any cross-conduction.

In the event that the converter is operating in the discon

tinuous conduction mode (DCM), the synchronous recti

fier needs to be turned off sooner, when the rectifier

current drops to zero. Otherwise, the output will begin to

discharge as the current reverses and goes back through

the rectifier to the input. (This obviously cannot happen

when using a conventional diode rectifier). To prevent

this, the UCC39421 incorporates a high speed compara

tor which senses the voltage on the synchronous rectifier

(using the RSEN input) for purposes of commutation. In

the boost and SEPIC topologies, the synchronous rectifier is turned off when the voltage on the RSEN pin goes

negative with respect to V

tant to have the V

pin well decoupled.

OUT

. For this reason it is impor

OUT

In the flyback topology however (using a ground refer

enced N-channel MOSFET rectifier), the rectifier voltage

is sensed on the MOSFET drain, with respect to ground

rather than V

. The voltage polarity in this case is op

OUT

posite that of the boost and SEPIC topologies. This prob

lem is solved with the adaptive logic within the

UCC39421. During each charge cycle, while the

N-channel charge FET is on, a latch is set if the voltage

on the RSEN pin exceeds V

/2. This indicates a flyback

IN

topology, since this node will be equal to or greater than

-

-

at this time. In the case of the boost and the SEPIC,

V

IN

the voltage at the RSEN input will be near or below

ground, and the latch will not be set. This allows the

UCC39421 to sense which topology is in use and adapt

the synchronous rectifier commutation logic accordingly.

Note that the RSEN input must have a series resistor to

limit the current when going below ground. Values less

-

than or equal to 1k are recommended to prevent time de

lay due to stray capacitance.

-

-

-

-

-

16

APPLICATION INFORMATION (cont.)

Current Sense Amplifier and Leading Edge Blanking

UCC29421/2

UCC39421/2

This pin should be grounded if not used.

The UCC39421 includes a high speed current sense am

plifier with a nominal gain of 10 to minimize losses asso

ciated with the current sense resistor. The amplifier was

designed to provide good response and minimal propa

gation delay, allowing switching frequencies over 2MHz.

The current sense resistor should be chosen to provide a

maximum peak voltage of 100mV at full load, with the

minimum input voltage.

A leading edge blanking time of 40nsec is provided to fil

ter out leading edge spikes in the current sense wave

form. In most applications, this will eliminate the need for

a filter cap on the ISENSE pin.

Overcurrent Protection

The UCC39421 includes a peak current limit function. If

the voltage on the ISENSE pin exceeds 0.15V after the

initial blanking period, the pulse will be terminated and

the charge MOSFET will be turned off.

Sync/Shutdown Input

The SYNC/SD pin has two functions; it may be used to

synchronize the UCC39421’s switching frequency to an

external clock, or to shutdown the IC entirely. In shutdown, the quiescent current is reduced to just a few

microamps.

To synchronize the internal clock to an external source,

the SYNC/SD pin must be driven high, above 2.0V minimum. The circuitry syncs to the rising edge of the input,

the pulse width is not critical.

To shutdown the converter, the SYNC/SD pin must be

held high (above 2.0V) for a minimum of 20µsec.

-

Changing the Low Power Mode Threshold

For some applications the user may want to lower the

Low Power (LP) mode threshold, or even eliminate this

feature altogether. For example, if a boost topology is

being used, and the input voltage is below 2.5V, the gate

drive to the charge FET may want to be derived from the

pump (or output) voltage under all load conditions, rather

than from V

allowed to operate in LP mode.

-

Although the LP mode threshold is internally fixed at

. This means the converter would never be

IN

0.5V (referenced to the pin), the point at which the LP

mode is entered can be easily modified by adding a sin

gle resistor, as shown in Fig 13. Resistor R

divider with R

SLOPE

(used for slope compensation) and

BIAS

adds a DC offset to the current sense input, raising the

output voltage of the sense amplifier and “fooling” the LP

mode comparator into thinking the load is higher than it

is. The required bias resistor to transition out of LP mode

for a given peak current can be calculated using the following equation:

R

BIAS

RV

=

•

SLOPE OUT

IR

−•002.

PEAK SENSE

Due to the current sense amplifier gain of 10 and the internal offset of 300mV, an offset of just 20mV or more at

the ISENSE pin will inhibit LP mode altogether. Note that

inhibiting LP mode does not prevent PFM from working,

as long as the PFM pin is set to a voltage higher than:

10 0 3•+

VV

()

ISENSE

.

-

forms a

(14)

(15)

FB

COMP

UCC39421

500mV

17

1.25V

18

PWM

CONTROL

DRIVE

+

300mV

LP

MODE

LOGIC

X10

Figure 13. Modifying Low Power (LP) mode threshold.

17

6

12

CHRG

ISENSE

R

R

SLOPE

BIAS

R

SENSE

C

OUT

C

OUT

UDG-98213

Y

APPLICATION INFORMATION (cont.)

UCC29421/2

UCC39421/2

VOUT

R1

R2

RT2

RT1

9ISENSE

2N7002

1

2

3

4

5

6

7

8

RSEN

VOUT

VGRECT

PGND

CHRG

VPUMP

CP

VIN

UCC39401

SYNC/SD

RSEL

COMP

FB

PFM

GND

RT

16

15

14

13

12

11

10

Figure 14. Changing the PWM frequency.

+3.0–8.0V

C

IN

100µF

16V

+

L1

6.8µH

FREQUENC

CONTROL

95%

Vin=3.3V Vin=5V

90%

85%

80%

75%

70%

EFFICIENCY

65%

60%

0.001 0.01 0.1 1

OUTPUT CURRENT (Amps)

Figure 15. Non-synchronous 12V boost efficiency.

(f=550KHz, L=6.8

µ

H DT3316P-682, IRF7601,

MBR0530, VPFM=0.5V)

UCC39421

1

RSEN

+12V

C

OUT

100µF

16V

+

D1

MBR0530T

R

SENSE

0.05Ω

Q1

(N)

+V

RG1

4.7

IN

2

VOUT

3

N/C

VGRECT

4

PGND

5

VGCHRG

6

VPUMP

7 10

CP

VIN

0.1µF

R

Figure 16. Non-synchronous boost converter for higher output voltages.

18

RSEL

COMP

FB

PFM

GND

RT

SYNC/SD

ISENSE

SLOPE

1.5K

16

15

14

13

12

11

R3

249K

C

POLE

1%

1.25V

R

COMP

C

COMP

R2

17.8K

1%

R1

11K

1%

RT

100K

98

UDG-98206

APPLICATION INFORMATION (cont.)

Programming the PWM Frequency

Some applications may want to remain in a fixed fre

quency mode of operation, even at light load, rather than

going into PFM mode. This lowers efficiency at light load.

One way to improve the efficiency while maintaining fixed

frequency operation is to lower the PWM frequency un

der light load conditions. This can be easily done, as

shown in Fig 14. By adding a second timing resistor and

a small MOSFET switch, the host can switch between

two discrete frequencies at any time.

Non-Synchronous Boost for Higher Output Voltage

Applications

The UCC39421 can also be used in a non-synchronous

application to provide output voltages greater than 8

volts from low voltage inputs. An example of a 12V boost

application is shown in Fig 16. Since none of the IC pins

are exposed to the boosted voltage, the output voltage is

limited only by the ratings of the external MOSFET, recti

fier and filter capacitor. At these higher output voltages,

good efficiency is maintained since the rectifier drop is

small compared to the output voltage. Note that PFM

mode can still be used to maintain high efficiency at light

load. Typical efficiency causes are shown in Fig. 15.

Since all the power supply pins (VIN, VOUT, VPUMP)

operate off the input voltage, it must be >2.5V and high

enough to assure proper gate drive to the charge FET.

UCC39422 Features

The UCC39422 is a 20 pin device which adds a reset

function and an uncommitted comparator to the

UCC39421. A simplified diagram of the reset circuit is

shown in Fig 17.

UCC29421/2

UCC39421/2

The reset circuit monitors the voltage at the feedback

(FB) pin and issues a reset if the feedback voltage drops

below 1.175V. This represents a 6% drop in output volt

age. Monitoring the voltage internally at the FB pin elimi

nates the need for another external voltage divider. The

RESET output is an open drain output which is active

low during reset. It stays low until the feedback voltage is

above 1.175V for a period of time called the reset pulse

width, which is user programmable. An external capacitor

on the RSADJ pin and an internal 1µA current source de

termine the reset pulse width, according to the following

equation:

tC

where t

C

RESET

An adaptive glitch filter is included to prevent nuisance

trips. This is implemented using a gm amplifier to charge

an 8pF capacitor to 1.175V before declaring a reset. This

provides a delay which is inversely proportional to the

magnitude of the feedback voltage error. The delay time

is approximated by the following equation:

t

where t

Note that the maximum current from the gm amplifier is

limited to 2µA, limiting the minimum time delay to

4.8µsec.

≅•118.

RESET RESET

RESET

is the reset pulse width in seconds, and

is the capacitor value in microFarads (µF).

025

DELAY

DELAY

≅

1 175..

−

is the filter delay time in microseconds.

secµ

V

FB

-

-

-

(16)

(17)

17

FB

1.175V

Figure 17. Reset circuitry.

gm=1/26k

8pF

1.175V

SQ

QR

19

1.175V

1µA

20

1 RESET

RSADJ

C

RESET

UDG-98121

APPLICATION INFORMATION (cont.)

A typical application schematic using the UCC39422 is

shown in Fig. 18. In this example, R1 and R2 have been

slected to trip the LOWBAT output when V

2.0V. Note that the RESET

and LOWBAT outputs are

open drain and require a pullup.

Selecting the Inductor

The inductor must be chosen based on the desired oper

ating frequency and the maximum load current. Higher

frequencies allow the use of lower inductor values, re

ducing component size. Higher load currents will require

larger inductors with higher current ratings and less wind

ing resistance to minimize losses. The inductor must be

rated for operation at the highest anticipated peak cur

rent. Refer to equations (8) and (12) to calculate the

peak inductor current for a boost or flyback design,

based on V

IN,VOUT

, maximum load, frequency and in

ductor value. Some manufacturers rate their parts for

drops below

IN

UCC29421/2

UCC39421/2

maximum energy storage in micro-Joules (µJ). This is

expressed by:

ELI

=••052.

where E is the required energy rating in micro-Joules. L

is the inductor value in microHenries (µH) (with current

applied), and I

inductor will see in the application. Another way in which

inductor ratings are sometimes specified is the maximum

volt-seconds applied. This is given simply by:

-

ET

•=

where ET is the required rating in V-µsec, D is the duty

cycle for a given V

-

quency in MHz. Refer to equations (7) and (11) to calcu

late the duty cycle for a CCM boost or flyback converter.

PEAK

is the peak current in amps that the

PEAK

VD

•

IN

f

and V

IN

, and f is the switching fre

OUT

(18)

(19)

-

-

+V

V

OUT

IN

RESET* (ACTIVE LOW)

RG

0.1µF

RG

0.1µF

0.1µF

10 VIN

1

2

3

4

5

6

7

8

9

UCC39422

RSEN

RSEN

VOUT

VGRECT

PGND

CHRG

VPUMP

CP

RSEL

COMP

FB

PFM

GND

RT

SYNC/SD

ISENSE

19

18

17

16

15

14

13

12

11VDET

C

RESET

20VIN

C

POLE

R1

C

COMP

150k

47pF

R2

+V

IN

R

COMP

RT

100k

250k

+C

+C

OUT

IN

Q1 (P)

Q1 (N)

+V

IN

R

SENSE

L1

1k

Figure 18. Typical UCC39422 application.

LOWBAT (ACTIVE HIGH)

20

R

SLOPE

THRESHOLD = 2.0V

UDG-99034

APPLICATION INFORMATION (cont.)

Table III. SMT commercial inductor manufacturers.

Coilcraft Inc. • (800) 322-2645.

1102 Silver Lake RD, Cary, IL 60013

Coiltronics Inc. • (407) 241-7876

6000 Park of Commerce Blvd, Boca Raton, FL 33487

Dale Electronics, Inc. • (605) 665-9301

East Highway 50, Yankton, SD 57078

Pulse Engineering Ltd. • (204) 633-4321

300 Keewatin Street, Winnipeg, MB R2X 2R9

Sumida • Voice (65) 296-3388 • Fax (65) 293-3390

Block 996, Bendemeer Rd., #04-05/06 Singapore 33944

BH Electronics • (612) 894-9590

12219 Wood Lake Drive, Burnsville, MN 55337

Tokin America Inc. • (408) 432-8020

155 Nicholson Lane, San Jose CA 95134

In any case, the inductor must use a low loss core de

signed for high frequency operation. High frequency fer

rite cores are recommended. Some manufacturers of

off-the-shelf surface mount designs are listed in Table III.

For flyback and SEPIC topologies, use a two winding

coupled inductor. SEPIC designs can also use two discrete inductors.

Selecting the Filter Capacitor

The input and output filter capacitors must have low ESR

and low ESL. Surface mount tantalum, OSCON or

multi-layer ceramics (MLC’s) are recommended. The capacitor selected must have the proper ripple current rating for the application. Some recommended capacitor

types are listed in Table IV.

Table IV. Recommended SMT Filter Capacitors

Manufacturer Part Number Features

AVX TPS series Low ESR tantalum

Kemet T410 series Low ESR tantalum

Murata GRM series Low ESR ceramic

Sanyo OSCON series Low ESR organic

Sprague 591D series Low ESR, low profile

tantalum

594D series Low ESR tantalum

Tokin Y5U, Y5V Type Low ESR ceramic

Circuit Layout and Grounding

As with any high frequency switching power supply, cir

cuit layout, hookup and grounding are critical for proper

operation. Although this may be a relatively low power,

low voltage design, these issues are still very important.

The MOSFET turn-on and turn-off times necessary to

maintain high efficiency at high switching frequencies of

1MHz or more result in high dv/dt and di/dt’s. This makes

stray circuit inductance especially critical. In addition, the

high impedances associated with low power designs,

UCC29421/2

UCC39421/2

such as in the feedback divider, make them especially

susceptible to noise pickup.

Layout

The component layout should be as tight as possible to

minimize stray inductance. This is especially true of the

high current paths, such as in series with the MOSFETs

and the input and output filter caps.

The components associated with the feedback, compen

sation and timing should be kept away from the power

components (MOSFETs, inductor). Keep all components

as close to the IC pins as possible. Nodes that are espe

cially noise sensitive are the FB and RT pins. Other sen

sitive pins are COMP and PFM.

Grounding

-

A ground plane is highly recommended. The PGND pin

-

of the UCC39421 should be close to the grounded end of

the current sense resistor, the input filter cap, and the

output filter cap. The GND pin should be close to the

grounded end of the RT resistor, the feedback divider resistor, the ISENSE cap (if used), and the compensation

network.

MOSFET Gate Resistors

The UCC39421 includes low impedance CMOS output

drivers for the two external MOSFET switches. The

CHRG output has a nominal resistance of 4

RECT has a nominal resistance of 2

quency operation using low gate charge MOSFETs, no

gate resistors are required. To reduce high frequency

ringing at the MOSFET gates, low value series gate re

sistors may be added. These should be non-inductive re

sistors, with a value of 2

to 10 , depending on the

frequency of operation. Lower values will result in better

switching times, improving efficiency.

Minimizing Output Ripple and Noise Spikes

The amount of output ripple will be determined primarily

by the type of output filter capacitor and how it is con

nected in the circuit. In most cases, the ripple will be

dominated by the ESR (Equivalent Series Resistance)

and ESL (Equivalent Series Inductance) of the cap,

rather than the actual capacitance value. Low ESR and

ESL capacitors are mandatory in achieving low output

ripple. Surface mount packages will greatly reduce the

ESL of the capacitor, minimizing noise spikes. To further

minimize high frequency spikes, a surface mount ce

ramic capacitor should be placed in parallel with the main

filter cap. For best results, a capacitor should be chosen

whose self-resonant frequency is near the frequency of

the noise spike. For high switch frequencies, ceramic ca

pacitors alone may be used, reducing size and cost.

For high fre-

-

-

-

, and the

-

-

-

-

-

21

APPLICATION INFORMATION (cont.)

For applications where the output ripple must be ex

tremely low, a small LC filter may be added to the output.

The resonant frequency should be below the selected

switching frequency, but above that of any dynamic

loads. The filter’s resonant frequency is given by:

f

RES

1

=

LC

•

2π

Where f is the frequency in Hz, L is the filter inductor

value in Henries and C is the filter capacitor value in

Farads. It is important to select an inductor rated for the

maximum load current and with minimal resistance to re

(20)

UCC29421/2

UCC39421/2

duce losses. The capacitor should be a low impedance

type, such as a tantalum.

If an LC ripple filter is used, the feedback point can be

taken before or after the filter, as long as the filter’s reso

nant frequency is well above the loop crossover fre

quency. Otherwise the additional phase lag will make the

loop unstable. The only advantage to connecting the

feedback after the filter is that any small voltage drop

across the filter inductor will be corrected for in the loop,

providing the best possible voltage regulation. However,

the resistance of the inductor is usually low enough that

-

the voltage drop will be negligible.

-

-

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

22

Loading...

Loading...