Texas Instruments UCC3807N-3, UCC3807N-2, UCC3807N-1, UCC3807DTR-3, UCC3807DTR-1 Datasheet

...

Programmable Maximum Duty Cycle PWM Controller

UCC1807-1/-2/-3

UCC2807-1/-2/-3

UCC3807-1/-2/-3

FEATURES

• User Programmable

Maximum PWM

Duty Cycle

• 100µA Startup Current

• Operation to 1MHz

• Internal Full Cycle

Soft Start

• Internal Leading Edge

Blanking of Current

Sense Signal

• 1 Amp Totem Pole

Output

DESCRIPTION

The UCC3807 family of high speed, low power integrated circuits contains all of the

control and drive circuitry required for off-line and DC-to-DC fixed frequency current

mode switching power supplies with minimal external parts count.

These devices are similar to the UCC3800 family, but with the added feature of a

user programmable maximum duty cycle.Oscillator frequency and maximum duty

cycle are programmed with two resistors and a capacitor.The UCC3807 family also

features internal full cycle soft start and internal leading edge blanking of the current sense input.

The UCC3807 family offers a variety of package options, temperature range

options, and choice of critical voltage levels.The family has UVLO thresholds and

hysteresis levels for off-line and battery powered systems. Thresholds are shown in

the table below.

6/97

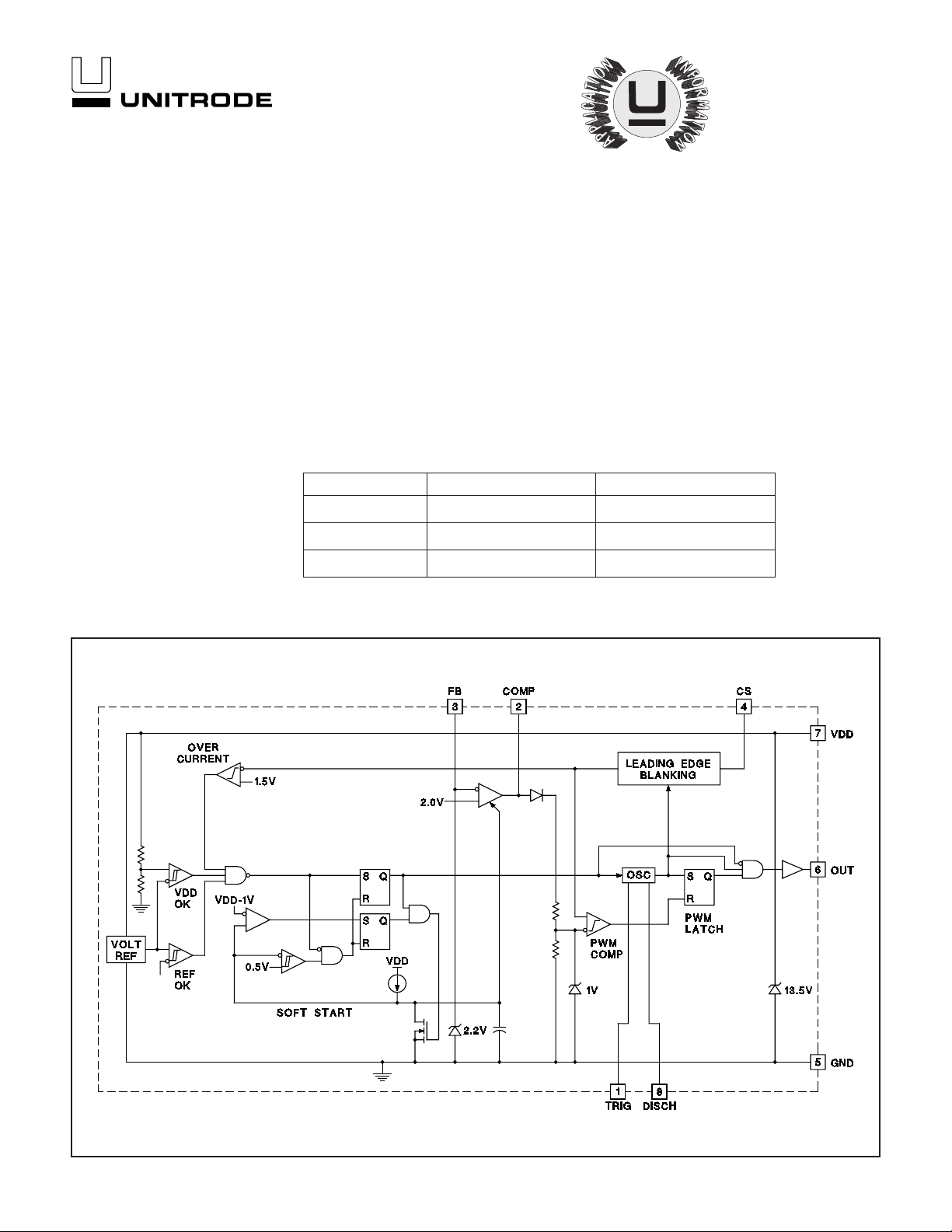

BLOCK DIAGRAM

Part Number Turn-on Threshold Turn-off Threshold

UCCx807-1 7.2V 6.9V

UCCx807-2 12.5V 8.3V

UCCx807-3 4.3V 4.1V

UDG-95001-1

2

UCC1807-1/-2/-3

UCC2807-1/-2/-3

UCC3807-1/-2/-3

ABSOLUTE MAXIMUM RATINGS

Supply Voltage (IDD ≤ 10mA) . . . . . . . . . . . . . . . . . . . . . . .13.5V

Supply Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30mA

OUT Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .±1A

Analog Inputs (FB, CS) . . . . . . . . . . . . .−0.3V to (VDD + 0.3V)

Power Dissipation at TA +25°C (N or J packages) . . . . . . . .1W

Power Dissipation at TA +25°C (D package) . . . . . . . . . .0.65W

Storage Temperature . . . . . . . . . . . . . . . . . . . .−65°C to +150°C

Junction Temperature . . . . . . . . . . . . . . . . . . .−65°C to +150°C

Lead Temperature (Soldering, 10 sec.) . . . . . . . . . . . . .+300°C

All currents are positive into, negative out of the specified terminal.

Consult Packaging Section of Databook for thermal limitations

and considerations of packages.

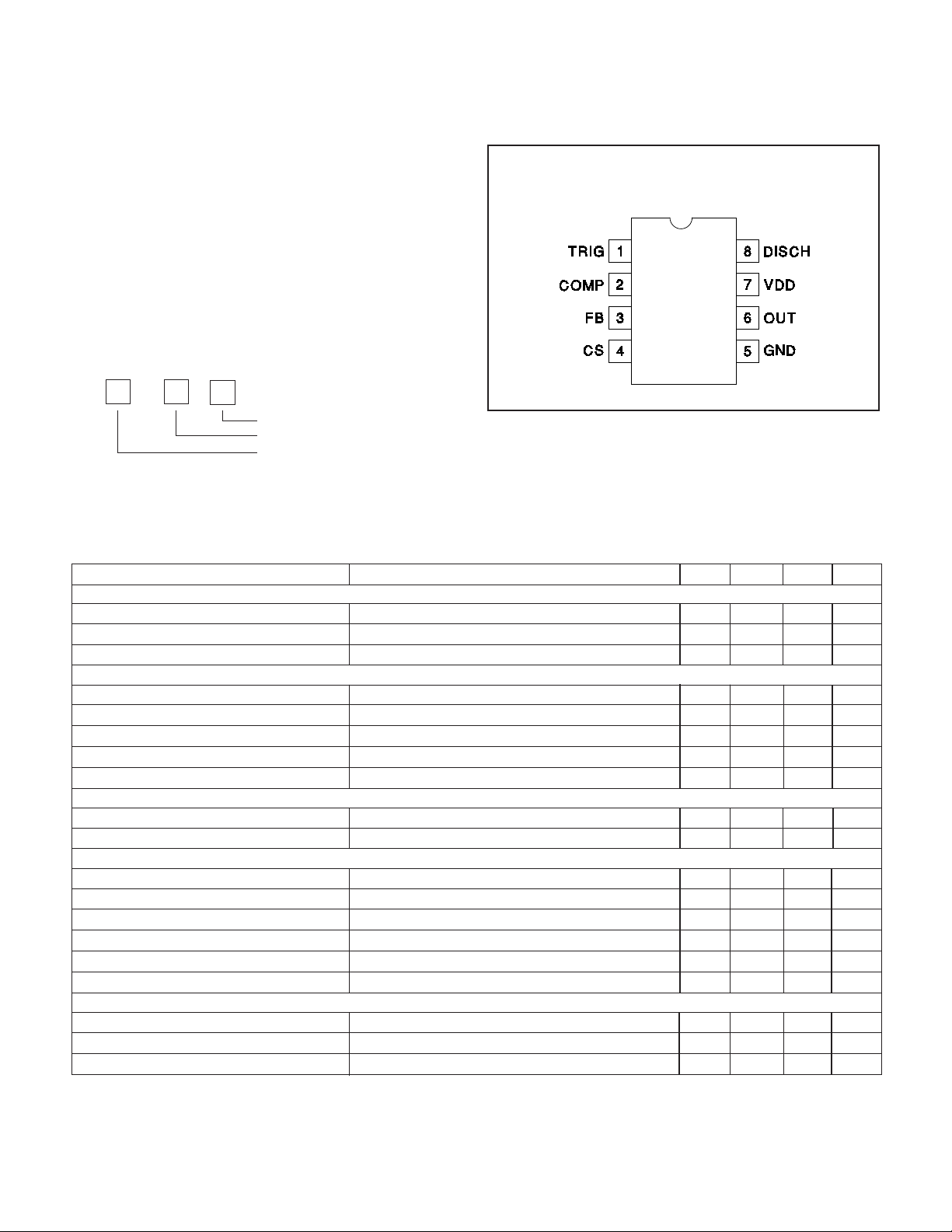

CONNECTION DIAGRAM

DIL-8,SOIC-8 (Top View)

J or N,D Packages

PARAMETER TEST CONDITION MIN TYP MAX UNITS

Oscillator Section

Frequency 175 202 228 kHz

Temperature Stability (Note 5) 2.5 %

Amplitude (Note 1) 1/3VDD V

Error Amplifier Section

Input Voltage COMP = 2.0V 1.95 2.00 2.05 V

Input Bias Current −1 1 µA

Open Loop Voltage Gain 60 80 dB

COMP Sink Current FB = 2.2V, COMP = 1.0V 0.3 2.5 mA

COMP Source Current FB = 1.3V, COMP = 4.0V −0.2 −0.5 mA

PWM Section

Maximum Duty Cycle 75 78 81 %

Minimum Duty Cycle COMP = 0V 0 %

Current Sense Section

Gain (Note 2) 1.1 1.65 1.8 V/V

Maximum Input Signal COMP = 5.0V (Note 3) 0.9 1.0 1.1 V

Input Bias Current −200 200 nA

CS Blank Time 50 100 150 ns

Overcurrent Threshold 1.4 1.5 1.6 V

COMP to CS Offset CS = 0V 0.55 1.1 1.65 V

Output Section

OUT Low Level I = 100mA 0.4 1 V

OUT High Level I = –100mA, VDD − OUT 0.4 1 V

Rise/Fall Time CL = 1nF (Note 5) 20 100 ns

ELECTRICAL CHARACTERISTICSUnless otherwise stated these specifications apply for TA = −55°C to +125°C for

UCC1807-1/-2/-3;−40°C to +85°C for UCC2807-1/-2/-3;and 0°C to +70°C for UCC3807-1/-2/-3;VDD = 10V (Note 6), RA = 12kΩ,

RB = 4.7kΩ, CT = 330pF, 1.0µF capacitor from VDD to GND, TA = TJ.

ORDERING INFORMATION

UCC 807 —

UVLO Threshold

Package

Temperature Range

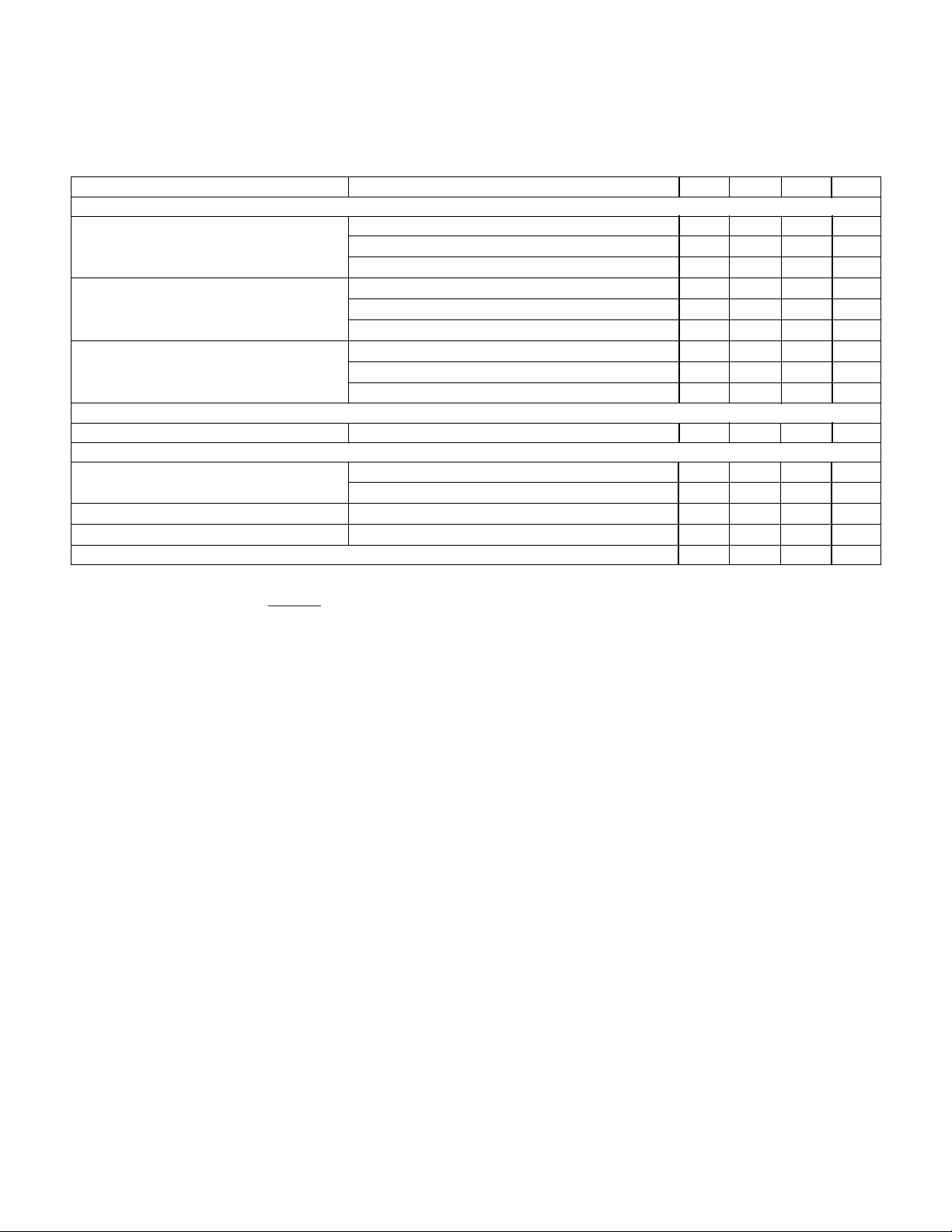

PARAMETER TEST CONDITION MIN TYP MAX UNITS

Undervoltage Lockout Section

Start Threshold UCCx807-1 (Note 4) 6.6 7.2 7.8 V

UCCx807-2 11.5 12.5 13.5 V

UCCx807-3 4.1 4.3 4.5 V

Minimum Operating Voltage After Start UCCx807-1 (Note 4) 6.3 6.9 7.5 V

UCCx807-2 7.6 8.3 9.0 V

UCCx807-3 3.9 4.1 4.3 V

Hysteresis UCCx807-1 0.1 0.3 0.5 V

UCCx807-2 3.5 4.2 5.1 V

UCCx807-3 0.1 0.2 0.3 V

Soft Start Section

COMP Rise Time FB = 1.8V, From 0.5V to 4.0V 4 ms

Overall Section

Startup Current VDD < Start Threshold (UCCx807-1,-3) 0.1 0.2 mA

VDD < Start Threshold (UCCx807-2) 0.15 0.25 mA

Operating Supply Current FB = 0V, CS = 0V, No Load (Note 7) 1.3 2.1 mA

VDD Zener Shunt Voltage IDD = 10mA 12.0 13.5 15.0 V

Shunt to Start Difference 0.5 1.0 V

3

UCC1807-1/-2/-3

UCC2807-1/-2/-3

UCC3807-1/-2/-3

ELECTRICAL CHARACTERISTICS (cont.) Unless otherwise stated these specifications apply for TA = −55°C to

+125°C for UCC1807-1/-2/-3;−40°C to +85°C for UCC2807-1/-2/-3;and 0°C to +70°C for UCC3807-1/-2/-3;VDD = 10V (Note 6),

RA = 12kΩ, RB = 4.7kΩ, CT = 330pF, 1.0µF capacitor from VDD to GND, TA = TJ.

Note 1:Measured at TRIG;signal minimum = 1/3 VDD, maximum = 2/3 VDD.

Note 2:Gain is defined by:A = , 0

≤ VCS≤ 0.8V

Note 3:Parameter measured at trip point of latch with FB at 0V.

Note 4:Start Threshold and Zener Shunt thresholds track one another.

Note 5:Guaranteed by design.Not 100% tested in production.

Note 6:Adjust VDD above the start threshold before setting at 10V for UCC3807-2.

Note 7:Does not include current in external timing RC network.

COMP: COMP is the output of the error amplifier and the

input of the PWM comparator. The error amplifier in the

UCC3807 is a low output impedance, 2MHz operational

amplifier. COMP can both source and sink current. The

error amplifier is internally current limited, which allows

zero duty cycle by externally forcing COMP to GND.

The UCC3807 family features built-in full cycle soft start.

Soft start is implemented as a clamp on the maximum

COMP voltage.

CS: Current sense input. There are two current sense

comparators on the chip, the PWM comparator and an

overcurrent comparator.

The UCC3807 also contains a leading edge blanking circuit, which disconnects the external CS signal from the

current sense comparator during the 100ns interval

immediately following the rising edge of the signal at the

OUT pin. In most applications, no analog filtering is

required on CS. Compared to an external RC filtering

technique, leading edge blanking provides a smaller

effective CS to OUT propagation delay. Note, however,

that the minimum non-zero on-time of the OUT signal is

directly affected by the leading edge blanking and the CS

to OUT propagation delay.

The overcurrent comparator is only intended for fault

sensing. Exceeding the overcurrent threshold causes a

soft start cycle.

FB: The inverting input to the error amplifier. For best

stability, keep connections to FB as short as possible

and stray capacitance as small as possible.

GND: Reference ground and power ground for all functions of the part.

OUT: The output of a high current power driver capable

of driving the gate of a power MOSFET with peak currents exceeding 1A.OUT is actively held low when VDD

is below the UVLO threshold.

The high current power driver consists of MOSFET output devices in a totem pole configuration. This allows the

output to switch from VDD to GND.The output stage also

provides a very low impedance which minimizes overshoot and undershoot. In most cases, external Schottky

clamp diodes are not required.

PIN DESCRIPTIONS

∆ V

COMP

∆ V

CS

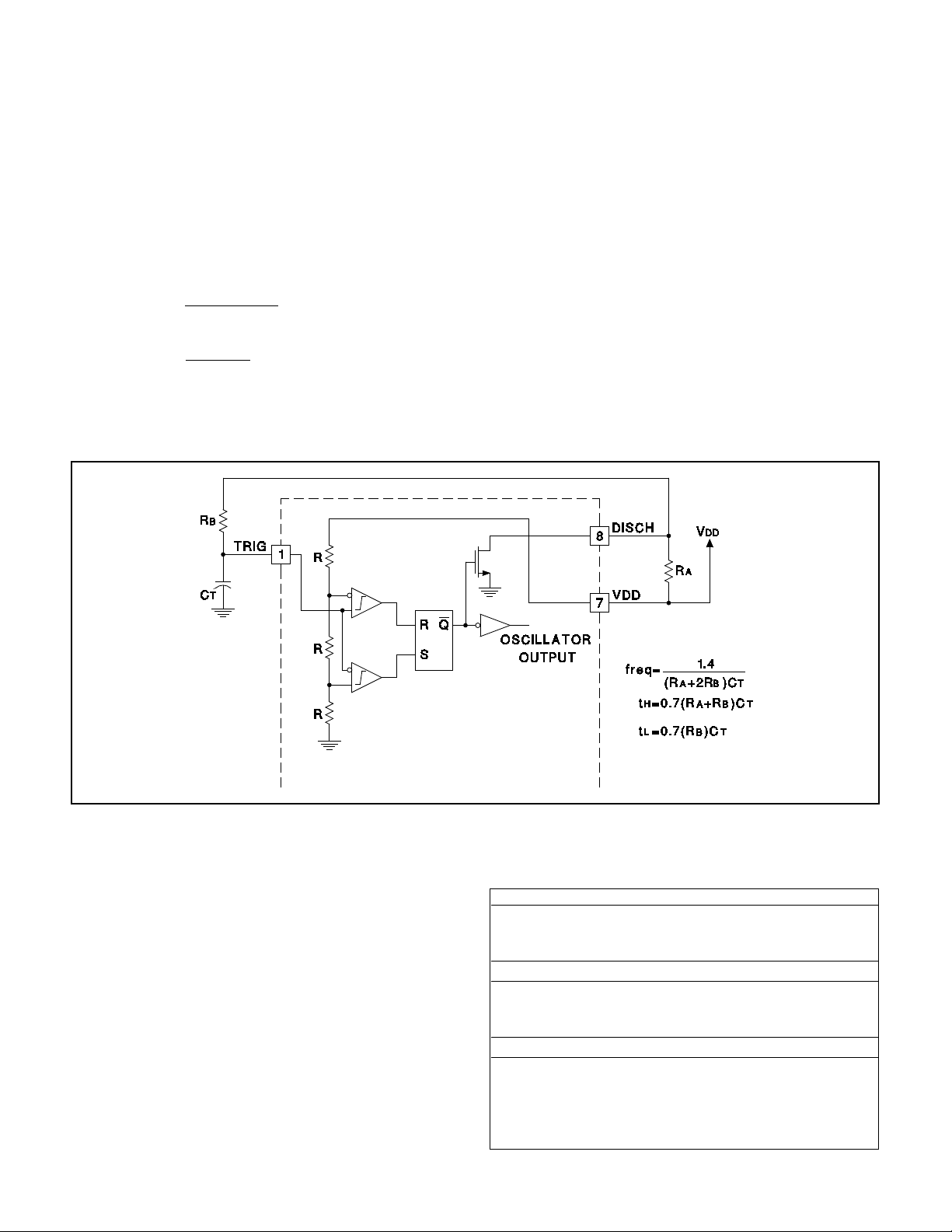

TRIG/DISCH: Oscillator control pins.TRIG is the oscillator timing input, which has an RC-type charge/discharge

signal controlling the chip’s internal oscillator. DISCH is

the pin which provides the low impedance discharge

path for the external RC network during normal operation. Oscillator frequency and maximum duty cycle are

computed as follows:

frequency ≈

duty cycle ≈

as shown in Figure 1.

For best performance, keep the lead from CT to GND as

short as possible.A separate ground connection for CT is

desirable.The minimum value of RA is 10kΩ, the minimum value of RB is 2.2kΩ, and the minimum value of CT

is 47pF.

VDD: The power input connection for this device. Total

VDD current is the sum of quiescent current and the

average OUT current. Knowing the operating frequency

and the MOSFET gate charge (Qg), average OUT current can be calculated from

IOUT = Qg ·F, where F is frequency.

To prevent noise problems, bypass VDD to GND with a

ceramic capacitor as close to the chip as possible in parallel with an electrolytic capacitor.

4

UCC1807-1/-2/-3

UCC2807-1/-2/-3

UCC3807-1/-2/-3

Figure 1.Oscillator Block Diagram

RA + RB

RA + 2RB

1.4

(RA + 2RB)CT

PIN DESCRIPTIONS (cont.)

APPLICATIONS INFORMATION

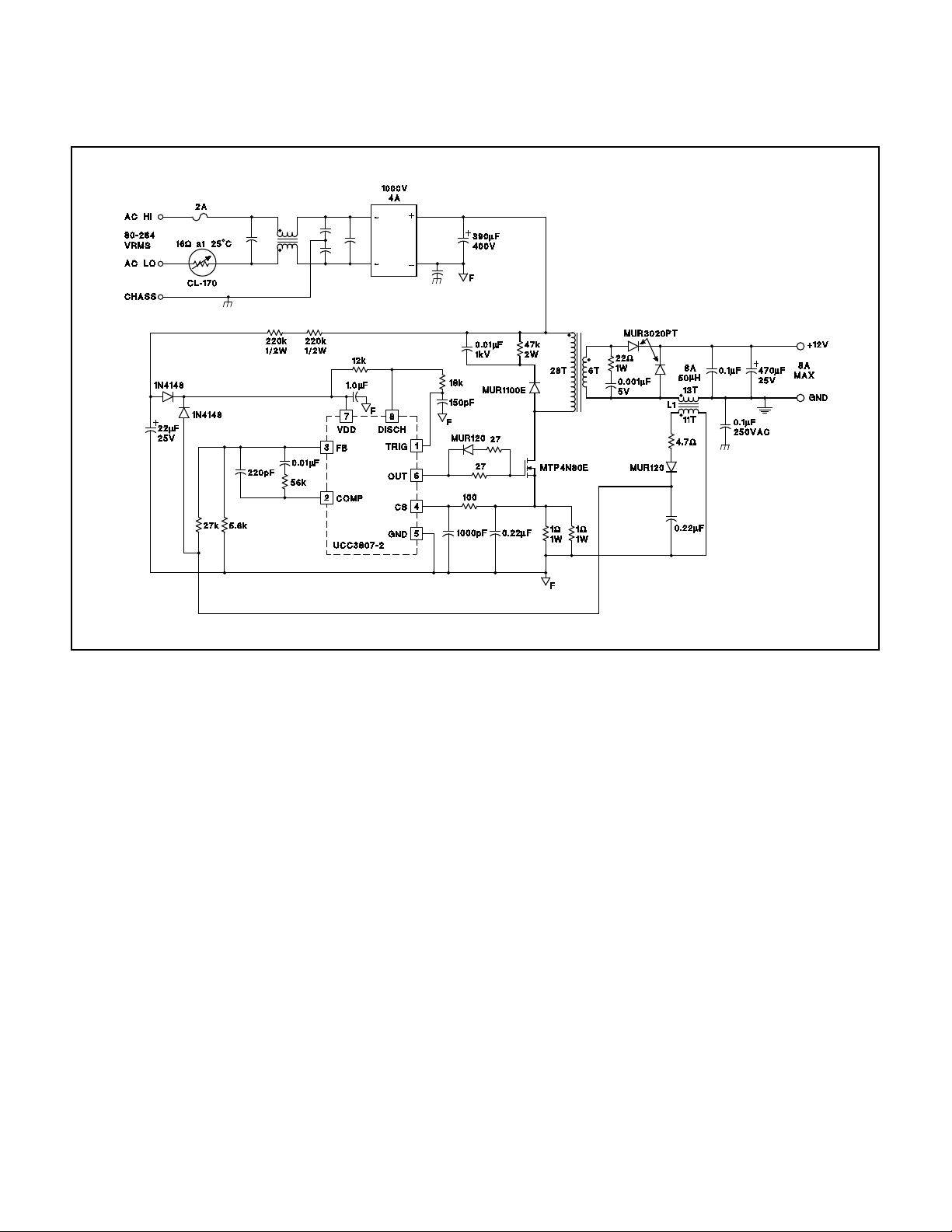

The circuit shown in Figure 2 illustrates the use of the

UCC3807 in a typical off-line application. The 100W,

200kHz, universal input forward converter produces a

regulated 12VDC at 8 Amps. The programmable maximum duty cycle of the UCC3807 allows operation down

to 80VRMS and up to 265VRMS with a simple RCD

clamp to limit the MOSFET voltage and provide core

reset. In this application the maximum duty cycle is set to

about 65%. Another feature of the design is the use of a

flyback winding on the output filter choke for both bootstrapping and voltage regulation. This method of loop

closure eliminates the optocoupler and secondary side

regulator, common to most off-line designs, while providing good line and load regulation.

T1:

Core: Magnetics Inc.#P-42625-UG (ungapped)

Primary: 28 turns of 2x #26AWG

Secondary: 6 turns of 50x0.2mm Litz wire

L1:

Core: Magnetics Inc.#P-42625-SG-37 (0.020” gap)

Main Winding: 13 turns of 2x #18AWG

Second Winding:11 turns of #26AWG

Magnetics Inc.

900 E.Butler Road

P.O.Box 391

Butler, PA 16003

Tel: (412) 282-8282

Fax:(412) 282-6955

UDG-95002-1

5

UNITRODE CORPORATION

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL.(603) 424-2410 • FAX (603) 424-3460

Figure 2.Typical Off-line Application Using UCC3807-2

UDG-96174

UCC1807-1/-2/-3

UCC2807-1/-2/-3

UCC3807-1/-2/-3

APPLICATIONS INFORMATION (cont.)

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...