Page 1

查询UCC2541PWPG4供应商

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

FEATURES

On-Chip Predictive Gate Drivet for

D

High-Efficiency Synchronous Buck

Operation

D Dual ±3-A TrueDrivet Outputs

D On-Board Programmable Oscillator with

1-MHz Frequency Operation

D TR Input for Sequencing Operation

D Overcurrent Protection using a Parallel

Average Current Mode Control Loop

D 3 Modes to Support 2.7-V to 35-V Input Bias

D Reverse Current Protection for Output Stage

D User Programmable Shutdown Using SS Pin

D ±1.0% Initial Tolerance Bandgap Reference

D High Bandwidth Error Amplifiers

D Thermally Enhanced HTSSOP 20-Pin

PowerPADt Package and QFN−32 Pin

D Synchronization Input

D Supports Pre-Bias Applications

SIMPLIFIED APPLICATION DIAGRAM

UCC2541

RSET

1

2

3

4

5

6

7

8

9

10

REF

G2C

SYNCIN

RAMP

GND

VEA−

CEA−

COMP

TR

SWS

BST

G1

SW

VDD

PGND

G2

VDRV

G2S

SS

20

19

18

17

16

15

14

13

12

11TR Input

APPLICATIONS

D

High Efficiency Non-Isolated Converters

Requiring Advanced Features such as

Pre-Bias Support and Tracking Capability

D Point-of-Load Modules for Servers, Telecom,

and Data communication Equipments

D Good for Input Voltages of 3.3 V, 5.0 V,

12.0 V, or Intermediate Bus Voltages

DESCRIPTION

The UCC2541 is a synchronous buck PWM

controller for high current and low output voltage

applications.

For higher efficiency, it incorporates the Predictive

Gate Drivet technology that virtually eliminates

body diode conduction losses in synchronous

rectifiers.

VIN

VOUT

Predictive Gate Drive, TrueDrive and PowerPAD are trademarks of Texas Instruments Incorporated.

!"#$ % &'!!($ #% )'*+&#$ ,#$(!,'&$% &!" $ %)(&&#$% )(! $.( $(!"% (/#% %$!'"($%

%$#,#!, 0#!!#$1- !,'&$ )!&(%%2 ,(% $ (&(%%#!+1 &+',(

$(%$2 #++ )#!#"($(!%-

www.ti.com

Copyright 2004, Texas Instruments Incorporated

1

Page 2

C

V

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

DESCRIPTION (CONT.)

The UCC2541 is available in the extended temperature range of –40°C to 105°C and is offered in thermally

enhanced PowerPADt 20-pin HTSSOP (PWP) or 32-pin quad flatpack (RHB) package. This space saving

package with standard 20-pin TSSOP footprint has a drastically lower thermal resistance of 1.4°C/W θ

accommodate the dual high-current drivers on board.

JC

to

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

Supply voltage range, VDD 36 V

Supply current, I

Analog input voltages

Sink current (peak), I

Source current (peak), I

Operating junction temperature range, T

Storage temperature, T

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 300

(1)

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions”

is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2)

All voltages are with respect to GND. Currents are positive into, and negative out of the specified terminal.

VDD

OUT_SINK

OUT_SOURCE

J

stg

VDD 50 mA

CEA−, COMP, G2C, RAMP, SS, TR, VEA− −0.3 to 3.6

VDRV −0.3 to 9

G1, BST SW−0.3 to SW+9

SW, SWS −1 to 36

G2, G2S −1 to 9

SYNCIN −0.3 to 8.0

G1, G2 3.5

G1, G2 −3.5

(1)(2)

UCC2541 UNIT

−55 to 150

−65 to 150

RECOMMENDED OPERATING CONDITIONS

MIN TYP MAX UNIT

Supply voltage, VDD Mode 1 8.5 35

Supply voltage, VDRV Mode 2 4.75 9.00

Supply voltage, REF Mode 3 3.0 3.3 3.6

Supply voltage bypass, C

Reference bypass capacitor, C

VDRV bypass capacitor, C

BST−SW bypass capacitor, C

Timer current resistor range, R

PWM ramp capacitor range, C

Turn-off capacitor range, C

COMP pin load range, R

Junction operating temperature, T

VDD

REF

VDRV

BST−SW

RSET

RAMP

G2C

LOAD

J

1.0 2.2

0.1 1.0 2.2

0.2

0.1

10 50 kΩ

100 680

120 1000

6.5 kΩ

−40 105 °C

V

A

°C

V

µF

pF

2

www.ti.com

Page 3

TA = T

PWP PACKAGE

RHB PACKAGE

ORDERING INFORMATION

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

J

−40°C to +105°C UCC2541PWP UCC2541RHB

(1)

The PWP and RHB packages are also available at 73 devices per tube and taped and reeled at

3,000 devices per reel. Add an R suffix to the device type (i.e., UCC2541PWPR). See

the application section of the data sheet for PowerPAD drawing and layout information.

HTSSOP−20 (PWP)

Bulk Bulk

(1)

CONNECTION DIAGRAM

(TOP VIEW)

RSET

REF

G2C

SYNCIN

RAMP

GND

VEA−

CEA−

COMP

TR

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

SWS

BST

G1

SW

VDD

PGND

G2

VDRV

G2S

SS

RSET

VREF

G2C

SYNCIN

RAMP

GND

VEA−

CEA−

NCNCNCNCNC

32

31

1

2

3

4

5

6

7

8

QFN−32 (RHB)

(TOP VIEW)

30

29

28

SWS

27

BST

26

BST

25

(1)

24

23

22

21

20

19

18

17

G1

G1

SW

VDD

PGND

PGND

G2

G2

9

COMP

NC − No internal connection

NOTE: The PowerPADt is not directly connected to any lead of the package, but is thermally connected to the substrate of the device. The

exposed dimension is 1.3 mm x 1.7 mm for the PWP package and 3.25 mm x 3.25 mm for the RHB package. However, the tolerances

can be +1.05 mm / −0.05 mm (+41 mils / −2 mils) due to position and mold flow variation.

10

TR

11

NC

12

NC

13

SS

14

G2S

15

NC

16

VDRV

THERMAL INFORMATION

PACKAGE

FAMILY

PowerPAD

HTSSOP−20

Quad Flatpack

QFN−32

PACKAGE

DESIGNATOR

PWP

RHB

θ

(°C/W)

JA

(with PowerPAD)

22.3 to 32.6

(500 to 0 LFM)

22.3 to 32.6

(500 to 0 LFM)

θ

(°C/W)

JC

(without PowerPAD)

19.9 1.4 125°C

19.9 1.4 125°C

θ

(°C/W)

JC

(with PowerPAD)

MAXIMUM DIE

TEMPERATURE

www.ti.com

3

Page 4

V

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

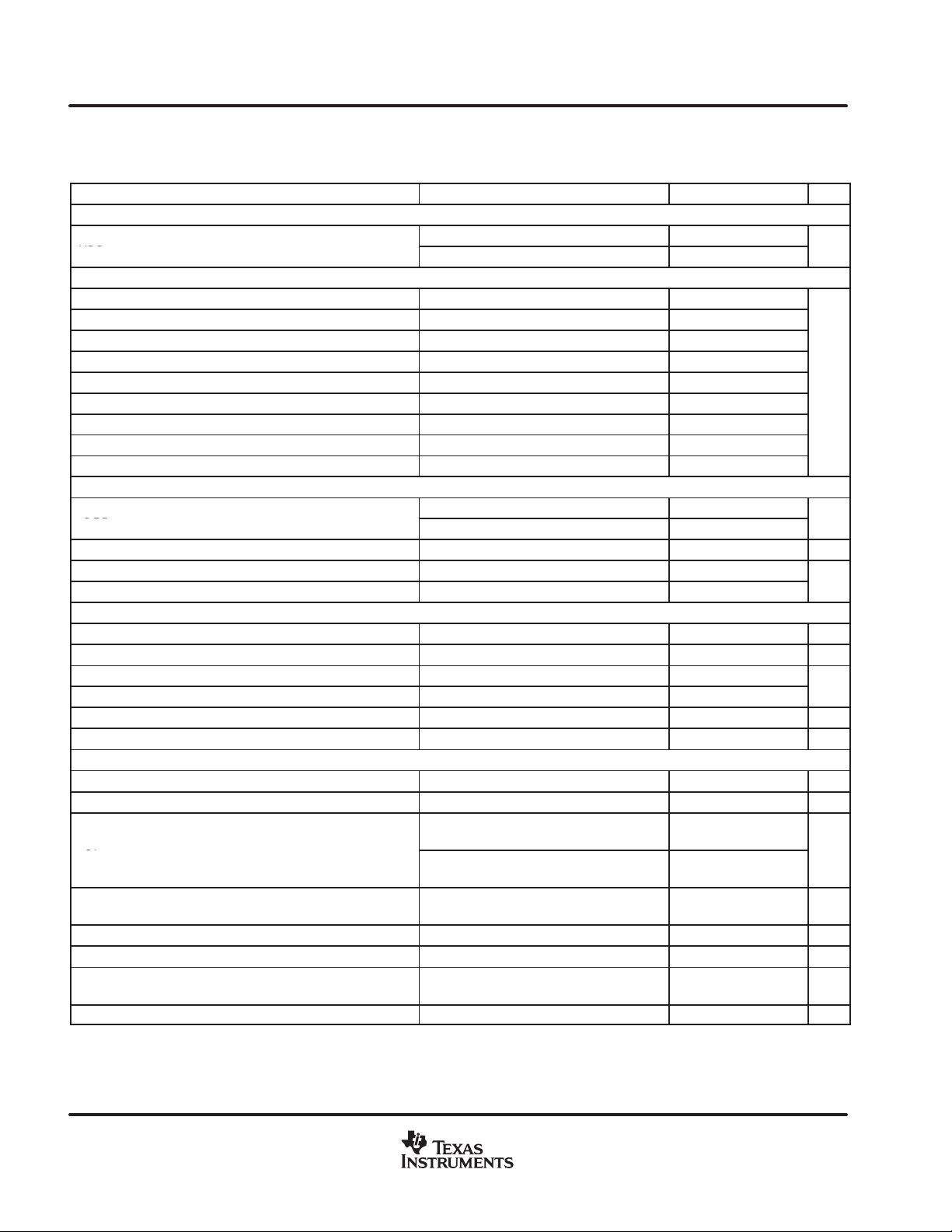

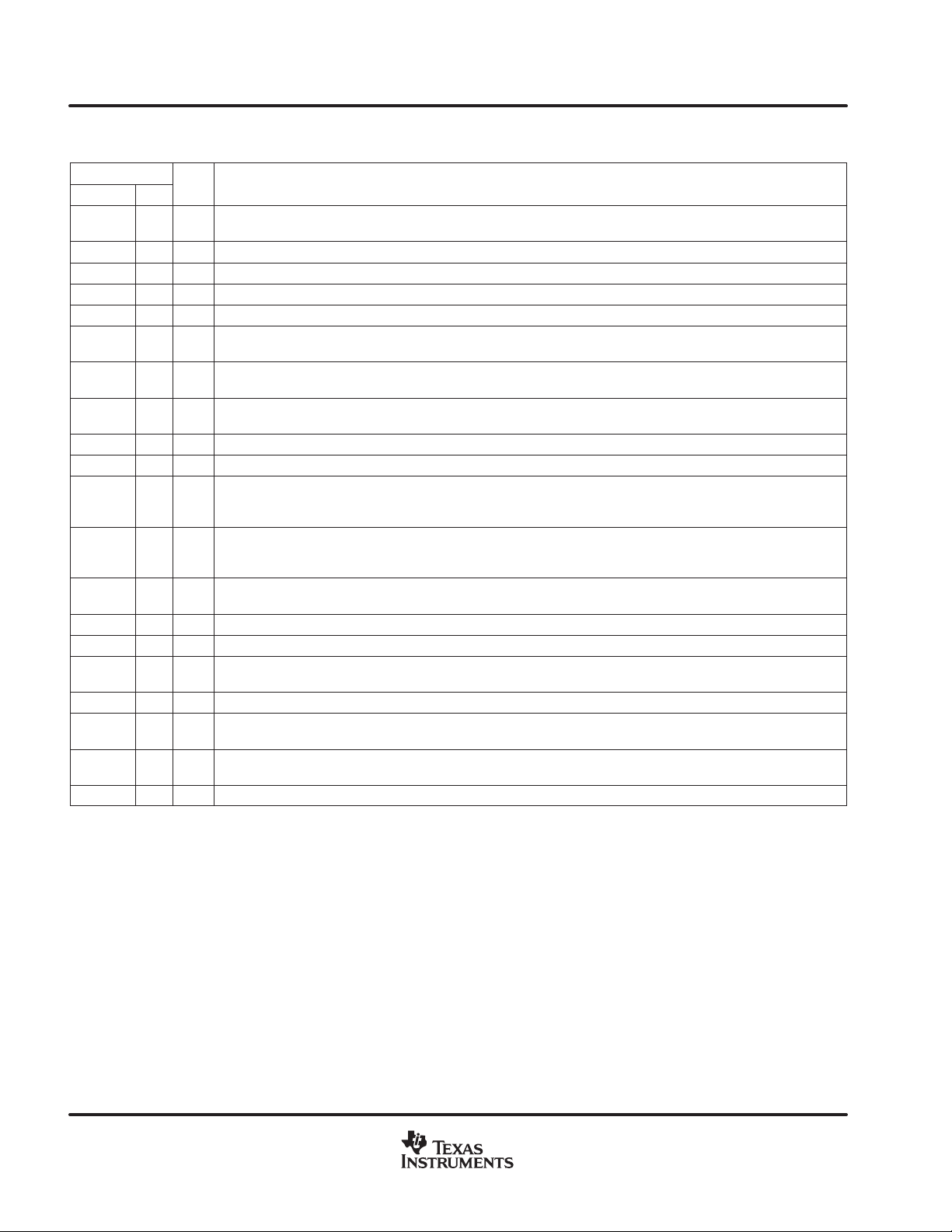

ELECTRICAL CHARACTERISTICS

VDD = 12 V, 1-µF capacitor from VDD to GND, 1-µF capacitor from BST to SW, 1-µF capacitor from REF to GND, 0.1-µF and 2.2-µF capacitors

from VDRV to PGND, C

RAMP

= 517 pF, R

= 10 kΩ, TA = TJ = −40°C to 105°C, (unless otherwise noted).

SET

PARAMETER

OVERALL

I

VDD

UNDERVOLTAGE LOCKOUT

V

VDD

V

VDD

V

VDD

V

VDRV

V

VDRV

V

VDRV

V

REF

V

REF

V

REF

VOLTAGE REFERENCE (REF)

V

REF

I

SC

OscillatorPWM (RAMP)

f

SW

D

MIN

V

RAMP

t

DEAD

I

RAMP

CURRENT ERROR AMPLIFIER

V

CEA+

GBW Gain bandwidth

V

OL

V

OH

A

VOL

I

BIAS

I

SINK

CMR Common mode input range

(3)

Ensured by design. Not production tested.

Operating current

Start threshold voltage MODE 1 8.0 8.5 9.0

Stop threshold voltage MODE 1 7.5 8.0 8.5

Hysteresis MODE 1 0.3 0.5 0.8

Start threshold voltage MODE 2 4.30 4.65 4.85

Stop threshold voltage MODE 2 4.0 4.3 4.6

Hysteresis MODE 2 0.15 0.35 0.55

Start threshold voltage MODE 3 V

Stop threshold voltage MODE 3 2.2 2.5 2.8

Hysteresis MODE 3 0.15 0.35 0.55

Reference output voltage

Short circuit current V

Line regulation 5.25 V ≤ V

Load regulation 0 mA ≤ I

Oscillator frequency 270 300 330 kHz

Minimum duty cycle 0%

Offset voltage 0.10 0.25 0.50

Oscillator peak voltage 1.7 2.0 2.3

G1 deadtime at maximum duty cycle ratio 150 175 200 ns

Ramp charge current R

Offset voltage Total variation 45 50 55 mV

(3)

Low-level output voltage

High-level output voltage

Open loop 60 100 160 dB

Bias current −200 −80 −10 nA

Sink current

(3)

TEST CONDITIONS MIN TYP MAX UNIT

DC, after G2 timeout 5 8 10

C

= 2.2 nF

LOAD

= V

VDD

VDRV

TA = 25°C 3.28 3.30 3.35

Total variation

= 0 V, TA = 25°C 10 13 20 mA

REF

≤ 7.2 V 0 1.5 15

DRV

≤ 5 mA 0 30 70

REF

= 10 kΩ −325 −300 −275 µA

RSET

I

COMP

V

VEA−

I

COMP

V

VEA−

I

COMP

V

VEA−

V

COMP

V

VEA−

= 0 A, V

= 2.0 V

= 100 µA, V

= 1 V

= 0 A, V

= 1 V

= 1.0 V, V

= 1 V

CEA−

CEA−

CEA−

CEA−

= 3.3 V,

= 1.5 V

= 0 V,

= 1.5 V,

9 18 30

2.5 2.8 3.2

3.2 3.3 3.4

3 4 MHz

0.1

0 0.60 0.90

2.2 2.5 3.0 V

0.30 0.80 1.70 mA

0 2 V

mA

V

V

mV

V

V

4

www.ti.com

Page 5

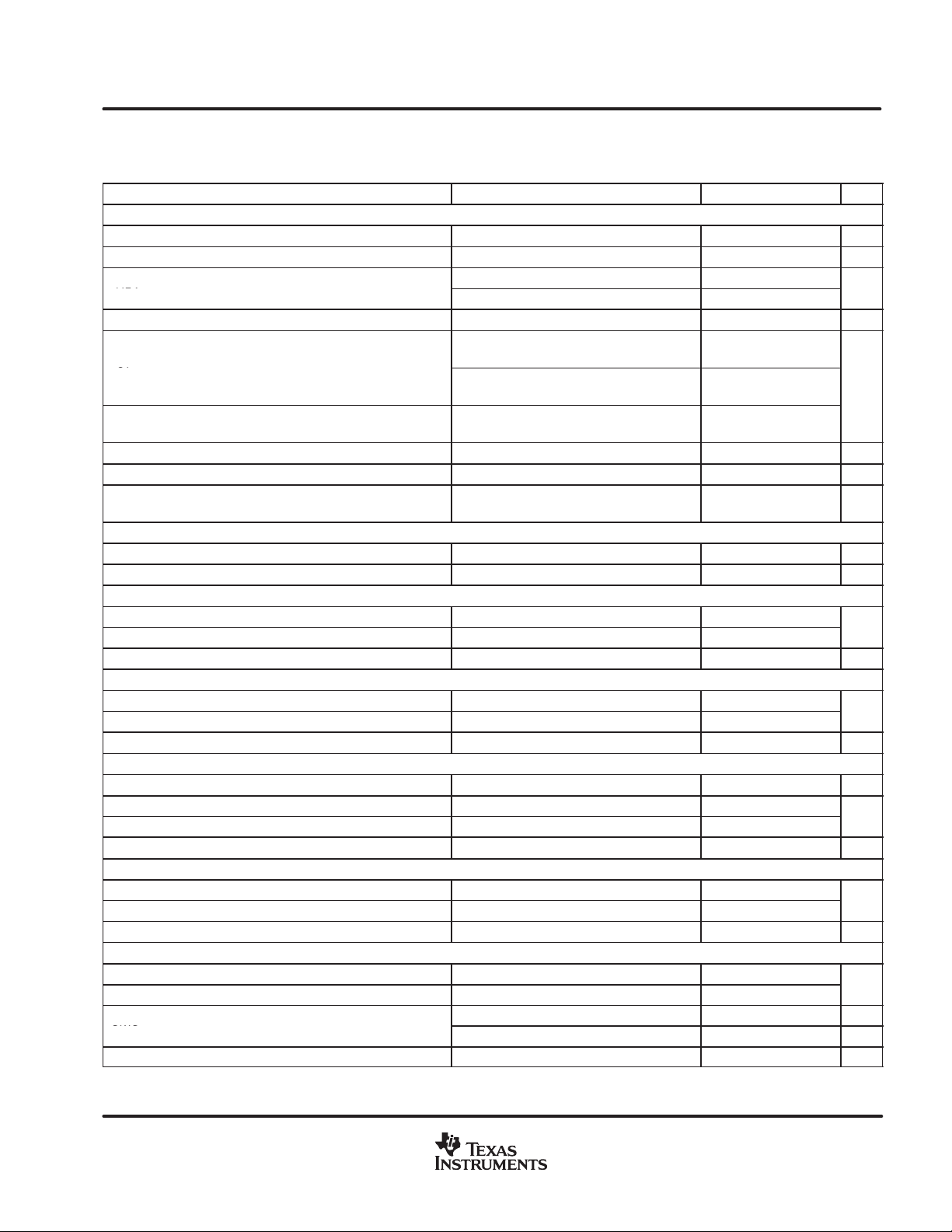

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

ELECTRICAL CHARACTERISTICS

VDD = 12 V, 1-µF capacitor from VDD to GND, 1-µF capacitor from BST to SW, 1-µF capacitor from REF to GND, 0.1-µF and 2.2-µF capacitors

from VDRV to PGND, C

RAMP

= 517 pF, R

= 10 kΩ, TA = TJ = −40°C to 105°C, (unless otherwise noted)

SET

PARAMETER

VOLTAGE ERROR AMPLIFIER

V

SS_OFF

V

TR_OFF

V

VEA+

GBW Gain bandwidth

V

OL

V

OH

A

VOL

I

BIAS

I

SINK

CURRENT SET

I

OUT

V

RSET

SYNCHRONIZATION AND SHUTDOWN TIMER (SYNCIN, G2C)

I

CHG(G2C)

SOFT-START (SS)

I

CH(SS)

I

DSCH(SS)

DRIVE REGULATOR (VDRV)

V

VDRV

I

SC

G2S GATE DRIVE SENSE

I

G2S

SWS SWITCH NODE SENSE

I

SWS

(3)

Ensured by design. Not production tested.

Offset voltage from soft-start input V

Offset voltage from tracking input VTR = 1.0 V −10 10 mV

Threshold voltage (from VEA− to COMP)

(3)

Low-level output voltage

High-level output voltage

Open loop 60 100 140 dB

Bias current −500 −250 −50 nA

Sink current

Output current R

R

voltage R

SET

Timer threshold 2.3 2.5 2.7

SYNCIN threshold 1.50 1.65 1.80

Shutdown timer charge current R

Charge current R

Discharge current R

Discharge/shutdown threshold 0.35 0.45 0.55 V

Output voltage 6.87 7.20 7.53 V

Line regulation 9 V ≤ V

Load regulation −5 mA ≤ I

Short-circuit current 15 30 50 mA

G2S rising threshold voltage V

G2S falling threshold voltage V

Current V

SWS rising threshold voltage V

SWS falling threshold voltage V

Current

Negative threshold voltage −0.5 −0.3 −0.1 V

TEST CONDITIONS MIN TYP MAX UNIT

= V

COMP

0°C ≤ TA ≤ 105°C 1.485 1.500 1.515

Total variation

I

COMP

V

VEA−

I

COMP

V

VEA−

I

COMP

V

VEA−

V

COMP

V

VEA−

RSET

RSET

RSET

RSET

RSET

SWS

SWS

G2S

G2S

G2S

V

SWS

Outputs disabled

VEA−, VSS−

= 0 A, V

= 2.0 V,

= 100 µA, V

= 1 V, VTR = 0 V

= 0 A, V

= 1 V

= 1.0 V, V

= 1.0 V, VTR = 0 V

= 10 kΩ −158 −150 −142 µA

= 10 kΩ 1.42 1.50 1.58 V

= 10 kΩ −325 −300 −275 µA

= 10 kΩ −230 −200 −170

= 10 kΩ 45 70 100

≤ 35 V 0 50 100

VDD

≤ 0 mA 0 50 100

VDRV

= 0 V 1.90 2.25 3.10

= 0 V 1.00 1.25 1.30

= 0 V −0.70 −0.50 −0.37 mA

= 0 V 1.90 2.25 2.90

= 0 V 1.0 1.2 1.3

= 0 V −1.8 −1.3 −0.9 mA

= 1.5 V 0.40 0.75 1.00 V

1.47 1.50 1.53

3 4 MHz

= 3.3 V,

CEA−

= 0 V,

CEA−

CEA−

CEA−

= 0 V

= 0 V,

0 0.60 0.9

2.2 2.5 3.0

0.30 0.80 1.70 mA

−1.0 1.0 µA

0.1

V

V

V

µA

mV

V

V

www.ti.com

5

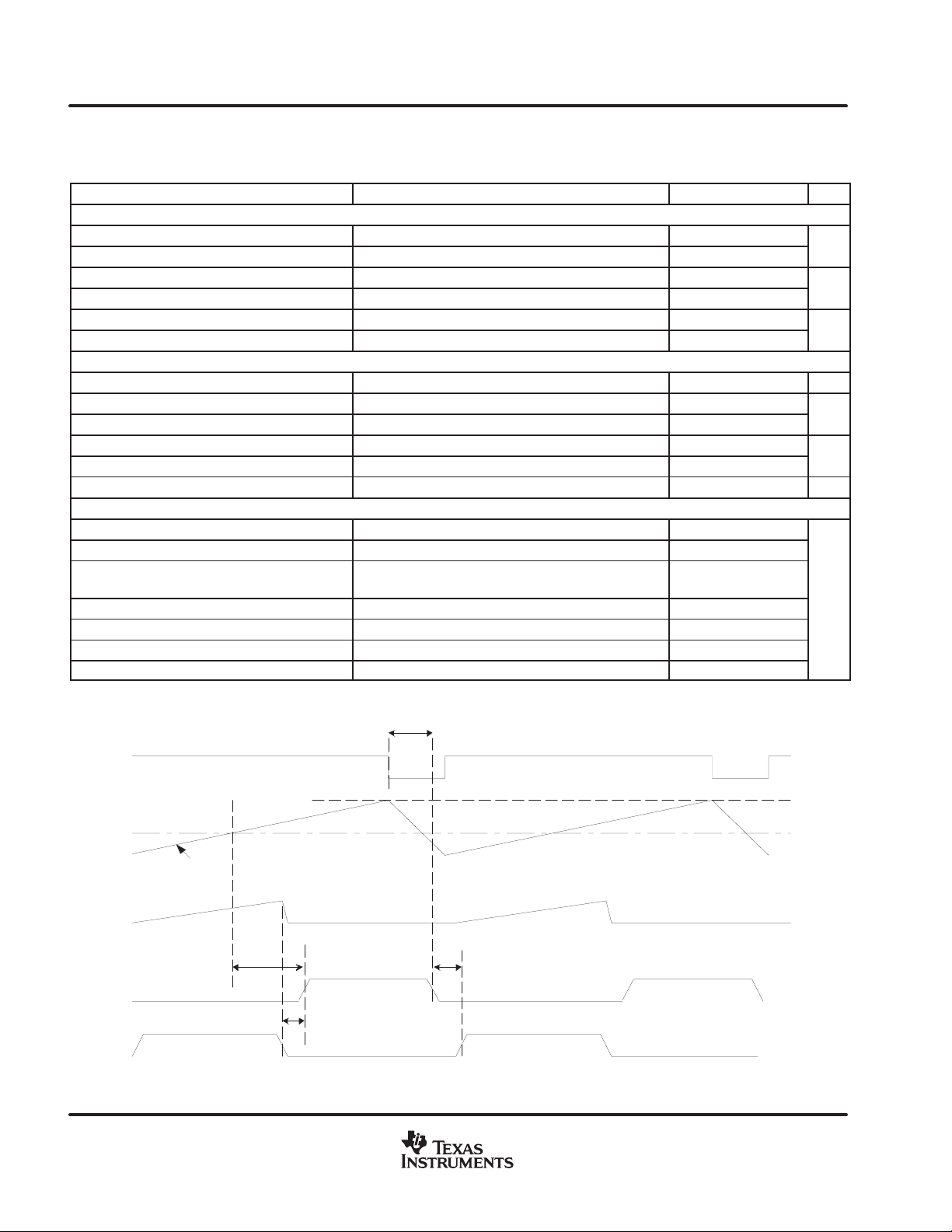

Page 6

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

ELECTRICAL CHARACTERISTICS

VDD = 12 V, 1-µF capacitor from VDD to GND, 1-µF capacitor from BST to SW, 1-µF capacitor from REF to GND, 0.1-µF and 2.2-µF capacitors

from VDRV to PGND, C

RAMP

= 517 pF, R

= 10 kΩ, TA = TJ = −40°C to 105°C, (unless otherwise noted)

SET

PARAMETER

G1 MAIN OUTPUT

R

SINK

R

SRC

I

SINK

I

SRCE

t

RISE

t

FALL

G2 SYNCHRONOUS RECTIFIER OUTPUT

R

SINK

I

SINK

I

SRC

t

RISE

t

FALL

V

OH

DEADTIME DELAY (see Figure 1)

t

ON(G1)

t

OFF(G1)

t

ON(G2)

t

OFF(G2)

t

ON(G2)

t

ON(G2)

t

OFF(G2)

t

OFF(G2)

(3)

Ensured by design. Not production tested.

Sink resistance VSW = 0 V, V

Source resistance VSW = 0 V, V

Sink current

Source current

Rise time C

Fall time C

Sink resistance VG2 = 0.3 V 5 15 30 Ω

Sink current

Source current

Rise time C

Fall time C

High-level output voltage, G2 VSW = GND 6.2 6.7 7.5 V

RAMP rising to G1 rising 90 115 130

SYNCIN falling to G1 falling 50 70 90

Delay control resolution 3.5 5.0 6.5

G2 on-time minimum wrt G1 falling −24

G2 on-time maximum wrt G1 falling 62

G2 off-time minimum wrt G1 rising −68

G2 off-time maximum wrt G1 rising 10

(3)

(3)

(3)

(3)

TEST CONDITIONS MIN TYP MAX UNIT

= 6 V, VG1 = 0.3 V 0.3 0.7 1.3

BST

= 6 V, VG1 = 5.7 V 10 25 45

BST

VSW = 0 V, V

VSW = 0 V, V

= 2.2 nF, from G1 to SW 12 25

LOAD

= 2.2 nF, from G1 to SW 12 25

LOAD

VG2 = 3.25 V 3

VG2 = 3.25 V −3

= 2.2 nF, from G2 to PGND 12 25

LOAD

= 2.2 nF, from G2 to PGND 12 25

LOAD

t

OFF,G1

= 6 V, VG1 = 3.0 V 3

BST

= 6 V, VG1 = 3.0 V −3

BST

Ω

A

ns

A

ns

ns

CLK

2.0V

V

ERR

RAMP

G2C

G1

G2

t

ON,G1

t

OFF,G2

t

ON,G2

Figure 1. Predictive Gate Drive Timing Diagram

6

www.ti.com

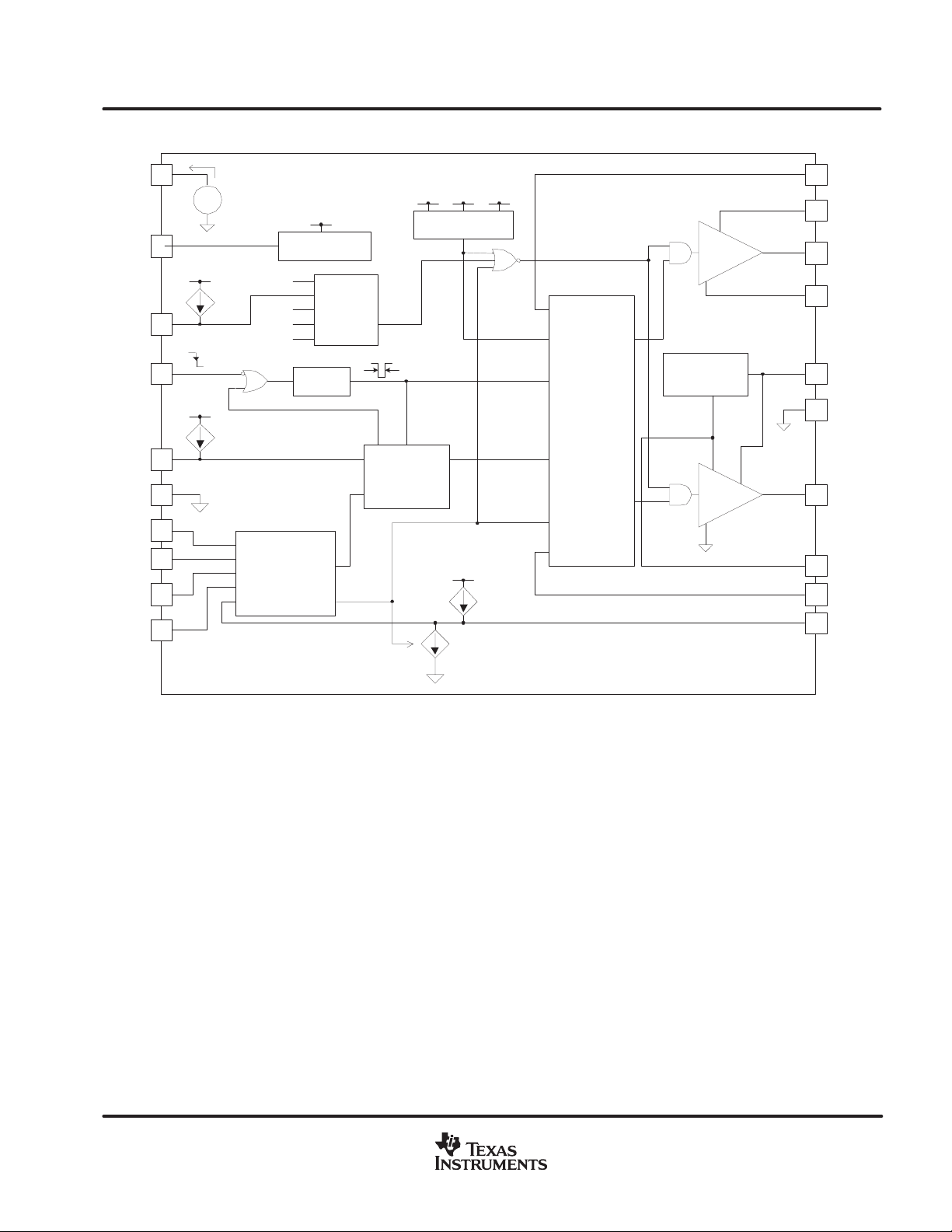

Page 7

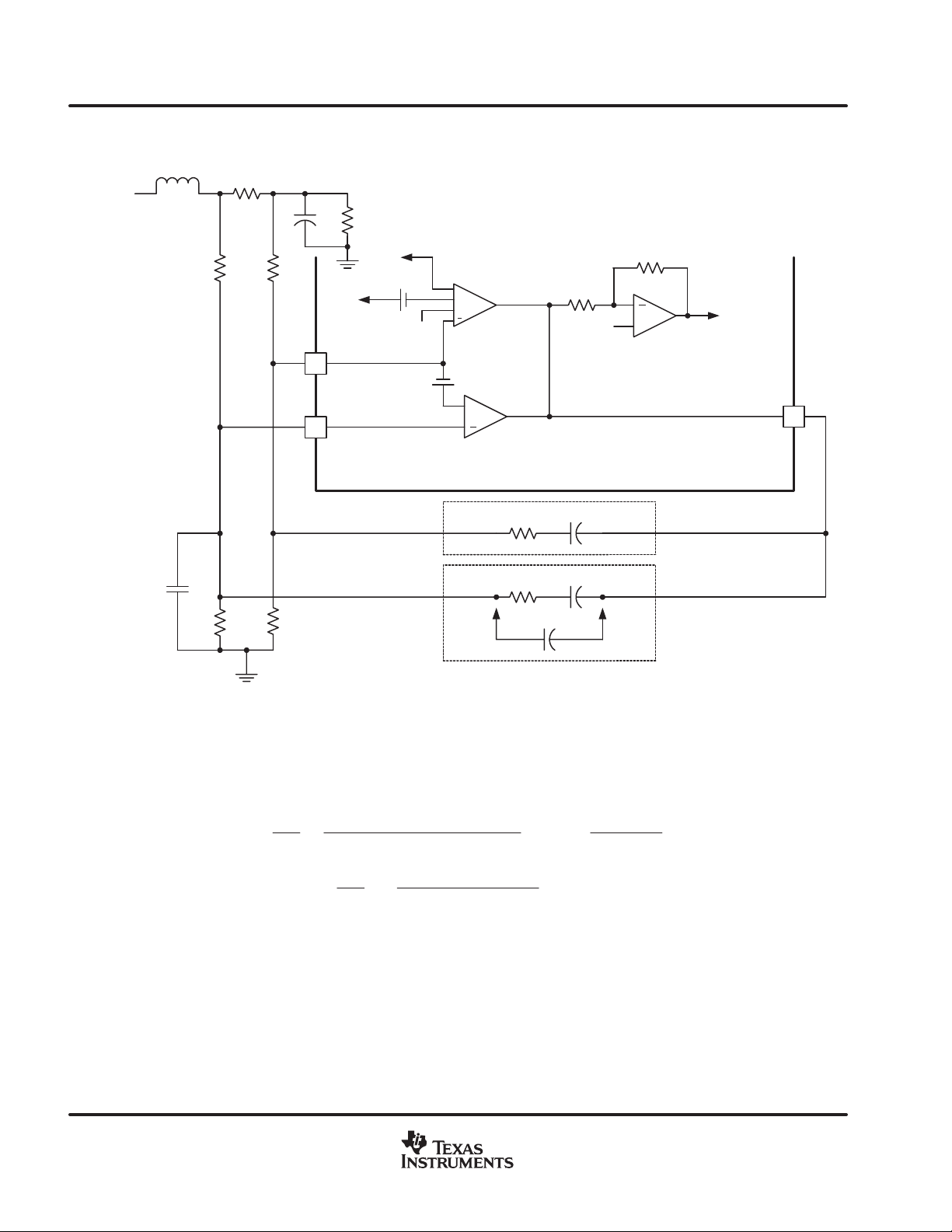

FUNCTIONAL BLOCK DIAGRAM

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

RSET

REF

G2C

SYNCIN

RAMP

GND

VEA−

CEA−

COMP

TR

10

1

2

3

4

5

6

7

8

9

+

−

VREF

VREF

I

SET

1.5V

VREF

2 I

SET

2 I

SET

AMPLIFIERS

FAULT LOGIC

REFERENCE

G1D

GLO

G2

UVLO

ERROR

AND

V

DRV

G2 TIMER

CLK

GEN

RAMP

VERR

G2TO

OSCILLATOR

PWM LOGIC

HUP

100ns

RAMP

&

VREF

UVLO

CLK

VREF

1.73 I

VDDVDRV

1.33 I

SET

UVLO

PWM

SET

GLO

PREDICTIVE

LOGIC

PWR

G1D

DRIVE

REGULATOR

BIAS

PWR

PGND

HIGH SIDE

DRIVER

PGND

LOW SIDE

DRIVER

20

19

18

17

16

15

14

13

12

11

SWS

BST

G1

SW

VDD

PGND

G2

VDRV

G2S

SS

www.ti.com

7

Page 8

I/O

DESCRIPTION

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

PIN ASSIGNMENTS

TERMINAL

NAME NO.

BST 19 I

CEA− 8 I Inverting input of the current error amplifier used for output current regulation.

COMP 9 I Output of the voltage and current error amplifiers for compensation.

G1 18 O High-side gate driver output that swings between SW and BST.

G2 14 O Low-side gate driver output that swings between PGND and VDRV.

G2C 3 I

G2S 12 I

GND 6 −

PGND 15 − Ground return for the G2 driver. Connect PGND to the pc-board ground plane with several vias.

RAMP 5 I Input pin to connect timing capacitor to GND to generate the oscillator PWM ramp.

(1)

REF

RSET 1 I

SS 11 I

SYNCIN 4 I Input pin for timing signal. Tie to logic high (V

SW 17 − G1 driver return connection.

SWS 20 I

TR 10 I Tracking input to the voltage error amplifier. Connect to REF when not used.

VDD 16 I

VDRV 13 I

VEA− 7 I Inverting input of the voltage error amplifier used for output voltage regulation.

(1)

REF is an input in Mode 3 only.

2 I/O

Floating G1 driver supply pin. VHI is fed by an external Schottky diode during the SR MOSFET on time. Bypass

BST to SW with an external capacitor.

Timer pin to turn off synchronous rectifier. The capacitor connected to this pin programs the maximum duration

that G2 is allowed to stay HIGH.

Used by the predictive deadtime controller for sensing the SR MOSFET gate voltage to set the appropriate deadtime.

Ground for internal circuitry. GND and PGND should be tied together under the device. See layout guidelines for

further details.

3.3-V reference pin. All analog control circuits are powered from this 3.3-V rail. Bypass this pin with at least 0.1

µF of capacitance for REF loads that are 0 mA to −1 mA. Bypass this pin with at least 1 µF of capacitance if it is

used as an input (Mode 3) or if it has large or pulsating loads.

Pin to program timer currents for G2C, RAMP, SS charge and SS discharge. This pin generates a current proportional to the value of the external resistor connected from RSET pin to GND. RSET range is 10 kΩ to 50 kΩ (giving a programmable nominal ISET range of 30 µA to 150 µA, respectively).

Soft start and shutdown pin. Connect a capacitor to GND to set the soft-start time. Add switch to GND for immediate shutdown functionality.

) when not used.

REF

Used by the predictive controller to sense SR body-diode conduction. Connect to SR MOSFET drain close to the

MOSFET package.

Power supply pin to the device and input to the internal VDRV drive regulator. Normal VDD range is from 4.5 V to

36 V. Bypass the pin with at least 1 µF of capacitance.

Output of the drive regulator and power supply pin for the G2 driver. VDRV is also the supply voltage for the internal logic and control circuitry.

8

www.ti.com

Page 9

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

The UCC2541 is a high-efficiency synchronous buck controller that can be used in many point-of-load

applications.

CEA− and VEA− pins: Current Limit and Hiccup Mode

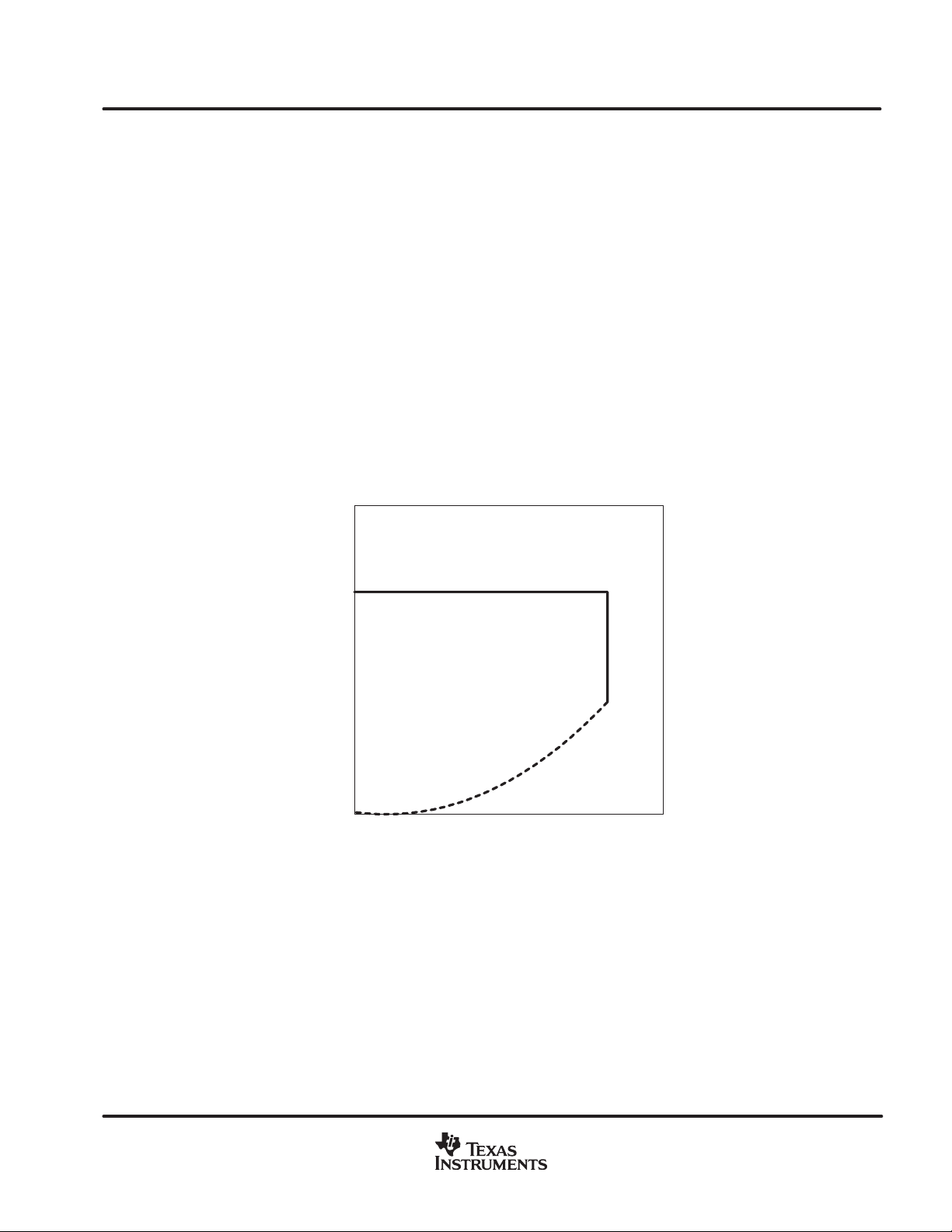

Typical power supply load voltage versus load current is shown in Figure 2. This figure shows steady state

operation for no-load to overcurrent shutdown (soft-start retry is not depicted in the diagram). During the voltage

regulation conditions, the voltage error amplifier output is lower than the current error amplifier, allowing the

voltage error amplifier to control operation. During the current limit conditions, the current error amplifier output

is lower than the voltage error amplifier, allowing the current error amplifier to control operation. The boundary

between voltage and current control occurs when the difference between CEA− and VEA− tries to exceed

50 mV.

Current limiting begins to occur when the difference between CEA− and VEA− exceeds 50 mV. For currents

that exceed this operating condition, the UCC2541 controls the converter to operate as a pure current source

until the output voltage falls to half of its rated steady state level. Then the UCC2541 sets both G1 and G2 outputs

to LOW and it latches a fault that discharges the soft-start voltage at 30% of its charging rate. The UCC2541

inhibits a retry until the soft-start voltage falls below 0.5 V. A functional diagram of the voltage and current error

amplifiers is shown in Figure 3.

V

REG

Limited

Current

− Load Voltage − V

LOAD

V

Shutdown

I

− Load Current − A

LOAD

Figure 2. Typical Power Supply Load Voltage vs Current

UDG−04053

www.ti.com

9

Page 10

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

From Power MOSFET

Switch Node

CST

R

S

R

SS

LOAD

TR

0.7 V

+

1.5 V

+

+

+

+

50 mV

+

Z

FV

Z

IV

Voltage

Error

Amplifier

Current

Error

Amplifier

R

FV

R

FI

R

C

C

1.5 V

FV

FI

ZFV

1.5 R

+

Inverting

Amplifier

V

ERR

Modulator

COMP

UCC2541

to

9

C

R

R

I1

V1

VEA−

7

CEA−

8

C

R

I2

R

V2

FIR

ZIV

Figure 3. Error Amplifier Configuration

Component selection includes setting the voltage regulation threshold, then the current limit threshold, as

described below.

Voltage vs. Current Programming (refer to Figure 3):

R

1. Determine the ratio

2. Sense resistor

V

offset = 50 mV (typ).

CEA+

V1

R

V2

+

R

S

3. Arbitrarily select either R

V

+

V

VEA*

R

ǒ

V1

1 )

R

V2

or RV2 so that the smallest of the two resistors is between 6.5 kΩ and 20 kΩ.

V1

LOAD(reg)

) Threshold Voltage

V

Ǔ

offset voltage

CEA)

I

S(max)

* 1V+

, where I

V

LOAD(reg)

1.5 V (typ)

S(max)

* 1V

is the current limit level,

Then calculate the value of the other resistor using the equation in the first step.

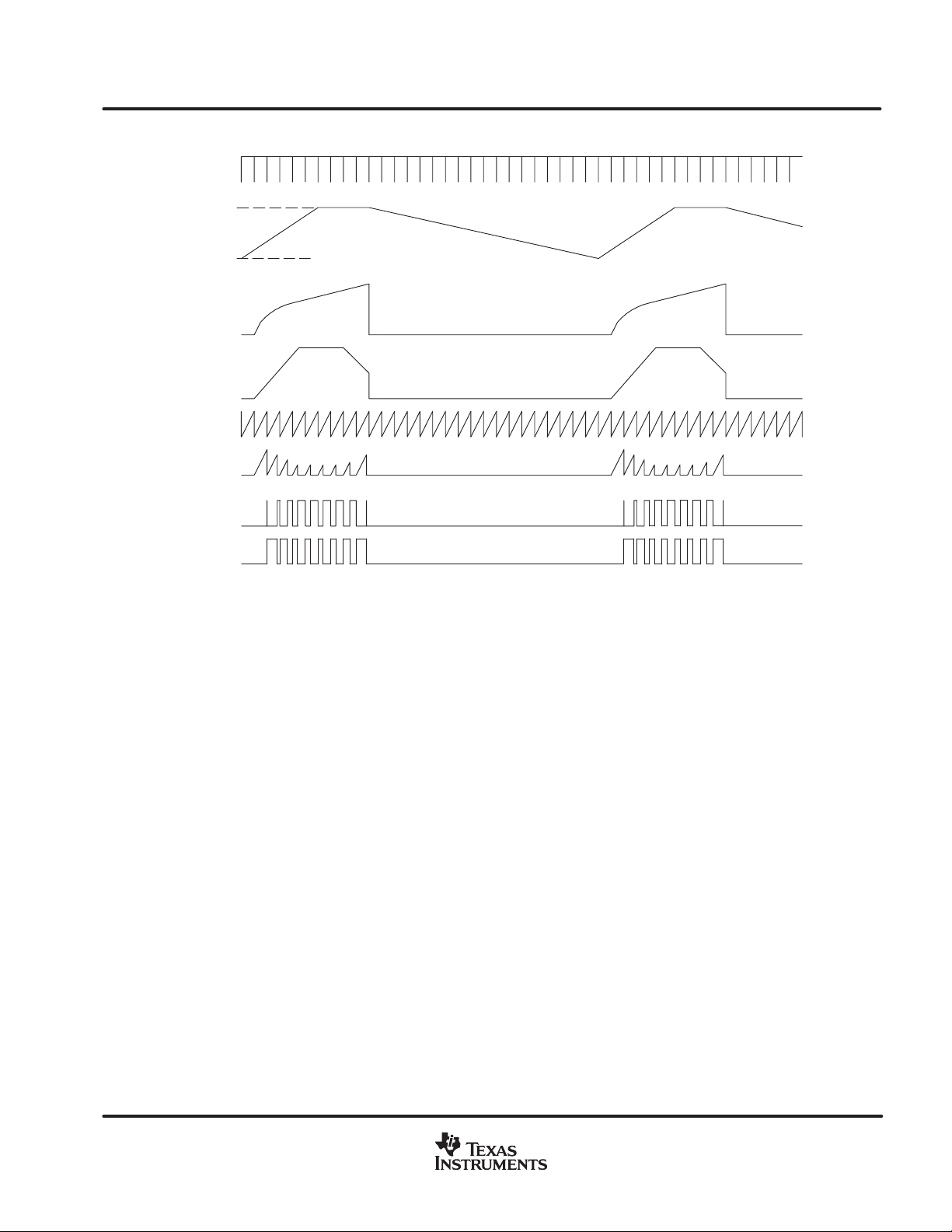

If the converter is in a current-limit condition and the output voltage falls below half of the regulated output

voltage, the UCC2541 enters into a hiccup (restart-retry) mode. Figure 4 shows typical signals during hiccup

mode.

10

www.ti.com

Page 11

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

SYNCIN

3.3 V

SS

0.5 V

I

LOAD

V

LOAD

RAMP

G2C

G1

G2

Figure 4. Typical Hiccup Mode waveforms

COMP, VEA− and CEA− pins: Voltage and Current Error Amplifiers

From no-load to full rated load operating conditions, the UCC2541 operates as a voltage mode controller . Above

the programmed rated current, there are two levels of over current protection; constant current limit and

overcurrent reset/retry. This section gives suggestions on how to design the voltage controller and current

controller so that they interact with one another in a stable fashion. Refer to the functional diagram of the voltage

and current error amplifiers in Figure 3. The voltage error amplifier in the figure shows three non-inverting inputs.

The lowest of the three non-inverting inputs (1.5 V, SS and TR) is summed with the inverting input to achieve

the voltage error signal. The lowest of the two outputs drives the inverting stage which in turn, drives the

modulator.

During steady state voltage control operation, the feedback elements in the current loop have no effect on the

loop stability. When current limit occurs, the voltage error amplifier effectively shuts OFF and the current error

amplifier takes control. During steady state current limit operation, the negative feedback elements in the

voltage error amplifier loop become positive feedback elements in the current error amplifier loop. In order for

the current error amplifier to be stable, the impedances in the feedback path of the current error amplifier must

be lower than the impedances in the feedback path of the voltage error amplifier. This means that resistors in

the current error amplifier negative feedback path must be less than the resistors in the voltage error amplifier

negative feedback path. Also capacitors in the current error amplifier negative feedback path must be larger

than capacitors in the negative feedback path of the voltage error amplifier negative feedback path.

(Capacitance is really an admittance value rather than an impedance value). This concept is illustrated in

Figure 3.

UDG−04046

In order for the current loop to be stable in Figure 3, ||Z

can be achieved if R

< RFV and C

FI

FI

> CFV.

www.ti.com

|| must be less than ||ZFV|| over all frequencies. This

IV

11

Page 12

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

Another issue that can occur during current limit operation is modulator stability. In order for the modulator to

be stable, the rising slope of the current ripple measured at the COMP pin must be smaller than the rising slope

that is measured at the RAMP pin. This can be met either in the selection of the ratio of ||Z

the addition of a capacitor in parallel to R

In some applications, this current and voltage error amplifier configuration may lead to difficulties with startup

at turn on and with restarting after current limit hiccup operation. A small capacitor from CEA− to ground can

filter this node to alleviate this issue. This capacitor is shown as C

Stable Dynamic Current Loop Design (refer to Figure 3):

1. Using any favorite approach, design the voltage error amplifier for stable voltage mode design. Use at least

15 kΩ for any resistors in the negative feedback path of the voltage error amplifier (between pins 9 and 7).

This does not apply to resistance values between the power supply output voltage and pin 7; it also does

not apply to resistance values between ground and pin 7.

2. The goal is to design the current limit control loop so that it drives the converter to maintain 50 mV between

the VEA− pin and the CEA− pin during current-limit conditions. Select the current sense element and the

voltage divider ratios for the VEA− pin to ground and the CEA− pin to ground to provide the desired current

limit level.

and CFI, such as C

FI

, in Figure 3.

FIR

in Figure 3.

ST

|| to ||ZFV||, or by

IV

3. Place the same configuration of components in the negative feedback path of the current error amplifier

(between pins 9 and 8), that are in the negative feedback path of the voltage error amplifier (between pins

9 and 7). However, use resistors with values that are 67% of the corresponding resistors that are between

pins 9 and 7 and use capacitors that are 150% of the corresponding capacitors that are between pin 9 and

pin 7.

4. Check the COMP signal. If it is unstable, place a capacitor (or increase the capacitance) between pins 9

and 8 in order to attenuate the current ripple. Raise the value of the capacitor until the COMP pin voltage

becomes stable. Compare the COMP voltage with the RAMP voltage. With stable operation, the rising slope

of the COMP voltage ripple is less than the rising slope of the RAMP pin.

12

www.ti.com

Page 13

(1)

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

RSET, RAMP, G2C, SS pins: Programming the Timer Currents

Set the base current to the timers with a resistor between RSET and GND. The block diagram of the UCC2541

shows the interaction of the RSET pin and the dependent current sources for the RAMP, G2C and SS features.

The RSET pin is a voltage source; the current of the RSET pin is reflected and multiplied by a gain and distributed

to the RAMP (gain = 2), G2C (gain = 2) and SS (charge gain = 1.33, net discharge gain = 0.4). The resistance

applied to the RSET pin and GND should be in the range of 10 kΩ < R

are programmed by the selection of capacitors tied between each of their respective pins and GND.

G2C pin: G2 Timer for Output Stage Reverse Current Protection

3

G2C

2 y I

RSET

2.5 V

G2 Timeout

Comparator

+

*G1D

< 50 kΩ. RAMP, G2C and SS timers

RSET

G2C

Latch

SQ

R

Q

D

G2TO

C

G2C

GLO

G2

UVLO

*G1 with delay, but not blanked

UDG−04047

Figure 5. Functional diagram of the G2 Timer

The G2C pin programs the maximum duration of the synchronous rectifier to facilitate low or zero duty ratio

operation. Figure 5 shows the functional diagram. This function is programmed by connecting a capacitor

between the G2C pin and GND. The capacitor on G2C should be slightly larger than the capacitor on the RAMP

pin. For best results, program the typical G2 time limit to be between 1.5 and 3 times the switching period (T).

Notice that when the G2 timer reaches its limit, both G1 and G2 are forced to a LOW output. This feature

prevents the current in the output inductor from excessive negative excursions during zero-duty ratio conditions.

Program the G2 time-out (G2TO) duration using equation (1):

C

G2C

+

2 V

R

RSET

RSET

G2 Timeout Duration

G2C Timer Threshold

, Farads

where

D V

D 1.5 T < G2 Timeout Duration < 3T

RSET

= 1.5 V(typ)

S

D G2C Timer Threshold = 2.5 V (typ)

www.ti.com

13

Page 14

(2)

(3)

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

RAMP pin: Oscillator and PWM Ramp

The RAMP pin serves two purposes: (1) a capacitor on this pin sets the oscillator charging time to program the

frequency of operation for the converter and (2) the peak voltage on RAMP defines the gain of the PWM

modulator. The UCC2541 has a leading edge modulator that compares the error output with the RAMP voltage.

A diagram of the oscillator and PWM modulator is shown in Figure 6.

The current charging the capacitor from RAMP to ground is equal to 2 x I

edge modulation, a switching cycle can be considered to begin when the oscillator ramp reaches 2.0 V. This

voltage level triggers the negative-going clock signal which enables the RAMP discharge transistor and

simultaneously sends a G1 turn-off command to the PWM control. The internal clock signal is held low for

approximately 100 ns, and this sets the maximum desired value for the capacitor on the RAMP pin. Note that

the RAMP discharge transistor must also sink 2 x I

2 y I

RSET

5

RAMP

ENA

CLK

CLK

Figure 6. Oscillator and PWM Modulator

The oscillator frequency is programmed by proper selection of the resistor connected to RSET (pin 1) and the

capacitor connected to RAMP (pin 5). With RSET selected within the preferred range of 10 kΩ to 50 kΩ the

RAMP capacitor C

can be selected from:

RAMP

GEN

V

ERR

2.0 V

while it is discharging the external RAMP capacitor.

RSET

PWM

COMPARATOR

0.25V

+

OSC RAMP

COMPARATOR

+

−

4

SYNCIN

PWM

LATCH

−

S

+

Q

R

Q

D

. In the UCC2541, with leading

RSET

PWM

1

ǒ

1.5

RAMP

I

RAMP

I

RSET

+

Ǔ

ǒ

V

V

RAMP(pk)

C

where fsw is the desired switching frequency, and R

derived by summing the time required for a linear current source to change the RAMP capaitor with the internal

delay of approximately 100 ns. The constant term 1.5 is equal to:

ǒ

14

f

SW

RSET

* 100 ns

R

SET

Ǔ

Ǔ

is the resistor connected to pin 1. This expression is

SET

www.ti.com

Page 15

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

The UCC2541 can be synchronized to an external source if an external SYNCIN signal (falling edge) is applied

to pin 4 before the oscillator reaches 2.0 V. The internal circuitry uses the falling edge on SYNCIN to generate

the 100-ns internal clock signal and turn off G1. The free-running frequency programmed by the internal

oscillator/RAMP capacitor should be approximately 20% lower than an intended external sync frequency. The

SYNCIN pin should be tied to V

900

800

if not used.

REF

OSCILLATOR FREQUENCY

vs

TIMING RESISTOR

700

600

500

400

300

− Oscillator Frequency − kHz

200

SW

f

100

0

10 20 30 40 50

150 pF

680 pF

V

VDD

270 pF

390 pF

− Timing Resistor − kΩ

Figure 7

VDD, VDRV, VREF and BST pins: Modes of Operation

Depending on the available bias voltage for the UCC2541, the startup, shutdown, and restart conditions are

different. There are three distinct configurations or modes of biasing the UCC2541. The mode is detected and

latched into an internal register during power-up when VREF crosses 2 V. The register is cleared when VDD,

VDRV and VREF are simultaneously less than 1 V. A summary of the modes and their programming

requirements are listed in Table 1.

Table 1. Modes and Programming Requirements

V

Mode

1 8.5 to 36 VDD [16] V

2 4.75 to 8.5 VDRV [13] V

3 3.0 to 3.6 VREF [2] V

BIAS

Range (V)

Bias Pin

UVLO ON

(V)

= 8.5 V

VDD

= 4.65 V

VDRV

= 2.8 V

REF

UVLO OFF

(V)

= 8.0

VDD

= 4.3

VDRV

= 2.5

REF

www.ti.com

Mode Requirement

at Power-Up and

V

VREF

VDD

VDRV

REF

ǒ

u

V

VDRV

ǒ

u

V

VDD

ǒ

u

V

VDD

V

V

V

= 2 V

and V

and V

and V

REF

REF

VDRV

Remarks

Ǔ

Widest line operation

Ǔ

Needs regulated bias and low

Ǔ

VTH power MOSFETs

15

Page 16

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

VDD, VDRV, VREF and BST pins: Modes of Operation (cont.)

D Mode 1, or normal operation requires the availability of a bias of 8.5 V or higher for the device. Here, the

bias drives the VDD pin. The low-side drive bias, V

and it directly draws current from the VDD pin. The high-side driver bias is a flying capacitor that is charged

from the VDRV pin through the G2 pin, when G2 is HI, via a diode between G2 and BST. The UCC2541

operates in Mode 1 if V

range of bias voltages, operational from 8.5 V < V

have a 12 V

bias supply already available.

DC

VDD

> (V

VDRV

and V

VREF

D Mode 2 is suitable for applications where the bias is typically 5 V (between 4.5 V and 8.0 V). The bias

voltage is applied to the VDRV terminal of the UCC2541. The high-side driver bias is a flying capacitor that

is charged from the VDRV pin through the G2 pin, when G2 is HI. Bias voltage to the VDD pin is obtained

through an external voltage-doubler charge pump. If the system uses low threshold voltage power

MOSFETs, VDD can be directly tied to the VDRV pin. The bias voltage could be either a bus converter output

or an auxiliary supply.

D Mode 3 is for synchronous buck converter applications where the bias voltage is a regulated 3.3-V source.

This is a common main output voltage in multiple output power converters. The bias voltage is applied to

the VREF pin of the UCC2541. The UCC2541 operates in Mode 3 if it detects (V

when V

Assorted combinations of modes and biasing schemes are shown in Figure 7 through Figure 12. In Mode 1 and

Mode 2, the bias voltage can either be an independent auxiliary supply or it can be supplied by the power stage

voltage, as shown in Figure 7 through Figure 11. A regulated auxiliary supply must be used with Mode 3 because

the tolerance of the VREF voltage is the control tolerance of the UCC2541. In Mode 3, the regulated auxiliary

supply can be independent of the power supply input voltage (as shown in Figure 12), or the regulated auxiliary

supply can be the same source as the power supply input voltage.

rises above 2 V.

VREF

= 7 V, is generated from an internal linear regulator

VDRV

) when V

< 35 V. This mode is compatible with systems that

VDD

rises above 2 V. Mode 1 permits the widest

VREF

> V

VREF

VDRV

and VDD)

16

www.ti.com

Page 17

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

UCC2541

Predictive

Logic

Drive (7.2 V)

Regulator

VREF (3.3 V)

Regulator

High−Side

Driver

Low−Side

Driver

VDD

VDRV

VREF

BST

G1

SWS

SW

G2

G2S

PGND

16

13

19

18

20

17

14

12

15

2

C2 C3 C4

C1

D1

8.5 V ≤ V

Q1

Q2

VDD

≤ 35 V

Figure 8. Mode 1 With Combined Power/Bias for Input Voltages Between 8.5 V and 35 V

UCC2541

Predictive

Logic

Drive (7.2 V)

Regulator

VREF (3.3 V)

Regulator

High−Side

Driver

Low−Side

Driver

VDD

VDRV

VREF

BST

G1

SWS

SW

G2

G2S

PGND

16

13

19

18

20

17

14

12

15

2

C2 C3 C4

C1

D1

AUX Bias

8.5 V ≤ V

≤ 35 V

VDD

0 V ≤ VIN ≤ 35 V

Q1

Q2

UDG−04038

UDG−04039

Figure 9. Mode 1 With Separate Power/ Bias Voltages Between 8.5 V and 35 V

www.ti.com

17

Page 18

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

UCC2541

Predictive

Logic

Drive (7.2 V)

Regulator

VREF (3.3 V)

Regulator

High−Side

Driver

Low−Side

Driver

VDD

VDRV

VREF

BST

G1

SWS

SW

G2

G2S

PGND

16

13

19

18

20

17

14

12

15

D2

D4

2

C2 C3 C4

C1

D1

C5

4.75 V ≤ V

D3

Q1

Q2

Bias and Power

≤ 8.0 V

VDRV

Figure 10. Mode 2 With Common Bias and Power Input Voltages Between 4.75 V and 8.0 V

AUX BiasUCC2541

4.75 V ≤ V

0 V ≤ VIN ≤ 35 V

Q1

Q2

VDRV

≤ 8.0 V

Predictive

Logic

Drive (7.2 V)

Regulator

VREF (3.3 V)

Regulator

High−Side

Driver

Low−Side

Driver

VDD

VDRV

VREF

BST

G1

SWS

SW

G2

G2S

PGND

16

13

19

18

20

17

14

12

15

D2

D4

D3

2

C2 C3 C4

C1

D1

C5

UDG−04040

UDG−04041

18

Figure 11. Mode 2 With Separate Power/ Bias (4.75 V and 8.0 V)

www.ti.com

Page 19

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

UCC2541

Predictive

Logic

Drive (7.2 V)

Regulator

VREF (3.3 V)

Regulator

High−Side

Driver

Low−Side

Driver

VDD

VDRV

VREF

BST

G1

SWS

SW

G2

G2S

PGND

16

13

19

18

20

17

14

12

15

2

C2 C3 C4

C1

D1

AUX Bias

4.75 V ≤ V

≤ 8.0 V

VDRV

0 V ≤ VIN ≤ 35 V

Q1

(Low VTH)

Q2

(Low VTH)

UDG−04042

Figure 12. Mode 2 With Auxiliary Biasing for Bias Voltages Between 4.75 V and 8.0 V and Logic Level or

Low Threshold Power MOSFET Transistors

UCC2541

Predictive

Logic

Drive (7.2 V)

Regulator

VREF (3.3 V)

Regulator

High−Side

Driver

Low−Side

Driver

VDD

VDRV

VREF

BST

G1

SWS

SW

G2

G2S

PGND

16

13

19

18

20

17

14

12

15

2

C2 C4

C1

D1

C5

Regulated 3.3-VDC Bias

D3D2

DC or Pulse Train

1.8 V ≤ VIN ≤ 5 V

Q1

(Low VTH)

Q2

(Low VTH)

Figure 13. Mode 3 With Regulated 3.3-VDC Bias, Low Threshold Power MOSFETs

www.ti.com

UDG−04043

19

Page 20

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

Figure 14 illustrates a combined operational mode (referred to as Mode 4) which allows a converter operating

from intermediate bus voltages ranging from 6 V to >14 V to safely cross the boundary between Mode 1 and

Mode 2 operation. A simple circuit utilizing an NPN transistor , zener diode, and resistor allows the circuit to start

under the control of Mode 2 UVLO thresholds. Once the power stage is operational VDD is pumped up by D2

and D3 and the internal VDRV regulator raises VDRV to 7.2 V, shutting off the NPN transitor. The zener clamp

on the NPN base prevents VDRV voltage rating from being exceeded during 12-V startup. It should be noted

the circuit will run down to input voltages below 3.5 V, shutting o ff when VDRV has fallen to its turn-off threshold

of 4.3 V.

D2 D3

1

2

3

4

5

6

7

8

UCC2541

RSET

REF

G2C

SYNCIN

RAMP

GND

VEA−

CEA−

SWS

BST

G1

SW

VDD

PGND

G2

VDRV

20

19

18

17

16

15

14

13

D1

6.2V

5k

VIN = 6−14V

VOUT

20

10

9

COMP

TR

G2S

SS

12

11

Figure 14. Mode 4 Operation

www.ti.com

Page 21

(4)

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

Charge Pump Capacitor Selection

Capacitors C1 through C5 are all part of a charge distribution network that allows the UCC2541 to pass charge

to the MOSFET gates of Q1 and Q2 (all reference designators in this section refer to the schematics in Figure 8

through Figure 13). This section gives guidelines on selecting the values of C1 through C5 so that the converter

functions properly. Specific capacitor values may need to be larger than the recommended value due to

MOSFET characteristics, diode D1 – D4 characteristics and closed-loop converter performance. All three

modes of operation require a charge pump capacitor and diode, C1 and D1, in order to drive the high-side power

MOSFET. Modes 2 and 3 require additional charge pump capacitors and diodes in order to supply voltage to

VDD. In general, all charge pump diodes should be Schottky diodes in order to have low forward voltage and

high speed. The charge pump capacitors should be ceramic capacitors with low effective series resistance

(ESR), such as X5R or X7R capacitors.

The value of the charge pump capacitor C1 depends on the power MOSFET gate charge and capacitance, the

voltage level of the Miller plateau threshold, the forward drop of D1 and the closed-loop response time. The

unloaded high-side gate driver typically draws 2 nC of charge per rising edge plus 30 µA of direct current from

C1. Usually, the unloaded high−side gate driver load is miniscule compared to the gate charge requirements

of the high-side power MOSFET, Q1. Typical values for C1 are approximately 50 to 100 times the input

capacitance (C

where C1 does not have sufficient time to fully recharge. If C1 is excessively large, its ESR and ESL prevents

it from recharging during transients, including the start-up transient.

) of MOSFET Q1. This usually allows for transient operation at extremely large duty ratio,

ISS

Capacitors C2 through C5 are then selected based on the direction of charge transfer and the requirements of

the UCC2541. Selection guidelines are shown in Table 2. Keep in mind that each converter design may require

adjustments for larger capacitor ratios than those that are suggested in Table 2. The selection process begins

at the left side of Table 2 and progresses towards the right side of the table, which is the reverse order of the

charge flow during the first few cycles of start-up. If iteration is required in the design process, review the

progression of the capacitors in the order from left to right that is shown in the table.

Table 2. Charge Pump and Bias Capacitor Selection Guidelines

Mode

1 C1 > 50 C

2 C1 > 50 C

3 C1 > 50 C

High-Side Drive

Capacitor (≥ 0.1 µF)

ISS

ISS

ISS

For Modes 2 and 3, the VDD filter capacitor, C4, in Table 2 must supply the I

VDRV Filter

Capacitor

C3 > 2 × C1 C2 > 0.1 µF C4 > 1 µF n/a

C3 > 2 × C1 C2 > 0.1 µF C4 > 1 µF, 2 × C3 C5 > 2 × C4

C4 > 1 µF

2 × C1

VREF Filter

Capacitor

C2 > 1.0 µF C4 > 1 µF, 2 × C1 C5 > 2 × C4

VDD Filter

Capacitor

VDD

VDD Charging

Capacitor

idle current to the UCC2541

(approximately 11 mA) plus the charge to drive the gates G1 and G2. Capacitor C4 must be large enough to

sustain adequate operating voltages during start-ups and other transients under the full operational I

current. Knowing the operating frequency and the MOSFET gate charges (QG), the average I

current can

VDD

VDD

be estimated as:

I

VDD

D where f

+ I

VDD(idle)

is switching frequency

S

ǒ

)

QG1) Q

G2

Ǔ

f

S

In order to prevent noise problems, C4 must be at least 1 µF. Furthermore, it needs to be large enough to pass

charge along to the power MOSFET gates. Thus C4 often needs to have at least twice the capacitance of the

VDRV filter capacitor, as shown in Table 2.

www.ti.com

21

Page 22

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

Output Stage

The UCC2541 includes dual gate drive outputs and each is capable of ±3-A peak current. The pull-up/ pull-down

circuits of the driver are bipolar and MOSFET transistors in parallel. High-side and low-side dual drivers provide

a true 3-A high-current capability at the MOSFET’s Miller Plateau switching region where it is most needed. The

peak output current rating is the combined current from the bipolar and MOSFET transistors. The output

resistance is the R

saturation voltage of the bipolar transistor.

The output drivers can switch from VDD to GND. Each output stage also provides a very low impedance to

overshoot and undershoot. This means that in many cases, external-schottky-clamp diodes are not required.

The outputs are also designed to withstand 500-mA reverse current without either damage to the device or logic

upset.

of the MOSFET transistor when the voltage on the driver output is less than the

DS(on)

For additional information on drive current requirements at MOSFET’s Miller plateau region, refer to the Power

Supply Seminar SEM−1400

[3]

.

Predictive Gate DriveTM Technology

The Predictive Gate Drive technology maximizes efficiency by minimizing body diode conduction. It utilizes

a digital feedback system to detect body diode conduction, and adjusts the deadtime delays to minimize the

conduction time interval. This closed loop system virtually eliminates body diode conduction while adjusting for

different MOSFETs, temperature, and load dependent delays. Since the power dissipation is minimized, a

higher switching frequency can be utilized, allowing for a smaller component size. Precise gate timing at the

nanosecond level reduces the reverse recovery time of the synchronous rectifier MOSFET body diode, which

reduces reverse recovery losses seen in the main (high-side) MOSFET. Finally, the lower power dissipation

results in increased reliability.

19 BST

G1

18

17

SW

Predictive

Logic

VDRV

20

12

SWS

G2S

14

G2

15

PGND

Figure 15.

For additional information on Predictive Gate Drive control and efficiency comparisons to earlier adaptive

delay and adaptive control techniques, refer to the Application Note SLUA285

22

www.ti.com

[1]

.

UDG−02149

Page 23

(5)

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

VDD and IDD

Although quiescent VDD current is low, total supply current is higher, depending on output gate drive

requirements and the programmed oscillator frequency. Total VDD current (I

current and the average output currents of G1 and G2, as described in equation (5). Knowing the operating

frequency and the MOSFET gate charge (Q

I

+ QG f

G

S

), average driver output current, per gate, can be calculated from:

G

where

D f

is switching frequency

S

To prevent noise problems, connect a 1-µF ceramic capacitor between the VDD and GND pins. Place the 1-µF

ceramic capacitor as close to the UCC2541 as possible. This capacitor is in addition to any electrolytic energy

storage capacitors that may be used in the bias supply design.

Soft-Start and Tracking Features

Separate pins are provided for the soft-start feature and the tracking feature. Soft-start or tracking (sequencing)

can be easily implemented with this configuration using a minimum number of external components. During a

power-up transient, the converter output tracks the lower of the SS voltage, the TR voltage or a 1.5-V internal

reference, provided the system is not in current limit. In other words, the voltage control loop is closed during

power-up, provided the system is not current limited. Figure 16 shows the UCC2541 configured for soft-start

operation. For applications that do not use the tracking feature, connect the TR pin to either SS or REF, as shown

in the figure. Remote shutdown and sequential power-up can be easily implemented as a transistor switch

across C

SS

.

) is the sum of quiescent VDD

VDD

C

SS

TR

SS

VEA−

10

11

7

HUP

REF (3.3 V)

1.33 y I

RSET

0.7 V

1.73 y I

+

1.5 V

RSET

UVLO

+

+

+

50 mV

+

Figure 16. Using the Soft-Start Feature

UCC2541

Voltage

Error

Amplifier

COMP

To Positive Input of

Current Error Amplifier

UDG−04045

www.ti.com

23

Page 24

(6)

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

The soft-start interval begins when the UCC2541 recognizes that the appropriate voltage (see Mode 1, 2 or 3)

is above the UVLO level. The voltage of C

3.3V. Regulation should be reached when the soft-start voltage reaches about 2.2 V (1.5 V plus a diode drop).

Select a C

C

capacitor value using equation (5) to program a desired soft-start duration, ∆tSS.

SS

+ 1.33

SS

V

R

RSET

SET

Dt

DV

SS

+ 1.33

SS

If a UVLO fault is encountered, both outputs of the UCC2541 are disabled and the soft-start pin (SS) is

discharged to GND. The UCC2541 does not retry until the UVLO fault is cleared.

Using the TR pin, the UCC2541 can be programmed to track another converter output voltage. If the voltage

to be tracked is between 0 V and 3.3 V, simply connect the TR pin to the voltage to be tracked with a resistor

that is approximately equal to the DC impedance that is connected to the VEA− terminal (R

If the voltage is above that range, use a voltage divider, again with an equivalent resistance that approximately

equals the DC impedance that is connected to the VEA− terminal. Other strategies can be used to achieve

sequential, ratiometric or simultaneous power supply tracking

An implementation of sequential sequencing using TPS3103K33

in Figure 17. Applications where the loads include a processor with a core voltage of 1.5 V and I/O ports that

require 3.3 V can require sequential sequencing in order to resolve system level bus contention problems during

start-up. In this circumstance the core must power-up first, then after an initialization period of 130 ms, the ports

are allowed to power-up. This is illustrated in Figure 18.

From dc Power Source

TPS3103K33

VDD

RESET

GND

PFO

MR

PFI

then linearly increases until it is clamped at the REF voltage of

SS

1.5 V

R

C

SS

1 kΩ

SET

Dt

SS

2.2 V

UCC2541

SS

1.6 kΩ

Farads

[4]

.

[2]

in a multiple output power supply

G1TR

G2

|| RV2, in Figure 3).

V1

I/O

3.3 V

[4]

is shown

24

10 kΩ

C

SS

UCC2541

REF

TR

SS

G1

G2

Figure 17. Sequencing a Multiple Output Post Regulated Power Supply

www.ti.com

Core

1.5 V

UDG−04061

Page 25

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

Regulation loss due to

loss of primary line

voltage

3.3

V − Voltage − V

1.5

1.43

0

V

CORE

130 ms

V

I/O

t − Time

UDG−04061

Figure 18.

Using the TR pin, the UCC2541 can be programmed to ratio-metrically track another converter output voltage

[4]

Ratio-metric tracking is when the ratio of the output voltages is constant from zero volts to the point where one

or more of the outputs lock into regulation. The TR pin is easier to use for tracking than the SS pin because the

external currents that would be applied to the SS pin may interfere with SS discharge currents and fault recovery.

It should be understood that the voltage that is being tracked must lag the bias voltages (VDD, VDRV and REF)

on start-up and lead the bias voltages during shutdown. Furthermore, the output that is being tracked must not

reach its steady state DC level before the output that is tracking reaches its steady state DC level. Figure 18

illustrates the concept of programming an output voltage V

M

Main Power Supply

(Leader)

+

V

M

M

, to ratio-metrically track another output, VM.

C

V

M

(Leader)

V

C

M

C

(Tracker)

(a)

ratio−metric

sequencing

.

Core Power Supply

(Trader)

UCC2541

7TR

Tracking Ratio

V

M

M

M

+

V

C

M

C

ǒ

A

T

Ǔ

^

M

M

M

C

M

M

M

C

(Leader)

V

C

(Tracker)

V

M

(Leader)

V

C

(Tracker)

(b)

simultaneous

sequencing

(c)

ratio−metric

sequencing

UDG−04061

Figure 19. Ratio−Metric Tracking

www.ti.com

25

Page 26

(7)

(8)

(9)

(10)

(11)

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

The general circuit to program the UCC2541 to track the leader supply voltage by the tracking ratio AT is shown

in Figure 20. To program the tracking profile gains G

that is listed below. The special case of simultaneous sequencing for V

R

= RV1 and RT2= RV2, GT2 is not needed. In many other cases, the circuit can be simplified with the removal

T1

of the operational amplifier for G

and the Zener clamping diode. If an operational amplifier is necessary, it

T2

should be capable of rail to rail operation and usually low voltage bias; the TLV271 is an inexpensive solution

for both of those requirements. Notice that the tracking circuit in Figure 20 also has a soft-start capacitor, C

The soft-start capacitor is useful for limiting the time between short-circuit retry attempts and it can prevent

overshoot when recovering from a fault that is experienced in only the tracking supply but not the main supply.

Ratio-Metric Tracking Design Procedure (see Figures 22 and 23)

1. Determine the tracking ratio, AT.

M

A

where MC and MM are the soft-start slopes of VC and VM, respectively.

C

+

T

M

M

and GT2, follow the ratio-metric tracking design procedure

T1

> 1.5V is the simplest to design; set

M

SS

.

2. Determine G

+

G

V

.

V

R

V2

RV1) R

V2

where RV2 and RV1are selected when designing the voltage control loop.

3. Test G

a. If G

G

if necessary when VM ≤ 1.5 V or ATGV > 1.

T2

is needed, set GT2 so that both equations (8) and (9) apply.

T2

R

T2

+ 1)

F1

R

F2

so that both of the following apply:

G

+

T2

b. If G

4. Set G

T1

+

G

T1

5. Select R

1.5 V

ǒ

V

M

is not needed, set GT2 = 1.

T2

.

AT G

G

T2

and R

T1

G

V

Ǔ

T1

+

so that R

T2

and G

R

T2

RT1) R

T1

T2

T2

|| R

u

T2

ǒ

AT G

≈ R

V1

|| R

Ǔ

V

to minimize offset differences.

V2

26

www.ti.com

Page 27

9

Z

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

R

F2

TLV271

G

+

T1

RT1) R

*D

needed only if VMGT1GT2 > 3 V

R

F1

+

R

T1

R

T2

R

T2

T2

GT2+ 1 )

Use GT2 stage if

ATGV > 1 OR if

VMGT1 ≤ 1.5 V at

steady-state

*D

Z

3.3 V

CSS

R

F1

R

F2

Rectified Secondary Voltage

UCC2541

G1TR

G2

SS

VEA−

R

V1

R

V2

Determined by voltage loop design

+

G

V

R

V2

RV1) R

Main

Power

Supply

(Leader)

nV

0 V

V2

+

V

M

IN

+

V

C

UDG−0405

Figure 20. Programming the UCC2541 to Track Another Output

More elaborate power supply sequencing and tracking can easily be implemented by extending the above

techniques. Consult Reference [4] for further information.

The following schematic shows an example POL (point of load) converter capable of delivering 20 A at 2.5 V

from an unregulated IBC (intermediate bus converter) providing 9 V to14 V. In this application, the UCC2541

is configured to operate in Mode 1, and the converter turns ON when the UCC2541 UVLO threshold of 8.5 V

is exceeded. The upper input voltage rating is limited by the MOSFET and capacitor voltage ratings, not the

UCC2541. For lower current requirements from 10 A to15 A a single lower MOSFET would suffice.

www.ti.com

27

Page 28

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

VIN=9−14V

22uF

22uF

Q1:

HAT2168H

0.18uF

1N5819

VOUT=2.5V

0.0032

2.2uH

POSCAP

2 x 330uF

Q2: 2 x

1uF

HAT2165H

0.39uF

787

17.8k

0.22uF

2.2nF

17.8k

IC through PowerPAD

GND and PGND tied together under

20

SWS

UCC2541

RSET

1

10k

19

18

17

16

15

14

13

12

G1

BST

REF

2

0.1uF

G2C

3

SW

SYNCIN

4

680pF

VDD

RAMP

5

470pF

PGND

GND

6

270pF

G2

VEA−

7

15k

3.3nF

VDRV

CEA−

8

8.2k

G2S

COMP

9

6.8nF

Figure 21. 20-A POL (Point of Load) Converter

11

SS

TR

10

26.7k26.7k

1nF

28

www.ti.com

Page 29

(12)

(13)

(14)

(15)

(16)

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

APPLICATION INFORMATION

In the 20-A converter the output current is sensed by R4. The UCC2541 limits output current when the CEA−

(pin 8) exceeds the V

up by the reciprocal of the output feedback divider ratio given by:

− (pin 7) by 50 mV . To select the current sense resistor the 50-mV signal must be gained

EA

R8

R8 ) R9

For this 2.5-V output, the divider ratio is 0.6, and the following calculation can determine the typical voltage

across the sense resistor to begin current limit operation:

RSNS

ǒ

PP

SNS

RSNS

+ V

1

*

f

S

+

1.2 IL

+ I

V

The peak inductor ripple current should also be considered in R

inductor current calculated during the OFF-time of the converter:

dI

with VO=2.5 V, VIN=12 V, fS=300 kHz, and L1=2.2 µH. In this design IL1, peak =21.5 A.

For a 20-A converter with current limiting at 20% overload the sense resistor can be calculated as:

R

With this value of sense resistor the average power dissipation can be calculated to be:

P

Low value current sense resistors are commonly available in 1-W surface mount packages, so two packages

should be paralleled to meet the power dissipation requirements in high current designs, and the final value used

will be a compromise of available components. In surface mount applications a Kelvin connection to the sense

resistor is not easily attainable, so the connection resistance from the sense resistors to the PCB must be

included in the effective sense resistance.

R12

+

R12 ) R10

+

R4

V

O

VIN f

V

RSNS

2

R

OUT

1

50 mV + 83.3 mV

0.6

V

O

Ǔ

+ 3A

S

PEAK

L

83.3 mV

+

1.2 21.5 A

+ 20 A2 3.2 mW + 1.28 W

SNS

PP

+ 3.2 mW

selection, and is 1/2 the peak-to-peak

SNS

The voltage and current feedback component magnitudes were ratioed according to the discussion in section,

COMP, VEA− AND CEA− pin: V oltage and Current Error Amplifiers. In this application, the optional component

CFIR was not needed. However , a 1-nF capacitor (CST in Figure 3) was needed to filter the C

the converter to start at turn on and to restart after current limit hiccup operation.

www.ti.com

− signal to allow

EA

29

Page 30

0

RAMP CURRENT

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

THERMAL INFORMATION

The useful temperature range of a controller that contains high-current output drivers is greatly affected by the

drive power requirements of the load and the thermal characteristics of the device package. In order for a power

driver to be useful over a particular temperature range the package must allow for the efficient removal of the

heat produced while keeping the junction temperature within rated limits. The UCC2541 is available in the 20-pin

HTSSOP PowerPADt package and also the 32-pin QFN PowerPAD

TM

The PowerPAD

offers the most effective means of removing the heat from the semiconductor junction and

therefore long term reliability improvement. As illustrated in [5], the PowerPAD packages offer a leadframe die

pad that is exposed at the base of the package. This pad is soldered to the copper on the PC board directly

underneath the device package, reducing the θjc down to 2°C/W. Data is presented in [5] to show that the power

dissipation can be quadrupled in the PowerP ADt configuration when compared to the standard packages. The

PC board must be designed with thermal lands and thermal vias to complete the heat removal subsystem, as

summarized in [6] to realize a significant improvement in heat−sinking over standard non-PowerPADt surface

mount packages.

TYPICAL CHARACTERISTICS

TM

package.

3.40

3.35

3.30

− Reference Voltage − V

3.25

VREF

V

3.20

−50

OUTPUT REFERENCE VOLTAGE

vs

TEMPERATURE

0

TJ − Junction Temperature − °C

50 100 150

Figure 22

vs

TEMPERATURE

−275

−285

−295

−305

− Ramp Current − µA

RAMP

I

−315

−325

−50 0 50 100 15

TJ − Junction Temperature − °C

R

Figure 23

RSET

= 10 kΩ

30

www.ti.com

Page 31

0

REGULATOR OUTPUT VOLTAGE

OSCILLATOR FREQUENCY

0

CURRENT ERROR AMPLIFIER OFFSET

0

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

TYPICAL CHARACTERISTICS

I

G2C/IRAMP

1.1

I

G2C/IRAMP

1.0

I

G2C/IRAMP

0.9

0.8

µA/µA

0.7

0.6

0.5

ISS/I

ISS/I

−50 0 50 100 150

, R

, R

, R

RAMP

, R

RAMP

TJ − Junction Temperature − °C

AND ISS/I

vs

TEMPERATURE

= 10 kΩ

RSET

= 50 kΩ

RSET

= 10 kΩ

RSET

= 50 kΩ

RSET

RAMP

Figure 24

vs

7.6

MODE 1

7.4

7.2

− Regulator Output Voltage − V

7.0

VDRV

V

6.8

−50 0 50 100 15

TEMPERATURE

TJ − Junction Temperature − °C

Figure 25

vs

TEMPERATURE

600

550

500

450

400

350

− Oscillator Frequency − kHz

300

SW

f

250

200

−50 0 50 100 15

C = 450 pF

C = 270 pF

TJ − Junction Temperature − °C

Figure 26

vs

55

53

51

49

47

− Current Error Amplifier Offset Voltage − m V

CEA−

V

45

−50 0 50 100 15

TEMPERATURE

TJ − Junction Temperature − °C

Figure 27

www.ti.com

31

Page 32

INVERTING AMPLIFIER GAIN AND PHASE

CURRENT ERROR AMPLIFIER GAIN AND PHASE

VOLTAGE ERROR AMPLIFIER GAIN AND PHASE

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

SYNCIN THRESHOLD VOLTAGE

vs

1.80

TEMPERATURE

TYPICAL CHARACTERISTICS

5

vs

FREQUENCY

0

1.75

1.70

1.65

− Timing Signal Voltage − V

1.60

SYNCHIN

1.55

V

1.50

−50 0 50 100 150

TJ − Junction Temperature − °C

Figure 28

vs

FREQUENCY

120

100

80

Gain

0

−45

Gain − dB

−5

−10

−15

−20

−25

120

100

0

Phase

Gain

10 k 100 M1 k 1 M

100 k 10 M

f − Frequency − Hz

−45

−90

−135

−180

−225

−270

Phase − °

Figure 29

vs

FREQUENCY

Gain

80

0

−45

60

Gain − dB

40

20

−20

−40

Phase

0

100 1 k 10 M 100 M10

f − Frequency − Hz

100 k 1 M10 k1

Figure 30

32

−90

−135

−180

www.ti.com

Phase − °

60

40

Gain − dB

20

0

−20

−40

−90

Phase − °

Phase

−135

−180

100 1 k 10 M 100 M10 100 k 1 M10 k1

f − Frequency − Hz

Figure 31

Page 33

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

TYPICAL CHARACTERISTICS

OPERATING CURRENT (DC)

vs

12

10

8

BIAS VOLTAGE

6

− Bias Current − mA

4

VDD

I

2

0

5 1525304003510 20

V

− Bias Voltage − V

VDD

Figure 32

5.0 V/div.

5.0 V/div.

t − Time − 20 ns/div

Figure 33. Predictive Gate Drive − G2 Falling

www.ti.com

33

Page 34

SLUS621A − AUGUST 2004 − SEPTEMBER 2005

RELATED PRODUCTS

UCC27223 High Efficiency Predictive Synchronous Buck Driver with Enable

D

D UCC2540 High-Efficiency Secondary-Side Synchronous Buck PWM Converter

D TPS40070/1 High-Efficiency Midrange Input Synchronous Buck Controller With Voltage Feed-Forward

REFERENCES

1. Application Note, Predictive Gate DriveE FAQ, by Steve Mappus (SLUA285)

2. Datasheet, TPS3103K33 Ultra-Low Supply Current/Supply Voltage Supervisory Circuits, (SLVS363)

3. Power Supply Seminar SEM−1400 Topic 2: Design And Application Guide For High Speed MOSFET Gate

Drive Circuits, by L. Balogh, (SLUP133)

4. Power Supply Seminar SEM1600 Topic 2: Sequencing Power Supplies in Multiple Voltage Rail

Environments, by D. Daniels, D. Gehrke, and M. Segal, (SLUP224)

5. Technical Brief, PowerPAD Thermally Enhanced Package, (SLMA002)

6. Application Brief, PowerPAD Made Easy, (SLMA004)

34

www.ti.com

Page 35

www.ti.com

35

Page 36

www.ti.com

36

Page 37

10 11

TR SS

www.ti.com

37

Page 38

VIN=9−14V

22uF

22uF

VOUT=2.5V

2 x 330uF

0.0032

POSCAP

787

2.2nF

17.8k

20

SWS

19

BST

Q1:

HAT2168H

0.18uF

18

G1

2.2uH

1N5819

17

SW

16

VDD

1uF

15

PGND

Q2: 2 x

HAT2165H

14

G2

13

VDRV

0.39uF

12

G2S

17.8k

0.22uF

11

SS

IC through PowerPAD

GND and PGND tied together under

UCC2541

RSET

1

10k

0.1uF

REF

2

G2C

3

SYNCIN

4

680pF

RAMP

5

470pF

GND

6

270pF

VEA−

7

15k

3.3nF

CEA−

8

8.2k

COMP

9

6.8nF

TR

10

26.7k26.7k

1nF

Page 39

www.ti.com

39

Page 40

PACKAGE OPTION ADDENDUM

www.ti.com

21-Nov-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

UCC2541PWP ACTIVE HTSSOP PWP 20 70 Green (RoHS &

no Sb/Br)

UCC2541PWPG4 ACTIVE HTSSOP PWP 20 70 Green (RoHS &

no Sb/Br)

UCC2541PWPR ACTIVE HTSSOP PWP 20 2000 Green (RoHS &

no Sb/Br)

UCC2541PWPRG4 ACTIVE HTSSOP PWP 20 2000 Green (RoHS &

no Sb/Br)

UCC2541RHBR ACTIVE QFN RHB 32 3000 Green (RoHS &

no Sb/Br)

UCC2541RHBT ACTIVE QFN RHB 32 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 41

Page 42

Page 43

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms