Texas Instruments UCC21520EVM-286, UCC20520EVM286, UCC21530EVM286, UCC21521CEVM-286 User Manual

Page 1

Using the UCC21520EVM-286, UCC20520EVM286, UCC21521CEVM-286, and UCC21530EVM286

User's Guide

Literature Number: SLUUBG8B

June 2016–Revised November 2018

Page 2

Contents

1 Trademarks......................................................................................................................... 4

2 Introduction......................................................................................................................... 4

3 Description.......................................................................................................................... 4

3.1 Features................................................................................................................... 5

3.2 I/O Description............................................................................................................ 5

3.3 Jumpers (Shunt) Setting ................................................................................................ 6

4 Electrical Specifications........................................................................................................ 6

5 Test Summary ..................................................................................................................... 7

5.1 Definitions................................................................................................................. 7

5.2 Equipment................................................................................................................. 7

5.3 Equipment Setup......................................................................................................... 7

6 Power-Up and Power-Down Procedure ................................................................................. 10

6.1 Power Up ................................................................................................................ 10

6.2 Power Down............................................................................................................. 10

7 Test Waveforms (C

7.1 DT Connected to VCCI(J-DT Option B in ).......................................................................... 11

7.2 DT Pin Floating or Left Open (J-DT Option A in ).................................................................. 11

7.3 DT Pin Connected to RDT (J-DT Option C in )..................................................................... 12

8 Schematic ......................................................................................................................... 13

9 Layout Diagrams ................................................................................................................ 14

10 List of Materials ................................................................................................................. 16

Revision History.......................................................................................................................... 17

=0pF) With Different DT Configurations .................................................... 11

L

2

Table of Contents

Copyright © 2016–2018, Texas Instruments Incorporated

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Page 3

www.ti.com

1 Jumpers Installation Position............................................................................................... 8

2 Bench Setup Diagram and Configuration................................................................................. 9

3 Example Input and Output Waveforms (Channels 3 and 4 are PWM Inputs, Channels 1 and 2 are Outputs) 10

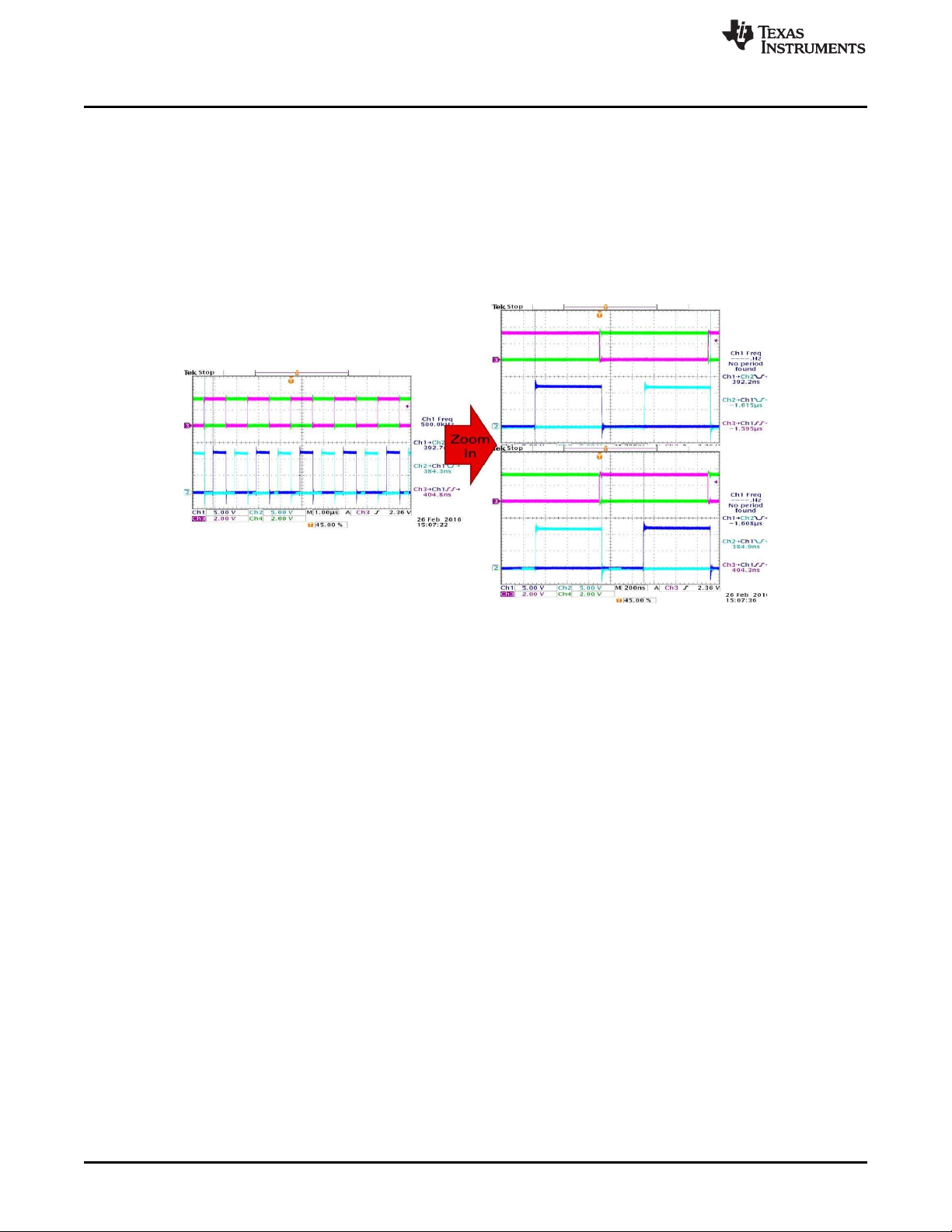

4 Overlap is Allowed When DT Connected to VCCI (Channels 3 and 4 are PWM Inputs, Channels 1 and 2

5 Test Waveforms if DT is Left Open (Channel 3 and 4 are PWM Inputs, and Channel 1 and 2 are Driver

6 Test Waveforms if DT Connected to RDT(Channel 3 and 4 is PWM Inputs, and Channel 1 and 2 is Driver

7 UCC21520EVM-286 Schematic.......................................................................................... 13

8 Top Overlay................................................................................................................. 14

9 Top Layer.................................................................................................................... 14

10 Bottom Layer................................................................................................................ 15

11 Bottom Overlay ............................................................................................................. 15

1 Jumpers Setting.............................................................................................................. 5

2 Jumpers Setting.............................................................................................................. 6

3 UCC2x5xxEVM-286 Electrical Specifications............................................................................ 6

4 Two-Channel Function Generator Settings............................................................................... 8

5 Oscilloscope Settings ....................................................................................................... 8

6 UCC2x5xxEVM-286 List of Materials.................................................................................... 16

List of Figures

are Driver Outputs) ........................................................................................................ 11

Outputs) ..................................................................................................................... 11

Outputs) ..................................................................................................................... 12

List of Tables

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

List of Figures

3

Page 4

User's Guide

SLUUBG8B–June 2016–Revised November 2018

Using the UCC21520EVM-286, UCC20520EVM-286,

UCC21521CEVM-286, and UCC21530EVM-286

UCC2x5xxEVM-286 evaluation modules are designed for evaluation of TI's 5.7-kV

channel gate driver family with 4-A source and 6-A sink peak current for driving Si MOSFETs, IGBTs and

WBG devices such as SiC and GaN transistors. This user's guide covers the UCC21520EVM-286,

UCC20520EVM-286, UCC21521CEVM-286, and UCC21530EVM-286 used to evaluate the

UCC21520DW, UCC20520DW, UCC21521CDW, and UCC21530DWK, respectively. To evaluate other

Iso-Drivers in the UCC2x5xx family, TI recommends that the user read the data sheet thoroughly before

switching the part in the EVMs covered by this user guide. In this user guide, the UCC21520EVM-286

evaluation module is shown as the primary example, and the key differences between the

UCC21520EVM-286 and the UCC20520EVM-286, UCC21521CEVM-286, and UCC21530EVM-286 will be

highlighted accordingly.

SPACER

1 Trademarks

All trademarks are the property of their respective owners.

2 Introduction

Developed for high voltage applications where isolation and reliability is required, the UCC2x5xx delivers

reinforced isolation of 5.7 kV

transient immunity (CMTI) greater than 100 V/ns. It has the industry’s fastest propagation delay of 19 ns

and the tightest channel-to-channel delay matching of less than 5 ns to enable high-switching frequency,

high-power density, and efficiency.

The flexible, universal capability of the UCC2x5xx with up to 18-V VCCI and 25-V VDDA/VDDB allows the

device to be used as a low-side, high-side, high-side/low-side, or half-bridge drivers with dual PWM input

or single PWM input. With its integrated components, advanced protection features (UVLO, dead time and

enable/disable), and optimized switching performances, the UCC2x5xx enables designers to build smaller,

more robust designs for enterprise, telecom, automotive, and industrial applications with a faster time to

market.

isolated dual-

RMS

and a surge immunity tested up to 12.8 kV along with a common-mode

RMS

3 Description

The UCC2x5xx evaluation board has three independent screw terminal blocks for VCCI, VDDA, and

VDDB. The 3-position headers with jumpers for all the key input signals, such as PWM INPUTs (INA, INB

or PWM), dead time (DT) programming and enable/disable function (EN/DIS), allow designers to easily

evaluate different protection functions. A variety of testing points also support most of the key feature

probing of the UCC2x5xx. Moreover, the PCB layout is not only optimized with minimized loop area in

each gate driver loop and power supply loop with bypassing capacitors, but the layout also supports high

voltage test between the primary side and secondary side with 120-mil PCB board cutout. Importantly, the

creepage distance between two output channels are maximized with bootstrap diode in footprint of

TO252-2(DPAK), which facilitates high-voltage, half-bridge testing for a wide variety of power converter

topologies. For detail device information, refer to UCC21520DW, UCC20520DW, UCC21521CDW and

UCC21530DWK data sheets and TI's Isolated gate driver solutions.

4

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

SLUUBG8B–June 2016–Revised November 2018

Copyright © 2016–2018, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

www.ti.com

3.1 Features

• Evaluation module for the UCC21520DW, UCC20520DW, and UCC21521CDW in a wide body SOIC16 (DW), along with the UCC21530DWK in wide body SOIC-14 (DWK) package

• 3-V to 18-V VCCI power supply range, and up to 25-V VDDA/VDDB power supply range

• 4-A and 6-A source/sink current capability

• 5.7-kV

Isolation for 1 minute per UL 1577

RMS

• TTL/CMOS-compatible inputs

• Onboard trimmer potentiometer for dead-time programming

• 3-position header with for INA, INB, DT and enable/disable

• PCB layout optimized for power supply bypassing cap, gate driver loop

• PCB board cutout that facilitates high voltage isolation test between primary side and secondary side

• Maximized creepage distance between two output channels

• Support for half-bridge test with MOSFETs, IGBTs and SiC MOSFETs with connection to external

power stage

• Testing points allows probing all the key pins of the UCC21520DW, UCC20520DW, UCC21521CDW,

UCC21530DWK, and other wide-body ISO driver family parts.

3.2 I/O Description

Description

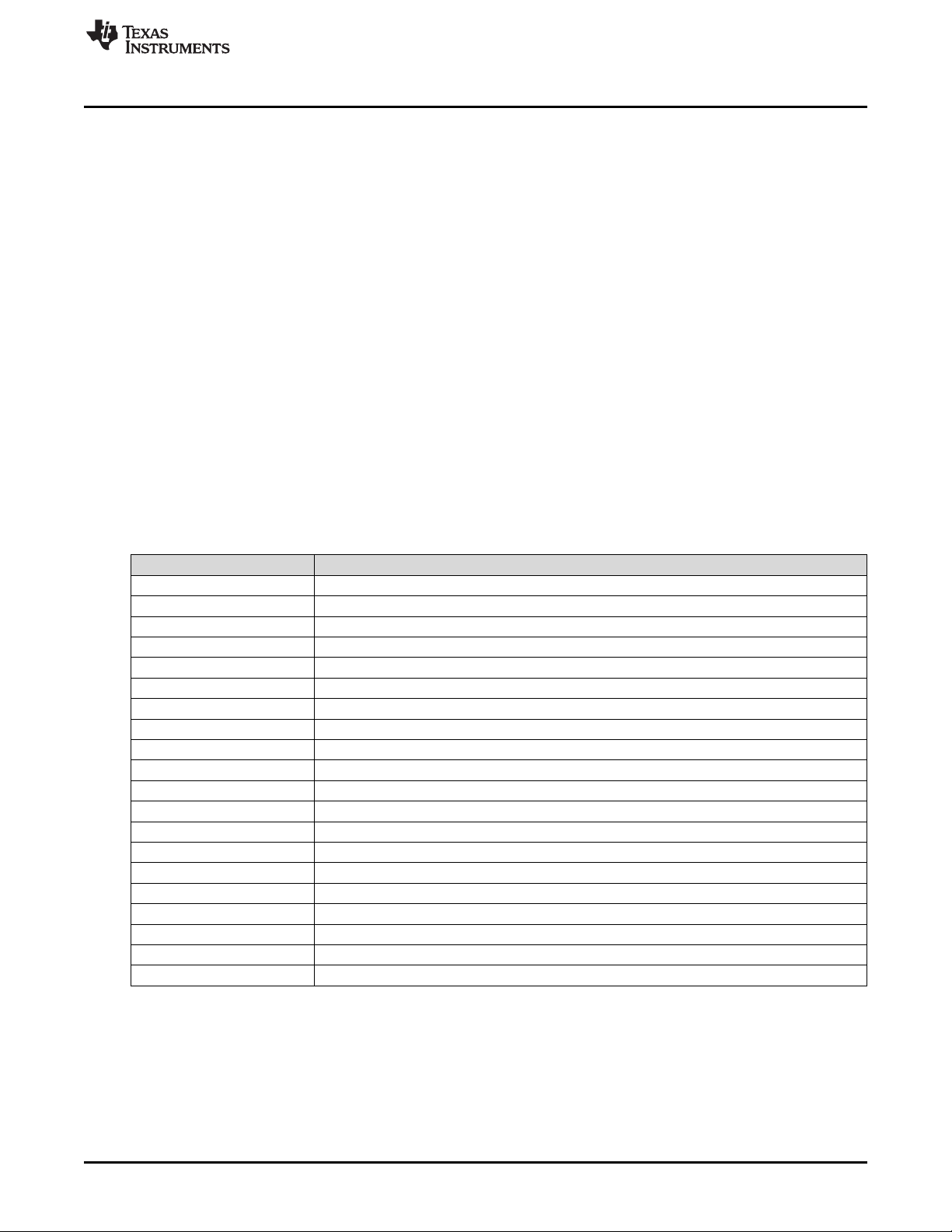

Table 1. Jumpers Setting

PINS DESCRIPTION

J1–1 VCCI positive input

J1–2 VCCI negative input

J2–1 VDDA negative input

J2–2 Driver A output

J2–3 VDDA positive input

J3–1 VDDB negative input

J3–2 Driver B output

J3–3 VDDB positive input

J-INA-1 Primary ground

J-INA-2 INA/PWM signal input

J-INA-3 Primary VCC

J-INB-1 Primary ground

J-INB-2 INB signal input

J-INB-3 Primary VCC

J-DIS-1 or J-DIS/EN-1 Primary VCC

J-DIS-2 or J-DIS/EN-2 Enable/Disable signal input

J-DIS-3 or J-DIS/EN-3 Primary ground

J-DT-1 Primary VCC

J-DT-2 Dead-time programming pin

J-DT-3 Connects to trimmer potentiometer

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

5

Page 6

Description

3.3 Jumpers (Shunt) Setting

JACK Jumper Setting Options FACTORY SETTING

Jumper not installed, INA/PWM signal provided by external signal and this

pin is default low if left open

Jumper not installed, INB signal provided by external signal and this pin is

default low if left open

enable/disable pin

Jumper on J-DT-2 and J-DT-1 allows driver output overlap or driver output

follows PWM input for UCC21520EVM and UCC21521CEVM. The dead

time will be around 0 ns in this option for UCC20520EVM

Jumper on J-DT-2 and J-DT-3 set the dead time by DT (in ns) = RDT(in kΩ)

× 10. For better noise immunity and dead-time matching, TI recommends

to parallel a 2.2-nF or above bypassing capacitor from DT pin to GND.

J-INA

J-INB

J-DIS or J-

DIS/EN

J-DT

Option A:

Option B: Jumper on J-INA-2 and J-INA-1 set INA low

Option C: Jumper on J-INA-2 and J-INA-3 set INA high

Option A:

Option B: Jumper on J-INB-2 and J-INB-1 set INB low

Option C: Jumper on J-INB-2 and J-INB-3 set INB high

Option D: Header J-INB is not installed, and no connection on the device under test

Option A: Jumper not installed, the devices under test are enabled when left open on

Option B: Jumper on J-DIS-2 and J-DIS-1 or J-DIS/EN-2 and J-DIS/EN-1

Option C: Jumper on J-DIS-2 and J-DIS-3 or J-DIS/EN-2 and J-DIS/EN-3

Option A: Jumper not installed, interlock with 8-ns dead time

Option B:

Option C:

www.ti.com

Table 2. Jumpers Setting

Option A

Option A for

UCC21520EVM-286,

UCC21521CEM-286 and

UCC21530EVM-286;

Option D for

UCC20520EVM-286

Option C for

UCC21520EVM-286 and

UCC20520EVM-286;

Option B for

UCC21521CEVM-286 and

UCC21530EVM-286

Option B

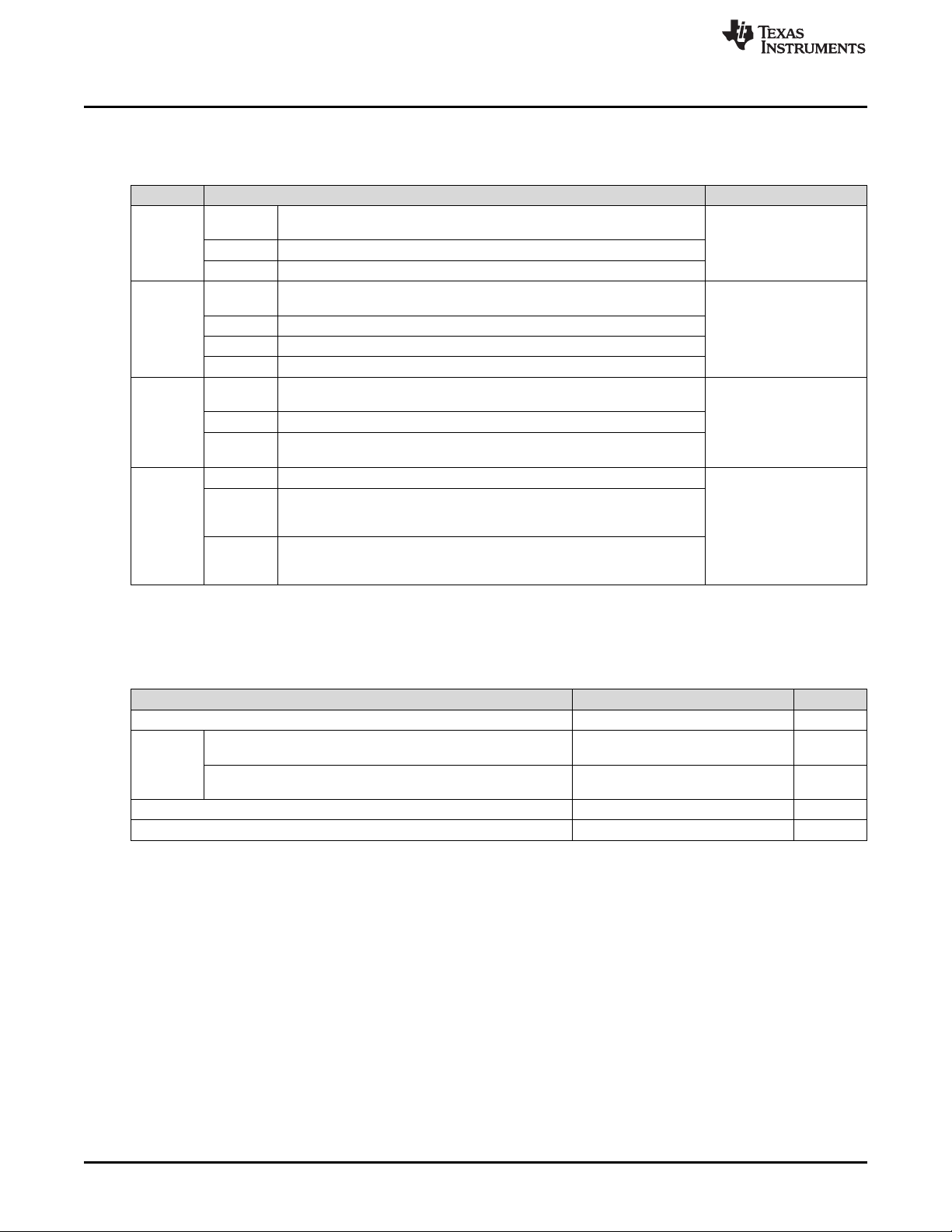

4 Electrical Specifications

Table 3. UCC2x5xxEVM-286 Electrical Specifications

DESCRIPTION MIN TYP MAX UNIT

V

CCI

V

DDA,VDDB

F

S

T

J

Primary-side power supply 3 18 V

Driver output power supply for UCC21520EVM-286 and

UCC20520EVM-286

Driver output power supply for UCC21521CEM-286 and

UCC21530EVM

Switching frequency 0 5 MHz

Operating junction temperature range –40 125 °C

9.2 25 V

14.7 25 V

6

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

Copyright © 2016–2018, Texas Instruments Incorporated

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Page 7

www.ti.com

5 Test Summary

The UCC21520EVM-286 is used as the primary example for this section. Different Jumper settings, PWM

signal input options and voltage source settings can be found in Section 3 and Section 4

5.1 Definitions

This procedure details how to configure the UCC2x5xx evaluation board. Within this test procedure the

following naming conventions are followed. Refer to the UCC21520EVM-286 Schematic in Figure 7 for

details.

VXX: External voltage supply name.

V

: Voltage at test point TPxx. For example, V(TP12) means the voltage at TP12.

(TPxx)

V

: Voltage at jack terminal Jxx.

(Jxx)

J

: Terminal or pin yy of jack xx.

xx(yy)

DMM: Digital multi-meters.

UUT: Unit under test

EVM: Evaluation module assembly, in this case the UUT assembly drawings have location for jumpers,

test points and individual components.

5.2 Equipment

Test Summary

5.2.1 Power Supplies

Three DC power supply with voltage/current above 25 V/1 A (for example: Agilent E3634A)

5.2.2 Function Generators

One two-channel function generator over 20 MHz (for example: Tektronics AFG3252)

5.3 Equipment Setup

5.3.1 DC Power Supply Settings

• DC power supply #1

– Voltage setting: 5 V

– Current limit: 0.05 A

• DC power supply #2

– Voltage setting: 12 V for UCC21520EVM and UCC20520EVM

– Voltage setting: 15 V for UCC21521CEVM and UCC21530EVM

– Current limit: 0.1 A

• DC power supply #3

– Voltage setting: 12 V for UCC21520EVM and UCC20520EVM

– Voltage setting: 15 V for UCC21521CEVM and UCC21530EVM

– Current limit: 0.1 A

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

7

Page 8

Test Summary

5.3.2 Digital Multi-Meter Settings

• Digital multi-meter #1

– DC current measurement, auto-range.

• Digital multi-meter #2

– DC current measurement, auto-range.

5.3.3 Two-Channel Function Generator Settings

Table 4. Two-Channel Function Generator Settings

www.ti.com

MODE FREQUENCY DUTY DELAY HIGH LOW OUTPUT

Channel A

Channel B 100 ns

Pulse DC ~ 5 MHz 50%

5.3.4 Oscilloscope Setting

BANDWIDTH COUPLING TERMINATION SCALE SETTINGS INVERTING

Channel A

Channel B

500 MHz or above DC 1 MΩ or automatic 10× or automatic OFF

5.3.5 Jumper (Shunt) Settings

There are two jumpers (shunts) need to be installed before test:

1. Install shunt #1 for header J-DIS on pin 2-3 for the UCC21520EVM shown in Figure 1. For the

UCC20520EVM, UCC21521CEVM and the UCC21530EVM, refer to Table 1. The UCC20520EVM is

set as disable high on the DIS pin while the UCC21521CEM and UCC21530EVM is set as enable high

on the EN pin.

2. Install shunt #2 on header J-DT on pin 1-2 as shown in Figure 1.

0 ns

Table 5. Oscilloscope Settings

IMPEDANCE

3.3 V 0 V High Z

Figure 1. Jumpers Installation Position

8

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

Copyright © 2016–2018, Texas Instruments Incorporated

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Page 9

+

s

Power

Supply #1

(5V/0.05A)

+

s

Power

Supply #2

(12V/0.1A)

+

s

DMM #2

DC Current

+

s

DMM #1

DC Current

+

s

Power

Supply #2

(12V/0.1A)

CH1 CH2

EVM

Function

Generator

Oscilloscope

www.ti.com

5.3.6 Bench Setup Diagram

The current bench setup diagram includes the function generator and oscilloscope connections.

Follow the connection procedure below and use Figure 2 as a reference:

• Make sure all the output of the function generator, voltage source are disabled before connection;

• Function generator channel-A channel applied on JINA ←→ TP14 as seen in Figure 2;

• Function generator channel-B channel applied on JINB ←→ TP15 as seen in Figure 2. For the

UCC20520EVM, JINB, J-INB and TP15 are not installed because the UCC20520 is a single PWM

input, dual-channel output Iso-Driver;

• Power supply #1: positive node applied on J1 pin-1 (or TP0), and negative node applied on J1 pin-2

(or TP13);

• Power supply #2: positive node connected to input of DMM #1 and DMM #1 output connected to J2

pin-3 (or TP10), negative node connected directly to J2 pin-1 (or TP17);

• Power supply #3: positive node connected to input of DMM #2 and DMM #2 output connected to J3

pin-3 (or TP 11), negative node connected directly to J3 pin-1 (or TP19);

• Oscilloscope channel-A probes TP9 ←→ TP17, smaller measurement loop is preferred;

• Oscilloscope channel-B probes TP12 ←→ TP19, smaller measurement loop is preferred;

Test Summary

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Figure 2. Bench Setup Diagram and Configuration

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

Copyright © 2016–2018, Texas Instruments Incorporated

and UCC21530EVM-286

9

Page 10

Power-Up and Power-Down Procedure

6 Power-Up and Power-Down Procedure

6.1 Power Up

1. Make sure that Section 5.3.6 is implemented for setting up all the equipment before starting the powerup sequence. Figure 3 can be used as a reference.

2. Enable supply #1;

3. Enable supply #2 and #3, the quiescent current on DMM1 and DMM2 ranges from 1 mA to

approximately 3 mA if everything is set correctly;

4. Enable the function generator, two-channel outputs: channel-A and channel-B;

5. There will be:

1. Stable pulse output on the channel-A and channel-B in the oscilloscope (refer to Figure 3);

2. Scope frequency measurement is the same with function generator output;

3. DMM #1 and #2 read measurement results should be around 10 mA, ±2 mA under no load

conditions. For more information about operating current, refer to the UCC21520 data sheet.

www.ti.com

Figure 3. Example Input and Output Waveforms (Channels 3 and 4 are PWM Inputs, Channels 1 and 2 are

Outputs)

6.2 Power Down

1. Disable function generator;

2. Disable power supply #2 and #3;

3. Disable power supply #1;

4. Disconnect cables and probes;

10

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

Copyright © 2016–2018, Texas Instruments Incorporated

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Page 11

www.ti.com

Test Waveforms (CL=0pF) With Different DT Configurations

7 Test Waveforms (CL=0pF) With Different DT Configurations

7.1 DT Connected to VCCI(J-DT Option B in Table 2)

The dead time (DT) between the outputs of the two channels is decided by inputs (see Figure 4). Overlap

between two output channels is allowed. Figure 4 shows a waveform with overlapped operations.

Figure 4. Overlap is Allowed When DT Connected to VCCI

(Channels 3 and 4 are PWM Inputs, Channels 1 and 2 are Driver Outputs)

7.2 DT Pin Floating or Left Open (J-DT Option A in Table 2)

The dead time (DT) between the outputs of the two channels is around 8 ns, which is preset for interlock

protections (see Figure 5).

Figure 5. Test Waveforms if DT is Left Open

(Channel 3 and 4 are PWM Inputs, and Channel 1 and 2 are Driver Outputs)

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

11

Page 12

Test Waveforms (CL=0pF) With Different DT Configurations

7.3 DT Pin Connected to RDT (J-DT Option C in Table 2)

The dead time (DT) between the outputs of the two channels is set according to: DT (in ns) = 10 × RDT

(in kΩ).

The steady-state voltage at DT pin is around 0.8 V, and the DT pin current will be less than 10 µA when

RDT= 100 kΩ. Therefore, TI recommends to parallel a ceramic bypass capacitor (2.2 nF or above) with

RDTto achieve better noise immunity and better dead-time matching between two channels, especially

when the dead time is larger than 300 ns. The major consideration is that the current through the RDTis

used to set the dead time, and this current decreases as RDTincreases. This bypass capacitor is not

installed in the EVM, but the user can easily install it on the bottom layer where the RDTis located.

www.ti.com

Figure 6. Test Waveforms if DT Connected to R

DT

(Channel 3 and 4 is PWM Inputs, and Channel 1 and 2 is Driver Outputs)

12

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

Copyright © 2016–2018, Texas Instruments Incorporated

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Page 13

0.22µF

C11

0.22µF

C12

0.22µF

C13

1µF

C14

1µF

C15

GND

GNDA

GNDB

GNDA

GNDB

1

2

J1

1727010

1

2

3

J-INA

TSW-103-07-G-S

1

2

3

J-INB

TSW-103-07-G-S

1

2

3

J-DIS

TSW-103-07-G-S

1

2

3

J-DT

TSW-103-07-G-S

GND

GND

GND

VCCIN VCC

VCC

VCC

GND

GND

DT

VCC

VCC

GND

INA

INB

1.00

R11

0

R_LB

GNDA

GNDB

GNDA

GNDB

GND

OUTA

OUTB

V_GA

VDDAIN

V_GB

VDDBIN

DISABLE

VCC

VDDA

VDDB

1

2

3

J2

1727023

1

2

3

J3

1727023

TP1

TP2

TP3

TP4

TP5

TP6

TP7

TP8

TP10

TP11

TP13

TP14

TP15

TP16

TP20

TP0

0

R_LA

1000pF

CL_A

1000pF

CL_B

GND

GND

GND

GND

GND

TP19

10pF

C1

10pF

C2

2.2

R12

2.2

R13

10µF

CIN

10µF

C16

100k

RDT

3266W-1-104LF

JINA

JINB

TP9

TP12

TP17

2.2

RB

i Ch-A

ClassName: Ch-A

i Ch-B

ClassName: Ch-B

GNDA

GNDB

INA

1

INB

2

VCCI

3

GND

4

DISABLE

5

DT

6

NC

7

VCCI

8

VSSB

9

OUTB

10

VDDB

11

NC

12

NC

13

VSSA

14

OUTA

15

VDDA

16

U1

UCC21520DW

VDDB

51

R4

51

R5

1

4

3

DB

C3D02060E

www.ti.com

8 Schematic

Figure 7 only shows the schematic diagram for UCC21520EVM. The schematic diagrams for the UCC20520EVM, UCC21521CEVM, and

UCC21530EVM are similar to Figure 7, with the exception that the device under test (U1) could be in one of the following driver ICs:

UCC21520DW, UCC20520DW, UCC21521CDW, or UCC21530DWK.

Schematic

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Figure 7. UCC21520EVM-286 Schematic

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

Copyright © 2016–2018, Texas Instruments Incorporated

13

and UCC21530EVM-286

Page 14

Layout Diagrams

9 Layout Diagrams

The PCB layout information for UCC21520EVM is shown in Figure 8, Figure 9, Figure 10, and Figure 11.

The layouts are the same for UCC20520EVM, UCC21521CEVM, and UCC21530EVM except for the

labels that designate the EVM part number with the device under test.

www.ti.com

Figure 8. Top Overlay

14

Figure 9. Top Layer

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

Copyright © 2016–2018, Texas Instruments Incorporated

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Page 15

www.ti.com

Layout Diagrams

Figure 10. Bottom Layer

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Figure 11. Bottom Overlay

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

15

Page 16

List of Materials

10 List of Materials

QTY DES DESCRIPTION MANUFACTURE PART NUMBER

2 C1, C2 Capacitor, ceramic, 10 pF, 50 V, ±5%, C0G/NP0, 0603. C2 is

3 C11, C12,

C13

2 C14, C15 Capacitor, ceramic, 1 μF, 50 V, ±10%, X5R, 0603 Std Std

2 C16, CIN Capacitor, ceramic, 10 μF, 50 V, ±10%, X5R, 1206_190 Std Std

0 CL_A, CL_B Capacitor, ceramic, 1000 pF, 50 V, ±5%, C0G/NP0, 0805 Not Populated Not Populated

0 DB Diode, Schottky, 600 V, 8 A, DPAK Not Populated Not Populated

4 H1, H2, H3,H4Machine screw, round, #4-40 x 1/4, nylon, philips panhead Std Std

4 H5, H6, H7,H8Standoff, hex, 0.5"L #4-40 nylon Std Std

www.ti.com

Table 6. UCC2x5xxEVM-286 List of Materials

Std Std

not populated in UCC20520EVM.

Capacitor, ceramic, 0.22 μF, 50 V, ±10%, X7R, 0603 Std Std

4 J-DIS, J-DT,

J-INA, J-INB

1 J1 Connection terminal block, 2 position, 3.81 mm, TH Std Std

2 J2, J3 Terminal block receptacle, 3 × 1, 3.81 mm, R/A, TH Std Std

15 JINA, JINB,

TP0, TP1,

TP2, TP3,

TP4, TP5,

TP6, TP7,

TP8, TP9,

TP10, TP11,

TP12

0 R4, R5 Resistor, 51 Ω, 5%, 0.1 W, 0603 Not Populated Not Populated

1 R11 Resistor, 1.00 Ω, 1%, 0.125 W, 0805 Std Std

2 R12, R13 Resistor, 2.2 Ω, 5%, 0.1 W, 0603 Std Std

1 RB Resistor, 2.2 Ω, 5%, 0.125 W, 0805 Std Std

2 R_LA, R_LB Resistor, 0 Ω, 5%, 0.125 W, 0805 Std Std

1 RDT Trimmer, 100 kΩ, 0.25 W, TH Std Std

2 SH1, SH2 Shunt, 100 mil, flash gold, black Std Std

6 TP13, TP14,

TP15, TP16,

TP19, TP20

1 TP17 Test point, miniature, SMT Std Std

1 U1 UCC21520DW, UCC20520DW, UCC21521CDW and

Header, 100 mil, 3 × 1, gold, TH. J-INB is not installed in

UCC20520EVM.

Test point, miniature, red, TH. JINB and TP4 are not installed

in UCC20520EVM.

Test point, miniature, black, TH. TP15 is not installed in

UCC20520EVM.

UCC21530DWK, 4-A and 6-A, 5-KV

Universal Gate Driver, DW0016A and DWK0014 for

UCC21530DWK

Dual Isolated-channel

RMS

Std Std

Std Std

Std Std

Texas Instruments UCC21520DW,

UCC20520DW,

UCC21521CDW,

or UCC21530DWK

16

Using the UCC21520EVM-286, UCC20520EVM-286, UCC21521CEVM-286,

and UCC21530EVM-286

Copyright © 2016–2018, Texas Instruments Incorporated

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Page 17

www.ti.com

Revision History

Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from A Revision (November 2016) to B Revision ........................................................................................... Page

• Added device type to include the UCC21530EVM-286 Evalustion Module ....................................................... 4

Changes from Original (June 2016) to A Revision ......................................................................................................... Page

• Added device type to include the UCC20520EVM-286 and UCC21521CEVM-286 Evalustion Modules ..................... 4

SLUUBG8B–June 2016–Revised November 2018

Submit Documentation Feedback

Copyright © 2016–2018, Texas Instruments Incorporated

Revision History

17

Page 18

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2018, Texas Instruments Incorporated

Loading...

Loading...