8/94

Stepper Motor Drive Circuit

UC1517

UC3517

ABSOLUTE MAXI MUM RATING S

Second Level Supply, V SS . . . . . . . . . . . . . . . . . . . . . . . . . . 40V

Phase Outp u t Sup ply, V

MM . . . . . . . . . . . . . . . . . . . . . . . . . 40 V

Logic Supply, V

CC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7V

Logic Input Volt age . . . . . . . . . . . . . . . . . . . . . . . . . -.3V to +7V

Logic Input Cur ren t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ±10mA

Output Current , Each Phas e . . . . . . . . . . . . . . . . . . . . . . 500mA

Output Current , Emit ter Follower . . . . . . . . . . . . . . . . . . -500mA

Power Dissipation , (Note). . . . . . . . . . . . . . . . . . . . . . . . . . . . 1W

Power Dissipation , (Note) . . . . . . . . . . . . . . . . . . . . . . . . . . . 2W

Junction Te mp era ture . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150°C

Ambient Temperatu re, UC151 7. . . . . . . . . . . . -55°C to +125°C

Ambient Temperature, UC3517 . . . . . . . . . . . . . . 0°C to +70°C

Storage Tem per at ure . . . . . . . . . . . . . . . . . . . -55°C to +150°C

Note: Consult Packag ing sect ion of Databo ok f or ther m al

limitations and cons idera tion s of package.

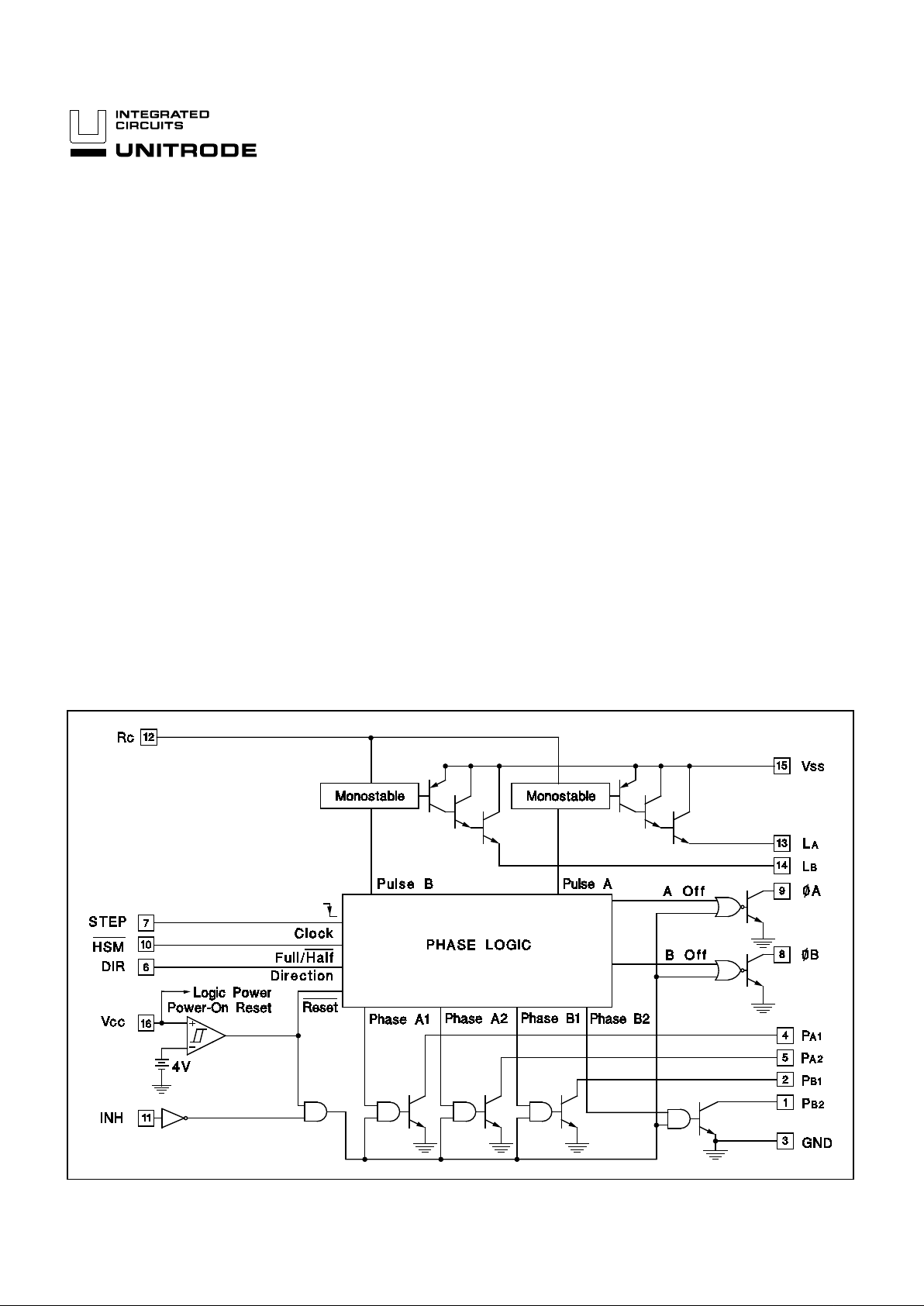

BLOCK DIAGRAM

FEATURES

• Complete Motor Driver and Encoder

• Continuous Drive Capability 350mA per Phase

• Contains all Required Logic for Full and Half

Stepping

• Bilevel Operation for Fast Step Rates

• Operates as a Voltage Doubler

• Useable as a Phase Generator and/or as a

Driver

• Power-On Reset Guarantees Saf e,

Predictable Power-Up

DESCRIPTI ON

The UC3517 contains four NPN drivers that operate in two-phase

fashion for full-step and half-step motor control. The UC3517

also contains two emitter fo llowers, two monostables, phase decoder logic, power-on reset, and low-voltage protection, making it

a versatile system for driving small stepper motors or for controlling large power devices.

The emitter followers and monostables in the UC3517 are configured to apply higher-voltage pulses to the motor at each step

command. This drive technique, called “Bilevel,” allows faster

stepping than common resistive current limiting, yet generates

less electrical noise than chopping techniques.

PARAMETER TEST CONDITIONS

UC1517 / UC3517 UNITS

MIN TYP MAX

Logic Supply, V

CC Pin 16 4.75 5.25 V

Second Supply, V

SS Pin 15 10 40 V

Logic Supply Current V

INH = 0.4V 45 60 mA

V

INH = 4.0V 12 mA

Input Low Voltage Pins 6, 7, 10, 11 0.8 V

Input High Voltage Pins 6, 7, 10, 11 2.0 V

Input Low Current Pins 6, 7, 10, 11; V = 0V -400 µA

Input High Current Pins 6, 7, 10, 11; V = 5V 20 µA

Phase Output Sat ura tion Voltag e Pins 1, 2, 4, 5; I = 350mA 0.6 0.85 V

Phase Output Leak age Cur rent Pins 1, 2, 4, 5; V = 39V 500 µA

Follower Saturation Voltage to V

SS Pins 13,14; I = 350mA -2 V

Follower Leakage Curre nt Pins 13,14; V = 0V 500 µA

Output Low Voltage , Ø

A, ØB Pins 8, 9; I = 1.6mA 0.1 0.4 V

Phase Turn-On Time Pins 1, 2, 4, 5 2 µs

Phase Turn-Off Time Pins 1, 2, 4, 5 1.8 µs

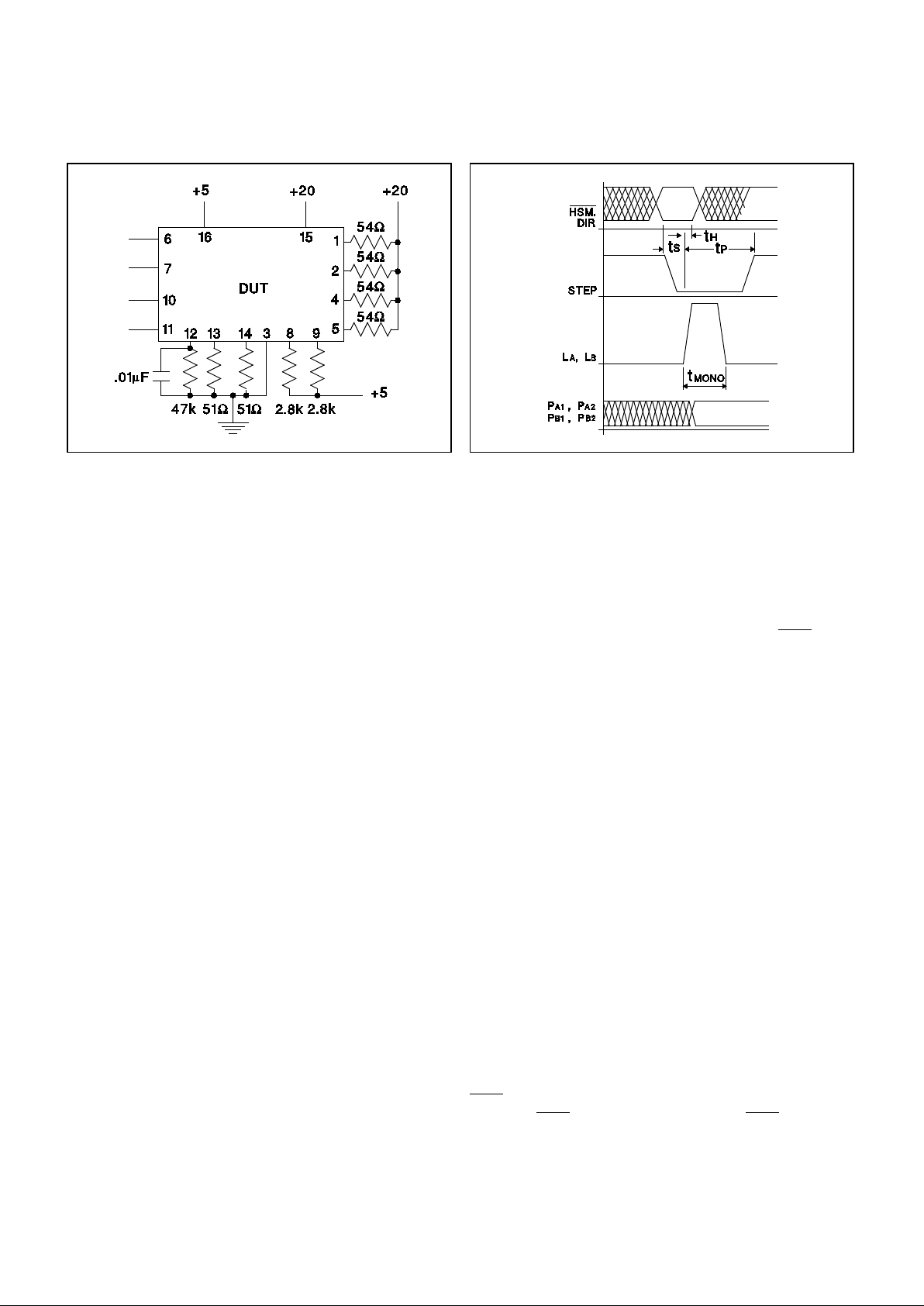

Second-Level On Time. T

MONO Pins 13,14; Figure 3 Test Circuit 275 325 375 µs

Logic Input Set-up Time, t

S Pins 6, 10; Figure 4 400 ns

Logic Input Hold Time, t

h Pins 6, 10; Figure 4 0 ns

STEP Pulse Width, t

P Pin 7; Figure 4 800 ns

Timing Resistor Valu e Pin 12 1k 100k Ω

Timing Capacitor Value Pin 12 0.1 500 nF

Power-On Threshold Pin 16 4.3 V

Power-Off Thr esho ld P in 16 3.8 V

Power Hysteresis Pin 16 0.5 V

UC1517

UC3517

PACKAGE PIN FUNCTION

FUNCTION PIN

N/C 1

PB2 2

PB1 3

GND 4

PA1 5

N/C 6

PA2 7

DIR 8

STEP 9

ØB 10

N/C 11

ØA 12

HSM 13

INH 14

RC 15

N/C 16

LA 17

LB 18

VSS 19

VCC 20

PLCC-20, LCC-20

(TOP VIEW)

Q & L PACKAGE

DIL-16 (TOP VIEW)

J or N Package

CONNECTION DIAGRAMS

Unless other wise stat ed, these specif icat ions ap ply fo r TA = -55°C to +125°C for the

UC1517 and 0°C to +70°C for the UC35 17, Vcc=5 V, V

SS = 20V, TA=TJ

.

Pin

numbers refer to DIL- 16 pa ckag e.

ELECTRICAL CHARACTERISTICS:

2

PIN DESCRIPTION

VCC: VCC is the UC3517’s logic supply. Connect to a

regulated 5VDC, and bypass with a 0.1µF ceramic ca-

pacitor to absorb switching transients.

V

MM: VMM is the pri mary motor supply. It connects to the

UC3517 phase outputs through the motor windings. Limit

this supply to less than 40V to prevent breakdown of the

phase output transistors. Select the nominal V

MM voltage

for the desired continuous winding current.

V

SS: VSS is the secondary motor supply. It drives the LA

and LB outputs of the UC35 17 w hen a mono stable in the

UC3517 is active. In the bilevel application, this supply is

applied to the motor to charge the winding inductance

faster than the primary supply could. Typically, Vss is

higher in voltage than V

MM, al though VSS must be less

than 40V. The V

SS supply should have good transient ca-

pability.

GROUND: The ground pin is the common reference for

all supplies, inputs and outputs.

RC: RC controls the timing functions of the monostables

in the UC3517. It is normally connected to a resistor (R

T)

and a capacitor (C

T) to ground, as shown in Figure 3.

Monostable on time is determined by the formula T

ON ≈

0.69 R

T CT. To keep the monostabl e on indefinitely, pull

RC to V

CC through a 50k resistor. The UC3517 contains

only one RC pin for two monostables. If step rates comparable to T

ON are commanded, incorrect pulsing can re-

sult, so consider maximum step rates when selecting R

T

and CT. Keep TON ≤ T STEP MAX.

Ø

A and ØB: These logic outputs indicate half-step posi-

tion. These outputs are open-col lector, low-current drivers, and may directly drive TTL logic. They can also drive

CMOS logic if a pull-up resistor is provided. Systems

which use the UC35 17 as an encoder and use a different

driver can use these outputs to disable the external driver,

as shown in Figure 8. The sequencing of these outputs is

shown in Figure 5.

P

A1, PA2, PB1, and PB2: The phase outputs pull to

ground sequentially to cause motor stepping, according to

the state diagram of Figure 5. The sequence of stepping

on these lines, as well as with the L

A and LB lines is con-

trolled by STEP input, the DIR input, and the

HSM input.

Caution: If these outputs or any other IC pins are pulled

too far below ground either continuously or in a transient,

step memory can be lost. I t is recommended that these

pins be clamped to ground and supply with high-speed diodes when driving inductive loads such as motor windings or solenoids. This clamping is very important

because one side of the wi nding can "ki ck" in a direction

opposite the swing of the other side.

L

A and LB: These outputs pull to VSS when their corre-

sponding monostable is active, and will remain high until

the monostable time elapses. Before and after, these outputs are high-impedance. For detail timing information,

consult Figure 5.

STEP: This logic input clocks the logic in the UC3517 on

every falling edge. Like all other UC3517 inputs, this input

is TTL/CMOS compatible, and should not be pulled below

ground.

DIR: This logic input controls the motor rotation direction

by controlling the phase output sequence as shown in

Figure 5. This signal must be stable 400ns before a falling

edge on S TEP, and must remain stable through the edge

to insure correct stepping.

HSM: This logic input switches the UC3517 between halfsteppin g (

HSM = low) and full-stepping (HSM = high) by

controlling the phase output sequence as show in Figure

5. This line requires the same set-up time as the DIR input, and has the same hold requirement.

UC1517

UC3517

Figure 3. Test Circuit Figure 4. T im ing Waveforms

3

UC1517

UC3517

INH: When the inhibit i nput is high, the phase and θ out-

puts are inhibited (high impedance). STEP pulses received while inhibi ted will continue t o update logic in the

IC, but the states will not be reflected at the outputs until

inhibit is pulled low. In stepper motor systems, this can be

used to save power or to allow the rotor to move freely for

manual repositioning.

OPERATING MODES

The UC3517 is a system component capable of many different operating modes, including:

Unipolar Stepper Driver: In its simplest form, the

UC3517 can be connected to a stepper motor as a unipolar driver. L

A, LB, RC and Vss are not used, and may be

left open. All other system design considerations mentioned above apply, including choice of motor supply

VMM, undershoot diodes and timing considerations.

Unipolar Bilevel Stepper Driver: If increased step rates

are desired, the ap plicatio n ci rcuit of Figure 6 makes use

of the monostables and emitter followers as well as the

configuration mentioned above to provide high-voltage

pulses to the motor windings when the phase is turned

on. For a given dissipation level, this mode offers faster

step rates, and very little additional electrical noise.

The choice of monostable co mponents can be estimated

based on the timing relationship of motor current and voltage: V = Ldl/dt. Assuming a fixed secondary supply voltage (V

SS), a fixed winding inductance (LM), a desired

winding peak current (I

W), and no back EMF from the mo-

tor, we can estimate that R

TCT = 1.449 IWLM/VSS. In

practice, these calculations should be confirmed and adjusted to accommodate for effect s not modeled.

V oltage-Dou bled Mo de: The UC3517 can also be used

to generate higher vol tages than available with the system power supplies using capacitors and diodes. Figure 9

shows how this might be done, and gives some estimates

for the component values.

Higher Current Op eratio n : For systems requiring more

than 350mA of drive per phase, the UC3717A can be

used in conjunction with discrete power transistors or

power driver ICs, like the L298. These can be connected

as current gain devices that turn on when the phase outputs turn on.

Bipolar Mot or D riv e: Bipolar motors can be controlled by

the UC3517 with the addition of bipolar integrated drivers

such as the UC3717A (Figure 8) and the L298, or discrete

devices. Care should be taken with discrete devices to

avoid potential cross-conduction prob lems.

LOGIC FLOW GRAPH

The UC3517 con tains a bi directional counter which is decoded to generate the correct phase and Ø outputs. This

counter is incremented on every falling edge of the STEP

input. Figure 5 shows a graph representing the counter

sequence, inputs that determine the next state (DIR and

HSM), and the outputs at each state. Each circle represents a unique logic state, and the four inside circles represent the half-step stat es.

The four bits inside the circl es represent the phase outputs in each state (P

A1, PA2, PB1, and PB2). For example,

the circle label ed 1010 is immediatel y entered when the

device is powered up, and represents P

A1 off ("1" or

high), P

A2 on ("0" or low), PB1 off ("1" or high) and PB2 on

("0" or low). The Ø

A and ØB outputs are both low (uniden-

tified).

The arrows in the graph show the state chan ges. For ex-

ample, if the IC is in state 0110, DIR is high,

HSM is high,

and STEP falls, the next state will be 0101, and a pulse

will be generated on the L

B line by the monostable.

Inhibit will not effect the logic state, but it will cause all

phase outputs and both Ø outputs to go high (off). A fall-

ing edge o n STEP will still cause a state change, but inhibit will have to toggle low for the state to be apparent.

A falling edge on STEP with

HSM high will cause the

counter to advance to the next full step state regardless

of whether or not it was in a full step state previously.

No L

A or LB pulses are generated entering half-states.

4

UC1517

UC3517

For applications requiring very fast step rates, a zener diode

permits windings to discharge at higher voltages, and higher

rates. Driver transistor breakdown must be considered when

selecting Vss and zener voltage to insure that the outputs will

not overshoot past 40V. I f the zener diodes are not used and

UC3610 pin 2 is connected directly to Vss then higher Vss can

be used.

Figure 6. Bilevel Motor Driver

Figure 5. Logic Flow Graph

5

UC1517

UC3517

Experimental selection of RT and CT allow the designer to select a small amount of winding current overshoot, as shown

above. Although the overshoot may exceed the continuous

rated current of the winding and the drive transistors, the dura-

tion can be well controlled. Average power dissipation for the

driver and motor must be considered when designing systems with intentional overshoot, and must stay within conservative limits for short duty cycles.

In this application, the ∅A and ∅B o utputs of the UC3517 are

connected to the current program inputs of the UC3717. This

allows the UC3517 inhibit signal to inhibit the UC3717, and

also allows half-step operation of the UC3717. Peak motor

winding current will be limited to approximately .42V/R1 by

chopping.

Figure 7. E ffects of Different RT & CT on Bilevel Syste ms

Figure 8. I nt erf ace to UC371 7 Bipolar Dr iv er

6

UC1517

UC3517

Although compo nent value s can be best opt imize d expe riment ally, good starting values speed developm ent . For this des ign,

start with: where:

RT CT = 3 LW/RW LW is winding inductance,

C

1 = C2 = LW IR/RW RW is winding resistance,

R

1 = R2 = 2.9 TMIN/C1 IR is rated winding current, and

T

MIN

is minimum step period expected.

UNITRODE INTEGRATED CIRCUITS

7 CONTINENTAL BL VD. •• MERRIMACK, NH 03054

TEL. (603) 424-2410 •• FAX (603) 424-3460

Figure 9. Using the UC3517 as a Voltage Dou bler

7

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...