High Power Factor Preregulator

UC1853

UC2853

UC3853

FEATURES

• Complete 8-pin Power Factor

Solution

• Reduced External Components

• RMS Line Voltage Compensation

• Precision Multiplier/Squarer/Divider

• Internal 75kHz Synchronizable

Oscillator

• Average Current Mode PWM

Control

• Overvoltage Protection Comparator

• High Current, Clamped Gate Driver

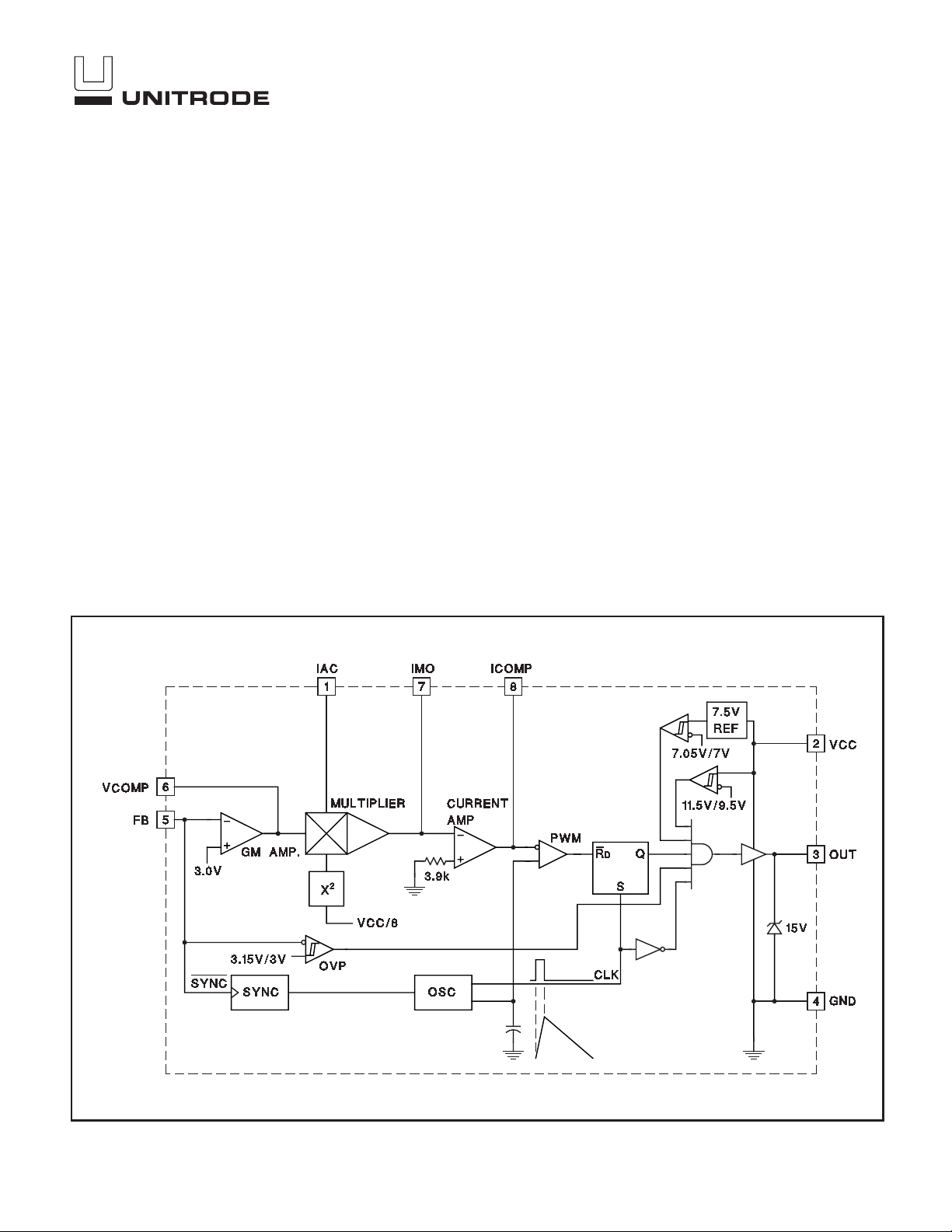

BLOCK DIAGRAM

DESCRIPTION

The UC3853 provides simple, yet high performance active power factor

correction. Using the same control technique as the UC1854, this 8-pin device exploits a simplified architecture and an internal oscillator to minimize

external component count. The UC3853 incorporates a precision multiplier/squarer/divider circuit, voltage and current loop error amplifiers, and a

precision voltage reference to implement average current mode control

with RMS line voltage compensation. This control technique maintains constant loop gain with changes in input voltage, which minimizes input line

current distortion over the worldwide input voltage range.

The internal 75kHz oscillator includes an external clock input, allowing synchronization to downstream converters. Additionally, the device features an

overvoltage protection comparator, a clamped MOSFET gate driver which

self-biases low during undervoltage lockout, and low startup and supply

current.

These devices are available in 8-pin plastic and ceramic dual in-line (DIP)

packages, and 8-lead small outline (SOIC) packages. The UC1853 is

specified for operation from –55°C to +125°C, the UC2853 is specified for

operation from –25°C to +85°C, and the UC3853 is specified for operation

from 0°C to +70°C.

11/97

UDG-94120-1

UC1853

UC2853

UC3853

ABSOLUTE MAXIMUM RATINGS

Supply Voltage (VCC) .............................40V

Output Drive Current,

Continuous ................................0.125A

Peak .......................................0.5A

Output Minimum Voltage.........................–0.3V

IAC Maximum Input Current........................1mA

IMO Maximum Output Current .....................–2mA

IMO Minimum Voltage ...........................–0.3V

FB Maximum Input Voltage ..........................5V

VCOMP Maximum Voltage.........................6.2V

ICOMP Sourcing Current ....................Self-Limiting

ICOMP Sinking Current ..........................20mA

ICOMP Maximum Voltage .........................7.2V

Storage Temperature ...................–65°C to +150°C

Junction Temperature...................–55°C to +150°C

Lead Temperature (Soldering, 10 sec.).............+300°C

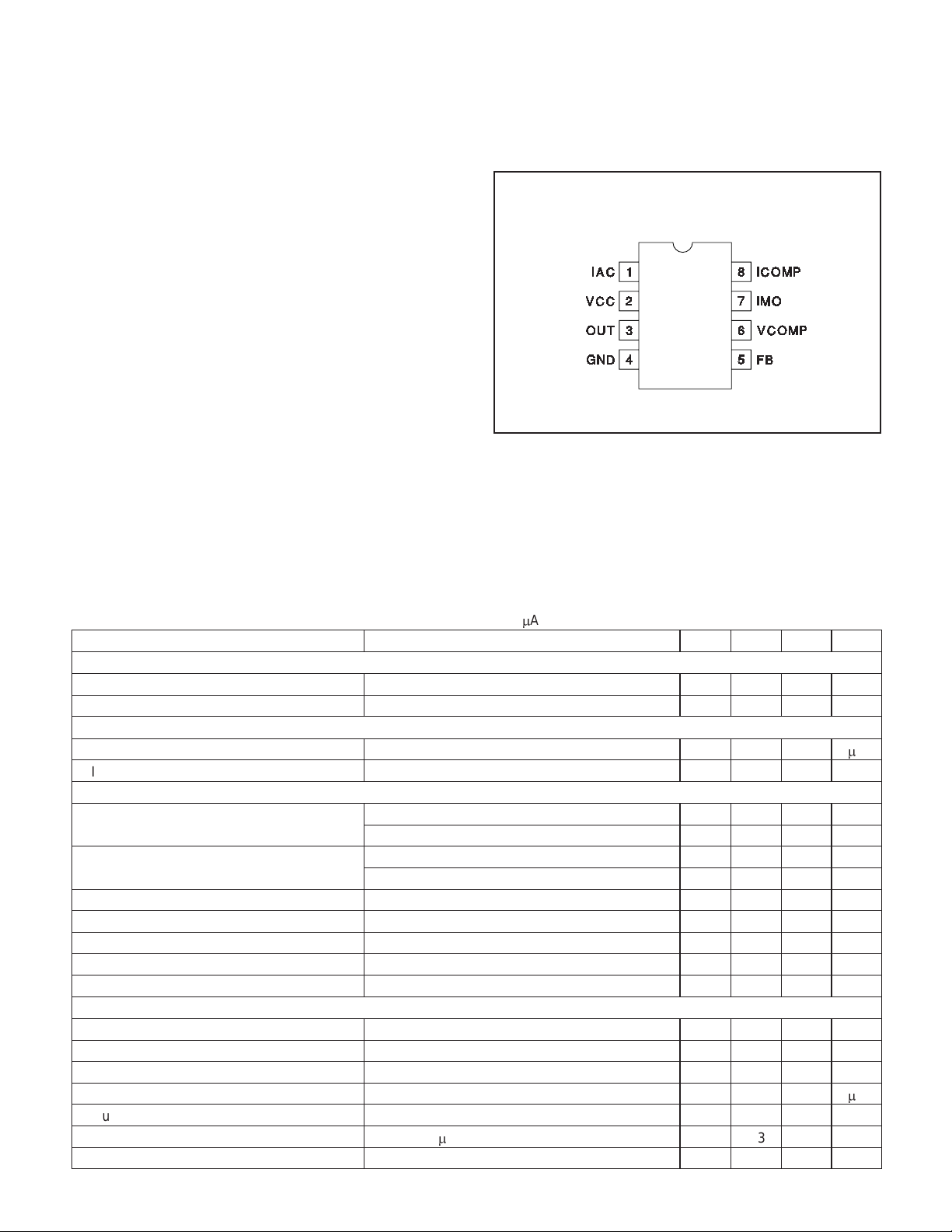

CONNECTION DIAGRAM

DIL-8, SOIC-8 (Top View)

JorN,DPackage

All voltages with respect to GND.Currents are positive into,

negative out of the specified terminal. Consult Packaging Section

of Databook for thermal limitations and considerations of

packages.

ELECTRICAL CHARACTERISTICS

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Undervoltage Lockout Section

VCC Turn-on Threshold V

Hysteresis 1.5 1.8 2.1 V

Supply Current Section

CC Startup VCC = 8V, IAC = 100µA; VVCOMP,VICOMP Open 250 500

IV

IVCC IAC=0µA, VICOMP =0V 10 15 mA

Voltage Loop Error Amplifier Section

Transconductance IOUT=±20µA 0-70C 300 450 575 µmho

Input Voltage 0-70C 2.925 3 3.075 V

AVOL V

Output Sink Current V

Output Source Current VFB = 2.8V, VVCOMP = 3.75V –50 –20 µA

Output Voltage High 5.5 6 V

Output Voltage Low 0.6 0.9 V

Current Loop Error Amplifier Section

Offset Voltage 06mV

Voltage Gain V

Sink Current VIMO = 100mV, VICOMP =3V 1 mA

Source Current VIMO = –0.1V, VICOMP = 3V –150 –80

Output High I

Output Low IICOMP =50mA 0.3 0.8 V

PWM Modulator Gain VICOMP = 2V – 3V (Note 1) 20 %/V

Unless otherwise stated, these parameters apply for TA = –55°C to +125°C for the

UC1853; –25°C to +85°C for the 2853; and 0°C to +70°C for the UC3853; VCC =

16V, VFB = 3V, IAC = 100mA, VVCOMP = 3.75V, VICOMP = 3V, TA =TJ.

VCOMP,VICOMP Open 11.5 13 V

m

A

Temperature 135 640 µmho

Temperature 2.9 3.1 V

VCOMP =1V–4V 50 60 dB

FB = 3.2V, VVCOMP = 3.75V 20 50 µA

ICOMP =1V–4V 70 dB

m

A

ICOMP = –50mA 6 6.8 V

2

UC1853

UC2853

UC3853

ELECTRICAL CHARACTERISTICS

(continued)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Multiplier Section

Output Current – IAC Limited VCC = 11V, VVCOMP = 6V –230 –200 –170 µA

Output Current – Zero IAC = 0µA –2 –0.2 2 µA

Output Current – Power Limited VCC = 12V, V

Output Current VCC= 12V, V

Multiplier Gain Constant VCC= 12V, VVCOMP = 5.5V (Note 2) –1.05 –0.9 –0.75 V

Oscillator Section

Oscillator Initial Frequency TA = 25°C 67.5 75 82.5 kHz

Oscillator Frequency Line, Load, Temperature 56 75 94 kHz

Synchronization Frequency Range 100 kHz

Synchronization Pulse Amplitude Pulse slew rate = 100V/msec (Note 3) 2 V

Output Driver Section

Maximum Output Voltage 0mA load, VCC = 20V 12 15 17.5 V

Output High 0mA load, VCC = 12V, ref. to VCC –2.7 –1.7 V

Output Low (Device Inactive) Vcc = 0V, 20mA load (Sinking) 0.9 2.0 V

Output Low (Device Active) 50mA load (Sinking) 0.5 1 V

OUT Rise Time 1nF from OUT to GND 55 100 ns

OUT Fall Time 1nF from OUT to GND 35 100 ns

OUT Maximum Duty Cycle V

OVP Comparator Section

Threshold Voltage Volts Above EA Input V 90 150 mV

Hysteresis 80 mV

Unless otherwise stated, these parameters apply for TA = –55°C to +125°C for the

UC1853; –25°C to +85°C for the 2853; and 0°C to +70°C for the UC3853; VCC =

16V, VFB = 3V, IAC = 100mA, VVCOMP = 3.75V, VICOMP = 3V, TA =TJ.

VCOMP = 5.5V –236 –178 –168 µA

VCOMP = 2V –22 µA

VCC= 12V, VVCOMP = 5V –156 µA

VCC= 40V, VVCOMP =2V –2 µA

VCC= 40V, V

–50mA load, VCC = 12V, ref. to VCC –3 –2.2 V

ICOMP =0V 88 93 %

VCOMP = 5V –14 µA

–1

Note 1:

DutyCycle

PWM modulator gain

∆

=

ICOMP

V

∆

Note 2:

Gain constant K

()

=

•

IMO VCC

••

15

VCC

64

, VCC = 12V.

IAC VCOMP V

(.)

Note 3.

Synchronization is accomplished with a falling edge of 2V mag-

µ

nitude and 100V/

sec slew rate.

3

PIN DESCRIPTIONS

FB: Voltage Amplifier Inverting Input, Overvoltage

Comparator Input, Sync Input. This pin serves three

functions. FB accepts a fraction of the power factor

corrected output voltage through a voltage divider, and is

nominally regulated to 3V. FB voltages 5% greater than

nominal will trip the overvoltage comparator, and shut

down the output stage until the output voltage drops 5%.

The internal oscillator can be synchronized through FB by

injecting a 2V clock signal though a capacitor. To prevent

false tripping of the overvoltage comparator, the clock

signal must have a fast falling edge, but a slow rising

edge.See Application Note U-159 for more information.

GND: Ground. All voltages are measured with respect to

GND. The VCC bypass capacitor should be connected to

ground as close to the GND pin as possible.

IAC: AC Waveform Input. This input provides voltage

waveform information to the multiplier. The current loop

will try to produce a current waveform with the same

shape as the IAC signal. IAC is a low impedance input,

nominally at 2V, which accepts a current proportional to

the input voltage. Connect a resistor from the rectified input line to IAC which will conduct 500mA at maximum line

voltage.

IMO: Multiplier Output and Current Sense Inverting Input.

The output of the multiplier and the inverting input of the

current amplifier are connected together at IMO. Avoid

bringing this input below –0.5V to prevent the internal protection diode from conducting. The multiplier output is a

current, making this a summing node and allowing a differential current error amplifier configuration to reject

ground noise. The input resistance at this node should be

3.9k to minimize input bias current induced offset voltage.

See the Applications section for the recommended circuit

configuration.

OUT: Gate Driver Output.OUT provides high current gate

drive for the external power MOSFET. A 15V clamp pre-

UC1853

UC2853

UC3853

vents excessive MOSFET gate-to-source voltage so that

the UC3853 can be operated with VCC and high as 40V.

A series gate resistor of at least 5 ohms should be used

to minimize clamp voltage overshoot. In addition, a

Schottky diode such as a 1N5818 connected between

OUT and GND may be necessary to prevent parasitic

substrate diode conduction.

ICOMP: Current Loop Error Amplifier Output. The current loop error amplifier is a conventional operational

amplifier with a 150µA current source class A output

stage. Compensate the current loop by placing an impedance between ICOMP and IMO. This output can

swing above the oscillator peak voltage, allowing zero

duty cycle when necessary.

VCC: Input Supply Voltage. This pin serves two functions. It supplies power to the chip, and an input voltage

level signal to the squarer circuit. When this input is connected to a DC voltage proportional to the AC input RMS

voltage, the voltage loop gain is reduced by

.

2

CC

This configuration maintains constant loop gain. The

UC3853 input voltage range extends from 12V to 40V,

allowing an AC supply voltage range in excess of 85VAC

to 265VAC. Bypass VCC with at least a 0.1µF ceramic

capacitor to ensure proper operation. See the Applications section for the recommended circuit configuration.

VCOMP: Voltage Loop Error Amplifier Output. The

voltage loop error amplifier is a transconductance type

operational amplifier. A feedback impedance between

VCOMP and FB for loop compensation must be avoided

to maintain proper operation of the overvoltage

protection comparator. Instead, compensate the voltage

loop with an impedance between VCOMP and GND.

When VCOMP is below 1.5V, the multiplier output

current is zero.

4

UC3853 TYPICAL APPLICATION

UC1853

UC2853

UC3853

Note: the application circuit shownis a 100W, 75KHz design.

Additional application information can be found in Application

Note U–159 and Design Note DN–78.

UNITRODE CORPORATION

7 CONTINENTAL BLVD.• MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

UDG-97127

5

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERTAIN APPLICA TIONS USING SEMICONDUCT OR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...