UC1841

UC2841

UC3841

Programmable, Off-Line, PWM Controller

• All Control, Driving, Monitoring, and

Protection Functions Included

• Low-current, Off-line Start Circuit

• Voltage Feed Forward or Current

Mode Control

• Guaranteed Duty Cycle Clamp

• PWM Latch for Single Pulse per Period

• Pulse-by-Pulse Current Limiting Plus

Shutdown for Over-Current Fault

• No Start-up or Shutdown Transients

• Slow Turn-on Both Initially and After

Fault Shutdown

• Shutdown Upon Over- or

Under-Voltage Sensing

• Latch Off or Continuous Retry After

Fault

• PWM Output Switch Usable to 1A

Peak Current

• 1% Reference Accuracy

• 500kHz Operation

• 18 Pin DIL Package

The UC1841 famil y of PWM controllers has been designed to increase

the level of versatility while retaining all of the performance features of

the earlier UC18 40 devices. Wh ile still optimized for highly-efficient bootstrapped pri mary-side operati on in forward or flyback power converters,

the UC1841 is equall y adept in impl ementing b oth low a nd high voltage

input DC to DC converters. Important performance features include a

low-current starting circuit, linear feed-forward for constant volt-second

operation, and compatibility with either voltage or current mode topologies.

In addition to start-up and normal regulating PWM functions, these devices include built in protection from over-voltage, under-voltage, and

over-current fault conditions with the option for either latch-of f or automatic restart.

While pin compatib le with the UC1840 in all respects except that the polarity of the External Stop has bee n re versed, the UC1841 offers the following improvements:

1. Fault latch reset is accomplished with slow start discharge rather

than recycling the input voltage to the chip.

2. The External Stop input can be used for a fault delay to resist

shutdown from short durat ion transients.

3. The duty-cycle clamping function has been characterized an d

specified.

The UC1841 is characteri zed for -55°C to +125°C operation while the

UC2841 and UC3841 are desi gned for -25°C to +85°C and 0°to +70°C,

respectively.

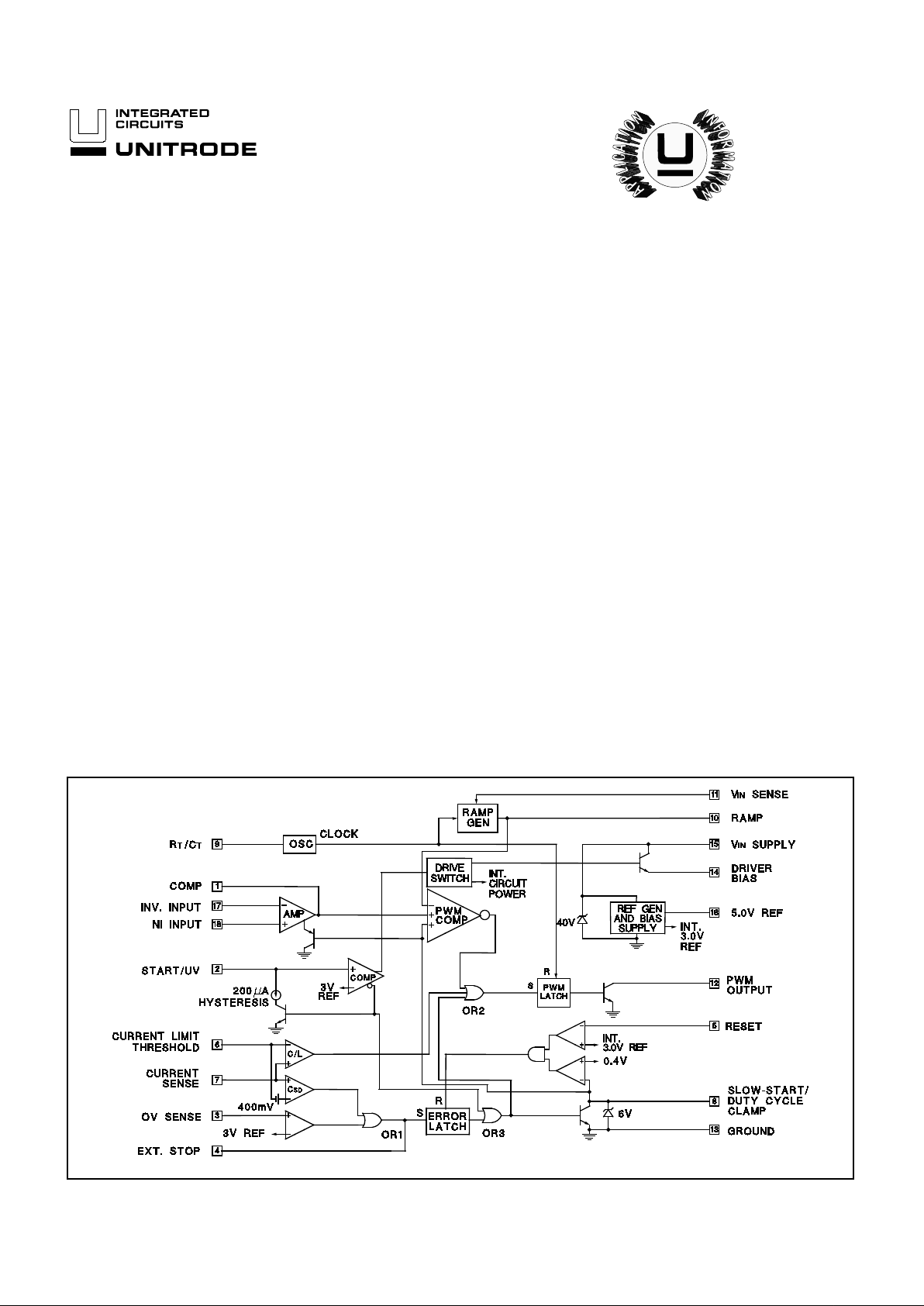

BLOCK DIAGRAM

Note: Positive tru e logic, latch out put s high with set , reset has prior ity.

6/93

DESCRIPTI ONFEATURES

PARAMETER TEST CONDITIONS

UC1841 / UC2841 UC3841 UNITS

MIN TYP MAX MIN TYP MAX

Power Inputs

Start-Up Curr ent V

IN = 30V, Pin 2 = 2.5V 4.5 6 4.5 6 mA

Operating Cur ren t V

IN = 30V, Pin 2 = 3.5V 10 14 10 14 mA

Supply OV Clamp I

IN = 20mA 33 40 45 33 40 45 V

Reference Sec tio n

Reference Voltage T

J = 25°C 4.95 5.0 5.05 4.9 5.0 5.1 V

Line Regulation V

IN = 8 to 30V 10 15 10 20 mV

Load Regulation I

L = 0 to 10mA 1020 1030mV

Temperature Stability Over Operating Temper ature Range 4.9 5.1 4 .8 5 5.15 V

Short Circuit Current V

REF = 0, TJ

= 25°C -80 -100 -80 -100 mA

Oscillator

Nominal Frequency T

J

= 25°C 47 50 53 45 50 55 kHz

Voltage Stability V

IN = 8 to 30V 0.5 1 0.5 1 %

Temperature Stability Over Operating Temper ature Range 45 55 43 57 kHz

Maximum Frequency R

T = 2kΩ, CT = 330pF 500 500 kHz

UC1841

UC2841

UC3841

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated , these spec ificat ions apply for TA = -55°C to +125°C for the

UC1841, -25°C to +85°C for the UC2841, and 0°C to +70 °C for the UC3841; V

IN = 20V, RT = 20k Ω, CT = .001mfd, RR = 10kΩ,

C

R = .001mfd, Current Limit Th res hold = 200 mV, TA = TJ.

Supply Voltage, +VIN (Pin 15) (Note 2)

Voltage Driven. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . +32V

Current Driven, 100mA maximum. . . . . . . . . . . . Self-limiting

PWM Output Volta ge (Pin 12 ) . . . . . . . . . . . . . . . . . . . . . . . 40V

PWM Out put Current, Ste ady-State (Pin 12). . . . . . . . . 400mA

PWM Output Peak Energy Disc harge . . . . . . . . . . . . 20 µJo ules

Driver Bias Current (Pin 14). . . . . . . . . . . . . . . . . . . . . -200mA

Reference Output Current (Pin 16) . . . . . . . . . . . . . . . . -50mA

Slow-Start Sink Curren t (Pin 8) . . . . . . . . . . . . . . . . . . . . 20mA

V

IN Sense Current (Pin 11). . . . . . . . . . . . . . . . . . . . . . . . 10mA

Current Limit Input s (Pins 6 & 7) . . . . . . . . . . . . . -0. 5 to +5.5 V

Stop Input (Pin 4) . . . . . . . . . . . . . . . . . . . . . . . . . -0.3 to +5.5V

Compara to r Inputs

(Pins 1, 7, 9-1 1, 16). . . . . . . . . . . . Internally clamped at 12V

Power Dissipation at T

A = 25°C (Note 3) . . . . . . . . . . . 1000mW

Power Dissipation at T

C = 25°C (Note 3). . . . . . . . . . . 2000mW

Operating Junct ion Te mp era tu re . . . . . . . . . . -55°C to +150°C

Storage Temperature Ra nge. . . . . . . . . . . . . . -65°C to +150°C

Lead Temp era ture (Solder ing, 10 sec). . . . . . . . . . . . . +300°C

Note 1: All voltages are with respect to ground, Pin 13.

Currents are positiv e-int o, neg at ive-o ut of the specif ie d

terminal.

Note 2: All p in num ber s are refer ence d to DIL- 18 pa ckag e.

Note 3: C on sult Packag in g Section of Dat aboo k for ther ma l

limitations and cons id era tion s of packa ge.

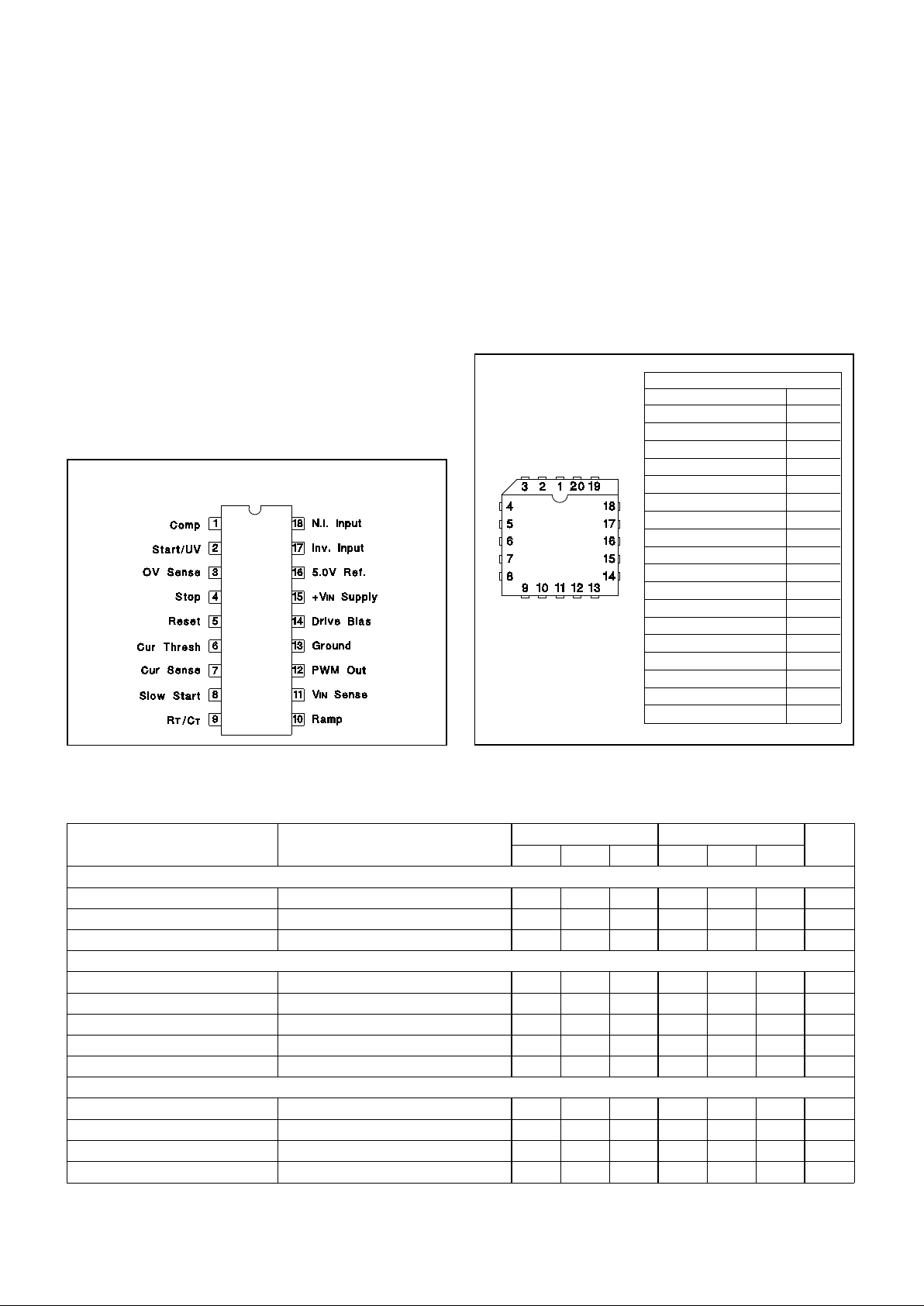

CONNECTION DIAGRAMS

PLCC-20, LCC-20

(TOP VIEW)

Q or L Package

DIL-18, SOIC- 18 (T O P VIEW)

J or N, DW Package

PACKAGE PIN FUNCTIONS

FUNCTION PIN

Comp 1

Start/UV 2

OV Sense 3

Stop 4

Reset 5

CUR Thresh 7

CUR Sense 8

Slow Start 9

R

T/CT 10

Ramp 11

V

IN Sense 12

PWM Out 13

Ground 14

Drive Bias 15

+V

IN Supply 17

5.0V REF 18

Inv. Input 19

N.I. Inpu t 20

ABSOLUTE MAXI MUM RATING S

2

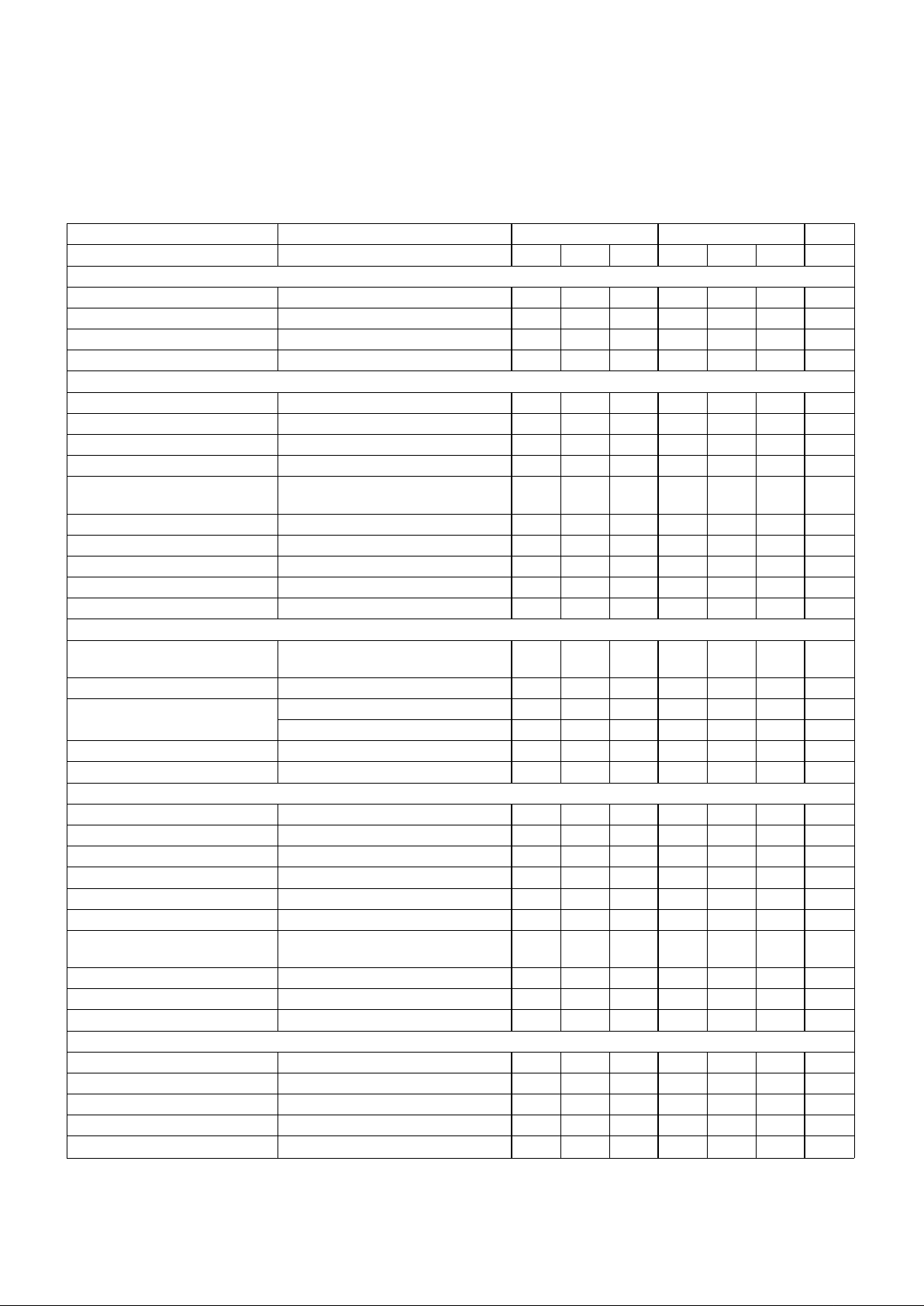

PARAMETER TEST CONDITIONS UC1841 / UC2841 UC3841 UNITS

MIN TYP MAX MIN TYP MAX

Ramp Ge nerator

Ramp Curren t, M in imum I

SENSE = -10µA -11 -14 -11 -14 µA

Ramp Current, Maximum I

SENSE = 1.0mA -0.9 -.95 -0.9 -.95 mA

Ramp Valley 0.3 0.4 0.6 0.3 0.4 0.6 V

Ramp Peak Clamp ing Leve l 3.9 4.2 4.5 3.9 4.2 4.5 V

Error Amplifier

Input Offs et Vo lta g e V

CM = 5.0V 0.5 5 2 10 mV

Input Bias Cur ren t 0.5 2 1 5 µA

Input Offs et Cu rr ent 0.5 0.5 µA

Open Loop Gain ∆V

O= 1 to 3V 60 66 60 66 dB

Output Swing (Max. Output ≤

Ramp Peak - 100mV)

Minimum Total Range 0.3 3.5 0.3 3.5 V

CMRR V

CM = 1.5 to 5.5V 70 80 70 80 dB

PSRR V

IN = 8 to 30V 70 80 70 80 dB

Short Circuit Current V

COMP = 0V -4 -10 -4 -10 mA

Gain Bandwidth* T

J = 25°C, AVOL = 0dB 1 2 1 2 MHz

Slew Rate* T

J = 25°C, AVCL

= 0dB 0.8 0.8 V/µs

PWM Section

Continuous Duty Cycle

Range* (other than zero)

Minimum Total Cont inuou s Range,

Ramp Peak < 4.2V

495495%

50% Duty Cycle Clamp R

SENSE to VREF = 10k 42 47 52 42 47 52 %

Output Saturation I

OUT = 20mA 0.2 0.4 0.2 0.4 V

I

OUT = 200mA 1. 7 2.2 1.7 2.2 V

Output Lea kage V

OUT = 40V 0.1 10 0.1 10 µA

Comparator Dela y* Pin 8 to Pin 12, T

J = 25°C, RL = 1kΩ 300 500 300 500 ns

Sequencing Functions

Comparator Thre sholds P ins 2, 3, 5 2.8 3.0 3.2 2.8 3.0 3.2 V

Input Bias Curren t Pins 3, 5 = 0V -1.0 -4.0 -1.0 -4.0 µA

Input Leakage Pins 3, 5 = 10V 0.1 2.0 0.1 2.0 µA

Start/UV Hyster esis Cur ren t Pin 2 = 2.5V 170 200 220 1 70 200 23 0 µA

Ext. Stop Threshold Pin 4 0.8 1.6 2.4 0.8 1.6 2.4 V

Error Latch Activat e Cur ren t P in 4 = 0V, Pin 3 > 3V -120 -200 -120 -200 µA

Driver Bias Saturation Volta ge,

V

IN - VOH

IB = -50mA 2 3 2 3 V

Driver Bias Leakage V

B = 0V -0.1 -10 -0.1 -10 µA

Slow-Start Saturation I

S = 10mA 0.2 0.5 0.2 0.5 V

Slow-Start Leakage V

S = 4.5V 0.1 2.0 0.1 2.0 µA

Current Control

Current Limit Off set 0 5 0 10 mV

Current Shutdown O ffs et 370 400 430 360 400 440 mV

Input Bias Current Pin 7 = 0V -2 -5 -2 -5 µA

Common Mode Ran ge* -0.4 3.0 -0.4 3.0 V

Current Limit Delay* T

J = 25°C, Pin 7 to 12, RL = 1k 200 400 200 400 n s

* These paramet ers are guara nt eed by design bu t not 100% teste d in prod uct ion.

UC1841

UC2841

UC3841

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated , these spec ificat ions apply for TA = -55°C to +125°C for the

UC1841, -25°C to +85°C for the UC2841, and 0°C to +70 °C for the UC3841; V

IN = 20V, RT = 20k Ω, CT = .001mfd, RR = 10kΩ,

C

R = .001mfd, Current Limit Thresh old = 200mV, TA = TJ.

3

PWM CONTROL

1. Oscillator Gen era tes a fixed-f requency int er nal clock fro m an extern al R

T and CT.

Frequency =

K

C

RTCT

where KC is a first order correction factor ≈ 0.3 log (CT X 1012).

2. Ramp Gener ator

Develops a linear ramp with a slope defined exter nally by

dv

dt

=

sense

voltage

R

RCR

CR is normally se le ct ed ≤ CT and its value will have some effect upon valley voltage.

Limiting the minimum value for I

SENSE will establish a maximum duty cycle clamp.

C

R terminal can be used as an input port for curren t mode cont rol.

3. Error Amplifier Conventional operation al amp lifier f or closed- loop ga in and phase com pe nsat ion.

Low output impedance; unity-gain stable.

The output is held low by the slow star t voltag e at turn on in order to minimize over shoo t.

4. Reference Ge n era tor Precision 5.0V for internal and extern al usage to 50mA.

Tracking 3.0V ref erence for internal usage only w ith nomina l accur acy of

± 2%.

40V clamp zener for chip OV prot ect ion, 100m A maxim um current .

5. PWM Comparat or Gen era tes out put pulse which start s at terminat ion of clock pulse and ends whe n the ramp

input crosses the lowest of two posit iv e input s.

6. PWM Latch Terminat es the PW M output pulse whe n set by inputs fro m either the PWM com pa rator , the

pulse-by-p ulse cur re nt limit com pa rator , or the error la tch. Reset s with each inter nal clock

pulse.

7. PWM Output Switch Transistor cap able of sinking cu rrent to ground which is of f during the PWM on- time and turns

on to terminate the power pulse. Curr ent capacit y is 400m A sat ur ated with peak

capacitance discha rge in excess of one amp.

SEQUENCING FUNCTIONS

1. Start/UV Sense With an increasing vo lta g e, it generat es a turn-on signa l and relea ses t he slow- star t clamp at

a start threshold.

With a decreasing voltage, it gen era tes a turn- off comma nd at a lower leve l separ at ed by a

200

µA hystere sis cur ren t.

2. Drive Switch Disab le s most of the chip to hold inter nal curre nt consump tion low, and Driver Bias OFF, until

input voltage reaches sta rt threshold.

3. Driver Bias Supplies drive current to exter nal power switch to prov ide turn- on bias .

4. Slow Start Clamps low to hold PWM OFF. Upon release, rises with rate contro lled by R

SCS for slow

increase of output pulse widt h.

Can also be used as an alt ernat e m axim um duty cycle clam p with an ext er nal volt age divid er.

PROTECTION FUNCTIO NS

1. Error Latch When set by mome nt ary input , this latch insur es im me diat e PWM shu tdown and hold of f until

reset. Input s t o Err or La tch are :

a. OV > 3.2V (typically 3V)

b. Stop > 2.4V (typically 1.6V)

c. Current Sense 400mV over thr esho ld (typical) .

Error Latch reset s whe n slow start voltage falls to 0.4V if Rese t Pin 5 < 2.8V. Wit h Pin 5 >

3.2V, Error Latch will remain set.

2. Current Lim iti ng Differential input comparator terminat es individual output pulses each t ime sense voltage

rises above thre shold.

When sense volta ge rise s to 400m V (typica l) above th res hold, a shutdo wn signal is sent to

Error Latch.

3. External Stop A voltage over 1.2 V will set the Erro r Latch and hold the ou tp ut off.

A voltage less than 0. 8V wi ll defe a t the erro r lat ch and prev ent shutd o wn.

A capacitor here will slow the action of the erro r latch for tra nsient prot ection by providing a

typical delay of 13ms/

µF.

UC1841

UC2841

UC3841

FUNCTIONAL DES CRIP TIO N

4

UC1841

UC2841

UC3841

Start/UV Hysteresis

PWM Output Minimu m Pu lse W idthOscillator Frequency

PWM Output-Saturation Voltage

Shutdown TimingError Amplifier Op en Loop Gain an d Phase

5

FLYBACK APPLICATION (A)

In this application (see Figure A, next page), complete

control is maintained on the primary side. Control power

is provide d by R

IN and CIN during start-up, and by a pri-

mary-referenced low voltage winding, N2, for efficient operation after start. The error amplifier loop is closed to

regulate the DC voltage from N2 with other outputs following through their magnetic coupling − a task made

even easier with the UC1841’s feed−forward line regula-

tion.

An extension t o this application for more precise regulation would be the use of the UC1901 Isolated Feedback

Generator for direct closed-loop control to an output.

Not shown, are protective snubbers or additional interface

circuitry which may be required by the choice of the highvoltage switch, Qs, or the application; however, one example of power transistor interfacing is provided on the

following page.

REGULATOR APP LI C ATION (B)

With the addition of a level shifting transistor, Q1, the

UC1841 is an ideal control circuit for DC to DC converters

such as the buck regulator shown in Figure B opposite. In

addition t o providin g constant current drive pulses to the

PIC661 power switch, this circuit has full fault protection

and high speed dynamic line regulation due to its feedforward capability. An additional feature is the ability to

UC1841

UC2841

UC3841

OPEN-LOOP TEST CIRCUIT

Nominal Frequency =

1

R

TCT

= 50 kHz

Start Voltage = 3

R1

+ R2 + R3

R2 + R3

+0.2R1 = 12V

UV Fault Volt age = 3

R1

+ R2 + R3

R2 + R3

= 8V

OV Fault V olt age = 3

R1

+ R2 + R3

R3

= 32V

Current Limit = 200mV

Current Fault Voltage = 600mV

Duty Cycle Clamp = 50%

6

UC1841

UC2841

UC3841

Figure A. UC1841 Programma ble PW M Cont roller In A Simplified Flyback Regulator

Figure B. Overall Schematic For A 300 Watt, Off -line Power Converter Using The UC 3 841 For Control

7

Since Pin 10 is a direct input to the PWM comparator, this

point can also serve as a current sense port for current mode

control. In this application, current sensing is ground referenced through R

CS. Resistor R1 sets a 400mV offset across

R2 (assuming R2 > R

CS) so that both the Error Amplifier and

Fault Shutdown can force the current complete ly to zero. R2 is

also used along with C

F as a small filter to attenuate leading-

edge spikes on the load current waveform. In this mode,

current limiting can be accomplished by divider R3/R4 which

forms a clamp o ver riding the out put of t he Er ror Am plifier.

In this circuit, R1 is used in conjunction with C

R (not shown) to

establish a minimum ramp charging current such that the ramp

voltage reaches 4.2V at the required maximum output pulse

width.

The purpose of Q1 is to provide an increasing ramp current

above a threshold established by R2 and R3 such that the d ut y

cycle is further reduc ed with increa sing VIN.

The minimum ramp current is:

l

R(MIN) =

V

REF − VIN SENSE

R1

≈

4

V

R1

The threshold where VIN begins to add extra ramp curren t is:

V

IN ≈ 5.6V

R2 + R3R3

Above the threshold, the ramp curr ent will be:

l

R (VARIAB ) ≈

4

R1

+

VIN − 5.6

R2

−

5.6

R3

UC1841

UC2841

UC3841

ERROR LATCH INTERNAL CIRCUITRY

PROGRAMMABLE SOFT START AND

RESTART DELAY CIRCUIT

The Error Latch consists of Q5 and Q6 which, when both on,

turns off the PWM Output and pulls the Slow-Start pin low . This

latch is set by either the Over-Voltage or Current Shutdown

comparators, or by a high signal on Pin 4. Reset is accomplished by either the Reset comparator or a low signal on Pin

4. An activation time delay can be provided with an external

capacitor on Pin 4 in conjunction with the ≈ 100µA collector

current from Q4.

UNITRODE INTEGRATED CIRCUITS

7 CONTINENTAL BLVD. • MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

VOLTAGE FEED-FO RWARD COMBINED WITH

MAXIMUM DUTY-CYCLE CLAMP

CURRENT MODE CONTROL

8

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...