Page 1

3

2

4

5

DDC, DBV PACKAGE

(Top View)

1

SW

GND

FB

V

IN

EN

GND SW

V

IN

NC

EN FB

3

2

1

4

5

6

DRV PACKAGE

(Top View)

70

72

74

76

78

80

82

84

86

88

90

0.1 1 10 100

VI = 5 V

VI = 3.6 V

VI = 2.4 V

EFFICIENCY

vs

OUTPUT CURRENT

IO − Output Current − mA

Efficiency − %

V

IN

SW

FB

EN

GND

L1

10 µH

D1

R1

R2

C

FF

C

O

1 µF

V

OUT

VIN to 28 V

V

IN

1.8 V to 6 V

C

IN

4.7 µF

5

4

2

3

1

VO = 18 V

www.ti.com

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

LOW-POWER DC/DC BOOST CONVERTER IN SOT-23 AND SON PACKAGES

Check for Samples: TPS61040, TPS61041

1

FEATURES

• 1.8-V to 6-V Input Voltage Range

• Adjustable Output Voltage Range up to 28 V

• 400-mA (TPS61040) and 250-mA (TPS61041)

Internal Switch Current

• Up to 1-MHz Switching Frequency

• 28-mA Typical No-Load Quiescent Current

• 1-mA Typical Shutdown Current

• Internal Soft Start

• Available in SOT23-5, TSOT23-5,

and 2 × 2 × 0.8-mm SON Packages

APPLICATIONS

• LCD Bias Supply

• White-LED Supply for LCD Backlights

• Digital Still Camera

• PDAs, Organizers, and Handheld PCs

• Cellular Phones

• Internet Audio Player

• Standard 3.3-V/5-V to 12-V Conversion

DESCRIPTION

The TPS61040/41 is a high-frequency boost

converter dedicated for small to medium LCD bias

supply and white LED backlight supplies. The device

is ideal to generate output voltages up to 28 V from a

dual cell NiMH/NiCd or a single cell Li-Ion battery.

The part can also be used to generate standard

3.3-V/5-V to 12-V power conversions.

The TPS61040/41 operates with a switching

frequency up to 1 MHz. This allows the use of small

external components using ceramic as well as

tantalum output capacitors. Together with the thin

SON package, the TPS61040/41 gives a very small

overall solution size. The TPS61040 has an internal

400 mA switch current limit, while the TPS61041 has

a 250-mA switch current limit, offering lower output

voltage ripple and allows the use of a smaller form

factor inductor for lower power applications. The low

quiescent current (typically 28 mA) together with an

optimized control scheme, allows device operation at

very high efficiencies over the entire load current

range.

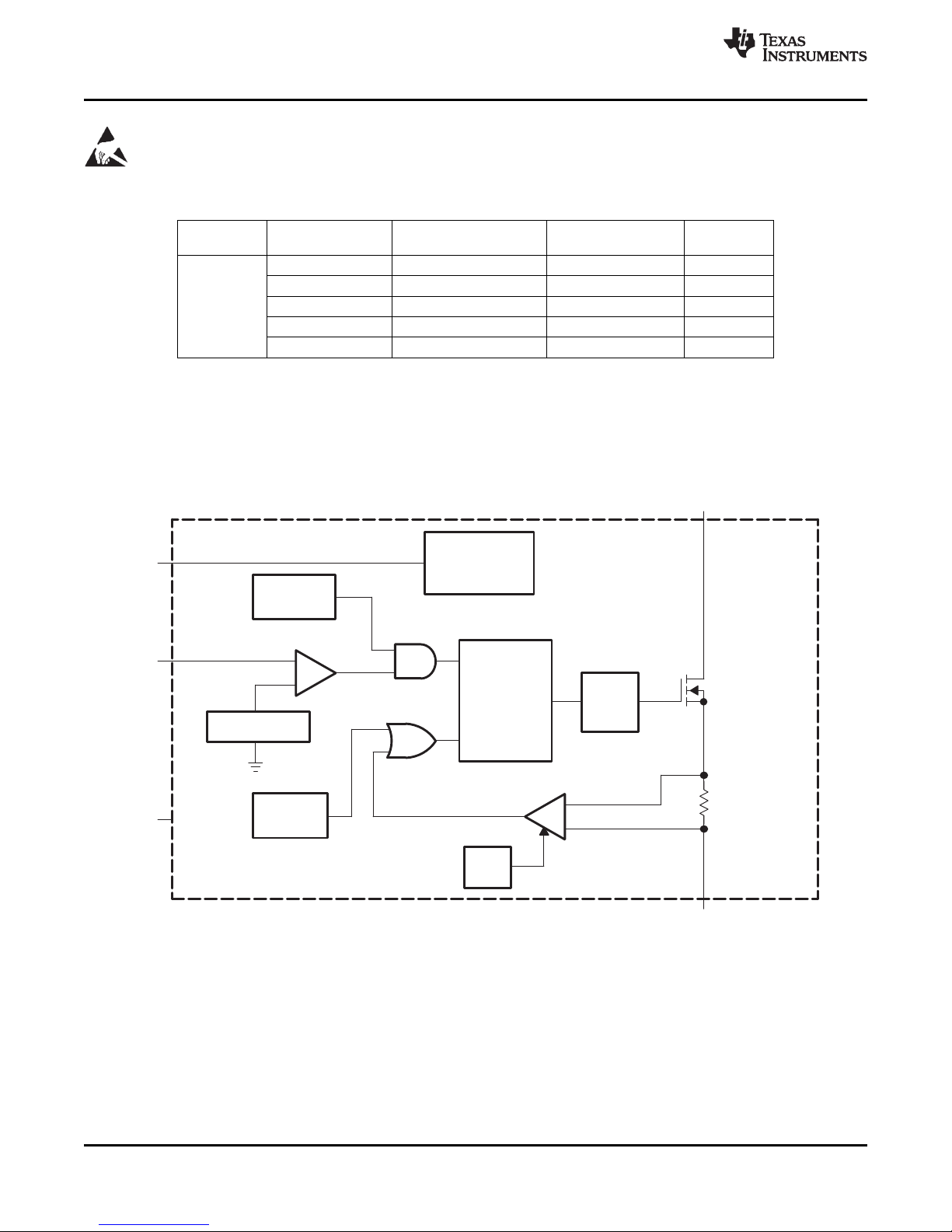

TYPICAL APPLICATION

1

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2002–2010, Texas Instruments Incorporated

Page 2

+

+

-

RS Latch

Logic

S

R

Gate

Driver

_

Current Limit

Power MOSFET

N-Channel

R

SENSE

Soft

Start

6 µs Max

On Time

V

REF

= 1.233 V

Error Comparator

400 ns Min

Off Time

Under Voltage

Lockout

Bias Supply

VIN

FB

EN

GND

SW

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

www.ti.com

Table 1. ORDERING INFORMATION

SWITCH CURRENT PACKAGE

T

A

–40°C to

85°C

(1) For the most current package and ordering information, see the Package Option Addendum at the end

of this document, or see the TI website at www.ti.com.

(2) The devices are available in tape and reel and in tubes. Add R suffix to the part number (e.g.,

TPS61040DRVR) to order quantities of 3000 parts in tape and reel or add suffix T (e.g.,

TPS61040DRVT) to order a tube with 250 pieces..

PART NUMBER

TPS61040DBV 400 SOT23-5 PHOI

TPS61040DDC 400 TSOT23-5 QXK

TPS61041DBV 250 SOT23-5 PHPI

TPS61040DRV 400 SON-6 2×2 CCL

TPS61041DRV 250 SON-6 2×2 CAW

(2)

LIMIT, mA MARKING

(1)

PACKAGE

FUNCTIONAL BLOCK DIAGRAM

2 Submit Documentation Feedback Copyright © 2002–2010, Texas Instruments Incorporated

Product Folder Link(s): TPS61040 TPS61041

Page 3

I

peak(typ)

+ I

LIM

)

V

IN

L

100 ns

I

peak(typ)

+ 400 mA )

V

IN

L

100 ns for the TPS61040

I

peak(typ)

+ 250 mA )

V

IN

L

100 ns for the TPS61041

TPS61040

TPS61041

www.ti.com

Table 2. Terminal Functions

TERMINAL

NAME DRV NO.

EN 4 3 I mode reducing the supply current to less than 1 mA. This pin should not be left floating and needs

FB 3 4 I

GND 2 1 – Ground

NC – 5 – No connection

SW 1 6 I

V

IN

DDC,

DBV NO.

5 2 I Supply voltage pin

I/O DESCRIPTION

This is the enable pin of the device. Pulling this pin to ground forces the device into shutdown

to be terminated.

This is the feedback pin of the device. Connect this pin to the external voltage divider to program

the desired output voltage.

Connect the inductor and the Schottky diode to this pin. This is the switch pin and is connected to

the drain of the internal power MOSFET.

DETAILED DESCRIPTION

OPERATION

The TPS61040/41 operates with an input voltage range of 1.8 V to 6 V and can generate output voltages up to

28 V. The device operates in a pulse-frequency-modulation (PFM) scheme with constant peak current control.

This control scheme maintains high efficiency over the entire load current range, and with a switching frequency

up to 1 MHz, the device enables the use of very small external components.

The converter monitors the output voltage, and as soon as the feedback voltage falls below the reference voltage

of typically 1.233 V, the internal switch turns on and the current ramps up. The switch turns off as soon as the

inductor current reaches the internally set peak current of typically 400 mA (TPS61040) or 250 mA (TPS61041).

See the Peak Current Control section for more information. The second criteria that turns off the switch is the

maximum on-time of 6 ms (typical). This is just to limit the maximum on-time of the converter to cover for extreme

conditions. As the switch is turned off the external Schottky diode is forward biased delivering the current to the

output. The switch remains off for a minimum of 400 ns (typical), or until the feedback voltage drops below the

reference voltage again. Using this PFM peak current control scheme the converter operates in discontinuous

conduction mode (DCM) where the switching frequency depends on the output current, which results in very high

efficiency over the entire load current range. This regulation scheme is inherently stable, allowing a wider

selection range for the inductor and output capacitor.

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

PEAK CURRENT CONTROL

The internal switch turns on until the inductor current reaches the typical dc current limit (I

(TPS61040) or 250 mA (TPS61041). Due to the internal propagation delay of typical 100 ns, the actual current

exceeds the dc current limit threshold by a small amount. The typical peak current limit can be calculated:

The higher the input voltage and the lower the inductor value, the greater the peak.

By selecting the TPS61040 or TPS61041, it is possible to tailor the design to the specific application current limit

requirements. A lower current limit supports applications requiring lower output power and allows the use of an

inductor with a lower current rating and a smaller form factor. A lower current limit usually has a lower output

voltage ripple as well.

Copyright © 2002–2010, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): TPS61040 TPS61041

) of 400 mA

LIM

(1)

Page 4

I

LIM

4

I

LIM

2

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

SOFT START

All inductive step-up converters exhibit high inrush current during start-up if no special precaution is made. This

can cause voltage drops at the input rail during start up and may result in an unwanted or early system shut

down.

The TPS61040/41 limits this inrush current by increasing the current limit in two steps starting from for 256

cycles to for the next 256 cycles, and then full current limit (see Figure 14).

ENABLE

Pulling the enable (EN) to ground shuts down the device reducing the shutdown current to 1 mA (typical).

Because there is a conductive path from the input to the output through the inductor and Schottky diode, the

output voltage is equal to the input voltage during shutdown. The enable pin needs to be terminated and should

not be left floating. Using a small external transistor disconnects the input from the output during shutdown as

shown in Figure 18.

UNDERVOLTAGE LOCKOUT

An undervoltage lockout prevents misoperation of the device at input voltages below typical 1.5 V. When the

input voltage is below the undervoltage threshold, the main switch is turned off.

www.ti.com

THERMAL SHUTDOWN

An internal thermal shutdown is implemented and turns off the internal MOSFETs when the typical junction

temperature of 168°C is exceeded. The thermal shutdown has a hysteresis of typically 25°C. This data is based

on statistical means and is not tested during the regular mass production of the IC.

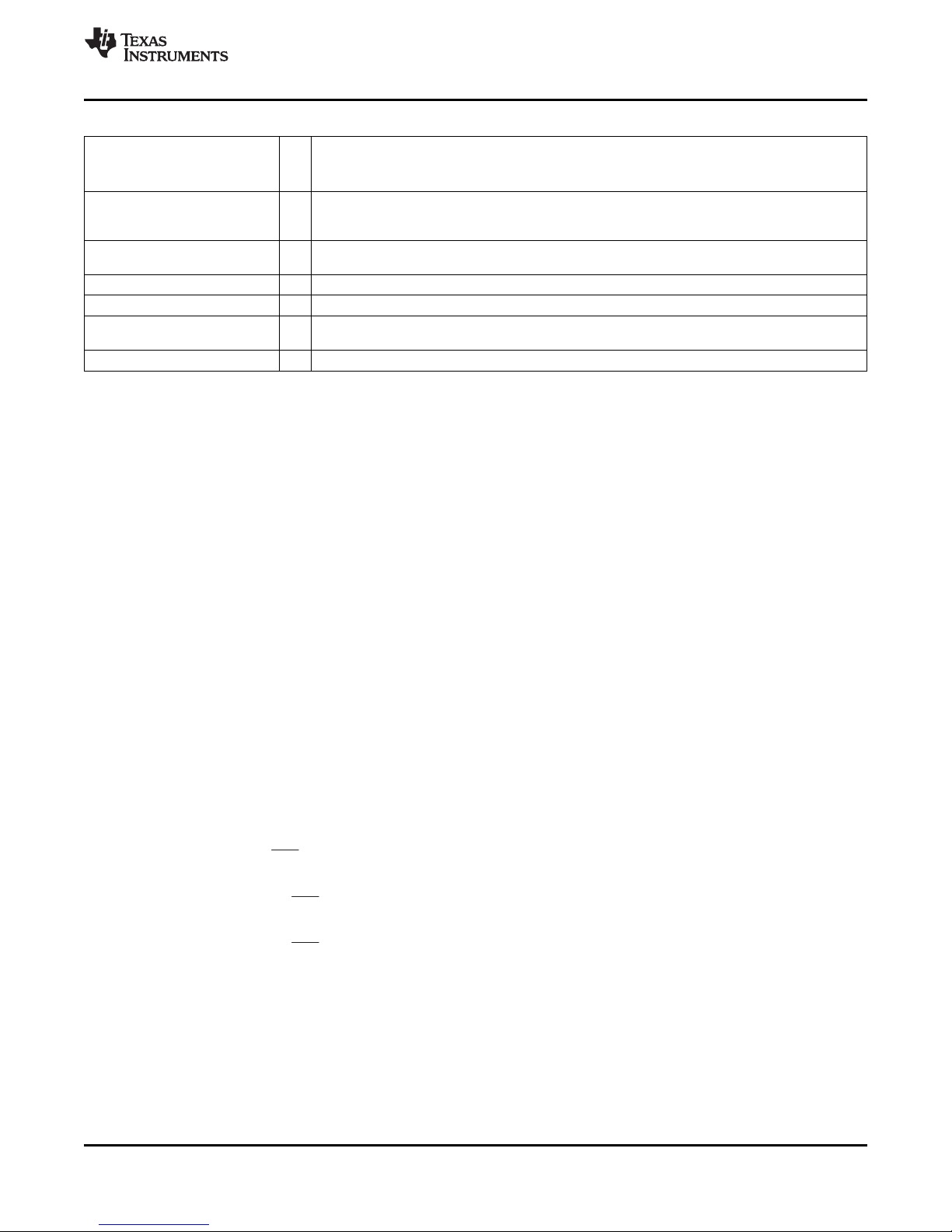

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature (unless otherwise noted)

Supply voltages on pin V

Voltages on pins EN, FB

Switch voltage on pin SW

Continuous power dissipation See Dissipation Rating Table

T

Operating junction temperature –40°C to 150°C

J

T

Storage temperature –65°C to 150°C

stg

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltage values are with respect to network ground terminal.

(2)

IN

(2)

(2)

(1)

UNIT

–0.3 V to 7 V

–0.3 V to VIN+ 0.3 V

30 V

DISSIPATION RATING TABLE

PACKAGE R

DBV 250°C/W 357 mW 3.5 mW/°C 192 mW 140 mW

DDC, DRV 76°C/W 1300 mW 13 mW/°C 688 mW 500 mW

qJA

TA≤ 25°C FACTOR TA= 70°C TA= 85°C

POWER RATING ABOVE POWER RATING POWER RATING

DERATING

TA= 25°C

4 Submit Documentation Feedback Copyright © 2002–2010, Texas Instruments Incorporated

Product Folder Link(s): TPS61040 TPS61041

Page 5

TPS61040

TPS61041

www.ti.com

RECOMMENDED OPERATING CONDITIONS

V

V

L Inductor

f Switching frequency

C

C

T

T

(1) See application section for further information.

Input voltage range 1.8 6 V

IN

Output voltage range 28 V

OUT

IN

OUT

A

J

(1)

(1)

Input capacitor

Output capacitor

(1)

(1)

Operating ambient temperature –40 85 °C

Operating junction temperature –40 125 °C

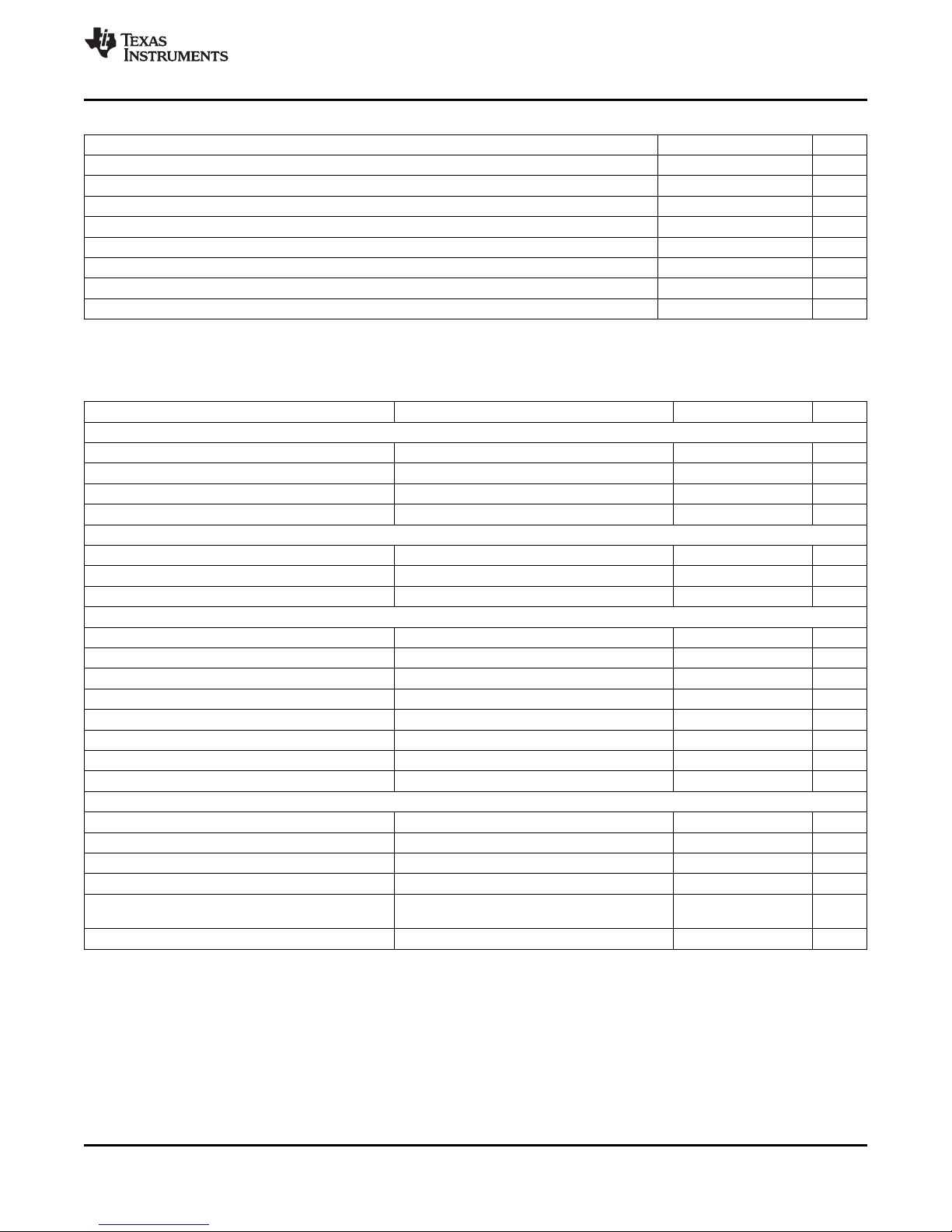

ELECTRICAL CHARACTERISTICS

VIN= 2.4 V, EN = VIN, TA= –40°C to 85°C, typical values are at TA= 25°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY CURRENT

V

IN

I

Q

I

SD

V

UVLO

ENABLE

V

IH

V

IL

I

I

POWER SWITCH AND CURRENT LIMIT

Vsw Maximum switch voltage 30 V

t

off

t

on

R

DS(on)

R

DS(on)

I

LIM

I

LIM

OUTPUT

V

OUT

V

ref

I

FB

V

FB

(1) The line and load regulation depend on the external component selection. See the application section for further information.

Input voltage range 1.8 6 V

Operating quiescent current I

= 0 mA, not switching, VFB= 1.3 V 28 50 mA

OUT

Shutdown current EN = GND 0.1 1 mA

Under-voltage lockout threshold 1.5 1.7 V

EN high level input voltage 1.3 V

EN low level input voltage 0.4 V

EN input leakage current EN = GND or V

IN

Minimum off time 250 400 550 ns

Maximum on time 4 6 7.5 ms

MOSFET on-resistance VIN= 2.4 V; ISW= 200 mA; TPS61040 600 1000 mΩ

MOSFET on-resistance VIN= 2.4 V; ISW= 200 mA; TPS61041 750 1250 mΩ

MOSFET leakage current VSW= 28 V 1 10 mA

MOSFET current limit TPS61040 350 400 450 mA

MOSFET current limit TPS61041 215 250 285 mA

Adjustable output voltage range V

Internal voltage reference 1.233 V

Feedback input bias current VFB= 1.3 V 1 mA

Feedback trip point voltage 1.8 V ≤ VIN≤ 6 V 1.208 1.233 1.258 V

Line regulation

Load regulation

(1)

(1)

1.8 V ≤ VIN≤ 6 V; V

CFF= not connected

VIN= 2.4 V; V

= 18 V; 0 mA ≤ I

OUT

OUT

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

MIN TYP MAX UNIT

2.2 10 mH

4.7 mF

1 mF

0.1 1 mA

IN

= 18 V; I

= 10 mA;

load

≤ 30 mA 0.15 %/mA

OUT

0.05 %/V

1 MHz

28 V

Copyright © 2002–2010, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): TPS61040 TPS61041

Page 6

Efficiency − %

70

72

74

76

78

80

82

84

86

88

90

0.1 1 10 100

VI = 5 V

VI = 3.6 V

VI = 2.4 V

IO − Output Current − mA

VO = 18 V

70

72

74

76

78

80

82

84

86

88

90

0.1 1 10 100

TPS61040

TPS61041

IL − Load Current − mA

L = 10 µH

VO = 18 V

Efficiency − %

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

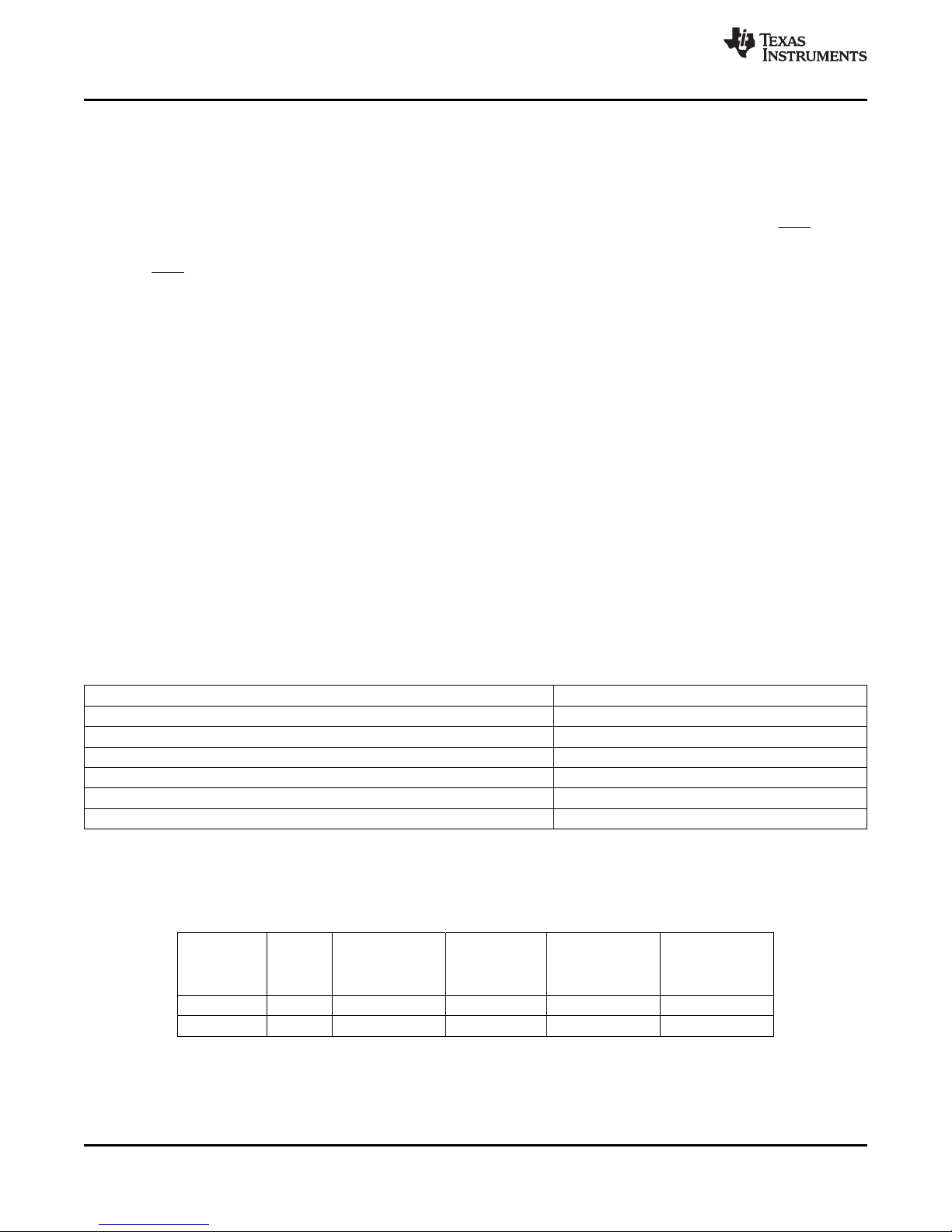

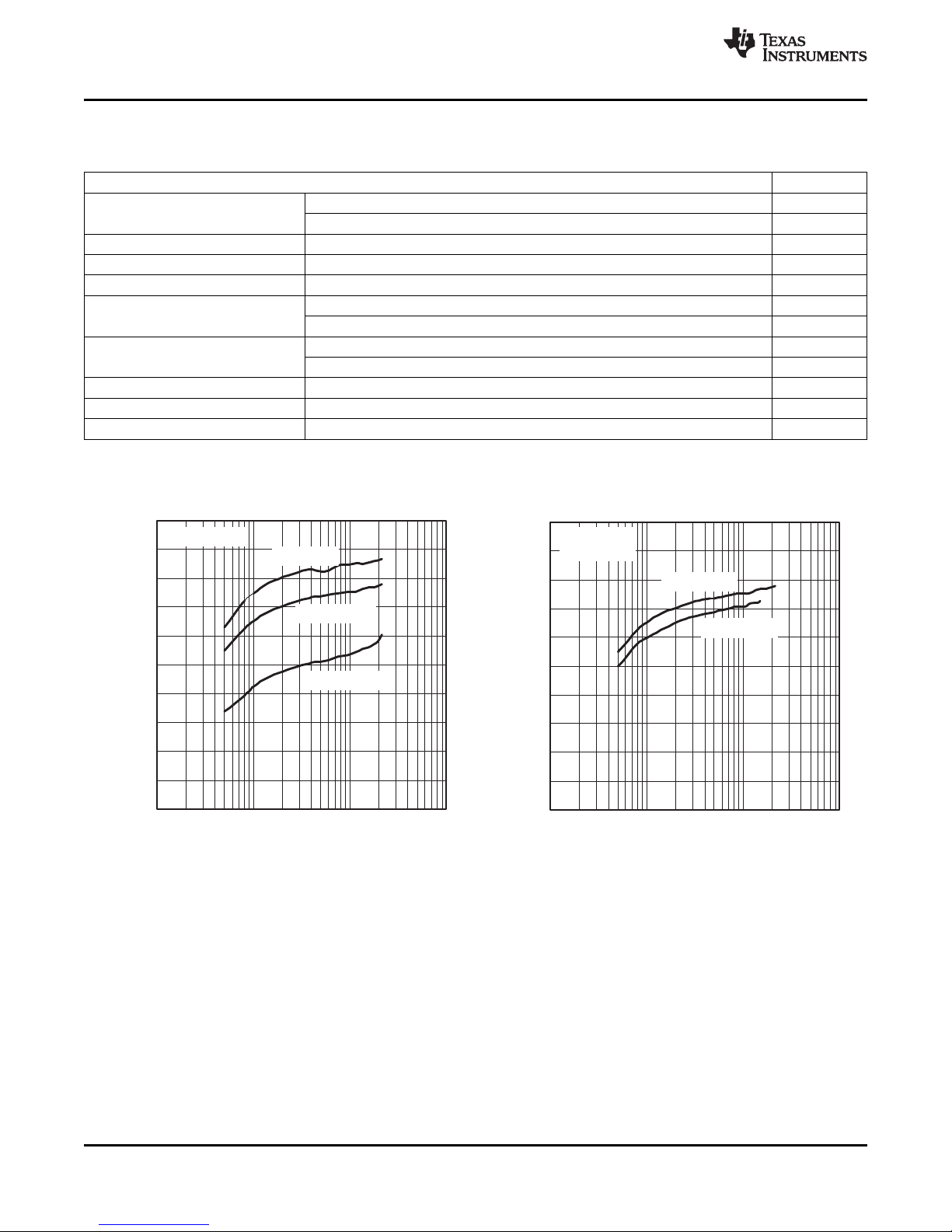

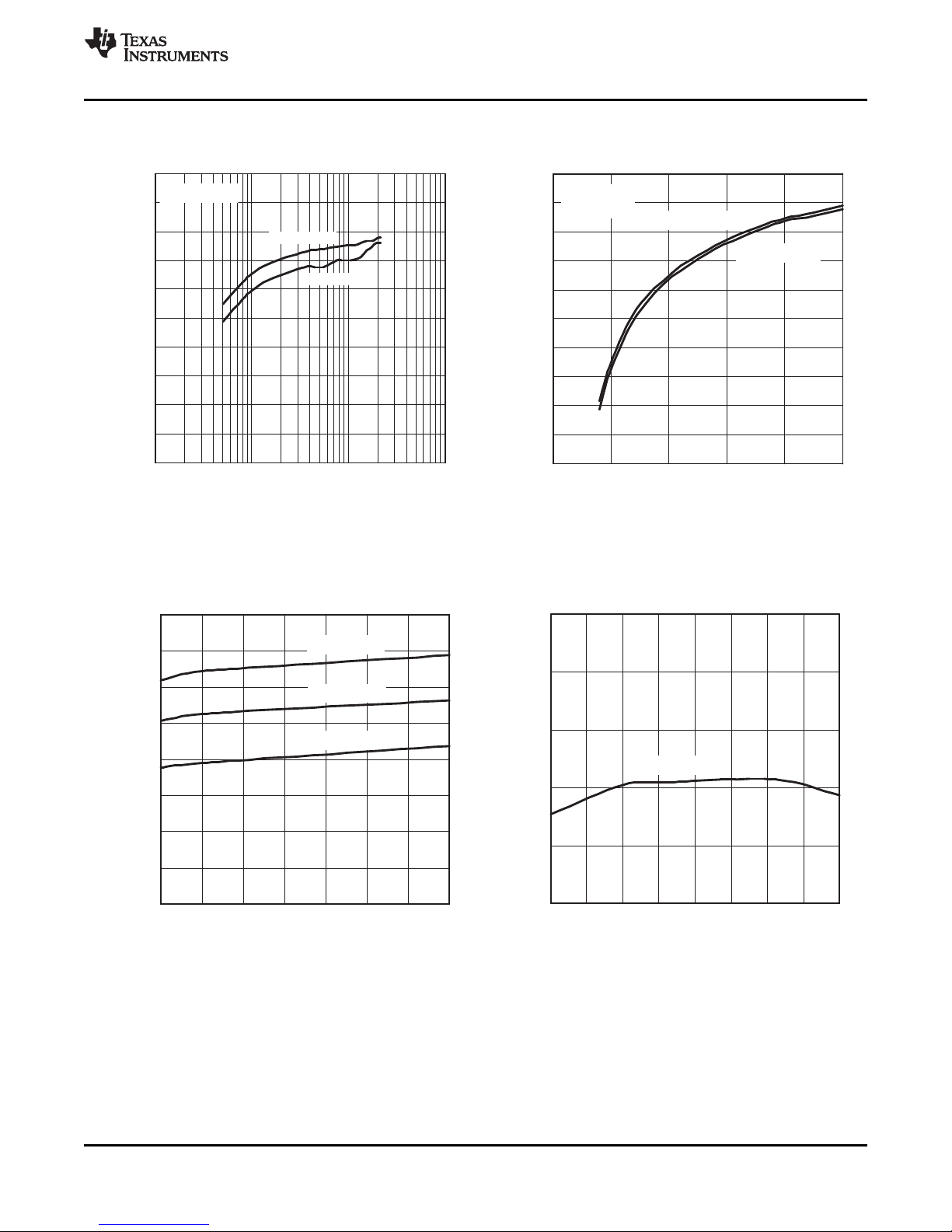

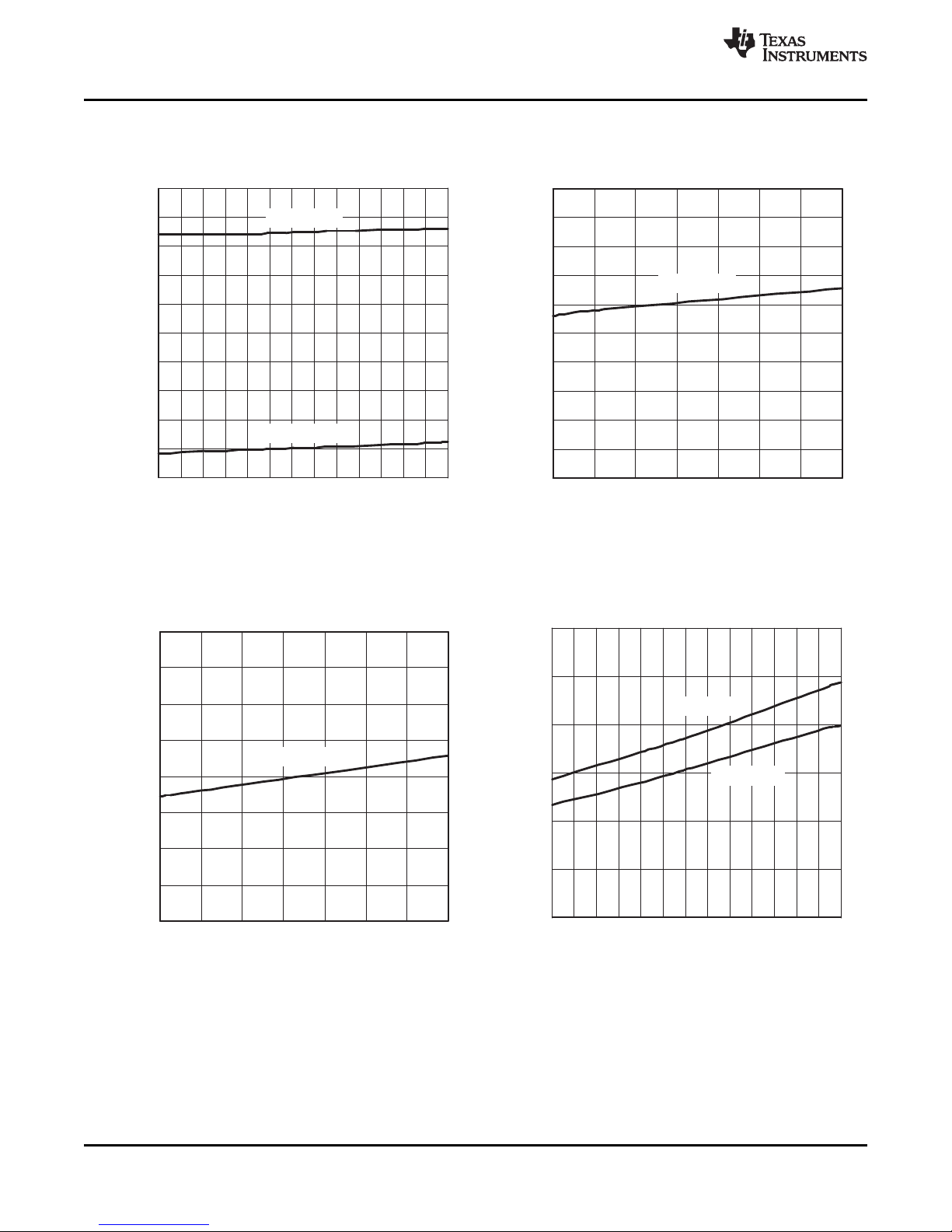

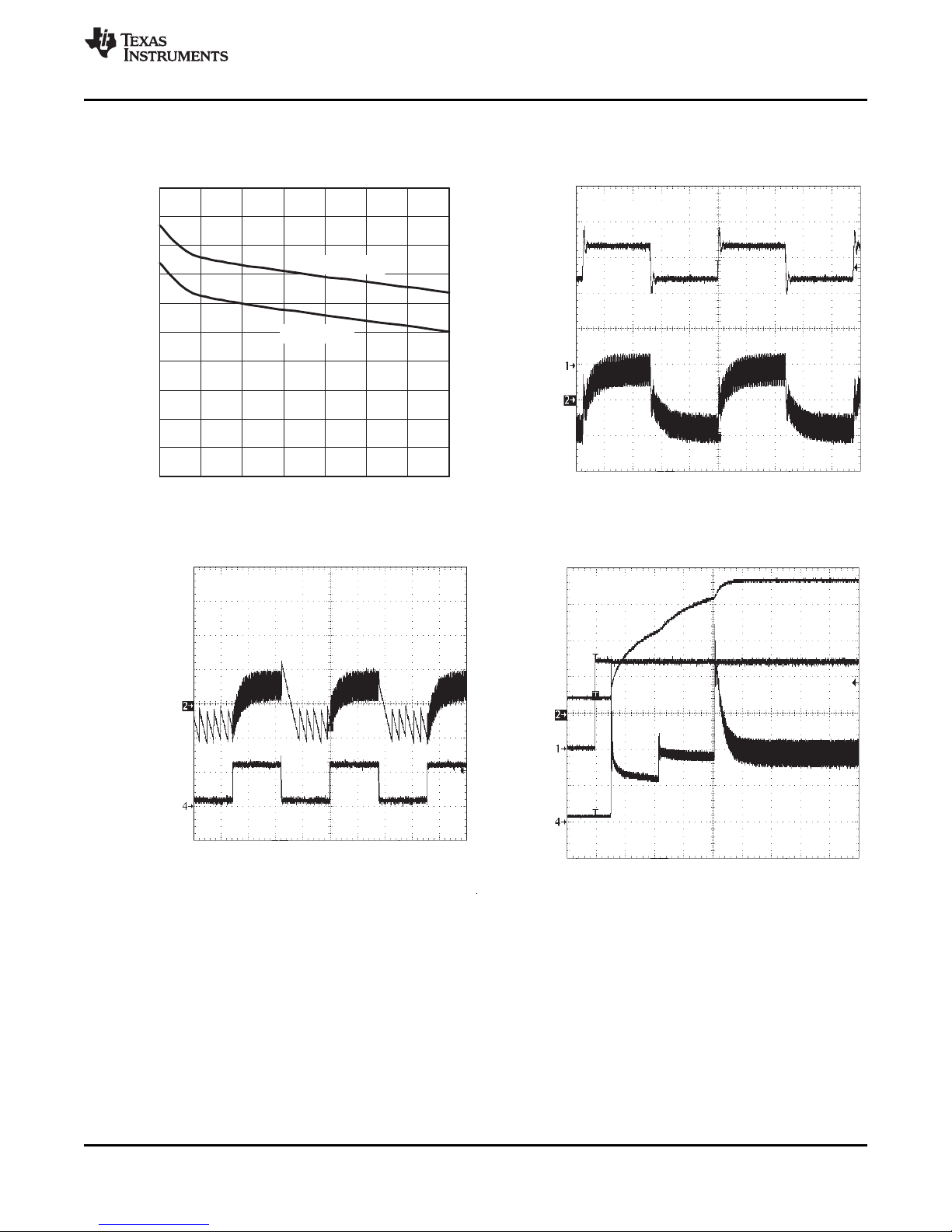

TYPICAL CHARACTERISTICS

h Efficiency

I

Q

V

FB

I

SW

I

CL

R

DS(on)

Quiescent current vs Input voltage and temperature 5

Feedback voltage vs Temperature 6

Switch current limit vs Temperature 7

Switch current limit

R

DS(on)

Line transient response 12

Load transient response 13

Start-up behavior 14

EFFICIENCY EFFICIENCY

OUTPUT CURRENT LOAD CURRENT

vs Load current 1, 2, 3

vs Input voltage 4

vs Supply voltage, TPS61041 8

vs Supply voltage, TPS61040 9

vs Temperature 10

vs Supply voltage 11

vs vs

www.ti.com

Table 3. Table of Graphs

FIGURE

Figure 1. Figure 2.

6 Submit Documentation Feedback Copyright © 2002–2010, Texas Instruments Incorporated

Product Folder Link(s): TPS61040 TPS61041

Page 7

70

72

74

76

78

80

82

84

86

88

90

0.1 1 10

100

L = 10 µH

L = 3.3 µH

IL − Load Current − mA

VO = 18 V

Efficiency − %

70

72

74

76

78

80

82

84

86

88

90

1 2 3 4 5 6

IO = 10 mA

IO = 5 mA

VI − Input Voltage − V

L = 10 µH

VO = 18 V

Efficiency − %

1.23

1.232

1.234

1.236

1.238

1.24

−40 −20 0 20 40 60 80 100 120

VCC = 2.4 V

TA − Temperature − °C

V

FB

− Feedback Voltage − V

0

5

10

15

20

25

30

35

40

1.8 2.4 3 3.6 4.2 4.8 5.4 6

VI − Input Voltage − V

TA = 85°C

TA = 27°C

TA = −40°C

Quiescent Current − µA

www.ti.com

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

EFFICIENCY EFFICIENCY

vs vs

LOAD CURRENT INPUT VOLTAGE

Figure 3. Figure 4.

TPS61040

QUIESCENT CURRENT FEEDBACK VOLTAGE

vs vs

INPUT VOLTAGE FREE-AIR TEMPERATURE

Copyright © 2002–2010, Texas Instruments Incorporated Submit Documentation Feedback 7

Figure 5. Figure 6.

Product Folder Link(s): TPS61040 TPS61041

Page 8

230

250

270

290

310

330

350

370

390

410

430

−40−30−20 −10 0 10 20 30 40 50 60 70 80 90

TPS61040

TPS61041

TA − Temperature − °C

I

(SW)

− Switch Current Limit − mA

240

242

244

246

248

250

252

254

256

258

260

1.8 2.4 3 3.6 4.2 4.8 5.4 6

VCC − Supply Voltage − V

TA = 27°C

I

(CL)

− Current Limit − mA

0

200

400

600

800

1000

1200

−40−30 −20−10 0 10 20 30 40 50 60 70 80 90

TA − Temperature − °C

TPS61041

TPS61040

r

DS(on)

− Static Drain-Source On-State Resistance − mΩ

380

385

390

395

400

405

410

415

420

1.8 2.4 3 3.6 4.2 4.8 5.4 6

VCC − Supply Voltage − V

TA = 27°C

I

(CL)

− Current Limit − mA

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

TPS61040/41 TPS61041

SWITCH CURRENT LIMIT CURRENT LIMIT

vs vs

FREE-AIR TEMPERATURE SUPPLY VOLTAGE

www.ti.com

Figure 7. Figure 8.

TPS61040 TPS61040/41

CURRENT LIMIT STATIC DRAIN-SOURCE ON-STATE RESISTANCE

vs vs

SUPPLY VOLTAGE FREE-AIR TEMPERATURE

8 Submit Documentation Feedback Copyright © 2002–2010, Texas Instruments Incorporated

Figure 9. Figure 10.

Product Folder Link(s): TPS61040 TPS61041

Page 9

V

I

2.4 V to 3.4 V

V

O

100 mV/div

200 µS/div

VO = 18 V

0

100

200

300

400

500

600

700

800

900

1000

1.8 2.4 3 3.6 4.2 4.8 5.4 6

VCC − Supply Voltage − V

TPS61041

TPS61040

r

DS(on)

− Static Drain-Source On-State Resistance − mΩ

V

O

5 V/div

EN

1 V/div

I

I

50 mA/div

VO = 18 V

V

O

1 mA to 10 mA

200 µS/div

V

O

100 mA/div

VO = 18 V

www.ti.com

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

TPS61040/41

STATIC DRAIN-SOURCE ON-STATE RESISTANCE

vs

SUPPLY VOLTAGE

Figure 11. Figure 12. Line Transient Response

Figure 13. Load Transient Response Figure 14. Start-Up Behavior

Copyright © 2002–2010, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): TPS61040 TPS61041

Page 10

fS

max

+

V

IN(min)

(V

OUT

* V

IN)

IP L V

OUT

fSǒI

load

Ǔ

+

2 I

load

(V

OUT

* VIN) Vd)

I

2

P

L

I

load max

+ h

I

2

P

L fS

max

2 (V

OUT

* V

IN)

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

APPLICATION INFORMATION

INDUCTOR SELECTION, MAXIMUM LOAD CURRENT

Because the PFM peak current control scheme is inherently stable, the inductor value does not affect the stability

of the regulator. The selection of the inductor together with the nominal load current, input and output voltage of

the application determines the switching frequency of the converter. Depending on the application, inductor

values between 2.2 mH and 47 mH are recommended. The maximum inductor value is determined by the

maximum on time of the switch, typically 6 ms. The peak current limit of 400 mA/250 mA (typically) should be

reached within this 6-ms period for proper operation.

The inductor value determines the maximum switching frequency of the converter. Therefore, select the inductor

value that ensures the maximum switching frequency at the converter maximum load current is not exceeded.

The maximum switching frequency is calculated by the following formula:

Where:

IP= Peak current as described in the Peak Current Control section

L = Selected inductor value

V

If the selected inductor value does not exceed the maximum switching frequency of the converter, the next step

is to calculate the switching frequency at the nominal load current using the following formula:

= The highest switching frequency occurs at the minimum input voltage (2)

IN(min)

www.ti.com

Where:

IP= Peak current as described in the Peak Current Control section

L = Selected inductor value

I

= Nominal load current

load

Vd = Rectifier diode forward voltage (typically 0.3V) (3)

A smaller inductor value gives a higher converter switching frequency, but lowers the efficiency.

The inductor value has less effect on the maximum available load current and is only of secondary order. The

best way to calculate the maximum available load current under certain operating conditions is to estimate the

expected converter efficiency at the maximum load current. This number can be taken out of the efficiency

graphs shown in Figure 1 through Figure 4. The maximum load current can then be estimated as follows:

Where:

IP= Peak current as described in the Peak Current Control section

L = Selected inductor value

fS

= Maximum switching frequency as calculated previously

max

h = Expected converter efficiency. Typically 70% to 85% (4)

10 Submit Documentation Feedback Copyright © 2002–2010, Texas Instruments Incorporated

Product Folder Link(s): TPS61040 TPS61041

Page 11

V

OUT

+ 1.233 V ǒ1 )

R1

R2

Ǔ

C

FF

+

1

2 p

fS

20

R1

TPS61040

TPS61041

www.ti.com

The maximum load current of the converter is the current at the operation point where the converter starts to

enter the continuous conduction mode. Usually the converter should always operate in discontinuous conduction

mode.

Last, the selected inductor should have a saturation current that meets the maximum peak current of the

converter (as calculated in the Peak Current Control section). Use the maximum value for I

Another important inductor parameter is the dc resistance. The lower the dc resistance, the higher the efficiency

of the converter. See Table 4 and the typical applications for the inductor selection.

Table 4. Recommended Inductor for Typical LCD Bias Supply (see Figure 15)

DEVICE INDUCTOR VALUE COMPONENT SUPPLIER COMMENTS

10 mH Sumida CR32-100 High efficiency

10 mH Sumida CDRH3D16-100 High efficiency

TPS61040 10 mH Murata LQH4C100K04 High efficiency

4.7 mH Sumida CDRH3D16-4R7 Small solution size

4.7 mH Murata LQH3C4R7M24 Small solution size

TPS61041 10 mH Murata LQH3C100K24

SETTING THE OUTPUT VOLTAGE

The output voltage is calculated as:

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

for this calculation.

LIM

High efficiency

Small solution size

(5)

For battery-powered applications, a high-impedance voltage divider should be used with a typical value for R2 of

≤200 kΩ and a maximum value for R1 of 2.2 MΩ. Smaller values might be used to reduce the noise sensitivity of

the feedback pin.

A feedforward capacitor across the upper feedback resistor R1 is required to provide sufficient overdrive for the

error comparator. Without a feedforward capacitor, or one whose value is too small, the TPS61040/41 shows

double pulses or a pulse burst instead of single pulses at the switch node (SW), causing higher output voltage

ripple. If this higher output voltage ripple is acceptable, the feedforward capacitor can be left out.

The lower the switching frequency of the converter, the larger the feedforward capacitor value required. A good

starting point is to use a 10-pF feedforward capacitor. As a first estimation, the required value for the feedforward

capacitor at the operation point can also be calculated using the following formula:

Where:

R1 = Upper resistor of voltage divider

fS = Switching frequency of the converter at the nominal load current (See the Inductor Selection, Maximum

Load Current section for calculating the switching frequency)

CFF= Choose a value that comes closest to the result of the calculation (6)

Copyright © 2002–2010, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): TPS61040 TPS61041

Page 12

DV

out

+

I

out

C

out

ǒ

1

fS(Iout)

–

IP L

Vout ) Vd–Vin

Ǔ

) IP ESR

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

The larger the feedforward capacitor the worse the line regulation of the device. Therefore, when concern for line

regulation is paramount, the selected feedforward capacitor should be as small as possible. See the following

section for more information about line and load regulation.

LINE AND LOAD REGULATION

The line regulation of the TPS61040/41 depends on the voltage ripple on the feedback pin. Usually a 50 mV

peak-to-peak voltage ripple on the feedback pin FB gives good results.

Some applications require a very tight line regulation and can only allow a small change in output voltage over a

certain input voltage range. If no feedforward capacitor CFFis used across the upper resistor of the voltage

feedback divider, the device has the best line regulation. Without the feedforward capacitor the output voltage

ripple is higher because the TPS61040/41 shows output voltage bursts instead of single pulses on the switch pin

(SW), increasing the output voltage ripple. Increasing the output capacitor value reduces the output voltage

ripple.

If a larger output capacitor value is not an option, a feedforward capacitor CFFcan be used as described in the

previous section. The use of a feedforward capacitor increases the amount of voltage ripple present on the

feedback pin (FB). The greater the voltage ripple on the feedback pin (≥50 mV), the worse the line regulation.

There are two ways to improve the line regulation further:

1. Use a smaller inductor value to increase the switching frequency which will lower the output voltage ripple,

as well as the voltage ripple on the feedback pin.

2. Add a small capacitor from the feedback pin (FB) to ground to reduce the voltage ripple on the feedback pin

down to 50 mV again. As a starting point, the same capacitor value as selected for the feedforward capacitor

CFFcan be used.

www.ti.com

OUTPUT CAPACITOR SELECTION

For best output voltage filtering, a low ESR output capacitor is recommended. Ceramic capacitors have a low

ESR value but tantalum capacitors can be used as well, depending on the application.

Assuming the converter does not show double pulses or pulse bursts on the switch node (SW), the output

voltage ripple can be calculated as:

where:

IP= Peak current as described in the Peak Current Control section

L = Selected inductor value

I

= Nominal load current

out

fS (I

) = Switching frequency at the nominal load current as calculated previously

out

Vd = Rectifier diode forward voltage (typically 0.3 V)

C

= Selected output capacitor

out

ESR = Output capacitor ESR value (7)

See Table 5 and the typical applications section for choosing the output capacitor.

Table 5. Recommended Input and Output Capacitors

DEVICE CAPACITOR VOLTAGE RATING COMPONENT SUPPLIER COMMENTS

4.7 mF/X5R/0805 6.3 V Tayo Yuden JMK212BY475MG CIN/C

10 mF/X5R/0805 6.3 V Tayo Yuden JMK212BJ106MG CIN/C

TPS61040/41 1 mF/X7R/1206 25 V Tayo Yuden TMK316BJ105KL C

1 mF/X5R/1206 35 V Tayo Yuden GMK316BJ105KL C

4.7 mF/X5R/1210 25 V Tayo Yuden TMK325BJ475MG C

OUT

OUT

OUT

OUT

OUT

12 Submit Documentation Feedback Copyright © 2002–2010, Texas Instruments Incorporated

Product Folder Link(s): TPS61040 TPS61041

Page 13

V

IN

SW

FB

EN

GND

L1

D1

R1

R2

C

FF

C

O

V

O

V

IN

C

IN

TPS61040

TPS61041

www.ti.com

INPUT CAPACITOR SELECTION

For good input voltage filtering, low ESR ceramic capacitors are recommended. A 4.7 mF ceramic input capacitor

is sufficient for most of the applications. For better input voltage filtering this value can be increased. See Table 5

and typical applications for input capacitor recommendations.

DIODE SELECTION

To achieve high efficiency a Schottky diode should be used. The current rating of the diode should meet the

peak current rating of the converter as it is calculated in the Peak Current Control section. Use the maximum

value for I

for this calculation. See Table 6 and the typical applications for the selection of the Schottky diode.

LIM

Table 6. Recommended Schottky Diode for Typical LCD Bias Supply (see Figure 15)

DEVICE REVERSE VOLTAGE COMPONENT SUPPLIER COMMENTS

30 V ON Semiconductor MBR0530

TPS61040/41

20 V ON Semiconductor MBR0520

20 V ON Semiconductor MBRM120L High efficiency

30 V Toshiba CRS02

LAYOUT CONSIDERATIONS

Typical for all switching power supplies, the layout is an important step in the design; especially at high peak

currents and switching frequencies. If the layout is not carefully done, the regulator might show noise problems

and duty cycle jitter.

The input capacitor should be placed as close as possible to the input pin for good input voltage filtering. The

inductor and diode should be placed as close as possible to the switch pin to minimize the noise coupling into

other circuits. Because the feedback pin and network is a high-impedance circuit, the feedback network should

be routed away from the inductor. The feedback pin and feedback network should be shielded with a ground

plane or trace to minimize noise coupling into this circuit.

Wide traces should be used for connections in bold as shown in Figure 15. A star ground connection or ground

plane minimizes ground shifts and noise.

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

Copyright © 2002–2010, Texas Instruments Incorporated Submit Documentation Feedback 13

Figure 15. Layout Diagram

Product Folder Link(s): TPS61040 TPS61041

Page 14

V

IN

SW

FB

EN

GND

L1

10 µH

D1

R1

2.2 MW

R2

160 kW

C

FF

22 pF

C2

1 µF

V

OUT

18 V

V

IN

1.8 V to 6 V

C1

4.7 µF

L1: Sumida CR32-100

D1: Motorola MBR0530

C1: Tayo Yuden JMK212BY475MG

C2: Tayo Yuden TMK316BJ105KL

TPS61040

V

IN

SW

FB

EN

GND

L1

10 µH

D1

R1

2.2 MW

R2

160 kW

C

FF

22 pF

C2

1 µF

V

O

18 V

VIN

1.8 V to 6 V

C1

4.7 µF

DAC or Analog Voltage

0 V = 25 V

1.233 V = 18 V

TPS61040

L1: Sumida CR32-100

D1: Motorola MBR0530

C1: Tayo Yuden JMK212BY475MG

C2: Tayo Yuden GMK316BJ105KL

V

IN

SW

FB

EN

GND

L1

10 µH

D1

R1

2.2 MW

R2

160 kW

C

FF

22 pF

C2

1 µF

V

OUT

18 V / 10 mA

V

IN

1.8 V to 6 V

C1

4.7 µF

R3

200 kW

BC857C

C3

0.1 µF

(Optional)

L1: Sumida CR32-100

D1: Motorola MBR0530

C1: Tayo Yuden JMK212BY475MG

C2: Tayo Yuden TMK316BJ105KL

TPS61040

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

www.ti.com

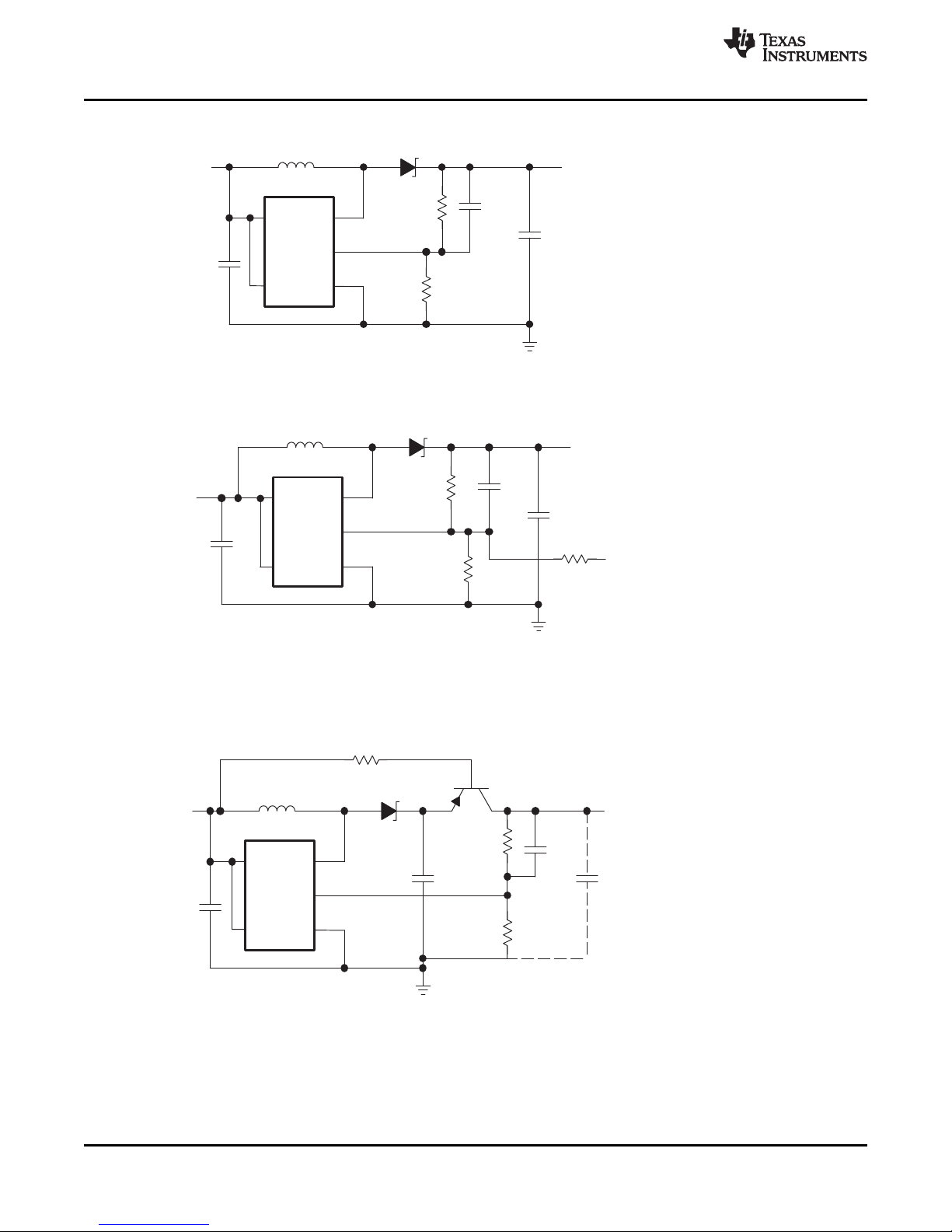

Figure 16. LCD Bias Supply

Figure 17. LCD Bias Supply With Adjustable Output Voltage

Figure 18. LCD Bias Supply With Load Disconnect

14 Submit Documentation Feedback Copyright © 2002–2010, Texas Instruments Incorporated

Product Folder Link(s): TPS61040 TPS61041

Page 15

V

IN

SW

FB

EN

GND

L1

6.8 µH

D1

R1

1.5 MW

R2

210 kW

C

FF

22 pF

C2

1 µF

V1 = 10 V/15 mA

VIN = 2.7 V to 5 V

C1

4.7 µF

C4

4.7 µF

C3

1 µF

V2 = –10 V/15 mA

D2

D3

L1: Murata LQH4C6R8M04

D1, D2, D3: Motorola MBR0530

C1: Tayo Yuden JMK212BY475MG

C2, C3, C4: Tayo Yuden EMK316BJ105KF

TPS61040

V

IN

SW

FB

EN

GND

L1

6.8 µH

D1

R1

1.8 MW

R2

205 kW

C

FF

4.7 pF

C2

4.7 µF

V

O =

12 V/35 mA

VIN 3.3 V

C1

10 µF

L1: Murata LQH4C6R8M04

D1: Motorola MBR0530

C1: Tayo Yuden JMK212BJ106MG

C2: Tayo Yuden EMK316BJ475ML

TPS61040

V

IN

SW

FB

EN

GND

3.3 µH

D1

C2

4.7 µF

5 V/45 mA

1.8 V to 4 V

C1

4.7 µF

TPS61040

L1: Murata LQH4C3R3M04

D1: Motorola MBR0530

C1, C2: Tayo Yuden JMK212BY475MG

C

FF

3.3 pF

R1

620 kW

R2

200 kW

www.ti.com

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

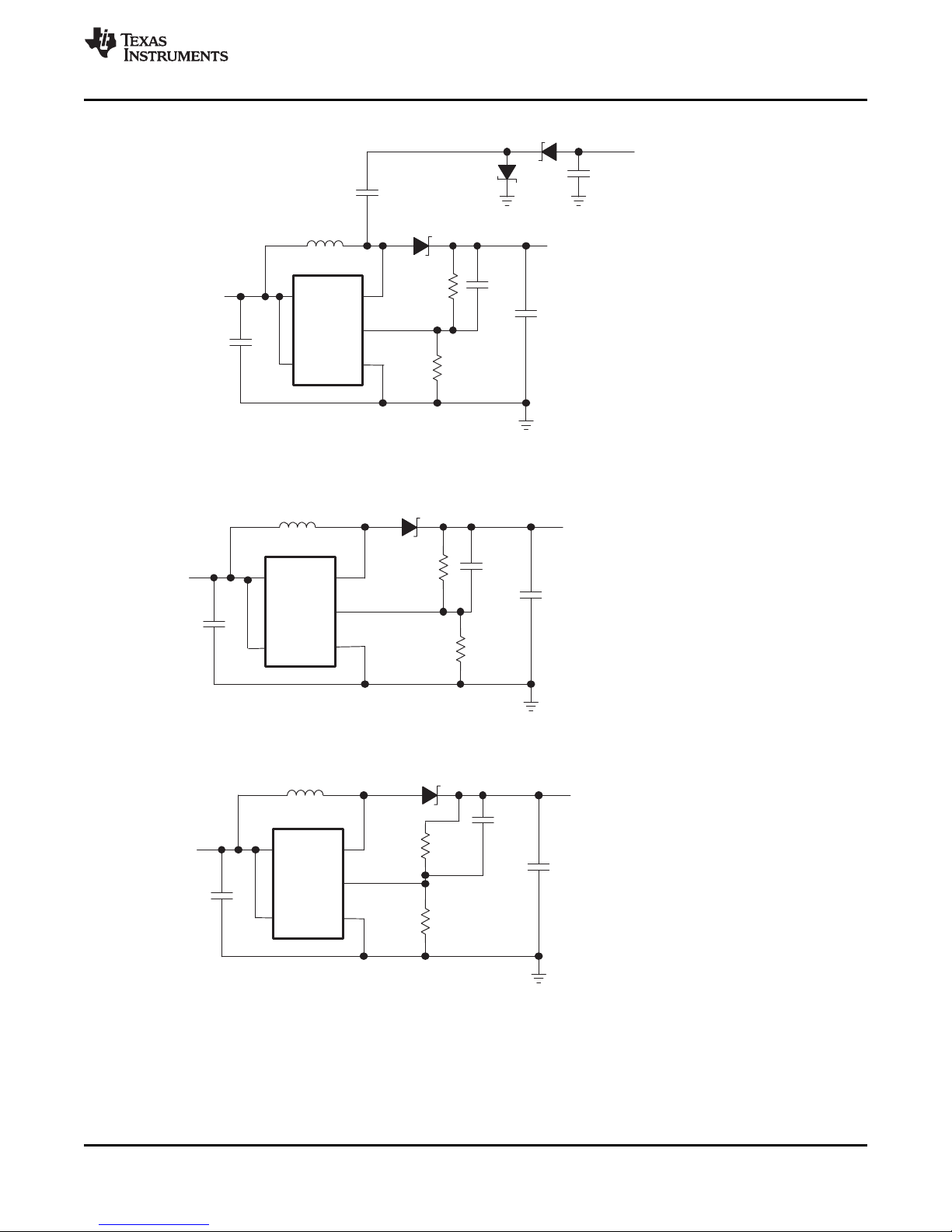

Figure 19. Positive and Negative Output LCD Bias Supply

Copyright © 2002–2010, Texas Instruments Incorporated Submit Documentation Feedback 15

Figure 21. Dual Battery Cell to 5-V/50-mA Conversion

Efficiency Approx. Equals 84% at VIN= 2.4 V to Vo = 5 V/45 mA

Figure 20. Standard 3.3-V to 12-V Supply

Product Folder Link(s): TPS61040 TPS61041

Page 16

V

IN

SW

FB

EN

GND

L1

10 µH

D1

C2

1 µF

C1

4.7 µF

R

S

82 Ω

VCC = 2.7 V to 6 V

PWM

100 Hz to 500 Hz

D2

24 V

(Optional)

L1: Murata LQH4C100K04

D1: Motorola MBR0530

C1: Tayo Yuden JMK212BY475MG

C2: Tayo Yuden TMK316BJ105KL

V

IN

SW

FB

EN

GND

L1

10 µH

D1

MBRM120L

C2

100 nF

(See

Note A)

C1

4.7 µF

R

S

110 Ω

VCC = 2.7 V to 6 V

R1

120 kΩ

R2

160 kΩ

Analog Brightness Control

3.3 V ≅ Led Off

0 V ≅ Iled = 20 mA

D2

24 V

(Optional)

L1: Murata LQH4C3R3M04

D1: Motorola MBR0530

C1: Tayo Yuden JMK212BY475MG

C2: Standard Ceramic Capacitor

TPS61040

TPS61041

SLVS413F –OCTOBER 2002–REVISED DECEMBER 2010

Figure 22. White LED Supply With Adjustable Brightness Control

Using a PWM Signal on the Enable Pin, Efficiency Approx. Equals 86% at VIN= 3 V, I

LED

www.ti.com

= 15 mA

A. A smaller output capacitor value for C2 causes a larger LED ripple.

Figure 23. White LED Supply With Adjustable Brightness Control

Using an Analog Signal on the Feedback Pin

16 Submit Documentation Feedback Copyright © 2002–2010, Texas Instruments Incorporated

Product Folder Link(s): TPS61040 TPS61041

Page 17

PACKAGE OPTION ADDENDUM

www.ti.com

17-May-2014

Addendum-Page 1

PACKAGING INFORMATION

Orderable Device Status

(1)

Package Type Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish

(6)

MSL Peak Temp

(3)

Op Temp (°C) Device Marking

(4/5)

Samples

TPS61040DBVR ACTIVE SOT-23 DBV 5 3000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 PHOI

TPS61040DBVRG4 ACTIVE SOT-23 DBV 5 3000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 PHOI

TPS61040DDCR ACTIVE SOT DDC 5 3000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 QXK

TPS61040DDCT ACTIVE SOT DDC 5 250 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR -40 to 85 QXK

TPS61040DRVR ACTIVE SON DRV 6 3000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 CCL

TPS61040DRVRG4 ACTIVE SON DRV 6 TBD Call TI Call TI -40 to 85

TPS61040DRVT ACTIVE SON DRV 6 250 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 CCL

TPS61040DRVTG4 ACTIVE SON DRV 6 250 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 CCL

TPS61041DBVR ACTIVE SOT-23 DBV 5 3000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 PHPI

TPS61041DBVRG4 ACTIVE SOT-23 DBV 5 3000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 PHPI

TPS61041DRVR ACTIVE SON DRV 6 3000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 CAW

TPS61041DRVRG4 ACTIVE SON DRV 6 3000 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 CAW

TPS61041DRVT ACTIVE SON DRV 6 250 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 CAW

TPS61041DRVTG4 ACTIVE SON DRV 6 250 Green (RoHS

& no Sb/Br)

CU NIPDAU Level-1-260C-UNLIM -40 to 85 CAW

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Page 18

PACKAGE OPTION ADDENDUM

www.ti.com

17-May-2014

Addendum-Page 2

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check http://www.ti.com/productcontent for the latest availability

information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements for all 6 substances, including the requirement that

lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and package, or 2) lead-based die adhesive used between

the die and leadframe. The component is otherwise considered Pb-Free (RoHS compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame retardants (Br or Sb do not exceed 0.1% by weight

in homogeneous material)

(3)

MSL, Peak Temp. - The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder temperature.

(4)

There may be additional marking, which relates to the logo, the lot trace code information, or the environmental category on the device.

(5)

Multiple Device Markings will be inside parentheses. Only one Device Marking contained in parentheses and separated by a "~" will appear on a device. If a line is indented then it is a continuation

of the previous line and the two combined represent the entire Device Marking for that device.

(6)

Lead/Ball Finish - Orderable Devices may have multiple material finish options. Finish options are separated by a vertical ruled line. Lead/Ball Finish values may wrap to two lines if the finish

value exceeds the maximum column width.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is provided. TI bases its knowledge and belief on information

provided by third parties, and makes no representation or warranty as to the accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and

continues to take reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on incoming materials and chemicals.

TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI to Customer on an annual basis.

OTHER QUALIFIED VERSIONS OF TPS61040, TPS61041 :

•

Automotive: TPS61040-Q1, TPS61041-Q1

NOTE: Qualified Version Definitions:

•

Automotive - Q100 devices qualified for high-reliability automotive applications targeting zero defects

Page 19

PACKAGE MATERIALS INFORMATION

www.ti.com 28-Nov-2013

TAPE AND REEL INFORMATION

*All dimensions are nominal

Device Package

TPS61040DBVR SOT-23 DBV 5 3000 178.0 9.0 3.23 3.17 1.37 4.0 8.0 Q3

TPS61040DBVR SOT-23 DBV 5 3000 179.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

TPS61040DDCR SOT DDC 5 3000 179.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

TPS61040DDCT SOT DDC 5 250 179.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

TPS61040DRVR SON DRV 6 3000 179.0 8.4 2.2 2.2 1.2 4.0 8.0 Q2

TPS61040DRVT SON DRV 6 250 179.0 8.4 2.2 2.2 1.2 4.0 8.0 Q2

TPS61041DBVR SOT-23 DBV 5 3000 179.0 8.4 3.2 3.2 1.4 4.0 8.0 Q3

TPS61041DBVR SOT-23 DBV 5 3000 178.0 9.0 3.23 3.17 1.37 4.0 8.0 Q3

TPS61041DRVR SON DRV 6 3000 179.0 8.4 2.2 2.2 1.2 4.0 8.0 Q2

TPS61041DRVR SON DRV 6 3000 180.0 8.4 2.25 2.25 1.0 4.0 8.0 Q2

TPS61041DRVT SON DRV 6 250 180.0 8.4 2.25 2.25 1.0 4.0 8.0 Q2

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0

(mm)B0(mm)K0(mm)P1(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 20

PACKAGE MATERIALS INFORMATION

www.ti.com 28-Nov-2013

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

TPS61040DBVR SOT-23 DBV 5 3000 180.0 180.0 18.0

TPS61040DBVR SOT-23 DBV 5 3000 203.0 203.0 35.0

TPS61040DDCR SOT DDC 5 3000 195.0 200.0 45.0

TPS61040DDCT SOT DDC 5 250 195.0 200.0 45.0

TPS61040DRVR SON DRV 6 3000 203.0 203.0 35.0

TPS61040DRVT SON DRV 6 250 203.0 203.0 35.0

TPS61041DBVR SOT-23 DBV 5 3000 203.0 203.0 35.0

TPS61041DBVR SOT-23 DBV 5 3000 180.0 180.0 18.0

TPS61041DRVR SON DRV 6 3000 203.0 203.0 35.0

TPS61041DRVR SON DRV 6 3000 205.0 200.0 33.0

TPS61041DRVT SON DRV 6 250 205.0 200.0 33.0

Pack Materials-Page 2

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components as meeting ISO/TS16949 requirements, mainly for automotive use. In any case of use of

non-designated products, TI will not be responsible for any failure to meet ISO/TS16949.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2014, Texas Instruments Incorporated

Loading...

Loading...