www.ti.com

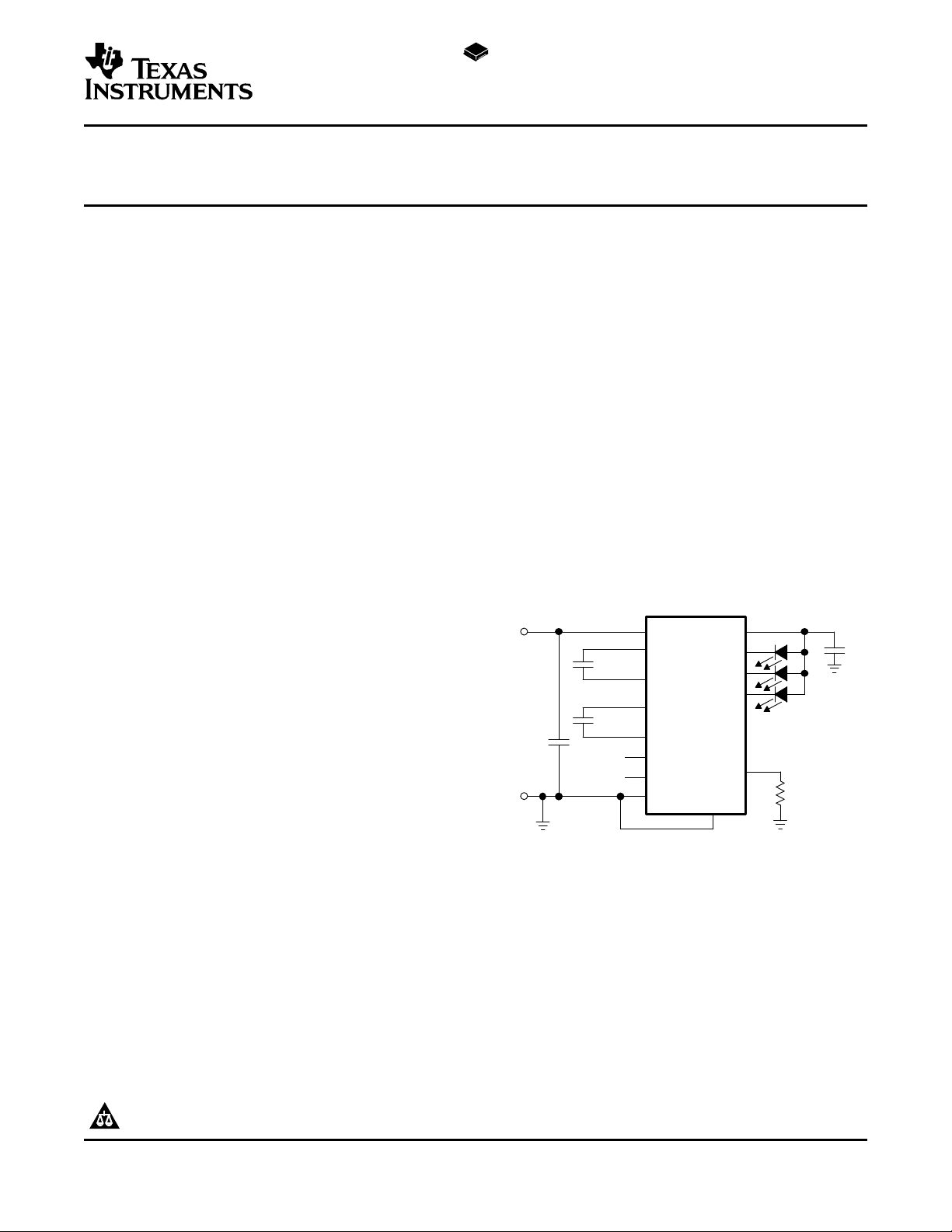

VIN

C1+

C1−

C2+

C2−

EN1

EN2

GND

PGND

VOUT

D1

D2

D3

ISET

0.47 F

0.47 F

1 F

1 F

VIN = 2.7 V

to 6.5 V

WHITE LED CHARGE PUMP CURRENT SOURCE

WITH PWM BRIGHTNESS CONTROL

FEATURES DESCRIPTION

• Regulated Output Current With 0.4%

Matching

• Drives up to 3 LEDs at 25 mA Each

• LED Brightness Control Through PWM

Control Signal

• High Efficiency by Fractional Conversion

With 1x and 1.5x Modes

• 1 MHz Switching Frequency

• 2.7 V to 6.5 V Operating Input Voltage Range

• Internal Softstart Limits Inrush Current

• Low Input Ripple and Low EMI

• Overcurrent and Overtemperature Protected

• Undervoltage Lockout With Hysteresis

• Ultra-Small 3mm x 3mm QFN Package

APPLICATIONS

• White LED Backlight for Color Displays in

Cellular Phones, Smart Phones, PDAs,

Handheld PCs, Digital Cameras, and

Camcorders

• Keypad Backlight

TPS60231

SLVS544 – OCTOBER 2004

The TPS60231 charge pump is optimized for white

LED supplies in color display backlight applications.

The device provides a constant current for each LED,

which the initial value can be set by an external

resistor. The supply voltage ranges from 2.7 V to

6.5 V and is ideally suited for all applications powered

by a single LI-Ion battery cell or three to four NiCd,

NiMH, or alkaline battery cells. Over an input voltage

range from 3.1 V to 6.5 V, the device provides a high

output current of up to 25 mA per LED with a total of

75 mA. High efficiency is achieved by utilizing a

1x/1.5x fractional conversion technique in combination with very low dropout current sources. In

addition, the current controlled charge pump ensures

low input current ripple and EMI. Only two external

1 µF and two 0.47 µF capacitors are required to build

a complete small and low cost power supply solution.

To reduce board space to a minimum, the device

switches at 1 MHz operating frequency and is available in a small 16-pin QFN (RGT) package.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2004, Texas Instruments Incorporated

www.ti.com

TPS60231

SLVS544 – OCTOBER 2004

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated

circuits be handled with appropriate precautions. Failure to observe proper handling and installation

procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision

integrated circuits may be more susceptible to damage because very small parametric changes could

cause the device not to meet its published specifications.

ORDERING INFORMATION

PACKAGED DEVICE

TPS60231RGTR QFN BKH

(1) T indicates shipment in tape and reel on a mini reel with 250 units

per reel.

(2) R indicates shipment in tape and reel with 3000 units per reel.

ABSOLUTE MAXIMUM RATINGS

over operating free-air temperature range (unless otherwise noted)

V

Supply voltage –0.3 V to 7 V

I

Voltage at EN1, EN2, VOUT, ISET –0.3 V to V

Output current at VOUT 150 mA

T

Maximum junction temperature 150 ° C

J

T

Operating free-air temperature –40 ° C to 85 ° C

A

T

Storage temperature –65 ° C to 150 ° C

st

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds 300 ° C

(1) Stresses beyond those listed under "absolute maximum ratings" may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under "recommended operating

conditions" is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(1) (2)

PACKAGE MARKING

(1)

UNIT

I

DISSIPATION RATINGS

PACKAGE

16-Pin QFN (RGT) 1.9 W 20 mW/ ° C 1 W 760 mW

(1) The thermal resistance junction to ambient of the QFN package is 52 ° C/W.

(1)

TA≤ 25 ° C DERATING FACTOR TA= 70 °C TA= 85 °C

POWER RATING ABOVE TA= 25 ° C POWER RATING POWER RATING

RECOMMENDED OPERATING CONDITIONS

MIN TYP MAX UNIT

Supply voltage at VIN 2.7 6.5 V

Maximum output current at VOUT 75 mA

C

Input capacitor 1 µF

i

C

Output capacitor 0.47 1 µF

o

Flying capacitor, C1, C2 0.22 0.47 µF

Operating junction temperature -40 125 °C

2

www.ti.com

TPS60231

SLVS544 – OCTOBER 2004

ELECTRICAL CHARACTERISTICS

VI= 3.6 V, EN1 = EN2 = VI, TA= -40 °C to 85 °C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SUPPLY VOLTAGE AND CURRENT

V

I

Q

I

SD

CHARGE PUMP STAGE

V

f Switching frequency 0.75 1 1.25 MHz

η Efficiency VI= 3.7 V, I

CURRENT SINKS

I

Dx

I

Dx

V

Iset Recommended ISET pin current range 4 130 µA

K IDxto ISET current ratio EN2 = EN1 = 1, ISET = 80 µA 230 260 280

V

ENABLE 1, ENABLE 2

V

V

I

IKG

I

IKG

V

Input voltage range IO= 0 mA to 75 mA 2.7 6.5 V

I

Operating quiescent current

VI= 4.2 V, x1-mode, EN1 = EN2 = 1, ISET = 20 µA 200 µA

IO= 0 mA, x1.5-mode 2.1 mA

Shutdown current EN2 = EN1 = GND 0.1 1 µA

Overvoltage limit LED1 unconnected, VI= 4.2 V 5.5 V

OUT

Startup time CO= 1 µF, IDX≥ 0.9 IDX, set 375 µs

Softstart duration 160 µs

= 15 mA each, V

LED

= 3.1 V 83%

DX

Shutdown temperature Temperature rising 160 ° C

Shutdown temperature hysteresis 20 ° C

Input current limit EN2 = EN1 = 1, ISET = 100 µA 350 mA

Recommended maximum current per cur- 3.2 V ≤ VI≤ 6.5 V 25 mA

rent sink

Current into each current sink when ISET 50 mA

is shorted to GND

Current matching between any two outputs V

Line regulation

3.0 V ≤ VI≤ 6.5 V, ISET shorted to GND

= 3.1 V, TA= 25 ° C –2% 0.4% 2%

Dx

3.2 V ≤ VI≤ 6.5 V, V

ISET = 80 µA

= 3.1 V, EN1 = EN2 = 1, ± 3%

Dx

EN2 = 0, EN1 = 1 200

Reference voltage for current set EN2 = 1, EN1 = 0 400 mV

ISET

EN2 = 1, EN1 = 1 580 600 620

EN2 = 0, EN1 = 1 200

Voltage at Dx to GND EN2 = 1, EN1 = 0 300 mV

source

EN2 = 1, EN1 = 1 400

EN1, EN2 high level input voltage 1.3 V

IH

EN1, EN2 low level input voltage 0.3 V

IL

EN1, EN2 trip point hysteresis 50 mV

EN2 input leakage current EN1, EN2 = GND or EN2 = VI, VI= 6.5 V 0.01 1 µA

EN1 input leakage current EN1 = VI, VI= 4.2 V 11 15 µA

Undervoltage lockout threshold Input voltage falling 2.1 V

(UVLO)

Undervoltage lockout hysteresis 50 mV

Frequency range at PWM 0 50 kHz

Recommended ON-time for PWM signal 2.5 µs

Shutdown delay time 0.5 0.85 1.5 ms

Delay time when EN1 = EN2 go to GND after which

the TPS60231 shuts down completely

3

www.ti.com

C2−

C1−

C1+

C2+

PGND

VIN

EN1

D2

D1

VOUT

GND

NC

NC

D3

31 2

7

5

6

8

12 11 10

9

15

13

14

16

EN2

4

QFN PACKAGE

(TOP VIEW)

TPS60231

SLVS544 – OCTOBER 2004

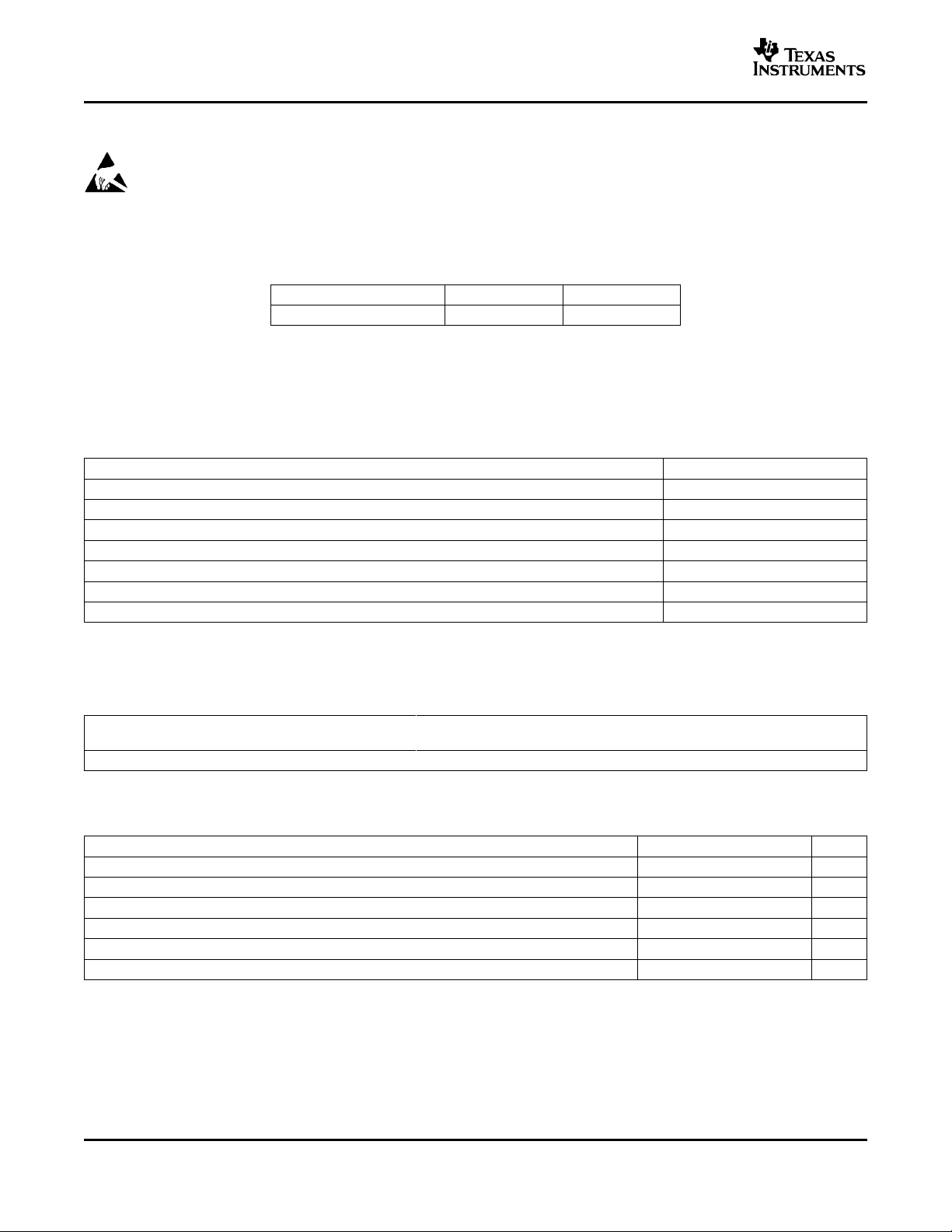

PIN ASSIGNMENT

Terminal Functions

TERMINAL

NAME NO.

C1+ 10 – Connect to the flying capacitor C1

C1– 11 – Connect to the flying capacitor C1

C2+ 9 – Connect to the flying capacitor C2

C2– 12 – Connect to the flying capacitor C2

D1-D3 6-4 I Current sink input. Connect the cathode of the white LEDs to these inputs.

EN1 15 I

EN2 16 I

GND 14 – Analog ground

ISET 1 I Connect a resistor between this pin and GND to set the maximum current through the LEDs.

NC 2, 3 – No internal connection

PGND 7 – Power ground

VIN 13 I Supply voltage input

VOUT 8 0 Connect the output capacitor and the anode of the LEDs to this pin.

Power PAD – – Connect with PGND and GND

I/O DESCRIPTION

Enable input. A logic high enables the converter, logic low forces the device into shutdown mode reducing

the supply current to less than 1 µA if EN2 is tied to GND.

An applied PWM signal reduces the LED current as a function of the duty cycle of the PWM signal. EN1 and

EN2 can be tied together for PWM dimming between 0 mA and the maximum set with ISET. EN1 and EN2

can also be used for digital dimming with 4 steps from 0 mA to the maximum current set with ISET. See the

application section for more details.

4

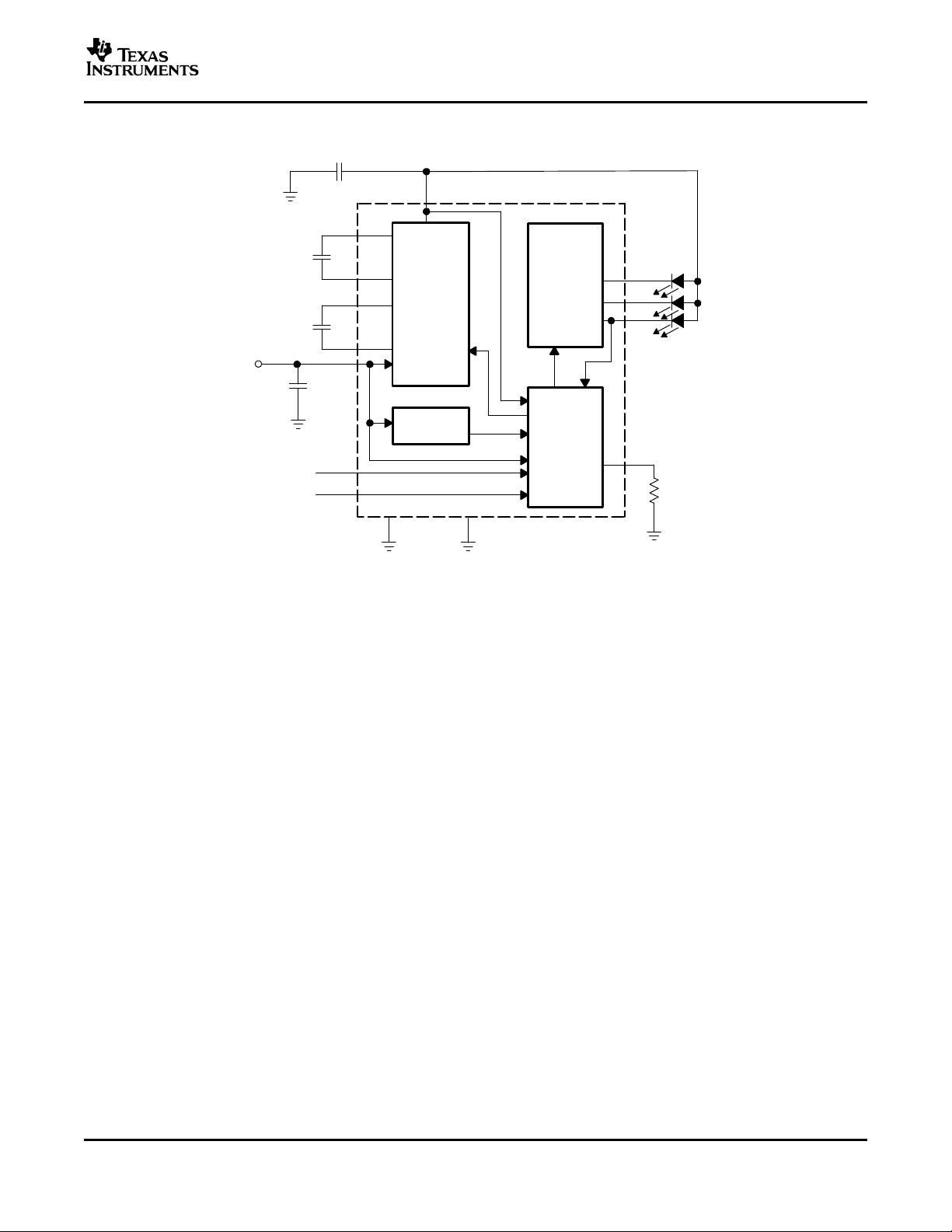

www.ti.com

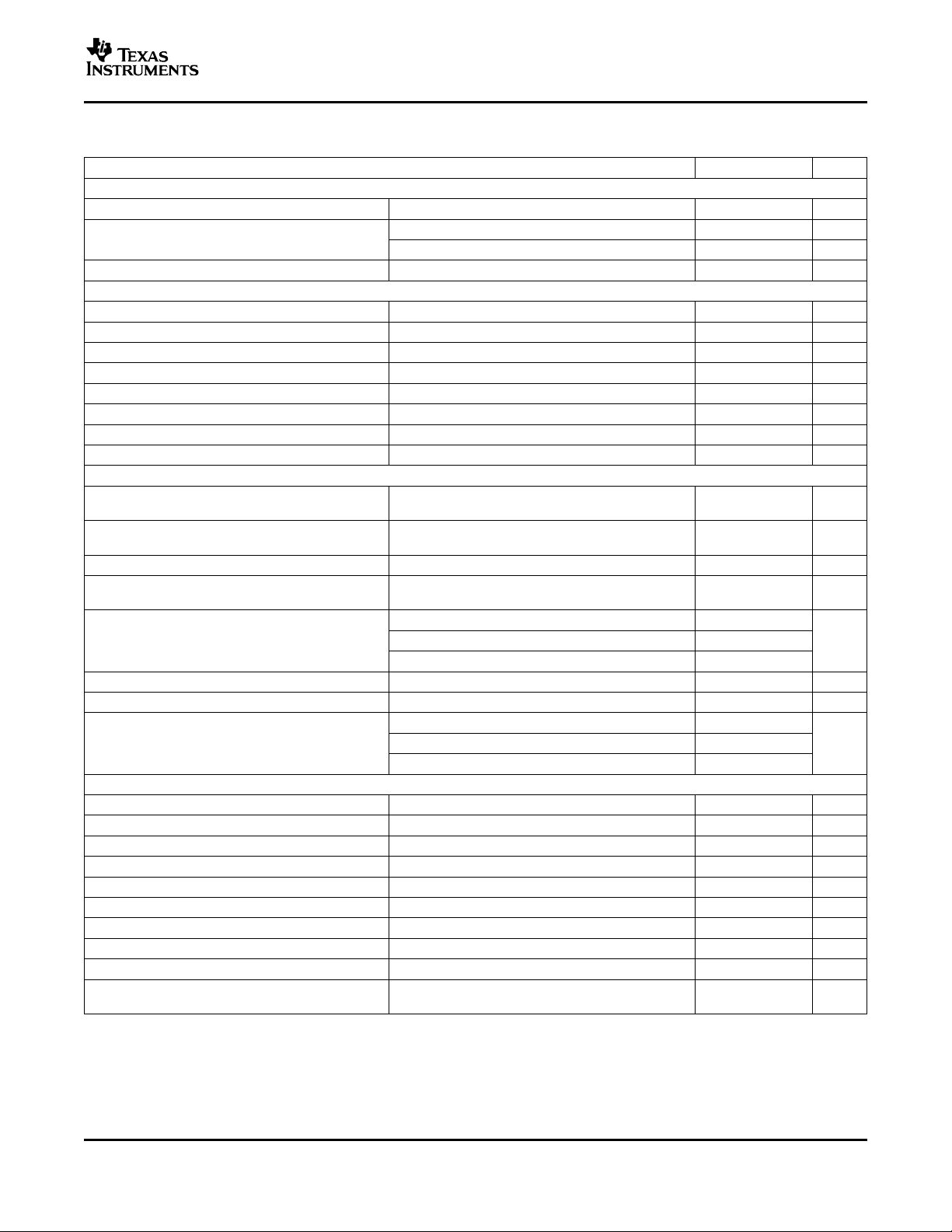

D3

D2

D1

C1+

C1−

C2+

C2−

EN2

VOUT

ISET

GND

EN1

Control

R

SET

VIN

Reference

0.47 F

0.47 F

1 F

Charge

Pump

Current

Sinks

1 F

PGND

FUNCTIONAL BLOCK DIAGRAM

TPS60231

SLVS544 – OCTOBER 2004

5

www.ti.com

0

10

20

30

40

50

60

70

80

90

100

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9 6.3

I

LED

= 25 mA

VI − Input Voltage − V

Efficiency − %

I

LED

= 15 mA

I

LED

= 10 mA

I

LED

= 5 mA

0

10

20

30

40

50

60

70

80

90

100

2.7 3.1

3.5 3.9 4.3 4.7 5.1 5.5

5.9 6.3

VI − Input Voltage − V

Efficiency − %

I

LED

= 25 mA

I

LED

= 10 mA

I

LED

= 15 mA

I

LED

= 5 mA

TPS60231

SLVS544 – OCTOBER 2004

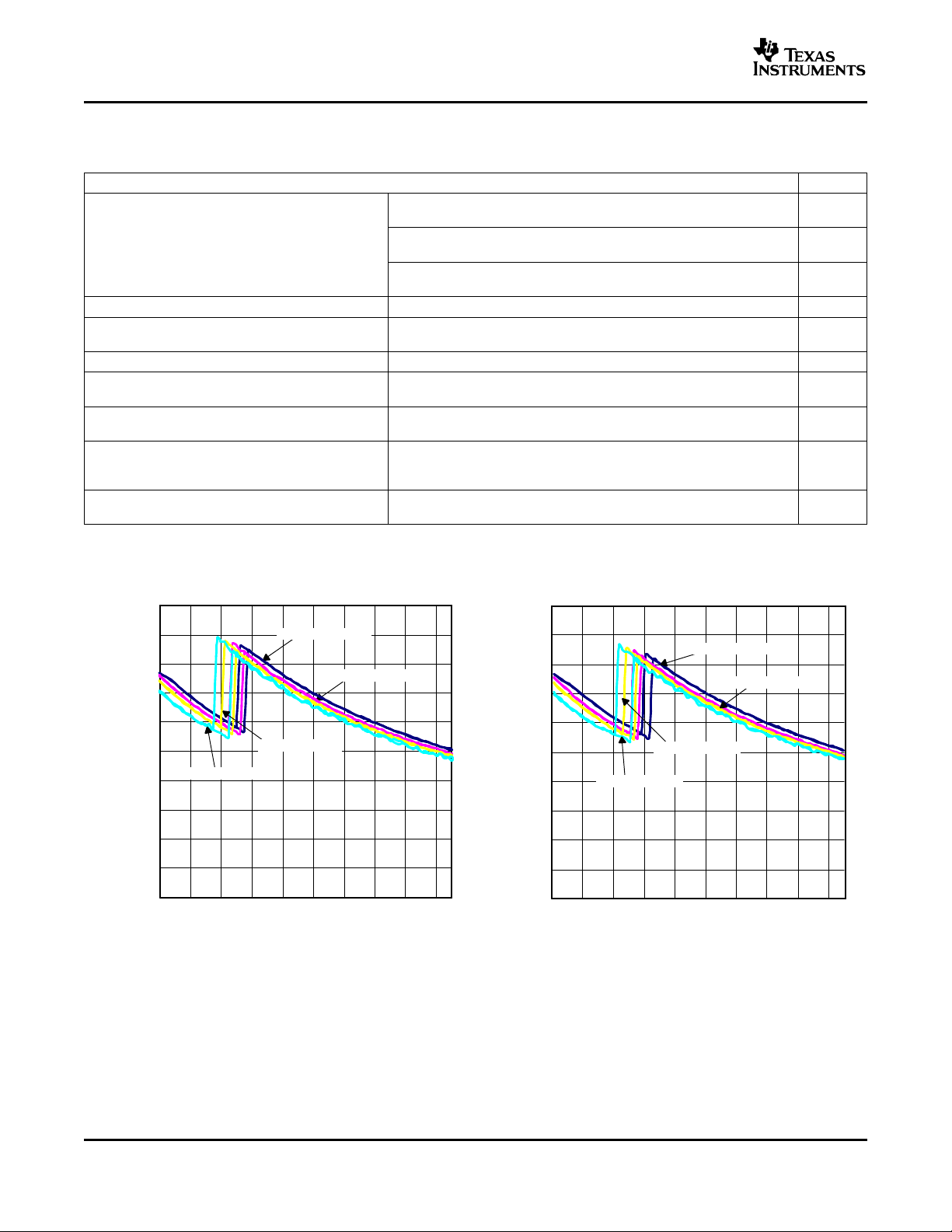

TYPICAL CHARACTERISTICS

Table of Graphs

vs Input voltage (I

EN2 = 0, EN1 = 1

η Efficiency

vs Input voltage (I

1, EN1 = 0

vs Input voltage (I

EN2 = EN1 = 1

IQQuiescent current vs Input voltage (T

Maximum output current from charge pump

stage

vs Input voltage (T

fsSwitching frequency vs Free-Air Temperature (T

LED current, I

Line transient response

LED

vs Duty cycle on PWM (I

For f = 32 kHz and f = 1 kHz, DC = 1% to 100%, VI= 3.6 V

VIand ID1vs time on scope, LED current at D1 with 8

VI= 4.2 V to 3.6 V to 4.2 V with EN2 = EN1 = 11, 3 x 20 mA

PWM signal and current at D1 vs time on scope 9, 10

Dimming response f = 32 kHz and f = 1 kHz, VI= 3.6 V, duty cycle = 50%,

EN1 = EN2 = PWM

Startup timing

VI= 3.6 V, 3 x 20 mA, EN1 = EN2 = 00 changed to 11

EN2 = EN1 = 11

= 25 mA, 15 mA, 10 mA, 5 mA per LED),

LED

= 25 mA, 15 mA, 10 mA, 5 mA per LED), EN2 = 2

LED

= 25 mA, 15 mA, 10 mA, 5 mA per LED), 3

LED

= –40 ° C, 25 ° C, 85 ° C) (measured with ID1= 5 mA) 4

A

= –40 ° C, 25 ° C, 85 ° C) 5

A

= -40 ° C to 85 ° C, VI= 3.6 V) 6

A

max set to 20 mA) 7

LED

FIGURE

1

EFFICIENCY EFFICIENCY

vs vs

INPUT VOLTAGE INPUT VOLTAGE

Figure 1. Figure 2.

6

www.ti.com

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5

5.9

6.3

VI − Input Voltage − V

I

Q

− Quiescent Current − mA

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

2.2

2.4

2.6

2.8

3

TA = −40C

TA = 25C

TA = 85C

0

10

20

30

40

50

60

70

80

90

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9 6.3

VI − Input Voltage − V

Efficiency − %

I

LED

= 25 mA

I

LED

= 10 mA

I

LED

= 5 mA

I

LED

= 15 mA

2.7 3.1 3.5 3.9 4.3 4.7 5.1 5.5 5.9 6.3

VI − Input Voltage − V

0

0.05

0.10

0.15

V

LED

= 3 V

V

LED

= 3.4 V

V

LED

= 3.6 V

V

LED

= 3.8 V

I

O

− Maximum Output Current − A

V

LED

= 3.2 V

TA = 25C

980

990

1000

1010

1020

1030

1040

−40

−30 −20 −10 0 10 20 30 40 50 60 70 80

TA − Free-Air Temperature − C

Switching Frequency − kHz

VI = 3.6 V

EFFICIENCY QUIESCENT CURRENT

vs vs

INPUT VOLTAGE INPUT VOLTAGE

TPS60231

SLVS544 – OCTOBER 2004

MAXIMUM OUTPUT CURRENT SWITCHING FREQUENCY

INPUT VOLTAGE FREE-AIR TEMPERATURE

Figure 3. Figure 4.

vs vs

Figure 5. Figure 6.

7

www.ti.com

1 mA/div 500 mV/div

V

I

I

LED(D1)

3.6 V

AC

EN1 = 1, EN2 = 1, VI = 3.6 V to 4.2 V ,

I

LED

= 20 mA, 3 LEDs Connected,

I

LED(D1)

Measured With 1 Resistor,

TA = 25C

100 s/div

0

5

10

15

20

25

0 10 20 30 40 50 60 70 80 90 100

Duty Cycle − %

f = 32 kHz

f = 1 kHz

VI = 3.6 V ,

I

LED

max set to 20 mA

I

LED(D1)

− D1 LED Current − mA

10 mA/div 2 V/div

PWM

I

LED(D1)

0 V

PWM Into EN1 and EN2, VI = 3.6 V ,

I

LED

= 20 mA, 3 LEDs Connected,

f = 1 kHz, TA = 25C

200 s/div

0 A

10 mA/div 2 V/div

PWM

I

LED(D1)

0 V

PWM Into EN1 and EN2, VI = 3.6 V ,

I

LED

= 20 mA, 3 LEDs Connected,

f = 32 kHz, TA = 25C

5 s/div

0 A

TPS60231

SLVS544 – OCTOBER 2004

D1 LED CURRENT

vs

DUTY CYCLE LINE TRANSIENT

Figure 7. Figure 8.

DIMMING RESPONSE DIMMING RESPONSE

8

Figure 9. Figure 10.

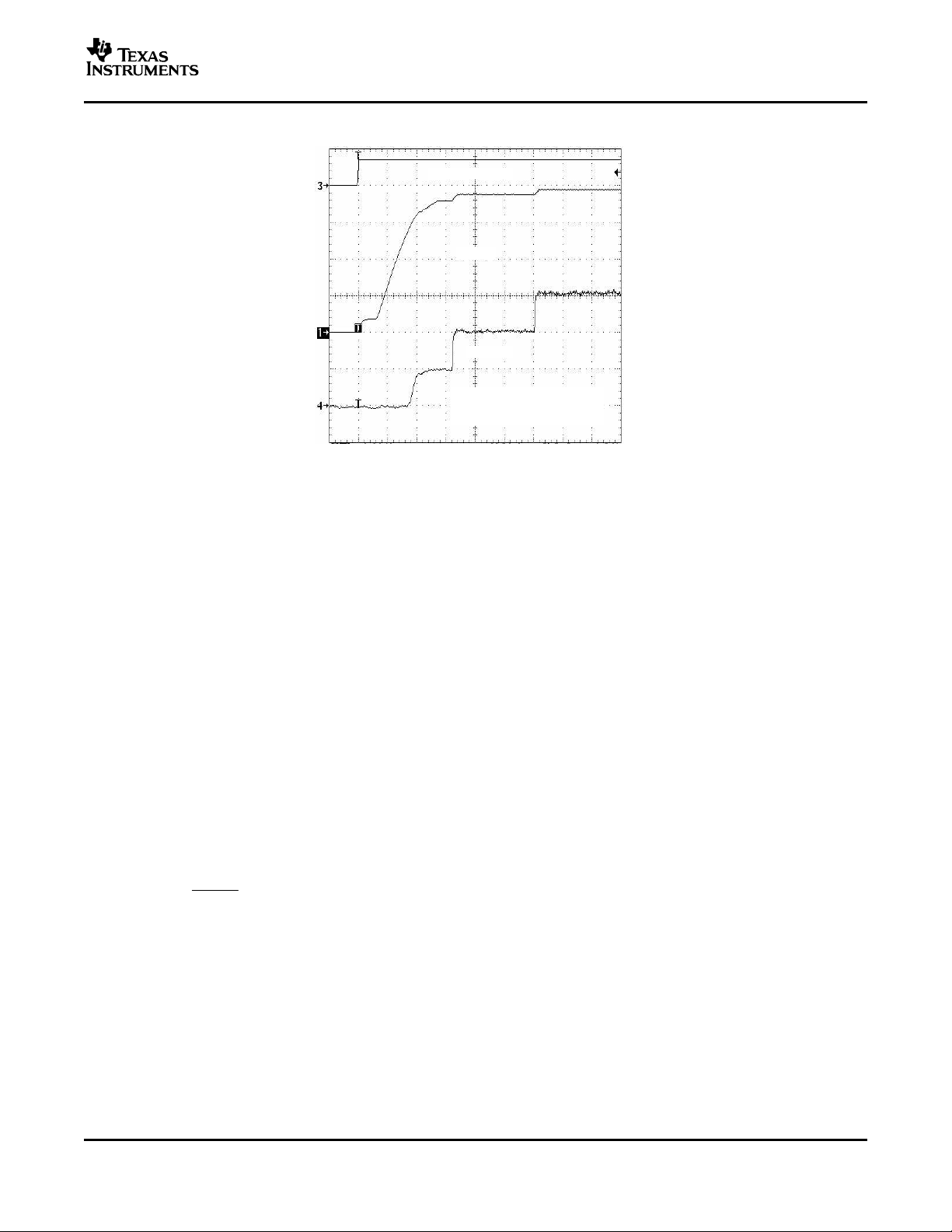

www.ti.com

EN1 + EN2

V

O

I

LED

0 V

0 A

0 V

20 mA/div 5 V/div1 V/div

20 s/div

VI = 3.6 V , I

LED

= 20 mA,

3 LED’s Connected,

TA = 25C

R

ISET

V

ISET

I

LED

K

STARTUP TIMING

TPS60231

SLVS544 – OCTOBER 2004

Figure 11.

DETAILED DESCRIPTION

OPERATION

The TPS60231 uses a fractional conversion charge pump to generate a supply voltage for the integrated current

sinks. These current sinks are used to ensure a constant current for each LED. Depending on the input voltage

and programmed LED current, the charge pump either operates in the 1x mode or in the 1.5x mode. By

switching automatically between these two modes, the circuit optimizes power conversion efficiency as well as

extends operating time by allowing the discharge of the battery completely.

The charge pump can generate 75 mA of output current, so each of the 3 LED outputs can be powered with up

to 25 mA of current. The maximum LED current is set by a resistor connected to the ISET pin. This resistor

programs a reference current, which is current mirrored to set the LED current.

Applying a PWM signal to the EN1 pin and/or the EN2 pin controls the LED brightness. See a detailed

description in the section Analog Dimming Using ISET Pin.

LED CURRENT ADJUSTMENT (ISET)

A resistor programs a reference current, which is current mirrored to set the LED current. The voltage at the

ISET pin depends on the status of EN1 and EN2. The current in each LED is typically 260 times the current

through the resistor at ISET.

V

— Voltage from ISET pin (0.2 V, 0.4 V or 0.6 V) to GND, see Table 1

ISET

I

— Current per LED from Dx pin to GND

LED

K — Dx to I

The LED current varies linearly from 0 mA to I

The LED brightness can however also be controlled by an analog control signal that is fed into the ISET pin.

current ratio (typically 260)

SET

LED(max)

mA by applying a PMW signal with 0% to 100% duty cycle.

9

www.ti.com

TPS60231

SLVS544 – OCTOBER 2004

DETAILED DESCRIPTION (continued)

SOFT START

The TPS60231 has an internal soft start circuit to limit the inrush current during startup. This prevents possible

voltage drops of the input voltage if a high impedance power source is connected to the input of the TPS60231.

When the device starts up with an output voltage that is below the input voltage, the output capacitor is charged

directly from the input with a current source. The output current increases linearly until the output reaches within

300 mV of the input voltage. When the programmed output current can be reached with the 1x mode, the

TPS60231 terminates the soft start and begins normal operation. When the desired output current cannot be

reached, the charge pump begins operation in 1.5x mode and pumps the output voltage up to the needed level

to reach the programmed output current.

ENABLE (EN1, EN2)

The enable pins EN1 and EN2 are used to enable the device or set it into shutdown. The TPS60231 is enabled if

one of the enable pins is pulled higher than the enable trip point of 1.3 V. The device starts up by going through

the soft start routine as described in the section Soft Start. Pulling both pins to GND, after a delay, programs the

device to shutdown. In shutdown, the charge pump, current sources, voltage reference, oscillator, and all other

functions are turned off and the supply current is reduced to 0.1 µA.

EN1 and EN2 can also be used for dimming. The logic levels at EN1 and EN2 set the minimum voltage at the

current mirrors and the voltage at the ISET pin to GND. This sets the current at the LEDs to be either the full

current or a fraction of the full current. See Table 1 for further details. The maximum current through the LEDs is

set by a resistor connected between ISET and GND.

EN1 and EN2 can also be used for PWM dimming. The PWM signal can either be applied to EN1 or EN2, or

both inputs can be tied together and the PWM signal can be applied to both pins. Depending on the

configuration, the current during PWM dimming is switched between 0 mA and its maximum (EN1 and EN2

connected to the PWM signal) or between 0 mA and 1/3 of the full LED current if EN2 = 0 and EN1 is toggled.

When EN1 = 0 and EN2 is toggled, the output current can be changed between 0 mA and 2/3 of the full range.

Table 1. Enable Levels

ENABLE LEVEL

EN2 EN1

0 0 SHUTDOWN 0

0 1 VISET = 200 mV 1/3

1 0 VISET = 400 mV 2/3

1 1 VISET = 600 mV Full

MODE LED CURRENT

UNDERVOLTAGE LOCKOUT

The undervoltage lockout circuit shuts down the device when the voltage at VIN drops below a typical threshold

of 2.15 V. This prevents damage to the device. The UVLO circuit allows the device to start up again after the

voltage on the VIN pin has increased by about 50 mV above the UVLO lockout threshold.

SHORT CIRCUIT AND OVERTEMPERTURE PROTECTION

The current at the VOUT pin is limited typically to 250 mA. When the junction temperature exceeds 160 ° C, the

device shuts down to protect the device from damage. After the temperature decreases to about 140 ° C, the

device starts up again if it is enabled.

OVERVOLTAGE PROTECTION AT VOUT

The device uses the voltage at D1 to regulate voltage at VOUT. In case D1 is not connected, an overvoltage

protection circuit ensures that the output voltage at VOUT does not exceed its limits. The connection of the LEDs

must be started using D1 first. For all other LEDs there is no restriction in the sequence. For example, if there

are only 2 LEDs used, the first LED is connected to D1 and the other LED can be connected to any other of the

D2 to D3 pins.

10

www.ti.com

P

D max, package

T

Jmax

T

A

R

ja

TPS60231

SLVS544 – OCTOBER 2004

THEORY OF OPERATION/DESIGN PROCEDURE

Capacitor Selection

Ceramic capacitors such as X5R or X7R are recommended to be used with the TPS60231. For the two flying

capacitors C1 and C2, it is important to use low ESR capacitors to avoid unnecessary efficiency losses. Low

ESR capacitors on VOUT reduce the ripple voltage on the supply of the current sources. Table 2 lists capacitor

types that have been tested with the TPS60231.

Table 2. Capacitors

PART VALUE VOLTAGE MANUFACTURER SIZE WEBSITE

C1608X5R1A105M 1 µ F 10 V 0603

C1608X5R1A474M 0.47 µ F 10 V TDK 0603 www.componnent.tdk.com

C2012X7R1C105M 1 µ F 16 V 0805

LMK107BJ105MA 1 µ F 10 V 0603

LMK107BJ474MA 0.47 µ F 10 V Taiyo Yuden 0603 www.t-yuden.com

LMK212BJ105MG 1 µ F 10 V 0805

Power Efficiency

The power conversion efficiency of the TPS60231 can be calculated by adding up the products of each LED

current and voltage and dividing it by the product of the input voltage and current. With a fully charged battery

where the input voltage is typically above the LED forward voltage, the charge pump operates in the 1x mode

and efficiency is very high. As the battery discharges, there is a point where the current sources no longer have

enough voltage overhead to maintain a constant current regulation. At that point, the charge pump switches into

the 1.5x mode. The conversion efficiency is lowest at the crossover. As the battery discharges further, the

efficiency again increases until at about 3.1 V where it reaches a second maximum. Below 3.1 V input voltage,

the maximum current per LED is less than 25 mA.

Power Dissipation

The maximum power dissipation inside the TPS60231 can be calculated based on the following equation:

P

= [(1.5 × VI) – V

D max

+ 0.4 V] × I

O

O

The maximum power dissipation occurs when the input voltage is just low enough to operate in 1.5x mode, with

a forward voltage of the white LED at maximum. This is typically for VI= 4.2 V and a forward voltage of 3.6 V.

This needs to be lower than the maximum allowed power dissipation of the package, which can be calculated

using the following equation:

For example, the worst case power dissipation occurs at the input voltage level where the charge pump switches

from the 1x mode to the 1.5x mode. At this operating point, the supply voltage to the current sources is at its

maximum and the current sources must drop the most voltage in order to maintain a regulated output current.

The worst case power dissipation occurs when all 3 LED outputs are fully loaded with 25 mA of LED current.

• With: VI= 4.2 V, Vf= 3.6 V, IO= 75 mA (1.5x mode)

• P

= 0.23 W

D max

11

www.ti.com

VIN

C1+

C1−

C2+

C2−

EN1

EN2

GND

VOUT

D1

D2

D3

ISET

0.47 F

0.47 F

1 F

1 F

VIN = 2.7 V

to 6.5 V

Typical Smartphone Display

PGND

VIN

C1+

C1−

C2+

C2−

EN1

EN2

GND

VOUT

D1

D2

D3

ISET

0.47 F

0.47 F

1 F

1 F

VIN = 2.7 V

to 6.5 V

6 k

V = 0 mV to

600 mV

PGND

TPS60231

SLVS544 – OCTOBER 2004

APPLICATION INFORMATION

TYPICAL APPLICATION OF A SMART PHONE DISPLAY WITH RESISTORS CONNECTED IN PARALLEL

If more than 25 mA of output current is needed, then the input pins to the current sinks can be connected in

parallel as shown in the following application figure. This method can also be used to connect a LC display with

only two connections for the white LEDs.

Figure 12. Typical Application With Resistors in Parallel

ANALOG DIMMING USING ISET PIN

The ISET pin can be used to connect an analog dc signal in the range of 0 mV to 600 mV (EN1 = EN2 = 1) for

analog dimming of the white LEDs. For an input voltage of 0 V at ISET, the current is at its maximum, whereas at

600 mV, the LED current is zero. The maximum current is:

• For EN2 = EN1 = 1: ILED = Vset/Rset × K = 0.6V/6kR × 260 = 26 mA per LED

• For EN2 = 1, EN0 = 1: ILED = Vset/Rset × K = 0.4V/6kR × 260 = 17 mA per LED

• For EN2 = 0, EN1 = 1: ILED = Vset/Rset × K = 0.2V/6kR × 260 = 8.6 mA per LED

• With EN2, EN1 set to 10 or 01, a voltage of 400 mV or 200 mV is required to set the LED current to zero.

12

Figure 13. Analog Dimming Connections Using ISET Pin

www.ti.com

V

OUT

= VD1 + V

FLEDD1

R

g

V

FLEDD1

V

Fg

I

g

VIN

C1+

C1−

C2+

C2−

EN1

EN2

GND

VOUT

D1

D2

D3

ISET

0.47 F

0.47 F

1 F

1 F

VIN = 2.7 V

to 6.5 V

6 Green

LEDs With

4 mA Each

2 White

LEDs With

25 mA Each

6.2 k

Sets Current to 25 mA

Per Current Sink

(With EN2 = EN1 = 1)

Rg = 220

TPS60231

SLVS544 – OCTOBER 2004

APPLICATION INFORMATION (continued)

TYPICAL APPLICATION USING 2 WHITE LEDs AND 6 GREEN LEDs FOR LCD BACKLIGHT AND

KEYBOARD LIGHTING

The TPS60231 can be used to power any kind of LED. It is also possible to mix white LEDs with color LEDs

which have a lower forward voltage. The LED with the highest forward voltage (typically the white LED) has to be

connected to D1, because the output voltage of the charge pump is regulated in such a way to keep the voltage

drop from D1 to GND at 400mV (with EN1 = EN2 = 1). Therefore the output voltage of the charge pump is

regulated to:

V

— Output voltage at VOUT

OUT

V

— Voltage from D1 to GND (Vsource at D1 pin, see electrical characteristics)

D1

V

Resistor R

V

Ig— Current per green LED

— Forward voltage of the LED connected to D1

FLEDD1

is used to provide current sharing between the 6 green LEDs. The upper value is calculated using:

g

— Forward voltage of a green LED

Fg

Figure 14. LED Connections for LCD Backlight and Keyboard Lighting

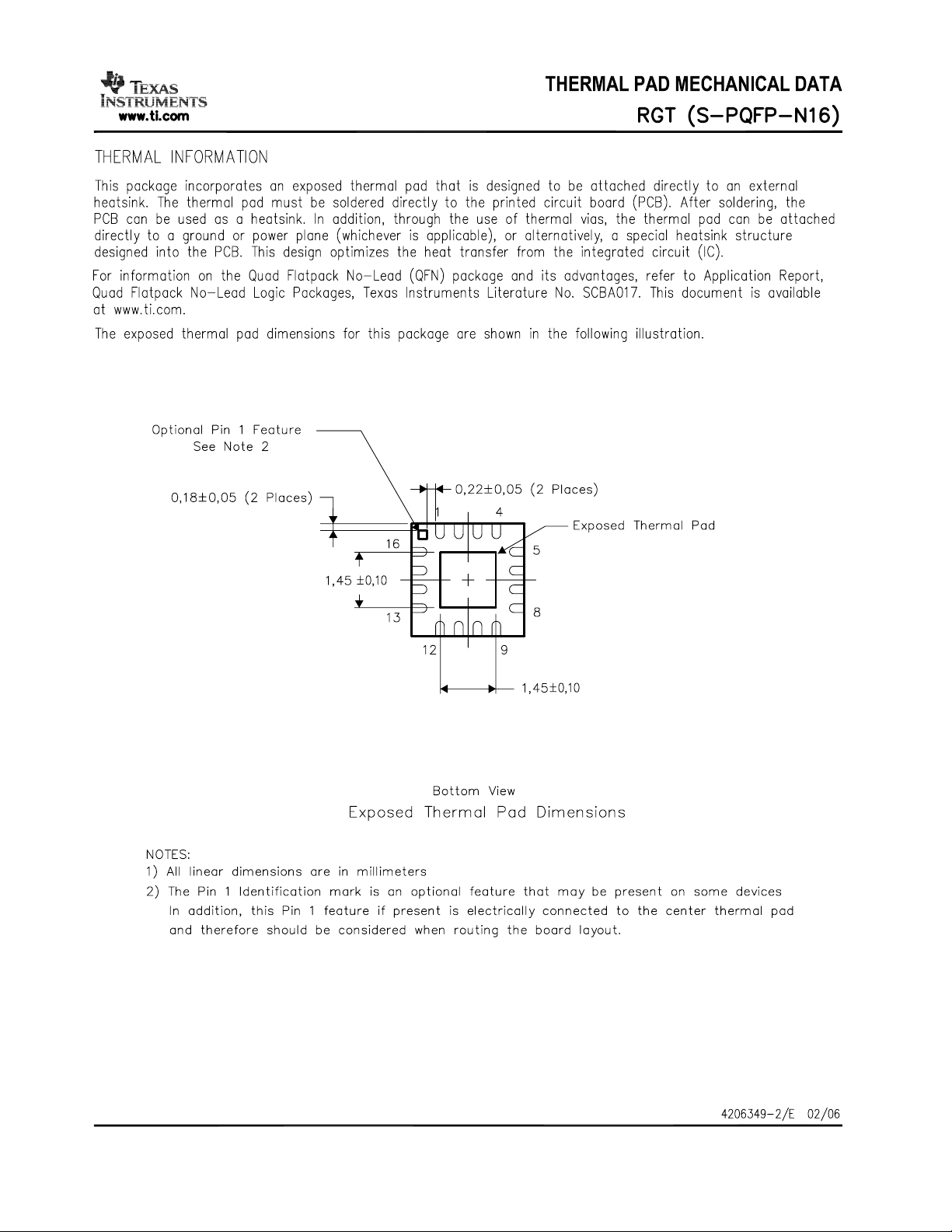

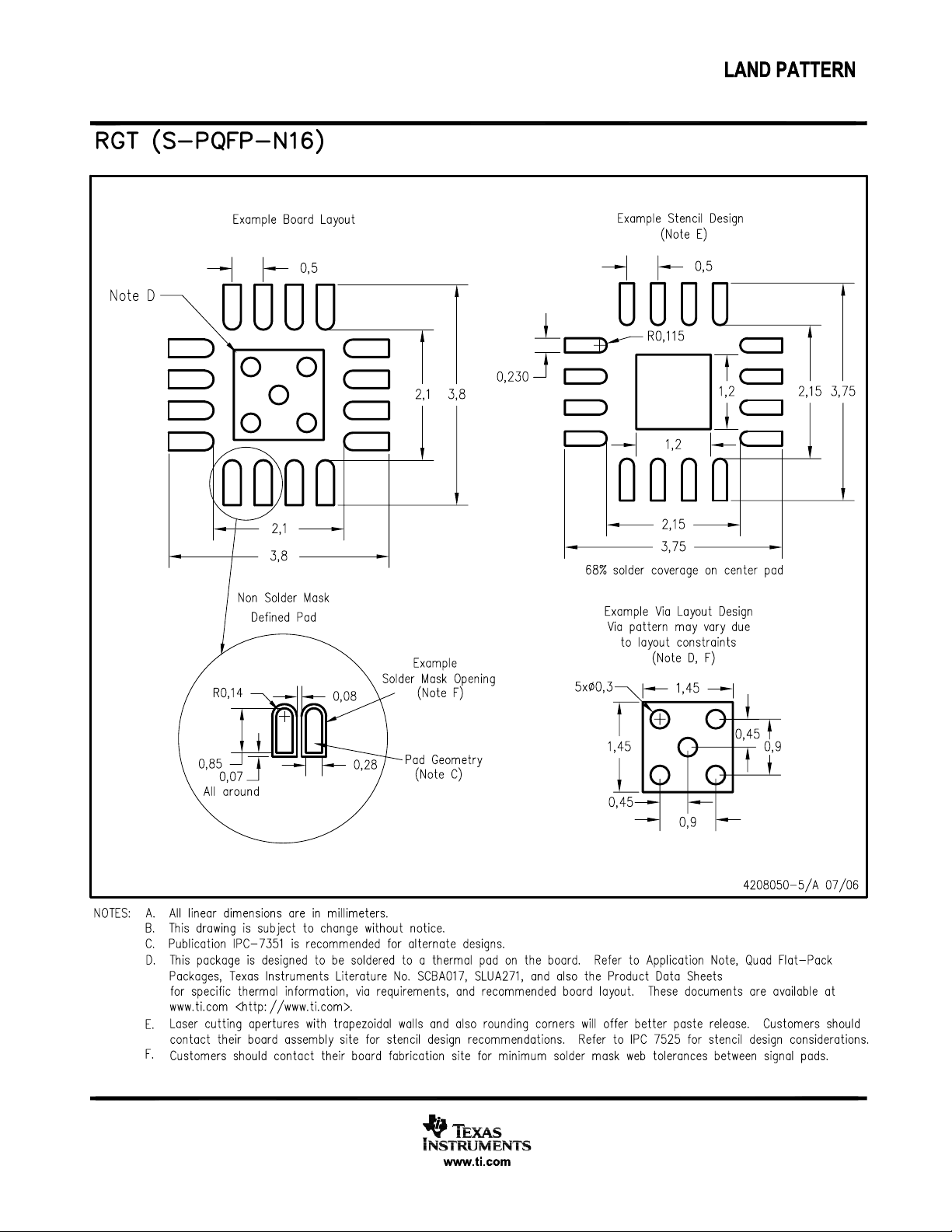

PROPOSED LAND PATTERN FOR PCB PRODUCTION

Refer to the application note SLUA271 for the proposed land pattern of the QFN package.

13

PACKAGE OPTION ADDENDUM

www.ti.com

27-Feb-2006

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

TPS60231RGTR ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS60231RGTRG4 ACTIVE QFN RGT 16 3000 Green (RoHS &

no Sb/Br)

TPS60231RGTT ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

TPS60231RGTTG4 ACTIVE QFN RGT 16 250 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Low Power Wireless www.ti.com/lpw Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2006, Texas Instruments Incorporated

Loading...

Loading...