TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Fast Throughput Rate: 1.25 MSPS

D

8-Pin SOIC Package

D

Differential Nonlinearity Error: < ±1 LSB

D

Integral Nonlinearity Error: < ±1 LSB

D

Signal-to-Noise and Distortion Ratio: 59 dB,

f

(input)

= 500 kHz

D

Single 3-V to 5-V Supply Operation

D

Very Low Power: 8 mW at 3V; 25mW at 5 V

D

Auto-Powerdown: 10 µA Maximum

D

Glueless Serial Interface to TMS320 DSPs

and (Q)SPI Compatible Micro-Controllers

D

Inherent Internal Sample and Hold

Operation

Applications

D

Mass Storage and HDD

D

Automotive

D

Digital Servos

D

Process Control

D

General Purpose DSP

D

Contact Image Sensor Processing

description

The TL V1572 is a high-speed 10-bit successive-approximation analog-to-digital converter (ADC) that operates

from a single 2.7-V to 5.5-V power supply and is housed in a small 8-pin SOIC package.

The TL V1572 accepts an analog input range from 0 to V

CC

and digitizes the input at a maximum 1.25 MSPS

throughput rate. The power dissipation is only 8 mW with a 3-V supply or 25 mW with a 5-V supply . The device

features an auto-powerdown mode that automatically powers down to 10 µA whenever a conversion is not

performed.

The TLV1572 communicates with digital microprocessors via a simple 3- or 4-wire serial port that interfaces

directly to the Texas Instruments TMS320 DSPs and (Q)SPI compatible microcontrollers without using

additional glue logic.

Very high throughput rate, simple serial interface, SO-8 package, 3-V operation, and low power consumption

make the TLV1572 an ideal choice for compact or remote high-speed systems.

AVAILABLE OPTIONS

PACKAGE

T

A

SMALL OUTLINE

(D)

0°C to 70°C TLV1572CD

–40°C to 85°C TLV1572ID

Copyright 1998, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

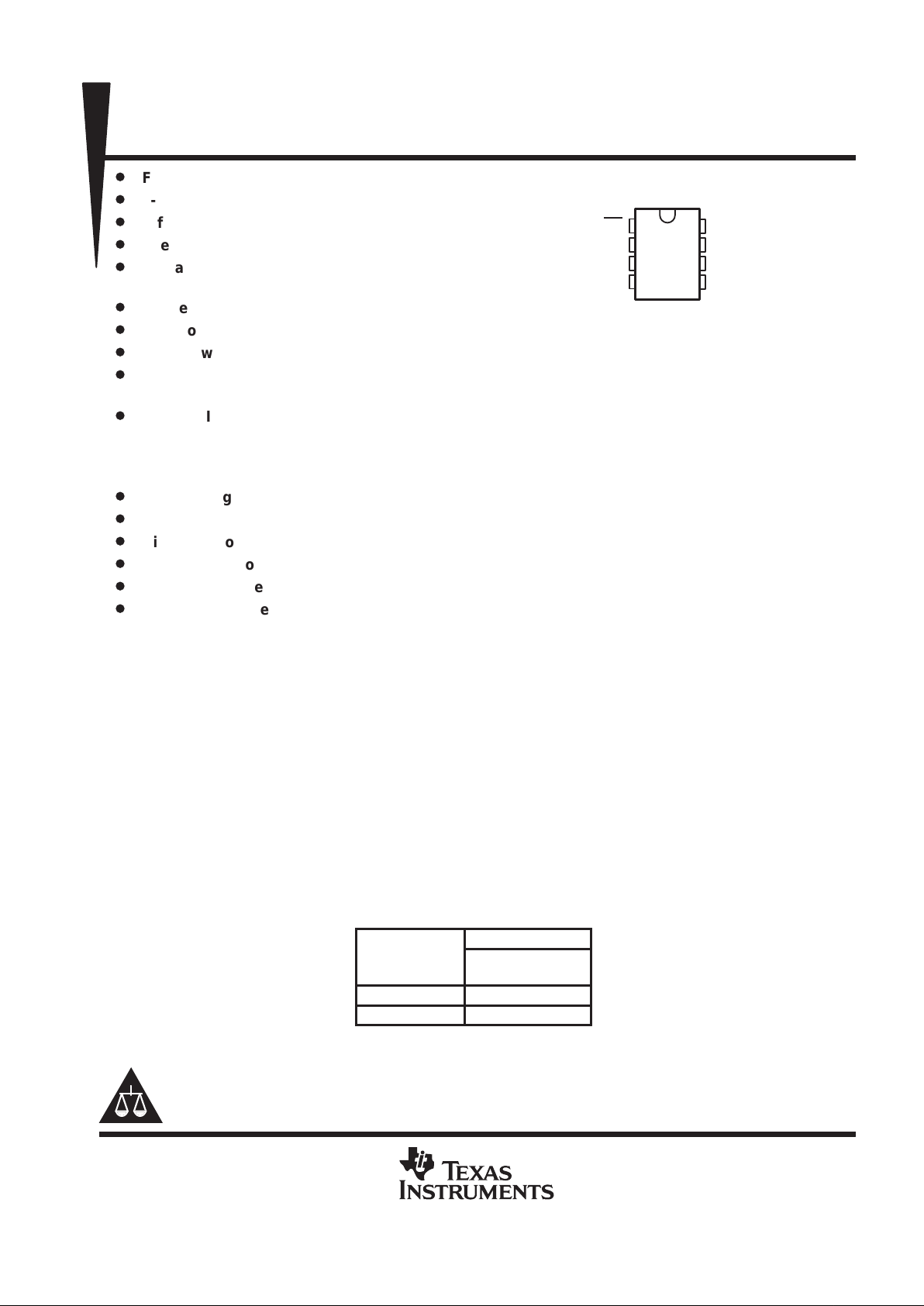

1

2

3

4

8

7

6

5

CS

VREF

GND

AIN

DO

FS

V

CC

SCLK

D PACKAGE

(TOP VIEW)

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

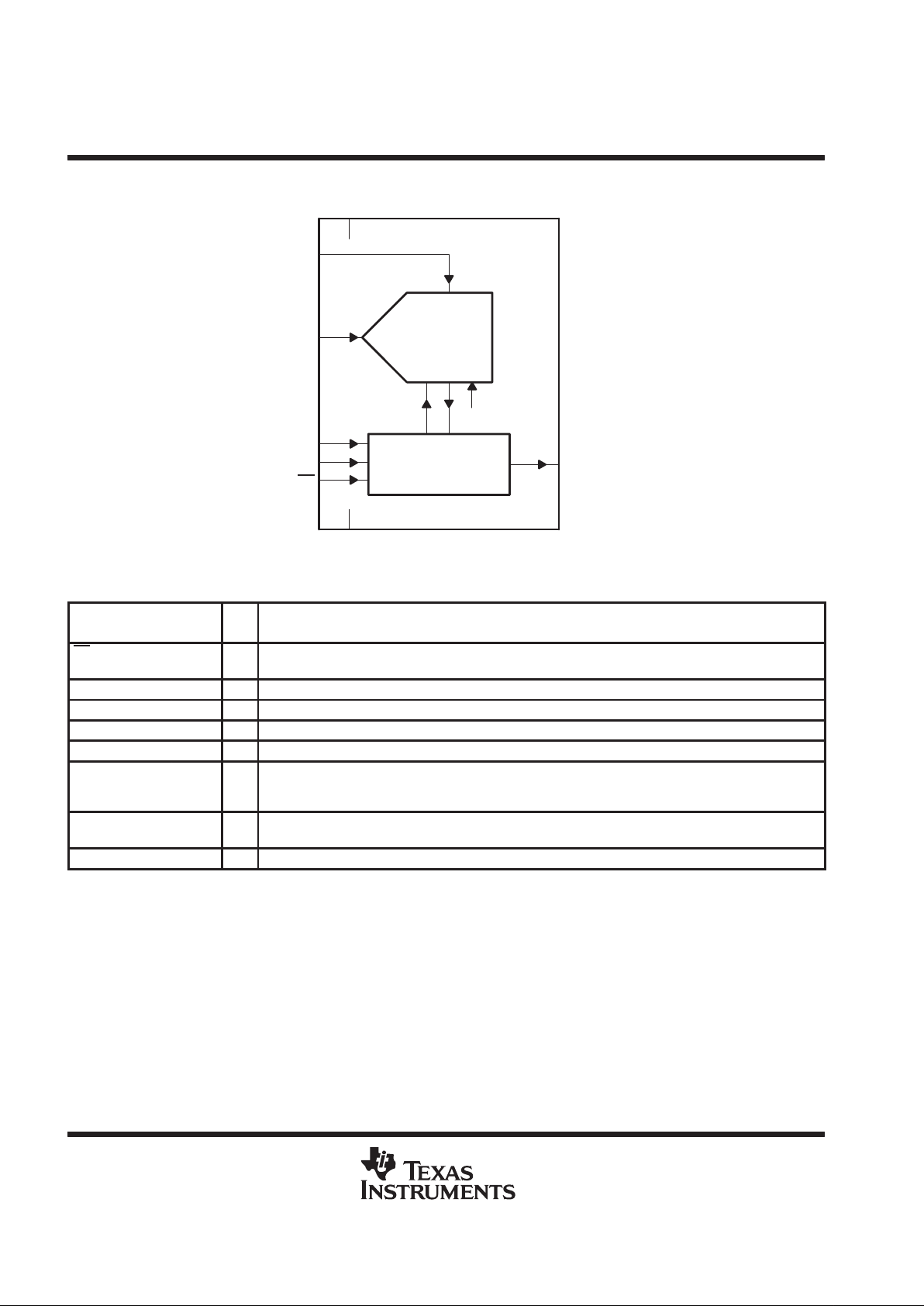

functional block diagram

AIN

SCLK

FS

CS

DO

10-BIT

SAR ADC

CONTROL LOGIC

V

CC

GND

VREF

GND

VREF

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

CS/Powerdown 1 I Chip Select. A low on this input enables the TLV1572. A high disables the device and disconnects the power

to the TLV1572.

AIN 2 I Analog input

V

REF

3 I Reference voltage input. The voltage applied to this pin defines the input span of the TLV1572.

GND 4 Ground

DO 5 O Serial data output. A/D conversion results are provided at this output pin.

FS 6 I Frame sync input in DSP mode. The falling edge of the frame sync pulse from DSP indicates the start of

a serial data frame shifted out of the TLV1572. The FS input is tied to VCC when interfacing to a

micro-controller.

SCLK 7 I Serial clock input. This clock synchronizes the serial data transfer and is also used for internal data

conversion.

V

CC

8 Power supply, recommend connection to analog supply

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

absolute maximum ratings over operating free-air temperature (unless otherwise noted)

†

Supply voltage, GND to V

CC

–0.3 V to 6.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog input voltage range –0.3 V to V

CC

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference input voltage V

CC

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital input voltage range –0.3 V to V

CC

+ 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating

virtual junction temperature range, T

J

–40°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

A

0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1.6 mm (1/16 inch) from case for 10 seconds 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

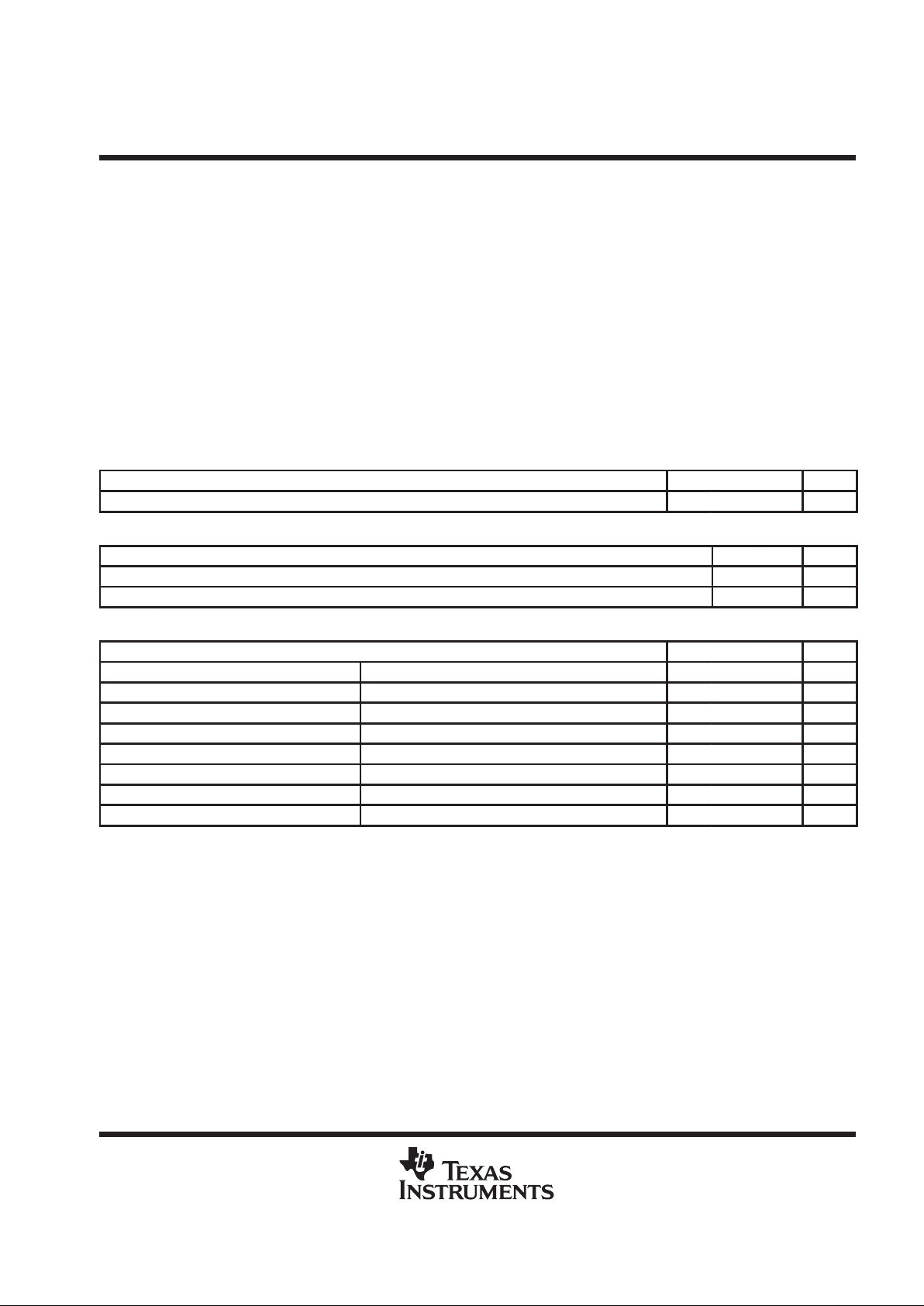

recommended operating conditions

power supply

MIN NOM MAX UNIT

V

CC

Supply voltage 2.7 5.5 V

analog inputs

MIN MAX UNIT

V

AIN

Analog input voltage GND V

REF

V

V

REF

Reference input voltage 2.7 V

CC

V

digital inputs

MIN NOM MAX UNIT

High-level input voltage, V

IH

VCC = 3 V to 5.5 V 2.1 2.4 V

Low-level input voltage, V

IL

VCC = 3 V to 5.5 V 0.8 V

Input SCLK frequency VCC = 4.5 V to 5.5 V 20 MHZ

SCLK pulse duration, clock high, t

w(SCLKH)

VCC = 4.5 V to 5.5 V 23 ns

SCLK pulse duration, clock low, t

w(SCLKL)

VCC = 4.5 V to 5.5 V 23 ns

Input SCLK frequency VCC = 3 V 10 MHZ

SCLK pulse duration, clock high, t

w(SCLKH)

VCC = 3 V 45 ns

SCLK pulse duration, clock low, t

w(SCLKL)

VCC = 3 V 45 ns

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range, V

CC

= 5 V,

V

REF

= 5 V, f

SCLK

= 20 MHz (unless otherwise noted)

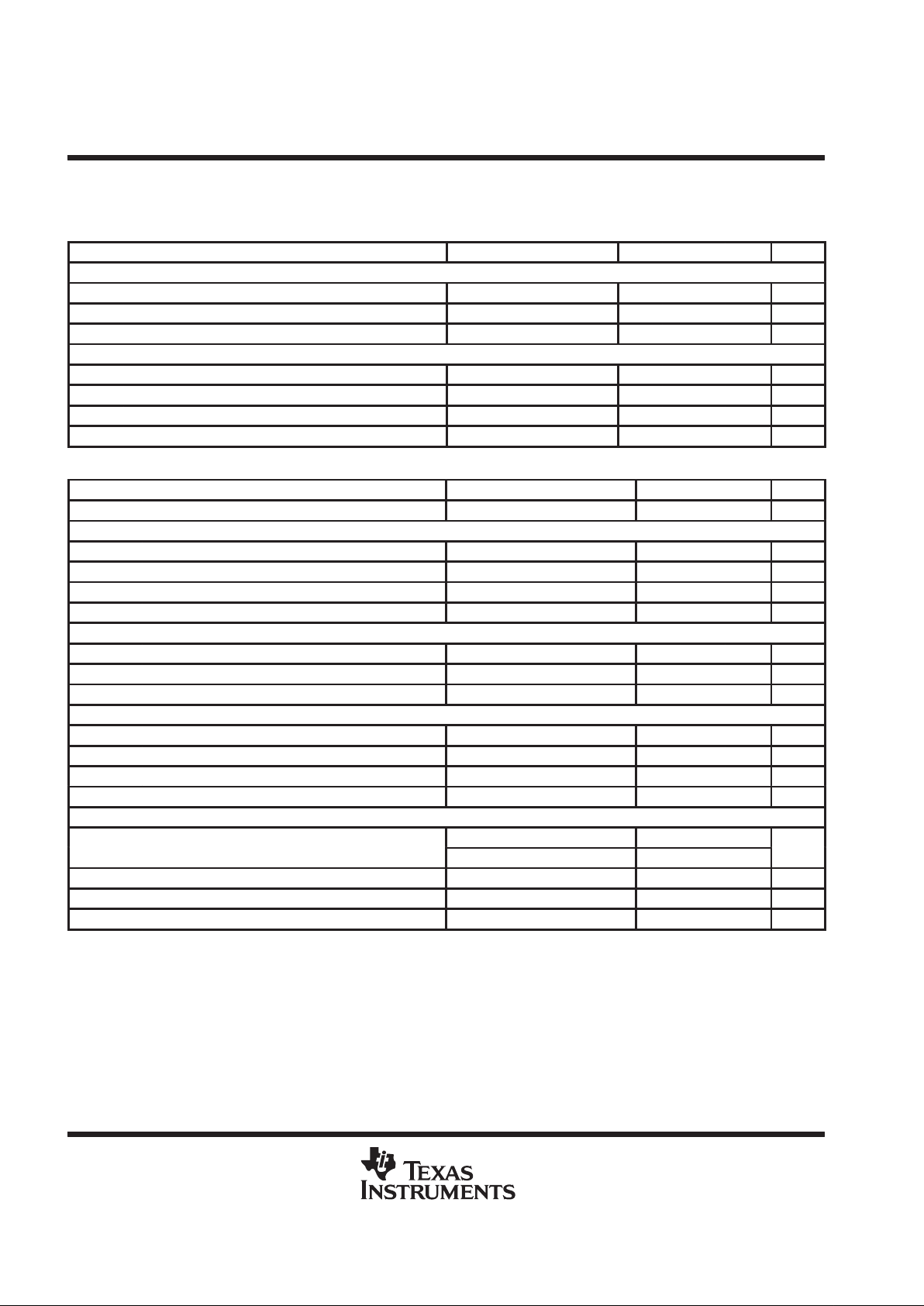

digital specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Logic inputs

I

IH

High-level input current VCC = 5 V –50 50 µA

I

IL

Low-level input current VCC = 5 V –50 50 µA

C

i

input capacitance 5 pF

Logic outputs

V

OH

High-level output voltage IOH = 50 µA – 0.5 mA VCC–0.4 V

V

OL

Low-level output voltage IOL = 50 µA – 0.5 mA 0.4 V

I

OZ

High-impedance-state output current –50 50 µA

C

O

Output capacitance 5 pF

dc specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Resolution 10 Bits

Accuracy

INL Integral nonlinearity Best fit ±0.5 ±1 LSB

DNL Differential nonlinearity ±0.3 ±1 LSB

Offset error ±0.1 ±0.15 %FSR

Gain error ±0.1 ±0.2 %FSR

Analog input

Input full scale range GND V

CC

V

Input capacitance 15 pF

input leakage current V

AIN

= 0 to V

CC

50 µA

Voltage reference input

V

REF+

Positive reference voltage 3 V

CC

V

V

REF–

Negative reference voltage Internally connects to GND GND V

Input resistance 2 KΩ

Input capcitance 300 pF

Power supply

p

pp

VCC = 5.5 V, f

SCLK

= 20 MHz 5.5 8.5

I

CC

+

I

REF

Operating supply current

VCC = 3 V, f

SCLK

= 10 MHz 2.7

mA

I

PD

Supply current in powerdown mode V

CC

10 µA

Power dissipation VCC = 5 V 25 mW

Power dissipation VCC = 3 V 8 mW

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics over recommended operating free-air temperature range, V

CC

= 5 V,

V

REF

= 5 V, f

SCLK

= 20 MHz (unless otherwise noted) (continued)

ac specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Signal-to-noise ratio + distortion f

(input)

= 200 kHz 54 58 dB

THD Total harmonic distortion f

(input)

= 200 kHz 56 60 dB

Effective number of bits f

(input)

= 200 kHz 8.7 9.35 Bits

Spurious-free dynamic range f

(input)

= 200 kHz 57 62 dB

Analog Input

BW Full-power bandwidth Source impedance = 1 kΩ 12 MHz

BW Small-signal bandwidth Source impedance = 1 kΩ 20 Mhz

timing specifications

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

c

SCLK period VCC = 4.5 V – 5.5 V 50 ns

t

c

SCLK period VCC = 2.7 V – 3.3 V 100 ns

t

rs

Reset and sampling period 6

SLCK

cycles

t

c

Conversion period 10

SLCK

cycles

t

su1

FS setup time to SCLK falling edge in DSP mode 10 ns

t

h1

FS hold time to SCLK falling edge in DSP mode 4 ns

t

su2

FS setup time to CS falling edge in DSP mode 6 ns

t

h2

FS hold time to CS falling edge in DSP mode 9 ns

t

d1

Output delay after SCLK rising edge in DSP mode 15 25 ns

t

d(L)1

FS falling edge to next SCLK falling edge in DSP mode 6 ns

t

d(L)2

SCLK rising edge after CS falling edge in µC mode 4 ns

t

d2

Output delay after SCLK rising edge in µC mode 15 25 ns

Specifications subject to change without notice.

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PARAMETER MEASUREMENT INFORMATION

t

c

1

2

3

t

h1

t

su1

t

su2

t

h2

t

d1

0

t

d(L)1

SCLK

CS

FS

DO

Figure 1. DSP Mode Timing Diagram

1

2

3

00

SCLK

CS

FS

DO

4

0

t

d(L)2

t

d2

Figure 2. µC Mode Timing Diagram

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

definitions of specifications and terminology

integral nonlinearity

Integral nonlinearity refers to the deviation of each individual code from a line drawn from zero through full scale.

The point used as zero occurs 1/2 LSB before the first code transition. The full scale point is defined as level

1/2 LSB beyond the last code transition. The deviation is measured from the center of each particular code to

the true straight line between these two points.

differential nonlinearity

An ideal ADC exhibits code transitions that are exactly 1 LSB apart. DNL is the deviation from this ideal value.

A differential nonlinearity error of less than ±1 LSB ensures no missing codes.

zero offset

The first code transistion should ideally occur at an analog value 1/2 LSB above V

REF

–. The zero offset error

is defined as the error between the ideal first transistion point and the actual first transistion. This error efectively

shifts left or right an ADC transfer function

gain error

The first code transition should occur at an analog value 1/2 LSB above negative full scale. The last transition

should occur at an analog value 1 1/2 LSB below the nominal full scale. Gain error is the deviation of the actual

difference between first and last code transitions and the ideal difference between first and last code transitions.

signal-to-noise ratio + distortion (SINAD)

SINAD is the ratio of the rms value of the measured input signal to the rms sum of all other spectral components

below the Nyquist frequency, including harmonics but excluding dc. The value for SINAD is expressed in

decibels.

effective number of bits (ENOB)

For a sine wave, SINAD can be expressed in terms of the number of bits. Using the following formula,

N = (SINAD – 1.76)/6.02

it is possible to get a measure of performance expressed as N, the effective number of bits. Thus, effective

number of bits for a device for sine wave inputs at a given input frequency can be calculated directly from its

measured SINAD.

total harmonic distortion (THD)

THD is the ratio of the rms sum of the first six harmonic components to the rms value of the measured input signal

and is expressed as a percentage or in decibels.

spurious free dynamic range (SFDR)

SFDR is the difference in dB between the rms amplitude of the input signal and the largest peak spurious signal.

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

The TLV1572 is a 600-ns, 10-bit analog-to-digital converter with the throughput up to 1.25 MSPS at 5 V and

up to 625 KSPS at 3 V respectively. To run at its fastest conversion rate, it must be clocked at 20 MHz at 5 V

or 10 MHz at 3 V. The TLV1572 can be easily interfaced to microcontrollers, ASICs, DSPs, or shift registers.

Its serial interface is designed to be fully compatible with Serial Peripheral Interface (SPI) and TMS320 DSP

serial ports. It requires no hardware to interface between the TL V1572 and the microcontrollers (µCs) with the

SPI serial port or the TMS320 DSPs. However, speed is limited by the SCLK rate of the µC or the DSP.

The TLV1572 interfaces to the DSPs over four lines: CS

, SCLK, DO, and FS, and interfaces to µCs over three

lines: CS

, SCLK, and DO. The FS input should be pulled high in µC mode. The chip is in 3-state and powerdown

mode when CS

is high. After CS falls, the TL V1572 checks the FS input at the CS falling edge to determine the

operation mode. If FS is low, DSP mode is set, else µC mode is set.

interfacing TLV1572 to TMS320 DSPs

The TL V1572 is compatible with Texas Instruments TMS320 DSP serial ports. Figures 3(a) and 3(b) show the

pin connections to interface the TLV1572 to the TMS320 DSPs.

CS

SCLK

FS

DO

XF

CLKX

CLKR

FSX

FSR

DR

TLV1572 TMS320

CS

SCLK

FS

DO

XF

CLKX

CLKR

FSR

DR

TLV1572 TMS320

a) DSP Serial Port Operating in Burst Mode b) FS Externally Generated

From

System

Figure 3. TL V1570 to DSP Interface

1234567 16

0

0 0 0 0 0

LSB

SCLK

CS

FS

DO

MSB

Figure 4. Typical Timing Diagram for DSP Application

In the DSP mode, the FS input should be low when the CS goes low. There is a hold time before the FS input

can go high after the CS

falling edge to ensure proper mode latching. With CS going low, DO comes out of

3-state but the device is still in powerdown until FS (frame sync signal from DSP) goes high.

The TL V1572 checks FS at the falling edges of SCLK. Once FS is detected high, the sampling of input is started.

As soon as FS goes low, the device starts shifting the data out on the DO line. After six null bits, the A/D

conversion data becomes available on the SCLK rising edges and is latched by DSP on the falling edges.

Figure 4 shows the DSP mode timing diagram.

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

interfacing TLV1572 to TMS320 DSPs (continued)

The TL V1572 goes into auto-powerdown after the LSB is shifted out. The next FS pulls it out of auto-powerdown

as shown in Figure 5. If FS comes on the 16th bit, the next conversion cycle starts from the next rising edge

of SCLK allowing back to back conversions as shown in Figure 6. An FS high in the middle of a conversion cycle

resets the device and starts a new conversion cycle. Therefore variable-bit transfer is supported if FS appears

earlier.

CS

can be pulled high asynchronously to put the device into 3-state and powerdown. CS can also be pulled low

asynchronously to start checking for FS on the falling edges of the clock.

1234567 16

0

0000

0

LSB(N)

SCLK

CS

FS

DO

MSB

1234567 16

00000

0

LSB(N+1)

MSB(N+1)

Auto-Powerdown

Sampling Conversion

Sample (N) Sample (N+1)

(N)

6 Leading Zeros

Figure 5. DSP Application Timing (Intermittent Conversion)

1234567 16

0

00

0

00

SCLK

CS

FS

DO

MSB

1234567 16

00000

0

0

LSB(N)

LSB(N+1)

Sampling Conversion

Sample (N) Sample (N+1)

(N)

6 Leading

Zeros

MSB(N+1)

Figure 6. DSP Application Timing (Continuous Conversion)

key points

1. When CS

goes low, if FS is low, it is in DSP mode. FS is sampled twice by a CS falling edge and again by

an internally delayed CS

falling edge. Even if a glitch appears and one latch latches 1 and another latches

0, the device goes into DSP mode (µC mode requires both latches to latch 1). There is a hold time before

FS can go high again after the CS

falling edge to ensure proper mode latching as detailed above. With CS

going low, DO is in 3-state and the device is in powerdown until a FS rising edge.

2. The TLV1572 checks for FS at every falling edge of SCLK. If FS is detected high, the device goes into reset.

When FS goes low, the TLV1572 waits for the DSP to latch the first 0 bit.

3. Sampling occurs from first falling edge of SCLK after FS going low until the rising edge when the 6th 0 bit

is sent out. Thereafter decisions are taken on the rising edges and data is sent out on the rising edges (1

bit delayed). The DSP samples on the falling edge of SCLK. Data is padded with 6 leading zeros.

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

key points (continued)123

4. Note that the device goes into autopowerdown on the 17th falling edge of SCLK (just after the LSB). The

FS rising edge pulls it out of autopowerdown. If FS comes on the 16th bit, the next conversion cycle starts

from the next rising edge allowing back to back conversions. An FS in the middle of a conversion cycle starts

a new conversion cycle. Thus variable-bit transfer is supported if FS appears earlier.

5. DO goes into 3-state on the 17th rising edge and comes out on a FS rising edge.

6. CS

can be pulled high asynchronously to put the device into 3-state and powerdown. CS may also be pulled

low asynchronously to start checking for FS on the falling edges of the clock.

For applications where the analog input must be sampled at a precise instant in time, data conversion can be

initiated by an external conversion start pulse which is completely asynchronous to the SCLK as shown in Figure

4. When a conversion start pulse is received, the pulse is used as a frame sync (FS) signal to initiate the data

conversion and transfer. The corresponding timing diagram is shown in Figure 6.

interfacing TLV1572 to SPI/QSPI compatible microcontrollers (µCs)

The TLV1572 is compatible with SPI and QSPI serial interface standards (Note: the TLV1572 supports the

following SPI clock options: clock_polarity= 0, i.e. SCLK idles low, and clock_phase = 1). Figure 7 shows the

pin connections to interface the TLV1572 to SPI/QSPI compatible microcontrollers.

CS

SCLK

FS

DO

XF

SCLK

DR

TLV1572 µC

V

CC

Figure 7. TLV1572 to µC Interface

1 2 345 67 16

0 0 0

0

0

0MSB

SCLK

CS

FS

SDOUT

LSB

Figure 8. Typical Timing Diagram for µC Application

To use the TLV1572 in a non-DSP application, the FS input should be pulled high as shown in Figure 8.

A total of 16 clocks are normally supplied for each conversion. If the µC cannot take in 16 bits at a time, it may

take 8 bits with 8 clocks and next 8 bits with another 8 clocks. CS

should be kept low throughout the conversion.

The delay between these two 8-clock periods should not be longer than 100 µs.

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

interfacing TLV1572 to SPI/QSPI compatible microcontrollers(µCs) (continued)

Unlike the DSP mode in which the conversion is initiated by the FS input signal from the DSP, the conversion

is initiated by the incoming SCLK after CS

falls. Sampling of the input is started on the first rising edge of SCLK

after CS

goes low. After six null bits, the A/D conversion data becomes available on SCLK rising edges and is

latched by the µC on the falling edges. CS

can be pulled high during the conversion before the LSB is shifted

out to use the device as a lower resolution ADC. Figure 9 shows the µC mode timing diagram.

The device goes into autopowerdown after the LSB is shifted out and is brought out of powerdown by the next

clock rising edge as shown in Figure 9.

12 34 5 6 7 16

0

0 0

0

0 0

LSB (N)

SCLK

CS

FS

DO

MSB

1234567 16

0 0 00

0

Auto-Powerdown

0

LSB(N+1)

Sampling Conversion

Sample (N)

(N)

MSB(N+1)

Figure 9. µC Application Timing Diagram

key points

1. When CS

goes low, if FS is high, it is in µ C ({Q}SPI) mode. Thus, FS should be tied to VDD. FS is latched

twice, on the falling edge of CS

and again on an internally delayed falling edge of CS. Only if both latches

latch 1, then µC mode is set else DSP mode is set. Only polarity = 0 is supported, i.e. SCLK idles low. Only

clock_phase = 1 is supported as shown in the timing diagrams.

2. For each conversion 16 clocks have to be supplied. If the µC cannot take in 16 bits at a time, it may take

8 bits with 8 clocks and the next 8 bits with another 8 clocks keeping CS

low throughout the conversion.

The delay between these two 8-clock periods should not be longer than 100 µs.

3. Sampling starts on the first rising edge of SCLK and ends on the edge when the 6th 0 bit is sent out.

Decisions are made on the rising edge and data is output on the same edge but a bit delayed to avoid noise.

4. The device goes into autopowerdown on the falling edge of the 16th clock and is brought out of powerdown

by next first (17th) clock rising edge.

5. If the (Q)SPI wants less than a 16-bit transfer, CS

must go high after each transfer. The falling edge of CS

resets the TL V1572 for the next conversion. Thus a 14-bit transfer is possible when using the device as an

8-bit A/D.

6. CS

going high puts the device in 3-state and complete powerdown. CS going low sets the mode and pulls

DO out of 3-state.

TLV1572

2.7 V TO 5.5 V, 10-BIT, 1.25 MSPS

SERIAL ANALOG-TO-DIGITAL CONVERTER WITH AUTO-POWERDOWN

SLAS171A – DECEMBER 1997– REVISED SEPTEMBER 1998

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL INFORMATION

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

4040047/D 10/96

0.228 (5,80)

0.244 (6,20)

0.069 (1,75) MAX

0.010 (0,25)

0.004 (0,10)

1

14

0.014 (0,35)

0.020 (0,51)

A

0.157 (4,00)

0.150 (3,81)

7

8

0.044 (1,12)

0.016 (0,40)

Seating Plane

0.010 (0,25)

PINS **

0.008 (0,20) NOM

A MIN

A MAX

DIM

Gage Plane

0.189

(4,80)

(5,00)

0.197

8

(8,55)

(8,75)

0.337

14

0.344

(9,80)

16

0.394

(10,00)

0.386

0.004 (0,10)

M

0.010 (0,25)

0.050 (1,27)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...