Texas Instruments TLC1551IFN, TLC1550MJ, TLC1550MFKB, TLC1550IFNR, TLC1550INW Datasheet

...

D

Power Dissipation...40 mW Max

D

Advanced LinEPIC Single-Poly Process

Provides Close Capacitor Matching for

Better Accuracy

D

Fast Parallel Processing for DSP and µP

Interface

D

Either External or Internal Clock Can Be

Used

D

Conversion Time ...6 µs

D

Total Unadjusted Error... ±1 LSB Max

D

CMOS Technology

description

The TLC1550x and TLC1551 are data acquisition

analog-to-digital converters (ADCs) using a 10-bit,

switched-capacitor, successive-approximation

network. A high-speed, 3-state parallel port directly

interfaces to a digital signal processor (DSP) or

microprocessor (µP) system data bus. D0 through

D9 are the digital output terminals with D0 being the

least significant bit (LSB). Separate power

terminals for the analog and digital portions

minimize noise pickup in the supply leads.

Additionally, the digital power is divided into two

parts to separate the lower current logic from the

higher current bus drivers. An external clock can be

applied to CLKIN to override the internal system

clock if desired.

The TLC1550I and TLC1551I are characterized for

operation from –40°C to 85°C. The TLC1550M is

characterized over the full military range of –55°C

to 125°C.

TLC1550I, TLC1550M, TLC1551I

10-BIT ANALOG-TO-DIGITAL CONVERTERS

WITH PARALLEL OUTPUTS

SLAS043C – MAY 1991 – REVISED MARCH 1995

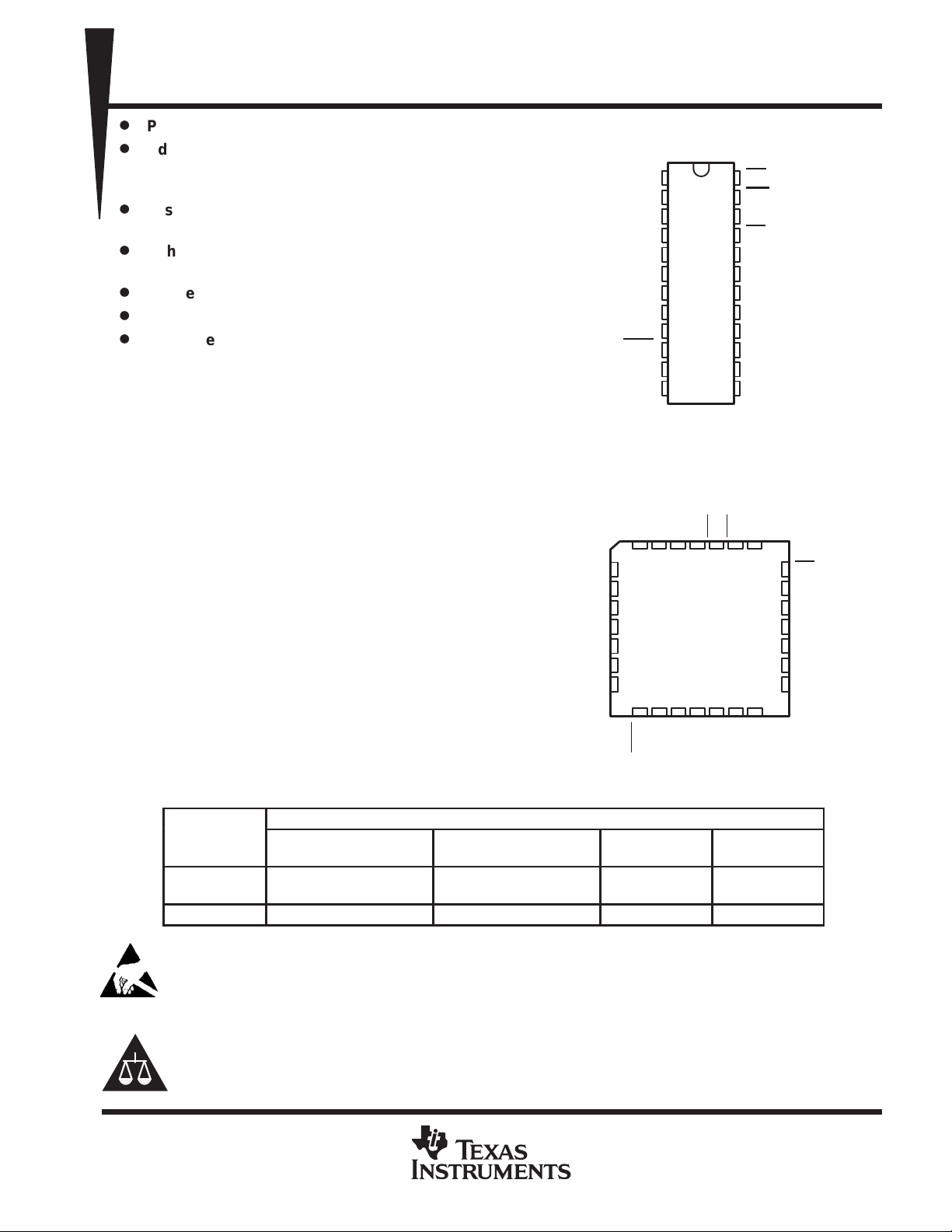

J† OR NW PACKAGE

(TOP VIEW)

REF+

REF–

ANLG GND

AIN

ANLG V

DD

DGTL GND1

DGTL GND2

DGTL V

DGTL V

DD1

DD2

EOC

D0

D1

†

Refer to the mechanical data for the JW

package.

FK OR FN PACKAGE

ANLG GND

4

321

5

AIN

ANLG V

DGTL GND1

DGTL GND2

DGTL V

DGTL V

DD

NC

DD1

DD2

6

7

8

9

10

11

12

13 14

EOC

NC – No internal connection

1

2

3

4

5

6

7

8

9

10

11

12

(TOP VIEW)

REF–

REF+

15 16 17

D0

D1NCD2D3D4

RD

24

WR

23

CLKIN

22

CS

21

D9

20

D8

19

D7

18

D6

17

D5

16

D4

15

D3

14

D2

13

RDWRCLKIN

NC

28 27 26

18

25

24

23

22

21

20

19

CS

D9

D8

NC

D7

D6

D5

AVAILABLE OPTIONS

T

A

–40°C to 85°C –

–55°C to 125°C TLC1550MFK – TLC1550MJ –

This device contains circuits to protect its inputs and outputs against damage due to high static voltages or electrostatic fields. These

circuits have been qualified to protect this device against electrostatic discharges (ESD) of up to 2 kV according to MIL-STD-883C,

Method 3015; however, it is advised that precautions be taken to avoid application of any voltage higher than maximum-rated

voltages to these high-impedance circuits. During storage or handling, the device leads should be shorted together or the device

should be placed in conductive foam. In a circuit, unused inputs should always be connected to an appropriated logic voltage level,

preferably either VCC or ground.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Advanced LinEPIC is a trademark of Texas Instruments Incorporated.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

CERAMIC CHIP CARRIER

(FK)

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PLASTIC CHIP CARRIER

PACKAGE

(FN)

TLC1550IFN

TLC1551IFN

CERAMIC DIP

(J)

–

Copyright 1995, Texas Instruments Incorporated

On products compliant to MIL-PRF-38535, all parameters are tested

unless otherwise noted. On all other products, production

processing does not necessarily include testing of all parameters.

PLASTIC DIP

(NW)

TLC1550INW

–

2–1

TLC1550I, TLC1550M, TLC1551I

10-BIT ANALOG-TO-DIGITAL CONVERTERS

WITH PARALLEL OUTPUTS

SLAS043C – MAY 1991 – REVISED MARCH 1995

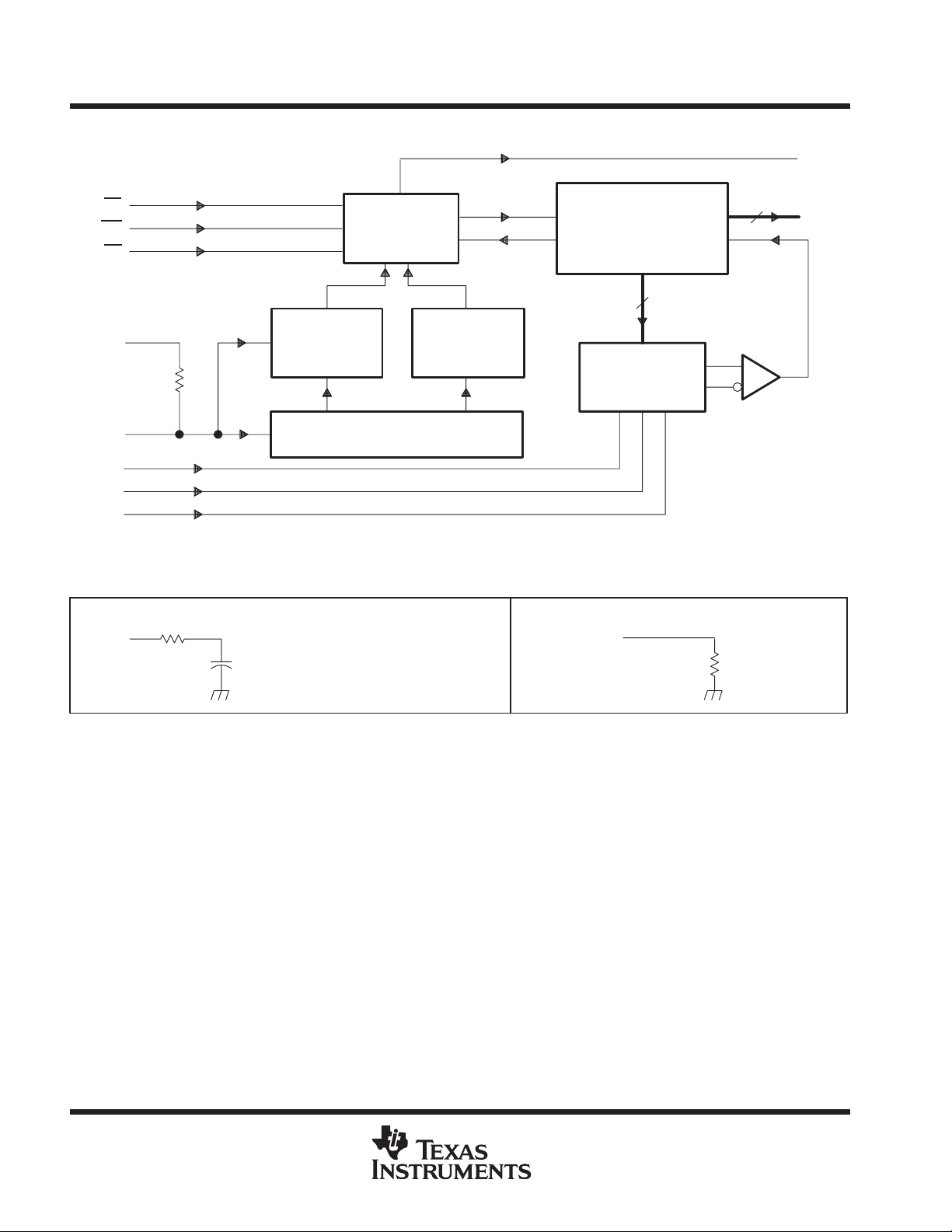

functional block diagram

EOC

CS

WR

RD

DGTL

V

DD1

100 kΩ

NOM

CLKIN

REF+

REF–

AIN

typical equivalent inputs

INPUT CIRCUIT IMPEDANCE DURING SAMPLING MODE INPUT CIRCUIT IMPEDANCE DURING HOLD MODE

1 kΩ TYP

AIN

Ci = 60 pF TYP

(equivalent input

capacitance)

Frequency

Divided by 2

Control

Logic

Clock Detector

Internal

Clock

Successive-

Approximation

Register

10

10-Bit

Capacitor

DAC and S/H

AIN

10

D0–D9

Comp

5 MΩ TYP

2–2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

DESCRIPTION

TLC1550I, TLC1550M, TLC1551I

10-BIT ANALOG-TO-DIGITAL CONVERTERS

WITH PARALLEL OUTPUTS

SLAS043C – MAY 1991 – REVISED MARCH 1995

Terminal Functions

TERMINAL

NAME NO.†NO.

ANLG GND 4 3 Analog ground. The reference point for the voltage applied on terminals ANLG VDD, AIN, REF+, and REF–.

AIN 5 4 Analog voltage input. The voltage applied to AIN is converted to the equivalent digital output.

ANLG V

DD

CLKIN 26 22 Clock input. CLKIN is used for external clocking instead of using the internal system clock. It usually takes a

CS 25 21 Chip-select. CS must be low for RD or WR to be recognized by the A/D converter.

D0 13 11 Data bus output. D0 is bit 1 (LSB).

D1 14 12 Data bus output. D1 is bit 2.

D2 16 13 Data bus output. D2 is bit 3.

D3 17 14 Data bus output. D3 is bit 4.

D4 18 15 Data bus output. D4 is bit 5.

D5 19 16 Data bus output. D5 is bit 6.

D6 20 17 Data bus output. D6 is bit 7.

D7 21 18 Data bus output. D7 is bit 8.

D8 23 19 Data bus output. D8 is bit 9.

D9 24 20 Data bus output. D9 is bit 10 (MSB).

DGTL GND1 7 6 Digital ground 1. The ground for power supply DGTL V

DGTL GND2 9 7 Digital ground 2. The ground for power supply DGTL V

DGTL V

DD1

DGTL V

DD2

EOC 12 10 End-of-conversion. EOC goes low indicating that conversion is complete and the results have been transferred

RD 28 24 Read input. When CS is low and RD is taken low , the data is placed on the data bus from the output latch. The

REF+ 2 1 Positive voltage-reference input. Any analog input that is greater than or equal to the voltage on REF+ converts

REF– 3 2 Negative voltage reference input. Any analog input that is less than or equal to the voltage on REF– converts

WR 27 23 Write input. When CS is low , conversion is started on the rising edge of WR. On this rising edge, the ADC holds

†

Terminal numbers for FK and FN packages.

‡

Terminal numbers for J and NW packages.

6 5 Analog positive power supply voltage. The voltage applied to this terminal is designated V

10 8 Digital positive power-supply voltage 1. DGTL V

11 9 Digital positive power-supply voltage 2. DGTL V

‡

.

DD3

few microseconds before the internal clock is disabled. To use the internal clock, CLKIN should be tied high

or left unconnected.

and is the substrate connection.

DD1

.

DD2

supplies the logic. The voltage applied to DGTL V

designated V

applied to DGTL V

to the output latch. EOC

output latch stores the conversion results at the most recent negative edge of EOC

resets EOC to a high within the t

to 1111111111. Analog input voltages between REF+ and REF– convert to the appropriate result in a ratiometric

manner.

to 0000000000.

the analog input until conversion is completed. Before and after the conversion period, which is given by t

the ADC remains in the sampling mode.

DD1

.

is designated V

DD2

can be connected to the µP- or DSP-interrupt terminal or can be continuously polled.

d(EOC)

DD1

supplies only the higher-current output buffers. The voltage

DD2

.

DD2

specifications.

. The falling edge of RD

DD1

conv

is

,

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

2–3

TLC1550I, TLC1550M, TLC1551I

Operating free-air temperature, T

°C

10-BIT ANALOG-TO-DIGITAL CONVERTERS

WITH PARALLEL OUTPUTS

SLAS043C – MAY 1991 – REVISED MARCH 1995

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

Supply voltage, V

Input voltage range, V

Output voltage range, V

DD1

, V

, and V

DD2

(any input) –0.3 V to VDD + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

–0.3 V to VDD + 0.3 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O

(see Note 1) 6.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DD3

†

Peak input current (any digital input) ±10 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Peak total input current (all inputs) ±30 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

: TLC1550I, TLC1551I –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . .

A

TLC1550M –55°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

–65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

stg

Case temperature for 10 seconds: FK or FN package 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from the case for 10 seconds: J or NW package 260°C. . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTE 1: V

is the voltage measured at DGTL V

DD1

DGND2. V

together (and represent 0 V). When V

is the voltage measured at ANLG VDD with respect to AGND. For these specifications, all ground terminals are tied

DD3

with respect to DGND1. V

DD1

, V

DD2

, and V

DD1

is the voltage measured at DGTL V

DD2

are equal, they are referred to simply as VDD.

DD3

with respect to the

DD2

recommended operating conditions

MIN NOM MAX UNIT

Supply voltage, V

Positive reference voltage, V

Negative reference voltage, V

Differential reference voltage, V

Analog input voltage range 0 V

High-level control input voltage, V

Low-level control input voltage, V

Input clock frequency, f

Setup time, CS low before WR or RD goes low, t

Hold time, CS low after WR or RD goes high, t

WR or RD pulse duration, t

Input clock low pulse duration, t

p

NOTE 2: Analog input voltages greater than that applied to REF+ convert to all 1s (1111111111), while input voltages less than that applied to

REF– convert to all 0s (0000000000). The total unadjusted error may increase as this differential voltage falls below 4.75 V.

DD1

, V

DD2

(CLKIN)

w(WR)

p

, V

DD3

(see Note 2) V

ref+

(see Note 2) 0 V

ref–

– V

ref+

IH

IL

wL(CLKIN)

A

(see Note 2) 0.3 0.3 V

ref–

su(CS)

h(CS)

TLC155xI

TLC1550M –55 125

4.75 5 5.5 V

DD3

DD3

2 V

0.5 7.8 MHz

0 ns

0 ns

50 ns

40% of

period

–40 85

80% of

period

V

V

0.8 V

°

2–4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

VOLLow-level output voltage

DD

,

V

IOZOff-state (high-impedance-state) output current

A

IOSShort-circuit output current

mA

CiInput capacitance

See typical equivalent inputs TLC1550/1I

pF

TLC1550I, TLC1550M, TLC1551I

10-BIT ANALOG-TO-DIGITAL CONVERTERS

WITH PARALLEL OUTPUTS

SLAS043C – MAY 1991 – REVISED MARCH 1995

electrical characteristics over recommended operating free-air temperature range,

V

DD=Vref+

V

High-level output voltage VDD = 4.75 V, IOH = –360 µA 2.4 V

OH

I

High-level input current VI = V

IH

I

Low-level input current (except CLKIN) VI = 0 –2.5 –0.005 µA

IL

I

Low-level input current (CLKIN) –150 –50 µA

IL

I

Operating supply current CS low and RD high 2 8 mA

DD

* On products compliant to MIL-STD-883, Class B, this parameter is not production tested.

†

All typical values are at VDD = 5 V, TA = 25°C.

= 4.75 to 5.5 V and V

PARAMETER TEST CONDITIONS MIN TYP†MAX UNIT

p

p

p

p

p

ref–

p

Analog inputs

Digital inputs

= 0 (unless otherwise noted)

V

= 4.75 V,

IOL = 2.4 mA

VO = VDD, CS and RD at V

VO = 0, CS and RD at V

DD

VO = 5 V, TA = 25°C 7 14

VO = 0, TA = 25°C –12 –6

p

TA = 25°C 0.4

TA = –55°C to 125°C 0.5

p

DD

DD

0.005 2.5 µA

10

–10

60 90*

5 15*

µ

p

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

2–5

TLC1550I, TLC1550M, TLC1551I

ELLinearity error

See Note 3

LSB

TLC1550M

EZSZero-scale error

See Notes 2 and 4

LSB

TLC1550M

EFSFull-scale error

See Notes 2 and 4

LSB

TLC1550M

10-BIT ANALOG-TO-DIGITAL CONVERTERS

WITH PARALLEL OUTPUTS

SLAS043C – MAY 1991 – REVISED MARCH 1995

operating characteristics over recommended operating free-air temperature range with internal

clock and minimum sampling time of 4

PARAMETER TEST CONDITIONS T

TLC1550I Full range ±0.5

TLC1551I

TLC1550I Full range ±0.5

TLC1551I

TLC1550I Full range ±0.5

TLC1551I

TLC1550I Full range ±0.5

Total unadjusted error

t

conv

t

a(D)

t

v(D)

t

dis(D)

t

d(EOC)

†

Full range is –40°C to 85°C for the TL155xI devices and –55°C to 125°C for the TLC1550M.

‡

All typical values are at VDD = 5 V, TA = 25°C.

NOTES: 2. Analog input voltages greater than that applied to REF+ convert to all 1s (1111111111), while input voltages less than that applied

Conversion time

Data access time after RD goes low 35 ns

Data valid time after RD goes high 5 ns

Disable time, delay time from RD high to high

impedance

Delay time, RD low to EOC high 0 15 ns

to REF– convert to all 0s (0000000000). The total unadjusted error may increase as this differential voltage falls below 4.75 V.

3. Linearity error is the difference between the actual analog value at the transition between any two adjacent steps and its ideal value

after zero-scale error and full-scale error have been removed.

4. Zero-scale error is the difference between the actual mid-step value and the nominal mid-step value at specified zero scale.

Full-scale error is the difference between the actual mid-step value and the nominal mid-step value at specified full scale.

5. Total unadjusted error is the difference between the actual analog value at the transition between any two adjacent steps and its

ideal value. It includes contributions from zero-scale error, full-scale error, and linearity error.

TLC1551I

TLC1550M 25°C ±1

µs, V

DD=Vref+

See Note 5

f

clock(external)

internal clock

See Figure 3

= 5 V and V

= 4.2 MHz or

= 0 (unless otherwise noted)

ref–

†

A

Full range ±1

25°C ±0.5

Full range ±1

Full range ±1

25°C ±0.5

Full range ±1

Full range ±1

25°C ±0.5

Full range ±1

Full range ±1

MIN TYP‡MAX UNIT

30 ns

LSB

6 µs

2–6

PARAMETER MEASUREMENT INFORMATION

Source Current = 6 mA

Test Point

Output

Under Test

CL = 62 pF

Vcp = voltage commutation point for switching between source and sink currents

NOTE A: Equivalent load circuit of the Teradyne A500 tester for timing parameter measurement

Figure 1. Test Load Circuit

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

See Note A

Vcp = 1 V

Sink Current = 6 mA

TLC1550I, TLC1550M, TLC1551I

10-BIT ANALOG-TO-DIGITAL CONVERTERS

WITH PARALLEL OUTPUTS

SLAS043C – MAY 1991 – REVISED MARCH 1995

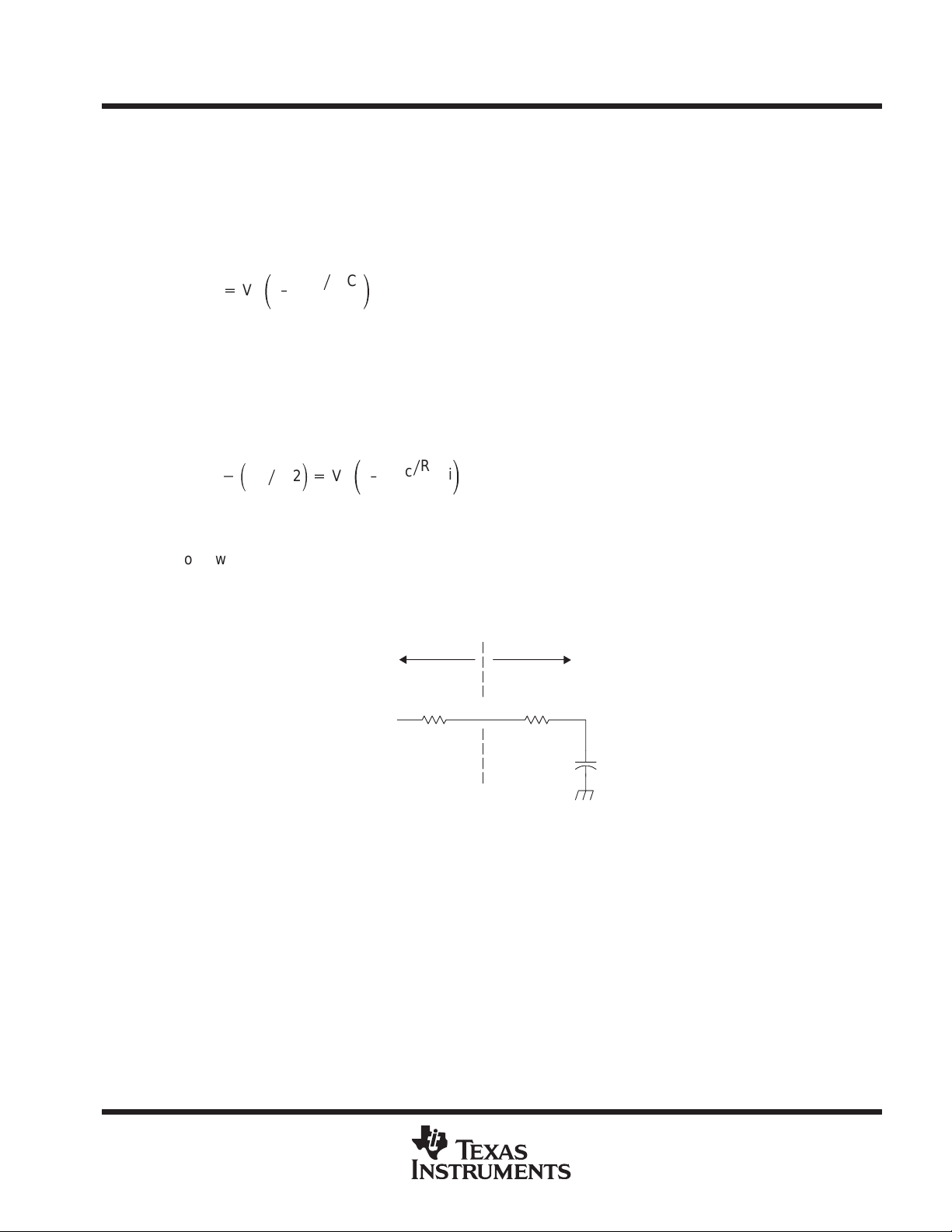

APPLICATION INFORMATION

simplified analog input analysis

Using the circuit in Figure 2, the time required to charge the analog input capacitance from 0 to VS within 1/2

LSB can be derived as follows:

The capacitance charging voltage is given by

–tcń

RtC

VC+

ǒ

V

1–e

S

where

= Rs + r

R

t

i

The final voltage to 1/2 LSB is given by

i

Ǔ

(1)

(1/2 LSB) = VS – (VS/1024)

C

Equating equation 1 to equation 2 and solving for time t

–tcń

VS*

ǒ

VSń

512Ǔ+

ǒ

V

1–e

S

RtC

i

Ǔ

gives

c

and

(1/2 LSB) = Rt × Ci × ln(1024) (4)

t

c

Therefore, with the values given, the time for the analog input signal to settle is

(1/2 LSB) = (Rs + 1 kΩ) × 60 pF × ln(1024)

t

c

This time must be less than the converter sample time shown in the timing diagrams.

Driving Source

†

R

s

V

S

VI= Input voltage at AIN

VS= External driving source voltage

Rs= Source resistance

ri= Input resistance

Ci= Input capacitance

V

I

1 kΩ MAX

r

i

TLC1550/1

V

C

C

i

50 pF MAX

(2)V

(3)

(5)

†

Driving source requirements:

• Noise and distortion for the source must be equivalent to the

resolution of the converter.

• Rs must be real at the input frequency.

Figure 2. Input Circuit Including the Driving Source

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

2–7

TLC1550I, TLC1550M, TLC1551I

10-BIT ANALOG-TO-DIGITAL CONVERTERS

WITH PARALLEL OUTPUTS

SLAS043C – MAY 1991 – REVISED MARCH 1995

PRINCIPLES OF OPERATION

The operating sequence for complete data acquisition is shown in Figure 3. Processors can address the TLC1550

and TLC1551 as an external memory device by simply connecting the address lines to a decoder and the decoder

output to CS

Once CS

converted data to be presented to the data bus with a simple read command. The device remains in a sampling (track)

mode from the rising edge of EOC

After the hold mode begins, the clock controls the conversion automatically. When the conversion is complete, the

end-of-conversion (EOC

Lowering CS

. Like other peripheral devices, the write (WR) and read (RD) input signals are valid only when CS is low.

is low, the on-board system clock permits the conversion to begin with a simple write command and the

until conversion begins with the rising edge of WR, which initiates the hold mode.

) signal goes low indicating that the digital data has been transferred to the output latch.

and RD then resets EOC and transfers the data to the data bus for the processor read cycle.

CS

WR

RD

D0–D9

EOC

0.8 V

1.4 V

0.8 V

t

su(CS)

t

w(WR)

2 V

1.4 V

t

h(CS)

0.8 V

t

conv

0.8 V

0.8 V

t

a(D)

0.8 V

Figure 3. TLC1550 or TLC1551 Operating Sequence

t

su(CS)

2 V

0.8 V

t

d(EOC)

t

v(D)

Data Valid

2 V

2 V

2 V

0.8 V

0.8 V

t

h(CS)

t

dis(D)

2–8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOL VE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICA TIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICATIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1998, Texas Instruments Incorporated

Loading...

Loading...