THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

T wo-Wire SMBus Serial Interface

D

3.3 V Operation

D

Low Operating and Standby Current

D

Remote and Local Temperature Monitoring

D

0 V to 2.5 V, 8-bit DAC for Fan Speed

Control

D

Two Voltage Supervisors With Reset

Functions

D

Fault Tolerant Fan Control With Automatic

Hardware Trip Point

D

Bidirectional Thermal Overload Indicator

D

ACPI Thermal Model Compliant

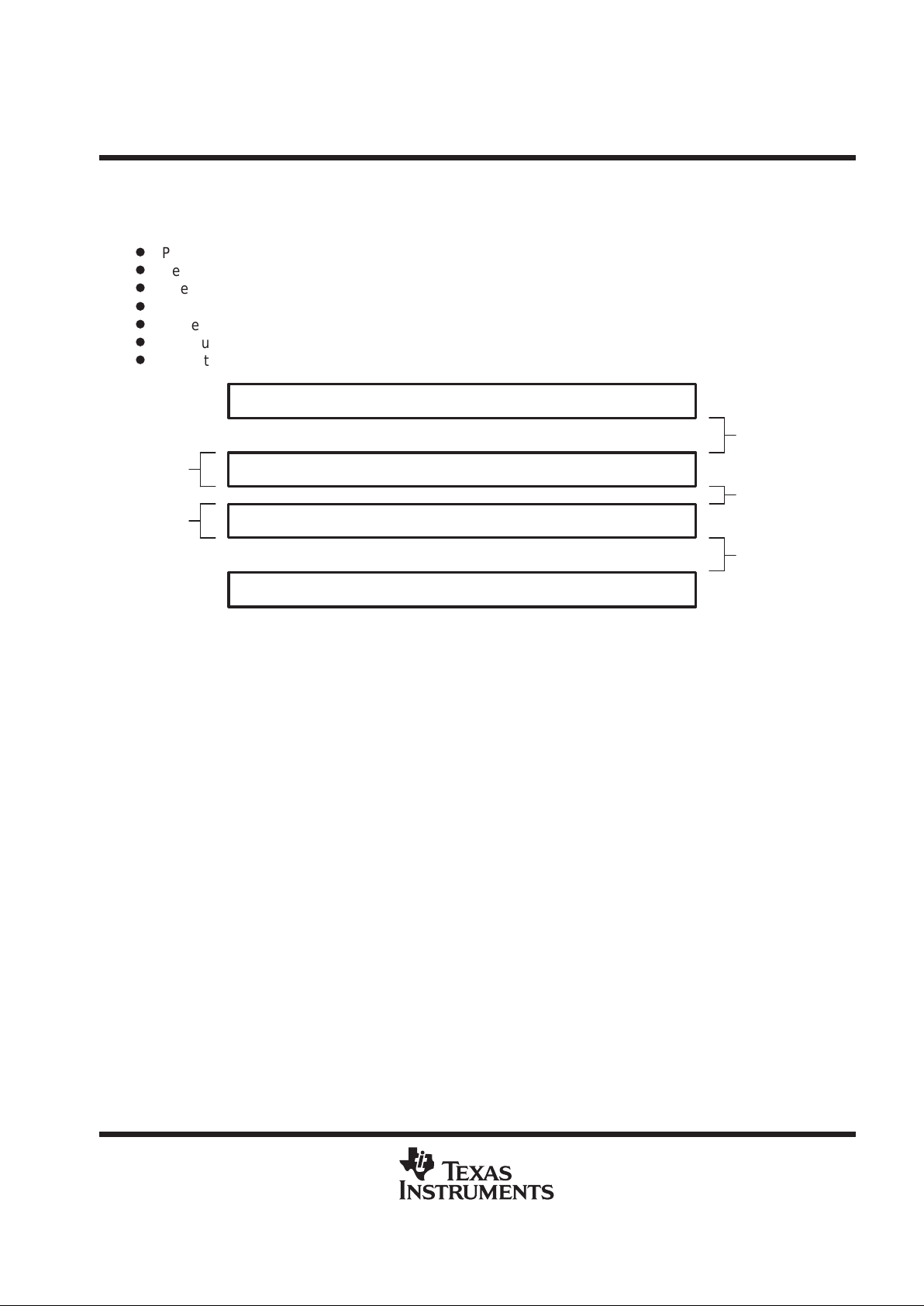

1

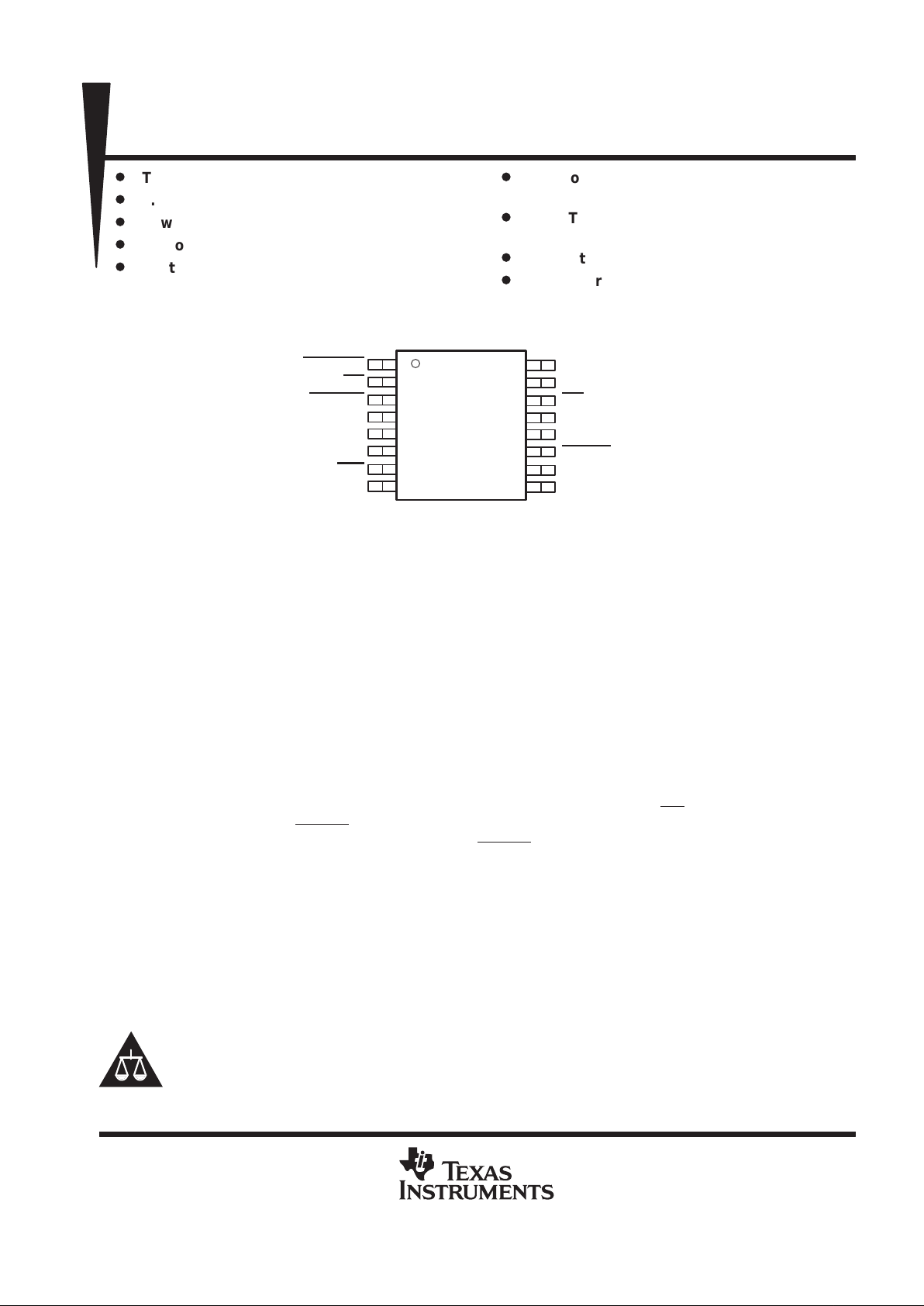

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

FAN_OFF

MR

AUXRST

GND

VCC3AUX

VCC3

RST

FAN_SPD/NTEST_IN

SDA

SCL

INT

ADD/NTEST_OUT

GPI

THERM

REMOTE_DIODE+

REMOTE_DIODE–

16-Pin SSOP DBQ Package

(TOP VIEW)

NOTE: Pin assignments are preliminary.

description

The THMC50 is a local/remote temperature monitor with two voltage supervisor circuits and an 8-bit, 0-V to

2.5-V DAC designed for temperature monitoring and fan control via a two-wire SMBus serial interface. The

THMC50 is intended for use in personal computer applications according to the Advanced Configuration and

Power Interface (ACPI) thermal model. The device is also suitable for use in network routers and hubs, office

equipment, telephone switching networks, industrial control applications, and any other application requiring

temperature monitoring, fan speed control, and two 3.3-V supply voltage supervisors.

T emperature data is reported in a 2s complement, 8-bit binary format. The local temperature sensor can be used

to monitor the ambient temperature, while a remote thermal diode, such as the one present on the Intel

Pentium II, III, and the Sun UltraSPARC microprocessors, can be used to monitor the actual CPU die

temperature. For applications not using a microprocessor with an integrated thermal diode, an inexpensive

diode-connected 2N3904 NPN transistor can also be used to sense the remote temperature.

The THMC50 provides maskable interrupts for under/over temperature condition with default or user adjustable

limit values. If the temperature limit values are exceeded, the THMC50 asserts INT

low. If the default thermal

limits are exceeded, the THERM

terminal is asserted low, and the F AN_SPD analog output automatically goes

to full-scale voltage to set the fan at maximum speed. THERM

can also be used as an input to instantly command

full fan speed.

The 8-bit, 0–2.5 V DAC output of the THMC50, along with an external amplifier circuit, provides the means to

control the speed of a cooling fan. Fault tolerant fan-speed control is achieved through default and

user-programmable values for high temperature limits that command the fan to full speed once the temperature

limits are exceeded.

The THMC50 also provides two reset functions for the V

(VCC3AUX)

and V

(VCC3)

supply voltage. The reset

functions are assured down to 1-V supply voltage.

Copyright 1999, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Intel and Pentium are registered trademarks of Intel Corporation.

Sun is a registered trademark and UltraSPARC is a trademark of Sun Microsystems.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

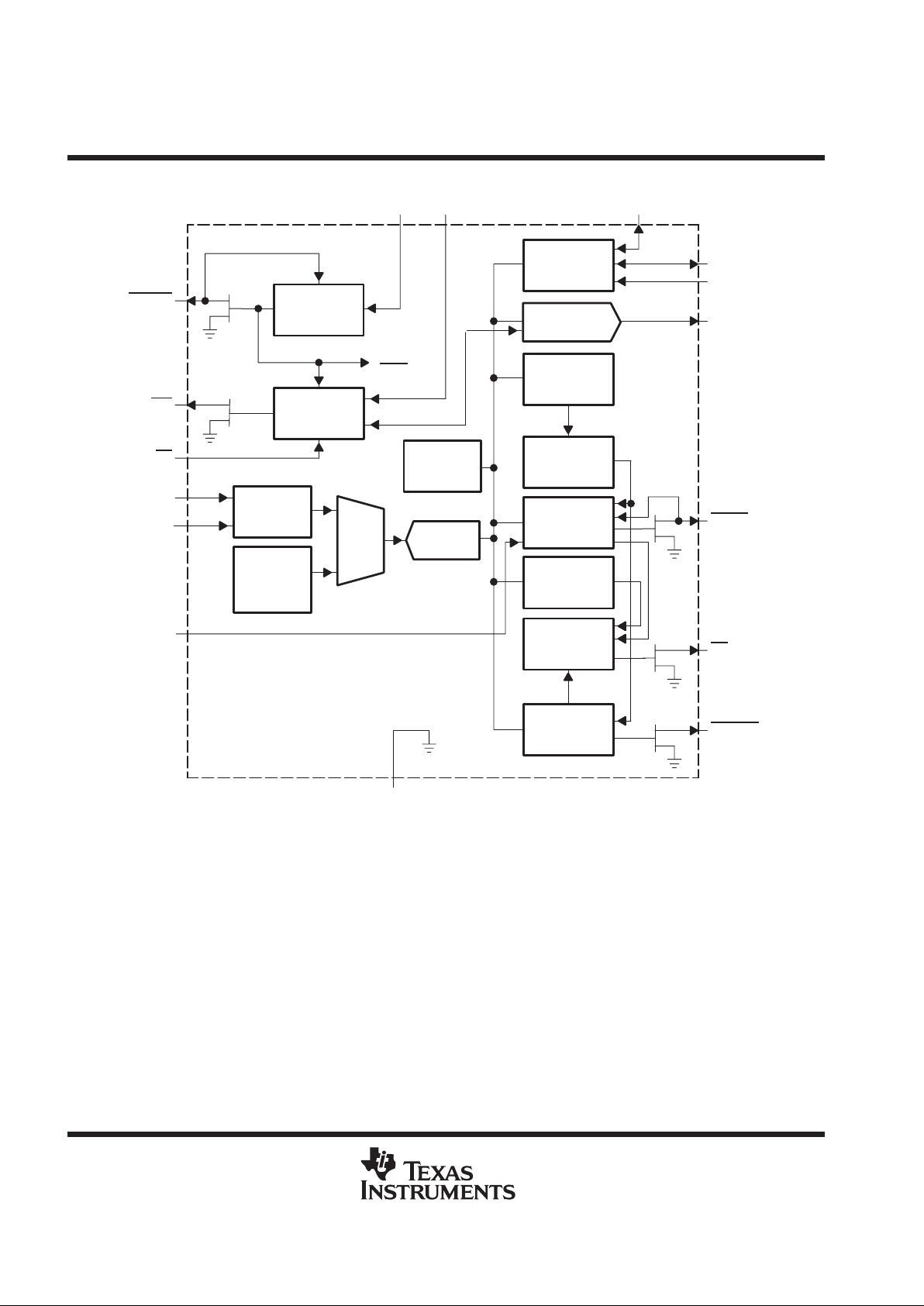

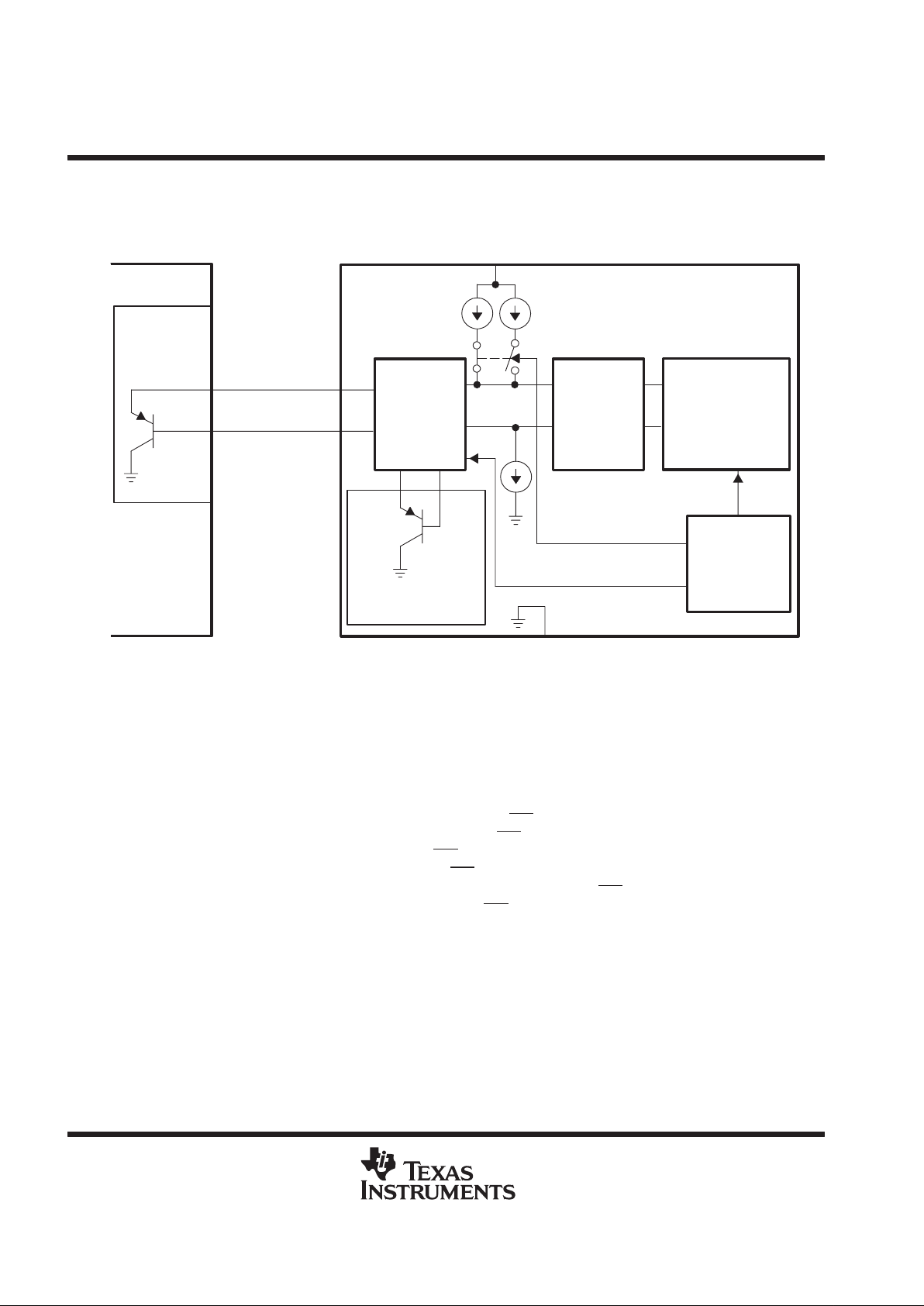

schematic/block diagram

ADC

Aux Reset

Generator

Bandgap

Temperature

Sensor

(Ambient)

Signal

Conditioning

Main Reset

Generator

Analog

Mux

SDA

Analog Output

Register & DAC

Configuration

Register

Mask

Gating

Interrupt

Mask

Register

Interrupt

Status

Registers

Limit

Comparators

Value & Limit

Registers

Serial Bus

Interface

GND

SCL

FAN_SPD/NTEST_IN

THERM

INT

FAN_OFF

AUXRST

RST

MR

REMOTE_DIODE+

REMOTE_DIODE–

GPI

VCC3AUX VCC3 ADD/NTEST_OUT

Address

Pointer

Register

Internal

Reset

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

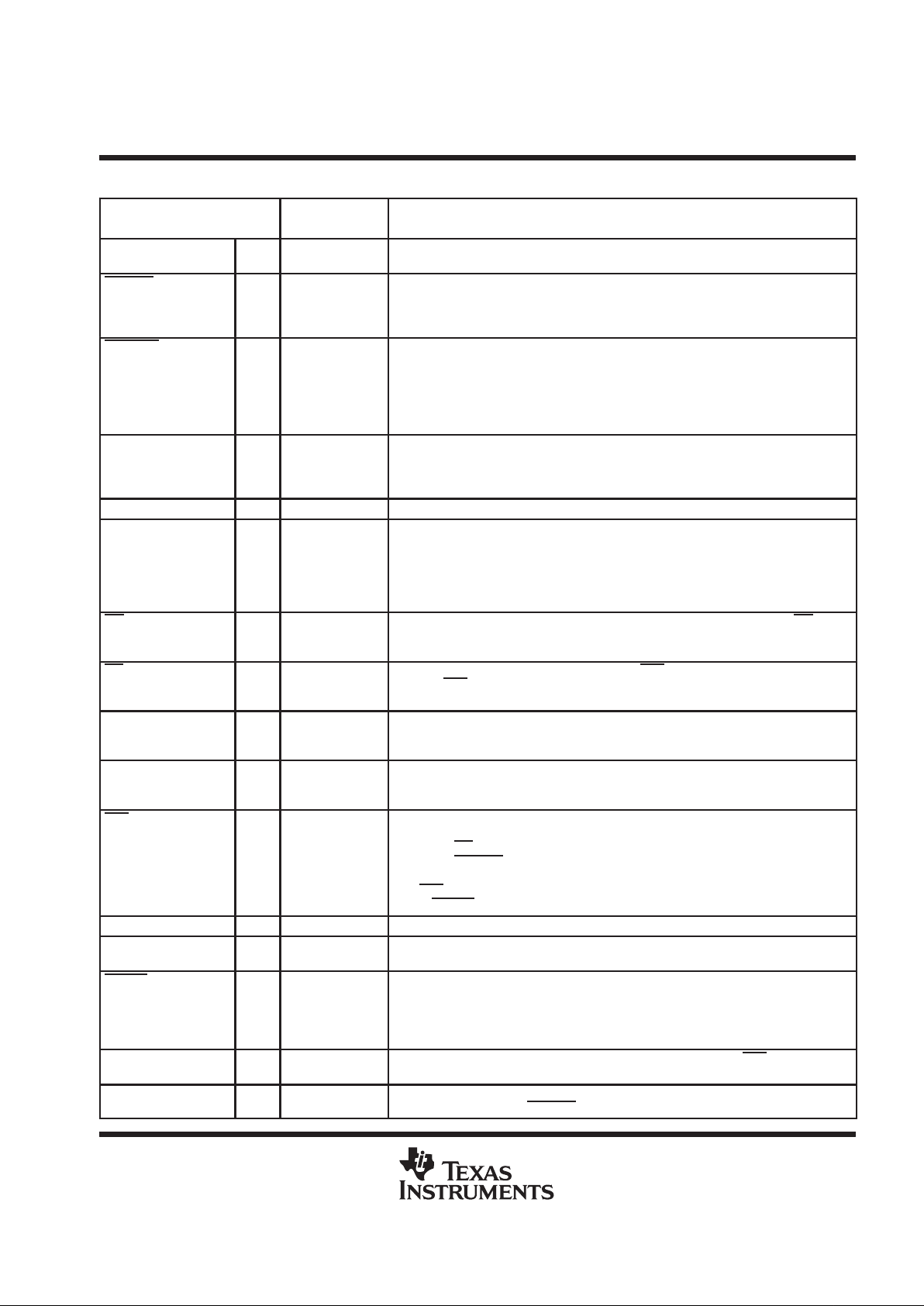

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

ADD/NTEST_OUT 13 Digital I/O This terminal is used to determine the two LSBs of the SMBus address during initial

power on and it also functions as a digital output when doing a NAND tree test.

AUXRST 3 Digital I/O

(open drain)

This terminal is asserted low while VCC3AUX remains below the reset threshold. It

remains asserted for the reset timeout period after the reset condition is terminated. It is

bidirectional so that the THMC50 can be optionally reset; external logic must be used to

prevent a system auxiliary reset from occurring.

FAN_OFF 1 Digital output

(open drain)

Fan off request output. When commanded low via bit 5 in the configuration register

(0×40), this indicates a request to shut the fan off independent of the F AN_SPD output.

When commanded high via bit 5 in the configuration register (0×40), it indicates that the

fan may be turned on. This is an open-drain output requiring an external pullup.

Note: This terminal requires external circuitry to turn the fan off. It does not command the

analog output to 0×00 (see

Typical Application Schematic

).

FAN_SPD/NTEST_IN 8 Analog

output/test input

This terminal is an active-high input that enables NAND tree board-level connectivity

testing during device power up. Refer to the section on NAND tree testing. Also used as

the analog output of the 8-bit DAC for fan speed control when not in NAND tree test

mode.

GND 4 Ground

GPI 12 Digital input General-purpose input. The logic state of this terminal is reflected in bit 4 of the interrupt

status register (0x41). The logic state of the GPI terminal reported in bit 4 of the interrupt

status register (0x41) is inverted from the actual GPI logic state if bit 6 of the configuration

register (0x40) is set to a 1. If bit 6 of the configuration register (0×40) is set to a 0, then bit

4 of the interrupt status register (0×41) reports the same logic state present on the GPI

terminal.

INT 14 Digital output

(open drain)

System interrupt output. This signal indicates a violation of a set trip point. The INT output

is enabled when bit 1 of the configuration register (0x40) is set to 1. The default state is

disabled.

MR 2 Digital input Manual reset. A logic low on this input causes RST to be asserted. Once this input is

negated, RST

remains asserted for approximately 180 ms. This input has an internal

20-kΩ pullup resistor. Leave unconnected if not used.

REMOTE_DIODE– 9 Remote thermal

diode negative

input

This is the negative input (current sink) from the remote thermal diode.

REMOTE_DIODE+ 10 Remote thermal

diode positive

input

This is the positive input (current source) from the remote thermal diode.

RST 7 Digital output

(open drain)

This terminal is asserted low under any of the following conditions:

• VCC3 remains below the reset threshold

• While MR

is held low

• While AUXRST

is asserted

It remains asserted for the reset timeout period after the reset conditions are terminated.

The RST

function also resets the FAN_SPD analog output to 0xoo when asserted,

unless THERM

is asserted, then the FAN_SPD analog output will be 0xFF.

SCL 15 Digital input Serial SMBus clock

SDA 16 Digital I/O

(open drain)

Serial SMBus bidirectional data

THERM 11 Digital I/O

(open drain)

This is an active low thermal overload output that indicates a violation of a temperature

set point (overtemperature) for at least three monitoring cycles. Also acts as an input to

indicate a thermal event for fan control. When this signal is asserted low externally, a

status bit is set. The automatic fan control is activated to full on whenever this signal is

low.

VCC3 6 Analog input This is a 3.3-V main voltage monitor input for main reset generator (RST). This is not the

power supply terminal for THMC50.

VCC3AUX 5 Power supply

voltage input

This 3.3-V auxiliary voltage is the THMC50 power source and voltage monitor input for

auxiliary reset generator (AUXRST

). This terminal powers all THMC50 internal circuitry.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

absolute maximum ratings over operating case temperature (see Note 1) (unless otherwise noted)

†

Voltage on VCC3AUX supply terminal, V

(VCC3AUX)

–0.3 V to 5.75 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum voltage allowed for FAN_OFF

pullup, V

(FAN_OFF)

5.5 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage on any I/O terminals (except analog inputs), V

(IOIN)

–0.3 V to V

(VCC3AUX)

+0.3 V. . . . . . . . . .

Input current on any I/O terminal (see Note 2), I

(IOIN)

–5 mA to 5 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Package input current (see Note 2), I

(PACKAGE)

–20 mA to 20 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage on REMOTE_DIODE– terminal,V

(REMOTE_DIODE–)

–0.3 V to 0.8 V. . . . . . . . . . . . . . . . . . . . . .

REMOTE_DIODE– input current, I

(REMOTE_DIODE–)

–1 mA to 1 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Human body model ESD susceptibility, V

(HBMESD)

±2 kV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation (see Note 3), P

D

330 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating case temperature range, T

C

–40°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature (see Note 4), T

stg

–65°C to 165°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction temperature, T

J

150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature (soldering, 10 sec), T

(LEAD)

300°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltages are measured with respect to GND, unless otherwise specified.

2. The 20-mA maximum package input current rating limits the number of terminals that can safely exceed the power supplies with

an input current of 5 mA to four terminals.

3. The maximum power dissipation must be derated at elevated temperatures and is dictated by T

Jmax

, θJA and the ambient

temperature, TA. The maximum allowable power dissipation at any temperature is PD = (T

Jmax

– TA)/θJA.

4. Solder accordingly to IPC standards.

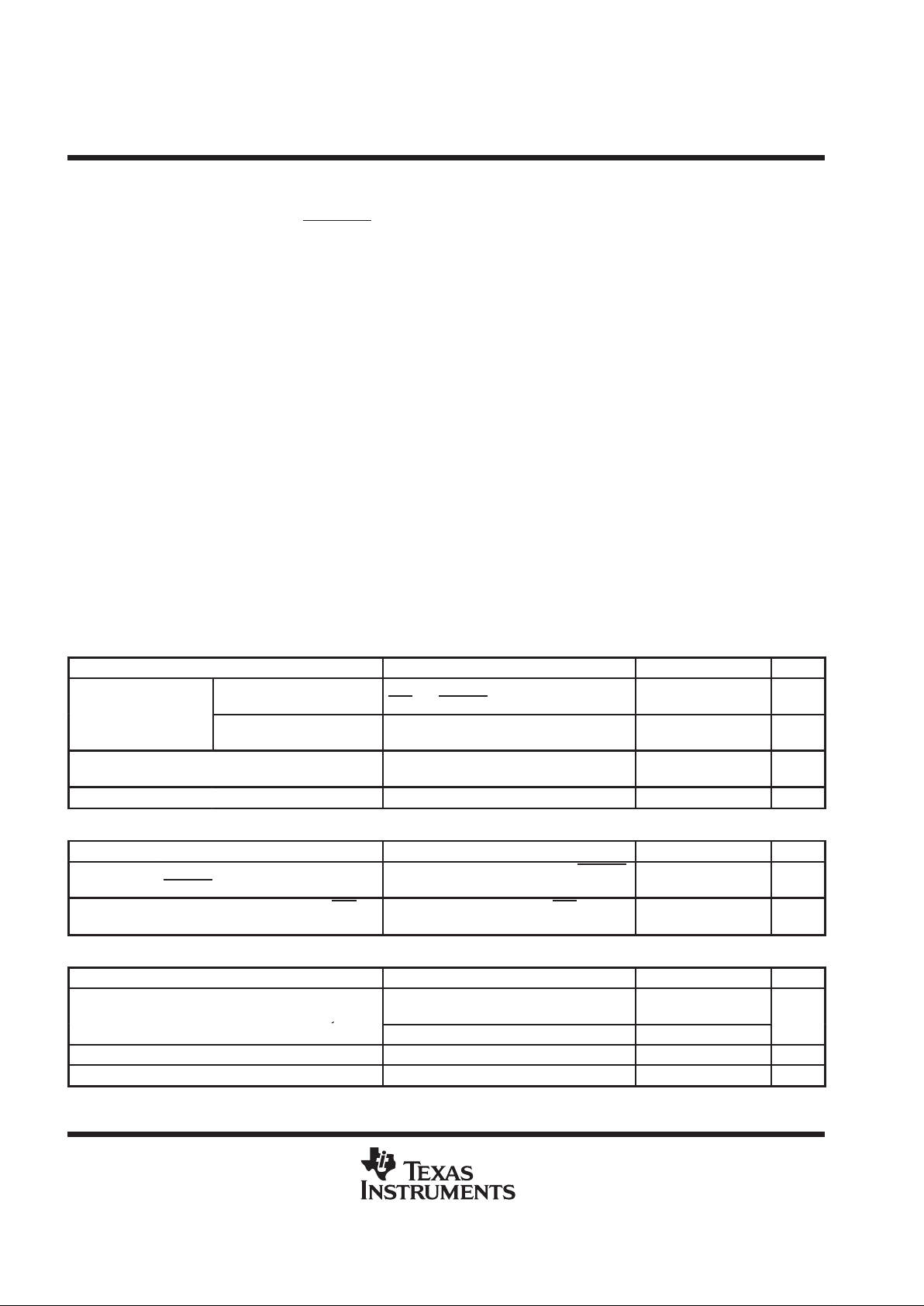

dc electrical characteristics, V

CC3

= V

(VCC3AUX)

= 3.3 V, TA = 25°C (unless otherwise noted)

power supply

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

VCC3AUX reset generator

supply voltage

Voltage on VCC3AUX needed to guarantee

RST

and AUXRST to stay valid

1 3.8 V

V

(VCC3AUX_RST)

VCC3AUX supply voltage

Normal operating supply voltage for all other

THMC50 circuits

3 3.3 3.8 V

I

(VCC3AUX)

Supply current

(interface inactive)

Exclude D/A converter source/sink current 1 2 mA

I

(VCC3AUX_STANDBY)

Standby mode 500 µA

voltage supervisors

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

THAUXRST

Threshold voltage on VCC3AUX for

AUXRST

active

Reduce VCC3AUX from 3.8 V until AUXRST

is low.

2.88 3 V

V

THRST

Threshold voltage on VCC3 for RST

active

Reduce VCC3 from 3.8 V until RST is low

with VCC3AUX = 3.3 V

2.88 3 V

temperature-to-digital converter

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

T

Measured temperature accurac

y

–40°C ≤TA < 60°C and

100°C <TA ≤ 125°C

–5 5

°C

(ACC)

y

60°C ≤TA ≤ 100°C –3 3

T

(RES)

Temperature resolution Design parameter – not tested 1 °C

V

(THRESH)

Remote_Diode+ open fault threshold 2.4 V

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

dc electrical characteristics, V

CC3

= V

(VCC3AUX)

= 3.3 V, TA = 25°C (unless otherwise noted)

(continued)

digital output: ADD/NTEST_OUT

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

OH

Logical 1 output voltage I

OUT

= –3 mA at V

(VCC3AUX)

= 2.85 V 2.4 V

V

OL

Logical 0 output voltage I

OUT

= 3 mA at V

(VCC3AUX)

= 3.8 V 0.4 V

open-drain digital outputs: THERM, INT

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

OL

Logical 0 output voltage I

OUT

= 3 mA at V

(VCC3AUX)

= 3.8 V 0.4 V

I

OH

High level output current V

OUT

= V

(VCC3AUX)

= 3.8 V 0.1 100 µA

open-drain digital outputs: RST, AUXRST

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

p

I

OUT

= 3 mA at V

(VCC3AUX)

= 3.8 V 0.4

VOLLogical 0 output voltage

I

OUT

= 3 mA at V

(VCC3AUX)

= 1 V 0.4

V

I

OH

High level output current V

OUT

= V

(VCC3AUX)

= 3.8 V 0.1 100 µA

open-drain digital output: FAN_OFF

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

OL

Logical 0 output voltage I

OUT

= 6 mA at V

(VCC3AUX)

= 3.8 V 0.4 V

I

OH

High level output current V

OUT

= V

(VCC3AUX)

= 3.8 V 0.1 100 µA

open-drain SMBus output: SDA

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

OL

Logical 0 output voltage I

OUT

= 3 mA at V

(VCC3AUX)

= 3.8 V 0.4 V

I

OH

High level output current V

OUT

= V

(VCC3AUX)

= 3.8 V 0.1 100 µA

SMBus digital inputs: SCL, SDA

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

IH

Logical 1 input voltage 0.7 × V

(VCC3AUX)

V

V

IL

Logical 0 input voltage 0.3 × V

(VCC3AUX)

V

digital inputs: FAN_SPD/NTEST_IN, ADD/NTEST_OUT, MR, GPI

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

IH

Logical 1 input voltage (5 V) 2.4 V

V

IL

Logical 0 input voltage (5 V) 0.8 V

V

IH

Logical 1 input voltage (3.3 V) 2 V

V

IL

Logical 0 input voltage (3.3 V) 0.4 V

I

IH

Logical 1 input current VIN = V

(VCC3AUX)

–0.005 –1 mA

Logical 0 input current (except MR)

0.005 1 mA

I

IL

Logical 0 input current (MR)

V

IN

=

0 V dc

165 250 µA

C

(IN)

Digital input terminal capacitance Design parameter only – not tested 20 pF

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

dc electrical characteristics, V

CC3

= V

(VCC3AUX)

= 3.3 V, TA = 25°C (unless otherwise noted)

(continued)

analog output: FAN_SPD/NTEST_IN

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

OUT

Output voltage range 0 2.5 V

Total unadjusted error (TUE) (see Note 5) IL = –2 mA –3% 3%

Full-scale error –3% ±1% 3%

Zero error, LSB No load 2

Differential nonlinearity (DNL), LSB (monotonic by design)

DAC setting

0 × 16 to 0 ×FF

–1 1

Integral nonlinearity , LSB ±1

C

(LOAD)

Maximum external load capacitance allow to insure DAC

stability

Design parameter only –

not tested

50 pF

I

(SOURCE)

Output source current

DAC setting

0 × 16 to 0 ×FF

–2 mA

I

(SINK)

Output sink current

DAC setting

0 × 16 to 0 ×FF

1 mA

NOTE 5: Total unadjusted error (TUE) includes offset, gain, and linearity errors of the DAC.

remote thermal diode sensing

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

T

(RES)

T emperature resolution 1 °C

I

Diode source current

REMOTE_DIODE+ = REMOTE_DIODE– + 0.65 V ,

high level

80 130

µ

A

(DIODE)

Low level 8 13

µ

I

(RATIO)

Diode source current ratio High level/low level 9.8 10 10.2

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

ac electrical characteristics, V

CC3

= V

(VCC3AUX)

= 3.3 V, TA = 25°C (see Notes 6 and 7) (unless

otherwise noted)

temperature-to-digital converter timing parameters: Remote_Diode+, Remote_Diode–

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

t

(SAMPLE)

T emperature-to-digital acquisition sample rate 0.75 1 1.25 sa/s

reset function timing parameters: VCC3, VCC3AUX, MR, AUXRST, RST

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

t

(RP)

RST and AUXRST pulse duration See Figures 17–20 140 560 ms

t

(VCC3RST)

VCC3 to RST delay See Figures 17–20 20 µs

t

(VCC3AUX1)

VCC3AUX to AUXRST delay See Figures 17–20 20 µs

t

(VCC3AUX2)

VCC3AUX to RST delay See Figures 17–20 20 µs

t

(MR)

MR input to RST delay See Figures 17–20 0.5 µs

t

(RST)

AUXRST input to RST delay See Figures 17–20 0.5 µs

t

(MRMIN)

MR input minimum pulse width 10 µs

t

(AUXRSTMIN)

AUXRST input minimum pulse width 10 µs

t

(GLITCH)

MR, AUXRST glitch immunity 100 ns

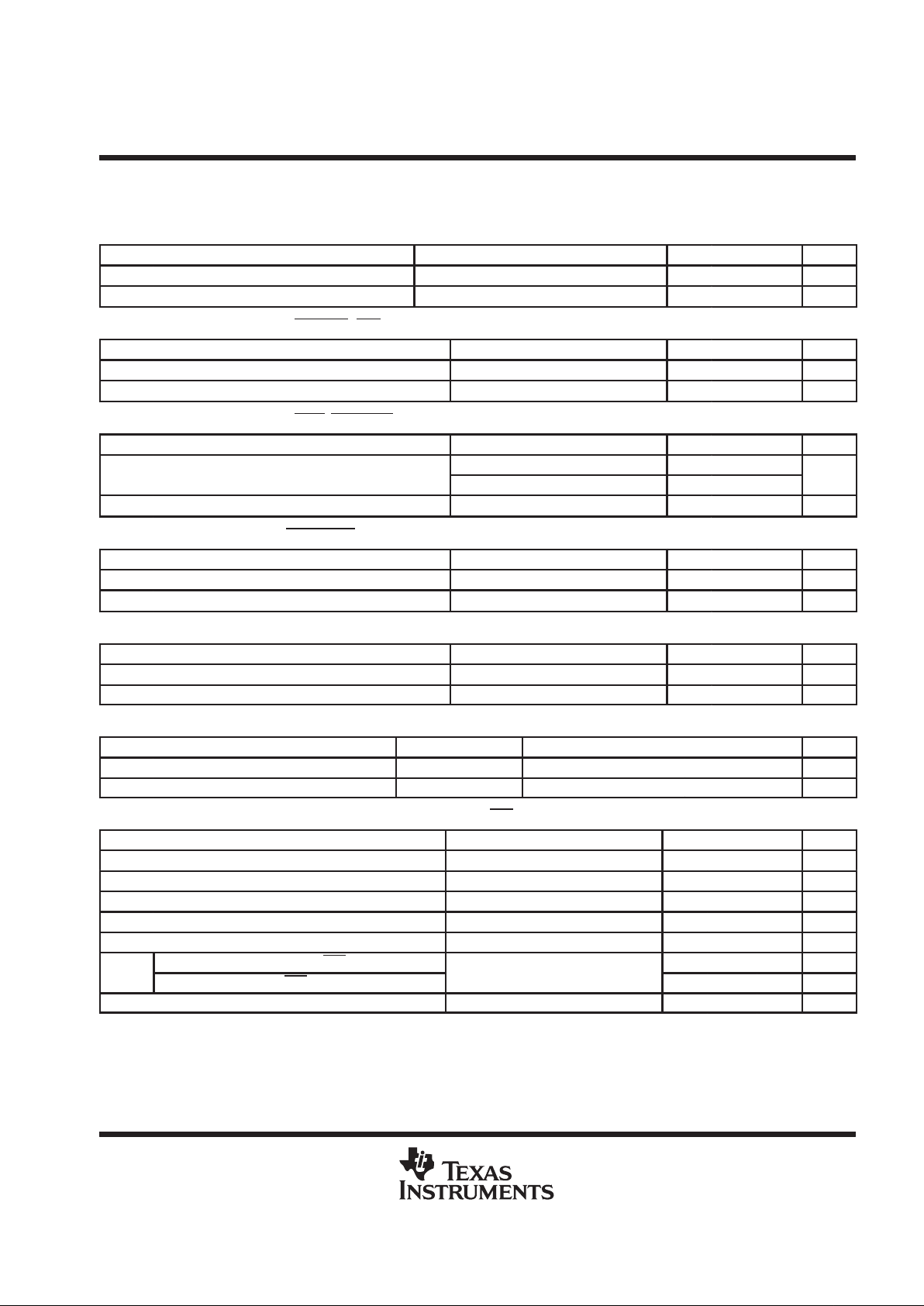

SMBus interface timing parameters: SCL, SDA

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

f

(SCL)

SCL operating frequency See Figure 1 10 100 kHz

t

(BUF)

Bus free time between stop and start condition See Figure 1 4.7 µs

t

(HDSTA)

Hold time after (repeated) start condition. After this period,

the first clock is generated

See Figure 1 4 µs

t

(SUSTA)

Repeated start condition setup time See Figure 1 4.7 µs

t

(SUSTO)

Stop condition setup time See Figure 1 4 µs

t

(HDDAT)

Data hold time See Figure 1 300 ns

t

(SUDAT)

Data setup time See Figure 1 250 ns

t

(LOW)

SCL clock low period See Figure 1 4.7 µs

t

(HIGH)

SCL clock high period See Figure 1 4 50 µs

t

(LOWSEXT)

Cumulative clock low extend time (slave device) See Figure 1 25 ms

t

(LOWMEXT)

Cumulative clock low extend time (master device) See Figure 1 10 ms

t

F

Clock/data fall time See Figure 1 300 ns

t

R

Clock/data rise time See Figure 1 1000 ns

NOTES: 6. Typicals are at TJ = TA = 25°C with V

(VCC3AUX)

= 3.3 V and represent most likely parametric norm.

7. Timing specifications are tested at the TTL logic levels, VIL = 0.4 V for a falling edge and VIH = 2.4 V for a rising edge. The 3-state

output voltage is forced to 1.4 V.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

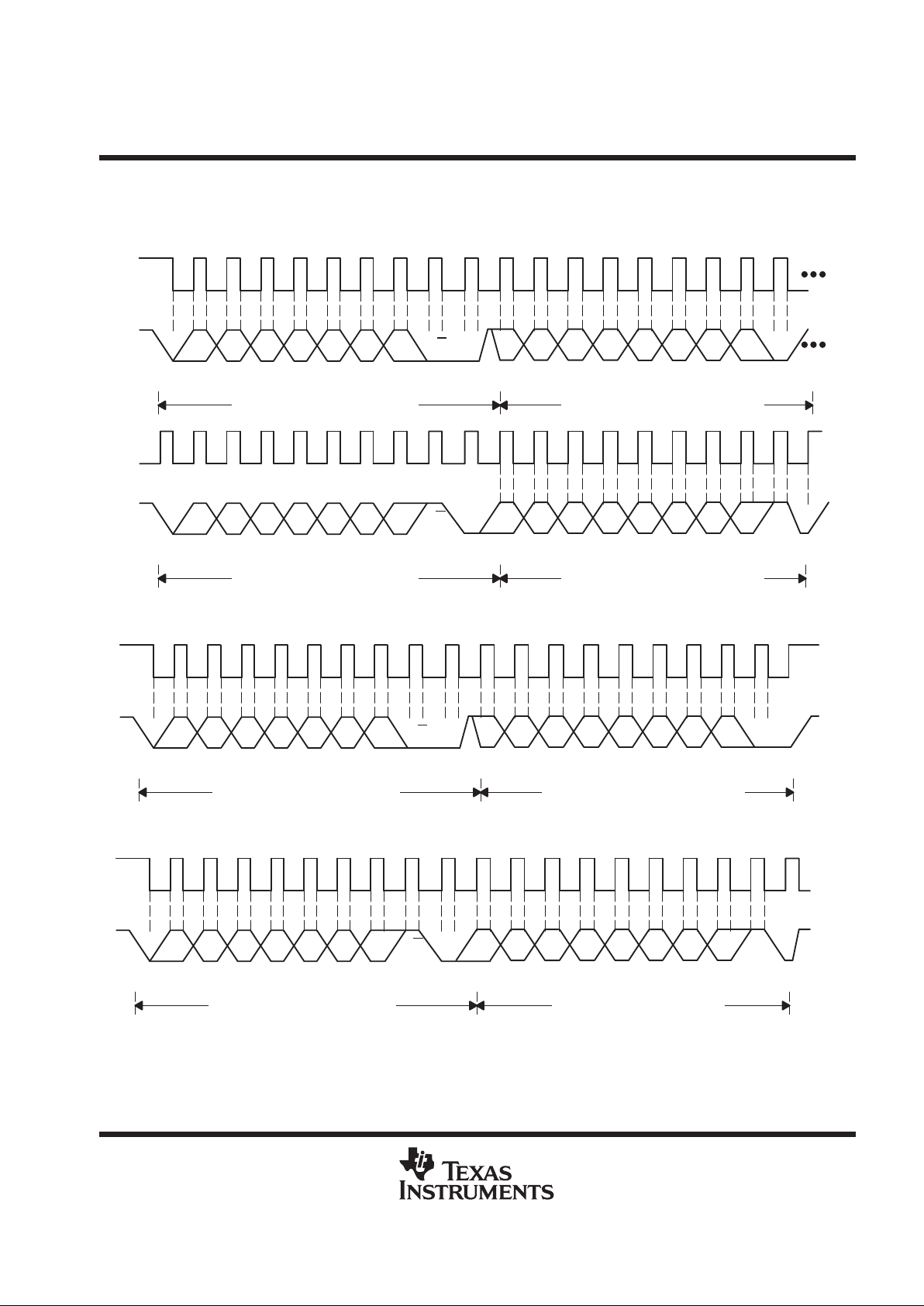

PARAMETER MEASUREMENT INFORMATION

SMBus timing diagrams

PS

t

(HDSTA)

t

(HDDAT)

t

(HIGH)

t

(SUDAT)

t

(SUSTA)

t

(HDSTA)

t

(SUSTO)

SP

SCLK

SDATA

Start

Stop

SCLK

ACK

SCLK

ACK

t

(LOWMEXT)

SCLK

SDATA

t

(LOW)

t

(LOWSEXT)

t

F

t

R

t

(BUF)

t

(LOWMEXT)

t

(LOWMEXT)

Figure 1. SMBus Timing Diagram

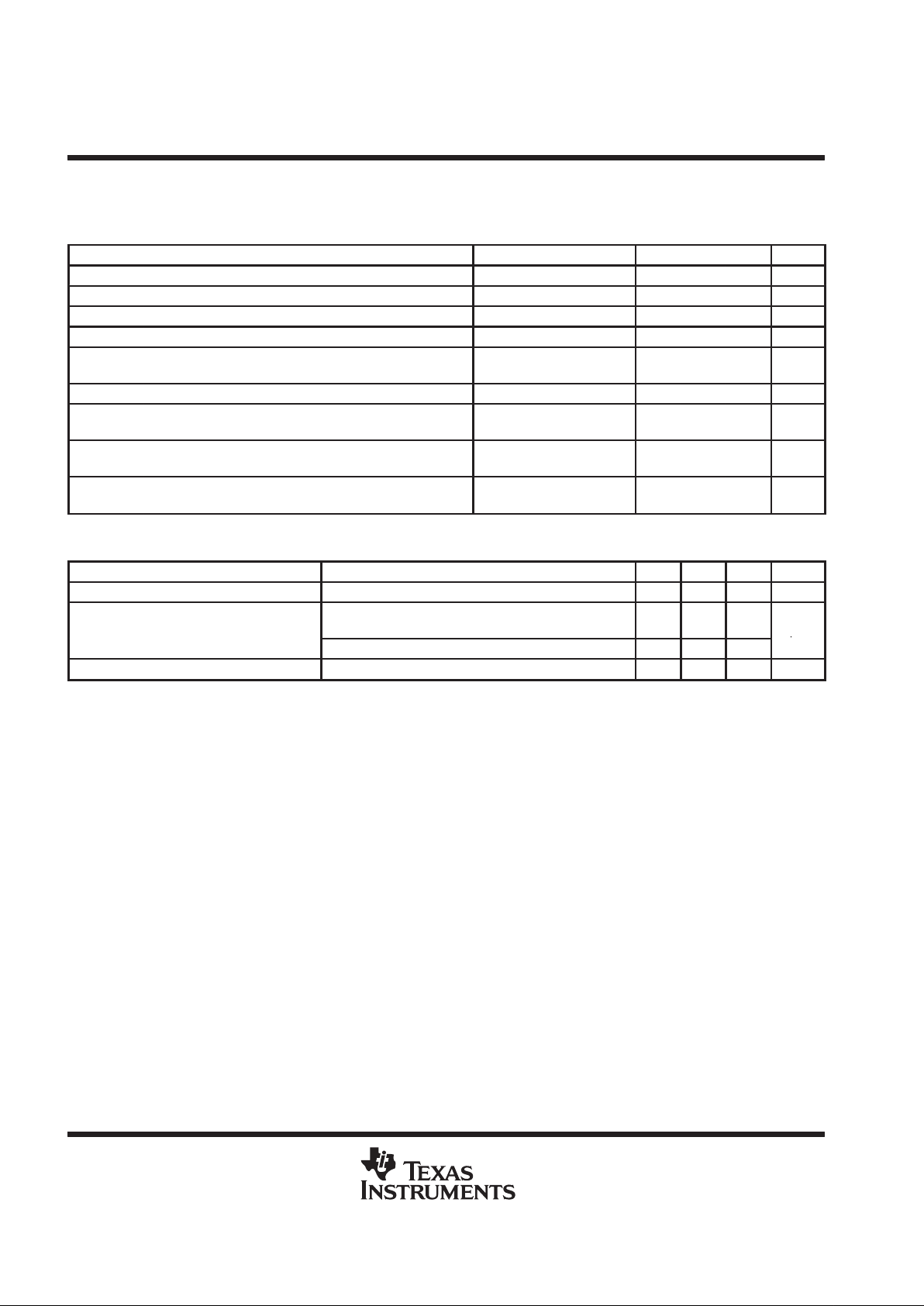

Frame 3 Data Byte

Frame 1 SMBus Slave Address Byte

Frame 2 Address Pointer Register Byte

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

SCLK

SDATA

Start By

Master

ACK By

THMC50

ACK By

Master

D7 D6 D5 D4 D3 D2 D1 D0

ACK By

THMC50

Stop By

Master

SCLK

(Continued)

SDATA

(Continued)

1

91 9

19

Figure 2. SMBus Timing Diagram for Write Byte Format

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

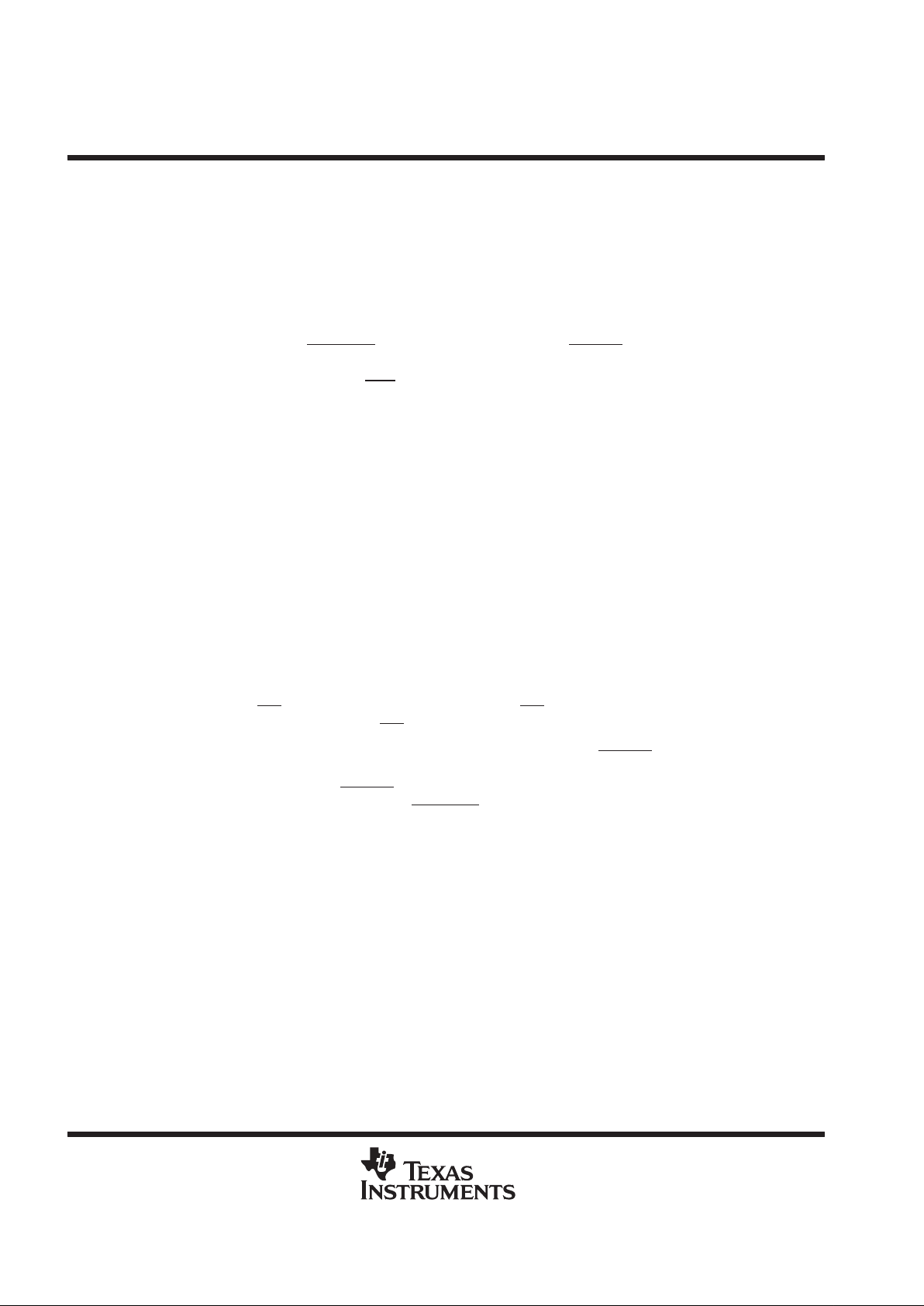

PARAMETER MEASUREMENT INFORMATION

SMBus timing diagrams (continued)

Frame 1 SMBus Slave Address Byte

Frame 2 Address Pointer Register Byte

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

SCLK

SDATA

Start By

Master

ACK By

THMC50

ACK By

Master

SCLK

(Continued)

SDATA

(Continued)

1

91 9

Frame 3 SMBus Slave Address Byte

Frame 4 Data Byte Read From THMC50

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

Start By

Master

ACK By

THMC50

NACK By

THMC50

1

91 9

Stop By

Master

Figure 3. SMBus Timing Diagram for Read Byte Format

Frame 1 SMBus Slave Address Byte

Frame 2 Address Pointer Register Byte

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

SCLK

SDATA

Start By

Master

ACK By

THMC50

ACK By

THMC50

1

91 9

Stop By

Master

Figure 4. SMBus Timing Diagram for Send Byte Format

Frame 1 SMBus Slave Address Byte

Frame 2 Data Byte From THMC50

A6 A5 A4 A3 A2 A1 A0 D7 D6 D5 D4 D3 D2 D1 D0R/W

SCLK

SDATA

Start By

Master

ACK By

THMC50

NACK

By Master

1

91 9

Stop By

Master

Figure 5. SMBus Timing Diagram for Recieve Byte Format

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

functional description

The THMC50 provides a remote thermal diode temperature sensor, an internal ambient temperature sensor,

an analog output, and two voltage supervisors/reset generators.

Temperatures read from the remote and internal sensors are converted into an 8-bit, 2s-complement digital

word with a 1°C LSB (least significant bit). The analog output is a 0-V to 2.5-V output from an 8-bit DAC that

is used along with external circuitry to control the fan speed. The analog output is automatically set by the

THMC50 to full on (0×FF), the FAN_OFF

output floats (fan is on), and THERM is asserted low when either of

two automatic trip points is exceeded for more than three monitoring cycle times. The FAN_SPD analog output

will be reset to full off (0x00) whenever RST

is asserted.

The THMC50 provides a number of internal registers, as detailed in Table 1. These include:

Register: Function:

Configuration register Provides control and configuration, as well as initialization

Interrupt status register Provides status of each limit or interrupt event

Interrupt status register mirror Mirror registers can be used by second agent needing to monitor

the THMC50 status.

Interrupt mask register Allows masking of individual interrupt sources, as well as

separate masking for the hardware interrupt output

Value RAM The monitoring results and limits for temperature are all

contained in the value RAM.

When the THMC50 is first started, it performs temperature conversions at a rate of 1Hz. Each measured

temperature value is compared to values stored in the limit registers. When the measured value exceeds the

programmed limit, the THMC50 sets a corresponding error bit in the interrupt status register. An open drain

hardware interrupt line, INT

, is available to generate an interrupt. INT is fully programmable with masking of each

interrupt source, and with masking of the INT

output.

The temperature monitoring section also has an open drain input/output, THERM

. This line is asserted low

internally whenever a critical temperature limit is exceeded for at least three monitoring cycles. It can also be

asserted low externally. Whenever THERM

is asserted low, either internally or externally, the analog output

automatically goes to full scale (0xFF) and the FAN_OFF

output floats (fan is on) in order to command the fan

to full speed.

SMBus interface

When using the SMBus interface, a write always consists of the THMC50 SMBus interface address byte,

followed by the internal address register byte, then the data byte (see Figure 2). There are two cases for a read:

1. If the internal address register is known to be at the desired address, simply read the THMC50 with the

SMBus interface address byte, followed by the data byte read from the THMC50 (see Figure 5).

2. If the internal address register value is unknown, write to the THMC50 with the SMBus interface address

byte, followed by the internal address register byte (see Figure 4). Next, restart the serial communication

with a read consisting of the SMBus interface address byte, followed by the data byte read from the

THMC50.

The default power-on SMBus address for the THMC50 is 0101 1XX binary, where XX reflects the state defined

by the add terminal. This allows up to three THMC50 devices to be used on a single system. T able 1 shows how

the state of the add terminal is used to define the THMC50 SMBus slave address.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

Table 1. THMC50 ADD Terminal States and Resulting SMBus Slave Address

ADD TERMINAL RESULTING THMC50 SMBUS ADDRESS

GND 0101110

No Connect 0101100

VCC 0101101

Refer to Figure 1 through Figure 5 for the SMBus timing diagrams. The THMC50 does not support the SMBSUS

or SMBALERT sideband signals referenced in the SMBus specification.

THMC50 usage

The following sections describe the typical usage for the THMC50.

power-on reset

Applying power to the VCC3AUX terminal causes a reset of all of the registers to their default states. Some

registers have indeterminate power-on values, such as the limit and RAM registers, and these are not shown

in the table. Writing limit values into the value RAM should be the first action performed after power up. Refer

to the register definition tables for default power-on values of all other registers.

If the FAN_SPD/NTEST_IN terminal is held high during power-on reset, the THMC50 enters the NAND tree test

mode. Once the NAND tree test mode is enabled, it can only be disabled by cycling VCC3AUX power.

The FAN_SPD analog output is reset to 0x00 whenever RST

is asserted low. During the time RST is asserted

low, a THERM

assertion will still cause the FAN_SPD analog output to go to full scale (0xFF).

The THMC50 contains a bidirectional reset terminal, AUXRST

, which causes an internal reset when pulled low

externally. Refer to the section describing AUXRST

for more detail.

soft reset

The THMC50 can be commanded to perform an internal soft reset by setting bit 4 of the configuration register

(0x40). This bit automatically clears itself after being set. A soft reset performs a similar reset to the power-on

reset, except that the value RAM remains unchanged. Registers that are reset by both types of reset include:

0×40 configuration register

0×41 interrupt status register

0×43 interrupt mask register

0×4C interrupt status register mirror

beginning a conversion

The THMC50 monitoring function is started by default. It is expected that the system BIOS initializes the

THMC50 as quickly as possible during POST. The BIOS should then clear the INT

clear (bit 2) and set INT

enable (bit 1) in the configuration register (0×40) in order to enable THMC50 interrupts and the INT function.

The results of the sampling and conversion can be found in the value RAM and are available at any time.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

interrupt status register/interrupt status register mirror

The THMC50 contains a pair of interrupt status registers. These registers reflect the state of all of the possible

error conditions that the THMC50 monitors. When an error occurs during the conversion cycle, the

corresponding bit is set in the interrupt status register and the interrupt status register mirror. Once set, the bit

in the interrupt status register is cleared upon reading that register. Reading the interrupt status register does

not clear the mirror register, and vice versa. If the error condition persists after being cleared, the bit is again

set in both the interrupt status register and the mirror register.

analog output - FAN_SPD

The THMC50 has a single analog output, FAN_SPD/NTEST_IN, from an unsigned 8-bit DAC which produces

0 V to 2.5 V. This register is set to 0x00 on RST

, which results in the minimal fan speed possible.

Note that if RST

is asserted low, it is still possible for the FAN_SPD analog output to go to full scale (0xFF) if

THERM

is asserted.

The FAN_SPD output must be amplified with external circuitry in order to achieve an output voltage range of

0 V to 12 V and an output current of at least 250 mA in order to drive a cooling fan. Figure 6 through Figure 1 1

illustrate external circuits that can be used to drive a fan.

+12 V +12 V

FAN_SPD/NTEST_IN

LM324

Q1

2N2219A

R1

36 kΩ

R2

10 kΩ

_

+

Figure 6. External Fan Drive Circuit Using 1/4 LM324 and NPN Emitter-Follower, Single Supply

+12 V +12 V

FAN_SPD/NTEST_IN

LM324

R4

1 kΩ

R3

1 kΩ

R1

39 kΩ

R2

10 kΩ

Q1

BD136

2SA968

+

–

Figure 7. External Fan Drive Circuit Using 1/4 LM324 and PNP Transistor, Single Supply

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

+12 V

FAN_SPD/NTEST_IN

LM324

R1

39 kΩ

R2

10 kΩ

R3

100 kΩ

Q1

IRF9620

+12 V

+

–

Figure 8. External Fan Drive Circuit Using 1/4 LM324 and P-Channel FET, Single Supply

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

analog output - FAN_SPD (continued)

FAN_SPD/NTEST_IN

+12 V

R1

100 kΩ

R2

100 kΩ

Q1/Q2

MBT3904

DUAL

Q3

IRF9620

R3

3.9 kΩ

R4

1 kΩ

R5

5 kΩ

Figure 9. External Fan Drive Circuit Using Discrete Components With P-Channel FET, Single Supply

+12 V

FAN_SPD/NTEST_IN

–12 V

R2

100 kΩ

Q1/Q2

MBT3904

DUAL

R1

4.7 kΩ

Q3

IRF9620

R3

39 kΩ

R4

10 kΩ

Figure 10. External Fan Drive Circuit Using Discrete Components With P-Channel FET, Dual Supply

+12 V

FAN_SPD/NTEST_IN

R1

100 kΩ

R2

100 kΩ

Q3

BC556

2N3906

R5

100 Ω

Q1/Q2

MBT3904

DUAL

Q4

BD132

TIP32A

R3

3.9 kΩ

R4

1 kΩ

R6

5 kΩ

Figure 11. External Fan Drive Circuit Using Discrete Components and

PNP Output Transistor, Single Supply

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

analog output - FAN_SPD (continued)

NOTE:

R5 in Figure 9 and R6 in Figure 11 are required to insure FAN_SPD/NTEST_IN is below the

NTEST_IN enable threshold during power up. Without these pulldown resistors, the external fan

drive circuit would cause the THMC50 to always power up in the NAND tree test mode. If an external

fan drive circuit other than the ones shown above is used, insure that the FAN_SPD/NTEST_IN

terminal is held below 0.3 × VCC3AUX during power up to prevent the THMC50 from entering the

NAND tree test mode inadvertently.

The circuits shown in Figure 6 through Figure 11 should be implemented with the following considerations:

D

The output transistor or FET used must be capable of sourcing a current greater than the maximum fan

current value, and it must be capable of handling the power dissipation generated by the voltage drop across

the device when the fan operates at less than full speed.

D

It may be necessary to add clamping diodes to protect the output transistor or FET from voltage transients

caused by a sudden drop in fan speed from full scale to 0 V.

D

All of the circuits shown in Figure 6 through Figure 1 1 deliver an output voltage swing from near 0 V to near

12 V. The exception is the circuit in Figure 6, which is only able to supply a voltage up to a V

BE

drop down

from 12 V due to the emitter-follower drive stage.

D

If a different circuit is implemented, the gain of the amplifier should be around 4.8 to amplify the F AN_SPD

output from 0 V-to-2.5 V to 0 V-to-12 V.

D

When selecting an operational amplifier, insure that its input common mode range accounts for the range

of the FAN_SPD output (0 V to 2.5 V) and that the output voltage swing of the operational amplifier is

suitable.

D

The operational amplifier can either be powered from 12 V alone or from a ±12 V dual supply. If the

operational amplifier is powered from 12 V only, then the input common mode range of the operational

amplifier should include ground to accommodate the FAN_SPD output voltage range (0 V to 2.5 V). The

output voltage swing of the operational amplifier should be less than 0.6 V, if it is desired to have the fan

turn off when the DAC is commanded to 0x00.

D

Insure that the FAN_SPD/NTEST_IN terminal is held below 0.3 × VCC3AUX during power up to prevent

the THMC50 from entering the NAND tree test mode inadvertently . A pulldown resistor, such as R5 in Figure

9 and R6 in Figure 1 1, may be needed for external circuits to source current into the F AN_SPD/NTEST_IN

terminal to satisfy this requirement.

D

Care should also be taken when using a dual supply for the operational amplifier. Clamping diodes from

the output of the operational amplifier to ground should be used to prevent the base-emitter junction of the

external transistor from being reversed bias if the output of the operational amplifier swings below ground.

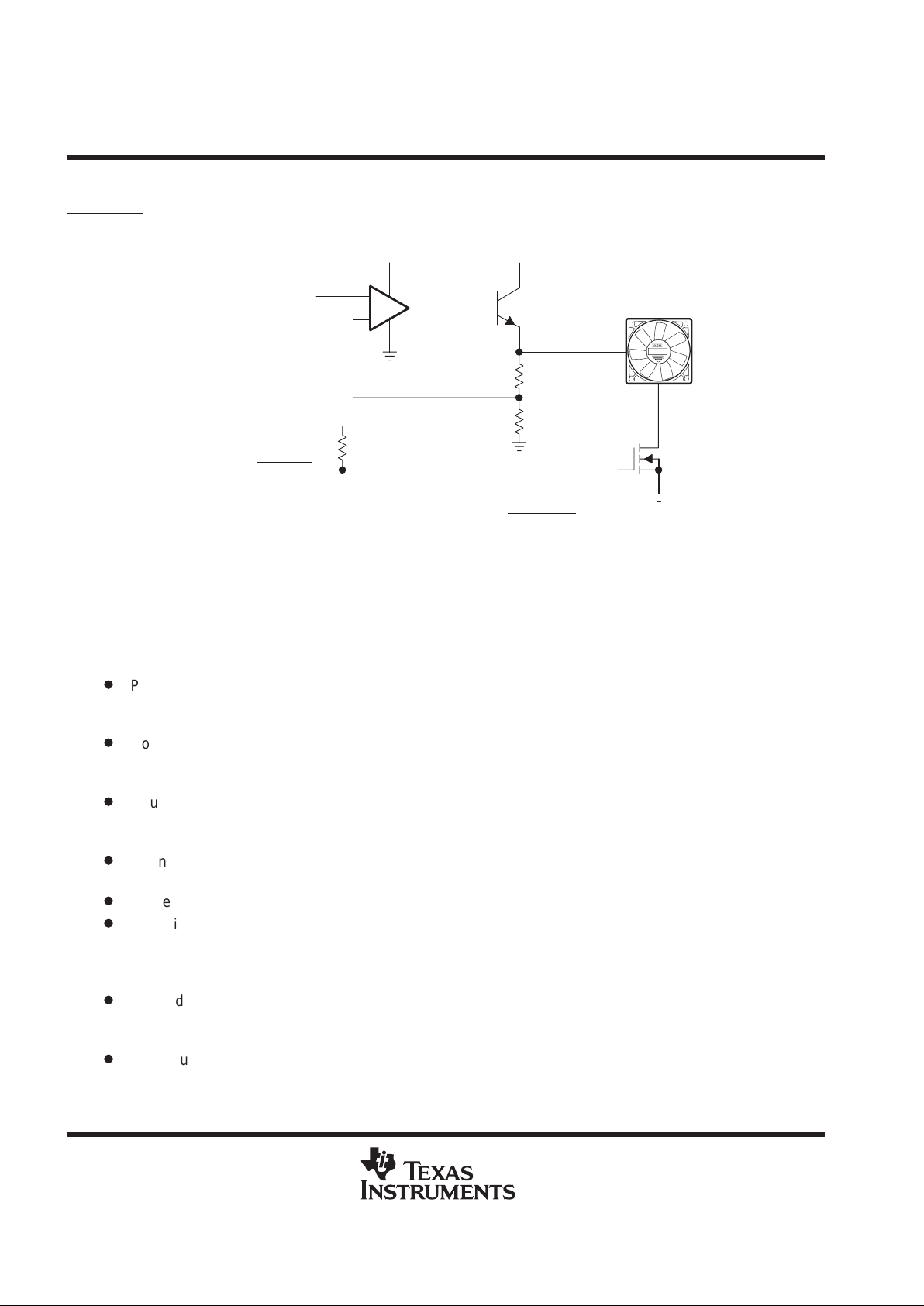

FAN_OFF output

The open drain FAN_OFF output of the THMC50 provides a way to turn off the cooling fan regardless of the

voltage on the FAN_SPD analog output terminal. Setting bit 5 in the configuration register (0x40) to a 1 causes

this output to float. Setting bit 5 in the configuration register (0x40) to a 0 causes the output to sink current (go

low). This output can be used in conjunction with an external FET or transistor to gate the fan on or off as shown

in Figure 12.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

FAN_OFF

output (continued)

FAN_SPD/NTEST_IN

FAN_OFF

Q1

2N2219A

+12 V+12 V

M1

MMFT3055EL

+5 V

R3

1 kΩ

R1

36 kΩ

R2

10 kΩ

LM324

_

+

Figure 12. Example for Implementing the FAN_OFF Output Signal

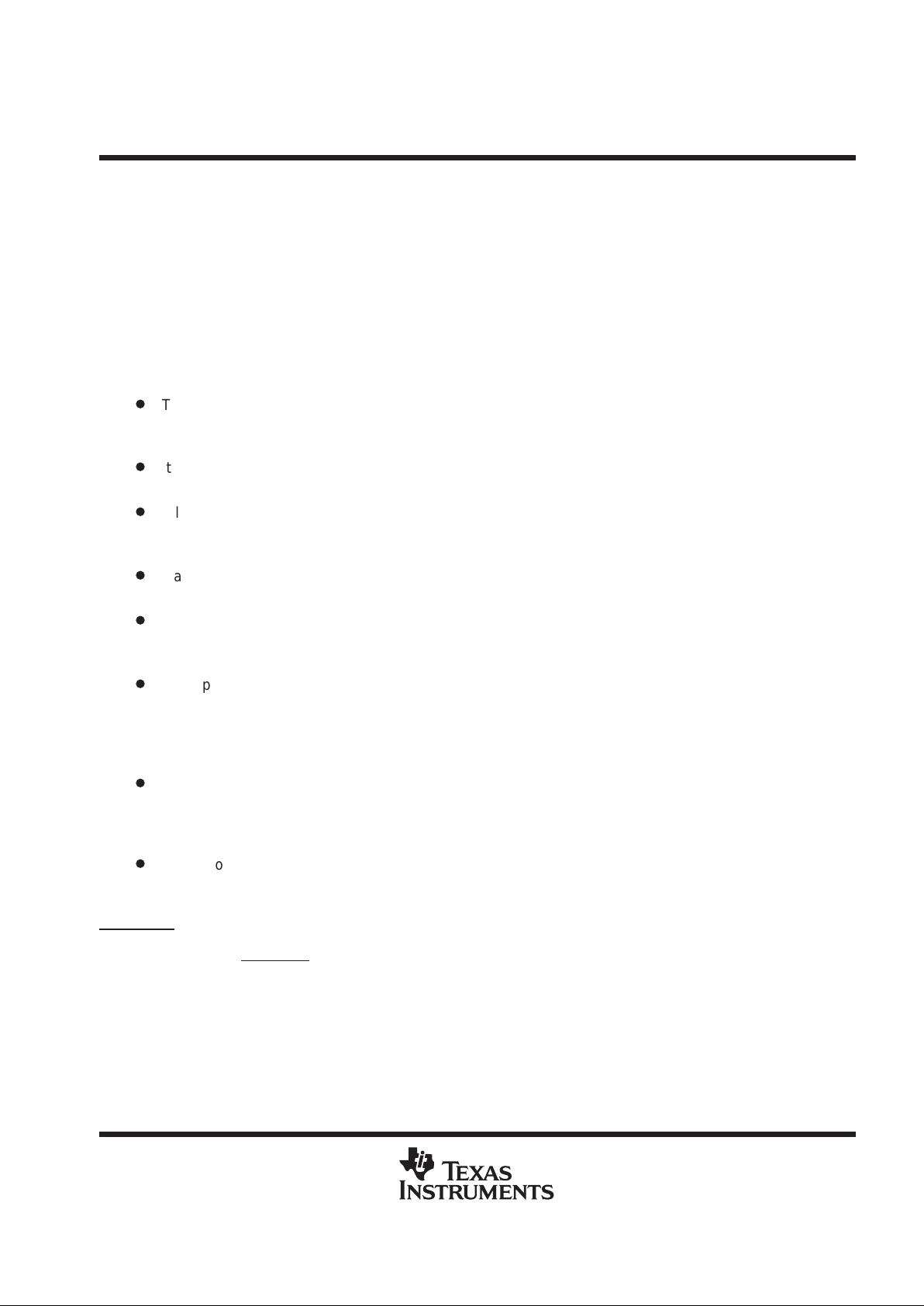

layout and grounding

The power supply bypass, the parallel combination of 10 µF (electrolytic or tantalum), and 0.1 µF (ceramic)

bypass capacitors connected between terminals 5, 7, and ground should also be located as close as possible

to the THMC50.

The following are general guidelines for generating the PCB layout for the THMC50:

D

Place the THMC50 as close as practical to the remote diode. In a noisy environment, such as a computer

motherboard, this distance can be 4 inches to 8 inches (typical) or more, as long as the worst noise sources

(such as CRTs, clock generators, memory buses, and ISA/PCI buses) are avoided.

D

Do not route the remote diode lines next to the deflection coils of a CRT . Also, do not route the traces across

a fast memory bus, which can easily introduce 30°C error even with good filtering. Otherwise, most noise

sources are fairly benign.

D

Route the remote diode traces in parallel and in close proximity to each other, away from any high-voltage

traces such as 12 Vdc. Leakage currents from PC board contamination must be taken into consideration,

since a 20 MΩ leakage path from REMOTE_DIODE+ to ground causes about 1°C error.

D

Connect guard traces to GND on either side of the remote diode traces (Figure 13). With guard traces in

place, routing near high-voltage traces is not an issue.

D

Route through as few vias and crossunders as possible to minimize copper/solder thermocouple effects.

D

When introducing a thermocouple, insure that both remote diode traces have matching thermocouples. In

general, PC board induced thermocouples are not a serious problem. A copper-solder thermocouple

exhibits 3 µV/°C, and it takes about 200 µV of voltage error at the remote diode terminals to cause a 1°C

measurement error. Hence, most parasitic thermocouple errors are swamped out.

D

Use wide traces, as narrow ones are more inductive and tend to pick up radiated noise. The 10-mil widths

and spacings recommended in Figure 13 are not absolutely necessary (as they offer only a minor

improvement in leakage and noise), but usage is recommended where practical.

D

Do not use copper as an EMI shield as only ferrous materials such as steel work well. Placing a copper

ground plane between the remote diode traces and traces carrying high-frequency noise signals does not

minimize EMI.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

PCB layout checklist

D

Place the THMC50 as close as possible to the remote diode.

D

Keep the remote diode traces away from high voltages (12-V bus).

D

Keep the remote diode traces away from fast data/memory buses and CRTs.

D

Use recommended trace widths and spacings.

D

Place a ground plane under the traces.

D

Use guard traces flanking the remote diode traces and connect them to ground.

D

Place the 0.1-µF VCC3AUX bypass capacitor as close to the THMC50 as possible.

10 MILS

REMOTE_DIODE–

REMOTE_DIODE+

GND

GND

10 MILS

MINIMUM

10 MILS

10 MILS

Figure 13. Recommended PC Board Layout for Remote Diode Traces

use of twisted pair and shielded cables for remote thermal sensor

For remote-sensor distances longer than 8 inches or in particularly noisy environments, a twisted pair is

recommended. Its practical length is 6 feet to 12 feet (typical) before noise becomes a problem, as tested in

a noisy electronics laboratory. For longer distances, the best solution is a shielded twisted pair like that used

for audio microphones. For example, Belden

#8451 works well for distances up to 100 feet in a noisy

environment. Connect the twisted pair to the remote diode terminals and the shield to ground, and leave the

shield’s remote end unterminated. Excess capacitance at REMOTE_DIODE– limits practical remote sensor

distances. For very long cable runs, the cable’s parasitic capacitance often provides noise filtering; hence, the

2200-pF capacitor can often be removed or reduced in value. Cable resistance also affects remote-sensor

accuracy. A 1-Ω series resistance introduces about 0.5°C error.

temperature measurement system

The remote thermal diode sensor monitors a remotely placed diode such as those found in some

microprocessors. A 2N3904 transistor can also be used for remote thermal sensing. The THMC50 also has an

internal thermal diode sensor which can be used to monitor the ambient temperature of the environment around

the device. Figure 14 shows the block diagram of the analog front end for the THMC50 temperature-to-digital

converter.

A digital 8-bit comparator is used to compare the temperature readings to the user-programmable high/low, to

over-temperature limit values, and to generate interrupts accordingly.

Belden is a registered trademark of Belden Corporation.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

temperature measurement system (continued)

8-Bit A/D

Converter

REMOTE_DIODE+

Substrate

On-Chip Temperature

Sensor

GND

10 µA 90 µA

Control

State

Machine

Analog

MUX

Die

Substrate

REMOTE_DIODE–

Low-Pass

Filter

Remote

Temperature

Sensor

(CPU)

THMC50

Front End

Remote

VCC3AUX

Figure 14. THMC50 Temperature-to-Digital Converter Analog Front-End Block Diagram

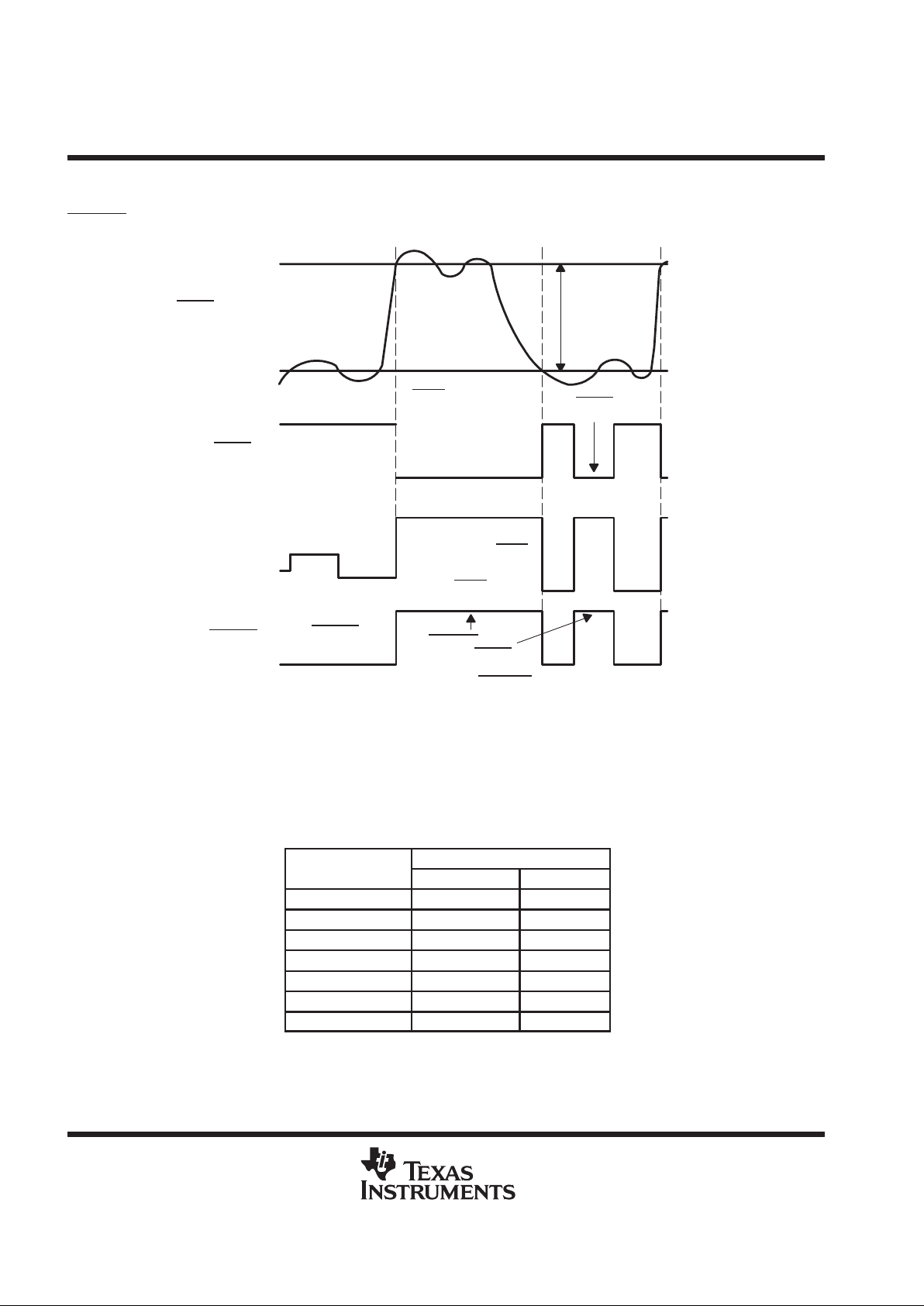

temperature interrupts

There are two value RAM limits for the temperature reading that affect the interrupt behavior of the THMC50.

They are remote thermal diode high limit and remote thermal diode low limit.

temperature interrupt operation

Exceeding any of the value RAM thermal limits results in the INT

output being asserted (if the corresponding

mask bits are not set) and respective status bit to be set. The INT

output remains asserted until cleared by either

reading the interrupt status register, or setting the INT

clear (bit 2) of the configuration register. Status bits are

cleared by reading the interrupt status register. The INT

output can only be asserted again if the appropriate

high limit is reprogrammed. If the high limit is not reprogrammed, then the INT

output is asserted again once

the temperature falls below the appropriate low limit. The INT

output is now asserted again if the temperature

again rises above the appropriate high limit or falls below the appropriate low limit. See Figure 15 for an example.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

temperature interrupt operation (continued)

100°C

High

Low

Temp

ACPI control

methods clear

event

ACPI control

methods clear

event

ACPI control

methods clear

event

†

†

†

†

†

†

90°C

80°C

70°C

60°C

50°C

40°C

†

ACPI control methods adjust temperature limit values.

INT

Figure 15. Examples of Temperature Interrupt Events

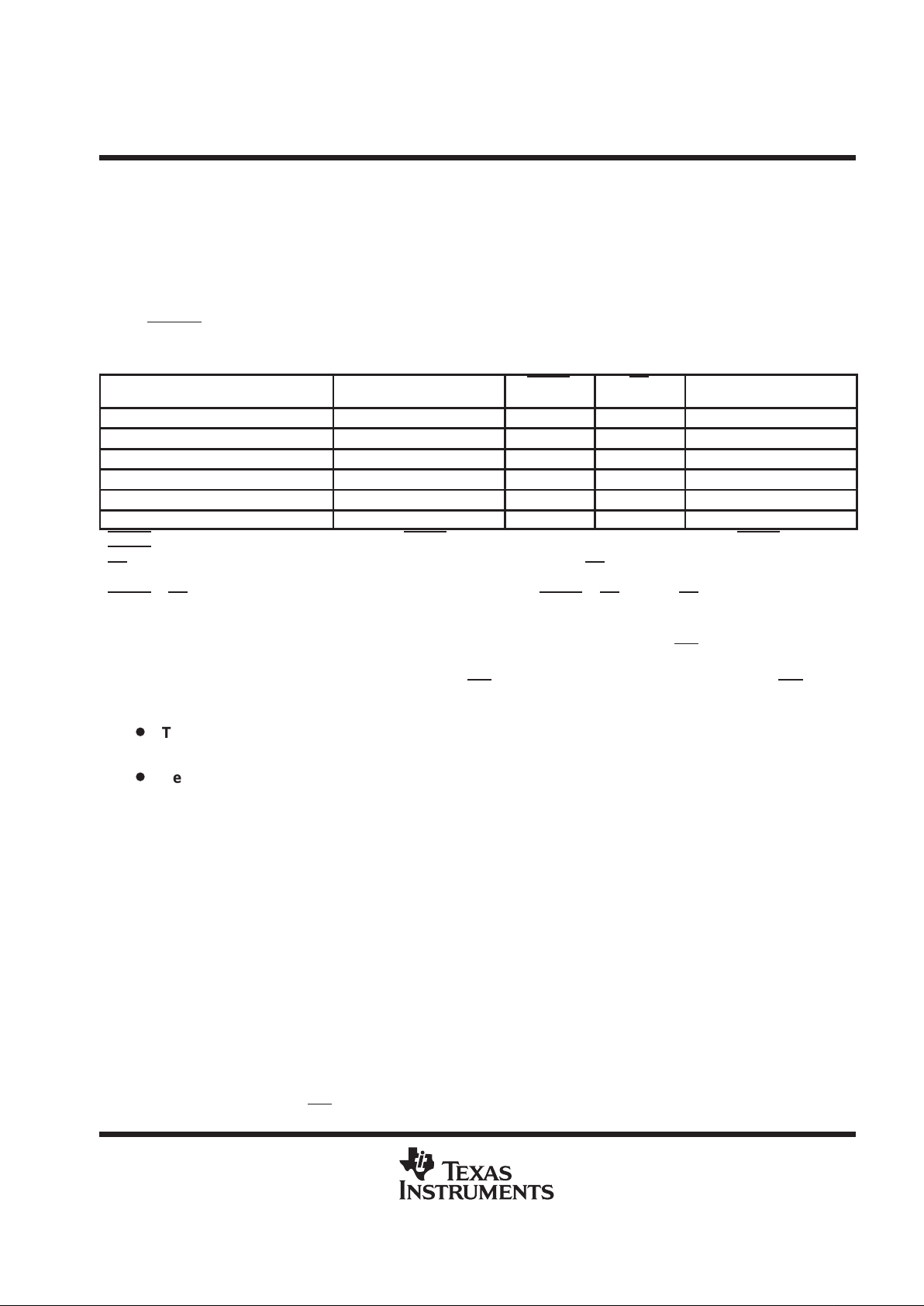

THERM operation

The THERM output is used for fault tolerant fan control. It is asserted by the THMC50 whenever the remote

thermal diode temperature or ambient temperature exceeds the appropriate automatic trip point for three

consecutive acquisitions (see Figure 16). The remote and local thermal diode trip point values are contained

in the programmable remote/local temperature automatic trip point registers (if bit 3 in the configuration register

is set) or the default remote/local temperature automatic trip point (if bit 3 in the configuration register is cleared).

The default trip points are hardware-set trip points that can be read from the value RAM. Programmable trip

points provide for increased flexibility in the ability to tailor the thermal characteristics of the system. The

programmable values can be written to, and then locked down, by writing a 1 to the

write once

bit located in the

configuration register.

THERM

is asserted after three consecutive acquisitions of a remote or an internal temperature that exceeds

the appropriate automatic trip points (based upon bit 3 of the configuration register). When THERM

is asserted

by the THMC50, it remains active (with FAN_SPD = 0xFF and F AN_OFF = FLOATING) until both the local and

remote temperatures fall 5°C below the appropriate automatic trip point values (based upon bit 3 of the

configuration register) for three consecutive temperature acquisitions. Once THERM

has been cleared, the

FAN_SPD output returns to its previously programmed value and FAN_OFF

returns to its previously

programmed state. Note that when FAN_SPD goes to full scale (0xFF) during a THERM

event, the value in the

analog output register (0x19) reflects the previously programmed value and not 0xFF, unless 0xFF was the

previously programmed value. When THERM

is asserted internally, it causes INT to be unconditionally

asserted.

An external device that pulls THERM low causes the fan control to be turned to full on and corresponding status

bits to be set. In addition, whenever THERM

is active, the FAN_OFF bit in the configuration register is

unconditionally set. Note that an INT

generated by an external device pulling THERM low is maskable, but an

INT

generated by an internally generated THERM condition is not maskable.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

THERM

operation (continued)

Temperature

5°C

FAN_SPD/NTEST_IN

0xFF

0xFF

Programmed

value

External

THERM

input

THERM

FAN_OFF

FAN_OFF

commanded

low by user

5°C Hysteresis

THERM goes low after three

consecutive readings that exceed

the trip point, and stays low until

three consecutive readings that

are at least 5°C below the trip

point.

Default or

Programmable

THERM

Limit

FAN_SPD/NTEXT_IN goes to full

scale (0xFF) whenever THERM

is

asserted internally or externally,

returns to previously programmed

value once THERM

is cleared.

FAN_OFF floats

high due to THERM

Figure 16. Examples of THMC50 THERM Event Behavior

temperature data format

T emperature data can be read from the remote diode temperature register or the ambient temperature register

in the value RAM (locations 0x26 and 0x27, respectively). Temperature data is represented by an 8-bit, 2s

complement word with an LSB equal to 1°C as shown in Table 2.

Table 2. T

emperature Data Format

DIGITAL OUTPUT

TEMPERATURE

BINARY HEX

125°C 0111 1101 0x7D

25°C 0001 1001 0x19

1°C 0000 0001 0x01

0°C 0000 0000 0x00

–1°C 1111 1111 0xFF

–25°C 1 110 0111 0xE7

–55°C 1100 1001 0xC9

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

diode fault status

The THMC50 provides for indications of a fault (open or short-circuited) with the remote thermal diode. Before

a remote thermal diode conversion is updated, the status of the remote thermal diode is checked for an

open-circuited or short-circuited condition. If such a fault condition occurs, a status bit is set in the status register,

and an interrupt is generated (unless masked). An open or shorted condition on the remote diode causes the

remote temperature value to read 0x80, does not have an effect on the F AN_SPD output, and does not cause

a THERM

condition.

The following table describes the THMC50 behavior under various remote diode fault conditions:

FAULT CONDITION ON

Remote_Diode+ and Remote_Diode_

REMOTE TEMPERATURE

(REGISTER 0x26)

THERM

ACTIVATED

INT

GENERATED

REMOTE DIODE DEFAULT

STATUS BITS SET

Any remote diode pin open 0x80 No

†

Yes

‡

Yes

Short between Remote_Diode± pins 0x80 No

†

Yes

‡

Yes

Remote_Diode+ short to supply 0x80 No

†

Yes

‡

Yes

Remote_Diode+ short to GND 0x80 No

†

Yes

‡

Yes

Remote_Diode– shorted to supply 0x80 No

†

Yes

‡

Yes

Remote_Diode– shorted to GND Normal operation No

§

No

§

No

†

THERM will not be asserted due to this fault, however, THERM could still activate due to a valid internal temperature THERM condition or if

THERM

is asserted externally.

‡

INT

will not be generated if the Remote diode fault is masked. A remote temperature error INT or a remote temperature error status bit will not

be generated by a faulted remote diode.

§

THERM

or INT will be asserted if the temperature in 0x26 meets the criteria for a THERM or INT event and INT is not masked.

interrupt output

All interrupts are indicated in the interrupt status register and its mirror register. The INT

output has an individual

mask register and individual masks for each interrupt. This hardware interrupt line can also be enabled/disabled

in the configuration register. When enabled, the INT

line reflects all interrupt error conditions. INT can be

generated from the following sources:

D

T emperature Interrupt: An interrupt is generated if a high or a low temperature limit has been exceeded

on either the local or remote thermal diode.

D

Remote Diode Fault Interrupt: An interrupt is generated if either a short-circuit or open-circuit fault exists

on the remote thermal diode inputs.

general-purpose input - GPI

The GPI logic input terminal allows the THMC50 SMBus host to read the logic state of this input terminal by

reading bit 4 of the interrupt status register (0x41). The logic state of the GPI terminal reported in bit 4 of the

interrupt status register (0x41) is inverted from the actual GPI logic state if bit 6 of the configuration register

(0x40) is set to a 1. If bit 6 of the configuration register (0x40) is set to a 0, then bit 4 of the interrupt status register

(0x41) reports the same logic state present on the GPI terminal. The GPI interrupt bit can be masked by setting

bit 4 of the interrupt mask register (0x43) to 1. Note that the state of GPI is not latched into bit 4; this bit simply

reflects the state or inverted state of the GPI terminal. If this bit is 1, reading this register does not clear it to 0.

interrupt clearing

Reading the interrupt status register or the interrupt status register mirror outputs the contents of the register

and resets that register only . A subsequent read done before the next conversion is complete indicates a cleared

register. Allow at least 1.5 seconds for all registers to be updated between reads. In summary, the interrupt

status register clears upon being read, and requires at least 1.5 seconds to be updated. When the interrupt

status register clears, the INT

output also clears until the registers are updated by the next conversion.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

interrupt clearing (continued)

The INT output can be cleared with the INT clear bit (bit 2 of the configuration register) without affecting the

contents of the interrupt status register.

reset generators

The THMC50 contains the equivalent of two MAX81 1 microprocessor voltage monitors for generation of system

resets. One of these functions monitors the THMC50 VCC3 terminal connected to the system’s 3.3-V main

power supply. The other function monitors the VCC3AUX terminal connected to the system’s 3.3-V auxiliary

power supply. Each function has a corresponding reset output (RST

, AUXRST) that is used by the core logic

for proper system hardware initialization.

When a particular power supply voltage falls below a threshold of 2.93V (max), the associated reset output is

asserted low for at least 140 ms after the power supply voltage has risen above the threshold (see Figure 18

and Figure 20). The reset outputs are a logic 0 for V

CC

(VCC3 or VCC3AUX) > 1 V.

The THMC50 includes a manual reset input, MR

. When asserted low (0), the RST output is asserted low. This

output remains asserted as long as the MR

input is asserted. Once MR is negated, this reset output continues

to be asserted for 180 ms (typical) (see Figure 17). The MR

input may be used by test equipment or external

logic (e.g., front bezel panel reset button) to initiate a reset independent of power supply voltage status. It is

recommended that a 0.1-µF capacitor be connected between MR

and ground if the terminal is connected to a

long lead/cable length.

Asserting the AUXRST

output causes the RST output to also be asserted regardless of the voltage level on the

VCC3 terminal. This insures that the auxiliary reset output (AUXRST

) is negated before the RST output is

negated. Once AUXRST

is negated, the RST output continues to remain asserted for 180 ms (typical) (see

Figure 19).

The AUXRST

terminal is bidirectional. It can be driven by an external device to force the THMC50 into a hard

reset condition. Insure that other devices connected to AUXRST

are not also reset, if that is an undesirable

behavior. If AUXRST

is only used as an output, then isolation is not necessary.

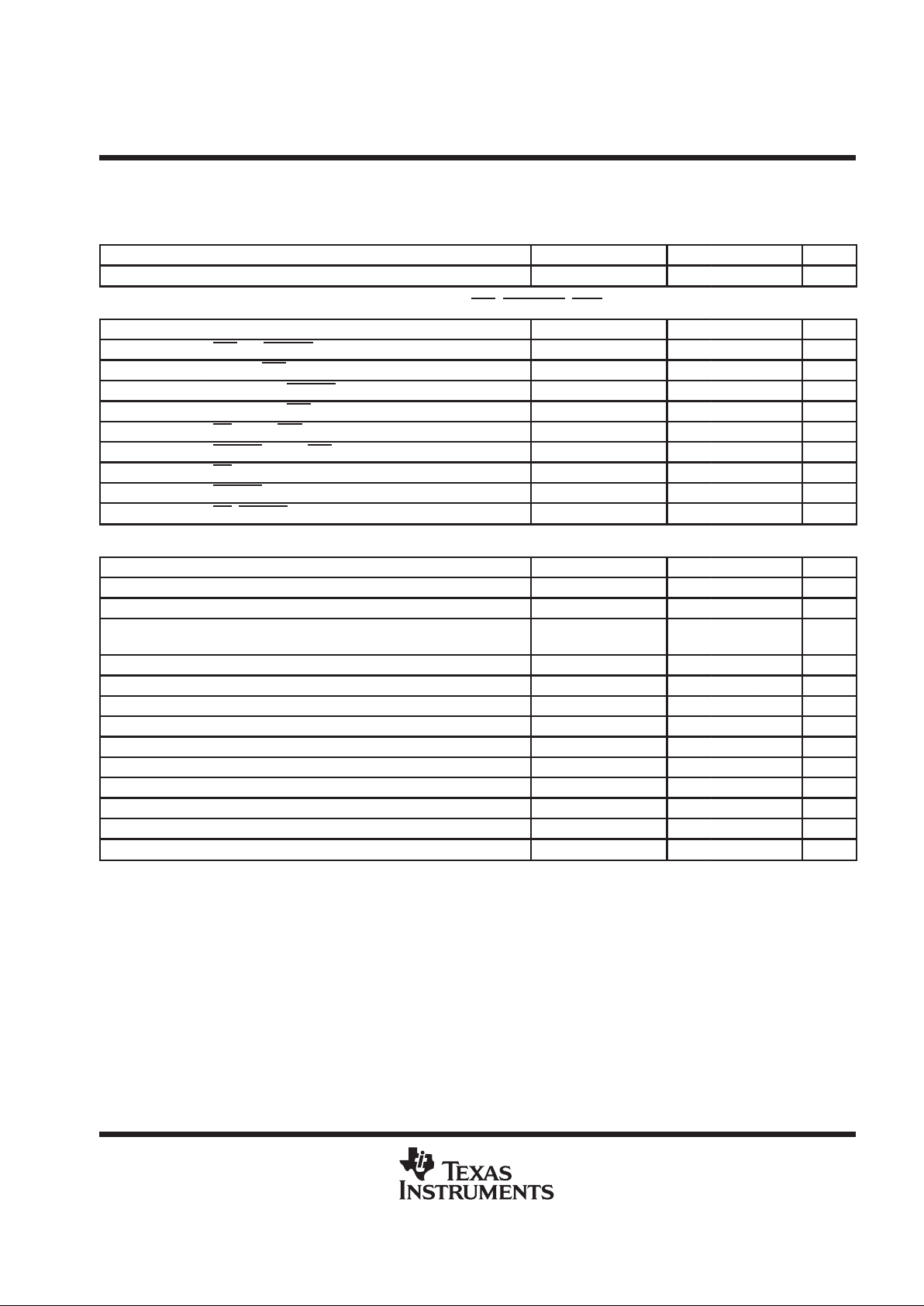

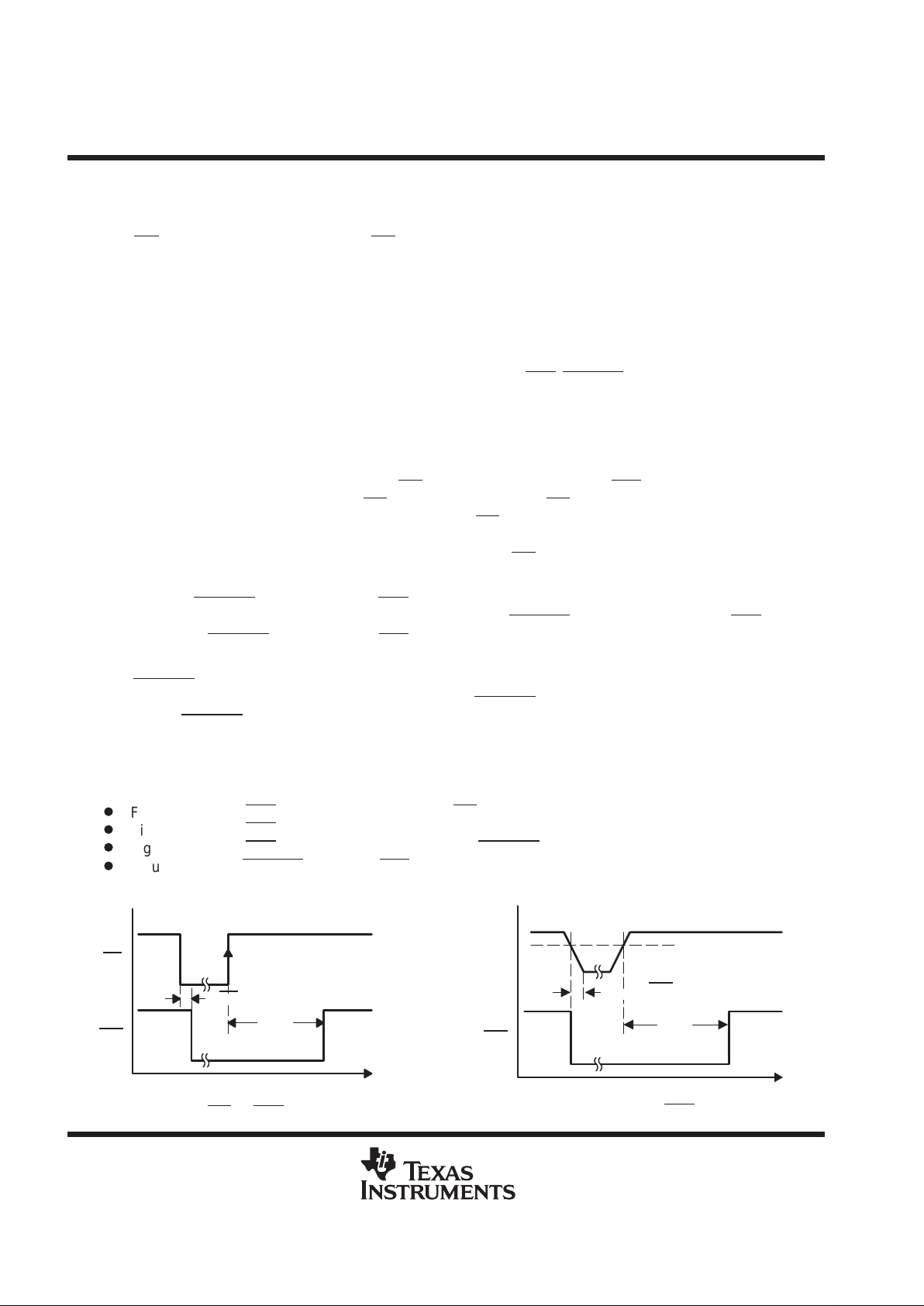

reset generators timing diagrams

Figure 17 through Figure 20 illustrate the timing relationship of the THMC50 reset generators.

D

Figure 17 shows RST output behavior when the MR input is asserted low.

D

Figure 18 shows RST output behavior according to the voltage seen at the VCC3 terminal.

D

Figure 19 shows RST output behavior whenever an AUXRST is generated or is asserted manually.

D

Figure 20 shows AUXRST output and RST output behavior according to the voltage seen at the VCC3AUX

terminal.

Figure 17. MR

to RST Timing

Figure 18. VCC3 to RST

Timing

MR

RST

TIME

t

(RP)

t

(MR)

VCC3

RST

2.93V

TIME

t

(RP)

t

(VCC3RST)

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

23

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

reset generators timing diagrams (continued)

Figure 19. AUXRST to RST Timing

Figure 20. VCC3AUX, AUXRST,

and RST Timing

RST

TIME

AUXRST

t

(RP)

t

(RST)

VCC3AUX

AUXRST

2.93V

TIME

RST

t

(RP)

t

(RP)

t

(VCC3AUX1)

t

(VCC3AUX2)

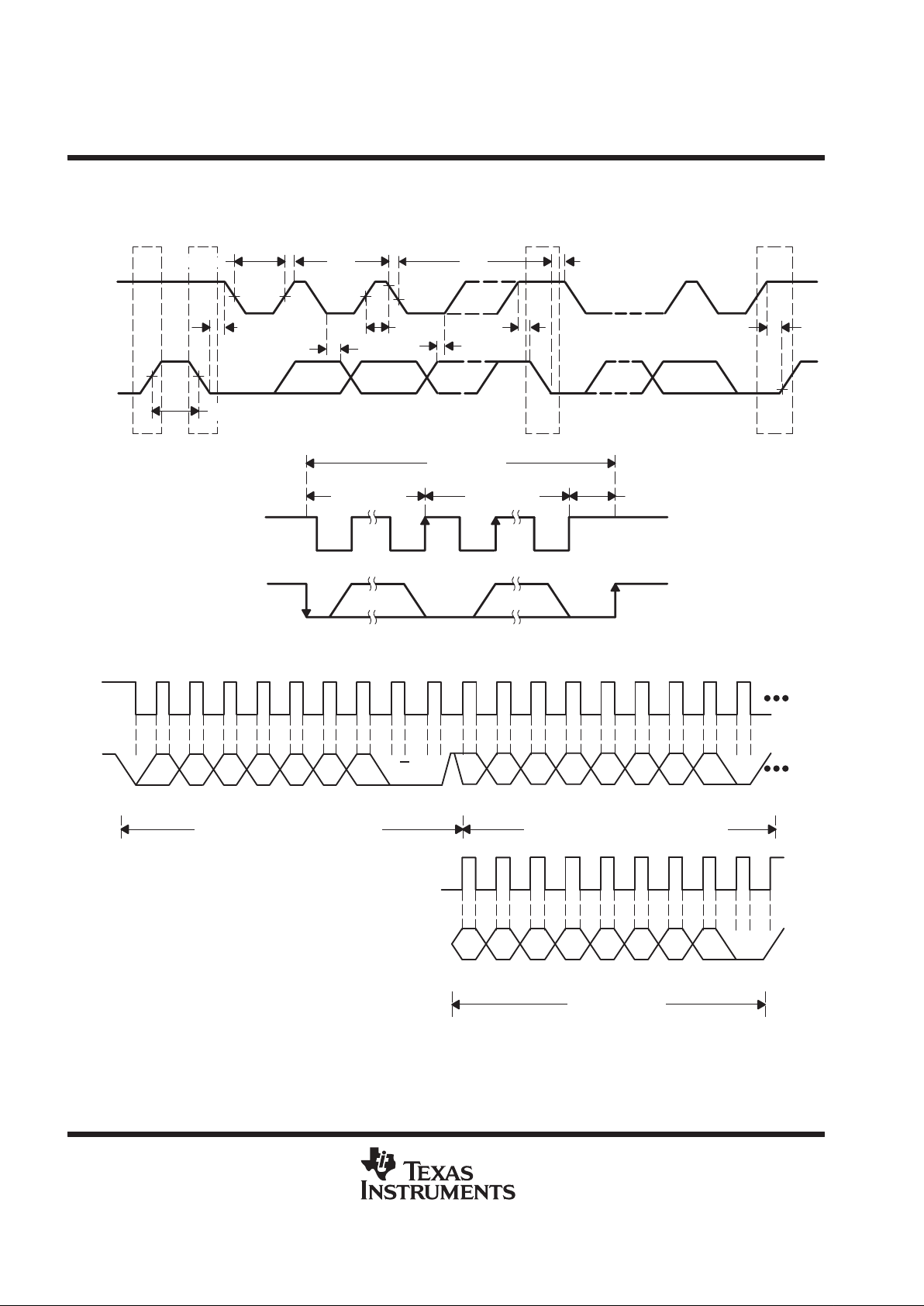

NAND tree tests - FAN_SPD/NTEST_IN and ADD/NTEST_OUT

A NAND tree is provided in the THMC50 for automated test equipment (A TE) board level connectivity testing.

If a logic 1 is applied to the FAN_SPD/NTEST_IN input terminal during initial power up, the device is in the NAND

tree test mode and the ADD/NTEST_OUT terminal becomes the NAND tree output. Power must be removed

from the device in order to return to normal operation. To perform a NAND tree test, MR

, SDA, SCL, and GPI

terminals should be initially driven low, and FAN_SPD/NTEST_IN initially driven high. Starting with MR

and

ending with GPI, each input should be toggled high and left high. This results in ADD/NTEST_OUT reflecting

the following pattern: (1 –> 0 –> 1 –> 0 –> 1) (see Figure 21).

Allow for a typical propagation delay of 500 ns.

GPI

SCL

SDA

MR

ADD/NTEST_OUT

D

Q

AUXRST

FAN_SPD/NTEST_IN

ENABLE

ENABLE

GPI

SCL SDA MR ADD/NTEST_OUT

0 0 0 0 1

0 0 0 1 0

0 0 1 1 1

0 1 1 1 0

1 1 1 1 1

Figure 21. NAND Tree Test Equivalent Circuit

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

NAND tree tests - FAN_SPD/NTEST_IN and ADD/NTEST_OUT (continued)

NOTE:

To properly implement the NAND tree test on the PCB, no terminals listed in the tree should be

connected directly to power or ground. If it is necessary to permanently connect a terminal to

ground, such as an address terminal, it should be connected to ground through a low value resistor,

such as 3.3 kΩ, to allow the system-level ATE to drive it high. All terminals listed in the NAND tree

which need to be permanently tied high should be pulled up to the supply via a resistor to allow the

ATE to drive the node low during the NAND tree test.

registers and RAM

REGISTERS AND RAM A7 - A0 IN HEX POWER ON VALUE OF REGISTERS: <7:0> IN BINARY

Configuration register 0x40 0010 0101

Interrupt status register 0x41 0000 0000

Interrupt mask register 0x43 0000 0000

Interrupt status register mirror 0x4C 0000 0000

Value RAM 0x13 – 0x3D, 0x43 – 0x4A See value RAM section for complete description

Company ID 0x3E Contains company number

Stepping 0x3F Contains stepping number and device version

register 0x40 configuration register

BIT NAME R/W DESCRIPTION

0 Start Read/write Setting this bit to a 1 enables start-up of the THMC50; clearing this bit to 0 places the THMC50 in

standby mode.

Caution: The INT output is not cleared if this bit was cleared after an interrupt has occurred (see INT

clear bit).

At start-up, temperature monitoring and limit checking functions begin. Note: All limit values should

be programmed into the THMC50 prior to using the standard thermal interrupt mechanism based

upon high and low limits. (power-up default=1)

1 INT enable Read/write Setting this bit to a 1 enables the INT output. 1=enabled 0=disabled (power-up default = 0)

2 INT clear Read/Write This bit clears the INT output when set (1) without affecting the contents of the interrupt status

register. (power-up default = 1)

3 Programmable

automatic trip

point control

register write

once bit

Read/write

once

Setting this bit to a 1 locks in the values set into the programmable remote thermal diode automatic

trip point and programmable ambient temperature automatic trip point (value RAM locations 0x14

and 0x13). Furthermore when this bit is set, the values in the default remote thermal diode

automatic trip point and default ambient temperature automatic trip point (value RAM locations

0x18 and 0x17) no longer have an effect on the THERM

, FAN_SPD, or FAN_OFF outputs. This

register is unable to be written again until AUXRST

is asserted. (power-up default = 0)

4 Soft reset Read/write Setting this bit to a 1 restores power-up default values to the configuration register , interrupt status

register, interrupt status register mirror, and interrupt mask register. This bit automatically clears

itself since the power-on default is zero.

5 FAN_OFF Read/write Setting this bit to a 1 causes the FAN_OFF terminal to be floated. Clearing this bit to 0 causes the

FAN_OFF

terminal to be driven low which requests that the fan be turned off. This bit is

unconditionally set if the THERM

terminal is ever asserted. Reading this bit reflects the state of the

FAN_OFF

output buffer. Due to the open drain nature of this terminal, the value read does not

represent the actual state of the external net connected to it. (power-up default =1)

6 GPI invert Read/write Setting this bit to a 1 inverts the GPI input for the purpose of level detection and interrupt generation.

Clearing this bit to 0 leaves the GPI input unmodified. (power-up default=0)

7 Reserved Read/write Reserved (default = 0)

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

25

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

register 0x41 interrupt status register

power-on default <7:0> = 00h

BIT NAME READ/WRITE DESCRIPTION

0 Ambient temperature error Read only A 1 indicates one of the ambient temperature limits has been exceeded.

1 Reserved Read only Undefined (reserved for remote thermal diode 2 temperature error)

2 Reserved Read only Undefined (reserved for remote thermal diode 2 fault)

3 Reserved Read only Undefined

4 GPI input Read only A 1 indicates that the GPI terminal is asserted. The polarity of the GPI terminal is

determined by GPI invert (bit 6) in the configuration register. For example, if GPI invert is

cleared, then this bit is 1 when the GPI terminal is high (1); this bit is 0 when the GPI

terminal is low (0). If GPI invert is set, then this bit is 1 when the GPI terminal is low (0); this

bit is 0 when the GPI terminal is high (1). Note: The state of GPI is not latched; this bit

simply reflects the state or inverted state of the GPI terminal. If this bit is 1, reading this

register does not clear it to 0.

5 Remote temperature error Read only A 1 indicates one of the remote thermal diode limits has been exceeded.

6 THERM input Read only A 1 indicates that the thermal overload (THERM) line has been asserted externally.

7 Remote diode fault Read only A 1 indicates either a short or open circuited fault on the remote thermal diode inputs.

NOTE: An error that causes continuous interrupts to be generated may be masked in its respective mask register, until the error can be alleviated.

register 0x43 interrupt mask register

power-on default <7:0> = 00h

BIT NAME READ/WRITE DESCRIPTION

0 Ambient temperature error Read/write A 1 disables the corresponding interrupt status bit for the INT output.

1 Reserved Read only Undefined (reserved for remote thermal diode 2 temperature error)

2 Reserved Read only Undefined (reserved for remote thermal diode 2 fault)

3 Reserved Read only Undefined

4 GPI input Read/write A 1 disables the corresponding interrupt status bit for the INT output.

5 Remote temperature error Read/write A 1 disables the corresponding interrupt status bit for the INT output.

6 THERM input Read/write A 1 disables the corresponding interrupt status bit for the INT output.

7 Remote diode fault Read/write A 1 disables the corresponding interrupt status bit for the INT output.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

register 0x4C interrupt status register 1 mirror

power-on default <7:0> = 00h

BIT NAME READ/WRITE DESCRIPTION

0 Ambient temperature error Read only A 1 indicates one of the ambient temperature limits has been exceeded.

1 Reserved Read only Undefined (reserved for remote thermal diode 2 temperature error)

2 Reserved Read only Undefined (reserved for remote thermal diode 2 fault)

3 Reserved Read only Undefined

4 GPI input Read only A 1 indicates that the GPI terminal is asserted. The polarity of the GPI terminal is

determined by GPI invert (bit 6) in the configuration register. For example, if GPI invert is

cleared, then this bit is 1 when the GPI terminal is high (1); this bit is 0 when the GPI

terminal is low (0). If GPI invert is set, then this bit is 1 when the GPI terminal is low (0); this

bit is 0 when the GPI terminal is high (1). Note: The state of GPI is not latched; this bit

simply reflects the state or inverted state of the GPI terminal. If this bit is 1, reading this

register does not clear it to 0.

5 Remote temperature error Read only A 1 indicates one of the remote thermal diode limits has been exceeded.

6 THERM input Read only A 1 indicates that the thermal overload (THERM) line has been asserted externally.

7 Remote diode fault Read only A 1 indicates either a short or open circuited fault on the remote thermal diode inputs.

register 0x13 - 0x4A value RAM

power-on default are undefined unless stated otherwise

ADDRESS READ/WRITE DESCRIPTION

0x13 Read/write Programmable ambient temperature automatic trip point ≥ default 70°C. This register can only be written if the

write-once bit in the configuration register (0x40, bit 3) has not been set.

0x14 Read/write Programmable remote thermal diode automatic trip point ≥ default 100°C. This register can only be written if the

write-once bit in the configuration register (0x40, bit 3) has not been set.

0x15 Read/write Manufacturer’s test register

0x17 Read only Default ambient temperature automatic trip point ≥ 70° C

0x18 Read only Default remote thermal diode automatic trip point ≥ 100°C

0x19 Read/write Analog output (defaults to 0x00)

0x20 N/A Reserved (for future second remote thermal diode temperature)

0x26 Read only Remote thermal diode temperature

0x27 Read only Ambient temperature

0x2B N/A Reserved (for future second remote thermal diode high limit)

0x2C N/A Reserved (for future second remote thermal diode low limit)

0x37 Read/write Remote thermal diode high limit

0x38 Read/write Remote thermal diode low limit

0x39 Read/write Ambient temperature high limit

0x3A Read/write Ambient temperature low limit

0x3E Read only Company ID number (0x49)

0x3F Read only Stepping ID number and THMC50 version number

0x44 Read/write For manufacturer’s test use (reads or writes have unpredictable results)

0x47 Read/write For manufacturer’s test use (reads or writes have unpredictable results)

0x4A Read/write For manufacturer’s test use (reads or writes have unpredictable results)

NOTE: All unspecified locations are considered as reserved and should not be accessed. Unpredictable results may occur.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

27

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

manufacturer’s test register - address 0x15

This register should only be used by Texas Instruments for testing. Reading or writing to this register during

normal use leads to erroneous events or measurements.

analog output - address 0x19

This register latches an 8-bit value into an R-2R D/A to provide a range of 0 V–2.5 V , accuracy can be ±5% or

more.

company ID - address 0x3E

This location contains the company identification number for TI – 0x49. This register is read only.

stepping - address 0x3F

This location contains the stepping number of the part in the lower four bits of the register [3:0]. The upper four

bits reflect the THMC50 version number [7:4]. The first version is 1 100. The next version of the THMC50 would

be 1 101, etc. For example, if the stepping were A0 and this part is a THMC50-1, then this register would read

1100 0000. This register is read only.

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

ESD protection structures (example method to be used as reference only)

To Internal Circuitry

D1

D2

D3

Analog/Digital Inputs

V+

GND

NOTE:

Diodes are forward biased when the forward voltage exceeds 50 mV.

TERMINAL NAME D1 D2 D3

FAN_OFF X X

MR X X

AUXRST X X

VCC3 X

RST X X

FAN_SPD/NTEST_IN X

SDA X X

SCL X

INT X X X

ADD/NTEST_OUT X X X

GPI X

THERM X X

REMOTE_DIODE+ X

REMOTE_DIODE– X

X - Diode exists

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

29

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Ambient

Temperature Error

GPI Input

Remote

Temperature Error

Remote Diode

Fault

INT

Enable

INT

Clear

THERM

INT

THERM Error

6

Ambient

Temperature Error

GPI Input

Remote

Temperature Error

Remote Diode

Fault

THERM

Error

THERM Input

THERM

6

Soft Reset

Soft Reset

Soft Reset

FAN_OFF

GPI Invert

GPI Invert

GPI Invert

0x41

Interrupt

Status

Register

0

4

5

6

7

Cleared on Power Up

After Register is

Read

or Soft Reset = 1

0x4C

Interrupt

Status

Register 1

Mirror

0

4

5

6

7

Cleared on Power Up

After Register is

Read

or Soft Reset = 1

0

4

5

6

7

0

4

5

6

7

0x43

Interrupt

Mask

Register

Cleared on Power Up

or Soft Reset = 1

Status Bit

Mask Bit

0x40

Configuration

12

4

5

6

on Power Up

or Soft Reset = 1

THERM Error

THERM

(Non-Maskable)

Register

Reset to Default Values

66

Figure 22. Interrupt Structure

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Embedded

Controller

With

SMBus

THMC50

VCC3AUX

VCC3AUX

C1

C2

R6

VCC3AUX

AUXRST

VCC3 R7

RST

MR

GPI

R8

THERM

VCC3AUX

R9

INT

VCC3AUX

R10

SCL

VCC3AUX R11

SDA

ADD/NTEST_OUT

VCC3AUX

GND

13 4

9

10

16

15

14

11

12

2

7

3

56

8

1

FAN_OFF

FAN_SPD/NTEST_IN

VCC3

C3

C4

+12V +12V

LM324

+5 V

R3

Q1

2N2219A

R1

R2

MMFT3055EL

M1

REMOTE_DIODE+

REMOTE_DIODE–

B14

B15

C5

2200 pF

R4 R5

VCC3

Pentium

Intel

10 kΩ

10 kΩ

0.1 µF

10 µF

0.1 µF

10 µF

10 kΩ

10 kΩ

36 kΩ

10 kΩ

10 kΩ

10 kΩ

10 kΩ

300 kΩ

10 kΩ

_

+

Figure 23. Typical Application Schematic

THMC50

REMOTE/LOCAL TEMPERATURE MONITOR AND

FAN CONTROLLER WITH SMBus INTERFACE

SLIS090 – JUL Y 1999

31

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

DBQ (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

Gage Plane

0.008 (0,20) NOM

0.010 (0,25)

0.016 (0,40)

0.035 (0,89)

2420

Seating Plane

(8,74)

(8,56)

0.3370.337

(8,56)

(8,74)

0.344 0.344

4073301/D 08/98

13

0.150 (3,81)

0.157 (3,99)

0.012 (0,30)

0.008 (0,20)

12

A

24–PIN SHOWN

1

24

16

DIM

PINS **

A MIN

A MAX

0.004 (0,10)

0.010 (0,25)

0.069 (1,75) MAX

0.244 (6,20)

0.228 (5,80)

0.197

(5,00)

(4,78)

0.188

0.004 (0,10)

M

0.005 (0,13)

0.025 (0,64)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0.006 (0,15).

D. Falls within JEDEC MO-137

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER