THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

DC Fan Drive Speed Control With No

External Power Drive Stage Required

D

11% to 100% PWM Range Adjustable Via

0–2.5 V DC Control Voltage – Suited for

Cooling Fan Applications Requiring

Variable RPM to Reduce Noise and/or

Increase MTBF

D

Speed Control Capability With Either DC or

PWM Input Signal for Greater System-Level

Flexibility

D

Sleep-State Mode to Eliminate External Fan

ON/OFF Power Device – Suited for Cooling

Fans

in Instantly Available

PCs

D

Thermal Shutdown Protection

D

High Impedance V

PWM

Input for Speed

Control of Multiple Fans With a Single

Signal

D

Locked Rotor Protection (THMC40,

THMC41) With Open-Drain Output

Indication (THMC41)

D

Open-Drain Tachometer Signal Valid Over

Entire RPM Range (THMC40)

D

Noise Immune Signal Conditioning to Allow

Use of Low-Cost Hall Effect Position

Sensor

D

Patented High Efficiency Drive Topology

With Integrated Low R

DS(ON)

LDMOS

Output Drivers

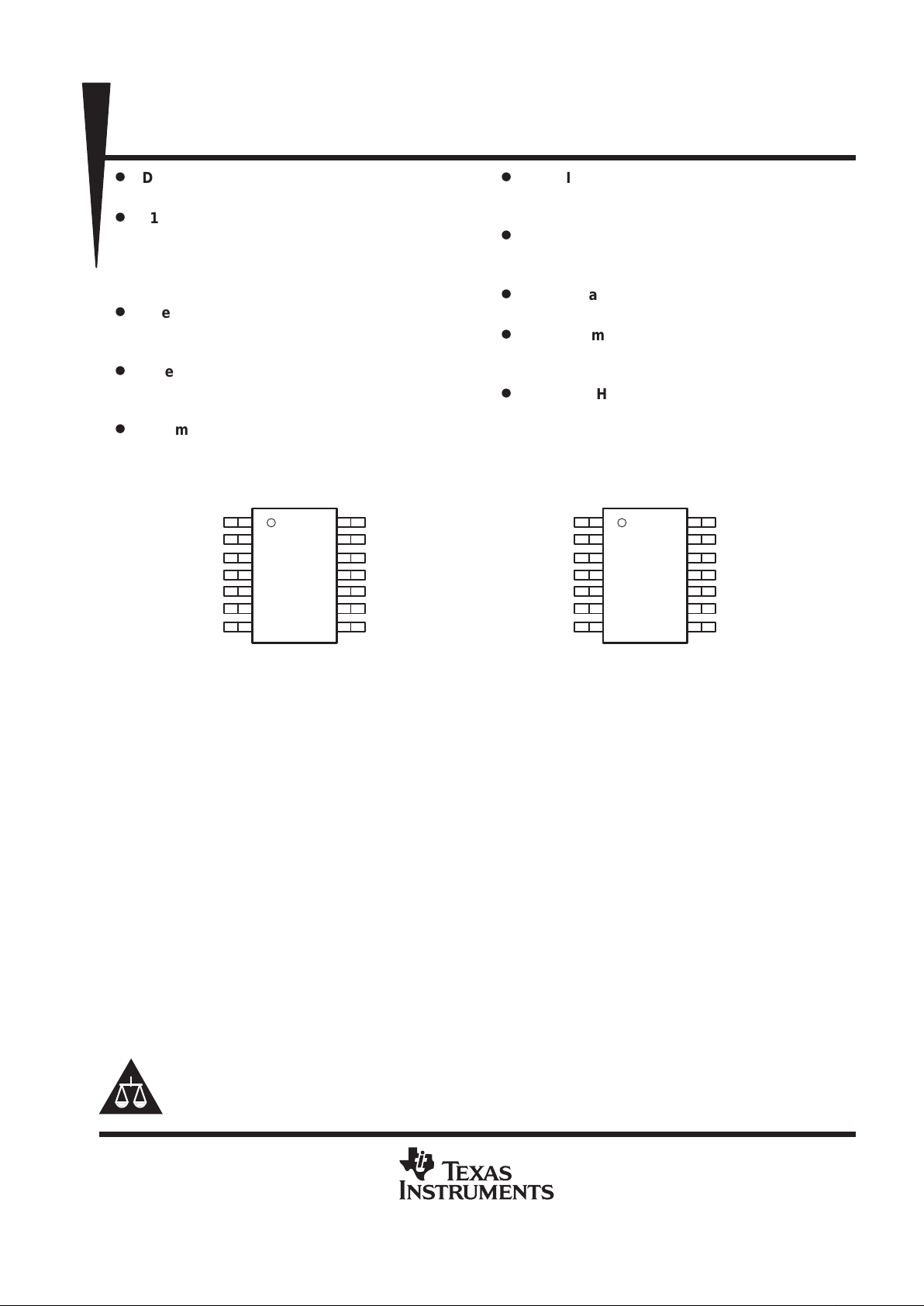

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

OSC

TACH

CP

V

PWR

V

OUT

NC

PGND

V

PWM

H+

H–

PHA

PHB

AGND

NC

THMC40 ...TACH OUTPUT

14-Pin SOP D Package

(TOP VIEW)

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

OSC

RD

CP

V

PWR

V

OUT

NC

PGND

V

PWM

H+

H–

PHA

PHB

AGND

NC

THMC41 . . . RD OUTPUT

14-Pin SOP D Package

(TOP VIEW)

description

The THMC40 and THMC41 are 2-phase, dc brushless motor (BLM) drive and control devices intended for use

with 12-Vdc cooling fans. Both devices include a high-efficiency PWM drive topology using integrated 0.5-Ω

(typical) LDMOS drivers, plus a speed control input stage to provide the industry’s first solution for efficient

speed control

inside

dc cooling fans. This patented solution eliminates the need for power drive components

on the main system board, thus reducing printed-circuit board (PCB) component count, PCB space, and

assembly time. This solution also offers other advantages over the two commonly used fan speed control

methods, adjustable external dc supply voltage, and adjustable external PWM drive duty cycle.

Unlike other methods which control speed external to the cooling fan, the THMC40 and THMC41 high-efficiency

PWM drive stage adjusts only the level of motor phase winding power. All other circuitry inside the fan obtains

power from the fixed dc voltage fan supply. This method eliminates the typical problem associated with an

external dc voltage regulation method causing loss of headroom to internal control circuitry at low fan supply

voltage and the resulting limitation of low-speed operation to ≈40%. The PWM drive method employed by the

THMC40 and THMC41 also reduces fan supply power consumption over the external linear regulation method,

which has V×I power loss due to the voltage drop across the regulator.

An external PWM drive method disrupts power to the motor and also to all internal fan circuitry . The THM40 and

THMC41 solution maintains all signal integrity with phase drive commutation and tachometer, while providing

reliable low speed fan operation down to 1 1% PWM. This method allows fan health monitoring over the full fan

speed range.

Copyright 2000, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

description (continued)

The V

OUT

duty cycle, and thus the motor speed, is proportional to the voltage present at the V

PWM

input terminal.

This terminal allows controlling the fan speed via a DAC output from an external control IC or an RC-filtered

PWM output from a PC Super I/O chip.

The THMC40 and THMC41 have an internal Hall sensor amplifier and signal conditioner, global thermal

shutdown, locked rotor protection, and automatic restart after a locked rotor condition. The THMC40 provides

an open-drain tachometer output signal, while the THMC41 provides an open-drain locked rotor detection

output signal. These devices also provide a sleep-state mode to eliminate the need for an external power

component to disconnect the fan from the supply during a system sleep state or

instantly available

power down.

The THMC40 and THMC41 are primarily intended for cooling fan applications that require RPM speed control

and the availability of a tachometer or locked rotor detection signal.

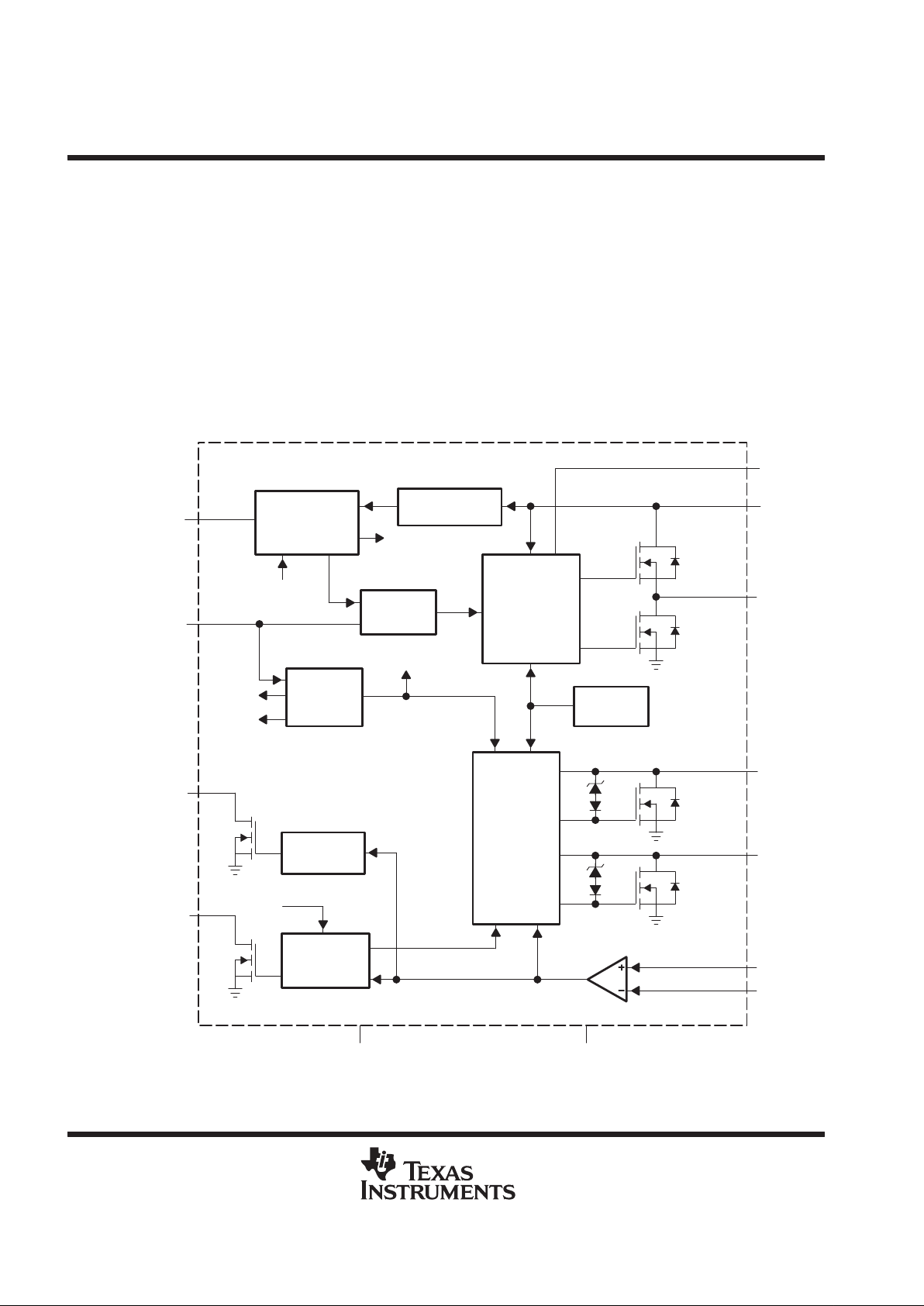

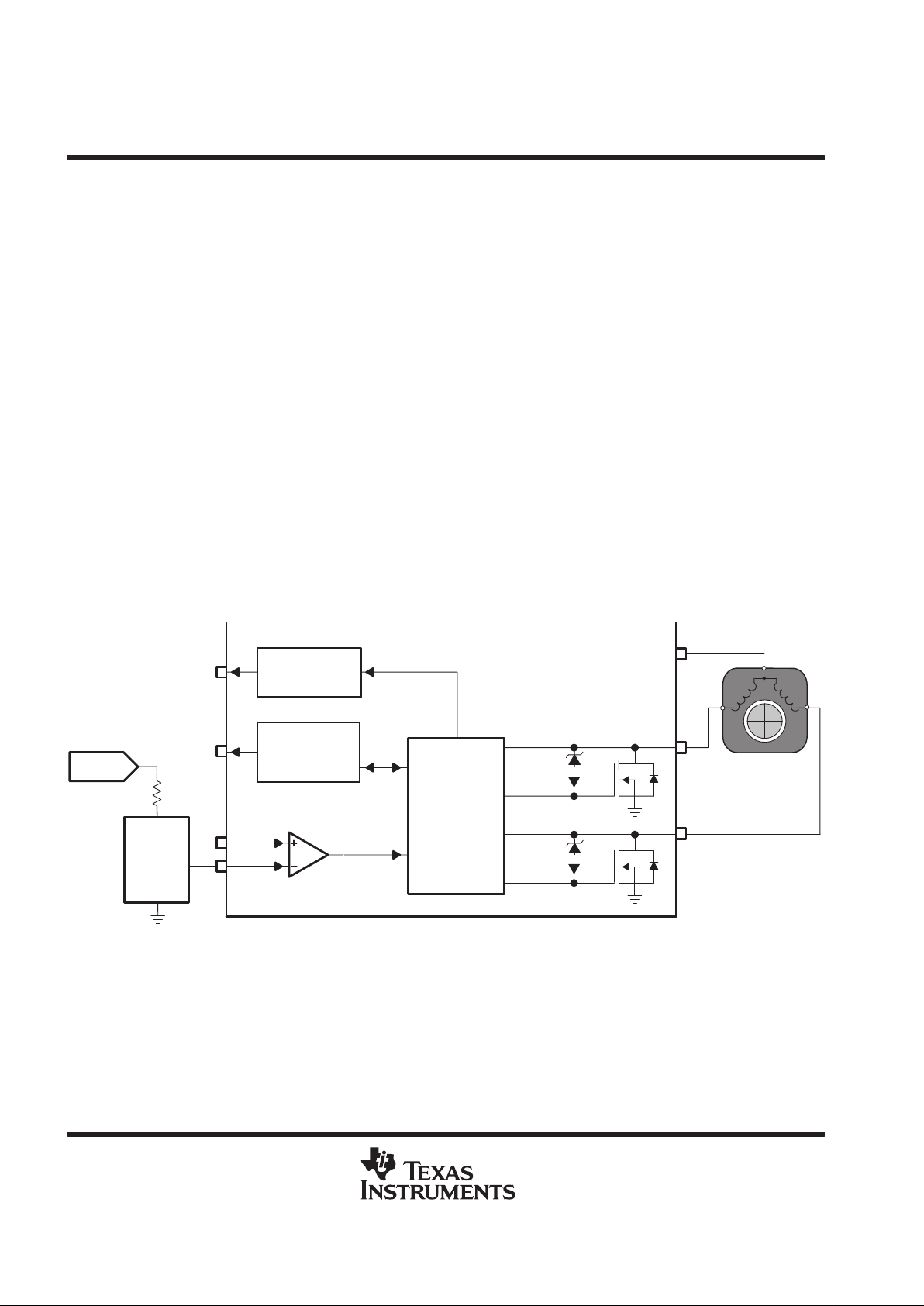

functional block diagram

Tachometer

Output

CP

V

PWM

Low-Side

Gate Drive

Control Logic

and Global

Thermal

Shutdown

High-Side Gate

Drive With

Synchronous

Rectification

Charge Pump

Locked Rotor

Detection and

Auto Restart

SLEEP

START and

SLEEP

Detection

PWM

Generator

PWM

Oscillator

23 kHz Nominal

PUC and V

REF

Thermal

Shutdown

OSC

V

START

V

SLEEP

OSC

PWM

SLEEP

C

OSC

TACH

(THMC40)

RD

(THMC41)

V

PWR

V

OUT

PHA

PHB

H+

H–

PGNDAGND

Hall Sensor

Comparator

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

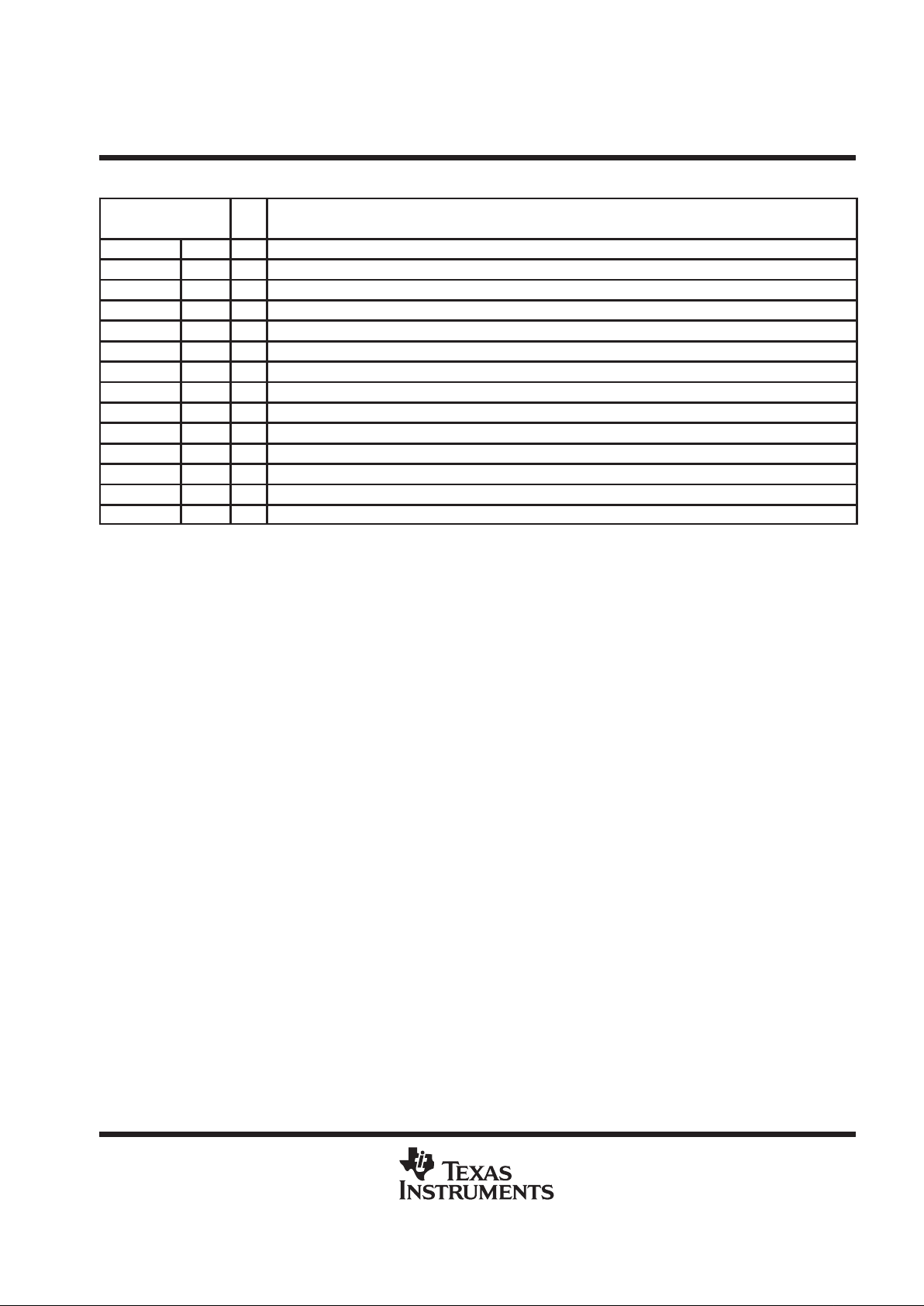

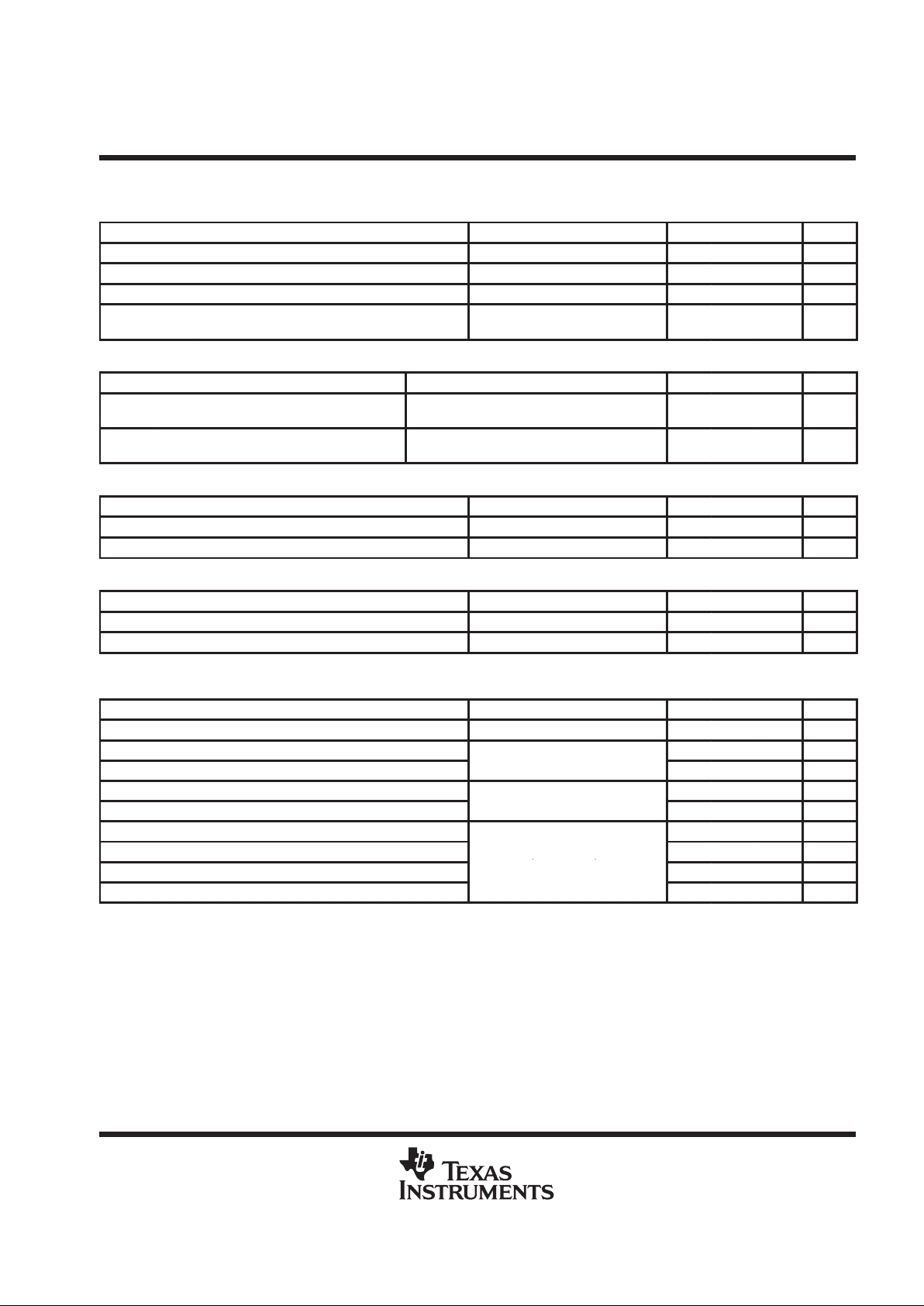

Terminal Functions

TERMINAL

NAME NO.

I/O

DESCRIPTION

AGND 9 I IC analog ground and substrate connection

CP 3 I External charge pump capacitor

C

OSC

1 I/O External oscillator capacitor

H– 12 I Hall sensor negative input

H+ 13 I Hall sensor positive input

NC 6, 8 – No connection

PGND 7 I Power ground for high-side charge pump

PHA 11 O Low-side driver for phase A motor winding

PHB 10 O Low-side driver for phase B motor winding

RD 2 O Open-drain locked rotor detection output—THMC41 only

TACH 2 O Open-drain tachometer output signal—THMC40 only

V

OUT

5 O High-side PWM driver output for motor windings

V

PWR

4 I Supply voltage input

V

PWM

14 I PWM duty cycle control voltage input

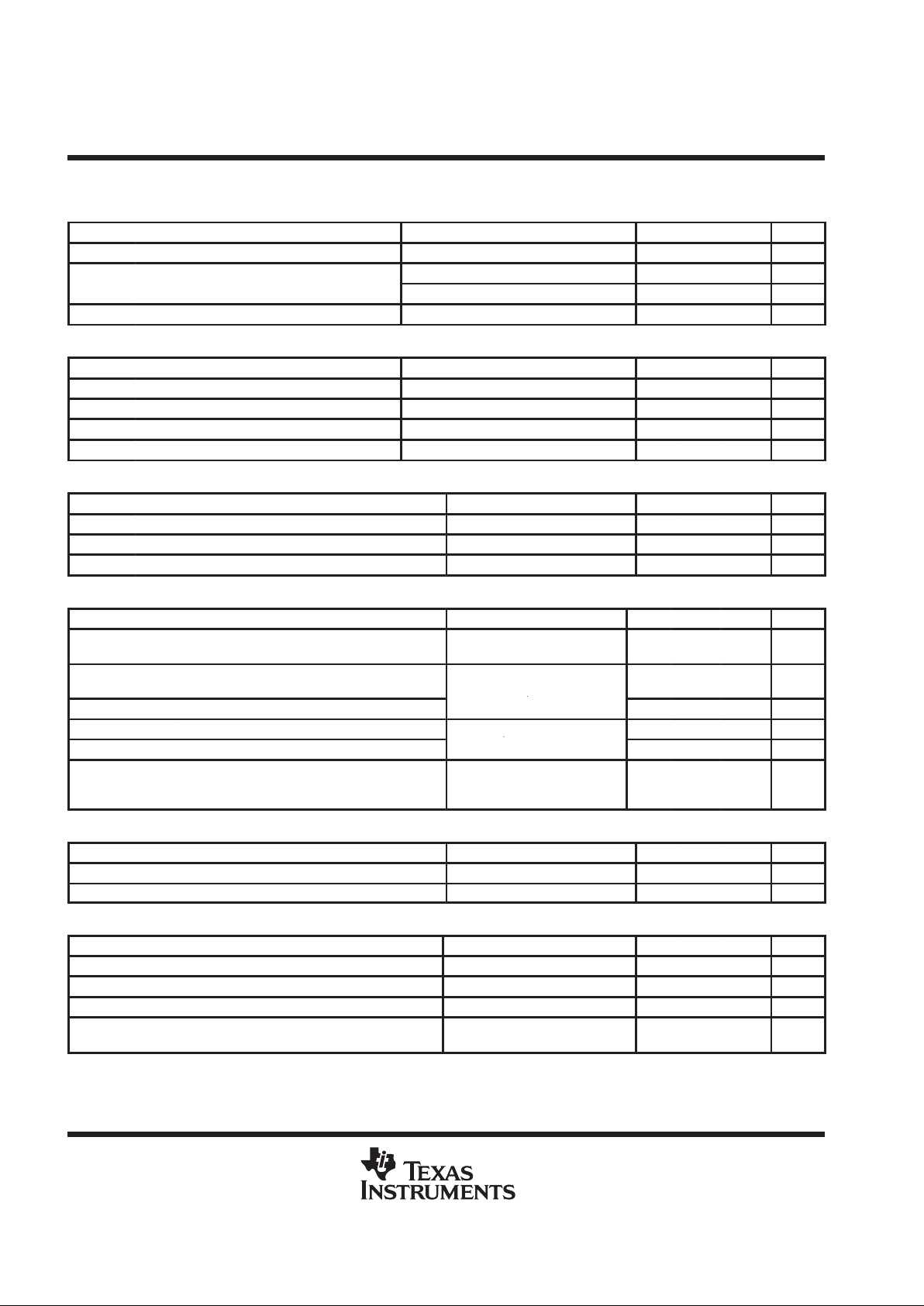

absolute maximum ratings over operating case temperature range (unless otherwise noted)

†

(see Note 1)

Supply voltage input, V

PWR

18 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High-side driver, PWM output voltage, V

OUT

18 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low-side drivers, phase A and B output, V

PHA

, V

PHB

40 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hall sensor amplifier input voltage, V

H+

, VH– 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWM duty cycle control input voltage, V

PWM

7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open-drain tachometer output voltage (THMC40), V

TACH

, or open-drain RD output voltage

(THMC41), VRD 7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oscillator capacitor voltage, V

COSC

7 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charge pump capacitor voltage, VCP 30 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous high-side PWM output source/sink current, I

OUT

1.5 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous low-side PWM output sink current, I

PHA

, I

PHB

1.5 A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction-to-case thermal resistance, R

θJC

26.9°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Junction-to-ambient thermal resistance , R

θJA

(see Note 2) 122.3°C/W. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous power dissipation at 25°C , P

D

(see Note 3) 1022 mW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power derating factor above 25°C ambient , P

DERA TING

(see Note 4) 8.18 mW/°C. . . . . . . . . . . . . . . . . . . . .

Operating case temperature range, TC –30°C to 80°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range, T

stg

–55°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum junction temperature, T

J

150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature (soldering, 10 sec), T

LEAD

300°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values are with respect to GND.

2. JEDEC low-K board with 0 LFM airflow

3. 150°C maximum junction temperature, JEDEC low-K board with 0 LFM airflow

4. 80°C maximum ambient and 150°C maximum junction temperature

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

dc electrical characteristics, V

PWR

= 12 V, TA = – 30°C to 80°C (unless otherwise noted)

supply current

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

PWR

Supply voltage range 11 12 13 V

pp

Idle condition in locked rotor detect 2.5 5 mA

I

VPWR

V

PWR

su

pply current

I

LOAD

= –1 A, V

OUT

low, TA = 25°C 5 mA

I

SLEEP

Sleep-state current V

PWM

≤ 0.4 V 300 400 µA

PHA, PHB low-side phase winding driver outputs

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

LEAK

PHA,PHB output leakage current Output = OFF, V

PHx

= 12 V 0.1 10 µA

V

OL

PHA, PHB low-level output voltage Output = ON, I

PHx

= 1 A, TA = 25°C 0.5 0.6 V

R

DS(ON)

PHA, PHB output ON resistance Output = ON, I

PHx

= 1A, TA = 25°C 0.5 0.6 Ω

V

CLAMP

PHA, PHB output active clamp voltage Output = OFF, I

PHx

= 200 mA 32 38 V

Hall sensor signal conditioning

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

IB(HL)

Hall input bias current ±0.1 ±1 µA

V

ICR(HL)

ICR(HL) common-mode input voltage range 1 3.5 V

V

IO

Hall comparator input offset voltage Over V

ICR(HL)

= 1 V to 3.5 V –7 0 7 mV

V

OUT

high-side phase winding driver output

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

LEAK

V

OUT

output sleep-state leakage current

Sleep state engaged,

V

VOUT

= 0 V to V

PWR

±0.1 ±10 µA

V

OH

V

OUT

high-level output voltage

Run state, Output high

I

= –1 A, T

= 25°C

V

PWR

– 0.4

V

PWR

– 0.6

V

R

DS(ON)

V

OUT

output high-side resistance to V

PWR

VOUT

,

A

0.4 0.6 Ω

V

RECIR

V

OUT

output recirculation voltage

Run state, Output low

– 0.3 – 0.5 V

R

DS(ON)(SYNC)VOUT

synchronous switch resistance to PGND

,

I

VOUT

= –1 A, TA = 25°C

0.3 0.5 Ω

I

LIMIT

Pulsed V

OUT

synchronous rectification current

limit

Run state, V

OUT=VPWR

=12V,

V

COSC

> V

PWM,

t

PULSE

= 100 µs, See Note 5

2 2.6 A

CP high-side gate drive charge pump capacitor input

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

V

CP

Charge pump voltage I

VCP

= –60 µA, V

PWM

= 2.5 V 22 26 V

V

CP(UVLO)VCP

undervoltage lock-out 6.5 7.6 8.5 V

C

OSC

external oscillator capacitor

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

CHARGE

C

OSC

charge source current V

COSC

= 1.4 V, Charge mode –130 –180 –230 µA

I

DISCHARGECOSC

discharge sink current V

COSC

= 1.4 V, Discharge mode 130 180 230 µA

V

DISCHARGECOSC

upper threshold for switching to current sink 2 2.3 2.6 V

V

CHARGE

C

OSC

lower threshold for switching to current

source

0.43 0.5 0.57 V

NOTE 5: V

OUT

current limit, in conjunction with thermal shutdown function, provides device survivability under V

OUT

-to-V

PWR

short condition.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

dc electrical characteristics, V

PWR

= 12 V , TA = –30°C to 80°C (unless otherwise noted) (continued)

V

PWM

high-side PWM duty cycle adjust input

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

IB(PWM)

V

PWM

input bias current V

PWM

= 0 V to 3 V ±1 µA

V

PWM

(100%) V

PWM

voltage equivalent to 100% duty cycle 2.3 V

V

SLEEP

V

PWM

voltage threshold to engage sleep mode 0.6 0.7 V

V

START

V

PWM

voltage threshold to disengage sleep

mode

0.8 0.9 V

thermal shutdown characteristics

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

T

TSD

V

OUT

, PHA, PHB global thermal shutdown

thresholds

Temperature increasing until outputs are off,

See Note 6

150 185 °C

T

HYST

Thermal shutdown hysteresis

After T

TSD

, temperature decreasing until out-

puts return to normal operation, See Note 6

15 °C

TACH Tachometer open-drain output (THMC40)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

TACHLEAK

TACH high-level output leakage current V

TACH

= 5 V 0.1 1 µA

V

OL

TACH low-level output voltage I

TACH

= 5 mA 0.1 0.3 V

RD locked rotor detection open-drain output (THMC41)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

I

RDLEAK

RD high-level output leakage current VRD = 5 V, Locked rotor condition 0.1 1 µA

V

OL

RD low-level output voltage IRD = 5 mA, No locked rotor 0.1 0.3 V

ac electrical characteristics, V

PWR

= 12 V, TA = –30°C to 80°C (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

f

PWM

High-side gate drive PWM frequency C

OSC

= 2200 pF 22.7 kHz

t

RD

Locked rotor detect delay time

p

1 s

t

RETRY

Auto-restart delay time

C

OSC

=

2200 pF, See Figure 9

8 s

t

HALL

Hall zero-crossing deglitch time

25 µs

t

DEAD(PHx)

Dead time between phase commutations

See Figure 2

5 µs

t

f(OUT)

V

OUT

output fall time 25 ns

t

r(OUT)

V

OUT

output rise time

R

= 20 Ω , L

= 5 mH,

25 ns

t

f(PHx)

PHA or PHB fall time

L

,

L

,

See Note 6

1 µs

t

r(PHx)

PHA or PHB rise time 1 µs

NOTE 6: Design targets only. Not tested in production.

THMC40, THMC41

VARIABLE SPEED 12-VDC BRUSHLESS FAN MOTOR DRIVERS

SLIS097 – MARCH 2000

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PRINCIPLES OF OPERATION

general overview

The THMC40 and THMC41 are 2-phase dc brushless fan motor drivers with PWM speed control intended

primarily for applications requiring a wide speed control range and an open-drain tachometer output signal

(THMC40), or a locked rotor detection output (THMC41). The V

OUT

drive duty cycle, and thus fan speed, is

proportional to the voltage level at the V

PWM

input terminal. Each device has an internal Hall sensor

comparator/signal conditioner, a low power sleep-state mode, locked rotor protection with automatic restart

after a locked rotor condition, and over-temperature protection. The tachometer signal (THMC40) can be used

to monitor the

health

of the fan or to close an external loop based on fan RPM. The THMC40 and THMC41

provide a more efficient drive solution to fan RPM control than external linear voltage control. This solution is

also considerably more efficient than controlling dc brushless fan RPM using external PWM drive.

low-side motor phase winding driver outputs (PHA, PHB)

The PHA and PHB outputs provide low-side drive of the motor’s two stator phase windings (see block diagram

and Figure 1). These outputs have a typical R

DS(ON)

of 400 mΩ at 25°C and a 1-A continuous current rating.

The PHA and PHB outputs have an active flyback clamp (V

ZCLAMP

in Figure 1) of 38 V (typical) to snub inductive

energy when a phase drive switches off. The outputs also have global thermal shutdown to prevent device

failure.

Drive commutation of PHA and PHB outputs is controlled according to rotor position monitored by a Hall-effect

position sensor. Discussion of this function is found in the following section, and the relationship between PHA

and PHB outputs to Hall input signal is shown in Figure 2.

Locked Rotor

Detection and

Auto-Restart

V

OUT

TACH

(THMC40)

NS

SN

Tachometer

Output Driver

V

ZCLAMP

V

ZCLAMP

Low-Side

Gate Drive

Control

Logic, and

Global

Thermal

Shutdown

Naked

Hall

Sensor

V

PWR

Hall Sensor

Comparator

RD

(THMC41)

H+

H–

PHA

PHB

Figure 1. Low-Side Gate Drive Block Diagram

Loading...

Loading...