Page 1

User's Guide

SLLU172–August 2012

SN65HVD257 CAN EVM:

Functional Safety and Redundant CAN Network

This User Guide details the SN65HVD257 CAN EVM (Controller Area Network Evaluation Module)

transceiver operation. It comes with two SN65HVD257 CAN transceivers factory installed, set up in a

redundant (parallel) CAN bus configuration. The EVM may be reconfigured by a user for other CAN

topologies. This User’s Guide explains the EVM configurations for basic redundant CAN evaluation, and

includes various load and termination settings.

Contents

1 Introduction .................................................................................................................. 2

1.1 Overview ............................................................................................................ 2

1.2 Example Using the SN65HVD257 in a Redundant Physical Layer CAN Network Topology ............ 2

2 SN65HVD257 CAN EVM .................................................................................................. 4

3 SN65HVD257 EVM Setup and Operation for Redundant (Parallel Networks) ..................................... 7

3.1 Overview and Basic Operation Settings ........................................................................ 7

3.2 Using CAN Bus Load and Termination Configuration ......................................................... 9

3.3 Using CAN Bus Protection and Filtering Configuration ...................................................... 10

3.4 Using Customer Installable IO Options for Current Limiting, Pull up or down, Noise Filtering ......... 11

3.5 Using customer installable IO options for 3.3V IO ........................................................... 11

4 SN65HVD257 EVM Configuration for Two Independent Networks ................................................. 12

4.1 Transceiver 1 Header (JMP3) .................................................................................. 12

4.2 Transceiver 2 Header (JMP7) .................................................................................. 12

5 Bill of Material (BOM) ..................................................................................................... 14

List of Figures

1 SN65HVD257 Basic Block Diagram and Pin Out....................................................................... 2

2 Typical SN65HVD257 Node To Build A Redundant Physical Layer Topology ..................................... 3

3 Typical Redundant Physical Layer Topology Using SN65HVD257 .................................................. 3

4 SN65HVD257 CAN EVM Top............................................................................................. 4

5 CAN EVM Schematic....................................................................................................... 5

6 Loopback Node 1 (JMP5 to JMP12) .................................................................................... 13

7 Loopback Node 2 (JMP10 to JMP13) .................................................................................. 13

List of Tables

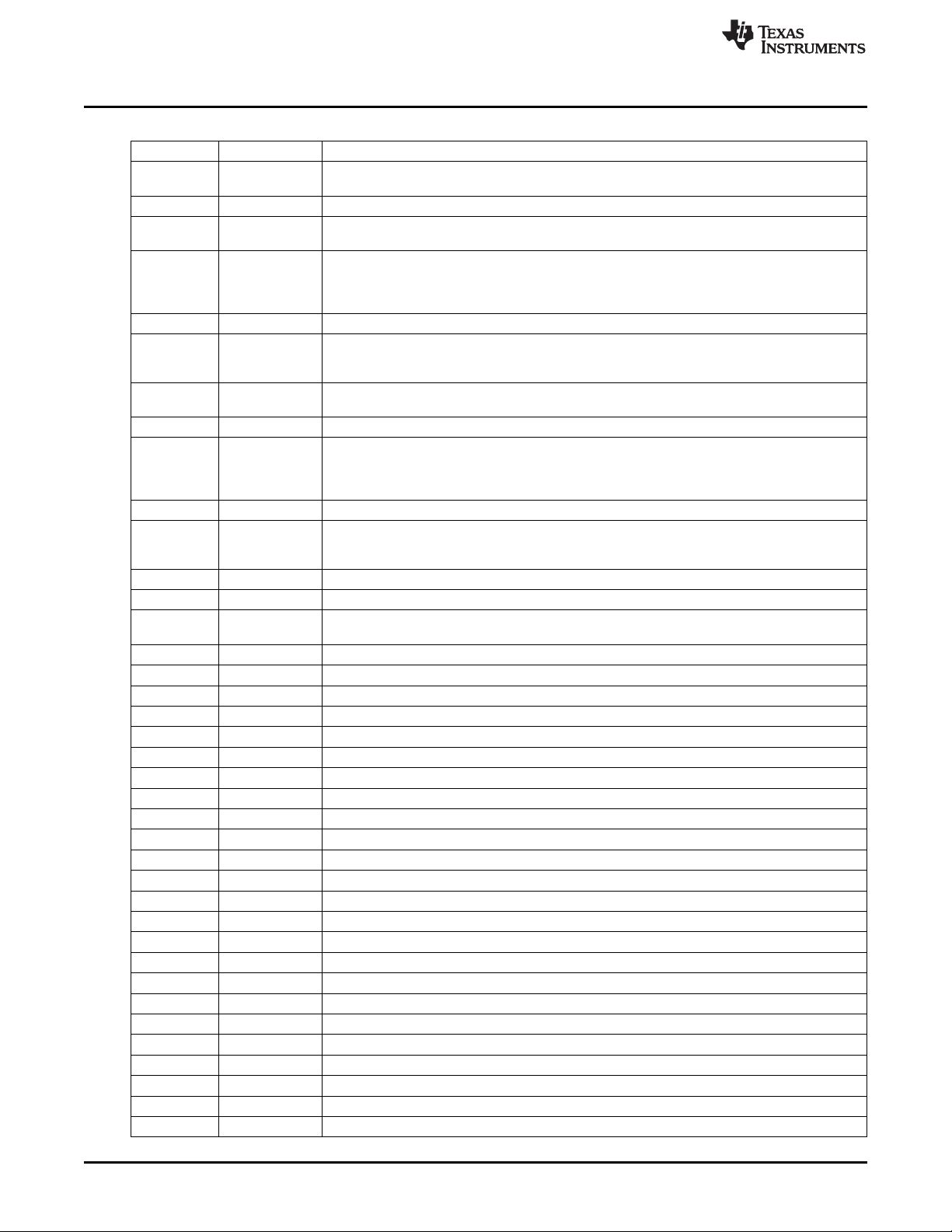

1 SN65HVD257 CAN EVM Connections .................................................................................. 6

2 Main Supply and IO Header (JMP1) Connections ..................................................................... 7

3 CAN Bus Termination Configuration ..................................................................................... 9

4 CAN Bus Protection and Filtering Configuration ...................................................................... 10

5 EVM Digital IO Configuration ............................................................................................ 11

6 EVM Digital IO Configuration ............................................................................................ 11

SLLU172–August 2012 SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

1

Page 2

S

CANH

CANL

FAULT

TXD

GND

V

CC

RXD

FAULT

DTO

DTO

Introduction

1 Introduction

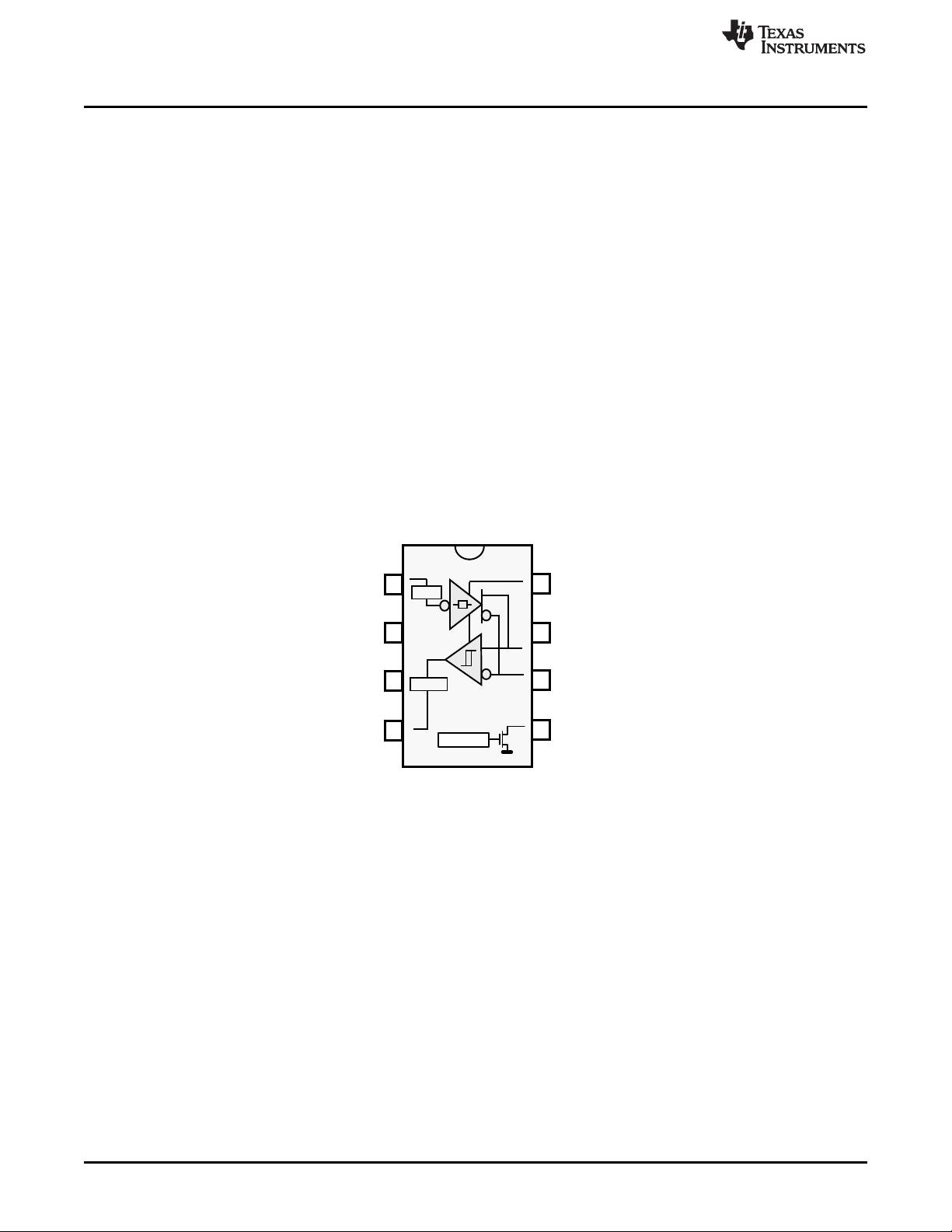

1.1 Overview

Texas Instruments offers a broad portfolio of High Speed (HS) CAN transceivers compatible with the

ISO11898-2 and ISO11898-5 High Speed CAN standards. These include 5V VCConly, 3.3V VCConly, 5V

VCCwith IO level shifting and galvanic isolated CAN transceivers. These CAN transceiver families include

product mixes with varying features such as low power standby modes with and without wake up, silent

modes, loop back and diagnostic modes.

The Texas Instruments SN65HVD257 CAN EVM helps designers evaluate the operation and performance

of the SN65HVD257 CAN transceiver. The SN65HVD257 includes many features for functional safety

network implementation such as redundant CAN networks. The SN65HVD257 CAN EVM also provides

PCB footprints for different bus terminations, bus filtering, and protection concepts. The EVM is provided

with two SN65HVD257 devices installed. A separate EVM is available for the other CAN transceivers,

SN65HVD255 CAN EVM, and another EVM uses the galvanic isolated CAN transceiver family (ISO1050).

The SN65HVD257 meets the ISO1189-2 High Speed CAN (Controller Area Network) Physical Layer

standard (transceiver). It is designed as a next-generation CAN for the SN65HVD251 and ISO1050, but

with added features for functional safety networks such as redundant networks. It has very fast loop times

with a wide range of bus loading, allowing for data rates up to 1 megabit per second (Mbps) in long and

highly loaded networks and higher data rates in small networks. The device includes many protection

features to provide device and CAN network robustness. The device has two modes: normal mode and

silent mode, selected on pin 8. The FAULT pin indicates TXD dominant time out, RXD dominant time out,

thermal shut down and under voltage faults.

www.ti.com

Figure 1. SN65HVD257 Basic Block Diagram and Pin Out

1.2 Example Using the SN65HVD257 in a Redundant Physical Layer CAN Network Topology

CAN is designed for standard linear bus topology using 120Ω twisted pair cabling. The SN65HVD257

CAN device includes several features that allow use of the CAN physical layer in nonstandard topologies

with only one CAN link layer controller (μP) interface. The SN65HVD257 allows much greater flexibility in

the physical topology of the bus while reducing the digital controller and software costs. The combination

of RXD dominant time out and the FAULT output provides great flexibility, control and monitoring of these

applications.

A simple example of this flexibility is to use two SN65HVD257 devices combined logically in parallel via an

AND gate to build a redundant (parallel) physical layer (cabling and transceivers) CAN network. Adding a

2

logic XOR with a filter adds automatic detection for a fault where one of the 2 networks goes open

(recessive) in addition to the faults detected by the SN65HVD257.

To allow CAN’s bit-wise arbitration to work, the RXD outputs of the transceivers must be connected via

AND gate logic so that the link layer logic (μP) receives a dominant bit (low) from any of the branches; the

transceivers appear to the link layer and above as a single physical network. The RXD dominant time out

(DTO) feature prevents a bus stuck dominant fault in a single branch from taking down the entire network

by returning the RXD pin for the transceivers on the branch with the fault to the recessive state (high) after

SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network SLLU172–August 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 3

Bus 1 Bus 2

µP

SN65HVD257

RXD2

TDX

FLT2

SN65HVD257

FLT1

S1

S2

FLT3

RXD1

RXD

1A 2A

µP

SN65HVD257

RXD2

TDX

FLT2

SN65HVD257

FLT1

S1

S2

FLT3

RXD1

RXD

1n 2n

µP

SN65HVD257

RXD2

TDX

FLT2

SN65HVD257

FLT1

S1

S2

FLT3

RXD1

RXD

1n 2n

µP

SN65HVD257

RXD2

TDX

FLT2

SN65HVD257

FLT1

S1

S2

FLT3

RXD1

RXD

1Z 2Z

µP

SN65HVD257

RXD2

TDX

FLT2

SN65HVD257

FLT1

S1

S2

FLT3

Bus 1 Bus 2

RXD1

RXD

www.ti.com

Introduction

the t

RXD_DTO

time. The remaining branch of the network continues to function. The FAULT pin of the

transceivers on the branch with the fault shows this via the FAULT output to their host processors, which

will diagnose the failure condition. The S-pin (silent mode pin) may be used to put a branch in silent mode

to check each branch for other faults, including to look for bus open (recessive) faults. For automatic

detection of a branch being open (recessive), an XOR gate may be used to combine the RXD outputs of

both branches. During dominant bits (low), were the branches do not match the XOR, the circuit outputs a

logic high. A small RC filter on the output eliminates false outputs due to small timing differences in the

branches and transceivers. This XOR and the FAULT outputs of the transceivers could be connected to

edge triggered interrupt pins on the host microprocessor to enter specialize software routines if there is an

issue on the redundant network.

Thus it is possible build up a robust and redundant CAN network topology in a very simple and low cost

manner. These concepts can be expanded into other more complicated and flexible CAN network

topologies to solve various other system-level challenges with a networked infrastructure.

SLLU172–August 2012 SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network

Submit Documentation Feedback

Figure 2. Typical SN65HVD257 Node To Build A Redundant Physical Layer Topology

Figure 3. Typical Redundant Physical Layer Topology Using SN65HVD257

Copyright © 2012, Texas Instruments Incorporated

3

Page 4

SN65HVD257 CAN EVM

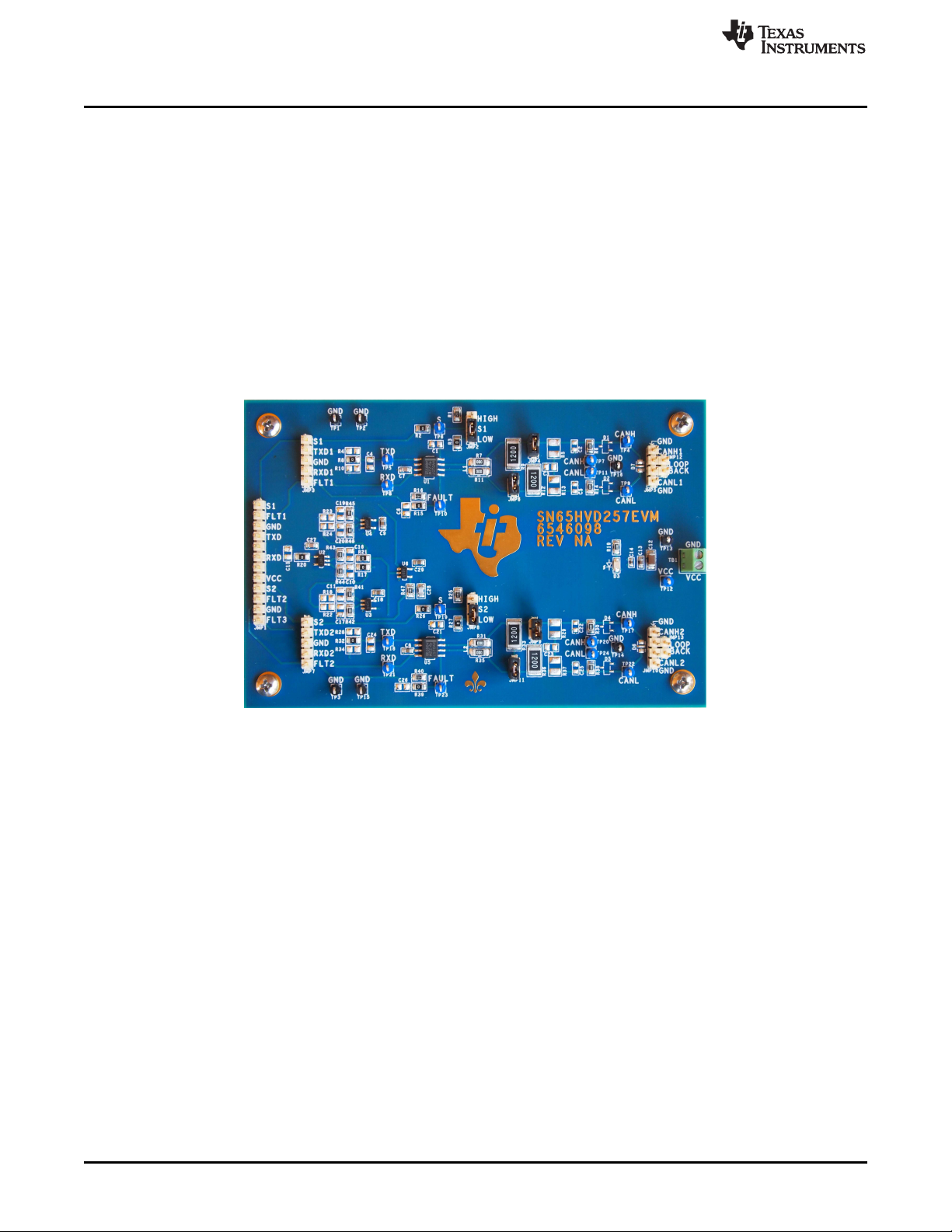

2 SN65HVD257 CAN EVM

The EVM consists of 2 CAN bus “nodes” and the necessary logic to build functional safety networks. It is

pre-configured for redundant CAN network applications with the 2 CAN bus “nodes”, including the AND

gate to combine the RXD output from both buses and the XOR gate and filter (50kHz) to detect a bus

open fault. The EVM has simple connections to all necessary pins of the CAN transceiver devices and the

necessary logic to create a redundant network. Jumpers are provided where necessary to provide

flexibility for device pin and CAN bus configuration. There are test points (loops) for all main points where

probing is necessary for evaluation such as GND, VCC, TXD, RXD, CANH, CANL, S, FAULT. The EVM

supports many options for CAN bus configuration. It is pre-configured with two 120Ω resistors that may be

connected on the bus via jumpers; a single resistor is used with the EVM as a terminated line end (CAN is

defined for 120Ω impedance twisted pair cable) or both resistors in parallel for electrical measurements

representing the 60Ω load the transceiver “sees” in a properly terminated network (120Ω termination

resistors at both ends of the cable). If the application requires “split” termination, TVS diodes for protection

or Common Mode (CM) Choke the EVM has footprints available for these components via customer

installation of the desired component(s).

www.ti.com

Figure 4. SN65HVD257 CAN EVM Top

4

SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network SLLU172–August 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 5

Place near DUT Pin

LOOPBACK

S1

RXD1

FLT1

S1

RXDprime

TXDA

TXD1

TXDprime

TXDA

RXD1

RXD2

TXDprime

RXD2

TXDB

TXDprime

RXD1

FLT1

TXDprime

RXDprime

S2

FLT2

S1

TXD1

RXD1

FLT1

S2

TXD2

FLT2

RXD2

RXD2

FLT2

S2

TXD2

TXDprime

TXDB

FAULT3

RXD2

RXD1

FAULT3

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

VCC

RXD2

R28

DNI

C16

DNI

R44

10k

1

JMP2

HIGH

S1

LOW

C23

DNI

C21

DNI

D5

DNI

1

2

3

C19

DNI

C5

DNI

R11

0

TP4

CANH

1

R39

0

A

B

Y

VCC

GND

G08

U3

1

2

3 5

4

R40

4.7k

R14

330

TP20

CANH

1

C14

.1uF

R33

120

R1

4.7k

R24

DNI

C3

DNI

R27

0

C4

DNI

A

B

Y

VCC

GND

G86

U6

1

2

5

4

3

1

JMP1

S1

FLT1

GND

TXD

GND

RXD

GND

VCC

S2

FLT2

GND

FLT3

1

JMP10

GND

CANH2

CANL2

GND

R16

4.7k

R3

0

C29

0.1uF

C25

DNI

D1

DNI

1

2

3

C10

DNI

TP16

GND

1

R7 0

C2

DNI

R29

DNI

R35

0

R2

0

TP21

RXD

1

C24

DNI

R21

0

TP11

CANL

1

1

JMP7

S2

TXD2

GND

RXD2

FLT2

C26

DNI

L1

1

4

2

3

R8

0

A

B

Y

VCC

GND

G08

U4

1

2

3 5

4

1

JMP8

HIGH

S2

LOW

TP22

CANL

1

TP17

CANH

1

TP15

GND

1

TP8

RXD

1

TP1

GND

1

C17

DNI

U1

SN65HVD257

TXD1GND2Vcc3RXD

4

FLT

5

CANL

6

CANH

7

S

8

C13

1uF

R10

DNI

R17

0

U5

SN65HVD257

TXD1GND2Vcc3RXD

4

FLT

5

CANL

6

CANH

7

S

8

R19

330

C1

DNI

TP7

CANH

1

1

JMP5

GND

CANH1

CANL1

GND

1

JMP6

R6

330

R30

330

C9

0.1uF

R38

330

TP6

S

1

R12

120

1

JMP11

R45

10k

R47

3.3k

D3

GREEN

21

TP14

GND.

1

TP23

FAULT

1

R46

10k

R20

0

TP12

VCC

1

C28

1nF

TP9

CANL

1

C7

4.7uF

TP10

FAULT

1

1

JMP3

S1

TXD1

GND

RXD1

FLT1

C15

DNI

C20

DNI

TB1

1

2

R22

DNI

1

JMP4

R43

10k

C6

DNI

R26

0

TP2

GND

1

C27

4.7uF

A

B

Y

VCC

GND

G08

U2

1

2

3 5

4

R15

0

R9

120

TP19

S

1

1

JMP9

C12

10uF

R5

DNI

TP24

CANL

1

1

JMP13

R18

DNI

R32

0

R4

DNI

1

JMP12

R41

10k

C11

DNI

D7

1

1

3

3

2

2

R31 0

TP13

GND

1

D2

DNI

1

2

3

R13

DNI

L2

1

4

2

3

TP18

TXD

1

C22

DNI

R36

120

R42

10k

D4

DNI

1

2

3

TP5

TXD

1

TP3

GND

1

C8

0.1uF

R23

DNI

D6

1

1

3

3

2

2

R37

DNI

C18

0.1uF

R25

4.7k

R34

DNI

www.ti.com

SLLU172–August 2012 SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network

Submit Documentation Feedback

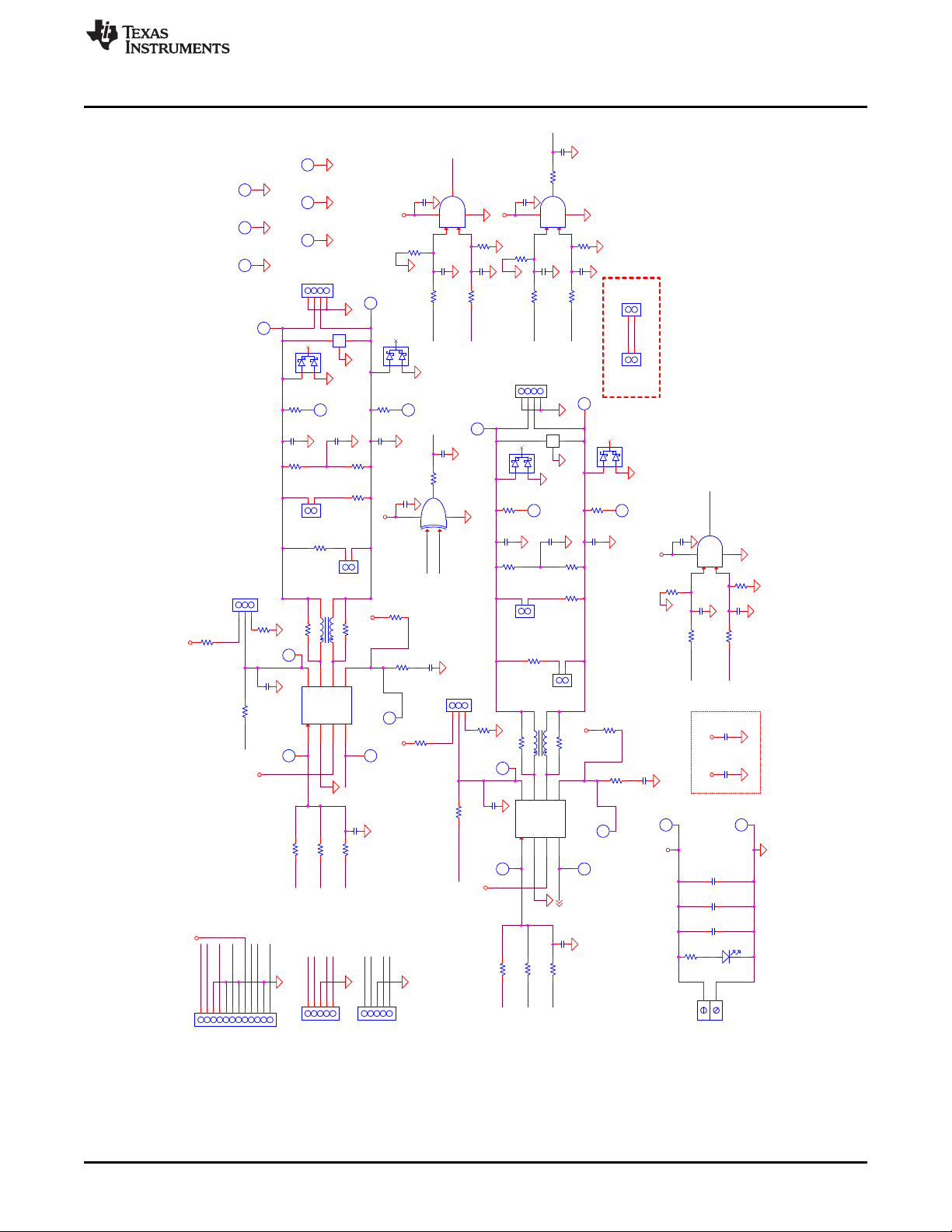

Figure 5. CAN EVM Schematic

Copyright © 2012, Texas Instruments Incorporated

SN65HVD257 CAN EVM

5

Page 6

SN65HVD257 CAN EVM

Connection Type Description

JMP1 12 pin header

JMP2 3 pin jumper S Mode Pin Control for transceiver 1

JMP3 5 pin header

JMP4 2 pin jumper

JMP5 4 pin header Connection for access to transceiver 1 CAN bus output: CANH1, CANL1, GND, GND

JMP6 2 pin jumper CAN termination to represent the combined 60Ω load for CAN transceiver parametric

JMP7 5 pin header

JMP8 3 pin jumper S Mode Pin Control for transceiver 2

JMP9 2 pin jumper

JMP10 4 pin header Connection for access to transceiver 2 CAN bus output: CANH2, CANL2, GND, GND.

JMP11 2 pin jumper CAN termination to represent the combined 60Ω load for CAN transceiver parametric

JMP12 2 pin jumper Next to JMP5 to allow jumping CAN bus 1 to CAN bus 2

JMP13 2 pin jumper Next to JMP10 to allow jumping CAN bus 1 to CAN bus 2

TB1 VCCsupply and GND connection for the EVM

TP1 Test Point GND test point

TP2 Test Point GND test point

TP3 Test Point GND test point

TP4 Test Point CANH (bus 1) test point

TP5 Test Point TXD, transceiver 1, test point

TP6 Test Point S, transceiver 1, test point

TP7 Test Point CANH (bus 1) via 330Ω serial resistor test point

TP8 Test Point RXD, transceiver 1, test point

TP9 Test Point CANL (bus 1) test point

TP10 Test Point FAULT (transceiver 1) test point

TP7 Test Point CANL (bus 1) via 330Ω serial resistor test point

TP12 Test Point Vcc test point

TP13 Test Point GND test point

TP14 Test Point GND test point

TP15 Test Point GND test point

TP16 Test Point GND test point

TP17 Test Point CANH (bus 2) test point

TP18 Test Point TXD, transceiver 2, test point

TP19 Test Point S, transceiver 2, test point

TP20 Test Point CANH (bus 2) via 330Ω serial resistor test point

TP21 Test Point RXD, transceiver 2, test point

TP22 Test Point CANL (bus 2) test point

TP23 Test Point FAULT (transceiver 2) test point

TP24 Test Point CANL (bus 2) via 330Ω serial resistor test point

www.ti.com

Table 1. SN65HVD257 CAN EVM Connections

Connection for access to all critical digital IO, supply and GND for driving the the CAN

transceivers externally with test equipment or interfaced to a processor EVM

Connection for access to all critical digital IO of the single transceiver 1 (bus) when EVM is used

for 2 separate buses

Connect 120Ω CAN termination to the bus. Used separately for a single termination if EVM is at

end of the CAN bus and termination isn’t in the cable. Used in combination with JMP6 to get to

second CAN termination to represent the combined 60Ω load for CAN transceiver parametric

measurement.

Connect 120Ω CAN termination to the bus. Used in combination with JMP4 to get to second

measurement.

Connection for access to all critical digital IO of the single transceiver 2 (bus) when EVM is used

for 2 separate buses

Connect 120Ω CAN termination to the bus. Used separately for a single termination if EVM is at

end of the CAN bus and termination is not in the cable. Used in combination with JMP6 to get to

second CAN termination to represent the combined 60Ω load for CAN transceiver parametric

measurement.

Connect 120Ω CAN termination to the bus. Used in combination with JMP4 to get to second

measurement.

2 pin terminal

block

6

SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network SLLU172–August 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 7

www.ti.com

SN65HVD257 EVM Setup and Operation for Redundant (Parallel Networks)

3 SN65HVD257 EVM Setup and Operation for Redundant (Parallel Networks)

This section describes the setup and operation of the EVM for parameter performance evaluation.

3.1 Overview and Basic Operation Settings

3.1.1 VCCPower Supply (TB1 or TP12 or JMP1)

The basic setup of the EVM requires a single power supply to evaluate transceiver and network design

performance. Supply VCCon TB1, JMP1 header or via the VCCand GND test point loops. The supplie

powerd must meet the required specification of VCCfor the transceiver being tested. LED D3 indicates VCC.

3.1.2 Main Supply and IO Header (JMP1)

All key IO and supply GND functions are brought to this header. It may be used to interface test

equipment, or a short cable can be made to connect to an existing customer application board or MCU or

DSP EVM board.

Table 2. Main Supply and IO Header (JMP1) Connections

Pin Connection Description

1 S1 Pin 5 of Transceiver 1. Used for Mode control.

2 FLT1 Pin 8 of Transceiver 1. Indicates fault with transceiver 1.

3 GND GND

4 TXD Pin 1 of Transceiver 1 and 2 (signal TXDprime). TXD (Transmit Data)

5 GND GND

6 RXD Pin 4 of Transceiver 1 and 2 combined via AND gate U2 (signal RXDprime). RXD (Receive Data)

7 GND GND

8 VCC Pin 3 of Transceiver. V

9 S2 Pin 5 of Transceiver 2. Used for Mode control.

10 FLT2 Pin 8 of Transceiver 2. Indicates fault with transceiver 2.

11 GND GND

12 FLT3 FAULT3: Open fault indicator. RXD (Pin 4) outputs of transceiver 1 and 2 combined via XOR gate U6 with

filter (signal FAULT3). Indicates bus open faults.

CC

3.1.3 TXD Input (JMP1)

The TXD input on JMP1 is connected via signal TXDprime to the TXD pin (pin 1) of both transceivers for

redundant (parallel) transmission on both buses. Individually this signal may be observed at the

transceiver pin via TP5 (transceiver 1) and TP18 (transceiver 2). The signal path TXDprime to the JMP1

header is pre-installed with a 0Ω series resistor, R10 and R34.

3.1.4 TXD Output (JMP1)

The RXD (combined) output of the transceivers via the AND gate for redundant (parallel) buses is JMP1.

Individually the RXD signals may be seen at the transceiver pin via TP8 (transceiver 1) and TP21

(transceiver 2). The combined RXD (RXDprime) signal path to the JMP1 header is pre-installed with a 0Ω

series resistor, R20 from the output of the AND gate U2.

3.1.5 S Pin (Mode Selection, pin 8) (JMP1, JMP2, JMP8, TP6 and TP19)

Pin 8 of the transceiver is the mode control pin of the device. Pin 8 of the devices is routed to JMP1,

JMP2 and JMP8.

SLLU172–August 2012 SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

7

Page 8

SN65HVD257 EVM Setup and Operation for Redundant (Parallel Networks)

MODE SELECTION OPTIONS

JMP1 configuration:

Using header JMP1 (which assumes all the digital IO signals), VCC, GND are routed to an external

system. Ensure that the MODE (JMP2 and JMP8) jumper settings are not conflicting with signals to

JMP1.

JMP2, transceiver 1 configuration (3 way jumper):

If using separate IO inputs, use JMP2 to configure the S pin (pin 8) of transceiver 1 to a pull up to

VCC(Silent Mode), or pull down to GND (Normal Mode).

JMP8, transceiver 2 configuration (3 way jumper):

If using separate IO inputs, use JMP8 to configure the S pin (pin 8) of transceiver 2 to a pull up to

VCC (Silent Mode) or pull down to GND (Normal Mode).

TP6, transceiver 1 configuration:

This test point connects directly to the S pin (pin 8) of transceiver 1. Ensure that JMP1 and JMP2

are not configured to conflict if TP3 is used as the input connection.

TP19, transceiver 2 configuration:

This test point connects directly to the S pin (pin 8) of transceiver 2. Ensure that JMP1 and JMP8

are not configured to conflict if TP19 is used as the input connection.

3.1.6 FLT 1 (FAULT, pin 5, transceiver 1) (JMP1, TP10)

Pin 5 of transceiver 1 is the fault output of the transceiver. This output is routed to JMP1 and TP10. This

output indicates a RXD DTO, TXD DTO, Thermal Shut Down or undervoltage fault with transceiver 1.

www.ti.com

3.1.7 FLT 2 (FAULT, pin 5, transceiver 2) (JMP1, TP23)

Pin 5 of transceiver 2 is the fault output of the transceiver. This output is routed to JMP1 and TP23. This

output indicates a RXD DTO, TXD DTO, Thermal Shut Down or undervoltage fault with transceiver 2.

3.1.8 FLT 3 (bus open fault) (JMP1)

FLT3 is the fault output of the filtered XOR combination of the two transceiver (bus) outputs. FLT3 will

transition any time the two buses do not match, and thus indicate that one of the buses is open. The

output filter of this logic is pre-installed with a cut off frequency of 50kHz to all for large deviations in timing

between 2 parallel buses. This filter could be tuned by the user to match the filtering requirements of the

target application with respect to bit timing and how much reaction time, or “missing” dominant bits the

application requires, the XOR filter output to then show a transition to the monitoring processor.

3.1.9 JMP3 configuration (not used for Redundant Networks):

Using header JMP3 requires EVM reconfiguration for other applications.

3.1.10 JMP7 configuration (not used for Redundant Networks):

Using header JMP7 requires EVM reconfiguration for other applications.

8

SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network SLLU172–August 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 9

www.ti.com

SN65HVD257 EVM Setup and Operation for Redundant (Parallel Networks)

3.2 Using CAN Bus Load and Termination Configuration

Each bus of the EVM is populated with two 120Ω power resistors selectable via jumpers between CANH

and CANL. By using one of the resistors, the EVM may be used as a terminated end of a bus. For

electrical measurements to represent the total loading of the bus, use both 120Ω resistors in parallel to

give the standard 60Ω load for parametric measurement. The EVM also has footprints for customer

installation of split termination if the application requires it. The table below summarizes how to use these

termination options. If split termination is used, care must be taken to match the resistors. The commonmode filter frequency may be calculated by: fc= 1 / (2 π R C). Normally, the split capacitance is in the

range of 4.7nF to 100nF. Keep in mind that this is the common-mode filter frequency, not a differential

filter that will impact the differential CAN signal directly.

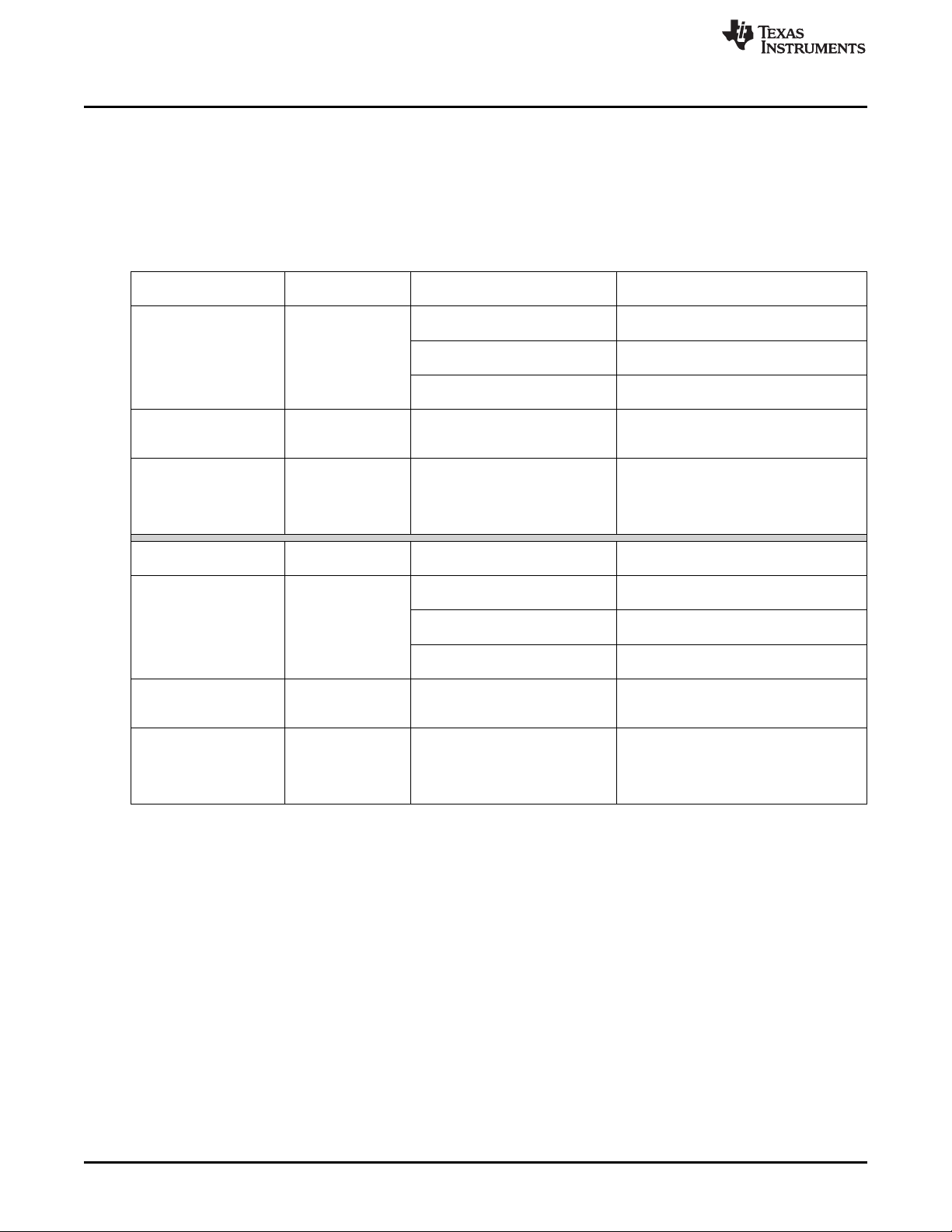

Table 3. CAN Bus Termination Configuration

"Termination Configuration Bus 1"

Standard Termination (120Ω) shorted open NA NA NA

60Ω load - Electrical Parameterics shorted shorted NA NA NA

Split Termination (Common Mode

Stabilization)

120Ω Resistors

JMP4 JMP6 R5 R13 C3

open open 60Ω 60Ω populated

Split Termination CM Stabilizing

Footprints Capacitor

"Termination Configuration Bus 2" 120Ω Resistors

JMP9 JMP11 R29 R37 C23

Standard Termination (120Ω) shorted open NA NA NA

60Ω load - Electrical Parameterics shorted shorted NA NA NA

Split Termination (Common Mode

Stabilization)

open open 60Ω 60Ω populated

Split Termination CM Stabilizing

Footprints Capacitor

SLLU172–August 2012 SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

9

Page 10

SN65HVD257 EVM Setup and Operation for Redundant (Parallel Networks)

3.3 Using CAN Bus Protection and Filtering Configuration

The EVM also has component footprints for various protection schemes to enhance robustness for

extreme system-level EMC requirements. Table 4 summarizes these options. Typical examples of for

these components are: CM choke (TDK ACT45B series and EPCOS B82789 series from 11µH to 100µH),

bus filter capacitors are typically 100pF or less, TVS diodes from the MMBZ series 27V or lower, varistors

such as the TDK AVR series).

Table 4. CAN Bus Protection and Filtering Configuration

Protection and Filtering Footprint

Bus 1 Reference

Direct CAN transceiver to bus R7 and R11 populated with 0Ω (default

connection population)

Series Resistors or R7 and R11 or L1 Series resistance protection CAN R7 and R11 populated with MELF resistor

Common Mode Choke (common footprint) transceiver to bus connection as necessary for harsh EMC environment

CM choke (bus filter)

Bus Filtering Caps C2 and C5 Bus filter environment. Filter caps may be used in

Transient Protection Transient & ESD Protection population option footprints D1 and D2 for

D1 and D2,

C2 and C7 or D7

Use Case Population and Description

www.ti.com

L1 populated with CM choke to filter noise

as necessary for harsh EMC environment

Filter noise as necessary for harsh EMC

combination with L1 CM choke.

To add extra protection for system level

transients and ESD protection, use the

TVS diodes, or C2 and C7 or D7 for

varistors.

Protection and Filtering Footprint

Bus 2 Reference

Direct CAN transceiver to bus R31 and R35 populated with 0Ω (default

connection population)

Series Resistors or R31 and R35 or L2 Series resistance protection CAN R31 and R35 populated with MELF resistor

Common Mode Choke (common footprint) transceiver to bus connection as necessary for harsh EMC environment

CM choke (bus filter)

Bus Filtering Caps C22 and C25 Bus filter environment. Filter caps may be used in

Transient Protection Transient & ESD Protection population option footprints D4 and D5 for

D4 and D5,

C22 and C25 or D6

Use Case Population and Description

L2 populated with CM choke to filter noise

as necessary for harsh EMC environment

Filter noise as necessary for harsh EMC

combination with L2 CM choke.

To add extra protection for system level

transients and ESD protection, use the

TVS diodes or C22 and C25 or D6 for

varistors.

10

SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network SLLU172–August 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 11

www.ti.com

SN65HVD257 EVM Setup and Operation for Redundant (Parallel Networks)

3.4 Using Customer Installable IO Options for Current Limiting, Pull up or down, Noise Filtering

The EVM has footprints on the PCB for the installation of various filtering and protection options to adapt

the EVM to match CAN network topology requirements if the EVM is being used as a CAN node.

Each digital input or output pin has footprints to allow for series current limiting resistors (default populated

with 0Ω), pull up or down resistors depending on pin use and a capacitor to GND which, configured with

the serial resistor, implements RC filters (for noisy environments). The table below lists these features for

each of the digital input and output pins of the EVM. Replace or populate the RC components as

necessary for the application. The RC output filter pads for may be reused as a resistor divider network to

level shift the outputs down to 3.3V levels. The SN65HVD257 already has 3.3V compatible inputs on TXD

and S pins.

Table 5. EVM Digital IO Configuration

Signal Jumper

Description Type Pull Up

TXD U1 Input NA NA R8 (R4/R10) NA NA TXD input from JMP1 to TXD U1

TXD U2 Input NA NA NA NA TXD input from JMP1 to TXD U2

RXD U1 Output NA NA R17 C10

RXD U2 Output NA NA R17 C16

RXDprime Output NA NA R20 NA C15

S U1 Input R1 (JMP2) R2 NA C1

S U2 Input R25 (JMP2) R26 NA C21

FLT3 Output NA NA R47 (3.3k) NA C28 (1nF)

Pull

Down

R3 S (Mode) pin input from JMP1 or PU or

(JMP2) PD to S U1

R27 S (Mode) pin input from JMP1 or PU or

(JMP2) PD to S U2

Series R C to GND Description

R32

(R28/R34)

Pull Up or

Down

R44 PD RXD U1 output to AND Gate for

(10k) combined RXD redundant output

R43 PD RXD U1 output to AND Gate for

(10k) combined RXD redundant output

RXDprime is the combined RXD output

from the parallel CAN buses via AND

gate U2 which is routed to JMP1 as

RXD

FAULT3 is the combined RXD output

from the parallel CAN buses via XOR

gate U6 with the RC filter populated

which is routed to JMP1 as FLT3.

3.5 Using customer installable IO options for 3.3V IO

The EVM may be configured to have a 3.3V level output through the repurposing of the RC output filter

pads. These RC pads may be reused as a resistor divider network to level shift the outputs down to 3.3V

levels. The SN65HVD257 already has 3.3V compatible inputs on the TXD and S pins. Table 6 shows

some examples. For use in applications, calculations must be made to ensure the resistor divider network

chosen adheres to the application requirement. Considerations should include: current biasing in the

resistor network (loading, power), ensuring that the VOHand VOLof the divider will meet the VIHand V

input threshold levels of the host processor, and that the output of the resistor divider will be below the

absolute maximum rating of the host processor at the absolute maximum rating of the transceiver (or the

worst case corner the application will provide).

Table 6. EVM Digital IO Configuration

Output R1 Pad and Value R2 Pad and Value Description

RXDprime R20 = 3.9 kΩ C15 = 6.8 kΩ C15 pad is repurposed as R2.

FLT1 R15 = 0 Ω C6 = 8.2 kΩ R1 is the pull up R16. C6 pad is repurposed as R2.

R16 = 4.7k Ω

FLT2 "R39 = 0 Ω C26 = 8.2 kΩ R1 is the pull up R 40. C26 pad is repurposed as R2.

R40 = 4.7kΩ

FLT3 R47 = 3.9 kΩ C28 = 1nF and 6.8 kΩ C28 pad is repurposed as R2 and filter C (stacked

components).

SLLU172–August 2012 SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

IL

11

Page 12

SN65HVD257 EVM Configuration for Two Independent Networks

4 SN65HVD257 EVM Configuration for Two Independent Networks

This section describes how to reconfigure the EVM into two independent networks. With this configuration,

the EVM could be used to host two node physical layers. The sections of the EVM not specifically

described below such as termination, filtering and protection are used in the same or similar fashion as

when the EVM is configured for a redundant network.

4.1 Transceiver 1 Header (JMP3)

4.1.1 TXD1 Input (JMP3, TP5)

The TXD1 input on JMP3 connects to transceiver 1 (U1) and TP5. To reconfigure the EVM, R8 must be

removed to disconnect TXDprime from U1, and R4 must be installed with a 0Ω resistor or current limiting

serial resistor of choice for the application to route the TXD1 signal to U1.

4.1.2 RXD1 Output (JMP3, TP8)

The RXD1 output of transceiver 1 (U1) is routed to JMP3 and TP8. If no parasitic loading to the combining

AND gate U2 is desired, then R17 may be removed.

4.1.3 S1 Input (Mode Selection,) (JMP3, JMP2 and TP6)

Pin 8 of the transceiver is the mode control pin of the device. Pin 8 of transceiver 1 is routed to JMP3,

JMP2 and TP6.

www.ti.com

MODE SELECTION OPTIONS

JMP3, transceiver 1 header configuration:

Header JMP3 handles all the digital IO signals for transceiver 1. JMP3 may be used to route these

signals to an external host processor or test system. Make sure that the MODE (JMP2) jumper

settings are not conflicting with signals to JMP3.

JMP2, transceiver 1 configuration (3 way jumper):

If the header is not used, then JMP2 may be used to configure the S pin (pin 8) of transceiver 1 to

a pull up to VCC(Silent Mode) or pull down to GND (Normal Mode).

TP6, transceiver 1 configuration:

This test point connects directly to the S pin (pin 8) of transceiver 1. Ensure that JMP3 and JMP2

are not configured to conflict if TP3 is used as the input connection.

4.1.4 FLT1 Output (JMP3, TP10)

Pin 5 of transceiver 1 is the fault output of the transceiver. This output routes to JMP3 and TP10. This

output indicates a RXD DTO, TXD DTO, Thermal Shut Down or undervoltage fault with transceiver 1.

4.2 Transceiver 2 Header (JMP7)

4.2.1 TXD2 Input (JMP7, TP18)

The TXD2 input on JMP7 is connected to transceiver 2 (U5) and TP5. To reconfigure the EVM, R32 must

be removed to disconnect TXDprime from U5, and R28 must be installed with a 0Ω resistor or current

limiting serial resistor of choice for the application to route the TXD2 signal to U5.

4.2.2 RXD2 Output (JMP7, TP21)

The RXD2 output of transceiver 2 (U5) is routed to JMP7 and TP21. If no parasitic loading to the

combining AND gate U2 is desired, then R21 may be removed.

12

SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network SLLU172–August 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 13

www.ti.com

SN65HVD257 EVM Configuration for Two Independent Networks

4.2.3 S2 Input (Mode Selection,) (JMP7, JMP8 and TP19)

Pin 8 of the transceiver is the mode control pin of the device. Pin 8 of transceiver 2 is routed to JMP7,

JMP8 and TP19.

MODE SELECTION OPTIONS

JMP7, transceiver 2 header configuration:

Header JMP7 handles all the digital IO signals for transceiver 2. JMP7 may be used to route the

signals to an external host processor or test system. Ensure that the MODE (JMP8) jumper settings

are not conflicting with signals to JMP7.

JMP8, transceiver 2 configuration (3 way jumper):

If the header is not used, then JMP8 may be used to configure S pin (pin 8) of transceiver 2 to a

pull up to VCC(Silent Mode) or pull down to GND (Normal Mode)

TP19, transceiver 2 configuration:

This test point connects directly to the S pin (pin 8) of transceiver 2. Ensure JMP7 and JMP8 are

not configured to conflict if TP19 is used as the input connection.

4.2.4 FLT2 Output (JMP7, TP23)

Pin 5 of transceiver 2 is the fault output of the transceiver. This output routed to JMP7 and TP23. This

output indicates a RXD DTO, TXD DTO, Thermal Shut Down or undervoltage fault with transceiver 2.

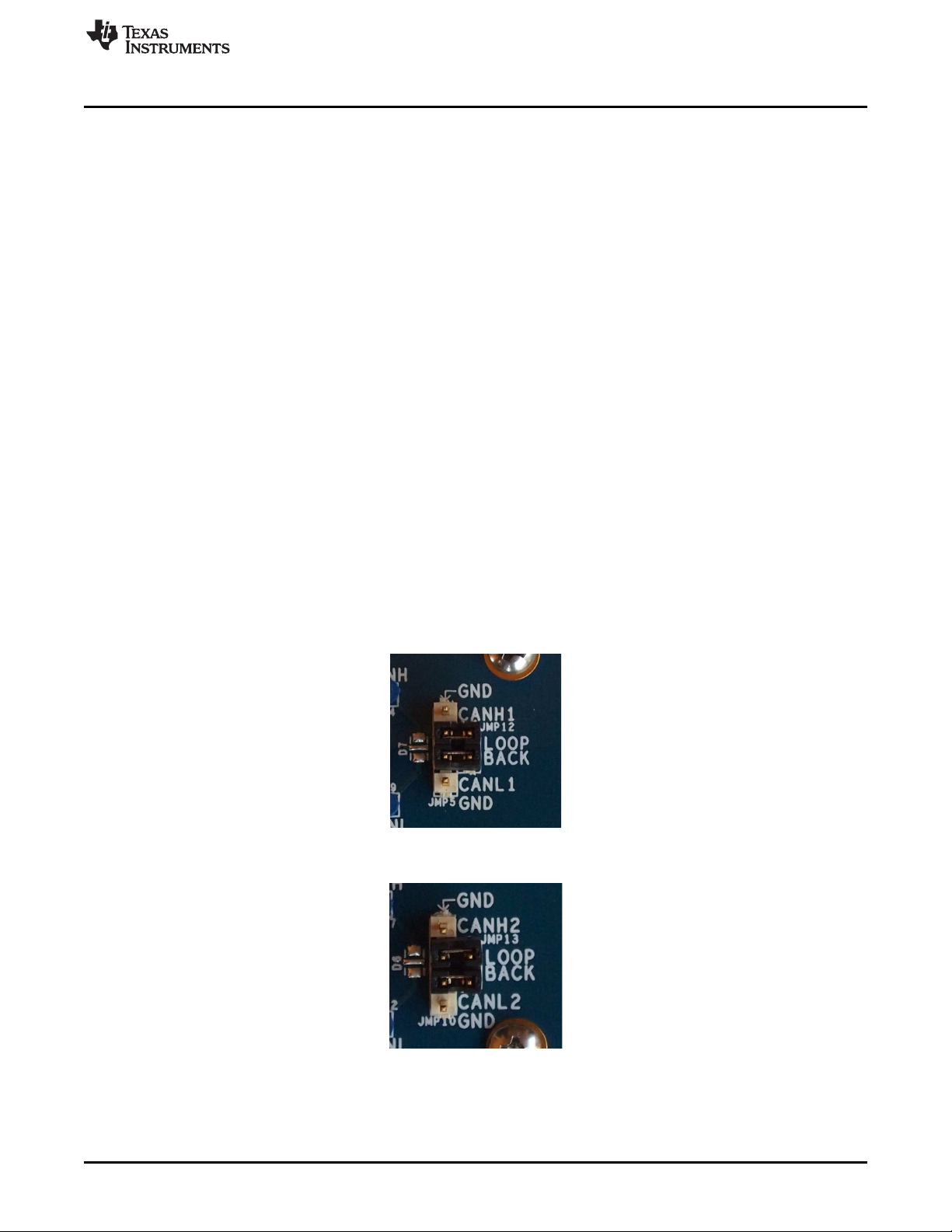

4.2.5 Loopback (single bus connection) of the Two Nodes (JMP12 and 13)

The EVM provides a path via JMP12 and JMP13 to connect to two nodes (transceivers) together on the

board as a single CAN network. On node 1 (transceiver 1, U1) connect CANH1 and CANL1 across JMP5

and JMP12 as shown below. On node 2 (transceiver 2, U5) connect CANH2 and CANL2 across JMP10

and JMP13 as shown below. CANH1 is now connected to CANH2 and CANL1 is connected to CANL2 in

one CAN network.

Figure 6. Loopback Node 1 (JMP5 to JMP12)

Figure 7. Loopback Node 2 (JMP10 to JMP13)

SLLU172–August 2012 SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network

Submit Documentation Feedback

Copyright © 2012, Texas Instruments Incorporated

13

Page 14

Bill of Material (BOM)

www.ti.com

5 Bill of Material (BOM)

Item QTY Reference Part Footprint Manufacturer

1 23 C16, C17, C18, C19, C20, 21, R22, R23, DNI 805 ANY

2 4 C2, C5, C22, C25 DNI 603 ANY

3 2 C7, C27 4.7uF 603 ANY

4 4 C8, C9, C18, C29 0.1uF 603 ANY

5 1 C12 10uF 1206 ANY

6 1 C13 1uF 603 ANY

7 1 C14 0.1uF 402 ANY

8 1 C28 1nF 805 ANY

9 4 D1, D2, D4, D5 DNI SOT_3DBZ ANY

10 1 D3 GREEN C170 ANY

11 2 D6, D7 DNI CA05M2S10T100HG TDK / EPCOS

12 1 JMP1 Header 1x12 HDR_THVT_1X12_100 ANY

13 2 JMP2, JMP8 Header 1x3 HDR_THVT_1X3_100 ANY

14 2 JMP3, JMP7 Header 1x5 HDR_THVT_1X5_100 ANY

15 6 Heder 1x2 HDR_THVT_1X2_100 ANY

16 2 JMP5, JMP10 Header 1x4 HDR_THVT_1X4_100 ANY

17 2 L1, L2 DNI TDK / EPCOS

18 4 R1, R16, R25, R40 4.7k 805 ANY

19 11 0 805 ANY

20 4 R3, R13, R29, R37 DNI 1210 ANY

21 5 R6, R14, 19, R30, R38 330 805 ANY

22 4 R7, R11, R31, R35 0 1206 ANY

23 4 R9, R12, R33, R36 120 2512 ANY

24 6 R41, R42, R43, R44, R45, R46 10k 805 ANY

25 1 R47 3.3k 805 ANY

26 1 TB1 2PIN_TERMINAL_BLOCK TB_THRTSCR_1x2_100 ANY

27 18 TP11, TP12, TP13, TP17, TP18, TP19, Test Point HDR_THVT_1x1_100 ANY

28 6 TP1, TP2, TP3, TP14, TP15, TP16 Test Point HDR_THVT_1x1_100 ANY

29 2 U1, U5 SN65HVD256D SOIC_8D TI

30 3 U2, U3, U4 SN74AHC1G86DBV SOT_5DBV TI

31 1 U6 SOT_5DBV TI

C1, C3, R4, C4, C6, R10, 10, C11, C15,

C23, R24, C24, C26, R28, R34

JMP4, JMP6, JMP9, JMP11, JMP12,

JMP13

ACT45B or B82789 series

CM choke

R2, R3, R8, R15, R17, R20, R21, R26,

R27, R32, R39

TP4, TP5, TP6, TP7, TP8,TP9, TP10,

TP20, TP21, TP22, TP23, TP24

14

SN65HVD257 CAN EVM: Functional Safety and Redundant CAN Network SLLU172–August 2012

Copyright © 2012, Texas Instruments Incorporated

Submit Documentation Feedback

Page 15

Evaluation Board/Kit Important Notice

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the product(s) must have

electronics training and observe good engineering practice standards. As such, the goods being provided are not intended to be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including product safety and environmental

measures typically found in end products that incorporate such semiconductor components or circuit boards. This evaluation board/kit does

not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling

(WEEE), FCC, CE or UL, and therefore may not meet the technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30 days from

the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO BUYER

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents or

services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the product. This

notice contains important safety information about temperatures and voltages. For additional information on TI’s environmental and/or

safety programs, please contact the TI application engineer or visit www.ti.com/esh.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and can radiate radio

frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15 of FCC rules, which are

designed to provide reasonable protection against radio frequency interference. Operation of this equipment in other environments may

cause interference with radio communications, in which case the user at his own expense will be required to take whatever measures may

be required to correct this interference.

EVM Warnings and Restrictions

It is important to operate this EVM within the input voltage range of and the output voltage range of .

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are questions

concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the EVM.

Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than . The EVM is designed to operate properly

with certain components above as long as the input and output ranges are maintained. These components include but are not limited to

linear regulators, switching transistors, pass transistors, and current sense resistors. These types of devices can be identified using the

EVM schematic located in the EVM User's Guide. When placing measurement probes near these devices during operation, please be

aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2012, Texas Instruments Incorporated

Page 16

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, enhancements, improvements and other

changes to its semiconductor products and services per JESD46, latest issue, and to discontinue any product or service per JESD48, latest

issue. Buyers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All semiconductor products (also referred to herein as “components”) are sold subject to TI’s terms and conditions of sale

supplied at the time of order acknowledgment.

TI warrants performance of its components to the specifications applicable at the time of sale, in accordance with the warranty in TI’s terms

and conditions of sale of semiconductor products. Testing and other quality control techniques are used to the extent TI deems necessary

to support this warranty. Except where mandated by applicable law, testing of all parameters of each component is not necessarily

performed.

TI assumes no liability for applications assistance or the design of Buyers’ products. Buyers are responsible for their products and

applications using TI components. To minimize the risks associated with Buyers’ products and applications, Buyers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any patent right, copyright, mask work right, or

other intellectual property right relating to any combination, machine, or process in which TI components or services are used. Information

published by TI regarding third-party products or services does not constitute a license to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual property of the

third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of significant portions of TI information in TI data books or data sheets is permissible only if reproduction is without alteration

and is accompanied by all associated warranties, conditions, limitations, and notices. TI is not responsible or liable for such altered

documentation. Information of third parties may be subject to additional restrictions.

Resale of TI components or services with statements different from or beyond the parameters stated by TI for that component or service

voids all express and any implied warranties for the associated TI component or service and is an unfair and deceptive business practice.

TI is not responsible or liable for any such statements.

Buyer acknowledges and agrees that it is solely responsible for compliance with all legal, regulatory and safety-related requirements

concerning its products, and any use of TI components in its applications, notwithstanding any applications-related information or support

that may be provided by TI. Buyer represents and agrees that it has all the necessary expertise to create and implement safeguards which

anticipate dangerous consequences of failures, monitor failures and their consequences, lessen the likelihood of failures that might cause

harm and take appropriate remedial actions. Buyer will fully indemnify TI and its representatives against any damages arising out of the use

of any TI components in safety-critical applications.

In some cases, TI components may be promoted specifically to facilitate safety-related applications. With such components, TI’s goal is to

help enable customers to design and create their own end-product solutions that meet applicable functional safety standards and

requirements. Nonetheless, such components are subject to these terms.

No TI components are authorized for use in FDA Class III (or similar life-critical medical equipment) unless authorized officers of the parties

have executed a special agreement specifically governing such use.

Only those TI components which TI has specifically designated as military grade or “enhanced plastic” are designed and intended for use in

military/aerospace applications or environments. Buyer acknowledges and agrees that any military or aerospace use of TI components

which have not been so designated is solely at the Buyer's risk, and that Buyer is solely responsible for compliance with all legal and

regulatory requirements in connection with such use.

TI has specifically designated certain components which meet ISO/TS16949 requirements, mainly for automotive use. Components which

have not been so designated are neither designed nor intended for automotive use; and TI will not be responsible for any failure of such

components to meet such requirements.

Products Applications

Audio www.ti.com/audio Automotive and Transportation www.ti.com/automotive

Amplifiers amplifier.ti.com Communications and Telecom www.ti.com/communications

Data Converters dataconverter.ti.com Computers and Peripherals www.ti.com/computers

DLP® Products www.dlp.com Consumer Electronics www.ti.com/consumer-apps

DSP dsp.ti.com Energy and Lighting www.ti.com/energy

Clocks and Timers www.ti.com/clocks Industrial www.ti.com/industrial

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Security www.ti.com/security

Power Mgmt power.ti.com Space, Avionics and Defense www.ti.com/space-avionics-defense

Microcontrollers microcontroller.ti.com Video and Imaging www.ti.com/video

RFID www.ti-rfid.com

OMAP Applications Processors www.ti.com/omap TI E2E Community e2e.ti.com

Wireless Connectivity www.ti.com/wirelessconnectivity

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2012, Texas Instruments Incorporated

Page 17

Mouser Electronics

Authorized Distributor

Click to View Pricing, Inventory, Delivery & Lifecycle Information:

Texas Instruments:

SN65HVD257EVM

Loading...

Loading...