Texas Instruments MSP430G2533, MSP430G2433, MSP430G2333, MSP430G2233, MSP430G2403 Datasheet

...

Product

Folder

Sample &

Buy

Technical

Documents

Tools &

Software

Support &

Community

Reference

Design

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2x33, MSP430G2x03 Mixed-Signal Microcontrollers

1 Device Overview

1.1 Features

1

• Low Supply-Voltage Range: 1.8 V to 3.6 V

• Ultra-Low Power Consumption

– Active Mode: 230 µA at 1 MHz, 2.2 V

– Standby Mode: 0.5 µA

– Off Mode (RAM Retention): 0.1 µA

• Five Power-Saving Modes

• Ultra-Fast Wake up From Standby Mode in Less

Than 1 µs

• 16-Bit RISC Architecture, 62.5-ns Instruction Cycle

Time

• Basic Clock Module Configurations

– Internal Frequencies up to 16 MHz With Four

Calibrated Frequencies

– Internal Very-Low-Power Low-Frequency (LF)

Oscillator

– 32-kHz Crystal

– External Digital Clock Source

• Two 16-Bit Timer_A With Three Capture/Compare

Registers

• Up to 24 Capacitive-Touch Enabled I/O Pins

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

• Universal Serial Communication Interface (USCI)

– Enhanced UART Supports Automatic Baud-

Rate Detection (LIN)

– IrDA Encoder and Decoder

– Synchronous SPI

– I2C

• 10-Bit 200-ksps Analog-to-Digital Converter (ADC)

With Internal Reference, Sample-and-Hold, and

Autoscan (See Table 3-1)

• Brownout Detector

• Serial Onboard Programming,

No External Programming Voltage Needed,

Programmable Code Protection by Security Fuse

• On-Chip Emulation Logic With Spy-Bi-Wire

Interface

• Section 3 Summarizes Available Family Members

• Package Options

– TSSOP: 20 Pin, 28 Pin

– PDIP: 20 Pin

– QFN: 32 Pin

• For Complete Module Descriptions, See the

MSP430x2xx Family User’s Guide (SLAU144)

1.2 Applications

• Power Management

• Sensor Interface

1.3 Description

The TI MSP family of ultra-low-power microcontrollers consists of several devices that feature different

sets of peripherals targeted for various applications. The architecture, combined with five low-power

modes, is optimized to achieve extended battery life in portable measurement applications. The device

features a powerful 16-bit RISC CPU, 16-bit registers, and constant generators that contribute to

maximum code efficiency. The digitally controlled oscillator (DCO) allows the device to wake up from lowpower modes to active mode in less than 1 µs.

The MSP430G2x03 and MSP430G2x33 devices are ultra-low-power mixed-signal microcontrollers with

built-in 16-bit timers, up to 24 I/O capacitive-touch enabled pins, and built-in communication capability

using the USCI. In addition, the MSP430G2x33 family members have a 10-bit ADC. See Section 3 for

configuration details.

Typical applications include low-cost sensor systems that capture analog signals, convert them to digital

values, and then process the data for display or for transmission to a host system.

1

• Capacitive Touch

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

Clock

System

Brownout

Protection

RST/NMI

DVCC DVSS

MCLK

Watchdog

WDT+

15-Bit

Timer0_A3

3 CC

registers

16-MHz

CPU

including

16 registers

Emulation

2BP

JTAG

interface

SMCLK

ACLK

Port P1

8 I/Os,

interrupt

capability,

pullup or

pulldown

resistors

P1.x

8

P2.x

Port P2

8 I/Os,

interrupt

capability,

pullup or

pulldown

resistors

Spy-Bi-

Wire

Timer1_A3

3 CC

registers

XIN

XOUT

Port P3

8 I/Os,

pullup or

pulldown

resistors

P3.x

8 8

RAM

512B

256B

Flash

16KB

8KB

4KB

2KB

USCI A0

UART,

LIN, IrDA,

SPI

USCI B0

SPI, I C

2

ADC

10 bit,

8 channel,

autoscan,

1-channel

DMA

MDB

MAB

Copyright © 2016, Texas Instruments Incorporated

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

www.ti.com

PART NUMBER PACKAGE BODY SIZE

MSP430G2533IRHB VQFN (32) 5 mm × 5 mm

MSP430G2533IPW

MSP430G2533IN PDIP (20) 24.33 mm × 6.35 mm

(1) For the most current part, package, and ordering information, see the Package Option Addendum in

Section 8, or see the TI website at www.ti.com.

(2) The sizes shown here are approximations. For the package dimensions with tolerances, see the

Mechanical Data in Section 8.

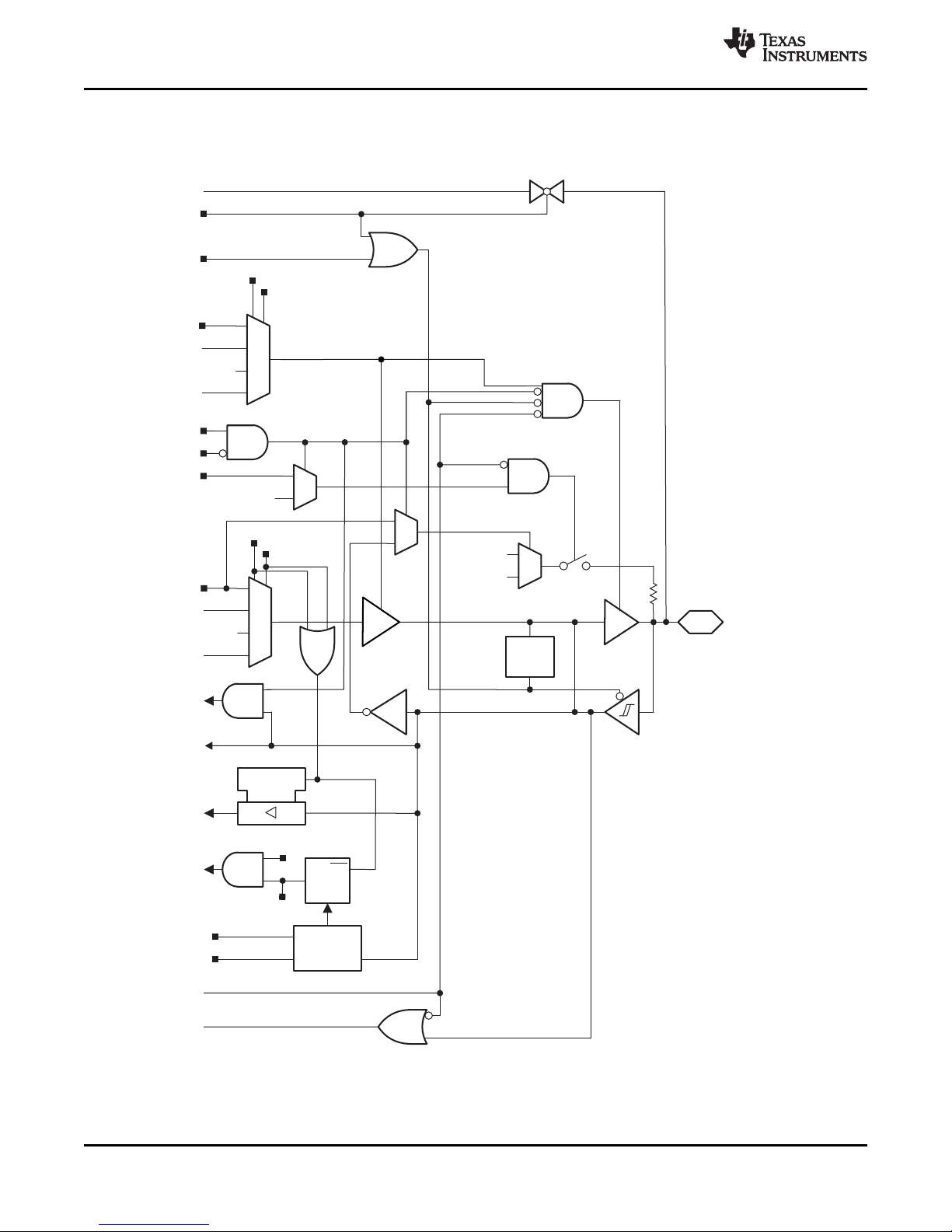

1.4 Functional Block Diagrams

Figure 1-1 shows the functional block diagram of the MSP430G2x33 MCUs.

Device Information

(1)

TSSOP (28) 9.7 mm × 4.4 mm

TSSOP (20) 6.5 mm × 4.4 mm

(2)

NOTE: Port P3 is available on 28-pin and 32-pin devices only.

2

Device Overview Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Figure 1-1. Functional Block Diagram, MSP430G2x33

Submit Documentation Feedback

MSP430G2203

Clock

System

Brownout

Protection

RST/NMI

DVCC DVSS

MCLK

Watchdog

WDT+

15-Bit

Timer0_A3

3 CC

registers

16-MHz

CPU

including

16 registers

Emulation

2BP

JTAG

interface

SMCLK

ACLK

Port P1

8 I/Os,

interrupt

capability,

pullup or

pulldown

resistors

P1.x

8

P2.x

Port P2

8 I/Os,

interrupt

capability,

pullup or

pulldown

resistors

Spy-Bi-

Wire

Timer1_A3

3 CC

registers

XIN

XOUT

Port P3

8 I/Os,

pullup or

pulldown

resistors

P3.x

8 8

RAM

256B

Flash

8KB

4KB

2KB

USCI A0

UART,

LIN, IrDA,

SPI

USCI B0

SPI, I C

2

MDB

MAB

Copyright © 2016, Texas Instruments Incorporated

www.ti.com

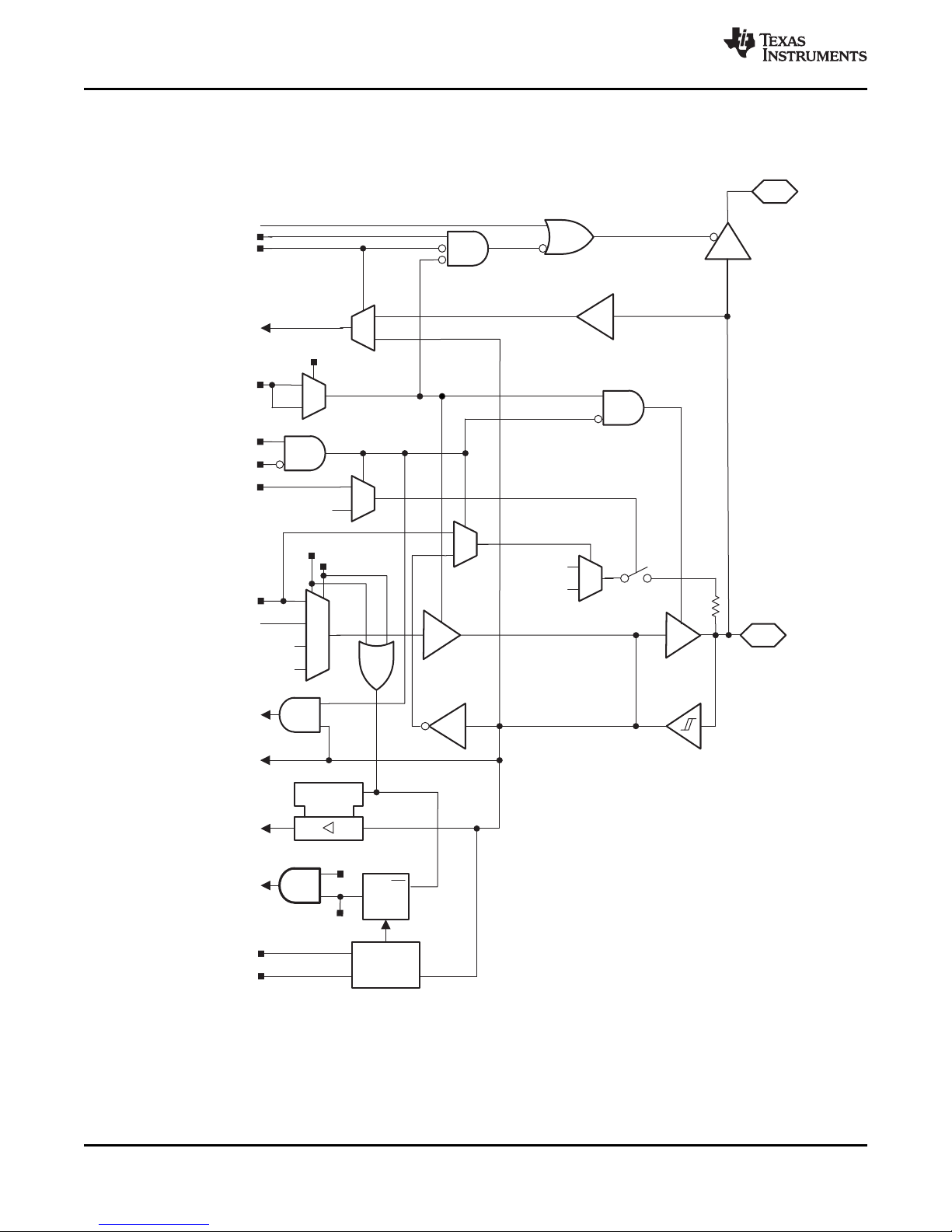

Figure 1-2 shows the functional block diagram of the MSP430G2x03 MCUs.

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

NOTE: Port P3 is available on 28-pin and 32-pin devices only.

Figure 1-2. Functional Block Diagram, MSP430G2x03

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

Device OverviewCopyright © 2011–2016, Texas Instruments Incorporated

3

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

Table of Contents

www.ti.com

1 Device Overview ......................................... 1

1.1 Features .............................................. 1

1.2 Applications........................................... 1

1.3 Description............................................ 1

1.4 Functional Block Diagrams........................... 2

2 Revision History ......................................... 5

3 Device Comparison ..................................... 6

3.1 Related Products ..................................... 7

4 Terminal Configuration and Functions.............. 8

4.1 Pin Diagrams ......................................... 8

4.2 Signal Descriptions.................................. 10

5 Specifications........................................... 13

5.1 Absolute Maximum Ratings ........................ 13

5.2 ESD Ratings ........................................ 13

5.3 Recommended Operating Conditions............... 13

5.4 Active Mode Supply Current Into VCCExcluding

External Current..................................... 14

5.5 Typical Characteristics, Active Mode Supply Current

(Into V

5.6 Low-Power Mode Supply Currents (Into VCC)

Excluding External Current.......................... 16

5.7 Typical Characteristics, Low-Power Mode Supply

Currents ............................................. 17

5.8 Thermal Resistance Characteristics ................ 18

5.9 Schmitt-Trigger Inputs, Ports Px .................... 19

5.10 Leakage Current, Ports Px.......................... 19

5.11 Outputs, Ports Px ................................... 19

5.12 Output Frequency, Ports Px ........................ 19

5.13 Typical Characteristics – Outputs................... 20

5.14 Pin-Oscillator Frequency – Ports Px ................ 21

5.15 Typical Characteristics – Pin-Oscillator Frequency. 21

5.16 POR, BOR .......................................... 22

5.17 Main DCO Characteristics .......................... 24

5.18 DCO Frequency..................................... 24

5.19 Calibrated DCO Frequencies, Tolerance ........... 25

5.20 Wake-up Times From Lower-Power Modes (LPM3,

LPM4) .............................................. 26

5.21 Typical Characteristics, DCO Clock Wake-up Time

From LPM3 or LPM4................................ 26

5.22 Crystal Oscillator, XT1, Low-Frequency Mode ..... 27

5.23 Internal Very-Low-Power Low-Frequency Oscillator

(VLO)................................................ 27

5.24 Timer_A ............................................. 27

)............................................ 15

CC

5.25 USCI (UART Mode)................................. 28

5.26 USCI (SPI Master Mode)............................ 28

5.27 USCI (SPI Slave Mode)............................. 29

5.28 USCI (I

5.29 10-Bit ADC, Power Supply and Input Range

5.30 10-Bit ADC, Built-In Voltage Reference

5.31 10-Bit ADC, External Reference (MSP430G2x33

5.32 10-Bit ADC, Timing Parameters (MSP430G2x33

5.33 10-Bit ADC, Linearity Parameters (MSP430G2x33

5.34 10-Bit ADC, Temperature Sensor and Built-In V

5.35 Flash Memory ....................................... 34

5.36 RAM................................................. 35

5.37 JTAG and Spy-Bi-Wire Interface.................... 35

5.38 JTAG Fuse .......................................... 35

2

C Mode) .................................... 30

Conditions (MSP430G2x33 Only)................... 31

(MSP430G2x33 Only)............................... 32

Only)................................................. 33

Only)................................................. 33

Only)................................................. 33

(MSP430G2x33 Only)............................... 34

MID

6 Detailed Description ................................... 36

6.1 CPU ................................................. 36

6.2 Instruction Set....................................... 37

6.3 Operating Modes.................................... 38

6.4 Interrupt Vector Addresses.......................... 39

6.5 Special Function Registers (SFRs) ................. 40

6.6 Memory Organization ............................... 41

6.7 Bootloader (BSL).................................... 41

6.8 Flash Memory ....................................... 42

6.9 Peripherals .......................................... 42

6.10 I/O Port Diagrams................................... 48

7 Device and Documentation Support ............... 64

7.1 Getting Started and Next Steps..................... 64

7.2 Device Nomenclature ............................... 64

7.3 Tools and Software ................................. 66

7.4 Documentation Support ............................. 68

7.5 Related Links........................................ 70

7.6 Community Resources .............................. 71

7.7 Trademarks.......................................... 71

7.8 Electrostatic Discharge Caution..................... 71

7.9 Glossary............................................. 71

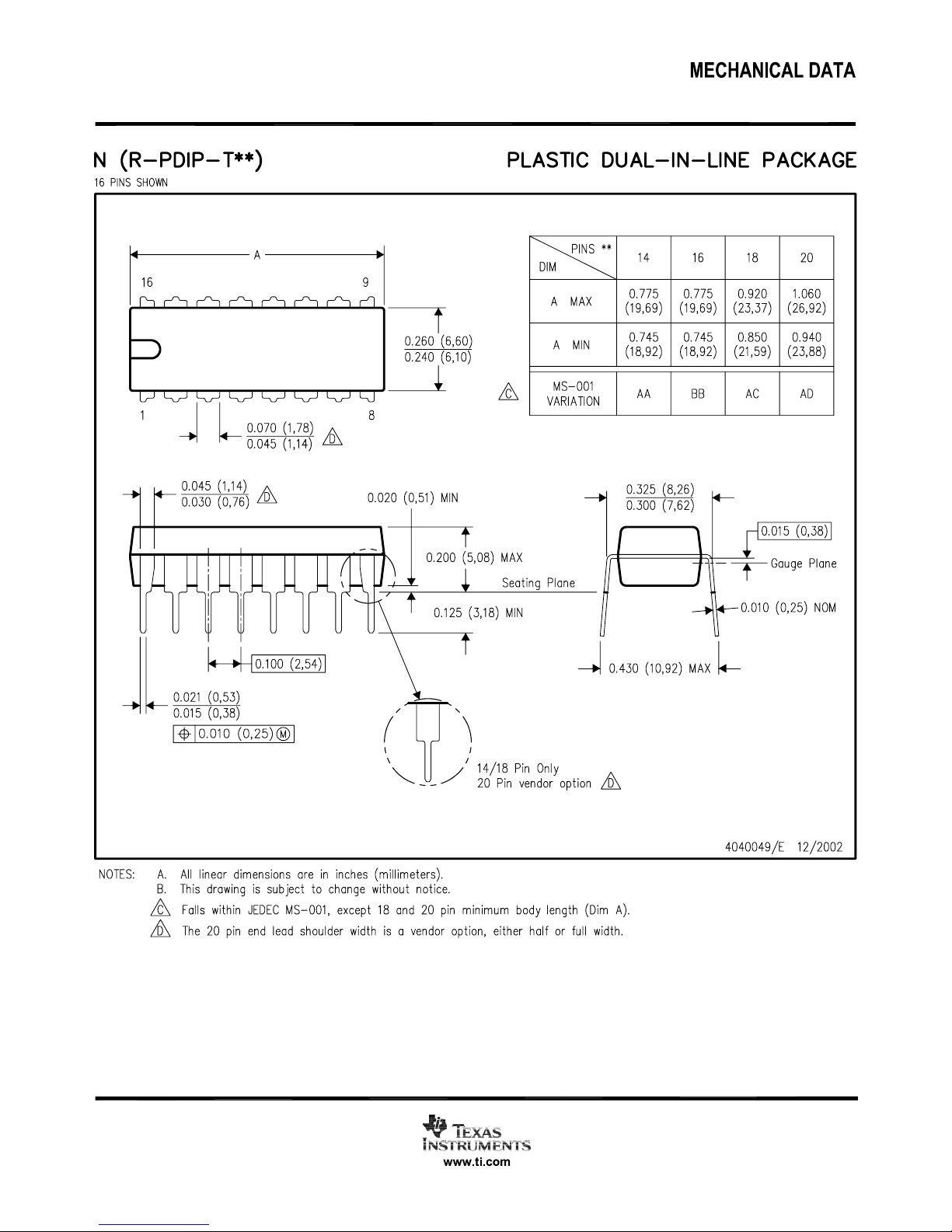

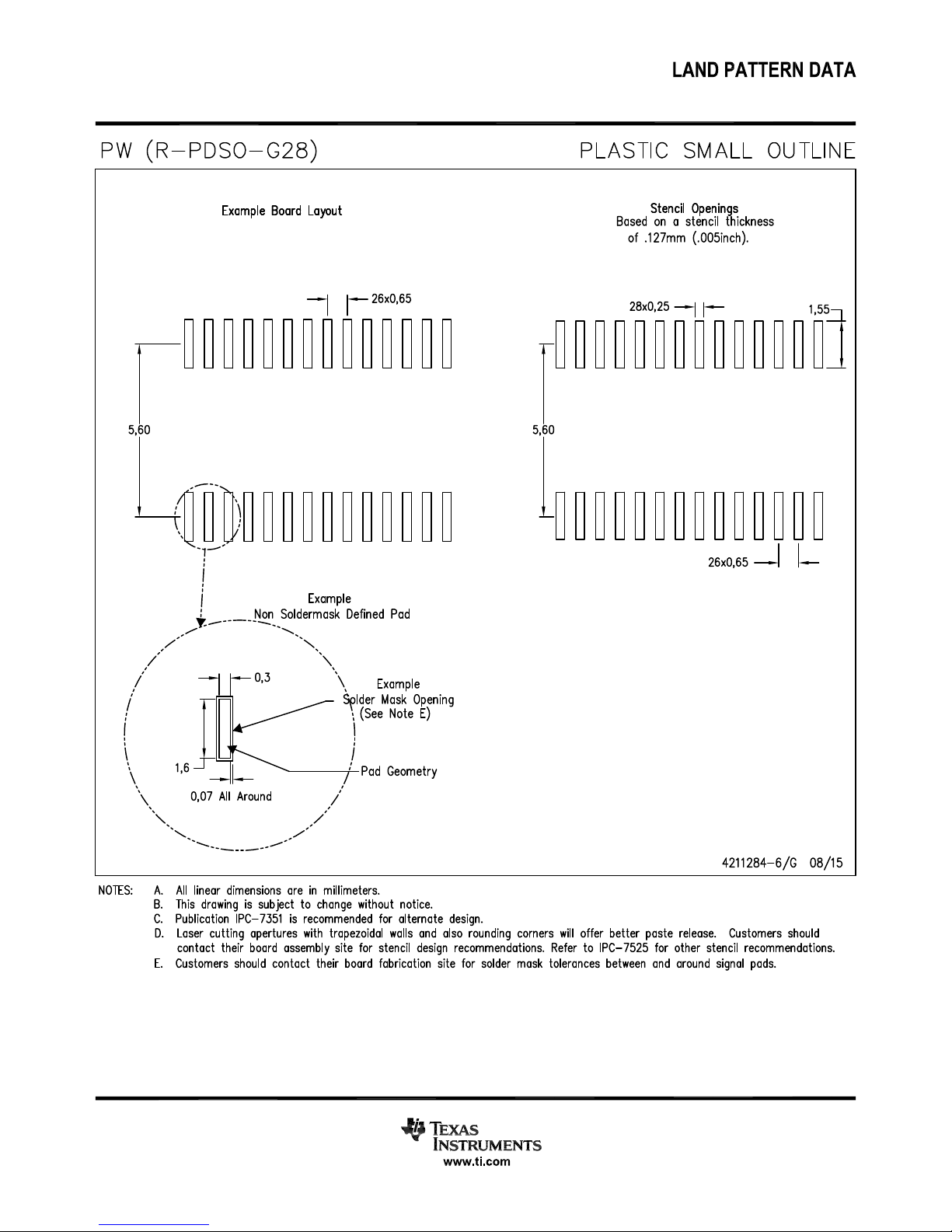

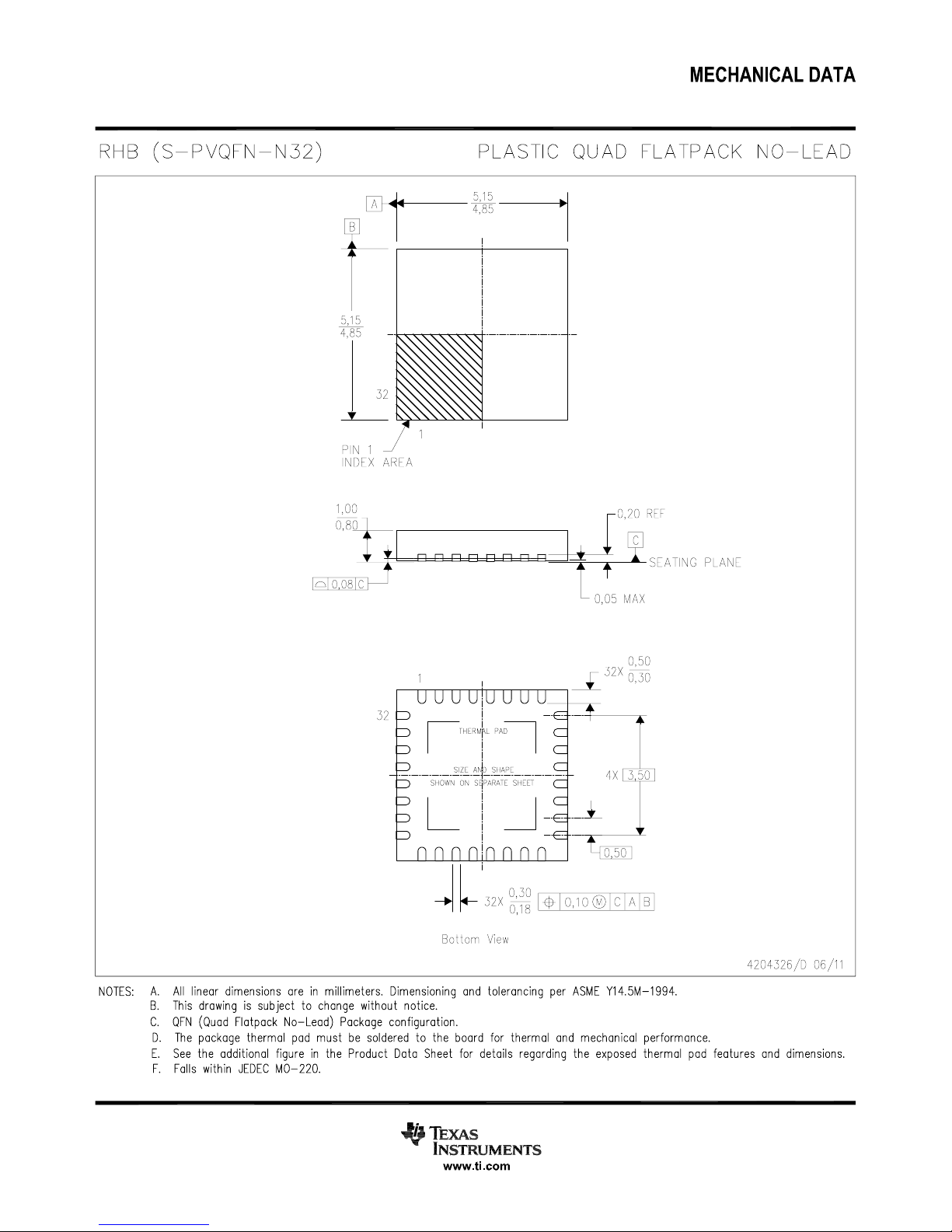

8 Mechanical, Packaging, and Orderable

Information .............................................. 72

4

Table of Contents Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

2 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from May 2, 2013 to April 27, 2016 Page

• Document format and organization changes throughout, including addition of section numbering........................ 1

• Added Device Information table .................................................................................................... 2

• Added Section 3.1, Related Products ............................................................................................. 7

• Moved Section 5, Specifications .................................................................................................. 13

• Added Section 5.2, ESD Ratings.................................................................................................. 13

• Added Section 5.8, Thermal Resistance Characteristics ...................................................................... 18

• Throughout document, changed all instances of "bootstrap loader" to "bootloader"....................................... 39

• Changed all instances of "INCHx = 0x1010" to "INCHx = 1010b" in Table 6-11, Labels Used by the ADC

Calibration Tags ..................................................................................................................... 43

• Moved and renamed Section 6.10, I/O Port Diagrams......................................................................... 48

• Added notes to UCB0STE and UCA0CLK in Table 6-18 ...................................................................... 53

• Added notes to UCB0CLK and UCA0STE in Table 6-19 ...................................................................... 55

• Added "and PW28" to title of Section 6.10.8 .................................................................................... 62

• Added "and PW28" to title of Table 6-23......................................................................................... 63

• Added Section 7, Device and Documentation Support......................................................................... 64

• Added Section 8, Mechanical, Packaging, and Orderable Information ...................................................... 72

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

Revision HistoryCopyright © 2011–2016, Texas Instruments Incorporated

5

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

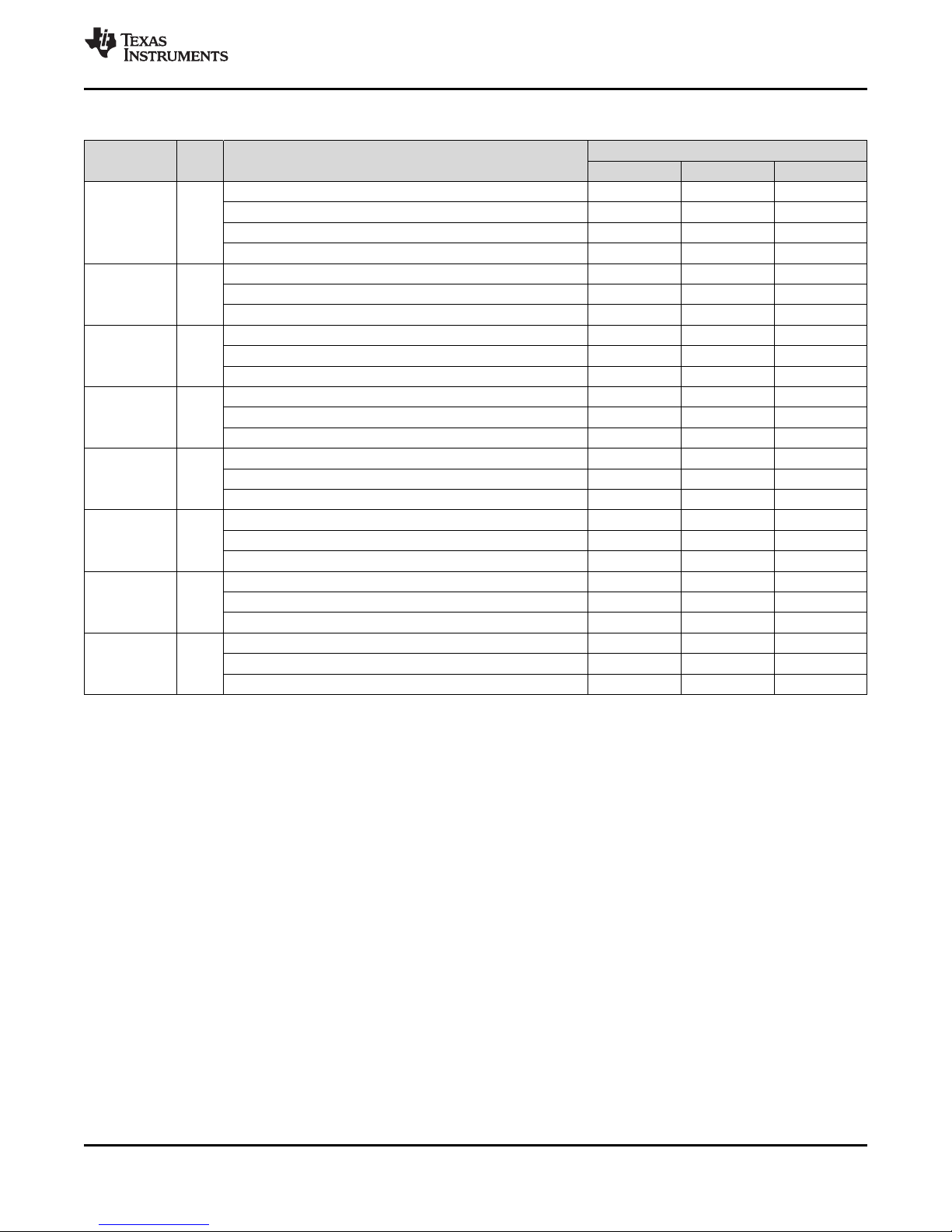

3 Device Comparison

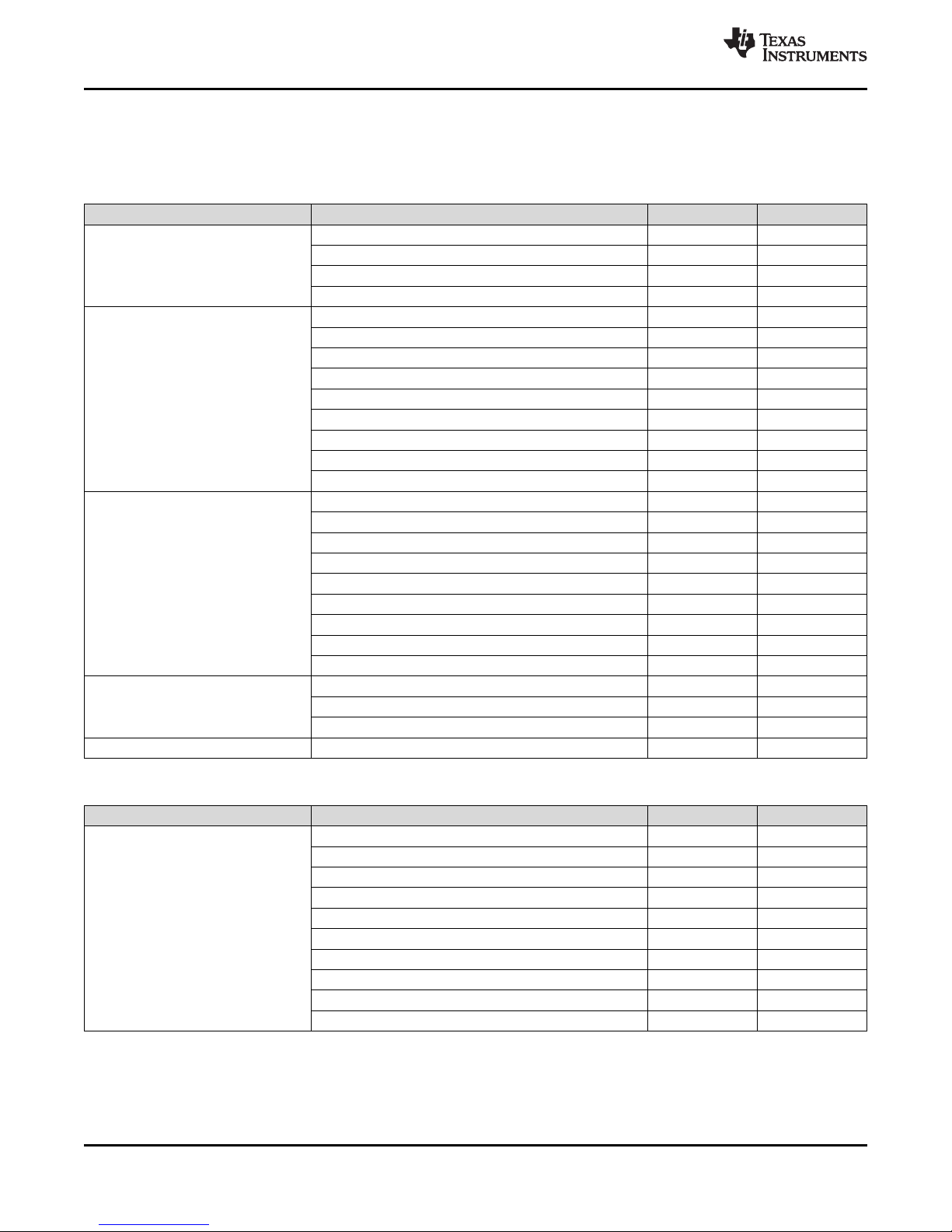

Table 3-1 compares the available family members.

www.ti.com

Table 3-1. Device Comparison

DEVICE BSL EEM

MSP430G2533 1 1 16 512 2x TA3 8 1

MSP430G2433 1 1 8 512 2x TA3 8 1

MSP430G2333 1 1 4 256 2x TA3 8 1

MSP430G2233 1 1 2 256 2x TA3 8 1

MSP430G2403 1 1 8 512 2x TA3 – 1

MSP430G2303 1 1 4 256 2x TA3 – 1

MSP430G2203 1 1 2 256 2x TA3 – 1

(1) For the most current device, package, and ordering information, see the Package Option Addendum in Section 8, or see the TI website

at www.ti.com.

(2) Package drawings, thermal data, and symbolization are available at www.ti.com/packaging.

FLASH

(KB)

RAM

(B)

Timer_A

ADC10

CHANNELS

(1)(2)

USCI_A0,

USCI_B0

CLOCK I/O PACKAGE

24 32-QFN

LF, DCO,

VLO

LF, DCO,

VLO

LF, DCO,

VLO

LF, DCO,

VLO

LF, DCO,

VLO

LF, DCO,

VLO

LF, DCO,

VLO

24 28-TSSOP

16 20-TSSOP

16 20-PDIP

24 32-QFN

24 28-TSSOP

16 20-TSSOP

16 20-PDIP

24 32-QFN

24 28-TSSOP

16 20-TSSOP

16 20-PDIP

24 32-QFN

24 28-TSSOP

16 20-TSSOP

16 20-PDIP

24 32-QFN

24 28-TSSOP

16 20-TSSOP

16 20-PDIP

24 32-QFN

24 28-TSSOP

16 20-TSSOP

16 20-PDIP

24 32-QFN

24 28-TSSOP

16 20-TSSOP

16 20-PDIP

6

Device Comparison Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

www.ti.com

3.1 Related Products

For information about other devices in this family of products or related products, see the following links.

Products for MSP 16-Bit and 32-Bit MCUs Low-power mixed-signal processors with smart analog and

digital peripherals for a wide range of industrial and consumer applications.

Products for Ultra-low Power MCUs MSP Ultra-Low-Power microcontrollers (MCUs) from Texas

Instruments (TI) offer the lowest power consumption and the perfect mix of integrated

peripherals for a wide range of low-power and portable applications.

Products for MSP430G2x/i2x Low-Cost Industrial MCUs MSP430G2x microcontrollers (MCUs) from

the MSP ultra-low-power MCU series, offers the low power and performance of 16-bit MSP

microcontrollers with a feature set targeted at cost sensitive applications.

Companion Products for MSP430G2533 Review products that are frequently purchased or used in

conjunction with this product.

Reference Designs for MSP430G2533 TI Designs Reference Design Library is a robust reference

design library that spans analog, embedded processor, and connectivity. Created by TI

experts to help you jump start your system design, all TI Designs include schematic or block

diagrams, BOMs, and design files to speed your time to market. Search and download

designs at ti.com/tidesigns.

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

Device ComparisonCopyright © 2011–2016, Texas Instruments Incorporated

7

PW28

(TOP VIEW)

1

DVCC

2

P1.0/TA0CLK/ACLK/A0

3

4

5

P1.3/ADC10CLK/VREF-/VEREF-/A3

6

7

8

P3.0/TA0.2

9

P3.1/TA1.0

10

P2.0/TA1.0

19

P3.5/TA0.1

20

P3.6/TA0.2

21

P3.7/TA1CLK

22

23

24

RST/NMI/SBWTDIO

25

TEST/SBWTCK

26

XOUT/P2.7

27

XIN/P2.6/TA0.1

28

DVSS

P1.6/TA0.1/ TDI/TCLKUCB0SOMI/UCB0SCL/A6/

P1.7/ /A7/TDO/TDIUCB0SIMO/UCB0SDA

P1.1/TA0.0/ A1/UCA0RXD/UCA0SOMI

P1.2/TA0.1/ A2/UCA0TXD/UCA0SIMO

P1.4/SMCLK/ TCK/VREF+/VEREF+/A4/UCB0STE/UCA0CLK

P1.5/TA0.0/ A5/TMS/UCB0CLK/UCA0STE

11

12

P2.2/TA1.1

13

P3.2/TA1.1

14

P3.3/TA1.2

15

P3.4/TA0.0

16

P2.3/TA1.0

17

P2.4/TA1.2

18

P2.5/TA1.2

P2.1/TA1.1

1

DVCC

2

P1.0/TA0CLK/ACLK/A0

3

4

5

P1.3/ADC10CLK/VREF-/VEREF-/A3

6

7

8

P2.0/TA1.0

9

P2.1/TA1.1

10

P2.2/TA1.1

11

P2.3/TA1.0

12

P2.4/TA1.2

13

P2.5/TA1.2

14

15

16

RST/NMI/SBWTDIO

17

TEST/SBWTCK

18

XOUT/P2.7

19

XIN/P2.6/TA0.1

20

DVSS

P1.6/TA0.1/ /TDI/TCLKUC

B0SOMI/UCB0SCL/A6

P1.7/ /A7/TDO/TDIUCB0SIMO/UCB0SDA

P1.1/TA0.0/ A1/UCA0RXD/UCA0SOMI

P1.2/TA0.1/ A2/UCA0TXD/UCA0SIMO

P1.4/SMCLK/ /TCK/VREF+/VEREF+/A4UCB0STE/UCA0CLK

P1.5/TA0.0/ A5/TMS/UCB0CLK/UCA0STE

N20

PW20

(TOP VIEW)

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

4 Terminal Configuration and Functions

4.1 Pin Diagrams

Figure 4-1 shows the pinout for the MSP430G2x03 and MSP430G2x33 devices in the 20-pin N or PW

package.

NOTE: ADC10 is available on MSP430G2x33 devices only.

NOTE: The pulldown resistors of port P3 should be enabled by setting P3REN.x = 1.

Figure 4-1. 20-Pin N or PW Package (Top View), MSP430G2x03 and MSP430G2x33

www.ti.com

Figure 4-2 shows the pinout for the MSP430G2x03 and MSP430G2x33 devices in the 28-pin PW

package.

NOTE: ADC10 is available on MSP430G2x33 devices only.

Figure 4-2. 28-Pin PW Package (Top View), MSP430G2x03 and MSP430G2x33

8

Terminal Configuration and Functions Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

RHB32

(TOP VIEW)

1

2

3

4

5

6

7

P2.1/TA1.1

8NC

9

P2.2/TA1.1

10

P3.0/TA0.2

11

P3.1/TA1.0

12

P3.2/TA1.1

131415

P3.5/TA0.1

16

17

18

P2.5/TA1.2

19

20

P3.6/TA0.2

21

P3.7/TA1CLK

22

23 RST/NMI/SBWTDIO

24 TEST/SBWTCK

25

XOUT/P2.7

26

XIN/P2.6/TA0.1

27

AVSS

28

DVSS

29

AVCC

30

DVCC

31

P1.0/TA0CLK/ACLK/A0/CA0

32

NC

P1.3/ADC10CLK/VREF-/VEREF-/A3

P1.1/TA0.0/ A1/

UCA0RXD/UCA0SOMI

P1.2/TA0.1/ A2/UCA0TXD/UCA0SIMO

P1.4/SMCLK/ /TCK/VREF+/VEREF+/A4UCB0STE/UCA0CLK

P1.5/TA0.0/ A5/TMS/UCB0CLK/UCA0STE

P1.6/TA0.1/ /TDI/TCLKUCB0SOMI/UCB0SCL/A6

P1.7 /TDO/TDI/UCB0SIMO/UCB0SDA/A7

www.ti.com

Figure 4-3 shows the pinout for the MSP430G2x03 and MSP430G2x33 devices in the 32-pin RHB

package.

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

NOTE: ADC10 is available on MSP430G2x33 devices only.

Figure 4-3. 32-Pin RHB Package (Top View), MSP430G2x03 and MSP430G2x33

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

Terminal Configuration and FunctionsCopyright © 2011–2016, Texas Instruments Incorporated

9

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

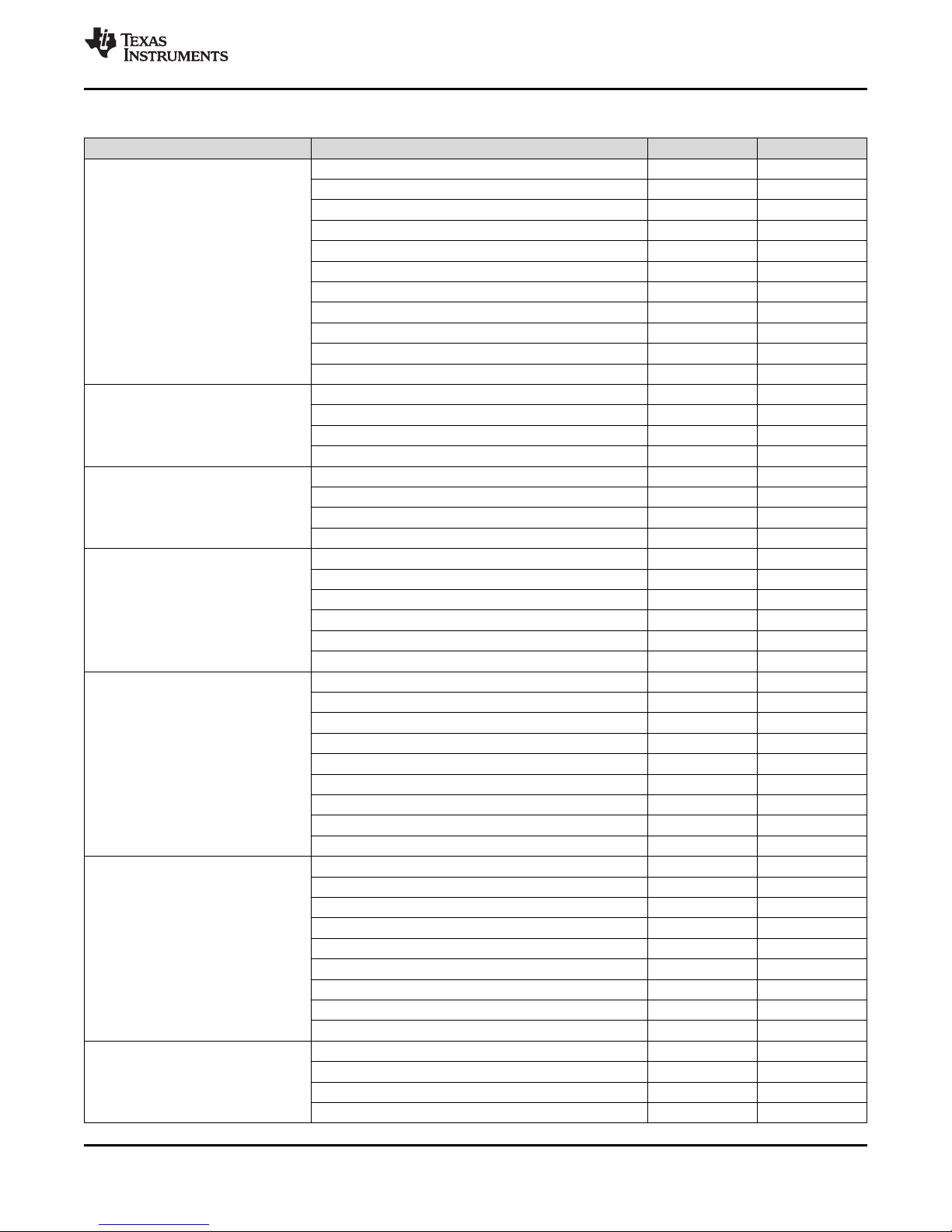

4.2 Signal Descriptions

Table 4-1 describes the signals.

Table 4-1. Terminal Functions

TERMINAL

NO.

NAME

PW20,

N20

PW28 RHB32

P1.0/

TA0CLK/ Timer0_A, clock signal TACLK input

ACLK/ ACLK signal output

2 2 31 I/O

A0 ADC10 analog input A0

P1.1/

TA0.0/ Timer0_A, capture: CCI0A input, compare: Out0 output / BSL transmit

UCA0RXD/ USCI_A0 receive data input in UART mode

3 3 1 I/O

UCA0SOMI/ USCI_A0 slave data out/master in SPI mode

A1 ADC10 analog input A1

P1.2/

TA0.1/ Timer0_A, capture: CCI1A input, compare: Out1 output

UCA0TXD/ USCI_A0 transmit data output in UART mode

4 4 2 I/O

UCA0SIMO/ USCI_A0 slave data in/master out in SPI mode

A2 ADC10 analog input A2

P1.3/

ADC10CLK/ ADC10, conversion clock output

A3/ ADC10 analog input A3

5 5 3 I/O

VREF-/VEREF- ADC10 negative reference voltage

P1.4/

SMCLK/ SMCLK signal output

UCB0STE/ USCI_B0 slave transmit enable

UCA0CLK/ USCI_A0 clock input/output

6 6 4 I/O

A4/ ADC10 analog input A4

VREF+/VEREF+ ADC10 positive reference voltage

TCK JTAG test clock, input terminal for device programming and test

P1.5/

TA0.0/ Timer0_A, compare: Out0 output / BSL receive

UCB0CLK/ USCI_B0 clock input/output

UCA0STE/ USCI_A0 slave transmit enable

7 7 5 I/O

A5/ ADC10 analog input A5

TMS JTAG test mode select, input terminal for device programming and test

P1.6/

TA0.1/ Timer0_A, compare: Out1 output

A6/ ADC10 analog input A6

UCB0SOMI/ USCI_B0 slave out/master in SPI mode,

14 22 21 I/O

UCB0SCL/ USCI_B0 SCL I2C clock in I2C mode

TDI/TCLK JTAG test data input or test clock input during programming and test

I/O DESCRIPTION

General-purpose digital I/O pin

(1)

General-purpose digital I/O pin

(1)

General-purpose digital I/O pin

(1)

General-purpose digital I/O pin

(1)

(1)

(1)

General-purpose digital I/O pin

(1)

(1)

General-purpose digital I/O pin

(1)

General-purpose digital I/O pin

(1)

www.ti.com

(1) MSP430G2x33 devices only

10

Terminal Configuration and Functions Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

Table 4-1. Terminal Functions (continued)

TERMINAL

NO.

NAME

PW20,

N20

PW28 RHB32

P1.7/

A7/ ADC10 analog input A7

UCB0SIMO/ USCI_B0 slave in/master out in SPI mode

15 23 22 I/O

UCB0SDA/ USCI_B0 SDA I2C data in I2C mode

TDO/TDI

P2.0/

TA1.0 Timer1_A, capture: CCI0A input, compare: Out0 output

P2.1/

TA1.1 Timer1_A, capture: CCI1A input, compare: Out1 output

P2.2/

TA1.1 Timer1_A, capture: CCI1B input, compare: Out1 output

P2.3/

TA1.0 Timer1_A, capture: CCI0B input, compare: Out0 output

P2.4/

TA1.2 Timer1_A, capture: CCI2A input, compare: Out2 output

P2.5/

TA1.2 Timer1_A, capture: CCI2B input, compare: Out2 output

8 10 9 I/O

9 11 10 I/O

10 12 11 I/O

11 16 15 I/O

12 17 16 I/O

13 18 17 I/O

XIN/

P2.6/ General-purpose digital I/O pin

19 27 26 I/O

TA0.1 Timer0_A, compare: Out1 output

XOUT/

P2.7 General-purpose digital I/O pin

P3.0/

TA0.2 Timer0_A, capture: CCI2A input, compare: Out2 output

P3.1/

TA1.0 Timer1_A, compare: Out0 output

P3.2/

TA1.1 Timer1_A, compare: Out1 output

P3.3/

TA1.2 Timer1_A, compare: Out2 output

P3.4/

TA0.0 Timer0_A, compare: Out0 output

P3.5/

TA0.1 Timer0_A, compare: Out1 output

P3.6/

TA0.2 Timer0_A, compare: Out2 output

P3.7/

TA1CLK Timer1_A, clock signal TACLK input

18 26 25 I/O

- 9 7 I/O

- 8 6 I/O

- 13 12 I/O

- 14 13 I/O

- 15 14 I/O

- 19 18 I/O

- 20 19 I/O

- 21 20 I/O

RST/

NMI/ Nonmaskable interrupt input

16 24 23 I

SBWTDIO Spy-Bi-Wire test data input/output during programming and test

I/O DESCRIPTION

General-purpose digital I/O pin

(1)

JTAG test data output terminal or test data input during programming and

(2)

test

General-purpose digital I/O pin

General-purpose digital I/O pin

General-purpose digital I/O pin

General-purpose digital I/O pin

General-purpose digital I/O pin

General-purpose digital I/O pin

Input terminal of crystal oscillator

Output terminal of crystal oscillator

(3)

General-purpose digital I/O pin

General-purpose digital I/O pin

General-purpose digital I/O pin

General-purpose digital I/O

General-purpose digital I/O

General-purpose digital I/O

General-purpose digital I/O

General-purpose digital I/O

Reset

(2) TDO or TDI is selected by JTAG instruction.

(3) If XOUT/P2.7 is used as an input, excess current flows until P2SEL.7 is cleared. This is due to the oscillator output driver connection to

this pad after reset.

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

Terminal Configuration and FunctionsCopyright © 2011–2016, Texas Instruments Incorporated

11

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

Table 4-1. Terminal Functions (continued)

TERMINAL

NO.

NAME

TEST/

SBWTCK Spy-Bi-Wire test clock input during programming and test

AVCC NA NA 29 NA Analog supply voltage

DVCC 1 1 30 NA Digital supply voltage

DVSS 20 28 27, 28 NA Ground reference

NC NA NA 8, 32 NA Not connected

QFN Pad NA NA Pad NA QFN package pad connection to VSS recommended.

PW20,

N20

17 25 24 I

PW28 RHB32

I/O DESCRIPTION

Selects test mode for JTAG pins on Port 1. The device protection fuse is

connected to TEST.

www.ti.com

12

Terminal Configuration and Functions Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

www.ti.com

5 Specifications

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.1 Absolute Maximum Ratings

(1)

over operating free-air temperature range (unless otherwise noted)

MIN MAX UNIT

Voltage applied at VCCto V

Voltage applied to any pin

SS

(2)

–0.3 4.1 V

–0.3 VCC+ 0.3 V

Diode current at any device pin ±2 mA

Storage temperature, T

(3)

stg

Unprogrammed device –55 150

Programmed device –55 150

°C

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages referenced to VSS. The JTAG fuse-blow voltage, VFB, is allowed to exceed the absolute maximum rating. The voltage is

applied to the TEST pin when blowing the JTAG fuse.

(3) Higher temperature may be applied during board soldering according to the current JEDEC J-STD-020 specification with peak reflow

temperatures not higher than classified on the device label on the shipping boxes or reels.

5.2 ESD Ratings

VALUE UNIT

V

Electrostatic discharge

(ESD)

Human-body model (HBM), per ANSI/ESDA/JEDEC JS-001

Charged-device model (CDM), per JEDEC specification JESD22-C101

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process. Pins listed as

±1000 V may actually have higher performance.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process. Pins listed as ±250 V

may actually have higher performance.

(1)

(2)

±1000

±250

V

5.3 Recommended Operating Conditions

Typical values are specified at VCC= 3.3 V and TA= 25°C (unless otherwise noted)

MIN NOM MAX UNIT

V

CC

V

SS

T

A

f

SYSTEM

Supply voltage

Supply voltage 0 V

Operating free-air temperature –40 85 °C

Processor frequency (maximum MCLK frequency

using the USART module)

(1)(2)

(1) The MSP430 CPU is clocked directly with MCLK. Both the high and low phases of MCLK must not exceed the pulse duration of the

specified maximum frequency.

(2) Modules might have a different maximum input clock specification. See the specification of the respective module in this data sheet.

During program execution 1.8 3.6

During flash programming or erase 2.2 3.6

VCC= 1.8 V,

Duty cycle = 50% ±10%

VCC= 2.7 V,

Duty cycle = 50% ±10%

VCC= 3.3 V,

Duty cycle = 50% ±10%

DC 6

DC 12

DC 16

V

MHz

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

13

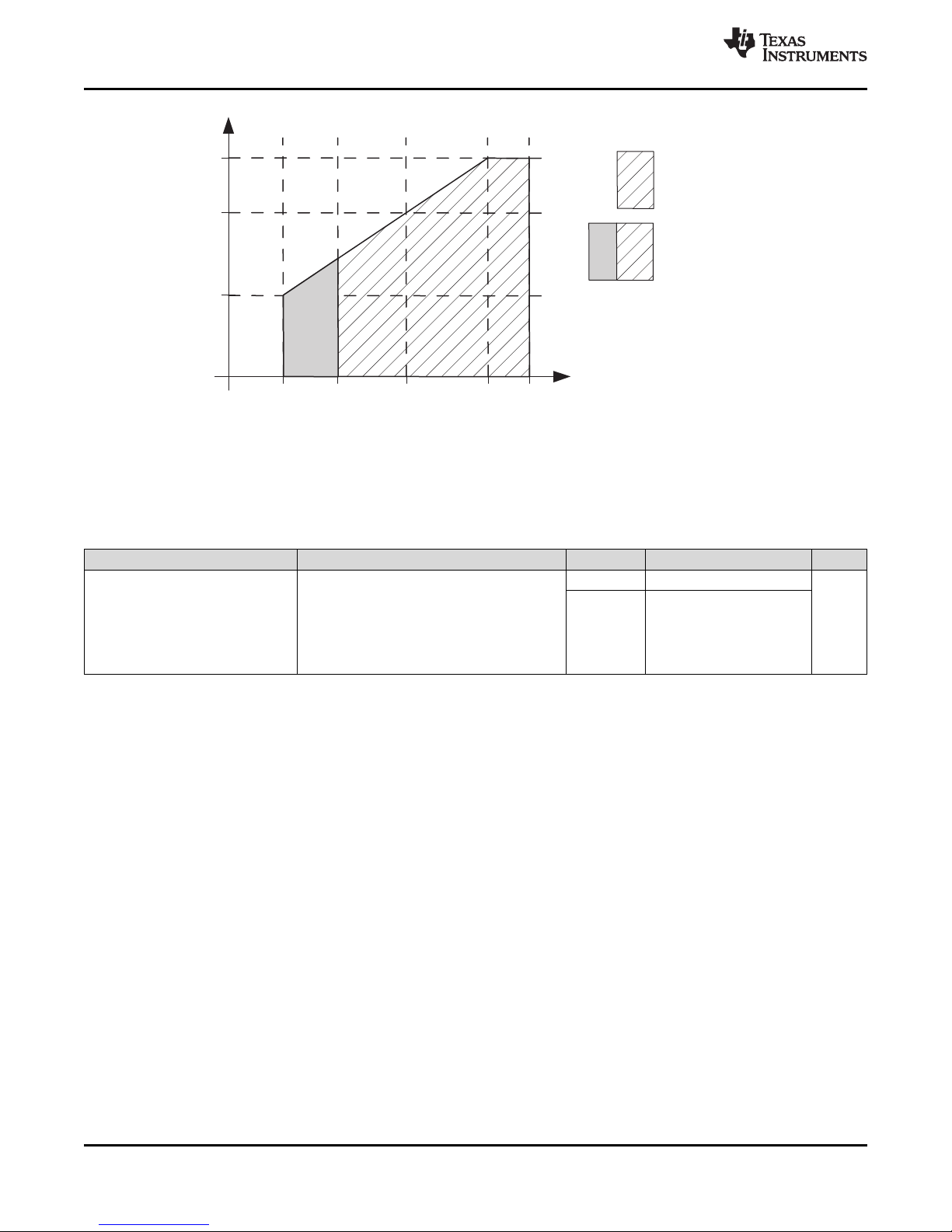

Supply voltage range,

during flash memory

programming

Supply voltage range,

during program execution

Legend:

16 MHz

System Frequency - MHz

12 MHz

6 MHz

1.8 V

Supply Voltage - V

3.3 V

2.7 V

2.2 V

3.6 V

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

www.ti.com

Note: Minimum processor frequency is defined by system clock. Flash program or erase operations require a minimum V

of 2.2 V.

CC

Figure 5-1. Safe Operating Area

5.4 Active Mode Supply Current Into VCCExcluding External Current

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

I

AM,1MHz

PARAMETER TEST CONDITIONS V

f

= f

Active mode (AM)

current at 1 MHz

MCLK

= 0 Hz,

= f

DCO

f

ACLK

Program executes in flash,

BCSCTL1 = CALBC1_1MHZ,

DCOCTL = CALDCO_1MHZ,

SMCLK

= 1 MHz,

CC

2.2 V 230

3 V 330 420

CPUOFF = 0, SCG0 = 0, SCG1 = 0,

OSCOFF = 0

(1) All inputs are tied to 0 V or to VCC. Outputs do not source or sink any current.

(2) The currents are characterized with a Micro Crystal CC4V-T1A SMD crystal with a load capacitance of 9 pF. The internal and external

load capacitance is chosen to closely match the required 9 pF.

MIN TYP MAX UNIT

(1)(2)

µA

14

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

0.0

1.0

2.0

3.0

4.0

5.0

1.5 2.0 2.5 3.0 3.5 4.0

VCC− Supply Voltage − V

Active Mode Current − mA

f

DCO

= 1 MHz

f

DCO

= 8 MHz

f

DCO

= 12 MHz

f

DCO

= 16 MHz

0.0

1.0

2.0

3.0

4.0

0.0 4.0 8.0 12.0 16.0

f

DCO

− DCO Frequency − MHz

Active Mode Current − mA

TA= 25 °C

TA= 85 °C

VCC= 2.2 V

VCC= 3 V

TA= 25 °C

TA= 85 °C

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.5 Typical Characteristics, Active Mode Supply Current (Into VCC)

Figure 5-2. Active Mode Current vs VCC, TA= 25°C Figure 5-3. Active Mode Current vs DCO Frequency

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

15

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

www.ti.com

5.6 Low-Power Mode Supply Currents (Into VCC) Excluding External Current

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

I

LPM0,1MHz

PARAMETER TEST CONDITIONS T

f

= 0 MHz,

MCLK

f

= f

= 1 MHz,

DCO

= 32768 Hz,

Low-power mode 0

(LPM0) current

(3)

SMCLK

f

ACLK

BCSCTL1 = CALBC1_1MHZ,

DCOCTL = CALDCO_1MHZ,

A

25°C 2.2 V 56 µA

CPUOFF = 1, SCG0 = 0, SCG1 = 0,

OSCOFF = 0

f

I

LPM2

Low-power mode 2

(LPM2) current

(4)

= f

MCLK

f

= 1 MHz,

DCO

f

= 32768 Hz,

ACLK

BCSCTL1 = CALBC1_1MHZ,

DCOCTL = CALDCO_1MHZ,

SMCLK

= 0 MHz,

25°C 2.2 V 22 µA

CPUOFF = 1, SCG0 = 0, SCG1 = 1,

OSCOFF = 0

f

= f

I

LPM3,LFXT1

Low-power mode 3

(LPM3) current

(4)

DCO

f

ACLK

CPUOFF = 1, SCG0 = 1, SCG1 = 1,

= f

MCLK

= 32768 Hz,

SMCLK

= 0 MHz,

25°C 2.2 V 0.7 1.5 µA

OSCOFF = 0

f

= f

I

LPM3,VLO

Low-power mode 3

current, (LPM3)

(4)

DCO

f

ACLK

CPUOFF = 1, SCG0 = 1, SCG1 = 1,

= f

MCLK

from internal LF oscillator (VLO),

SMCLK

= 0 MHz,

25°C 2.2 V 0.5 0.7 µA

OSCOFF = 0

f

= f

I

LPM4

Low-power mode 4

(LPM4) current

(5)

MCLK

= 0 Hz,

= f

DCO

f

ACLK

CPUOFF = 1, SCG0 = 1, SCG1 = 1,

OSCOFF = 1

SMCLK

= 0 MHz,

25°C

85°C 0.8 1.7

(1) All inputs are tied to 0 V or to VCC. Outputs do not source or sink any current.

(2) The currents are characterized with a Micro Crystal CC4V-T1A SMD crystal with a load capacitance of 9 pF. The internal and external

load capacitance is chosen to closely match the required 9 pF.

(3) Current for brownout and WDT clocked by SMCLK included.

(4) Current for brownout and WDT clocked by ACLK included.

(5) Current for brownout included.

V

CC

2.2 V

(1) (2)

MIN TYP MAX UNIT

0.1 0.5

µA

16

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

2.75

3.00

-40

I – Low-Power Mode Current – µA

LPM3

V = 3.6 V

CC

T – Temperature – °C

A

VCC= 1.8 V

VCC= 3 V

VCC= 2.2 V

-20

0

20

40 60 80

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

-40

I – Low-Power Mode Current – µA

LPM4

V = 3.6 V

CC

T – Temperature – °C

A

VCC= 1.8 V

VCC= 3 V

VCC= 2.2 V

-20

0

20

40 60 80

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.7 Typical Characteristics, Low-Power Mode Supply Currents

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

Figure 5-4. LPM3 Current vs Temperature

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Figure 5-5. LPM4 Current vs Temperature

Submit Documentation Feedback

MSP430G2203

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

17

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

www.ti.com

5.8 Thermal Resistance Characteristics

PARAMETER VALUE

VQFN (RHB-32) 32.1

Rθ

JA

Junction-to-ambient thermal resistance, still air

(2)

TSSOP (PW-28) 72.2

TSSOP (PW-20) 86.5

PDIP (N-20) 49.3

VQFN (RHB-32) 22.3

Rθ

JC(TOP)

Junction-to-case (top) thermal resistance

(3)

TSSOP (PW-28) 18.3

TSSOP (PW-20) 20.8

PDIP (N-20) 41

VQFN (RHB-32) 1.4

Rθ

JC(BOTTOM)

Junction-to-case (bottom) thermal resistance

TSSOP (PW-28) N/A

TSSOP (PW-20) N/A

PDIP (N-20) N/A

VQFN (RHB-32) 6.1

θ

JB

Junction-to-board thermal resistance

(4)

TSSOP (PW-28) 30.4

TSSOP (PW-20) 39

PDIP (N-20) 30.2

VQFN (RHB-32) 0.3

Ψ

JT

Junction-to-package-top characterization parameter

TSSOP (PW-28) 0.7

TSSOP (PW-20) 0.8

PDIP (N-20) 18.1

VQFN (RHB-32) 6.1

Ψ

JB

Junction-to-board characterization parameter

TSSOP (PW-28) 29.9

TSSOP (PW-20) 38.1

PDIP (N-20) 30.1

(1) These values are based on a JEDEC-defined 2S2P system (with the exception of the Theta JC (RθJC) value, which is based on a

JEDEC-defined 1S0P system) and will change based on environment and application. For more information, see these EIA/JEDEC

standards:

• JESD51-2, Integrated Circuits Thermal Test Method Environmental Conditions - Natural Convection (Still Air)

• JESD51-3, Low Effective Thermal Conductivity Test Board for Leaded Surface Mount Packages

• JESD51-7, High Effective Thermal Conductivity Test Board for Leaded Surface Mount Packages

• JESD51-9, Test Boards for Area Array Surface Mount Package Thermal Measurements

(2) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, High-K board, as

specified in JESD51-7, in an environment described in JESD51-2a.

(3) The junction-to-case (top) thermal resistance is obtained by simulating a cold plate test on the package top. No specific JEDEC-

standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(4) The junction-to-board thermal resistance is obtained by simulating in an environment with a ring cold plate fixture to control the PCB

temperature, as described in JESD51-8.

(1)

UNIT

°C/W

°C/W

°C/W

°C/W

°C/W

°C/W

18

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.9 Schmitt-Trigger Inputs, Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

V

Positive-going input threshold voltage

IT+

V

Negative-going input threshold voltage

IT–

V

Input voltage hysteresis (V

hys

R

Pullup or pulldown resistor

Pull

C

Input capacitance VIN= VSSor V

I

IT+

– V

) 3 V 0.3 1 V

IT–

For pullup: VIN= V

For pulldown: VIN= V

SS

CC

CC

CC

3 V 1.35 2.25

3 V 0.75 1.65

3 V 20 35 50 kΩ

MIN TYP MAX UNIT

0.45 V

0.25 V

CC

CC

0.75 V

0.55 V

5 pF

CC

CC

5.10 Leakage Current, Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

I

lkg(Px.y)

PARAMETER TEST CONDITIONS V

High-impedance leakage current See

(1) (2)

CC

3 V ±50 nA

(1) The leakage current is measured with VSSor VCCapplied to the corresponding pins, unless otherwise noted.

(2) The leakage of the digital port pins is measured individually. The port pin is selected for input and the pullup/pulldown resistor is

disabled.

MIN MAX UNIT

V

V

5.11 Outputs, Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

V

V

High-level output voltage I

OH

Low-level output voltage I

OL

(1) The maximum total current, I

specified.

(OHmax)

and I

= –6 mA

(OHmax)

= 6 mA

(OLmax)

, for all outputs combined should not exceed ±48 mA to hold the maximum voltage drop

(OLmax)

(1)

(1)

CC

3 V VCC– 0.3 V

3 V VSS+ 0.3 V

MIN TYP MAX UNIT

5.12 Output Frequency, Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

f

Px.y

f

Port_CLK

PARAMETER TEST CONDITIONS V

Port output frequency (with load) Px.y, CL= 20 pF, RL= 1 kΩ

Clock output frequency Px.y, CL= 20 pF

(2)

(1) (2)

CC

3 V 12 MHz

3 V 16 MHz

(1) A resistive divider with two 50-kΩ resistors between VCCand VSSis used as load. The output is connected to the center tap of the

divider.

(2) The output voltage reaches at least 10% and 90% VCCat the specified toggle frequency.

MIN TYP MAX UNIT

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

19

VOH− High-Level Output Voltage − V

−25

−20

−15

−10

−5

0

0 0.5 1 1.5 2 2.5

VCC= 2.2 V

P1.7

TA= 25°C

TA= 85°C

OH

I − Typical High-Level Output Current − mA

VOH− High-Level Output Voltage − V

−50

−40

−30

−20

−10

0

0 0.5 1 1.5 2 2.5 3 3.5

VCC= 3 V

P1.7

TA= 25°C

TA= 85°C

OH

I − Typical High-Level Output Current − mA

VOL− Low-Level Output Voltage − V

0

5

10

15

20

25

30

0 0.5 1 1.5 2 2.5

VCC= 2.2 V

P1.7

TA= 25°C

TA= 85°C

OL

I − Typical Low-Level Output Current − mA

VOL− Low-Level Output Voltage − V

0

10

20

30

40

50

0 0.5 1 1.5 2 2.5 3 3.5

VCC= 3 V

P1.7

TA= 25°C

TA= 85°C

OL

I − Typical Low-Level Output Current − mA

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.13 Typical Characteristics – Outputs

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

www.ti.com

Figure 5-6. Typical Low-Level Output Current vs Low-Level

Figure 5-8. Typical High-Level Output Current vs High-Level

Output Voltage

Output Voltage

Figure 5-7. Typical Low-Level Output Current vs Low-Level

Figure 5-9. Typical High-Level Output Current vs High-Level

Output Voltage

Output Voltage

20

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

C − External Capacitance − pF

LOAD

0.00

0.15

0.30

0.45

0.60

0.75

0.90

1.05

1.20

1.35

1.50

10 50 100

P1.y

P2.0 to P2.5

P2.6, P2.7

V = 3.0 V

CC

f − Typical Oscillation Frequency − MHz

osc

C − External Capacitance − pF

LOAD

0.00

0.15

0.30

0.45

0.60

0.75

0.90

1.05

1.20

1.35

1.50

10 50 100

P1.y

P2.0 to P2.5

P2.6, P2.7

V = 2.2 V

CC

f − Typical Oscillation Frequency − MHz

osc

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.14 Pin-Oscillator Frequency – Ports Px

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

fo

fo

fo

fo

Port output oscillation frequency

P1.x

Port output oscillation frequency

P2.x

Port output oscillation frequency

P2.6/7

Port output oscillation frequency

P3.x

P1.y, CL= 10 pF, RL= 100 kΩ

P1.y, CL= 20 pF, RL= 100 kΩ

P2.0 to P2.5, CL= 10 pF, RL= 100 kΩ

P2.0 to P2.5, CL= 20 pF, RL= 100 kΩ

P2.6 and P2.7, CL= 20 pF, RL= 100

(1)(2)

kΩ

P3.y, CL= 10 pF, RL= 100 kΩ

P3.y, CL= 20 pF, RL= 100 kΩ

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

3 V

3 V

3 V 700 kHz

3 V

(1) A resistive divider with two 50-kΩ resistors between VCCand VSSis used as load. The output is connected to the center tap of the

divider.

(2) The output voltage reaches at least 10% and 90% VCCat the specified toggle frequency.

MIN TYP MAX UNIT

CC

1400

900

1800

1000

1800

1000

5.15 Typical Characteristics – Pin-Oscillator Frequency

kHz

kHz

kHz

Figure 5-10. Typical Oscillating Frequency vs Load Capacitance

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

One output active at a time.

Figure 5-11. Typical Oscillating Frequency vs Load Capacitance

Submit Documentation Feedback

MSP430G2203

One output active at a time.

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

21

V

CC(drop)

V

CC

3 V

t

pw

0

0.5

1

1.5

2

0.001 1 1000

Typical Conditions

1 ns 1 ns

tpw− Pulse Width − µs

V

CC(drop)

− V

tpw− Pulse Width − µs

VCC= 3 V

0

1

t

d(BOR)

V

CC

V

(B_IT−)

V

hys(B_IT−)

V

CC(s tar t)

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

www.ti.com

5.16 POR, BOR

(1)(2)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER

V

CC(start)

V

(B_IT–)

V

hys(B_IT–)

t

d(BOR)

t

(reset)

See Figure 5-12 dVCC/dt ≤ 3 V/s 0.7 V

See Figure 5-12 through Figure 5-14 dVCC/dt ≤ 3 V/s 1.35 V

See Figure 5-12 dVCC/dt ≤ 3 V/s 140 mV

See Figure 5-12 2000 µs

Pulse duration needed at RST/NMI pin to accepted

reset internally

(1) The current consumption of the brownout module is already included in the ICCcurrent consumption data. The voltage level V

V

hys(B_IT–)

(2) During power up, the CPU begins code execution following a period of t

must not be changed until VCC≥ V

is ≤ 1.8 V.

CC(min)

, where V

is the minimum supply voltage for the desired operating frequency.

CC(min)

TEST

CONDITIONS

d(BOR)

V

CC

MIN TYP MAX UNIT

(B_IT--)

2.2 V 2 µs

after VCC= V

(B_IT–)

+ V

. The default DCO settings

hys(B_IT–)

(B_IT–)

V

+

Figure 5-12. POR and BOR vs Supply Voltage

Figure 5-13. V

CC(drop)

Level With a Square Voltage Drop to Generate a POR or BOR Signal

22

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

V

CC

0

0.5

1

1.5

2

V

CC(drop)

t

pw

tpw− Pulse Width − µs

V

CC(drop)

− V

3 V

0.001 1 1000

t

f

t

r

tpw− Pulse Width − µs

tf= t

r

Typical Conditions

VCC= 3 V

www.ti.com

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

Figure 5-14. V

CC(drop)

Level With a Triangle Voltage Drop to Generate a POR or BOR Signal

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

23

DCO(RSEL,DCO+1)

DCO(RSEL,DCO)

average

DCO(RSEL,DCO) DCO(RSEL,DCO+1)

32 × f × f

f =

MOD × f + (32 – MOD) × f

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.17 Main DCO Characteristics

• All ranges selected by RSELx overlap with RSELx + 1: RSELx = 0 overlaps RSELx = 1, ... RSELx = 14 overlaps RSELx = 15.

• DCO control bits DCOx have a step size as defined by parameter S

• Modulation control bits MODx select how often f

f

DCO(RSEL,DCO)

is used for the remaining cycles. The frequency is an average equal to:

DCO(RSEL,DCO+1)

.

DCO

is used within the period of 32 DCOCLK cycles. The frequency

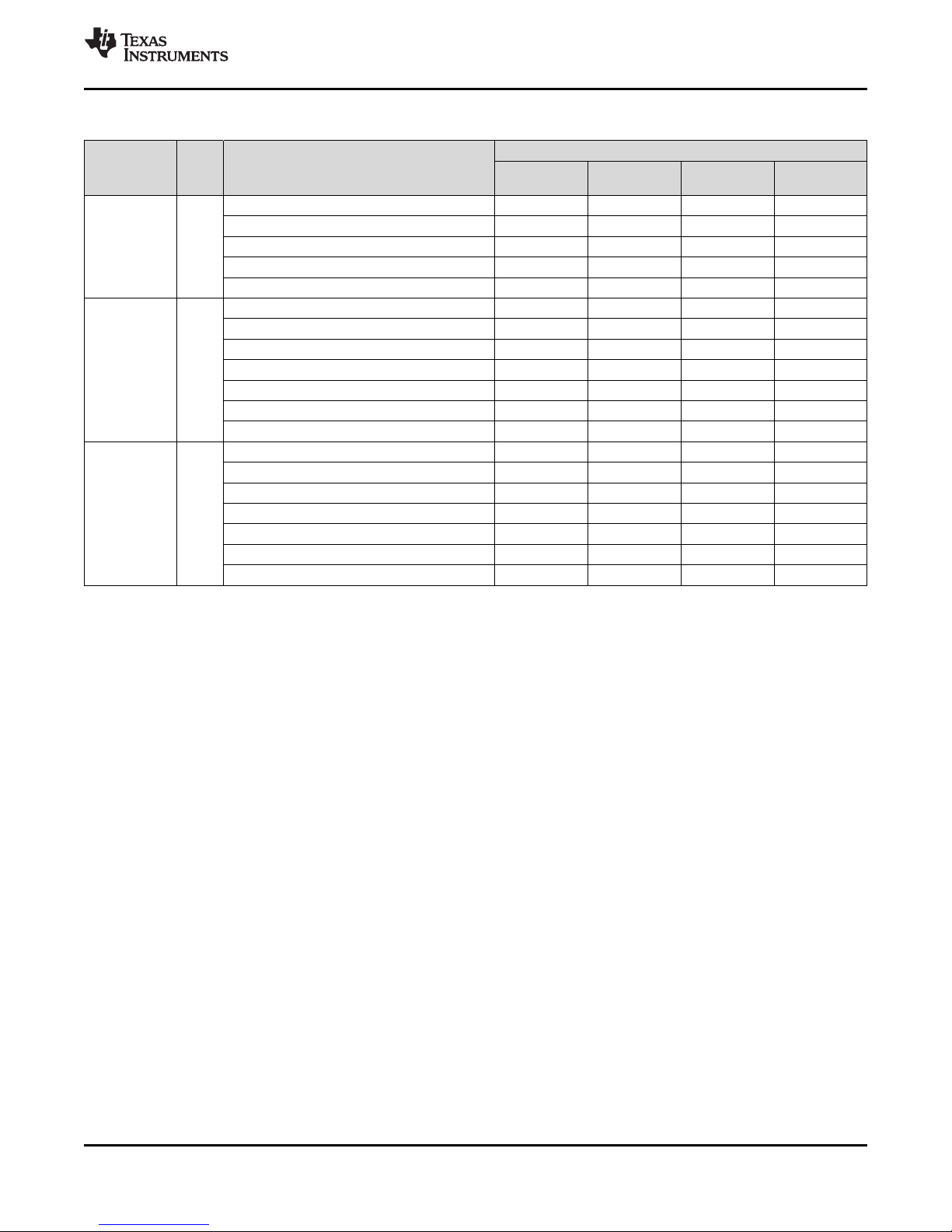

5.18 DCO Frequency

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

CC

RSELx < 14 1.8 3.6

V

CC

Supply voltage

RSELx = 15 3 3.6

f

DCO(0,0)

f

DCO(0,3)

f

DCO(1,3)

f

DCO(2,3)

f

DCO(3,3)

f

DCO(4,3)

f

DCO(5,3)

f

DCO(6,3)

f

DCO(7,3)

f

DCO(8,3)

f

DCO(9,3)

f

DCO(10,3)

f

DCO(11,3)

f

DCO(12,3)

f

DCO(13,3)

f

DCO(14,3)

f

DCO(15,3)

f

DCO(15,7)

S

RSEL

S

DCO

DCO frequency (0, 0) RSELx = 0, DCOx = 0, MODx = 0 3 V 0.06 0.14 MHz

DCO frequency (0, 3) RSELx = 0, DCOx = 3, MODx = 0 3 V 0.07 0.17 MHz

DCO frequency (1, 3) RSELx = 1, DCOx = 3, MODx = 0 3 V 0.15 MHz

DCO frequency (2, 3) RSELx = 2, DCOx = 3, MODx = 0 3 V 0.21 MHz

DCO frequency (3, 3) RSELx = 3, DCOx = 3, MODx = 0 3 V 0.30 MHz

DCO frequency (4, 3) RSELx = 4, DCOx = 3, MODx = 0 3 V 0.41 MHz

DCO frequency (5, 3) RSELx = 5, DCOx = 3, MODx = 0 3 V 0.58 MHz

DCO frequency (6, 3) RSELx = 6, DCOx = 3, MODx = 0 3 V 0.54 1.06 MHz

DCO frequency (7, 3) RSELx = 7, DCOx = 3, MODx = 0 3 V 0.80 1.50 MHz

DCO frequency (8, 3) RSELx = 8, DCOx = 3, MODx = 0 3 V 1.6 MHz

DCO frequency (9, 3) RSELx = 9, DCOx = 3, MODx = 0 3 V 2.3 MHz

DCO frequency (10, 3) RSELx = 10, DCOx = 3, MODx = 0 3 V 3.4 MHz

DCO frequency (11, 3) RSELx = 11, DCOx = 3, MODx = 0 3 V 4.25 MHz

DCO frequency (12, 3) RSELx = 12, DCOx = 3, MODx = 0 3 V 4.30 7.30 MHz

DCO frequency (13, 3) RSELx = 13, DCOx = 3, MODx = 0 3 V 6.00 9.60 MHz

DCO frequency (14, 3) RSELx = 14, DCOx = 3, MODx = 0 3 V 8.60 13.9 MHz

DCO frequency (15, 3) RSELx = 15, DCOx = 3, MODx = 0 3 V 12.0 18.5 MHz

DCO frequency (15, 7) RSELx = 15, DCOx = 7, MODx = 0 3 V 16.0 26.0 MHz

Frequency step between

range RSEL and RSEL+1

Frequency step between

tap DCO and DCO+1

S

S

= f

RSEL

DCO(RSEL+1,DCO)/fDCO(RSEL,DCO)

= f

DCO

DCO(RSEL,DCO+1)/fDCO(RSEL,DCO)

3 V 1.35 ratio

3 V 1.08 ratio

Duty cycle Measured at SMCLK output 3 V 50%

MIN TYP MAX UNIT

www.ti.com

VRSELx = 14 2.2 3.6

24

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.19 Calibrated DCO Frequencies, Tolerance

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS T

1-MHz tolerance over

temperature

(1)

BCSCTL1 = CALBC1_1MHZ,

DCOCTL = CALDCO_1MHZ,

calibrated at 30°C and 3 V

A

0°C to 85°C 3 V –3% ±0.5% +3%

BCSCTL1 = CALBC1_1MHZ,

1-MHz tolerance over V

CC

DCOCTL = CALDCO_1MHZ,

calibrated at 30°C and 3 V

30°C 1.8 V to 3.6 V –3% ±2% +3%

BCSCTL1 = CALBC1_1MHZ,

1-MHz tolerance overall

DCOCTL = CALDCO_1MHZ,

–40°C to 85°C 1.8 V to 3.6 V –6% ±3% +6%

calibrated at 30°C and 3 V

8-MHz tolerance over

temperature

(1)

BCSCTL1 = CALBC1_8MHZ,

DCOCTL = CALDCO_8MHZ,

calibrated at 30°C and 3 V

0°C to 85°C 3 V –3% ±0.5% +3%

BCSCTL1 = CALBC1_8MHZ,

8-MHz tolerance over V

CC

DCOCTL = CALDCO_8MHZ,

calibrated at 30°C and 3 V

30°C 2.2 V to 3.6 V –3% ±2% +3%

BCSCTL1 = CALBC1_8MHZ,

8-MHz tolerance overall

DCOCTL = CALDCO_8MHZ,

–40°C to 85°C 2.2 V to 3.6 V –6% ±3% +6%

calibrated at 30°C and 3 V

12-MHz tolerance over

temperature

(1)

BCSCTL1 = CALBC1_12MHZ,

DCOCTL = CALDCO_12MHZ,

calibrated at 30°C and 3 V

0°C to 85°C 3 V –3% ±0.5% +3%

BCSCTL1 = CALBC1_12MHZ,

12-MHz tolerance over V

CC

DCOCTL = CALDCO_12MHZ,

calibrated at 30°C and 3 V

30°C 2.7 V to 3.6 V –3% ±2% +3%

BCSCTL1 = CALBC1_12MHZ,

12-MHz tolerance overall

DCOCTL = CALDCO_12MHZ,

–40°C to 85°C 2.7 V to 3.6 V –6% ±3% +6%

calibrated at 30°C and 3 V

16-MHz tolerance over

temperature

(1)

BCSCTL1 = CALBC1_16MHZ,

DCOCTL = CALDCO_16MHZ,

calibrated at 30°C and 3 V

0°C to 85°C 3 V –3% ±0.5% +3%

BCSCTL1 = CALBC1_16MHZ,

16-MHz tolerance over V

CC

DCOCTL = CALDCO_16MHZ,

calibrated at 30°C and 3 V

30°C 3.3 V to 3.6 V –3% ±2% +3%

BCSCTL1 = CALBC1_16MHZ,

16-MHz tolerance overall

DCOCTL = CALDCO_16MHZ,

–40°C to 85°C 3.3 V to 3.6 V –6% ±3% +6%

calibrated at 30°C and 3 V

(1) This is the frequency change from the measured frequency at 30°C over temperature.

V

CC

MIN TYP MAX UNIT

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

25

DCO Frequency − MHz

0.10

1.00

10.00

0.10 1.00 10.00

DCO Wake Time − µs

RSELx = 0...11

RSELx = 12...15

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

www.ti.com

5.20 Wake-up Times From Lower-Power Modes (LPM3, LPM4)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

t

DCO,LPM3/4

t

CPU,LPM3/4

PARAMETER TEST CONDITIONS V

DCO clock wake-up time from LPM3 or

(1)

LPM4

CPU wake-up time from LPM3 or

(2)

LPM4

BCSCTL1 = CALBC1_1MHz,

DCOCTL = CALDCO_1MHz

CC

3 V 1.5 µs

(1) The DCO clock wake-up time is measured from the edge of an external wake-up signal (for example, port interrupt) to the first clock

edge observable externally on a clock pin (MCLK or SMCLK).

(2) Parameter applicable only if DCOCLK is used for MCLK.

MIN TYP MAX UNIT

1/f

+

MCLK

t

Clock,LPM3/4

5.21 Typical Characteristics, DCO Clock Wake-up Time From LPM3 or LPM4

Figure 5-15. DCO Wake-up Time From LPM3 vs DCO Frequency

26

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

www.ti.com

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.22 Crystal Oscillator, XT1, Low-Frequency Mode

(1)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

f

LFXT1,LF

PARAMETER TEST CONDITIONS V

LFXT1 oscillator crystal

frequency, LF mode 0, 1

XTS = 0, LFXT1Sx = 0 or 1 1.8 V to 3.6 V 32768 Hz

CC

LFXT1 oscillator logic level

f

LFXT1,LF,logic

square-wave input frequency,

LF mode

XTS = 0, XCAPx = 0, LFXT1Sx = 3 1.8 V to 3.6 V 10000 32768 50000 Hz

XTS = 0, LFXT1Sx = 0,

OA

LF

Oscillation allowance for

LF crystals

f

XTS = 0, LFXT1Sx = 0,

f

LFXT1,LF

LFXT1,LF

= 32768 Hz, C

= 32768 Hz, C

L,eff

L,eff

= 6 pF

= 12 pF

XTS = 0, XCAPx = 0 1

C

L,eff

Integrated effective load

capacitance, LF mode

(2)

XTS = 0, XCAPx = 1 5.5

XTS = 0, XCAPx = 2 8.5

XTS = 0, XCAPx = 3 11

XTS = 0, Measured at P2.0/ACLK,

f

LFXT1,LF

= 32768 Hz

XTS = 0, XCAPx = 0, LFXT1Sx = 3

2.2 V 30% 50% 70%

(4)

2.2 V 10 10000 Hz

f

Fault,LF

Duty cycle, LF mode

Oscillator fault frequency,

LF mode

(3)

(1) To improve EMI on the XT1 oscillator, the following guidelines should be observed.

• Keep the trace between the device and the crystal as short as possible.

• Design a good ground plane around the oscillator pins.

• Prevent crosstalk from other clock or data lines into oscillator pins XIN and XOUT.

• Avoid running PCB traces underneath or adjacent to the XIN and XOUT pins.

• Use assembly materials and processes that avoid any parasitic load on the oscillator XIN and XOUT pins.

• If conformal coating is used, make sure that it does not induce capacitive or resistive leakage between the oscillator pins.

• Do not route the XOUT line to the JTAG header to support the serial programming adapter as shown in other documentation. This

signal is no longer required for the serial programming adapter.

(2) Includes parasitic bond and package capacitance (approximately 2 pF per pin).

Because the PCB adds additional capacitance, verify the correct load by measuring the ACLK frequency. For a correct setup, the

effective load capacitance should always match the specification of the used crystal.

(3) Frequencies below the MIN specification set the fault flag. Frequencies above the MAX specification do not set the fault flag.

Frequencies in between might set the flag.

(4) Measured with logic-level input frequency but also applies to operation with crystals.

MIN TYP MAX UNIT

500

200

kΩ

pF

5.23 Internal Very-Low-Power Low-Frequency Oscillator (VLO)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER T

f

VLO

df

VLO/dT

df

VLO

VLO frequency –40°C to 85°C 3 V 4 12 20 kHz

VLO frequency temperature drift –40°C to 85°C 3 V 0.5 %/°C

/dVCCVLO frequency supply voltage drift 25°C 1.8 V to 3.6 V 4 %/V

5.24 Timer_A

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

f

TA

t

TA,cap

Timer_A input clock frequency SMCLK, duty cycle = 50% ±10% f

Timer_A capture timing TA0, TA1 3 V 20 ns

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

A

Submit Documentation Feedback

MSP430G2203

V

CC

CC

MIN TYP MAX UNIT

MIN TYP MAX UNIT

SYSTEM

MHz

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

27

t

SU,MI

t

HD,MI

UCLK

SOMI

SIMO

t

VALID,MO

CKPL = 0

CKPL = 1

1/f

UCxCLK

t

HD,MO

t

LO/HI

t

LO/HI

t

SU,MI

t

HD,MI

UCLK

SOMI

SIMO

t

VALID,MO

t

HD,MO

CKPL = 0

CKPL = 1

t

LO/HI

t

LO/HI

1/f

UCxCLK

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

www.ti.com

5.25 USCI (UART Mode)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

f

USCI

f

max,BITCLK

t

τ

USCI input clock frequency SMCLK, duty cycle = 50% ±10% f

Maximum BITCLK clock frequency

(equals baud rate in MBaud)

UART receive deglitch time

(1)

(2)

3 V 2 MHz

3 V 50 100 600 ns

(1) The DCO wake-up time must be considered in LPM3 and LPM4 for baud rates above 1 MHz.

(2) Pulses on the UART receive input (UCxRX) shorter than the UART receive deglitch time are suppressed. To ensure that pulses are

correctly recognized, their duration should exceed the maximum specification of the deglitch time.

MIN TYP MAX UNIT

CC

SYSTEM

MHz

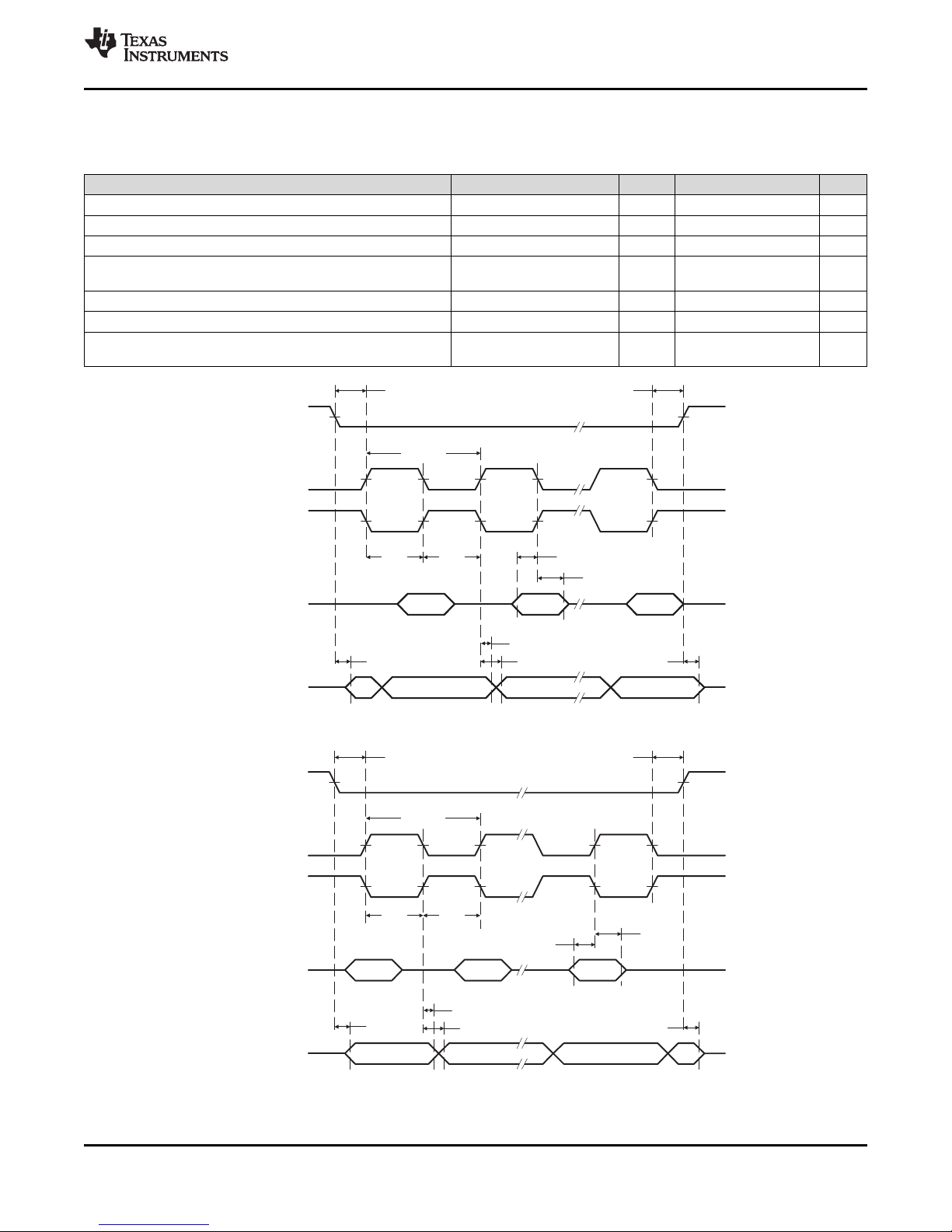

5.26 USCI (SPI Master Mode)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted) (see Figure 5-16

and Figure 5-17)

f

USCI

t

SU,MI

t

HD,MI

t

VALID,MO

PARAMETER TEST CONDITIONS V

CC

USCI input clock frequency SMCLK, duty cycle = 50% ±10% f

SOMI input data setup time 3 V 75 ns

SOMI input data hold time 3 V 0 ns

SIMO output data valid time UCLK edge to SIMO valid, CL= 20 pF 3 V 20 ns

MIN MAX UNIT

SYSTEM

MHz

28

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Figure 5-16. SPI Master Mode, CKPH = 0

Figure 5-17. SPI Master Mode, CKPH = 1

Submit Documentation Feedback

MSP430G2203

STE

UCLK

CKPL = 0

CKPL = 1

SOMI

SIMO

t

SU,SI

t

HD,SI

t

VALID,SO

t

STE,LEAD

1/f

UCxCLK

t

STE,LAG

t

STE,DIS

t

STE,ACC

t

HD,MO

t

LO/HI

t

LO/HI

STE

UCLK

CKPL = 0

CKPL = 1

SOMI

SIMO

t

SU,SI

t

HD,SI

t

VALID,SO

t

STE,LEAD

1/f

UCxCLK

t

LO/HI

t

LO/HI

t

STE,LAG

t

STE,DIS

t

STE,ACC

t

HD,SO

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

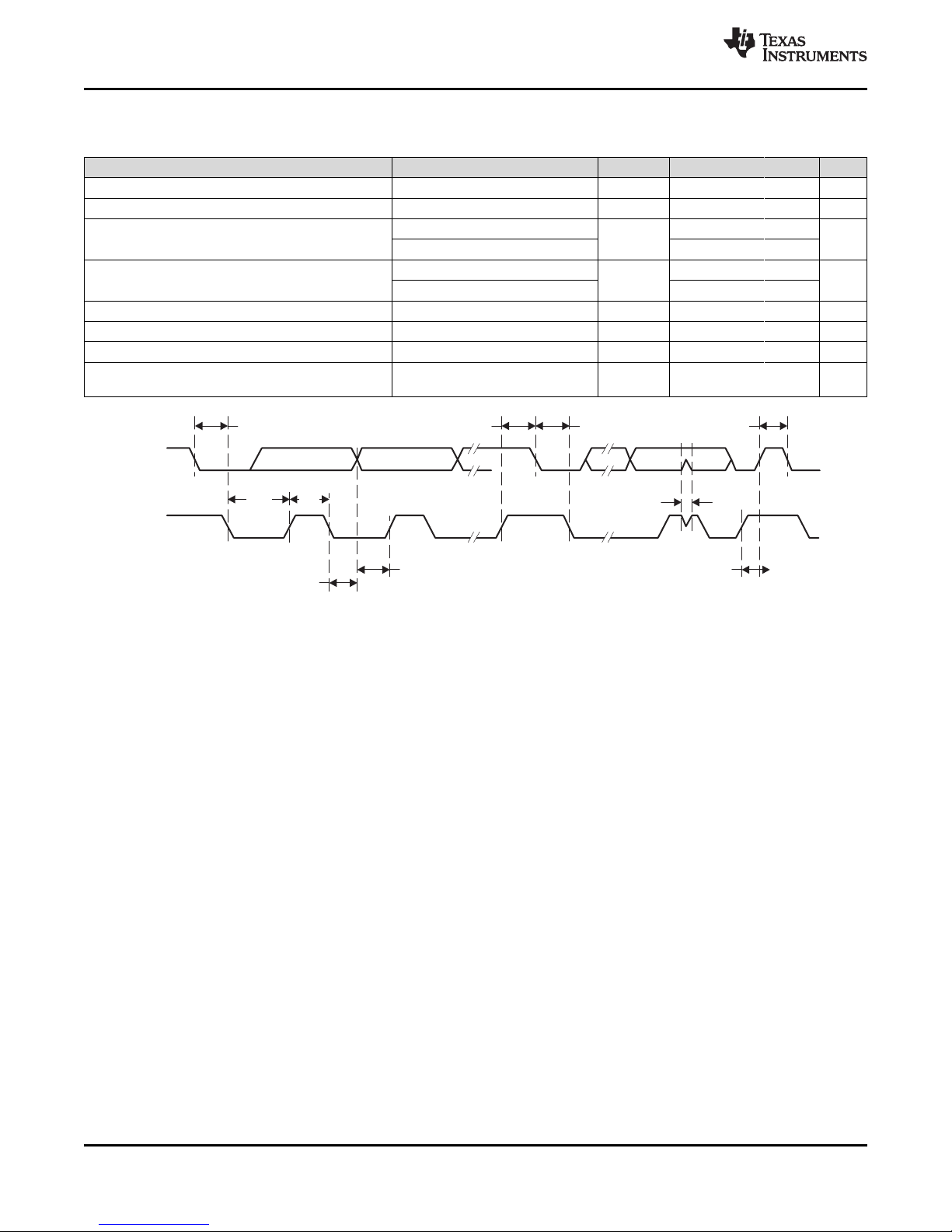

5.27 USCI (SPI Slave Mode)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted) (see Figure 5-18

and Figure 5-19)

t

STE,LEAD

t

STE,LAG

t

STE,ACC

t

STE,DIS

t

SU,SI

t

HD,SI

t

VALID,SO

PARAMETER TEST CONDITIONS V

CC

STE lead time, STE low to clock 3 V 50 ns

STE lag time, Last clock to STE high 3 V 10 ns

STE access time, STE low to SOMI data out 3 V 50 ns

STE disable time, STE high to SOMI high

impedance

3 V 50 ns

SIMO input data setup time 3 V 15 ns

SIMO input data hold time 3 V 10 ns

SOMI output data valid time

UCLK edge to SOMI valid,

CL= 20 pF

3 V 50 75 ns

MIN TYP MAX UNIT

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Figure 5-18. SPI Slave Mode, CKPH = 0

Figure 5-19. SPI Slave Mode, CKPH = 1

Submit Documentation Feedback

MSP430G2203

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

29

SDA

SCL

t

HD,DAT

t

SU,DAT

t

HD,STA

t

HIGH

t

LOW

t

BUF

t

HD,STA

t

SU,STA

t

SP

t

SU,STO

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

www.ti.com

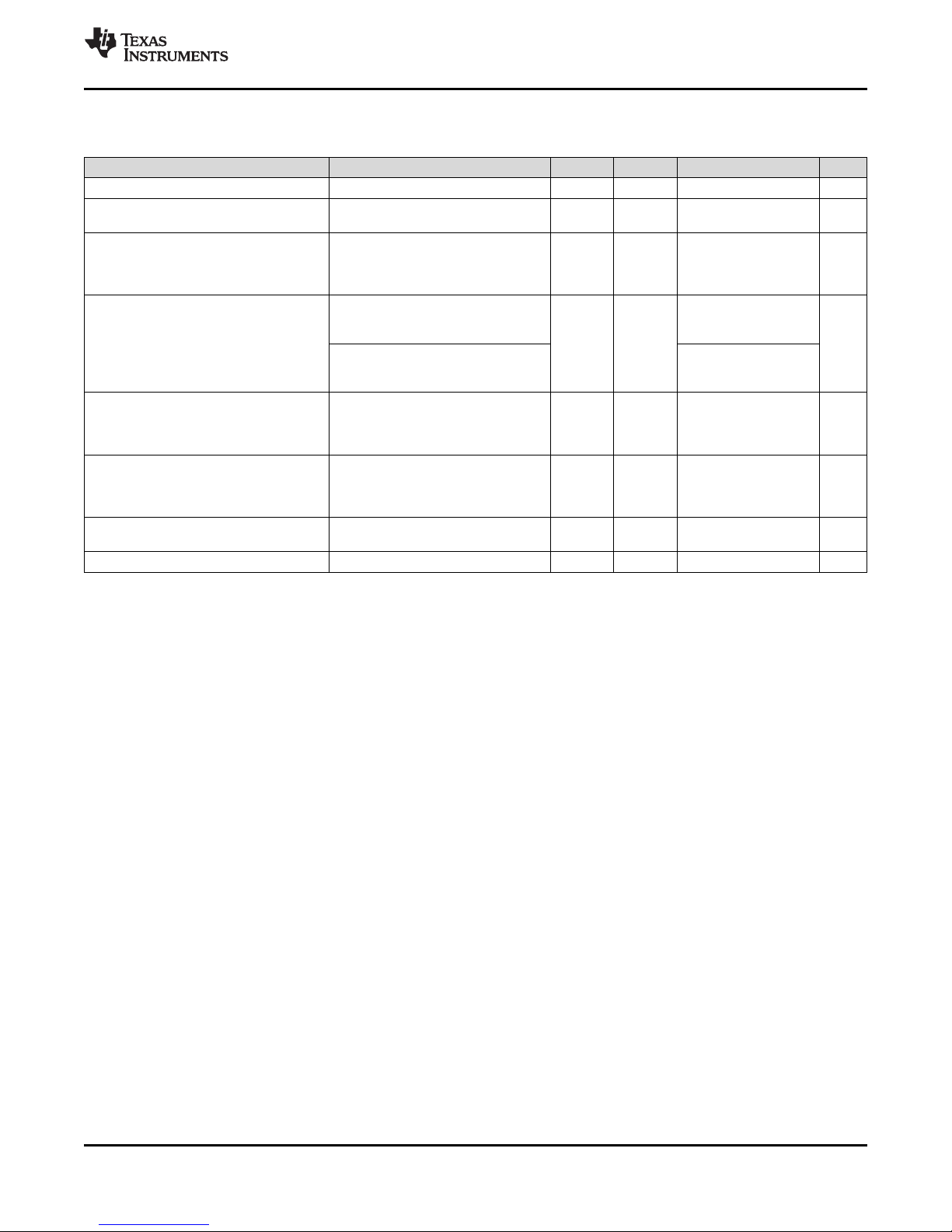

5.28 USCI (I2C Mode)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted) (see Figure 5-20)

f

USCI

f

SCL

t

HD,STA

t

SU,STA

t

HD,DAT

t

SU,DAT

t

SU,STO

t

SP

PARAMETER TEST CONDITIONS V

CC

USCI input clock frequency SMCLK, duty cycle = 50% ±10% f

SCL clock frequency 3 V 0 400 kHz

f

≤ 100 kHz

Hold time (repeated) START

Setup time for a repeated START

SCL

f

> 100 kHz 0.6

SCL

f

≤ 100 kHz

SCL

f

> 100 kHz 0.6

SCL

3 V

3 V

Data hold time 3 V 0 ns

Data setup time 3 V 250 ns

Setup time for STOP 3 V 4.0 µs

Pulse duration of spikes suppressed by

input filter

3 V 50 100 600 ns

MIN TYP MAX UNIT

SYSTEM

MHz

4.0

4.7

µs

µs

Figure 5-20. I2C Mode Timing

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

30

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

www.ti.com

SLAS734G –APRIL 2011–REVISED APRIL 2016

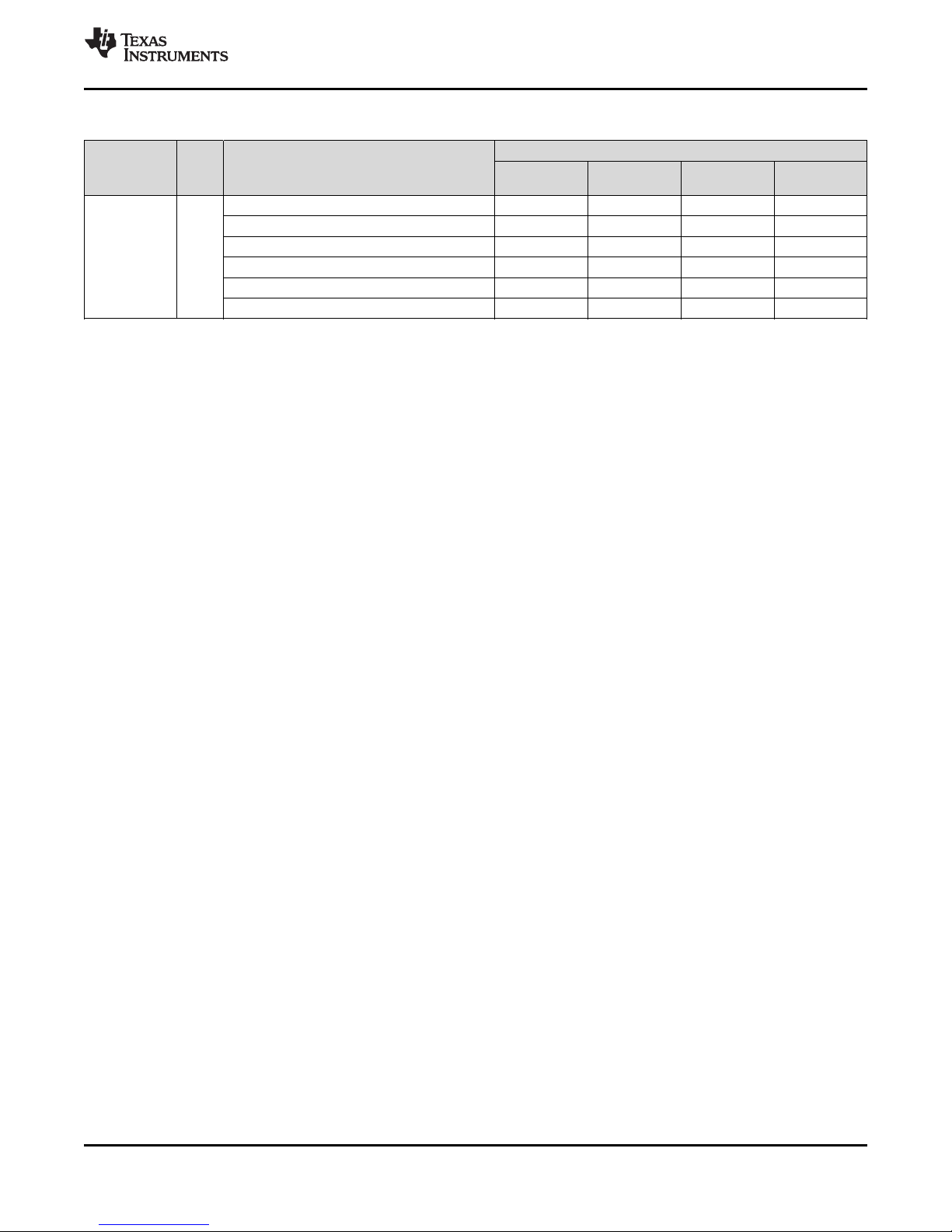

5.29 10-Bit ADC, Power Supply and Input Range Conditions (MSP430G2x33 Only)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

V

CC

V

Ax

I

ADC10

PARAMETER TEST CONDITIONS T

Analog supply voltage VSS= 0 V 2.2 3.6 V

Analog input voltage

ADC10 supply current

(2)

(3)

All Ax terminals, Analog inputs

selected in ADC10AE register

f

ADC10CLK

ADC10ON = 1, REFON = 0,

= 5.0 MHz,

ADC10SHT0 = 1, ADC10SHT1 = 0,

A

25°C 3 V 0.6 mA

ADC10DIV = 0

I

REF+

Reference supply current,

reference buffer disabled

f

ADC10CLK

ADC10ON = 0, REF2_5V = 0,

(4)

REFON = 1, REFOUT = 0

f

ADC10CLK

ADC10ON = 0, REF2_5V = 1,

= 5.0 MHz,

= 5.0 MHz,

25°C 3 V

REFON = 1, REFOUT = 0

I

REFB,0

Reference buffer supply current

with ADC10SR = 0

(4)

f

ADC10CLK

ADC10ON = 0, REFON = 1,

REF2_5V = 0, REFOUT = 1,

= 5.0 MHz,

25°C 3 V 1.1 mA

ADC10SR = 0

I

REFB,1

Reference buffer supply current

with ADC10SR = 1

(4)

f

ADC10CLK

ADC10ON = 0, REFON = 1,

REF2_5V = 0, REFOUT = 1,

= 5.0 MHz,

25°C 3 V 0.5 mA

ADC10SR = 1

C

R

Input capacitance

I

Input MUX ON resistance 0 V ≤ VAx≤ V

I

Only one terminal Ax can be selected

at one time

CC

25°C 3 V 27 pF

25°C 3 V 1000 Ω

(1) The leakage current is defined in the leakage current table with Px.y/Ax parameter.

(2) The analog input voltage range must be within the selected reference voltage range VR+to VR–for valid conversion results.

(3) The internal reference supply current is not included in current consumption parameter I

(4) The internal reference current is supplied through terminal VCC. Consumption is independent of the ADC10ON control bit, unless a

conversion is active. The REFON bit enables the built-in reference to settle before starting an A/D conversion.

V

CC

3 V 0 V

.

ADC10

(1)

MIN TYP MAX UNIT

CC

0.25

0.25

V

mA

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

SpecificationsCopyright © 2011–2016, Texas Instruments Incorporated

31

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.30 10-Bit ADC, Built-In Voltage Reference (MSP430G2x33 Only)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

V

CC,REF+

V

REF+

I

LD,VREF+

C

VREF+

TC

REF+

t

REFON

t

REFBURST

PARAMETER TEST CONDITIONS V

I

≤ 1 mA, REF2_5V = 0 2.2

Positive built-in reference

analog supply voltage range

Positive built-in reference

voltage

VREF+

I

≤ 1 mA, REF2_5V = 1 2.9

VREF+

I

≤ I

VREF+

I

VREF+

max, REF2_5V = 0

VREF+

≤ I

max, REF2_5V = 1 2.35 2.5 2.65

VREF+

CC

3 V

Maximum VREF+ load current 3 V ±1 mA

I

= 500 µA ±100 µA,

VREF+

Analog input voltage VAx≈ 0.75 V,

VREF+ load regulation

REF2_5V = 0

I

= 500 µA ±100 µA,

VREF+

Analog input voltage VAx≈ 1.25 V,

3 V

REF2_5V = 1

I

= 100 µA → 900 µA,

V

load regulation response

REF+

time

VREF+

VAx≈ 0.5 × VREF+,

Error of conversion result ≤ 1 LSB,

3 V 400 ns

ADC10SR = 0

Maximum capacitance at pin

VREF+

Temperature coefficient I

Settling time of internal

reference voltage to 99.9%

VREF

Settling time of reference buffer

to 99.9% VREF

I

≤ ±1 mA, REFON = 1, REFOUT = 1 3 V 100 pF

VREF+

= const with 0 mA ≤ I

VREF+

I

= 0.5 mA, REF2_5V = 0,

VREF+

REFON = 0 → 1

I

= 0.5 mA,

VREF+

REF2_5V = 1, REFON = 1,

≤ 1 mA 3 V ±100

VREF+

3.6 V 30 µs

3 V 2 µs

REFBURST = 1, ADC10SR = 0

MIN TYP MAX UNIT

1.41 1.5 1.59

www.ti.com

V

V

±2

LSB

±2

ppm/

°C

32

Specifications Copyright © 2011–2016, Texas Instruments Incorporated

Product Folder Links: MSP430G2533 MSP430G2433 MSP430G2333 MSP430G2233 MSP430G2403 MSP430G2303

Submit Documentation Feedback

MSP430G2203

www.ti.com

MSP430G2533,MSP430G2433,MSP430G2333,MSP430G2233

MSP430G2403, MSP430G2303, MSP430G2203

SLAS734G –APRIL 2011–REVISED APRIL 2016

5.31 10-Bit ADC, External Reference

(1)

(MSP430G2x33 Only)

over recommended ranges of supply voltage and operating free-air temperature (unless otherwise noted)

PARAMETER TEST CONDITIONS V

CC

VEREF+ > VEREF–,

VEREF+

VEREF–

ΔVEREF

Positive external reference input

voltage range

Negative external reference input

voltage range

(2)

(4)

Differential external reference input

voltage range,

SREF1 = 1, SREF0 = 0

VEREF– ≤ VEREF+ ≤ VCC– 0.15 V,

SREF1 = 1, SREF0 = 1

(3)

VEREF+ > VEREF– 0 1.2 V

VEREF+ > VEREF–

(5)

ΔVEREF = VEREF+ – VEREF–

I

VEREF+

I

VEREF–

0 V ≤ VEREF+ ≤ VCC,

Static input current into VEREF+

SREF1 = 1, SREF0 = 0

0 V ≤ VEREF+ ≤ VCC– 0.15 V ≤ 3 V,

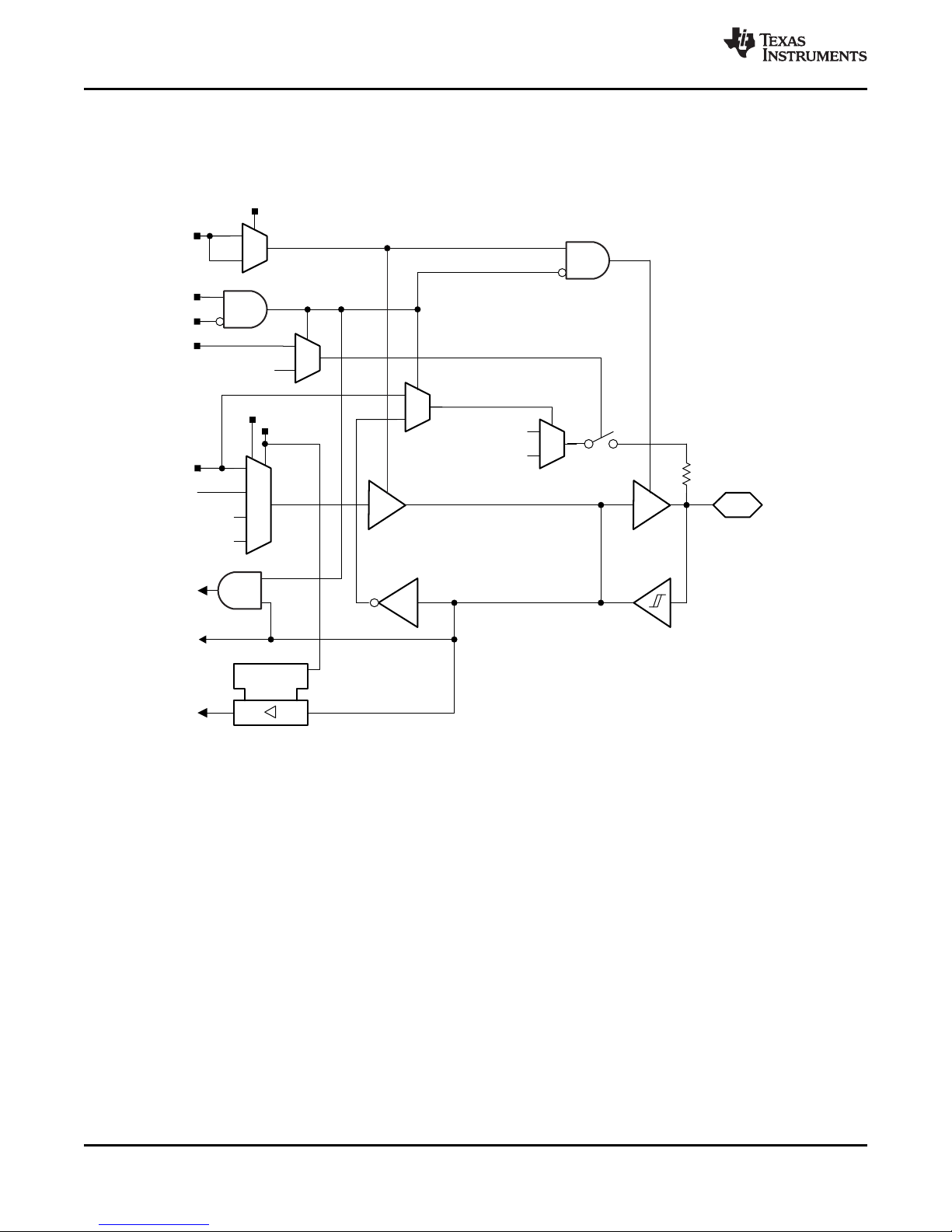

SREF1 = 1, SREF0 = 1