Page 1

DLPC3430, DLPC3432, DLPC3433, DLPC3435 and DLPC3438 Software

Programmer's Guide

Literature Number: DLPU020C

July 2014–Revised May 2018

Page 2

Contents

1 Trademarks......................................................................................................................... 7

2 Introduction......................................................................................................................... 7

2.1 Software Programmer’s Guide Overview ............................................................................. 7

3 Interface Specification .......................................................................................................... 8

3.1 I

4 System Initialization ............................................................................................................. 8

4.1 Boot ROM Concept ...................................................................................................... 8

4.2 Resident Boot Software ................................................................................................. 8

4.3 HOST_IRQ Initialization Sequence .................................................................................... 8

5 Software Interface ................................................................................................................ 9

5.1 I

Revision History.......................................................................................................................... 68

2

C Interface and Ports for DLPC343x................................................................................. 8

2

C Considerations ....................................................................................................... 9

2

Table of Contents

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 3

www.ti.com

1 DLPC343x Embedded Configuration...................................................................................... 7

2 HOST_IRQ Timing Diagram................................................................................................ 9

3 Write Parameters........................................................................................................... 11

4 Return Parameters......................................................................................................... 15

5 Byte 1 Write Parameter.................................................................................................... 17

6 Byte 2 Write Parameter.................................................................................................... 17

7 Example of Solid Field Test Pattern (Red).............................................................................. 19

8 Example of Fixed Step Horizontal Ramp Test Pattern................................................................ 20

9 Example of Fixed Step Vertical Ramp Test Pattern ................................................................... 20

10 Example of Horizontal Lines Test Pattern .............................................................................. 21

11 Example of Vertical Lines Test Pattern.................................................................................. 21

12 Example of Diagonal Lines Test Pattern................................................................................ 22

13 Example of Grid Lines Test Pattern ..................................................................................... 23

14 Example of Checkerboard Test Pattern................................................................................. 23

15 Example of Color Bars Test Pattern..................................................................................... 24

16 Return Parameters......................................................................................................... 24

17 Cropping Rules when Crop Size exceeds Input Size ................................................................. 28

18 Write Parameters........................................................................................................... 30

19 Rotation and Non-Rotation of Portrait Source.......................................................................... 31

20 Long-Axis Flip............................................................................................................... 31

21 Short-Axis Flip .............................................................................................................. 31

22 Return Parameters......................................................................................................... 32

23 Write Parameters........................................................................................................... 32

24 Return Parameters......................................................................................................... 33

25 Write Parameters........................................................................................................... 34

26 Return Parameters......................................................................................................... 35

27 Write Parameters........................................................................................................... 36

28 Byte 1 Return Parameters ................................................................................................ 37

29 Byte 2 Return Parameters ................................................................................................ 37

30 Bit Weight and Bit Order for Duty Cycle Data.......................................................................... 38

31 Maximum Number of Sequence Vectors................................................................................ 38

32 Return Parameters......................................................................................................... 39

33 Write Parameters........................................................................................................... 42

34 Return Parameters......................................................................................................... 43

35 Write Parameters........................................................................................................... 43

36 Return Parameters......................................................................................................... 44

37 Byte 1 Return Parameters ................................................................................................ 48

38 Return Parameters......................................................................................................... 49

39 Byte 1 Return Parameters ................................................................................................ 49

40 Bit Weight Definition for LABB Gain Value ............................................................................. 49

41 Byte 1 Write Parameters .................................................................................................. 50

42 Bit Weight Definition for the CAIC Maximum Gain Value............................................................. 50

43 Bit Weight Definition for the CAIC Clipping Threshold Value......................................................... 50

44 Bit Weight Definition for the CAIC RGB Intensity Gain Values....................................................... 51

45 Byte 1 Return Parameters ................................................................................................ 52

46 Write Parameters........................................................................................................... 52

47 Return Parameters......................................................................................................... 53

List of Figures

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

List of Figures

3

Page 4

www.ti.com

48 Byte 1 Write Parameters .................................................................................................. 53

49 Bit Weight Definition for the Optical Throw Ratio Data................................................................ 54

50 Visual Definition and Calculation for Optical Throw Ratio Data...................................................... 54

51 Bit Weight Definition for the Optical DMD Offset Data ................................................................ 54

52 Method for Calculation for Optical DMD Offset Data .................................................................. 55

53 Sign Determination for Optical DMD Offset Data ...................................................................... 55

54 Examples of Non-Inverted and Inverted Projector Orientations...................................................... 56

55 Byte 1 Return Parameters ................................................................................................ 57

56 Write Parameters........................................................................................................... 57

57 Pillar-Box Border Example ................................................................................................ 58

58 Return Parameters......................................................................................................... 58

59 Bit Weight Definition for the Projection Pitch Angle Data............................................................. 59

60 Examples of Projection Pitch Angle...................................................................................... 60

61 Byte 1 Return Parameters ................................................................................................ 61

62 Byte 1 Return Parameters ................................................................................................ 62

63 Byte 2 Return Parameters ................................................................................................ 62

64 Byte 3 Return Parameters ................................................................................................ 63

65 Byte 4 Return Parameters ................................................................................................ 63

66 Byte 1 Read Parameters.................................................................................................. 64

67 Byte 5 Return Parameters ................................................................................................ 65

68 Byte 6 Return Parameters ................................................................................................ 66

69 Return Parameters......................................................................................................... 66

70 Read Parameters........................................................................................................... 67

4

List of Figures

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 5

www.ti.com

1 I

2 Supported TI Generic Commands ....................................................................................... 10

3 Source Specific Associated Commands ................................................................................ 13

4 Common Commands ...................................................................................................... 14

5 Write Parameters........................................................................................................... 15

6 Return Parameters......................................................................................................... 16

7 Write Parameters........................................................................................................... 16

8 Foreground and Background Color Use ................................................................................ 18

9 Descriptions and Bit Assignments for Parameters 1-4 ................................................................ 18

10 Number of Bytes Required based on Pattern Selection .............................................................. 19

11 Parameter Bytes............................................................................................................ 24

12 Write Parameters........................................................................................................... 25

13 Return Parameters......................................................................................................... 26

14 Read Parameters........................................................................................................... 26

15 Return Parameters......................................................................................................... 26

16 Splash Screen Header Definitions ....................................................................................... 27

17 Write Parameters........................................................................................................... 27

18 Scaling Limits ............................................................................................................... 28

19 Return Parameters......................................................................................................... 28

20 Write Parameters........................................................................................................... 29

21 Return Parameters......................................................................................................... 30

22 Partial List of Commands that May Benefit from the Use of Image Freeze ........................................ 34

23 Splash Screen Example Using Image Freeze ......................................................................... 35

24 Test Pattern Generator Example Using Image Freeze................................................................ 35

25 Return Parameters......................................................................................................... 36

26 Return Parameters......................................................................................................... 37

27 Write Parameters........................................................................................................... 39

28 Write Parameters........................................................................................................... 40

29 Input Source Limits for Active Data ...................................................................................... 40

30 Return Parameters......................................................................................................... 41

31 Available Commands Based on LED Control Method................................................................. 42

32 Write Parameters........................................................................................................... 44

33 Return Parameters......................................................................................................... 45

34 Return Parameters......................................................................................................... 45

35 Write Parameters........................................................................................................... 46

36 Return Parameters......................................................................................................... 46

37 Return Parameters......................................................................................................... 47

38 Write Parameters........................................................................................................... 48

39 Write Parameters........................................................................................................... 49

40 LABB and CAIC Modes ................................................................................................... 51

41 Return Parameters......................................................................................................... 51

42 Write Parameters........................................................................................................... 53

43 Return Parameters......................................................................................................... 56

44 Write Parameters........................................................................................................... 59

45 Return Parameters......................................................................................................... 60

46 Return Parameters......................................................................................................... 61

47 Return Parameters......................................................................................................... 62

List of Tables

2

C Write and Read Transactions.......................................................................................... 9

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

List of Tables

5

Page 6

www.ti.com

48 Return Parameters......................................................................................................... 64

49 Read Parameters........................................................................................................... 64

50 Return Parameters......................................................................................................... 65

51 Controller Device ID Decode ............................................................................................. 66

52 DMD Device ID Reference Table ........................................................................................ 67

53 Return Parameters......................................................................................................... 67

6

List of Tables

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

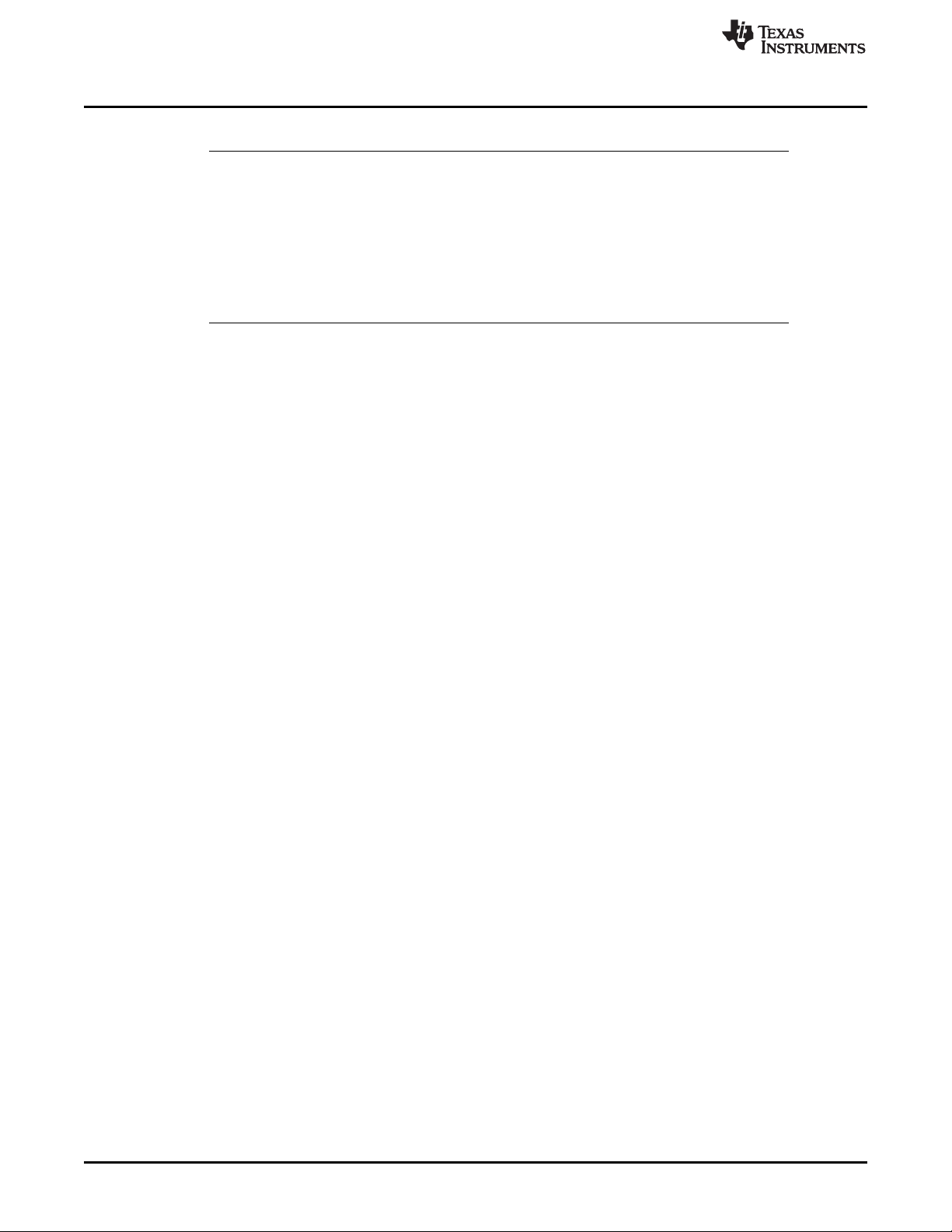

Page 7

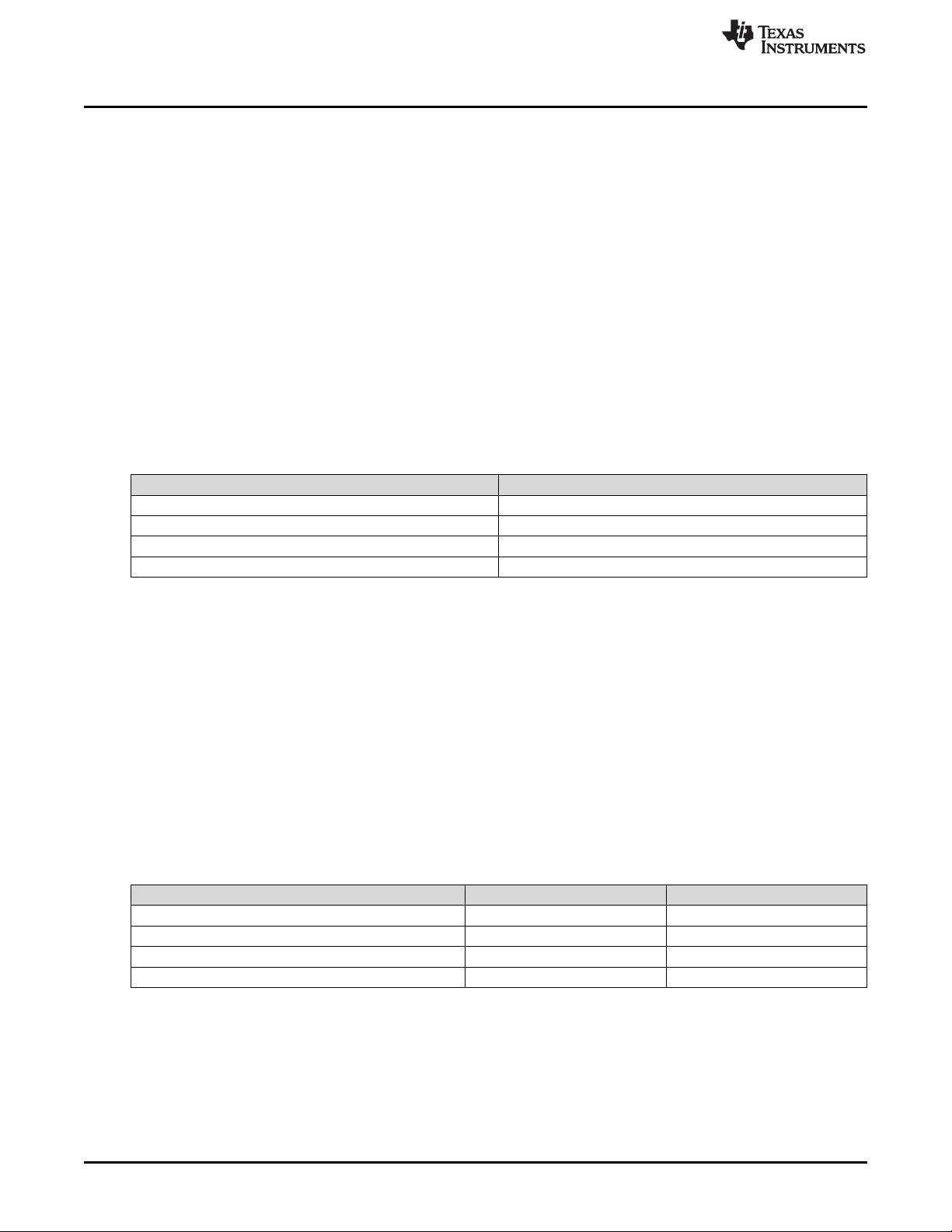

...

LED_SEL(2)

DC Supplies

BAT

+

±

1.1 V

WVGA

DDR DMD

DLP2010

(WVGA

DMD)

RESETZ

Included in DLP® Chip Set

CMP_PWM

1.8 V

PROJ_ON

PROJ_ON

2.3 to 5.5 V

CMP_OUT

Projector Module Electronics

INTZ

DLPA200x

PARKZ

1.1 V

1.8 V

VCORE

VIO

Illumination

Optics

3

BIAS, RST, OFS

Thermistor

LABB

I2C

28

Parallel I/F

HOST_IRQ

VCC_INTF

4

EEPROM

DLPC343x

VCC_FLSH

SPI_1

I2C_1

L3

SYSPWR

1.8 V

1.8 V

Other

Supplies

1.1-V

Reg

Sub-LVDS DATA

CTRL

Cal data

(optional)

FLASH,

SDRAM

Keypad

Front-End

Chip

- OSD

- AutoLock

- Scaler

- Microcontroller

HDMI

Receiver

Triple

ADC

Charger

DC_IN

VDD

On/Off

HDMI

VGA

SD Card

Reader, and

so forth

(optional)

FLASH

L1

L2

VLED

BLUE

GREEN

RED

Current

Sense

Spare R/W

GPIO

18

TVP5151

Video

Decoder

CVBS

BT.656

Keystone

Sensor

WPC

GPIO_8 (Normal Park)

1.8 V VSPI

4 SPI_0

eDRAM

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and

DLPC3438 Software Programmer’s Guide

1 Trademarks

LightCrafter is a trademark of Texas Instruments.

2 Introduction

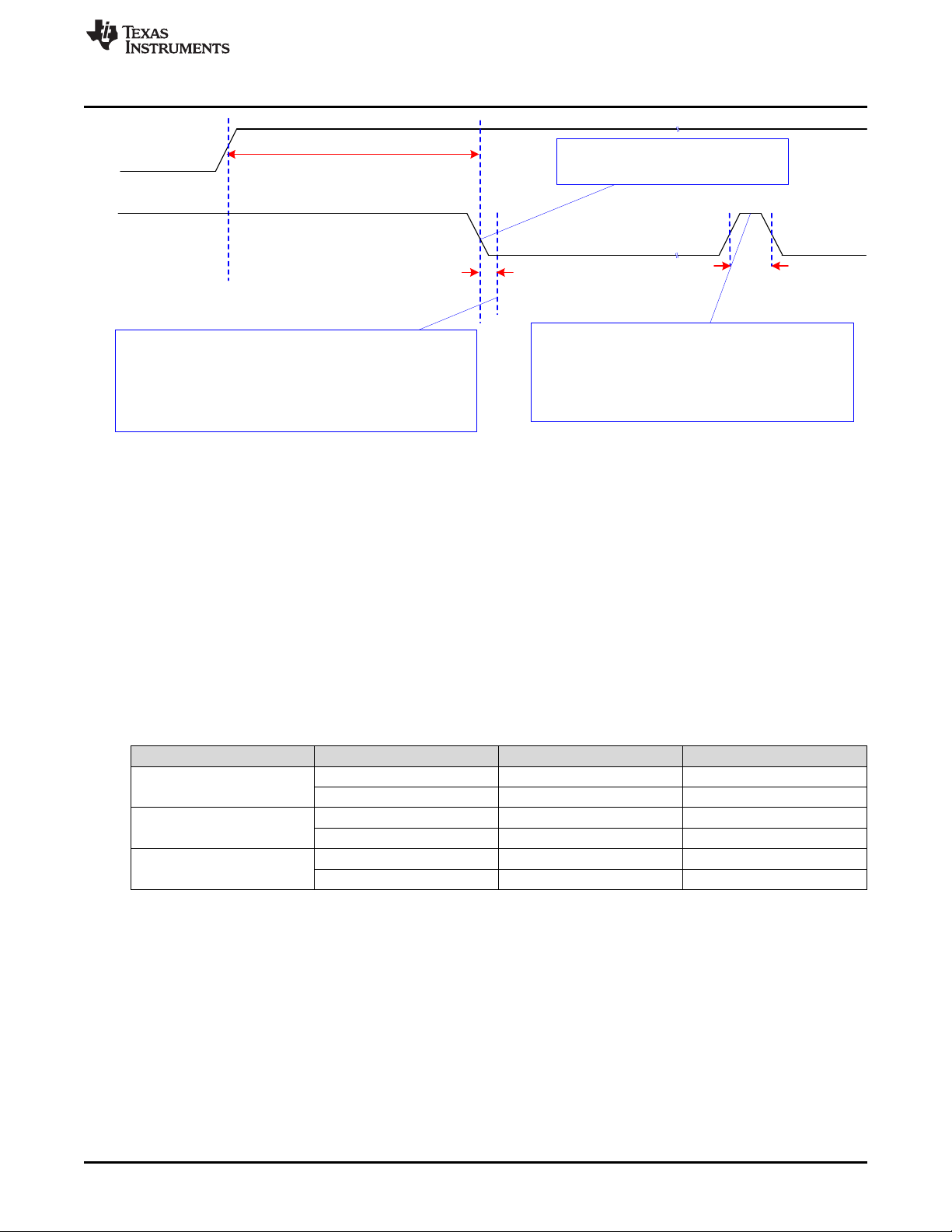

2.1 Software Programmer’s Guide Overview

This guide details the software interface requirements for a DLPC343x ASIC-based system. It defines all

applicable communication protocols including I2C initialization, default settings and timing. The DLPC343x

system can be used in Figure 1.

Programmer's Guide

DLPU020C–July 2014–Revised May 2018

Figure 1. DLPC343x Embedded Configuration

2.1.1 I2C-Based Command Data Interface

The legacy interface configurations make use of an I2C interface for commands and a 24-bit parallel

interface.

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

7

Page 8

Interface Specification

3 Interface Specification

The protocol used in communicating information to DLPC343x consist of a serial data bus conforming to

the Philips I2C specification, up to 100 kHz. MIPI DSI is supported in DLPC343x, but this feature is not

supported in LightCrafter™ Display EVM.

3.1 I2C Interface and Ports for DLPC343x

DLPC343x commands are executed using I2C and support two I2C ports, port-0 and port-1.

Port-0 is primarily used for command and control interface. While using this port, DLPC343x behaves as

an I2C slave.

4 System Initialization

This section describes the methodology used for system initialization.

4.1 Boot ROM Concept

The DLPC343x employs a boot ROM and associated boot software. This resident boot code consists of

the minimum code necessary to complete the program loading. For most DLPC343x product

configurations, an external flash device can store the main application code, along with the other

configuration and operational data required by the system for normal operation.

4.2 Resident Boot Software

The resident boot code consists of the minimum code necessary to load the ARM software from flash to

internal RAM for execution.

www.ti.com

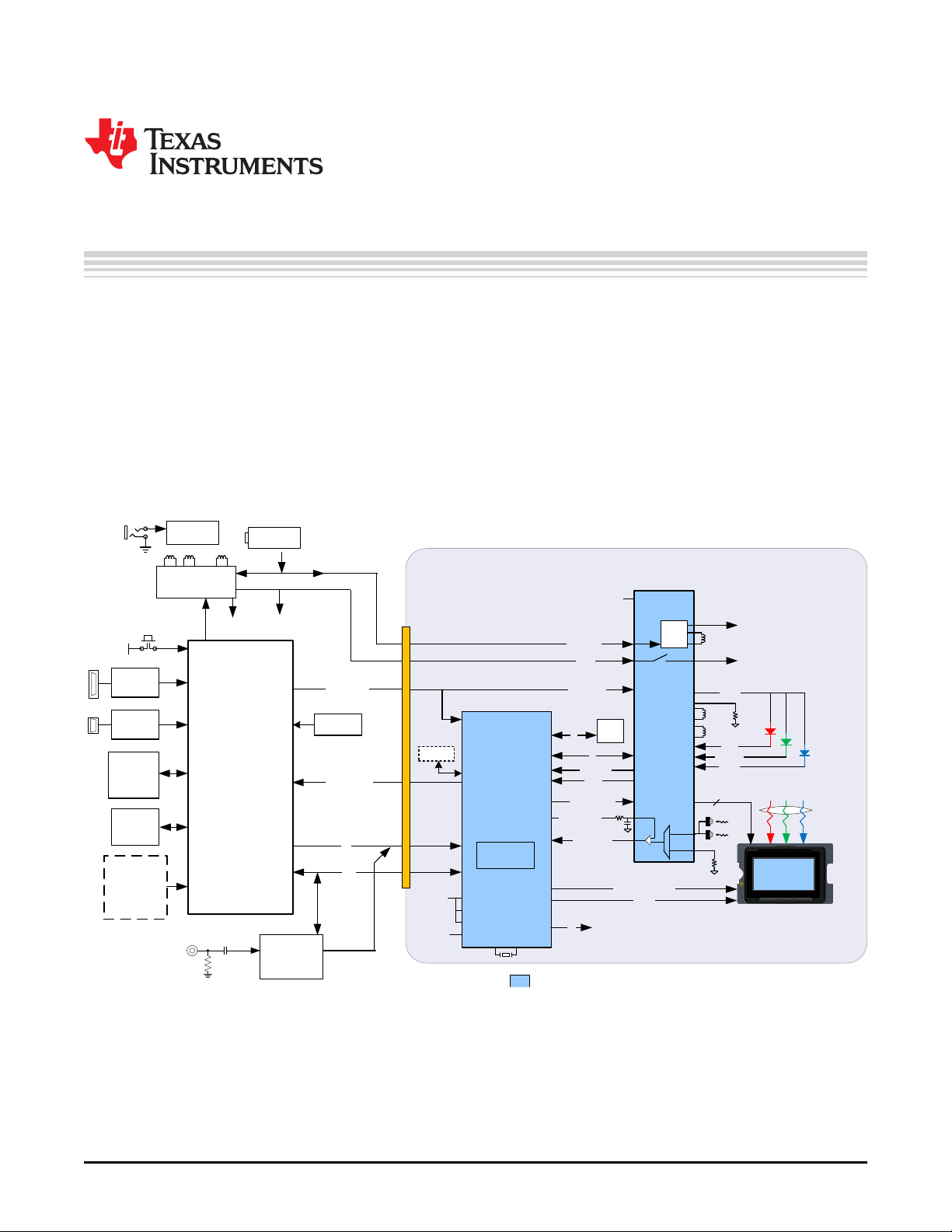

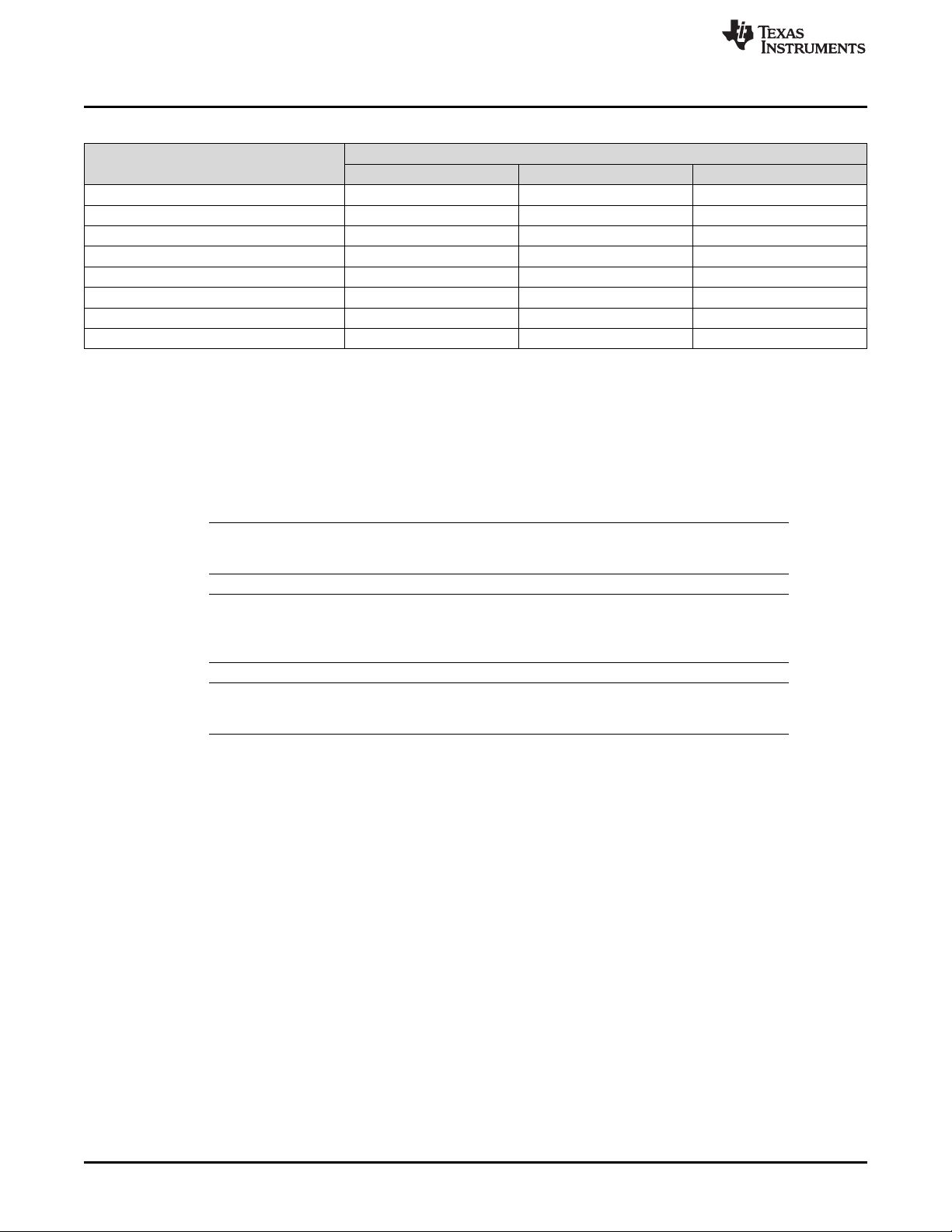

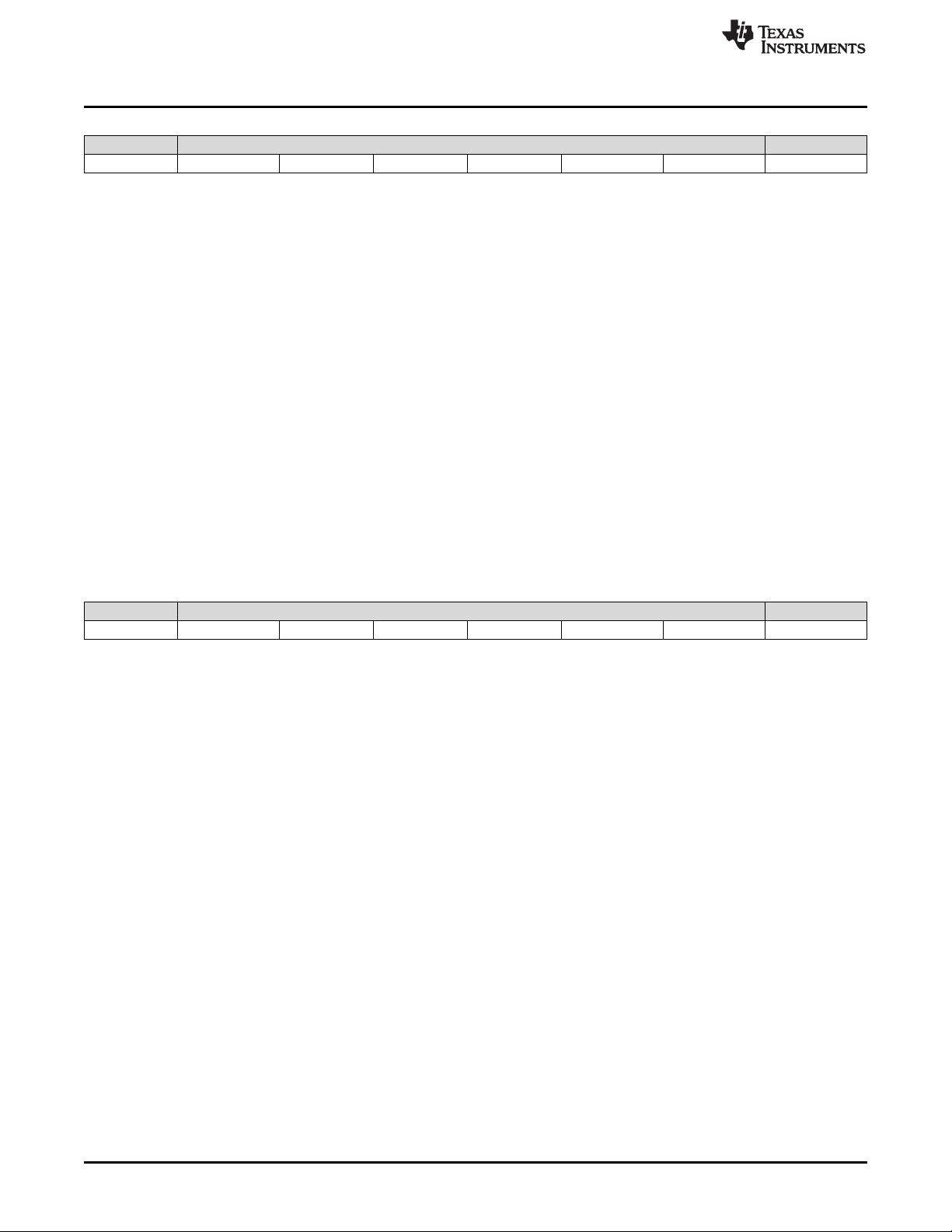

4.3 HOST_IRQ Initialization Sequence

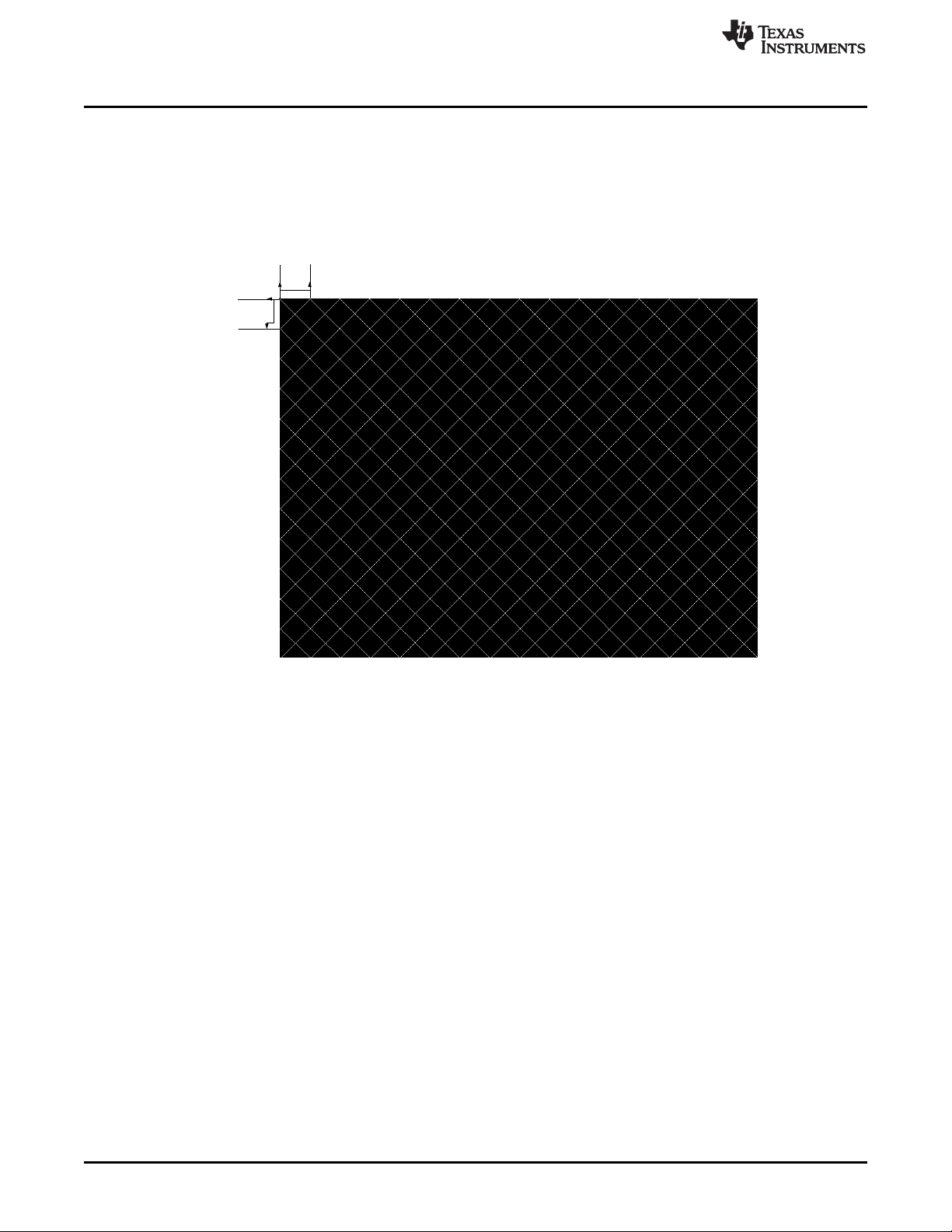

HOST_IRQ is a signal indicating the status of DLPC343x initialization. While reset is applied, HOST_IRQ

resets to tri-state (an external pullup pulls the line high). HOST_IRQ remains tri-state (pulled high

externally) until the microprocessor boot completes. While the signal is pulled high, the controller performs

boot-up and auto-initialization.

Immediately after boot-up, the microprocessor drives HOST_IRQ to a logic high state to indicate that the

controller is performing auto-initialization (no real state change occurs on the external signal). Upon

completion of auto-initialization, ARM software sets HOST_IRQ to a logic low state to indicate the

completion of auto-initialization. At the falling edge, the system is said to enter the INIT_DONE state.

After auto-initialization completes, HOST_IRQ generates a logic high interrupt pulse to the host through

software control; this interrupt indicates that the controller detects an error condition or requires service.

8

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 9

RESETZ

500 ms max

I2C access to DLPC343x should not start until HOST_IRQ goes low

(this should occur within 500 ms from the release of RESETZ.

HOST_IRQ

(with External Pullup)

0 ms min

(INIT_BUSY)

(ERR IRQ)

3 µs min

An active-high pulse on HOST_IRQ following the

initialization period will indicate an error condition has been

detected. The source of the error is reported in the system

status.

The first falling edge of HOST_IRQ

indicates auto-initialization done.

www.ti.com

5 Software Interface

There is generally one set of software commands supported by the DLPC343x controller.

Software Interface

Figure 2. HOST_IRQ Timing Diagram

5.1 I2C Considerations

5.1.1 I2C Transactions

5.1.1.1 Data Flow Control

5.1.2 List of System Write/Read Software Commands

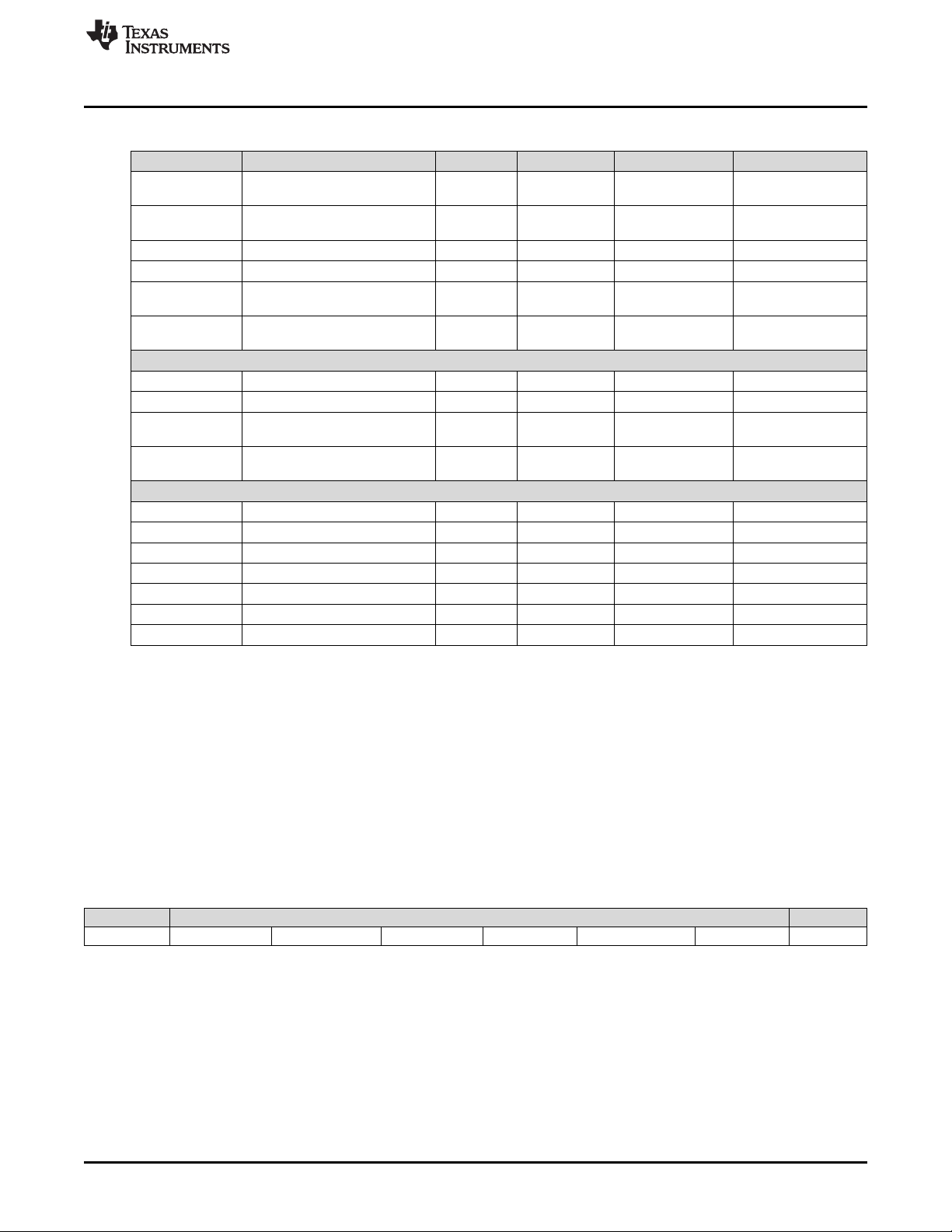

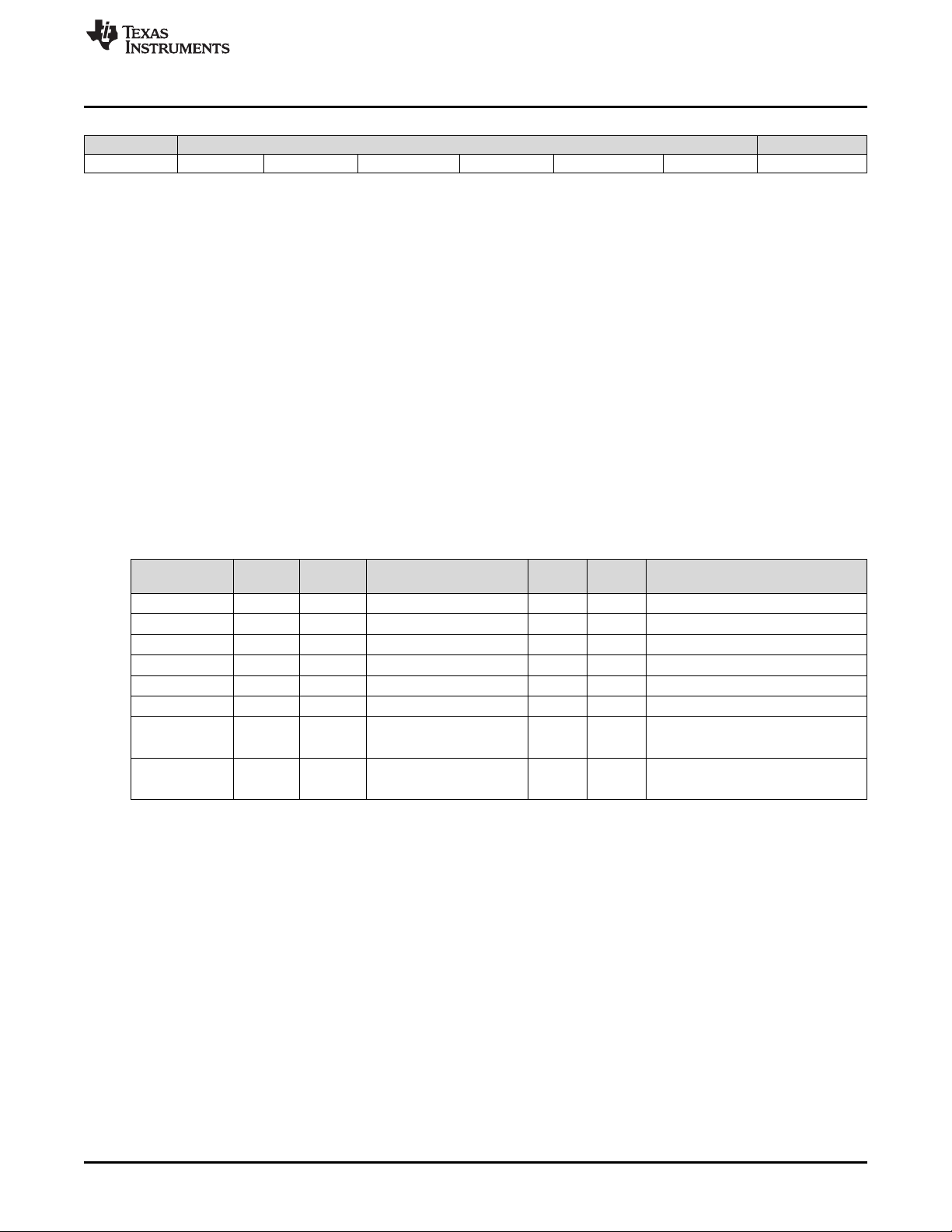

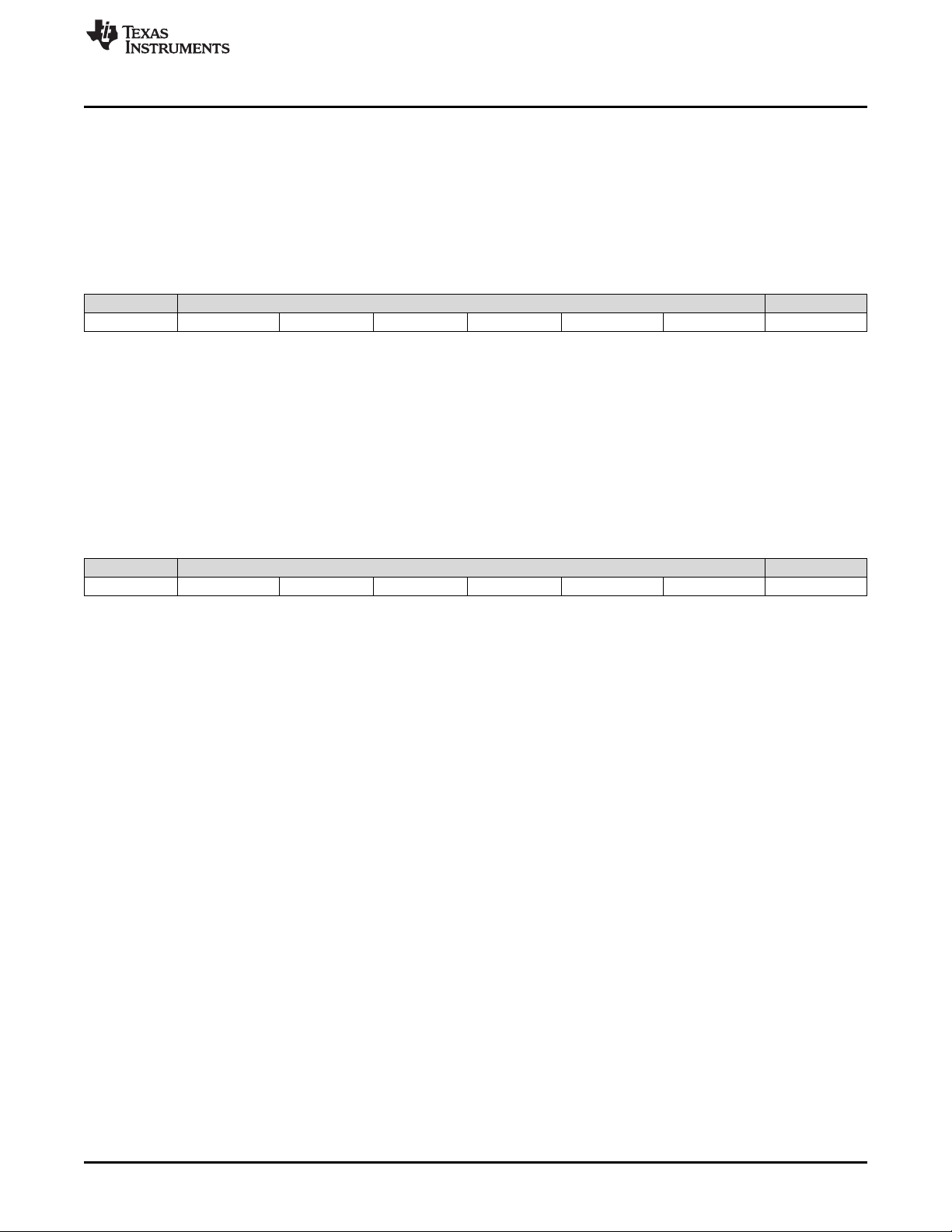

Since all I2C commands are processed by software, only one type of I2C transaction is supported. This

transaction type is shown in Table 1 for both writes and reads. The I2C interface supports variably-sized

transactions for example, a one byte transaction, a nine byte transaction) to match the TI commands

discussed later in this document.

Table 1. I2C Write and Read Transactions

Transaction Address

Write

Read Request

Read Response

(1)

The address corresponds to the chip address of the controller.

(2)

The subaddress will correspond to a TI command.

(3)

The data (if present) will correspond to any required command parameters.

36h (or 3Ah) Command value Parameter values

36h (or 3Ah) Command value Parameter values

37h (or 3Bh) Parameter values

(1)

8-bits 8-bits 8-bit parameter bytes (0 → N)

8-bits 8-bits 8-bit parameter bytes (0 → N)

8-bits 8-bit parameter bytes (0 → N)

Sub-Address

While the I2C interface inherently supports flow control by holding the clock, this is not sufficient for all

transactions (for example, sequence and CMT updates). In this case, the host software should use the

(2)

Remaining Data Bytes

Read Short status to determine if the system is busy.

The commands supported by the I2C interfaces are discussed in the following sections.

(3)

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Copyright © 2014–2018, Texas Instruments Incorporated

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

9

Page 10

Software Interface

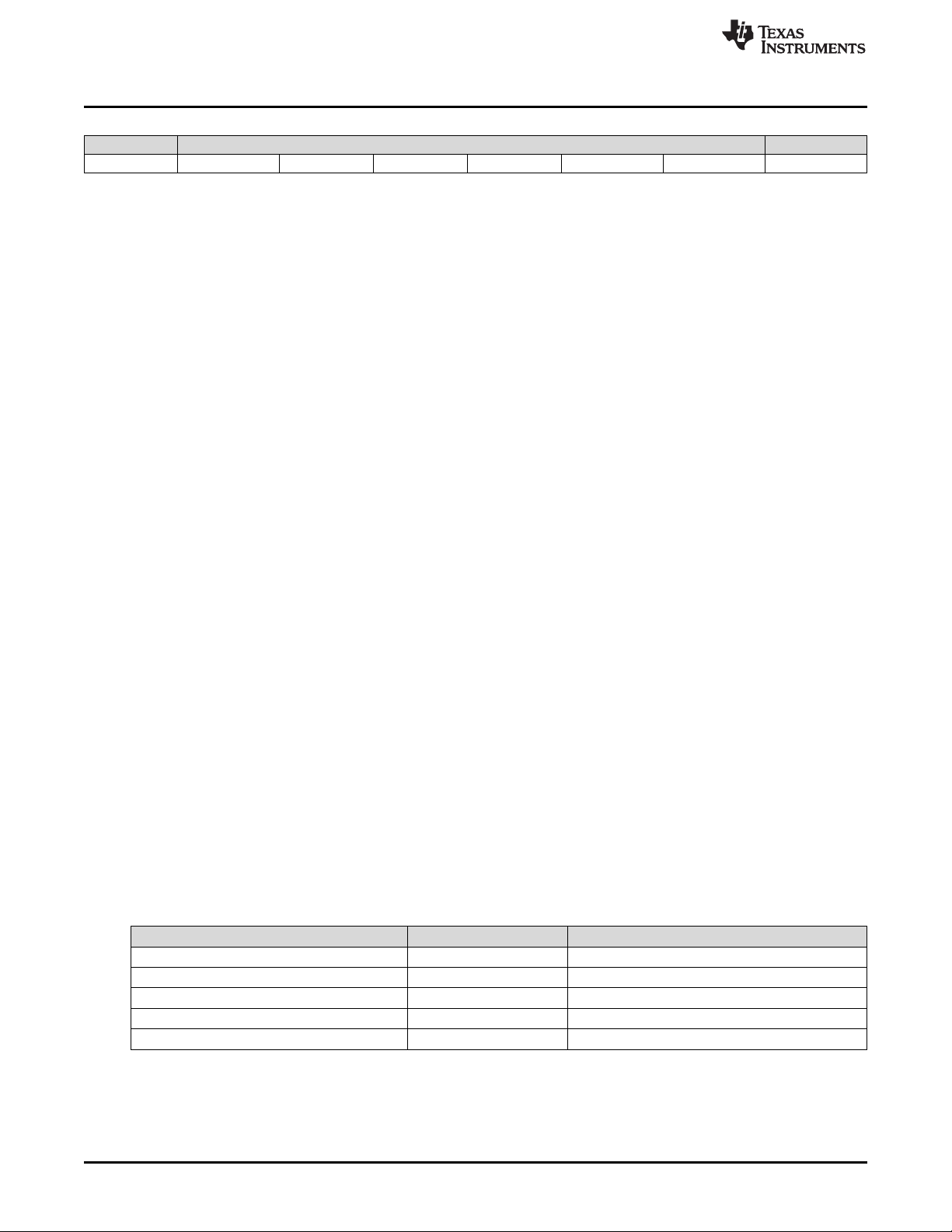

Command Type Command Description Reset Value OpCode (hex) Default Action Section

General Operation

Write Write Input Source Select 1 05 Test pattern Section 5.1.3.1

Write

Write Write Test Pattern Select 7000h 0B White solid field Section 5.1.3.5

Write Write Splash Screen Select 0D User-specified Section 5.1.3.7

Write Write Image Crop

Write Write Display Size DMD Res 12 Section 5.1.3.12

Write Write Display Image Orientation 14 User-specified Section 5.1.3.14

Write Write Display Image Curtain 1 16 Black Section 5.1.3.16

Write Write Image Freeze 0 1A No freeze Section 5.1.3.18

Write Write LOOK Select 22 User-specified Section 5.1.3.20

Write Write Execute Batch File 0 2D Section 5.1.3.24

Write Write External Input Image Size DMD Res 2E Section 5.1.3.25

Write Write Splash Screen Execute 35 Section 5.1.3.27

Illumination Control

Write

Write Write RGB LED Enable 7h 52 Enabled Section 5.1.3.30

Write Write RGB LED Current 54 User-specified Section 5.1.3.32

Write Write RGB LED Max Current 5C User-specified Section 5.1.3.35

Image Processing Control

Write

www.ti.com

Table 2. Supported TI Generic Commands

Read Read Input Source Select 06 Section 5.1.3.2

Write External Video Source

Format Select

Read Read Test Pattern Select 0C Section 5.1.3.6

Read Read Splash Screen Select 0E Section 5.1.3.8

Read Read Splash Screen Header 0F Section 5.1.3.9

Read Read Image Crop 11 Section 5.1.3.11

Read Read Display Size 13 Section 5.1.3.13

Read Read Display Image Orientation 15 Section 5.1.3.15

Read Read Display Image Curtain 17 Section 5.1.3.17

Read Read Image Freeze 1B Section 5.1.3.19

Read Read LOOK Select 23 Section 5.1.3.21

Read Sequence Header

Read

Attributes

Read DMD Sequencer Sync

Read

Mode

Read Read External Input Image Size 2F Section 5.1.3.26

Write LED Output Control

Method

Read LED Output Control

Read

Method

Read Read RGB LED Enable 53 Section 5.1.3.31

Read Read RGB LED Current 55 Section 5.1.3.33

Read CAIC LED Max Available

Read

Power

Read Read RGB LED Max Current 5D Section 5.1.3.36

Read Read CAIC RGB LED Current 5F Section 5.1.3.37

Write Local Area Brightness

Boost Control

Read Local Area Brightness

Read

Boost Control

43h 07 RGB888 Section 5.1.3.3

ffffffff000000

00h

1 80

10 No crop Section 5.1.3.10

26 Section 5.1.3.22

2C Section 5.1.3.23

50 User-specified Section 5.1.3.28

51 Section 5.1.3.29

57 Section 5.1.3.34

Manual strength

control

81 Section 5.1.3.39

Section 5.1.3.38

10

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 11

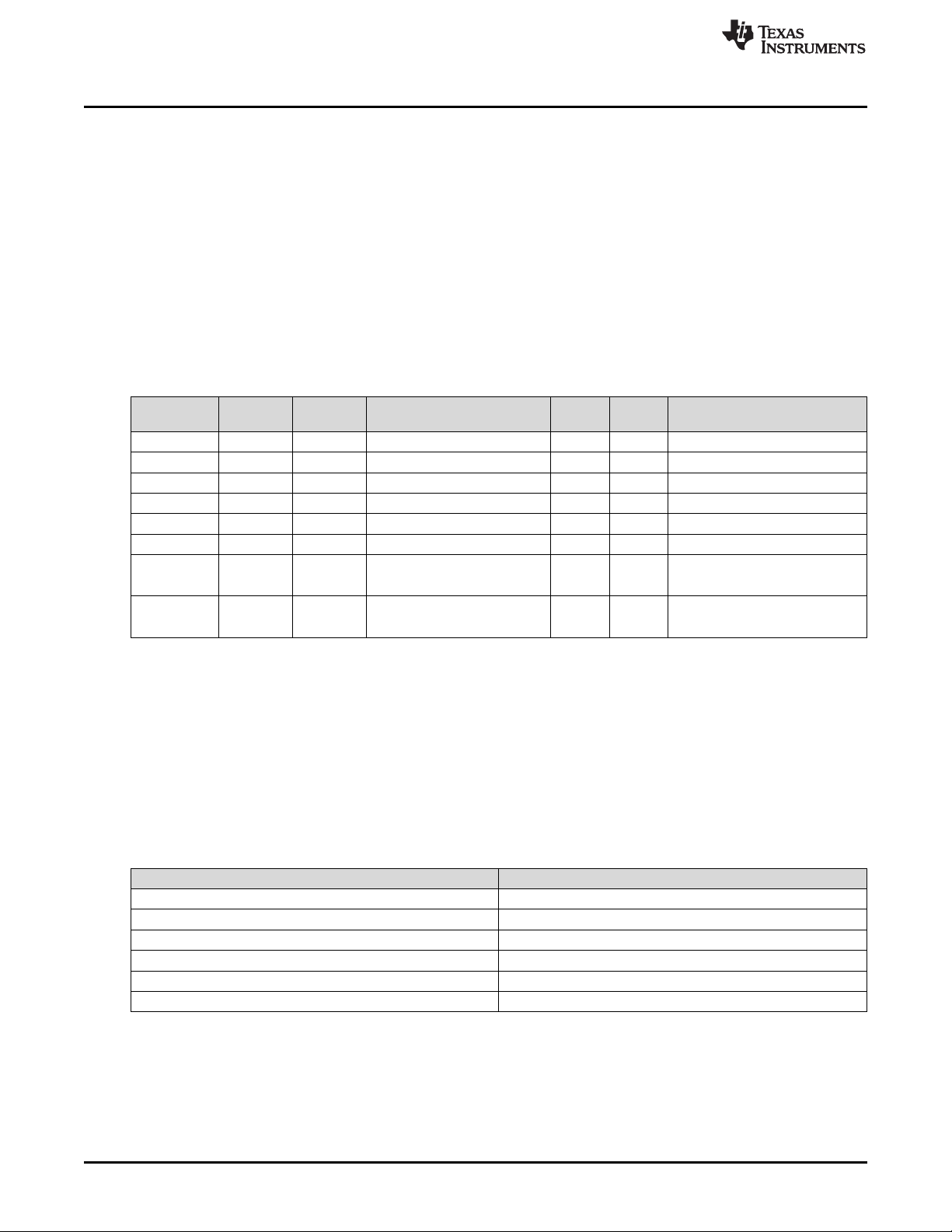

www.ti.com

General Setup

Administrative Commands

Software Interface

Table 2. Supported TI Generic Commands (continued)

Command Type Command Description Reset Value OpCode (hex) Default Action Section

Write

Write Write CCA Control 1 86 Enabled Section 5.1.3.42

Write

Write Write Border Color 0 B2 Black Section 5.1.3.46

Write

Write CAIC Image Processing

Control

Read CAIC Image Processing

Read

Control

Read Read CCA Control 87 Section 5.1.3.43

Write Keystone Correction

Control

Read Keystone Correction

Read

Control

Read Read Border Color B3 Section 5.1.3.47

Write Keystone Projection Pitch

Angle

Read Keystone Projection Pitch

Read

Angle

Read Read Short Status D0 Section 5.1.3.50

Read Read System Status D1 Section 5.1.3.51

Read Read System Software Version D2 Section 5.1.3.52

Read Read Communication Status D3 Section 5.1.3.53

Read Read Controller Device ID D4 Section 5.1.3.54

Read Read DMD Device ID D5 Section 5.1.3.55

Read Read Flash Build Version D9 Section 5.1.3.56

0 88 Disabled Section 5.1.3.44

0 BB 0 Pitch angle Section 5.1.3.48

84 User-specified Section 5.1.3.40

85 Section 5.1.3.41

89 Section 5.1.3.45

BC Section 5.1.3.49

5.1.3 System Write/Read Commands

5.1.3.1 Write Input Source Select (05h)

5.1.3.1.1 Write

This command selects the image input source for the display module.

5.1.3.1.2 Write Parameters

Figure 3 describes the command parameters.

Figure 3. Write Parameters

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

b(7:2)

Reserved

b(1:0) Input Source:

• 0h: External Video Port

• 1h: Test Pattern Generator

• 2h: Splash Screen

• 3h: Reserved

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

11

Page 12

Software Interface

Default: 01h

NOTE: When selecting the external video port, there is a set of associated commands applicable

These associations are also shown in Table 3.

www.ti.com

only to this source selection. These associated commands are the Write External Input

image Size and the Write External Video Source Format Select.

When selecting the test pattern generator, only one associated command is applicable to this

source selection. This associated command is the Write Test Pattern Select command.

When selecting the splash screen, only two associated commands are applicable to this

source selection. These associated commands are the Write Splash Screen Select and Write

splash Screen Execute commands.

12

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 13

www.ti.com

Software Interface

Table 3. Source Specific Associated Commands

Source Specific Associated Commands

Write External Video Source Format Select Only N/A N/A

Write External Input Image Size Only N/A N/A

Write Test Pattern Select N/A Only N/A

Write Splash Screen Select N/A N/A Only

Write Splash Screen Execute N/A N/A Special

(1)

The Write Splash Screen Execute command is special in that there is no maintained state or history. Thus this command has no settings

to be stored and reused by the system.

External Video Port Test Pattern Generator Splash Screen

Input Source Select Options

These commands (other than Write Splash Screen Execute) describe the characteristics of their

associated source, and once these settings are defined the system stores them. Afterwards, each time an

input source selection is made (using the Write Input Source Select command), the system remembers

the settings described by the commands associated with the selected source, and automatically applies

them. The user only needs to send these associated commands when the source is first defined, or when

the source characteristics for that port must be changed. The appropriate associated commands must be

updated when source characteristics change.

The user can send source-associated commands every time they make an input source selection. The

source associated commands should be sent prior to sending the Write Input Source Select command.

When source-associated commands are sent when that source is not active, the controller software saves

the new settings, but does not execute these commands. When that source becomes active (via the Write

Input Source Select command), the controller applies these new settings, as in the following example:

1. The user sends the following commands (active input source = test pattern generator):

• Write image Freeze = freeze

• Write External Video Source Format Select (settings stored, command not executed)

• Write External Input Image Size (settings stored, command not executed)

• Write Input Source Select = external port (see step 2 below)

• Write Image Freeze = unfreeze

2. When the Write Input Source Select command is received, the software applies the settings from these

external video port-associated commands:

• External Video Source Format Select

• External input Image Size

If source-associated commands are sent for a source that is already active, the controller software

executes these commands when received, as in the following example:

• The user sends the following commands (active input source = external video port):

– Write Image Freeze = freeze

– Write external Video Source Format Select (command executed)

– Write Image Freeze = unfreeze

The rest of the commands that apply to image setup have settings applicable across all source selections,

and typically remain the same across the three input source selections. A few examples are Write Display

Size and Write Display Image Orientation. A representative list of these commands is shown in Table 4.

(1)

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

13

Page 14

Software Interface

www.ti.com

Table 4. Common Commands

Common Commands

Write Image Crop Common Common Common

Write Display Image Size Common Common Common

Write Keystone Correction Control Common Common Common

Write Display Image Orientation Common Common Common

Write Display Image Curtain Common Common Common

Write Look Select Common Common Common

Write Local Area Brightness Boost Control Common Common Common

Write CAIC Image Processing Control Common Common Common

External Video Port Test Pattern Generator Splash Screen

Input Source Select Options

While the values for these commands may be the same across the different input source types, the

hardware settings may change (for example: display image size = 1080p = DMD size – the external port

input source size is WXGA, which is scaled up to the display size of 1080p. If the user changes to the

TPG Input Source, the size of the test pattern must match the size of the DMD. Therefore, the scaler

settings must to be changed). The controller software manages the underlying hardware settings. This

also applies to those commands which specify automatic operation. While the automatic setting remains

the same, the underlying algorithm might change its settings based on the characteristic of the selected

source.

NOTE: The user is required to specify the active data size for all external input sources, using the

Write Input Image Size command.

NOTE: When a test pattern is selected, it is generated at the resolution of the DMD, modified by the

settings specified by the Write Image Crop command, and displayed at the resolution

specified by the Write Display Size command.

NOTE: The user should see the Write Image Freeze command for information on hiding on-screen

artifacts when selecting an input source.

5.1.3.2 Read Input Source Select (06h)

5.1.3.2.1 Read

This command reads the state of the image input source for the display module.

5.1.3.2.2 Read Parameters

This command has no command parameters.

5.1.3.2.3 Return Parameters

Figure 4 describes the return parameters.

14

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 15

www.ti.com

Figure 4. Return Parameters

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

Software Interface

b(7:2)

Reserved

b(1:0) Input source

• 0h: External video port

• 1h: Test Pattern generator

• 2h: Splash screen

• 3h: Reserved

5.1.3.3 Write External Video Source Format Select (07h)

5.1.3.3.1 Write

This command specifies the active external video port and the source data type for the display module.

5.1.3.3.2 Write Parameters

Table 5 describes the command parameters.

Table 5. Write Parameters

CMD Parameter Port Bits/Pixel Data Type

40h Parallel 16 RGB 565 16 1 Auto-select RGB CSC

41h Parallel 18 RGB 666 18 1 Auto-select RGB CSC

42h Parallel 24 RGB 888 8 3 Auto-select RGB CSC

43h Parallel 24 RGB 888 24 1 Auto-select RGB CSC

50h Parallel 18 YCbCr 666 18 1 Auto-select YCbCr CSC

51h Parallel 24 YCbCr 888 24 1 Auto-select YCbCr CSC

60h Parallel 16 YCbCr 4:2:2 88 8 2

61h Parallel 16 YCbCr 4:2:2 88 16 1

Bus

Width

Clks/Pix

el

Notes

Auto-select YCbCr CSC

Auto-select 4:2:2 → 4:4:4

Auto-select YCbCr CSC

Auto-select 4:2:2 → 4:4:4

Default: 43h

This command is used in conjunction with the Write Input Source Select command. This command

specifies which input port displays when the Write Input Source Select command selects external video

port as the image source. The settings for this command are retained until changed using this command.

These settings are automatically applied each time the external video port is selected.

When the external video port is selected as the input source, the software automatically selects and loads

the proper CSC, based on the selected parameter of this command (appropriate matrix for RGB, selected

matrix for YCbCr including offset).The appropriate data path is also automatically selected for 4:2:2 versus

4:4:4 processing.

The selection of video source port is independent from the selected command port.

The user should review the notes for the Write Input Source Select command to understand the concept

of source-associated commands. This concept determines when source-associated commands are

executed by the system. This command is a source-associated command.

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

15

Page 16

Software Interface

5.1.3.4 Read External Video Source Format Select (08h)

5.1.3.4.1 Read

This command reads the state of the active external video port and the source data type for the display

module.

5.1.3.4.2 Read Parameters

This command has no read parameters.

5.1.3.4.3 Return Parameters

Table 6 describes the return parameters.

Table 6. Return Parameters

www.ti.com

CMD

Parameter

40h Parallel 16 RGB 565 16 1 Auto-select RGB CSC

41h Parallel 18 RGB 666 18 1 Auto-select RGB CSC

42h Parallel 24 RGB 888 8 3 Auto-select RGB CSC

43h Parallel 24 RGB 888 24 1 Auto-select RGB CSC

50h Parallel 18 YCbCr 666 18 1 Auto-select YCbCr CSC

51h Parallel 24 YCbCr 888 24 1 Auto-select YCbCr CSC

60h Parallel 16 YCbCr 4:2:2 88 8 2

61h Parallel 16 YCbCr 4:2:2 88 16 1

Port Bits/Pixel Data Type

5.1.3.5 Write Test Pattern Select (0Bh)

5.1.3.5.1 Write

This command specifies an internal test pattern for display on the display module.

5.1.3.5.2 Write Parameters

Table 7 describes the command parameters.

Bus

Width

Table 7. Write Parameters

Clks/Pix

el

Notes

Auto-select YCbCr CSC

Auto-select 4:2:2 → 4:4:4

Auto-select YCbCr CSC

Auto-select 4:2:2 → 4:4:4

16

Parameter Bytes Description

Byte 1 TPG pattern select

Byte 2 Foreground and background color (see Table 8)

Byte 3 Parameter 1 (see Table 9)

Byte 4 Parameter 2 (see Table 9)

Byte 5 Parameter 3 (see Table 9)

Byte 6 Parameter 4 (see Table 9)

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 17

www.ti.com

Figure 5. Byte 1 Write Parameter

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

Software Interface

b(7)

Test pattern border:

• 00h: Disabled

• 01h: Enabled

b(6:4) Reserved

b(3:0) Left pattern select:

• 00h: Solid field

• 01h: Fixed step horizontal ramp

• 02h: Fixed step vertical ramp

• 03h: Horizontal lines

• 04h: Diagonal lines

• 05h: Vertical lines

• 06h: Horizontal and vertical grid

• 07h: Checkerboard

• 08h: Color bars

• 09h-0Fh: Reserved

Byte 1 default: 00h

Figure 6. Byte 2 Write Parameter

MSB Byte 2 LSB

b7 b6 b5 b4 b3 b2 b1 b0

b(7)

Reserved

b(6:4) Foreground color:

• 0h: Black

• 1h: Red

• 2h: Green

• 3h: Blue

• 4h: Cyan

• 5h: Magenta

• 6h: Yellow

• 7h: White

b(3:0) Reserved

b(2:0) Background color:

• 0h: Black

• 1h: Red

• 2h: Green

• 3h: Blue

• 4h: Cyan

• 5h: Magenta

• 6h: Yellow

• 7h: White

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

17

Page 18

Software Interface

www.ti.com

Table 8. Foreground and Background Color Use

Pattern

Solid field Yes No

Fixed step horizontal ramp Yes No

Fixed step vertical ramp Yes No

Horizontal lines Yes Yes

Vertical lines Yes Yes

Diagonal lines Yes Yes

Grid lines Yes Yes

Checkerboard Yes Yes

Color bars No No

Foreground Color Background Color

Byte 2

Byte 2 default: 70h

Table 9. Descriptions and Bit Assignments for Parameters 1-4

Pattern

Solid field N/A N/A N/A N/A

Fixed step

horizontal ramp

Fixed step

vertical ramp

Horizontal lines N/A N/A

Vertical lines N/A N/A

Diagonal lines N/A N/A Vertical spacing 8 Horizontal spacing 8

Grid lines

Checkerboard

Color bars N/A N/A N/A N/A

Byte 6 (Parameter 4) Byte 5 (Parameter 3) Byte 4 (Parameter 2) Byte 3 (Parameter 1)

Description Bits Description Bits Description Bits Description Bits

N/A N/A End value 8 Start value 8

N/A N/A End value 8 Start value 8

Vertical

background line

width

Number of vertical

checkers

Vertical foreground

8

3

line width

Number of vertical

checkers

Background line

Background line

8

8

Horizontal

background line

Number of

horizontal checkers

width

width

width

8 Foreground line width 8

8 Foreground line width 8

Horizontal foreground

8

3

line width

Number of horizontal

checkers

8

8

18

This command is used in conjunction with the Write Input Source Select command. This command

specifies which test pattern displays when the Write Input Source Select command selects test pattern

generator as the image source. The settings for this command are retained until changed using this

command. These settings automatically apply each time the test pattern generator is selected.

Batch files are created and stored in flash, and recall the settings for predefined test patterns.

Test patterns are created at the resolution of the display (DMD), are modified by the Write Image Crop

command, and displayed at the resolution specified by the Write Display Size command.

Test patterns display at the default frame rate 60 Hz.

The Test Pattern Border Selection creates a white border, a single pixel wide and tall, around the specified

test pattern.

The user must review the notes for the Write Input Source Select command to understand the concept of

source-associated commands. This concept determines when source-associated commands are executed

by the system. This command is a source-associated command.

When a foreground or background color is not used, the bit values are ignored (see Table 8). If both

foreground and background color are not used, or when a parameter byte (bytes 3 thru 6) is not used, the

byte should not be sent. Table 10 shows the number of bytes required, based on the specified pattern.

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 19

www.ti.com

As noted in Table 8, the color for the solid field pattern is specified using the foreground color. An example

of a solid field pattern is shown in Figure 7.

Software Interface

Table 10. Number of Bytes Required based on Pattern Selection

Specified Pattern Number of Bytes Required

Solid field 2

Fixed step horizontal ramp 4

Fixed step vertical ramp 4

Horizontal lines 4

Vertical lines 4

Diagonal lines 4

Grid lines 6

Checkerboard 7

Color bars 1

Figure 7. Example of Solid Field Test Pattern (Red)

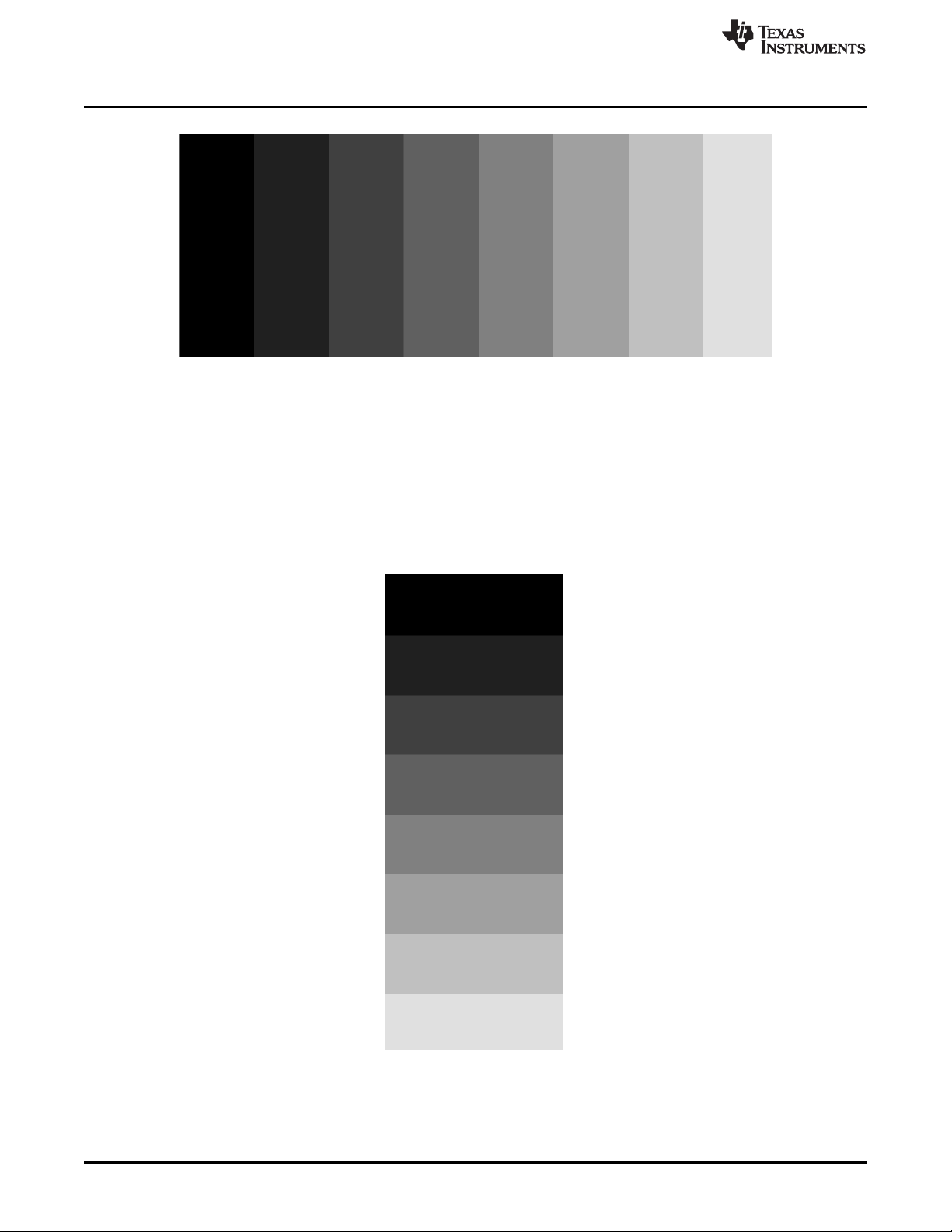

As noted in Table 8, the color for the fixed step horizontal ramp pattern is specified using the foreground

color. As noted in Table 9, the user specifies the start value and the stop value for the ramp. For this

pattern, the system automatically determines the step size based on the start and stop values and the size

of the display (DMD). The minimum start value is 0, the maximum stop value is 255, and the start value

must always be smaller than the stop value. For example, if the start value = 0, the stop value = 255, and

the DMD resolution is 1280 wide, the step size would be 5 (1280 pixels / 256 values = 5). Thus every gray

shade value from 0 to 255 would have a step size of 5 pixels (such that each step would have 5 columns

of pixels with the same gray scale value). The gray scale value always increments by 1 for each step

between the start and stop values. An example of a fixed step horizontal ramp pattern is shown in

Figure 8.

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

19

Page 20

Software Interface

As noted in Table 8, the color for the fixed step vertical ramp pattern is specified using the foreground

color. As noted in Table 9, the user specifies the start value and the stop value for the ramp. For this

pattern, the system automatically determines the step size based on the start and stop values and the size

of the display (DMD). The minimum start value = 0, the maximum stop value = 255, and the start value

must always be smaller than the stop value. For example, if the start value = 0, the stop value = 255, and

the DMD resolution is 768 tall, then the step size would be 3 (768 pixels / 256 values = 3). Thus every

value from 0 to 255 would have a step size of 3 pixels (such that each step would have 3 rows of pixels

with the same gray scale value). The gray scale value always increments by 1 for each step between the

start and stop values. An example of a fixed step vertical ramp pattern is shown in Figure 9.

www.ti.com

Figure 8. Example of Fixed Step Horizontal Ramp Test Pattern

20

Figure 9. Example of Fixed Step Vertical Ramp Test Pattern

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 21

www.ti.com

As noted in Table 8, the colors for the horizontal lines pattern are specified using both the foreground and

background colors. The foreground color is used for the horizontal lines, and the background color is used

for the space between the lines. As noted in Table 9, the user specifies the foreground line width, as well

as the background line width. The user must determine the line spacing for each resolution display. For

example, if the foreground line width = 1, and the background line width = 9, there would be a single pixel

horizontal line on every tenth line. An example of a horizontal lines pattern is shown in Figure 10.

Software Interface

Figure 10. Example of Horizontal Lines Test Pattern

As noted in Table 8, the colors for the vertical lines pattern are specified using both the foreground and

background colors. The foreground color is used for the vertical lines, and the background color is used

for the space between the lines. As noted in Table 9, the user specifies the foreground line width, as well

as the background line width. The user must determine the line spacing for each resolution display. For

example, if the foreground line width = 1, and the background line width = 9, there would be a single pixel

vertical line on every tenth line. An example of a vertical lines pattern is shown in Figure 11.

Figure 11. Example of Vertical Lines Test Pattern

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

21

Page 22

HORZSPACING

VERTSPACING

Software Interface

As noted in Table 8, the colors for the diagonal lines pattern are specified using both the foreground and

background colors. The foreground color is used for the diagonal lines, and the background color is used

for the space between the lines. As noted in Table 9, the user specifies the horizontal and vertical line

spacing. The line width is always one pixel. The user determines the line spacing for each resolution

display. Both horizontal and vertical line spacing must use the same value, and are limited to values of 3,

7, 15, 31, 63, 127, and 255. Invalid values result in a communication error (invalid command parameter).

An example of a diagonal lines pattern is shown in Figure 12.

www.ti.com

Figure 12. Example of Diagonal Lines Test Pattern

As noted in Table 8, the colors for the grid lines pattern are specified using both the foreground and

background colors. The foreground color is used for the grid lines, and the background color is used for

the space between the lines. As noted in Table 9, the user specifies the horizontal foreground and

background line width, as well as the vertical foreground and background line width. The user determines

the line spacing for each resolution display. For example, if the horizontal foreground line width = 1, and

background line width = 9, there would be a single pixel horizontal line on every tenth line. If the vertical

foreground line width = 1, and background line width = 9, there would be a single pixel vertical line on

every tenth line. An example of a grid lines pattern is shown in Figure 13.

22

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 23

www.ti.com

Software Interface

Figure 13. Example of Grid Lines Test Pattern

As noted in Table 8, the colors for the checkerboard pattern are specified using both the foreground and

background colors. The foreground color is used for one of the checkers, and the background color is

used for the alternating checker. As noted in Table 9, the user specifies the number of horizontal checkers

and the number of vertical checkers. For this pattern, the system automatically determines the checker

size in each direction based on the number of checkers and the size of the display (DMD). For example, if

the number of horizontal checkers = 4, the number of vertical checkers = 4, and the DMD resolution is

1280x720, the size of the horizontal checkers is 320 pixels, and the size of the vertical checkers is 180

pixels (1280 pixels / 4 checkers = 320 pixels: 720 pixels / 4 checkers = 180 pixels). An example of a

checkerboard pattern (16 checkers by 12 checkers) is shown in Figure 14.

Figure 14. Example of Checkerboard Test Pattern

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

23

Page 24

Software Interface

As noted in Table 8 and Table 9, there is no user programmability associated the color bars test pattern.

This pattern is made up of eight vertical color bars: white, yellow, cyan, green, magenta, red, blue, and

black. For this pattern, the system automatically determines the width for each color bar based on the size

of the display (DMD). An example of the color bars pattern is shown in Figure 15.

www.ti.com

Figure 15. Example of Color Bars Test Pattern

5.1.3.6 Read Test Pattern Select (0Ch)

5.1.3.6.1 Read

This command reads the state of the test pattern select command for the display module.

5.1.3.6.2 Read Parameters

This command has no read parameters.

5.1.3.6.3 Return Parameters

Figure 16 describes the return parameters.

Figure 16. Return Parameters

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

Table 11. Parameter Bytes

Parameter Bytes Description

Byte 1 TPG pattern select

Byte 2 Foreground and background color (see Table 8)

Byte 3 Parameter 1 (see Table 9)

Byte 4 Parameter 2 (see Table 9)

Byte 5 Parameter 3 (see Table 9)

Byte 6 Parameter 4 (see Table 9)

24

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 25

www.ti.com

This command always returns six bytes, since the host does not know how many bytes are valid until the

pattern is selected. All unnecessary bytes (see Table 10) are set to 0.

If a batch file is used to specify the parameters of the test pattern generator, those parameters are

returned by this command.

5.1.3.7 Write Splash Screen Select (0Dh)

5.1.3.7.1 Write

This command selects a stored splash screen to be displayed on the display module.

5.1.3.7.2 Write Parameters

Table 12 describes the command parameters.

Parameter Bytes Description

Byte 1 Splash screen reference number (integer)

Default: User defined

This command is used in conjunction with the Write Input Source Select and the Write Splash Screen

Execute commands, and specifies which splash screen is selected by the Input Source Select command.

The settings for this command are retained until changed using this command.

The steps required to display a splash screen are:

1. Select the desired splash screen (using this command)

2. Change the input source to splash screen (using Write Input Source Select)

3. Start the splash screen retrieval process (using Write Splash Screen Execute).

The splash screen is read from flash and sent down the processing path of the controller once, to be

stored in memory for display at the end of the processing path. As such, all image processing settings

(such as image crop, image orientation, display size, splash screen select, splash screen as input source,

and so forth) should be set by the user before executing the Write Splash Screen Execute command.

The user should review the notes for the Write Input Source Select command to understand the concept

of source-associated commands. This concept determines when source-associated commands are

executed by the system. This command is a source-associated command.

The availability of the splash screen is limited by the available space in flash memory. All splash screens

must be landscape oriented.

For single-controller applications which support DMD resolutions of up to 1280 x 720, the minimum splash

image size allowed for flash storage is 427 x 240, with the maximum being the resolution of the product

DMD. Typical splash image sizes for flash are 427 x 240 and 640 x 360. The full resolution size is typically

used to support an optical test splash screen.

For dual-controller applications which support DMD resolutions up to 1980 x 1080, the minimum splash

image size allowed for flash storage is 854 x 480, with the maximum being the resolution of the product

DMD. Typical splash image sizes for flash are 854 x 480. The full resolution size is typically used to

support an optical test splash screen.

The user must specify how the splash image is displayed on the screen. Key commands for this are Write

Image Crop and Write Display Size.

When this command is received while splash screen is the active source, other than storing the specified

splash screen value, the only action taken by the controller software is to obtain the header information

from the selected splash screen and store this in internal memory. When the Write Splash Screen Execute

command is received, the controller software uses this stored information to set up the processing path

prior to pulling the splash data from flash.

Software Interface

Table 12. Write Parameters

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

25

Page 26

Software Interface

5.1.3.8 Read Splash Screen Select (0Eh)

5.1.3.8.1 Read

This command reads the state of the Splash Screen Select command of the display module.

5.1.3.8.2 Read Parameters

This command has no command parameters.

5.1.3.8.3 Return Parameters

Table 13 describes the return parameters.

Table 13. Return Parameters

Parameter Bytes Description

Byte 1 Splash screen selected (integer)

5.1.3.9 Read Splash Screen Header (0Fh)

5.1.3.9.1 Read

This command reads the splash screen header information for the selected splash screen of the display

module.

www.ti.com

5.1.3.9.2 Read Parameters

The read parameter specifies the splash screen for which the header parameters are returned. If a splash

screen value is provided for an unavailable splash screen, this is considered an error (invalid command

parameter value – communication status) and the command is be executed.

Parameter Bytes Description

5.1.3.9.3 Return Parameters

Table 15 describes the return parameters.

Parameter Bytes Description

Byte 10 Compression type

Byte 11 Color order

Byte 12 Chroma order

Table 14. Read Parameters

Byte 1 Splash screen reference number (integer)

Table 15. Return Parameters

Byte 1 Splash image width in pixels (LSByte)

Byte 2 Splash image width in pixels (MSByte)

Byte 3 Splash image height in pixels (LSByte)

Byte 4 Splash image height in pixels (MSByte)

Byte 5 Splash image size in bytes (LSByte)

Byte 6 Splash image size in bytes

Byte 7 Splash image size in bytes

Byte 8 Splash image size in bytes (MSByte)

Byte 9 Pixel format

26

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 27

www.ti.com

Parameter definitions are referenced in Table 16.

Table 15. Return Parameters (continued)

Parameter Bytes Description

Byte 13 Byte order

Table 16. Splash Screen Header Definitions

Parameter Values

0h = 24-bit RGB unpacked (not used)

Pixel format

Compression type

Color order

Chroma order

Byte order

1h = 24-bit RGB packed (not used)

2h = 16-bit RGB 5-6-5

3h = 16-bit YCbCr 4:2:2

0h = Uncompressed

1h = RGB RLE compressed

2h = User-defined (not used)

3h = YUV RLE compressed

0h = 00RRGGBB

1h = 00GGRRBB

0h = Cr is first pixel

1h = Cb is first pixel

0h = Little endian

1h = Big endian

Software Interface

5.1.3.10 Write Image Crop (10h)

5.1.3.10.1 Write

This command specifies which portion of the input image is captured and output from the cropping

function of the display module.

5.1.3.10.2 Write Parameters

Table 17 describes the command parameters.

Parameter Bytes Description

Byte 1 Capture start pixel (LSByte)

Byte 2 Capture start pixel (MSByte)

Byte 3 Capture start line (LSByte)

Byte 4 Capture start line (MSByte)

Byte 5 Pixels per line (LSByte)

Byte 6 Pixels per line (MSByte)

Byte 7 Lines per frame (LSByte)

Byte 8 Lines per frame (MSByte)

Default: Bytes (8:1) = FFh FFh FFh FFh 00h 00h 00h 00h (no cropping)

The capture start parameters for this command are referenced to active data, and are 0-based (such that

specifying the capture start pixel to be a value of zero indicates the first active pixel of a line). The

pixel/line and lines/frame parameters are 1-based (such that specifying the pixels/line value to be a value

of 640 indicates 640 pixels to be captured).

Table 17. Write Parameters

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

27

Page 28

Software Interface

This command applies to all sources including test patterns, splash screens, and external sources. Making

a change to the source or port does not impact the application of this command.

Cropping is done prior to the scaling function in the display module. As such, the size difference between

the crop size and display size determines the amount of scaling needed in both dimensions. The scaling

limits are listed in Table 18.

www.ti.com

Table 18. Scaling Limits

Controller Configuration

Single controller (excluding

interlaced NTSC/PAL)

Single controller (interlaced

NTSC/PAL only)

Dual controller

Maximum Horizontal

Interpolation Scale

Factor

3.0 3.0 3.0 3.0

3.0 3.0 3.0 6.0

Scaling not supported

except for splash

screen.

Maximum Horizontal

Decimation Scale

Factor

Scaling not supported

except for splash

screen.

Maximum Vertical

Interpolation Scale

Factor

Scaling not supported

except for splash

screen.

Maximum Vertical

Decimation Scale

Factor

Scaling not supported

except for splash

screen.

The scaling limits noted in Table 18 may not be possible depending on other factors, such as keystone

correction. In this case, the system does what is requested even if this results in a broken image. The

OEM is responsible for providing the appropriate input settings to meet the display needs.

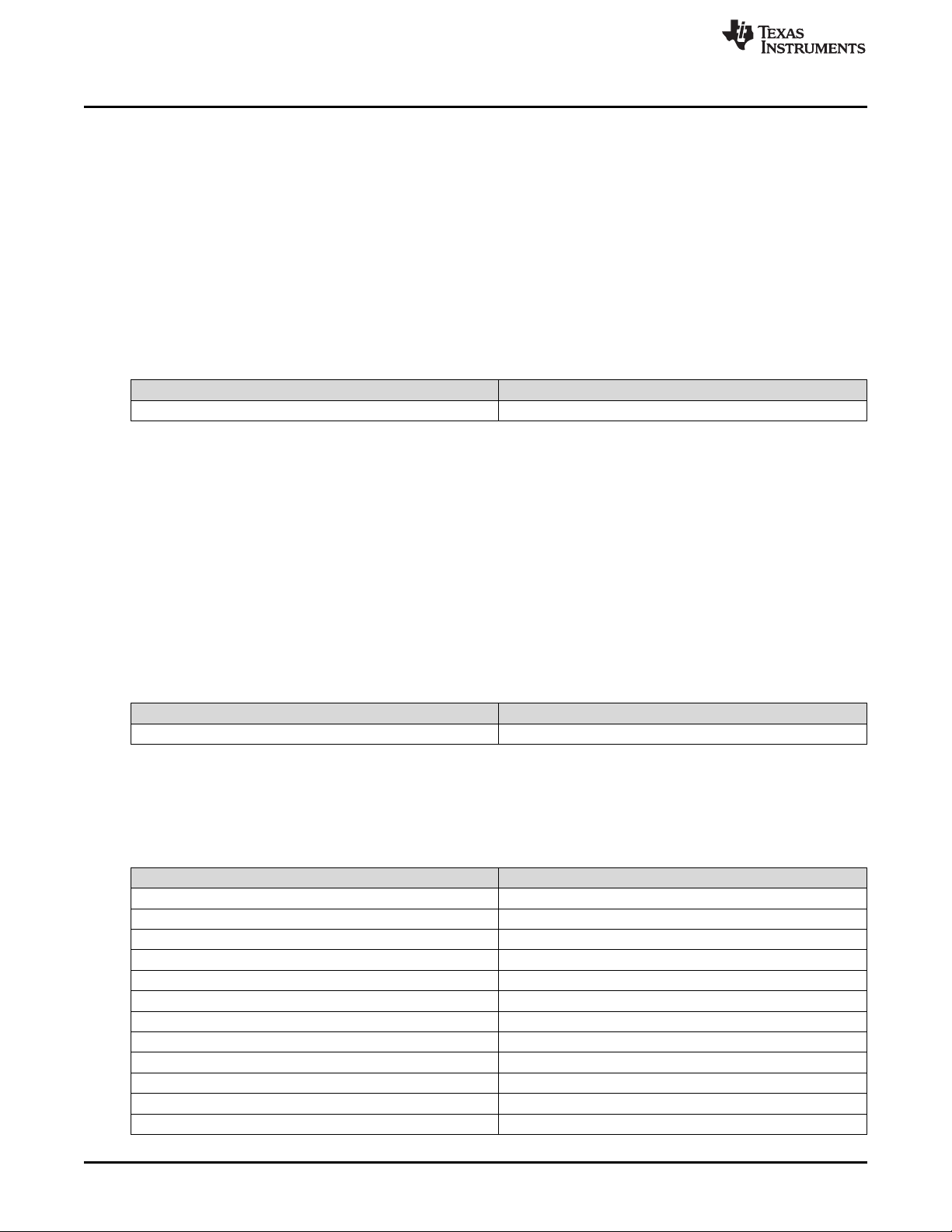

If a crop size parameter exceeds the size of the input image, the input image size minus the capture start

pixel/line is be used (as shown in Figure 17). The crop size parameters returned by the read image crop

command are always the values specified by the Write Image Crop command.

Figure 17. Cropping Rules when Crop Size exceeds Input Size

5.1.3.11 Read Image Crop (11h)

5.1.3.11.1 Read

This command reads the state of the image crop command for the display module.

5.1.3.11.2 Read Parameters

This command has no command parameters.

5.1.3.11.3 Return Parameters

Table 19 describes the return parameters.

Table 19. Return Parameters

Parameter Bytes Description

Byte 1 Capture start pixel (LSByte)

Byte 2 Capture start pixel (MSByte)

28

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 29

www.ti.com

Parameter Bytes Description

Byte 3 Capture start line (LSByte)

Byte 4 Capture start line (MSByte)

Byte 5 Pixels per line (LSByte)

Byte 6 Pixels per line (MSByte)

Byte 7 Lines per frame (LSByte)

Byte 8 Lines per frame (MSByte)

All parameters for this command are referenced to active data, and are 1-based. (such that specifying the

capture start pixel to be a value of one indicates the first active pixel of a line).

5.1.3.12 Write Display Size (12h)

5.1.3.12.1 Write

This command specifies the size of the active image to be displayed on the display module.

5.1.3.12.2 Write Parameters

Table 20 describes the command parameters.

Software Interface

Table 19. Return Parameters (continued)

Table 20. Write Parameters

Parameter Bytes Description

Byte 1 Pixels per line (LSByte)

Byte 2 Pixels per line (MSByte)

Byte 3 Lines per frame (LSByte)

Byte 4 Lines per frame (MSByte)

Default: DMD resolution.

This command specifies the size of the non-keystone corrected image to be output from the scaler

function, which is the size of the active displayed image.

The parameter values are to be 1-based. (such that a value of 1280 pixels displays 1280 pixels per line).

All sub-images (images smaller than the DMD display) are horizontally and vertically centered on the

display (DMD).

If the display size exceeds the resolution of the DMD, this is considered an error (invalid command

parameter value – communication status) and the command does not execute. The display size

parameters are checked against the DMD resolution in both rotation image orientations (non-rotated and

rotated), and if the DMD resolution is exceeded in both of these orientations, it is considered an error. The

system does not check for proper image orientation setup.

DMD resolution = 854 × 480:

• Example 1: Display size parameter = 480 × 854 (not an error)

• Example 2: Display size parameter = 900 × 320 (error)

• Example 3: Display size parameter = 500 × 600 (error)

If the source, crop, and display parameter combinations exceed the capabilities of the scaler, the system

implements the user request as best it can, and the displayed image may be broken. The user must

provide updated parameters to fix the image.

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

29

Page 30

Software Interface

5.1.3.13 Read Display Size (13h)

5.1.3.13.1 Read

This command reads the state of the display size command for the display module.

5.1.3.13.2 Read Parameters

This command has no read parameters.

5.1.3.13.3 Return Parameters

Table 21 describes the return parameters.

Parameter Bytes Description

Byte 1 Pixels per line (LSByte)

Byte 2 Pixels per line (MSByte)

Byte 3 Lines per frame (LSByte)

Byte 4 Lines per frame (MSByte)

The parameter values are 1-based. (such that a value of 1280 pixels displays 1280 pixels per line).

www.ti.com

Table 21. Return Parameters

5.1.3.14 Write Display Image Orientation (14h)

5.1.3.14.1 Write

This command specifies the image orientation of the displayed image for the display module.

5.1.3.14.2 Write Parameters

Figure 18 describes the command parameters.

Figure 18. Write Parameters

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

b(7:3)

Reserved

b(2) Short axis image flip:

• 0: Image not flipped.

• 1: Image flipped.

b(1) Long axis image flip:

• 0: Image not flipped.

• 1: Image flipped.

b(0) Image rotation (for portrait source only):

• 0: No rotation

• 1: Minus 90° rotation

30

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 31

Flip Disabled Flip EnabledDMD

Flip Disabled Flip EnabledDMD

Non-Rotated Display -90o Rotated Display

www.ti.com

Default: User-defined

Figure 19 shows the result of non-rotation and rotation of a portrait source. If a portrait image is not

rotated, it is centered and padded with black bars.

Landscape images typically should not be rotated, but the system allows this as it may be appropriate for

some situations or configurations. The user is responsible for determining if the result is acceptable.

Image rotation is allowed while keystone correction is enabled, though it may not be appropriate for all

situations or configurations. The user is responsible for determining if the result is acceptable.

Software Interface

Figure 19. Rotation and Non-Rotation of Portrait Source

Figure 20. Long-Axis Flip

Figure 21 shows the short-axis flip.

Figure 21. Short-Axis Flip

5.1.3.15 Read Display Image Orientation (15h)

5.1.3.15.1 Read

This command reads the state of the displayed image orientation function for the display module.

5.1.3.15.2 Read Parameters

This command has no read parameters.

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

31

Page 32

Software Interface

5.1.3.15.3 Return Parameters

Figure 22 describes the return parameters.

Figure 22. Return Parameters

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

www.ti.com

b(7:3)

Reserved

b(2) Short-axis image flip:

• 0: Image not flipped.

• 1: Image flipped.

b(1) Long-axis image flip:

• 0: Image not flipped.

• 1: Image flipped.

b(0) Image rotation (for portrait source only):

• 0: No rotation

• 1: Minus 90° rotation

5.1.3.16 Write Display Image Curtain (16h)

5.1.3.16.1 Write

This command controls the display image curtain for the display module.

5.1.3.16.2 Write Parameters

Figure 23 shows the command parameters.

Figure 23. Write Parameters

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

32

b(7:4)

Reserved

b(3:1) Select curtain color:

• 0h: Black

• 1h: Red

• 2h: Green

• 3h: Blue

• 4h: Cyan

• 5h: Magenta

• 6h: Yellow

• 7h: White

b(0) Curtain enable:

• 0: Curtain disabled

• 1: Curtain enabled

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Programmer’s Guide

Copyright © 2014–2018, Texas Instruments Incorporated

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

Page 33

www.ti.com

Default: 01h

The image curtain fills the entire display with a user-specified color. The curtain color specified by this

command is separate from the border color defined in the Write Border Color command, though both are

displayed using the curtain capability.

5.1.3.17 Read Display Image Curtain (17h)

5.1.3.17.1 Read

This command reads the state of the image curtain control function for the display module.

5.1.3.17.2 Read Parameters

This command has no read parameters.

5.1.3.17.3 Return Parameters

Figure 24 describes the return parameters.

Figure 24. Return Parameters

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

Software Interface

b(7:4)

Reserved

b(3:1) Select curtain color:

• 0h: Black

• 1h: Red

• 2h: Green

• 3h: Blue

• 4h: Cyan

• 5h: Magenta

• 6h: Yellow

• 7h: White

b(0) Curtain enable:

• 0: Curtain disabled

• 1: Curtain enabled

5.1.3.18 Write Image Freeze (1Ah)

5.1.3.18.1 Write

This command enables or disables the image freeze function for the display module.

5.1.3.18.2 Write Parameters

Figure 25 describes the command parameters.

DLPU020C–July 2014–Revised May 2018

Submit Documentation Feedback

DLPC3430, DLPC3432, DLPC3435, DLPC3433, and DLPC3438 Software

Copyright © 2014–2018, Texas Instruments Incorporated

Programmer’s Guide

33

Page 34

Software Interface

Figure 25. Write Parameters

MSB Byte 1 LSB

b7 b6 b5 b4 b3 b2 b1 b0

www.ti.com

b(7:1)

Reserved

b(0) Image freeze:

• 0: Image freeze disabled

• 1: Image freeze enabled

Default: 00h

The image freeze capability has two main functions. The first function allows the user to freeze the current

image on the screen. The second function allows the user (host system or OEM) to reduce or prevent

system changes on the display as visual artifacts. In this second case, the image is frozen, system

changes are made, and the image is unfrozen when complete. In all cases, when the image is unfrozen,

the display shows the most resent input image. Input data between the freeze point and the unfreeze point

is lost.

The controller software never automatically freezes or unfreezes the image. This applies when software is

making updates to the system on its own volition, and for any operation commanded via the I2C interface.

The controller software will not freeze or unfreeze the image for any reason except when explicitly

commanded by the Write Image Freeze command.

The user must review the notes for the Write Input Source Select command to understand the concept of

source-associated commands. This concept determines when source-associated commands are executed

by the system.

If the OEM chooses not to make use of image freeze, they should change the source before changing the

image parameters, to minimize transition artifacts.

5.1.3.18.3 Use of Image Freeze to Reduce On-Screen Artifacts