Product

Folder

Order

Now

Technical

Documents

Tools &

Software

Support &

Community

DLPS013G –APRIL 2010–REVISED JANUARY 2019

DLP5500 DLP®0.55 XGA Series 450 DMD

DLP5500

1 Features

1

• 0.55-Inch Micromirror Array Diagonal

– 1024 × 768 Array of Aluminum, Micrometer-

Sized Mirrors (XGA Resolution)

– 10.8-µm Micromirror Pitch

– ±12° Micromirror Tilt Angle

(Relative to Flat State)

– Designed for Corner Illumination

• Designed for Use With Broadband Visible Light

(420 nm – 700 nm):

– Window Transmission 97% (Single Pass,

Through Two Window Surfaces)

– Micromirror Reflectivity 88%

– Array Diffraction Efficiency 86%

– Array Fill Factor 92%

• 16-Bit, Low Voltage Differential Signaling (LVDS)

Double Data Rate (DDR) Input Data Bus

• 200 MHz Input Data Clock Rate

• Dedicated DLPC200 Controller for High-Speed

Pattern Rates:

– 5,000 Hz (1-Bit Binary Patterns)

– 500 Hz (8-Bit Grayscale Patterns)

• Series 450 Package Characteristics:

– Thermal Area 18 mm × 12 mm Enabling High

on Screen Lumens (>2000 lm)

– 149 Micro Pin Grid Array Robust Electrical

Connection

– Package Mates to Amphenol InterCon

Systems 450-2.700-L-13.25-149 Socket

2 Applications

• Industrial

– 3D Scanners for Machine Vision and Quality

Control

– 3D Printing

– Direct Imaging Lithography

– Laser Marking and Repair

– Industrial and Medical Imaging

– Medical Instrumentation

– Digital Exposure Systems

• Medical

– Opthamology

– 3D Scanners for Limb and Skin Measurement

– Hyperspectral Imaging

• Displays

– 3D Imaging Microscopes

– Intelligent and Adaptive Lighting

3 Description

Featuring over 750000 micromirrors, the high

resolution DLP5500 (0.55" XGA) digital micromirror

device (DMD) is a spatial light modulator (SLM) that

modulates the amplitude, direction, and/or phase of

incoming light. This advanced light control technology

has numerous applications in the industrial, medical,

and consumer markets. The DLP5500 enables fine

resolution for 3D printing applications.

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

DLP5500 CPGA (149) 22.30 mm × 32.20 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

(1)

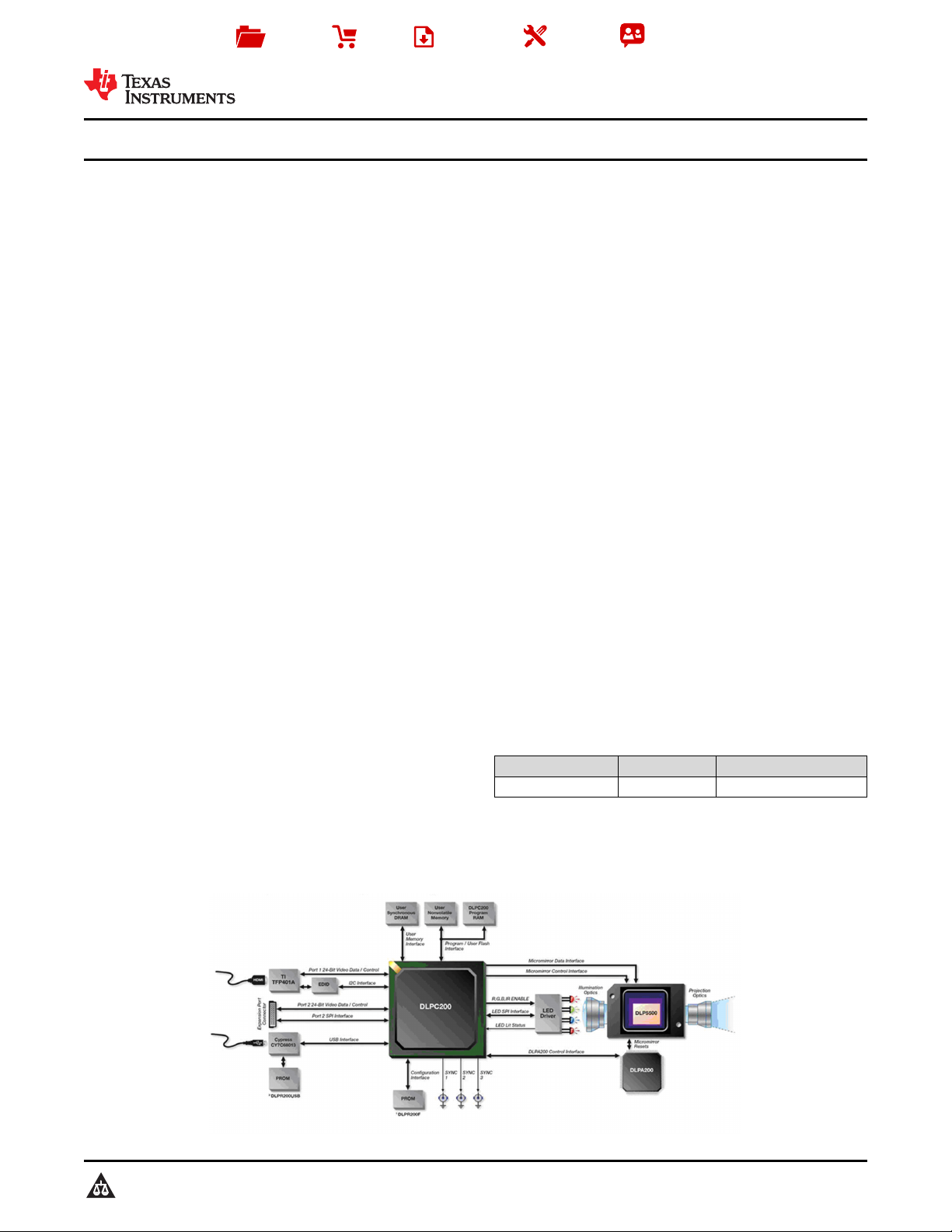

4 Typical Application Schematic

1

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Typical Application Schematic............................. 1

5 Revision History..................................................... 2

6 Description (continued)......................................... 4

7 Pin Configuration and Functions......................... 4

8 Specifications......................................................... 7

8.1 Absolute Maximum Ratings...................................... 7

8.2 Storage Conditions.................................................... 7

8.3 ESD Ratings.............................................................. 7

8.4 Recommended Operating Conditions....................... 8

8.5 Thermal Information................................................ 10

8.6 Electrical Characteristics......................................... 10

8.7 Timing Requirements.............................................. 11

8.8 System Mounting Interface Loads .......................... 15

8.9 Micromirror Array Physical Characteristics............. 16

8.10 Micromirror Array Optical Characteristics............. 17

8.11 Window Characteristics......................................... 18

8.12 Chipset Component Usage Specification ............. 18

9 Detailed Description............................................ 19

9.1 Overview................................................................. 19

9.2 Functional Block Diagram....................................... 20

9.3 Feature Description................................................. 21

9.4 Device Functional Modes........................................ 24

9.5 Window Characteristics and Optics ....................... 24

9.6 Micromirror Array Temperature Calculation............ 25

9.7 Micromirror Landed-on/Landed-Off Duty Cycle...... 27

10 Application and Implementation........................ 29

10.1 Application Information.......................................... 29

10.2 Typical Application................................................ 30

11 Power Supply Recommendations ..................... 32

11.1 DMD Power-Up and Power-Down Procedures..... 32

12 Layout................................................................... 32

12.1 Layout Guidelines ................................................. 32

12.2 Layout Example .................................................... 33

13 Device and Documentation Support................. 34

13.1 Device Support .................................................... 34

13.2 Documentation Support ........................................ 34

13.3 Related Documentation......................................... 34

13.4 Community Resources.......................................... 34

13.5 Trademarks........................................................... 35

13.6 Electrostatic Discharge Caution............................ 35

13.7 Glossary................................................................ 35

14 Mechanical, Packaging, and Orderable

Information........................................................... 35

5 Revision History

Changes from Revision F (May 2015) to Revision G Page

• Changed DMD Marking Image Object for Figure 19 ........................................................................................................... 34

Changes from Revision E (September 2013) to Revision F Page

• Added ESD Ratings, Feature Description section, Device Functional Modes, Application and Implementation

section, Power Supply Recommendations section, Layout section, Device and Documentation Support section, and

Mechanical, Packaging, and Orderable Information section ................................................................................................. 1

• Changed Incorrect V

• Changed LVDS ƒ

• Added Max Recommended DMD Temperature – Derating Curve......................................................................................... 9

• Added LVCMOS Output Measurement Condition Figure..................................................................................................... 10

• Changed Incorrect tCvalue from 4 ns to 5 ns (200 MHz clock) ........................................................................................... 11

• Changed Incorrect tWvalue from 1.25 ns to 2.5 ns (200 MHz clock)................................................................................... 11

• Changed SCP Bus Diagrams............................................................................................................................................... 11

• Added LVDS Voltage Definition Figure ................................................................................................................................ 12

• Changed LVDS Waveform Requirements Figure................................................................................................................. 13

• Added LVDS Equivalent Input Circuit Figure ....................................................................................................................... 13

• Added LVDS & SCP Rise and Fall Time Figures................................................................................................................. 14

• Moved the Mechanical section from Recommended Operating Conditions table to the System Mounting Interface

Loads section ...................................................................................................................................................................... 15

• Added Micromirror Array Physical Characteristics section .................................................................................................. 16

• Changed Micromirror Array Physical Characteristics Figure to generic image (M x N)....................................................... 16

value from 9V to 8V......................................................................................................................... 7

CC2

to200 MHz - previously incorrectly listed as 150 MHz......................................................................... 9

clock

2

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

DLP5500

www.ti.com

• Added Micromirror Array Optical Characteristics section .................................................................................................... 17

• Changed specular reflectivity wavelength range to 420 - 700 nm (from 400 - 700 nm) to match Recommended

Operating Conditions............................................................................................................................................................ 17

• Changed Micromirror Landed Orientation and Tilt Figure to generic image (M x N) ........................................................... 18

• Added Window Characteristics section ............................................................................................................................... 18

• Added Chipset Component Usage Specification section .................................................................................................... 18

• Changed Micromirror Array, Pitch, Hinge Axis Orientation Figure to generic image (M x N).............................................. 22

• Changed Micromirror States: On, Off, Flat Figure to generic DMD image .......................................................................... 23

• Changed Test Point locations from TC1 & TC2 to TP1 - TP5 ............................................................................................. 25

• Changed Test Point location Diagram to show TP1 - TP5................................................................................................... 26

• Added Micromirror Landed-on/Landed-Off Duty Cycle section............................................................................................ 27

• Changed Typical Application diagram.................................................................................................................................. 30

• Replaced "DAD" with "DLPA200"......................................................................................................................................... 31

Changes from Revision D (October 2012) to Revision E Page

• Deleted the Device Part Number Nomenclature section...................................................................................................... 34

Changes from Revision C (June 2012) to Revision D Page

DLPS013G –APRIL 2010–REVISED JANUARY 2019

• Changed the Device Part Number Nomenclature From: DLP5500FYA To: DLP5500AFYA............................................... 34

• Updated Mechanical ICD to V2 with a minor change in the window height......................................................................... 34

Changes from Revision B (Spetember 2011) to Revision C Page

• Added the Package Footprint and Socket information in the Features list ........................................................................... 1

• Deleted redundant information from the Description.............................................................................................................. 1

• Changed the Illumination power density Max value of <420 mm From: 20 To: 2 mW/cm2................................................... 7

• Changed Storage temperature range and humidity values in Absolute Maximum Ratings .................................................. 7

• Added Operating Case Temperature, Operating Humidity, Operating Device Temperature Gradient and Operating

Landed Duty-Cycle to RECOMMENDED OPERATING CONDITIONS................................................................................. 8

• Added Mirror metal specular reflectivity and Illumination overfill values to "Micromirror Array Optical Characteristics"

table...................................................................................................................................................................................... 17

• Corrected the C

, Qarray and T

L2W

values in Micromirror Array Temperature Calculation for Uniform Illumination. ...... 26

array

• Corrected the document reference in Related Documents section...................................................................................... 34

Changes from Revision A (June 2010) to Revision B Page

• Changed the window refractive index NOM spec From: 1.5090 To: 1.5119 ....................................................................... 17

• Added table note "At a wavelength of 632.8 nm"................................................................................................................. 17

Changes from Original (April 2010) to Revision A Page

• Changed V

REF

to V

............................................................................................................................................................. 7

CC1

• Added |VID| to the absolute max table.................................................................................................................................... 7

• Added V

to the absolute max table................................................................................................................................ 7

MBRST

• Clarified Note6 measurement point ....................................................................................................................................... 7

• Changed the Illumination power density Max value of <420 mm From: 2 To: 20 mW/cm2................................................... 7

• Added Additional Related Documents.................................................................................................................................. 34

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

3

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

6 Description (continued)

The XGA resolution has the direct benefit of scanning large objects for 3D machine vision applications. Reliable

function and operation of the DLP5500 requires that it be used in conjunction with the DLPC200 digital controller

and the DLPA200 analog driver. This dedicated chipset provides a robust, high resolution XGA, and high speed

system solution.

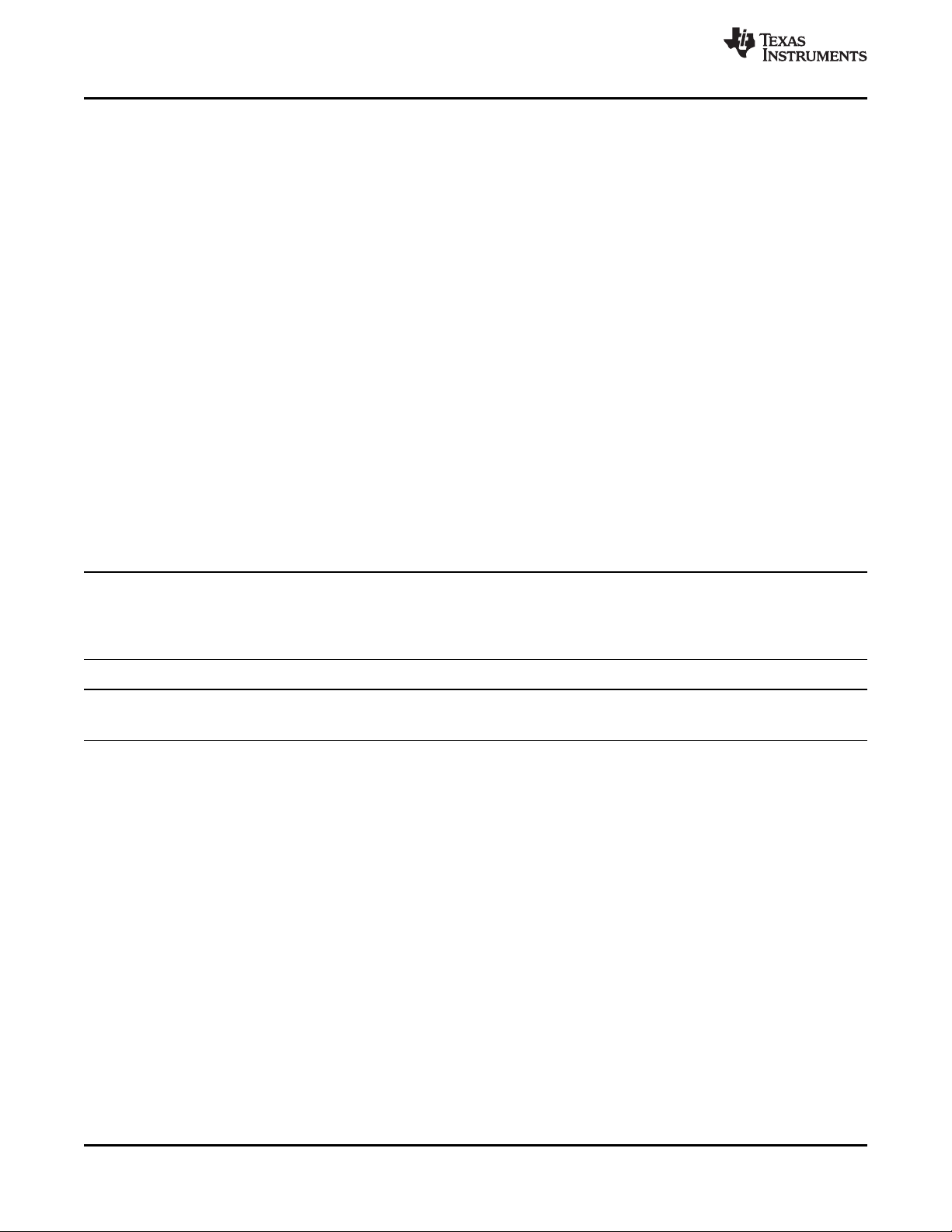

7 Pin Configuration and Functions

FYA Package

149-Pin CPGA Series 450

Bottom View

(1)

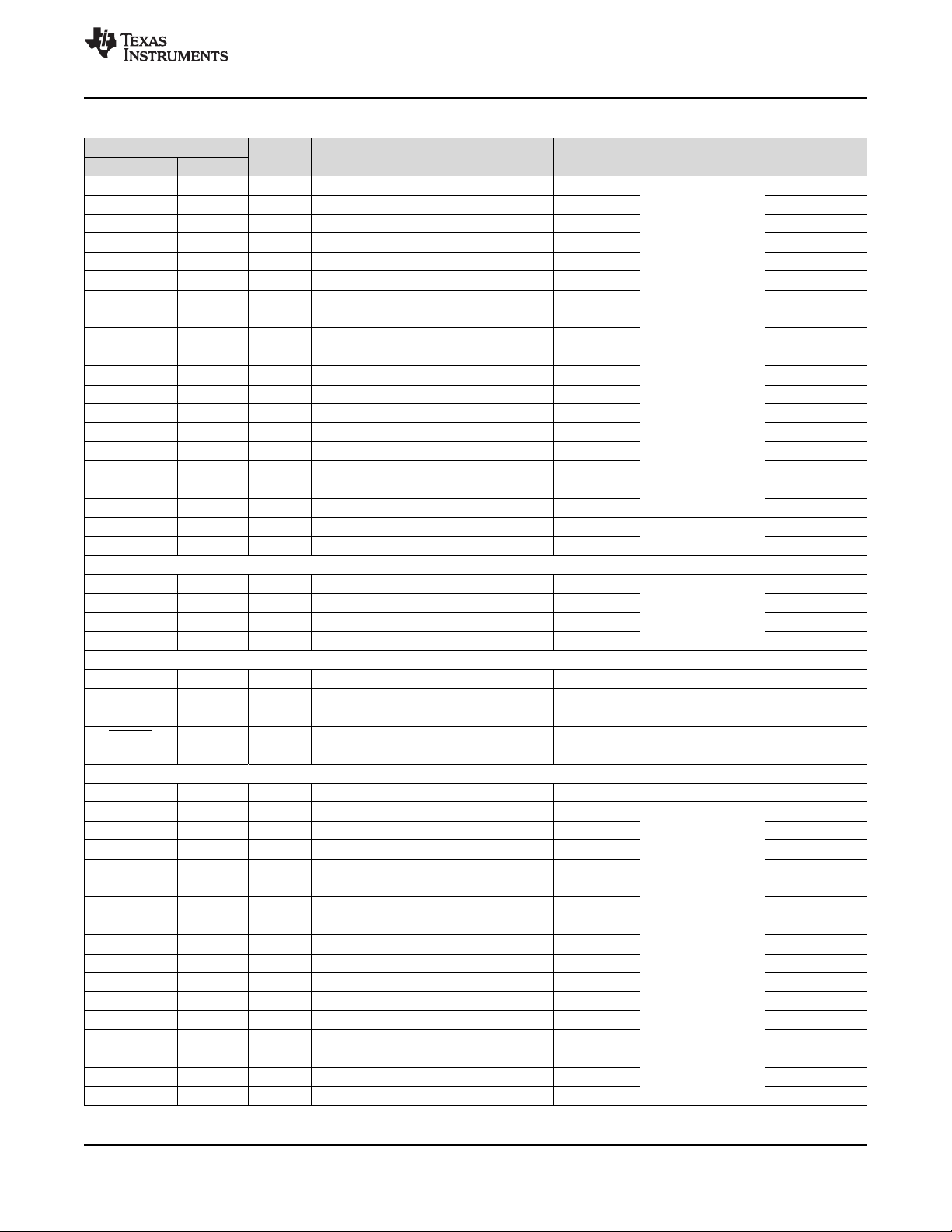

Pin Functions

PIN

NAME NO.

DATA INPUTS

D_AN1 G20 Input LVCMOS DDR Differential DCLK_A

D_AP1 H20 Input LVCMOS DDR Differential DCLK_A 744

D_AN3 H19 Input LVCMOS DDR Differential DCLK_A 688

D_AP3 G19 Input LVCMOS DDR Differential DCLK_A 703

D_AN5 F18 Input LVCMOS DDR Differential DCLK_A 686

D_AP5 G18 Input LVCMOS DDR Differential DCLK_A 714

D_AN7 E18 Input LVCMOS DDR Differential DCLK_A 689

D_AP7 D18 Input LVCMOS DDR Differential DCLK_A 705

D_AN9 C20 Input LVCMOS DDR Differential DCLK_A 687

D_AP9 D20 Input LVCMOS DDR Differential DCLK_A 715

D_AN11 B18 Input LVCMOS DDR Differential DCLK_A 715

D_AP11 A18 Input LVCMOS DDR Differential DCLK_A 732

D_AN13 A20 Input LVCMOS DDR Differential DCLK_A 686

D_AP13 B20 Input LVCMOS DDR Differential DCLK_A 715

D_AN15 B19 Input LVCMOS DDR Differential DCLK_A 700

D_AP15 A19 Input LVCMOS DDR Differential DCLK_A 719

(1) The following power supplies are required to operate the DMD: VCC, VCCI, VCC2. VSS must also be connected.

(2) DDR = Double Data Rate. SDR = Single Data Rate. Refer to the Timing Requirements for specifications and relationships.

(3) Refer to Electrical Characteristics for differential termination specification.

(4) Internal Trace Length (mils) refers to the Package electrical trace length. See the DLP®0.55 XGA Chip-Set Data Manual (DLPZ004) for

details regarding signal integrity considerations for end-equipment designs.

4

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

TYPE

(I/O/P )

SIGNAL

DATA

RATE

INTERNAL

(2)

TERM

(3)

Product Folder Links: DLP5500

CLOCK DESCRIPTION

Input data bus A

(LVDS)

TRACE

(mils)

715

(4)

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

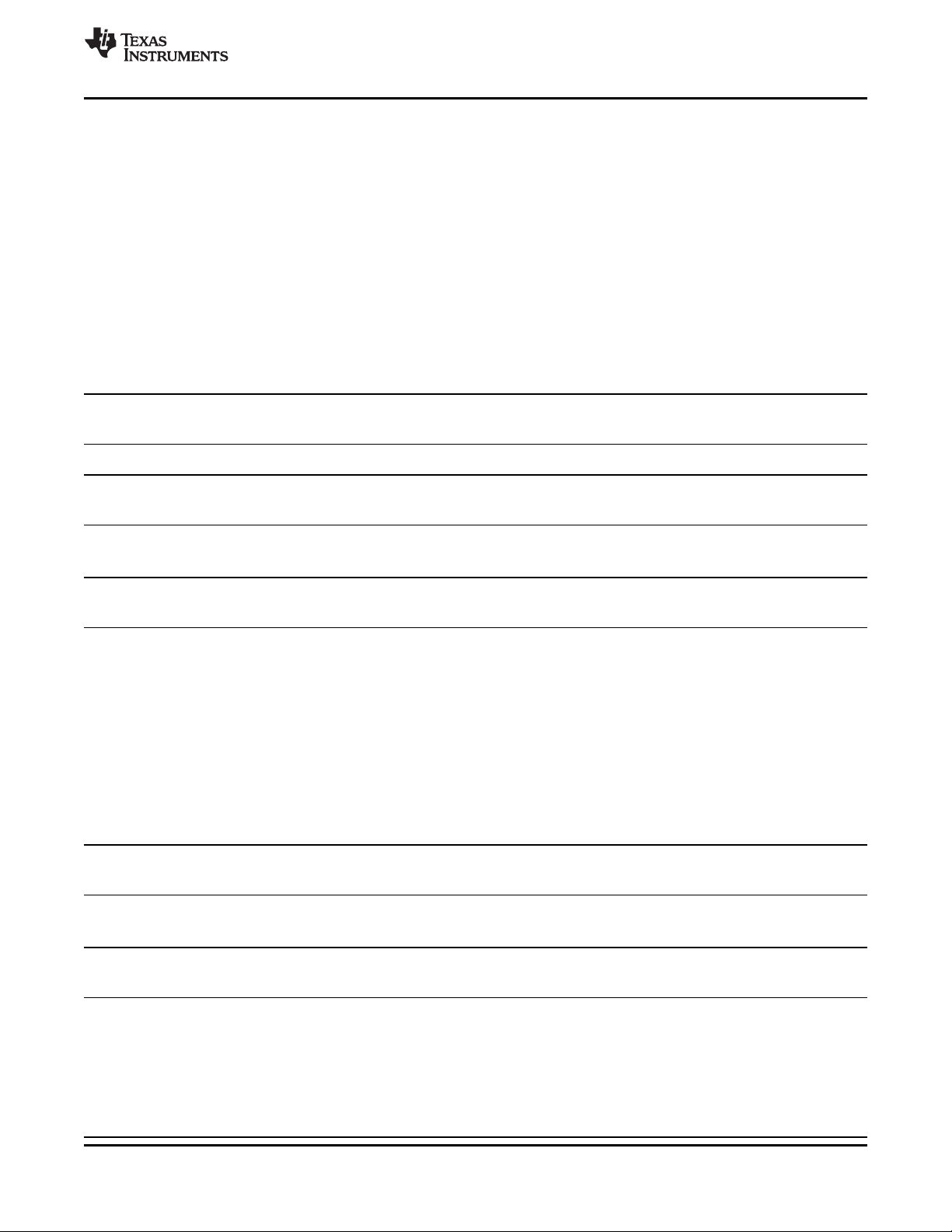

Pin Functions (continued)

(1)

PIN

NAME NO.

D_BN1 K20 Input LVCMOS DDR Differential DCLK_B

D_BP1 J20 Input LVCMOS DDR Differential DCLK_B 745

D_BN3 J19 Input LVCMOS DDR Differential DCLK_B 686

D_BP3 K19 Input LVCMOS DDR Differential DCLK_B 703

D_BN5 L18 Input LVCMOS DDR Differential DCLK_B 686

D_BP5 K18 Input LVCMOS DDR Differential DCLK_B 714

D_BN7 M18 Input LVCMOS DDR Differential DCLK_B 693

D_BP7 N18 Input LVCMOS DDR Differential DCLK_B 709

D_BN9 P20 Input LVCMOS DDR Differential DCLK_B 687

D_BP9 N20 Input LVCMOS DDR Differential DCLK_B 715

D_BN11 R18 Input LVCMOS DDR Differential DCLK_B 702

D_BP11 T18 Input LVCMOS DDR Differential DCLK_B 719

D_BN13 T20 Input LVCMOS DDR Differential DCLK_B 686

D_BP13 R20 Input LVCMOS DDR Differential DCLK_B 715

D_BN15 R19 Input LVCMOS DDR Differential DCLK_B 680

D_BP15 T19 Input LVCMOS DDR Differential DCLK_B 700

DCLK_AN D19 Input LVCMOS - Differential –

DCLK_AP E19 Input LVCMOS - Differential – 728

DCLK_BN N19 Input LVCMOS - Differential –

DCLK_BP M19 Input LVCMOS - Differential – 728

DATA CONTROL INPUTS

SCTRL_AN F20 Input LVCMOS DDR Differential DCLK_A

SCTRL_AP E20 Input LVCMOS DDR Differential DCLK_A 731

SCTRL_BN L20 Input LVCMOS DDR Differential DCLK_B 707

SCTRL_BP M20 Input LVCMOS DDR Differential DCLK_B 722

SERIAL COMMUNICATION (SCP) AND CONFIGURATION

SCP_CLK A8 Input LVCMOS – Pull-Down – –

SCP_DO A9 Output LVCMOS – – SCP_CLK –

SCP_DI A5 Input LVCMOS – Pull-Down SCP_CLK –

SCP_EN B7 Input LVCMOS – Pull-Down SCP_CLK –

PWRDN B9 Input LVCMOS – Pull-Down – –

MICROMIRROR BIAS CLOCKING PULSE

MODE_A A4 Input LVCMOS – Pull-Down – –

MBRST0 C3 Input Analog – – –

MBRST1 D2 Input Analog – – – –

MBRST2 D3 Input Analog – – – –

MBRST3 E2 Input Analog – – – –

MBRST4 G3 Input Analog – – – –

MBRST5 E1 Input Analog – – – –

MBRST6 G2 Input Analog – – – –

MBRST7 G1 Input Analog – – – –

MBRST8 N3 Input Analog – – – –

MBRST9 M2 Input Analog – – – –

MBRST10 M3 Input Analog – – – –

MBRST11 L2 Input Analog – – – –

MBRST12 J3 Input Analog – – – –

MBRST13 L1 Input Analog – – – –

MBRST14 J2 Input Analog – – – –

MBRST15 J1 Input Analog – – – –

TYPE

(I/O/P )

SIGNAL

DATA

RATE

INTERNAL

(2)

TERM

(3)

CLOCK DESCRIPTION

Input data bus B

(LVDS)

Input data bus A Clock

(LVDS)

Input data bus B Clock

(LVDS)

Data Control (LVDS)

Micromirror Bias

Clocking Pulse

"MBRST" signals

"clock" micromirrors

into state of LVCMOS

memory cell associated

with each mirror.

DLP5500

TRACE

(4)

(mils)

716

700

700

716

–

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

5

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Pin Functions (continued)

(1)

PIN

NAME NO.

POWER

B11,B12,B1

V

CC

3,B16,R12,

R13,R16,R1

7

A12,A14,A1

V

CCI

V

CC2

6,T12,T14,T16Power Analog – – –

C1,D1,M1,N

1

A6,A11,A13,

A15,A17,B4,

B5,B8,B14,

B15,B17,C2

,C18,C19,F

1,F2,F19,H1

V

SS

,H2,H3,H18,

J18,K1,K2,L

19,N2,P18,

P19,R4,R9,

R14,R15,T7

,T13,T15,T1

7

RESERVED SIGNALS (Not for use in system)

RESERVED_R7 R7 Input LVCMOS – Pull-Down –

RESERVED_R8 R8 Input LVCMOS – Pull-Down – –

RESERVED_T8 T8 Input LVCMOS – Pull-Down – –

RESERVED_B6 B6 Input LVCMOS – Pull-Down – –

A3, A7,

A10, B2,

B3, B10,

E3, F3, K3,

L3, P1, P2,

NO_CONNECT

P3, R1, R2,

R3, R5, R6,

R10, R11,

T1, T2, T3,

T4, T5, T6,

T9, T10,

T11

TYPE

(I/O/P )

SIGNAL

Power Analog – – –

DATA

RATE

INTERNAL

(2)

TERM

(3)

CLOCK DESCRIPTION

Power for LVCMOS

Logic

Power supply for LVDS

Interface

Power Analog – – –

Power Analog – – –

Power for High Voltage

CMOS Logic

Common return for all

power inputs

Pins should be

connected to V

SS

– – – – – DO NOT CONNECT –

www.ti.com

TRACE

(4)

(mils)

–

–

–

–

–

6

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

8 Specifications

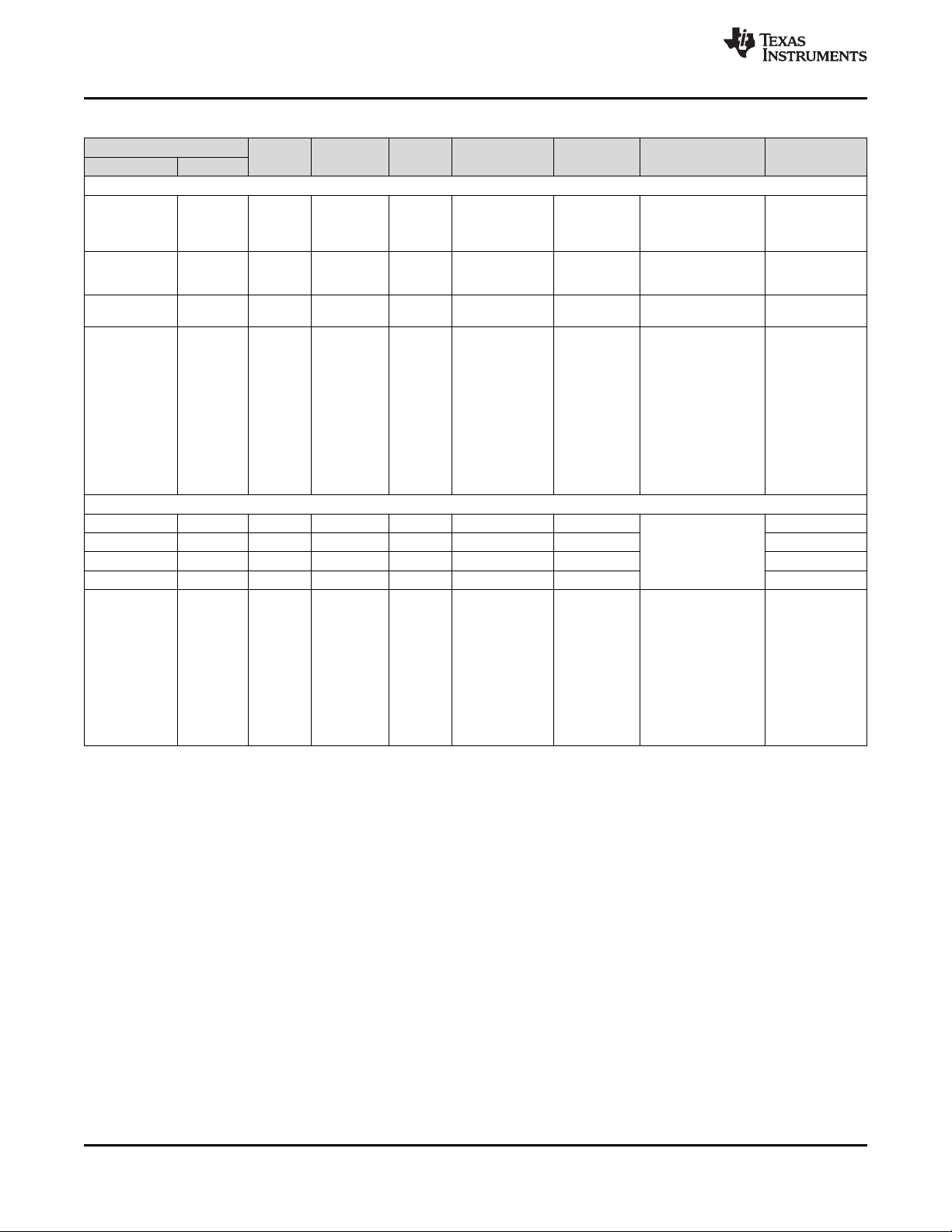

8.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

ELECTRICAL

V

CC

V

CCI

Voltage applied to V

Voltage applied to V

Delta supply voltage |VCC– V

|VID|

V

CC2

V

MBRST

Maximum differential voltage, Damage can occur to internal resistor if exceeded,

See Figure 6

Voltage applied to V

Voltage applied to MBRST[0:15] Input Pins –28 28 V

Voltage applied to all other pins

I

OH

I

OL

Current required from a high-level

output

Current required from a low-level

output

ENVIRONMENTAL

T

CASE

Case temperature: operational

Case temperature: non–operational

Dew Point (Operating and non-Operating) 81 ºC

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Conditions. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages referenced to VSS(ground).

(3) Voltages VCC, V

(4) Exceeding the recommended allowable absolute voltage difference between VCCand V

CCI

, and V

difference between VCCand V

(5) Exposure of the DMD simultaneously to any combination of the maximum operating conditions for case temperature, differential

temperature, or illumination power density (see Recommended Operating Conditions).

(6) DMD Temperature is the worst-case of any test point shown in Figure 16, or the active array as calculated by the Micromirror Array

Temperature Calculation.

(2)(3)

CC

(2)(3)

CCI

OFFSET

CCI

(2)(3)(4)

(4)

|

(2)

VOH= 2.4 V –20 mA

VOL= 0.4 V 15 mA

(5) (6)

(6)

are required for proper DMD operation.

CC2

, | VCC- V

CCI

|, should be less than .3V.

CCI

(1)

MIN MAX UNIT

–0.5 4 V

–0.5 4 V

0.3 V

700 mV

–0.5 8 V

–0.5 VCC+ 0.3 V

–20 90 ºC

–40 90 ºC

may result in excess current draw. The

CCI

8.2 Storage Conditions

applicable before the DMD is installed in the final product

MIN MAX UNIT

T

stg

T

DP

(1) Long-term is defined as the usable life of the device.

(2) Dew points beyond the specified long-term dew point are for short-term conditions only, where short-term is defined as less than 60

DMD storage temperature –40 80 °C

Storage dew point

Storage Dew Point - long-term

Storage Dew Point - short-term

(1)

(2)

cumulative days over the usable life of the device (operating, non-operating, or storage).

24

28

°C

8.3 ESD Ratings

VALUE UNIT

Electrostatic discharge immunity for LVCMOS [I/O] pins

V

(ESD)

Electrostatic discharge

Human body model (HBM), per ANSI/ESDA/JEDEC JS-001, all other

pins [power, control pins] except MBRST

(2)

Electrostatic discharge immunity for MBRST[0:15] pins

(1) Tested in accordance with JESD22-A114-B Electrostatic Discharge (ESD) sensitivity testing Human Body Model (HBM).

(2) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

Product Folder Links: DLP5500

(1)

±2000

±2000

(1)

<250

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

V

7

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

www.ti.com

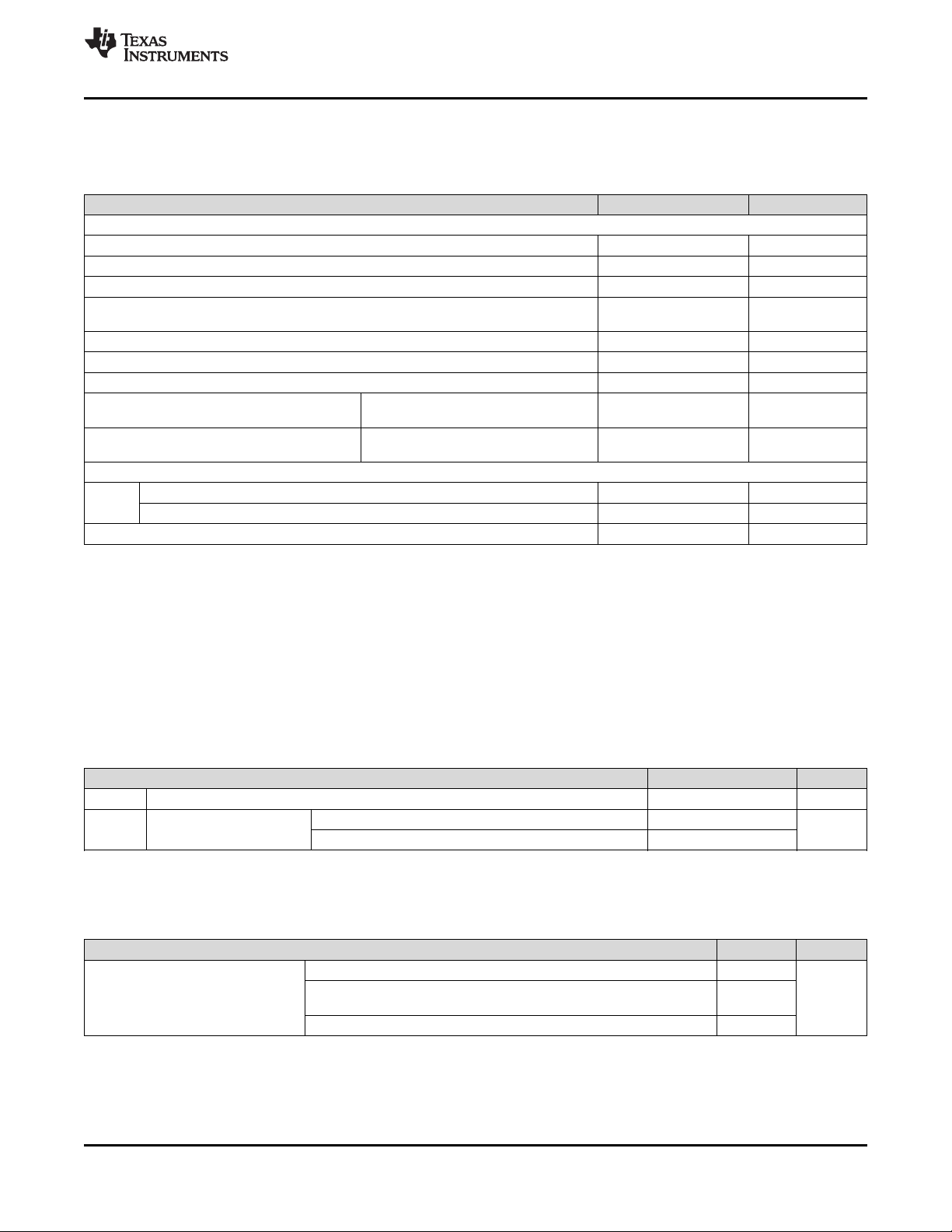

8.4 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

SUPPLY VOLTAGES

V

CC

V

CCI

V

CC2

|V

V

| Supply voltage delta (absolute value)

CCI–VCC

MBRST

(1) (2)

Supply voltage for LVCMOS core logic 3.15 3.3 3.45 V

Supply voltage for LVDS receivers 3.15 3.3 3.45 V

Mirror electrode and HVCMOS supply voltage 8.25 8.5 8.75 V

(3)

Micromirror clocking pulse voltages -27 26.5 V

LVCMOS PINS

V

IH

V

IL

I

OH

I

OL

T

PWRDNZ

High level Input voltage

Low level Input voltage

High level output current at VOH= 2.4 V –20 mA

Low level output current at VOL= 0.4 V 15 mA

PWRDNZ pulse width

(4)

(4)

(5)

SCP INTERFACE

ƒ

clock

t

SCP_SKEW

t

SCP_DELAY

t

SCP_BYTE_INTERVAL

t

SCP_NEG_ENZ

t

SCP_PW_ENZ

t

SCP_OUT_EN

ƒ

clock

SCP clock frequency

Time between valid SCPDI and rising edge of SCPCLK

Time between valid SCPDO and rising edge of SCPCLK

Time between consecutive bytes 1 µs

Time between falling edge of SCPENZ and the first rising edge of SCPCLK 30 ns

SCPENZ inactive pulse width (high level) 1 µs

Time required for SCP output buffer to recover after SCPENZ (from tri-state) 1.5 ns

SCP circuit clock oscillator frequency

(6)

(7)

(7)

(8)

(1) Supply voltages VCC, VCCI, VOFFSET, VBIAS, and VRESET are all required for proper DMD operation. VSS must also be connected.

(2) VOFFSET supply transients must fall within specified max voltages.

(3) To prevent excess current, the supply voltage delta |VCCI – VCC| must be less than specified limit.

(4) Tester Conditions for VIHand VIL:

Frequency = 60MHz. Maximum Rise Time = 2.5 ns at (20% to 80%)

Frequency = 60MHz. Maximum Fall Time = 2.5 ns at (80% to 20%)

(5) PWRDNZ input pin resets the SCP and disables the LVDS receivers. PWRDNZ input pin overrides SCPENZ input pin and tri-states the

SCPDO output pin.

(6) The SCP clock is a gated clock. Duty cycle shall be 50% ± 10%. SCP parameter is related to the frequency of DCLK.

(7) Refer to Figure 3.

(8) SCP internal oscillator is specified to operate all SCP registers. For all SCP operations, DCLK is required.

MIN NOM MAX UNIT

0.3 V

1.7 2.5 VCC + 0.15 V

– 0.3 0.7 V

10 ns

500 kHz

–800 800 ns

700 ns

9.6 11.1 MHz

8

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

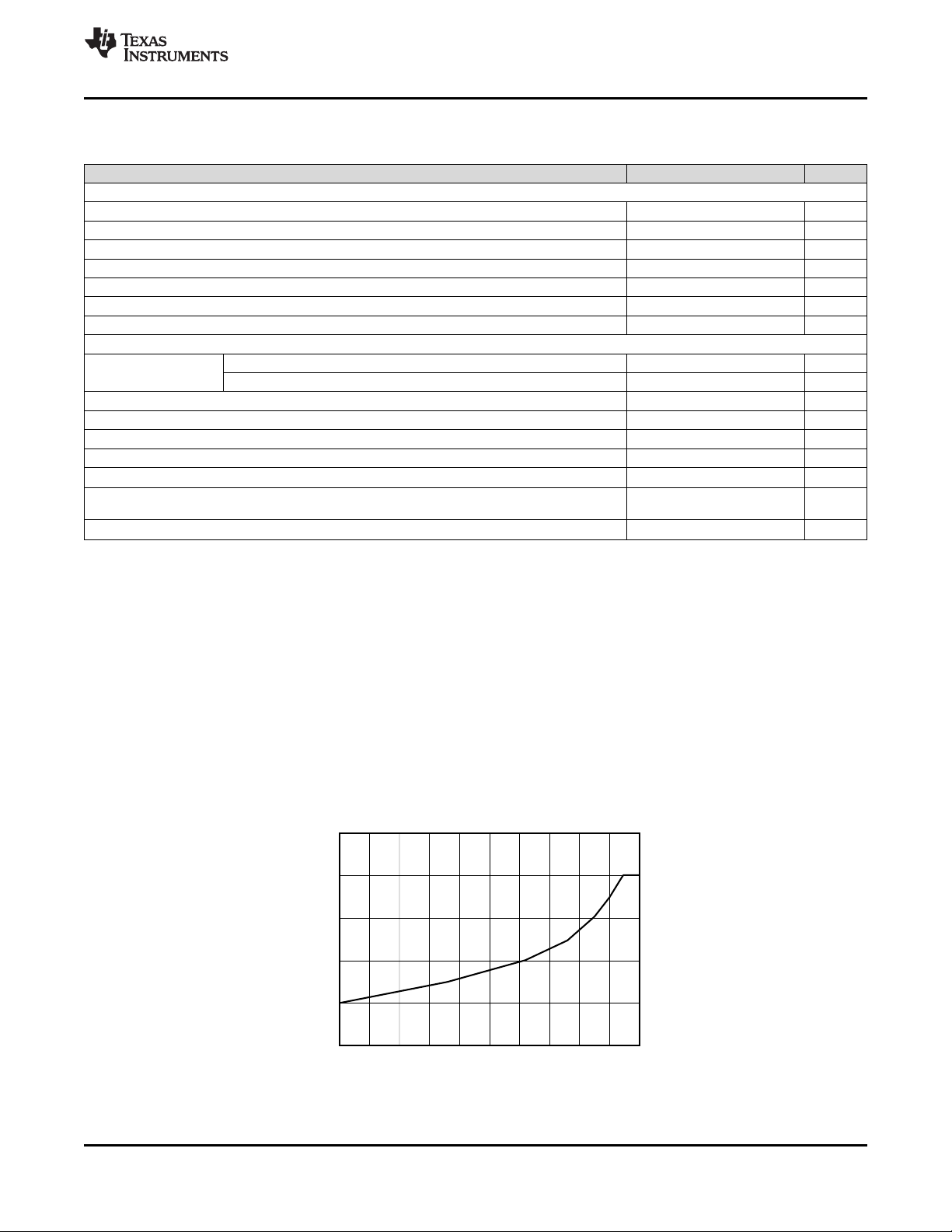

Micromirror Landed Duty Cycle

Operational (°C)

0/100 5/95 10/90 15/85 20/80 25/75 30/70 35/65 40/60 45/55

30

40

50

60

70

80

D001

50/50

100/0 95/5 90/10 85/15 80/20 75/25 70/30 65/35 60/40 55/45

Max Recommended Array Temperature –

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Recommended Operating Conditions (continued)

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

LVDS INTERFACE

ƒ

clock

|VID| Input differential voltage (absolute value)

V

CM

V

LVDS

t

LVDS_RSTZ

Z

IN

Z

LINE

ENVIRONMENTAL

T

DMD

T

WINDOW

T

CERAMIC-WINDOW-DELTA

ILL

UV

ILL

VIS

ILL

IR

(9) Refer to Figure 5, Figure 6, and Figure 7.

(10) Optimal, long-term performance and optical efficiency of the Digital Micromirror Device (DMD) can be affected by various application

parameters, including illumination spectrum, illumination power density, micromirror landed duty-cycle, ambient temperature (storage

and operating), DMD temperature, ambient humidity (storage and operating), and power on or off duty cycle. TI recommends that

application-specific effects be considered as early as possible in the design cycle.

(11) DMD Temperature is the worst-case of any thermal test point in Figure 16, or the active array as calculated by the Micromirror Array

Temperature Calculation for Uniform Illumination.

(12) Per Figure 1, the maximum operational case temperature should be derated based on the micromirror landed duty cycle that the DMD

experiences in the end application. Refer to Micromirror Landed-on/Landed-Off Duty Cycle for a definition of micromirror landed duty

cycle.

(13) Long-term is defined as the average over the usable life of the device.

(14) Short-term is defined as less than 60 cumulative days over the over the usable life of the device.

(15) Window temperature as measured at thermal test points TP2, TP3, TP4 and TP5 in Figure 16.The locations of thermal test points TP2,

TP3, TP4 and TP5 in Figure 16 are intended to measure the highest window edge temperature. If a particular application causes

another point on the window edge to be at a higher temperature, a test point should be added to that location.

(16) Ceramic package temperature as measured at test point 1 (TP 1) in Figure 16.

(17) Dew points beyond the specified long-term dew point (operating, non-operating, or storage) are for short-term conditions only, where

short-term is defined as< 60 cumulative days over the usable life of the device.

(18) Refer to Thermal Information and Micromirror Array Temperature Calculation.

Clock frequency for LVDS interface, DCLK (all channels) 200 MHz

Common mode

LVDS voltage

(9)

(9)

(9)

100 400 600 mV

1200 mV

0 2000 mV

Time required for LVDS receivers to recover from PWRDNZ 10 ns

Internal differential termination resistance 95 105 Ω

Line differential impedance (PWB/trace) 90 100 110 Ω

(10)

(15)

(11) (12) (13)

(11) (14)

10 40 to 70

–20 75 °C

(15) (16)

Long-term DMD temperature (operational)

Short-term DMD temperature (operational)

Window temperature – operational

Delta ceramic-to-window temperature -operational

Long-term dew point (operational & non-operational) 24 °C

Short-term dew point

(13) (17)

(operational & non-operational) 28 °C

Illumination, wavelength < 420 nm 0.68

Illumination, wavelengths between 420 and 700 nm

Thermally

Limited

Illumination, wavelength > 700 nm 10

(12)

90 °C

30 °C

mW/cm

mW/cm

(18)

mW/cm

°C

2

2

2

Figure 1. Max Recommended DMD Temperature – Derating Curve

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

9

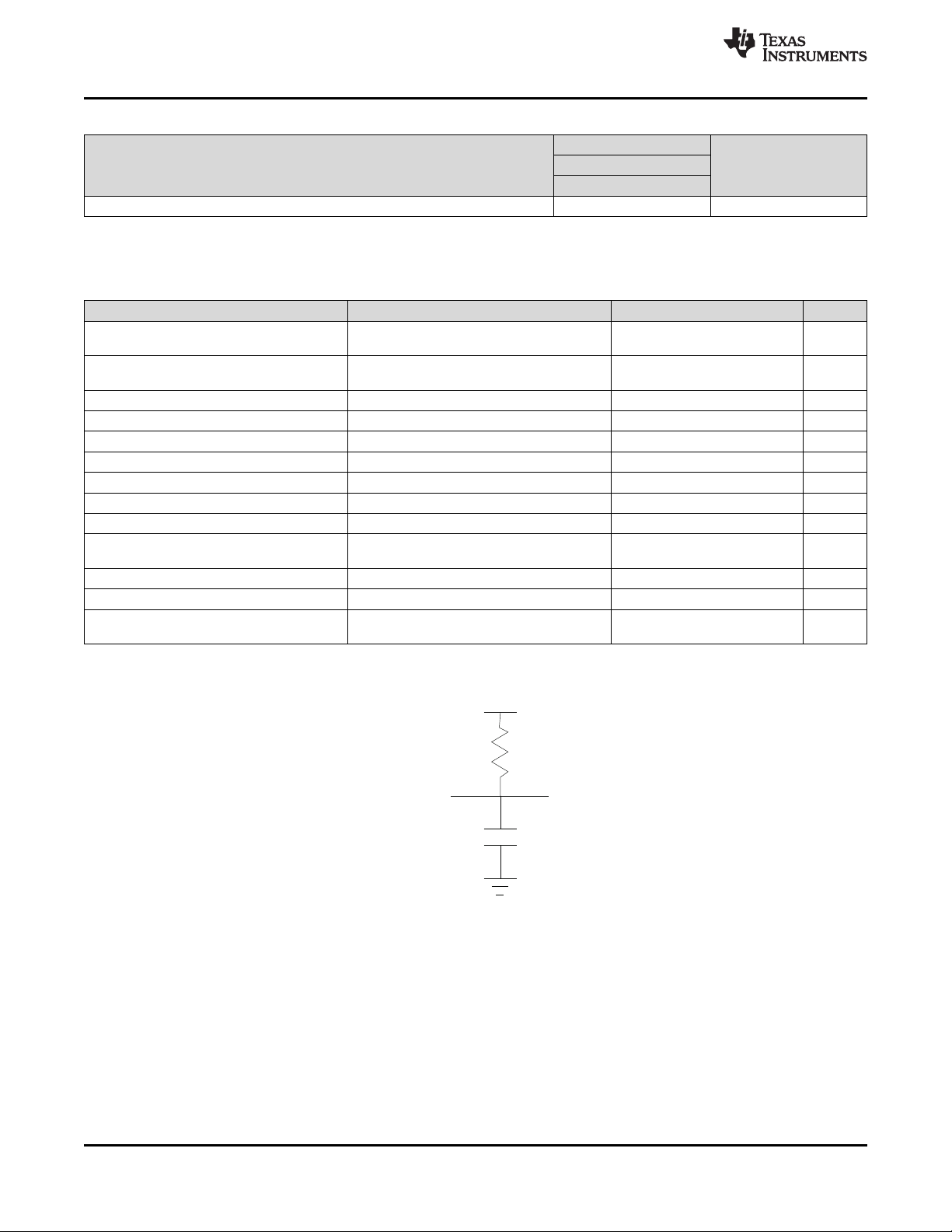

From Output

Under Test

Tester

Channel

LOAD CIRCUIT

C = 50 pF

C = 5 pF for Disable Time

L

L

R

L

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

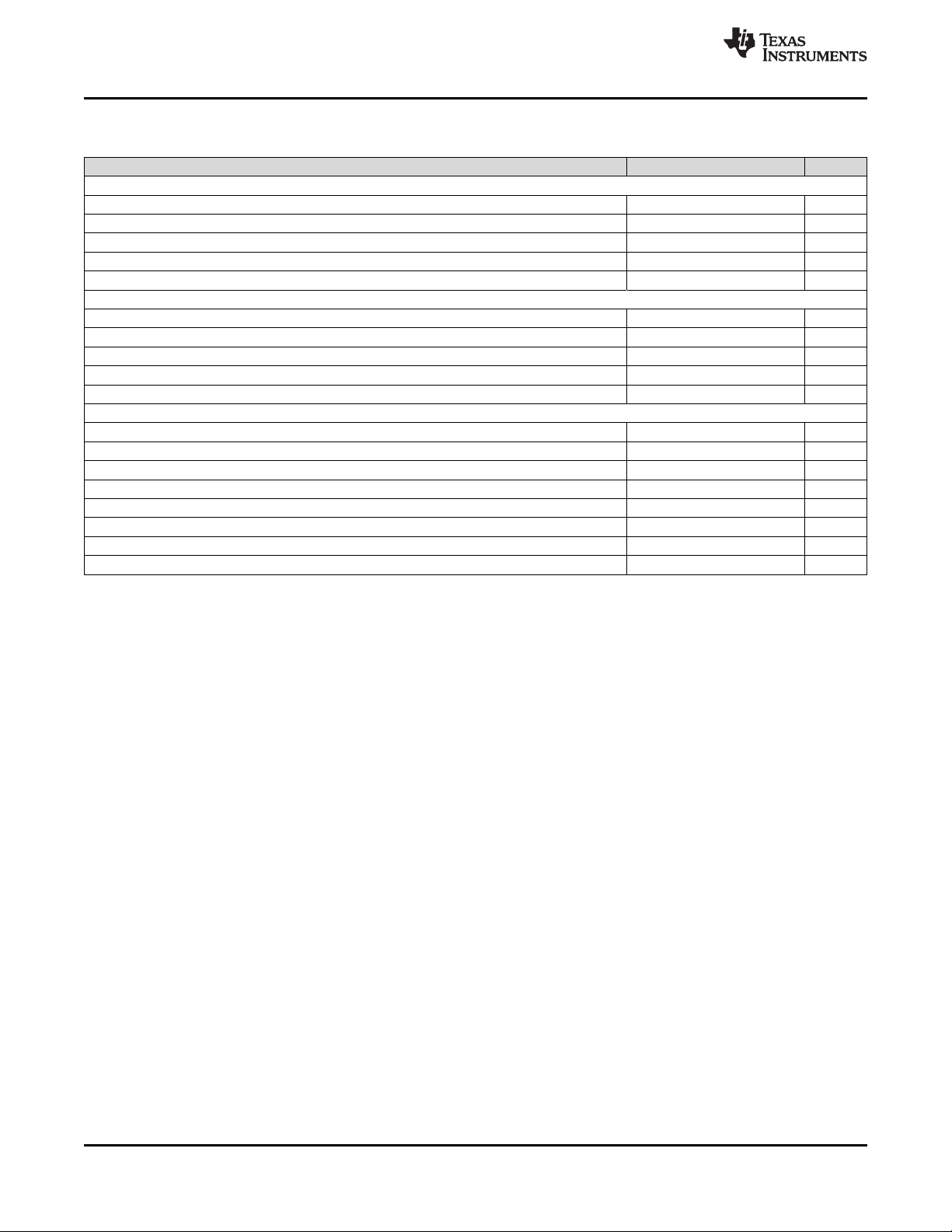

8.5 Thermal Information

THERMAL METRIC

Thermal resistance from active array to specified point on case (TP1)

(1)

(1) For more information, see Micromirror Array Temperature Calculation.

8.6 Electrical Characteristics

over operating free-air temperature range (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

V

I

I

I

I

I

I

Z

Z

C

C

C

OH

OL

OZ

IL

IH

CC

CCI

CC2

IN

LINE

I

O

IM

High-level output voltage

Figure 2

Low-level output voltage

Figure 2

High impedance output current

Low-level input current

High-level input current

Current into VCCpin VCC= 3.6 V, 750 mA

Current into V

Current into V

OFFSET

CC2

Internal Differential Impedance 95 105 Ω

Line Differential Impedance (PWB

or Trace)

Input capacitance

Output capacitance

Input capacitance for

MBRST[0:15] pins

(1) Applies to LVCMOS pins only

(2) Exceeding the maximum allowable absolute voltage difference between VCCand V

Absolute Maximum Ratings for details)

(1)

, See

(1)

, See

(1)

(1)

(1)

(2)

pin

pin V

(1)

(1)

VCC= 3.0 V, IOH= –20 mA 2.4 V

VCC= 3.6 V, IOL= 15 mA 0.4 V

VCC= 3.6 V 10 µA

VCC= 3.6 V, VI= 0 V –60 µA

VCC= 3.6 V, VI= V

V

= 3.6 V 450 mA

CCI

= 8.75V 25 mA

CC2

CC

f = 1 MHz 10 pF

f = 1 MHz 10 pF

f = 1 MHz 160 210 pF

DLP5500

UNITFYA (CPGA)

149 PINS

0.6 °C/W

200 µA

90 100 110 Ω

may result in excess current draw. (Refer to

CCI

www.ti.com

10

Figure 2. Measurement Condition for LVCMOS Output

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

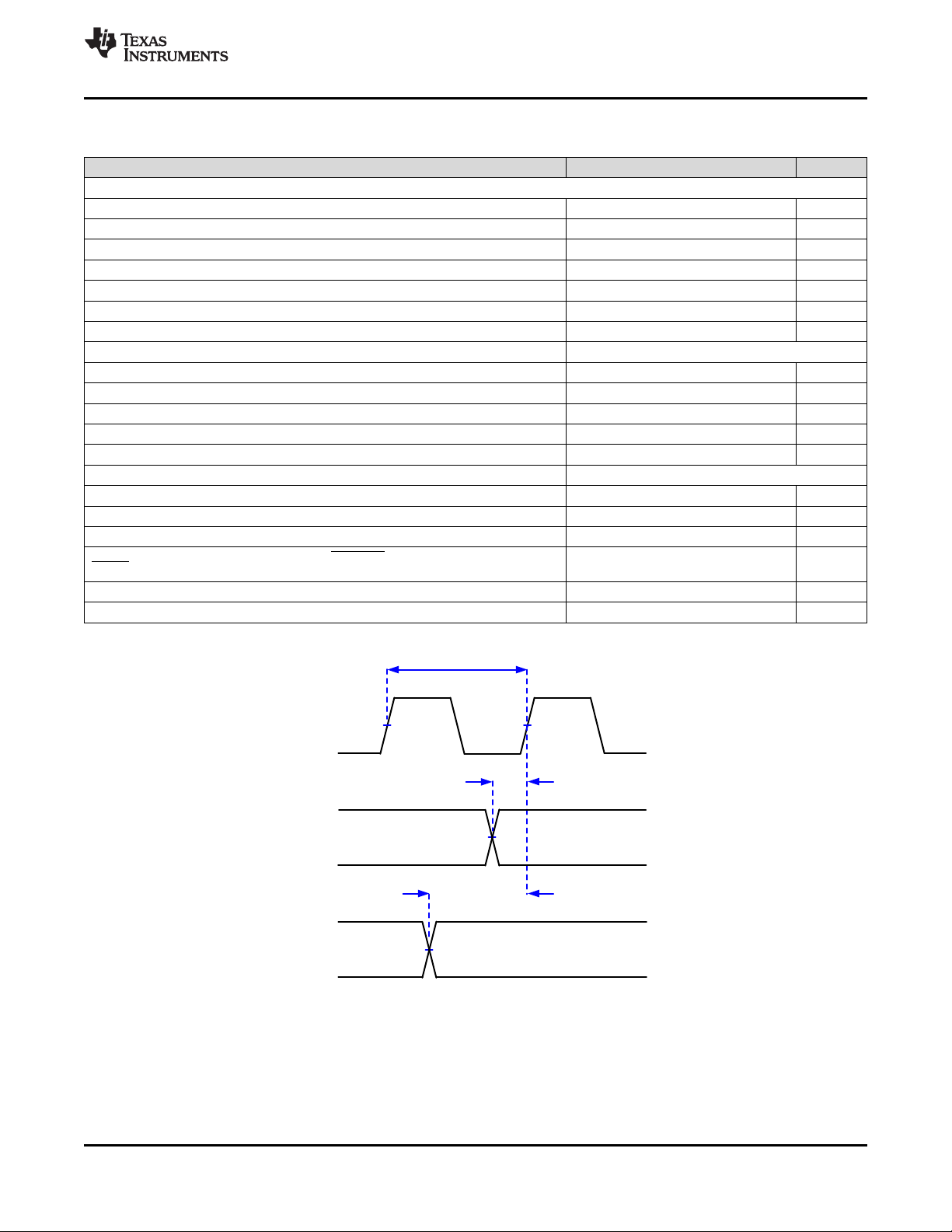

50% 50%

t

c

f

clock

= 1 / t

c

SCPCLK

SCPDI

50%

t

SCP_SKEW

SCPD0

50%

t

SCP_DELAY

DLP5500

www.ti.com

DLPS013G –APRIL 2010–REVISED JANUARY 2019

8.7 Timing Requirements

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

LVDS TIMING PARAMETERS (See Figure 9)

t

c

t

w

t

s

t

s

t

h

t

h

t

skew

LVDS WAVEFORM REQUIREMENTS (See Figure 6)

|VID| Input Differential Voltage (absolute difference) 100 400 600 mV

V

CM

V

LVDS

t

r

t

r

SERIAL CONTROL BUS TIMING PARAMETERS (See Figure 3 and Figure 4)

f

SCP_CLK

t

SCP_SKEW

t

SCP_DELAY

t

SCP_EN

t

r_SCP

t

fP

Clock Cycle DLCK_A or DCLKC_B 5 ns

Pulse Width DCLK_A or DCLK_B 2.5 ns

Setup Time, D_A[0:15] before DCLK_A .35 ns

Setup Time, D_B[0:15] before DCLK_B .35 ns

Hold Time, D_A[0:15] after DCLK_A .35 ns

Hold Time, D_B[0:15] after DCLK_B .35 ns

Channel B relative to Channel A –1.25 1.25 ns

Common Mode Voltage 1200 mV

LVDS Voltage 0 2000 mV

Rise Time (20% to 80%) 100 400 ps

Fall Time (80% to 20%) 100 400 ps

SCP Clock Frequency 50 500 kHz

Time between valid SCP_DI and rising edge of SCP_CLK –300 300 ns

Time between valid SCP_DO and rising edge of SCP_CLK 2600 ns

Time between falling edge of SCP_EN and the first rising edge of

SCP_CLK

30 ns

Rise time for SCP signals 200 ns

Fall time for SCP signals 200 ns

Figure 3. Serial Communications Bus Timing Parameters

Product Folder Links: DLP5500

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

11

V /2

CC

0 v

SCP_CLK,

SCP_DI,

SCP_EN

Input Controller V

CC

t

r_SCP

t

f_SCP

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Figure 4. Serial Communications Bus Waveform Requirements

www.ti.com

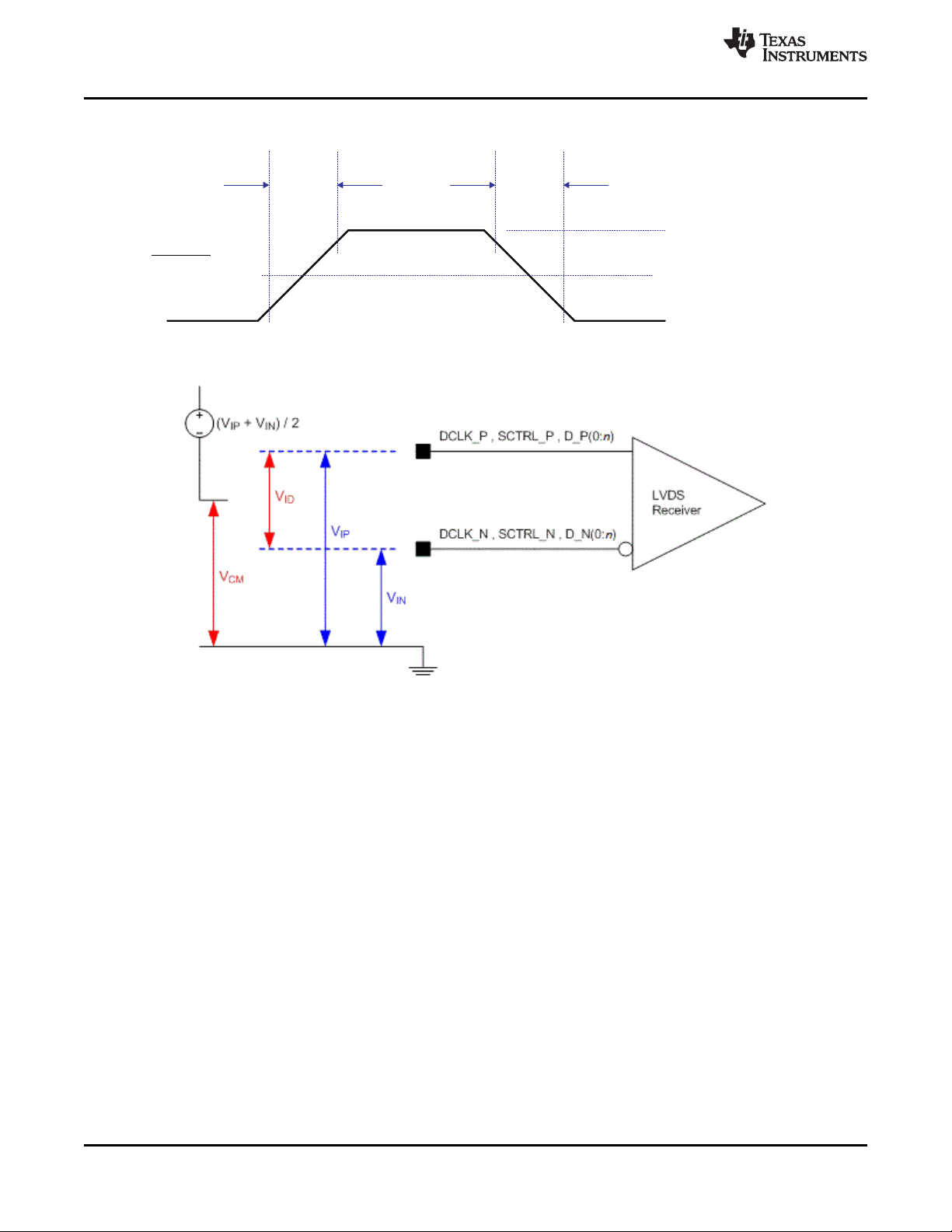

12

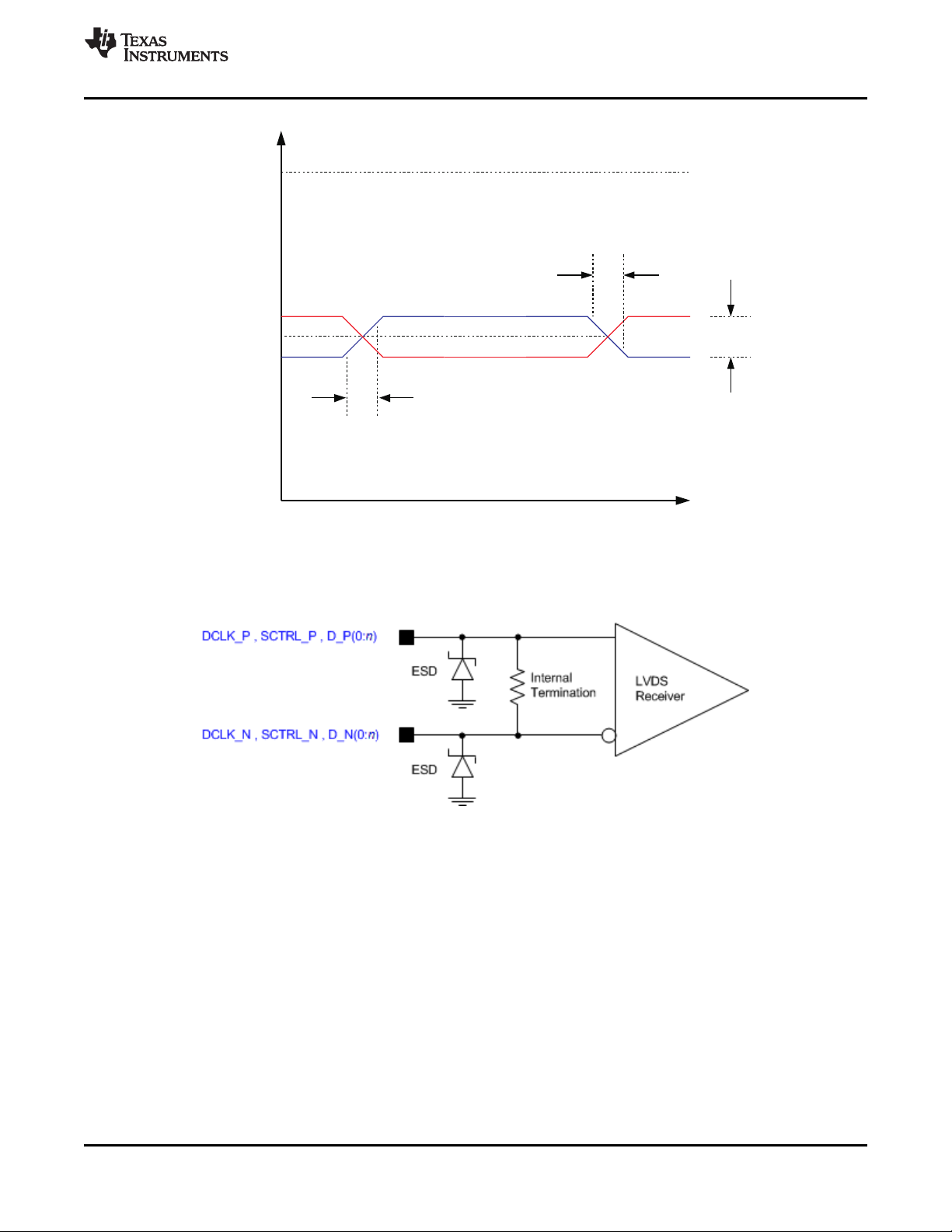

Refer to LVDS Interface section of the Recommended Operating Conditions.

Refer to Pin Configuration and Functions for list of LVDS pins.

Figure 5. LVDS Voltage Definitions (References)

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

V

CM

V

LVDS

(v)

V

ID

Tr(20% - 80%)

Tf(20% - 80%)

Time

V

LVDSmax

V

LVDS min

V = V + |½V |

IDLVDSmax CM

V

LVDS

= VCM+/- | 1/2 VID|

V

LVDS min

= 0

www.ti.com

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Not to scale.

Refer to LVDS Interface section of the Recommended Operating Conditions.

Figure 6. LVDS Waveform Requirements

Refer to LVDS Interface section of the Recommended Operating Conditions.

Refer to Pin Configuration and Functions for list of LVDS pins.

Figure 7. LVDS Equivalent Input Circuit

13

Submit Documentation FeedbackCopyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

SCTRL_AN

SCTRL_AP

D_AN(15:0)

D_AP(15:0)

D_BN(15:0)

D_BP(15:0)

DCLK_BN

DCLK_BP

SCTRL_BN

SCTRL_BP

DCLK_AN

DCLK_AP

Tw

Tc

Tw

Th

Th

Ts

Ts

Tskew

Tw

Tc

Tw

Th

Th

Ts

Ts

0.0 * VCC

1.0 * VCC

t

f

t

r

1.0 * V

ID

0.0 * V

ID

V

CM

t

f

t

r

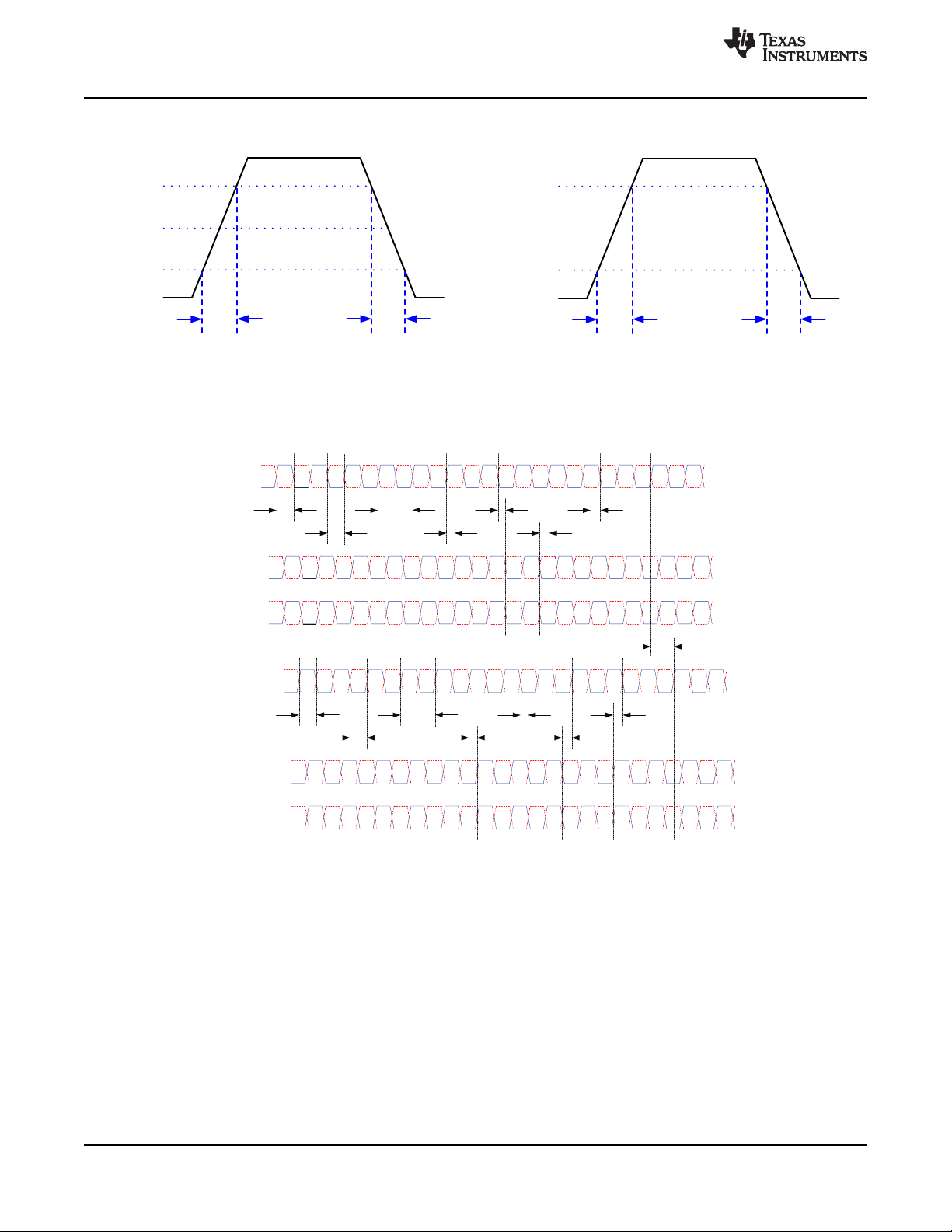

LVDS Interface SCP Interface

DLP5500

DLPS013G –APRIL 2010–REVISED JANUARY 2019

Not to scale.

Refer to the Timing Requirements.

Refer to Pin Configuration and Functions for list of LVDS pins and SCP pins.

www.ti.com

Figure 8. Rise Time and Fall Time

Figure 9. LVDS Timing Waveforms

14

Submit Documentation Feedback Copyright © 2010–2019, Texas Instruments Incorporated

Product Folder Links: DLP5500

Loading...

Loading...