TE Technology TCA User Manual

.

Thermoelectric Cooling Assembly (TCA)

Instruction Manual

Drawing 4921-1 Rev. D, 07 July 2010

TE

1590 Keane Drive Phone: (231) 929-3966

Traverse City, MI 49696 USA Fax: (231) 929-4163

http://www.tetech.com e-mail: cool@tetech.com

All Materials Copyright © 2007 - 2009 TE Technology, Inc.

TECHNOLOGY, INC

.

TE Technology, Inc. does not make any warranty, expressed or implied, that the

use or operation of the equipment will be functional or effective if the equipment

is not installed and used in accordance with this manual.

TE Technology, Inc. shall not be liable, and Purchaser shall defend, hold

harmless, and indemnify TE Technology, Inc. from and against, any losses,

costs, expenses (including reasonable attorneys’ fees), injuries, liabilities or

damages of any kind or nature whatsoever, arising out of or from the omission or

failure to use protective devices or comply with this manual. This provision is in

addition to any other indemnification provisions which are a part of the Purchase

Order or contract with Purchaser.

TE

http://www.tetech.com email: cool@tetech.com

TECHNOLOGY, INC

2/22

.

This Thermoelectric Cooling Assembly (TCA) Instruction Manual must

be read and followed carefully before installation and operation.

! Follow all recommendations and suggestions, heed all warnings contained in

this manual and use the product as intended. Failure to do so could result in

hazards and loss or damage to the TCA and/or secondary equipment.

! Only qualified technicians should install and configure the TCA.

! Use of the TCA is restricted to operators capable of understanding one of the

languages presented in this manual, as stated by agreement between TE

Technology, Inc. and the Purchaser.

! The TCA is intended to be operated in a light industrial environment only.

! Do not use in an explosive or potentially explosive environment.

! Do not use the TCA if damaged.

! Do not disassemble TCA. No user serviceable parts inside.

! Do not operate the TCA outside the specified operating temperature range.

Condensation could form on cooled sections of the TCA and on secondary

equipment. This condensate and any subsequent drainage onto other secondary

equipment could pose hazards and/or damage to the TCA and/or secondary

equipment. If such hazards are present, devices should be added to prevent or

remove the condensate such as dehumidifiers, dry gas purge systems,

desiccants, etcetera. Alternatively, cooled sections of the TCA and secondary

equipment should be restricted from being cooled below the dew-point

temperature.

Portions of the TCA could exceed 60 °C during normal operating

conditions resulting in a hazard. Use caution! Protect against contact with hot

surfaces.

TE

http://www.tetech.com email: cool@tetech.com

TECHNOLOGY, INC

3/22

.

! When using a temperature controller, improper configuration of the

temperature controller, improper installation of a temperature sensor, or the use

of an incorrect temperature sensor can result in hazards or damage to the TCA

or secondary equipment.

! Hazards, excessive hot or cold temperatures, and damage to the TCA or

secondary equipment can occur from fault conditions or human errors such as:

1. Incorrect wiring of the TCA.

2. Failure or misuse of the TCA.

3. Failure or misuse of the control device used with the TCA.

4. Reduction in the flow of cooling air or liquid.

Special Liquid Heat Exchanger Warnings:

If the TCA has one or more liquid heat exchangers, mount the TCA in a

position so that an unexpected liquid leak will be diverted away from electrical

circuitry and sensitive equipment into a containment area where damage to the

equipment and/or hazards will not result.

Do not allow the liquid in the liquid heat exchanger to freeze or overheat, whether

in operation or in storage. Before use, purge all air from the liquid heat

exchanger for proper operation and to prevent overheating.

! The liquid heat exchangers are designed for use with filtered, distilled water.

Other fluids may be acceptable for use if and only if TE Technology has provided

express written notice that they are compatible with the liquid exchanger. Do not

use fluids which have not been approved by TE Technology. Otherwise, damage

and/or hazards could result.

! Do not exceed the specified operating maximum liquid pressure as noted on

the TCA specification sheet or 205 kPa if it is not otherwise specified.

Additional Operation Warnings:

! Proper operation of the TCA is dependant on sufficient air flow through the

fans, heat sink fins, and/or the liquid heat exchanger if so equipped.

! Do not obstruct air flow or liquid flow to the TCA or use in areas where the

heat sink is not well ventilated. The fan and cooling fins should be kept clear of

dirt and dust. Clean by directing compressed air over the fins.

TE

http://www.tetech.com email: cool@tetech.com

TECHNOLOGY, INC

4/22

.

Do not operate the TCA if the heat-sink fan is not operational. This could

cause damage and create hazards from the heat sink being greater than 60 °C.

Do not operate the TCA if the heat-sink fan is operational but exhibits bearing

noise or is otherwise not operating as normally expected.

! Frost/ice should not be allowed to form on the heat sink, fan(s), or cold sink (if

so equipped) as this could obstruct air flow and decrease performance and/or

cause damage to the TCA and secondary equipment. If frost/ice contacts the

cold-sink or heat-sink fan, de-energize the TCA until the frost/ice has been

removed.

Do not operate TCA without finger guards. This could result in a hazard.

Portions of the TCA (the heat sink, for example) will become warmer

than the ambient temperature. They can become hotter than 60 °C even if

control temperatures of greater than 60 °C are not desired. The operating

temperature of the TCA depends on many factors: ambient temperature, input

power, and heat pumping. If the TCA is to be used in conditions where a portion

of the TCA could possibly exceed 60 °C (for example, if the TCA is operated in

ambient temperatures greater than 35 °C) test the surface temperatures of the

TCA under the worst-case operating conditions of maximum ambient

temperature, highest heat pumping, and maximum input power. If any portion of

the TCA exceeds 60 °C place adequate guards around the TCA to prevent

contact with hot surfaces.

See “Electrical Connections” section for proper connection from controller/power

supply.

Do not:

1. Install the TCA,

2. Attach anything to the TCA, or

3. Operate the TCA or attached equipment,

that would create a voltage potential of 50 V or more on the TCA.

Protective Devices:

TE

http://www.tetech.com email: cool@tetech.com

TECHNOLOGY, INC

5/22

.

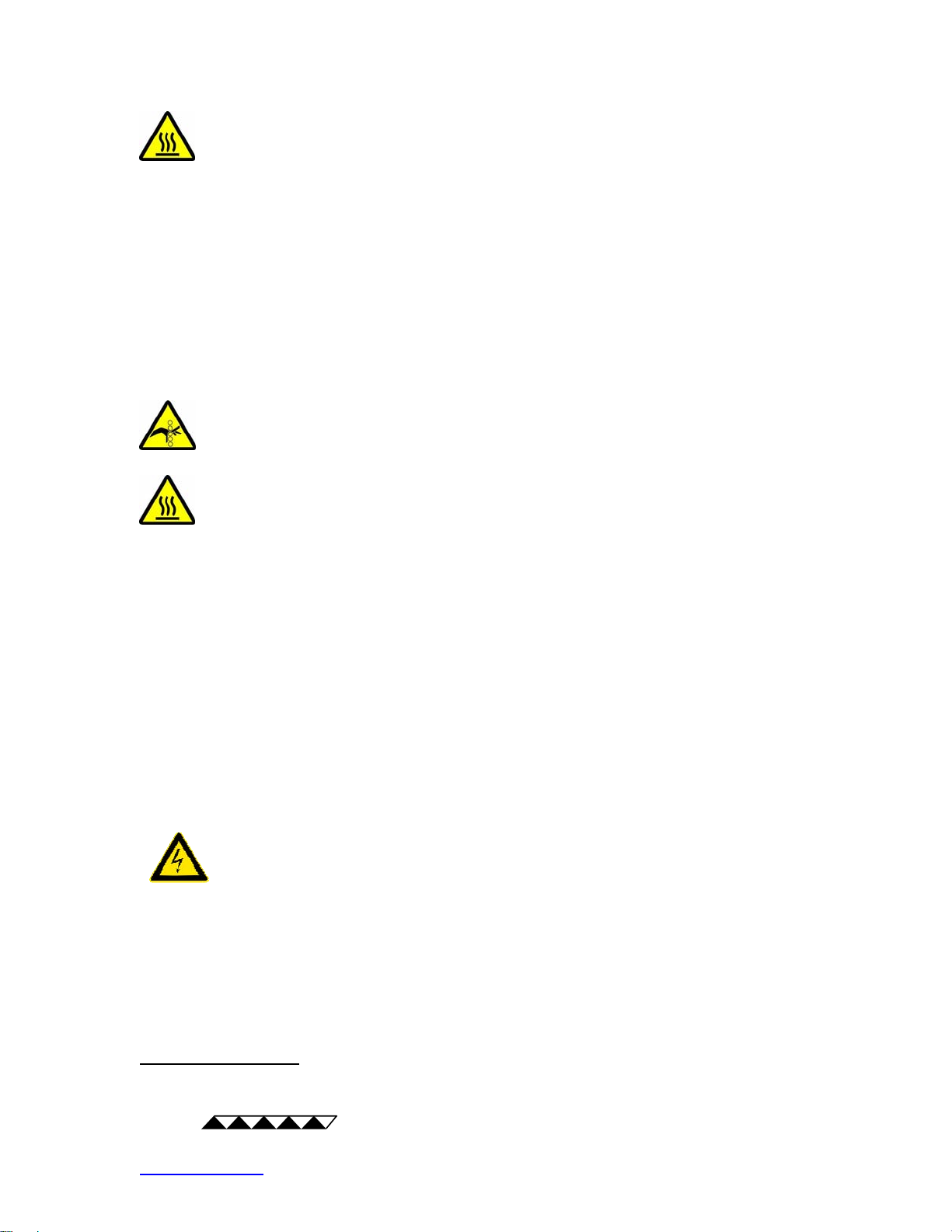

! Use protective devices to prevent hazardous conditions and/or damage to the

TCA and secondary equipment (refer to connection diagram). Protective devices

should be placed at all points on the TCA and secondary equipment where a

hazardous condition can be detected. NOTE: Unless noted in the product

specifications, protective devices are not included.

Protective devices should de-energize the TCA and, as necessary, related

secondary equipment. It is recommended that such devices require the user to

remove and correct the root cause of a fault before allowing the TCA and related

equipment to be re-energized.

! Protective devices must operate independently of the primary temperature

control circuitry.

! Some temperature controllers can detect under-temperature and over-

temperature conditions and can be configured to deenergize the TCA when such

a condition is detected. If a temperature controller is used to provide undertemperature and/or over-temperature detection, it is recommended to monitor the

heat sink and, as necessary, the cold side (cold sink, cold plate, liquid heat

exchanger) for under-temperature and over-temperature conditions. However,

hazards and/or risk of loss or damage to the TCA and/or secondary equipment

could still occur if the temperature controller and/or sensors were to malfunction.

Therefore, independent, redundant protective devices are recommended in

addition to the safeguards provided by the temperature controller. For the

purposes of this manual temperature controllers are not considered protective

devices.

! TE Technology, Inc. shall not be liable, and Purchaser shall defend, hold

harmless, and indemnify TE Technology, Inc. from and against, any losses,

costs, expenses (including reasonable attorneys’ fees), injuries, liabilities or

damages of any kind or nature whatsoever, arising out of or from the omission or

failure to use protective devices.

! Protective devices should include, but are not limited to:

• Fuses to prevent against electrical overloads,

• Over/under temperature thermostats to prevent against hazardous and/or

damaging temperatures,

• Liquid flow meters to prevent against damage due to loss of coolant flow

See “Protective Device Options” below for suggested options.

TE

http://www.tetech.com email: cool@tetech.com

TECHNOLOGY, INC

6/22

.

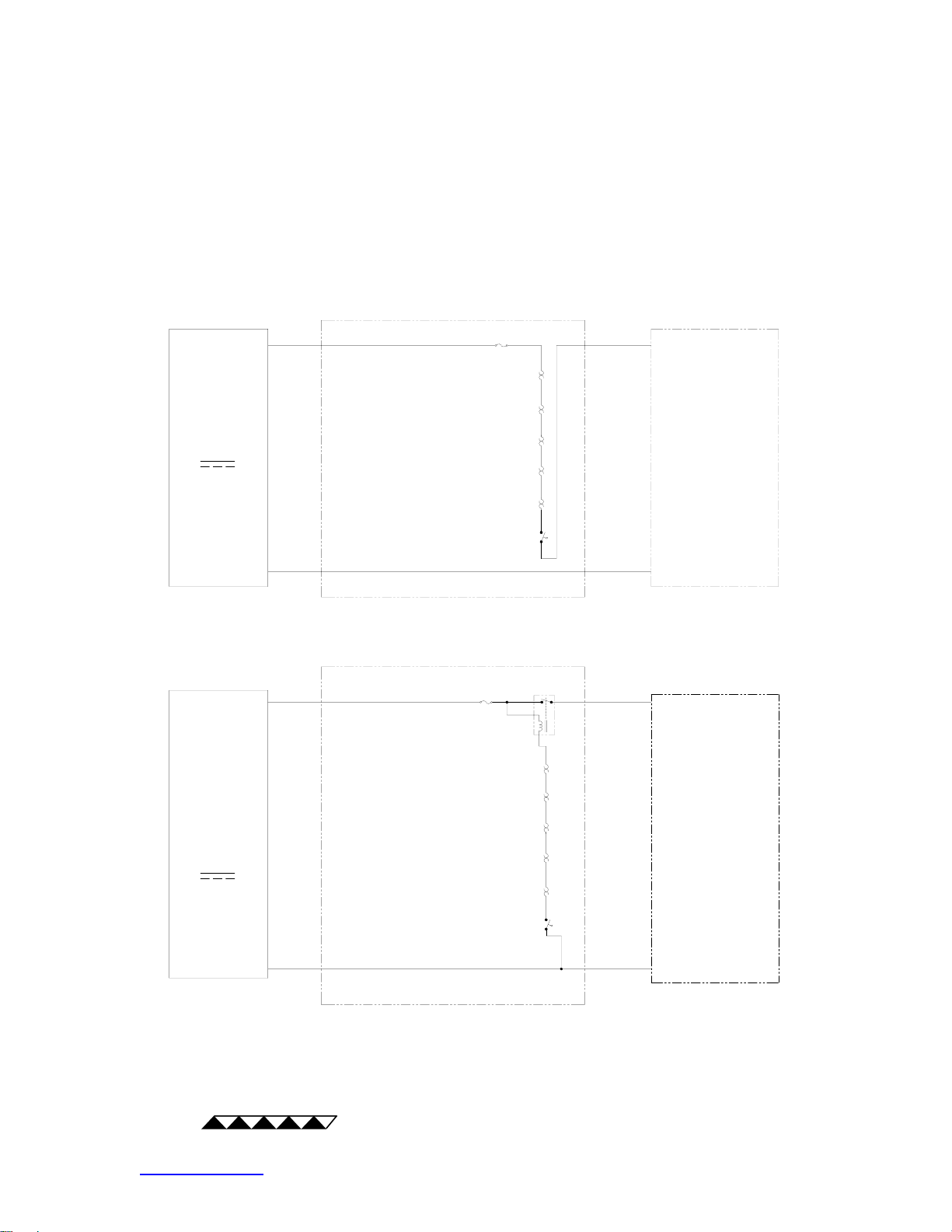

Protective Device Options

(+) (+)

HOT-SIDE, OVER-TEMPERATURE THERMOSTAT

FUSE

DC

POWER

SUPPLY

DC

POWER

SUPPLY

HOT-SIDE, UNDER-TEMPERATURE T HERMOSTAT

COLD-SIDE, OVER-TEMPERATURE THERMOSTAT

COLD-SIDE, UNDER-TEMPERATURE THERMOSTAT

OTHER PROTECTIVE DEVICE (AS REQUIRED)

LIQUID FLOW SENSOR (AS REQUIRED)

(-) (-)

or

FUSE

RELAY

HOT-SIDE, OVER-TEMPERATURE THERMOSTAT

HOT-SIDE, UNDER-TEMPERATURE THERMOSTAT

COLD-SIDE, OVER-TEMPERATURE THERMOSTAT

COLD-SIDE, UNDER-TEMPERATURE THERMOSTAT

OTHER PROTECTIVE DEVICE (AS REQUIRED)

(+)(+)

TCA

(AND OPTIONAL

TEMPERATURE

CONTROLLER)

TCA

(AND OPTIONAL

TEMPERATURE

CONTROLLER)

LIQUID FLOW SENSOR (AS REQUIRED)

TE

http://www.tetech.com email: cool@tetech.com

TECHNOLOGY, INC

7/22

(-)(-)

Loading...

Loading...