Page 1

OPERATING INSTRUCTIONS FOR

Model 3110

Portable Trace & Percent

Oxygen Analyzer

P/N M82155

12/05/11

DANGER

Toxic gases and or flammable liquids may be present in this monitoring system.

Personal protective equipment may be required when servicing this instrument.

Hazardous voltages exist on certain components internally which may persist

for a time even after the power is turned off and disconnected.

Only authorized personnel should conduct maintenance and/or servicing.

Before conducting any maintenance or servicing, consult with authorized

supervisor/manager.

Teledyne Analytical Instruments

Page 2

Model 3110

Copyright © 2011 Teledyne Instruments/ Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed,

stored in a retrieval system, or translated into any other language or computer language in

whole or in part, in any form or by any means, whether it be electronic, mechanical,

magnetic, optical, manual, or otherwise, without the prior written consent of Teledyne

Instruments/Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-

1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free from

defects of material and of construction, and that our liability shall be limited to replacing or

repairing at our factory (without charge, except for transportation), or at customer plant at

our option, any material or construction in which defects become apparent within one year

from the date of shipment, except in cases where quotations or acknowledgements provide

for a shorter period. Components manufactured by others bear the warranty of their

manufacturer. This warranty does not cover defects caused by wear, accident, misuse,

neglect or repairs other than those performed by TI/AI or an authorized service center. We

assume no liability for direct or indirect damages of any kind and the purchaser by the

acceptance of the equipment will assume all liability for any damage which may result from

its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our apparatus,

and to make any alterations in the dimensions, shape or weight of any parts, in so far as

such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its use r, an d serves as a tool b y whic h

valuable data can be gathered. The information provided by the instrument may assist the user

in eliminating potential hazards caused by his process; however, it is essential that all

personnel involved in the use of the instrument or its interface, with the process being

measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent

danger, it has no control over process conditions, and it can be misused. In particular, any

alarm or control systems installed must be tested and understood, both as to how they

operate and as to how they can be defeated. Any safeguards required such as locks, labels,

or redundancy, must be provided by the user or specifically requested of TI/AI at the time

the order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The purchaser

is responsible for the training of personnel, for providing hazard warning methods and

instrumentation per the appropriate standards, and for ensuring that hazard warning devices

and instrumentation are maintained and operated properly.

Teledyne Instruments/ Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control under

the user’s process conditions.

Teledyne Analytical Instruments ii

Page 3

Portable Trace Oxygen Analyzer

Safety Messages

Your safety and the safety of others is very important. We have

provided many important safety messages in this manual. Please read

these messages carefully.

A safety message alerts you to potential hazards that could hurt you

or others. Each safety message is associated with a safety alert symbol.

These symbols are found in the manual and inside the instrument. The

definition of these symbols is described below:

No

Symbol

GENERAL

WARNING/CAUTION: Refer to the instructions

for details on the specific danger. These cautions warn of

specific procedures which if not followed could cause bodily

Injury and/or damage the instrument.

CAUTION: HOT SURFACE WARNING: This warning is

specific to heated components within the instrument. Failure

to heed the warning could result in serious burns to skin and

underlying tissue.

WARNING: ELECTRICAL SHOCK HAZARD: Dangerous

voltages appear within this instrument. This warning is

specific to an electrical hazard existing at or nearby the

component or procedure under discussion. Failure to heed this

warning could result in injury and/or death from

electrocution.

Technician Symbol: All operations marked with this symbol

are to be performed by qualified maintenance personnel only.

NOTE: Additional information and comments regarding a

specific component or procedure are highlighted in the form

of a note.

CAUTION: THE ANALYZER SHOULD ONLY BE USED FOR THE

PURPOSE AND IN THE MANNER DESCRIBED IN

THIS MANUAL.

IF YOU USE THE ANALYZER IN A MANNER OTHER

THAN THAT FOR WHICH IT WAS INTENDED,

UNPREDICTABLE BEHAVIOR COULD RESULT

Teledyne Analytical Instruments iii

Page 4

Model 3110

POSSIBLY ACCOMPANIED WITH HAZARDOUS

CONSEQUENCES.

This manual provides information designed to guide you through

the installation, calibration operation and maintenance of your new

analyzer. Please read this manual and keep it available.

Occasionally, some instruments are customized for a particular

application or features and/or options added per customer requests.

Please check the front of this manual for any additional information in

the form of an Addendum which discusses specific information,

procedures, cautions and warnings that may be peculiar to your

instrument.

Manuals do get lost. Additional manuals can be obtained from TAI

at the address given in the Appendix. Some of our manuals are available

in electronic form via the internet. Please visit our website at:

www.teledyne-ai.com.

Teledyne Analytical Instruments iv

Page 5

Portable Trace Oxygen Analyzer

Table of Contents

List of Figures .............................................................................. vii

Introduction ................................................................................... 1

1.1 Introduction 1

1.2 Features 2

1.3 Method of Analysis 3

1.4 Micro-Fuel Cell 4

1.4.1 Cell Warranty 4

1.5 Accuracy and Response 5

1.6 Signal Output 5

1.7 Compact Packaging 5

Installation ..................................................................................... 7

2.1 Charging the Batteries 7

2.2 Gas Connections 8

2.3 Sensor Installation 10

2.3.1 Installing a Percent Sensor 10

2.3.2 Installing a Trace Sensor 10

2.4 Calibration 11

2.4.1 Calibration Using Air for Percent Analysis 11

2.4.2 Calibration Procedure for Trace Analysis 12

2.4.3 Bleeding the Regulator and Purging the Gas Line 12

2.5 Set the Sample Flowrate 13

2.6 External Signal 13

Operation ..................................................................................... 15

3.1 Front Panel Interface 15

3.1.1 ENTER Key 15

3.1.2 ESCAPE Key 16

3.1.3 UP/DOWN Keys 16

3.2 Operation and Setup Screens and Menus 16

3.2.1 POWER ON Screen 17

3.2.2 HOME Screen 18

Teledyne Analytical Instruments v

Page 6

Model 3110

3.2.3 DATE Screen 18

3.2.4 TIME Screen 19

3.2.5 AO Rng Screen 19

3.2.6 SPAN VALUE Screen 20

3.2.7 SPAN Screen 21

3.2.8 Filter Screen 22

3.2.9 LOG INTV Screen (Optional) 22

3.2.10 LOG RESET & START Screen (Optional) 23

3.2.11 LOG TRANSMIT Screen 24

3.2.12 POWER DOWN Screen 25

Maintenance & Troubleshooting ................................................ 27

4.1 Routine Maintenance 27

4.2 Opening the Instrument Case 27

4.3 Replacing the Battery 27

4.4 Battery Power Supply Service 28

4.5 Cell Replacement 29

4.6 Cell Warranty 30

4.7 Temperature Compensation 31

4.8 Leak Testing 31

Appendix ...................................................................................... 35

A.1 Specifications 35

A.2 Spare Parts List 36

Teledyne Analytical Instruments vi

Page 7

Portable Trace Oxygen Analyzer

List of Figures

Figure 1-1: Model 3110 Portable Trace Oxygen Analyzer ............... 2

Figure 2-1: Model 3110 Rear Panel ................................................ 8

Figure 3-1: Front Panel Keys ......................................................... 16

Figure 3-2: Available Menus and Their Sequence ......................... 17

Figure 4-1: Battery Charger Port on the Model 3110 ..................... 29

Figure 4-2: Effects of CO2 on B-2 Cell Life ................................... 33

Teledyne Analytical Instruments vii

Page 8

Model 3110

DANGER

COMBUSTIBLE GAS USAGE

This instrument is approved as an intrinsically safe gas

analyzer for use in a Division 1 Group A-D hazardous area.

Note that this approval does not apply to the non-conductive

LCD window and micro-fuel cell. Also, although the analyzer

is capable of being ranged up to 25% oxygen, the approval

does not apply to oxygen exposure above 20.9%. This

approval applies only to the equipment specified and

installed in accordance with the information contained within

this manual. It is the customer's responsibility to ensure

safety especially when combustible gases are being

analyzed since the potential of gas leaks always exist.

WARNING

The customer should ensure that the principles of operating

this equipment are well understood by the user. Misuse of

this product in any manner, tampering with its components,

or unauthorized substitution of any component may

adversely affect the safety of this instrument.

Since the use of this instrument is beyond the control of

Teledyne Analytical Instruments, referred as TAI, no

responsibility by TAI, its affiliates, and agents for damage or

injury from misuse or neglect of this equipment is implied or

assumed.

Teledyne Analytical Instruments viii

Page 9

Portable Trace Oxygen Analyzer Introduction

Introduction

1.1 Introduction

The Teledyne Analytical Instruments (TAI) Model 3110 Portable

Oxygen Analyzer is a portable, intrinsically safe oxygen analyzer

capable of analyzing oxygen levels from 0-10 parts per million (ppm)

oxygen to 25% oxygen (dependent on configuration). These units are

rated as intrinsically safe and may be used in a Class I, Div 1, Group AD hazardous environment. The instrument operates from internal

rechargeable batteries and is supplied with a universal AC charge

adapter. It features quick-disconnect fittings for sample connections and

a rugged, lightweight housing with handle. This versatile instrument can

be brought to the sample site and set up for analysis quickly and easily.

Because of the intrinsically safe design, the instrument can be employed

even in hazardous environments without compromise once calibrated.

The Model 3110 incorporates a large standard feature list designed for

versatile, accurate oxygen analysis for a wide range of applications.

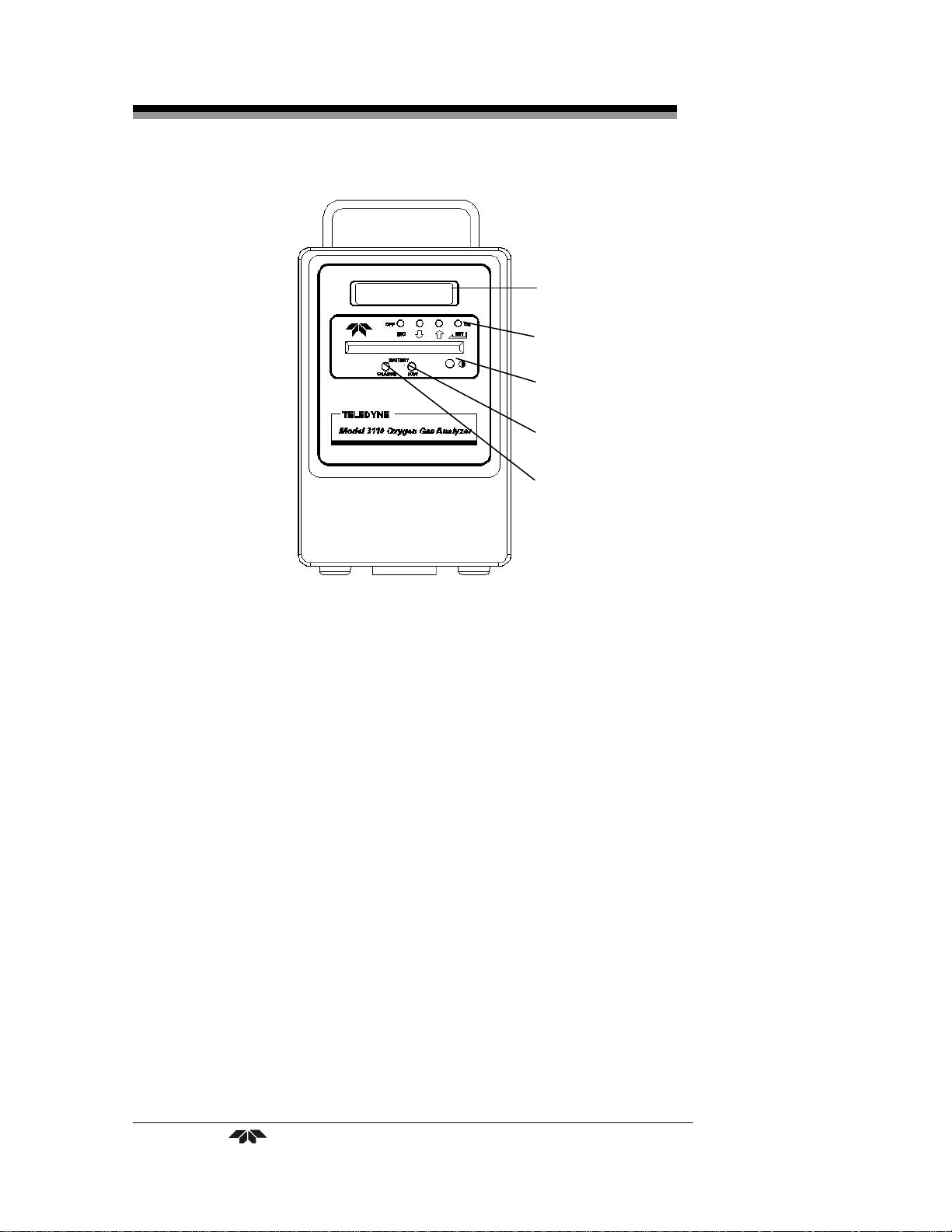

Figure 1-1 shows the standard Model 3110 Portable Trace Oxygen

Analyzer.

The microprocessor based Model 3110 instrument provides one

user settable analysis range in both trace and percent sensitivities. The

range can be set from 0-10 ppm to 25% oxygen with lower ranges or

percent sensitivity models available.

Sample oxygen is displayed on a 2-line 20 character alphanumeric

LCD display mounted on the front panel. Four buttons are used to

interface with the instrument and access all of the analyzer features.

Sample gas is introduced and vented via a pair of quick-disconnect

fittings that feature integral shutoff valves which automatically close

when the mating male fitting is withdrawn. The fittings are an integral

part of the measuring cell manifold so that internal sample passage

volume is at an absolute minimum.

Teledyne Analytical Instruments 1

Page 10

Introduction Model 3110

j

r

Alphanumeric

LCD

User Interface

Buttons

Contrast

ustment

Ad

Low Battery

Indicato

Battery

Charging

Indicator

Figure 1-1: Model 3110 Portable Trace Oxygen Analyzer

1.2 Features

This instrument is designed to be versatile analytical instrument

and to perform reliably and accurately in analyzing oxygen

concentrations in gas mixtures from ppm levels through 25% oxygen.

The following features are standard on the Model 3110:

Display: A 2-line 20 character alphanumeric LCD

on the front panel displays data and

operational information through various

screens. The contrast is adjustable for

various lighting conditions.

Four-Button User Interface: Operation is performed using the

four front panel mounted buttons. These

buttons are used to enter data, select items

and move through operational screens that

appear on the display.

Universal AC Charge Adapter: The batteries can be recharged

without removing them from the

instrument. The charger operates over the

range of 100-240 VAC.

Teledyne Analytical Instruments 2

Page 11

Portable Trace Oxygen Analyzer Introduction

LEDs: Two front panel-mounted LEDs are used

to indicate low battery condition and when

the battery is recharging.

Contrast Control: This feature allows the user to easily

adjust the contrast of the display for

optimum viewing under different lighting

conditions. The adjustment is made using

a front panel control dial.

Percent of Range Voltage Output: A 0-1 VDC output is

available that represents the percentage of

the current analysis range.

Data Logger: The optional built-in data logging feature

allows the user to specify the time interval

between data recording sets. The date,

time, and oxygen concentration readings

are stored in internal RAM at the user

specified interval. The data set can be

downloaded using the instrument’s 9-pin

serial interface.

Real-time Clock: This feature allows the Model 3110 to date

and time stamp the data set recorded on

the data logger. It uses a 24 hour clock.

Quick Disconnect Fittings: Dual self-sealing quick disconnect

fittings are installed for easy sample

connections.

1.3 Method of Analysis

The sample oxygen is measured by a unique electrochemical

transducer which functions as a fuel cell; in this instance, the fuel is

oxygen. Oxygen diffusing into the cell reacts chemically to produce an

electrical current that is proportional to the oxygen concentration in the

gas phase immediately adjacent to the transducer’s sensing surface. The

linear, but minute signal produced by the transducer from trace oxygen

is amplified by a two-stage amplifier. Sensor output signal is digitized

and fed to the microprocessor. Additional signal conditioning and

temperature compensation are handled electronically and appropriate

signals are directed to the display and output ports.

Teledyne Analytical Instruments 3

Page 12

Introduction Model 3110

1.4 Micro-Fuel Cell

The micro-fuel cell (U.S. Pat. Nos. 3,767,552 and 3,668,101) is a

sealed electrochemical transducer with no electrolyte to change or

electrodes to clean. When the cell reaches the end of its useful life, it is

thrown away and replaced. The life of the cell is warranted by TAI (see

below).

The cell is specific for oxygen and is not sensitive to flowrate or

reducing agents such as hydrocarbons, carbon monoxide, sulfur dioxide,

etc. In the absence of oxygen, no current is produced; thus, no zeroing is

required.

1.4.1 Cell Warranty

The Class B1, B2-C, A2C, B2C-XL, Insta-trace and NG series

micro-fuel cells used in the Model 3110 carry a six (6) month warranty.

With regard to spare cells, service time starts when the cell is

removed from its shipping package. You should stock only one spare

cell per instrument at a time.

If a cell was working satisfactorily but ceases to function before the

warranty period expires, you will receive credit on a pro-rated basis

toward the purchase of a new cell.

If you have a warranty claim, return the cell in question to the

factory for evaluation. If it is determined that failure is due to faulty

workmanship or material, the cell will be replaced at no cost to you.

WARNING: EVIDENCE OF DAMAGE DUE TO TAMPERING OR

MISHANDLING WILL RENDER THE CELL

WARRANTY NULL AND VOID.

The Model 3110 is rated as intrinsically safe and may be used in a

Class I, Div 1, Group A-D hazardous environments.

This safety feature does not apply when the instrument is being

charged with the 100- 240 VAC external charge adapter. The instrument

should be removed from hazardous areas when the batteries are being

charged.

Note: Do not use the analyzer when the battery level is low.

Teledyne Analytical Instruments 4

Page 13

Portable Trace Oxygen Analyzer Introduction

1.5 Accuracy and Response

The Model 3110 provides monitoring accuracies of ±2% of full

scale or ±1 ppm, whichever is greater, at constant temperature.

With a sample flowrate of 1 SCFH, a 90% response can be

achieved in 10 seconds when analyzing in the percent range. At the trace

levels (ppm analysis), a 90% response can be realized in 60 seconds or

less. The response time on the 3110 is limited by the filter setting.

1.6 Signal Output

This analyzer includes a 0-1 VDC output as standard. This signal is

suitable for driving external devices that have an input impedance of

10,000 or more. The signal output is available from a port on the rear

panel.

1.7 Compact Packaging

The instrument is housed in 6 1/8" × 9 1/2" × 5 5/8" (156 × 241 ×

143mm) aluminum case that is equipped with a carrying handle and foot

pads.

Teledyne Analytical Instruments 5

Page 14

Introduction Model 3110

BLANK PAGE

Teledyne Analytical Instruments 6

Page 15

Portable Oxygen Analyzer Installation

Installation

The Model 3110 Trace/Percent Oxygen Analyzer is designed to be

portable and easy to setup and configure. To setup the analyzer:

Read the manual

Charge the batteries

Install the sample and vent gas lines

Install the trace sensor and purge the analyzer

Install the percent sensor (no purging required)

Set the sample gas flowrate

Calibrate the analyzer

2.1 Charging the Batteries

The unit is powered by two intrinsically safe rated sub-C Ni-Cd

batteries and is shipped with batteries fully charged. The batteries,

however, will require periodic recharging. For recharging, access to an

AC power source of 100 to 240 volt, 50/60 Hz will be required. The

instrument should not be recharged in a hazardous area. Connect the

universal AC charger adapter supplied with the instrument to the AC

power outlet. Plug the other end of the charger into the port on the rear

panel as shown in Figure 2-1. The green charge indicator LED should be

illuminated to indicate that the unit is charging.

To fully recharge a set of batteries will take approxim ately 16

hours. The instrument should not be left on the charger for longer than

20 hours nor should the charger be left attached to the instrument when

the unit is not charging. The Model 3110 cannot be operated while the

battery charger is attached.

CAUTION: DO NOT CHARGE THE BATTERY IN A HAZARDOUS

AREA. THE INTRINSICALLY SAFE CLASSIFICATION

OF THIS INSTRUMENT DOES NOT APPLY WHEN

THE CHARGER IS ATTACHED TO THE

INSTRUMENT. REMOVE THE INSTRUMENT TO A

NON-HAZARDOUS AREA BEFORE CONNECTING

THE BATTERY CHARGER TO THE INSTRUMENT.

Teledyne Analytical Instruments 7

Page 16

Installation Model 3110

The unit can operate continuously for approximately 4 days on a set

of fully charged batteries. If more frequent charging is required, the

batteries are approaching the end of their useful life and should be

replaced. See Battery Replacement in Section 4.3 of this manual.

A low battery condition is indicated by a blinking red Low Battery

LED on the front panel. This will also cause the display to flicker along

with the blinking LED due to the power drain and low battery condition.

At this point the unit should be removed from service and the batteries

recharged.

Data-logger

Port (optional)

Battery

Charger

0-1 VDC

Signal Output

Sample In

and Vent

Connections

Figure 2-1: Model 3110 Rear Panel

2.2 Gas Connections

The customer must provide a means of controlling the pressure and

flowrate of the applied gas. For positive pressure applications, TAI

suggests a simple throttle valve installed in the sample line between the

sample point and the analyzer. The flowrate should be limited to

between 0.2 and 2.5 SCFH. The Sample In port is used for both sample

and calibration gas. For sampling at atmospheric pressure, connect a

pump and flow control valve downstream of the analyzer and draw

(rather than push) the sample through the instrument.

Teledyne Analytical Instruments 8

Page 17

Portable Oxygen Analyzer Installation

IMPORTANT: IF A PRESSURE REGULATOR IS USED, IT MUST

HAVE A METALLIC DIAPHRAGM. REGULATORS

WITH ORGANIC OR PLASTIC DIAPHRAGMS ARE

PERMEABLE TO OXYGEN AND, IF USED IN THE

SAMPLING SYSTEM, WILL LEAD TO HIGH OXYGEN

READINGS.

The instrument is shipped with a gas sampling and calibration kit.

This includes a 12” piece of clear tubing with a quick disconnect line for

use as a sample return or vent line plus two quick disconnect fittings to

be installed on the sample and calibration lines. These fittings employ

1/4” tube fittings which can be removed to reveal a 1/8” NPT internal

thread.

It is important in trace analysis applications to use metal for all

wetted components of the sample system. This includes gas lines, filters,

pump housing, diaphragms and any components in contact with the

sample gas. Plastic tubing and parts can be used for percent analysis but

will result in slow and inaccurate measurements at the ppm level.

There are two quick disconnect fittings installed on the rear panel

for mating the instrument with the sample or calibration gas and the vent

line. As shown in Figure 2-1, each fitting has a button which when

depressed allows the rapid detachment of the gas line from the

instrument. It is not necessary to press the button when inserting the

line, just push the male fitting into the mating connector. When a line is

removed, an internal seal prevents gas escape from the female sections

of the fitting.

Note: To avoid pressurizing the sensor, the vent line should be

installed first and removed last.

In setting up the sample lines, any valves used to set the sample

flow or filters must be located on the Sample In line. Do not place any

valves or restrictions on the vent line except as noted above for

atmospheric pressure sampling when using a downstream pump. Doing

so would increase the sensor operating pressure and result in inaccurate

analysis.

For trace analysis applications, a flowmeter should be installed in

the vent line but should not incorporate any control valves or restrictive

devices. For percent measurement applications, flowmeters or

rotameters (with or without control) valves can be placed upstream of

the analyzer, i.e. on the Sample In line.

Teledyne Analytical Instruments 9

Page 18

Installation Model 3110

2.3 Sensor Installation

The Model 3110 can accept either a percent or trace analysis

sensor. The procedure is similar for either sensor; however, a trace

sensor requires that the instrument lines be immediately purged with

zero gas after installing the cell.

2.3.1 Installing a Percent Sensor

To install a percent sensor:

1. Remove the cell holder cap from the bottom of the

instrument.

2. Remove the sensor from its packaging.

3. Remove the shorting plug at the top of the sensor.

4. Place the sensor on the top of the cell holder cap with the

concentric gold rings facing up.

5. Screw the cell holder cap and sensor into the bottom of the

analyzer.

2.3.2 Installing a Trace Sensor

Prior to installing the trace sensor, make sure the analyzer is ready

to purge with zero gas. Connect the vent line to the analyzer then

connect the zero gas line to the sample in port. Set the zero gas flow rate

to between 0.2 and 2.5 SCFH.

Prior to using any bottled gas for calibration or purge, it is good

practice to bleed the regulator and sample line to remove any traces of

trapped air. See Section 2.4.3 Bleeding the Regulator and Purging the

Gas Line.

Once the vent and zero gas lines are attached and the lines are

properly purged, proceed to install the trace sensor as follows:

1. Remove the cell holder cap from the bottom of the

instrument.

2. Remove the outer packaging from the sensor.

3. While the sensor is still in its packaging, grip the shorting

plug through the bag and remove it from the sensor.

4. Remove the packaging and rapidly place the sensor on the

top of the cell holder cap with the concentric gold rings

facing up.

Teledyne Analytical Instruments 10

Page 19

Portable Oxygen Analyzer Installation

5. Screw the cell holder cap and sensor into the bottom of the

analyzer.

Note: Minimize the time the sensor is exposed to air.

6. Start the purge flow through the analyzer and purge

overnight before calibrating the unit.

2.4 Calibration

Calibration involves using a span gas to calibrate the instrument.

The proper span gas oxygen concentration depends on the range that the

instrument will be used. The correct concentration should be 80-90% of

the range used. For instance, if the analyzer is to be used on a range of 0100 ppm oxygen, then a span gas should be prepared with 80-90 ppm

oxygen in nitrogen. If the analyzer is going to be used on a percent

range, acceptable accuracy may be obtained using air as a span gas.

2.4.1 Calibration Using Air for Percent Analysis

Note: Calibration requires a familiarity with the operational

screens and general operation of the instrument. Read

Chapter 3 to understand how to operate the instrument

before proceeding with the calibration step.

To calibrate the instrument using ambient air as a span gas:

1. If not already powered up, press the ENTER key to turn the

instrument on.

2. Set the filter to 1 or 2 on the filter screen.

3. Navigate to the SPAN VALUE screen and set the span to

20.9%. See Section 3.2.6.

4. Select the SPAN screen.

5. Install the vent and sample in lines in that order.

6. Remove the cell holder cap on the bottom of the instrument.

This exposes the cell to air for calibration.

7. Replace the cell holder cap after a few seconds and observe

the oxygen reading on the SPAN screen.

8. When the reading appears stable, select SPAN: START.

9. When the screen changes to SPAN: FINISH, select SPAN:

FINISH.

Teledyne Analytical Instruments 11

Page 20

Installation Model 3110

10. Expose the cell holder to air again by removing the cell

holder cap for a few seconds. Verify that the oxygen reading

is 20.9%.

Once the cell holder cap is sealed, the sensor will slowly consume

the trapped oxygen. You should notice that the on-screen oxygen

reading should slowly decrease as the oxygen is consumed.

The instrument is now calibrated and you can remove the sample-in

line and the vent line in that order.

2.4.2 Calibration Procedure for Trace Analysis

To calibrate the Model 3110 for trace oxygen measurements, the

instrument must be fitted with a trace sensor. The instrument must also

be purged overnight using a zero gas (a pure gas with no oxygen,

typically O2 free N2) before calibrating.

To calibrate the analyzer for trace analysis:

1. Purge the analyzer overnight.

2. Purge the calibration gas sample line, regulator, and control

valve. See Section 2.4.3.

3. Set the calibration gas flowrate to 1 SCFH.

4. Attach the vent line followed by the span gas line using the

quick disconnect fittings.

5. Navigate to the SPAN VALUE screen (see Section 3.2.6)

and set the span value to the known oxygen concentration in

ppm of the span gas.

6. Observe the oxygen reading on the screen to determine when

the reading has stabilized.

7. Navigate to the SPAN screen and select SPAN: START.

8. When the screen changes and displays SPAN: FINISH, select

SPAN: FINISH to set the span.

9. Allow the span gas to flow for several minutes to verify the

proper span setting.

10. Calibration is complete. Remove the span gas line first

followed by the vent line.

2.4.3 Bleeding the Regulator and Purging the Gas Line

When using bottled gas (gas cylinder) as a calibration gas for trace

analysis applications, the regulator and sample lines should be purged to

Teledyne Analytical Instruments 12

Page 21

Portable Oxygen Analyzer Installation

remove traces of trapped air. Otherwise, trapped air in the lines

(especially between the regulator and cylinder) will cause the analyzer

reading to slowly change over a period of hours.

To bleed the regulator and sample line:

1. Attach the regulator to the gas cylinder. Then attach a sample

line with a flow control/shut off valve preferably at the far

end of the sample line.

2. Open the shut off valve slightly, and then open the valve on

the gas cylinder.

3. Adjust the regulator to the desired pressure (usually 5 psi)

then close the cylinder valve.

4. Open the cylinder valve to pressurize the regulator fully then

close the cylinder valve again.

5. Open the sample flow control valve and allow the gas to

bleed down and vent to a safe area. Observe the secondary

gauge (low pressure side) on the regulator. As the low

pressure gauge starts to fall, close the sample flow control

valve.

6. Repeat steps 4 and 5 seven (7) times.

The sample delivery system is now purged and ready for calibration

or analysis. Keep the cylinder valve open to maintain system

pressurization.

Note: Make sure there are no leaks in the sample line and

regulator connections. Check also the cylinder connection

for leaks.

2.5 Set the Sample Flowrate

Once the system has been calibrated, the instrument can be brought

to the analysis site and the sample gas line can be connected to the unit.

Using the quick disconnect fittings supplied, connect the vent line

followed by the sample line to the rear panel. See Figure 2-1.

Once the sample gas is flowing, set the flow rate to 0.2-2.5 SCFH.

2.6 External Signal

A 0-1 VDC output signal is included with the Model 3110. When

installed, the output signal represents the percentage of oxygen in the

current range. For instance, if the range was set for 0 to 10 ppm, then 0.1

Teledyne Analytical Instruments 13

Page 22

Installation Model 3110

V would represent 1 ppm, 0.2V would be 2 ppm; 0.3V would be 3 ppm

etc.

This output signal, when installed, is accessible from the rear panel.

Teledyne Analytical Instruments 14

Page 23

Portable Trace Oxygen Analyzer Operation

Operation

The Model 3110 is supplied completely assembled and ready for

use. The micro-fuel cell is supplied in a separate sealed bag, and in the

case of trace sensors, was purged with an inert gas.

Turning the instrument on by pressing the ENTER key will power

the display and show the power on screen briefly (if the display shows

nothing or is very dark, adjust the contrast). The display will then

change to indicate the oxygen concentration within the internal sample

passageways if no sample line is attached.

Note: To extend cell life and minimize the time required to make

the next analysis, the instrument should always be purged

with an oxygen free inert gas prior to being taken out of

service for standby or storage.

3.1 Front Panel Interface

The Model 3110 is controlled from the keys on the front panel and

is shown in Figure 3-1. These keys are also used to setup the instrument

for your application. The keys are:

ENTER/ON

ESC/OFF

UP

DOWN

3.1.1 ENTER Key

The ENTER key is context sensitive. It is used as follows:

Powering ON or OFF—Pressing the ENTER key turns the

power ON. The ENTER key is also used the power OFF

from within the POWER OFF screen.

Enter SETUP—In certain menus, pressing the ENTER key

selects a setup screen for that particular function. Navigation

arrows on the left and right of the bottom line identify these

screens as setup screens by changing from UP/DOWN to

LEFT/RIGHT. The setup screens also blink.

Teledyne Analytical Instruments 15

Page 24

Operation Model 3110

Select a value—When multiple options or values exist for a

function, pressing ENTER selects the currently displayed

option.

Save changes—If a value or option has been modified,

pressing ENTER saves the change and brings you back to the

previous screen.

ESC/OFF

Down

Up

Enter/ON

Figure 3-1: Front Panel Keys

3.1.2 ESCAPE Key

The Escape (ESC) key is used to exit a setup menu without saving

any changes made to that screen. The values will revert to the last value

saved for that entry.

3.1.3 UP/DOWN Keys

The UP/DOWN keys are used to:

Navigate from one screen to another

Toggle between multiple options within a menu

Increment or decrement a value

3.2 Operation and Setup Screens and Menus

The Model 3110 operation and setup functions are arranged in a set

of 15 menus. All but the POWER ON screen are accessible via the

Teledyne Analytical Instruments 16

Page 25

Portable Trace Oxygen Analyzer Operation

UP/DOWN keys. Figure 3-2 shows the available menus and the

sequence of screens when scrolling.

Figure 3-2: Available Menus and Their Sequence

3.2.1 POWER ON Screen

The POWER ON screen automatically appears on the display when

the unit is first powered up. The display appears briefly and shows the

model number and software version. After a few seconds the display

reverts to the HOME screen.

Teledyne Analytical Instruments 17

Page 26

Operation Model 3110

3.2.2 HOME Screen

The HOME screen displays the oxygen concentration at the level of

the current range (ppm or %). The concentration is shown in the upper

line the current range is indicated on the second line.

Note: In almost all available screens, the first line displays the

oxygen concentration.

3.2.3 DATE Screen

Use the UP/DOWN keys to navigate to the DATE screen. The

second line of the DATE screen displays the current date and is used by

the data logger for date stamping data records. The currently set date is

displayed on the second line of the display.

To change the currently set date:

1. Press ENTER to enter the date setup function. Note the

navigation arrows that appear on the left and right sides of

the display change from UP/DOWN to pointing

LEFT/RIGHT.

2. Use the UP/DOWN keys to alter the month. Then press

ENTER. The cursor will move over to the next editable field.

3. Use the UP/DOWN keys to alter the day. Then press

ENTER. The cursor will move over to the next editable field.

4. Use the UP/DOWN keys to alter the year. Then press

ENTER.

Teledyne Analytical Instruments 18

Page 27

Portable Trace Oxygen Analyzer Operation

5. Press ENTER again to save the current date and

automatically return to the DATE screen.

At any time you can press the ESC key to abort the entry and return

to the DATE screen.

3.2.4 TIME Screen

Use the UP/DOWN keys to navigate to the TIME screen. The

second line of the this screen displays the current time in 24 hour

military format. This information is used by the data logger for time

stamping data records. The currently set time is displayed on the second

line of the display.

To change the currently set time:

1. Press ENTER to enter the time setup function. Note the

navigation arrows that appear on the left and right sides of

the display change from UP/DOWN to pointing

LEFT/RIGHT.

2. Use the UP/DOWN keys to alter the hour field. Then press

ENTER. The cursor will move over to the next editable field.

3. Use the UP/DOWN keys to alter the minute field. Then press

ENTER. The cursor will move over to the next editable field.

4. Use the UP/DOWN keys to alter the seconds field. Then

press ENTER.

5. Press ENTER again to save the current time and

automatically return to the TIME screen.

At any time you can press the ESC key to abort the entry and return

to the DATE screen.

3.2.5 AO Rng Screen

In this screen, the user defines the analysis range which sets the

scaling of the analog output to correspond to the range setting. For

instance, if the range is set to 100 ppm then the 0-1 VDC output would

track the concentration as follows:

Teledyne Analytical Instruments 19

Page 28

Operation Model 3110

Concentration

(ppm)

0 0 60 0.6

10 0.1 70 0.7

20 0.2 80 0.8

30 0.3 90 0.9

40 0.4 100 1.0

50 0.5

Output

(V)

Concentration

(ppm)

Use the UP/DOWN keys to navigate to the AO RNG screen and

then press ENTER. The following screen appears:

Output

(V)

To define or change the range setting:

1. Use the UP /DOWN keys to change the range value. Press

ENTER when the desired value is shown. The value will be

accepted and the cursor will move to the next editable field

(units).

2. Use the UP/DOWN keys to cycle between ppm and percent

for units. Press ENTER to accept the displayed unit. The

display will then return to the HOME screen.

Note: The range setting resolution is 0.1 PPM for trace analysis

and 0.01% for percent analysis.

3.2.6 SPAN VALUE Screen

The SPAN VALUE screen displays the oxygen concentration of the

span gas used for calibration. This is not a measured value; it is the

known span gas concentration that is input to the analyzer by the

operator.

Teledyne Analytical Instruments 20

Page 29

Portable Trace Oxygen Analyzer Operation

To change the span gas concentration:

1. Use the UP/DOWN keys to navigate to the SPAN VALUE

screen. Then press ENTER to enter the setup screen.

2. Use the UP /DOWN keys to change the span value. Press

ENTER to accept the displayed value and to return to the

SPAN VALUE screen.

3.2.7 SPAN Screen

This screen is used to perform a span calibration on the Model

3110. The appropriate span value must have already been input to the

instrument. See Section 3.2.6 for entering a span value into the analyzer.

CAUTION: THE CORR ECT SPAN VALUE MUST BE ENTERED

INTO THE INSTRUMENT THAT CORRESPONDS TO

THE ACTUAL SPAN GAS USED. FAILURE TO ENTER

THE PROPER VALUE WILL RESULT IN ERRONEOUS

READINGS.

Note: The filter should be set to a low value to avoid errors

during span setting. Allow the oxygen reading to become stable

prior to setting the span.

To perform a span calibration:

1. Use the UP/DOWN keys to navigate to the SPAN screen.

Then press ENTER to start the span calibration.

Once the span calibration has begun, the screen changes to reveal a

span finish selection.

Teledyne Analytical Instruments 21

Page 30

Operation Model 3110

2. When the FINISH selection appears, press ENTER once the

analyzer is providing a stable oxygen concentration on the

span gas. This will end the span calibration. The analyzer

will accept the calibration and return to the HOME screen.

Note: After successfully performing a span calibration, you are

returned directly to the HOME screen rather than back to

the previous menu.

3.2.8 Filter Screen

The 3110 includes user adjustable digital filter. The filter has

settings 1-10. Setting 1 is the least amount of filtering and 10 is the

highest level of damping. The filter is used to reduce the noise level of

the O2 readings. More filtering is required for lower trace ranges such as

10 ppm. Adding filtering will slow down analyzers response to changing

O2 levels. The lowest effective level of filtering should always be

selected. The filter level should be lowered to 1 or 2 when setting the

span to avoid delays. For a 0-10PPM range a filler setting or 6 or 7

should typically provide good results.

To use this feature:

1. Use the UP/DOWN keys to navigate to the FILTER screen.

Then press ENTER to enter the setup screen.

2. Use the ENT/ON key to change the filter to the active mode.

The arrows will point left and right and the filter setting will

blink.

3. Use the UP/DOWN keys to select the desired setting.

4. Select the ENT/ON key to save the setting and to return to

the non-active mode on the filter screen.

3.2.9 LOG INTV Screen (Optional)

This screen is for use with the data logger option only. It indicates the

time interval between data samples taken by the data-logger. The interval

Teledyne Analytical Instruments 22

Page 31

Portable Trace Oxygen Analyzer Operation

can be set between 1 second (00m 01sec) to 60 minutes (60m 00sec) in

increments of 1 second.

To change the interval between data samples:

1. Use the UP/DOWN keys to navigate to the LOG INTV

screen. Then press ENTER to enter the setup screen.

2. Use the UP /DOWN keys to change the interval value. The

value of the seconds will increase or decrease followed by

the minutes. Press ENTER to accept the displayed value and

return to the LOG INTV screen.

3.2.10 LOG RESET & START Screen (Optional)

Once a log interval has been input, the LOG RESET & START

screen is used to start the data-logger.

The data logger has a 3200 record capacity and each record uses 10

bits of data. The data set is retained until it is reset by using the START

RESET menu again. The data set can be downloaded using the LOG

TRANSMIT screen (see Section 3.2.11).

To start the data logger:

1. Use the UP/DOWN keys to navigate to the LOG RESET &

START screen and press ENTER.

2. When the screen begins to blink press ENTER again to start

the data logger. Once the data logger has started, the screen

changes RESET&START to STOP. During logging a

blinking “L” appears in the upper left corner of the screen.

To stop the data logger:

Teledyne Analytical Instruments 23

Page 32

Operation Model 3110

1. Press ENTER to stop the data logger and return to the LOG

RESET & START screen.

3.2.11 LOG TRANSMIT Screen

Data can be downloaded to a computer using the 9-pin Dsubminiature port and cable attached to a PC. The D-sub port accepts a

standard data cable with a DB-9 connector. The computer must be able

to accept data from a source with the following characteristics:

9600 baud

8 bit data

no parity

1 stop bit

no flow control

Refer to your computer manual for details on how to setup the RS232 communications port on your computer.

To download a data log:

1. Use the UP/DOWN keys to navigate to the LOG TRANSMIT

screen. Then press ENTER to enter the setup screen.

2. Press ENTER again to transmit the current data log.

Note: The data set will be transmitted each time you press the

ENTER key. Use the ESC key to exit the LOG TRANSMIT

Teledyne Analytical Instruments 24

Page 33

Portable Trace Oxygen Analyzer Operation

menu.

3. Press ESC to exit out of the LOG TRANSMIT screen and go

to the home screen.

Note: The Date Log does not need to be stopped in order to

transmit the date.

3.2.12 POWER DOWN Screen

This screen is used to power off the instrument. This can also be

achieved by holding the ESC button for a few seconds.

To turn the analyzer off:

1. Use the UP/DOWN keys to navigate to the POWER DOWN

screen. Then press ENTER.

2. Press ENTER again to turn the instrument OFF.

In a few seconds the analyzer will turn off.

Teledyne Analytical Instruments 25

Page 34

Operation Model 3110

Teledyne Analytical Instruments 26

Page 35

Portable Trace Oxygen Analyzer Maintenance

Maintenance & Troubleshooting

4.1 Routine Maintenance

Other than replacing the sensor, there are no user-serviceable

components within the instrument housing other than the cell holder Oring. Routine maintenance consists of wiping down the instrument case,

cleaning the screen and checking for leaks.

CAUTION: USING ABRASIVE CLEANSERS OR SOLVENTS WILL

DAMAGE THE SCREEN. USE ONLY A MILD

DETERGENT AND SOFT CLOTH WHEN REMOVING

DIRT OR GREASE MARKS FROM THE SCREEN.

When cleaning the instrument case, do not flood with water or use

harsh, abrasive or solvent cleansers. These cleansers will attack the LCD

lens material as well as eventually wear off the silk-screened legends.

4.2 Opening the Instrument Case

CAUTION: DEPENDING ON THE APPLICATION, IT MAY BE

NECESSARY TO PURGE THE INSTRUMENT THEN

REMOVE THE INSTRUMENT TO A NONHAZARDOUS AREA BEFORE OPENING THE

INSTRUMENT CASE.

To open the enclosure:

1. Loosen (counter-clockwise) the three (3) ¼-turn screwdriver-

type fasteners on the back of the outer enclosure.

2. Pull off the back section of the cover

4.3 Replacing the Battery

After many charge/recharge cycles of the battery, eventually the

Ni-Cd batteries will have to be replaced. Usually, when the instrument

requires more frequent charge cycles than before it is time to change the

batteries. Refer to the Spare Parts Listing in the Appendix for the correct

replacement battery. Note: The batteries should only be replaced by a

qualified technician.

Teledyne Analytical Instruments 27

Page 36

Maintenance Model 3110

4.4 Battery Power Supply Service

The Model 3110 is designed to be intrinsically safe, and is designed

for use only when not connected to the AC power line. TAI suggests

that an overnight recharge be performed every few days for continuous

use.

The low battery LED will begin to blink and the display will flicker

when the batteries are getting low. At this point, the batteries should be

recharged. To recharge the batteries, turn the instrument OFF (see

Section 3.2.12. Remove the instrument to a safe non-hazardous location.

Note: Depending on the application, purging may be required

before disconnecting the analyzer and moving it to a safe

location.

Plug the AC charger into a suitable 100-240 VAC 50/60 Hz power

source. Plug the other end of the charger cable into the port on the rear

of the instrument. Figure 4-1 shows the AC charger port on the rear

panel.

Note: During charging, the green battery charging indicator LED

will illuminate.

When recharging is completed, unplug the unit from the AC outlet

and disconnect the cable from the AC charger port.

Note: The analyzer cannot be turned on while the AC charger is

attached.

Teledyne Analytical Instruments 28

Page 37

Portable Trace Oxygen Analyzer Maintenance

Battery

Charger

Figure 4-1: Battery Charger Port on the Model 3110

4.5 Cell Replacement

The characteristics of the micro-fuel cell are similar to those of a

NiCad battery in that both provide an almost constant output through their

useful life, and then fall off sharply towards zero at the end. If the sample

being analyzed has a low oxygen concentration, cell failure will probably

be indicated by the inability to properly calibrate the analyzer. You will find

that very little span adjustment will be required to keep the analyzer

calibrated properly during the duration of a given cell’s useful life. If large

span adjustments are required to calibrate the instrument, or calibration

cannot be achieved within the range of the control, the cell shou ld be

immediately replaced. Refer to Section 4.4 before replacing the cell.

To offset the possibility of not having a replacement cell available

when it is needed, TAI recommends that a spare cell be purchased

shortly after the instrument is placed in service, and each time the cell is

replaced thereafter.

The spare cell should be carefully stored in an area that is not

subject to large variations in ambient temperature (75 °F nominal), and

in such a way as to obviate any possibility of incurring damage. Under

no circumstances should you disturb the integrity of the cell

package until the cell is to be actually used. If the cell package is

punctured and air permitted to enter, the cell will immediately start to

react to the presence of oxygen.

Teledyne Analytical Instruments 29

Page 38

Maintenance Model 3110

CAUTION: THE MICRO-FUEL CELL CONTAINS KOH SOLUTION,

WHICH IS CAUSTIC. SHOULD THE CELL RUPTURE,

A LEAK MAY CAUSE INJURY. PLEASE REFER TO

MATERIAL SAFETY DATA SHEET IN THE APPENDIX

TO LEARN ABOUT POTENTIAL HAZARDS AND

CORRECTIVE ACTION IN CASE OF ACCIDENT.

No tools are required to replace the cell in the instrument. Simply

unscrew (counterclockwise) the plug at the bottom of the analyzer and

the cell will drop out of the manifold cavity.

Remove the new cell from its package, and carefully remove the

shorting clip. Do not touch the silver-colored sensing surface of the cell,

as it is covered with a delicate Teflon membrane that can be ruptured in

handling.

Place the cell on the end of the cell holder cap so that the sensing

surface of the cell is in contact with the cap and the electrical contact

plate end of the cell is facing upwards. Insert the cell and cap in the

manifold cavity, and screw the cap back into place. Apply as much

pressure as you can with your fingers, but use no tools.

After the cell has been installed, purge the instrument with an inert

gas (or the sample), and then proceed as directed in section 3.1.1.

4.6 Cell Warranty

The majority of micro-fuel cells used in the Model 3110 carry a

six-month warranty from date of service.

With regard to spare cells, service time starts when the cell is

removed from its shipping package. The customer should stock only one

spare cell per instrument at a time. Do not attempt to stockpile spare

cells.

If the Model 3110 is used in trace analysis applications where CO

is a major component in the sample, the A2C micro-fuel cell should be

used. At low CO2 concentrations (1,000 PPM or less) the standard B2C

cell performance will not be affected. Figure 4-2 shows the effects of

CO

on the cell life of a Class B-2C cell.

2

If the analyzer is going to be used on percent ranges, a B-1 cell can

be used. The B-1 sensor will provide better service life in percent

applications.

2

Teledyne Analytical Instruments 30

Page 39

Portable Trace Oxygen Analyzer Maintenance

WARNING: EVIDENCE OF DAMAGE DUE TO TAMPERING OR

MISHANDLING WILL RENDER THE CELL

WARRANTY NULL AND VOID.

4.7 Temperature Compensation

The micro-fuel cell has an inherent positive temperature coefficient.

Compensation is performed internally by the microprocessor and needs no

further adjustment.

Contact the factory if you suspect temperature related inaccuracies

during monitoring and are operating within the instrument’s temperature

operation range.

4.8 Leak Testing

WARNING: IF A LEAK IS SUSPECTED IN THE UNIT, DO NOT

ATTEMPT TO TIGHTEN THE DISCONNECT

FITTINGS. THE FITTINGS ARE POTTED IN EPOXY

AND TIGHTENING THEM WILL BREAK THE SEAL.

To check for leaks, TAI recommends one of the following

procedures:

Procedure I:

1. Purge the instrument to as low a value as possible. Use a

sensitive range for analysis for instance, 0-1% range Take

note of the oxygen concentration.

2. Place the vent line in water and disconnect the sample.

3. Next, disconnect the vent line and use the same analysis

range. The reading should not increase above the level to

which you purged to.

Procedure II:

1. Purge the instrument with nitrogen at the sample port.

2. Note the reading once is has stabilized (at least 24 hours on

the 0-10 PPM range) and at a flowrate of approximately 1

SCFH.

3. Increase the flowrate from 1 SCFH to 2 SCFH.

Teledyne Analytical Instruments 31

Page 40

Maintenance Model 3110

4. Note how much the reading has changed after a few minutes.

5. Reduce the flowrate to 0.5 SCFH.

6. Note how much the reading has changed.

7. The reading should change by less than 10% of the original

value

Teledyne Analytical Instruments 32

Page 41

Portable Trace Oxygen Analyzer Maintenance

Effect of CO2 on B-2C Cell Life

1. This curve assumes continuous exposure.

2. Intermittent exposure will extend life. In

general, the CO2 effect is cumulative and

the average CO2 concentration should be

used to find the predicted cell life.

3. Cells can be used to make spot check

measurements of O

high concentrations of CO

in the presence of

2

(up to 50%

2

and more). Any sample containing CO2

should be purged as soon as a constant

reading is obtained.

4. Abnormally slow response and recovery

is characteristic of cells used as indicated

in notes 1, 2, and 3 above.

5. The reduction in cell life is primarily due

to a drop in output. Cell life will reduce

to a point where the instrument can no

longer be spanned. Instruments using B-2

cells in CO2 atmospheres should be

spanned at intervals of 10-20% of the

predicted cell life.

6. The CO2 effect on B-2 cells is

independent of the O2 level. Usage in

contributes significantly to cell life

CO

2

reduction and thus affects cell warranty.

Figure 4-2: Effects of CO2 on B-2 Cell Life

Teledyne Analytical Instruments 33

Page 42

Maintenance Model 3110

Teledyne Analytical Instruments 34

Page 43

Portable Trace Oxygen Analyzer Appendix

Appendix

A.1 Specifications

Certification: FM-approved, Intrinsically Safe,

Class I Div 1 Group A-D T6

Micro-fuel Cell Class: B-2C, B-1, A-2C, A-5, B-2CXL, A-

2CXL, B-2C Insta-trace, A-2C Insta-trace,

B-2CHS, A-2CNG

Ranges of Analysis: 1 user defined range

0-10 ppm to 0-25% (std 3110)

0-2 ppm to 0-25% (3110XL)

0-1% to 0-25% (3110P)

Accuracy: ±2% of scale or ±1 PPM (whichever is

greater) at constant temperature;

±5% of reading or ±1 PPM (whichever is

greater) over the operating temperature

range.

Operating Temp. Range: 0°C to 40°C (32°F to 104°F)

Sample Temp. Range: 0-40°C

Sample Flow Rate: 0.5 – 2.5 SCFH

Recommended Span Gas: Atmospheric air for percent analysis or

80-90% of range most likely to be used

Signal Output: 0-1 VDC

Electrical safety parameters

Uo = 4.65 V, Io = 193.74 mA,

Po = 225.2 mW, Co = 90 uF,

Lo = 0.7 mH, Lo/Ro = 157.86 uH/Ohm

:

Dimensions: 10.9” x 6.2” x 5.2” deep

Weight: 4.4 lbs. (2.0 kg.)

Power Requirements: 100-240 VAC 47-63 Hz Charging Adapter

Teledyne Analytical Instruments 35

Page 44

Appendix Model 3110

A.2 Spare Parts List

QTY P/N DESCRIPTION

1 O-165 Cell Cap O-Ring (standard)

2 B82162 Battery (must be installed by a

qualified technician)

1 A761 Battery Charger, Universal

1 CP2487 2-pin 0-1 VDC Output Plug

1 A36289 Calibration Kit Std.

2 F1378 Fuse 200 mA (T)

1 C78853 Cell Cap with O-Ring (standard)

* Micro Fuel Cell Options

1 C6689-B2C* Micro-Fuel Cell, Class B-2C

1 C6689-B1 Micro-Fuel Cell, Class B-1

1 C6689-A2C Micro-Fuel Cell, Class A-2C

1 C6689-A5 Micro-Fuel Cell, Class A-5

1 C6689-B2CXL Micro-Fuel Cell, Class B-2CXL

1 B74033-A2CXL Micro-Fuel Cell, Class A-2CXL

1 B71875 Micro-Fuel Cell, B-2C Insta-trace

1 B73016 Micro-Fuel Cell, A-2C Insta-trace

1 B73592 Micro-Fuel Cell, B-2CXL Insta-

trace

1 B78640 Micro-Fuel Cell, Class B-2CHS

1 B76953 Micro-Fuel Cell, Class A-2CNG

A minimum charge of US$200.00 applies to spare parts orders.

IMPORTANT: Orders for replacement parts should include the model

number, serial number, and range of the analyzer for

which the parts are intended.

Teledyne Analytical Instruments 36

Page 45

Portable Trace Oxygen Analyzer Appendix

Orders should be sent to:

TELEDYNE ANALYTICAL INSTRUMENTS

16830 Chestnut Street

City of Industry, CA 91748

Phone: (626) 961-9221

FAX: (626) 961-2538

TWX: (626) 934-1651

or your local representative

Teledyne Analytical Instruments 37

Loading...

Loading...