Percent Paramagnetic Oxygen Analyzer

OPERATING INSTRUCTIONS FOR

Model 3020M

Percent Paramagnetic

Oxygen Analyzer

DANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS MONITORING

SYSTEM.

PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

HAZARDOUS VOLTAGES EXIST ON CERTAIN COMPONENTS INTERNALLY WHICH MAY PERSIST

FOR A TIME EVEN AFTER THE POWER IS TURNED OFF AND DISCONNECTED.

ONLY AUTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SERVICING. BEFORE

CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED SUPERVISOR/

MANAGER.

Teledyne Analytical Instruments

P/N M69993

12/18/98

ECO:#98-0569

i

Model 3020M

Copyright © 1998 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any other language or computer

language in whole or in part, in any form or by any means, whether it be electronic,

mechanical, magnetic, optical, manual, or otherwise, without the prior written consent of

Teledyne Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free

from defects of material and of construction, and that our liability shall be limited to

replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of shipment, except in cases where quotations or

acknowledgements provide for a shorter period. Components manufactured by others bear

the warranty of their manufacturer. This warranty does not cover defects caused by wear,

accident, misuse, neglect or repairs other than those performed by Teledyne or an authorized service center. We assume no liability for direct or indirect damages of any kind and

the purchaser by the acceptance of the equipment will assume all liability for any damage

which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any parts, in

so far as such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by

which valuable data can be gathered. The information provided by the instrument may

assist the user in eliminating potential hazards caused by his process; however, it is

essential that all personnel involved in the use of the instrument or its interface, with the

process being measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent danger,

it has no control over process conditions, and it can be misused. In particular, any alarm or

control systems installed must be tested and understood, both as to how they operate and

as to how they can be defeated. Any safeguards required such as locks, labels, or redundancy, must be provided by the user or specifically requested of Teledyne at the time the

order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The

purchaser is responsible for the training of personnel, for providing hazard warning

methods and instrumentation per the appropriate standards, and for ensuring that hazard

warning devices and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments, the manufacturer of this instrument, cannot

accept responsibility for conditions beyond its knowledge and control. No statement

expressed or implied by this document or any information disseminated by the manufacturer or its agents, is to be construed as a warranty of adequate safety control under the

user’s process conditions.

ii

Teledyne Analytical Instruments

Percent Paramagnetic Oxygen Analyzer

Specific Model Information

The instrument for which this manual was supplied may incorporate one or

more options not supplied in the standard instrument. Commonly available

options are listed below, with check boxes. Any that are incorporated in the

instrument for which this manual is supplied are indicated by a check mark in the

box.

Instrument Serial Number: _______________________

Options Included in the Instrument with the Above Serial Number:

❑❑

❑

3020M-C: In addition to all standard features, this model also has

❑❑

separate ports for zero and span gases, and built-in control

valves. The internal valves are entirely under the control of

the 3020M electronics, to automatically switch between

gases in synchronization with the analyzer’s operations

❑❑

❑

3020M-F: Includes flame arrestors for Group C and D service.

❑❑

❑❑

❑

3020M-G: Includes flame arrestors for Groups C and D service, plus

❑❑

gas control valves as in –C option, above

❑❑

❑

3020M-H: Includes flame arrestors for Group B (hydrogen) service.

❑❑

❑❑

❑

3020M-I: Includes flame arrestors for Group B (hydrogen) service,

❑❑

plus gas control valves as in –C option, above.

❑❑

❑

3020M-M: 4-20 mA dc Signal and Range ID outputs (in addition to

❑❑

the standard dc voltage outputs.

Teledyne Analytical Instruments

iii

Model 3020M

1 Introduction

1.1 Overview........................................................................ 1-1

1.2 Typical Applications ....................................................... 1-1

1.3 Main Features of the Analyzer ....................................... 1-1

1.4 Model Designations ....................................................... 1-2

1.5 Operator Interface .......................................................... 1-2

1.5.1 UP/DOWN Switch.................................................. 1-4

1.5.2 ESCAPE/ENTER Switch ....................................... 1-4

1.5.3 Displays ................................................................. 1-5

1.6 Recognazing Difference Between LCD & VFD .............. 1-5

1.7 Rear Panel (Equipment Interf ace).................................. 1-5

1.7.1 Electr ical Connector Panel .................................... 1-5

1.7.2 Gas Connector Panel............................................. 1-7

Table of Contents

2 Operational Theory

2.1 Introduction .................................................................... 2-1

2.2 Paramagnetic Sensor..................................................... 2-1

2.2.1 Principles of Operation ............................................ 2-1

2.3 Cross Interference.......................................................... 2-3

2.4 Sample System.............................................................. 2-5

2.5 Electronics and Signal Processing ................................ 2-6

2.6 Temperature Control ...................................................... 2-6

3 Installation

3.1 Unpacking the Analyzer................................................. 3-1

3.2 Mounting the Analyzer ................................................... 3-1

3.3 Electrical Connections................................................... 3-3

3.3.1 Primary Input Pow er............................................... 3-4

3.3.2 Fuse Installation..................................................... 3-4

3.3.3 Analog Outputs ...................................................... 3-4

3.3.4 Alarm Relays ......................................................... 3-7

3.3.5 Digital Remote Cal Inputs ...................................... 3-8

3.3.6 Range ID Relays ................................................... 3-9

3.3.7 Network I/O ............................................................ 3-9

3.3.8 RS-232 Port ........................................................... 3-9

3.3.9 Remote Sensor and Solenoid Valves ....................3-11

3.4 Gas Connections .......................................................... 3-12

3.5 Testing the System........................................................ 3-13

iv

Teledyne Analytical Instruments

Percent Paramagnetic Oxygen Analyzer

4 Operation

4.1 Introduction .................................................................... 4-1

4.2 Using the Controls ......................................................... 4-1

4.2.1 Mode/Function Selection ....................................... 4-2

4.2.1.1 Analysis Mode ............................................... 4-2

4.2.1.2 Setup Mode ................................................... 4-2

4.2.2 Data Entry .............................................................. 4-4

4.2.2.1 ENTER .......................................................... 4-4

4.2.2.2 ESCAPE........................................................ 4-4

4.3 The AUTO-CAL Function ............................................... 4-5

4.4 The PWD Function ........................................................ 4-5

4.4.1 Entering the Password........................................... 4-6

4.4.2 Installing or Changing the Password ..................... 4-7

4.5 The LOGOUT Function.................................................. 4-8

4.6 The VERSION Screen ................................................... 4-8

4.7 The SELF TEST Function.............................................. 4-9

4.8 The SPAN Functions ..................................................... 4-9

4.8.1 Span Cal................................................................ 4-10

4.8.1.1 Auto Mode Spanning ..................................... 4-10

4.8.1.2 Manual Mode Spanning................................. 4-11

4.9 The CAL Function.......................................................... 4-11

4.10 The ALARMS Function.................................................. 4-13

4.11 The RANGE Function.................................................... 4-15

4.11.1 Setting the Analog Output Ranges......................... 4-16

4.11.2 Automatic Ranging ................................................ 4-16

4.11.3 Fixed Range Analysis ............................................ 4-16

4.12 The CONTRAST Function............................................. 4-17

4.13 The STANDBY Function................................................ 4-17

4.14 The

4.15 The

Analysis Mode ........................................................

Sensor Function .....................................................

4-18

4-18

Maintenance

5.1 Routine Maintenance..................................................... 5-1

5.2 Major Internal Components............................................ 5-1

5.3 Sensor Replacement ..................................................... 5-2

5.4 Fuse Replacement ......................................................... 5-2

5.5 System Self Diagnostic Test........................................... 5-3

5.6 Output Goes Negative.................................................... 5-4

Teledyne Analytical Instruments

v

Model 3020M

Appendix

A-1 Specifications ................................................................ A-1

A-2 Recommended 2-Year Spare Parts List ......................... A-3

A-3 Drawing List................................................................... A-4

vi

Teledyne Analytical Instruments

Percent Paramagnetic Oxygen Analyzer Introduction 1

Introduction

1.1 Overview

The Teledyne Analytical Instruments Model 3020M Percent Paramagnetic Oxygen Analyzer is a versatile microprocessor-based instrument for

detecting oxygen in a variety of gases. This manual covers the Model

3020M, percent oxygen, explosion-proof, bulkhead-mount units only.

1.2 Typical Applications

A few typical applications of the Model 3020M are:

• Monitoring inert gas blanketing

• Air separation and liquefaction

• Chemical reaction monitoring

• Semiconductor manufacturing

• Petrochemical process control

• Quality assurance

• Gas analysis certification.

1.3 Main Features of the Analyzer

The Model 3020M Percent Oxygen Analyzer is sophisticated yet

simple to use. The main features of the analyzer include:

• A 2-line alphanumeric display screen, driven by microprocessor

electronics, that continuously prompts and informs the operator.

• High resolution, accurate readings of oxygen content from low %

levels through 100%. Large, bright, meter readout.

• Stainless steel sample system.

Teledyne Analytical Instruments

1-1

1 Introduction Model 3020M

• Versatile analysis over a wide range of applications.

• Microprocessor based electronics: 8-bit CMOS microprocessor

with 32 kB RAM and 128 kB ROM.

• Three user definable output ranges (from 0-5 % through 0-100

%) allow best match to users process and equipment.

• Auto Ranging allows analyzer to automatically select the proper

preset range for a given measurement. Manual override allows

the user to lock onto a specific range of interest.

• Two adjustable concentration alarms and a system failure alarm.

• Extensive self-diagnostic testing, at startup and on demand, with

continuous power-supply monitoring.

• RS-232 serial digital port for use with a computer or other digital

communication device.

• Analog outputs for concentration and range identification.

(0-1 VDC standard, and isolated 4–20 mADC)

1.4 Model Designations

3020M: Standard model.

3020M-C: In addition to all standard features, this model also has

separate ports for zero and span gases, and built-in control

valves. The internal valves are entirely under the control of

the 3020M electronics, to automatically switch between gases

in synchronization with the analyzer’s operations

3020M-F: Includes flame arrestors for Groups C and D.

3020M-G: Includes flame arrestors for Groups C and D, & -C option.

3020M-H: Includes flame arrestors for Group B (Hydrogen service).

3020M-I: Includes flame arrestors for Group B, & -C option.

n.

1.5 Operator Interface

All controls and displays on the standard 3020M are accessible from

outside the housing. The instrument has two simple operator controls. The

operator has constant feedback from the instrument through an alphanumeric

display, a digital oxygen meter, and a sample flow meter. The displays and

1-2

Teledyne Analytical Instruments

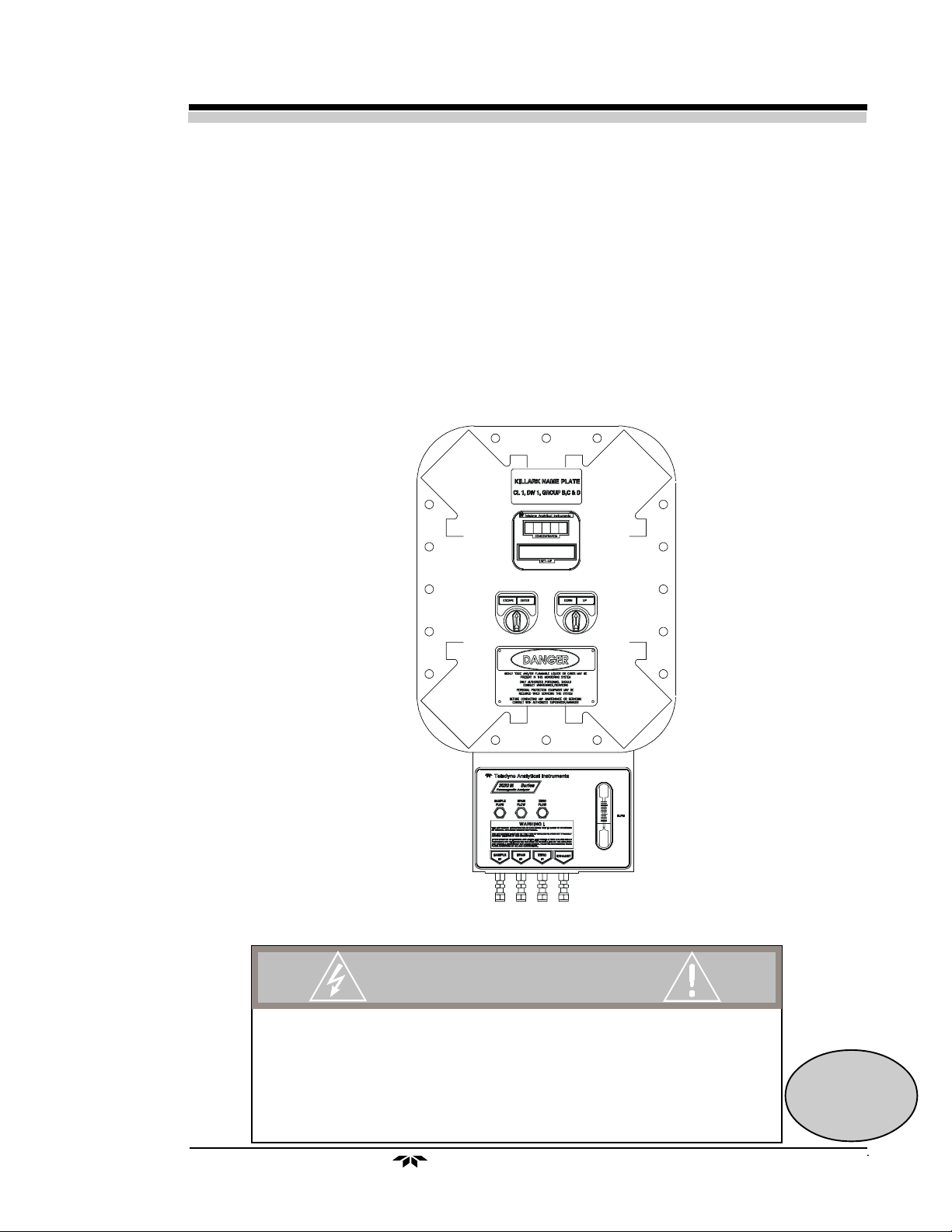

Percent Paramagnetic Oxygen Analyzer Introduction 1

controls are described briefly here and in greater detail in chapter 4. See

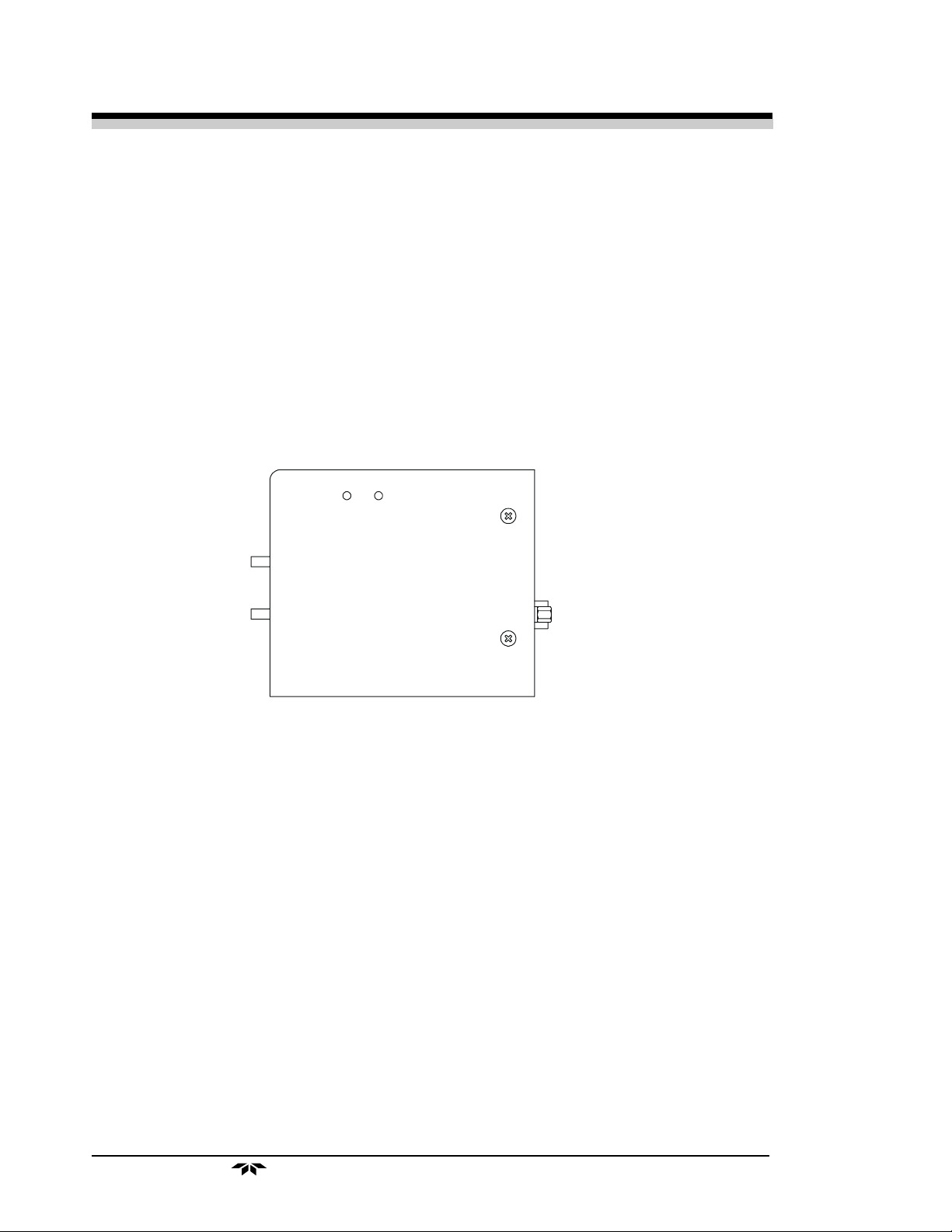

Figure 1-1.

Through Side Port

DIGITAL METER

VFD SCREEN

Through Side Port

Through Side Port

DOWN/UP

Through Side Port

SCCM

CONTROL

ESCAPE/ENTER

CONTROL

Figure 1-1: Model 3020M Controls, Indicators, and Connectors

Teledyne Analytical Instruments

1-3

1 Introduction Model 3020M

1.5.1 UP/DOWN Switch

Functions: The UP/DOWN switch is used to select the function to be

performed. Choose UP or DOWN to scroll through the following list of

twelve functions:

• Auto-Cal Set up an automatic calibration sequence.

• PWD Install a password to protect your analyzer setup.

• Logout Locks Setup Mode.

• Version Displays model and version of analyzer.

• Self-Test Runs internal diagnostic program, displays results.

• Span Span calibrate the analyzer.

• Zero Zero calibrate the analyzer.

• Alarms Set the alarm setpoints and attributes.

• Range Set up the 3 user definable ranges for the instrument.

• Contrast Adjust LCD contrast.

• Standby Leave analyzer powered, but no outputs or displays.

Contrast Function is

(Refer to Section 1.6)

DISABLED

WARNING: THE POWER CABLE MUST BE DISCONNECTED TO

FULLY REMOVE POWER FROM THE INSTRUMENT.

CAUTION: VOLTAGE MAY BE PRESENT ON ALARM CON-

TACTS WHEN LINE POWER IS DISCONNECTED.

Subfunctions: Once a Function is entered, the UP/DOWN switch is

used to select between any subfunctions displayed on the VFD screen.

Parameter values: When modifiable values are displayed on the

VFD, the UP/DOWN switch can be used to increment or decrement the

values.

1.5.2 ESCAPE/ENTER Switch

Data Entry: The ESCAPE/ENTER switch is used to input data, from

the alphanumeric VFD screen into the instrument:

• Escape Moves VFD display back to the previous screen in a

series. If none remains, returns to the

Analyze

screen.

With subfunction selected, moves VFD back through

items on screen, to first item, then moves VFD to

previous display.

1-4

• Enter With a Subfunction Selected: Moves VFD on to the

next screen in a series. If none remains, returns to the

Analyze

Teledyne Analytical Instruments

screen.

Percent Paramagnetic Oxygen Analyzer Introduction 1

With a Value Selected: Enters the value into the

analyzer as data. Advances VFD to next operation.

(See Chapter 4 for details.)

1.5.3 Displays

Digital Meter Display: The meter display is a LED device that

produces large, bright, 7-segment numbers that are legible in any lighting. It

produces a continuous readout from 0-100 %. It is accurate across all

analysis ranges without the discontinuity inherent in analog range switching.

Alphanumeric Interface Screen: The backlit VFD screen is an easy-

to-use interface from operator to analyzer. It displays values, options, and

messages that give the operator immediate feedback.

Flowmeter: Monitors the flow of gas past the sensor. Readout is 100 to

1000 standard cc per minute (cc/min x 100) valid for air or nitrogen.

1.6 Recognizing Difference Between LCD &

VFD

LCD has GREEN background with BLACK characters. VFD has

DARK background with GREEN characters. In the case of VFD - NO

CONTRAST ADJUSTMENT IS NEEDED.

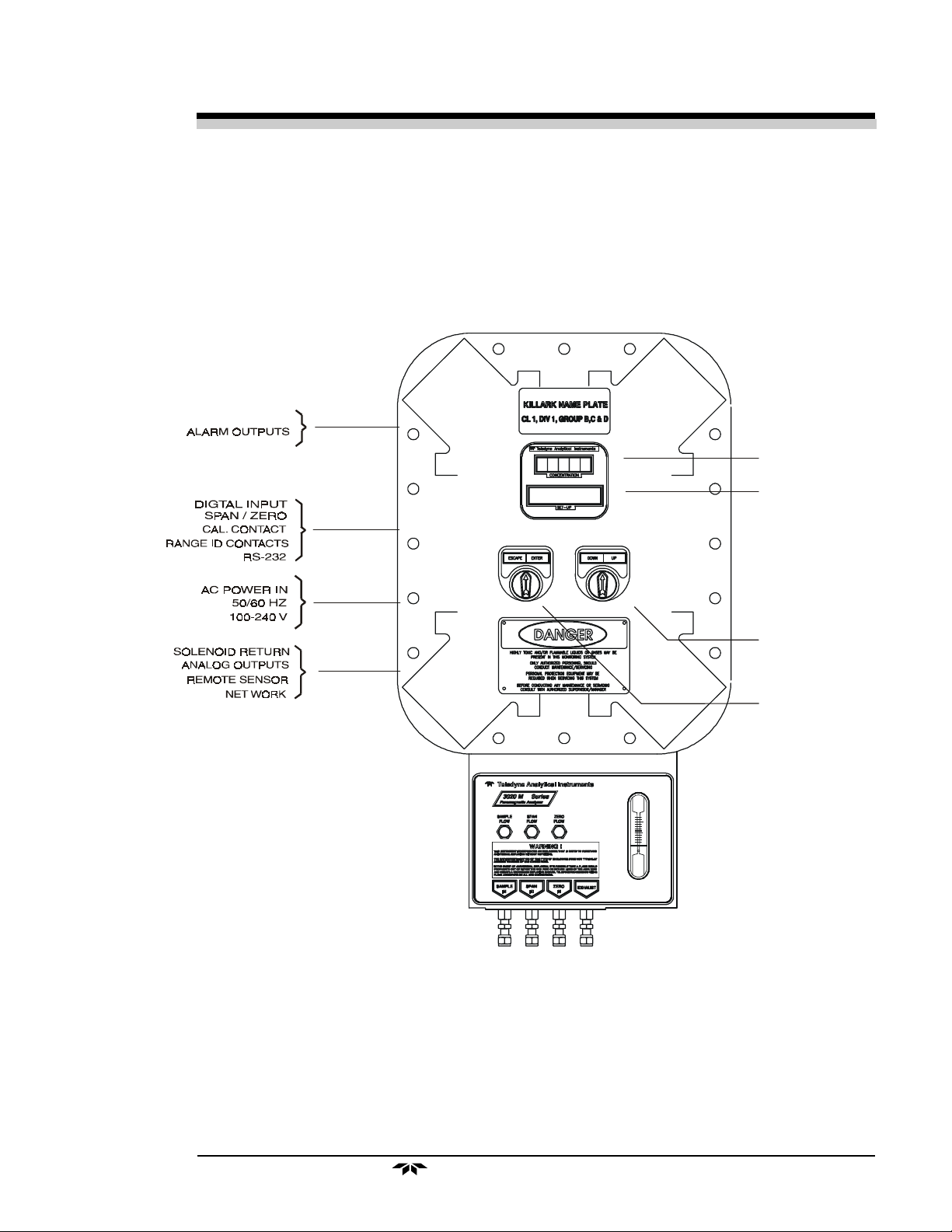

1.7 Equipment Interface

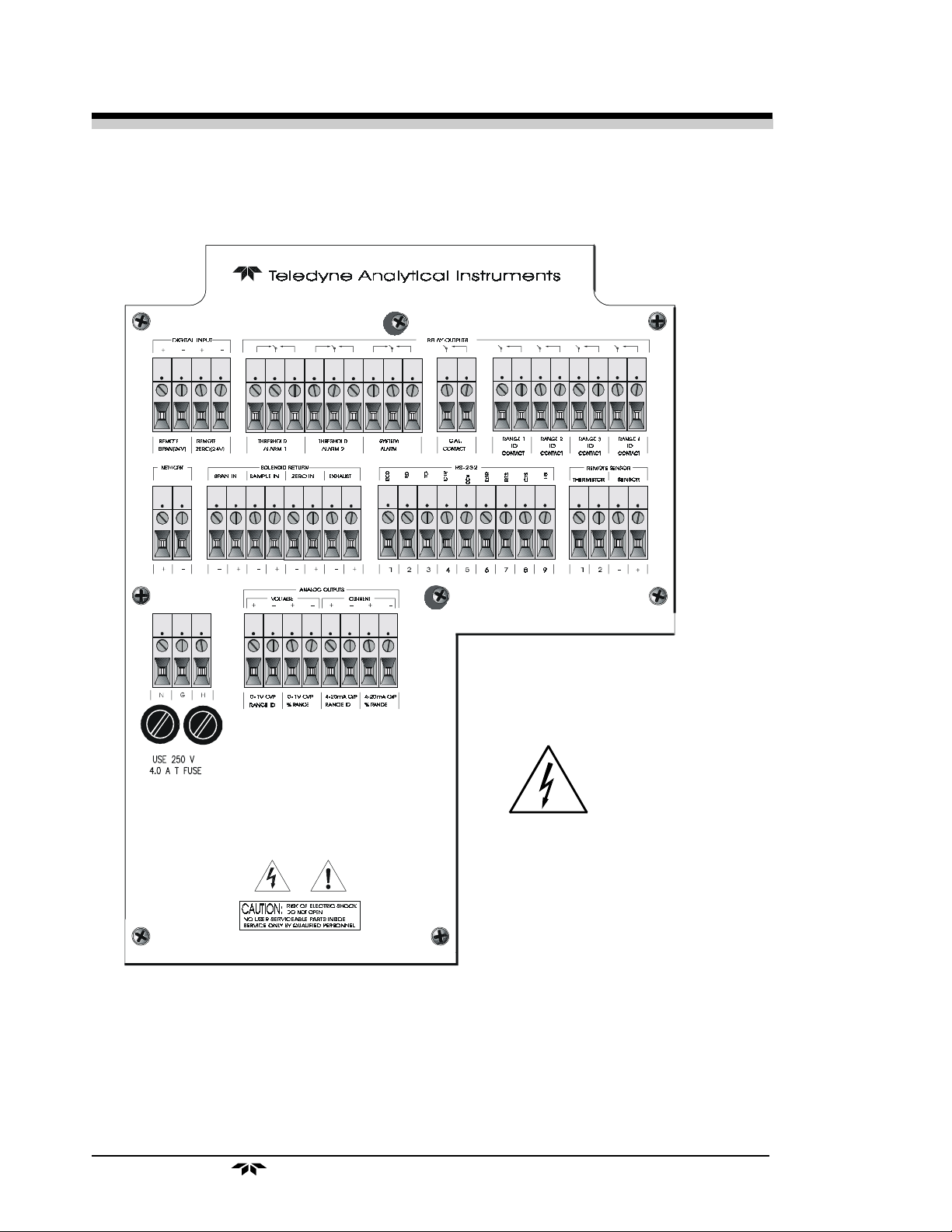

1.7.1 Electrical Connector Panel

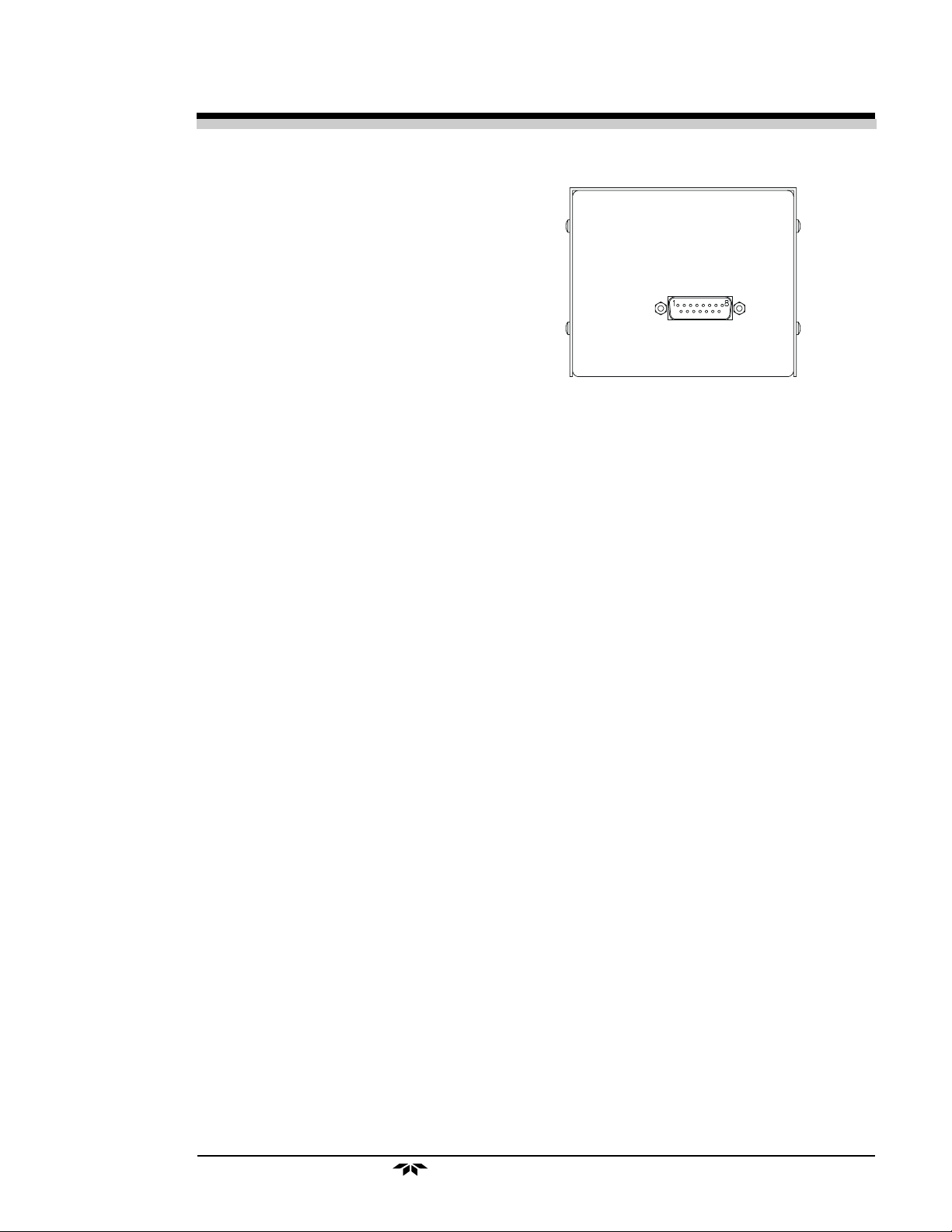

The electrical connector panel, shown in Figure 1-2, contains the

electrical connections for external inlets and outlets. The connectors are

described briefly here and in detail in the Installation chapter of this manual.

CAUTION: The power cable must be disconnected to fully

remove power from the instrument.

CAUTION: VOLTAGE MAY BE PRESENT ON ALARM CON-

TACTS WHEN LINE POWER IS DISCONNECTED.

Teledyne Analytical Instruments

1-5

1 Introduction Model 3020M

100-240 V

50/60Hz

3.0A Max.

1-6

Figure 1-2: Electrical Connector Panel

Teledyne Analytical Instruments

Percent Paramagnetic Oxygen Analyzer Introduction 1

Electrical Connections: The electrical connections on the electrical

connector panel are described briefly here, and in more detail in chapter 3

Installation.

• Power Connection 100-240 VAC, 50 or 60 Hz.

• Analog Outputs 0-1 VDC concentration plus 0-1 V dc

range ID. Additional, isolated 4-20 mA

DC plus 4-20 mADC range ID

available.

• Alarm Connections 2 concentration alarms and 1 system

alarm.

• RS-232 Port Serial digital concentration signal output

and control input.

• Remote Valves Used for controlling external solenoid

valves, if desired.

• Remote Span/Zero Digital inputs allow external control of

analyzer calibration.

• Calibration Contact To notify external equipment that

instrument is being calibrated and

readings are not monitoring sample.

• Range ID Contacts Four separate, dedicated, range relay

contacts. Low, Medium, High, Cal.

• Network I/O Serial digital communications for local

network access. For future expansion.

Not implemented at this printing.

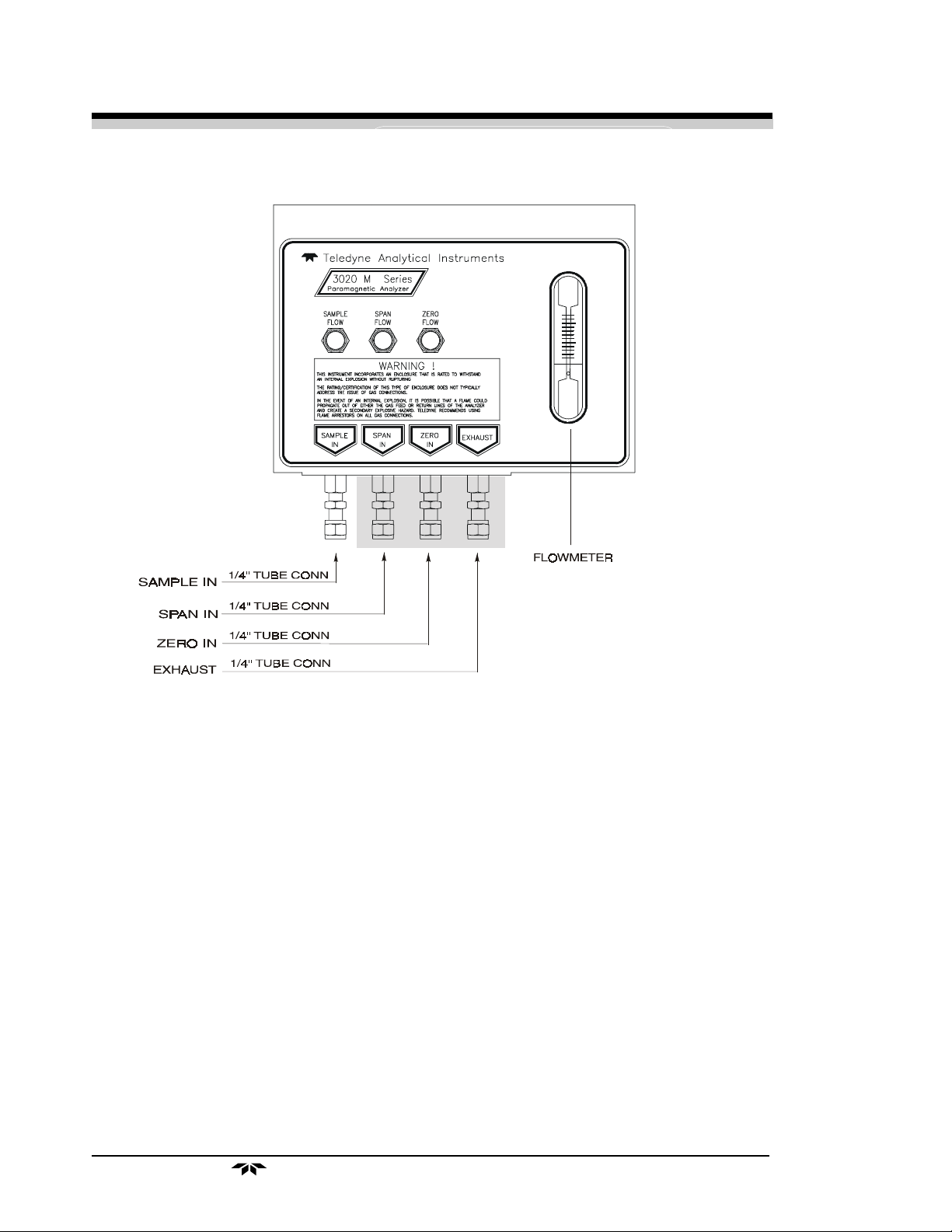

1.7.2 Gas Connector Panel

The gas connector panel, shown in Figure 1-3, contains the gas connections for external inlets and outlets. Those that are optional are shown

shaded in the figure. The connectors are described briefly here and in detail

in the Installation chapter of this manual.

Teledyne Analytical Instruments

1-7

1 Introduction Model 3020M

SCCM

Figure 1-3: Model 3020M Gas Connector Panel

• Gas Sample Inlet and Outlet One inlet and one exhaust out.

Optional:

• Calibration Gas Ports Separate fittings for zero, span and

sample gas input, plus internal valves for

automatically switching the gases in

sync with the 3020M electronics.

Note: If you require highly accurate Auto-Cal timing, use external

Auto-Cal control where possible. The internal clock in the

Model 3020M is accurate to 2-3 %. Accordingly, internally

scheduled calibrations can vary 2-3 % per day.

1-8

Teledyne Analytical Instruments

Percent Paramagnetic Oxygen Analyzer Operational Theory 2

Operational Theory

2.1 Introduction

The analyzer is composed of three subsystems:

1. Paramagnetic Sensor

2. Sample System

3. Electronic Signal Processing, Display and Control

The sample system is designed to accept the sample gas and transport it

through the analyzer without contaminating or altering the sample prior to

analysis. The Paramagnetic Sensor is an electromechanical device that

translates the amount of oxygen present in the sample into an electrical

signal. The electronic signal processing, display and control subsystem

simplifies operation of the analyzer and accurately processes the sampled

data. The microprocessor controls all signal processing, input/output and

display functions for the analyzer.

2.2 Precise Paramagnetic Sensor

2.2.1 Principles of Operation

The heart of the 3020M is a paramagnetic type oxygen sensor that is

maintanance free and has a long lifetime. Oxygen has a very high magnetic

sucseptibility compared to other gases and thus displays a particularly paramagnetic behaviour. A small glass dumbbell filled with nitrogen and rotating on a taut platinum wire is suspended in an inhomogneous magnetic field.

This glass dumbbell is diamagnetic and tends to rotate out of the magnetic

field. The strength of the resulting torque determined by an susceptibility of

the sample gas. This torque is compensated for by a counter torque induced

by an electrically charged platinum coil on the dumbbell. The zero position

of the dumbbell is controlled by means of an optical system consisting of a

light source, a mirror at the dumbbell axis and a pair of detectors. The

difference between the compensating currents required to bring the dumb-

Teledyne Analytical Instruments

2-1

2 Operational Theory Model 3020M

bell to the zero position in the presence of zero gas (i.e. no O2 present) or of

sample gas is proportional to the partial pressure of oxygen in the sample

gas.

The sensor enclosure is temperature controlled to 55 degrees centigrade

to insure that the magnetic susceptibility of oxygen in the sample is not

affected by the ambient temperature. The measuring cell has a measuring

volume of approximately 3 cm

3

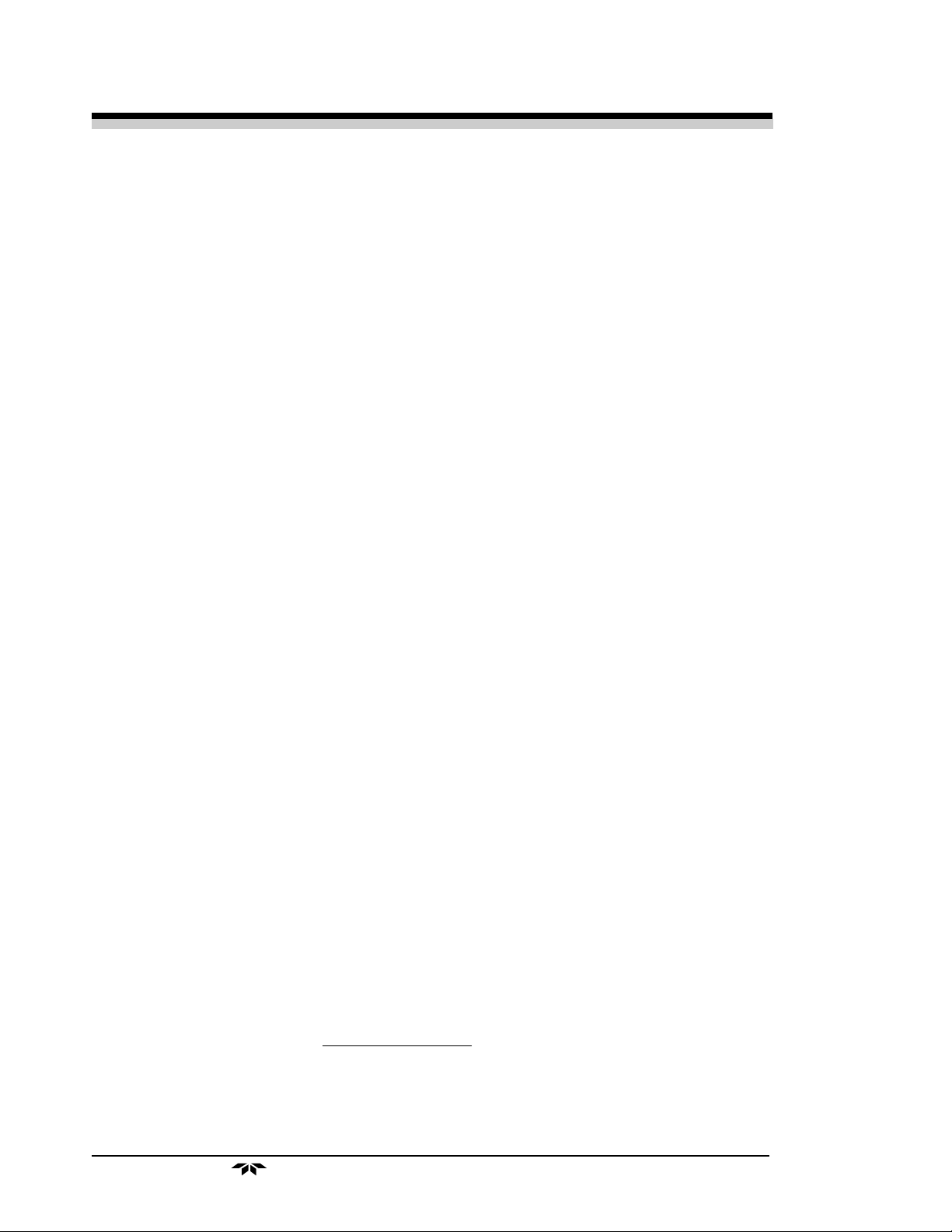

Sensor

(side view shown)

The Paramagnetic sensor enclosure holds not only the sensing elements,

but the temperature controller electronics, heating elements, sensor electronics, and preamplifier. The Electronics and heating elements require a separate

power source, from the rest of the 3020M capable of delivering 1.5 amps

approximately at 24 volts dc. The output of the sensor is roughly calibrated

to be 0 to 1 volt DC for the the range of 0 to 100 % 02. The true calibration

of the sensor is carried out by the microprocessor as described later in chapter 4. The electrical interconnections to the sensor are done through a 15 pin

D connector. Some signals from the sensor are not connected. They are only

useful for troubleshooting, by trained personnel, as test points.

2-2

Teledyne Analytical Instruments

Percent Paramagnetic Oxygen Analyzer Operational Theory 2

Sensor

(rear view shown)

Pin out:

1 -15Vdc test pin (Not connected)

2 +15Vdc test pin (Not connected)

3 Measuring ground

4 Not used

5 Preamplifier output ~0- 1 Vdc

6 Not used

7 24 Vdc return, power ground

8 Collector of transistor switching heating element (Not con-

nected)

9 Fault signal: <0 Vdc= OK, >4.6 Vdc = Fault (Not connected)

10 Not used

11 Negative reference voltage (Not connected)

12 Positive reference voltage (Not connected)

13 Nominal temperature voltage signal (Not connected)

14 Actual temperature voltage signal (Not connected)

15 +24 Vdc power.

2. 3 Cross Interference

As mentioned previously, the selectivity of the measuring system is

based on the extraordinarily high magnetic susceptibility of Oxygen compared to other gases. In most cases the presence of other gases can be ignored but significant errors can occur when the sensor is calibrated with a

mixture of oxygen and nitrogen and the sample gas consists mainly of other

gases with considerable magnetic susceptibility. In this case, the reading

shows a measured value even if the sample gas contains no Oxygen. It is

actually displaying the cross sensitivity to another gas.

The following table shows the cross sensitivity of some gases when

changing from pure nitrogen to 100% of one of the gases listed.

Teledyne Analytical Instruments

2-3

2 Operational Theory Model 3020M

Gas Cross Gas Cross

Sensitivity Sensitivity

in vol. % in vol. %

Acetylene C2H

Allene C3H

4

Ammonia NH

2

3

-0.24 Hydrogen chloride HCI -0.30

-0.44 Hydrogen fluoride HF +0.10

-0.2 6 Hydrogen iodide HI -1.10

Argon Ar -0.22 Hydrogen sulphide H2S -0.39

Bromine Br

2

1.2 Butadiene C4H

1.3 Butadiene C4H

n-Butane C4H

10

6

6

-1.30 Iodine I -2.40

-0.49 Isobutane C4H

-0.49 Isopantane C5H

10

12

-1.11

-1.11 Krypton Kr -0.51

I-Butane C4H8 -085 Laughing gas N2O -0.20

cis 2-Butane C4H

trans 2-Butane C4H

Carbon dioxide CO

8

8

2

Carbon monoxide CO +0.06 Nitric acid HNO

Chlorine Cl

Cyclo hexane C6H

Ethane C2H

Ethylene C2H

2

12

6

4

Helium He +0.30 Propane C3H

n-Heptane C7H

n-Hexane C6H

Hydrogen H

16

14

2

-0.89 Methane CH

4

-0.20

-0.92 Neon Ne +0.13

-0.27 Neopentane C5H

12

3

-0.77 Nitrogen dioxide NO

2

-1.49

+0.43

+28.00

-1. 56 Nitrous oxide NO +40.00

-0.43 n-Octane C8H

-0.26 n-Pentane C5H

8

-2.10 Propylene C3H

18

12

6

-2.50

-1.45

-0.86

-0.55

-1. 70 Vinyl chloride -0.63

+0.24 Water H2O -0.02

Hydrogen bromide HBr -.0.61 Xenon Xe -0.95

-1.49

With gas mixtures the components are weighted according to their

proporational volumes.

The cross interference with a gas mixture can be determined in advance if the

concentration of the individual background gases is known.

Example:

Cross sensitivity calculation for a gas mixture:

The gas to be measured consists of 10 % CO2, 40 % of N2, and 50%

of Ar.

C02: -0.27 x 10% = -0.027

Ar: -0.22x5O%= -0.11

TOTAL CROSS INTERFERENCE -0.137

Calculation of the zero value:

2-4

Teledyne Analytical Instruments

Percent Paramagnetic Oxygen Analyzer Operational Theory 2

(0% 02) - (Cross Interference Value) = Zero Point Value

0%-(-0.137) = +0.137%0

2

2.4 Sample System

The sample system delivers gases to the sensor from the analyzer gas

panel inlets. Depending on the mode of operation either sample or calibration

gas is delivered.

The Model 3020M sample system is designed and fabricated to ensure that

the oxygen concentration of the gas is not altered as it travels through the

sample system. The sample encounters almost no dead space. This minimizes

residual gas pockets that can interfere with low percent range analysis.

The sample system for the standard instrument incorporates ¼ inch tube

fittings for sample inlet and outlet connections at the rear panel. For metric

system installations, 6 mm adapters are supplied with each instrument to be used

if needed. The sample or calibration gas flowing through the system is monitored by a flowmeter downstream from the sensor.

The gases delivered to the instrument should be at constant pressures and

flow rates and must exit freely into the ambient atmosphere. The Span, Zero

and Sample gases should be delivered at constant pressures of about 10 psig

(Range 5-20). The flow rate must be maintained at about 700 cc/minute (Range

600-1000) and must exit freely into atmospheric pressure.

Supplied at

constant

pressure

of 10 psig

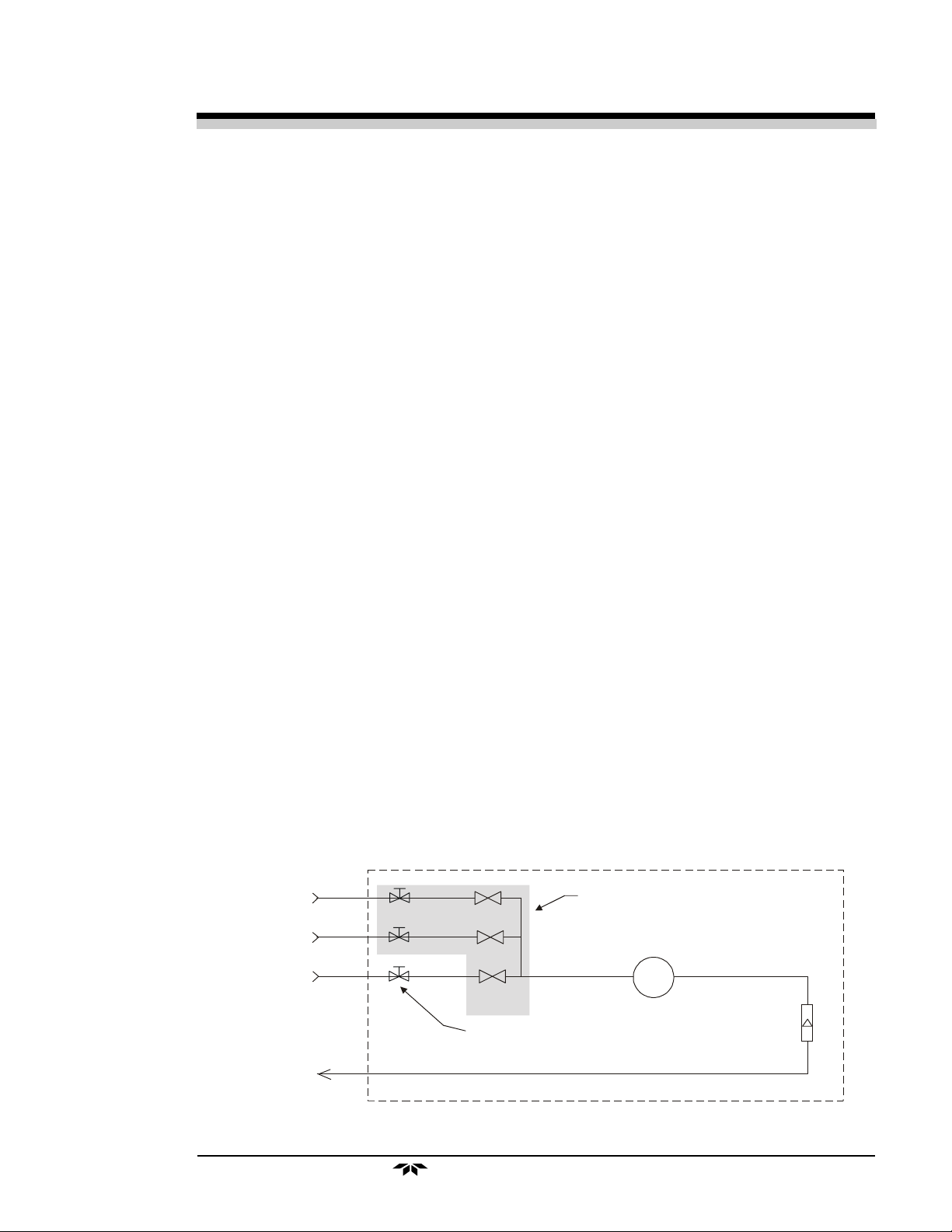

Figure 2-4 is the flow diagram for the sampling system. In the standard

instrument, calibration gases (zero and span) can be connected directly to the

Sample In port by teeing to the port with appropriate valves. The shaded portions of the diagram show the components added when the –C and/or –F

options are ordered. The solenoid valves, when supplied, are installed inside the

3020M enclosure and are regulated by the instruments internal electronics. The

flame arrestors, when supplied, are installed in the Gas Connector Panel.

Span In

Zero In

Sample In

Exhaust Out

into at hmospher e

Components in the shaded area are in

the -C option (internal control valves)

only and are not shown in the piping

diagram above.

Solenoid

Valves

Needle Valves

to adjust the flow

Figure 2-4: Flow Diagram

Sensor

Flowmeter

(Maintain at 700 cc/minute)

Teledyne Analytical Instruments

2-5

2 Operational Theory Model 3020M

2.5 Electronics and Signal Processing

The Model 3020M Percent Oxygen Analyzer uses an 8031 microcontroller with 32 kB of RAM and 128 kB of ROM to control all signal processing, input/output, and display functions for the analyzer. System power

is supplied from a universal power supply module designed to be compatible

with most international power sources. See chapter 5 Maintenance for the

location of the power supply and the main electronic PC boards. The Paramagnetic Sensor has its own dedicated universal 24V power supply that

feeds the sensors internal heater and electronics.

The signal processing electronics including the microprocessor, analog

to digital, and digital to analog converters are located on the main PCB, on

the front door (see figure 5-1). The preamplifier board is mounted on top of

the motherboard. These boards are accessible by opening the front door of

the explosion proof enclosure. Figure 2-5 is a block diagram of the Analyzer

electronics.

In the presence of oxygen the chamber is rotated in the magnetic field,

but the cell generates a current to countertorque the oxygen action. This

current is converted to a voltage, which is preamplified in the sensor internal

electronics.

The preamplified signal (0-1 Volt) is fed to the 3020M amplifier for

minor processing.

The digital concentration signal along with input from the control panel

is processed by the microprocessor, and appropriate control signals are

directed to the display, alarms and communications port. The same digital

information is also sent to a 12 bit digital to analog converter that produces

the 4-20 mA dc and the 0-1 V dc analog concentration signal outputs, and

the analog range ID outputs.

Signals from the power supply are also monitored, and through the

microprocessor, the system failure alarm is activated if a malfunction is

detected.

2.6 Temperature Control

2-6

For accurate analysis the sensor temperature is controlled internally at

55OC.

Teledyne Analytical Instruments

Loading...

Loading...