Teledyne 3010 Installation And Operation Manual

3010 Flow Transmitter

Part #60-3403-171 of Assembly #60-3404-070

Copyright © 2001. All rights reserved, Teledyne Isco

Revision V, February 2012.

Installation and Operation Guide

3010 Flow Transmitter

CAUTION

WARNING

DANGER

Safety

3010 Flow Transmitter

Safety

General Warnings Before installing, operating, or maintaining this equipment, it is

imperative that all hazards and preventive measures are fully

understood. While specific hazards may vary according to

location and application, take heed in the following general

hygiene mishaps. In all cases use good laboratory practices and

standard safety procedures.

Hazard Severity Levels This manual applies Hazard Severity Levels to the safety alerts,

These three levels are described in the sample alerts below.

Cautions identify a potential hazard, which if not avoided, may

result in minor or moderate injury. This category can also warn

you of unsafe practices, or conditions that may cause property

damage.

Warnings identify a potentially hazardous condition, which

if not avoided, could result in death or serious injury.

DANGER – limited to the most extreme situations

to identify an imminent hazard, which if not

avoided, will result in death or serious injury.

iii

3010 Flow Transmitter

Safety

Hazard Symbols The equipment and this manual use symbols used to warn of

hazards. The symbols are explained below.

Hazard Symbols

Warnings and Cautions

The exclamation point within the triangle is a warning sign alerting you of

important instructions in the instrument’s technical reference manual.

The lightning flash and arrowhead within the triangle is a warning sign alerting you of “dangerous voltage” inside the product.

Symboles de sécurité

Ce symbole signale l’existence d’instructions importantes relatives au

produit dans ce manuel.

Ce symbole signale la présence d’un danger d’électocution.

Warnungen und Vorsichtshinweise

Advertencias y Precauciones

Das Ausrufezeichen in Dreieck ist ein Warnzeichen, das Sie darauf

aufmerksam macht, daß wichtige Anleitungen zu diesem Handbuch

gehören.

Der gepfeilte Blitz im Dreieck ist ein Warnzeichen, das Sei vor “gefährlichen

Spannungen” im Inneren des Produkts warnt.

Esta señal le advierte sobre la importancia de las instrucciones del manual

que acompañan a este producto.

Esta señal alerta sobre la presencia de alto voltaje en el interior del

producto.

iv

3010 Flow Transmitter

Table of Contents

Section 1 Introduction

1.1 Manual Organization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1.2.1 Interfacing Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3 Ultrasonic Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.3.1 SETUP Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.3.2 Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.4 Controls, Indicators, and Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.5 Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Section 2 Programming

2.1 Operating Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2.1.1 Ultrasonic Level Sensor Theory and Applications . . . . . . . . . . . . . . . . . . . . 2-1

2.1.2 Error Factors Affecting Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

2.1.3 Error Factors and Flow Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.1 Keypad Layout and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.2.2 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.2.3 Power Failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

2.3 Programming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.1 Programming Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.3.2 List of Program Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

2.3.3 Programming Sequence in Detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.3.4 Equations Used in Flow Conversion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2.3.5 Default Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

2.4 Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.4.1 Programming for a Parshall Flume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

2.4.2 Programming for a Cipolletti Weir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

2.4.3 Programming with the Equation (Device #34) . . . . . . . . . . . . . . . . . . . . . . 2-22

2.4.4 Rectangular Weirs with End Contractions . . . . . . . . . . . . . . . . . . . . . . . . 2-26

2.4.5 Programming Example for a Rectangular Weir with End Contractions . 2-27

Section 3 Installation

3.1 General Comments on Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.1 Location of the Flow Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3.1.2 Portable Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2 General Wiring Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.1 Mounting and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

3.2.2 Connection to a Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.3 Voltage Selector Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

3.2.4 Wiring the Ultrasonic Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

3.3 Connection to an Isco Sampler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

3.4 Connection to a Non-Isco Sampler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.5 Connection to Other Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

3.6 Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

3.7 Installing the Ultrasonic Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

v

3010 Flow Transmitter

Table of Contents

Section 4 Options and Accessories

Section 5 Maintenance and Troubleshooting

3.7.1 Mounting the Ultrasonic Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

3.7.2 Minimization of Level Measurement Errors . . . . . . . . . . . . . . . . . . . . . . . . 3-9

4.1 High-Low Alarm Relay Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.1.1 Setting the Limit Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4.1.3 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4.2 Connection to External Serial Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4.3 Remote Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.3.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

4.4 Extension Cables for the Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.4.1 Connecting the Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.5 Quick-Disconnect Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.6 4-20 mA Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

4.6.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

5.1 Care of the Flow Transmitter Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.1 Care of the Case Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.1.2 Preventing Moisture Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

5.2 Care of the Sensor and Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.2.1 Cable Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3 Mechanical and Electrical Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.1 Accessing the Terminal PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.3.2 Accessing the Flow Transmitter PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

5.4 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.5 Display Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.6 Troubleshooting Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

5.6.1 If Serious Problems Occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.6.2 Processor Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.6.3 Preliminary Troubleshooting Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

5.6.4 Precautions for Servicing AC-Powered Equipment . . . . . . . . . . . . . . . . . . . 5-5

5.6.5 Precautions for Servicing CMOS Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

5.6.6 Call for Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.7 Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.7.1 Terminal Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.7.2 CPU Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

5.7.3 Ultrasonic Board Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Appendix A Replacement Parts List

A.1 Replacement Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

A.2 Accessories List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Appendix B General Safety Procedures

B.1 Practical Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.1.1 Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

B.1.2 Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.1.3 Adverse Atmospheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.1.4 Entering Manholes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

B.1.5 Traffic Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.1.6 Falling Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.1.7 Removing the Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

B.1.8 Other Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

vi

3010 Flow Transmitter

Table of Contents

B.1.9 Emergencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.1.10 Field Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.2 Lethal Atmospheres in Sewers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

B.3 Hazardous Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

List of Figures

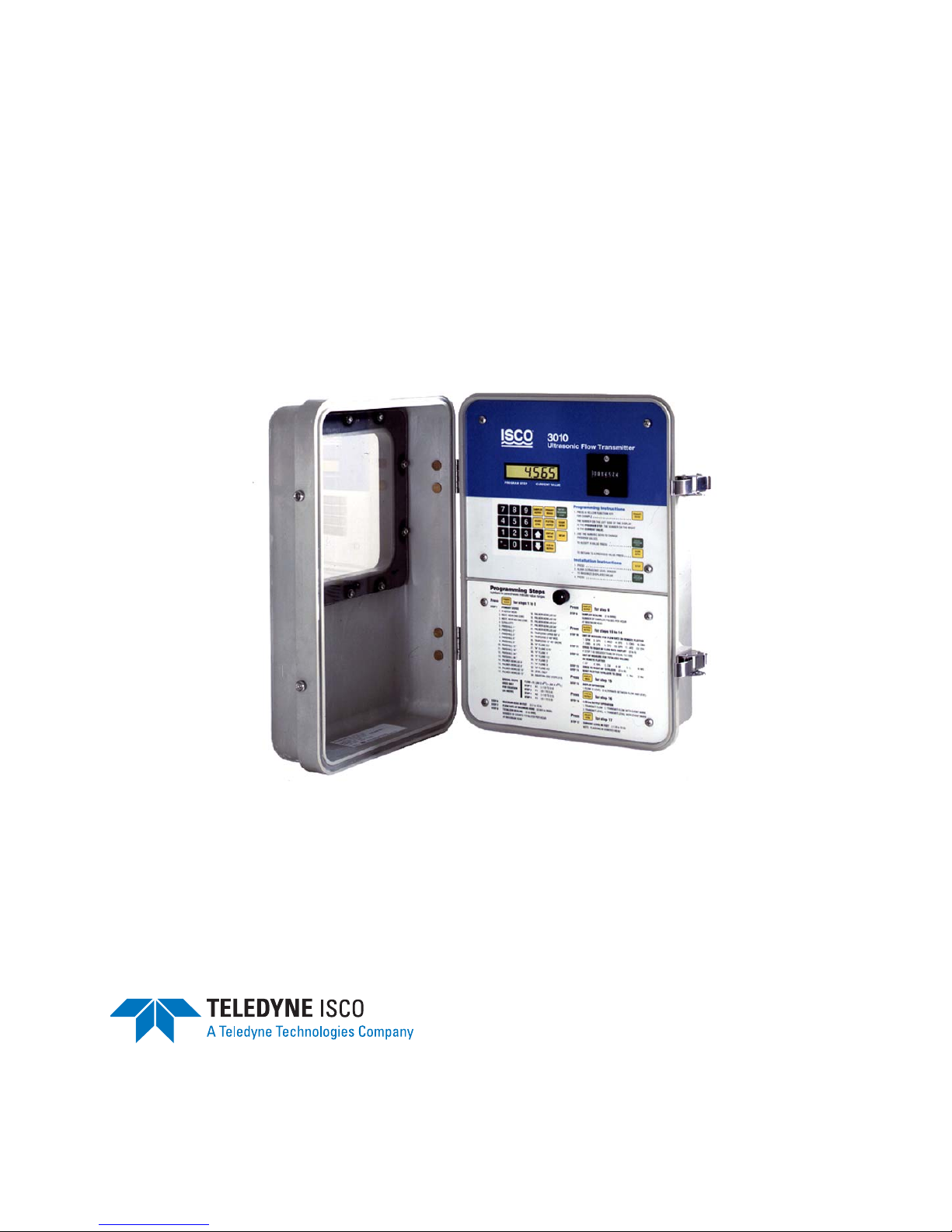

1-1 Model 3010 Flow Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

1-2 Ultrasonic Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Interior View of Transmitter, Showing Terminal Blocks . . . . . . . . . . . . . . . . . . . 1-5

2-1 Simplified 3010 Programming Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

3-1 View of Case Latch, Showing Lock Shackle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

3-2 USLS Floor Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

3-3 Foam and Oil on the Surface of the Stream . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-4 Small Pipes and Narrow Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

3-5 Ultrasonic Level Sensor “Dead Band” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

3-6 USLS Mounting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

3-7 USLS Mounting Methods (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

4-1 High-Low Alarm Relay Box (Cover Removed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

4-2 Interconnection of 3010 and Alarm Boxe(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

4-3 Remote Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

5-1 Terminal Printed Circuit Board Component Layout . . . . . . . . . . . . . . . . . . . . . . 5-11

5-2 CPU PCB Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12

5-3 Ultrasonic PCB Component Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-13

List of Tables

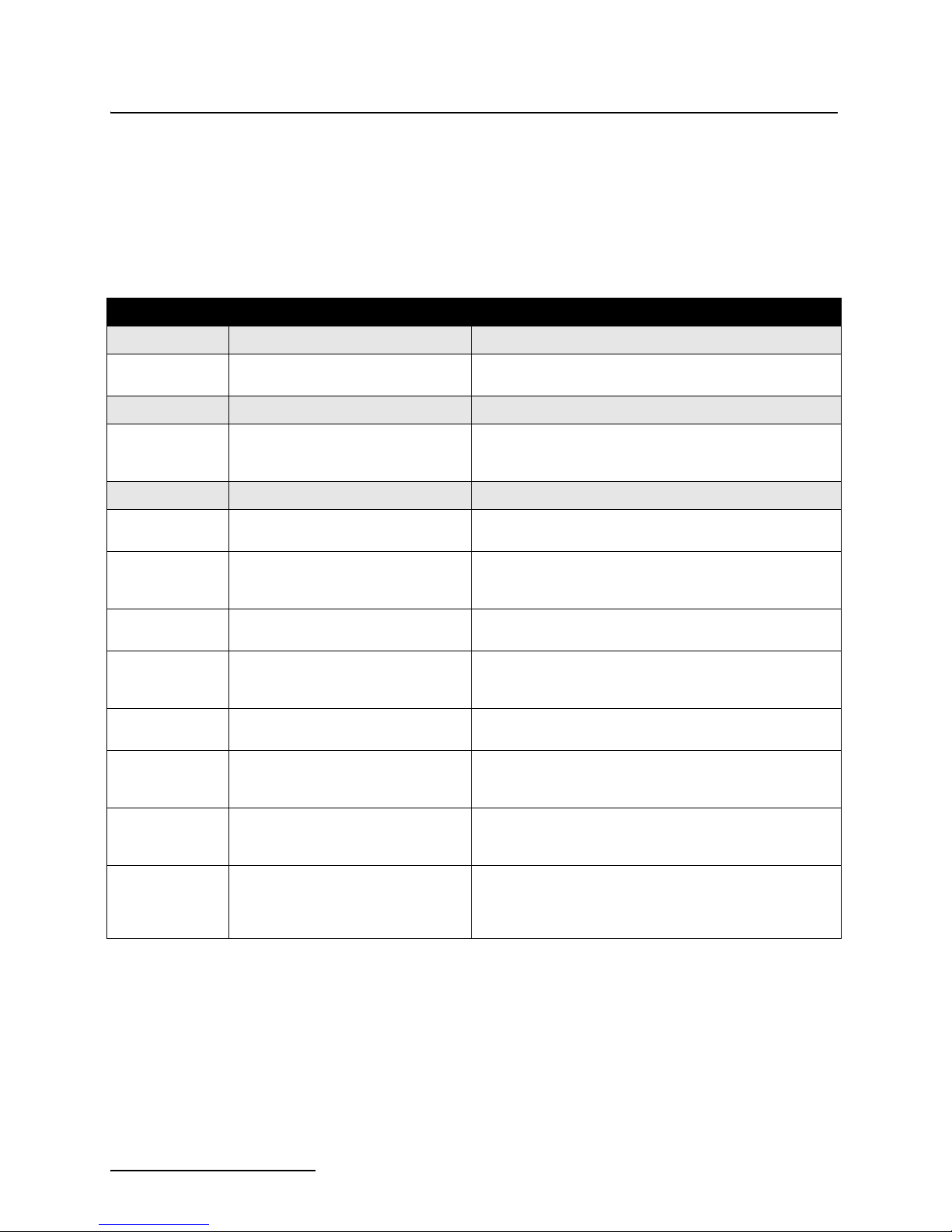

1-1 3010 Controls, Indicators, and Wiring Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2 Technical Specifications for the Model 3010 Flow Transmitter . . . . . . . . . . . . . . 1-6

1-3 Technical Specification for the USLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

2-1 Primary Measuring Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-2 Equations Used in the Model 3010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-3 Values of N1 for Flow Rate in CFS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

2-4 Values of N2 for Flow Rate in CFS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-27

4-1 3000 Series Wiring Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

B-1 Hazardous Gases . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

vii

3010 Flow Transmitter

Table of Contents

viii

3010 Flow Transmitter

Section 1 Introduction

The first section of the 3010 Flow Transmitter instruction

manual provides a general introduction to the instrument. It

includes a brief discussion of the organization of the manual, an

overall description of the flow transmitter and ultrasonic level

sensor (USLS), and technical specifications.

1.1 Manual Organization The purpose of this manual is to provide the information nec-

essary to program, operate, maintain, and service the 3010 Flow

Transmitter. To accomplish this, the manual is organized into

five sections and an appendix. This first section is a general

introduction to the flow transmitter. The second section contains

information on operation, programming, and some examples of

programming for specific objectives. The third section provides

installation instructions. The fourth section describes available

options and their uses. The fifth section contains maintenance

information and servicing tips to assist you in correcting

problems that may occur. Appendix A contains lists of

replacement parts and accessories.

1.2 Description The 3010, shown in Figure 1-1, uses ultrasonic level mea-

surement. You normally use the flow transmitter with some type

of primary measuring device to measure flow rate in an open

channel. The 3010 uses level-to-flow rate conversions derived

from a stored equation, covering the majority of open channel

flow measurement situations. If needed, you can enter the coefficients and powers of the flow equation. However, you can use

most standard weirs and flumes without the need for the

equation. A 6-digit LCD (Liquid Crystal Display) prompts you

through setup, displays the choices for the current programming

step, and displays level and/or flow rate.

Figure 1-1 Model 3010 Flow Transmitter

1-1

3010 Flow Transmitter

Note

Section 1 Introduction

1.2.1 Interfacing Equipment The 3010 is compatible with the following Teledyne Isco

equipment:

• 3700 series samplers, 6700 series samplers, and GLS

and Glacier compact samplers

Options and Accessories:

• Resettable 7-digit mechanical flow totalizer. (A nonresettable flow totalizer is a standard feature of the 3010.)

• High-Low Alarm Relay Box

• Quick-Disconnect Box

• Extension Cables for the Ultrasonic Level Sensor

• Ultrasonic Level Sensor Cable Clamp and Spreader Bar

• Ultrasonic Mount, Calibration Target, Cable

Straightener, and Sunshade

• Remote Totalizer

• Flow Transmitter-to-Sampler Connect Cable

1.3 Ultrasonic Level

Sensor

Throughout this manual, we describe various accessories

available for the 3010. We have listed the part numbers for all

these items on an Accessory List, that you will find at the back

of Appendix A Replacement Parts List. You can obtain part

numbers for other Teledyne Isco equipment by calling the factory.

The Ultrasonic Level Sensor, or USLS, shown in Figure 1-2, measures liquid level without contacting the flow stream. The USLS

consists of an ultrasonic transducer and associated electronics

mounted in a housing, and a shielded cable that connects the

level sensor to the flow transmitter. This cable lets you suspend

the level sensor by the cable alone over a flow stream in temporary installations. For more permanent installations, a

mounting bracket is available to attach the ultrasonic level

sensor securely to the mounting surface. The level sensor is provided with a 50-foot cable (15.2 meters). For distances greater

than 50 feet, you must use the Quick-Disconnect Box (a type of

splice box) with extension cables. The maximum distance

between the flow transmitter and the level sensor is 1,000 feet

(304.8 meters).

The USLS mounts over the flow stream, and periodically

transmits an ultrasonic pulse to the surface of the stream. The

water surface reflects the echo of the pulse back from the stream

to the level sensor. The elapsed time between pulse and return

echo is proportional to the distance from the level sensor to the

liquid surface. The 3010 uses this time/distance relationship and

a referenced “zero” point in the flow stream to calculate liquid

level. Then, by applying values specific for the primary device in

use, the 3010 calculates flow rate from the measured level. The

USLS has a temperature probe built into its housing to measure

1-2

3010 Flow Transmitter

E## ##

Section 1 Introduction

ambient air temperature. The 3010 uses this temperature measurement to compensate for inaccuracies in ultrasonic measurement caused by changes in the air temperature between the

transducer and the flow stream.

Figure 1-2 Ultrasonic Level Sensor

1.3.1 SETUP Step The 3010 has a special feature to help you correctly align the

ultrasonic level sensor. This Setup step lets you orient the ultrasonic level sensor over the flow stream while an assistant

watches the flow transmitter's display.

The number on the left represents the strength of the sensor’s

return signal, or gain. The number on the right indicates how

much noise is in the return signal due to surface roughness, etc.

(the higher the number, the less noise is present). As long as the

number on the left side of the display is increasing, the sensor is

approaching optimal alignment. When the Setup number

reaches the highest reading, the level sensor is in proper

alignment. If you continue to adjust the level sensor and the

number displayed begins to fall, you have gone past the optimal

alignment.

1.3.2 Labels The 3010 comes with a set of adhesive labels to permit the

display and the mechanical totalizer to express greater values

than the number of digits available on the display. Where

extremely large flow volumes are involved, you can add trailing

zeroes to the display to make more meaningful numbers. To

1-3

3010 Flow Transmitter

Section 1 Introduction

provide a handy reference for your programming selections,

there are adhesive labels for units of measure you can attach to

the flow transmitter.

1.4 Controls, Indicators,

and Terminal Blocks

Table 1-1 lists the controls, indicators, and terminal blocks for

wiring to the 3010 Flow Meter, and briefly describes their functions. Refer to Figure 1-3 for a view of the terminal blocks.

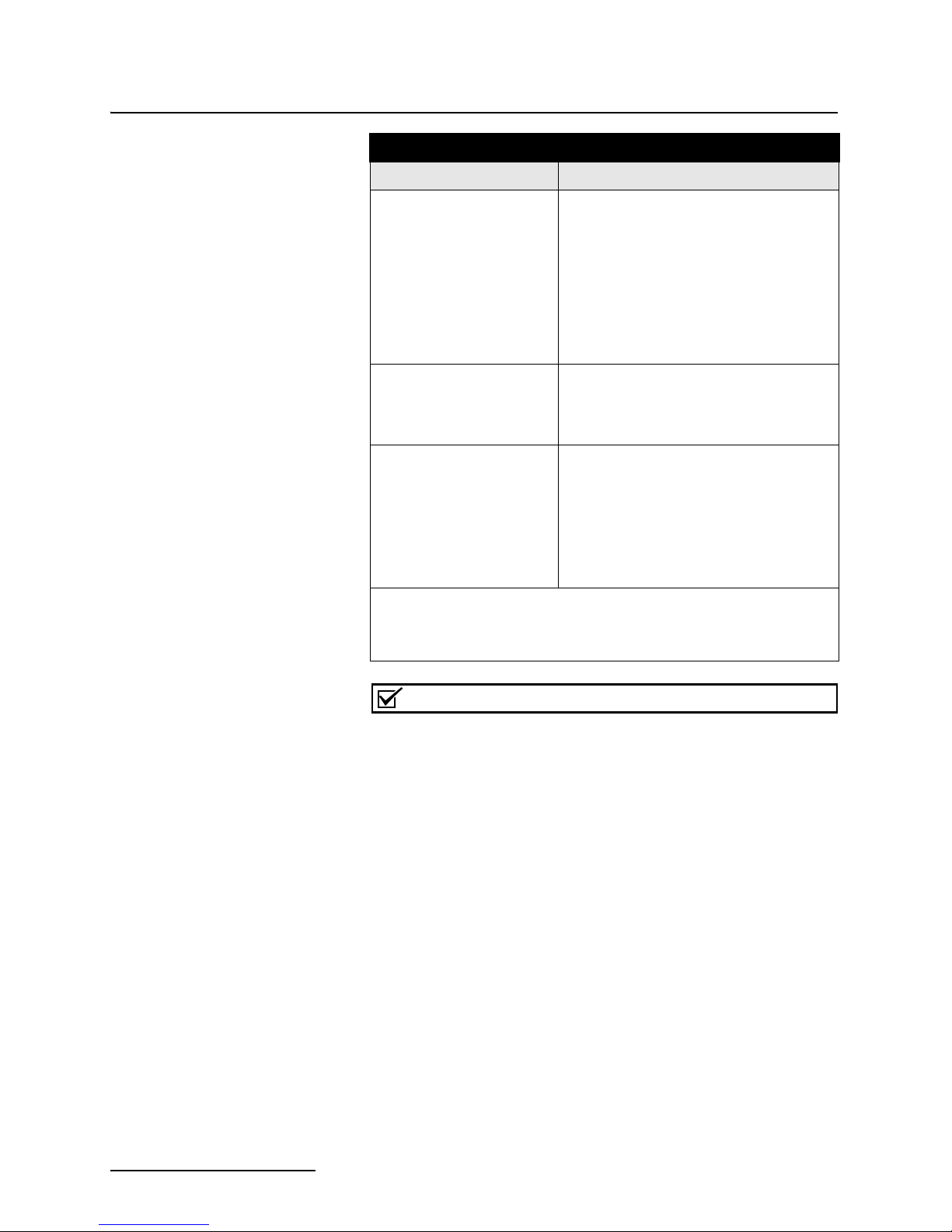

Table 1-1 3010 Controls, Indicators, and Wiring Terminals

CONTROLS SETTINGS FUNCTION

Keypad None Specific 23 key, 6-column matrix. Program flow transmitter by key-

strokes prompted by messages on the display.

INDICATORS READING FUNCTION

Display Multifunction 6-digit, 7-segment liquid crystal display (LCD). Prompts

TERMINALS TYPE FUNCTION

Power 3 #8 screws on block TS1. Large Ter -

minals 1, 2, and 3.

4-20 mA Output 2 #6 screws on block TS2. Terminals

4 and 5.

Remote Totalizer 2 #6 screws on block TS2. Terminals

6 and 7.

2312 Interface 3 #6 screws on block TS2. Terminals

8, 9, and 10.

you through program set up; displays current menu selections, displays level or flow rate.

Connects 120/240 VAC power to flow transmitter. #1 = Hot.

#2 = Ground. #3 = Neutral.

Provides standard 4-20 mA current loop output (variable

with level or flow rate) to be used to control compatible

equipment such as a chart recorder or a chlorinator.

Connects flow transmitter to external mechanical remote

totalizer.

Originally for connecting the 3010 to the Model 2312 strip

chart plotter (obsolete). Currently used for connecting to

other external serial devices or an alarm relay box.

Bottle Number

(BLT NUM)

Event Mark 2 #6 screws on TS2.

Sampler Output 2 #6 screws on TS3.

Ultrasonic Level

Sensor

and Temperature

Sensor

2 #6 screws on block TS2. Terminals

11 and 12.

Terminal 13 = + 12VDC

Terminal 14 = - Event Mark

Terminal 15 = Sampler

Terminal 16 = Dry Contact

4 #6 screws on block TS3. Terminals

20, 21, 22, and 23.

Provides bottle number input signal to flow transmitter from

an Isco automatic wastewater sampler.

Provides event mark input signal to flow transmitter from an

Isco Sampler.

Provides flow pulse from flow transmitter to flow pace an

Isco sampler.

Provides connection for ultrasonic level sensor and temperature sensor.

1-4

3010 Flow Transmitter

Section 1 Introduction

Figure 1-3 Interior View of Transmitter, Showing Terminal Blocks

1-5

3010 Flow Transmitter

Section 1 Introduction

1.5 Technical

Specifications

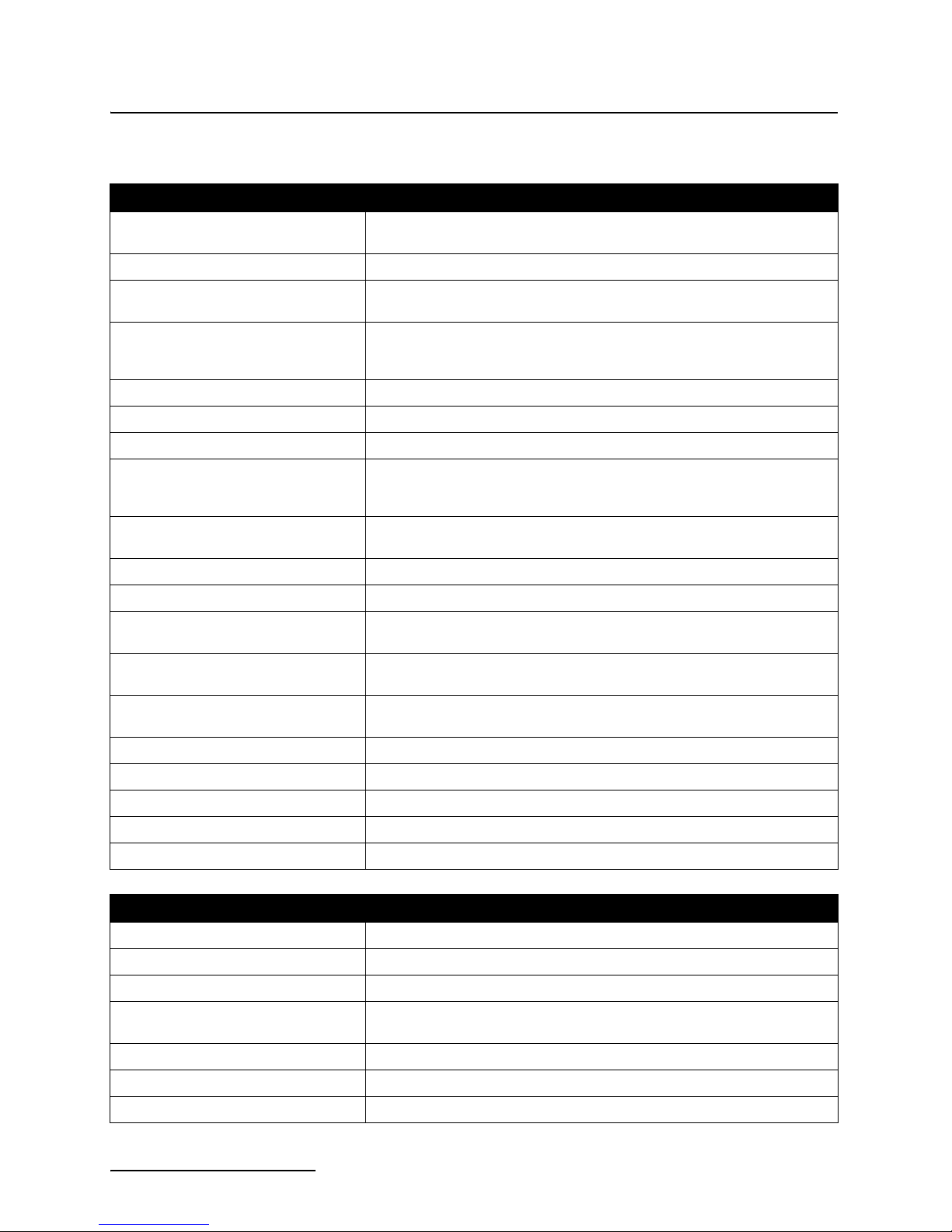

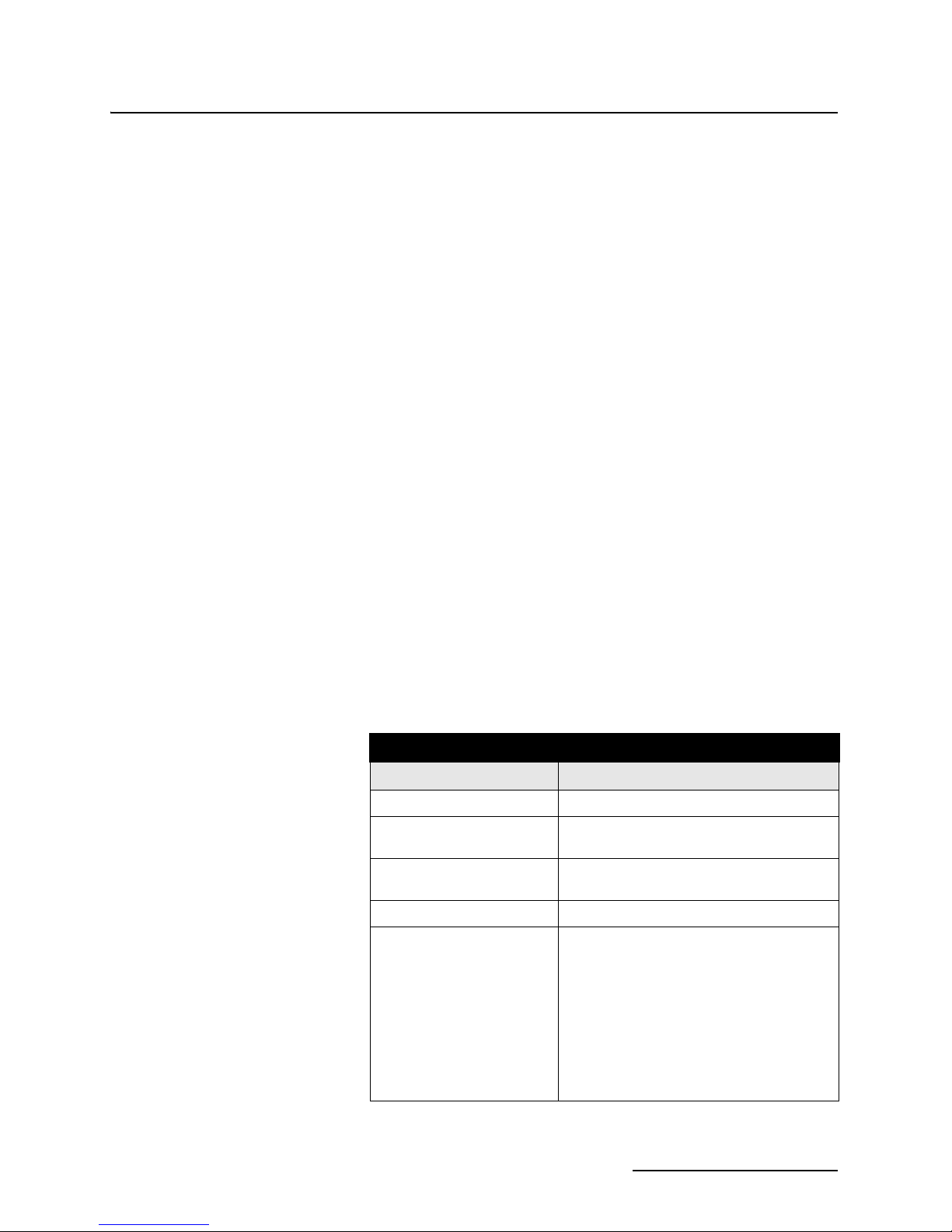

The technical specifications for the 3010 and ultrasonic level

sensor (USLS) are listed below in Tables 1-2 and 1-3.

Table 1-2 Technical Specifications for the Model 3010 Flow Transmitter

Size (H x W x D) 15

Weight 10 lbs (4.5 kg)

Material High-impact molded polystyrene structural foam.

Power 104-127 VAC, 0.075 amp, 50 to 60 Hz

Overcurrent Protection

Display 6-character, 7-segment, alphanumeric liquid crystal

Display Modes Level, flow rate, alternating

Built-in Level-to-Flow Rate Conversions Weirs: V-notch, Rectangular with/without end contractions, Cipolletti.

Level-to-Flow Rate Conversion Accuracy

Sampler Output Isolated contact closure, rated 1 amp @ 48 VDC

Sampler Input Event marks (sample events), bottle numbers

1

/4 inches x 105/8 inches x 73/8 inches

(38.7 cm x 27 cm x 18.7 cm)

Self-certified NEMA 4X enclosure.

or

210-260 VAC, 0.038 amp, 50 to 60 Hz (see Section 3)

1

/2 amp slow-blow fuse

Flumes: Parshall, Palmer-Bowlus, Trapezoidal, “H”.

Equation: Two-term power equation.

1% Full Scale

Analog Output Isolated 4-20 mA into 0 to 1,000 ohm; level or flow rate, with or without sam-

Serial Data Port Compatible with 2312 Plotter (no longer sold), High-Low Alarm Relay Box,

Compatible Isco Recording Devices Model 2410 Circular Chart Recorder (no longer sold), Model 2312 Plotter

Totalizer 7-Digit mechanical counter, non-resettable

External Totalizer Output 12 VDC pulse

Operating Temperature -20° F to 140° F (-30° C to 60° C)

Storage Temperature -50° F to 150° F (-46° C to 66° C)

Relative Humidity 0 - 100%

pler event marks. Accuracy: 1 % of full scale.

and other external serial devices.

(no longer sold)

Table 1-3 Technical Specification for the USLS

Length 6.9 inches (17.5 cm)

Diameter 3.6 inches (9.1 cm)

Weight 2 lbs, 10 oz (1.2 kg)

Range Minimum distance from sensor face to liquid: 24 inches (0.61 meters)

Maximum distance form sensor face to liquid: 12 feet (3.6 meters)

Span 0 to 10 feet (0 to 3 meters)

Operating Temperature -22 ° F to 140°F (-30° C to 60° C)

Storage Temperature -40° F to 158° F (-40° C to 70° C)

1-6

3010 Flow Transmitter

Section 2 Programming

The following section explains how to program the flow transmitter. There are also sections on the operating theory, control

and indicator descriptions, setup procedures, and programming

examples.

2.1 Operating Theory When measuring flow rate, the 3010 normally uses a primary

measuring device (weir or flume) or other open channel flow

arrangement, where a known relationship exists between level

and flow rate. The level measuring device is an Ultrasonic Level

Sensor that measures the liquid level in the flow stream. The

flow transmitter electronically converts the level reading into a

properly scaled flow rate value. The flow transmitter also provides standard flow-related output signals to be used for:

• Flow-paced wastewater sampling.

• Recording flow rate information on an external

printer/plotter, circular chart recorder, or other external

serial device

• Connection to a 4 - 20 mA compatible device

• Tripping remote high and low alarm relays

The flow transmitter contains microprocessor-controlled circuitry to calculate level and flow rates from the signals produced

by the level sensor. It stores programming instructions and

operates the display. A backlit alphanumeric liquid crystal

display (LCD) shows level and flow rate information. The display

also prompts programming of the flow transmitter during initial

setup or subsequent changes. Auxiliary equipment used with the

3010 connects to the terminal blocks on the printed circuit board

in the bottom section of the flow transmitter case.

2.1.1 Ultrasonic Level

Sensor Theory and

Applications

The Ultrasonic Level Sensor (USLS) is mounted over the flow

stream. It measures liquid level by emitting an ultrasonic pulse

and then measuring the time it takes for the echo to return from

the surface of the liquid. The USLS consists of an enclosure with

a single transducer acting both as the pulse transmitter and the

echo receiver. Since the speed of the pulse through the air varies

with temperature, the level sensor has temperature compensation built in. The microprocessor program automatically compensates for speed-of-sound changes caused by air temperature

changes.

Transducer Operation – The USLS emits a strong ultrasonic

pulse several times a second. After transmitting the pulse, the

flow transmitter electronically switches the level sensor transducer into a receiver or microphone, ready to receive or hear the

2-1

3010 Flow Transmitter

Section 2 Programming

echo reflected back from the flow stream. The transducer converts the echo sound into a small pulse that the circuitry in the

flow transmitter amplifies and detects to produce an “echo

received” signal. The time between the transmitted pulse and

received echo is proportional to the distance between the transducer and the surface of the stream. The flow transmitter uses

this distance to determine the liquid level in the stream.

Validity Tests and Error Display – The flow transmitter subjects the measured level to several validity tests. If the unit

cannot obtain a valid level, it repeats the process. Meanwhile, the

last good level reading will continue to appear on the display. If,

after approximately four minutes, the flow transmitter cannot

obtain a valid reading, the 3010 will show EE 80 on the display.

In such instances, it may be necessary to realign the level sensor

or check the operation of the flow transmitter.

Ambient Air Temperature Factor – The 3010 uses an ultrasonic distance measurement technique based on the speed of

sound in air. Since the speed of sound in air varies with temperature (approximately 1% for 10× of variation), you must provide

compensation. The level sensor uses the air temperature sensor

and microprocessor-based compensation to accurately account

for air temperature variations. See also Section 2.1.2.

Return Echo Amplifier Compensation – The signal strength

of the returned echo depends on several factors including the distance from the transducer to the water surface. For every

1

2

/2-foot increase in the distance between the transducer and the

liquid surface, the strength of the returned echo decreases by

half, so designers must compensate the gain of the return echo

amplifier for distance. As the distance increases between the

transducer and the liquid surface, the gain of the echo amplifier

increases with time to compensate for the decreasing signal

strength of the echo. This type of amplifier, whose gain characteristic is based on a repeating time interval, is referred to as a

“ramp gain” amplifier.

2.1.2 Error Factors Affecting

Performance

2-2

Several external factors can influence both the initial pulse and

reflected sound wave, causing the ultrasonic measurement

system to produce errors. These factors fall broadly into two

classes.

Velocity Errors – These errors result when the flow transmitter is unable to accurately calculate the velocity of sound.

They are “proportional” errors, in that the degree of error

increases as the distance between the level sensor and the

surface of the flow stream increases.

Echo Detection Errors – These errors arise from problems the

flow transmitter can have measuring the time between transmitting the ultrasonic pulse and receiving the echo. Anything

that absorbs sound can cause these errors. This makes the echo

amplifier detect the returned signal either earlier or later than

intended in the design of the “ramp gain” amplifier. Errors of this

3010 Flow Transmitter

Velocity 1050 1 Temperature459.67+=

Section 2 Programming

sort will generally be of an “absolute” nature; the distance

between the transducer and the water will not affect them to any

great extent.

2.1.3 Error Factors and Flow

Compensation

Following are specific factors affecting the accuracy of the 3010

with the measures used for compensation of the more significant

factors.

Barometric Pressure – The velocity of sound is essentially

independent of barometric pressure. Changes in barometric

pressure provide no significant cause of error.

Beam Angle – The flow transmitter must only respond to surfaces within a specific area. The transducer can only “see” items

inside a “cone” whose apex is the ultrasonic transducer. The

beam angle is the angle across this cone. If the beam angle is too

wide, the flow transmitter will detect unwanted surfaces, such as

the walls of the channel. If the beam angle is too narrow, setup of

the installation is difficult and the flow transmitter may never

detect an echo.

Humidity – The velocity of sound varies only slightly with

humidity (maximum 0.35% at 68°F). Because the effect is small,

the 3010 does not provide compensation for humidity. Humidity,

however, does have an effect on the reduction of the echo. Under

extreme humidity conditions, the reduction of the sound wave

may be inconsistent with the characteristics of the “ramp gain”

amplifier, causing an echo detection error.

Noise – Background noise can interfere with the operation of the

flow transmitter. The unit must filter out this noise, or it may

trigger on the noise rather than the returned echo. The 3010 uses

a tuned circuit to filter out unwanted noise outside the operating

frequency. Noise in the operating frequency range (49 kHz) can

render the system unstable. The unit uses software algorithms to

eliminate most sporadic noise pulses occurring within the flow

transmitter's operating frequency range.

Surface Objects – Objects or foam floating on the surface of the

flow stream can absorb or weaken the ultrasonic pulse. If the

foam or material reduce the pulses enough, the unit will lose the

echo altogether. In less severe cases, there may be an echo

detection error.

Temperature – The velocity of sound at a given temperature

may be approximated by the following equation:

Where velocity is in feet per second and temperature is in

degrees F. Temperature changes have a significant effect on the

velocity of sound (approximately 7% between 32°F and 104°F).

This variable is significant enough to require compensation. Consequently, the 3010 provides temperature compensation. There is

a temperature sensor embedded in the level sensor. However, the

temperature of the level sensor and air may not be exactly the

same, and the temperature sensor cannot measure temperature

2-3

3010 Flow Transmitter

Note

Section 2 Programming

perfectly. As a result, the equations used to calculate the velocity

of sound in air are approximations, including the equation shown

above.

Waves – Waves or extreme turbulence on the surface of the flow

stream can deflect the sound energy so it does not return to the

transducer. Waves may also make the sound return to the transducer by an indirect path. In the first case, the flow transmitter

will not receive an echo. In the second case, the additional time

lapse will cause an echo error that will appear as an incorrect

level reading. The 3010 has a software algorithm to reject occasional readings that deviate substantially from normal. However,

if the waves are severe, the flow transmitter will not function and

will indicate a “no echo” condition.

Wavelength – You can determine the wavelength of sound by

dividing the velocity of the sound by the frequency. The frequency

of the 3010 is about 49 kHz. You can find the length of a 49 kHz

sound wave by dividing 1,125 feet /second by 49,000, which is

0.02296 feet or 0.276 inches.

Wave (Echo) Detect Error – Under ideal conditions the transducer can detect the same wave front of the returning echo.

However, any noise or abnormal attenuation may cause some

transducers to detect an earlier or a later wave. When the attenuation of the returned echo does not match the gain slope of the

amplifier, the circuit will eventually detect a different cycle of the

returned echo as the distance changes. The impact of this

wave-detect error is determined by the wavelength.

Wind – Wind can blow the sound away or significantly reduce

the intensity of the returned echo. Narrow beam angles, advantageous for measuring small flow streams, are a disadvantage in

this situation. Likewise, greater distances to the surface of the

flow stream are more affected by wind.

2.2 Controls and

Indicators

2.2.1 Keypad Layout and

Functions

2-4

You can reduce the effects of these factors substantially by following the suggestions for ultrasonic level sensor installation

found in Section 3.7.

(Arrow Down) – Use this key in the Level Adjust step of the

program; you can use it in place of the number keys to decrease

the level shown on the display.

(Arrow Up) – Use this key with the display in the Level

Adjust step of the program; you can use it instead of the number

keys to increase the level shown on the display.

CLEAR ENTRY – This key lets you return to a previous entry of

a program step. Pressing the key twice in succession will exit you

from the program.

3010 Flow Transmitter

Section 2 Programming

. (DECIMAL) – Use this key with the number keys when

entering numeric values into the program.

ENTER/PROGRAM STEP – Pressing this key will allow you to

enter changes made to the program into memory. To access the

program, first press one of the yellow Function Keys (See below.)

Pressing one of the Function Keys stops the program and allows

you to make changes. After the you make the change and it

appears on the display, pressing ENTER/PROGRAM STEP will

enter the change into memory. It is also possible to step through

the program retained in memory by pressing this key. The

number of the program step will appear on the left side of the

display and the number of the current selection (or value

entered) will appear next to it.

NUMBER KEYS – Use the number keys to enter numeric

values into the program. You can also use them to make a

selection from the options displayed on the label.

+

- (PLUS/MINUS) – Use this key to enter positive or negative

numbers when programming an equation.

FUNCTION KEYS – The yellow keys let you enter the program

of the 3010 at specific steps so you can change selections or

numerical values. These keys govern specific programming steps,

and will be described elsewhere. Refer to Section 2.3.3 for the

detailed descriptions of the Function Keys.

2.2.2 Display The flow transmitter display shows programming choices. After

you complete programming and installation, the display shows

the present flow rate and/or level. There are three operating

modes for the display: level, flow rate, or an alternation between

the two. You can see the display through the window when the

door is closed. The display is a 6- digit, 7-segment liquid crystal.

The letter H on the left side of the display indicates level (or

Head). For better visibility in low light conditions, the LCD is

lighted.

2.2.3 Power Failures If there is a power failure, the LCD will blank and the flow trans-

mitter will stop operating. Momentary power failures (less than

three seconds) should not affect the operation of the unit, as

power stored in the filters will provide some carryover for a brief

period of time. However, if power is off long enough for the

display to blank, flow pulses to the sampler will stop, as will the

mechanical totalizer and the totalizer signal sent to the external

plotter, which will be reset. The unit will not be able to recognize

changes in level during the time power is off. However, memory

will retain the program selections made during setup and when

power is restored, you won't need to reprogram the flow transmitter.

2-5

3010 Flow Transmitter

Section 2 Programming

2.3 Programming Enter program quantities and control certain functions through

the keypad. The number of the selected entry appears on the

display. The display also indicates operational status, and guides

you through the programming sequence by showing the step programmed. Each time you press a key, the unit will beep.

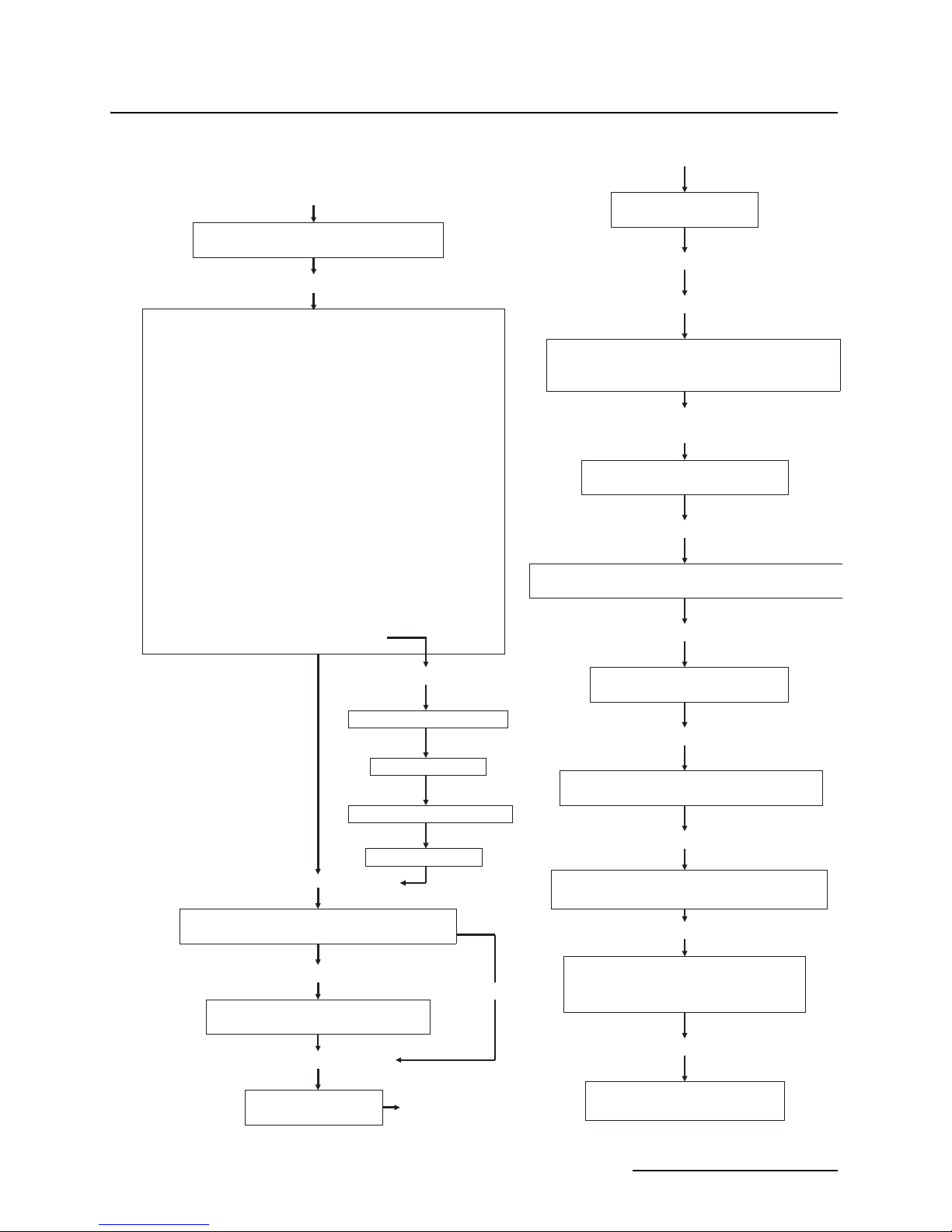

Refer to Figure 2-1 for a flowchart showing programming. At the

back of this manual is a worksheet on which you may write

program selections.

2.3.1 Programming

Overview

Remember that the flow transmitter always has a program in it,

stored in memory, even if it is only the default program installed

at the factory. To program the 3010, press the yellow FUNCTION

KEYS. The display will show the step number on the left and the

number of the choice currently selected (or the numerical value

entered for steps requiring a value) on the right. You will not

need to program all steps. For example, if there is no remote

plotter, you would skip Steps 11 to 15, all involved with operation

of the plotter.

The program steps are printed on the flow transmitter label, and

normally programming proceeds in a logical manner, starting

with Step 1, which sets level in feet or meters. Step 2 selects the

primary measuring device. Then you select maximum head, flow

rate at maximum head, and totalizer scaling. If you aren't using

any other equipment with the 3010, you need to program only

Step 16 PROGRAM OPERATION, and 18 LEVEL ADJUST. If

you are installing the unit for the first time, use the SETUP key

to optimize transducer alignment. Then you use the LEVEL

ADJUST key to calibrate the level sensor.

You only make selections in Steps 10 through 15 and Step 17

when the flow transmitter is connected with associated

equipment. Step 10 governs the relationship between the flow

transmitter and a sampler. Steps 11 - 15 control the output to an

Isco High-Low Alarm Relay Box (a device to trigger other

equipment when flow exceeds or falls below a pre-set value), or

an external serial device.

Step 17 determines the operation of the 4-20 mA current loop

output. Examples of devices that operate from the 4-20 mA

current loop are the Isco Model 2410 Circular Chart Recorder

(discontinued) and process equipment, such as a chlorinator.

After you have installed and programmed the flow transmitter

the first time, it is not necessary to completely reprogram the

unit to enter any changes. Instead, simply select the yellow

function key where you want to make a change and press

ENTER until the desired step is reached; then enter the change.

Automatic Program Advance – After you press ENTER, the

display will automatically advance to the next step and show the

current choice or value entered for that step; the process continues until you have made selections for all steps necessary to

complete the step sequence you have selected, or you press the

CLEAR ENTRY key twice to exit the program.

2-6

3010 Flow Transmitter

Note

Note

Note

Section 2 Programming

Note that you can do all programming for the 3010 in the shop,

except for Setup (concerned with sensor alignment) and the

Adjust Level step, which you must do at the job site after completing the installation.

2.3.2 List of Program Steps Following is a list of the program steps used in the 3010 along

with the choices available or applicable range of values. After the

list there is a detailed explanation of the purpose for each step

and the choices offered.

1. Units of Measure for Level (Feet or Meters).

2. Primary Device (See list of devices in Table 2-1 or refer to

flow transmitter front panel label.)

Steps 3 to 6 are programmed only if #34, Equation, is chosen

in Step 2.

3. N1 (–4,999 to 4,999)

4. P1 (0.1 to 3.0)

5. N2 (–4,999 to 4,999)

6. P2 (0.1 to 3.0)

7. Maximum Head in — (0.1 to 12.0 Feet) (0.03 to 3.66

Meters)

8. Flow Rate at Maximum Head (0.001 to 9999)

9. Totalizer Scaling (Number of counts totalized per hour of

flow at maximum head; 0-9,999.)

Program step 10 only if the flow transmitter is connected to a

sampler.

10. Sampler Scaling (Number of sampler pulses per hour at

maximum head; 0-9,999.)

Program steps 11 to 15 only if there is a remote plotter or other

serial device installed.

11. Unit of Measure for Flow Rate on Remote Plotter

1. GPM 2. GPS 3. MGD 4. CFS 5. CMS 6. CMH

7. CMD 8. LPS 9. CFD 10. GPH 11. AFD 12. CFH

12. Zeros to Right of Flow Rate Display (0 to 6) if value of Step

7 is 1000

13. Unit of Measure for Totalized Volume on Remote Plotter

1. CF 2. GAL 3. CM 4. AF 5. L 6. MG

14. Zeros to Right of Totalizer (0 to 9)

15. Reset Plotter Totalizer to Zero (1. Yes 2. No)

2-7

3010 Flow Transmitter

Note

Section 2 Programming

16. Display Operation

(1. Flow rate 2. Level 3. Alternate between the two)

Program step 17 only if the 3010 controls other external process equipment which operates from the standard 4–20 mA

current loop.

17. 4–20 mA Output Operation (level, flow rate, with or without event mark.)

1. Transmit Flow Rate 2. Transmit Flow Rate with Event

Mark

3. Transmit Level 4. Transmit Level with Event Mark

18. Adjust Level – Current Level in: (Feet –1.0 to 12.5) (Meters

–0.31 to 3.81)

2.3.3 Programming

Sequence in Detail

Following is an explanation for each of the program steps from

the list above.

Step 1 – The first step determines whether the flow transmitter

displays level in feet or meters.

Step 2 – In this step of the programming sequence, identify the

primary measuring device used; then choose the number

referring to that device from the list printed on the label or in

Table 2-1. The 3010 supports 32 common primary measuring

devices. If you wish to use the flow transmitter to measure level

only, select #33. If you want to use the general flow equation,

select #34, and continue to Step 3.

2-8

3010 Flow Transmitter

Section 2 Programming

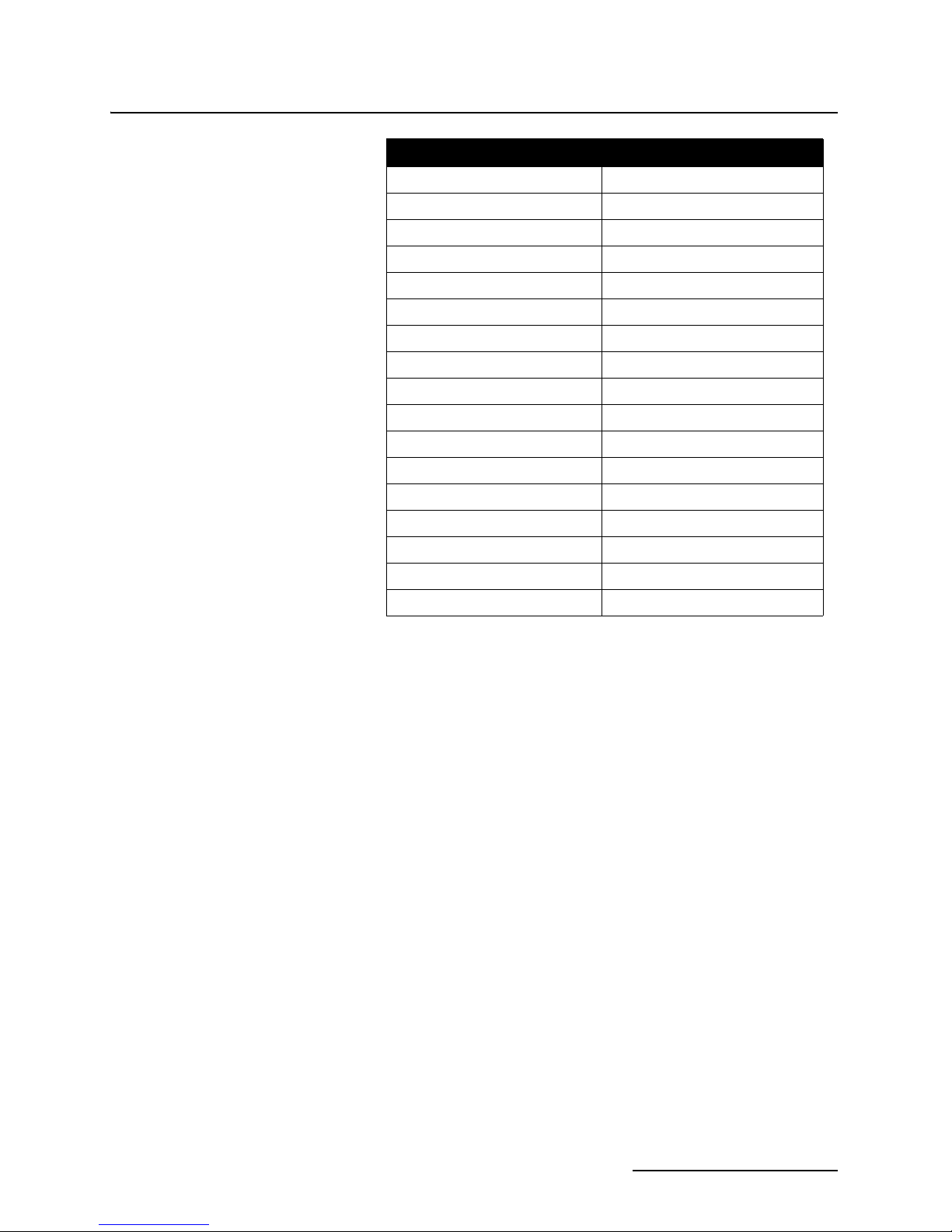

Table 2-1 Primary Measuring Devices

1. V-NOTCH WEIR 18. PALMER-BOWLUS 15”

2. RECT. WEIR END CONT. 19. PALMER-BOWLUS 18”

3. RECT. WEIR NO END CONT. 20. PALMER-BOWLUS 24”

4. CIPOLETTI 21. PALMER-BOWLUS 30”

5. PARSHALL 1” 22. PALMER-BOWLUS 48”

6. PARSHALL 2” 23. TRAPEZOID LARGE 60 ° V

7. PARSHALL 3” 24. TRAPEZOID 2” 45° WSC

8. PARSHALL 6” 25. TRAPEZOID 12” 45° SRCRC

9. PARSHALL 9” 26. “H” FLUME 0.5’

10. PARSHALL 12” 27. “H” FLUME 0.75’

11. PARSHALL 18” 28. “H” FLUME 1’

12. PARSHALL 24” 29. “H” FLUME 1.5’

13. PARSHALL 36” 30. “H” FLUME 2’

14. PALMER-BOWLUS 6” 31. “H” FLUME 3’

15. PALMER-BOWLUS 8” 32. “H” FLUME 4.5’

16. PALMER-BOWLUS 10” 33. LEVEL ONLY

17. PALMER-BOWLUS 12” 34. EQUATION (SEE STEPS 3-6)

Steps 3 to 6 – These steps will only appear on the display and be

used when you select #34, Equation. These steps allow you to

program the values N1, P1, N2, and P2 for the general flow

equation:

Q (flow rate) = K x (N1 x H

P1

+ N2 x HP2)

See Section 2.4.3 for a detailed discussion about the equation.

With any choice but #34 in Step 2, the program advances automatically to Step 7.

Step 7 - Maximum Head – The 3010 will request entry of a

value for MAXIMUM HEAD. The display will show the value

already in memory. You can enter possible values from 0.1 to 10

feet (0.31 to 3.04 meters). Note that you should always select a

value for maximum head that is reasonable for your particular

application, rather than the maximum value allowable, as the

accuracy of the level-to-flow rate conversion is based on this

value.

Step 8 – Step 8 requests entry of flow rate at maximum head.

Values range from of 0.001 to 9999. Remember to base the flow

rate at maximum head on the value for maximum head you

entered in Step 7, rather than the maximum head allowable for

the device. This information is available from the manufacturer

of the primary measuring device used. The information is also

available from tables published for specific devices in the

Teledyne Isco Open Channel Flow Measurement

Handbook.

2-9

3010 Flow Transmitter

Section 2 Programming

If the value you enter is greater than 9,999, round it off and

reduce it to a number the display can show. For example, 32,537

GPM is greater than the four digits available on the display. So,

first you round the number to 32,540 and then enter the four

most significant digits into the flow transmitter: 3, 2, 5, 4. To

show the overflow from the display, attach a “0” label to the right

of the display to indicate the value displayed is in tens of gallons

rather than gallons. Finally, attach a units of measurement label

for the appropriate units, in this case, “GPM.”

Note also that if the installation includes a plotter, enter the

same flow rate units in Step 11 and the same number of zeroes in

Step 12. For the example just given of 32,537 GPM, you would

enter 1 (GPM) in Step 11 and 1 in Step 12.

Step 9 – In Step 9, the flow transmitter will ask for scaling for

the flow totalizer. This is the number of counts on the totalizer

per hour of flow at maximum head. The value entered ranges

from 0 to 9,999. Note that the selection of the number of counts

per hour is based on flow at maximum head, so the actual

number of counts per hour may be much lower. Note also that if

your installation includes an Isco Model 2312 Plotter (no longer

sold), the units of measure selected for this step will also be

entered for the 2312 in Step 13 and the number of zeroes in Step

14. For example, if you want to totalize in cubic feet and the flow

rate at maximum head is 72.5 CFS:

72.5 CFS x 60 sec/min x 60 min/hr

= 261,000 cubic feet per hour (CFH)

For this example, each count on the totalizer is equal to 1,000

cubic feet.

261,000 CFH 1,000 CF per count = 261 counts per hour

You would then enter 2, 6, 1 for this step. In this instance, you

would place three “0” labels and the CF label to the right of the

display. If the 3010 is connected to a Model 2312, you would then

enter 1 (CF) in Step 13 and 3 in Step 14.

Step 10 – In Step 10, the flow transmitter requests selection of

sampler scaling (flow pulses to the sampler). You don't need to

program this step unless the 3010 is being used with a sampler.

The purpose of this program step is to provide signals to the

sampler to run its own program. The range is from 0 to 9, 999

pulses per hour. Determine this number the same way as in Step

9, previously. Note that selection of the number of flow pulses to

the sampler per hour is based on flow rate at maximum head, so

the actual number of pulses per hour will probably be considerably lower. Determine the number chosen by the volume of flow

that must pass through the primary device before a sample is

taken, rather than a particular interval of time.

For example, assume the flow rate at maximum head for a particular installation is 32,540 GPM.

32,540 GPM x 60 min/hr

= 1,952,400 gallons per hour (GPH)

2-10

3010 Flow Transmitter

Section 2 Programming

We want to send a flow pulse to the associated sampler every

10,000 gallons.

1,952,400 GPH 10,000 gallons per pulse

= 195 pulses per hour

You would then enter 1, 9, 5. If you programmed the associated

sampler to take a sample every 50 pulses, it will take a sample

every 500,000 gallons.

10,000 gallons per pulse x 50 pulses per sample

= 500,000 gallons per sample

If you programmed the sampler to take a sample every 200

pulses, it will take a sample every 2,000,000 gallons.

10,000 gallons per pulse x 200 pulses per sample

= 2 million gallons per sample

Steps 11 to 15 - Plotter Output – You only need to program

these steps if your installation includes an Isco Model 2312

Plotter or other serial device. The selections made here do not

affect operation of the 3010. However, you should choose values

consistent with the choices you made for earlier steps.

Step 11 - Units of Measure for Flow Rate on Remote

Plotter – There are several selections for units of measure

available here. The selection you make will be the units printed

out on the chart. of the 2312. You should select the same units

you selected for Step 8.

Step 12 - Zeros to the Right of the Flow Rate Display (0 to

9) – Program this step with the number of zeros overflowing the

display from the value entered in Step 8. Note that the remote

plotter displays flow rate with scientific notation. For example, a

plotter display of 5.57E+3 would equal 5.57 x 10

3

, which is the

same as 5.57 x 1,000 and that would be 5,570. Consequently, in

this case there is no need to add labels to the plotter display.

Step 13 - Units of Measure for Totalized Volume on

Remote Plotter – Again, selection is dependent on the units of

measure you selected for a previous step, in this case, Step 9.

Step 14 - Zeros to Right of Totalizer (0 to 9) – This step

allows you to add the correct number of trailing zeros to the

plotter’s totalizer to make meaningful numbers from large flow

rates. The number you select is the same as the number of zeros

overflowing the display in Step 9. Again, these are actually

expressed on the plotter’s display in terms of scientific notation,

so there is no need to add stickers to the plotter’s display.

Step 15 - Reset Plotter Totalizer to Zero – This step allows

you the option of resetting the totalizer on the remote plotter. It

does not affect the mechanical totalizer on the 3010. An example

of where you might use this is for studies of flow over specific

periods of time. It might be convenient to reset the flow totalizer

between each study. This is a user/application-determined

option. The totalizer is reset whenever power is turned off.

Step 16 - Display Operation – This step lets you choose the

method of display most useful for your particular application.

Choose between displaying 1. Flow Rate or 2. Level, or select 3.

2-11

3010 Flow Transmitter

CAUTION

Note

Section 2 Programming

Alternate which will cause the display to switch between level

and flow rate. This step defines the display when the flow transmitter is in normal operation. The appearance of the letter H on

the left side of the display designates level (or Head).

Step 17 - 4–20 mA Output Operation – This step determines

how associated external equipment connected to the 3010

through the 4–20 mA current loop will operate. The selection of

1. Flow Rate and 3. Level are user/application specified. The

selections of 2. Flow Rate with Event Mark and 4. Level with

Event Mark are specifically intended for use only with the

Teledyne Isco Model 2410 Circular Chart Recorder to

indicate on the chart that an associated wastewater sampler has

taken a sample.

Do not transmit level or flow rate with event marks to any

external equipment other than a circular- or strip-chart

recorder. Transmission of event marks causes momentary

jumps of the 4 - 20 mA loop current to 100% (full-scale) operation. This will cause erratic operation of some process control

equipment and could possibly have hazardous conse-

quences with certain equipment.

This output, a variable DC current of 4-20 mA, changes with the

level or flow rate measured by the 3010: 4 mA=0% flow or 0 level;

20 mA=100% flow rate, full-scale, or maximum head. The 4-20

mA current output is a standard industrial control format. It provides an analog (variable) signal to associated process equipment

that must respond to the changing conditions measured by the

flow transmitter. The operation of such equipment is like a lamp

controlled by a dimmer. You can make the lamp can burn at

many levels of brightness between fully off and fully on. Compare

this with equipment that is either on or off.

Step 18 - Adjust Level – This step allows you to adjust the

measured level for the 3010. Acceptable values range from –1 to

12.5 feet (–0.304 to 3.81 meters). There are various ways to calibrate the level sensor after you have installed it, depending on

the primary device used. Make your measurement from the zero

(level) point of the primary device to the surface of the flow

stream very carefully, to determine the level in the flow stream.

Commonly, you would use a measuring staff. Then enter this

level into the 3010 by adjusting the displayed level with the up

and down arrow keys, or by entering the desired value with the

numeric keys. The flashing letter H denotes head (level).

If the flow transmitter shows a negative level or flow rate during

initial setup and displays codes with EE on the left side of the

display, adjust the level to a positive value and then make the

entries necessary for selecting a primary device. This should

stabilize the display.

2-12

3010 Flow Transmitter

Section 2 Programming

The SETUP Step – This feature helps align the level sensor.

For proper operation, you must place the sensor so the echo

comes only from the liquid surface and not from the sides or

walls of the channel. To use the SETUP feature, you install the

level sensor and power it up. There need not be an echo, as “0”

will be displayed. After you select this step, the number on the

left represents the strength of the sensor’s return signal, or gain.

The number on the right indicates how much noise is in the

return signal due to surface roughness, etc. (the higher the

number, the less noise present). As long as the number on the

left side of the display is increasing, the sensor is approaching

optimal alignment. If no numbers appear, first try to align the

sensor to the point where numbers do appear. Orient the sensor

so the highest reading appears on the display. When the left

number reaches the highest reading, the level sensor is in proper

alignment. If you continue to adjust the sensor, the number displayed will begin to fall, as you have gone past the optimal

alignment.

2.3.4 Equations Used in

Flow Conversion

The equations used for flow conversions in the 3010 are in Table

2-2. Note that the equations provided for primary devices with

data-only flow conversions (Palmer-Bowlus, “H” and Trapezoidal

flumes), are approximations that fit the manufacturer's data

within 1% of full-scale. If you want to use level-to-flow rate conversions other than those built in, select #34, equation in Step 2.

Section 2.4.3 has a discussion of the use of the general flow

equation

Q (flow rate) = K x (N1 x H

P1

+ N2 x HP2)

that is followed by two programming examples, including a rectangular weir with end contractions.

Table 2-2 Equations Used in the Model 3010

Type and # of Device Flow Equation

1.5

Q = KH

2.5

- 0.034H

1.5

1.5

1.55

1.55

1.55

1.58

1.53

1.52

1.53

1.53

1.54

2.5

)

1. V-Notch Weir Q = KH

2. Rectangular Weir

with End Contractions

3. Rectangular Weir

without End Contractions

4. Cipoletti Weir Q = KH

5-13. Parshall Flume

5. 1”

6. 2”

7. 3”

8. 6”

9. 9”

10. 12”

11. 18”

12. 24”

13. 36”

Q = K(1.034H

(see Section 2.4.3)

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

2-13

3010 Flow Transmitter

Note

Section 2 Programming

Table 2-2 Equations Used in the Model 3010 (Contin-

Type and # of Device Flow Equation

14-22. Palmer-Bowlus Flume

1.9

14. 6”

15. 8”

16. 10”

17. 12”

18. 15”

19. 18”

20. 24”

21. 30”

22. 48”

23-25. Trapezoidal Flume*

23. Large 60° V

24. 2” 45° WSC

25. 12” 45° SRCRC

26-32. “H” Flume

26. 0.5’

27. .75’

28. 1.0”

29. 1.5’

30. 2.0’

31. 3.0’

32. 4.5’

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

Q = KH

1.9

1.9

1.9

1.9

1.9

1.9

1.9

1.9

2.58

2.32

2.29

2.31

2.31

2.31

2.31

2.31

2.31

2.31

**

**

**

* Palmer-Bowlus and Trapezoidal Flumes manufactured by Plasti-Fab,

Tualatin, Oregon.

**Flow equations for Palmer-Bowlus, “H,” and Trapezoidal Flumes are

approximations that fit data within 1% of full-scale flow rate.

Please do not attempt programming with the equation without

first studying the explanation and examples presented in Section 2.4.3.

2.3.5 Default Program You program the flow transmitter with selections appropriate for

your particular installation. When Teledyne Isco ships the flow

transmitter, there is already a default program in memory, used

to test the unit. This is only an example program to allow testing

of the unit as it is manufactured. It is not intended to fit any particular application.

2-14

FLOW RATE AT MAXIMUM

HEAD

(0.001 to 9,999)

Step 10 - Press Sampler Output

Steps 11 - 15 Press Plotter Output

Step 11 - Flow Rate Units on Plotter

Step 14 - Plotter Totalizer Zeros

Step 16 - Display Mode

Step 17 - 4-20 mA Output

Step 18 - Adjust Level

Step 9 -Totalizer

Step 8 - Flow Rate at Max. Head

Step 7 - Maximum Head

Selection 34 only (Equation)

Step 2 Select Primary Device

TOTALIZER

SCALING

(0 to 9,999)

6. P2 (0.1 to 3.0)

MAXIMUM HEAD:

(FEET 0.1 to 10.0) (METERS 0.03 to 3.04)

DISPLAY OPERATION

1. FLOW 2. LEVEL 3. ALTERNATE FLOW & LEVEL

CURRENT LEVEL

(FT. –1.0 to 10.0)(M –0.31 to

3.05)

4 - 20 mA OUTPUT OPERATION

1. FLOW 2. FLOW W/EVENT MARK

3. LEVEL 4. LEVEL W/EVENT MARK

RESET PLOTTER TOTALIZER TO

ZERO

SAMPLER SCALING

(0 to 9,999)

UNIT OF MEAS. FOR FLOW RATE ON PLOTTER

1. GPM 2. GPS 3. MGD 4. CFS 5. CMS 6. CMH

7. CMD 8. LPS 9. CFD 10. GPH 11. AFD. 12. CFH

ZEROS TO RIGHT OF FLOW

RATE DISPLAY (0 to 6)

UNIT OF MEAS. FOR TOTALIZED VOLUME ON

PLOTTER

1. CF 2. GAL 3. CM 4. AF 5. L. 6. MG

ZEROS TO RIGHT OF

TOTALIZER

(0 to 9)

Step 13 - Totalized Volume Units on Plotter

Step 12 - Plotter Flow Rate Zeros

(skipped if no zeros to right of display)

Step 15 - Reset Plotter Totalizer

3. N1 (–4,999 to 4,999)

4. P1 (0.1 to 3.0)

5. N2 (–4,999 to 4,999)

To Remainder of Program

(Equation Only)

Step 1 Units of Measure for Level

1. FEET 2. METERS

Steps 1-9 Press PRIMARY DEVICE

Step 1 Select Units of Measurement

1. V-NOTCH WEIR

2. RECTANG. WEIR W/END

CONTRACTIONS

3. RECTANG. WEIR W/O

END CONTRACTIONS

4. CIPOLLETTI

5. PARSHALL 1"

6. PARSHALL 2"

7. PARSHALL 3"

8. PARSHALL 6"

9. PARSHALL 9"

10. PARSHALL 12"

11. PARSHALL 18"

12. PARSHALL 24"

13. PARSHALL 36"

14. PALMER-BOWLUS 6"

15. PALMER-BOWLUS 8"

16. PALMER-BOWLUS 10"

17. PALMER-BOWLUS 12"

18. PALMER-BOWLUS 15"

19. PALMER-BOWLUS 18"

20. PALMER-BOWLUS 24"

21. PALMER-BOWLUS 30"

22. PALMER-BOWLUS 48"

23. TRAPEZOID LARGE 60o V

24. TRAPEZOID 2" 45o WSC

25. TRAPEZOID 12" 45o

SRCRC

26. “H” FLUME 0.5’

27. “H” FLUME 0.75’

28. “H” FLUME 1’

29. “H” FLUME 1.5’

30. “H” FLUME 2’

31. “H” FLUME 3’

32. “H” FLUME 4.5’

33. LEVEL ONLY

34. EQUATION (SEE STEPS

3-6)

3010 Flow Transmitter

Section 2 Programming

Figure 2-1 Simplified 3010 Programming Flowchart

2-15

3010 Flow Transmitter

1

1

2

8

7

1.5

8

1754

Section 2 Programming

2.4 Programming

Examples

2.4.1 Programming for a

Parshall Flume

In the following sections are examples showing the keystrokes

necessary to program the 3010 for specific applications. When

programming the flow transmitter, note that the number on the

left side of the display is the Program Step, while the number on

the right is the value currently held in memory.

In this example, we will program the 3010 to select a 6-inch

Parshall flume with a maximum head of 1.5 feet. Flow rate will

be displayed in GPM. The flow rate at maximum head in GPM is

1754 GPM. You can either get this value from the flume manufacturer or you can find it in the Teledyne Isco Open Channel

Flow Measurement Handbook. We want the totalizer to

totalize in gallons, and the 4-20 mA output to transmit level with

100% equal to 1.5 feet. Assume that the level is 0.75 feet. Attach

the “GPM” sticker to the right of the display.

Calculations for Example 1 – The totalizer will read out in

gallons. To find the flow per hour at maximum head, multiply the

flow in GPM by 60 (1754 gallons per minute x 60 minutes per

hour = 105,240 gallons per hour). The totalizer scaling value can

only be a value from 0 to 9,999. Since 105,240 is larger than

9,999, we divide by 100: 105,240 100 = 1,052.

1. Press PRIMARY DEVICE.

2. Select units of measure for level. To select feet, press 1.

Press ENTER.

3. Select the primary device from the list shown on the front

panel. To select a 6-inch Parshall Flume, press 8.

Press ENTER.

4. Enter the maximum expected head in feet. For this example, press 1, (decimal), 5.

Press ENTER.

5. Enter the flow at maximum head, 1754 GPM. Press 1, 7, 5

4.

2-16

Loading...

Loading...