Page 1

PP

erer

cent Oxygcent Oxyg

P

er

cent Oxyg

PP

erer

cent Oxygcent Oxyg

en en

TT

ransmitterransmitter

en

T

ransmitter

en en

TT

ransmitterransmitter

OPERATING INSTRUCTIONS

FOR

Model 300P

Percent Oxygen Transmitter

DANGER

HIGHLY TOXIC AND OR FLAMMABLE LIQUIDS OR GASES MAY BE PRESENT IN THIS MONITORING SYSTEM.

PERSONAL PROTECTIVE EQUIPMENT MAY BE REQUIRED WHEN SERVICING THIS SYSTEM.

HAZARDOUS VOLTAGES EXIST ON CERTAIN COMPONENTS INTERNALLY WHICH MAY PERSIST FOR A

TIME EVEN AFTER THE POWER IS TURNED OFF AND DISCONNECTED.

ONLY AUTHORIZED PERSONNEL SHOULD CONDUCT MAINTENANCE AND/OR SERVICING. BEFORE

CONDUCTING ANY MAINTENANCE OR SERVICING CONSULT WITH AUTHORIZED SUPERVISOR/MANAGER.

Teledyne Analytical Instruments

P/N M50965

08/06/99

ECO # 99-0323

i

Page 2

Model 300PModel 300P

Model 300P

Model 300PModel 300P

Copyright © 1999 Teledyne Analytical Instruments

All Rights Reserved. No part of this manual may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any other language or computer

language in whole or in part, in any form or by any means, whether it be electronic,

mechanical, magnetic, optical, manual, or otherwise, without the prior written consent of

Teledyne Analytical Instruments, 16830 Chestnut Street, City of Industry, CA 91749-1580.

Warranty

This equipment is sold subject to the mutual agreement that it is warranted by us free

from defects of material and of construction, and that our liability shall be limited to

replacing or repairing at our factory (without charge, except for transportation), or at

customer plant at our option, any material or construction in which defects become

apparent within one year from the date of shipment, except in cases where quotations or

acknowledgements provide for a shorter period. Components manufactured by others bear

the warranty of their manufacturer. This warranty does not cover defects caused by wear,

accident, misuse, neglect or repairs other than those performed by Teledyne or an authorized service center. We assume no liability for direct or indirect damages of any kind and

the purchaser by the acceptance of the equipment will assume all liability for any damage

which may result from its use or misuse.

We reserve the right to employ any suitable material in the manufacture of our

apparatus, and to make any alterations in the dimensions, shape or weight of any parts, in

so far as such alterations do not adversely affect our warranty.

Important Notice

This instrument provides measurement readings to its user, and serves as a tool by

which valuable data can be gathered. The information provided by the instrument may

assist the user in eliminating potential hazards caused by his process; however, it is

essential that all personnel involved in the use of the instrument or its interface, with the

process being measured, be properly trained in the process itself, as well as all instrumentation related to it.

The safety of personnel is ultimately the responsibility of those who control process

conditions. While this instrument may be able to provide early warning of imminent danger,

it has no control over process conditions, and it can be misused. In particular, any alarm or

control systems installed must be tested and understood, both as to how they operate and

as to how they can be defeated. Any safeguards required such as locks, labels, or redundancy, must be provided by the user or specifically requested of Teledyne at the time the

order is placed.

Therefore, the purchaser must be aware of the hazardous process conditions. The

purchaser is responsible for the training of personnel, for providing hazard warning

methods and instrumentation per the appropriate standards, and for ensuring that hazard

warning devices and instrumentation are maintained and operated properly.

Teledyne Analytical Instruments (TAI), the manufacturer of this instrument,

cannot accept responsibility for conditions beyond its knowledge and control. No statement expressed or implied by this document or any information disseminated by the

manufacturer or its agents, is to be construed as a warranty of adequate safety control

under the user’s process conditions.

ii

Teledyne Analytical Instruments

Page 3

PP

erer

cent Oxygcent Oxyg

P

er

cent Oxyg

PP

erer

cent Oxygcent Oxyg

en en

TT

ransmitterransmitter

en

T

ransmitter

en en

TT

ransmitterransmitter

Table of Contents

1 Introduction

1.1 General .......................................................................... 1-1

1.2 Features......................................................................... 1-1

1.3 Typical Applications....................................................... 1-2

2 Operational Theory

2.1 Transmitter Description.................................................... 2-1

2.2 Sensor Description.......................................................... 2-1

2.3 Circuit Description ......................................................... 2-2

2.4 RFI Protection ................................................................ 2-3

3 Operation

3.1 Installation...................................................................... 3-1

3.1.1 System Power Requirements................................. 3-1

3.1.2 Transmitter ............................................................. 3-1

3.1.3 Junction Box .......................................................... 3-1

3.2 Calibration ..................................................................... 3-2

3.2.1 Installing the Milliammeter ..................................... 3-2

3.2.2 Setting the Electronic Zero (P2) ............................. 3-3

3.2.3 Setting the Span Pot (P1)....................................... 3-3

3.3 Operating The Oxygen T ransmitter................................. 3-3

4 Maintenance

4.1 Routine Maintenance..................................................... 4-1

4.2 Cell Replacement .......................................................... 4-1

4.3 Cell Warranty ................................................................. 4-2

Appendix

Specifications ........................................................................ A-1

Recommended Spare Parts List ............................................ A-2

Drawing List........................................................................... A-2

Teledyne Analytical Instruments

iii

Page 4

Model 300PModel 300P

Model 300P

Model 300PModel 300P

Model 300P complies with all of the requirements of the Commonwealth of Europe (CE) for Radio Frequency Interference, Electromagnetic Interference (RFI/EMI), and Low Voltage Directive

(LVD).

The following International Symbols are used throughout the Instruction Manual for your visual and immediate warnings and when you

have to attend CAUTION while operating the instrument:

GROUND

Protective Earth

CAUTION, The operator needs to refer to the manual

for further information. Failure to do so may

compromise the safe operation of the equipment.

iv

Teledyne Analytical Instruments

Page 5

PP

erer

cent Oxygcent Oxyg

P

er

cent Oxyg

PP

erer

cent Oxygcent Oxyg

en en

TT

ransmitterransmitter

en

T

ransmitter Introduction 1

en en

TT

ransmitterransmitter

Introduction

1.1 General

The Model 300P Percent Oxygen Transmitter is designed to accurately monitor the oxygen content on a percent basis in a wide variety of

gases. The Percent Oxygen Transmitter is equipped with two oxygen

analysis ranges, 0–25% and 0–20.9% (air calibration range). The Model

300P is approved by Factory Mutual (FM) as intrinsically safe for operation in Class 1, Division 1, Groups A, B, C, and D hazardous environments.

The heart of the transmitter is Teledyne Brown Engineering's MicroFuel Cell oxygen sensor. This cell is a sealed electrochemical device which

translates the amount of oxygen present in a sample into an electrical

current. Since it is sealed, there is no electrolyte to change or electrodes to

clean and therefore, virtually maintenance free.

The transmitter operates from a 24 VDC (nominal) power source and

produces a 4–20 mA dc current output that is directly and linearly proportional to the oxygen concentration. The output current is used to interface

with devices such as recorders, alarms, computers or other current driven

devices.

1.2 Features

The following features describe the basic model. The exact configuration depends on the options selected at the time of purchase.

• Two analysis ranges: 0–25% and 0–20.9%

• High sensitivity (0.5%)

• Accurate (±2% of full scale at constant temperature and

pressure of calibration) or ±5% of full scale over the operating

temperature range.

Teledyne Analytical Instruments

1-1

Page 6

1 1

1 Introduction Model 300P

1 1

• Insensitive to flow variations

• Fast response and recovery

• Long life, maintenance-free Micro-Fuel Cell oxygen sensor

• Unaffected by reducing agents (HC's, CO, SO2, etc.)

• Easy to calibrate, no zero gas required

• RFI Protection

• 2-wire (loop-powered) with 4–20 mA dc output

• Rugged bulkhead mounted metal enclosure

• FM approved as intrinsically safe (when used with approved

safety barriers)

• Compact size, easy to install

1.3 Typical Applications

The Model 300P Percent Oxygen Transmitter is capable of monitoring oxygen at the % level in a variety of gases. It is widely used in industry. A few typical applications are:

• Monitoring inert gas blanketing

• Air separation and liquefaction

• Chemical feedstock analysis

• Semiconductor manufacturing

• Petrochemical process control

• Heat treating and bright annealing processes

• Quality assurance

• Gas certification

• Welding applications

• Flue gas analysis.

1-2

Teledyne Analytical Instruments

Page 7

Percent Oxygen Transmitter Operational Theory 2

Operational Theory

2.1 Transmitter Description

The transmitter consists of an RFI proof enclosure which contains the

O2 Sensor Assembly, 2-Wire Transmitter Circuitry and RFI Filters.

Mounted on the left side is a junction box which contains a three conductor

terminal strip for all external electrical connections. The bottom of the box

contains two bulkhead fittings for the 1/8" tubing used for bringing the

sample into and out of the sensor assembly. The transmitter assembly

contains four holes in the mounting flange for vertical surface mounting.

Access to the junction box is obtained by the removal of two screws

followed by the removal of the cover. Access to the O2 sensor and PC

board is through an RFI gasketed door held shut by 4 screw clamps.

2.2 Sensor Description

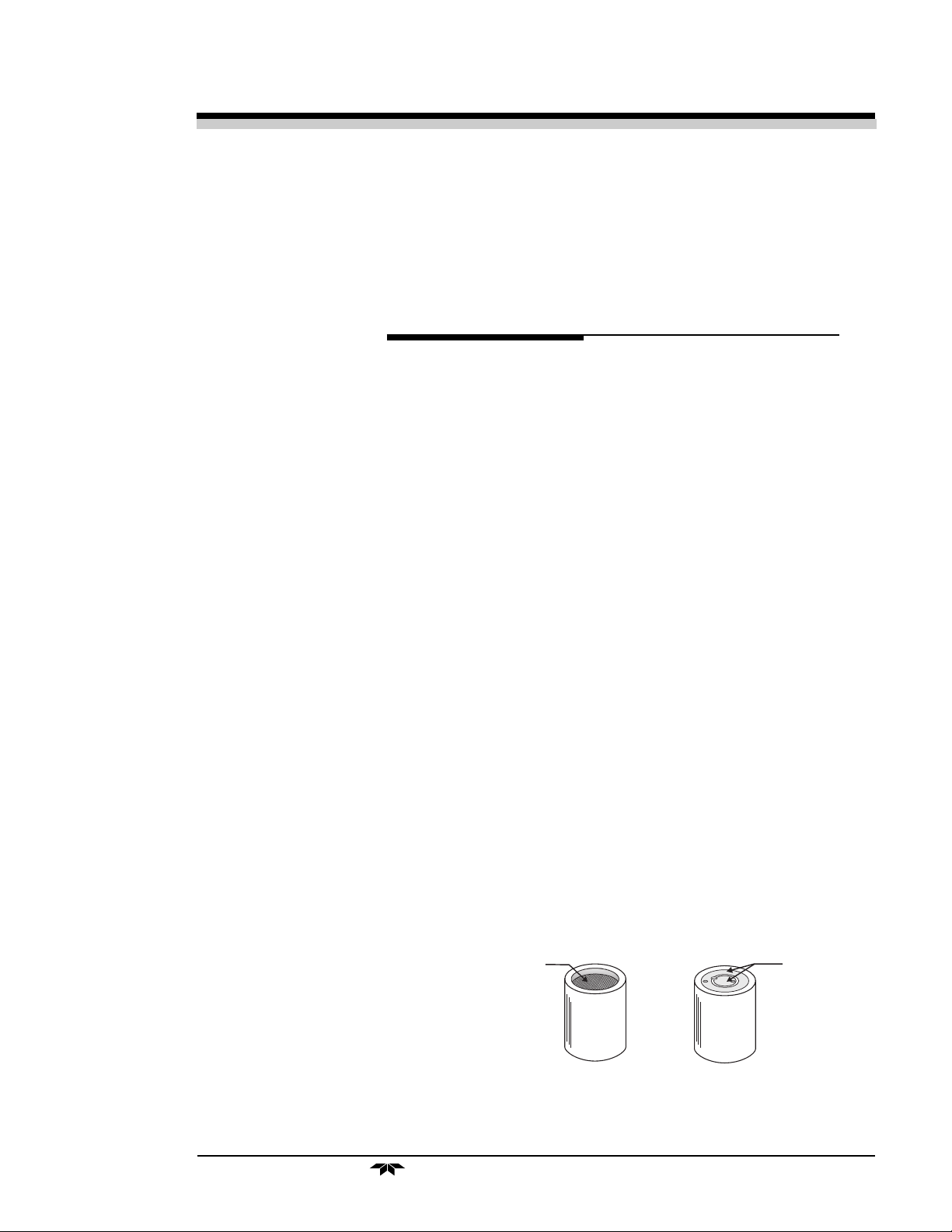

The Micro-Fuel Cell is a sealed plastic disposable oxygen transducer

that measures 1¼ inches in diameter and is ¾ inch thick (see Figure 2-1).

Inside of the cell are a cathode and anode immersed in 15% aqueous KOH

electrolyte. At one end of the sensor is a Teflon diffusion membrane; the

other end is sealed with a polyethylene membrane. At the rear of the cell is

a contact plate consisting of

two concentric foils. The

Top View

Bottom View

foils mate with springloaded contacts in the sensor

Screen

Concentric Foil

Contact Rings

block assembly and provide

the electrical connection to

the rest of the analyzer.

The sensing cathode,

located beneath the diffu-

Figure 2-1: Micro-Fuel Cell

Teledyne Analytical Instruments

2-1

Page 8

2 2

2 Operational Theory Model 300P

2 2

sion membrane, has a surface area of 2.48 cm2. The sample gas enters the

sensor block through an inlet tube between the cathode and the sensor

block cap, diffuses through the Teflon membrane, and any oxygen in the

sample gas is reduced on the surface of the cathode by the following

mechanism:

O2 + 2H2O + 4e

––

–

––

→ 4OH

––

–

––

(cathode)

When the oxygen is reduced at the cathode, lead is simultaneously

oxidized at the anode by the following mechanism.

––

–

2Pb → 2Pb+2 + 4e

––

(anode)

The electrons released at the surface of the anode flow to the cathode

surface via an external circuit. This current is proportional to the amount of

oxygen. It is measured and used to determine the oxygen concentration in

the gas mixture.

The overall reaction for the fuel cell is:

2Pb + O2 → 2PbO

The output of the fuel cell is limited by the amount of oxygen in the

cell at any one time, and the amount of stored anode material. In the

absence of oxygen, there is no current generated.

Warning: The sensor used in the Model 300P uses electrolytes which

contain substances that are extremely harmful if touched,

swallowed, or inhaled. Avoid contact with ANY fluid or powder

in or around the unit. What may appear to be plain water could

contain one of these toxic substances. In case of eye contact,

immediately flush eyes with water for at least 15 minutes. Call

physician. (See Appendix - Material Safety Data Sheet (MSDS)).

2.3 Circuit Description

The 300P circuitry consists of four stages: an input stage, a temperature compensation/ gain stage, a low-pass filter and an output voltage-tocurrent stage. The output of the O2 cell is a current directly proportional to

the amount of oxygen present. The input stage converts this current to a

voltage signal.

The temperature compensation stage consists of circuitry that amplifies the signal by a factor which is dependent upon the O2 cell temperature.

This temperature dependent gain is used to compensate for the rise in

output current of the O2 cell with temperature. A thermistor mounted in

the sensor assembly monitors this temperature and changes resistance (up

2-2

Teledyne Analytical Instruments

Page 9

Percent Oxygen Transmitter Operational Theory 2

with lower temperature, down with higher temperature) so that the output

of this stage is constant over the temperature range at any given O

tration.

The output voltage-to-current stage (E to I) draws 4 mA from the

power supply loop when there is no oxygen present in the sample gas, and

20 mA when there is full scale oxygen present in the sample gas. It also

supplies the +5V and -5V required by the circuitry.

A 24V power supply is recommended to power the transmitter for

most applications. The actual minimum and maximum values of this

supply depend upon the total loop resistance, which consists of the input

resistance of the receiver and the resistance of the wires between the transmitter and the power supply. Power applied across the terminals of the

transmitter must be between 14V and 30V. Using this criteria, the maximum line resistance can be determined. For example, with a 24V power

supply, a maximum of 10V is available (24V-14V) for drop across the

input resistance of the receiver and the line resistance. This amounts to a

maximum loop resistance of approximately 500 ohms (10V divided by

0.02A).

concen-

2

The B-2 or B-2C cell used in this instrument normally generates

about 500 µA output current in air (20.9% O

). This is about 2 nA per

2

ppm.

2.4 RFI Protection

The Model 300P is designed to be RFI protected by virtue of the

electronics being mounted inside a grounded metallic enclosure. The RFI

protection, therefore, is maximized when the enclosure door is closed.

Teledyne Analytical Instruments

2-3

Page 10

2 2

2 Operational Theory Model 300P

2 2

2-4

Teledyne Analytical Instruments

Page 11

Percent Oxygen Transmitter Operation 3

Operation

Operation of the Model 300P Percent Oxygen Transmitter involves

installing the unit, making appropriate sample gas connections, and calibration.

3.1 Installation

WARNING: For FM approved intrinsically safe operation, an approved safety

barrier must be used to limit the line power to 26 VDC and 125

mA.

3.1.1 System Power Requirements

The Model 300P Percent Oxygen Transmitter requires a 24 VDC

(nominal), reverse polarity protected power source. The maximum and

minimum voltage is dependent on the safety barrier used.

3.1.2 Transmitter

The transmitter enclosure is a weather resistant bulkhead mounted

enclosure. Mount the enclosure to a vertical surface using the four mounting

holes in the flange. Mount the enclosure with the sensor pointing down in a

location where service personnel can reach it.

WARNING: If the enclosure is to be installed in a hazardous area, it must be

interconnected with approved intrinsic safety barriers.

Make gas line connections to the sample in and sample out 1/8 " tube

fittings at the bottom of the enclosure.

3.1.3 Junction Box

Power connections are made at the junction box located on the side of

the transmitter housing.

1. Remove the two screws securing the junction box cover and

remove the cover.

Teledyne Analytical Instruments

3-1

Page 12

3 Operation3 Operation

3 Operation Model 300P

3 Operation3 Operation

2. Connect the 2-wire shielded cable to the three terminal barrier

strip.

3. Replace the cover and screws.

3.2 Calibration

The calibration process consists of:

• Installing a milliammeter in series with the output signal as

described below

• Setting the electronic zero level

• Setting the span

Setting the zero and span of the transmitter requires adjustment of two

potentiometers (Pl and P2) located on the PC board inside the transmitter box.

NOTE: If the analyzer has more than one range, the selector switch should be

set to “B” (0-21%) during calibration and “A” during measurement

operations.

The Transmitter can be calibrated using either AIR or SPAN GAS.

Both methods are accomplished by adjusting two potentiometers (ZERO and

SPAN) located on the PC board inside the transmitter box.

Procedure:

1. Remove the junction box cover and remove the incoming wire

from terminal 2 of the barrier strip.

2. Connect a milliammeter in series between this wire and terminal

2.

3.2.1 Installing the Milliammeter

3. Remove the junction box cover and remove the incoming wire

from terminal 2 of the barrier strip.

4. Connect a milliammeter in series between this wire and terminal

2.

3.2.2 Setting the Electronic Zero Potentiometer (P2)5. Open

the transmitter box door and remove the Micro-Fuel Cell. Adjust P2 for a

meter reading of 4.00 +/- 0.01 mA.

3-2

6. Replace the Micro-Fuel Cell. Allow the reading to drop to a

stable low level (dependent upon the length of time that the

Micro-Fuel Cell was unshorted).

TeledyneAnalytical Instruments

Page 13

Percent Oxygen Transmitter Operation 3

3.2.2 Setting the Span Potentiometer (P1) using AIR

7. Set switch SW-1 to position “B” (AIR CAL) and flow air

through the system. This can be done by either disconnecting the

sample line and allowing air to flow or inserting a tee with

appropriate valves to allow switching between sample and air

without having to disconnect the sample in line.

8. After the reading was stabilized, set P1 to read a stable

20.00 +/- 0.01 mA output.

9. Return switch SW-1 to the operating position “A”.

3.2.3 Setting the Span Potentiometer (P1) using SPAN GAS

8. Set switch SW-1 to the normal operating position “A”. Flow a

span gas through the system and allow time for stabilization.

NOTE: The span gas should have an O2 concentration of 80% 100% of full scale. For example, if you have a 0-10%

transmitter, the span gas should be a certified grade gas of about

9% O2 in N2 or Argon.

9. Adjust span potentiometer P1 to read an output current

determined by the following equation:

Span Gas Concentration in %

+

mA = Output in mA

4

Full Scale Concentration in %

10. Remove meter and reconnect incoming wire to Terminal 2.

Replace junction box cover and close transmitter box door.

3.3 Operating the OxygenTransmetter

1. After calibrating the instrument, reconnect the sample in line if it

was disconnected.

2. Open the transmitter door and set switch SW-1 back to position

"A" if this has not already been done.

CAUTION: The 0–25% oxygen analysis range can be used to accurately

measure the oxygen concentration in a gas mixture containing up

to 24% Oxygen. Oxygen concentrations above 24% under extreme

conditions can cause the instrument to produce unreliable readings on the 0–25% oxygen scale. Use this range for gas mixtures

containing 0–24% oxygen only.

Teledyne Analytical Instruments

3-3

Page 14

3 Operation3 Operation

3 Operation Model 300P

3 Operation3 Operation

3-4

TeledyneAnalytical Instruments

Page 15

Percent Oxygen Transmitter Maintenance 4

Maintenance

4.1 Routine Maintenance

Aside from normal cleaning and checking for leaks at the gas connections, routine maintenance is limited to installing replacement Micro-Fuel

cells and recalibration. For recalibration, see section 3.2 Calibration.

4.2 Cell Replacement

The Micro-Fuel Cell is a sealed electrochemical transducer with no

electrolyte to change or electrodes to clean. When the cell reaches the end

of its useful life, it is replaced. The spent fuel cell should be discarded

according to local regulations.

The characteristics of the Micro-Fuel Cell are similar to those of a

mercury battery in that both provide an almost constant output throughout

their useful life, and then fall off sharply towards zero at the end. If the

process being analyzed has a low oxygen concentration, cell failure will

probably be indicated by the inability to properly span calibrate the transmitter, or excessively long response time to changes in oxygen concentration.

To avoid downtime, TBE/AI recommends that a spare cell be purchased shortly after the instrument is placed in service, and each time the

cell is replaced.

The spare cell should be carefully stored in an area that is not subject

to large variations in ambient temperature (75°F nominal), and in such a

way as to eliminate the possibility of incurring damage.

NOTE: Do not disturb the integrity of the cell package until the cell is to

actually be used. If the cell package is punctured and air is permitted to enter, the useful life of the cell will be adversely affected.

Teledyne Analytical Instruments

4-1

Page 16

4 Maintenance4 Maintenance

4 Maintenance Model 300P

4 Maintenance4 Maintenance

To replace the cell:

1. Open the enclosure door.

2. The cell block is located in the center of the unit. Unscrew the

cap on the bottom of the cell block. The micro-fuel cell should

drop down once the cap is removed.

NOTE: Minimize the amount of time the cell is exposed to air. This will

lessen the time it will take the newly installed cell to drop to a zero

reading.

3. Remove the new cell from its package, and carefully remove

the shorting clip.

NOTE: Do not touch the silver colored sensing surface of the cell, as it is

covered with a delicate Teflon membrane that can be ruptured in

handling. Puncturing or other damage will require replacement of

the sensor

WARNING:The sensor used in the Model 300P uses electrolytes which

contain substances that are extremely harmful if touched,

swallowed, or inhaled. Avoid contact with ANY fluid or powder

in or around the unit. What may appear to be plain water could

contain one of these toxic substances. In case of eye contact,

immediately flush eyes with water for at least 15 minutes. Call

physician. (See Appendix - Material Safety Data Sheet (MSDS)).

4. Place the new cell on the cap with the sensing surface face

down and the gold contact rings up.

5. Position the cell and cap so that the cell is inside the cell block.

Press up on the cap and rotate until it threads. Tighten the cap.

4.3 Cell Warranty

The Class B-1 cell employed in the Model 300P is warranted for six

months of service. Other special cells may be used on occasion, depending

upon the application. Note any Addenda attached to the front of this

manual for special information applying to your instrument.

With regard to spare cells, warranty period begins on the date of

shipment. The customer should stock only one spare cell per instrument at

a time. Do not attempt to stockpile spare cells.

The B-1 cell should not be used in applications where CO2 is a major

component in the sample, however concentrations of 1,000 ppm or less

will not adversely effect the cell performance. Consult TBE/AI for optional

4-2

Teledyne Analytical Instruments

Page 17

Percent Oxygen Transmitter Maintenance 4

cells which are available for either intermittent or continuous CO2 exposure.

If a cell was working satisfactorily, but ceases to function before the

warranty period expires, the customer will receive credit toward the purchase of a new cell.

If you have a warranty claim, you must return the cell in question to

the factory for evaluation. If it is determined that failure is due to faulty

workmanship or material, the cell will be replaced at no cost to the cus-

tomer.

NOTE: Evidence of damage due to tampering or mishandling will render

the cell warranty null and void.

Teledyne Analytical Instruments

4-3

Page 18

4 Maintenance4 Maintenance

4 Maintenance Model 300P

4 Maintenance4 Maintenance

4-4

Teledyne Analytical Instruments

Page 19

Percent Oxygen Transmitter Appendix

Appendix

System Enclosure: Weather resistant, bulkhead mounted

Power Requirements: 24V nominal, reverse polarity protected.

V

and V

max

used. For Factory Mutual Approved Intrinsically Safe Operation, an approved safety

barrier must be used to limit line power to

V

= 26 VDC and I

max

Ranges: 0–25% Oxygen

dependent upon safety barrier

min

= 125mA.

max

Accuracy: ± 2% of full scale at constant temperature and

pressure (temperature and pressure of calibration), except ± 1ppm on 0–10ppm range.

± 5% of full scale over operating temperature

range (once thermal equilibrium has been

reached), except ± 1ppm on 0–10ppm range.

Response Time (90%): Sensor Response Time + Electronic

Response Time = 61 seconds @ 77°F (25°C).

Operating Temperature: 32–122°F (0–50°C)

Stability: ± 1% in 24 hours (at constant temperature)

Reproducibility: ± 1% of full scale at constant temperature

Sensor Type: Micro-Fuel Cell class B-3

Signal Output: 4–20 mA DC

Teledyne Analytical Instruments

A-1

Page 20

AppendixAppendix

Appendix Model 300P

AppendixAppendix

Recommended Spare Parts List

QTY.PART NUMBER DESCRIPTION

1 C48672 PC Board — 2 Wire Transmitter

1 I109 IC — XTR101AG

1 C6689-B3 Micro-Fuel Cell

A minimum charge is applicable to spare parts orders.

NOTE: Orders for replacement parts should include the part number (if

available ) and the model and serial number of the instrument for

which the parts are intended.

Orders should be sent to:

Teledyne Analytical Instruments

16830 Chestnut Street

City of Industry, CA 91749-1580

Phone (626) 934-1500, Fax (626) 961-2538

TWX (910) 584-1887 TDYANLY COID

Web: www.teledyne-ai.com

or your local representative

Drawing List

B-50966 Outline Diagram

B-49326 Wiring Diagram

A-41453 Interconnection Diagram

B-48671 Schematic — 2 Wire Transmitter

NOTE: The MSDS on this material is available upon request

through the Teledyne Environmental, Health and

Safety Coordinator. Contact at (626) 934-1592

A-2

Teledyne Analytical Instruments

Page 21

Percent Oxygen Transmitter Appendix

Material Safety Data SheetMaterial Safety Data Sheet

Material Safety Data Sheet

Material Safety Data SheetMaterial Safety Data Sheet

Section I – Product Identification

Product Name: Micro-Fuel Cells

Mini-Micro-Fuel Cells, all classes

Super Cells, all classes except T–5F

Electrochemical Oxygen Sensors, all classes.

Manufacturer: Teledyne Analytical Instruments

Address: 16830 Chestnut Street, City of Industry, CA 91749

Phone: (818) 961-9221

Date Prepared or Last Revised: 08/08/91

Emergency Phone Number: (818) 961-9221

Section II – Physical and Chemical Data

Chemical and Common Names: Potassium Hydoxide (KOH), 15% (w/v)

Lead (Pb), pure

CAS Number: KOH 1310–58–3

Pb 7439–92–1

KOH (15%) Pb (pure)

Melting Point/Range: –10 to 0 °C 328 °C

Boiling Point/Range: 100 to 115 °C 1744 °C

Specific Gravity: 1.09 @ 20 °C 11.34

pH: >14 N/A

Solubility in Water: Completely soluble Insoluble

Percent Volatiles by Volume: None N/A

Appearance and Odor: Colorless, odorless solution Grey metal, odor-

less

Teledyne Analytical Instruments

A-3

Page 22

AppendixAppendix

Appendix Model 300P

AppendixAppendix

Section III – Physical Hazards

Potential for fire and explosion: The electrolyte in the Micro-Fuel Cells is not flammable. There are no fire or explosion hazards associated with Micro-Fuel Cells.

Potential for reactivity: The sensors are stable under normal conditions of use.

Avoid contact between the sensor electrolyte and strong acids.

Section IV – Health Hazard Data

Primary route of entry: Ingestion, eye/skin contact

Exposure limits:OSHA PEL: .05 mg/cu.m. (Pb)

ACGIH TLV: 2 mg/cu.m. (KOH)

Effects of overexposure

Ingestion: The electrolyte could be harmful or fatal if swal-

lowed.

Oral LD50 (RAT) = 3650 mg/kg

Eye: The electrolyte is corrosive; eye contact could result

in permanent loss of vision.

Dermal: The electrolyte is corrosive; skin contact could result

in a chemical burn.

Inhalation: Liquid inhalation is unlikely.

Signs/symptoms of exposure: Contact with skin or eyes will cause a burning sensa-

tion and/or feel soapy or slippery to touch.

Medical conditions

aggravated by exposure: None

Carcinogenicity: NTP Annual Report on Carcinogens: Not listed

LARC Monographs: Not listed

OSHA: Not listed

Other health hazards: Lead is listed as a chemical known to the State of

California to cause birth defects or other reproductive harm.

A-4

Teledyne Analytical Instruments

Page 23

Percent Oxygen Transmitter Appendix

Section V – Emergency and First Aid Procedures

Eye Contact: Flush eyes with water for at least 15 minutes and get immediate

medical attention.

Skin Contact: Wash affected area with plenty of water and remove contaminated

clothing. If burning persists, seek medical attention.

Ingestion: Give plenty of cold water. Do not induce vomiting. Seek medical

attention. Do not administer liquids to an unconscious person.

Inhalation: Liquid inhalation is unlikely.

Section VI – Handling Information

NOTE: The oxygen sensors are sealed, and under normal circumstances, the contents

of the sensors do not present a health hazard. The following information is

given as a guide in the event that a cell leaks.

Protective clothing: Rubber gloves, chemical splash goggles.

Cleanup procedures:Wipe down the area several times with a wet paper towel. Use a

fresh towel each time.

Protective measures

during cell replacement:Before opening the bag containing the sensor cell, check the

sensor cell for leakage. If the sensor cell leaks, do not open

the bag. If there is liquid around the cell while in the instrument, put on gloves and eye protection before removing the

cell.

Disposal: Should be in accordance with all applicable state, local and

federal regulations.

NOTE: The above information is derived from the MSDS provided by the manufacturer.

The information is believed to be correct but does not purport to be all inclusive and shall be used only as a guide. Teledyne Analytical Instruments shall

not be held liable for any damage resulting from handling or from contact with

the above product.

Teledyne Analytical Instruments

A-5

Page 24

AppendixAppendix

Appendix Model 300P

AppendixAppendix

A-6

Teledyne Analytical Instruments

Loading...

Loading...