Teledyne 300M User Manual

INSTRUCTION MANUAL

MODEL 300M

CARBON MONOXIDE ANALYZER

TELEDYNE INSTRUMENTS

ADVANCED POLLUTION INSTRUMENTATION DIVISION

(T-API)

6565 NANCY RIDGE DRIVE

SAN DIEGO, CA 92121-2251

TOLL-FREE: 800-324-5190

FAX: 858-657-9816

TEL: 858-657-9800

E-MAIL: api-sales@teledyne.com

WEB SITE: www.teledyne-api.com

Copyright 2001 API Inc 1/15/01

04033

Revision A

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety

messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety

message is associated with a safety alert symbol. These symbols are found in the manual and

inside the instrument. The definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions for details on the

specific danger.

CAUTION: Hot Surface Warning

CAUTION: Electrical Shock Hazard

TECHNICIAN SYMBOL: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

CAUTION

The analyzer should only be used for the purpose

and in the manner described in this manual.

If you use the analyzer in a manner other than that for which

it was intended, unpredictable behavior could ensue with

possible hazardous consequences.

ii

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

TABLE OF CONTENTS

SAFETY MESSAGES .........................................................................................II

TABLE OF CONTENTS .....................................................................................III

LIST OF FIGURES ........................................................................................... VII

LIST OF TABLES............................................................................................ VIII

1 INTRODUCTION .......................................................................................... 1-1

REFACE

1.1 P

1.2 W

1.3 P

1.4 S

1.5 I

1.6 E

ARRANTY

RINCIPLE OF OPERATION

PECIFICATIONS

NSTALLATION AND OVERVIEW

LECTRICAL AND PNEUMATIC CONNECTIONS

1.6.1 Electrical Connections .........................................................................................1-11

1.6.2 Remote Contact Closures Zero/Span Inputs .......................................................1-11

1.6.3 Status Outputs (Optional) ....................................................................................1-11

1.6.4 RS-232 ................................................................................................................1-12

1.6.5 Pneumatic System...............................................................................................1-12

1.6.6 Sample Gas Connection......................................................................................1-13

1.6.7 Zero/Span Valve Connections .............................................................................1-13

1.6.8 Exhaust Connections...........................................................................................1-13

1.7 O

PERATION VERIFICATION

PTIONS

1.8 O

1.8.1 Rack Mount With Slides ......................................................................................1-17

1.8.2 Span Valve ..........................................................................................................1-17

.......................................................................................................................1-1

....................................................................................................................1-1

...............................................................................................1-3

.............................................................................................................1-5

.........................................................................................1-6

..................................................................1-11

.............................................................................................1-15

......................................................................................................................1-17

2 OPERATION ................................................................................................ 2-1

EY FEATURES

2.1 K

2.1.1 CO Readout...........................................................................................................2-1

2.1.2 CO Analog Output .................................................................................................2-1

2.1.3 E

2

ROM Backup Of Software Configuration ...........................................................2-1

2.1.4 Adaptive Filter........................................................................................................2-1

2.1.5 Data Acquisition (DAS)..........................................................................................2-2

2.1.6 RS-232 Interface ...................................................................................................2-2

2.1.7 Password Protection..............................................................................................2-2

2.2 F

RONT PANEL

2.2.1 Front Panel Display ...............................................................................................2-3

2.2.2 Programmable Push Buttons.................................................................................2-7

2.2.3 Status LED’s..........................................................................................................2-8

...............................................................................................................2-1

................................................................................................................2-3

iii

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

3 PERFORMANCE TESTING ......................................................................... 3-1

ANUAL ZERO/SPAN CHECK

3.1 M

...........................................................................................3-1

3.1.1 Zero Check............................................................................................................3-1

3.1.2 Span Check...........................................................................................................3-2

3.1.3 Dual Range Calibration .........................................................................................3-3

3.2 SPAN

ERO/SPAN VALVES (OPTION

3.3 Z

UTOMATIC ZERO/SPAN CHECK

3.4 A

UMMARY OF FRONT PANEL CHECK AND CALIBRATION CONTROLS

3.5 S

EMOTE ZERO/SPAN CHECK OR ADJUSTMENT (CONTACT CLOSURE

3.6 R

EMOTE ZERO/SPAN CHECK OR ADJUSTMENT

3.7 R

OWER-ON HOLD OFF

3.8 P

OLD OFF

3.9 H

ALVE (OPTION

V

)....................................................................................................3-4

).........................................................................................3-4

......................................................................................3-5

.....................................3-8

).................................3-9

(RS-232) ................................................3-10

..................................................................................................3-10

...................................................................................................................3-10

4 SETUP MODE .............................................................................................. 4-1

ETUP MODE OPERATION

4.1 S

XAMINING THE CARBON MONOXIDE FORMULA SLOPE AND OFFSET

4.2 E

ETTING THE TIME-OF-DAY

4.3 S

ETTING THE DATE

4.4 S

DJUSTING THE CLOCK SPEED

4.5 A

ETTING THE

4.6 S

.........................................................................................................4-2

ONCENTRATION RANGE

CO C

4.6.1 Single Range Mode (SNGL) ..................................................................................4-3

4.6.2 Dual Range Mode (DUAL).....................................................................................4-3

4.6.3 Auto Range Mode (AUTO) ....................................................................................4-3

4.7 SETTING THE

ETTING THE

4.8 S

ETTING THE ANALYZER

4.9 S

4.10 D

4.11 D

ISABLING THE CALIBRATION PASSWORD

ATA ACQUISITION SYSTEM

NALOG OUTPUT OFFSET

A

RS-232 B

4.11.1 Data Channels.....................................................................................................4-5

4.12 S

4.13 G

OFTWARE CONFIGURATION

AS ALARMS

................................................................................................................4-7

4.13.1 Summary of Setup Functions ..............................................................................4-7

...............................................................................................4-1

...................................4-1

.............................................................................................4-2

........................................................................................4-2

......................................................................4-3

...........................................................................4-4

AUD RATE

...................................................................................4-4

I.D. ...........................................................................................4-4

.......................................................................4-4

(DAS)................................................................................4-5

.........................................................................................4-6

5 DIAGNOSTICS............................................................................................. 5-1

EST MEASUREMENTS

5.1 T

IAGNOSTIC TESTS

5.2 D

....................................................................................................5-1

........................................................................................................5-2

5.2.1 Signal I/O...............................................................................................................5-3

5.2.2 Analog Output Test................................................................................................5-6

5.2.3 Electric Test...........................................................................................................5-6

5.3 M300M INTERNAL

ARIABLES

V

.........................................................................................5-7

6 HANDLING WARNINGS.............................................................................. 6-1

7 RS-232 COMMUNICATIONS....................................................................... 7-1

7.1 DAS R

EPORTING

...........................................................................................................7-2

iv

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

7.2 W

7.3 S

7.4 D

7.5 T

7.6 V

ARNINGS

TATUS/CONTROL

IAGNOSTICS

EST MEASUREMENTS

IEWING AND MODIFYING VARIABLES

.....................................................................................................................7-4

..........................................................................................................7-6

.................................................................................................................7-8

....................................................................................................7-9

.............................................................................7-11

8 CALIBRATION ............................................................................................. 8-1

EQUIRED EQUIPMENT AND GAS STANDARDS

8.1 R

ULTI-POINT CALIBRATION

8.2 M

.............................................................................................8-3

...................................................................8-1

8.2.1 Procedure..............................................................................................................8-4

ERO/SPAN CHECKING

8.3 Z

...................................................................................................8-7

9 ADJUSTMENTS........................................................................................... 9-1

OWER SUPPLY BOARD ADJUSTMENT

9.1 P

9.1.1 Box Temperature Limits ........................................................................................9-1

9.2 A/D - D/A C

ARK CURRENT SIGNAL ADJUST PROCEDURE

9.3 D

UTPUT VOLTAGE RANGE CHANGES

9.4 O

LOW READOUT ADJUSTMENT

9.5 F

9.6 DC P

OWER SUPPLY

ALIBRATION PROCEDURE

.........................................................................................9-6

.......................................................................................................9-7

9.7 CPU .............................................................................................................................9-7

..............................................................................9-1

..............................................................................9-3

..................................................................9-5

................................................................................9-5

10 TROUBLESHOOTING ............................................................................. 10-1

10.1 O

10.2 T

10.3 TROUBLESHOOTING

10.4

10.5 T

10.6 T

10.7 W

VERVIEW

ROUBLESHOOTING FUNDAMENTAL ANALYZER OPERATION

.................................................................................................................10-1

............................................10-2

10.2.1 Checking the Power Sub-Systems ....................................................................10-2

10.2.2 Checking the CPU and Display .........................................................................10-3

10.2.3 Checking the Keyboard .....................................................................................10-3

SING WARNING MESSAGES

U

TROUBLESHOOTING USING TEST FUNCTION VALUES

ROUBLESHOOTING DYNAMIC PROBLEMS

.....................................................................10-7

..........................................................10-3

.....................................................10-5

10.5.1 Noisy or Unstable Readings at Zero..................................................................10-7

10.5.2 Noisy, Unstable, or Non-Linear Span Readings ................................................10-7

10.5.3 Slow Response to Changes in Concentration ...................................................10-7

10.5.4 Analog Outputs Do Not Agree With Front Panel Readings ...............................10-8

10.5.5 Cannot Zero or Cannot Dynamic Zero...............................................................10-8

10.5.6 Cannot Span or Cannot Dynamic Span.............................................................10-8

ROUBLESHOOTING INDIVIDUAL SUB-ASSEMBLIES AND COMPONENTS

............................10-8

10.6.1 Troubleshooting Flow Problems ........................................................................10-8

10.6.2 Troubleshooting Temperature Problems .........................................................10-10

10.6.3 Checking the V/F Card ....................................................................................10-11

10.6.4 Checking the DC Power Supply Board............................................................10-14

10.6.5 Checking the Synchronous Demodulator Board..............................................10-15

10.6.6 Checking the Opto Interrupter .........................................................................10-16

10.6.7 Flow/Pressure Sensor .....................................................................................10-17

ARRANTY/REPAIR QUESTIONNAIRE

.........................................................................10-18

v

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

11 ROUTINE MAINTENANCE ...................................................................... 11-1

11.1 M

11.2 R

11.3 L

ODEL

300M M

EPLACEMENT OF SAMPLE FILTER

EAK CHECKING

AINTENANCE SCHEDULE

......................................................................11-1

...............................................................................11-2

.........................................................................................................11-2

11.3.1 Using a Leak Checker .......................................................................................11-2

11.3.2 Leak Self Test....................................................................................................11-3

12 SPARE PARTS LISTS ............................................................................. 12-1

12.1 S

12.2 M

12.3 M

12.4 M

PARE PARTS FOR

ODEL

ODEL

ODEL

300M E

300M S

300M L

XPENDABLES KIT

PARE PARTS KIT (FOR ONE UNIT

EVEL 1 PARTS KIT (FOR TEN UNITS

CE M

ARK UNITS

.................................................................................12-2

.............................................................................12-1

)...........................................................12-2

) .......................................................12-3

APPENDIX A TIPS ON CONNECTING THE TELEDYNE API ANALYZER RS-

232 INTERFACE .........................................................................................A-1

APPENDIX B ELECTRICAL DRAWING INDEX............................................. B-1

vi

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

LIST OF FIGURES

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

1-1: P

1-2: C

1-3: R

1-4: R

2-1: M

2-2: I

8-1: G

8-2: I

NEUMATIC DIAGRAM

ARBON MONOXIDE ANALYZER

EAR PANEL ELECTRICAL/PNEUMATIC CONNECTIONS

EAR PANEL

ODEL

LLUSTRATION OF NORMAL DISPLAY

AS GENERATION SYSTEM

NLET VENTING RECOMMENDATIONS

9-1: M300M E

10-1: O

10-2: D

PTO PICKUP WAVEFORM

ETECTOR WAVEFORM

A-1: RS-232 P

...........................................................................................1-4

.............................................................................1-9

...........................................1-10

......................................................................................................1-14

300M F

RONT PANEL

.................................................................................2-4

.......................................................................2-8

...................................................................................8-2

......................................................................8-2

LECTRICAL BLOCK DIAGRAM

..................................................................9-2

..............................................................................10-16

..................................................................................10-16

IN ASSIGNMENTS

................................................................................. A-1

vii

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

LIST OF TABLES

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

1-1: S

1-2: F

2-1: P

2-2: S

2-3: T

2-4: W

2-5: S

3-1: C

4-1: S

4-1: S

5-1: D

5-2: I/O S

5-2: I/O S

5-2: I/O S

5-2: I/O S

TATUS OUTPUTS

INAL TEST AND CALIBRATION VALUES

ASSWORD LEVELS

YSTEM MODES

EST MEASUREMENTS

ARNING MESSAGES

TATUS

ALIBRATION CONTROLS

ETUP FUNCTIONS

ETUP FUNCTIONS (CONTINUED

IAGNOSTIC TESTS

LED’S......................................................................................................2-9

IGNALS

IGNALS (CONTINUED

IGNALS (CONTINUED

IGNALS (CONTINUED

5-3: M300M V

7-1: RS-232 P

7-2: RS-232 M

7-3: RS-232 W

7-4: S

7-5: C

7-6: D

7-7: D

7-8: T

TATUS REPORTS

ONTROL COMMANDS

IAGNOSTIC COMMANDS

IAGNOSTIC REPORTS

EST MEASUREMENT REQUEST COMMANDS

7-9: RS-232 V

10-1: W

10-2: T

10-3: V/F B

10-4: V/F B

11-1: M

ARNING MESSAGES

EST FUNCTION VALUES

OARD JUMPERS

OARD SWITCH SETTINGS

AINTENANCE SCHEDULE

................................................................................................1-12

..................................................................1-16

...............................................................................................2-2

....................................................................................................2-5

...........................................................................................2-6

.............................................................................................2-7

........................................................................................3-8

.................................................................................................4-8

) ............................................................................4-9

................................................................................................5-2

..........................................................................................................5-3

) .....................................................................................5-4

) .....................................................................................5-5

) .....................................................................................5-6

ARIABLES

ORT SETUP

ESSAGE TYPES

ARNING MESSAGE CLEAR COMMANDS

...............................................................................................5-7

RONT PANEL

- F

....................................................................7-1

......................................................................................7-2

.....................................................7-5

..................................................................................................7-6

............................................................................................7-7

........................................................................................7-8

...........................................................................................7-8

..........................................................7-10

ARIABLE NAMES

...................................................................................7-12

.........................................................................................10-4

....................................................................................10-6

ACTORY SETTINGS

- F

ANGES FOR ANALOG OUTPUT

- R

......................................................10-12

.........................10-12

..................................................................................11-1

viii

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

1 INTRODUCTION

1.1 Preface

Teledyne API is pleased that you have purchased the Model 300M. This manual has been

designed to allow easy commissioning and operation but if we may be of assistance Teledyne

API will be pleased to provide you with any support required.

The Teledyne API Model 300M keyboard/operator interface is user-friendly. We hope you will

not experience any problems with the Model 300M and the built-in tests and diagnostics should

allow you to quickly and easily rectify any problems you may encounter. In addition, our

customer service department is always available to answer your questions.

1.2 Warranty

WARRANTY POLICY (02024c)

Prior to shipment, Teledyne API equipment is thoroughly inspected and tested. Should

equipment failure occur, Teledyne API assures its customers that prompt service and support

will be available.

COVERAGE

After the warranty period and throughout the equipment lifetime, Teledyne API stands ready to

provide on-site or in-plant service at reasonable rates similar to those of other manufacturers in

the industry. All maintenance and the first level of field troubleshooting is to be performed by

the customer.

NON-TELEDYNE API MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by Teledyne API is warranted and will be repaired to

the extent and according to the current terms and conditions of the respective equipment

manufacturers warranty.

GENERAL

Teledyne API warrants each Product manufactured by T Teledyne API to be free from defects in

material and workmanship under normal use and service for a period of one year from the date of

delivery. All replacement parts and repairs are warranted for 90 days after the purchase.

If a Product fails to conform to its specifications within the warranty period, Teledyne API shall

correct such defect by, in Teledyne API's discretion, repairing or replacing such defective

Product or refunding the purchase price of such Product.

1-1

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

The warranties set forth in this section shall be of no force or effect with respect to any Product:

(i) that has been altered or subjected to misuse, negligence or accident, or (ii) that has been used

in any manner other than in accordance with the instruction provided by Teledyne API or (iii)

not properly maintained.

THE WARRANTIES SET FORTH IN THIS SECTION AND THE REMEDIES

THEREFORE ARE EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR OTHER

WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED. THE

REMEDIES SET FORTH IN THIS SECTION ARE THE EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONTAINED HEREIN. TELEDYNE API SHALL

NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

ARISING OUT OF OR RELATED TO THIS AGREEMENT OF TELEDYNE API'S

PERFORMANCE HEREUNDER, WHETHER FOR BREACH OF WARRANTY OR

OTHERWISE.

TERMS AND CONDITIONS

All units or components returned to Teledyne API should be properly packed for handling and

returned freight prepaid to the nearest designated Service Center. After the repair, the equipment

will be returned, freight prepaid.

1-2

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

1.3 Principle of Operation

The detection and measurement of Carbon Monoxide in the Model 300M is based on the

absorption of Infra Red (IR) radiation by CO molecules at wavelengths near 4.5 microns. As

illustrated in Figure 1-1, the Model 300M uses a high energy heated element to generate broadband IR light. This light is passed through a rotating Gas Filter Wheel causing the beam to

alternately pass through a gas cell filled with Nitrogen, (the Measure Cell) and a cell filled with

CO/Nitrogen Mixture (the Reference Cell). This alternation occurs at a rate of 30 cycles/second

and causes the beam to be modulated into Reference and Measure pulses. During a Reference

pulse, the CO in the gas filter wheel effectively strips the beam of all IR energy at wavelengths

where CO can absorb. This results in a beam which is unaffected by any CO in the Sample Cell.

During the Measure pulse, the Nitrogen in the filter wheel does not affect the beam which can

subsequently be absorbed by any CO in the sample cell. The Gas Filter wheel also incorporates

an optical chopping mask which superimposes a 180 Cycles/Second Light/Dark modulation on

the IR Beam. This high frequency modulation is used to maximize detector signal-to-noise

performance.

After the gas filter wheel, the IR beam enters the single pass sample cell. The beam then passes

through a band-pass interference filter to limit the light to the wavelengths of interest. Finally,

the beam strikes the detector which is a thermoelectrically cooled solid-state photo-conductor.

This detector, along with its pre-amplifier converts the light signal into a modulated voltage

signal.

The detector output is electronically demodulated to generate two DC voltages, CO MEAS and

CO REF. These voltages are proportional to the light intensity striking the detector during the

Measure pulse and Reference pulse, respectively.

1-3

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

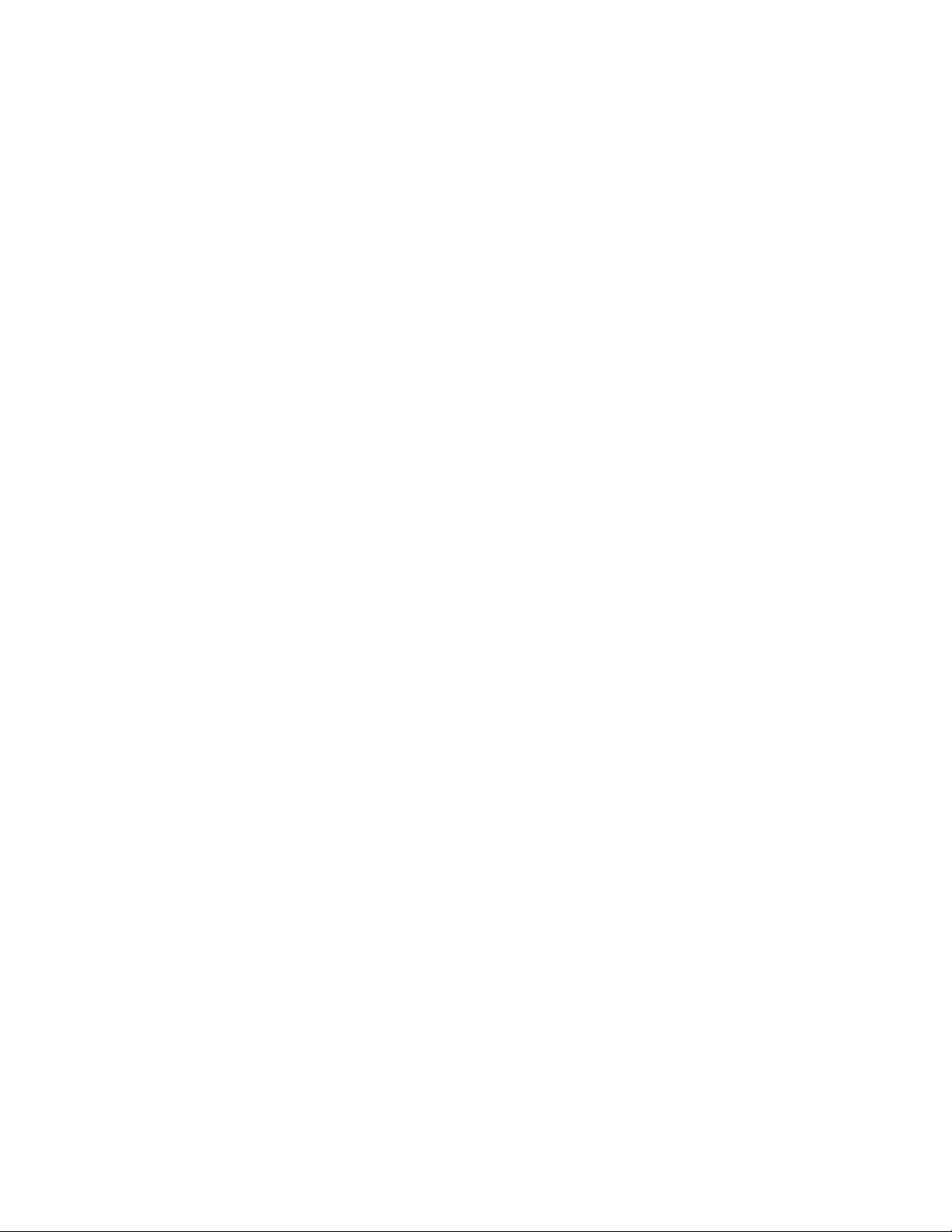

Figure 1-1: Pneumatic Diagram

1-4

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

1.4 Specifications

Ranges User selectable to any full-scale range from 0 - 30 PPM up to 0 - 3,000 PPM

Zero Noise < 0.1 PPM (rms)

Span Noise < 0.5% of reading (rms) or 0.1 PPM (rms)

Lower Detectable Limit 0.2 PPM

Zero Drift (24 hours) * <0.5 PPM

Zero Drift (7 days) * <1.0 PPM

Span Drift (7 days) * 1% of reading

Linearity 1% of Full Scale

Rise/Fall Time (95%) <60 sec to 95%

Sample Flow Rate

Temperature Range

Humidity Range 0-95%RH, non-condensing

Dust Sample must be dust free

Temp Coefficient

Voltage Coefficient < 0.5 PPM per Volt

Dimensions HxWxD 7" x 17" x 25" (178 mm x 432 mm x 635 mm)

Weight 50 lbs (22.7 kg)

Power 100 50/60 Hz, 115 60 Hz, 220V 50/60 Hz., 240 V 50 Hz. 250 Watts

Power, CE 230 V/50 Hz, 250 Watts

Recorder Outputs

Status Output 9 status outputs from opt-isolators

Alarm output 3 opto-isolators to drive TTL relays

* at constant temperature and voltage

800cc/min. ± 10%

5-40°C

< 0.5 PPM per °C

± 100 mV, ± 1 V, ±5 V, ±10 V (Bi-Polar)

1-5

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

1.5 Installation and Overview

The Model 300M is shipped with the following standard equipment:

1. Power cord

2. Operation manual

CAUTION

To avoid personal injury, always use two persons to

lift and carry the Model 300M.

Upon receiving the Model 300M please do the following:

1. Verify no apparent shipping damage. (If damage has occurred please advise shipper first,

then Teledyne API.)

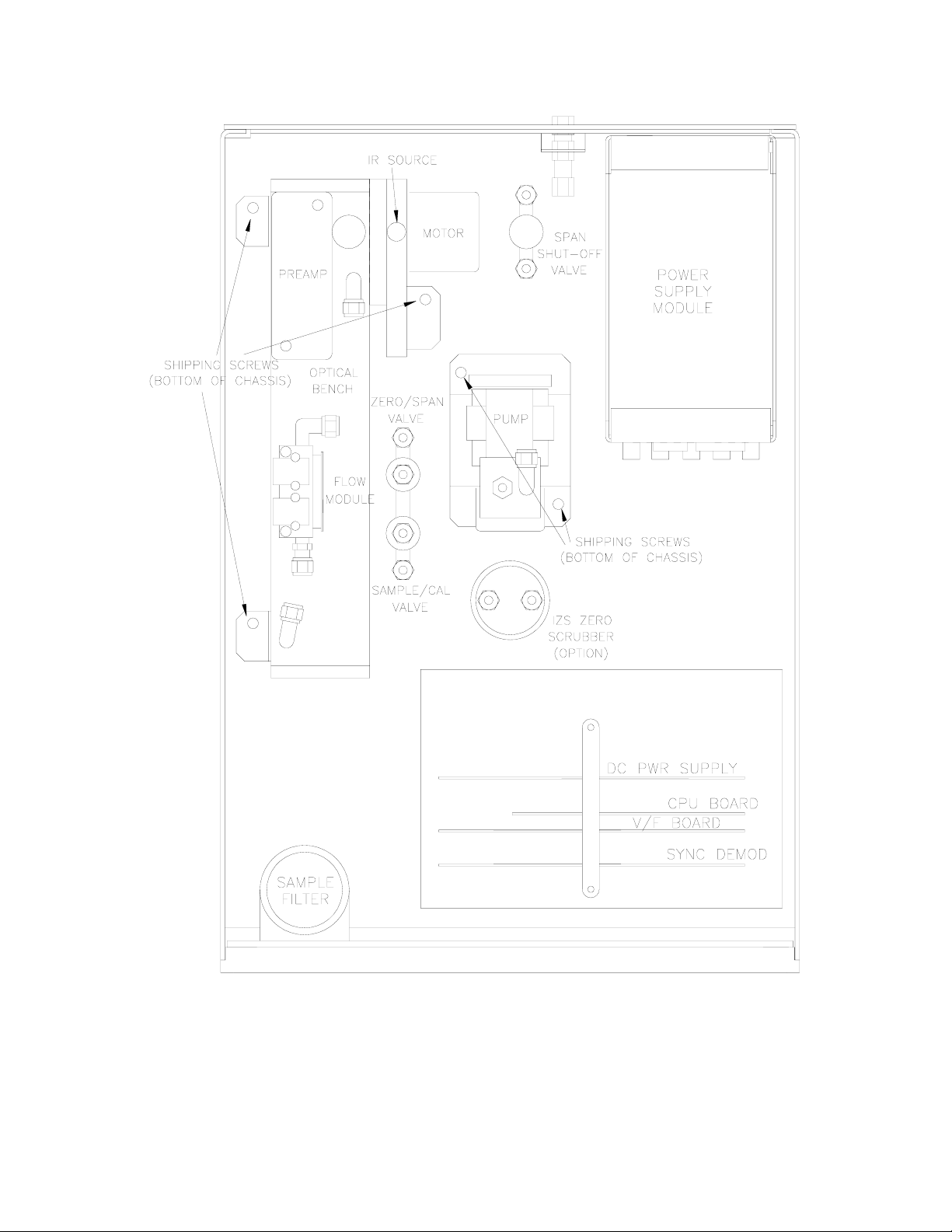

2. Before operation it is necessary to remove the shipping hold down screws. Remove the

instrument cover, then refer to Figure 1-2 for screw location.

3. When installing the Model 300M, allow a minimum of 4 inches (10 cm) of clearance at the

back of the instrument and 1 inch (2.5 cm) of clearance on each side for proper ventilation.

Also, be sure that the clearance below the chassis is unobstructed by at least the height of the

instrument feet.

4. Connect sample inlet line to the sample port on rear panel.

NOTE

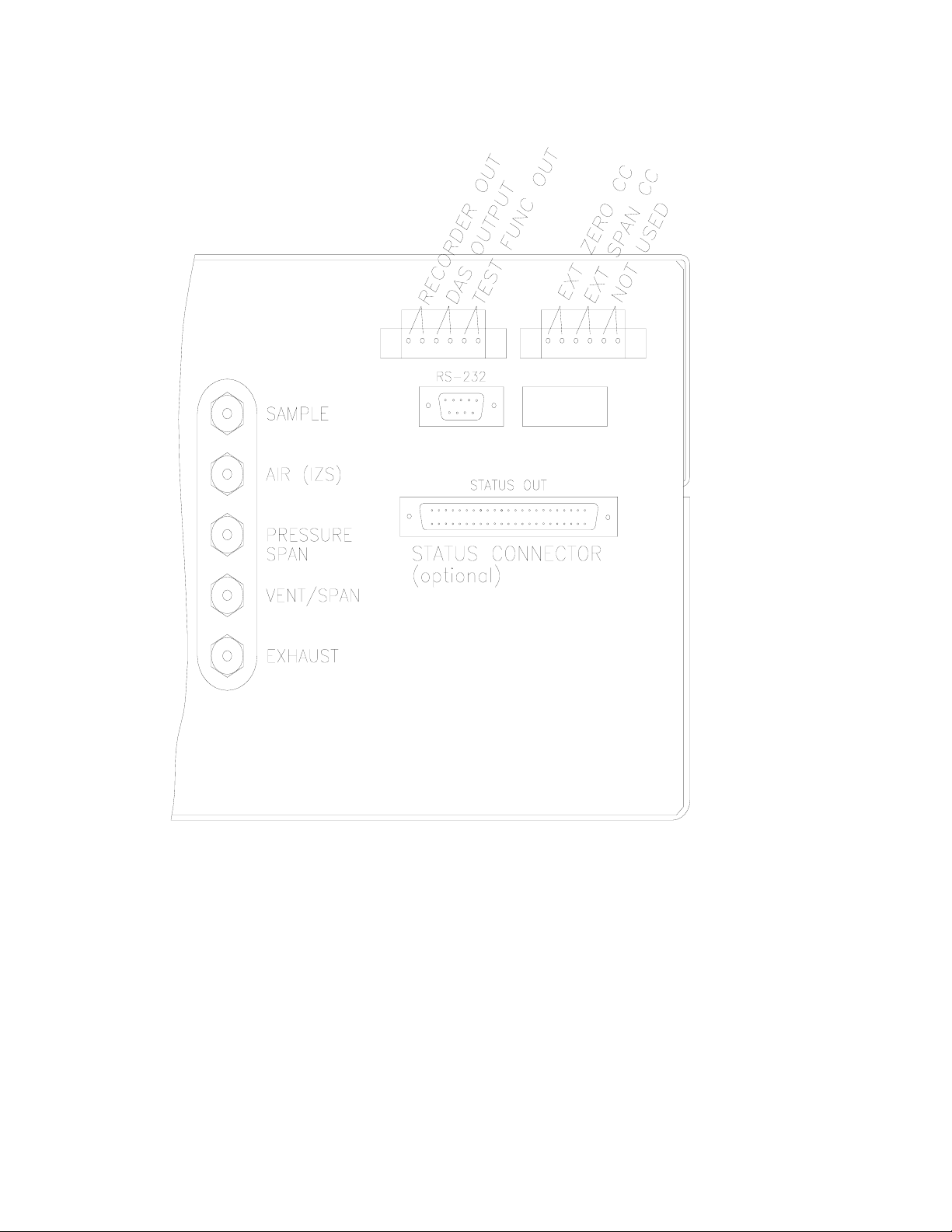

See Figure 1-3 for rear panel pneumatic connections. Sample gas

should only come into contact with PTFE, glass or stainless steel.

Leak check all fittings with soap solution.

CAUTION

Connect the exhaust fitting on the rear panel (see Figure 1-4) to a

suitable vent outside the analyzer area.

5. Connect a recording device to the terminal strip connections on the rear panel (See

Figure 1-3).

6. Connect the power cord to an appropriate power outlet (see the serial number tag for correct

voltage and frequency).

1-6

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

CAUTION

Check that analyzer is set up for proper voltage and frequency.

CAUTION

Power plug must have ground lug.

7. Turn on the M300M by switching the switch on the lower right corner of the front panel (See

Figure 2-1). The front panel display should light with a sequence of messages, -API M300M - software version number, then a normal display as shown in Figure 2-2.

8. Allow about 30 minutes for the temperatures to come up to their respective set-points, then

press the left most button on the front keyboard to scroll through the TEST values. Compare

these values to those noted during the final factory checkout listed in Table 1-2. The values

observed should closely match the Table 1-2 values.

9. Select the range on which the analyzer will be calibrated.

A. From the SAMPLE menu, press SETUP to enter the SETUP menu. (See Figure 2-2 for

appearance of front panel.)

B. Enter the PASSWORD (818).

C. Press RNGE (RANGE).

D. Press SET.

E. Enter the derived full scale range for analog outputs and press ENTR.

F. Press EXIT 2 times to return to the SAMPLE menu.

10. Adjust the analyzer zero point.

A. Input zero air into the sample port.

B. Press CAL from the SAMPLE menu and enter the password (818).

C. Press ZERO.

D. It usually takes about 5 to 10 minutes for the reading to stabilize near zero. After a stable

reading has been obtained press ENTR. The display should now read 0.0 PPM Carbon

Monoxide.

1-7

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

NOTE

Repeatedly pressing enter during span/zero calibration does not

improve the accuracy of the calibration, nor does it speed up

stabilization Allow 5 - 10 minutes to establish an accurate average

for the span/zero reading.

11. Adjust the analyzer span point.

A. Input span gas of approximately 80% of the related full scale range concentration from a

known source through the sample port of the analyzer.

B. Go to manual calibration by pressing the CAL button while in the sample mode.

C. Enter the operator password (818).

D. The menu should now show SPAN, CONC, and EXIT. Enter the concentration of the CO

calibration gas by pressing CONC and entering the value from the keyboard.

E. Wait 10 minutes for a stable reading to be attained and then press SPAN, followed by

ENTR. If the SPAN button is not displayed, this means that the analyzer is too far out of

adjustment to do a reliable calibration and thus it is not permitted (see Section 3.1 for

information on the calibration). The operator can exit the manual calibration procedure

only by pressing the EXIT button.

1-8

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

Figure 1-2: Carbon Monoxide Analyzer

1-9

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

Figure 1-3: Rear Panel Electrical/Pneumatic Connections

1-10

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

1.6 Electrical and Pneumatic Connections

1.6.1 Electrical Connections

Output #1 Carbon Monoxide concentration - Chart Recorder (REC)

Output #2 Carbon Monoxide concentration - Data Acquisition System (DAS)

Output #3 Test function analog output

Input #4 Zero valve request

Input #5 Span valve request

Input #6 Not Used

There are 2 six-pin connector strips on the rear panel shown in Figure 1-3. The pins are divided

into 3-plus/minus pairs and have the functions shown above.

Outputs 1 and 2 have identical signals and electrical characteristics. Output 3 is the same as 1

and 2 electrically, but has analog TEST function signals routed to it. See Diagnostics in Section

5 for details.

1.6.2 Remote Contact Closures Zero/Span Inputs

Remote contact closures can be used to remotely energize the zero/span valves to do a zero or

span check. The external contact closure should be capable of switching 12 VDC at 50 ma.

Refer to Figure 1-3 for connection location. See Sections 1.8.2 and 3.6 for further details.

NOTE

Zero or span checks can be performed in any order.

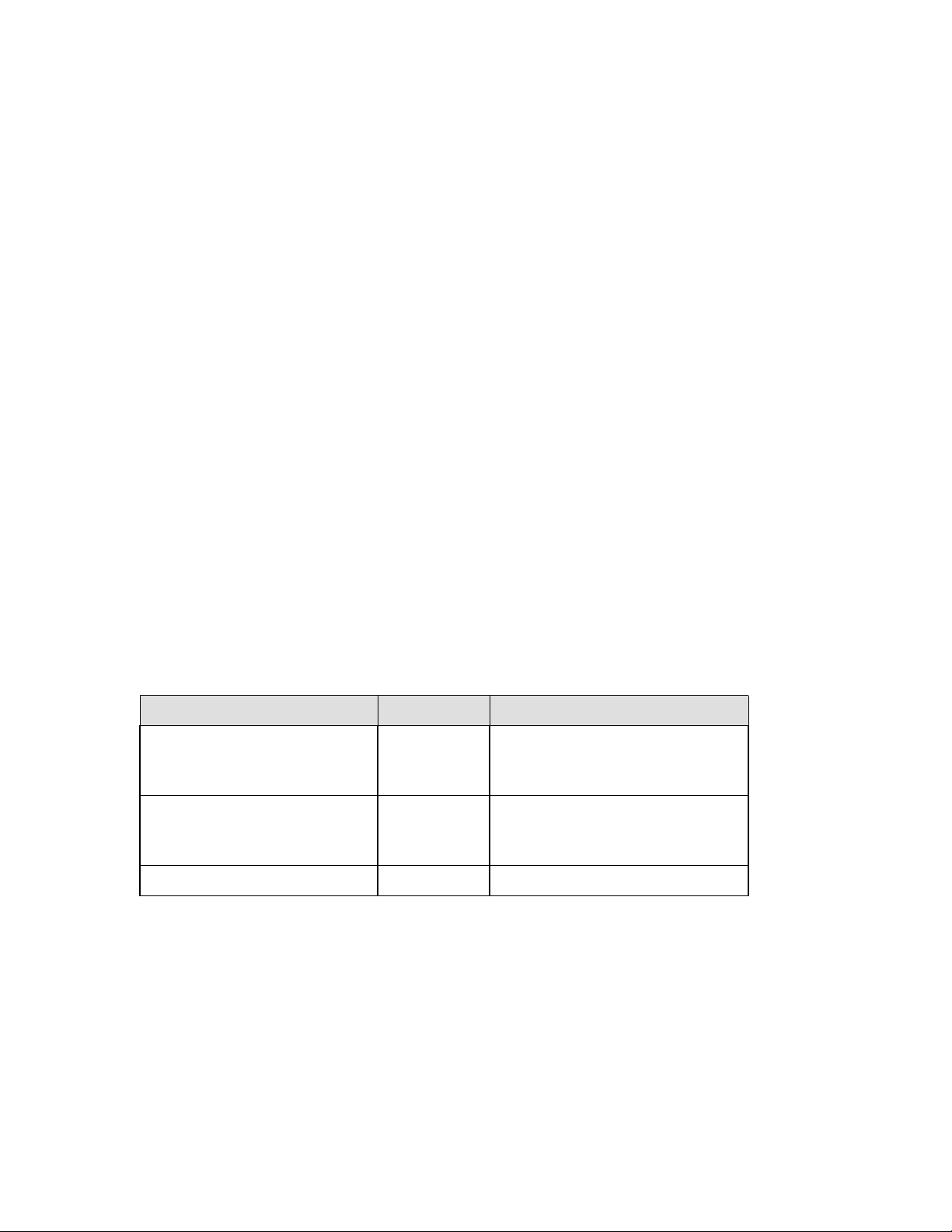

1.6.3 Status Outputs (Optional)

Status outputs report analyzer conditions via contact closures located on the optional DB-50

connector on the rear panel. The contacts are NPN transistors which can sink 50 mA of DC

current. The pin assignments are listed in Table 1-1.

1-11

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

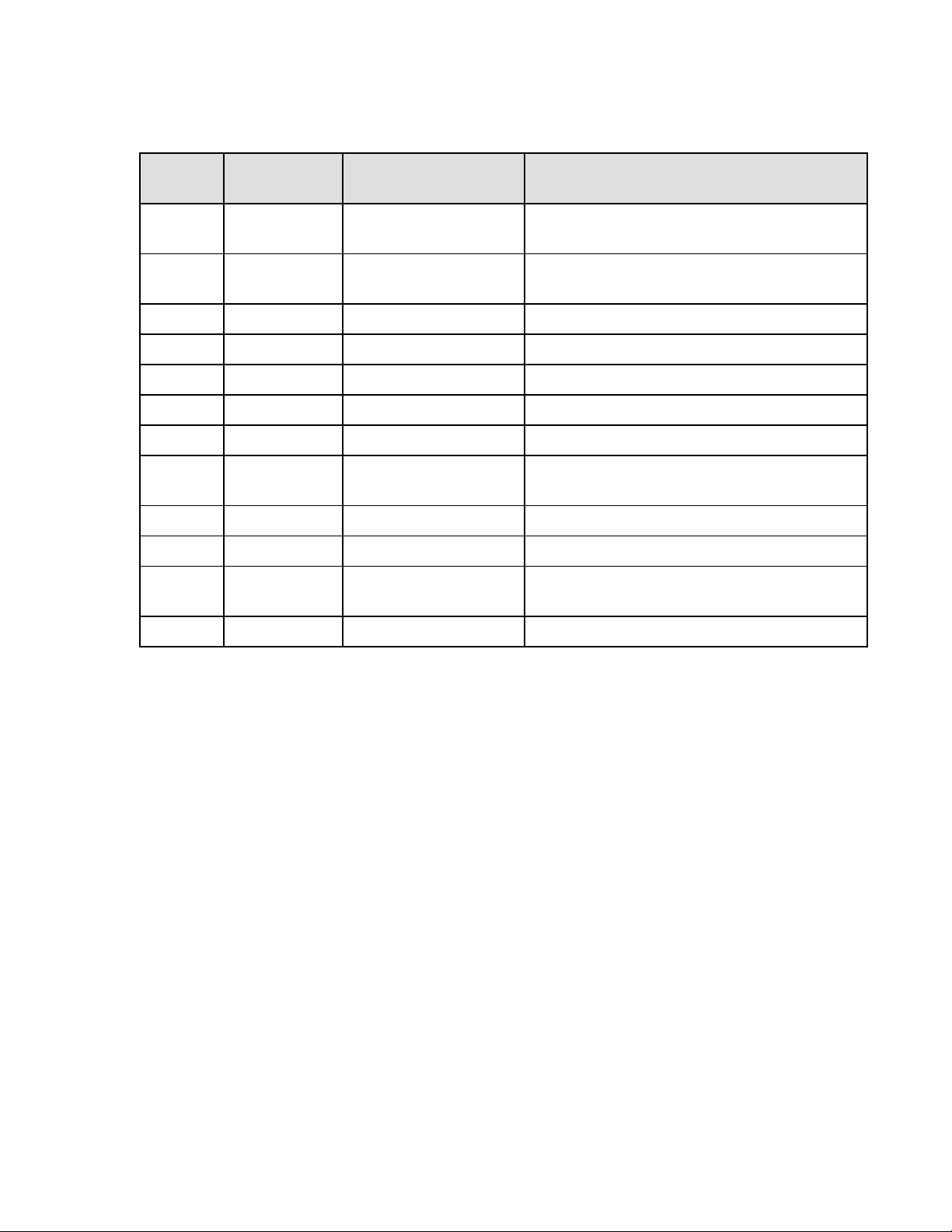

Table 1-1: Status Outputs

Output#

1 1,2 ALARM 1

2 3,4 ALARM 2

3 5,6 SYSTEM OK True if no alarm conditions exist

4 7,8 TEMP ALARM True if any temp warning exists

5 9, 10 DIAG MODE True if in diagnostic mode

6 11,12 POWER ON True if main power is on

7 13,14 PRESS ALARM True on low pressure

8 15,16 HIGH RANGE

9 17,18 FLOW ALARM True if a flow warning exists

10 19,20 RESERVED

11 21,22

Pin Pair

(Low, High)

Definition Condition

Gas concentration is exceeding the Hi set

limit.

Gas concentration is exceeding the HiHi set

limit.

True if the auto-range function has switched

SELECTED

SOURCE

WARNING

the analyzer into high range.

True if the analyzer source intensity is out

of limits.

12 23,24 RESERVED

1.6.4 RS-232

The RS-232 connection is a male, 9-pin D-sub connector at the location shown in Figure 1-3.

See also Appendix A for additional information.

1.6.5 Pneumatic System

The Model 300M is equipped with a vacuum pump capable of pulling 800 cc/min across a flow

restrictor. This allows a smooth, stable flow of sample through the analyzer.

Sample enters the analyzer through a particulate filter element (47 mm diameter) mounted

immediately behind the front panel. The sample then enters directly into the sample cell. Please

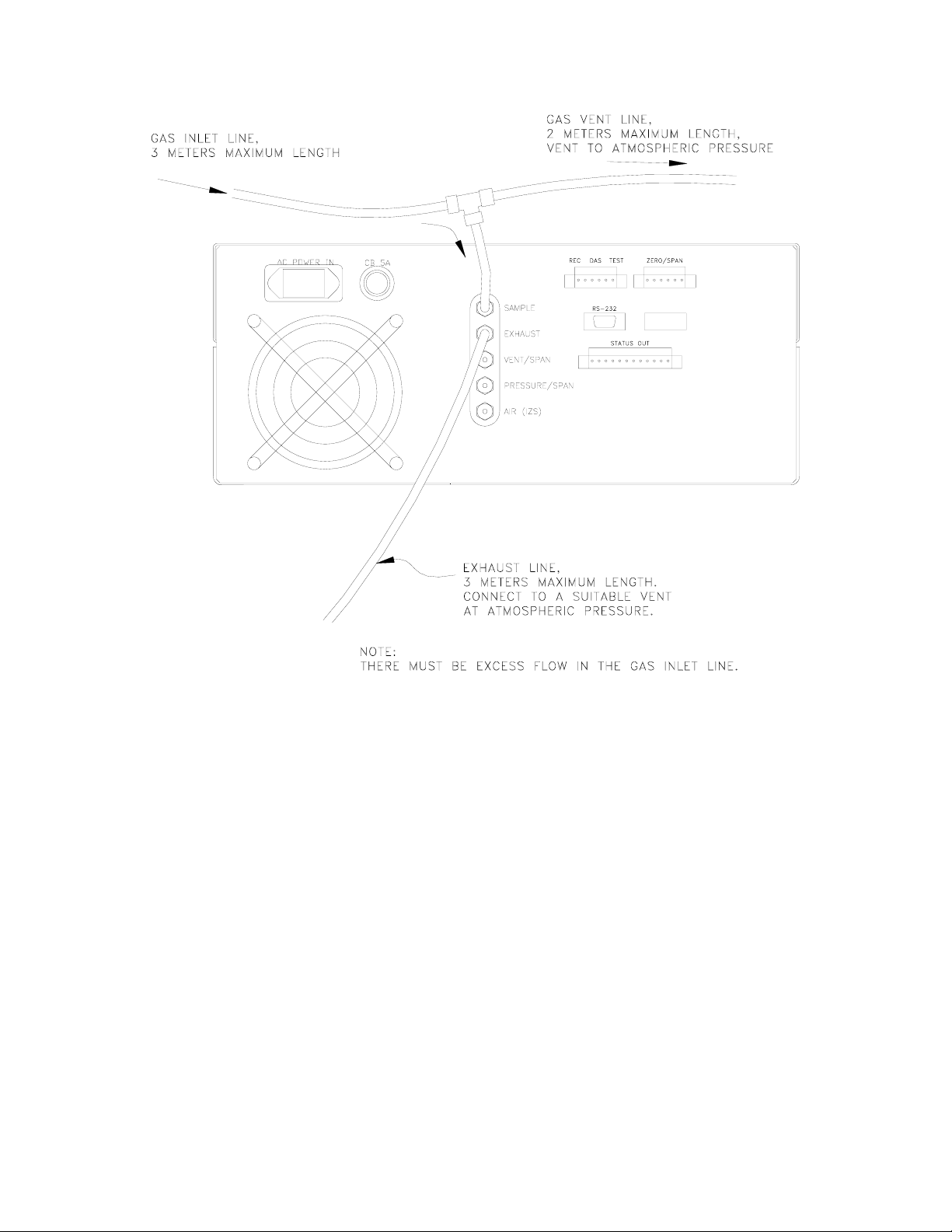

see Figure 1-1 for a flow diagram and Figure 1-4 for pneumatic connections.

1-12

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

1.6.6 Sample Gas Connection

1/4" O.D. PTFE tubing is needed to connect the sample source to the analyzer. See Figure 1-4.

NOTE

Use PTFE, glass, stainless steel or non-reactive materials for

sample gas connections.

NOTE

Use vent line when sampling from pressurized manifold - sample

pressure should not exceed ± 2 mm Hg.

1.6.7 Zero/Span Valve Connections

Zero air and span gas manifolds should supply their respective gases in excess of 800cc/min

demand of the analyzer. The manifold should be vented to the outside atmosphere and be of

sufficient length and diameter to prevent back diffusion and pressure effects. See Figure 1-4.

1.6.8 Exhaust Connections

A single 1/4" O.D. tube should be connected from the analyzer sample exhaust to an area outside

of the room the analyzer occupies. The maximum length of the exhaust line should not exceed 3

meters (See Figure 1-4).

Connect the exhaust (and vent) fitting on the rear panel to a suitable

vent outside the analyzer area and away from personnel.

CAUTION

1-13

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

Figure 1-4: Rear Panel Pneumatic Connections

1-14

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

1.7 Operation Verification

The Model 300M Analyzer is now ready for operation.

1. Read Sections 1.3 and all of Section 4 of the manual to understand the analyzer operation.

2. Turn on the power by pressing the on/off switch on the front panel (see Figure 2-1). The

display should turn on and green (sample) status LED should be energized. The green LED

should blink indicating the instrument has entered the HOLD-OFF mode. Sample mode can

be entered immediately by pressing the EXIT button on the front panel. The red "fault" light

will also be on until the flows, temperatures and voltages are within operating limits. Clear

the fault messages.

3. After a 30-minute warm-up, review the TEST function values in the front panel display by

pushing the left most keyboard button labeled TEST. Not every TEST function is a

diagnostic of correct analyzer operation, therefore TEST functions not covered below can be

ignored for now.

4. CO REF, CO MEAS - TEST function values should be between 2500 mV and 4700 mV.

5. Pressure - 29 to 30 Inches-Mercury-Absolute at sea level. Other values will be displayed

depending on altitude of analyzer.

6. Sample Flow - 800 cc/min ±20 %.

7. Sample Temp - Ambient temperature (10 - 40°C) ± 10°C.

8. Optical Bench Temp - 48°C ± 1° The computer drives the temp to this setpoint.

9. Filter Wheel Temp - 68°C ± 2° The computer drives the temp to this setpoint.

10. Box Temp - Ambient +10°C.

11. DC Power Supply - 2500 mV ± 200 mV - This is a composite of all of the DC voltages in the

instrument. The value is not important but it should be within the range indicated.

12. If the TEST functions are within the limits given above, the instrument should function

correctly. If there is a problem, please read the manual and check your setup and test values.

The Model 300M is now ready for calibration (see Section 3.1).

1-15

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

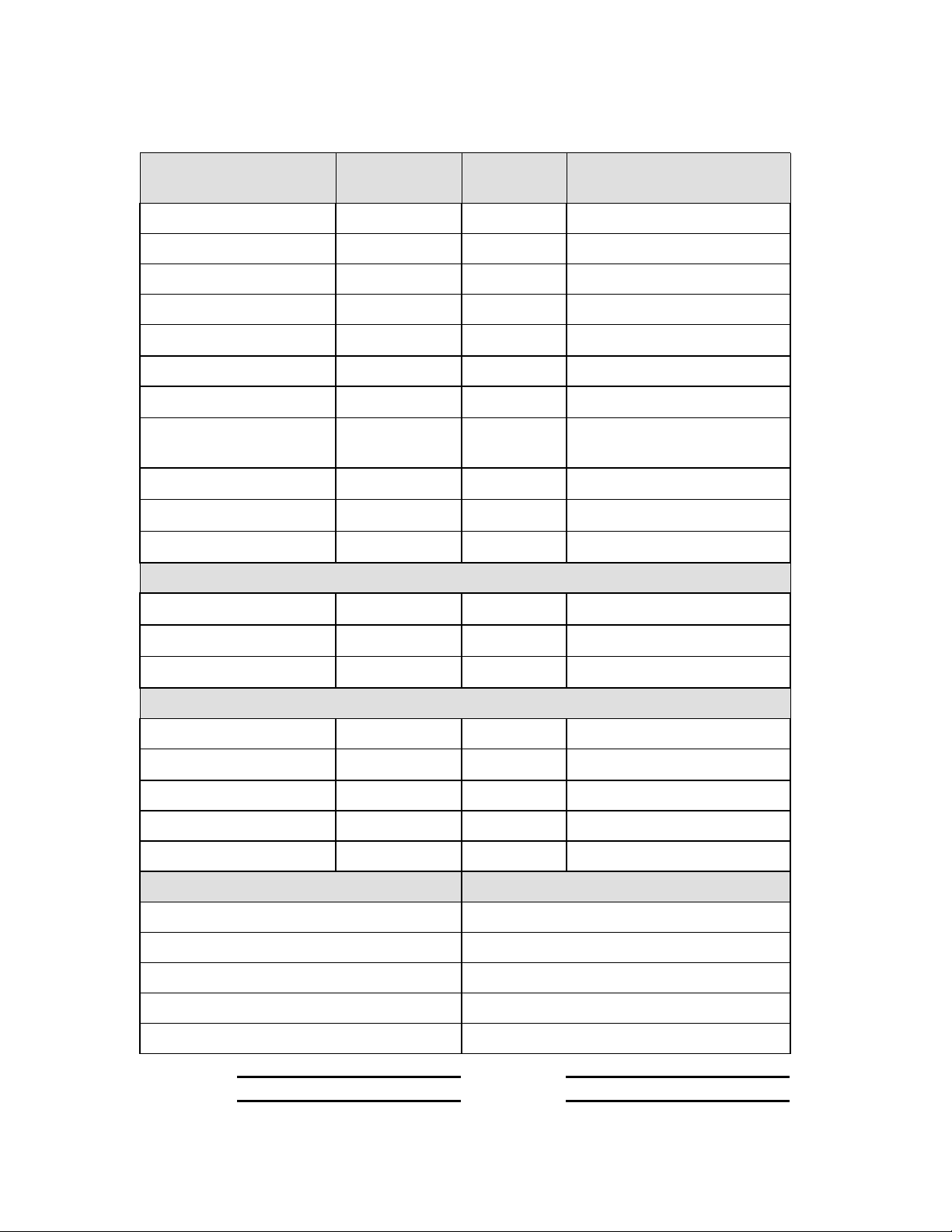

Table 1-2: Final Test and Calibration Values

Test Values

CO MEAS mV 2500 - 4700

CO REF mV 2500 - 4700

MR RATIO 1.1 – 1.22

SAMPLE PRESS in-Hg 27 - 30

VACUUM PRESS in-Hg

SAMPLE FLOW CC/MIN 700 - 900

BENCH TEMP

DC POWER

SUPPLY

SAMPLE TEMP

BOX TEMP

WHEEL TEMP

Dark Ref mV

Observed

Value

mV

Diagnostic

Units Nominal Range

10 ± 5

°C 48 ± 1

2500 ± 200

°C

°C

°C 68 ± 2

45-50

8- 40

125 ± 50

Dark Meas mV

Electrical test PPM

Span and CAL Values

CO Span Conc PPM 400

CO Slope

CO Offset -0.1 to +0.1

Noise at Zero (p-p) PPM 0.5

Noise at Span (p-p) PPM <1.0% of reading

Factory Installed Options Option Installed

Factory Installed Options Option Installed

Power Voltage/Frequency

Rack Mount, w/ Slides

Internal Zero Span Valves

Analog Voltage Range 0 - V

125 ± 50

400 ± 4

1.0 ± 0.3

PROM # Serial #

Date Technician

1-16

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

1.8 Options

1.8.1 Rack Mount With Slides

This option, including slides and rack mounting ears, permits the analyzer to be mounted in a

standard 19" wide x 30" deep RETMA rack.

NOTE

A 1¾ minimum separation between each instrument must be

maintained to allow for air circulation. Blocking the air inlet vent on

the bottom of the analyzer will result in internal overheating.

1.8.2 Span Valve

The Span Valve option consists of stainless steel solenoid valve mounted inside the analyzer

connected to admit sample gas or customer-generated span gas.

The valve is controlled from the front panel push-buttons, the auto-timer via the RS-232

interface, or by remote contact closure.

A span gas manifold should supply at least 1000 cc/min. The manifold should be vented to the

outside atmosphere away from the personnel.

A span gas manifold can be connected to the analyzer in either of two ways.

1. If it is desired to use span gas directly from a pressurized source (e.g. a gas cylinder) the

connection can be made directly to the Pressure Span port on the analyzer rear panel. In this

case the Vent/Span port at the rear panel should be vented to a suitable exhaust manifold at

ambient atmosphere pressure. The pressure regulator on the gas source (cylinder should be

sent to provide 20 - 25 PSI delivery pressure).

2. If it is desired to use span gas from a source which delivers gas at atmosphere pressure (e.g. a

calibrator), the span gas manifold should be connected at the Vent/Span port at the analyzer's

rear panel, and the Pressure/Span port should be capped.

1-17

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

INTENTIONALLY BLANK

1-18

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

2 OPERATION

2.1 Key Features

The important features of the Teledyne API Model 300M CO Analyzer are listed below.

2.1.1 CO Readout

The Teledyne API Model 300M CO Analyzer constantly displays the current Carbon Monoxide

reading (in PPM) in the upper right hand corner of the alphanumeric display.

2.1.2 CO Analog Output

The Teledyne API CO Analyzer provides a buffered analog output of the current CO readings on

each of two pairs of outputs on the rear panel (see Figure 1-3) for DAS and recorder reporting.

The analog outputs provide for 20% over-range. For example, on the 500 PPM range the

M300M will correctly report concentrations up to 600 PPM and output up to 6.00 volts to the

DAS and recorder outputs. In addition TEST function values can be routed to a third analog

output.

2.1.3 E2ROM Backup Of Software Configuration

The Teledyne API CO Analyzer has a few jumpers that need to be set by the operator.

Configuration of the analyzer is done under software control and the configuration options are

stored in electrically erasable (E

analyzer is powered off.

There is one exception to this. The analog output voltage ranges are set by jumpers on the A/DI/O board as shown in Section 10.6.3.

2

) ROM. Thus, configuration options are saved even when the

2.1.4 Adaptive Filter

The M300M CO Analyzer is able to provide a smooth, stable output by means of an adaptive

filter. During conditions of constant or nearly constant concentration the filter is allowed to grow

to 200 samples (1 minute) in length, providing a smooth, stable reading. If a rapid change in

concentration is detected, the filter is cut to 20 samples to allow the analyzer to quickly respond

to rapidly varying signals.

2-1

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

2.1.5 Data Acquisition (DAS)

The Model 300M contains a flexible and powerful built in data acquisition system (DAS) that

enables the analyzer to store concentration data as well as many diagnostic parameters in its

battery backed memory. For more information on programming custom Data Channels, a

supplementary document containing this information can be requested from Teledyne API.

2.1.6 RS-232 Interface

The M300M CO Analyzer features an RS-232 interface which can output the instantaneous

and/or average CO data to another computer. It can also be used as a command and status

channel to allow another computer to control the analyzer. Refer to Appendix Figure A-1 or

Appendix A for details on the RS-232 interface.

2.1.7 Password Protection

The M300M CO Analyzer provides password protection of the calibration and setup functions to

prevent incorrect adjustments to the analyzer. There are two levels of passwords which

correspond to operator, supervisor/maintenance, and analyzer configuration functions. When

prompted for a password, any of the valid passwords can be entered, but the CPU will limit

access to the functions allowed for that password level. Each level allows access to the functions

of all the levels below plus some additional functions. Table 2-1 lists the password levels and the

functions allowed for each level.

Table 2-1: Password Levels

Password Level Functions Allowed

No password 0 TEST

MSG

CLR

Calibration (512) 1 CALZ

CALS

CAL

Setup (818) 2 SETUP

2-2

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

NOTE

The operator and setup passwords can be disabled. To do this, enter

setup-password and toggle “ON” to “OFF”. Push “ENTR” and the

passwords will be displayed.

2.2 Front Panel

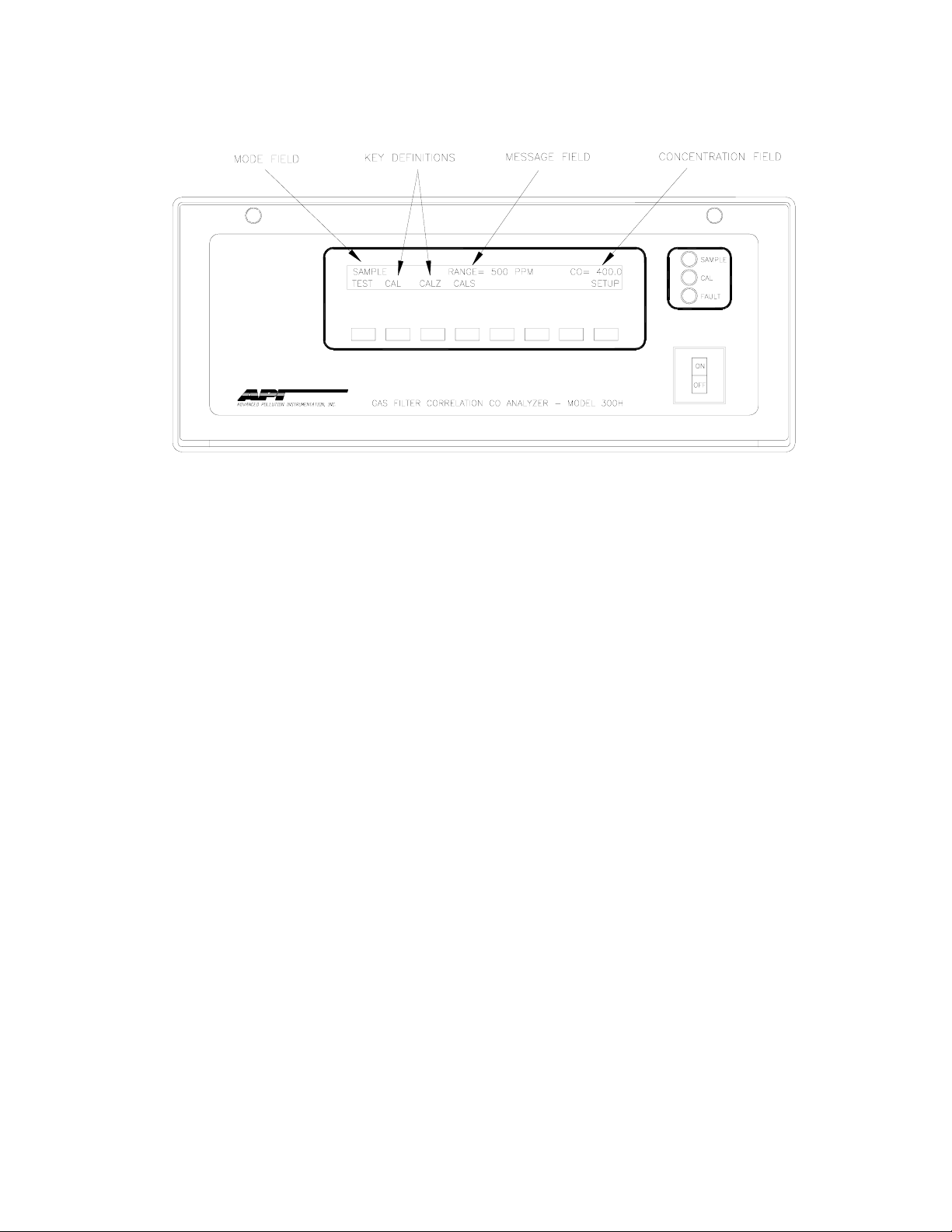

This section describes the operator interface from the point of view of the front panel. The front

panel consists of a 2-line by 40-character alphanumeric display, 8 push buttons, and 3 status

LED’s. Each of these features is described below.

2.2.1 Front Panel Display

The display is divided into 4 main "fields": the mode field in the upper left, the message field in

the top center, the sample concentration field consisting of the most recent instantaneous Carbon

Monoxide value field in the upper right, and the MENU field which occupies the entire bottom

line of the display. A typical display is shown in Figure 2-1.

2-3

Teledyne API Model 300M CO Analyzer Instruction Manual, 04033, Rev. A

Figure 2-1: Model 300M Front Panel

The mode field indicates the current mode of the analyzer. Usually, it shows "SAMPLE",

indicating that the instrument is in the sample mode. Manual span checking or calibration can

only be performed by pressing the buttons on the front panel labeled "CALZ", "CALS", or

"CAL". Automatic span check only occurs at the preset time. Dynamic span adjust can be

performed during automatic or remote span checks. Remote span adjustment is performed via a

command from the RS-232 or the external contact closure inputs. Calibration and span

adjustments are discussed in greater detail in Section 3.1. Table 2-2 lists all the possible modes

in the analyzer and their meanings.

2-4

Loading...

Loading...