Page 1

MANUAL ADDENDUM

MODEL 201A

AMMONIA ANALYZER

TELEDYNE ADVANCED POLLUTION INSTRUMENTATION

Copyright 2005 T-API Inc.

(T-API)

9480 CARROLL PARK DRIVE

SAN DIEGO, CA 92121-5201

TOLL-FREE: 800-324-5190

FAX: 858-657-9816

TEL: 858-657-9800

E-MAIL: api-sales@teledyne.com

WEB SITE:

12 September, 2005

www.teledyne-api.com

04689

REV. B1

Page 2

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety

messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety

message is associated with a safety alert symbol. These symbols are found in the manual and

inside the instrument. The definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions for details on

the specific danger.

CAUTION: Hot Surface Warning

CAUTION: Electrical Shock Hazard

Technician Symbol: All operations marked with this symbol are to be

performed by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central

safety grounding point for the instrument.

CAUTION

The analyzer should only be used for the purpose

and in the manner described in this manual.

If you use the analyzer in a manner other than that for which

it was intended, unpredictable behavior could ensue with

possible hazardous consequences.

1

Page 3

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

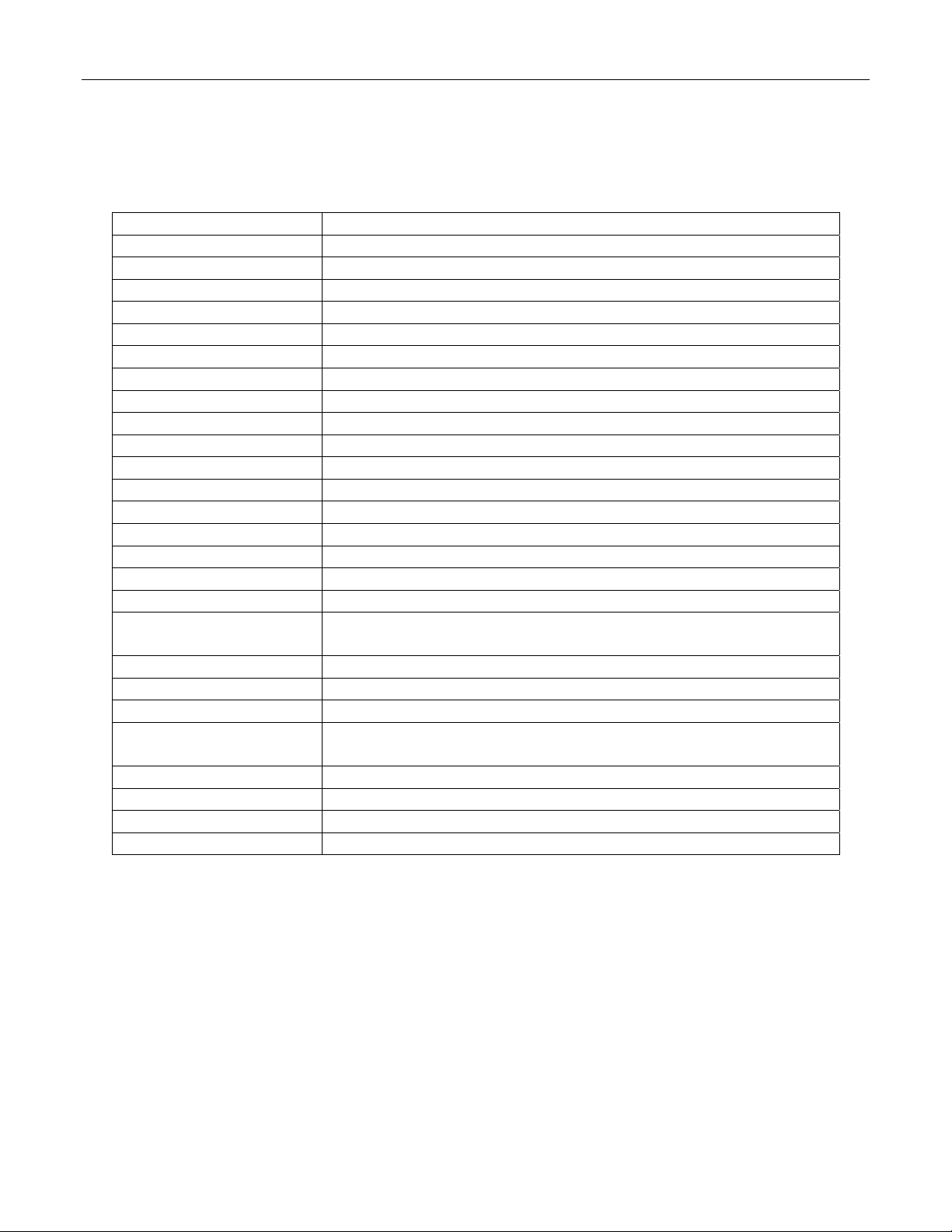

TABLE OF CONTENTS

SAFETY MESSAGES .......................................................................................................1

TABLE OF CONTENTS...................................................................................................2

1 .0 M201A AMMONIA ANALYZER............................................................................6

1.1 PRINCIPLE OF OPERATION................................................................................................... 6

1.1.1 Special Considerations for Ammonia Measurement.................................................. 7

1.1.2 Sample Filtration........................................................................................................ 8

1.2 M201A ANALYZER SPECIFICATIONS..................................................................................... 9

2 .0 CALIBRATION PROCEDURE..............................................................................10

2.1 ZERO/SPAN CALIBRATION – BASIC INSTRUMENT.................................................................. 10

2.1.1 Zero/Span Calibration with Z/S Valves or ECO Option............................................ 13

2.1.2 TN/TNx Channel Calibration Quality........................................................................ 15

2.1.3 NH3 Calibration....................................................................................................... 16

2.1.4 Channel Calibration Quality..................................................................................... 17

3 .0 MAINTENANCE SCHEDULE...............................................................................18

3.1 M201A MAINTENANCE SCHEDULE ..................................................................................... 18

3.2 MAINTAINING THE M501NH CONVERTER............................................................................ 18

3.3 AUTOZERO FLOW CHECK.................................................................................................. 20

4 .0 M201A SPARE PARTS LIST..................................................................................28

2

Page 4

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

LIST OF FIGURES

FIGURE 1 - M201A AMMONIA ANALYZER – BLOCK DIAGRAM ................................................................. 21

FIGURE 2 - M201A EXTERNAL PNEUMATIC CONNECTION DIAGRAM WITH ECO (EXTERNAL CALIBRATOR

OPTION)............................................................................................................................................. 22

FIGURE 3 - M201A PNEUMATIC DIAGRAM BASIC...................................................................................... 23

FIGURE 4 - M201A PNEUMATIC DIAGRAM Z/S OPTION............................................................................. 24

FIGURE 5 - M201A PNEUMATIC DIAGRAM EXTERNAL CALIBRATOR OPTION (ECO) ................................ 25

FIGURE 6 – M501NH CONVERTER CARTRIDGE ......................................................................................... 26

3

Page 5

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

LIST OF TABLES

TABLE 2.1 - ZERO CALIBRATION PROCEDURE - ZERO GAS THROUGH THE SAMPLE PORT ......................... 11

TABLE 2.2 - ENTER THE EXPECTED SPAN GAS CONCENTRATIONS PROCEDURE......................................... 11

TABLE 2.3 - SPAN CALIBRATION PROCEDURE - SPAN GAS THRU SAMPLE PORT ........................................ 12

TABLE 2.4 - ZERO CALIBRATION PROCEDURE - ZERO GAS FROM REAR PANEL ZERO AIR INLET................. 13

TABLE 2.5 - ENTER THE EXPECTED SPAN GAS CONCENTRATIONS PROCEDURE......................................... 14

TABLE 2.6 - CALS - SPAN CAL PROCEDURE - GAS FROM REAR PANEL SPAN GAS INLET............................ 15

TABLE 3.1: PREVENTATIVE MAINTENANCE SCHEDULE............................................................................. 18

TABLE 3.2 – M501NH CONVERTER REBUILD PARTS LIST......................................................................... 19

4

Page 6

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

5

Page 7

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

1.0 M201A AMMONIA ANALYZER

This manual is to be used in conjunction with the M200A NOx Analyzer manual p/n

02246 supplied with this instrument.

The M201A Ammonia Analyzer consists of a modified M200A Nitrogen Oxides Analyzer

and M501NH Ammonia Converter:

A functional block diagram of the system is shown in Figure 1.

The instrument comes in three pneumatic configurations:

• The basic system is shown in Figure 3;

• The M201A with Z/S valves is shown in Figure 4;

• The M201A with External Calibrator Option (ECO) is shown in Figure 5.

Figure 2 can be used to connect the M201A system for installation. Please note that for a

M201A with either a Zero/Span or ECO option, you must connect the umbilical cord,

02255, between the analyzer and the converter assembly.

1.1 Principle of Operation

The Teledyne API Model 201A Analyzer measures ammonia by converting NH3 to nitric

oxide by the following reaction:

4NH

The resulting NO is then measured by the chemiluminescent reaction of NO with ozone.

Consult Section 4.1 in the M200A manual (provided with this instrument) for more

details on NO measurement.

A molybdenum converter is continuously in the pneumatic pathway, providing the TN

channel signal. The

converters are in series, creating the TNx signal.

The ammonia concentration is computed by the difference between the TNx and TN

channels, as shown in the following equation:

NH

See the pneumatic diagram in Figure 1.

+ 5O2 → 4NO + 6H2O

3

M501NH ammonia converter is periodically switched so both

→ TNx - TN

3

The actual formula for computation of ammonia concentration is more complicated than

the above equation, as it includes converter efficiencies, plus sample temperature and

pressure. The difficulty in ammonia measurement is that the molybdenum converter

6

Page 8

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

converts some of the ammonia to NO, thus the TN channel data contains a small

ammonia signal. Secondly, the ammonia converter does not convert all of the ammonia

or ambient NO2 to NO. Finally, the high temperature in the ammonia converter causes

the oxygen and nitrogen in ambient air to react, creating a background of NOx which

needs to be factored into computing the result. Fortunately, all of the above

shortcomings have been overcome in the M201A by careful calibration, and calculation

of the result. .

Periodically, the AutoZero valve switches allowing the analyzer to read zero

background. The AutoZero readings are subtracted from all of the other readings. This

improves zero baseline stability.

As with many chemical reactions the conversion of ammonia in the presence of other

oxides of nitrogen is complicated.

In the molybdenum converter operating at 315

o

C, the following significant reactions are

taking place:

Mo + NO

+ Mo + O2 → MoO3 + NO <10% Eff

NH

3

→ MoO3 + NO ~100% Eff

2

Notice in the second reaction some of the ammonia is converted to NO by the

molybdenum metal.

The M501NH NH3 Converter operates at 825

o

C. At this high temperature, several

reactions occur:

NO → NO Efficiency = ~100 %

NOx → NO Efficiency = ~85%

NH3 → NO Efficiency = ~85%

N2 + O2 → NO Efficiency = <1%

As can be seen from the above reactions, the calculation of the ammonia concentration

and overall calibration of the instrument must be done carefully if accurate ammonia

concentrations are to be measured. The calibration procedure is covered in Section 2.

1.1.1 Special Considerations for Ammonia Measurement

Ammonia is a difficult gas to measure due to its chemical characteristics. Because of

its large dipole moment, the gas tends to adsorb on surfaces and diffuse into many

materials. The following precautions should be observed when designing an ammonia

sampling system and connecting the M201A analyzer to the system:

Materials:

Do NOT use TEFLON tubing or fittings in contact with NH3 sample or span gas.

7

Page 9

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Do NOT use copper tubing or fittings designed for household plumbing.

Use ONLY Chromatography grade (cleaned, passivated) stainless steel tubing

Use ONLY Glass tubing for sample inlet manifold.

These rules apply also to your calibrator’s internal plumbing. Verify that the calibrator

pneumatic pathway that contacts ammonia only uses stainless steel or glass tubing.

The M702SS calibrator supplied with the External Calibration Option is built with

stainless steel fittings and tubing for all internal plumbing wetted by NH3.

Typical ambient NH3 levels are < 15 ppb, unless there is some large source of

ammonia nearby, so the sampling and analysis system must be carefully designed and

well maintained.

1.1.2 Sample Filtration

The M201A does not come with a sample filter installed. Depending on the options

ordered, a sample filter may be separately packaged with the instrument. If the filter is

installed, the instrument response time is significantly increased, due to its large surface

area. Also, the condition of the filter (particulate loading and type) can adversely affect

the response time.

For minimum response time operation, the instrument should be supplied with clean

sample gas at ambient pressure.

If the sample filter is not included, the only additional filter in the M201A pneumatic

pathway is a ¼” dia stainless steel sintered filter used to protect the flow control orifice

from plugging. This filter will plug rapidly if the sample gas is not filtered before entering

the analyzer. Some means of filtering the sample gas, such as an external stainless

steel filter should be added upstream of the analyzer.

8

Page 10

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

1.2 M201A Analyzer Specifications

Ranges 0-50 to 0-2000 ppb in 1 ppb increments

Range Modes Single, Independent, AutoRange

Noise at Zero

Noise at Span

Lower Detectable Limit 1 ppb RMS

Zero Drift

Span Drift < 1.0% FS Range / 7 days

Lag Time 40 sec

Rise Time 90% 120 sec

Fall Time 90% 120 sec

Sample Flow Rate 1000 cc/min

Linearity 2% of full scale

Precision 1.0% of reading

Temp Range 10-30oC

Dimensions HxWxD 7” x 17” x 23.6” (18cm x 43cm x 61cm)

Weight, Analyzer 43 lbs (20 kg)

Weight, Converter 24 lbs (11 kg)

Weight, Pump 16 lbs (7 kg)

Power, Analyzer 100V ~50/60 Hz, 120V ~60 Hz, 220V ~50Hz, 240V ~50 Hz,

Power, Analyzer

Power, Pump 110V ~60 Hz, 220V ~50 Hz, 240V ~50 Hz, 295 watts

Power, Pump CEMark5230 V ~50 Hz, 2.5 A peak

Environmental Installation Category Pollution Degree 2, Over-voltage

Analog Output 0-100, 0-1, 0-5, 0-10VDC bi-polar, 4-20mA isolated

Analog Resolution 1 part in 2048

Status Option 12 Status Outputs

Measurement Units ppb, ug/m3

1

1

3

0.5 ppb RMS

< 1.0% of reading above 50 ppb

2 ppb / 24 hours

125 watts

5

230V ~50 Hz, 125 watts

Category II

1. As defined by USEPA

2. Defined as twice the zero noise level

3. At constant temperature and voltage

4. Bi-polar

5. Electrical rating for CE Mark Compliance

9

Page 11

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

2.0 CALIBRATION PROCEDURE

Calibration of the M201A is done by first calibrating the TN and TNx channels with NO

span gas diluted with zero air. In the second phase of calibration, ammonia span gas is

introduced to measure the overall system efficiency for NH3 conversion. Unlike NOx

analysis, the NH3 converter efficiency must be measured because it is considerably

lower than 100% and may change as the converter ages.

If the instrument is configured as a basic model, all zero/span gasses are introduced

through the sample port. If the Zero/Span valves option or the ECO option is ordered,

the zero/span gas is introduced through the zero/span valves. There are several ways

of automating the calibration or span check process, they are covered in Section 7 of

the M200A manual. After reviewing the procedure described below, it should be simple

to adapt the procedures in Section 7 to the M201A, if necessary.

2.1 Zero/Span Calibration – Basic Instrument

Since the zero gas concentration is defined as 0 ppb, it is not necessary to enter the

expected zero value.

10

Page 12

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Table 2.1 - Zero Calibration Procedure - Zero Gas Through the Sample Port

Step No.

Action Comment

1. Press

CAL

The M201A enters the calibrate mode from

sample mode. Input zero gas through the

sample port.

2. Wait 20

Wait for reading to stabilize at zero value.

min

3. Press

ZERO

If you change your mind after pressing ZERO,

you can still press EXIT here without zeroing

the instrument.

4. Press

ENTR

5. Press

EXIT

Pressing ENTR actually changes the

calculation equations.

M201A returns to sampling. Immediately after

calibration, data is not added to the DAS

averages.

Table 2.2 - Enter the Expected Span Gas Concentrations Procedure

Step No.

Action Comment

1. Press

This key sequence causes the M201A to

prompt for the expected TNX concentration.

CAL-CONC-TNX

Enter the TNX span concentration value by

pressing the key under each digit until the

expected value is set. This menu can also be

entered from CALS or CALZ.

2. Press ENTR ENTR stores the expected TNX span value.

3.

Press

CAL-CONC-TN

Now enter the expected TN span concentration

as in step one.

4. Press ENTR Pressing ENTR stores the TN span value and

returns the prompt to the CONC menu.

5.

Press EXIT Returns instrument to SAMPLE mode.

11

Page 13

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Table 2.3 - Span Calibration Procedure - Span Gas thru Sample Port

Step No.

Action Comment

1. Press CAL The M201A enters the calibrate mode. Input NO span

gas through the sample port.

2. Press

CAL-CONV-SET

Set the converter efficiency parameter to 1.0000, then

press ENTR-EXIT.

2. Wait 20 min Wait for reading to stabilize at span value.

3. Press SPAN If you change your mind after pressing SPAN, you can

still press EXIT here without spanning the instrument.

4. Press ENTR Pressing ENTR actually changes the calculation

equations and causes the instrument to read the TN

and TNx span concentrations.

5. Press EXIT M201A returns to sampling. Immediately after

calibration, data is not added to the DAS averages.

12

Page 14

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

2.1.1 Zero/Span Calibration with Z/S Valves or ECO Option

The zero gas enters through the zero gas inlet port on the rear panel. Make sure that

the umbilical cord that makes the control connections between the analyzer and the

converter is connected (see Figure 2 below). The zero gas valve can be activated by a

variety of methods discussed in Section 7 of the M200A manual. The example below

will use the front panel keyboard to activate the valves.

Table 2.4 - Zero Calibration Procedure - Zero Gas from rear panel zero air inlet

Step No.

1. Press

2. Wait 20

3. Press

4. Press

5. Press

Action Comment

CALZ

min

ZERO

ENTR

EXIT

The M201A enters the calibrate mode from

sample mode. The zero gas is supplied

through the zero air inlet port on the rear panel.

Wait for reading to stabilize at zero. If the

instrument has recently been exposed to high

levels of NH3, you may need to wait up to 2

hours for the instrument to return to zero.

If you change your mind after pressing ZERO,

you can still press EXIT here without zeroing

the instrument.

Pressing ENTR actually changes the

calculation equations.

M201A returns to sampling. This switches the

ZS valves so that sample gas is coming in the

sample port on the rear of the instrument.

Immediately after calibration, data is not added

to the DAS averages.

Since the zero gas concentration is defined as 0 ppb, it is not necessary to enter the

expected zero value.

The expected value of the span gas is entered into the instrument by the following

procedure.

13

Page 15

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Table 2.5 - Enter the Expected Span Gas Concentrations Procedure

Step No.

Action Comment

1. Press

CALCONCTNX

2. Press

ENTR

3. Press

CALCONC-TN

4. Press

ENTR

5. Press

EXIT

This key sequence causes the M201A to

prompt for the expected TNX concentration.

Enter the TNX span concentration value by

pressing the key under each digit until the

expected value is set. This menu can also be

entered from CALS or CALZ.

ENTR stores the expected TNX span value.

Now enter the expected TN span concentration

as in step one.

Pressing ENTR stores the TN span value and

returns the prompt to the CONC menu.

Returns instrument to SAMPLE mode.

14

Page 16

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Table 2.6 - CALS - Span Cal Procedure - Gas from rear panel span gas inlet

Step No.

1. Press

2. Press

CAL-CONV-SET

2. Wait 20

3. Press

4. Press

5. Press EXIT M201A returns to sampling. Immediately after

Action Comment

The M201A enters the calibrate mode. The

CALS

Set the converter efficiency parameter to 1.0000, then

press ENTR-EXIT.

min

SPAN

ENTR

Z/S valves are activated to route span gas into

the analyzer.

Wait for the reading to stabilize at span value.

If you change your mind after pressing SPAN,

you can still press EXIT here without spanning

the instrument.

Pressing ENTR actually changes the

calculation equations and causes the

instrument to read the TN and TNx span

concentrations.

calibration, data is not added to the DAS

averages.

2.1.2 TN/TNx Channel Calibration Quality

After the TN and TNx channel calibration it is important to check the slopes and offsets

to make sure they fall within the acceptable range. The tolerances are different than a

typical NOx analyzer primarily because of the performance of the M501NH ammonia

converter.

Slopes can vary from 2.0 to 0.7, and should be within 20% of each other with the TNx

slope typically smaller than the TN slope.

Offsets should be zero ±250 mV and be within 100mV of each other.

If the slope and offsets are within specifications, proceed on the ammonia channel

calibration.

15

Page 17

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

2.1.3 NH3 Calibration

Since the system efficiency is less than 100%, it is necessary to determine a conversion

efficiency factor for ammonia and enter it into the system.

1. Set the converter efficiency to 1.0000 by:

Press CAL-CONC-CONV-SET on the keyboard

Press the keys under the numbers until 1.0000 appears.

Press EXIT to return to the sample mode.

2. Introduce ammonia span gas of known concentration into the instrument. Allow time for

instrument stabilization. The final readings will be less than the concentration calculated

from flows. For example with 400 ppb NH3 span gas:

TN = 40 ppb

TNx = 380 ppb

The 40 ppb TN reading is due to the fact that the moly converts a small amount of the

NH3 gas to NO. The 380 ppb TNx reading is due to ammonia conversion plus some

conversion of nitrogen and oxygen in the dilution air.

3. Continuing with the example above, the instrument will report a NH3 concentration value of

340 ppb. Divide the reported NH3 concentration by the concentration computed from flow

data.

NH3 converter eff. = [NH3

M201A

] / [NH3

FLOWS

]

From the above example :

M201A NH3 reading = 340 ppb

NH3 conc from flows = 400 ppb

340 / 400 = 0.85 NH3 converter system efficiency

4. This value now is entered into the instrument.

Press CAL-CONC-CONV-SET

Press the buttons under the numbers until the desired value is entered, in this case

0.8500, then press ENTR.

Press EXIT to return to SAMPLE mode.

16

Page 18

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

The instrument is now fully calibrated.

2.1.4 Channel Calibration Quality

After the ammonia channel is calibrated via the converter efficiency parameter, it is

important to check the calibration by sampling the NH3 calibration gas and confirming

that the instrument responds with the correct concentration. In the above example the

M201A should report 400 ppb NH3 concentration when measuring the 400 ppb NH3

span gas used.

17

Page 19

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

3.0 MAINTENANCE SCHEDULE

3.1 M201A Maintenance Schedule

The maintenance requirements of the M201A are essentially like a standard M200A

NOx analyzer. Please refer to Table 8-1 in the M200A Operator Manual for the M200A

maintenance schedule.

In Table 3.1 below, there are the extra maintenance items required by the M201A.

Table 3.1: Preventative Maintenance Schedule

Item Maintenance Interval Reference Section

M501NH3 Converter Check every 6 months Section 3.2

Reaction Cell Clean quarterly as

necessary

AutoZero flow check Quarterly as needed Section 3.3

3.2 Maintaining the M501NH Converter

The M501NH Converter is operated at very high temperature. The center tube in the

converter slowly oxidizes and requires replacement. The most obvious indicator of

failure is no ammonia conversion, despite the converter being at temperature. This is

caused by the oxidized tube breaking off in the converter.

The following procedure describes how to disassemble and replace converter parts.

The various parts in the converter become delicate and brittle after prolonged exposure

to high temperatures. It is therefore a good idea to have a complete set of replacement

parts on hand before starting, as listed in Table 3.1.

Sect 9.3.8, Fig 8-3 in

the M200A Manual

18

Page 20

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Table 3.2 – M501NH Converter Rebuild Parts List

Part No. Description

KIT000191 Converter Rebuild Kit

KIT000139 Ceramic Bushings

HE0000007 Ceramic Heater 220W 60 VAC

Procedure:

1. Turn off power to the converter and allow to cool. IT IS VERY IMPORTANT THAT

THE CONVERTER BE COOL BEFORE ATTEMPTING ANY DISASSEMBLY OR

REPAIRS.

CAUTION VERY HOT

Will cause severe burns – disassembly while hot will

damage other converter components. Allow sufficient

time to cool.

2. Remove the chassis cover of the M501NH, remove the aluminum cover over the

oven, remove the two U-shaped hold down clamps.

3. Disconnect the 1 stainless steel and 2 PTFE tubes from the converter cartridge.

4. Loosen the nut holding the cartridge assembly in the U-shaped angle bracket

mounted on the chassis floor.

5. Gently lift and tilt the converter assembly out of the U-shaped bracket and slide the

assembly out of the oven.

6. Loosen the ¼” SS tube fitting nearest the hold-down bracket, this fitting holds the

central tube in the converter. Replace the tube that is part of KIT000191

7. Re-assemble the converter by doing the above steps in reverse order.

19

Page 21

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

3.3 AutoZero Flow Check

Since the M201A is an ammonia analyzer, the flow through the AutoZero orifice is

especially important. Check the AutoZero flow as follows:

1. This procedure should be performed with the sample pump running.

2. Fold down the rear panel on the M201A chassis. Locate the vacuum manifold at the

center rear of the chassis. Locate the 1/8” tube fitting 2

label of “0.010”, indicating the flow orifice installed.

3. Remove the fitting and attach a calibrated flowmeter capable of measuring in the

range of 500 cc/min. The flowmeter should indicate a flow of 500 cc/min ±10%.

4. If the flow is outside this range (most likely lower, due to plugging):

1. Turn off the sample pump and instrument.

2. Remove the 1/8” pipe-to-tube fitting and remove the ¼” sintered filter (p/n

FL0001). This filter is meant to protect the orifice, it will usually become plugged and

need replacement rather than the orifice. Replace the filter, then re-assemble the

manifold. Re-start the sample pump and re-check the flow.

nd

from the left. It will have a

20

Page 22

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Figure 1 - M201A Ammonia Analyzer – Block Diagram

21

Page 23

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

POWER

UMBILICAL

EXHAUST

OUT

NO SPAN GAS

SAMPLE

IN

50 PSIG MAX

INLET PRESSURE

NH3 SPAN GAS

CYL 1

CYL 2

IN

IN

TNTN

OUTOUT

TNX

OUT

ZERO AIR IN

CAL GAS OUT

SS TUBING

ZERO

SPAN

GAS

FROM

ZERO

AIR

MODULE

SS TUBING

AIR

SS TUBING

SS TUBING

VENT

TO VACCUM PUMP

TO

CONV

FROM

CONV

UMBILICAL

02522 UMBILICAL CORD

Figure 2 - M201A External Pneumatic Connection Diagram with ECO (External Calibrator Option)

22

Page 24

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Figure 3 - M201A Pneumatic Diagram Basic

23

Page 25

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Figure 4 - M201A Pneumatic Diagram Z/S Option

24

Page 26

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Figure 5 - M201A Pneumatic Diagram External Calibrator Option (ECO)

25

Page 27

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

Figure 6 – M501NH Converter Cartridge

26

Page 28

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

27

Page 29

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

4.0 M201A SPARE PARTS LIST

000940400 Orifice, 4 mil, 80 cc, Rx Cell

000940600 Orifice, 10 mil, 500 cc, Rx Cell

002270100 Gasket (Rx Cell) Qty. 12

002730000 Window 665 NM

002761020 CPU Board (201A AMX))

003290000 Thermistor Assembly

004020200 Flow/Pressure Sensor Board

005140300 V/F Board

007040000 Keyboard

007280000 NEW Display

010680100 Heater, MOLY Converter

010860000 Status/Temperature Board

011310000 Drier Assembly Complete with Flow Control

011930000 PMT, NOx

011980000 Assembly, MOLY Thermocouple (Type J)

012360000 Fan, Power Supply Module

013140000 Fan, PMT Cooler

013570000 Thermistor Assembly (Cooler)

013600000 Operators Manual for M200A

014020300 M200A 37 mm 1 um Filter Expendables Kit

014020400 M200A 47 mm 1 um Filter Expendables Kit

014040000 M200A Level 1 Spare Parts Kit (for 10 units)

014040100 M200A Spares Kit for 1 Unit

014080100 Assembly, High Voltage Power Supply

014610000 Cooler Assembly

28

Page 30

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

M201A Spare Parts List (cont.)

016810200 O3 Generator Assembly for M200A/200AH Low Output

017230000 Dryer Material, Drierite

018720000 Welded Moly Conv. Assy, w/ O3 Scrubber, w/ valves

021070000 PMT Pre-amplifier Board Assembly

022300000 DC Power Supply Board

024710000 Tubing: 6’, 1/8” CLR

024720000 Tubing: 6’, 1/8” BLK

024730000 Tubing: 6’, 1/4” BLK

024750000 Tubing: 6’, 1/4” TYGON

046890000 M201A Manual Addendum

046570100 Catalytic Converter Insert

CB0000001 FUSE O3, 1A

CP0000014 Fuji Temperature Controller

DR0000002 PMT Desiccant Baggies

FL0000001 Sintered Filter

FL0000003 Filter, DFU

FM0000004 Flow Meter, 0-1000 cc

HE0000007 Ceramic Heater 220W 60 VAC

HE0000017 Heater, Reaction Cell, 12W

HE0000019 Heater, MOLY Converter

HW0000020 Spring, Flow Control

HW0000036 TFE Thread Tape (48 FT)

HW0000150 Clamp, Hose, Nylon, 1/4”

KIT000019 Replacement Cooler Assembly, M100A/M200A

KIT000021 Replacement PWR SW BD, 'A', M100A/200A

KIT000036 Retrofit, O3 Killer

KIT000041 Retrofit, Moly Valves, M200A

KIT000051 Rebuild Kit, RX Cell Ambient, M200/A/251/252

KIT000058 Leak Checker with Gauge

KIT000059 Leak Checker without Gauge

KIT000067 Retrofit, M200A Rcell Rebuild Kit

KIT000103 Replacement, Welded Moly Cart, Type J Tc, Heater

KIT000110 Repl, Welded Moly Type J Tc w/o valves, w/o O3 killer, in can

29

Page 31

Teledyne API Model 201A NH3 Analyzer Instruction Manual, 04689, Rev. B1

M201A Spare Parts List (cont.)

KIT000129 Welded Moly, Cartridge only

KIT000191 Rebuild, NH3 INNER TUBE & CATALYST

OR0000001 O-Ring, Flow Control

OR0000002 O-Ring, Bearing, Cell

OR0000010 O-Ring, S, O3 Generator

OR0000012 O-Ring, Permeation Oven-Units with IZS

OR0000014 O-Ring, Permeation Oven

OR0000021 O-Ring, Scrubber

OR0000025 O-Ring, Zero Air Scrubber

OR0000034 O-Ring, Input/Output Mirror/Detector

OR0000042 O-Ring, Sensor Assembly

OR0000044 O-Ring, Reaction Cell

OR0000045 O-Ring, Sample Filter

PS0000010 15V Switching Power Supply

PU0000005 Pump 1150V/60Hz

PU0000006 Pump 220V/50Hz

PU0000011 607 Pump Rebuild Kit

RL0000003 Solid State Relay, 12 Vdc

RL0000007 3 AMP Opto Relay

RL0000008 Solid State Relay, 12 VDC

RL0000015 Solid State Relay, 115 Vac

SW0000006 Overheat SW, Cell/Oven

SW0000008 Pressure Sensor

VA0000007 Solenoid Valve, Stainless Steel, 12V

VA0000024 Manifold Valve, 3-Way, Vent

30

Loading...

Loading...