Teledyne 200AU-NOy User Manual

MANUAL ADDENDUM

M200AU

NOy CONVERTER OPTION

(for use with M200AU Operators Manual, 02293)

Teledyne Advanced Pollution Instrumentation

9480 Carroll Park Dr.

San Diego, CA 92121-5201

TOLL-FREE: 800-324-5190

FAX: 858-657-9818

TEL: 858-657-9800

E-MAIL:

WEB SITE: www.teledyne-api.com

02808

Copyright 2007 API Inc. July 2007

api-sales@teledyne.com

REV. E

Model 200AU-NOy Option Manual Addendum

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety

messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety message is

associated with a safety alert symbol. These symbols are found in the manual and inside the

instrument. The definition of these symbols is described below:

General Warning/Caution: Refer to the instructions for details on the specific danger.

Hot Surface Warning

Electrical Shock Hazard

Technician Symbol: All operations marked with this symbol are to be performed by qualified

maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central safety grounding

point for the instrument.

CAUTION

The analyzer should only be used for the purpose and in the manner

described in this manual.

If you use the analyzer in a manner other than that for which it was

intended, unpredictable behavior could ensue with possibly hazardous

consequences.

02808 Rev. D

Model 200AU-NOy Option Manual Addendum

Table of Contents

SAFETY MESSAGES............................................................................................................................................2

Table of Contents....................................................................................................................................................3

List of Figures.........................................................................................................................................................5

List of Tables...........................................................................................................................................................6

1.0 GETTING STARTED.................................................................................................7

1.1 Unpacking ......................................................................................................................................................... 7

1.2 Electrical and Pneumatic Connections...........................................................................................................7

1.3 Initial Operation.............................................................................................................................................10

2.0 SPECIFICATIONS, WARRANTY............................................................................11

2.1 Specifications ..................................................................................................................................................11

2.2 Warranty.........................................................................................................................................................12

3.0 THE M501Y NOY CONVERTER.............................................................................13

3.1 Principle of Operation....................................................................................................................................13

4.0 CALIBRATION AND ZERO/SPAN CHECKS .........................................................15

4.1 Calibration or Cal Check Procedure............................................................................................................17

5.0 MAINTENANCE......................................................................................................21

5.1 Maintenance Schedule....................................................................................................................................21

5.2 Replacing the Sample Particulate Filter.......................................................................................................24

5.3 Check Bypass Flow Rates..............................................................................................................................26

5.4 Replacing the Converter................................................................................................................................26

5.5 Pneumatic Line Inspection ............................................................................................................................28

5.6 Leak Check Procedure.................................................................................................................................. 30

6.0 TROUBLESHOOTING, ADJUSTMENTS ...............................................................31

6.0.1 General Troubleshooting Hints.................................................................................................................31

02808 Rev. D

Model 200AU-NOy Option Manual Addendum

6.1 Operation Verification - M501Y Diagnostic Techniques............................................................................ 31

6.1.1 Pneumatic System.....................................................................................................................................31

6.1.2 Leak Check...............................................................................................................................................32

6.1.3 Bypass Pump Diagnostic Procedures .......................................................................................................32

6.1.4 Electrical Fault Isolation...........................................................................................................................32

6.2 Setting the Converter Temperature.............................................................................................................32

6.1.4 Temperature Controller Setup.................................................................................................................. 33

PRESS........................................................................................................................................................... 33

DISPLAY......................................................................................................................................................33

ACTION ....................................................................................................................................................... 33

PRESS........................................................................................................................................................... 34

DISPLAY......................................................................................................................................................34

ACTION ....................................................................................................................................................... 34

7.0 M501Y SPARE PARTS LIST..................................................................................36

02808 Rev. D

Model 200AU-NOy Option Manual Addendum

List of Figures

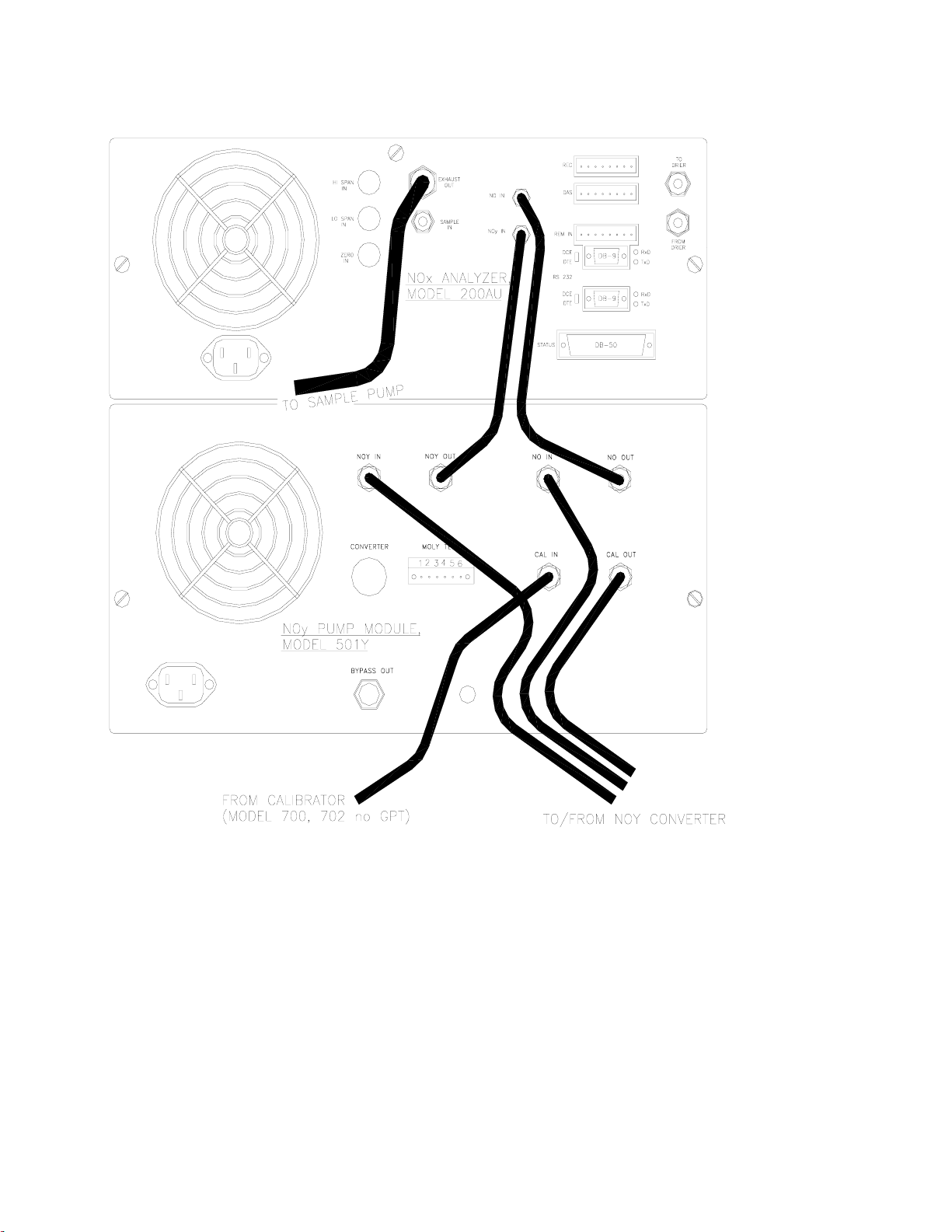

FIGURE 1.1 - REAR PANEL PNEUMATIC CONNECTIONS.................................................................................9

FIGURE 4.1 - CALIBRATION SETUP.....................................................................................................................16

FIGURE 5.1 - REPLACING THE PARTICULATE FILTER...................................................................................25

FIGURE 5.2 - CONVERTER ASSEMBLY...............................................................................................................27

FIGURE 5.3 - PNEUMATIC DIAGRAM.................................................................................................................. 29

FIGURE 6.1 – ELECTRICAL DIAGRAM................................................................................................................35

02808 Rev. D

Model 200AU-NOy Option Manual Addendum

List of Tables

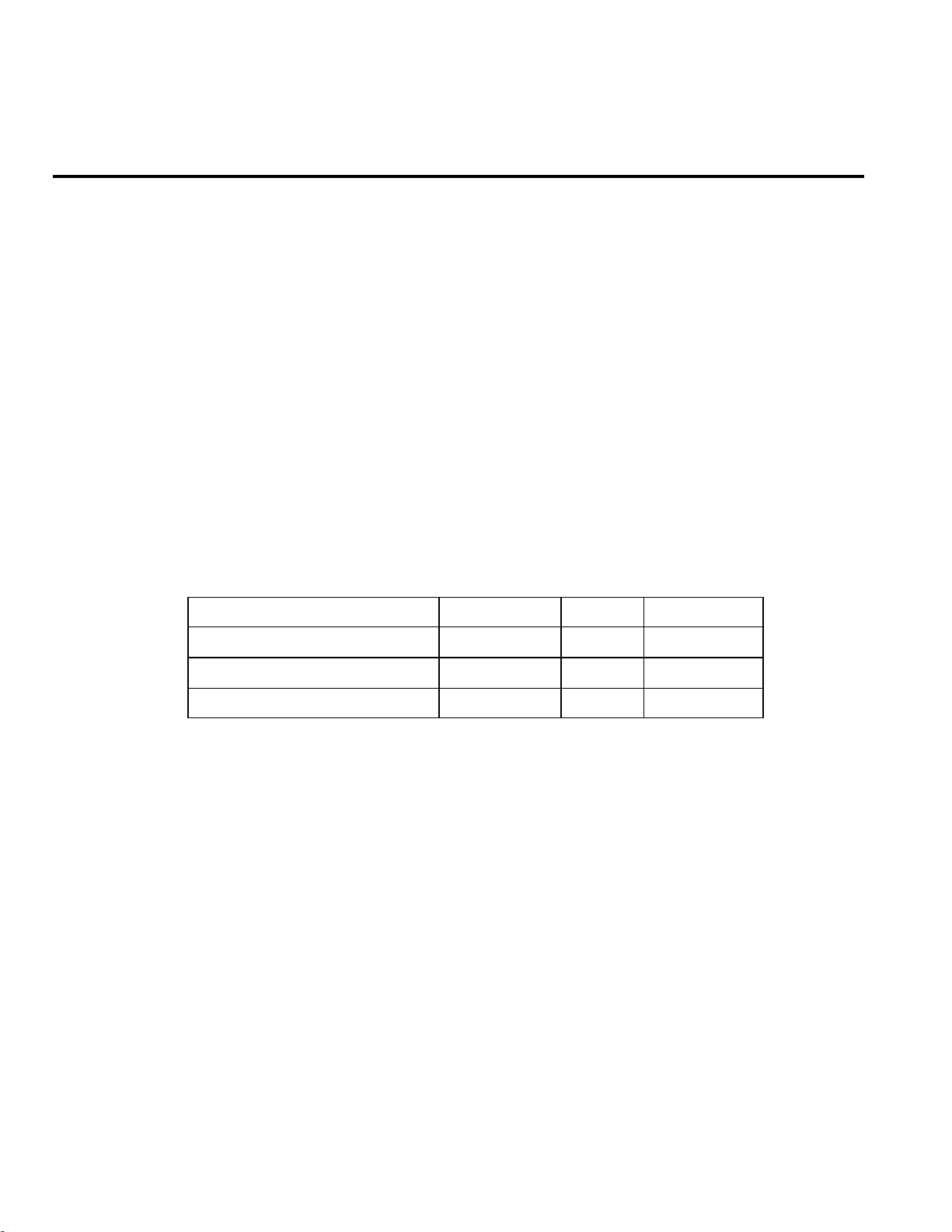

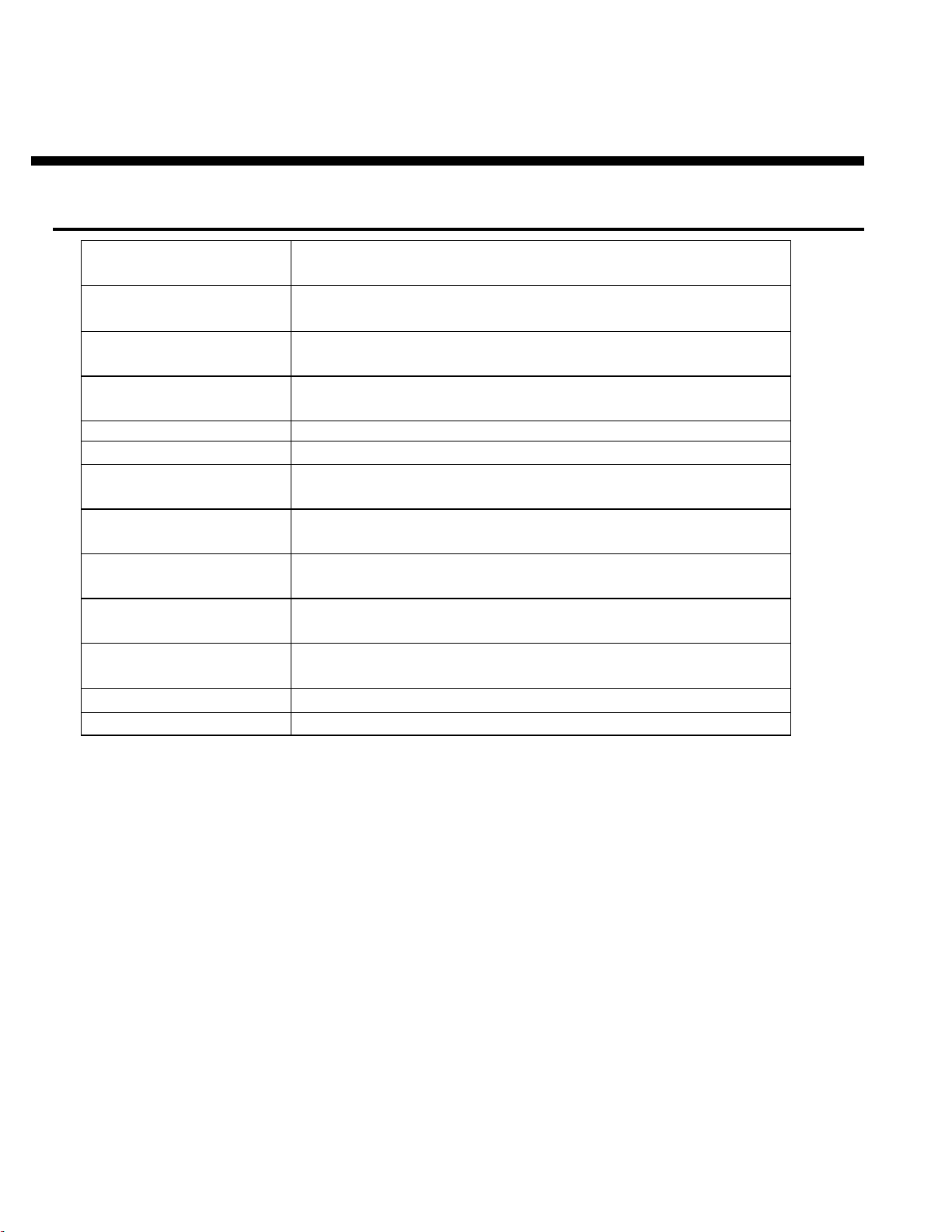

TABLE 2.1 - FINAL TEST AND CALIBRATION VALUES..................................................................................10

TABLE 4.1 - MANUAL ZERO CALIBRATION PROCEDURE - ZERO GAS THRU SAMPLE PORT...............17

TABLE 4.2 - ENTER EXPECTED SPAN GAS CONCENTRATIONS PROCEDURE...........................................18

TABLE 4.3 - SPAN CALIBRATION PROCEDURE................................................................................................ 19

TABLE 5.1- PREVENTATIVE MAINTENANCE CALENDAR ............................................................................ 23

TABLE 6.1 – TEMPERATURE CONTROLLER PROGRAMMING GUIDE.........................................................33

02808 Rev. D

Model 200AU-NOy Option Manual Addendum

1.0 Getting Started

The M501Y has been designed to operate with the M200AU low level NOx analyzer. The M200AU

manual, part number 02293, is a required reference to properly set up and operate this system.

1.1 Unpacking

1. The M200AU with NOy Option comes in three boxes.

• The M200AU analyzer

• The Bypass Pump Chassis

• The External Converter and umbilical cable assembly

2. Verify that there is no apparent shipping damage. If damage has occurred please advise shipper

first, then API.

To avoid personal injury, always use two persons to lift and

carry the Model 501 Pump Pack Chassis.

CAUTION

3. Before operation of the M200AU, remove the shipping screws as shown in the M200AU Manual.

4. Please check the voltage and frequency label on the rear panel of the instrument for compatibility

with the local power before plugging in the M501Y.

1.2 Electrical and Pneumatic Connections

1. Mount the converter on a suitable mast outside of the enclosure.

2. Route the umbilical cable assembly into the shelter.

3. Locate the M200AU and M501Y Bypass Pump Chassis in close proximity, preferably mounting

one over the other in a 19” rack.

4. Connect the electrical/pneumatic cable fittings to the rear of the Bypass Pump Chassis. Use the

tags on each tube and Figure 1.1 to match up the correct tube with the rear panel bulkhead fitting.

5. Connect the 7-pin power and signal cable to the connector on the rear of the Bypass Pump Chassis.

6. Connect the power cord to the correct line voltage.

02808 Rev. E Page 7

Model 200AU-NOy Option Manual Addendum

• Lethal voltages are present inside case

• Do not operate with cover off during normal operation

• Before operation, check for correct input voltage and frequency.

• Do not operate without proper chassis grounding

• Do not defeat the ground wire on power plug

• Turn off power before disconnecting electrical subassemblies

WARNING

02808 Rev. E Page 8

Model 200AU-NOy Option Manual Addendum

Figure 1.1 - Rear Panel Pneumatic Connections

02808 Rev. E Page 9

Model 200AU-NOy Option Manual Addendum

1.3 Initial Operation

1. After confirming proper supply voltage, turn on the instrument power. If you are unfamiliar with

the M200AU with NOy Option, we recommend that you read the overview in Section 3 before

proceeding.

2. The power indicator light and display should immediately light, in addition the bypass pump

should start up. The M501Y requires about 30 minutes for the converter to come up to

temperature.

3. While the converter is coming up to temperature, the M200AU should be powered-up also. Follow

the instructions in Section 2 of the M200AU Manual to confirm proper operation of that

instrument. Note: It will take 30 minutes for the ozone generator to start up in the M200AU.

During that time the instrument will not respond to span gas.

4. After 30 min, the display on the Bypass Pump Chassis should read 315

converter is up to temperature.

5. Proceed to Section 4 of this manual to do a zero/span check.

Table 2.1 - Final Test and Calibration Values

Test Values Observed Value Units Nominal Range

o

C, indicating that the

CONVERTER TEMP oC

BYPASS FLOW – NO CHANNEL CC/MIN

BYPASS FLOW – NOx CHANNEL CC/MIN 1100 ± 200

Converter Serial # __________________________

Date _______________________ Technician __________________________

315 ±7

1100 ± 200

02808 Rev. E Page 10

Model 200AU-NOy Option Manual Addendum

2.0 Specifications, Warranty

2.1 Specifications

Converter Remotely mounted molybdenum converter with temperature

controller in a NEMA – 4 enclosure.

Converter Temperature

Tube/Electrical Cable

Assembly

Power, Bypass Pump

Assembly

Power, Converter Assembly 120V~ 50/60 Hz, 60 watts

Converter Efficiency >96% for NO2

Weight, Bypass Pump

Assembly

Weight, Remote

Converter

Bypass Pump Chassis

Dimensions HxWxD

Remote Converter Assy

Dimensions HxWxD

Environmental Installation Category (Over-voltage Category) II

Bypass Flowrate

Analog output Converter temp analog output. 3.15 VDC = 315oC

315oC ± 7oC with read-out on front panel of bypass pump

chassis.

Up to 50 feet (15 m) maximum length

120V~ 60 Hz, 230V~ 50 Hz 360 watts

35 lbs (16 kg)

30 lbs (11 kg)

9" x17" x23.6" (23cm x 43cm x 61cm)

12"x19"x7" (31cm x 48cm x 18cm)

Pollution Degree 2

1100 cc/min ± 20%, each channel

02808 Rev. E Page 11

Model 200AU-NOy Option Manual Addendum

2.2 Warranty

ADVANCED POLLUTION INSTRUMENTATION, INC.

02024c

Prior to shipment, API equipment is thoroughly inspected and tested. Should equipment failure occur, API assures

its customers that prompt service and support will be available.

COVERAGE

After the warranty period and throughout the equipment lifetime, API stands ready to provide on-site or in-plant

service at reasonable rates similar to those of other manufacturers in the industry. All maintenance and the first level

of field troubleshooting are to be performed by the customer.

NON-API MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by API is warranted and will be repaired to the extent and according to

the current terms and conditions of the respective equipment manufacturers warranty.

GENERAL

API warrants each Product manufactured by API to be free from defects in material and workmanship under normal

use and service for a period of one year from the date of delivery. All replacement parts and repairs are warranted for

90 days after the purchase.

If a Product fails to conform to its specifications within the warranty period, API shall correct such defect by, in

API's discretion, repairing or replacing such defective Product or refunding the purchase price of such Product.

The warranties set forth in this section shall be of no force or effect with respect to any Product:

(i) that has been altered or subjected to misuse, negligence or accident, or (ii) that has been used in any manner other

than in accordance with the instruction provided by API or (iii) not properly maintained.

THE WARRANTIES SET FORTH IN THIS SECTION AND THE REMEDIES THEREFORE ARE EXCLUSIVE

AND IN LIEU OF ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE OR OTHER WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED. THE

REMEDIES SET FORTH IN THIS SECTION ARE THE EXCLUSIVE REMEDIES FOR BREACH OF ANY

WARRANTY CONTAINED HEREIN. API SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARISING OUT OF OR RELATED TO THIS AGREEMENT OF API'S

PERFORMANCE HEREUNDER, WHETHER FOR BREACH OF WARRANTY OR OTHERWISE.

TERMS AND CONDITIONS

All units or components returned to API should be properly packed for handling and returned freight prepaid to

the nearest designated Service Center. After the repair, the equipment will be returned, freight prepaid.

02808 Rev. E Page 12

Loading...

Loading...