Page 1

INSTRUCTION MANUAL

MODEL 200AU

NITROGEN OXIDES ANALYZER

TELEDYNE INSTRUMENTS

ADVANCED POLLUTION INSTRUMENTATION DIVISION

(T-API)

6565 NANCY RIDGE DRIVE

SAN DIEGO, CA 92121-2251

TOLL-FREE: 800-324-5190

FAX: 858-657-9816

TEL: 858-657-9800

E-MAIL: api-sales@teledyne.com

WEB SITE: www.teledyne-api.com

Copyright 1999 API Inc.

02293

REV. F

07/06/99

Page 2

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

SAFETY MESSAGES

Your safety and the safety of others is very important. We have provided many important safety

messages in this manual. Please read these messages carefully.

A safety message alerts you to potential hazards that could hurt you or others. Each safety

message is associated with a safety alert symbol. These symbols are found in the manual and

inside the instrument. The definition of these symbols is described below:

GENERAL WARNING/CAUTION: Refer to the instructions for details on the

specific danger.

CAUTION: Hot Surface Warning

CAUTION: Electrical Shock Hazard

Technician Symbol: All operations marked with this symbol are to be performed

by qualified maintenance personnel only.

Electrical Ground: This symbol inside the instrument marks the central safety

grounding point for the instrument.

CAUTION

The analyzer should only be used for the purpose

and in the manner described in this manual.

If you use the analyzer in a manner other than that for which

it was intended, unpredictable behavior could ensue with

possible hazardous consequences.

ii

Page 3

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

TABLE OF CONTENTS

SAFETY MESSAGES .........................................................................................II

TABLE OF CONTENTS .....................................................................................III

LIST OF FIGURES ........................................................................................... VII

LIST OF TABLES............................................................................................ VIII

1 HOW TO USE THIS MANUAL..................................................................... 1-1

2 GETTING STARTED.................................................................................... 2-1

NPACKING

2.1 U

LECTRICAL AND PNEUMATIC CONNECTIONS

2.2 E

NITIAL OPERATION

2.3 I

....................................................................................................................2-1

....................................................................2-1

.........................................................................................................2-6

3 SPECIFICATIONS, AGENCY APPROVALS, WARRANTY ........................ 3-1

PECIFICATIONS

3.1 S

3.2 EPA E

3.3 W

ARRANTY

QUIVALENCY DESIGNATION

.............................................................................................................3-1

...................................................................................3-2

....................................................................................................................3-3

4 THE M200AU NOX ANALYZER ................................................................... 4-1

RINCIPLE OF OPERATION

4.1 P

PERATION SUMMARY

4.2 O

4.2.1 Sensor Module, Reaction Cell, Detector................................................................4-3

4.2.2 Pneumatic Sensor Board.......................................................................................4-3

4.2.3 Computer Hardware and Software ........................................................................4-4

4.2.4 V/F Board ..............................................................................................................4-4

4.2.5 Front Panel............................................................................................................4-5

4.2.6 Power Supply Module............................................................................................4-7

4.2.7 Pump, Valves, Pneumatic System.........................................................................4-7

4.2.8 Ozone Generator...................................................................................................4-7

4.2.9 Molybdenum Converter – Ozone Scrubber ...........................................................4-8

...............................................................................................4-1

....................................................................................................4-3

5 SOFTWARE FEATURES............................................................................. 5-1

NDEX TO FRONT PANEL MENUS

5.1 I

5.1.1 Sample Menu ........................................................................................................5-4

5.1.2 Set-Up Menu .........................................................................................................5-6

......................................................................................5-1

iii

Page 4

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

AMPLE MODE

5.2 S

.............................................................................................................5-10

5.2.1 Test Functions .....................................................................................................5-10

5.2.2 CAL, CALS, CALZ, Calibration Functions............................................................5-13

5.3 SET-UP M

ODE

.............................................................................................................5-16

5.3.1 Configuration Information (CFG) .........................................................................5-16

5.3.2 Automatic Calibration (AutoCal) ..........................................................................5-16

5.3.3 Data Acquisition System (DAS) ...........................................................................5-16

5.3.4 Range Menu........................................................................................................5-19

5.3.5 Password Enable.................................................................................................5-21

5.3.6 Time of Day Clock ...............................................................................................5-22

5.3.7 Diagnostic Mode..................................................................................................5-22

5.3.8 Communications Menu........................................................................................5-22

5.3.9 Variables Menu (VARS) ......................................................................................5-22

5.3.10 M200AU Operating Modes ................................................................................5-22

TATUS OUTPUT

5.4 S

5.5 RS-232 I

NTERFACE

..........................................................................................................5-23

......................................................................................................5-24

5.5.1 Setting Up the RS-232 Interface..........................................................................5-25

5.5.2 Command Summary............................................................................................5-28

5.5.3 TEST Commands and Messages........................................................................5-32

5.5.4 WARNING Commands and Messages................................................................5-33

5.5.5 CALIBRATION Commands and Messages .........................................................5-34

5.5.6 DIAGNOSTIC Commands and Messages...........................................................5-36

5.5.7 DAS Commands and Message ...........................................................................5-37

5.5.8 Internal Variables.................................................................................................5-39

6 OPTIONAL HARDWARE AND SOFTWARE............................................... 6-1

ACK MOUNT OPTIONS

6.1 R

ERO/SPAN VALVES

6.2 Z

UTOCAL

6.3 A

- S

6.4 4-20 MA, C

6.5 NO

CONVERTER

Y

ETUP ZERO/SPAN VALVES

URRENT LOOP OUTPUT

...................................................................................................6-1

.......................................................................................................6-1

............................................................................6-2

..................................................................................6-4

...........................................................................................................6-4

7 CALIBRATION & ZERO/SPAN CHECKS ................................................... 7-1

ANUAL ZERO/SPAN CHECK OR CAL WITH ZERO/SPAN GAS IN THE SAMPLE PORT

7.1 M

ANUAL ZERO/SPAN CHECK OR CALIBRATION WITH ZERO/SPAN VALVES OPTION

7.2 M

UTOMATIC ZERO/SPAN CHECK

7.3 A

YNAMIC ZERO/SPAN CALIBRATION

7.4 D

SE OF ZERO/SPAN VALVES WITH REMOTE CONTACT CLOSURE

7.5 U

7.6 EPA P

ROTOCOL CALIBRATION

......................................................................................7-7

.................................................................................7-7

........................................7-8

........................................................................................7-9

7.6.1 Calibration of Equipment .......................................................................................7-9

7.6.2 Calibration Gas and Zero Air Sources .................................................................7-11

7.6.3 Data Recording Device........................................................................................7-12

7.6.4 Gas Phase Titration (GPT) System .....................................................................7-12

..............7-4

...............7-6

iv

Page 5

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

7.6.5 Dynamic Multipoint Calibration Procedure...........................................................7-16

7.6.6 Moly Converter Efficiency....................................................................................7-23

7.6.7 Calibration Frequency .........................................................................................7-25

7.6.8 Other Quality Assurance Procedures ..................................................................7-25

7.6.9 Summary of Quality Assurance Checks ..............................................................7-27

7.6.10 ZERO and SPAN Checks..................................................................................7-29

7.6.11 Recommended Standards for Establishing Traceability ....................................7-30

7.6.12 Certification Procedures of Working Standards .................................................7-31

ALIBRATION OF INDEPENDENT RANGES OR AUTORANGING

7.7 C

.............................................7-32

7.7.1 Zero Calibration with AutoRange or Independent Range ....................................7-32

7.7.2 Span Calibration with AutoRange or Independent Range ...................................7-33

ALIBRATION QUALITY

7.8 C

7.9 R

EFERENCES

...............................................................................................................7-35

..................................................................................................7-33

8 MAINTENANCE ........................................................................................... 8-1

AINTENANCE SCHEDULE

8.1 M

EPLACING THE SAMPLE PARTICULATE FILTER

8.2 R

AMPLE PUMP MAINTENANCE

8.3 S

LEANING THE REACTION CELL

8.4 C

EPLACING THE MOLYBDENUM CONVERTER

8.5 R

NEUMATIC LINE INSPECTION

8.6 P

EAK CHECK PROCEDURE

8.7 L

IGHT LEAK CHECK PROCEDURE

8.8 L

ROM REPLACEMENT PROCEDURE

8.9 P

...............................................................................................8-1

.................................................................8-3

..........................................................................................8-5

.......................................................................................8-7

.....................................................................8-9

........................................................................................8-11

.............................................................................................8-15

...................................................................................8-16

................................................................................8-16

9 TROUBLESHOOTING, ADJUSTMENTS .................................................... 9-1

PERATION VERIFICATION

9.1 O

-M200AU D

9.1.1 Fault Diagnosis with TEST Variables ....................................................................9-3

9.1.2 Fault Diagnosis with WARNING Messages...........................................................9-8

9.1.3 Fault Diagnosis using DIAGNOSTIC Mode .........................................................9-11

9.1.4 M200AU Internal Variables..................................................................................9-19

9.1.5 Test Channel Analog Output ...............................................................................9-21

9.1.6 Factory Calibration Procedure .............................................................................9-23

ERFORMANCE PROBLEMS

9.2 P

............................................................................................9-26

9.2.1 AC Power Check .................................................................................................9-26

9.2.2 Flow Check..........................................................................................................9-27

9.2.3 No Response to Sample Gas ..............................................................................9-27

9.2.4 Negative Output...................................................................................................9-28

9.2.5 Excessive Noise ..................................................................................................9-28

9.2.6 Unstable Span .....................................................................................................9-29

9.2.7 Unstable Zero ......................................................................................................9-30

9.2.8 Inability to Span ...................................................................................................9-30

9.2.9 Inability to Zero ....................................................................................................9-31

IAGNOSTIC TECHNIQUES

.........................................9-3

v

Page 6

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

9.2.10 Non-Linear Response........................................................................................9-31

9.2.11 Slow Response..................................................................................................9-32

9.2.12 Analog Output Doesn't Agree with Display Concentration.................................9-32

UBSYSTEM TROUBLESHOOTING AND ADJUSTMENTS

9.3 S

9.3.1 Computer, Display, Keyboard..............................................................................9-32

9.3.2 RS-232 Communications.....................................................................................9-36

9.3.3 Voltage/Frequency (V/F) Board ...........................................................................9-39

9.3.4 Status/Temp Board..............................................................................................9-45

9.3.5 Power Supply Module..........................................................................................9-47

9.3.6 Ozone Generator.................................................................................................9-52

9.3.7 Flow/Pressure Sensor .........................................................................................9-55

9.3.8 NOx Sensor Module.............................................................................................9-60

9.3.9 Z/S Valves ...........................................................................................................9-64

9.3.10 Pneumatic System.............................................................................................9-65

.......................................................9-32

10 M200AU SPARE PARTS LIST ................................................................ 10-1

APPENDIX A ELECTRICAL SCHEMATICS ..................................................A-1

vi

Page 7

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

LIST OF FIGURES

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

IGURE

F

2-1: R

2-2: R

2-3: I

2-4: F

2-5: A

4-1: B

5-1: S

5-2: S

7-1: C

7-2: D

8-1: R

8-2: S

8-3: R

8-4: M

8-5: P

8-6: P

8-7: P

9-1: S

9-2: CPU B

EMOVAL OF SHIPPING SCREWS

EAR PANEL

NLET AND EXHAUST VENTING

RONT PANEL

SSEMBLY LAYOUT

LOCK DIAGRAM

AMPLE MENU TREE

ETUP MENU TREE

ALIBRATION SETUP

IAGRAM OF

EPLACING THE PARTICULATE FILTER

AMPLE PUMP ASSEMBLY

EACTION CELL ASSEMBLY

OLYBDENUM CONVERTER ASSEMBLY

NEUMATIC DIAGRAM

NEUMATIC DIAGRAM WITH ZERO/SPAN VALVE OPTION

NEUMATIC DIAGRAM WITH EXTERNAL CONVERTER OPTION

PAN CALIBRATION VOLTAGE

OARD JUMPER SETTINGS

9-3: RS-232 PIN A

9-4: V/F B

9-5: P

9-6: E

9-7: O

9-8: F

9-9: NO

9-10: NO

9-11: PMT C

9-12: H

OARD SETTINGS

OWER SUPPLY MODULE LAYOUT

LECTRICAL BLOCK DIAGRAM

ZONE GENERATOR SUBSYSTEM

LOW/PRESSURE SENSOR

SENSOR MODULE

X

SENSOR MODULE

X

OOLER SUBSYSTEM

IGH VOLTAGE POWER SUPPLY

HECK FOR CORRECT POWER

& C

..........................2-3

........................................................................................................2-4

...............................................................................2-5

....................................................................................................2-10

............................................................................................2-11

..................................................................................................4-2

............................................................................................5-2

..............................................................................................5-3

............................................................................................7-3

GPT C

ALIBRATION SYSTEM

.............................................................7-18

...................................................................8-4

.....................................................................................8-6

..................................................................................8-8

................................................................8-10

TANDARD CONFIGURATION

- S

.............................................8-12

........................................8-13

.................................8-14

.............................................................................9-25

.........................................................................9-34

SSIGNMENTS

...............................................................................9-38

........................................................................................9-44

.......................................................................9-49

.............................................................................9-50

........................................................................9-54

..................................................................................9-57

.......................................................................................9-58

.....................................................................................9-59

...............................................................................9-61

........................................................................9-63

vii

Page 8

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

LIST OF TABLES

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

2-1: F

2-1: F

4-1: F

4-2: O

5-1: S

5-2: S

5-3: S

5-3: S

5-4: S

5-5: S

5-6: DAS D

5-7: C

INAL TEST AND CALIBRATION VALUES

INAL TEST AND CALIBRATION VALUES (CONTINUED

RONT PANEL STATUS

ZONE GENERATOR START-UP TIMING

AMPLE MENU

AMPLE MENU

ETUP MENU

ETUP MENU (CONTINUED

ETUP MENU

ETUP MENU

ATA CHANNEL EDITING

ALIBRATE

, S

5-8: M200AU O

5-9: S

TATUS OUTPUT PIN ASSIGNMENTS

5-10: RS-232 P

5-11: RS-232 S

5-12: RS-232 T

5-13: RS-232 C

5-14: RS-232 C

5-15: RS-232 I

NTERFACE COMMAND TYPES

5-16: RS-232 T

5-17: RS-232 W

5-18: RS-232 C

5-19: RS-232 C

5-20: RS-232 C

5-21: RS-232 D

6-1: Z

6-2: E

7-1: T

7-2: M

7-3: E

7-4: M

7-5: M

7-6: M

7-7: E

7-8: Z/S V

7-9: A

7-10: A

7-11: Z

7-12: E

ERO/SPAN VALVE OPERATION

XAMPLE OF AUTOCAL SETUP

YPES OF ZERO/SPAN CHECK AND CALIBRATION

ANUAL ZERO CALIBRATION PROCEDURE

NTER EXPECTED SPAN GAS CONCENTRATIONS PROCEDURE

ANUAL SPAN CALIBRATION PROCEDURE

ANUAL ZERO CALIBRATION PROCEDURE

ANUAL SPAN CALIBRATION PROCEDURE

NABLING DYNAMIC ZERO/SPAN

ALVES MODES WITH REMOTE CONTACT CLOSURE

CTIVITY MATRIX FOR CALIBRATION EQUIPMENT AND SUPPLIES

CTIVITY MATRIX FOR CALIBRATION PROCEDURE

ERO CALIBRATION PROCEDURE

XPECTED SPAN GAS CONCENTRATION PROCEDURE

..................................................................2-12

) .............................................2-13

LED'S.................................................................................4-6

....................................................................4-8

......................................................................................................5-4

......................................................................................................5-5

.........................................................................................................5-6

) ....................................................................................5-7

.........................................................................................................5-8

.........................................................................................................5-9

..............................................................................5-19

ETUP PASSWORDS

PERATING MODES

..........................................................................5-21

..............................................................................5-23

......................................................................5-24

ORT SETUP

WITCHING FROM TERMINAL MODE TO COMPUTER MODE

ERMINAL MODE EDITING KEYS

OMMAND SUMMARY

OMMAND SUMMARY

RONT PANEL

- F

............................................................................5-29

............................................................................5-30

................................................................5-25

.......................5-27

.............................................................5-27

................................................................5-31

EST MESSAGES

ARNING MESSAGES

ALIBRATION COMMANDS

ALIBRATION EXAMPLES

ALIBRATION MESSAGES

IAGNOSTIC COMMAND SUMMARY

..................................................................................5-32

...........................................................................5-33

......................................................................5-34

.......................................................................5-35

......................................................................5-36

.........................................................5-37

..............................................................................6-1

................................................................................6-4

.....................................................7-2

ERO GAS THRU SAMPLE PORT

- Z

..............7-4

..................................7-5

PAN GAS THRU SAMPLE PORT

- S

- Z/S V

- Z/S V

ALVES

ALVES

..........................................7-6

..........................................7-7

..............7-5

.............................................................................7-8

...........................................7-9

..............................7-10

.................................................7-11

........................................................................7-19

...........................................7-20

viii

Page 9

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

ABLE

T

7-13: S

7-14: A

7-15: D

7-16: A

7-17: NIST-SRM'S A

PAN CALIBRATION PROCEDURE

UTOMATIC CALCULATION OF CONVERTER EFFICIENCY

EFINITION OF LEVEL 1 AND LEVEL

CTIVITY MATRIX FOR DATA QUALITY

VAILABLE FOR TRACEABILITY OF CALIBRATION AND AUDIT GAS STANDARDS

.........................................................................7-20

2 Z

........................................................................................................................7-31

7-18: C

8-1: P

8-2: P

9-1: T

9-1: T

9-1: T

9-1: T

9-2: F

9-2: F

9-3: S

9-4: D

9-4: D

9-4: D

9-4: D

9-5: M

9-6: T

9-6: T

9-7: M

9-8: V/F B

9-9: P

9-10: P

9-11: O

10-1: TELEDYNE API M200AU S

10-1: TELEDYNE API M200AU S

ALIBRATION QUALITY CHECK

REVENTATIVE MAINTENANCE SCHEDULE

REVENTATIVE MAINTENANCE CALENDAR

EST FUNCTIONS

EST FUNCTIONS (CONTINUED

EST FUNCTIONS (CONTINUED

EST FUNCTIONS (CONTINUED

RONT PANEL WARNING MESSAGES

RONT PANEL WARNING MESSAGES (CONTINUED

UMMARY OF DIAGNOSTIC MODES

IAGNOSTIC MODE

IAGNOSTIC MODE

IAGNOSTIC MODE

IAGNOSTIC MODE

ODEL

200AU V

EST CHANNEL READINGS

EST CHANNEL READINGS (CONTINUED

OTHERBOARD JUMPER SETTINGS

OARD SWITCH SETTINGS

OWER SUPPLY MODULE SUBASSEMBLIES

OWER SUPPLY MODULE

ZONE GENERATOR CONTROL CONDITIONS

...................................................................................................9-4

IGNAL

- S

IGNAL

- S

IGNAL

- S

IGNAL

- S

ARIABLES

............................................................................7-34

) ..............................................................................9-5

) ..............................................................................9-6

) ..............................................................................9-7

.......................................................................9-9

........................................................................9-12

I/O...........................................................................9-13

I/O (C

I/O (C

I/O (C

ONTINUED

ONTINUED

ONTINUED

...................................................................................9-20

....................................................................................9-21

.......................................................................9-41

.............................................................................9-42

LED O

PERATION

PARE PARTS LIST

PARE PARTS LIST (CONTINUED

10-2: TELEDYNE API MODEL 200AU E

A-1: E

LECTRICAL SCHEMATICS

..................................................................................... A-1

........................................7-24

ERO AND SPAN CHECKS

............................7-26

..................................................................7-28

................................................................8-1

...............................................................8-2

).................................................9-10

) ......................................................9-14

) ......................................................9-15

) ......................................................9-16

) ...............................................................9-22

............................................................9-48

.........................................................9-51

........................................................9-53

...................................................10-1

) ..............................10-2

XPENDABLE KIT

...........................................10-3

ix

Page 10

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

INTENTIONALLY BLANK

x

Page 11

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

1 HOW TO USE THIS MANUAL

The Model 200AU has been designed to provide serviceability, reliability and ease of operation.

The M200AU’s microprocessor continually checks operating parameters such as temperature,

flow, and critical voltages. The instrument’s modular design uses captive screws to facilitate

repair and ease of access. If you encounter any difficulty refer to Section 9 General

Troubleshooting Hints.

We recognize that the need for information in this manual changes as time passes. When the

instrument first arrives, it is necessary to get it up and running quickly and verify its correct

operation. As time passes, more detailed information is often required on special configurations,

calibration alternatives and other operational details. Finally there is the need for periodic

maintenance and to quickly troubleshoot problems to assure maximum reliability and data

integrity.

To address these needs, we have created three indexes to the information inside. They are:

Table of Contents:

Outlines the contents of the manual in the order the information is presented. This is a good

overview of the topics covered in the manual. There is also a list of Tables and a list of Figures.

Index to M200AU Front Panel Menus:

The Menu Index (Figure 5-1, Figure 5-2, Table 5-1 and Table 5-2) briefly describes the front

panel menus and refers you to other sections of the manual that have a detailed explanation of

each menu selection.

Troubleshooting Section 9:

The Troubleshooting Section, outlined in the Table of Contents, allows you to diagnose and

repair the instrument based on variables in the TEST menu, the results of DIAGNOSTIC tests,

and performance faults such as excessive noise or drift. The troubleshooting section also

explains the operation, adjustment, diagnosis and testing of each instrument subsystem.

If you are unpacking the instrument for the first time, please refer to Getting Started in

Section 2.

1-1

Page 12

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

INTENTIONALLY BLANK

1-2

Page 13

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

2 GETTING STARTED

2.1 Unpacking

1. Verify that there is no apparent shipping damage. If damage has occurred please advise

shipper first, then Teledyne API.

CAUTION

To avoid personal injury, always use two persons to

lift and carry the Model 200AU.

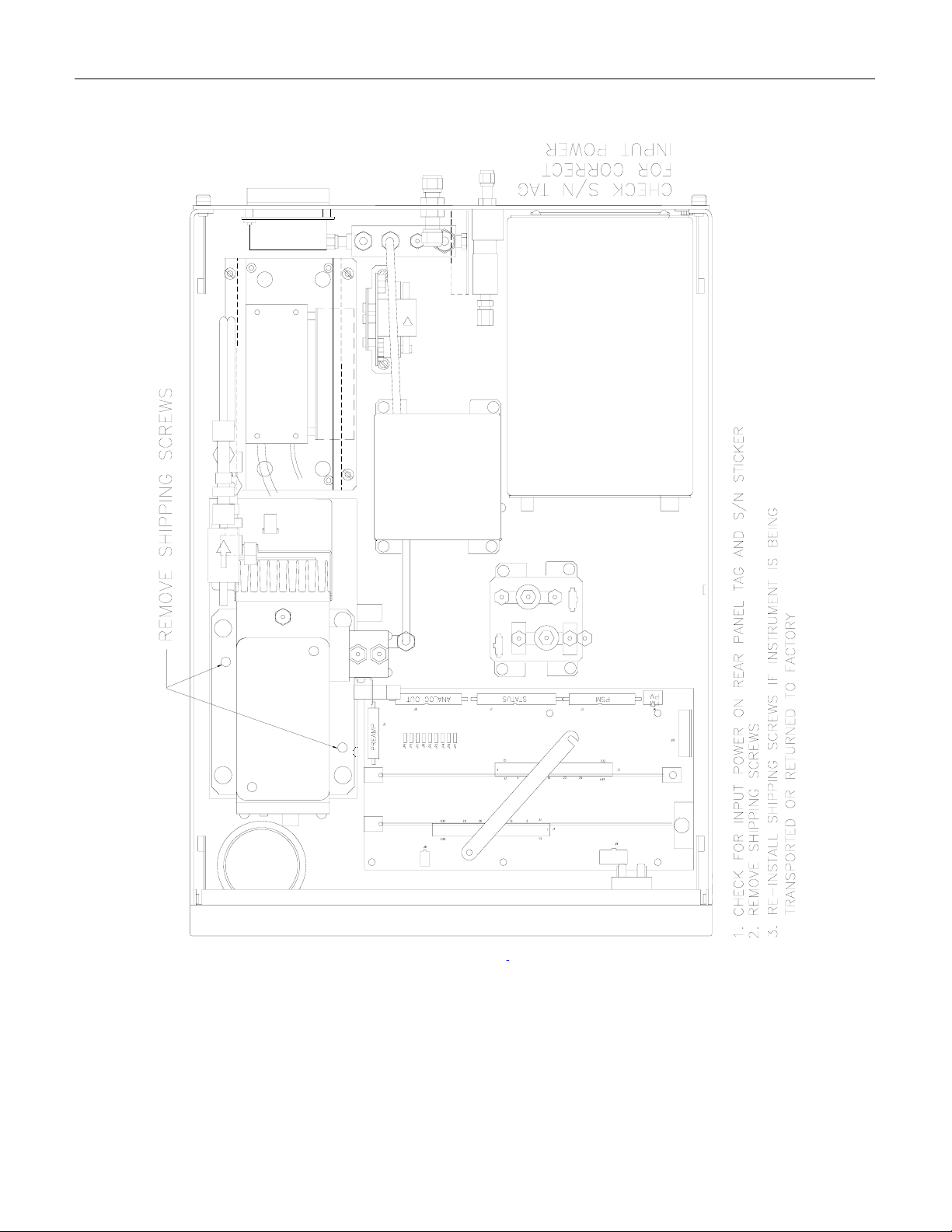

2. Before operation, it is necessary to remove the shipping hold-down screws. Remove the

instrument cover, then refer to Figure 2-1 for screw location.

3. Also check for internal shipping damage, and generally inspect the interior of the

instrument to make sure all circuit boards and other components are in good shape.

4. Please check the voltage and frequency label on the rear panel of the instrument for

compatibility with the local power before plugging in the M200AU.

2.2 Electrical and Pneumatic Connections

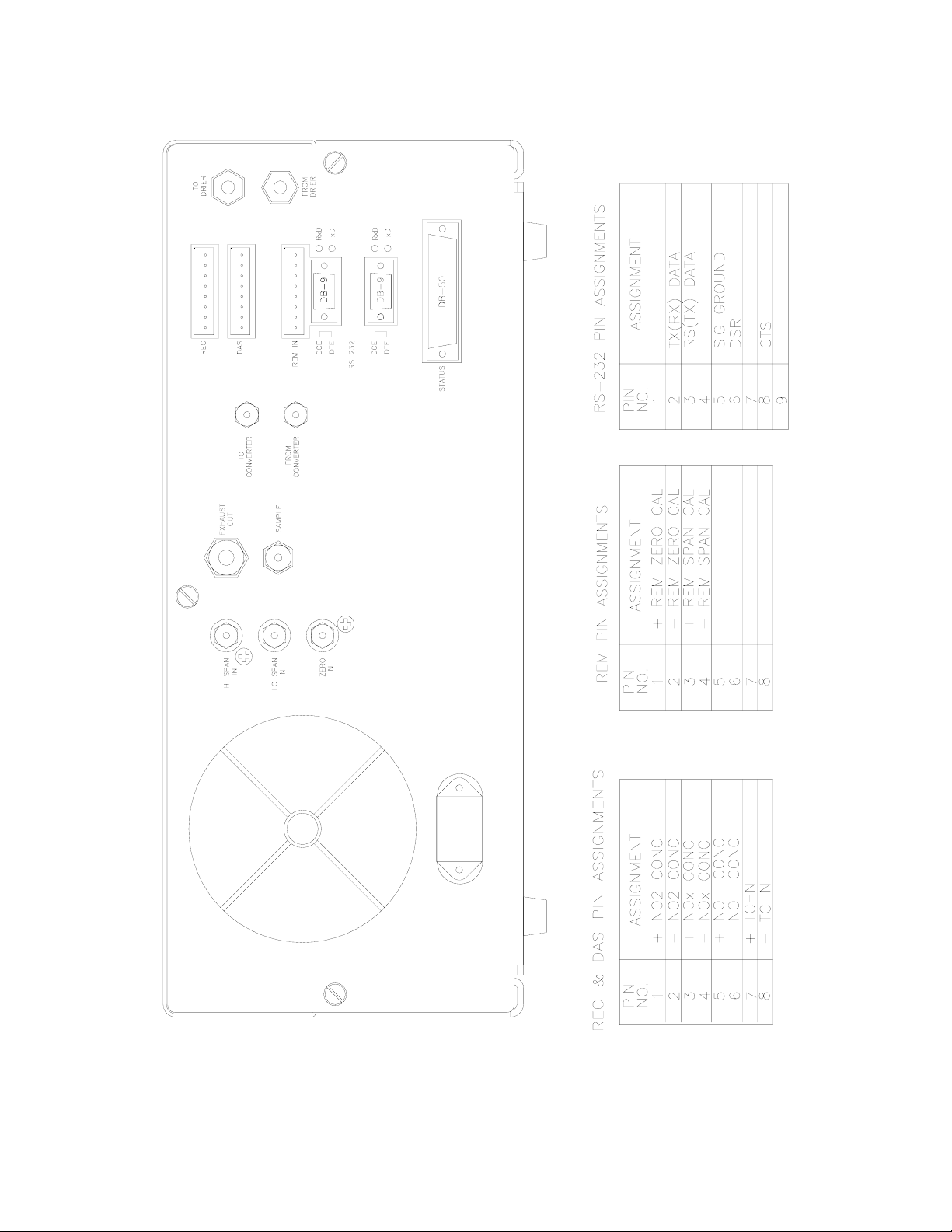

Refer to Figure 2-2 to locate the rear panel electrical and pneumatic connections.

1. Attach the pump to the Exhaust Out port on the instrument rear panel.

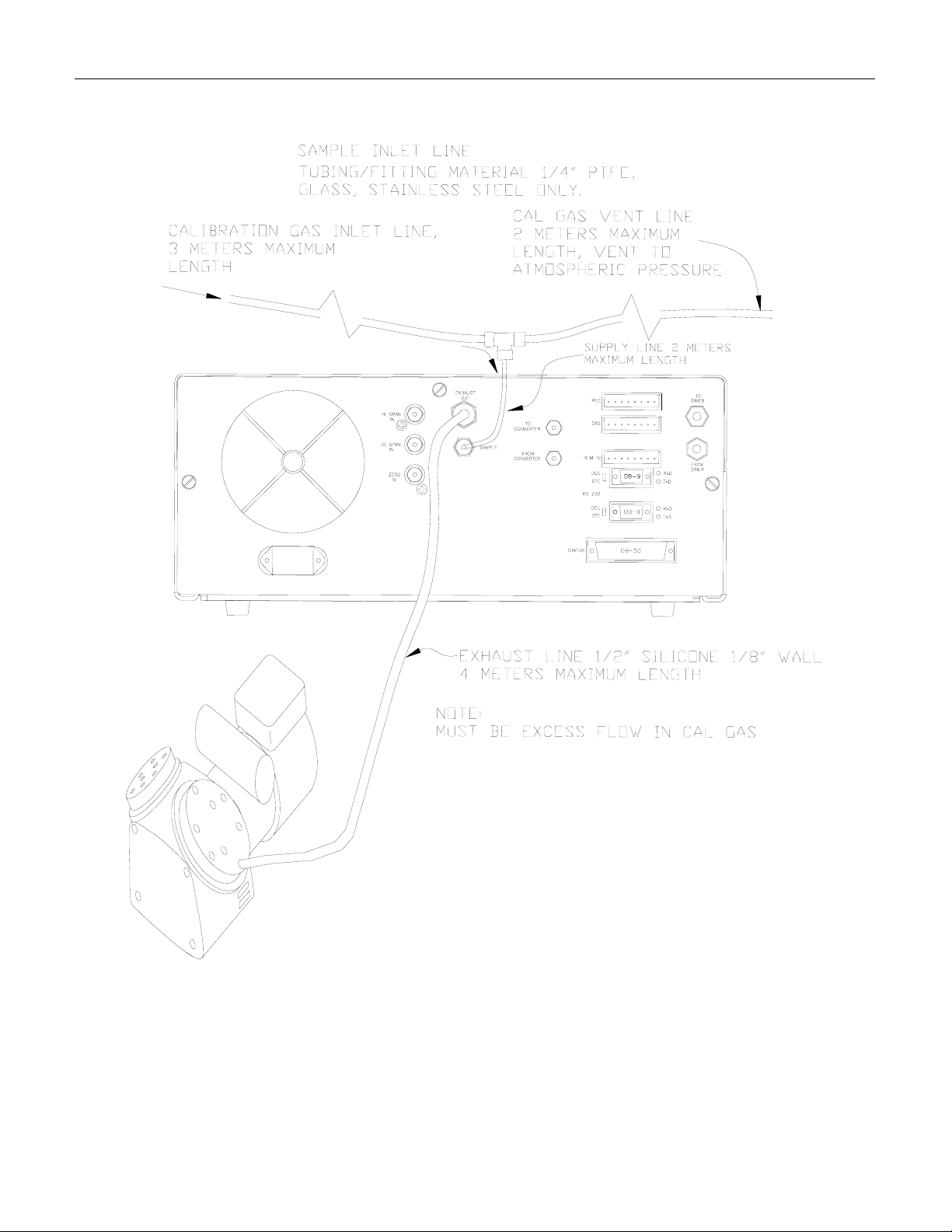

2. If you are connecting to a calibrator, attach a vented sample inlet line to the sample inlet

port. The pressure of the sample gas at the inlet port should be at ambient pressure. The

exhaust from the pump should be vented to atmospheric pressure. See Figure 2-3 for inlet

and exhaust line venting recommendations during calibration.

3. If desired, attach the analog output connections to a strip chart recorder and/or

datalogger. Refer to Figure 9-4 for the jumper settings for the desired analog output voltage

range. Factory default setting is 0-5VDC.

4. Connect the power cord to the correct voltage line, then turn to Section 2.3 Initial

Operation.

2-1

Page 14

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

WARNING

Analyzer Exhaust –Sample Pump

For brief periods after power-up, analyzer

exhaust may contain ozone.

Make sure pump exhaust is routed to well ventilated

area at atmospheric pressure.

WARNING

Lethal voltages present inside case.

Do not operate with cover off during normal operation.

Before operation check for correct input voltage and frequency for

both the analyzer and the sample pump.

Do not operate without proper chassis grounding.

Do not defeat the ground wire on power plug.

Turn off analyzer power before disconnecting

electrical subassemblies.

2-2

Page 15

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Figure 2-1: Removal of Shipping Screws & Check for Correct Power

2-3

Page 16

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Figure 2-2: Rear Panel

2-4

Page 17

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Figure 2-3: Inlet and Exhaust Venting

2-5

Page 18

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

2.3 Initial Operation

1. After confirming proper supply voltage, turn on the instrument power.

2. The display should immediately light, displaying the instrument type (M200AU) and the

computer's memory configuration. If you are unfamiliar with the M200AU, we recommend

that you read the overview Section 4 before proceeding. A diagram of the software menu

trees is in Figure 5-1 and Figure 5-2.

3. The M200AU requires about 30 minutes for all internal components to come up to

temperature. During this time the ozone generator power is OFF until the membrane dryer

has time to purge itself, therefore there will be no response from the instrument, even if span

gas is coming in the sample port. During this time temperatures and other conditions are out

of specification. Because many warning conditions could be displayed the software

suppresses warning conditions for 30 minutes after power up. After 30 minutes, warning

messages will be displayed until the respective warning conditions are within specifications.

Use the CLR key on the front panel to clear warning messages.

4. While waiting for instrument temperatures to come up, you can check for correct

operation by using some of the M200AU's diagnostic and test features.

5. Examine the TEST functions by comparing the values listed in Table 2-1 to those in the

display. Remember that as the instrument warms up the values may not have reached their

final values yet. If you would like to know more about the meaning and utility of each TEST

function, refer to Table 9-1. Also, now is a good time to verify that the instrument was

shipped with the options you ordered. Table 2-1 also contains the list of options. Section 6

covers setting up the options.

6. When the instrument is warmed up, re-check the TEST functions against Table 2-1. All

of the readings should compare closely with those in the Table. If they do not, see Section

9.1.1. The next task is to calibrate the analyzer. There are several ways to do a calibration,

they are summarized in Table 7-1. For instruments not equipped with the external converter

option, we recommend calibration with zero air and span gas coming in through the sample

port. The procedure is:

2-6

Page 19

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Step 1 - Enter the expected NOx and NO span gas concentrations:

Step Number Action Comment

1. Press

CAL-CONC-NOX

This key sequence causes the M200AU to prompt for the

expected NO

concentration. Enter the NOx span

x

concentration value by pressing the key under each digit until

the expected value is set.

2. Press ENTR ENTR stores the expected NOx span value. This value will be

used in the internal formulas to compute subsequent NO

x

concentration values.

3. Press

CAL-CONC-NO

In the same CAL-CONC sub menu press the NO button and

enter the expected NO span value, then ENTR. As before this

value will be used in the internal formulas to compute the

subsequent NO concentration values.

4. Press EXIT-EXIT Returns instrument to SAMPLE mode.

5. Press

SETUP-RNGEMODE-SING-ENTR

6. Press

SETUP-RNGE-SET

If necessary, you may want to change ranges. Normally the

instrument is shipped in single range mode set at 500 ppb. We

recommend doing the initial checkout on the 500 ppb range.

After SETUP-RNGE-SET, enter 500 and press ENTR. The

instrument will now be in the 500 ppb range.

7. Press EXIT Returns instrument to SAMPLE mode.

2-7

Page 20

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Step 2 - Calibrate the instrument:

Zero/Span Calibration Procedure

Step Number Action Comment

1. Input Zero gas Allow Zero gas to enter the sample port on the rear of the

instrument.

2. Press CAL The M200AU enters the calibrate mode from sample mode.

When the CAL button is pressed, the adaptive filter is

activated. This allows the instrument to respond rapidly to

concentration changes regardless of their magnitude.

3. Wait 10 min Wait for reading to stabilize at the zero value. If you wait less

than 10 minutes the final zero value may drift.

4. Press ZERO The ZERO button will be displayed.

5. Press ENTR Pressing ENTR actually changes the calculation equations and

zeroes the instrument.

6. Input Span Gas Switch gas streams to span gas.

7. Wait 10 min Wait for reading to stabilize at the span value. If you wait less

than 10 minutes the final span value may drift.

8. Press SPAN The SPAN button should be displayed. If it is not, check the

Troubleshooting Section 9.2.8 for instructions on how to

proceed. In certain circumstances at low span gas

concentrations (<100ppb), both the ZERO and SPAN buttons

will appear.

9. Press ENTR Pressing ENTR actually changes the calculation equations so

that the concentration displayed is the same as the expected

span concentration you entered above, thus spanning the

instrument.

10. Press EXIT Pressing EXIT returns the instrument to SAMPLE mode.

2-8

Page 21

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Step 3 - Review the quality of the calibration:

Calibration Quality Check Procedure

Step Number Action Comment

1. Scroll the TEST

function menu until

the NO

SLOPE is

x

displayed.

2. Scroll the TEST

function menu until

the NO SLOPE is

displayed.

The SLOPE value for NO

not in this range, check Section 7.8 or 9. If the SLOPE value

is in the acceptable range, the instrument will perform

optimally.

The SLOPE value for NO should be 1.0 ± 0.3. If the value is

not in this range, check Section 7.8 or 9. If the SLOPE is in

the acceptable range, the instrument will perform optimally.

should be 1.0 ± 0.3. If the value is

x

NOTE:

slopes should be equal within ± 0.1.

x

x

4. Scroll the TEST

function menu until

the NO

OFFSET is

x

displayed.

The NO and NO

The M200AU will display the OFFSET parameter for the NO

equation. This number should be near zero. A value of 0.0 mV

–10 +150 mV indicates calibration in the optimal range. If the

OFFSET value is outside this range, check Section 7 or 9 for

procedures to correct the OFFSET value to near zero.

5. Scroll the TEST

function menu until

The instrument will now display the NO OFFSET value. It

should also have a value near zero (0.0 mV –10 +150 mV).

the NO OFFSET is

displayed.

Step 4 - The M200AU is now ready to measure sample gas.

2-9

Page 22

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

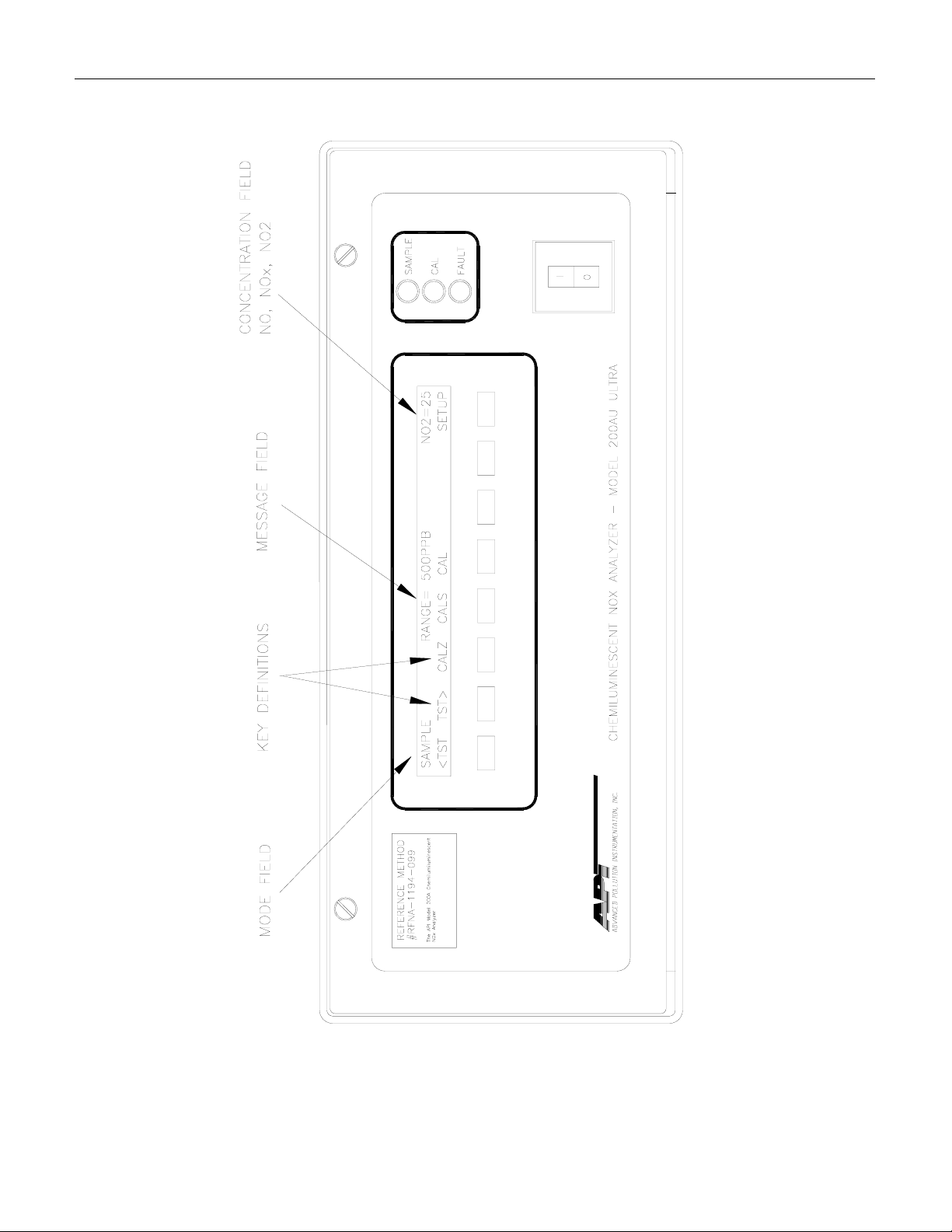

Figure 2-4: Front Panel

2-10

Page 23

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

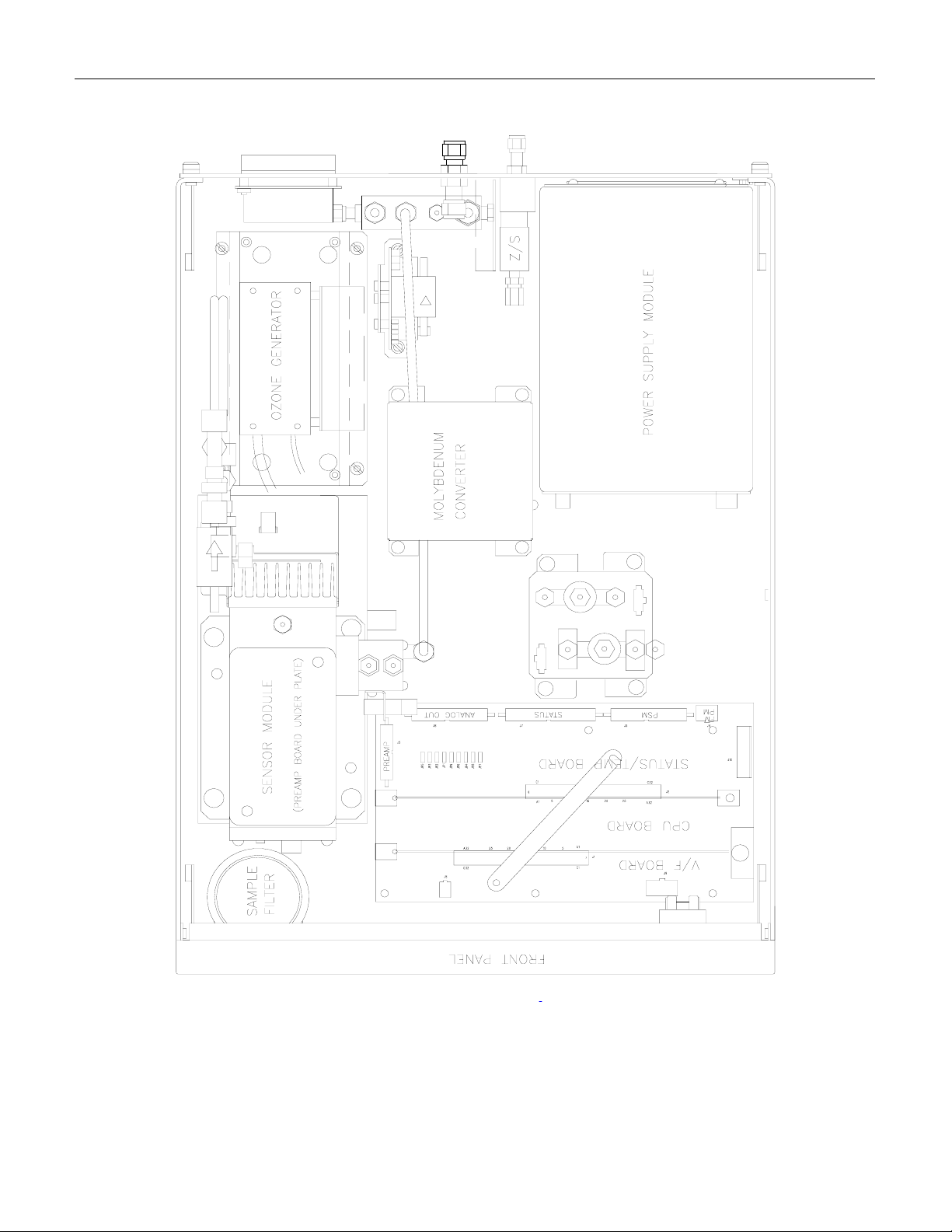

Figure 2-5: Assembly Layout

2-11

Page 24

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

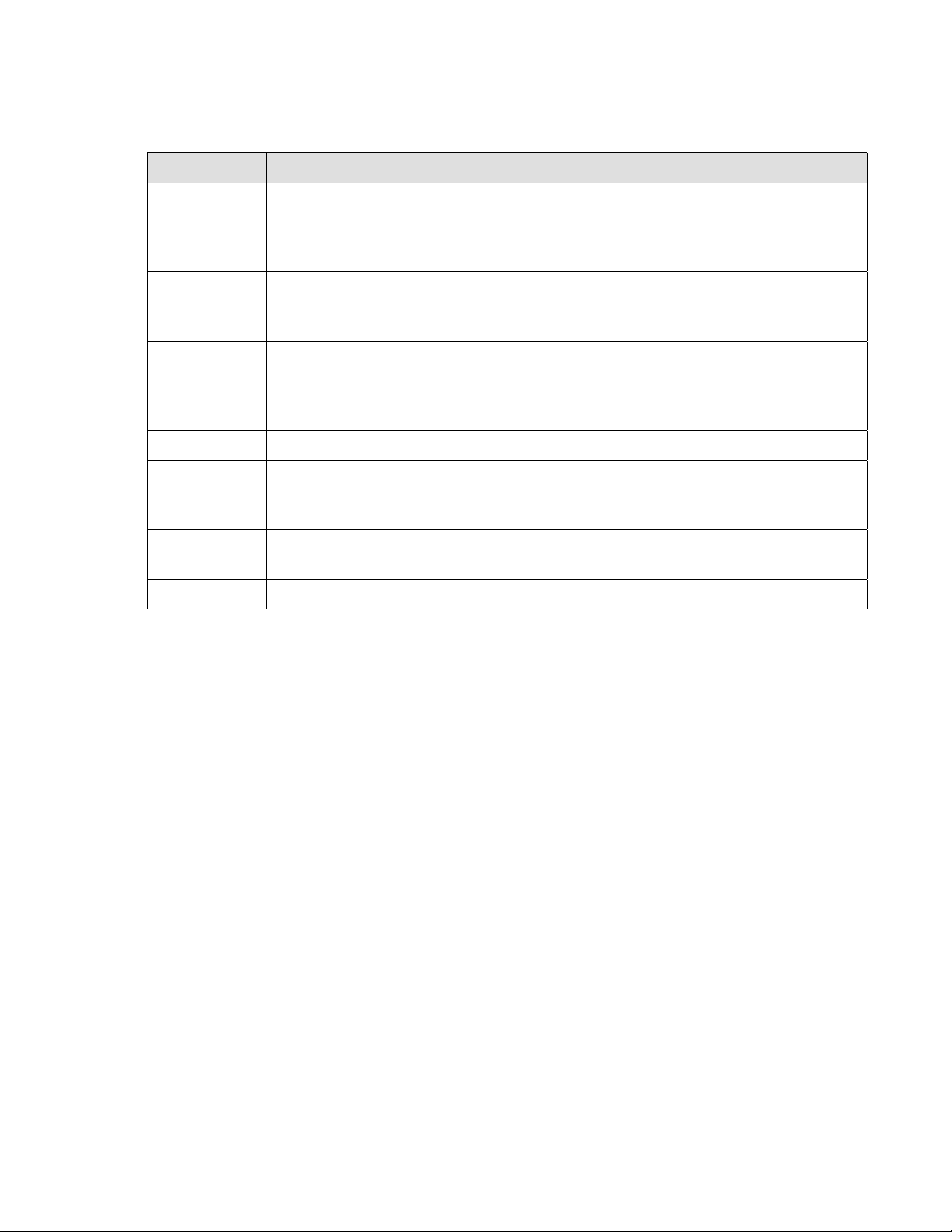

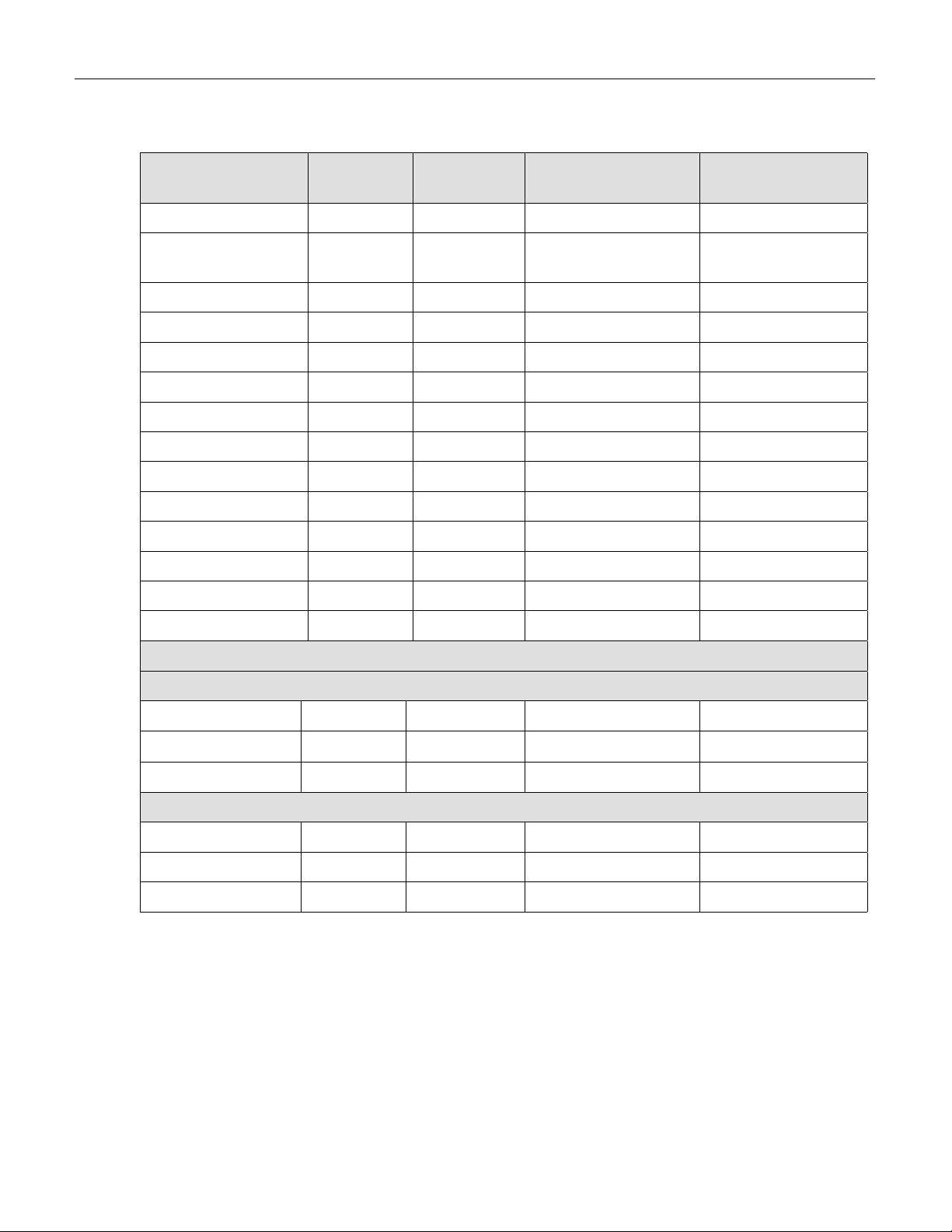

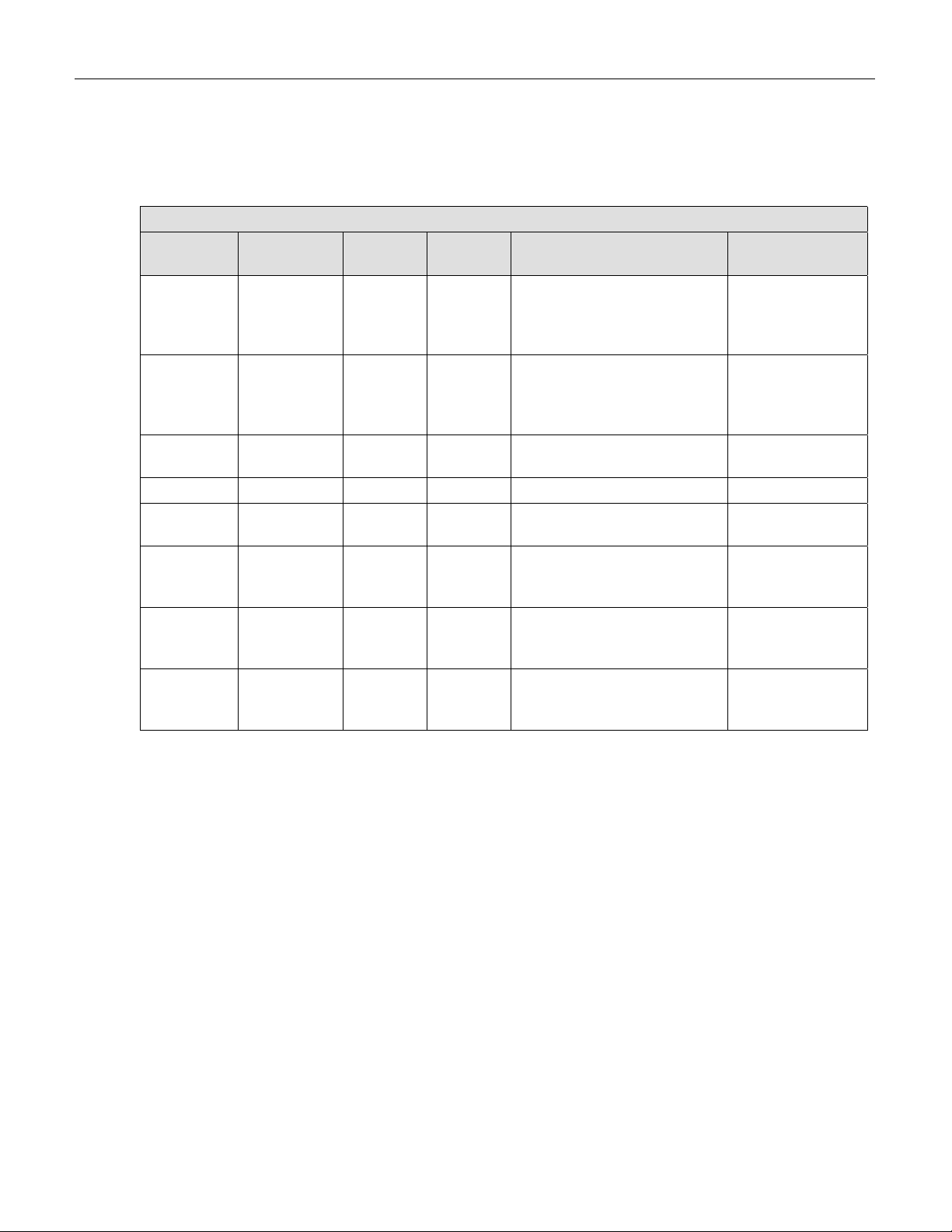

Table 2-1: Final Test and Calibration Values

Test Values

Observed

Value

Units Nominal Range Reference Section

RANGE ppb 5-2000 5.3.4

STABILITY ppb 0.001-2000 9.1.1, 9.2.5,

Table 9-1

SAMP FLW cc/min 1000 ± 100 9.3.7, Table 9-1

OZONE FL cc/min 80 ± 15 9.3.6, 9.3.7

PMT mV 0-5000 9.3.8.1, Table 9-1

PREREACT mV 0-1000 Table 9-1

HVPS V 450 - 900 constant 9.3.8.5

DCPS mV 2500 ± 200 9.3.5, 9.3.4

RCELL TEMP

BOX TEMP

PMT TEMP

MOLY TEMP

o

C 40 ± 1 9.3.8.2

o

C 8-48 9.3.4.1

o

C -5 ± 1 9.3.8.4

o

C 315 ± 5 9.3.4.1

RCEL PRES IN-Hg-A 1 - 4 constant 9.3.7

SAMP PRES IN-Hg-A 25 - 30 constant 9.3.7

Electric Test & Optic Test

Electric Test

PMT Volts mV 2000 ± 500 9.1.3.2

NO Conc PPB 1000 ± 250 9.1.3.2

NOx Conc PPB 1000 ± 250 9.1.3.2

Optic Test

PMT Volts mV 2000 ± 1000 9.1.3.3

NO Conc PPB 1000 ± 500 9.1.3.3

NOx Conc PPB 1000 ± 500 9.1.3.3

(table continued)

2-12

Page 25

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

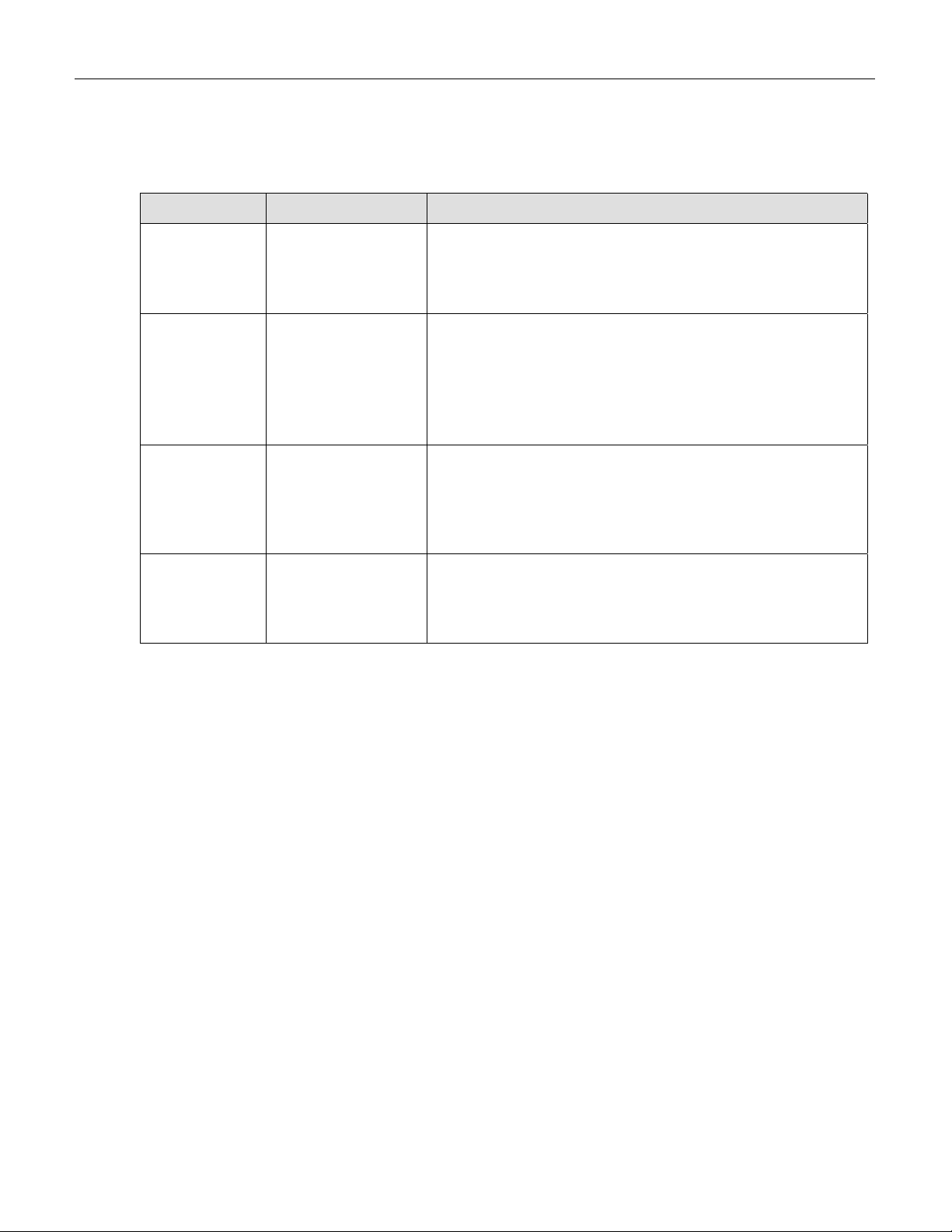

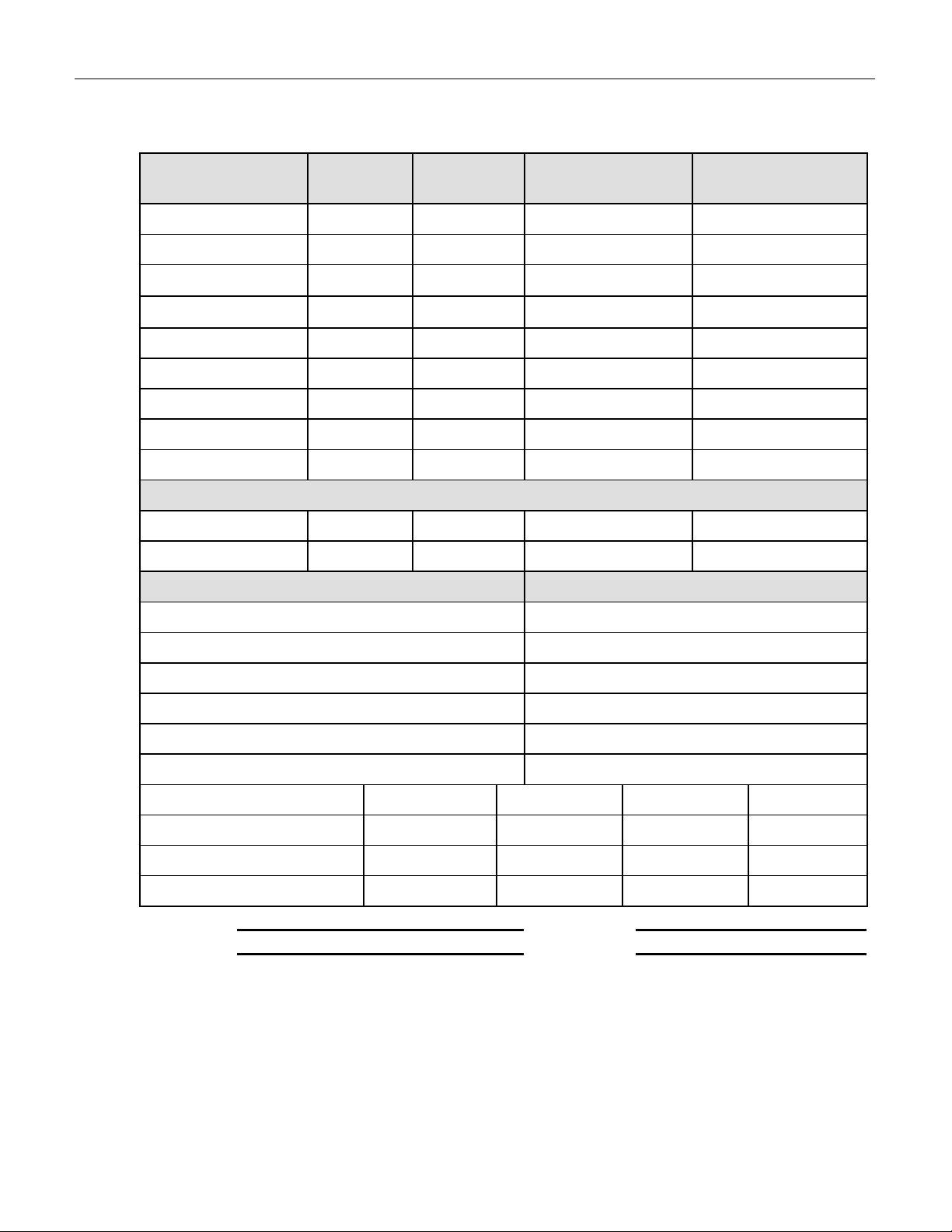

Table 2-1: Final Test and Calibration Values (Continued)

Parameter

NO Span Conc PPB 1 - 2000 Table 7-3

NOx Span Conc PPB 1 - 2000 Table 7-3

NO Slope -

NOx Slope -

NO Offset mV -10 to +150 Table 7-18

NOx Offset mV -10 to +150 Table 7-18

Moly Efficiency % 0.96 - 1.02 7.6.6, 5.2.2.6

Stability at Zero PPB 0.001 - 2000 Table 9-1

Stability at Span PPB < 1 @ 400 ppb Table 9-1

Sample Flow cc/min 1000 ± 100 9.3.7, Figure 9-8

Ozone Flow cc/min 80 ± 15 9.3.7, Figure 9-8

Factory Installed Options Option Installed

Power Voltage/Frequency

Observed

Value

Units Nominal Range Reference Section

1.0 ± 0.3

1.0 ± 0.3

Measured Flows

Table 7-18

Table 7-18

Rack Mount, w/ Slides

Rack Mount, w/ Ears Only

Rack Mount, External Pump w/ Slides

Rack Mount, External Pump w/o Slides

Stainless Zero/Span Valves

Current Loop - NOx Chan 4-20 mA 0-20 mA Isolated Non-Isolated

Current Loop - NO Chan 4-20 mA 0-20 mA Isolated Non-Isolated

Current Loop - NO2 Chan 4-20 mA 0-20 mA Isolated Non-Isolated

Current Loop - TST Chan 4-20 mA 0-20 mA Isolated Non-Isolated

PROM # Serial #

Date Technician

2-13

Page 26

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

INTENTIONALLY BLANK

2-14

Page 27

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

3 SPECIFICATIONS, AGENCY APPROVALS,

WARRANTY

3.1 Specifications

Ranges In 1ppb increments from 5ppb to 2000ppb

independent ranges or autoranging

Noise at Zero

Noise at Span

Lower Detectable Limit

Zero Drift

Span Drift

Lag Time 20 sec

Rise Time

Fall Time

Sample Flow Rate 1000 cc/min. ± 10%

Linearity

Precision 0.5% of reading above 50 ppb

Hydrocarbon Interference Propylene rejection ratio > 20,000:1

Temperature Range 20-30

Temp Coefficient < 0.1% per

Humidity 0-95% RH non-condensing

Voltage Coefficient < 0.1% per V

Dimensions HxWxD 7" H x 17" W x 23.6" D (18cm x 43cm x 61cm)

Weight, Analyzer 43 lbs (20 kg)

Weight, Ext Pump Pack 21 lbs (9.5 kg)

Power, Analyzer

Power, Analyzer

Power, Ext Pump 110V~ 60 Hz, 220V~ 50 Hz, 240V~ 50Hz, 150 watts

Power, Ext Pump

Environmental

Recorder Output 100 mV, 1, 5, 10V, isolated or non-isolated current loop

Analog Resolution 1 part in 1024 of selected voltage or current range

Status Option 12 Status Outputs from opto-isolator

Measurement Units ppb, ug/m

1

<25 ppt RMS

1

<0.25% RMS of reading above 50 ppb

2

<0.1 ppb / 24 hours

2

<0.5% FS or 50 ppt RMS whichever is greater / 7 days

3

95% in <50 sec6

3

95% in <50 sec6

1

50 ppt RMS

<0.2 ppb / 7 days

1% of full scale or ± 0.1 ppb whichever is greater

Ethylene rejection ratio > 40,000:1

o

C within drift and noise specifications

o

C safe operating range

5-35

4

230V~ 50 Hz, 2.5A

4

230V~ 50 Hz, 2.2A

4

Installation Category (Over-voltage Category) II

100V~ 50/60 Hz, 120V~ 60 Hz, 230V~ 50 Hz, 2.5A, 125 watts

o

C

Pollution Degree 2

3

1. As defined by USEPA.

2. At constant temperature and voltage.

3. With adaptive filter, > 20 ppb change.

4. Electrical rating for CE Mark compliance.

3-1

Page 28

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

3.2 EPA Equivalency Designation

Teledyne Instruments Advanced Pollution Instrumentation Division, Model 200AU High

Sensitivity Nitrogen Oxides Analyzer is designated as Reference Method Number RFNA-1194099 as defined in 40 CFR Part 53, when operated under the following conditions:

1. Range: Any range from 50 parts per billion (ppb) to 1 ppm.

2. Ambient temperature range of 20 to 30oC.

3. Line voltage range of 105-125 VAC, 60Hz; 220-240 VAC, 50Hz.

4. With 5-micron TFE filter element installed in the internal filter assembly.

5. Sample flow of 1000 ± 100 cc/min.

6. Vacuum pump capable of 6"Hg Abs pressure @ 2 slpm or better.

7. Software settings:

A. Dynamic span OFF

B. Dynamic zero OFF

C. Cal-on-NO2 OFF

D. Dilution factor OFF

E. AutoCal ON or OFF

F. Independent range ON or OFF

G. Autorange ON or OFF

H. Temp/Pres compensation ON

I. Converter Efficency 0.96 to 1.02

Under the designation, the Analyzer may be operated with or without the following options:

1. Rack mount with slides.

2. Rack mount without slides, ears only.

3. Rack mount for external pump w/o tray.

4. Stainless steel zero/span valves.

5. 4-20mA, isolated outputs.

6. Status outputs.

7. RS-232 output.

8. 1 micron sample filter.

3-2

Page 29

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

3.3 Warranty

WARRANTY POLICY

Prior to shipment, Teledyne API equipment is thoroughly inspected and tested. Should

equipment failure occur, Teledyne API assures its customers that prompt service and support

will be available.

COVERAGE

After the warranty period and throughout the equipment lifetime, Teledyne API stands ready to

provide on-site or in-plant service at reasonable rates similar to those of other manufacturers in

the industry. All maintenance and the first level of field troubleshooting is to be performed by

the customer.

NON-TELEDYNE API MANUFACTURED EQUIPMENT

Equipment provided but not manufactured by Teledyne API is warranted and will be repaired to

the extent and according to the current terms and conditions of the respective equipment

manufacturers warranty.

GENERAL

TELEDYNE API warrants each Product manufactured by Teledyne API to be free from defects

in material and workmanship under normal use and service for a period of one year from the date

of delivery. All replacement parts and repairs are warranted for 90 days after the purchase.

If a Product fails to conform to its specifications within the warranty period, Teledyne API shall

correct such defect by, in Teledyne API's discretion, repairing or replacing such defective

Product or refunding the purchase price of such Product.

The warranties set forth in this section shall be of no force or effect with respect to any Product:

(i) that has been altered or subjected to misuse, negligence or accident, or (ii) that has been used

in any manner other than in accordance with the instruction provided by Teledyne API or (iii)

not properly maintained.

THE WARRANTIES SET FORTH IN THIS SECTION AND THE REMEDIES

THEREFORE ARE EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE OR OTHER

WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED. THE

REMEDIES SET FORTH IN THIS SECTION ARE THE EXCLUSIVE REMEDIES FOR

BREACH OF ANY WARRANTY CONTAINED HEREIN. TELEDYNE API SHALL

NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES

ARISING OUT OF OR RELATED TO THIS AGREEMENT OF TELEDYNE API'S

PERFORMANCE HEREUNDER, WHETHER FOR BREACH OF WARRANTY OR

OTHERWISE.

3-3

Page 30

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

TERMS AND CONDITIONS

All units or components returned to Teledyne API should be properly packed for handling and

returned freight prepaid to the nearest designated Service Center. After the repair, the equipment

will be returned, freight prepaid.

3-4

Page 31

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

4 THE M200AU NOX ANALYZER

4.1 Principle of Operation

The Teledyne API Model 200AU Analyzer is designed to measure the concentration of nitric

oxide [NO], total oxides of nitrogen [NOx] and, by calculation, nitrogen dioxide [NO2].

The instrument measures the light intensity of the chemiluminescent gas phase reaction of nitric

oxide [NO] and ozone [O3] as follows:

O*NOONO

223

+→+

hvNO*NO

22

+→

The reaction of NO with ozone results in electronically excited NO2 molecules as shown in the

first equation above. The excited NO2 molecules release their excess energy by emitting a

photon and dropping to a lower energy level as shown in the second equation. It has been shown

that the light intensity produced is directly proportional to the [NO] concentration present.

The Analyzer samples the gas stream and measures the [NO] concentration by digitizing the

signal from the Analyzer's photomultiplier tube (PMT). A valve then routes the sample stream

through a converter containing heated molybdenum to reduce any NOx present to NO by the

following reaction:

315o C

MoONO3MoNO3

+→+

The Analyzer now measures the total NOx concentration. The [NOx] and [NO] values are

subtracted from each other by the built-in computer, yielding the [NO2] concentration. In the

third measurement phase, the instrument measures sample gas which has been mixed with ozone

outside of the reaction cell. This Pre-Reactor allows the measurement of any hydrocarbon

interferents present in the sample gas stream. The three results [NO], [NOx], and [NO2] are then

further processed and stored by the computer yielding several instantaneous and long term

averages of all three components.

The software uses an adaptive filter to accommodate rapid changes in concentration. The

algorithm monitors the rate of change in concentration for both the NO and NOx channels. When

a change in concentration is detected, the software changes the sample filters to rapidly respond

to the change. The filters are adjusted to minimize the errors introduced by the time delay

between the NOx and NO channel measurements; this assures accurate NO2 measurements.

When the rate of change decreases, the filters are lengthened to provide better signal/noise ratio.

The parameters used to operate the adaptive filter have been tuned to match the electrical and

pneumatic characteristics of the M200AU.

3x

4-1

Page 32

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Figure 4-1: Block Diagram

4-2

Page 33

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

4.2 Operation Summary

4.2.1 Sensor Module, Reaction Cell, Detector

The sensor module (Figure 9-9) is where light from the chemilumenescent reaction is generated

and detected. It is the most complicated and critical sub-assembly in the entire analyzer. It

consists of the following assemblies and functions:

1. The reaction cell and flow control module

2. Reaction cell heater/thermistor

3. PMT and high voltage power supply

4. PMT cooler/cold block/heatsink/fan

5. Preamp assembly:

A. Preamp range control hardware

B. HVPS control

C. PMT cooler temp control

D. Electric test electronics

E. Optic test electronics

4.2.2 Pneumatic Sensor Board

The sensor board consists of 2 pressure sensors and a flow sensor. One pressure sensor measures

the pressure in the reaction cell. The reaction cell is maintained at about 0.1 atmospheric

pressure. The second pressure sensor measures the pressure just upstream of the reaction cell,

which is near ambient pressure. From these two pressures the sample flow rate can be computed

and is displayed as sample flow in the TEST menu. Finally, a solid state flow meter measures the

ozone flow using a resistive bridge. Likewise, it is displayed as a TEST function.

The M200AU displays all pressures in inches of mercury-absolute (in-Hg-A). Absolute pressure

is the reading referenced to a vacuum or zero absolute pressure. This method was chosen so that

ambiguities of pressure relative to ambient pressure can be avoided.

4-3

Page 34

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

NOTE

On vacuum vs absolute pressure:

Many vacuum gauges read relative to ambient pressure, therefore

a reading of 25" of mercury (Hg) at sea level (which would give an

absolute pressure of about 5" Hg in the reaction cell) would read

only 20" Hg at high altitude sites. Therefore in this manual the vacuum

specification of 5" Hg pressure is given as an absolute pressure

- 5"Hg-A - reference against zero absolute pressure (a perfect vacuum)

thus removing ambiguities for high altitude sites.

4.2.3 Computer Hardware and Software

CPU Board

The M200AU Analyzer is operated by an V40 series micro computer. The computer's

multitasking operating system allows it to do instrument control, monitor test points, provide

analog output and provide a user interface via the display, keyboard and RS-232 port. These

operations appear to be happening simultaneously but are actually done sequentially based on a

priority queuing system maintained by the operating system. The jobs are queued for execution

only when needed, therefore the system is very efficient with computer resources.

The M200AU is a true computer based instrument. The microprocessor does most of the

instrument control functions such as temperature control, valve switching. Data collection and

processing are done entirely in the CPU with the final concentration values being sent to a D/A

converter to produce the instrument analog output.

The computer memory is divided into 3 sections: ROM memory contains the multi-tasking

operating system code plus the instructions that run the instrument. The RAM memory is used to

hold temporary variables, current concentration data and data acquisition system data. The

EEPROM memory contains the instrument set-up variables such as range and instrument ID

number. The EEPROM data is non-volatile so the instrument can lose power and the current setup information is preserved.

4.2.4 V/F Board

The V/F board is multifunctional, consisting of A/D input channels, digital I/O channels, and

analog output channels. Communication with the computer is via a STD bus interface. The

computer receives all of the instrument data and provides all control functions through the V/F

board.

4-4

Page 35

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

4.2.5 Front Panel

The front panel of the M200AU is shown in Figure 2-4. The front panel consists of a 2 line

display and keyboard, 3 status LED's and power switch. Communication with the display,

keyboard, and status LED's is done via the computer's on-board parallel port. The M200AU was

designed as a computer controlled instrument, therefore all major operations can be controlled

from the front panel display and keyboard.

The display consists of 2 lines of 40 characters each. The top line is divided into 3 fields, and

displays information. The first field is the mode field. A list of operating modes is given in

Table 5-8.

The center field displays TEST values. The TEST functions allow you to quickly access many

important internal operating parameters of the M200AU. This provides a quick check on the

internal health of the instrument. The right hand field shows current concentration values of NO,

NOx, and NO2. The display scrolls between the 3 values every 4 seconds.

4.2.5.1 Keyboard

The second line of the display contains eight fields. Each field defines the key immediately

below it. By redefining the keys dynamically it is possible to simplify the instrument electronics

and user interface.

When entering data in the keyboard, if the entered value is not accepted, the M200AU will

"beep" to notify the user that the value keyed in was not accepted. The original value remains

unchanged.

4.2.5.2 Status LED's

At the right of the display there are 3 status LED's. They can be in three states, OFF, ON, and

Blinking. The meanings of the LED's are given in Table 4-1.

4-5

Page 36

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Table 4-1: Front Panel Status LED's

LED State Meaning

Green On

Off

Blinking

Yellow Off

On

Blinking

Red Off

Blinking

(1) This occurs during Calibration, DAS holdoff, power-up holdoff, and when in Diagnostic mode.

Monitoring normally, taking DAS data

NOT monitoring, DAS disabled

Monitoring, DAS in HOLDOFF mode (1)

Auto cal. disabled

Auto/Dynamic cal. enabled

Calibrating

No warnings exist

Warnings exist

4.2.5.3 Power Switch

The power switch has two functions. The rocker switch controls overall power to the instrument,

in addition it includes a circuit breaker. If attempts to power up the M200AU result in a circuit

breaker trip, the switch automatically returns to the off position, and the instrument will not

power up.

4-6

Page 37

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

4.2.6 Power Supply Module

The Power supply module supplies AC and DC power to the rest of the instrument. It consists of

a 4 output linear DC power supply and a 15 volt switching supply. In addition, it contains the

switching circuitry to drive the DC operated valves and several switched AC loads to operate the

Rx cell heater, the Moly heater, and the ozone generator.

4.2.7 Pump, Valves, Pneumatic System

A standard M200AU comes with 2 valves. The NO/NOx valve switches sample from either the

sample inlet port or from the moly converter into the reaction cell. Each NO/NOx cycle, the Prereactor valve re-routes sample gas into the Pre-reactor volume which allows time for the NOOzone reaction to complete. The pneumatic timing of the Pre-reactor is set so that any

hydrocarbon interferences are measured and eliminated from the signal.

The M200AU is equipped with a high performance pump, capable of producing a reaction cell

pressure of less than 4” Hg-A. See Figure 2-3 for hook-up information. A catalytic ozone

scrubber protects the pump from the corrosive effects of ozone. See Section 4.2.8.

4.2.8 Ozone Generator

Because of the instability of ozone, it is necessary to generate this gas inside the analyzer. The

ozone generation module consists of a high frequency switching AC supply and pulse

transformer connected to a silent discharge tube. Air is supplied to the generator from a

permeation type air drier. A complete description of its function and service requirements can be

found in Section 9.3.6.

Although there are dangerous high voltages generated in the ozone generator, they are isolated

from the user by sealing the system in a single potted assembly. The dry air supply for the ozone

generator uses a membrane drier to supply air with a dew point of 0o C or less. The exhaust side

of the membrane is connected to the vacuum manifold at the rear of the instrument.

Normal room air contains enough water vapor to damage the generator and components

downstream. Because of this, the ozone generator may not turn on immediately at power up.

A heated catalytic ozone scrubber, located in the molybdenum converter assembly removes

excess ozone from the instrument exhaust. The delay is built into the instrument to allow the

dryer to start operating and purge the system with dry air. Table 4-2 details the conditions for

turning on the ozone generator.

4-7

Page 38

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Table 4-2: Ozone Generator Start-up Timing

Time Since Last

Power-up

< 1 hour ON at power-up Gen ON immediately after power-up.

> 1 hour OFF at power-up Wait 30 min, then turn gen ON.

Ozone Gen State Program Action

4.2.9 Molybdenum Converter – Ozone Scrubber

The molybdenum converter is a stainless steel cartridge containing molybdenum chips heated to

315° C. The converter's function is to reduce NOx to nitric oxide NO. The temperature control

for this module is done by the Switch Card in the Power Supply Module using commands

generated by the CPU. The temperature is measured by a type J thermocouple and is conditioned

on the Status/Temp board. The analog voltage representing the Moly temperature is read by the

V/F board and sent to the CPU where signals are generated for temperature control. The

digitized voltage is translated to degrees for the TEST function on the front panel and for

warnings.

The molybdenum converter assembly also contains a catalytic ozone scrubber that removes

excess ozone from the instrument exhaust.

4-8

Page 39

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

5 SOFTWARE FEATURES

5.1 Index To Front Panel Menus

The M200AU has 2 main operating modes, namely the SAMPLE and SETUP modes. The

instrument is operating in the SAMPLE mode when it is measuring gas. The SETUP mode is

used to create or change operating parameters such as range. Also in SETUP mode the

instrument has extensive fault diagnosis tools. A list of M200AU operating modes is given in

Table 5-8.

The next several pages contain two different styles of indexes that will allow you to navigate the

M200AU software menus. The first two pages show a "tree" menu structure to let you see at a

glance where each software feature is located in the menu. The second menu contains a brief

description of each key mnemonic and a reference to the section of the manual that describes its

purpose and function in detail.

5-1

Page 40

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Figure 5-1: Sample Menu Tree

5-2

Page 41

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Figure 5-2: Setup Menu Tree

5-3

Page 42

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

5.1.1 Sample Menu

Table 5-1: Sample Menu

Menu Level

Level 1 Level 2 Level 3 Level 4 Description

TEST

TST>

CAL Zero/Span calibration w/ gas

CALZ Zero calibration w/ zero gas

CALS Span calibration w/ span gas

ZERO Press ZERO then ENTR will

SPAN Press SPAN then ENTR will

CONC Expected NO/NOx span

NOX

NO

Test functions 5.2.1, Table 9-1

through sample port

from zero valve option

from span valve option

zero analyzer

span analyzer

concentrations and Moly conv.

efficiency setup

Enter expected NOx span

CONC

Enter expected NO span

CONC

concentration

concentration

Reference

Section

5.2.2.1, 7.1

5.2.2.2, 7.2, 7.3

5.2.2.3, 7.2, 7.3

5.2.2.2, 7.2, 7.3

5.2.2.3, 7.2, 7.3

7.1

5.2.2, Table 7-3

5.2.2, Table 7-3

5-4

Page 43

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Table 5-2: Sample Menu

Menu Level

Level 1 Level 2 Level 3 Level 4 Description

CONV Sub-menu for converter

efficiency setup and

verification

NO2 Expected NO2 concentration for

converter efficiency calculation

CAL Automatic converter efficiency

calibration and entry

SET Set the converter efficiency

manually

MSG Displays warning messages 9.1.2

CLR Clears warning messages 9.1.2

SETUP The SETUP Menu - See next

table

Reference

Section

5.2.2.6, 7.6.6

5.2.2.6, 7.6.6

5.2.2.6, 7.6.6

5.2.2.6, 7.6.6

Table 5-2

5-5

Page 44

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

5.1.2 Set-Up Menu

Table 5-3: Setup Menu

Setup Menu #1

Level 1 Level 2 Level 3 Level 4 Description

CFG CFG is primarily used for

showing special configuration

options and factory special

software

PREV,

NEXT, LIST

AUTOCAL Automatic span check or

SEQUENCE Selects Sequence 5.3.2, 6.4

PREV-

MODE Selects mode of calibration

SET For a given Sequence and

DAS Data Acquisition System

(table continued)

PREV, NEXT can be used to

scroll through the

configuration list. LIST

automatically scrolls the list

calibration

Scrolls display to select

NEXT

calibration sequence 1, 2, or 3

(zero, span, zero-span) plus

disable

Mode, sets timing and

calibration attributes

(DAS) - keeps 1 to 1500

minute averages of data

Reference

Section

5.3.1

5.3.1

5.3.2, 6.4

5.3.2, 6.4

5.3.2, 6.4

5.3.2, 6.4

5.3.3

5-6

Page 45

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Table 5-3: Setup Menu (Continued)

Setup Menu #1

Level 1 Level 2 Level 3 Level 4 Description

VIEW Select which DAS data

collector to view

PREV-

NEXT

EDIT Allows editing of the several

UP Displays the DAS data buffer

UP10 Move UP 10 averages in the

DOWN Move down 1 average in the

DOWN10 Move DOWN 10 averages in

PRNT Prints the setup parameters of

Scroll through data collectors

CONC, PNUMTC, CAL

DAT, STABILITY

attributes of a data collection

channel.

- Move UP 1 average in the

DAS data buffer

DAS data buffer

DAS data buffer

the DAS data buffer

a data collector to the RS-232

port

Reference

Section

5.3.3

5.3.3

5.3.3

5.3.3

5.3.3

5.3.3

5.3.3

5.3.3

5-7

Page 46

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Table 5-4: Setup Menu

Setup Menu #2

Level 1 Level 2 Level 3 Level 4 Description

RANGE Range control menu 5.3.4

MODE Range mode select - Single,

Autorange, Independent,

Remote

SET Sets range if mode is Single

range

NO Sets NO concentration range if

indep ranges enabled

NOx Sets NOx concentration range if

indep ranges enabled

NO2 Sets NO2 concentration range if

indep ranges enabled

LO Sets low range if Autorange

enabled

HI Sets high range if Autorange

enabled

UNITS Unit selection menu 5.3.4.5

PPB, UGM Select units that instrument uses 5.3.4.5

DIL Enter dilution factor if

connected to stack dilution

probe

PASS Password enable/disable menu 5.3.5

ON-OFF Enable/disable password

checking

CLOCK TIME Adjusts time on the internal

time of day clock

DATE Adjusts date on the internal

time of day clock

MORE Continue menus on next level

down

COMM RS-232 communications

control menu

BAUD Sets the BAUD rate to 300 -

19,200

ID Sets the instrument ID -

(included on all RS-232

messages)

Reference

Section

5.3.4

5.3.4.1

5.3.4.3

5.3.4.3

5.3.4.3

5.3.4.2

5.3.4.2

5.3.4.4

5.3.5

5.3.6

5.3.6

5.3.8, 5.5

5.3.8, 5.5

5.3.8, 5.5

5-8

Page 47

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

Table 5-5: Setup Menu

Setup Menu #3

Level 1 Level 2 Level 3 Level 4 Description

VARS Internal variables 5.3.9, 9.2

PREV,

NEXT,

JUMP,

EDIT

DIAG Diagnostic menu 5.3.7, 9.1.3

PREV,

NEXT

SIG I/O Examines, changes analog and

ANALOG

D/A CAL Calibrates V/F board and the

TEST

PREV, NEXT scroll up and

down through the VARS menu.

JUMP will go to variable

number selected, EDIT will

allow editing of the selected

variable.

PREV, NEXT scroll up and

down through the DIAG menu.

digital internal signals

Writes a stepped analog output

OUT

CHNL

voltage to the 4 analog outputs

analog outputs

Routes several internal signals

to TCHAN analog output - used

for diagnosis

Reference

Section

5.3.9, 9.2

5.3.7, 9.1.3

9.1.3.1

9.1.3.5

9.1.3.6

9.1.1

OPTIC

TEST

ELEC

TEST

O3 GEN Turns OFF/ON ozone generator 9.1.3.4

RS-232 Writes test data to RS-232 port

Activates Optic Test feature 9.1.3.3

Activates Electric Test feature 9.1.3.2

9.1.3.7

- used for diagnosis

5-9

Page 48

Teledyne API Model 200AU NOX Analyzer Instruction Manual, 02293, Rev. F

5.2 Sample Mode

5.2.1 Test Functions

NOTE

In any of the following TEST functions, if a value of

XXXX is displayed, that indicates an off scale and

therefore meaningless reading.

To use the TEST functions to diagnose instrument faults, refer to Troubleshooting Section 9.1.

Range

This is the range of the instrument. Electronically, there is only one physical range. The range of

the instrument is just the software expanding various portions of the single physical range to fill

the selected analog output voltage range. In standard configuration there is one range for all 3

outputs.

Independent range option allows different ranges for each output. When enabled, there will be

three range values displayed, NO, NOx and NO2.

Auto range mode allows a low range and high range. The M200AU will automatically switch to

the other range dynamically as concentration values require. The TEST values will show the

range the instrument is currently operating in, and will dynamically display the alternate range as

the range changes occur.

NOTE

Each of the range modes Single range, Auto range, and

Independent ranges are mutually exclusive.

Stability

The instrument noise is computed using the standard deviation of the last 10 minutes of data,

with the value being computed at the end of each NO/NOx cycle. It is computed for the NOx

channel only. The stability value only becomes meaningful if sampling a constant concentration

for more than 10 minutes. The value should be compared to the value observed in the factory

check-out.