Page 1

Technical Reference

TDS 500C, TDS 600B & TDS 700C

Digitizing Oscilloscopes

Performance Verification and Specifications

070-9874-02

Page 2

Copyright T ektronix, Inc. All rights reserved.

T ektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

Printed in the U.S.A.

T ektronix, Inc., P.O. Box 1000, Wilsonville, OR 97070–1000

TEKTRONIX and TEK are registered trademarks of T ektronix, Inc.

Page 3

WARRANTY

T ektronix warrants that this product will be free from defects in materials and workmanship for a period of three (3) years

from the date of shipment. If any such product proves defective during this warranty period, T ektronix, at its option, either

will repair the defective product without charge for parts and labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration of the

warranty period and make suitable arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by T ektronix, with shipping charges prepaid.

T ektronix shall pay for the return of the product to Customer if the shipment is to a location within the country in which the

T ektronix service center is located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any

other charges for products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. T ektronix shall not be obligated to furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than T ektronix representatives to install, repair or service the product; b) to repair

damage resulting from improper use or connection to incompatible equipment; or c) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time or

difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THIS PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUST OMER FOR BREACH OF THIS WARRANTY. TEKTRONIX

AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT , SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

General Safety Summary v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preface ix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting Tektronix x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Verification Procedures

Performance Verification Procedures 1–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Input Channels vs. Model 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brief Procedures 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional T ests 1–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance Tests 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prerequisites 1–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Required 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 600B T est Record 1–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 500C/700C T est Record 1–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Acquisition System Checks 1–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Time Base System Checks 1–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger System Checks 1–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Signal Checks 1–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option 05 Video Trigger Checks 1–67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sine Wave Generator Leveling Procedure 1–84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optical Filters Checks (TDS 500C/TDS 700C Only) 1–87. . . . . . . . . . . . . . . . . . . . .

Specifications

Specifications 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Description 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signal Acquisition System 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horizontal System 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trigger System 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquisition Control 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On-Board User Assistance 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Measurement Assistance 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Display 2–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nominal Traits 2–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranted Characteristics 2–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Characteristics 2–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

i

Page 6

Table of Contents

List of Figures

Figure 1–1: Map of display functions 1–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–2: Verifying adjustments and signal-path compensation 1–6. .

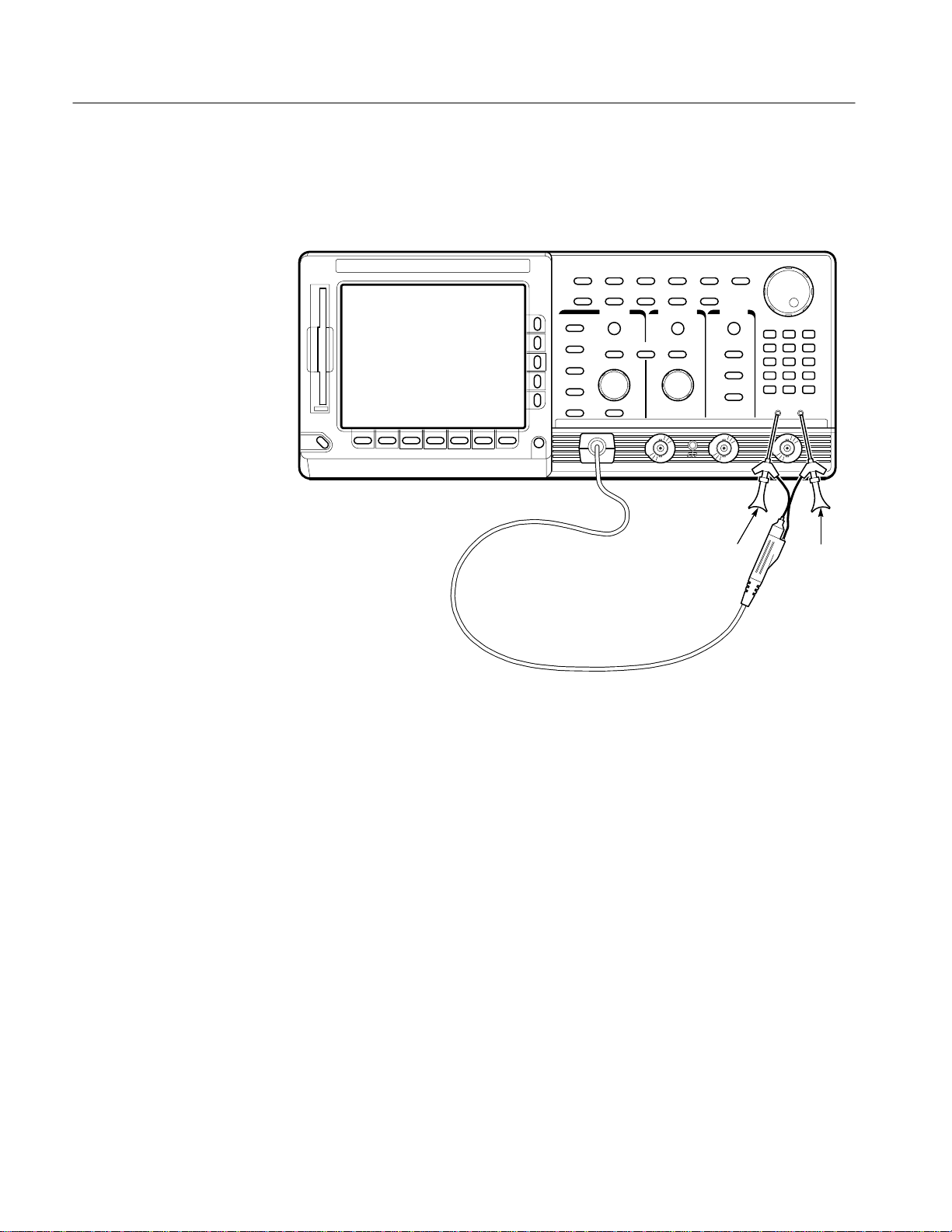

Figure 1–3: Universal test hookup for functional tests –

TDS 600B shown 1–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–4: Measurement of DC offset accuracy at zero setting 1–29. . . .

Figure 1–5: Initial test hookup 1–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–6: Measurement of DC accuracy at maximum offset

and position 1–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–7: Initial test hookup 1–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–8: Optional initial test hookup 1–34. . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–9: Measurement of analog bandwidth 1–37. . . . . . . . . . . . . . . . . .

Figure 1–10: Initial test hookup 1–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–11: Measurement of channel delay – TDS 684B shown 1–41. . . .

Figure 1–12: Initial test hookup 1–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–13: Measurement of accuracy — Long-term and delay time 1–45

Figure 1–14: Initial test hookup 1–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–15: Measurement of time accuracy for pulse and

glitch triggering 1–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–16: Initial test hookup 1–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–17: Measurement of trigger-level accuracy 1–51. . . . . . . . . . . . .

Figure 1–18: Initial test hookup 1–54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–19: Measurement of trigger sensitivity — 50 MHz results

shown on a TDS 684B screen 1–55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–20: Initial test hookup 1–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–21: Measurement of main trigger out limits 1–60. . . . . . . . . . . . .

Figure 1–22: Initial test hookup 1–62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–23: Measurement of probe compensator frequency 1–64. . . . . . .

Figure 1–24: Subsequent test hookup 1–65. . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–25: Measurement of probe compensator amplitude 1–66. . . . . .

Figure 1–26: Jitter test hookup 1–68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–27: Jitter test displayed waveform – TDS 684B shown 1–69. . . .

Figure 1–28: Jitter test when completed – TDS 684B shown 1–70. . . . . . .

Figure 1–29: Triggered signal range test – 300 mV 1–72. . . . . . . . . . . . . . .

Figure 1–30: Triggered signal range test – 75 mV 1–73. . . . . . . . . . . . . . . .

Figure 1–31: 60 Hz Rejection test hookup 1–74. . . . . . . . . . . . . . . . . . . . . .

Figure 1–32: 60 Hz Rejection test setup signal 1–74. . . . . . . . . . . . . . . . . . .

ii

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 7

Table of Contents

Figure 1–33: Subsequent 60 Hz Rejection test hookup 1–75. . . . . . . . . . . .

Figure 1–34: 60 Hz Rejection test result – TDS 684B shown 1–76. . . . . . .

Figure 1–35: Line count accuracy test hookup 1–77. . . . . . . . . . . . . . . . . . .

Figure 1–36: Line count accuracy test setup waveform –

TDS 684B shown 1–78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–37: Line count accuracy correct result waveform 1–79. . . . . . . .

Figure 1–38: Setup for sync duty cycle test 1–81. . . . . . . . . . . . . . . . . . . . . .

Figure 1–39: Sync duty cycle test: one-div neg pulse waveform 1–82. . . . .

Figure 1–40: Sync duty cycle test: critically adjusted pulse 1–83. . . . . . . .

Figure 1–41: Sine wave generator leveling equipment setup 1–85. . . . . . .

Figure 1–42: Equipment setup for maximum amplitude 1–86. . . . . . . . . .

Figure 1–43: Reference-receiver performance-verification set up 1–89. . .

Figure 1–44: Optical impulse of Ch1 input from OA5022 Optical

Attenuator (OIG501 / OIG502 fed into optical attenuator

in Step 1) 1–91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–45: Optical impulse response for OC–12 SONET

Reference Receiver 1–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1–46: Optical impulse response for OC–12 SONET

Reference Receiver 1–95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

iii

Page 8

Table of Contents

List of Tables

Table 1–1: Test equipment 1–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–2: DC offset accuracy (zero setting) 1–28. . . . . . . . . . . . . . . . . . . .

Table 1–3: DC Voltage measurement accuracy 1–31. . . . . . . . . . . . . . . . . .

Table 1–4: Analog bandwidth 1–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–5: Delay between channels worksheet 1–42. . . . . . . . . . . . . . . . . .

Table 1–6: Available Filters 1–87. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–7: Reference Receiver Filter Options: 1–88. . . . . . . . . . . . . . . . . . .

Table 1–8: Option 3C and 4C Specifications 1–88. . . . . . . . . . . . . . . . . . . .

Table 1–9: Available receivers 1–88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1–10: Bessel Thompson frequency response and reference

receiver limits 1–96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–1: Key features of the TDS 500C, 600B and 700C

oscilloscopes 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–2: Record length and divisions per record vs. TDS model 2–4. .

Table 2–3: Nominal traits — Signal acquisition system 2–9. . . . . . . . . . .

Table 2–4: Nominal traits — Time base system 2–10. . . . . . . . . . . . . . . . . .

Table 2–5: Nominal traits — Triggering system 2–11. . . . . . . . . . . . . . . . .

Table 2–6: Nominal traits — Display system 2–13. . . . . . . . . . . . . . . . . . . .

Table 2–7: Nominal traits — GPIB interface, output ports, and

power fuse 2–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2–8: Nominal traits — Data handling and reliability 2–14. . . . . . . .

Table 2–9: Nominal traits — Mechanical 2–15. . . . . . . . . . . . . . . . . . . . . . .

Table 2–10: Warranted characteristics — Signal acquisition system 2–18

Table 2–11: Warranted characteristics — Time base system 2–19. . . . . . .

Table 2–12: Warranted characteristics — Triggering system 2–20. . . . . .

Table 2–13: Warranted characteristics — Output ports, probe

compensator, and power requirements 2–20. . . . . . . . . . . . . . . . . . . . .

Table 2–14: Warranted characteristics — Environmental 2–22. . . . . . . . .

Table 2–15: Certifications and compliances 2–24. . . . . . . . . . . . . . . . . . . . .

Table 2–16: Typical characteristics — Signal acquisition system 2–25. . .

Table 2–17: Typical characteristics — Triggering system 2–28. . . . . . . . .

iv

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 9

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it. To avoid potential hazards, use the

product only as specified.

Only qualified personnel should perform service procedures.

While using this product, you may need to access other parts of the system. Read

the General Safety Summary in other system manuals for warnings and cautions

related to operating the system.

Injury Precautions

Use Proper Power Cord

Avoid Electric Overload

Ground the Product

Do Not Operate Without

Covers

Use Proper Fuse

Do Not Operate in

Wet/Damp Conditions

Do Not Operate in

Explosive Atmosphere

To avoid fire hazard, use only the power cord specified for this product.

To avoid electric shock or fire hazard, do not apply a voltage to a terminal that is

outside the range specified for that terminal.

This product is grounded through the grounding conductor of the power cord. To

avoid electric shock, the grounding conductor must be connected to earth

ground. Before making connections to the input or output terminals of the

product, ensure that the product is properly grounded.

To avoid electric shock or fire hazard, do not operate this product with covers or

panels removed.

To avoid fire hazard, use only the fuse type and rating specified for this product.

To avoid electric shock, do not operate this product in wet or damp conditions.

To avoid injury or fire hazard, do not operate this product in an explosive

atmosphere.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

v

Page 10

General Safety Summary

Product Damage Precautions

Use Proper Power Source

Provide Proper Ventilation

Do Not Operate With

Suspected Failures

Do Not Immerse in Liquids

Do not operate this product from a power source that applies more than the

voltage specified.

To prevent product overheating, provide proper ventilation.

If you suspect there is damage to this product, have it inspected by qualified

service personnel.

Clean the probe using only a damp cloth. Refer to cleaning instructions.

Safety Terms and Symbols

Terms in This Manual

These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

Terms on the Product

vi

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 11

General Safety Summary

Symbols on the Product

The following symbols may appear on the product:

DANGER

High Voltage

Certifications and Compliances

CSA Certified Power

Cords

CSA Certification includes the products and power cords appropriate for use in

the North America power network. All other power cords supplied are approved

for the country of use.

Protective Ground

(Earth) T erminal

ATTENTION

Refer to

Manual

Double

Insulated

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

vii

Page 12

General Safety Summary

viii

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 13

Preface

Related Manuals

This is the Performance Verification and Specifications for the TDS 500C,

TDS 600B, and TDS 700C Oscilloscopes. It contains procedures suitable for

determining if each instrument functions, was adjusted properly, and meets the

performance characteristics as warranted. The following models are covered:

TDS 500C: TDS 520C and TDS 540C

TDS 600B: TDS 620B, TDS 644B, TDS 680B, and TDS 684B

TDS 700C: TDS 724C, TDS 754C, and TDS 784C

This document also contains the technical specifications for these oscilloscopes.

The following documents are related to the use or service of this digitizing

oscilloscope:

H The TDS 500C, TDS 600B & 700C User Manual describes how to use this

digitizing oscilloscope.

H The TDS Family Programmer Manual describes using a computer to control

the digitizing oscilloscope through the GPIB interface.

H The TDS 500C, TDS 600B & 700C Reference describes a quick overview of

how to operate your digitizing oscilloscope.

H The TDS 500C, TDS 600B & 700C Service Manual describes information

for maintaining and servicing the digitizing oscilloscope to the module level.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

ix

Page 14

Preface

Contacting Tektronix

Product

Support

Service

Support

For other

information

To write us Tektronix, Inc.

For application-oriented questions about a Tektronix measurement product, call toll free in North America:

1-800-TEK-WIDE (1-800-835-9433 ext. 2400)

6:00 a.m. – 5:00 p.m. Pacific time

Or, contact us by e-mail:

tm_app_supp@tek.com

For product support outside of North America, contact your

local Tektronix distributor or sales office.

Contact your local Tektronix distributor or sales office. Or, visit

our web site for a listing of worldwide service locations.

http://www.tek.com

In North America:

1-800-TEK-WIDE (1-800-835-9433)

An operator will direct your call.

P.O. Box 1000

Wilsonville, OR 97070-1000

x

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 15

Performance Verification

Procedures

Page 16

Page 17

Performance Verification Procedures

Two types of Performance Verification procedures can be performed on this

product: Brief Procedures and Performance Tests. You may not need to perform

all of these procedures, depending on what you want to accomplish.

H To rapidly confirm that the oscilloscope functions and was adjusted properly,

just do the brief procedures under Self Tests, which begin on page 1–5.

Advantages: These procedures are quick to do, require no external

equipment or signal sources, and perform extensive functional and accuracy

testing to provide high confidence that the oscilloscope will perform

properly. They can be used as a quick check before making a series of

important measurements.

H To further check functionality, first do the Self Tests just mentioned; then do

the brief procedures under Functional Tests that begin on page 1–7.

Advantages: These procedures require minimal additional time to perform,

require no additional equipment other than a standard-accessory probe, and

more completely test the internal hardware of the oscilloscope. They can be

used to quickly determine if the oscilloscope is suitable for putting into

service, such as when it is first received.

H If more extensive confirmation of performance is desired, do the Perform-

ance Tests, beginning on page 1–15, after doing the Functional and Self Tests

just referenced.

Advantages: These procedures add direct checking of warranted specifica-

tions. They require more time to perform and suitable test equipment is

required. (See Equipment Required beginning on page 1–16).

If you are not familiar with operating this oscilloscope, read the TDS 500C,

TDS 600B & TDS 700C Reference (070-9861-XX) or the TDS 500C, TDS 600B

& TDS 700C User Manual (070-9869-XX). These contain instructions that will

acquaint you with the use of the front-panel controls and the menu system.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–1

Page 18

Performance Verification Procedures

Input Channels vs. Model

When performing the procedures in this section, be aware that some TDS models

refer to input channels Ch 3 and Ch 4 as Aux 1 and Aux 2 respectively. Where

appropriate, both names will appear in the procedure, for example, Ch 3 (Aux 1).

The channel names for the various TDS models are shown below.

TDS Model Channel Names

TDS 540C, 644B, 684B, 754C, and 784C

TDS 520C, 620B, 680B, and 724C Ch 1, Ch 2, Aux 1, and Aux 2

Conventions

Throughout these procedures the following conventions apply:

Ch 1, Ch 2, Ch 3, and Ch 4

H Each test procedure uses the following general format:

Title of Test

Equipment Required

Prerequisites

Procedure

H Each procedure consists of as many steps, substeps, and subparts as required

to do the test. Steps, substeps, and subparts are sequenced as follows:

1. First Step

a. First Substep

H First Subpart

H Second Subpart

b. Second Substep

2. Second Step

H In steps and substeps, the lead-in statement in italics instructs you what to

do, while the instructions that follow tell you how to do it, as in the example

step below, “Initialize the oscilloscope” by doing “Press save/recall SETUP.

Now, press the main-menu button...”.

1–2

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 19

Performance Verification Procedures

Initialize the oscilloscope: Press save/recall SETUP. Now, press the

main-menu button Recall Factory Setup; then the side-menu button OK

Confirm Factory Init.

H Where instructed to use a front-panel button or knob, or select from a main

or side menu, or verify a readout or status message, the name of the button or

knob appears in boldface type: “press SHIFT; then UTILITY, press the

main-menu button System until Cal is highlighted in the pop-up menu.

Verify that the status message is Pass in the main menu under the Voltage

Reference label.”

STOP. The symbol at the left is accompanied by information you must read to do

the procedure properly.

H Refer to Figure 1–1: “Main menu” refers to the menu that labels the seven

menu buttons under the display; “side menu” refers to the menu that labels

the five buttons to the right of the display. “Pop-up menu” refers to a menu

that pops up when a main-menu button is pressed.

Brief status

information

Graticule and waveforms

Waveform reference

symbols show ground levels

and waveform sources

Vertical scale, horizontal scale,

and trigger level readouts

Pop-up menu

Position of waveform

record relative to

the screen and display

General purpose

knob readout

Side menu area.

Readouts for

measurements

move here when

CLEAR MENU

is pressed.

Main menu display area. Readouts in lower graticule

area move here when CLEAR MENU is pressed.

Figure 1–1: Map of display functions

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–3

Page 20

Performance Verification Procedures

1–4

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 21

Brief Procedures

Self Tests

The Self Tests use internal routines to confirm basic functionality and proper

adjustment. No test equipment is required to do these test procedures.

The Functional Tests utilize the probe-compensation output at the front panel as

a test-signal source for further verifying that the oscilloscope functions properly.

A probe is required to do these test procedures.

This procedure uses internal routines to verify that the oscilloscope functions and

was adjusted properly. No test equipment or hookups are required.

Verify Internal Adjustment,

Self Compensation, and

Diagnostics

Equipment

required

Prerequisites Power on the digitizing oscilloscope and allow a 20 minute warm-up

1. Verify that internal diagnostics pass: Do the following substeps to verify

passing of internal diagnostics.

a. Display the System diagnostics menu:

H Press SHIFT; then press UTILITY.

H Repeatedly press the main-menu button System until Diag/Err is

highlighted in the pop-up menu.

b. Run the System Diagnostics:

H First disconnect any input signals from all four channels.

H Press the main-menu button Execute; then press the side-menu

button OK Confirm Run Test.

c. Wait: The internal diagnostics do an exhaustive verification of proper

oscilloscope function. This verification will take up to three and a half

minutes on some models. When the verification is finished, the resulting

status will appear on the screen.

None

before doing this procedure.

d. Confirm no failures are found: Verify that no failures are found and

reported on-screen.

e. Confirm the three adjustment sections have passed status:

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–5

Page 22

Brief Procedures

H Press SHIFT; then press UTILITY.

H Highlight Cal in the pop-up menu by repeatedly pressing the

main-menu button System. See Figure 1–2.

H Verify that the word Pass appears in the main menu under the

following menu labels: Voltage Reference, Frequency Response,

and Pulse Trigger. See Figure 1–2.

f. Run the signal-path compensation: Press the main-menu button Signal

Path; then press the side-menu button OK Compensate Signal Paths.

g. Wait: Signal-path compensation may take five minutes on the

TDS 500C/700C and fifteen minutes on the 600B to run. While it

progresses, a “clock” icon (shown at left) is displayed on-screen. When

compensation completes, the status message will be updated to Pass or

Fail in the main menu. See step h.

h. Confirm signal-path compensation returns passed status: Verify that the

word Pass appears under Signal Path in the main menu. See Figure 1–2.

1–6

Highlight Cal

1

3

Verify Pass

2

Verify Pass

Figure 1–2: Verifying adjustments and signal-path compensation

2. Return to regular service: Press CLEAR MENU to exit the system menus.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 23

Functional Tests

Brief Procedures

The purpose of these procedures is to confirm that the oscilloscope functions

properly. The only equipment required is one of the standard-accessory probes

and, to check the file system, a 3.5 inch, 720 K or 1.44 Mbyte floppy disk.

CAUTION. The P6243 and P6245 probes that can be used with this oscilloscope

provide an extremely low loading capacitance (<1 pF) to ensure the best

possible signal reproduction. These probes should not be used to measure

signals exceeding ±8 volts, or errors in signal measurement will be observed.

Above 40 volts, damage to the probe may result. To make measurements beyond

±10 volts, use either the P6139A probe (good to 500 volts peak), or refer to the

catalog for a recommended probe.

STOP. These procedures verify functions; that is, they verify that the oscilloscope

features operate. They do not verify that they operate within limits.

Verify All Input Channels

Therefore, when the instructions in the functional tests that follow call for you to

verify that a signal appears on-screen “that is about five divisions in amplitude”

or “has a period of about six horizontal divisions,” etc., do NOT interpret the

quantities given as limits. Operation within limits is checked in Performance

Tests, which begin on page 1–15.

STOP. DO NOT make changes to the front-panel settings that are not called out

in the procedures. Each verification procedure will require you to set the

oscilloscope to certain default settings before verifying functions. If you make

changes to these settings, other than those called out in the procedure, you may

obtain invalid results. In this case, just redo the procedure from step 1.

When you are instructed to press a menu button, the button may already be

selected (its label will be highlighted). If this is the case, it is not necessary to

press the button.

Equipment

required

Prerequisites None

One probe such as the P6243, P6245 or P6139A

1. Install the test hookup and preset the oscilloscope controls:

a. Hook up the signal source: Install the probe on CH 1. Connect the probe

tip to PROBE COMPENSATION SIGNAL on the front panel;

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–7

Page 24

Brief Procedures

connect the probe ground (typically black) to PROBE COMPENSA-

TION GND. If using a P6243 or P6245 probe, you may want to attach a

Y-lead connector and two SMD KlipChips as shown in Figure 1–3.

Signal Gnd

Figure 1–3: Universal test hookup for functional tests – TDS 600B shown

b. Initialize the oscilloscope:

H Press save/recall SETUP.

H Press the main-menu button Recall Factory Setup.

H Press the side-menu button OK Confirm Factory Init.

2. Verify that all channels operate: Do the following substeps — test CH 1

first, skipping substep a and b since CH 1 is already set up for verification

and as the trigger source from step 1.

a. Select an unverified channel:

H Press WAVEFORM OFF to remove the channel just verified from

display.

1–8

H Press the front-panel button that corresponds to the channel you are

to verify.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 25

Brief Procedures

H Move the probe to the channel you selected.

b. Match the trigger source to the channel selected:

H Press TRIGGER MENU.

H Press the main-menu button Source.

H Press the side-menu button that corresponds to the channel selected,

Ch2, Ch3, or Ch4. (Some TDS models use Ax1 and Ax2 instead of

Ch3 and Ch4).

c. Set up the selected channel:

H Set the vertical SCALE to 200 mV.

H Set the horizontal SCALE to 200 s. Press CLEAR MENU to

remove any menu that may be on the screen.

H Press SET LEVEL TO 50%.

d. Verify that the channel is operational: Confirm that the following

statements are true.

H The vertical scale readout for the channel under test shows a setting

of 200 mV, and a square-wave probe-compensation signal about

2.5 divisions in amplitude is on-screen. See Figure 1–1 on page 1–3

to locate the readout.

H The vertical POSITION knob moves the signal up and down the

screen when rotated.

H Turning the vertical SCALE knob counterclockwise decreases the

amplitude of the waveform on-screen, turning the knob clockwise

increases the amplitude, and returning the knob to 200 mV returns

the amplitude to about 2.5 divisions.

e. Verify that the channel acquires in all acquisition modes: Press SHIFT;

then press ACQUIRE MENU. Use the side menu to select, in turn, each

of the three hardware acquire modes and confirm that the following

statements are true. Refer to the icons at the left of each statement as you

confirm those statements.

H Sample mode displays an actively acquiring waveform on-screen.

(Note that there is noise present on the peaks of the square wave).

H Peak Detect mode displays an actively acquiring waveform

on-screen with the noise present in Sample mode “peak detected.”

H Hi Res mode (TDS 500C and 700C only) displays an actively

acquiring waveform on-screen with the noise that was present in

Sample mode reduced.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–9

Page 26

Brief Procedures

H Envelope mode displays an actively acquiring waveform on-screen

with the noise displayed.

H Average mode displays an actively acquiring waveform on-screen

with the noise reduced.

f. Test all channels: Repeat substeps a through e until all four input

channels are verified.

3. Remove the test hookup: Disconnect the probe from the channel input and

the probe-compensation terminals.

Verify the Time Base

Equipment

required

Prerequisites None

One probe such as the P6243, P6245 or P6139A

1. Install the test hookup and preset the oscilloscope controls:

a. Hook up the signal source: Install the probe on CH 1. Connect the probe

tip to PROBE COMPENSATION SIGNAL on the front panel;

connect the probe ground to PROBE COMPENSATION GND. See

Figure 1–3 on page 1–8.

b. Initialize the oscilloscope:

H Press save/recall SETUP.

H Press the main-menu button Recall Factory Setup; then press the

side-menu button OK Confirm Factory Init.

c. Modify default settings:

H Set the vertical SCALE to 200 mV.

H Set the horizontal SCALE to 200 s.

H Press SET LEVEL TO 50%.

1–10

H Press CLEAR MENU to remove the menus from the screen.

2. Verify that the time base operates: Confirm the following statements.

a. One period of the square-wave probe-compensation signal is about five

horizontal divisions on-screen for the 200 s horizontal scale setting (set

in step 1c).

b. Rotating the horizontal SCALE knob clockwise expands the waveform

on-screen (more horizontal divisions per waveform period), counterclockwise rotation contracts it, and returning the horizontal scale to

200 s returns the period to about five divisions.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 27

Brief Procedures

c. The horizontal POSITION knob positions the signal left and right

on-screen when rotated.

3. Remove the test hookup: Disconnect the probe from the channel input and

the probe-compensation terminals.

Verify the Main and

Delayed Trigger Systems

Equipment

required

Prerequisites None

One probe such as the P6243, P6245, or P6139A

1. Install the test hookup and preset the oscilloscope controls:

a. Hook up the signal source: Install the probe on CH 1. Connect the probe

tip to PROBE COMPENSATION SIGNAL on the front panel;

connect the probe ground to PROBE COMPENSATION GND. See

Figure 1–3 on page 1–8.

b. Initialize the oscilloscope:

H Press save/recall SETUP.

H Press the main-menu button Recall Factory Setup.

H Press the side-menu button OK Confirm Factory Init.

c. Modify default settings:

H Set the vertical SCALE to 200 mV.

H Set the horizontal SCALE for the M (main) time base to 200 s.

H Press SET LEVEL TO 50%.

H Press TRIGGER MENU.

H Press the main-menu button Mode & Holdoff.

H Press the side-menu button Normal.

H Press CLEAR MENU to remove the menus from the screen.

2. Verify that the main trigger system operates: Confirm that the following

statements are true.

H The trigger level readout for the main trigger system changes with the

trigger-LEVEL knob.

H The trigger-LEVEL knob can trigger and untrigger the square-wave

signal as you rotate it. (Leave the signal untriggered, which is indicated

by the display not updating).

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–11

Page 28

Brief Procedures

H Pressing SET LEVEL TO 50% triggers the signal that you just left

untriggered. (Leave the signal triggered).

3. Verify that the delayed trigger system operates:

a. Select the delayed time base:

H Press HORIZONTAL MENU.

H Press the main-menu button Time Base.

H Press the side-menu button Delayed Triggerable; then press the

side-menu button Delayed Only.

H Set the horizontal SCALE for the D (delayed) time base to 200 s.

b. Select the delayed trigger level menu:

H Press SHIFT; then press DELAYED TRIG.

H Press the main-menu button Level; then press the side-menu button

Level.

c. Confirm that the following statements are true:

H The trigger-level readout for the delayed trigger system changes as

you turn the general purpose knob.

H As you rotate the general purpose knob, the square-wave probe-com-

pensation signal can become triggered and untriggered. (Leave the

signal untriggered, which is indicated by the display not updating).

H Pressing the side-menu button Set to 50% triggers the probe-com-

pensation signal that you just left untriggered. (Leave the signal

triggered).

d. Verify the delayed trigger counter:

H Press the main-menu button Delay by Time.

H Use the keypad to enter a delay time of 1 second. Press 1, then press

ENTER.

H Verify that the trigger READY indicator on the front panel flashes

about once every second as the waveform is updated on-screen.

4. Remove the test hookup: Disconnect the probe from the channel input and

the probe-compensation terminals.

1–12

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 29

Brief Procedures

Verify the File System

Equipment

required

Prerequisites None

One probe such as the P6243, P6245 or P6139A

One 720 K or 1.44 Mbyte, 3.5 inch DOS-compatible disk.

You can use a disk of your own or you can use the Programming

Examples Software 3.5 inch disk (Tektronix part number 063-1 134-XX)

contained in the TDS Family Programmer Manual (Tektronix part

number 070-9556-XX).

1. Install the test hookup and preset the oscilloscope controls:

a. Hook up the signal source: Install the probe on CH 1. Connect the probe

tip to PROBE COMPENSATION SIGNAL on the front panel;

connect the probe ground to PROBE COMPENSATION GND. See

Figure 1–3 on page 1–8.

b. Insert the test disk: Insert the floppy disk in the floppy disk drive to the

left of the monitor.

H Position the disk so the metal shutter faces the drive.

H Position the disk so the stamped arrow is on the top right side. In

other words, place the angled corner in the front bottom location.

H Push the disk into the drive until it goes all the way in and clicks

into place.

c. Initialize the oscilloscope:

H Press save/recall SETUP.

H Press the main-menu button Recall Factory Setup.

H Press the side-menu button OK Confirm Factory Init.

d. Modify default settings:

H Set the vertical SCALE to 200 mV.

H Set the horizontal SCALE for the M (main) time base to 200 s.

Notice the waveform on the display now shows two cycles instead of

five.

H Press SET LEVEL TO 50%.

H Press CLEAR MENU to remove the menus from the screen.

e. Save the settings:

H Press SETUP.

H Press the main-menu button Save Current Setup; then press the

side-menu button To File.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–13

Page 30

Brief Procedures

H Turn the general purpose knob to select the file to save. Choose

(or fd0:, the floppy disk drive, or hd0:, the optional

hard disk drive). With this choice, you will save a file starting with

, then containing 5-numbers, and a extension. For example,

the first time you run this on a blank, formatted disk or on the

Example Programs Disk, the oscilloscope will assign the name

to your file. If you ran the procedure again, the

oscilloscope would increment the name and call the file

.

f. To test the optional hard disk drive, use the general purpose knob to

select the file to save. Then choose the hard disk drive (hd0:). Save the

file as in step e.

H Press the side-menu button Save To Selected File.

2. Verify the file system works:

H Press the main-menu button Recall Factory Setup and the side-menu

button OK Confirm Factory Init to restore the 500 s time base and

the five cycle waveform.

H Press the main-menu button Recall Saved Setup; then press the

side-menu button From File.

H Turn the general purpose knob to select the file to recall. For example, if

you followed the instructions previously and saved the file to either the

floppy disk drive (fd0:), or the optional hard disk drive (hd0:), you had

the oscilloscope assign the name TEK00000.SET to your file.

H Press the side-menu button Recall From Selected File.

H Verify that digitizing oscilloscope retrieved the saved setup from the

disk. Do this by noticing the horizontal SCALE for the M (main) time

base is again 200 s and the waveform shows only two cycles just as it

was when you saved the setup.

3. Remove the test hookup:

H Disconnect the probe from the channel input and the probe-compensa-

tion terminals.

H Remove the floppy disk from the floppy disk drive.

1–14

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 31

Performance Tests

This section contains a collection of procedures for checking that the TDS 500C,

TDS 600B, and TDS 700C Digitizing Oscilloscopes perform as warranted.

The procedures are arranged in four logical groupings: Signal Acquisition System

Checks, Time Base System Checks, Triggering System Checks, and Output Ports

Checks. They check all the characteristics that are designated as checked in

Specifications. (The characteristics that are checked appear in boldface type

under Warranted Characteristics in Specifications).

STOP. These procedures extend the confidence level provided by the basic

procedures described on page 1–5. The basic procedures should be done first,

then these procedures performed if desired.

Prerequisites

The tests in this section comprise an extensive, valid confirmation of performance and functionality when the following requirements are met:

H The cabinet must be installed on the digitizing oscilloscope.

H You must have performed and passed the procedures under Self Tests, found

on page 1–5, and those under Functional Tests, found on page 1–7.

H A signal-path compensation must have been done within the recommended

calibration interval and at a temperature within ±5_ C of the present

operating temperature. (If at the time you did the prerequisite Self Tests, the

temperature was within the limits just stated, consider this prerequisite met).

H The digitizing oscilloscope must have been last adjusted at an ambient

temperature between +20_ C and +30_ C, must have been operating for a

warm-up period of at least 20 minutes, and must be operating at an ambient

temperature between +4_ C and either +45_ C for the TDS 600B or +50_ C

for the TDS 500C and 700C. (The warm-up requirement is usually met in

the course of meeting the Self Tests and Functional Tests prerequisites listed

above).

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–15

Page 32

Performance Tests

Equipment Required

T able 1–1: Test equipment

Item number and

description

These procedures use external, traceable signal sources to directly check

warranted characteristics. The required equipment list follows this introduction.

Minimum requirements Example Purpose

1. Attenuator ,10X

(two required)

2. Attenuator , 5X Ratio: 5X; impedance 50 ; connec-

3. Adapter, BNC female to

Clip Leads

4. Terminator, 50 Impedance 50 ; connectors: female

5. Cable, Precision 50

Coaxial (two required)

6. Connector , Dual-Banana

(two required)

7. Connector , BNC “T” Male BNC to dual female BNC Tektronix part number

8. Coupler, Dual-Input Female BNC to dual male BNC Tektronix part number

9. Generator , DC Calibration

10. Generator, Calibration 500 mV square wave calibrator

11. Generator, Time Mark Variable marker frequency from 10 ms

12. Probe, 10X A P6139A, P6243, or P6245 probe

13. 3.5 inch, 720 K or

1.44 Mbyte, DOS-compatible floppy disk

Ratio: 10X; impedance 50 ; connectors: female BNC input, male BNC

output

tors: female BNC input, male BNC

output

BNC female to Clip Leads T ektronix part number

BNC input, male BNC output

50 , 36 in, male to male BNC

connectors

Female BNC to dual banana Tektronix part number

Variable amplitude to ±104 V; accuracy to 0.1%

amplitude; accuracy to 0.25%

to 10 ns; accuracy within 2 ppm

Tektronix part number

01 1-0059-02

Tektronix part number

01 1-0060-02

013-0076-00

Tektronix part number

01 1-0049-01

Tektronix part number

012-0482-00

103-0090-00

103-0030-00

067-0525-02

Data Precision 8200 Checking DC Offset, Gain,

Wavetek 9100 with options

100 and 250 (or, optionally,

Tektronix PG 506A Calibration Generator

Wavetek 9100 with options

100 and 250 (or, optionally,

Tektronix TG 501A Time

Mark Generator

2

Tektronix part number

P6139A or P6245

Programming Examples

Software Disk (Tektronix part

number 063-1134-XX) that

comes with the TDS Family

Programmer Manual (Tektronix part number

070-9556-XX)

1

)

1)

Signal Attenuation

Signal Attenuation

Signal Coupling for Probe

Compensator Output Check

Signal Termination for

Channel Delay Test

Signal Interconnection

Various Accuracy Tests

Checking Trigger Sensitivity

Checking Delay Between

Channels

and Measurement Accuracy

To check accuracy of CH 3

Signal Out

Checking Sample-Rate and

Delay-time Accuracy

Signal Interconnection

Checking File System Basic

Functionality

1–16

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 33

Performance Tests

T able 1–1: Test equipment (cont.)

Item number and

description

14. Generator, Video Signal Provides PAL compatible outputs Tektronix TSG 121 Used to Test Video Option 05

15. Oscillator, Leveled Sine

wave Generator

60 Hz Sine wave Wavetek 9100 with options

100 and 250 (or, optionally,

Tektronix SG 502)

16. Pulse Generator Tektronix CFG280

(or, optionally, PG 502)

17. Cable, Coaxial

(two required)

18. Terminator, 75

(two required)

19. Generator, Sine Wave 100 kHz to at least 400 MHz. Variable

75 , 36 in, male to male BNC

connectors

Impedance 75 ; connectors: female

BNC input, male BNC output

amplitude from 12 mV to 2 V

p-p

.

Tektronix part number

012-1338-00

Tektronix part number

01 1-0102-01

Rohde & Schwarz SMY

3

Frequency accuracy >2.0%

20. Meter, Level and Power

Sensor

21. Splitter, Power Frequency range: DC to 1 GHz.

Frequency range:10 MHz to 400MHz.

Amplitude range: 6 mVp-p to 2 V

p-p

Rohde & Schwarz URV 35,

with NRV-Z8 power sensor

Rohde & Schwarz RVZ

3

Tracking: >2.0%

22. Generator, Function Frequency range 5 MHz to 10 MHz.

T ektronix CFG280 Checking External Clock

Square wave transition time 25 ns.

Amplitude range: 0 to 10 V

p-p

into 50

23. Adapter (four required) Male N to female BNC T ektronix 103-0045-00 Checking Analog Bandwidth

24. Adapter Female N to male BNC Tektronix 103-0058-00 Checking Analog Bandwidth

25. Generator,

Leveled Sine Wave,

Medium-Frequency

200 kHz to 250 MHz; Variable amplitude from 5 mV to 4 V

into 50

p-p

Tegam/Tektronix SG 503

Leveled Sine Wave Genera-

1, 3

tor

(optional)

26. Generator, Leveled Sine

Wave, High-Frequency

(optional)

250 MHz to 1 GHz; Variable amplitude from 5 mV to 4 V

into 50 ;

p-p

6 MHz reference

Tegam/Tektronix SG 504

Leveled Sine Wave Genera-

1

with SG 504 Output

tor

3

Head

PurposeExampleMinimum requirements

Equipped Instruments Only

Used to Test Video Option 05

Equipped Instruments Only

Used to Test Video Option 05

Equipped Instruments Only

Used to Test Video Option 05

Equipped Instruments Only

Used to Test Video Option 05

Equipped Instruments Only

Checking Analog Bandwidth,

Trigger Sensitivity , Samplerate, External Clock, and

Delay-Time Accuracy

Checking Analog Bandwidth

3

and Trigger Sensitivity

Checking Analog Bandwidth

Checking Trigger Sensitivity

at low frequencies

Checking Analog Bandwidth

and Trigger Sensitivity at high

frequencies

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–17

Page 34

Performance Tests

T able 1–1: Test equipment (cont.)

Item number and

description

PurposeExampleMinimum requirements

27. Generator, Optical Impulse

28. Generator, Optical Impulse

29. Attenuator, Optical 62.5 micron optical attenuator Tektronix OA5022 Optical

850 nm optical impulse T ektronix OIG501 Optical

Impulse Generator

1

1300 nm optical impulse T ektronix OIG502 Optical

Impulse Generator

Attenuator

1

1

Checking Option 3C

Checking Option 4C

Checking Option 3C and 4C

30. Cable, Fibre Optic FC-FC fiber cable 174-2322-00 Checking Option 3C and 4C

31. Optical-to-Electrical

Converter

P6701B (used with Option 3C) or

P6703B (used with Option 4C)

Tektronix part number

P6701B or P6703B

Checking Option 3C and 4C

optical-to-electrical converter

1

Requires a TM 500 or TM 5000 Series Power Module Mainframe.

2

Warning: The P6243 and P6245 probes that may be used with this oscilloscope provide an extremely low loading

capacitance (<1 pF) to ensure the best possible signal reproduction. These probes should not be used to measure

signals exceeding ±8 V , or errors in signal measurement will be observed. Above 40 V, damage to the probe may result.

To make measurements beyond ±8 V, use either the P6139A probe (good to 500 V), or refer to the catalog for a recommended probe.

3

You can replace items 19, 20, or 21 with a Tegam/Tektronix SG503 (item 25) or SG504 (item 26) – if available.

1–18

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 35

Performance Tests

TDS 600B Test Record

Photocopy this and the next three pages and use them to record the performance

test results for your TDS 600B.

TDS 600B T est Record

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

TDS 600B Performance Test Minimum Incoming Outgoing Maximum

Offset Accuracy

CH1 Offset +1 mV

+101 mV

+1.01 V

CH2 Offset +1 mV

+101 mV

+1.01 V

CH3 or AX1 +1 mV

Offset +101 mV

+1.01 V

CH4 or AX2 +1 mV

Offset +101 mV

+1.01 V

DC Voltage Measurement Accuracy (Averaged)

CH1 5 mV Vert scale setting,

–5 Div position setting, +1 V offset

CH1 5 mV Vert scale setting,

+5 Div position setting, –1 V offset

CH1 200 mV Vert scale setting,

–5 Div position setting, +10 V offset

CH1 200 mV Vert scale setting,

+5 Div position setting, –10 V offset

CH1 1 V Vert scale setting,

–5 Div position setting, +10 V offset

CH1 1 V Vert scale setting,

+5 Div position setting, –10 V offset

CH2 5 mV Vert scale setting,

–5 Div position setting, +1 V offset

CH2 5 mV Vert scale setting,

+5 Div position setting, –1 V offset

CH2 200 mV Vert scale setting,

–5 Div position setting, +10 V offset

– 2.1 mV

– 75.6 mV

– 756 mV

– 2.1 mV

– 75.6 mV

– 756 mV

– 2.1 mV

– 75.6 mV

– 756 mV

– 2.1 mV

– 75.6 mV

– 756 mV

+ 1.0329 V __________ __________ + 1.0471 V

– 1.0471 V __________ __________ – 1.0329 V

+ 11.4165 V __________ __________ + 11.7835 V

– 11.7835 V __________ __________ – 11.4165 V

+ 17.2425 V __________ __________ + 18.7575 V

– 18.7575 V __________ __________ – 17.2425 V

+ 1.0329 V __________ __________ + 1.0471 V

– 1.0471 V __________ __________ – 1.0329 V

+ 11.4165 V __________ __________ + 11.7835 V

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

+ 2.1 mV

+ 75.6 mV

+ 756 mV

+ 2.1 mV

+ 75.6 mV

+ 756 mV

+ 2.1 mV

+ 75.6 mV

+ 756 mV

+ 2.1 mV

+ 75.6 mV

+ 756 mV

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–19

Page 36

Performance Tests

TDS 600B T est Record (Cont.)

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

TDS 600B Performance Test MaximumOutgoingIncomingMinimum

CH2 200 mV Vert scale setting,

+5 Div position setting, –10 V offset

CH2 1 V Vert scale setting,

–5 Div position setting, +10 V offset

CH2 1 V Vert scale setting,

+5 Div position setting, –10 V offset

CH3 5 mV Vert scale setting,

or AX1 –5 Div position setting, +1 V offset

CH3 5 mV Vert scale setting,

or AX1 +5 Div position setting, –1 V offset

CH3 200 mV Vert scale setting,

or AX1 –5 Div position setting, +10 V offset

CH3 200 mV Vert scale setting,

or AX1 +5 Div position setting, –10 V offset

CH3 1 V Vert scale setting,

or AX1 –5 Div position setting, +10 V offset

CH3 1 V Vert scale setting,

or AX1 +5 Div position setting, –10 V offset

CH4 5 mV Vert scale setting,

or AX2 –5 Div position setting, +1 V offset

CH4 5 mV Vert scale setting,

or AX2 +5 Div position setting, –1 V offset

CH4 200 mV Vert scale setting,

or AX2 –5 Div position setting, +10 V offset

CH4 200 mV Vert scale setting,

or AX2 +5 Div position setting, –10 V offset

CH4 1 V Vert scale setting,

or AX2 –5 Div position setting, +10 V offset

CH4 1 V Vert scale setting,

or AX2 +5 Div position setting, –10 V offset

Analog Bandwidth

CH1 100 mV 424 mV __________ __________ N/A

CH2 100 mV 424 mV __________ __________ N/A

CH3 100 mV

or AX1

CH4 100 mV

or AX2

– 11.7835 V __________ __________ – 11.4165 V

+ 17.2425 V __________ __________ + 18.7575 V

– 18.7575 V __________ __________ – 17.2425 V

+ 1.0329 V __________ __________ + 1.0471 V

– 1.0471 V __________ __________ – 1.0329 V

+ 11.4165 V __________ __________ + 11.7835 V

– 11.7835 V __________ __________ – 11.4165 V

+ 17.2425 V __________ __________ + 18.7575 V

– 18.7575 V __________ __________ – 17.2425 V

+ 1.0329 V __________ __________ + 1.0471 V

– 1.0471 V __________ __________ – 1.0329 V

+ 11.4165 V __________ __________ + 11.7835 V

– 11.7835 V __________ __________ – 11.4165 V

+ 17.2425 V __________ __________ + 18.7575 V

– 18.7575 V __________ __________ – 17.2425 V

424 mV __________ __________ N/A

424 mV __________ __________ N/A

1–20

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 37

Performance Tests

TDS 600B T est Record (Cont.)

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

TDS 600B Performance Test MaximumOutgoingIncomingMinimum

Delay Between Channels

Delay Between Channels N/A __________ __________ 100 ps

Time Base System

Long Term Sample Rate/

Delay Time @ 500 ns/10 ms

Trigger System Accuracy

Pulse-Glitch or Pulse-Width,

Hor. scale ≤ 1 ms

Lower Limit

Upper Limit

Pulse-Glitch or Pulse-Width,

Hor. scale > 1 ms

Lower Limit

Upper Limit

Main Trigger, DC Coupled, Positive Slope 9.863 V __________ __________ 10.137 V

Main Trigger, DC Coupled, Negative Slope 9.863 V __________ __________ 10.137 V

Delayed Trigger, DC Coupled, Positive Slope 9.863 V __________ __________ 10.137 V

Delayed Trigger, DC Coupled, Negative Slope 9.863 V __________ __________ 10.137 V

CH1 Sensitivity, 50 MHz, Main Pass/Fail __________ __________ Pass/Fail

CH1 Sensitivity , 50 MHz, Delayed Pass/Fail __________ __________ Pass/Fail

CH1 AUX Trigger Input Pass/Fail __________ __________ Pass/Fail

CH1 Sensitivity, 1 GHz, Main Pass/Fail __________ __________ Pass/Fail

CH1 Sensitivity, 1 GHz, Delayed Pass/Fail __________ __________ Pass/Fail

Output Signal Checks

MAIN TRIGGER OUTPUT, 1 MW

High

Low

MAIN TRIGGER OUTPUT, 50 W

High

Low

DELA YED TRIGGER OUTPUT, 50 W

DELA YED TRIGGER OUTPUT, 1 MW

–2.0 Div __________ __________ +2.0 Div

3.5 ns

3.5 ns

1.9 ms

1.9 ms

High ≥ 2.5 V __________

High ≥ 1.0 V __________

High ≥ 1.0 V __________

High ≥ 2.5 V __________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

6.5 ns

6.5 ns

2.1 ms

2.1 ms

Low ≤ 0.7 V

Low ≤ 0.25 V

Low ≤ 0.25 V

Low ≤ 0.7 V

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–21

Page 38

Performance Tests

TDS 600B T est Record (Cont.)

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

TDS 600B Performance Test MaximumOutgoingIncomingMinimum

CH 3 or AX1 SIGNAL OUTPUT, 1 M Pk-Pk ≥ 80 mV __________ __________ Pk-Pk ≤ 120 mV

CH 3 or AX1 SIGNAL OUTPUT, 50 Pk-Pk ≥ 40 mV __________ __________ Pk-Pk ≤ 60 mV

Probe Compensator Output Signal

Frequency (CH1 Freq). 950 Hz __________ __________ 1.050 kHz

Voltage (difference) 495 mV __________ __________ 505 mV

1–22

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 39

Performance Tests

TDS 500C/700C Test Record

Photocopy this and the next three pages and use them to record the performance

test results for your TDS 500C/700C.

TDS 500C/700C T est Record

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

TDS 500C/700C Performance Test Minimum Incoming Outgoing Maximum

Offset Accuracy

CH1 Offset +1 mV

+101 mV

+1.01 V

CH2 Offset +1 mV

+101 mV

+1.01 V

CH3 or AX1 Offset +1 mV

+101 mV

+1.01 V

CH4 or AX2 Offset +1 mV

+101 mV

+1.01 V

DC Voltage Measurement Accuracy (Averaged)

CH1 5 mV Vert scale setting,

–5 Div position setting, +1 V offset

CH1 5 mV Vert scale setting,

+5 Div position setting, –1 V offset

CH1 200 mV Vert scale setting,

–5 Div position setting, +10 V offset

CH1 200 mV Vert scale setting,

+5 Div position setting, –10 V offset

CH1 1 V Vert scale setting,

–5 Div position setting, +10 V offset

CH1 1 V Vert scale setting,

+5 Div position setting, –10 V offset

CH2 5 mV Vert scale setting,

–5 Div position setting, +1 V offset

CH2 5 mV Vert scale setting,

+5 Div position setting, –1 V offset

CH2 200 mV Vert scale setting,

–5 Div position setting, +10 V offset

– 1.6 mV

– 25.1 mV

– 251 mV

– 1.6 mV

– 25.1 mV

– 251 mV

– 1.6 mV

– 25.1 mV

– 251 mV

– 1.6 mV

– 25.1 mV

– 251 mV

+ 1.0355 V __________ __________ + 1.0445 V

– 1.0445 V __________ __________ – 1.0355 V

+ 11.5195 V __________ __________ + 11.6805 V

– 11.6805 V __________ __________ – 11.5195 V

+ 17.7575 V __________ __________ + 18.2425 V

– 18.2425 V __________ __________ – 17.7575 V

+ 1.0355 V __________ __________ + 1.0445 V

– 1.0445 V __________ __________ – 1.0355 V

+ 11.5195 V __________ __________ + 11.6805 V

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

+ 1.6 mV

+ 25.1 mV

+ 251 mV

+ 1.6 mV

+ 25.1 mV

+ 251 mV

+ 1.6 mV

+ 25.1 mV

+ 251 mV

+ 1.6 mV

+ 25.1 mV

+ 251 mV

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–23

Page 40

Performance Tests

TDS 500C/700C T est Record (Cont.)

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

TDS 500C/700C Performance Test MaximumOutgoingIncomingMinimum

CH2 200 mV Vert scale setting,

+5 Div position setting, –10 V offset

CH2 1 V Vert scale setting,

–5 Div position setting, +10 V offset

CH2 1 V Vert scale setting,

+5 Div position setting, –10 V offset

CH3 5 mV Vert scale setting,

or AX1 –5 Div position setting, +1 V offset

CH3 5 mV Vert scale setting,

or AX1 +5 Div position setting, –1 V offset

CH3 200 mV Vert scale setting,

or AX1 –5 Div position setting, +10 V offset

CH3 200 mV Vert scale setting,

or AX1 +5 Div position setting, –10 V offset

CH3 1 V Vert scale setting,

or AX1 –5 Div position setting, +10 V offset

CH3 1 V Vert scale setting,

or AX1 +5 Div position setting, –10 V offset

CH4 5 mV Vert scale setting,

or AX2 –5 Div position setting, +1 V offset

CH4 5 mV Vert scale setting,

or AX2 +5 Div position setting, –1 V offset

CH4 200 mV Vert scale setting,

or AX2 –5 Div position setting, +10 V offset

CH4 200 mV Vert scale setting,

or AX2 +5 Div position setting, –10 V offset

CH4 1 V Vert scale setting,

or AX2 –5 Div position setting, +10 V offset

CH4 1 V Vert scale setting,

or AX2 +5 Div position setting, –10 V offset

Analog Bandwidth

CH1 100 mV 424 mV __________ __________ N/A

CH2 100 mV 424 mV __________ __________ N/A

CH3

or AX1 100 mV

CH4

or AX2 100 mV

– 11.6805 V __________ __________ – 11.5195 V

+ 17.7575 V __________ __________ + 18.2425 V

– 18.2425 V __________ __________ – 17.7575 V

+ 1.0355 V __________ __________ + 1.0445 V

– 1.0445 V __________ __________ – 1.0355 V

+ 11.5195 V __________ __________ + 11.6805 V

– 11.6805 V __________ __________ – 11.5195 V

+ 17.7575 V __________ __________ + 18.2425 V

– 18.2425 V __________ __________ – 17.7575 V

+ 1.0355 V __________ __________ + 1.0445 V

– 1.0445 V __________ __________ – 1.0355 V

+ 11.5195 V __________ __________ + 11.6805 V

– 11.6805 V __________ __________ – 11.5195 V

+ 17.7575 V __________ __________ + 18.2425 V

– 18.2425 V __________ __________ – 17.7575 V

424 mV __________ __________ N/A

424 mV __________ __________ N/A

1–24

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 41

Performance Tests

TDS 500C/700C T est Record (Cont.)

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

TDS 500C/700C Performance Test MaximumOutgoingIncomingMinimum

Delay Between Channels

Delay Between Channels N/A __________ __________ 50 ps

Time Base System

Long Term Sample Rate/

Delay Time @ 100 ns/10.0 ms

Trigger System Accuracy

Pulse-Glitch or Pulse-Width,

Hor. scale ≤ 1 ms

Lower Limit

Upper Limit

Pulse-Glitch or Pulse-Width,

Hor. scale > 1 ms

Lower Limit

Upper Limit

Main Trigger, DC Coupled, Positive Slope 9.9393 V __________ __________ 10.1147 V

Main Trigger, DC Coupled, Negative Slope 9.9393 V __________ __________ 10.1147 V

Delayed Trigger, DC Coupled, Positive Slope 9.9393 V __________ __________ 10.1147 V

Delayed Trigger, DC Coupled, Negative Slope 9.9393 V __________ __________ 10.1 147 V

CH1 Sensitivity, 50 MHz, Main Pass/Fail __________ __________ Pass/Fail

CH1 Sensitivity , 50 MHz, Delayed Pass/Fail __________ __________ Pass/Fail

CH1 AUX Trigger Input Pass/Fail __________ __________ Pass/Fail

CH1 Sensitivity , full bandwidth, Main Pass/Fail __________ __________ Pass/Fail

CH1 Sensitivity , full bandwidth, Delayed Pass/Fail __________ __________ Pass/Fail

Output Signal Checks

MAIN TRIGGER OUTPUT, 1 MW

High

Low

MAIN TRIGGER OUTPUT, 50 W

High

Low

DELA YED TRIGGER OUTPUT, 50 W

High

Low

DELA YED TRIGGER OUTPUT, 1 MW

High

Low

–2.5 Div __________ __________ +2.5 Div

3.5 ns

3.5 ns

1.9 ms

1.9 ms

High ≥ 2.5 V __________

High ≥ 1.0 V __________

High ≥ 1.0 V __________

High ≥ 2.5 V __________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

__________

6.5 ns

6.5 ns

2.1 ms

2.1 ms

Low ≤ 0.7 V

Low ≤ 0.25 V

Low ≤ 0.25 V

Low ≤ 0.7 V

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–25

Page 42

Performance Tests

TDS 500C/700C T est Record (Cont.)

Instrument Serial Number: Certificate Number:

Temperature: RH %:

Date of Calibration: Technician:

TDS 500C/700C Performance Test MaximumOutgoingIncomingMinimum

CH 3 or AX 1 SIGNAL OUTPUT, 1 M Pk-Pk ≥ 88 mV __________ __________ Pk-Pk ≤ 132 mV

CH 3 or AX 1 SIGNAL OUTPUT, 50 Pk-Pk ≥ 44 mV __________ __________ Pk-Pk ≤ 66 mV

Probe Compensator Output Signal

Frequency (CH1 Freq). 950 Hz __________ __________ 1.050 kHz

Voltage (difference) 495 mV __________ __________ 505 mV

1–26

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 43

Signal Acquisition System Checks

These procedures check those characteristics that relate to the signal-acquisition

system and are listed as checked under Warranted Characteristics in Specifica-

tions.

Performance Tests

Check Offset Accuracy

(Zero Setting)

Equipment

required

Prerequisites The oscilloscope must meet the prerequisites listed on page 1–15.

1. Preset the instrument controls:

a. Initialize the oscilloscope:

H Press save/recall SETUP.

H Press the main-menu button Recall Factory Setup.

H Press the side-menu button OK Confirm Factory Init.

H Press CLEAR MENU to remove the menus from the screen.

b. Modify the default settings:

H Press SHIFT; then press ACQUIRE MENU.

H On the TDS 600B, press the main-menu button Mode; then press the

side-menu button Average 16.

None

See Input Channels vs. Model on page 1–2.

H On the TDS 500C and 700C, press the main-menu button Mode;

then press the side-menu button Hi Res.

H Press CURSOR.

H Press the main-menu button Function; then press the side-menu

button H Bars.

H Press CLEAR MENU.

H Be sure to disconnect any input signals from all four channels.

2. Confirm input channels are within limits for offset accuracy at zero offset:

Do the following substeps — test CH 1 first, skipping substep a since CH 1

is already set up to be checked from step 1.

a. Select an unchecked channel: Press WAVEFORM OFF to remove the

channel just confirmed from the display. Then, press the front-panel

button that corresponds to the channel you are to confirm.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–27

Page 44

Performance Tests

b. Set the vertical scale: Set the vertical SCALE to one of the settings

listed in Table 1–2 that is not yet checked. (Start with the first setting

listed).

H Press VERTICAL MENU. Press the main-menu button Fine Scale.

H Use the keypad to enter the vertical scale. For the 1 mV setting,

press 1, SHIFT, m, then ENTER. For the 101 mV setting, press

101, SHIFT, m, then ENTER. For the 1.01 V setting, press 1.01,

then ENTER.

H Press CLEAR MENU.

T able 1–2: DC offset accuracy (zero setting)

Vertical

Vertical scale

setting

1 mV 0 ±2.1 mV ±1.6 mV

101 mV 0 ±75.6 mV ±25.1 mV

1.01 V 0 ±756 mV ±251 mV

1

Vertical position is set to 0 divisions and vertical offset to 0 V when the

oscilloscope is initialized in step 1.

position and

offset setting

TDS 600B offset

1

accuracy limits

TDS 500C/700C

offset accuracy

limits

c. Display the test signal: The waveform position and offset were

initialized for all channels in step 1 and are displayed as you select each

channel and its vertical scale.

d. Measure the test signal: Align the active cursor over the waveform by

rotating the general purpose knob. Ignore the other cursor. See

Figure 1–4.

e. Read the measurement results at the absolute (@:) cursor readout, not

the delta (D:) readout on screen. That is, read the offset relative to the

ground reference. See Figure 1–4.

f. Check against limits: Do the following subparts in the order listed.

1–28

H CHECK that the measurement results are within the limits listed for

the current vertical scale setting.

H Enter voltage on test record.

H Repeat substeps b through f until all vertical scale settings listed in

Table 1–2, are checked for the channel under test.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 45

Read the

measurement

results.

Performance Tests

2

Align the active cursor

over the waveform.

1

Check DC Voltage

Measurement Accuracy

Figure 1–4: Measurement of DC offset accuracy at zero setting

g. Test all channels: Repeat substeps a through f for all input channels.

3. Disconnect the hookup: No hookup was required.

WARNING. The generator is capable of outputting dangerous voltages. Be sure to

set the DC calibration generator to 0 volts before connecting, disconnecting,

and/or moving the test hookup during the performance of this procedure.

Equipment

required

Prerequisites The oscilloscope must meet the prerequisites listed on page 1–15

Two dual-banana connectors (Item 6)

One BNC T connector (Item 7)

One DC calibration generator (Item 9)

Two precision 50 W coaxial cables (Item 5)

See Input Channels vs. Model on page 1–2.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

1–29

Page 46

Performance Tests

1. Install the test hookup and preset the instrument controls:

a. Hook up the test-signal source:

H Set the output of a DC calibration generator to 0 volts.

H Connect the output of a DC calibration generator through a

dual-banana connector followed by a 50 W precision coaxial cable to

one side of a BNC T connector. See Figure 1–5.

H Connect the Sense output of the generator through a second

dual-banana connector followed by a 50 W precision coaxial cable to

the other side of the BNC T connector. Now connect the BNC T

connector to CH 1. See Figure 1–5.

Output Sense

DC Calibrator

Dual banana to

BNC adapters

Figure 1–5: Initial test hookup

b. Initialize the oscilloscope:

H Press save/recall SETUP.

H Press the main-menu button Recall Factory Setup.

H Press the side-menu button OK Confirm Factory Init.

c. Modify the default settings:

50 coaxial cables

Digitizing Oscilloscope

BNC T

connector

1–30

H Press SHIFT; then press ACQUIRE MENU.

H Press the main-menu button Mode; then press the side-menu button

Average 16.

2. Confirm input channels are within limits for DC accuracy at maximum offset

and position: Do the following substeps — test CH 1 first, skipping substep

2a since CH 1 is already selected from step 1.

TDS 500C, TDS 600B & TDS 700C Performance Verification and Specifications

Page 47

Performance Tests

a. Select an unchecked channel: