Page 1

Service Manual

TDS1000 and TDS2000 Series

Digital Storage Oscilloscopes

071-1076-02

This document supports firmware version 1.00

and above.

Warning

The servicing instructions are for use by

qualified personnel only. To avoid personal

injury, do not perform any servicing unless you

are qualified to do so. Refer to all safety

summaries prior to performing service.

www.tektronix.com

Page 2

Copyright © Tektronix, Inc. All rights reserved. Licensed software products are owned by Tektronix or its subsidiaries or

suppliers, and are protected by national copyright laws and international treaty provisions.

Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supercedes

that in all previously published material. Specifications and price change privileges reserved.

TEKTRONIX and TEK are registered trademarks of Tektronix, Inc.

Contacting Tektronix

Tektronix, Inc.

14200 SW Karl Braun Drive

P.O. Box 500

Beaverton, OR 97077

USA

For product information, sales, service, and technical support:

H In North America, call 1-800-833-9200.

H Worldwide, visit www.tektronix.com to find contacts in your area.

Page 3

Warranty 16

Tektronix warrants that the product will be free from defects in materials and workmanship for a period of three

(3) years from the date of original purchase from an authorized Tektronix distributor. If the product proves

defective during this warranty period, Tektronix, at its option, either will repair the defective product without

charge for parts and labor, or will provide a replacement in exchange for the defective product. Batteries are

excluded from this warranty. Parts, modules and replacement products used by Tektronix for warranty work may

be new or reconditioned to like new performance. All replaced parts, modules and products become the property

of Tektronix.

In order to obtain service under this warranty, Customer must notify Tektronix of the defect before the expiration

of the warranty period and make suitable arrangements for the performance of service. Customer shall be

responsible for packaging and shipping the defective product to the service center designated by Tektronix,

shipping charges prepaid, and with a copy of customer proof of purchase. Tektronix shall pay for the return of the

product to Customer if the shipment is to a location within the country in which the Tektronix service center is

located. Customer shall be responsible for paying all shipping charges, duties, taxes, and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure or damage caused by improper use or improper or inadequate

maintenance and care. Tektronix shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than Tektronix representatives to install, repair or service the product;

b) to repair damage resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Tektronix supplies; or d) to service a product that has been

modified or integrated with other products when the effect of such modification or integration increases the time

or difficulty of servicing the product.

THIS WARRANTY IS GIVEN BY TEKTRONIX WITH RESPECT TO THE PRODUCT IN LIEU OF ANY

OTHER WARRANTIES, EXPRESS OR IMPLIED. TEKTRONIX AND ITS VENDORS DISCLAIM ANY

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

TEKTRONIX’ RESPONSIBILITY TO REPAIR OR REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND

EXCLUSIVE REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS WARRANTY.

TEKTRONIX AND ITS VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF WHETHER TEKTRONIX OR THE VENDOR HAS

ADVANCE NOTICE OF THE POSSIBILITY OF SUCH DAMAGES.

Page 4

Page 5

Table of Contents

Specifications

Operating Information

General Safety Summary vii...................................

Service Safety Summary ix....................................

Environmental Considerations xi...............................

Preface xiii...................................................

Related Manuals xiii.................................................

Certifications and Compliances 1--8.....................................

General Features 2--2.................................................

Installation 2--4......................................................

Power Cord 2--4.................................................

Security Loop 2--4................................................

Extension Modules 2--5...............................................

Functional Check 2--6................................................

Self Calibration 2--7..................................................

Default Setup 2--7...................................................

Theory of Operation

Main Board 3--4.....................................................

Power Supply 3--6...................................................

Display Module 3--6..................................................

Front Panel 3--6.....................................................

Extension Modules 3--7...............................................

Performance Verification

Required Equipment 4--1..............................................

Test Record 4--2.....................................................

Performance Verification Procedures 4--3.................................

Acquisition System 3--4...........................................

Processing and Display System 3--5..................................

Input Signal Interface 3--5..........................................

Probe Compensation 3--5..........................................

External Trigger 3--5..............................................

Main Board Power 3--5............................................

Two-Channel Oscilloscopes 3--6.....................................

Four-Channel Oscilloscopes 3--7....................................

LEDs 3--7......................................................

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

i

Page 6

Table of Contents

Adjustment Procedures

Maintenance

Self Test 4--3....................................................

Self Calibration 4--3..............................................

Check DC Gain Accuracy 4--3......................................

Check Bandwidth 4--5.............................................

Check Sample Rate and Delay Time Accuracy 4--6......................

Check Edge Trigger Sensitivity 4--7..................................

Check External Edge Trigger Sensitivity 4--9...........................

Required Equipment 5--1..............................................

Adjustment Procedure 5--3.............................................

Enable the Service Menu 5--3.......................................

Adjustment Procedure 5--5.........................................

Preparation 6--1.....................................................

Preventing ESD 6--1..................................................

Inspection and Cleaning 6--2...........................................

General Care 6--2................................................

Inspection and Cleaning Procedures 6--2..............................

Removal and Installation Procedures 6--5.................................

Preparation 6--5..................................................

List of Modules 6--5..............................................

Summary of Procedures 6--6........................................

Required Tools 6--6...............................................

Rear Feet 6--7...................................................

Flip Feet 6--9....................................................

Front-Panel Knobs 6--10............................................

Power Button 6--10................................................

Rear Case 6--10...................................................

Front Feet 6--14...................................................

Power Supply Module 6--15.........................................

Internal Assembly 6--17............................................

Display Cable 6--19................................................

Front-Panel Cable 6--21............................................

Main Board Module 6--22...........................................

Display Module 6--24..............................................

Front-Panel Module 6--26...........................................

Keypad 6--28.....................................................

Front Case 6--30..................................................

ii

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 7

Diagrams

Replaceable Parts

Table of Contents

Troubleshooting 6--31.................................................

Adjustment After Repair 6--31.......................................

Required Tools and Equipment 6--31..................................

Troubleshooting Tree 6--31..........................................

PROBE COMP Output 6--35........................................

Troubleshooting the Power Supply 6--35...............................

Troubleshooting the Display 6--36....................................

Troubleshooting the Backlight 6--38...................................

Troubleshooting the Front Panel 6--40.................................

Troubleshooting the Main Board 6--43.................................

Running Diagnostics 6--43..........................................

Troubleshooting Input Connections 6--43...............................

Using the Error Log 6--44...........................................

Repackaging Instructions 6--46..........................................

Packaging 6--46...................................................

Storage 6--46.....................................................

Parts Ordering Information 8--1.........................................

Module Servicing 8--1.............................................

Using the Replaceable Parts List 8--2.....................................

Abbreviations 8--2................................................

Mfr. Code to Manufacturer Cross Index 8--3...........................

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

iii

Page 8

Table of Contents

List of Figures

Figure 2--1: Routing the power cord and security cable 2--4..........

Figure 2--2: Installing and removing an extension module 2--5........

Figure 3--1: Module-level block diagram (two channel) 3--2..........

Figure 3--2: Module-level block diagram (four channel) 3--3..........

Figure 5--1: Adjustment setups 5--4...............................

Figure 6--1: Removing the rear feet 6--7...........................

Figure 6--2: Installing the rear feet 6--8............................

Figure 6--3: Removing and installing the flip feet 6--9................

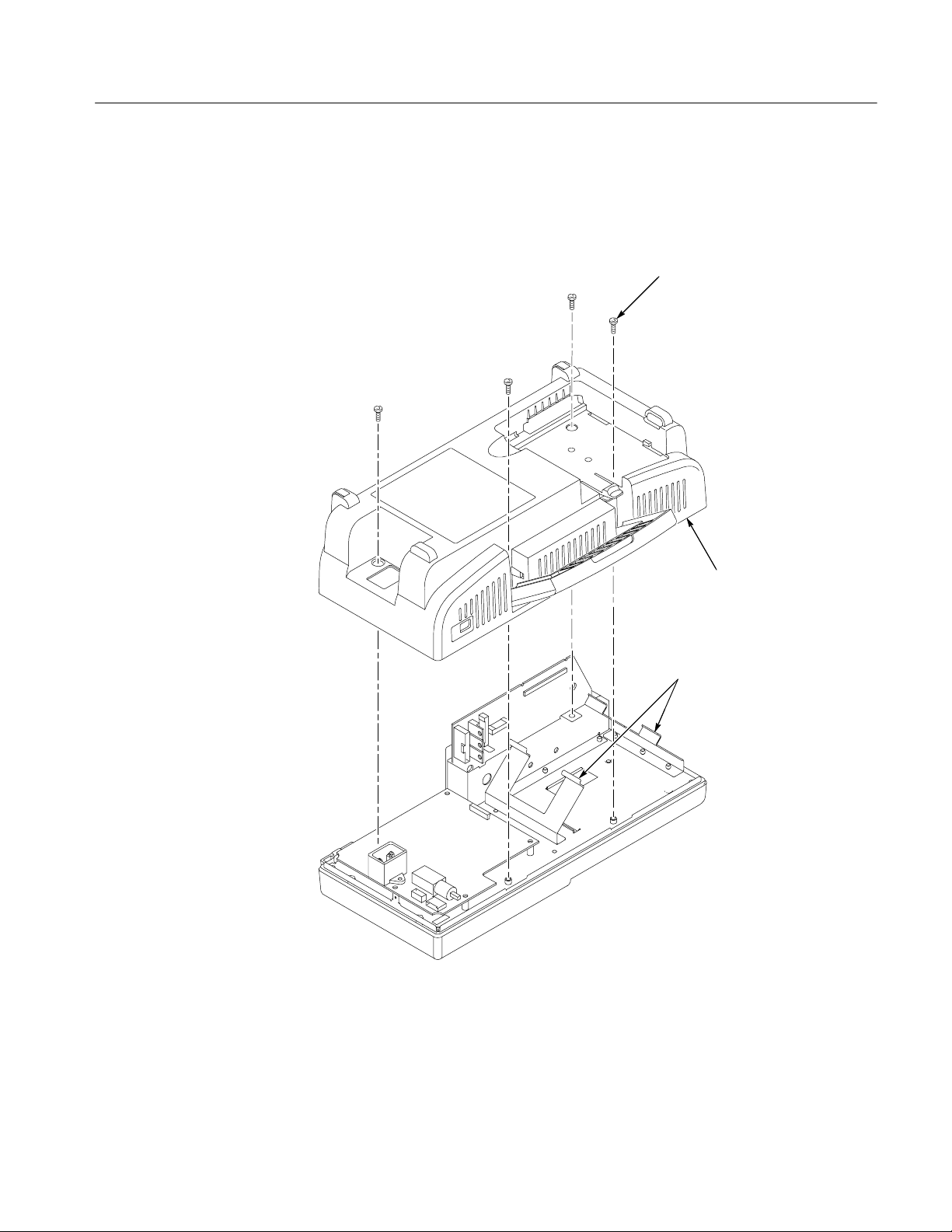

Figure 6--4: Removing and installing the rear case 6--11..............

Figure 6--5: Aligning the oscilloscope rear case 6--13.................

Figure 6--6: Removing and installing the front feet 6--14..............

Figure 6--7: Removing the power supply module 6--15................

Figure 6--8: Installing the power supply module 6--16................

Figure 6--9: Removing and installing the internal assembly 6--17.......

Figure 6--10: Removing the display cable 6--19......................

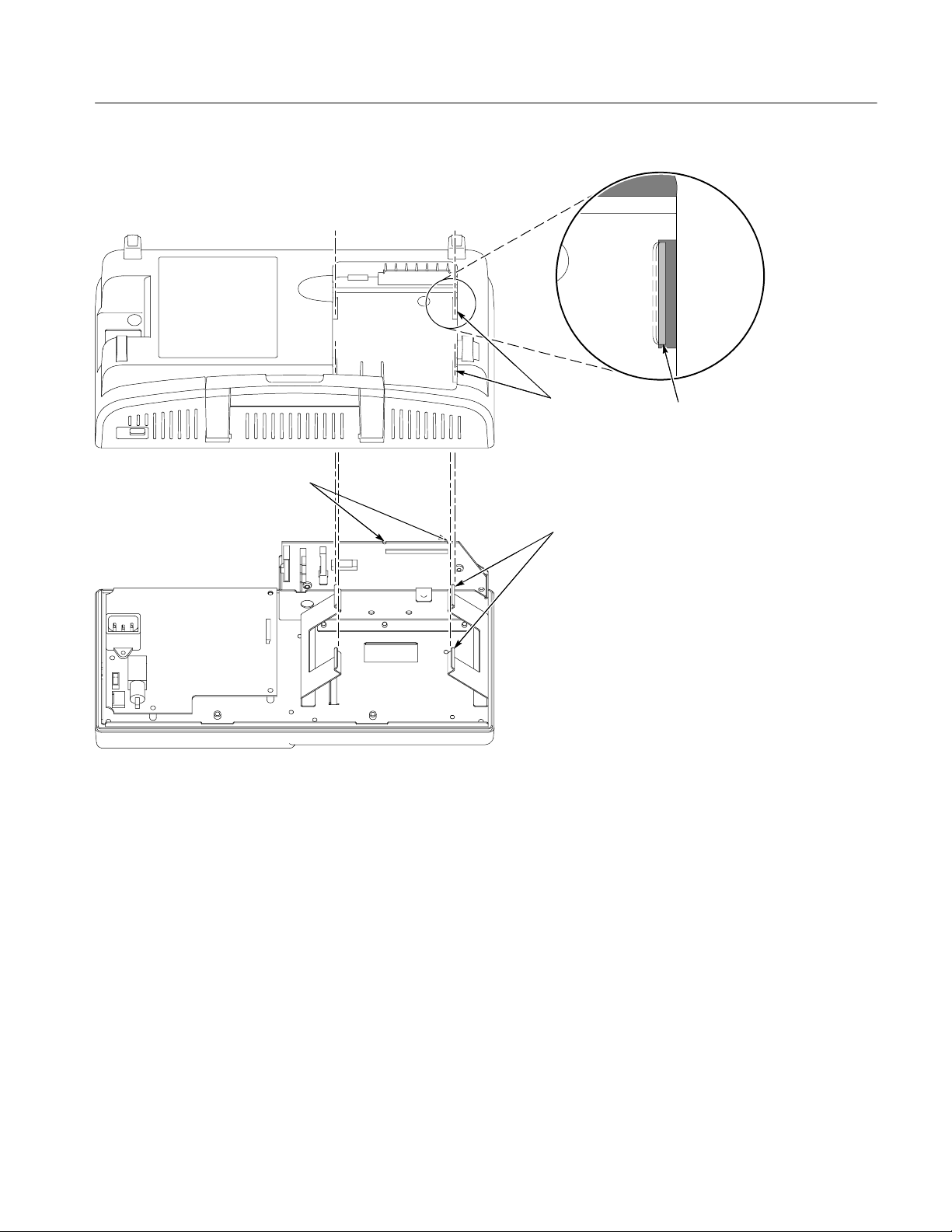

Figure 6--11: Installing the display cable 6--20.......................

Figure 6--12: Removing and installing the front-panel cable 6--21.......

Figure 6--13: Main board removal 6--23............................

Figure 6--14: Removing the display module 6--24....................

Figure 6--15: Installing the display module 6--25.....................

Figure 6--16: Removing the front-panel module 6--26.................

Figure 6--17: Installing the front-panel module 6--27.................

Figure 6--18: Removing and installing the keypad 6--28...............

Figure 6--19: Oscilloscope troubleshooting tree (1 of 3) 6--32...........

Figure 6--20: Oscilloscope troubleshooting tree (2 of 3) 6--33...........

Figure 6--21: Oscilloscope troubleshooting tree (3 of 3) 6--34...........

Figure 6--22: Measuring the backlight voltage 6--39..................

Figure 7--1: TDS1000 and TDS2000 series block diagram 7--2........

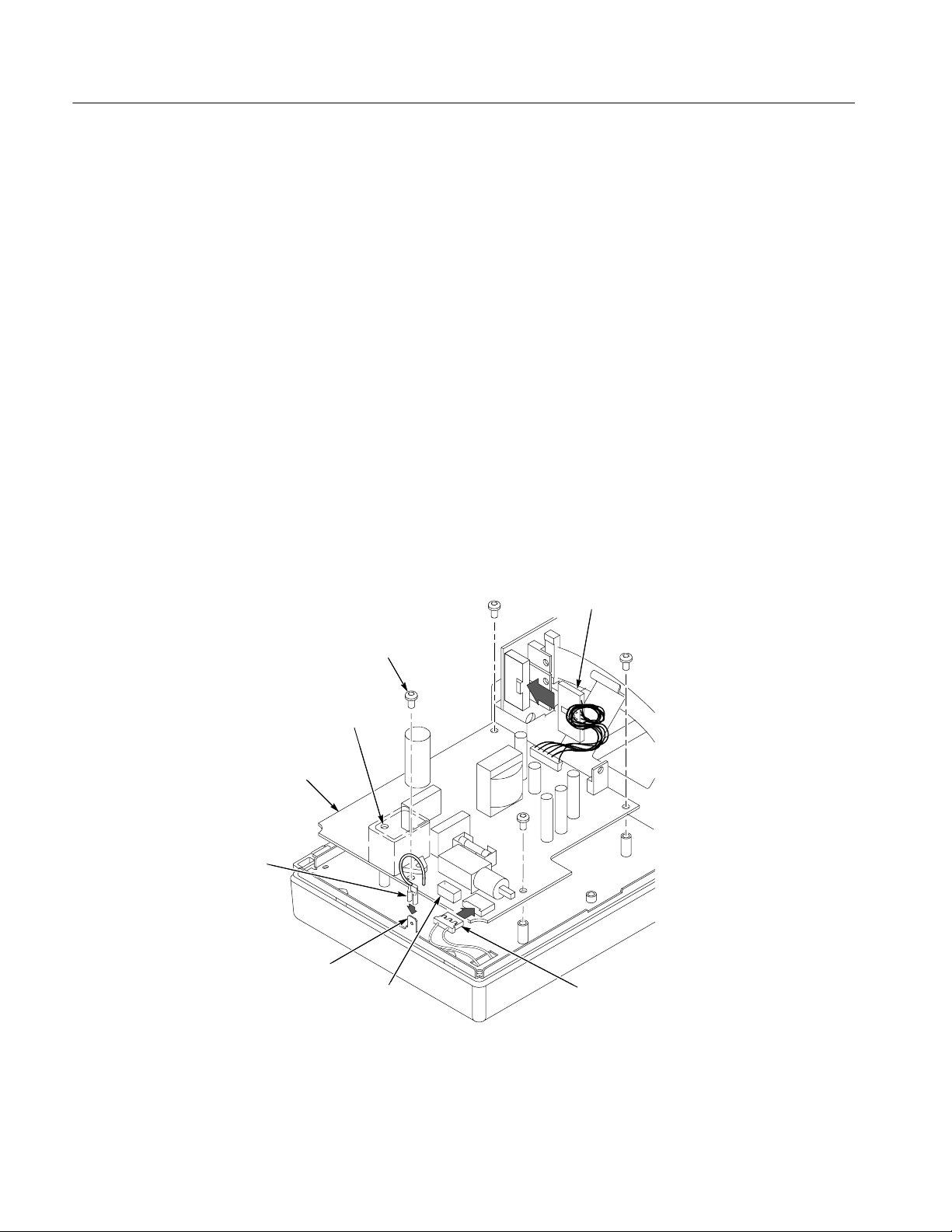

Figure 8--1: Exploded diagram 8--7...............................

iv

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 9

List of Tables

Table of Contents

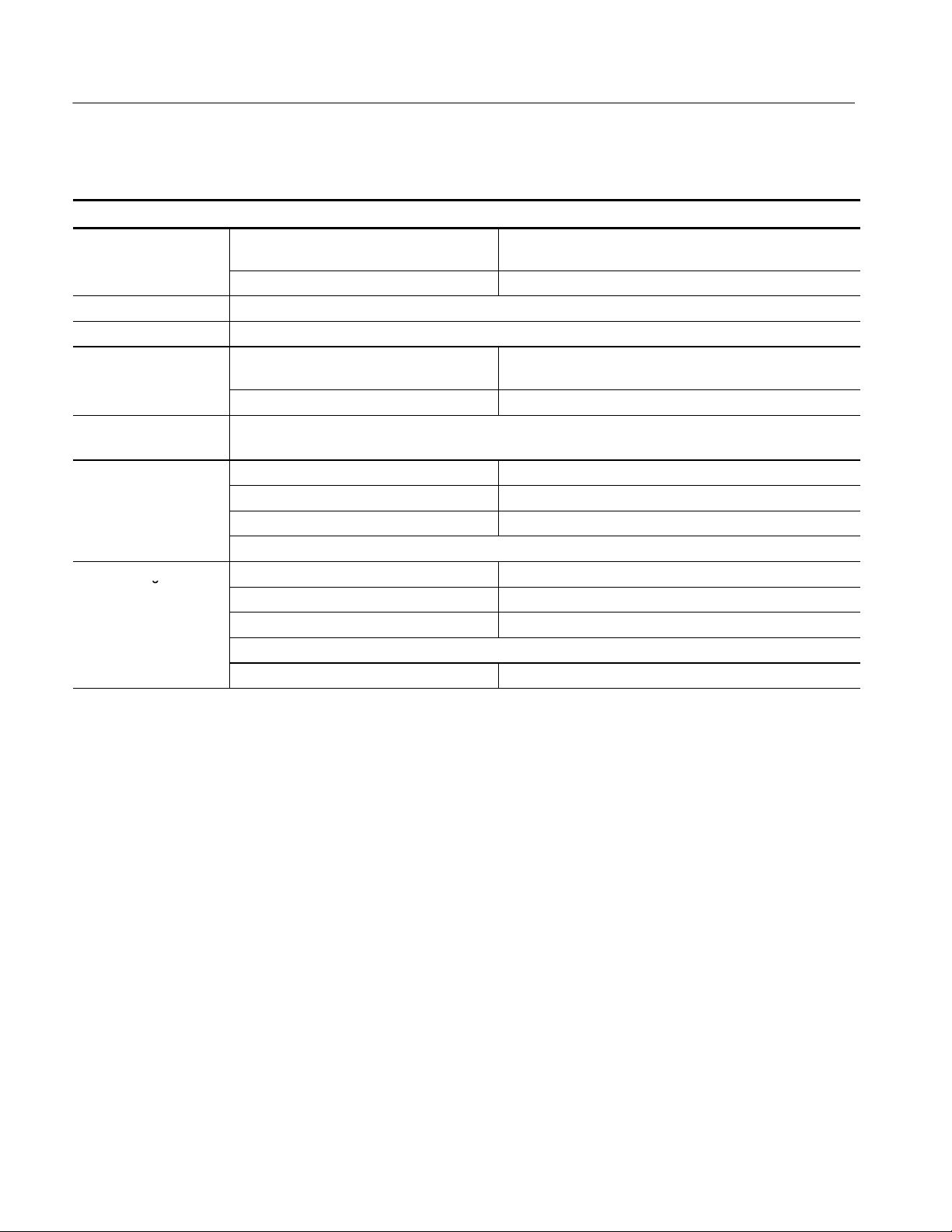

Table 1--1: Oscilloscope specifications 1--1........................

Table 1--2: Oscilloscope general specifications 1--7..................

Table 2--1: Default settings 2--7..................................

Table 5--1: Required equipment 5--1.............................

Table 5--2: Adjustment steps 5--6................................

Table 6--1: Internal inspection check list 6--3......................

Table 6--2: List of procedures 6--6................................

Table 6--3: List of error codes 6--44...............................

Table 8--1: Parts list column descriptions 8--2......................

Table 8--2: Manufacturers cross index 8--3........................

Table 8--3: Replaceable parts list 8--4.............................

Table 8--4: Replaceable standard accessories 8--8...................

Table 8--5: Replaceable optional accessories 8--8...................

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

v

Page 10

Table of Contents

vi

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 11

General Safety Summary

Review the following safety precautions to avoid injury and prevent damage to

this product or any products connected to it.

Only qualified personnel should perform service procedures.

Injury Precautions

Use Proper Power Cord. To avoid fire hazard, use only the power cord specified

for this product.

Avoid Electric Overload. To avoid electric shock or fire hazard, do not apply a

voltage to a terminal that is outside the range specified for that terminal.

Avoid Overvoltage. To avoid electric shock or fire hazard, do not apply potential

to any terminal, including the common terminal, that varies from ground by more

than the maximum rating for that terminal.

Avoid Electric Shock. To avoid injury or loss of life, do not connect or disconnect

probes or test leads while they are connected to a voltage source.

Ground the Product. This product is grounded through the grounding conductor

of the power cord. To avoid electric shock, the grounding conductor must be

connected to earth ground. Before making connections to the input or output

terminals of the product, ensure that the product is properly grounded.

Connect the Probe Properly. The probe ground lead is at ground potential. Do not

connect the ground lead to an elevated voltage.

Do Not Operate Without Covers. To avoid electric shock or fire hazard, do not

operate this product with covers or panels removed.

Use Proper Fuse. To avoid fire hazard, use only the fuse type and rating specified

for this product.

Do Not Operate in Wet/Damp Conditions. To avoid electric shock, do not operate

this product in wet or damp conditions.

Do Not Operate in an Explosive Atmosphere. To avoid injury or fire hazard, do not

operate this product in an explosive atmosphere.

Product Damage

Precautions

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Use Proper Power Source. Do not operate this product from a power source that

applies more than the voltage specified.

Provide Proper Ventilation. To prevent product overheating, provide proper

ventilation.

Do Not Operate With Suspected Failures. If you suspect there is damage to this

product, have it inspected by qualified service personnel.

vii

Page 12

General Safety Summary

Symbols and Terms

Terms in this Manual. These terms may appear in this manual:

WARNING. Warning statements identify conditions or practices that could result

in injury or loss of life.

CAUTION. Caution statements identify conditions or practices that could result in

damage to this product or other property.

Terms on the Product. These terms may appear on the product:

DANGER indicates an injury hazard immediately accessible as you read the

marking.

WARNING indicates an injury hazard not immediately accessible as you read the

marking.

CAUTION indicates a hazard to property including the product.

Symbols on the Product. The following symbols may appear on the product:

Probe Safety

DANGER

High Voltage

Protective Ground

(Earth) Terminal

ATTENTION

Refer to Manual

Double

Insulated

A guard around the probe body provides a finger barrier for protection from

electric shock.

Finger guard

WARNING. To avoid electric shock when using the probe, keep fingers behind the

guard on the probe body, and do not touch metallic portions of the probe head

while it is connected to a voltage source.

Connect the probe to the oscilloscope and connect the ground terminal to ground

before you take any measurements.

viii

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 13

Service Safety Summary

Only qualified personnel should perform service procedures. Read this Service

Safety Summary and the General Safety Summary before performing any service

procedures.

Do Not Service Alone. Do not perform internal service or adjustments of this

product unless another person capable of rendering first aid and resuscitation is

present.

Disconnect Power. To avoid electric shock, disconnect the main power by means

of the power cord or, if provided, the power switch.

Use Care When Servicing With Power On. Dangerous voltages or currents may

exist in this product. Disconnect power, remove battery (if applicable), and

disconnect test leads before removing protective panels, soldering, or replacing

components.

To avoid electric shock, do not touch exposed connections.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

ix

Page 14

Service Safety Summary

x

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 15

Environmental Considerations

This section provides information about the environmental impact of the

product.

Product End-of-Life

Handling

Observe the following guidelines when recycling an instrument or component:

Equipment Recycling. Production of this equipment required the extraction and

use of natural resources. The equipment may contain substances that could be

harmful to the environment or human health if improperly handled at the

product’s end of life. In order to avoid release of such substances into the

environment and to reduce the use of natural resources, we encourage you to

recycle this product in an appropriate system that will ensure that most of the

materials are reused or recycled appropriately.

The symbol shown to the left indicates that this product

complies with the European Union’s requirements

according to Directive 2002/96/EC on waste electrical and

electronic equipment (WEEE). For information about

recycling options, check the Support/Service section of the

Tektronix Web site (www.tektronix.com).

Mercury Notification. This product uses an LCD backlight lamp that contains

mercury. Disposal may be regulated due to environmental considerations. Please

contact your local authorities or, within the United States, the Electronics

Industries Alliance (www.eiae.org) for disposal or recycling information.

Restriction of Hazardous

Substances

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

This product has been classified as Monitoring and Control equipment, and is

outside the scope of the 2002/95/EC RoHS Directive. This product is known to

contain lead, cadmium, mercury , and hexavalent chromium.

xi

Page 16

Environmental Considerations

xii

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 17

Preface

Related Manuals

The service manual for the TDS1000- and TDS2000-Series Digital Storage

Oscilloscopes provides instructions to verify the performance of, calibrate,

troubleshoot, and repair the oscilloscopes to the module level.

Unless noted otherwise, the term “oscilloscope” refers to all of the models in the

TDS1000 and TDS2000 series.

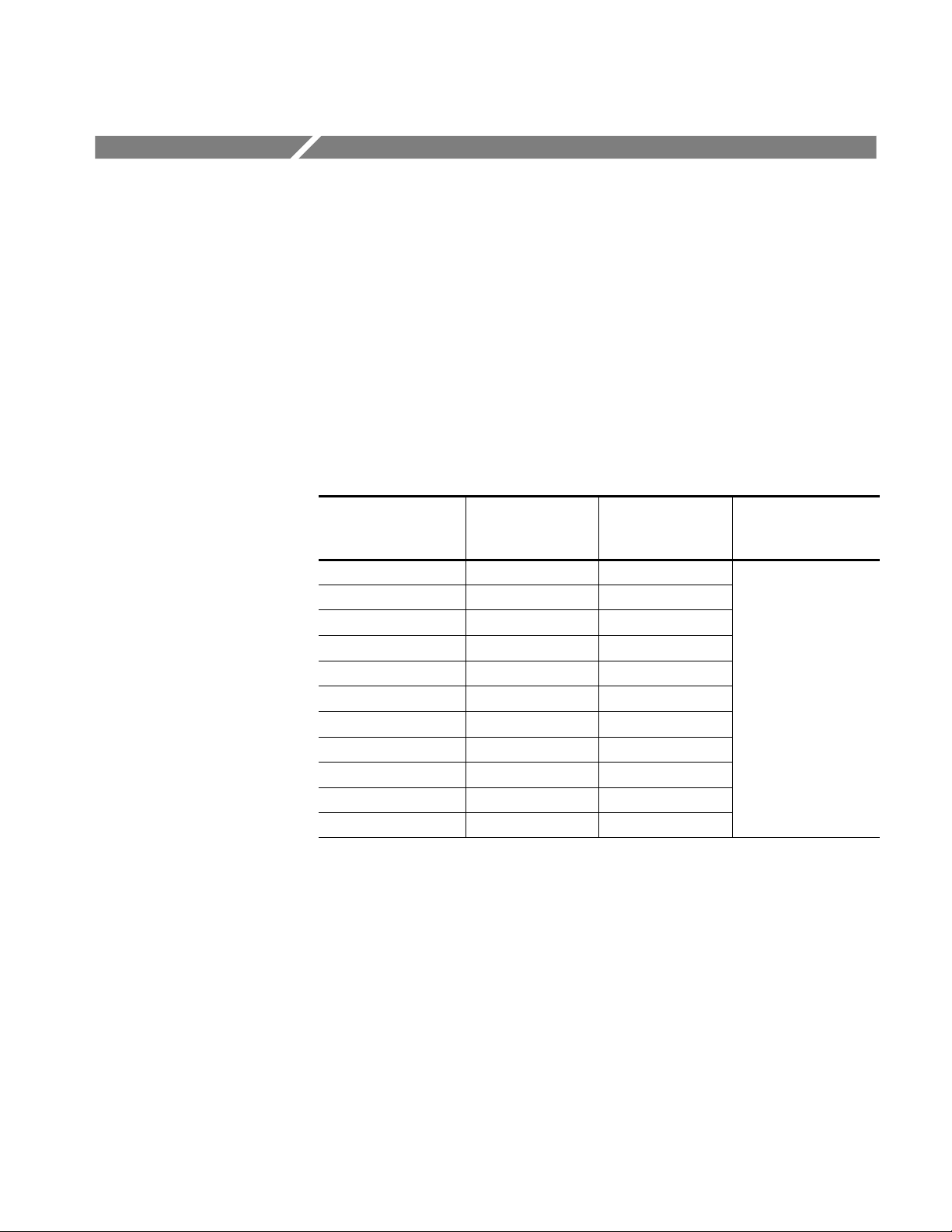

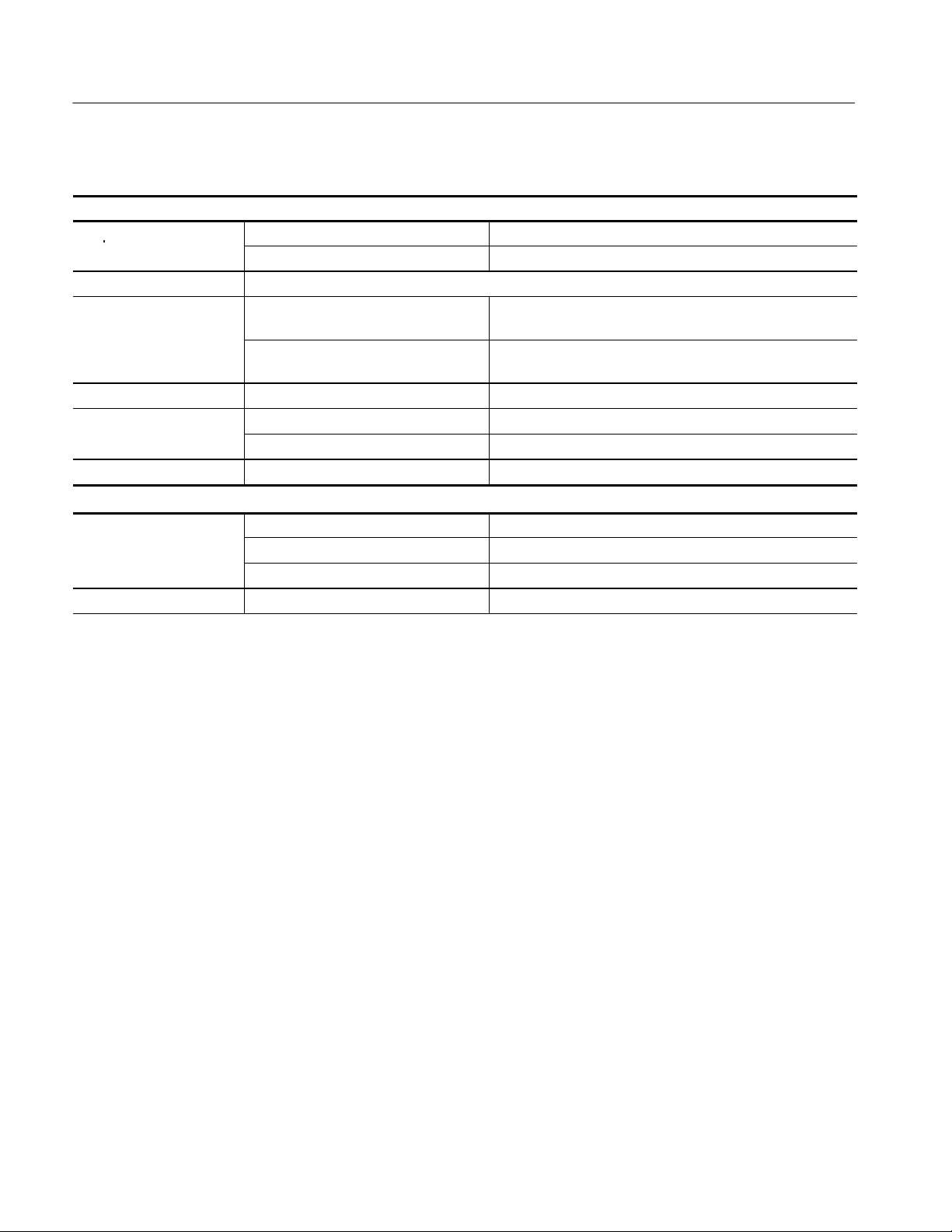

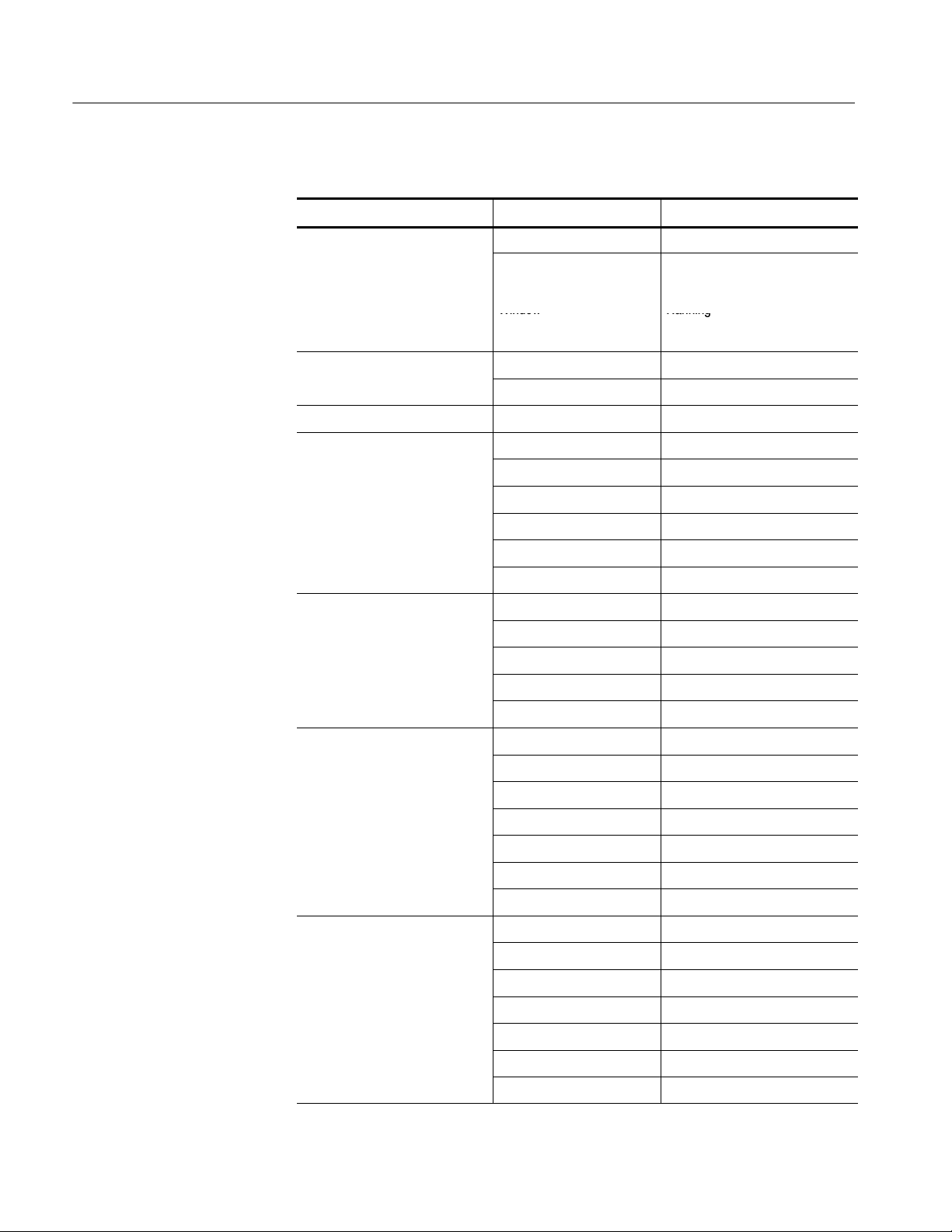

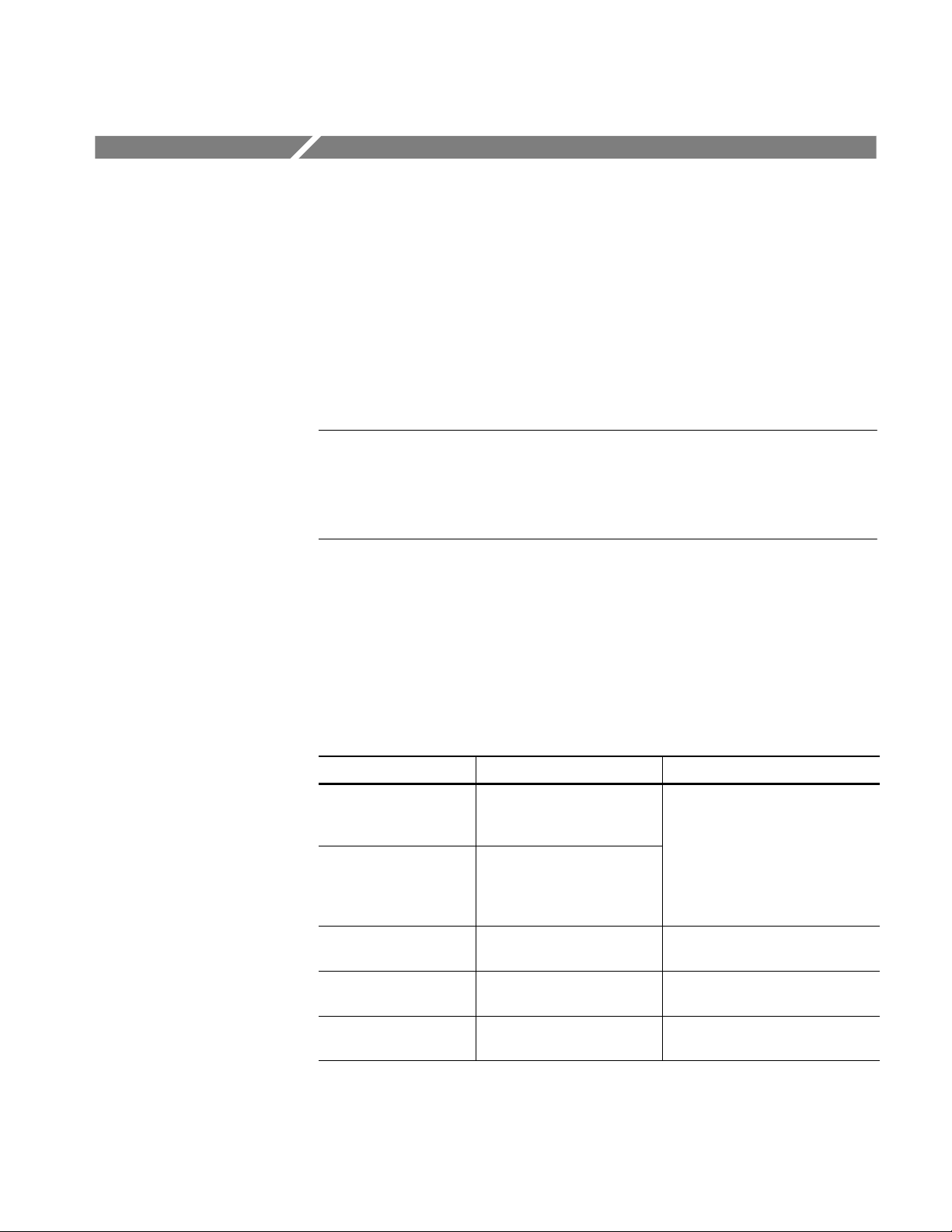

These manuals contain additional documentation for the oscilloscopes:

Extension module

User manual

Language

English 071-1064-XX 071-0409-XX 071-1075-XX

French 071-1065-XX* 071-0483-XX

German 071-1067-XX* 071-0485-XX

Italian 071-1066-XX* 071-0484-XX

Spanish 071-1068-XX* 071-0482-XX

Portuguese 071-1070-XX* 071-0486-XX

Japanese 071-1069-XX* 071-0488-XX

Korean 071-1073-XX* 071-0491-XX

Simplified Chinese 071-1071-XX* 071-0489-XX

Traditional Chinese 071-1072-XX* 071-0490-XX

Russian 071-1074-XX* 071-0487-XX

*These manuals contain a language overlay for the front-panel controls.

part number

instructions part

number

Programmer manual

part number

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

xiii

Page 18

Preface

xiv

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 19

Specifications

Page 20

Page 21

Specifications

g

q

These specifications apply to all TDS1000- and TDS2000-series oscilloscopes.

To verify that an oscilloscope meets specifications, it must first meet the

following conditions:

H The oscilloscope must have been operating continuously for twenty minutes

within the specified operating temperature.

H You must perform the Do Self Cal operation, accessible through the Utility

menu, if the operating temperature changes by more than 5 °C.

H The oscilloscope must be within the factory calibration interval of one year.

Specifications begin in Table 1--1. All specifications are guaranteed unless noted

“typical.” Specifications that are marked with the n symbol are checked in the

chapter Performance Verification.

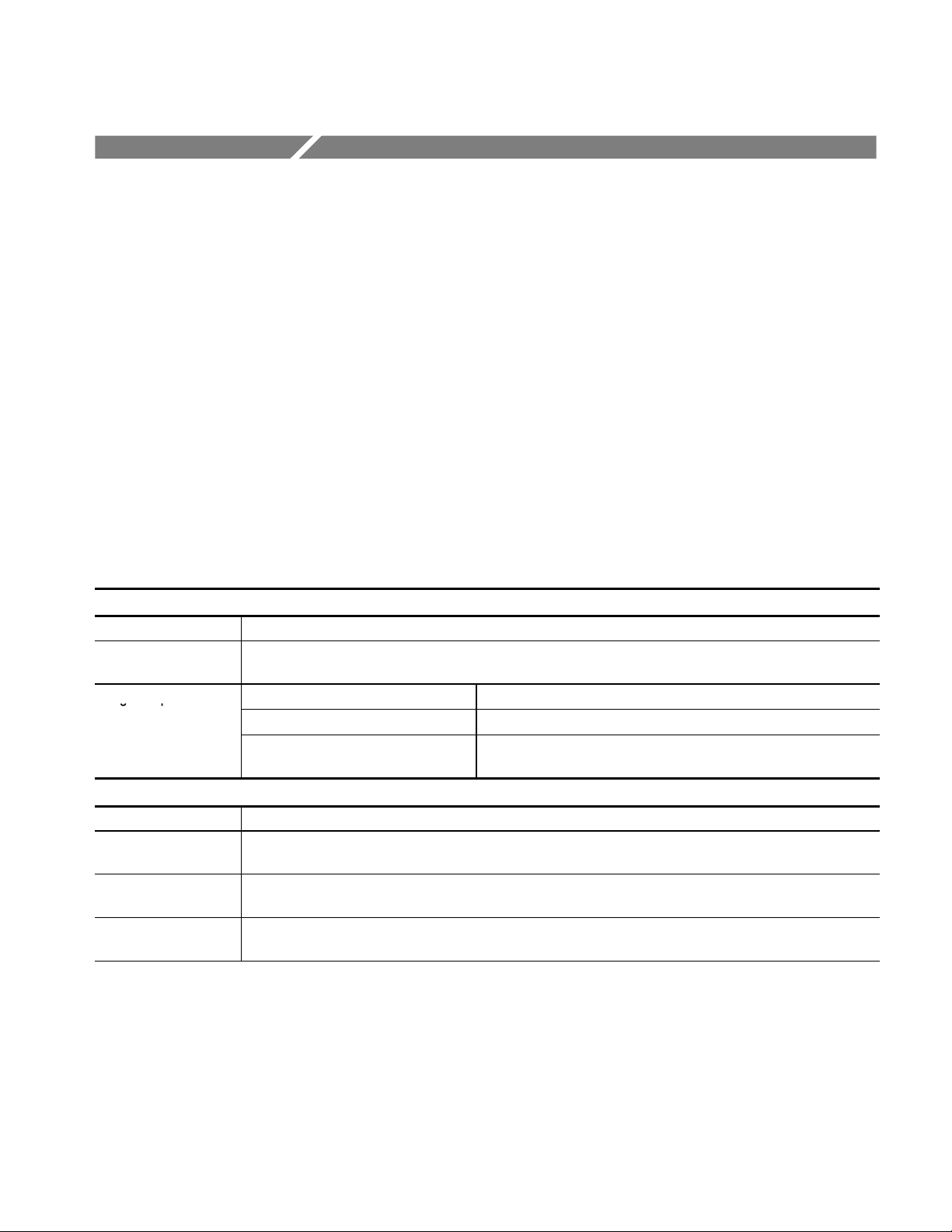

Table 1- 1: Oscilloscope specifications

Acquisition

Acquisition Modes Sample, Peak Detect, and Average

Acquisition Rate,

typical

Single Sequence Acquisition Mode Acquisition Stops After

Up to 180 waveforms per second, per channel (Sample acquisition mode, no measurements)

Sample, Peak Detect Single acquisition, all channels simultaneously

Average N acquisitions, all channels simultaneously. N is selectable from 4,

16, 64, and 128

Inputs

Input Coupling DC, AC, or GND

Input Impedance, DC

Coupled

P2200 Probe

Attenuation

Supported Probe

Attenuation Factors

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

1MΩ ±2% in parallel with 20 pF ±3pF

1X, 10X

1X, 10X, 100X, 1000X

1- 1

Page 22

Specifications

g

C

ati

tBN

C

I

fth

val

x

ceeded,d

ama

cil

losc

a

y

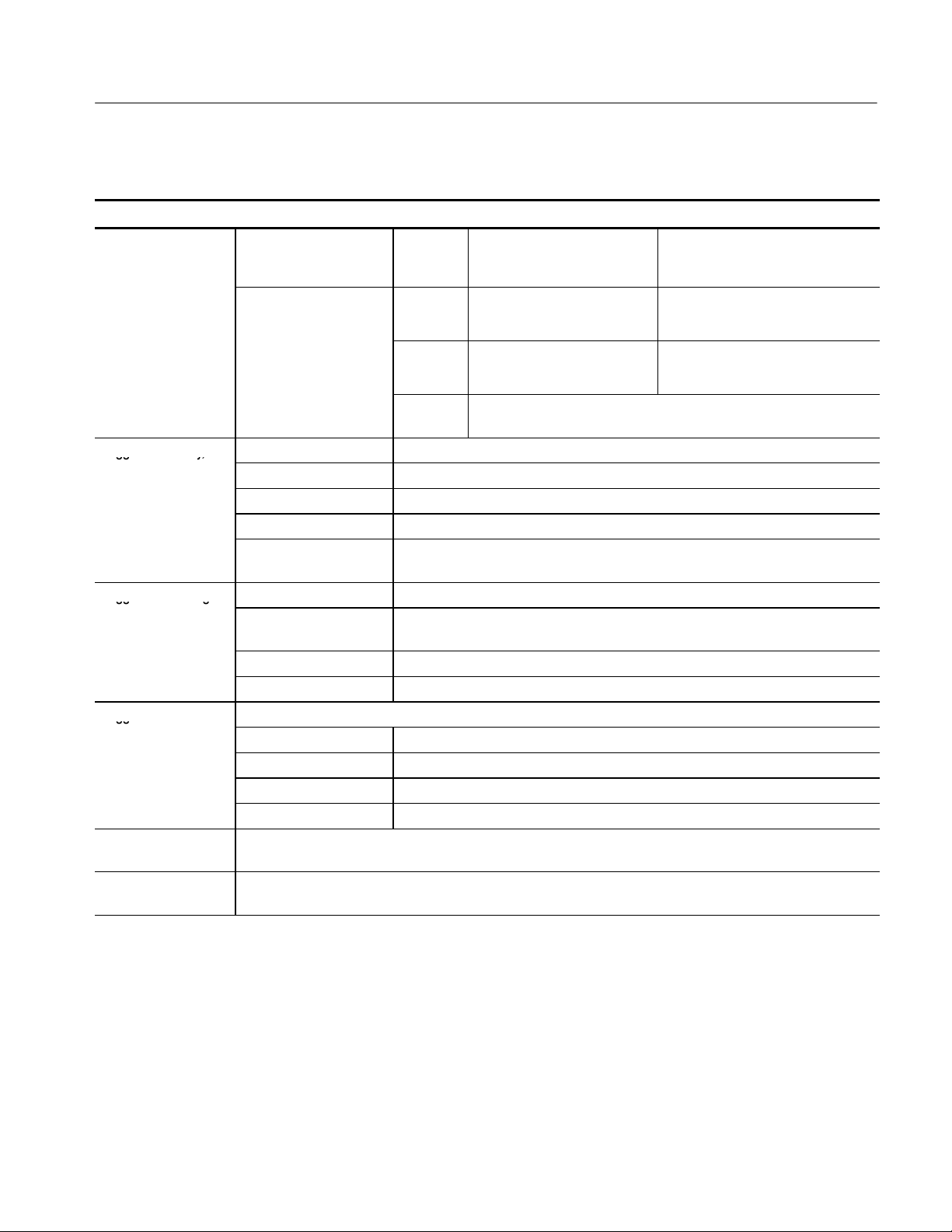

Table 1- 1: Oscilloscope specifications (Cont.)

Inputs

Maximum Voltage Overvoltage Category* Maximum Voltage

Between Signal and

ommon

npu

Channel-to-Channel TDS1001 TDS1002, TDS2002, TDS2004 TDS1012, TDS2012, TDS2014, TDS2022, TDS2024

Common Mode

Rejection, typical

CAT I and CAT II 300 V

CAT III 150 V

RMS

RMS

Derate at 20 dB/decade above 100 kHz to 13 V peak AC at 3 MHz and above.

For non-sinusoidal waveforms, peak value must be less than 450 V. Excursion above 300 V should be less

than 100 ms duration.

RMS signal level including any DC component removed through AC coupling must be limited to 300 V.

ese

uesare e

100:1 at 60 Hz

20:1at20MHz

100:1 at 60 Hz

20:1at30MHz

ge to theos

ope m

result.

100:1 at 60 Hz

10:1at50MHz

Measured on MATH Ch1 -- Ch2 waveform, with test signal applied between signal and common of both

channels, and with the same VOLTS/DIV and coupling settings on each channel

Measured on MATH Ch3 -- Ch4 waveform for 4-channel models

Channel-to-Channel TDS1001 TDS1002, TDS2002, TDS2004 TDS1012, TDS2012, TDS2014 TDS2022, TDS2024

Crosstalk

≥ 100:1 at 20 MHz ≥ 100:1 at 30 MHz ≥ 100:1 at 50 MHz ≥ 100:1 at 100 MHz

Measured on one channel, with test signal applied between signal and common of the other channel, and

with the same VOLTS/DIV and coupling settings on each channel

Vertical

Digitizers 8-bit resolution (except when set to 2 mV/div), each channel sampled simultaneously

VOLTS/DIV Range 2 mV/div to 5 V/div at input BNC

Position Range 2 mV/div to 200 mV/div, ±2V

> 200 mV/div to 5 V/div, ±50 V

*

Refer to the Overvoltage Category description on page 1--10.

1- 2

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 23

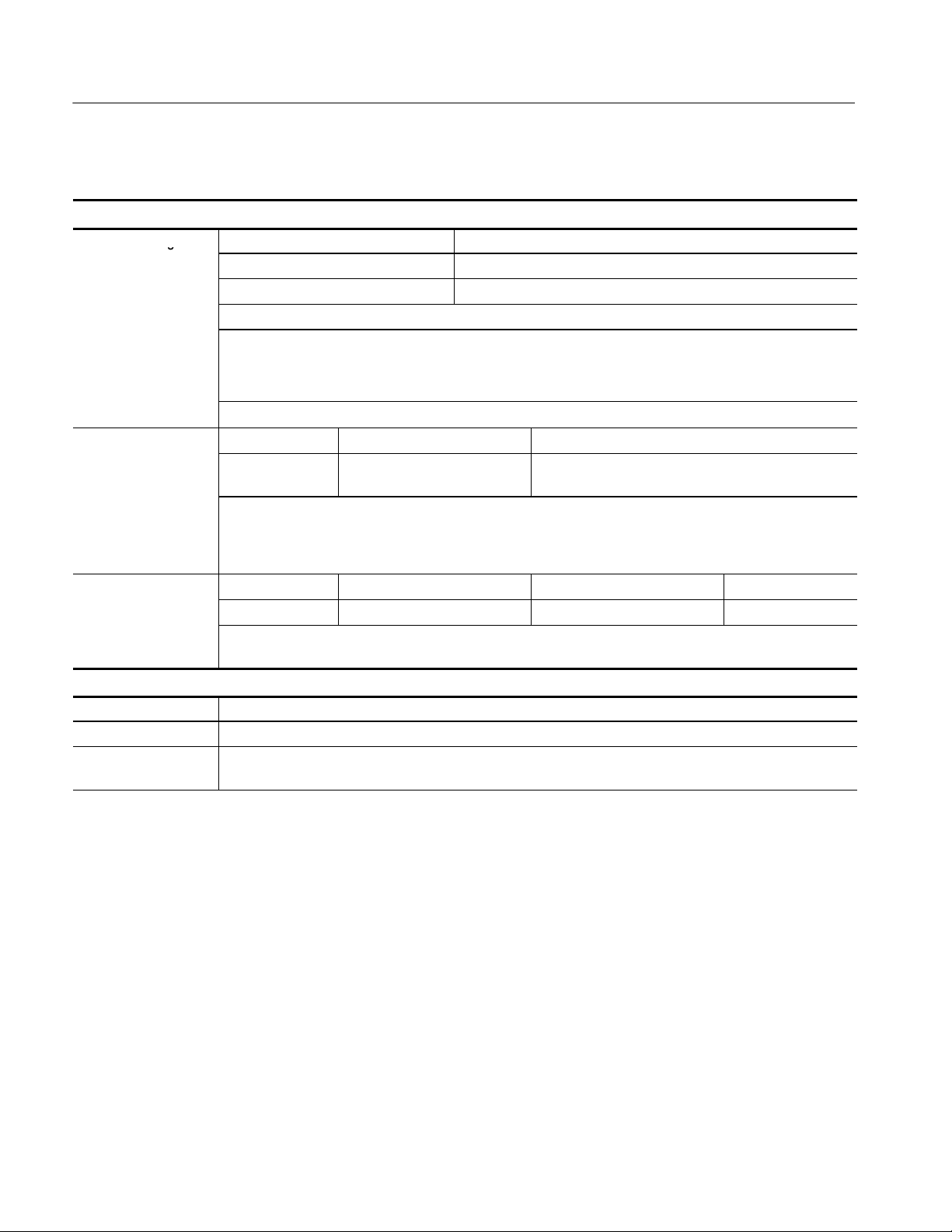

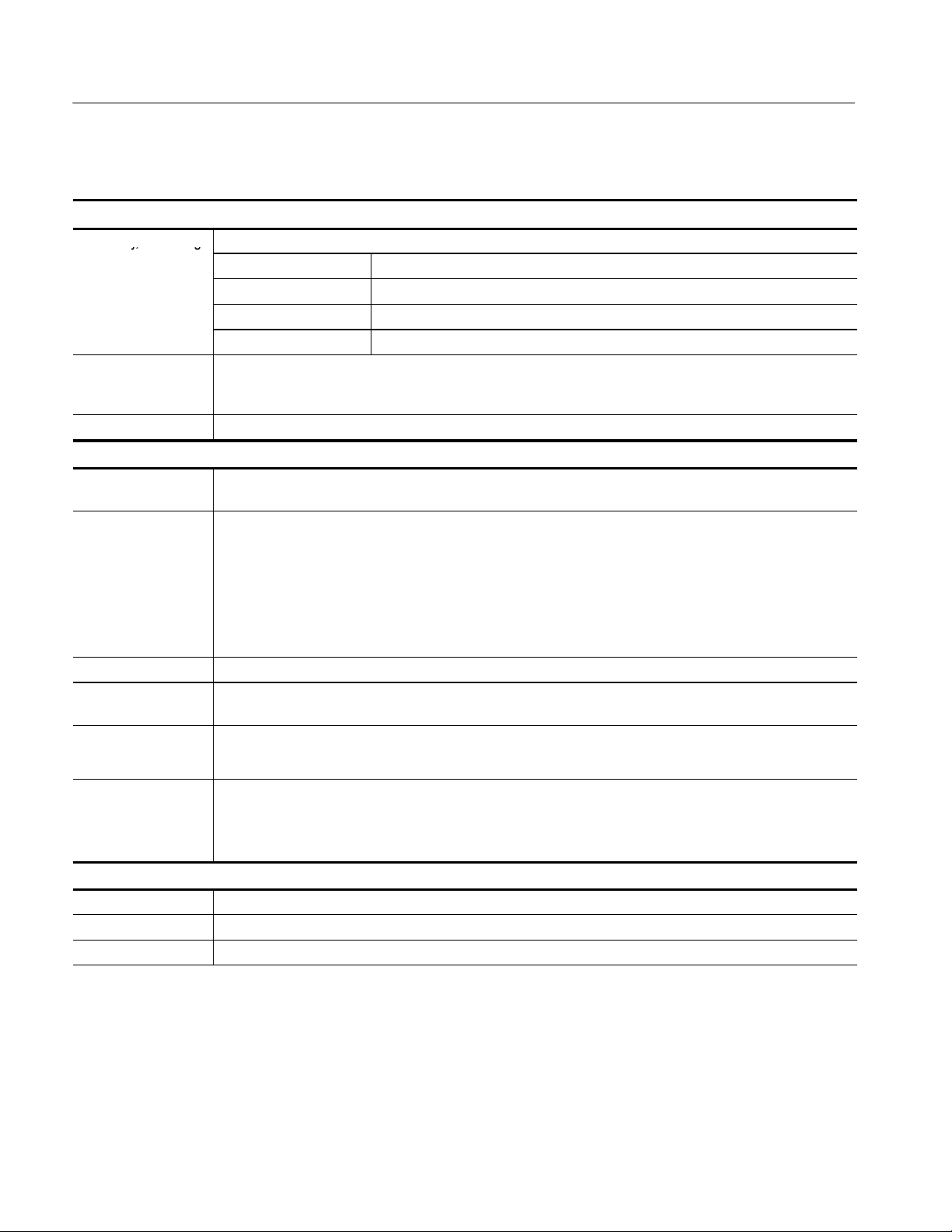

Table 1- 1: Oscilloscope specifications

n

AnalogBandwidth

g

(50s/divto5s/div**)

,

n

DCGainAccurac

y

n

DCMeasurement

Vertical

Specifications

n Analog Bandwidth

in Sample and Average

modes at BNC or with

P2200 probe,

DC Coupled

Analog Bandwidth in TDS1001 TDS1002, TDS2002, TDS2004 TDS1012, TDS2012, TDS2014, TDS2022, TDS2024

Peak Detect mode

typical

Selectable Analog Bandwidth Limit, typical

Lower Frequency

Limit, AC Coupled

Rise Time at BNC, TDS1001 TDS1002, TDS2002, TDS2004 TDS1012, TDS2012, TDS2014 TDS2022, TDS2024

typical

Peak Detect Response** Captures 50% or greater amplitude of pulses ≥12 ns wide typical (50 s/div to 5 s/div) in the center 8

n DC Gain Accuracy

n DC Measurement

Accuracy, Average

Acquisition Mode

TDS1001 TDS1002, TDS2002, TDS2004 TDS1012, TDS2012, TDS2014 TDS2022, TDS2024

40 MHz{*

20 MHz* (when vertical scale is set to < 5 mV)

30 MHz{* 50 MHz{* 75 MHz{*

**

,

20 MHz* (when vertical scale is set to < 5 mV)

20 MHz*

≤ 10 Hz at BNC

≤ 1 Hz when using a 10X passive probe

< 8.4ns <5.8ns <3.5ns <2.1ns

vertical divisions

±3% for Sample or Average acquisition mode, 5 V/div to 10 mV/div

±4% for Sample or Average acquisition mode, 5 mV/div and 2 mV/div

Measurement Type Accuracy

Average of ≥ 16 waveforms with vertical

position at zero

Average of ≥ 16 waveforms with vertical

position not at zero

60 MHz{* 100 MHz{* 200 MHz{*

0 °Cto+40°C(32°F

to 104 °F)

160 MHz{*

0 °Cto+50°C(32°F

to 122 °F)

±(3% × reading + 0.1 div + 1 mV) when 10 mV/div or greater

is selected

±[3% × (reading + vertical position) + 1% of vertical position

+0.2div]

Add 2 mV for settings from 2 mV/div to 200 mV/div

Add 50 mV for settings from > 200 mV/div to 5 V/div

Volts Measurement

Repeatability, Average

Acquisition Mode

{ When vertical scale is set to ≥ 5mV.

* Bandwidth reduced to 6 MHz with a 1X probe.

** The oscilloscope reverts to Sample mode when the SEC/DIV (horizontal scale) is set from 2.5 s/div to 5 ns/div on 1 GS/s models,

or from 2.5 s/div to 2.5 ns/div on 2 GS/s models. The Sample mode can still capture 10 ns glitches.

Delta volts between any two averages of ≥

16 waveforms acquired under same setup

and ambient conditions

±(3% × reading + 0.05 div)

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

1- 3

Page 24

Specifications

idth)

g

Table 1- 1: Oscilloscope specifications (Cont.)

Horizontal

Sample Rate Range TDS2022, TDS2024 TDS1001, TDS1002, TDS2004, TDS1012, TDS2002,

TDS2012, TDS2014

5S/sto2GS/s 5S/sto1GS/s

Waveform Interpolation (sin x)/x

Record Length 2500 samples for each channel

SEC/DIV Range TDS2022, TDS2024 TDS1001, TDS1002, TDS2004, TDS1012, TDS2002,

TDS2012, TDS2014

2.5 ns/div to 50 s/div, in a 1, 2.5, 5 sequence 5 ns/div to 50 s/div, in a 1, 2.5, 5 sequence

n Sample Rate and

Delay Time Accuracy

Delta Time Measurement Conditions Accuracy

Accuracy (Full Bandw

Position Range 5ns/divto10ns/div (--4 div × s/div) to 20 ms

±50 ppm over any ≥1 ms time interval

Single-shot, Sample mode ±(1 sample interval + 50 ppm × reading + 0.6 ns)

> 16 averages ±(1 sample interval + 50 ppm × reading + 0.4 ns)

Sample interval = s/div ÷ 250

25 ns/div to 100 s/div (--4 div × s/div) to 50 ms

250 s/divto50s/div (--4 div × s/div) to 50 s

TDS2022, TDS2024

2.5 ns/div (--4 div × s/div) to 20 ms

1- 4

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 25

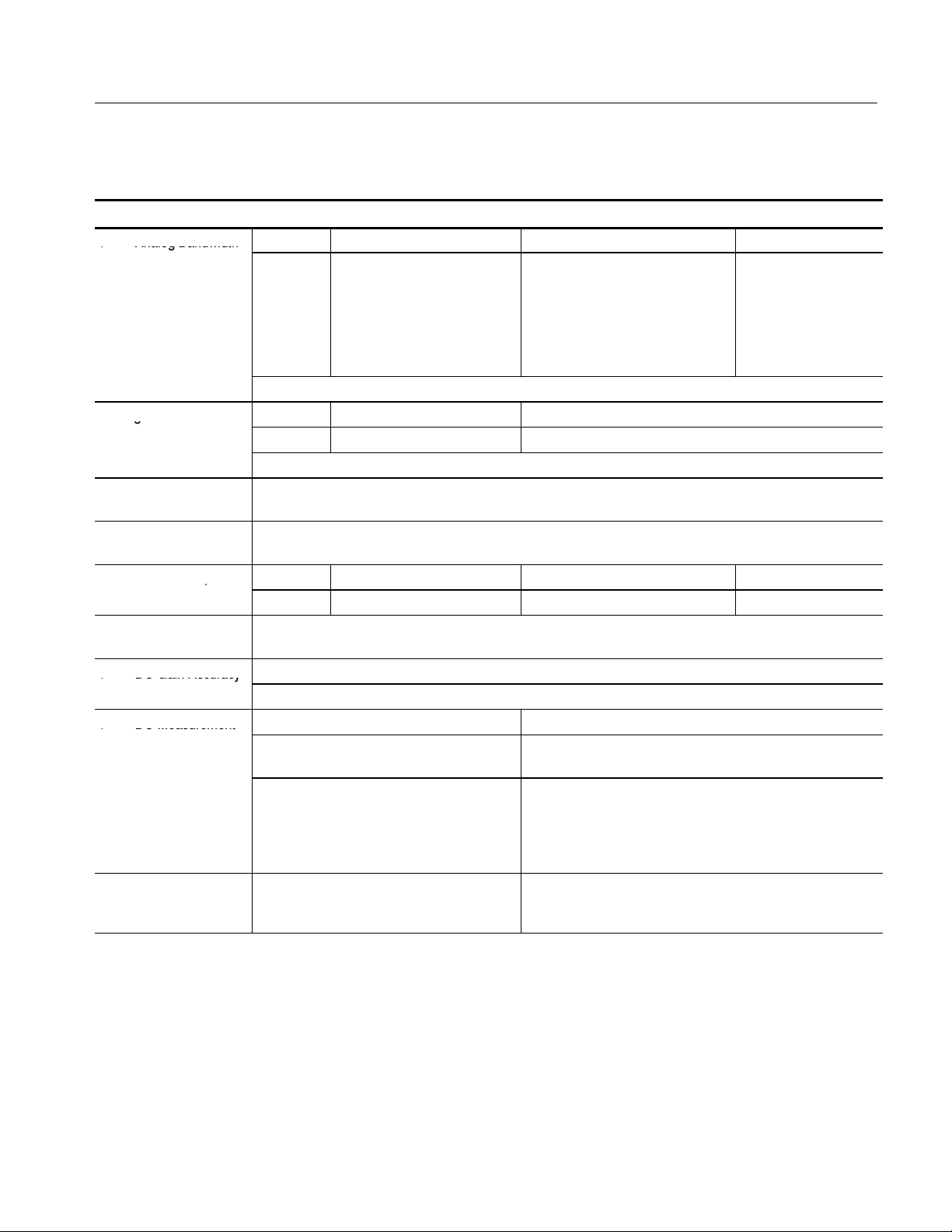

Table 1- 1: Oscilloscope specifications

ggy

,

ggg

g

g

Trigger

Specifications

n Trigger Sensitiv-

ity, Edge Trigger Type

Trigger Sensitivity, Coupling Sensitivity

Edge Trigger Type

Trigger Level Range Source Range

Trigger Level Accura- Accuracies are for signals having rise and fall times ≥ 20 ns

cy, typical

SET LEVEL TO 50%,

typical

Default Settings,

Video Trigger

* Bandwidth reduced to 6 MHz with a 1X probe.

Coupling Sensitivity TDS1001, TDS1002,

TDS1012, TDS2002,

TDS2004, TDS2012, TDS2014

DC EXT 200 mV from DC to 100 MHz* 200 mV from DC to 100 MHz*

EXT/5 1 V from DC to 100 MHz* 1 V from DC to 100 MHz*

CH1, CH2,

CH3, CH4

AC Same as DC at 50 Hz and above

NOISE REJ Reduces the DC-coupled trigger sensitivity by 2 times for > 10 mv/div to 5 V/div

HF REJ Same as the DC-coupled limit from DC to 7 kHz, attenuates signals above 80 kHz

LF REJ Same as the DC-coupled limits for frequencies above 300 kHz, attenuates signals

below 300 kHz

CH1, CH2, CH3, and

CH4

EXT ±1.6 V

EXT/5 ±8V

Source Accuracy

Internal ±0.2 div × volts/div within ±4 divisions from center screen

EXT ±(6%ofsetting+40mV)

EXT/5 ±(6% of setting + 200 mV)

Operates with input signals ≥ 50 Hz

Coupling is AC and Auto except for a single sequence acquisition

±8 divisions from center of screen

1 div from DC to 10 MHz*, 1.5 div from 10 MHz to Full

TDS2022, TDS2024

350 mV from 100 MHz to 200 MHz*

1.75 V from 100 MHz to 200 MHz*

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

1- 5

Page 26

Specifications

y,g

Table 1- 1: Oscilloscope specifications (Cont.)

Trigger

Sensitivity, Video Trig- Composite video signal

ger Type, typical

Signal Formats and

Field Rates, Video

Trigger Type

Holdoff Range 500 ns to 10 s

Pulse Width Trigger

Source Range

Internal Pk-pk amplitude of 2 divisions

EXT 400 mV

EXT/5 2V

Supports NTSC, PAL, and SECAM broadcast systems for any field or any line

Pulse Width

Trigger modes

Pulse Width

Trigger Point

Pulse Width Range Selectablefrom33nsto10s

Pulse Width

Resolution

Equal Guardband t > 330 ns: ±5% ≤ guardband < ±(5.1% + 16.5 ns)

Not Equal Guardband t > 330 ns: ±5% ≤ guardband < ±(5.1% + 16.5 ns)

Trigger Frequency Counter

Readout Resolution 6 digits

Accuracy (typical) ±51 ppm including all frequency reference errors and ±1 count errors

Frequency Range AC coupled, 10 Hz minimum to rated bandwidth

Trigger when < (Less than), > (Greater than), = (Equal), or ≠ (Not Equal);

Positive pulse or Negative pulse

Equal: The oscilloscope triggers when the trailing edge of the pulse crosses the trigger level.

Not Equal: If the pulse is narrower than the specified width, the trigger point is the trailing edge. Otherwise, the

oscilloscope triggers when a pulse continues longer than the time specified as the Pulse Width.

Less than: The trigger point is the trailing edge.

Greater than (also called time-out trigger): The oscilloscope triggers when a pulse continues longer than the

time specified as the Pulse Width.

16.5 ns or 1 part per thousand, whichever is larger

t ≤ 330 ns: guardband = ±16.5 ns

165 ns < t ≤ 330 ns: guardband = --16.5 ns/+33 ns

t ≤ 165 ns: guardband = ±16.5 ns

1- 6

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 27

Table 1- 1: Oscilloscope specifications (Cont.)

Trigger Frequency Counter

Signal Source Pulse Width or Edge Trigger modes: all available trigger sources

The Frequency Counter measures trigger source at all times, including when the oscilloscope acquisition is

halted due to changes in the run status, or acquisition of a single shot event has completed.

Pulse Width Trigger mode: The oscilloscope counts pulses of significant magnitude inside the 250 ms

measurement window that qualify as triggerable events, such as narrow pulses in a PWM pulse train if set to <

mode and the width is set to a relatively small time.

Edge Trigger mode: The oscilloscope counts all edges of sufficient magnitude and correct polarity.

Video Trigger mode: The Frequency Counter does not operate.

Measurements

Cursors Voltage difference between cursors (ΔV)

Time difference between cursors (ΔT)

Reciprocal of ΔTinHertz(1/ΔT)

Automatic Measurements

Frequency, Period, Mean, Pk-Pk, Cycle RMS, Min, Max, Rise Time, Fall Time, Pos Width, Neg Width

Specifications

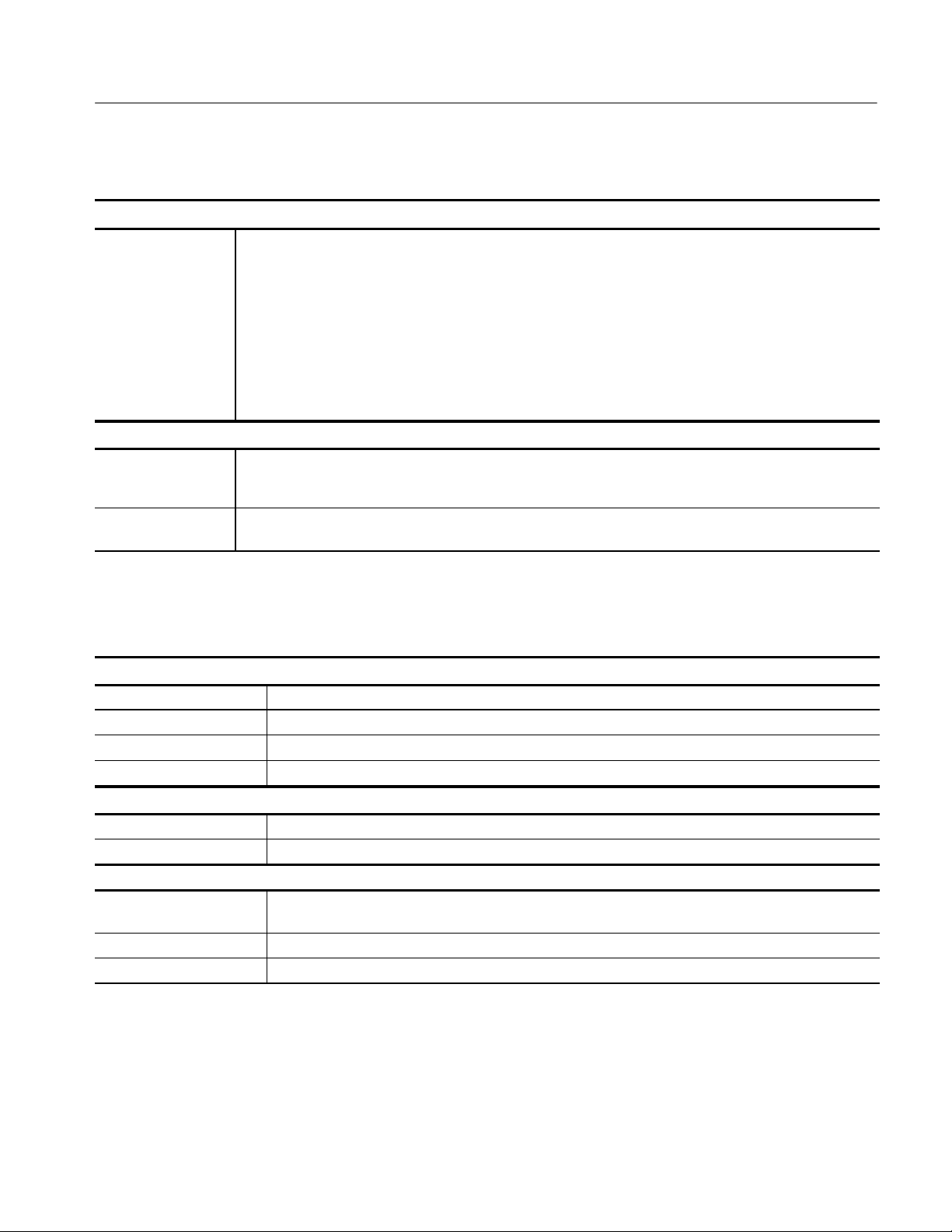

Table 1- 2: Oscilloscope general specifications

Display

Display Type 145 mm (5.7 in) diagonal liquid crystal

Display Resolution 320 horizontal by 240 vertical pixels

Display Contrast Adjustable, temperature compensated

Backlight Intensity, typical 65 cd/m

Probe Compensator Output

Output Voltage, typical 5Vinto≥ 1MΩ load

Frequency, typical 1 kHz

Power Source

Source Voltage 100 -- 120 VAC

120 -- 240 VAC

Power Consumption Less than 30 W

Fuse 1 A, T rating, 250 V

2

( 10%) from 45 Hz through 440 Hz, CAT II

RMS

( 10%) from 45 Hz through 66 Hz, CAT II

RMS

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

1- 7

Page 28

Specifications

p

Table 1- 2:

Environmental

Temperature Operating 0 °Cto+50°C(32°F to 122 °F)

Cooling Method Convection

Humidity +40 °C or below

Altitude Operating and Nonoperating 3,000 m (10,000 ft)

Random Vibration Operating 0.31 g

Mechanical Shock Operating 50 g, 11 ms, half sine

Mechanical

Size Height 151.4 mm (5.96 in)

Weight (approximate) When packaged for domestic shipment 3.6kg(8.0lbs)

Oscilloscope general specifications (Cont.)

Nonoperating -- 4 0 °Cto+71°C(--40°F to 159.8 °F)

(+104 °F or below)

+41° Cto+50° C

(106 °F to 122 °F)

Nonoperating 2.46 g

Width 323.8 mm (12.75 in)

Depth 124.5 mm (4.90 in)

≤ 90% relative humidity

≤ 60% relative humidity

from 5 Hz to 500 Hz, 10 minutes on each axis

RMS

from 5 Hz to 500 Hz, 10 minutes on each axis

RMS

Certifications and Compliances

EN 61326. EMC requirements for Class A electrical equipment for measurement,

control, and laboratory use. Annex D.

H IEC 61000--4--2. Electrostatic discharge immunity

H IEC 61000--4--3. RF electromagnetic field immunity

H IEC 61000--4--4. Electrical fast transient / burst immunity

H IEC 61000--4--5. Power line surge immunity

H IEC 61000--4--6. Conducted RF Immunity

H IEC 61000--4--11. Voltage dips and interruptions immunity

EN 61000- 3- 2. AC power line harmonic emissions

EN 61000- 3- 3. Voltage changes, fluctuations, and flicker

1

Emissions which exceed the levels required by this standard may occur when this

equipment is connected to a test object.

1

1- 8

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 29

Specifications

Australia / New Zealand

Declaration of Conformity

-EMC

EMC Compliance

FCC Compliance

Russian Federation

Peoples Republic of China

EC Declaration of

Conformity - Low Voltage

Complies with EMC provision of Radiocommunications Act per these standard(s):

H AS/NZS 2064.1/2. Industrial, Scientific, and Medical Equipment: 1992

Meets the intent of Directive 89/336/EEC for Electromagnetic Compatibility

when it is used with the product(s) stated in the specifications table. Refer to the

EMC specification published for the stated products. May not meet the intent of

the directive if used with other products.

Emissions comply with FCC 47 CFR, Part 15, Subpart B for Class A equipment.

This product was certified by the GOST ministry of Russia to be in compliance

with all applicable EMC regulations.

This product has received the Chinese Metrology Certification. (CMC).

Compliance was demonstrated to the following specification as listed in the

Official Journal of the European Communities:

U.S. Nationally

Recognized Testing

Laboratory Listing

Canadian Certification

Additional Compliance

Low Voltage Directive 73/23/EEC, amended by 93/68/EEC.

H EN 61010-1:2001. Safety requirements for electrical equipment for

measurement control and laboratory use.

H EN 61010-2-031:2002. Particular requirements for handheld probe assem-

blies for electrical measurement and test equipment.

H UL 61010B--1:2004, 2nd Edition. Standard for electrical measuring and test

equipment.

H UL 61010B--2--031:2003. Particular requirements for handheld probe

assemblies for electrical measurement and test equipment.

H CAN/CSA C22.2 No. 1010.1:1997. Particular requirements for electrical

equipment for measurement, control, and laboratory use. Part 1.

H CAN/CSA C22.2 No. 61010--2--031:1994. Particular requirements for

handheld probe assemblies for electrical measurement and test equipment.

H IEC 61010--1:2001. Safety requirements for electrical equipment for

measurement, control, and laboratory use.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

1- 9

Page 30

Specifications

H IEC 61010--031:2002. Particular requirements for handheld probe assemblies

for electrical measurement and test equipment.

Equipment Type

Pollution Degree

Descriptions

Test and measuring equipment.

A measure of the contaminates that could occur in the environment around and

within a product. Typically the internal environment inside a product is

considered to be the same as the external. Products should be used only in the

environment for which they are rated.

H Pollution Degree 1. No pollution or only dry, nonconductive pollution

occurs. Products in this category are generally encapsulated, hermetically

sealed, or located in clean rooms.

H Pollution Degree 2. Normally only dry, nonconductive pollution occurs.

Occasionally a temporary conductivity that is caused by condensation must

be expected. This location is a typical office/home environment. Temporary

condensation occurs only when the product is out of service.

H Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution

that becomes conductive due to condensation. These are sheltered locations

where neither temperature nor humidity is controlled. The area is protected

from direct sunshine, rain, or direct wind.

H Pollution Degree 4. Pollution that generates persistent conductivity through

conductive dust, rain, or snow. Typical outdoor locations.

Pollution Degree

Installation (Overvoltage)

Category Descriptions

Overvoltage Category

1- 10

Pollution Degree 2 (as defined in IEC 61010-1). Note: Rated for indoor use only.

Terminals on this product may have different installation (overvoltage) category

designations. The installation categories are:

H Measurement Category IV . For measurements performed at the source of

low-voltage installation.

H Measurement Category III. For measurements performed in the building

installation.

H Measurement Category II. For measurements performed on circuits directly

connected to the low-voltage installation.

H Measurement Category I. For measurements performed on circuits not

directly connected to MAINS.

Overvoltage Category II (as defined in IEC 61010-1)

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 31

Operating Information

Page 32

Page 33

Operating Information

TDS1000- and TDS2000-series oscilloscopes are two- or four-channel instruments in small, lightweight, benchtop chassis that you can use to take

ground-referenced measurements.

In addition to a list of general features, this chapter covers:

H How to install your product

H How to add extended functions

H How to perform a brief functional check

H How to use the self-calibration routine

H How to restore factory default settings

For more detailed information about oscilloscope operation, refer to your user

manual.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

2--1

Page 34

Operating Information

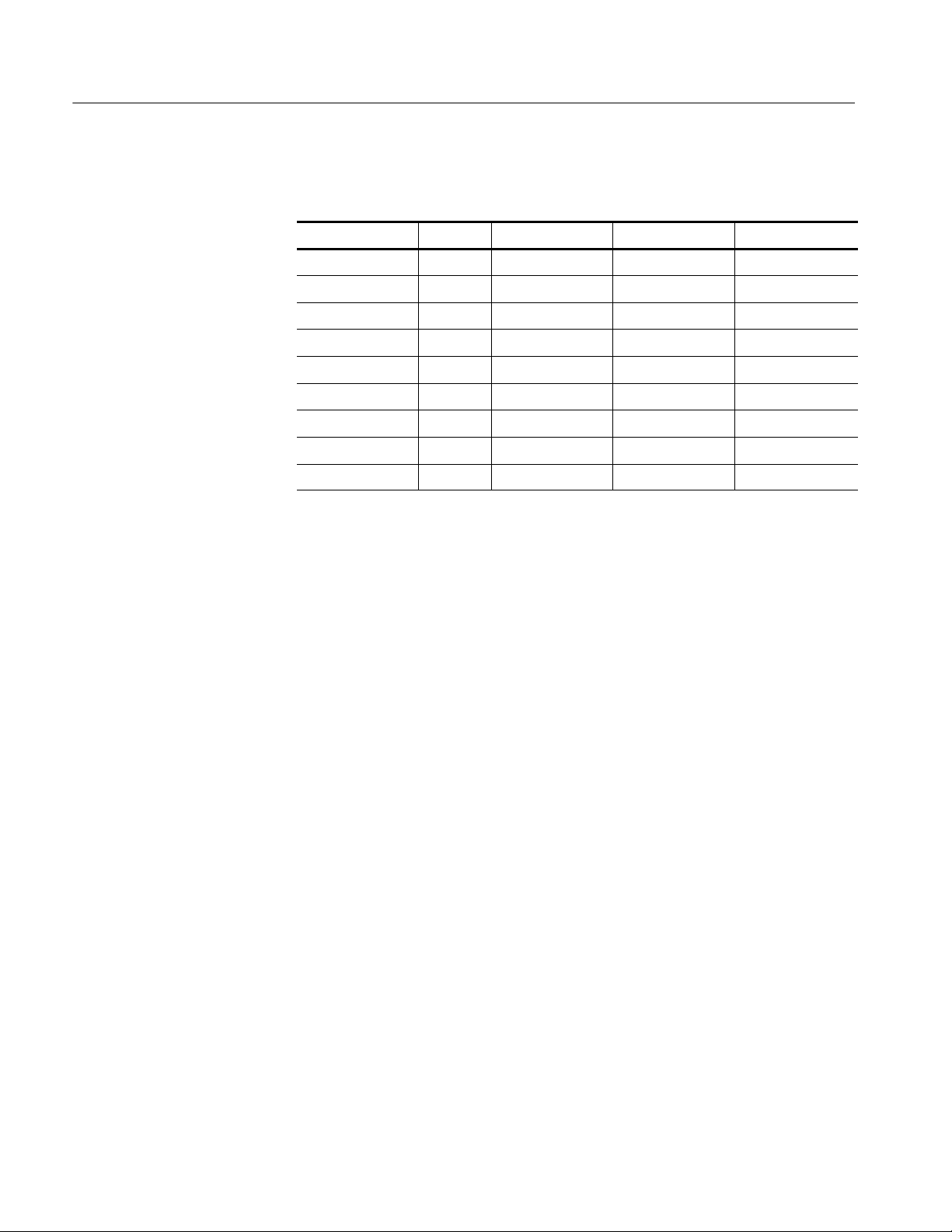

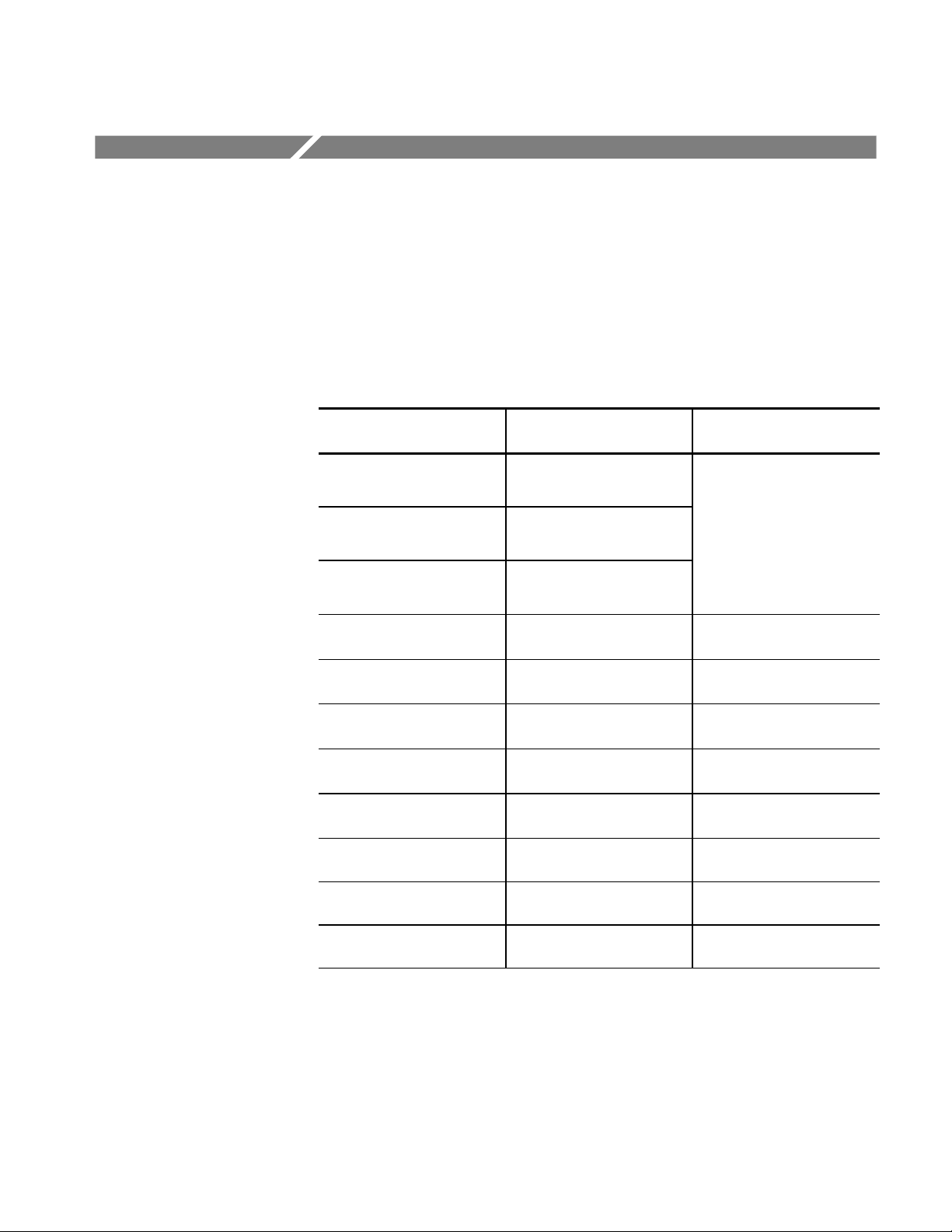

General Features

Model Channels Bandwidth Sample rate Display

TDS1001 2 40 MHz 1.0 GS/s Monochrome

TDS1002 2 60 MHz 1.0 GS/s Monochrome

TDS1012 2 100 MHz 1.0 GS/s Monochrome

TDS2002 2 60 MHz 1.0 GS/s Color

TDS2004 2 60 MHz 1.0 GS/s Color

TDS2012 2 100 MHz 1.0 GS/s Color

TDS2014 4 100 MHz 1.0 GS/s Color

TDS2022 2 200 MHz 2.0 GS/s Color

TDS2024 4 200 MHz 2.0 GS/s Color

H Context-sensitive Help system

H Color or monochrome LCD display

H Selectable 20 MHz bandwidth limit

H 2500-point record length for each channel

H Autoset Menu

H Probe Check Wizard

H Cursors with readouts

H Trigger frequency readout

H Eleven automatic measurements

H Waveform averaging and peak detection

H Dual time base

H Math Fast Fourier Transform (FFT)

H Pulse Width trigger capability

H Video trigger capability with line-selectable triggering

H External trigger

2--2

H Setup and waveform storage

H Variable persistence display

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 35

Operating Information

H RS-232, GPIB, and Centronics ports with the optional TDS2CMA Commu-

nications Extension Module

H User interface in ten user-selectable languages

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

2--3

Page 36

Operating Information

Installation

Power Cord

Use only power cords designed for your oscilloscope. Use a power source that

delivers 90 to 264 VAC

must deliver 90 to 132 VAC

, 45 to 66 Hz. If you have a 400 Hz power source, it

RMS

, 360 to 440 Hz.

RMS

Refertopage8--8intheReplaceable Parts chapter for a list of power cords

available from Tektronix. All power cords must be rated for > 3 Amps, 3 wire,

and have an 18 AWG (1.0 mm) Safety Ground lead, or larger.

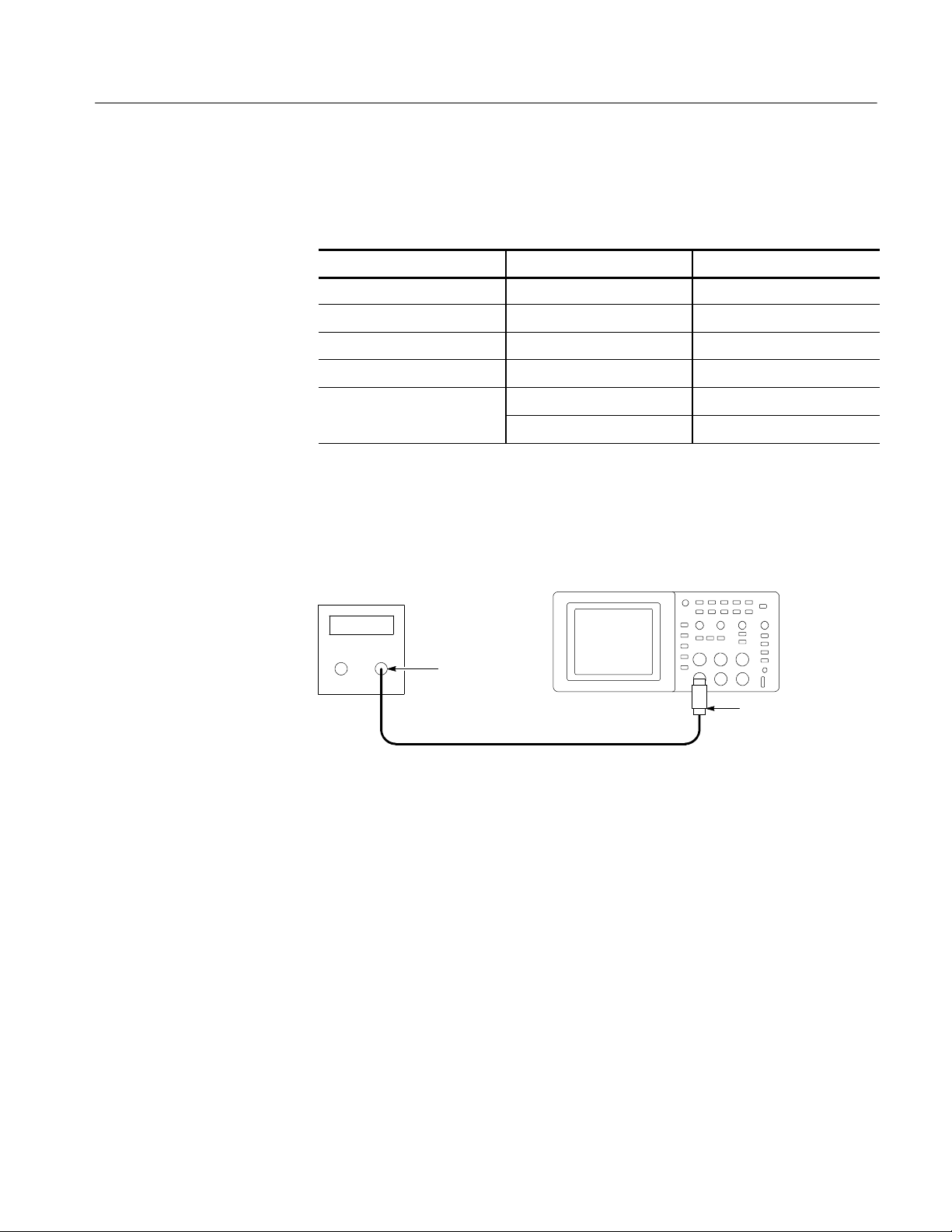

Securing cable

2--4

Security Loop

Power cable

Figure 2--1: Routing the power cord and security cable

Use the built-in cable channels to secure both your oscilloscope and extension

module to your location.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 37

Extension Modules

Operating Information

You can increase the feature set of your oscilloscope by inserting an extension

module. Refer to page 8--8 for more information. Figure 2--2 shows the proper

way to install and remove a module without bending the connecting pins.

For more information on extension modules, see your oscilloscope user manual.

CAUTION. Electrostatic discharge (ESD) can damage components in the

extension module and the oscilloscope. Do not operate your instrument with the

extension module connector exposed.

Module release tab

Remove

extension

module

Install

extension

module

Figure 2--2: Installing and removing an extension module

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

2--5

Page 38

Operating Information

Functional Check

Perform this quick functional check to verify that your oscilloscope is operating

correctly.

ON/OFF

button

PASSED

CH1

PROBE COMP

1. Turn on the oscilloscope.

Wait until the display shows that all power-on tests passed. Push the DEFAULT

SETUP button. The default Probe menu attenuation setting is 10X.

2. Set the switch to 10X on the P2200 probe and connect the oscilloscope probe to

channel 1. To do this, align the slot in the probe connector with the key on the

CH1 BNC, push to connect, and twist to the right to lock the probe in place.

Attach the probe tip and reference lead to the PROBE COMP connectors.

3. Push the AUTOSET button. Within a few seconds, you should see a square

wave in the display (approximately 5 V at 1 kHz peak-to-peak).

Move the probe to the CH2 BNC. Repeat step 3. For four-channel models,

repeat step 3 for CH3 and CH4. A similar test, described below, can be

performed on the EXT TRIG connector, although the amplitude scale factor is

undefined.

2--6

Connect the probe to the EXT TRIG BNC. Attach the probe tip and reference

lead to the PROBE COMP connectors. Push TRIG MENU and push the top

option button to select Edge triggering. Then, push the second option button to

select Ext as the source. Finally, push and hold the front-panel TRIG VIEW

button. Once again, you should see a square wave in the display.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 39

Self Calibration

SEC/DIV50

0

Default Setup

Operating Information

The self-calibration routine lets you quickly optimize the oscilloscope signal path

for maximum measurement accuracy. You can run the routine at any time but you

should always run the routine if the ambient temperature changes by 5 _Cor

more.

To compensate the signal path, disconnect any probes or cables from the channel

input connectors. Then, press the UTILITY button and select the Do Self Cal

option. Follow the on-screen instructions to proceed.

Table 2--1 lists the state of the oscilloscope after you press DEFAULT SETUP.

NOTE. When you push the DEFAULT SETUP button, the oscilloscope displays

the CH1 waveform and removes all other waveforms.

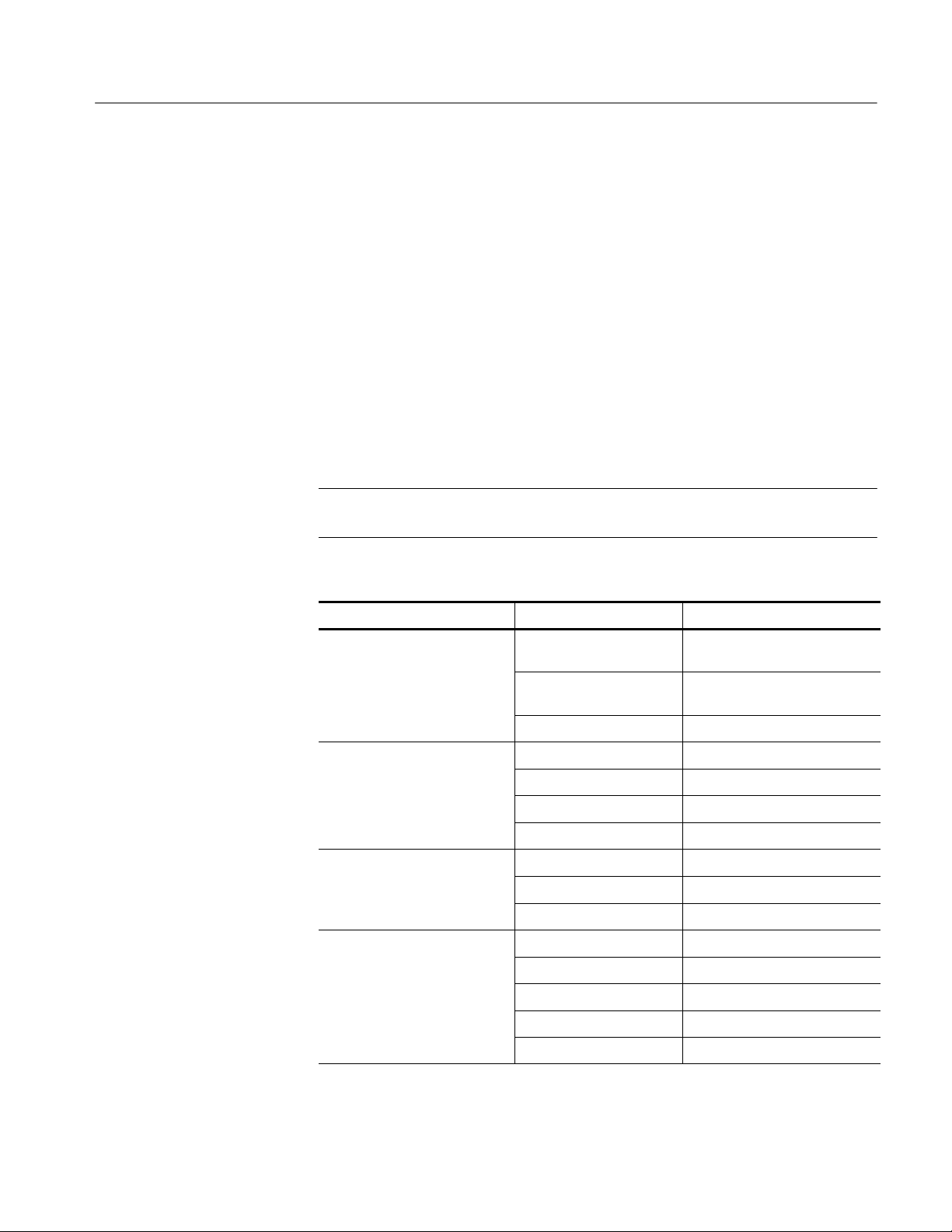

Table 2--1: Default settings

Menu or system Option, button or knob Default setting

ACQUIRE Sample, Peak Detect, and

Average

Averages: 4, 8, 16, 64, and

128

RUN/STOP RUN

CURSOR Type Off

Source CH1

Horizontal (voltage) +/-- 3.2 divs

Vertical (time) +/-- 4 divs

DISPLAY Type Vectors

Persist Off

Format YT

HORIZONTAL Window Main

Trig Knob Level

POSITION 0.00 s

Sample

16

s

Window Zone

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

50 s

2--7

Page 40

Operating Information

Sourc

e

CH1

Windo

w

Hanning

Table 2--1: Default settings (Cont.)

Menu or system Default settingOption, button or knob

MATH Operation CH1 -- CH2

FFT operation:

Window

FFT Zoom

MEASURE Source CH1

Type None

TRIGGER Mode Type Edge

Edge TRIGGER Type Edge

Source CH1

Slope Rising

Mode Auto

Coupling DC

LEVEL 0.00 V

Video TRIGGER Type Video

Source CH1

Polarity Normal

Sync All Lines

Standard NTSC

Pulse Width TRIGGER Type Pulse

Hanning

X1

2--8

Source CH1

When =

Set Pulse Width 1.00 ms

Polarity Positive

Mode Auto

Coupling DC

Vertical system,

all channels

Coupling DC

BW Limit

Volts/Div Coarse

Probe 10X

Invert Off

POSITION 0.00 divs (0.00 V)

VOLTS/DIV 1.00 V

Off

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 41

The DEFAULT SETUP button does not reset the following:

H Language option

H Saved setup files

H Saved reference waveform files

H Display contrast

H Calibration data

H Printer setup

H RS-232 setup

H GPIB setup

Operating Information

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

2--9

Page 42

Operating Information

2--10

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 43

Theory of Operation

Page 44

Page 45

Theory of Operation

This chapter describes the electrical operation of the TDS1000- and

TDS2000-series oscilloscopes to the module level. It describes the basic

operation of each functional circuit block shown in Figures 3--1 and 3--2. Of

necessity, the descriptions for the two and four channel units, and the color and

monochrome units, are slightly different.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

3--1

Page 46

Theory of Operation

AC Line

Power Supply

3

AC Line In

Backlight Power

(Color)

P3

Backlight Power

(Mono)

Through

chassis

Front Panel

12

Probe Comp

Probe Comp

CH1

CH2

Signal

J300

J350

P53

GND

GND

J202

P/O J203

P/O J203

A1 Main

GND

DC Out

&Line

Trigger

DC In

LCD

18 Pins

J101

J201

J690

P131

50

11

(Color)

16

J1

2

(Mono)

12

Extension

Module

TDS1000 (Mono)

TDS2000 (Color)

J90

1

J902

9

J2

24

J4

Display

Backlight

Display Control

RS-232

GPIB

J380

EXT

TRIG

Figure 3--1: Module-level block diagram (two channel)

3--2

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

25

J3

CENTRONICS

Page 47

AC Line

Theory of Operation

Power Supply

3

AC Line In

Through

chassis

Front Panel

J1

12

Probe Comp

Signal

Probe Comp

GND

GND

A1 Main

GND

J1

J104 P/O J203

J104 P/O J203

Backlight Power

(Mono)

Backlight Power

(Color)

DC Out

&Line

Trigger

J101

DC In

J201

LCD

18 Pins

Not used

P3

2

11

Color Display

J90

1

Backlight

J902

16

Display Control

CH1

CH2

CH3

CH4

EXT

TRIG

J300

J990

J350

J600

J650

J680

Figure 3--2: Module-level block diagram (four channel)

50

Extension

Module

J1

25

24

9

RS-232

GPIB

CENTRONICS

J2

J4

J3

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

3--3

Page 48

Theory of Operation

Main Board

The main board of a four-channel oscilloscope is essentially 2, two-channel

oscilloscopes tied together through a common microprocessor, and some special

interconnects to support combining the display and trigger systems. For this

reason, the focus of the main board discussion will be the two-channel system,

with differences noted as necessary.

At a minimum, the main board contains attenuators, an amplifier ASIC, a

digitizer/trigger system ASIC, a signal processing/display/system services ASIC,

RAM, flash PROM, a microprocessor, and special power supplies. For a

four-channel oscilloscope, the attenuators and ASICs are duplicated. Most of the

other aspects of the circuitry remain unchanged.

Acquisition System

Signals from the CH 1, CH 2 and other input connectors pass through attenuators

and an AC-coupling switch to the amplifier ASIC. The EXT TRIG input has an

abbreviated version of this path, lacking some of the attenuator settings and the

AC coupling switch.

The amplifier ASIC contains buffers and variable gain amplifiers, as well as

filters that provide 20 MHz bandwidth limiting. The task of the amplifier ASIC is

to convert from a 1 MΩ single-ended environment in the front end to a much

lower impedance differential (and thus less noise-sensitive) environment for the

acquisition process. The amplifier ASIC assures that the input signal is amplified

to approximately the correct level to allow the fullest possible use of the digitizer.

The acquisition ASIC contains samplers and peak detectors for each input

channel, a common amplifier, an A/D converter, and the trigger logic. The

digitized waveform samples are transferred to the processing and display ASIC.

In four-channel systems, the two acquisition ASICs are interconnected so that a

trigger on one ASIC can cause a trigger on the other.

The processor system adds the microprocessor and flash PROM to the processing

and display system. The processor system interprets the front-panel control

changes detected by the display ASIC, provides control parameters based upon

user setting requests, computes waveform measurements, and manages the

extension module interface. Saved setups, waveforms, and calibration constants

are stored in nonvolatile memory (NVRAM). The processor system shares

DRAM with the display system.

3--4

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 49

Theory of Operation

Processing and Display

System

Input Signal Interface

The processing and display system consists of the display ASIC, DRAM, and

system oscillator. Digitized acquisition samples are received by the display ASIC

and stored in DRAM. Once data are received by the display ASIC, various

corrections are applied, display rasterization is performed, and the waveform is

placed into a display buffer. At the same time, the waveform is being read from

the display buffers and written to the LCD. Additional circuitry in the display

ASIC supports scanning the front panel, handling DRAM refresh, providing the

processor clock, and performing various memory mapping tasks required by all

elementary microprocessor based systems. In a four-channel system, the two

display ASICs are interconnected so that one ASIC may provide display

information for the second.

The processing and display system handles some of the computational tasks.

Other tasks are performed by the processor system. Since all array processing is

performed in the processing and display system, no computations can be

performed that involve data from two different channel sets. Thus, subtracting

channel 3 data from channel 2 is prohibited. Channel 1 and Channel 2 data may

be combined in all of the supported ways.

BNC connectors are mounted on the main board for all signal inputs. The signal

inputs are compatible with the supplied P2200 probes.

Probe Compensation

External Trigger

Main Board Power

The PROBE COMP and ground terminals are provided for probe adjustment.

The EXT TRIG channel is processed on the chain containing the highest

numbered normal input channel.

To support various functions on the main board, a number of secondary power

supplies are generated. For the amplifier and acquisitions ASICs, the main board

creates a +2.5 V and --2.5 V supply. The +2.5 V supply is derived from the

+3.3 V logic supply. The --2.5 V supply is derived from the --4 V supply. A three

terminal regulator provides +5 V for option modules and the LCD display.

An additional power supply provides the LCD bias voltage which ranges from

+19 V to +28 V, depending on contrast setting and display type. This +28 V

supply has a temperature sensor on the front-panel board that varies the output

voltage of the supply to maintain contrast over a wide temperature range.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

3--5

Page 50

Theory of Operation

Power Supply

Display Module

The main power supply module for the TDS1000- and TDS2000-series

oscilloscopes is a wide input range universal supply. It is capable of providing

about 17 W of power for the oscilloscope while allowing the input to run from

about +90 V to +264 V. Input frequency ranges from 47 Hz to 440 Hz, which

allows operation in virtually all countries in the world and in a number of

off-grid environments such as military power on aircraft.

The secondary supplies from the power supply and the approximate current

draws are listed in the table on page 6--35 with the associated connector pins on

J101.

For information on voltages used in the oscilloscope, refer to the Troubleshooting

section of this manual.

Front Panel

Two-Channel

Oscilloscopes

The display module is a standard passive liquid crystal display (LCD). The

monochrome unit is patterned with 320 columns by 240 rows, and has the

associated drivers and backlight. The backlight is based on a 5 mA side light

fluorescent tube.

The color unit is patterned with 320 columns x 3 sub-columns by 240 rows and

has associated drivers and backlight. The backlight is based upon a 5 mA top

light fluorescent tube which runs a higher voltage and is longer to provide

sufficient extra light to overcome the higher loss associated with the color filters.

You can access all of the switches, position encoders, and LEDs on the front-panel board of two-channel oscilloscopes. Additionally, an IC on the front-panel

board provides buffering and multiplexing of switch signals to the main board.

Two signals and a sense line are provided by the main board to support the front

panel. One of these lines resets the scan; a second clocks the scan to the next

position; and the sense line receives the current state of the selected switch or

encoder position.

For the encoders, some amount of debouncing occurs inside the front-panel IC.

All key debouncing is handled in the display ASIC on the main board.

3--6

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 51

Theory of Operation

Four-Channel

Oscilloscopes

LEDs

Extension Modules

The front-panel board of the four channel units is effectively two panels in

parallel. The left side of the board is largely handled by the display ASIC for

channels 1 and 2. The right side of the board is handled by the channel 3 and 4

ASIC. Separate front-panel ICs support these data paths.

The LEDs are lighted to indicate an alternative use for the associated front-panel

knob. For more information, see the User Manual for this oscilloscope.

The LEDs are controlled by latching the value of the Channel 1--2 front panel

scan counter when the appropriate scan value is set.

Optional extension modules add the capability for the microprocessor to interface

with IEEE-488 (GPIB) controllers and RS-232 controllers, and provide a PC-like

parallel printer interface. These modules contain the necessary chips to provide

standard RS-232 and IEEE-488 states. The parallel port interface is controlled by

software without significant hardware assistance.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

3--7

Page 52

Theory of Operation

3--8

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 53

Performance Verification

Page 54

Page 55

Performance Verification

c

OscilloscopeCalibration

This chapter contains performance verification procedures for the specifications

marked with the n symbol. The following equipment, or a suitable equivalent,

is required to complete these procedures.

Required Equipment

Description

DC Voltage Source 17.5mVto7V,±0.5%

Leveled Sine Wave Generator 50 kHz and 200 MHz, ±3%

Time Mark Generator 10 ms period, ±10 ppm

Minimum

requirements

accuracy

amplitude accuracy

accuracy

Examples

Wavetek 9100 Universal

Calibration System with

Os

illoscopeCalibration

Module (Option 250)

Fluke 5500A Multi-product

Calibrator with Oscilloscope

Calibration Option (Option

5500A-SC)

50 Ω BNC Cable BNCmaletoBNCmale,

≈ 1 m (36 in) long

50 Ω BNC Cable BNCmaletoBNCmale,

≈ 25 cm (10 in) long

50 Ω Feedthrough

Termination

Dual Banana to BNC Adapter Banana plugs to BNC female Tektronix part number

BNC T Adapter BNC male to dual BNC

Splitter, Power Frequency range: DC to

Adapter (four required) Male N--to--female BNC Tektronix part number

Adapter Female N-- to--male BNC Tektronix part number

BNC male and female

connectors

female connectors

4 GHz. Tracking: >2.0%

Tektronix part number

012-0482-XX

Tektronix part number

012-0208-XX

Tektronix part number

011-0049-XX

103-0090-XX

Tektronix part number

103-0030-XX

Tektronix part number

015--0565--XX

103--0045--XX

103--0058--XX

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

4- 1

Page 56

Performance Verification

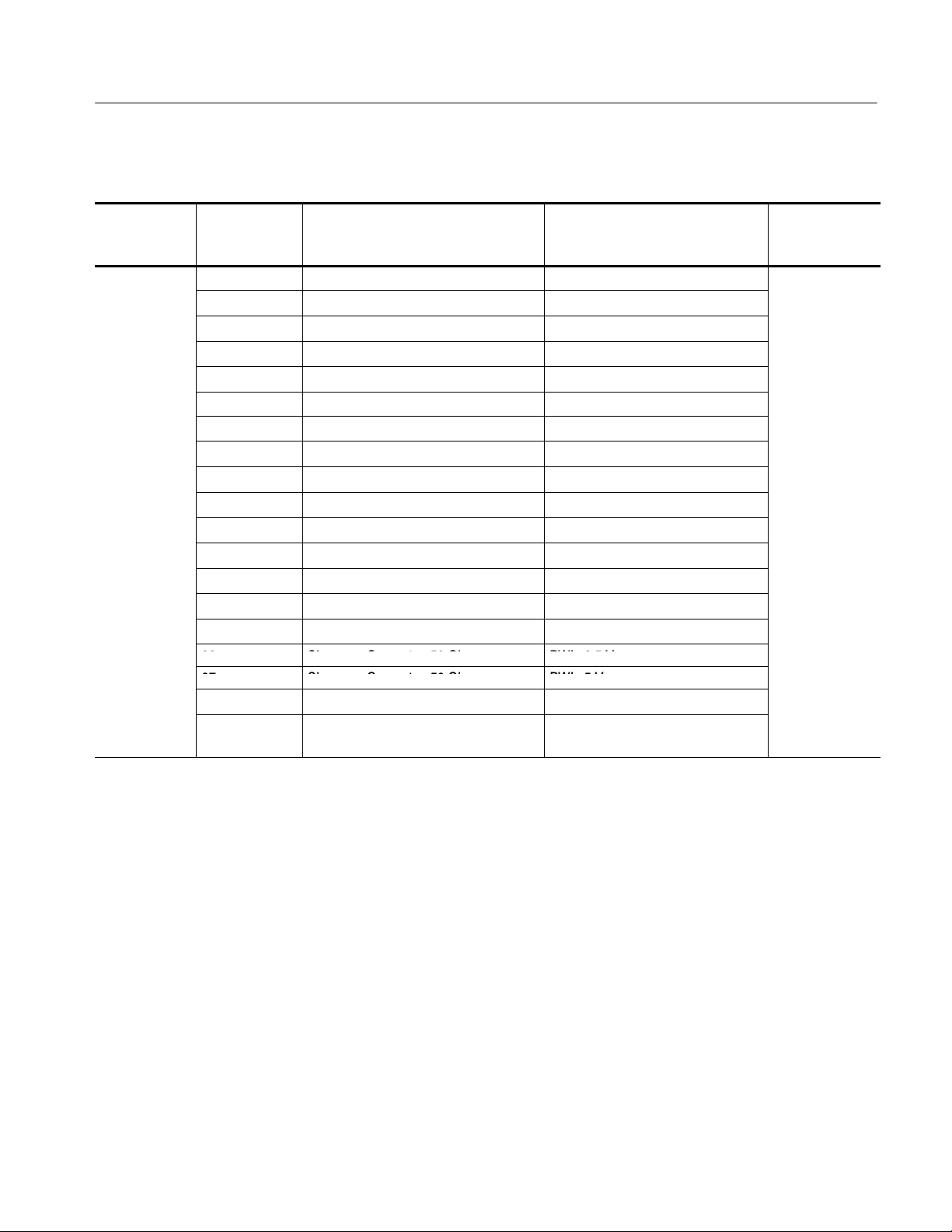

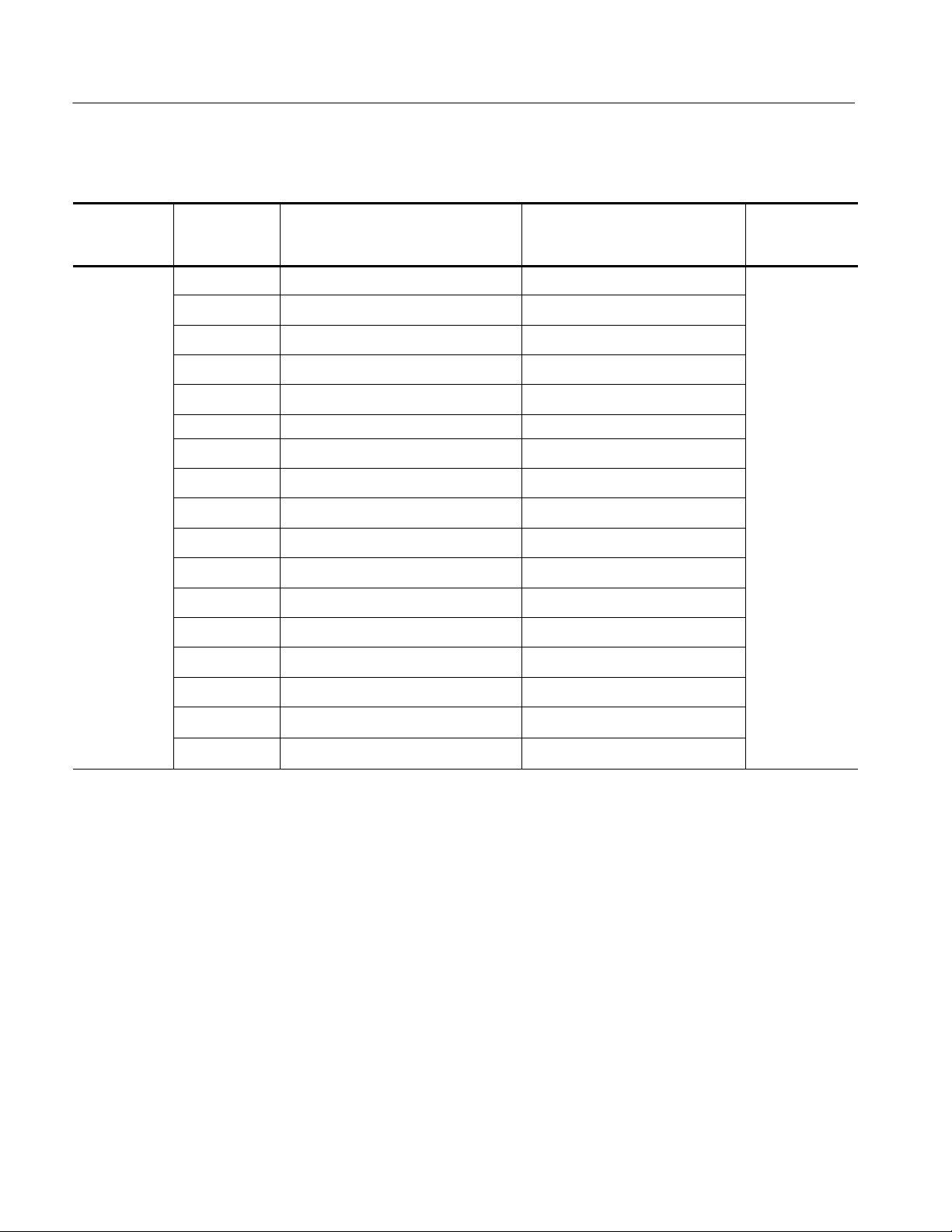

Test Record

Serial

number

Test Passed Failed

Self Test

Oscilloscope tests Low limit Test result High limit

Channel 1 DC Gain Accuracy 5mV/div 33.6 mV 36.4 mV

Procedure performed by Date

200 mV/div 1.358 V 1.442 V

2V/div 13.58 V 14.42 V

Channel 2 DC Gain Accuracy 5mV/div 33.6 mV 36.4 mV

200 mV/div 1.358 V 1.442 V

2V/div 13.58 V 14.42 V

Channel 3 DC Gain Accuracy15mV/div 33.6 mV 36.4 mV

200 mV/div 1.358 V 1.442 V

2V/div 13.58 V 14.42 V

Channel 4 DC Gain Accuracy15mV/div 33.6 mV 36.4 mV

200 mV/div 1.358 V 1.442 V

2V/div 13.58 V 14.42 V

Channel 1 Bandwidth 2.12 V —

Channel 2 Bandwidth 2.12 V —

Channel 3 Bandwidth

Channel 4 Bandwidth

1

1

2.12 V —

2.12 V —

Sample Rate and Delay Time Accuracy -- 2 d i v s +2 divs

Channel 1 Edge Trigger Sensitivity Stable trigger —

Channel 2 Edge Trigger Sensitivity Stable trigger —

Channel 3 Edge Trigger Sensitivity

Channel 4 Edge Trigger Sensitivity

1

1

Stable trigger —

Stable trigger —

External Edge Trigger Sensitivity Stable trigger —

1

Channels 3 and 4 are only on four channel oscilloscopes.

4- 2

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 57

Performance Verification Procedures

Before beginning these procedures, two conditions must first be met:

H The oscilloscope must have been operating continuously for twenty minutes

within the operating temperature range specified.

H You must perform the Self Calibration operation described below. If the

ambient temperature changes by more than 5 °C, you must perform the Self

Calibration operation again.

The time required to complete the entire procedure is approximately one hour.

WARNING. Some procedures use hazardous voltages. To prevent electrical shock,

always set voltage source outputs to 0 V before making or changing any

interconnections.

Performance Verification

Self Test

Self Calibration

Check DC Gain Accuracy

This internal procedure is automatically performed every time the oscilloscope is

powered on. No test equipment or hookups are required. Verify that no error

messages are displayed before continuing with this procedure.

The self calibration routine lets you quickly optimize the oscilloscope signal path

for maximum measurement accuracy. You can run the routine at any time, but

you should always run the routine if the ambient temperature changes by 5 _Cor

more.

1. Disconnect any probes or cables from the CH1 and CH2 input connectors.

2. Press the UTILITY button and select the Do Self Cal option to start the

routine. The routine takes approximately one minute to complete.

3. Verify that self calibration passed.

This test checks the DC gain accuracy of all input channels.

1. Set the DC voltage source output level to 0V.

2. Set up the oscilloscope using the following steps:

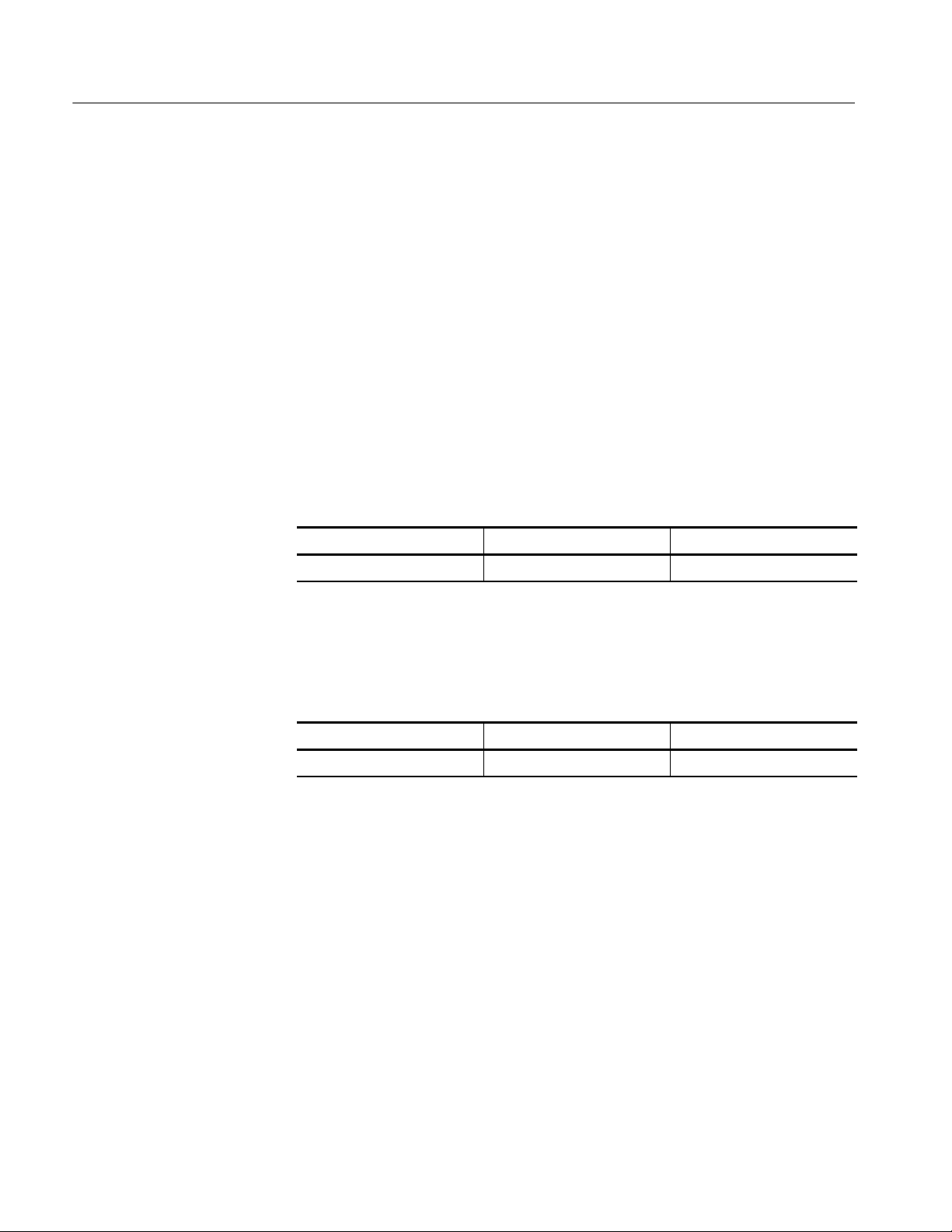

Press menu button Select menu option Select setting

1. DEFAULT SETUP — —

2. CH 1 Probe 1X

3. ACQUIRE Average 16

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

4- 3

Page 58

Performance Verification

Press menu button Select settingSelect menu option

4. MEASURE

Source An unchecked channel

Type Mean

3. As shown below, connect the oscilloscope channel selected in the table to the

DC voltage source.

DC voltage

source

+--

Dual banana

to BNC

adapter

BNC cable

Digitizing oscilloscope

4. For each VOLTS/DIV setting listed below, perform the following steps:

a. Set the DC voltage source output level to the positive voltage listed and

then record the mean measurement as V

pos

.

b. Reverse the polarity of the DC voltage source and then record the mean

measurement as V

c. Calculate V

diff

=V

neg

pos

.

-- V

and then compare V

neg

to the accuracy

diff

limits in the table.

VOLTS/DIV setting DC voltage source output levels Accuracy limits for V

5mV/div +17.5 mV, --17.5 mV 33.6 mV to 36.4 mV

diff

4- 4

200 mV/div +700 mV, --700 mV 1.358 V to 1.442 V

2V/div +7.00 V, --7.00 V 13.58 V to 14.42 V

5. Set DC voltage source output level to 0V.

6. Disconnect the test setup.

7. Repeat steps 1 through 6 until all input channels have been checked.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 59

Performance Verification

Check Bandwidth

This test checks the bandwidth of all input channels.

1. Set up the oscilloscope using the following steps:

Press menu button Select menu option Select setting

DEFAULT SETUP — —

CH 1 Probe 1X

ACQUIRE Average 16

TRIGGER Coupling Noise

MEASURE

Source An unchecked channel

Type Pk-Pk

2. As shown below, connect the oscilloscope channel selected in the table to the

leveled sine wave generator.

Leveled

sine wave

generator

Digitizing oscilloscope

Output

50 Ω feedthrough

BNC cable

terminator

3. Set the oscilloscope VOLTS/DIV to 500 mV/div.

4. Set the oscilloscope SEC/DIV to 10 s/div.

5. Set the leveled sine wave generator frequency to 50 k Hz.

6. Set the leveled sine wave generator output level so the peak-to-peak

measurement is between 2.98 V and 3.02 V.

7. Set the leveled sine wave generator frequency to:

H 40 MHz if you are checking a TDS1001

H 60 MHz if you are checking a TDS1002/2002/2004

H 100 MHz if you are checking a TDS1012/2012/2014

H 200 MHz if you are checking a TDS2022/2024.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

4- 5

Page 60

Performance Verification

8. Set the oscilloscope SEC/DIV to 10 ns/div.

9. Check that the peak-to-peak measurement is ≥2.12 V.

10. Disconnect the test setup.

11. Repeat steps 1 through 10 until all input channels have been checked.

Check Sample Rate and

Delay Time Accuracy

This test checks the time base accuracy.

1. Set up the oscilloscope using the following steps:

Press menu button Select menu option Select setting

DEFAULT SETUP — —

CH 1 Probe 1X

2. Connect the oscilloscope to the time mark generator as shown below.

Time mark

generator

Output

BNC cable

Digitizing oscilloscope

50 Ω feedthrough

terminator

4- 6

3. Set the time mark generator period to 10 ms.

4. Set the oscilloscope VOLTS/DIV to 500 mV/div.

5. Set the oscilloscope Main SEC/DIV to 1ms/div.

6. Press SET LEVEL TO 50%.

7. Use the vertical POSITION control to center the test signal on screen.

8. Use the horizontal POSITION control to set the position to 10.00 ms.

9. Set the oscilloscope SEC/DIV to 250 ns/div.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 61

Performance Verification

10. Check that the rising edge of the marker crosses the center horizontal

graticule line within ±2 divisions of center graticule.

NOTE. One division of displacement from graticule center corresponds to

a 25 ppm time base error.

11. Disconnect the test setup.

Check Edge Trigger

Sensitivity

This test checks the edge trigger sensitivity for all input channels.

1. Set up the oscilloscope using the following steps:

Press menu button Select menu option Select setting

DEFAULT SETUP — —

CH 1 Probe 1X

TRIGGER Mode Normal

ACQUIRE Sample —

MEASURE

Source An unchecked channel

Type Pk-Pk

2. As shown below, connect the oscilloscope channel selected in the table to the

leveled sine wave generator.

Leveled

sine wave

generator

Digitizing oscilloscope

Output

BNC cable

3. Set the oscilloscope VOLTS/DIV to 500 mV/div.

4. Set the oscilloscope SEC/DIV to 25 ns/div.

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

50 Ω feedthrough

terminator

4- 7

Page 62

Performance Verification

5. Set the leveled sine wave generator frequency to 10 MHz.

6. Set the leveled sine wave generator output level to approximately 500 mV

p-p

so that the measured amplitude is approximately 500 mV. (The measured

amplitude can fluctuate around 500 mV.)

7. Press SET LEVEL TO 50%. Adjust TRIGGER LEVEL as necessary and

then check that triggering is stable.

8. Set the leveled sine wave generator frequency to

H 40 MHz if you are checking a TDS1001

H 60 MHz if you are checking a TDS1002/2002/TDS2004

H 100 MHz if you are checking a TDS1012/2012/2014

H 200 MHz if you are checking TDS2022/2024.

9. Set the oscilloscope SEC/DIV to 10 ns/div.

10. Set the leveled sine wave generator output level to approximately 750 mV

p-p

so that the measured amplitude is approximately 750 mV. (The measured

amplitude can fluctuate around 750 mV.)

11. Press SET LEVEL TO 50%. Adjust TRIGGER LEVEL as necessary and

then check that triggering is stable.

12. Change the oscilloscope setup using the following step:

Press menu button Select menu option Select setting

TRIGGER Slope Falling

13. Press SET LEVEL TO 50%. Adjust TRIGGER LEVEL as necessary and

then check that triggering is stable.

14. Change the oscilloscope setup using the following step:

Press menu button Select menu option Select setting

TRIGGER Slope Rising

15. Disconnect the test setup.

16. Repeat steps 1 through 15 until all input channels have been checked.

4- 8

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 63

Performance Verification

Check External Edge

Trigger Sensitivity

This test checks the edge trigger sensitivity for the external trigger.

1. Set up the oscilloscope using the following steps:

Press menu button Select menu option Select setting

DEFAULT SETUP — —

CH 1 Probe 1X

TRIGGER

Source Ext

Mode Normal

ACQUIRE Sample —

MEASURE

Source CH1

Type Pk-Pk

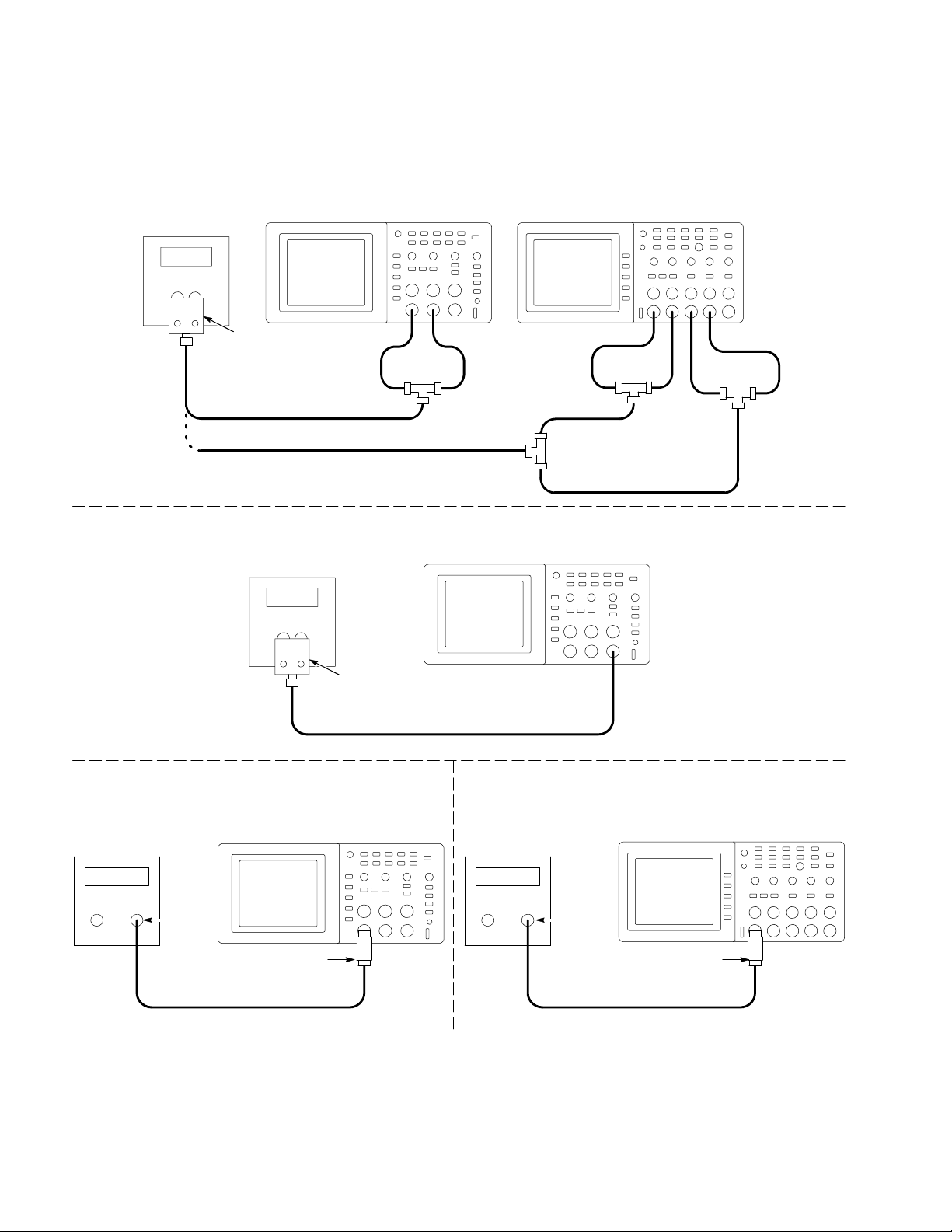

2. Connect the oscilloscope to the leveled sine wave generator as shown below.

Leveled

sine wave

generator

Digitizing oscilloscope

Output

Power divider

Male SMA to

female BNC

SMA female-to--female

3Pieces

3. Set the leveled sine wave generator frequency to

H 40 MHz if you are checking a TDS1001

H 60 MHz if you are checking a TDS1002/2002/TDS2004

H 100 MHz if you are checking a TDS1012/2012/2014

H 200 MHz if you are checking TDS2022/2024.

4. Set the oscilloscope VOLTS/DIV to 100 mV/div.

5. Set the oscilloscope SEC/DIV to 10 ns/div.

50 Ω

feedthrough

terminator

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

4- 9

Page 64

Performance Verification

6. Set the sine wave generator output level so that CH1 indicates approximately

200 mV

so that the measured amplitude is approximately 200 mV.(The

p-p

measured amplitude can fluctuate around 200 mV.) The output level of the

sine wave generator will be approximately 400 mV.

7. Press SET LEVEL TO 50%. Adjust TRIGGER LEVEL as necessary and

then check that triggering is stable.

8. For TDS2022 and TDS2024 models, set the sine wave generator frequency

to 200 MHz.

9. For TDS2022 and TDS2024 models, set the sine wave generator output level

for CH1 to approximately 350 mV

p-p

.

10. Press SET LEVEL TO 50%. Adjust TRIGGER LEVEL as necessary and

then check that triggering is stable.

11. Change the oscilloscope setup using the following step:

Press menu button Select menu option Select setting

TRIGGER Slope Falling

12. Press SET LEVEL TO 50%. Adjust TRIGGER LEVEL as necessary and

then check that triggering is stable.

13. Change the oscilloscope setup using the following step:

Press menu button Select menu option Select setting

TRIGGER Slope Rising

14. Disconnect the test setup.

4- 10

TDS1000 and TDS2000 Series Digital Storage Oscilloscopes Service Manual

Page 65

Adjustment Procedures

Page 66

Page 67

Adjustment Procedures

This chapter contains adjustment procedures for the TDS1000- and

TDS2000-series oscilloscopes.

Only qualified personnel should perform service procedures. Read the Service

Safety Summary and the General Safety Summary at the beginning of this manual

before performing any service procedures. Also refer to the chapter Operating

Information for information about using the TDS1000 and TDS2000 oscilloscopes.

NOTE. The voltage references inside the TDS1000 and TDS2000 oscilloscopes

are very stable over time and should not require routine updates. Before

performing any procedure in this chapter, first verify that the oscilloscope does