Page 1

- Wiring Brochure

W 161

tekmarNet®4 Setpoint Control 161

Overview

1

Information

Brochure

Choose controls

to match

application

2

Application

Brochure

Design your

mechanical

applications

3

Rough In

Wiring

Rough-in

wiring

instructions

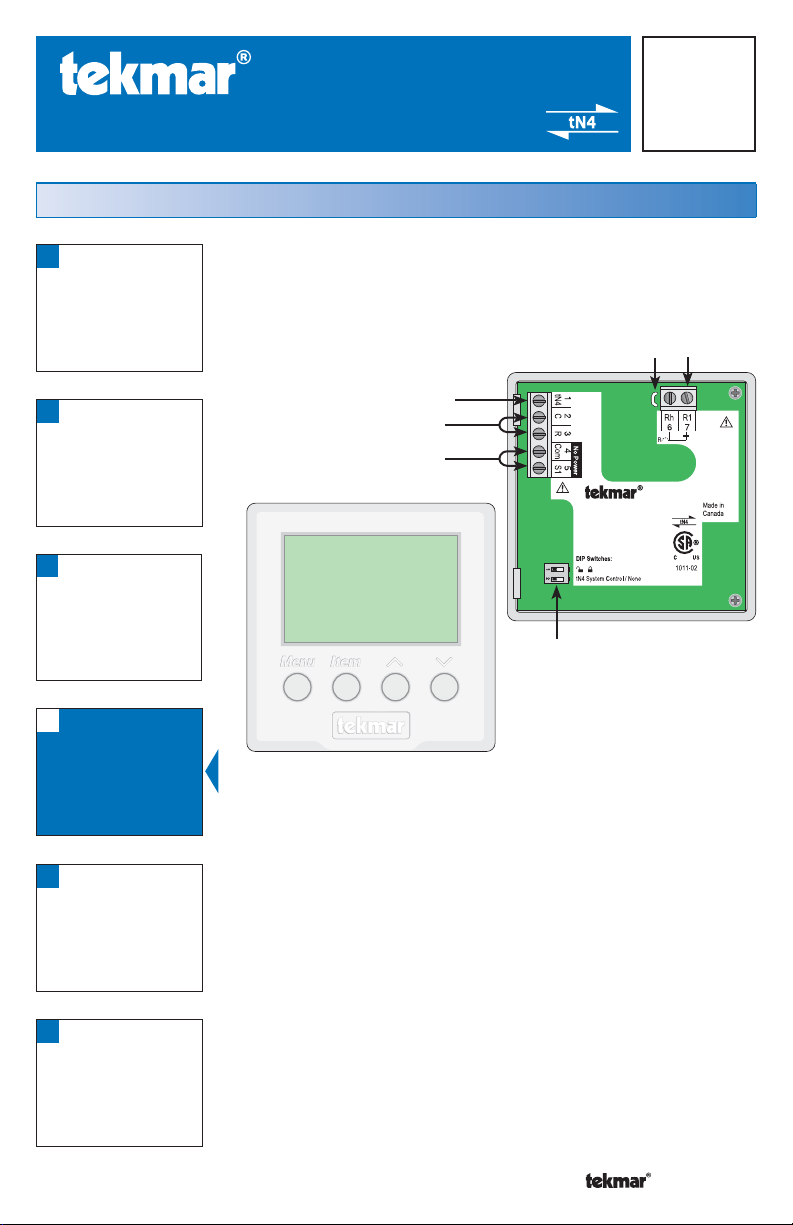

The following brochure describes how to wire the

tekmarNet®4 (tN4) Setpoint Control 161. The 161 has a

single output for heat. The 161 has one sensor input.

tN4 Network

24 V (ac) Power

Sensor Input

Power:

Relays:

DIP

Switches

Jumper

For product instructions see brochure

Use at least 194°F (90°C) conductors

tN4 Setpoint Control 161

One Stage Heat

24 V ±10% 50/60 Hz 1.7 VA

24 V (ac) 2 A

/

12/08

Relay

Contact

Cut jumper to

isolate relay

Feb 2006

Lot 1948

Meets Class B:

Canadian ICES

FCC Part 15

161

4

Wiring

Brochure

Wiring and

installation of

Table of Contents

specific control

Definitions ....................................................................... 2

5

Data

Brochure

Control settings

and sequence of

operation

Rough-In Wiring .............................................................2

Remove the Wiring Cover ...............................................3

Mounting the Setpoint Control ........................................3

Wiring Symbols ...............................................................4

Electrical Drawings .........................................................4

6

Job

Record

Record settings &

wiring details for

future reference

1 of 12 © 2008 W 161 - 12/08

Wiring the Setpoint Control .............................................7

Troubleshooting the Wiring .............................................9

Testing the Wiring .........................................................10

Technical Data ..............................................................12

Page 2

Defi nitions

•

•

•

•

•

•

•

The following defined terms and symbols are used throughout this manual to bring

attention to the presence of hazards of various risk levels, or to important information

concerning the life of the product.

– Caution: Refer to accompanying documents.

– Caution: Refer to accompanying documents.

INSTALLATION

CATEGORY II

– Local level appliances.

Caution

Improper installation and operation of this control could result in damage to the

equipment and possibly even personal injury or death. It is your responsibility to ensure

that this control is safely installed according to all applicable codes and standards.

This electronic control is not intended for use as a primary limit control. Other controls

that are intended and certified as safety limits must be placed into the control circuit.

Do not attempt to service the control. Refer to qualified personnel for servicing. There

are no user serviceable parts. Attempting to do so voids warranty and could result in

damage to the equipment and possibly even personal injury or death.

Rough-In Wiring

Choose the placement of the setpoint control early in the construction process to

enable proper wiring during rough-in.

Consider the following:

Interior Wall.

Keep dry. Avoid potential leakage onto the control. RH 80% to 88°F (31°C),

down to 50% from 104 to 122°F (40 to 50°C). Non-condensing environment.

No exposure to extreme temperatures beyond 32 - 122°F (0 - 50°C).

No draft, direct sun, or other cause for inaccurate temperature readings.

Away from equipment, appliances, or other sources of electrical interference.

Easy access for wiring, viewing, and adjusting the display screen.

Approximately 5 ft. (1.5 m) off the finished floor.

Use standard 18 AWG wire for the control power, relays, tN4 and sensor

connections.

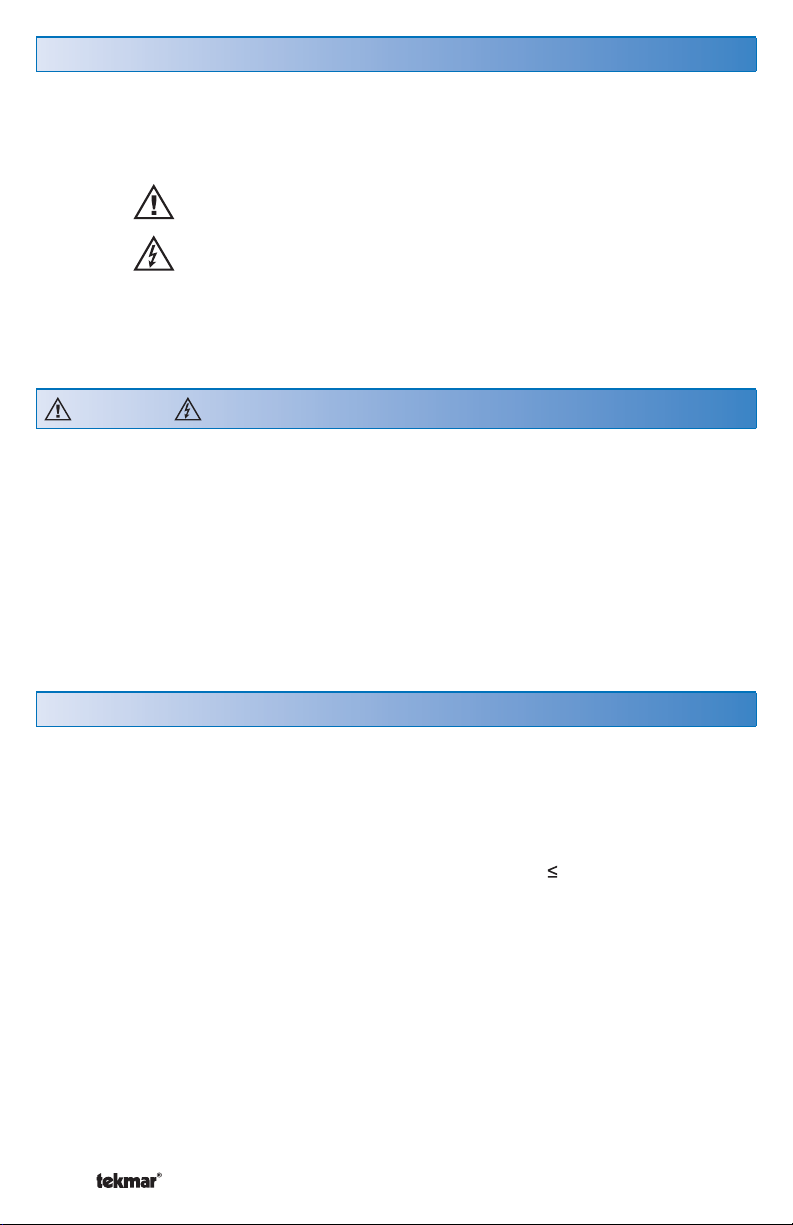

Refer to the diagram below to determine the number of conductors to run from each

piece of equipment to the control location.

© 2008 W 161 - 12/08 2 of 12

Page 3

•

•

•

•

•

2 Cond. / 18 AWG

2 Cond. / 18 AWG

Sensor

Pump

or

Valve

Note: When multiple wires

run to the same equipment

location, wiring conductors

can share one wire jacket.

3 Cond. / 18 AWG

R

C

tN4

Zone Manager

Remove the Wiring Cover

To remove the wiring cover:

Place a small slot screwdriver or similar tool into the slot located on the top of the

control.

While pushing against the plastic tab, pull the top of the front cover so that it pivots

around the bottom edge of the control’s base.

1

2

Remove cover

Push tab

Item

u

en

M

Mounting the Setpoint Control

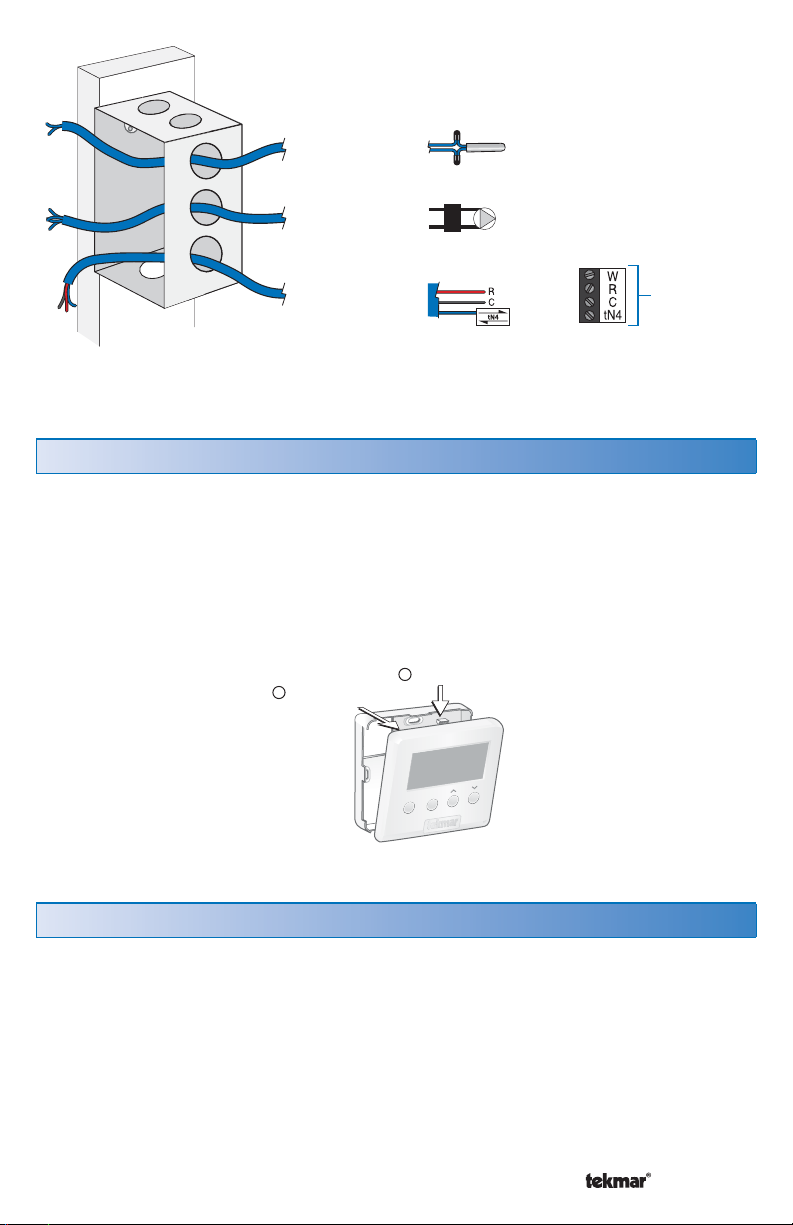

If a single gang switch box is used, an Adaptor Plate 007 is required to mount the

control to the box.

Fasten the base of the control to the adaptor plate.

Feed the wiring through the openings in the back of the adaptor plate and control.

Use the upper and lower screw holes to fasten the adaptor plate to the box.

3 of 12 © 2008 W 161 - 12/08

Page 4

23/8”

(60 mm)

screwhole

If a switch box was not used, mount the control directly to the wall.

•

•

Feed the wiring through the openings in the back of the control.

Use screws in the screw holes to fasten the control to the wall. At least one of the

screws should enter a wall stud or similar rigid material.

Mounted on switch box Mounted on wallboard

007 Adaptor

Plate

Control

Control

Base

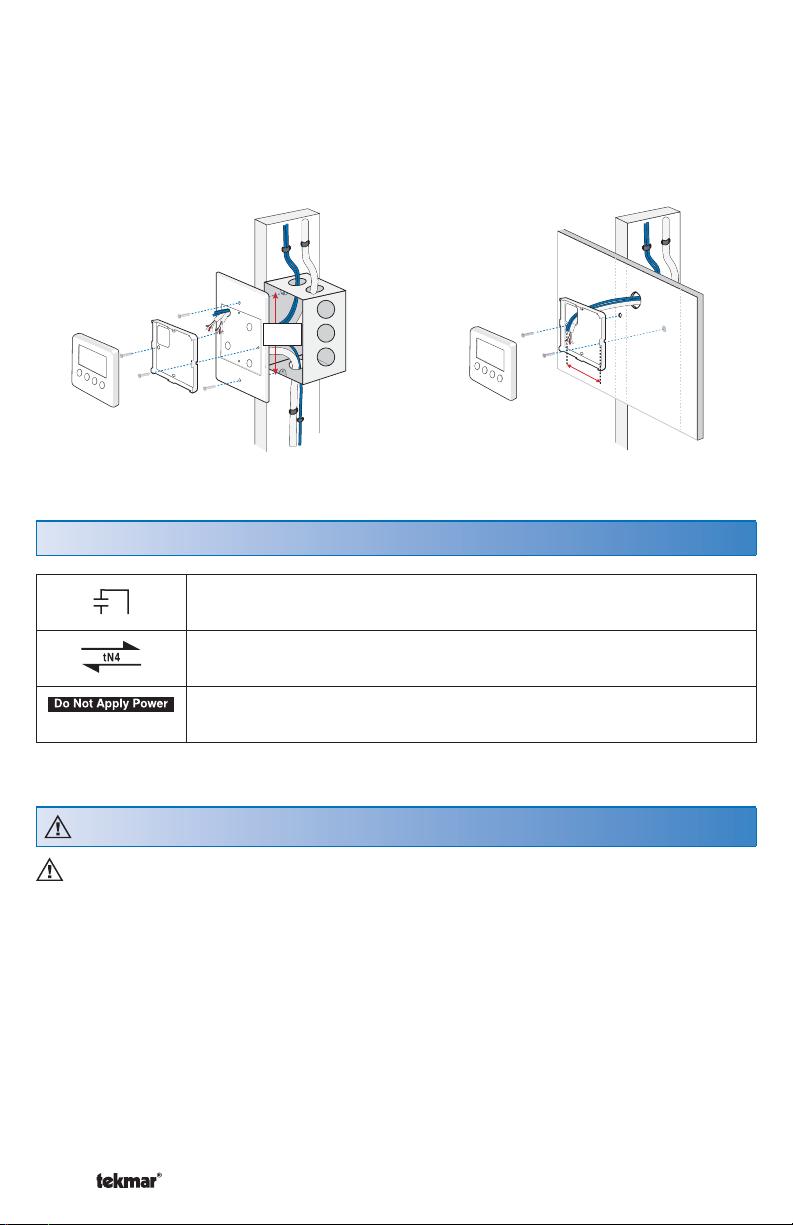

Wiring Symbols

Dry contact switch. Operates a device.

tekmarNet®4

Do not apply power to these terminals. Serious control damage

will result.

1

3

/4”

(83 mm)

Stud

Switch

Box

Control

Control

Base

23/8”

(60 mm)

screwhole

Stud

Wall

Electrical Drawings

The electrical drawing examples on the following pages show the 161 in common

applications. Choose the drawing that most accurately depicts the components in

your system and use that drawing as a guide to aid in wiring your system.

These are only concept drawings, not engineered drawings. They are not intended

to describe a complete system nor any particular system. It is up to the system

designer to determine the necessary components for and configuration of the

particular system being designed including additional equipment isolation relays

(for loads greater than the controls specified output ratings) and any safety devices

which in the judgement of the designer are appropriate in order to properly size,

configure and design that system and to ensure compliance with building and safety

code requirements.

© 2008 W 161 - 12/08 4 of 12

Page 5

Electrical Application 161 E1

Description:

Setpoint Control used with tN4 System Zone Manager.

161

Meets Class B:

Canadian ICES

Feb 2006

Lot 1948

FCC Part 15

24 V ±10% 50/60 Hz 1.7 VA

24 V (ac) 2 A

Power:

Relays:

/

tN4 Setpoint Control 161

One Stage Heat

161

Cut jumper to

isolate relay

For product instructions see brochure

Use at least 194°F (90°C) conductors

Sensor

Heat Zone

tN4 C R W

Zone Manager

Zone Pump

or

Valve

5 of 12 © 2008 W 161 - 12/08

Page 6

Electrical Application 161 E2

Description:

Setpoint Control used as a stand alone device. Relay 1 is used to cycle a pump to

provide heat.

Legend:

P1 = Pump cycled for heating

161

Meets Class B:

Canadian ICES

Feb 2006

Lot 1948

FCC Part 15

24 V ±10% 50/60 Hz 1.7 VA

24 V (ac) 2 A

Power:

Relays:

/

tN4 Setpoint Control 161

One Stage Heat

161

Relay 003

3

4

5

6

Cut jumper to

isolate relay

2

1

8

7

For product instructions see brochure

Use at least 194°F (90°C) conductors

P1

N

L

External Class 2

Transformer

24 V (ac)

© 2008 W 161 - 12/08 6 of 12

RC

Sensor

Page 7

Wiring the Setpoint Control

•

•

•

•

•

•

•

Power 24 V (ac) Terminals 2, 3

Wire 24 V (ac) to terminals C and R.

If a Zone Manager is used:

Connect C on the setpoint control to C on the proper zone of the Zone Manager.

Connect R on the setpoint control to R on the proper zone of the Zone Manager.

If a 24 V (ac) transformer is used:

Connect C on the setpoint control to C on the transformer.

Connect R on the setpoint control to R on the transformer.

tN4 C R Com S1

12345

Setpoint Control

tN4 C R W

Zone Manager

tN4 Communication Terminals 1, 2

Wire the tN4 communication to terminals tN4 and C.

If a Zone Manager is used:

Connect tN4 on the setpoint control to the tN4 on the proper zone of the Zone

Manager. The C terminal is already connected.

If a Zone Manager is not used:

Connect tN4 on the setpoint control to the tN4 terminal on another tN4 device on

the same tN4 bus.

Connect C on the setpoint control to the C terminal on another tN4 device on the

same tN4 bus.

tN4 C R Com S1

12345

Setpoint Control

tN4 C R W

Zone Manager

7 of 12 © 2008 W 161 - 12/08

Page 8

Relay 1 Terminals 6, 7

•

•

•

•

•

Relay 1 is used to switch the heat.

If a Zone Manager is used:

Connect Relay 1 to W on the proper zone on the Zone Manager.

If a Zone Manager is not used:

Determine if the jumper must be cut.

When the jumper is not cut, Relay 1 is internally powered through terminal 3.

When the jumper is cut, Rh and Relay 1 is an isolated switch.

RRhR1

367

Setpoint Control

tN4 C R W

Zone Manager

Sensor Input Terminals 4, 5

The sensor is connected to the setpoint control on terminals Com and S1.

• Connect sensor to terminals S1 and Com.

Do not apply power

sensors and / or setpoint control will result!

tN4 C R Com S1

12345

Setpoint Control

to terminals S1 and Com, permanent damage to the

Universal

Sensor

Do Not Apply Power

© 2008 W 161 - 12/08 8 of 12

Page 9

Troubleshooting the Wiring

General

The following tests are to be performed using standard testing practices and procedures

and should only be carried out by properly trained and experienced persons.

A good quality electrical test meter, capable of reading from at least 0 - 300 V (ac),

0 - 2,000,000 Ohms, and testing for continuity is essential to properly test the wiring

and sensors.

7

###

R1

6

Rh

tN4 C R Com S1

12345

9 of 12 © 2008 W 161 - 12/08

Page 10

Testing the Wiring

•

•

Testing 24 V (ac) Power Supply

1. Remove the front cover from the setpoint control.

2. Use an electrical test meter to measure (ac) voltage between the R and C

terminals. The reading should be 24 V (ac) +/– 10%.

3. Install the front cover.

Testing the Relay

1. Remove the front cover from the setpoint control.

2. Disconnect the wires from the relay.

3. Use an electrical test meter and check for continuity across the relay.

• When the relay symbol is displayed in the LCD, there should be continuity.

• When the relay symbol is not displayed in the LCD, there should be no continuity.

4. Reconnect the wires to the relay.

5. Install the front cover on the setpoint control.

161 LCD Display

Relay 1

© 2008 W 161 - 12/08 10 of 12

Page 11

Testing the Sensor

To test the sensor, the actual temperature at the sensor location must be

measured.

Use a good quality digital thermometer with a surface temperature probe for

ease of use and accuracy. Where a digital thermometer is not available, place

a spare sensor alongside the one to be tested and compare the readings.

1. Remove the front cover from the setpoint control.

2. Disconnect the wires from the sensor.

3. Test the sensor’s resistance according to the instructions in the sensor Data

Brochure D 070, D 074 or D 079.

4. Reconnect the wires.

5. Install the front cover on the setpoint control.

Testing the tN4 Network

To test the tN4 Network, check the wires for continuity.

1. Remove the front cover from the setpoint control.

2. Disconnect the two wires (tN4 and C) at one end and connect them together.

3. Go to the other end of the wires and disconnect them.

4. Using an electrical test meter, check for continuity.

5. Reconnect the wires.

6. Install the front cover on the setpoint control.

11 of 12 © 2008 W 161 - 12/08

Page 12

Technical Data

tekmarNet®4 Setpoint Control 161 One Stage Heat

Control Microprocessor PID control;

This is not a safety (limit) control

Packaged Weight 0.46 lb. (210 g)

Enclosure White PVC plastic

Dimensions 2-7/8” H x 2-7/8” W x 13/16” D (73 x 73 x 21 mm)

Approvals

Ambient Conditions Indoor use only, 32 to 122°F (0 to 50°C)

Power Supply 24 V (ac) ± 10% 50/60 Hz, 1.7 VA, NEC / CEC Class 2

Relays 24 V (ac) 2 A

Sensors NTC thermistor, 10 k @ 77°F (25°C ± 0.2°C) ß = 3892

– Included Universal Sensor 071

– Optional tekmar type #070, 071, 072, 073, 076, 077, 078, 079, 082,

CSA C US, CSA/UL 61010-1, meets Class B: ICES and

FCC Part 15

92% RH up to 104°F (40°C), 50% RH if > 104°F (40°C)

Altitude <9840 feet (3000 m), Installation Category II,

Pollution Degree 2

083, 084

The installer must ensure that this control and its wiring are isolated and / or shielded

from strong sources of electromagnetic noise. Conversely, this Class B digital

apparatus complies with Part 15 of the FCC Rules and meets all requirements of the

Canadian Interference-Causing Equipment Regulations. However, if this control does

cause harmful interference to radio or television reception, which is determined by

turning the control off and on, the user is encouraged to try to correct the interference

by re-orientating or relocating the receiving antenna, relocating the receiver with

respect to this control, and / or connecting the control to a different circuit from that

to which the receiver is connected.

Cet appareil numérique de la classe B respecte toutes les exigences du Règlement

sur le matériel brouilleur du Canada.

tekmar Contro l System s Ltd., Cana da

tekmar Contro l System s, Inc., U.S. A.

Head O ffic e: 5100 Silver Sta r Road

Vernon, B.C. Can ada V1B 3K4

(250) 54 5-7749 Fax. (2 50) 545-0650

Web Site: w ww.te kmar contr ols.com

All specifications are subject

to change without notice

12 of 12 W 161 - 12/08.

Product design, soft ware and literature

are Copyright © 2008 by:

tekmar Control Systems Ltd. and tekmar

Control Systems, Inc.

Loading...

Loading...