Page 1

INSTRUCTION MANUAL

Automatic Drum Washing Machine

LSE-1200 S

0020505090C

Page 2

Content

Specification

Pre-usage

Part Names ………………………………1

Precaution……………….2-4

Installation………………5-6

Control Panel ……..7-8

Display Screen …………….….9

Using Process

Program Setting…..10-11

Preparation…………………………….….12

Washing Methods……………………...13-14

Flexible Applications ………15

Laundry Operation Illustrations……….….16

Other Functions ……………..17

Repair and Maintenance

Maintenance………………..18-19

ITEM

Power Source

Maximal Working Current Ampere (A)

Tap Water Pressure Megapascal(Mpa)

Waterproof Degree

Washing Power Watts (W)

Spining Power Watts (W)

Rating Laundry Quantity Kilogram (kg)

Velocity Revolutions /minute(r/min)

Washing Procedure

Drying Power Watts (W)

Water Heating Power Watts (W)

External Dimension(H*D*W Millimeter(mm))

Weight Kilogram (kg)

MODEL

LSE-1200 S

220-240V~/50H

10

0.03≤P≤1

IPX4 IPX4

350

550

6

1200

11

1800

850×600×595

88

Z

LSE-1000 S

220-240V~/50H

10

0.03≤P≤1

350

450

6

1000

11

10001000

1800

850×600×595

88

Z

Trouble-shooting……………….….20

Wiring Circuit …………….…21

Codes on Display Screen………………….22

Specification…………..……23

23

Page 3

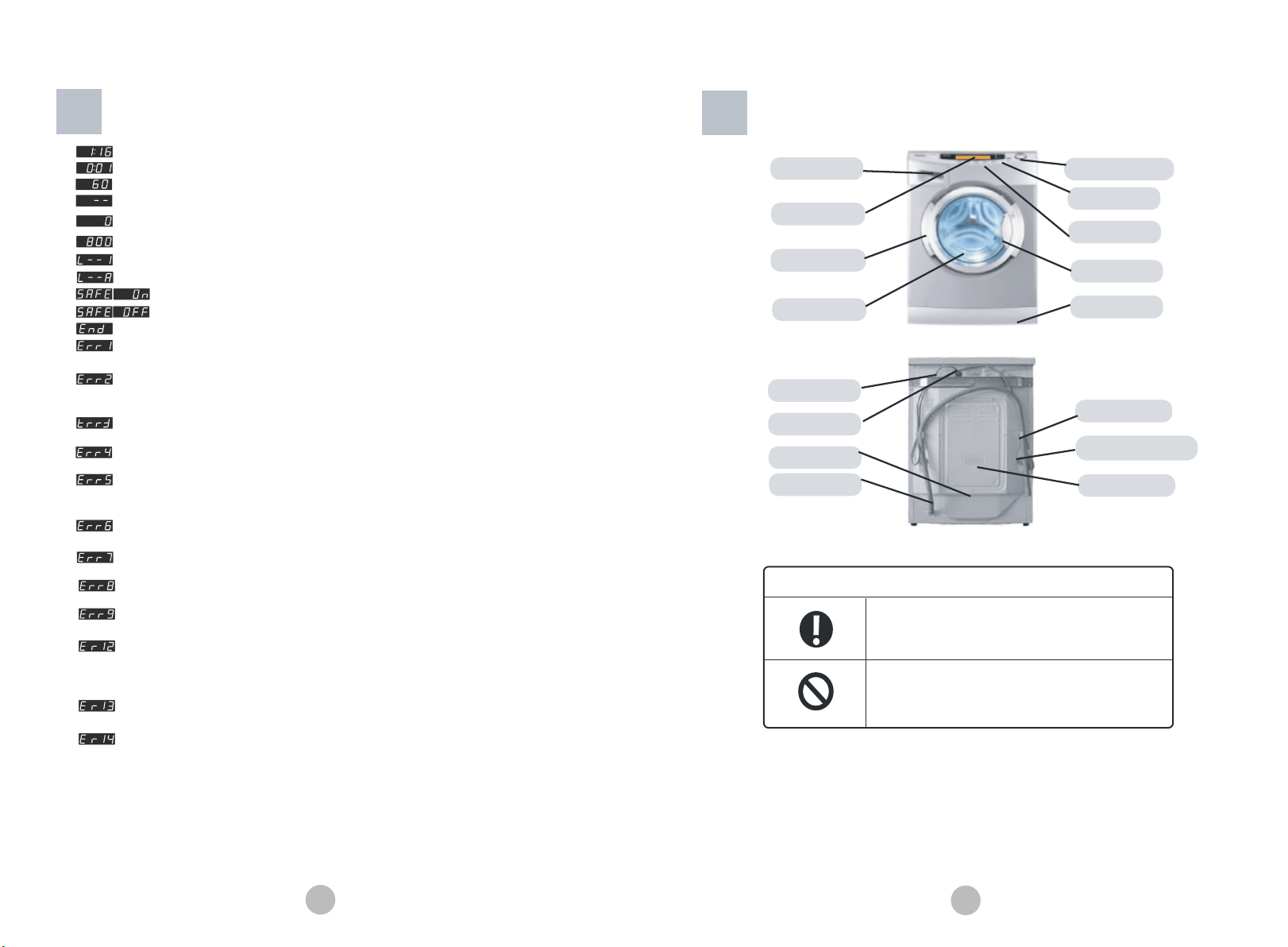

Codes on Display Screen

Part names

Detergent distribution drawer

Display

Door

Glass

Power cable

Screws for rear

panel

Drainage hose

Earth terminal

Remaining time 1 hour and 16 minutes

Remaining time 1 minute

Setting washing temperature at 60

Setting washing without heating process

Setting no Spin process

Setting dehydration revolutions 800r/min

Code for manual selection of weight, when clothes are less than 1kg

Code for manual selection of weight, when clothes are almost full of the roller

Procedure is entirely finished

Failure information: locking door function abnormity

Processing mode: reclose the door, if there is still any alarm, please contact service people

Failure information: draining malfunction

Processing mode: rinse the filter of draining pump, examine whether the drainpipe

is blocked if there is still any alarm, please contact service people.

Failure information: temperature pickup malfuntion

Processing mode: please contact the service people.

Failure information: fuser malfunction (display after procedure operation)

Processing mode: please contact the service people.

Failure information: water intake abnormity

Processing mode: check whether the water hydraulic pressure is too low or water

supply is cut off. Please contact the service people.

Failure information: dehumidification and heating abnormity.

Processing mode: Please contact the service people.

Failure information: superabundant spume in the roller or motor failure

Processing mode: inflow water and vent the spume or please contact the service people.

Failure information: drying temperature sensor malfunction

Processing mode: Please contact the service people.

Failure information: waterlevel sensor malfunction

Processing mode: Please contact the service people.

Failure information: drying waterlevel sensor abnormity

Processing mode: check whether the clothes is dried or not, and whether there is water

in the roller,Dry it again after the dehumidifying process. If there is still any alarm, please

contact the service people.

Failure information: The door is not properly closed after the activation of the procedure

Processing mode: Reclose the door. If there is still any alarm, please contact the service people.

Failure information: when spined, clothes is unevenly distributed

Processing mode: Quiver and scatter the clothes to make it even. If there is still any

alarm, please contact the service people

Start-up keyboard locking function

Cancel keyboard locking function

Programme selector

Control panel

Function button

Door handle

Skirting

Hose clip

Bolts for transport

Rear panel

Caution and Warning Symbols

For your safety, any instructions in this manual with this "Warning"

sign shall be strictly followed.

For your safety and to prevent damages to the washing machine,

any instructions in this manual with this "Stop" sign shall be strictly

followed.

This diagram may vary slightly with the layout of the washing machine you have just purchased

due to technical improvements.

22

1

Page 4

Precaution

7. Do not allow children play with the packing materials after unpacking.

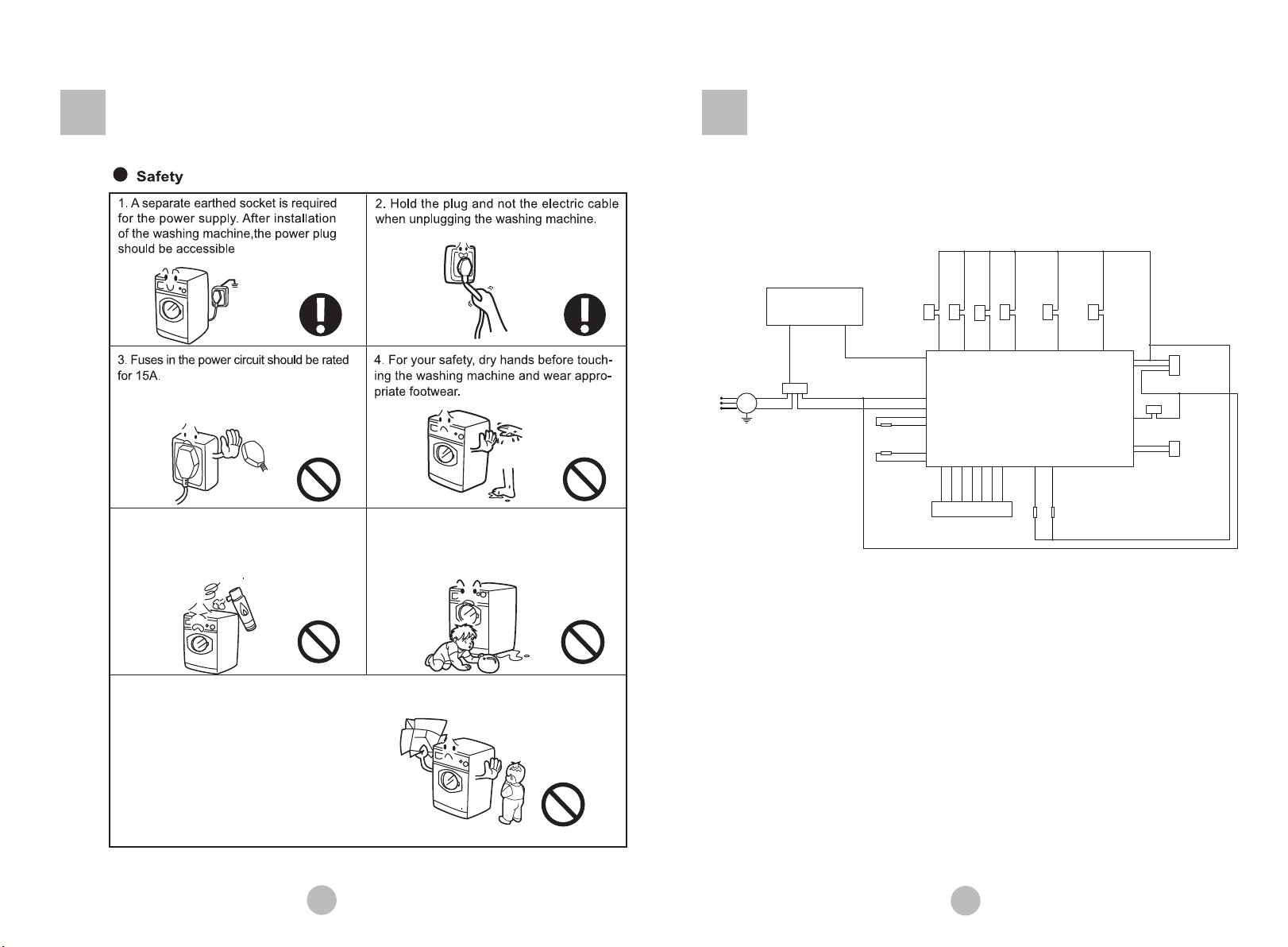

Wiring Circuit

.

The power cable must be replaced

by a qualifed engineer; if not, please

consult the Service Center.

5. Do not use inflammable detergents or

dry-cleaning agents. Do not use inflammable

spray containers in close vicinity to the

washing machine. In the event of gas leaks,

remove the washing machine plug and do not

connect.

6. The door of the washing machine will

become very hot during the water-heating

process. Avoid contact with the door during

the heating process. For safety, keep children

away from the washing machine.

N'

Water supply

Solenoid Valve

Water supply

Solenoid Valve

Water supply

VFD

Program Selector

123

Filter

L

G

N

4

L

N

N

L

Heating Temperature Sensor

Drying Temperature Sensor

2

1

JB1

X1

JB9

VCC

JB6

JC5

JC4

X4

JA1

Solenoid Valve

2

2

1

1

JB2

JB3

JA2

JA3

JA4

JA5

JA6

JA7

Motor

Drain Pump

Water supply

Solenoid Valve

2

2

1

1

JB4

PCB

JB10

Heater

N

Drying Fan

2

1

JB5

JB8

JC1

JB7

Drying Switch

JC6

JC2

JC3

JB11

Drying Heater125

X3

N'

1

2

3

1

2

1

Pressure Switch

2

1-

MRC

2-

MRL

3-

MRN

2

21

Page 5

precaution

8. The washing machine must not be installed

outside or in a very humid areaas drops of

water may form on electricalcomponents,

If drops of water have splashed on the

warming on the washing machine,leave it

dry before use.

10. Keep away from heat sources and direct sunlight to prevent plastic and rubber

components from aging.

●Use

1. Before starting the wash programme,

ensure that the washing machine is

correctly connected to the water supply. In

the event of water leakage, turn off the

water supply and reconnect, or call the

Service Center.

2. Keep the door slightly open when the

washing machine is not being used. Never

cover the machine with a plastic sheet.

3

Page 6

Precaution

The following problems are not always caused by faults, Before calling the Service

Center, please

check to see if the faults can be self-corrected.

Problem

Possible cause

l

Poor connection to power supply

l

Power failure

l

Door is not properly closed (Err 1)

l

The machine is not switched on

.

l

Water tap is not turned on

l

Water pressure is less than 0.05Mpa

l

The inlet hose is kinked

l

Water supply failure

l

The program knob is not properly set

l

The door is not properly closed

The machine is draining while is

being filled

l

The height of the drainage hose is below 80cm (it

should be within 80-100cm)

Drainage failure

l

Drainage hose is blocked

l

Drainage hose end is below 100cm above the floor

level

l

The filter is blocked

Strong vibration during spinning

l

Not all packing bolts have been removed

l

Washing machine is located on an uneven surface or is

not level

l

Machine load is over 6kg.

Operation stops before completion

of a wash cycle

l

Water or electricity failure

l

Washing machine is in a soaking cycle

l

Washing machine gives an error message.

Excessive foam in the drum, which

is spilled to the distribution drawer

l

The detergent is not a low-foaming type

l

Excessive use of detergent

Trouble-shooting

3.Do not place heavy objects or container

with water on the washing machine,so as to

4. Do not wash articles containing

polystyrene or similar elastic materials.

prevent deformation of the flat surface and

plastic parts.

5. Before washing, do up zippers and ensure

that buttons are securely fastened. Place

small items, such as socks,belts,etc. in a

small washing bag or a pillow-case . To

protect the washing machine, do not wash

garments containing wire parts.

7. The door is fitted with a self-lock device

and can not be opened until 2-3 minutes

after the end of the programme.You are not

recommended not to force the door open

before the programme end. Do not open the

door if the water level is above the lower

part of the door.

9.For appliances with type Y attachment,the

intructions shall contain the substance of the

following.

If the supply cord is damaged,it must be

replaced by the manufacturer,its service

agent or similarly qualifled persons in order

to avoid a hazard.

6.Do not open the detergent drawing

during the wash cycle.

8. At the end of the wash cycle, turn off the

water supply to prevent water leakage, unplug the washing machine and thoroughly

clean the trim so as not to dirty the laundry

in the next wash cycle.

10.The installation instructions shall state

that the appliance is to be connected to the

water mains using new hose-sets and that

the old should not be used.

For washing machines with ventilation

openings in the base,that a carpet must not

obstruct the openings.

4

The washing machine does not start

Washing machine cannot be filled

with water

20

Page 7

Maintenance

5. Rinse intake pipe joint and the inlet valve gauze filter

frequently in case foreign substances in water blocks

the water pipe connection.

6. Reinstall the shakeproof components that are dismantled when moving

the house(including bolt,gum sleeve,shakeproof cell type basin,etc.)

according to the following direction. Tighten the inner components in

case they are shaken and destroyed.

Installation

Remove all the packing materials (including the

●

EPS base)to prevent vibration during use, as

shown in the right picture.Upon opening of the

package, water drops may be seen on the plastic

bag and the porthole. This is normal phenomenon

resulting from water test in the factory.

●

Check attachments and materials with reference to the following

Name

Qty

Model

LSE-1200 S

Operation

manual

1

Quality

certificate

Water

hose

1 2

Drainage

holder

1

Warrantly

card

1

Plastic

plugs

3

Plastic plugs

Quality certificate

Drainage holder

Water hose

Fig

. 1

Warrantly card

Operation

manual

Dismantlethe cover plate

in the back and take down

3 splash shield plastic plugs.

Fit on the shakeproof

cell type steel,and insert

the packaging screw.

Tighten the packaging

screw with a spanner.

Fix the rubber sleeving to

the packaging screw from

the interior of the rear cover plate.

Screw tight the rear cover plate.

7. When the equipment has not been used for a long time,

disconnect the power supply and turn off the tap. Keep the

door of the machine open to let out the smell. If the machine

is not in use temporarily, keep the door slightly open.

19

●

Dismantle the packing bolts as shown in Fig. 2.

The packing bolts are designed for clamping anti-vibration components

inside of the washing machine during the transportation process.

Before use:

1. Remove the back plate;

2. Remove the three packing bolts on the back plate and take out the

rubber hose;

3. Replace the back plate;

4. Fill the holes left by the packing bolts with plastic plugs.

(Attention: The packing bolts and rubber hose should be kept in a safe

place for later use)

Adjusting the washing machine

●

There are adjustable feet under the bottom of the washing machine. Before

use, the washing machine should be adjusted, as shown in Fig. 3, so that it

is level.

5

Fig.2

Fig.3

Page 8

Maintenance

18

图1

图3

图2

图4

Page 9

Other functions

1. Power off memory function: In case there is power breakdown or the plug

accidentally falls out of the outlet when the machine is in operation, this

machine can memorize the running of the program so that it continues with

its work after the resume of power.

Installation

1. Place the threaded end of the water inlet hose on

the water inlet valve connector. threaded end of

2. The machine can memorize the preset condition of precious washing, which

means it can memorize the habit of the user in washing clothes. You can just

press the button "start/pause" to begin washing or re-set the program before

operating.

3. keyboard-locking function

2. Check that the connection is correct by

tightening the threaded end on the connector.

water inlet valve connector

Positioning the drainage hose

After starting the program, press the buttons "reserve" and "start/pause" at

one time for about 3seconds and the keyboard-locking function is started up.

In this condition, pressing any other function keys or turning any knobs,

resulting in suggestive sound, won't change the program. Press the buttons

"reserve" and "start/pause" at one time again for about 3seconds and the

keyboard-locking function is closed.

4. Cancel the program or choose another program as well as other accessional

functions when the machine is in operation (the keyboard-locking function closed)

A. Turn the program knot to the position of turning off, and the program

automatically stops; turn the knot again to choose new program.

· The free end must be at a height of between 80 and 100 cm. The drainage hose must be

fastened on the rear panel with the retaining clip.

· Fix the drainage hose in the correct position with the support supplied.

It is inadvisable to lengthen the hose; if necessary, contact the Service

Centre. The extension must not exceed 250 cm in length (an overlong

extension could cause the water to drain while the washing machine is

still loading). The diameter of the extension hose must be the same as

that of the original drainage hose.

Note: the free end must not be immersed in water. Connect the

drainage hose securely in order to prevent leakage.

B. If some accessional functions need to be chosen when the program is at work,

press the button "start/pause". After choosing the accessional functions press

the same button again.

Note: Refer to the program setting guide for information concerning functions

attachable to different programs.

Connection of power supply

5. After the completion of the whole program, this machine provides a short piece

of enjoyable music, reminding you of the finish of the washing process. Just open

the door of the machine to take out your clean clothes.

Check the following items before connection to the power supply.

· whether the socket is able to support the washing machine’s maximum load (the socket

and the power cable must be able to support a maximum current of no less than 15A).

· whether the mains voltage conforms to the required value.

· if the power socket to which the washing machine is connected is not the same as the plug,

replace it with a suitable one; alternatively, consult a specialised engineer or the Service

Centre for a suitable socket. The washing machine must be correctly earthed.

· the supplementary earth cable is not necessary if the power socket is earthed.

· the supplementary earth cable is installed at the top of the rear panel of the washing

machine and earthed if the power supply socket has no earth connection.

Note: do not connect the supplementary earth cable to the water hose or heating pipe.

17

6

Page 10

Control Panel

Control Panel (LSE-1200 S)

2

9

K

A Program knob

By turning this knob, it is possible to select the desired program

Refer to "Program Guide" to select the Program .The program

selector knob is at the same time a power swith; when the knob is

.

at " ", the washing machine is off; when the knob is in the other 11

positions, the washing machine is on.

B Temperature button

By pressing and holding down this button, it is possible to select the desired washing temperature ( ,

30, 40 60, 90°C). Refer to "Program Guide" to Select the maximum temperature of each program.

When seledcted, the temperature is displayed in the digital display area on the screen.

Caution: Cold wash is selected when the symbol " " is displayed in the temperature display area .

C Speed button

By pressing and holding down this button, it is possible to select the desired spin speed (0, 400,

600, 800, MAX). Refer to the “Program Guide” to choose the maximum speed of each program.

When selected, the speed value is displayed inthe digital display area of the

screen.

Caution: the washing machine does not spin when the number “0” is displayed in the speed

display area of the screen. The washing machine spins at 1200 rpm when “MAX” is displayed in

the speed display area of the screen.

D Start / Pause button

When the electric cable of the washing machine is plugged in and a program is selected, after

the washing temperature, spinning speed and other required functions are set, lightly press

this button, operation will start. During a wash cycle, press this buttonlightly, operation will

pause. Press it again to resume operation.

Note: After operation is suspended, the washing temperature, spinning speed and other functions

can be reset. After that, press the Start/Pause button to continue operation.

E Economic

Press the key and manually select different programs a nd power-saving and water-seaving fea-

ture based on the volume of load.

Laundry Operation Illustration

Illistration of the washing operation process with "cotton" as an

example

1.Joint the intake pipe and the drain pipe,switch the program button

to the position of closedown indication,and plug in the pin.

2.Open the door of the washing machine,trim up the cotton clothing that require

washing and put them into the cylindrical washer evenly.

3.Draw out the detergent dispensing package,put proper amount of detergent into the case2.If it is

needed to be softened,proper amount of liquid soften erorpliancy agent can be poured into the

softening room3.Notice that the volume should not above the position of “MAX” on the stopper

of the softening case.Then close the dispensing package.If the clothing are sodirty that need

pre-washing,proper amount of detergent can be put into case1 at the same time.

4.Choosing the washing temperature,rotation rate of dehydration and additional function.

①If the heating temperature needs to be adjusted,you can press the temperature-choosing

button before start-up and choose proper heating temperature. The currently set temperature

will be presented in the digital display area and temperature display area of the display screen.

②If the rotation rate of dehydration need stobe adjusted,you can press the rate-choosing button

before start-up and choose rotation rate of dehydration.Thecurrently setrotation rate of dehydration

will be presented in the digital display area and temperature display area of the display screen.

③you can select the button of the automatic catch manually,and will be presented on the

digital display area of the display screen.If the button is being pressed with in 2 seconds you can

choose a proper code of clothing weight from to cyclically,the currently set clothing

weight will be presented in the digital display area,if any other codes or buttons will not be

chosen with in 5 seconds,the currently set clothing weight will be carried on.

④If you need the drying function you can press the drying button and the icon of drying will be

lighted on the display screen.

⑤If you need the ultra-clean rinsing function you can press the ultra-clean rinsing button and the

icon of ultra-clean rinsing will be lighted on the display screen.

⑥If you need the prewashing function you can press the prewashing button and the icon of

prewashing will be lighted on the display screen.

⑦If you need to set the washing time previously,you can press the reservation button,the

pre-engaging state of will be lighted in the digital display area of the display screen.Every

pressing of the reservation button will increase there servation time by 30 minutes(0—24hours).

If the reservation time is 4 hours, will be presented on the display screen,according to the

above set time 1:34,and 2 hours and 26 minutes later the program will start up,and finish it 4 hours later.

5.Press the Start/Pause button to start the washing process,meanwhile the left time will be

presented in the digital display area(there are towspots in the middle of the left time glittering),

the current heating temperature will be presented on the heating indication stripa ccordingly.30

seconds later the locking icon on the display screen will glitter which indicates that the door has

been locked and the program will be carry on.

6.When in the process of heating,the locking icon on the display screen will extinguish,the door

will be unlocked and can be opened at any time.When the inner temperature of the roller

reaches 55℃ or above the door will be locked to prevent accidental scald when opening the

door.When the inner temperature of the roller is below 55℃ the door will be unlocked.

7. will be presented on the display screen when the program is over,after a short noticing sound

the locking icon will extinguish indicates that the washing process is finished.Now you can switch

the program button to the position of close down,open the door,take put the clothing,and atlastd

is connect the water and electricity power.The laundry operation process is finished.Prompt:the

rate,temperature and function key scan be reselected and reset during some phases of the

processing of the program.

Notice:1.When the program has been started up,please don’t switch the program button as best

as you can,lest it will impact the processing program.You can also press down the

program knob.2.The left time on the display screen is just for reference,because of the

factors such as the temperature of the intake water,the heating temperature and the

equilibrium condition of the clothing when is being dehydrated,it is normal phenomenath

at the presented left time has been adjusted(increased or decreased)during some of the

washing processes.

(The other processes resemble with this)

7

16

Page 11

Flexible Applications

Control Panel

Saving water,electric power and detergent is not only good for

environment protection but also good for saving the disbursements.

If you wash many clothes together,please separate the clothes that are easy to lose color.

For some extremely dirty clothes,please pre-wash them before put them together with the other.

For some clothes that are not very dirty,you can relevantly reduce the volume of

detergent or choose the fast-washing program.

Choosing proper temperature:only choose the temperature above 60℃ in the Room

of the clothes are too dirty.

Using softener:the clothes will be soft for ironing and can save your time.

Adding the clothing amendment can not only make the clothes soft but also can

eliminate electrostatic bonding so that the clothes are prone to be ironed.

This machine consists of recyclable materials,in order to protect environment,when

discard it please help dispose properly or recycle and reuseit.

Using properamount of detergent:don’t use over much detergent;otherwise it will not

only cause environmental pollution but also difficulties in rinsing.

Drying

It depends on the texture of the clothes that whether can be dried or not.

Before the process of drying please make sure the water valve has been turned on,

and make sure the water is cold.

The dehydrated clothes should be taken out from the roller,untangled and put into the

roller again before the process of separate drying.

In order to ensure the effect of drying,please dry the clothes after dehydrating process.

If too many clothes were put into the roller for drying,the drying effect will be impacted

and further more the clothes are prone to be wrinkled.

For the large piece of clothes,it is better to put into the roller less than two pieces once.

The following table indicates different drying times for different kinds and quantities of

the clothes.You can choose the correspondent drying program according to the

weight of the clothes and your expected degree of drying;when the drying process is

finished the whole program will close automatically.

Weight

Set drying program

Drying

Ironing

Anti-virus

Notice:If the quantity of the clothes exceeds the standard volume or mix with the other

clothes when washed,it will take a longer drying time(left time will cease to change).If

it is not dried sufficiently you can use the spin program for another drying process.

Degree of dryingLeft time(min)

Totally drying

Totally drying or ready for ironing

Anti-virus program

for dry clothes

F drying button

Press this button and the drying icon of the display screen brightens.When the

program finally comes to the drying process,the drying icon twinkles,indicating the

start of the drying program.If you want to cancel the program,press the start/pause

button before the program comes to the end of the drying process.Press the drying

button again and the drying function is canceled while the drying icon extinguishes.

G super-clean rinse button

Press this button and the super-clean rinse icon of the display screen brightens.Before

the program comes to the softening process,the machine will automatically add one

more rinse program.At the same time the super-clean rinse icon twinkles until the

super-clean rinse program comes to an end.The program continues until the end.

H pre-washing button

In room dirty clothes are to be washed,press down this button before the start of the program and

the pre-washing icon of the display screenbrightens.After starting the washing machine,the pre washing program is the first to be operated.At this time the pre-washing icon twinkles and there is

water inflow in room1of detergent-dispersing package.At the end of the pre-washing program,the

pre-washing icon extinguishes and other programs begin to operate.

I Reservation button

Press down the reservation button when needed before the program starts.The default time is 9

hours.Each time the button is pressed the default time increases by30minutes.If the button is

pressed continuously,the default time can be accumulated.It cycles from 0 hour to 24 hours until

you stop pressing the button.After setting the reservation time,the reservation icon brightens and it

won’t extinguish until the end of the reservation program.The reservation time includes the period

from the operation of the program till it send.Therefore,the preset reservation time should be at

least longer than the time span of the operation of the program,orelse the program won’t perform

the reservation function and goes directly to the washing process.

J Display screen

The remaining time of the washing process,the set temperature and speed,the additional functions

as well as the warning message are to be shown on the display screen.For details please refer to

the introduction of the display screen.

K Detergent-dispersing package

Open the detergent-dispersing package and you will see 3 little rooms fordetergent:

Room1:If pre-washing function is needed,put detergent in this room.Otherwise,

no detergent should be put in here.

Room2:When washing in the first 6 programs,put detergent in this room whether

a pre-washing program is needed or not.

Room3:Put some softener,conditioner or spice in this room to soften or do other treatment to ward

the clothes.

D+1 Keyboard lock button

After starting the program,press down the reservation button and the start/pause button

simultaneously for 3 seconds and the keyboard lock function will be started.At this time the digital

area shows “SAFEON”.Press the buttons again for 3 seconds and the function is canceled.And the

digital area shows “SAFEOFF”.This function is set for fear of outside intrusion in the operation of

the program.For example,if children press the functional or program buttons out of curiosity,it will

do affect the washing program or even interrupt the program.

Note:if the keyboard lock is started when the program is in operation,the keyboard lock function

will be canceled automatically at the end of the program when it shows “End”.

Note:In the washing process,if the keyboard lock is not started,turn the program button to the off

position of the machine and the current program will be canceled.Turn the program button again to

choose a new program.

15

8

Page 12

Display Screen

The content of the displayscreen

30

spin speed indicator

temp.

temp. indicator

load

load indicator

content of program

off

cotton

anti-virus

ironing

drying

spin

rinse

1.Digital display area:The time the machine is turnedon,it shows the set time,such as ,

it also shows the current heating temperature and the dehydrating speed,such as ,it

tells the remaining time when the program is in operation.Choose the code manually,like

.When adjusting the reservation time,it tells the value such as ;When the key

board lock is chosen,it tells while it shows when the keyboard lock is

canceled.When there is any warning,it shows the malfunction code ,At the end of

the program,it shows

2.Speed(rpm):The current value twinkles and remains bright after the program is started

3.Dehydrating indication stripe:It remains bright before the program is started and after that in

the process of dehydrating the set values change in accordance with the dehydrating speed.

4.Temperature(℃):The current value twinkles and remains bright after the start up of the

program.

5.Temperature indication stripe:It remains bright before the program is started and after that in the

process of heating the set values change in accordance with the change of temperature

6.Clothes quantity and quantity indication stripe:.the stripe remains bright and the current

value twinkles.After the start up of the program,the current value and the corresponding

stripe remain bright.

7.Reservation icon:It brightens when the reservation button is pressed or the reservation

time is adjusted.It twinkles when ther eservation program is in operation and extinguishes

at the beginning of the washing program.

8.Pre-washing icon:It brightens when the pre-washing program is chosen,twinkles when the

pre-washing program is in operation and extinguishes at the end of the program.

9.Super-clean rinse icon:It brightens when the super-clean rinse program is chosen,twinkles

when the program is in operation and extinguishes at the end of the program.The super clean rinse function can be set before the start of the program or by pressing start/pause

button before the program comes to the rinse process.

10.Drying icon:It brightens when the drying button is pressed,twinkles when the drying

program is in operation and extinguishes at the end of the program.The drying function can

be set before the start of the program or by pressing start/pause button before the program

comes to the end of the dehydrating process.

11.Lock icon:It brightens when the door is locked after the start of the machine.Only when it

extinguishes can the door be opened.

12.Warning icon:It brightens together with the malfunction code after some malfunction

occurs.In no cases except that does it brightens.

2

9

sport quick silk

digital display area warning

synthetic cashmere

delay

prewash extra rinse drying door lock

spin speed

Washing Methods

4. Set the washing temperature and spin speed

If you don’t need heating,press the temperature-choosing key to the “ ”position.If

you need heating choose proper washing temperature according to your requirement.

If you don’t need spin,press the speed choosing key to the “0” position.If you need

spin,choose proper spin speed according to your requirement.Refer the heating

temperature and spin speed to the program setting guide table according different

kind of clothes.It is suggested use there commend data.

5. Choosing additional function keys

You can choose additional function keys according to your requirement and refer to

the introduction of control panel functions and the program setting guide table.If you

want to select the sorting step of clothes quantity,please press the eco key and make

choice between .

6. Washing

Press the Start/Pause key,the washing machine will carry on the set program

automatically.

7. End of the washing process

When the selected washing program finished,the washing machine will cease working

automatically.When is presented on the display screen,you can switch the

program button to the close down position,open the door and take out the clothes shut

the water valve and unplug the attaching pin.

Suggestion: after washing please take out the clothes immediately.It is prone to cause

wrinkles if the clothes stay in the roller too long.

9

14

Page 13

Washing Methods

Program Setting

1.

Laundry loading Open the door, put in

the laundry inside. Close the door tightly.

Notes:1) When using the washing

machine the first time, let it run unloaded for one program to prevent

● Overalls

the laundry from being tainted by

●

oil or dirty water from the washing

machine.

Blended fabric

clothes

(appr 800g)

2) Do not overload the washing

machine.

2. Adding detergent Slide out the detergent drawer and put the right amount of

● Sark (appr

300g)

● Jackets

(cotton appr

1000g)

(cotton

appr 800g)

Load Reference

●

●

Woolen blankets

(appr 2000g)

● Jeans

(appr 800g)

● Ladies pajamas

(appr 200g)

● Vest

(cotton

appr 300g)

●

Briefs (blended fabrics appr

70g)

● Socks

(blended fabrics

appr 50g)

Bed sheets

(cotton appr 800g)

detergent and softening agent into the corresponding compartments, depending on the

wash cycle. Push the drawer back in gently.

Note: 1) For pre-washing program,detergent should be added to both compartments 1

and 2.Compartment 2 allows only solid detergents. For other programs ,do not add

detergent to compartment 1.

2) Do not overuse softener; otherwise, it will damage the artificial fibers.

program setting mode

cotton

synthetic

cashmere

silk

quickwash

sport

rinse

spin

drying

ironing

anti-virus

recommended

laundry

cotton

fabric

fsat-colour

fiber

cashmere

silk

slightly-soiled

textiles

cotton

synthetic

cotton

synthetic

cotton

synthetic

cotton

synthetic

cotton

synthetic

cotton

synthetic

temperature

range

suggested

temperature

speed range

(rpm)

suggested

speed

-- ,30,40,

60,90

--,30,40,60

--,30,40

--,30,40

--

--

--,30,40

--,30,40,60

Used for drying the cotton or synthetic cloth.

Used for drying the cotton or synthetic cloth.The

cloth dried needs to be ironed.

Used for getting rid of the smell and virus.

3. Selecting the program Select the program best suited to the type of fabric so you get

the best washing results. There are instructions on the handle of the detergent

distribution drawer. Turn the program knob clockwise to select the program you want.

13

off

The power is off

Note:

The time that program needs differing from the time shown on the screen because of the

differences in water pressure,drainage condition,cloth texture,quality and equilibrium condition,

water quality,temperature and surrounding temperature,etc..

The remaining time of the drying process would suddenly reduce or stays at a certain value for

a long time in accordance with the texture and the quantity of the clothes.

10

Page 14

Program Setting

Preparation

Program setting mode

cotton

synthetic

cashmere

silk

quickwash

sport

rinse

spin

drying

ironing

anti-virus

off

additional functions attachable to the program

extra

pre-

delay

wash

The power is off

rinse

drying eco

Usage of detergent

1.Power supply

Plug in the power supply 220-240 V~/50HZ

3.Detergent selection

Only special low foam detergent should

be used in automatic drum washing

mashine,form blended or wool fabrics

special deter-gent should ne used.dry

clearning solvent should not be used

such as trichhloroethy-lene or alike

(caution :load the required amount of

detergent only).

2.Water supply

Turn on the tap ensure that the water in clear.

Caution:Before staring the washing machine turn on the water

faucet to ensure the water faucet and the water inlet hose are

connected correctly and do not leak

4.Laundry treatment

Sort out clothes according to type and extent of dirt.There are

three types of clothes:cotton,synthetical and woolen (silk) fabrics.

Separate white clothes from colored.If whites and coloreds

are combimed for one load,make sure the coloreds are colorfast

-Clothing with frayed edges or yams should be put in a wash

bag or special bag before washing

-repair damged clothing,lose buttons or damaged zips

and hooks before washing.

-Bed sheets and table ware should be loosely loaded and not

folded.

○means softener,conditioner or spice can be added when necessary.

★means detergent must be added.×means softener,conditioner or spice can not be added.

√means the functions that can be chosen and operated by this program.

-means functions that can not be chosen by this program.

Note:

1)If the pre-washing function is added,detergent must be put into Room1 of the detergent dispersing package.

2)When the laundry load is on 4.MAX,drying function can not be chosen.

3)For some special clothes such as wool fabric,please check if it can be washed in the

machine or if there is special requirement for the temperature.

11

5.Wash load

Type

Max load

This washing mashine is for househould use and designed

for mechanically washable clothes.When washing,separate

unwashable clothes with reference to clothes labels.

Cotton fabrics Synthetic fabrics Wool/cashmare/silk fabrics

6kg 3kg 3kg

12

Loading...

Loading...