Page 1

Manual de Instrucciones

Campanas Extractoras DX ISLA Vr. 03

Bedienungsanleitung

Dunstabzugshauben DX ISLA Vr. 03

Instructions Manual

Kitchen Hoods DX ISLA Vr. 03

Manuel d’instructions

Hottes aspirantes DX ISLA Vr. 03

Manual de Instruções

Exaustores DX-90 ISLA 03

ПДЗГЙЕУ ˘СЗУЕЩУ

КБМЙНБДБ ФПЙ˘ПХ DX ISLA Vr. 03

Kullan˝m K˝lavuzu

Davlum DX ISLA Vr. 03

Rev. 0505

Page 2

10

ENG

Dear client:

Congratulations on your choice. We are sure

that this modern, functional and practical

appliance, made with top quality materials,

will fully satisfy your needs.

Please read every section of this

INSTRUCTIONS MANUAL before using your

kitchen hood for the first time, to ensure

maximum performance from the appliance

and to avoid breakdowns, which may be

caused by incorrect use, as well as to allow

any minor problems to be solved.

Store this manual, as it will provide useful

information about your kitchen hood at all

times and will also help other people to use it.

• Please be aware of current local

regulations with reference to domestic

electrical fittings and gas eduction.

• Verify that the tension and frequency of the

network match those indicated on the label

located inside the kitchen hood.

• The appliance must be connected to the

network using a break switch with a

universal cut off and minimum contact

separation of 3 mm. THE NET CABLE

MUST NOT BE SUBTITUTED.

• Once the kitchen hood has been installed,

ensure that the mains cable to the network

is not in contact with any live metal edges.

• Avoid connecting the appliance to

conductors used as exits for fumes

produced by a non-electric energy source,

e.g.: boilers, chimneys, etc.

• If the extractor fan is going to be used

simultaneously with equipment powered by

a non-electric energy source, e.g.: gas

cookers, then the room must have

sufficient ventilation.

• Excessive fat accumulation in the kitchen

hood and metal filters is a fire risk and may

also cause dripping, therefore the inside of

the kitchen hood and the metal filters must

be cleaned at least once a month.

• The lower part of the kitchen hood must be

fitted at least 50 cm. over electric hobs and

65 cm. over gas or mixed hobs. FOLLOW

THE HOBS´ MANUFACTURER'S

MINIMUM RECOMMENDATIONS.

• Never leave gas hobs lit if not covered by a

container. The fat accumulated in the filters

may drip or catch fire when the

temperature increases.

• Avoid cooking under the kitchen hood if the

metal filters are not fitted, e.g.: while they

are being cleaned in the dishwasher.

• You must not produce flames under the

kitchen hood.

• Disconnect the appliance before any

interior manipulation, e.g. during cleaning

or maintenance.

• We recommend the use of gloves and to

be extremely careful when cleaning the

kitchen hood's interior.

• Your kitchen hood is designed for domestic

use and only for extraction and purification

of fumes produced during food

preparation. It will be your responsibility if it

is used for other purposes, which may be

dangerous. The manufacturer cannot

accept responsibility for damage caused

by improper use of the appliance.

• For repairs please contact the nearest

TEKA Technical Assistance Service, and

always use genuine spare parts. Repairs

or modifications carried out by unqualified

personnel can cause malfunctions or may

damage the appliance, putting your safety

in danger.

• This appliance is marked according to the

European directive 2002/96/EC on “Waste

Electrical and Electronic Equipment”

(WEEE). This guideline is the frame of a

European-wide validity of return and

recycling on Waste Electrical and

Electronic Equipment, .

Safety Instructions

Page 3

11

ENG

Index

Page

Description of the appliance 11

Instructions for use 11

Cleaning and maintenance 12

Problem solving 12

Sizes and specifications 12

Accessories supplied 13

Installation 13

Active charcoal filters 13

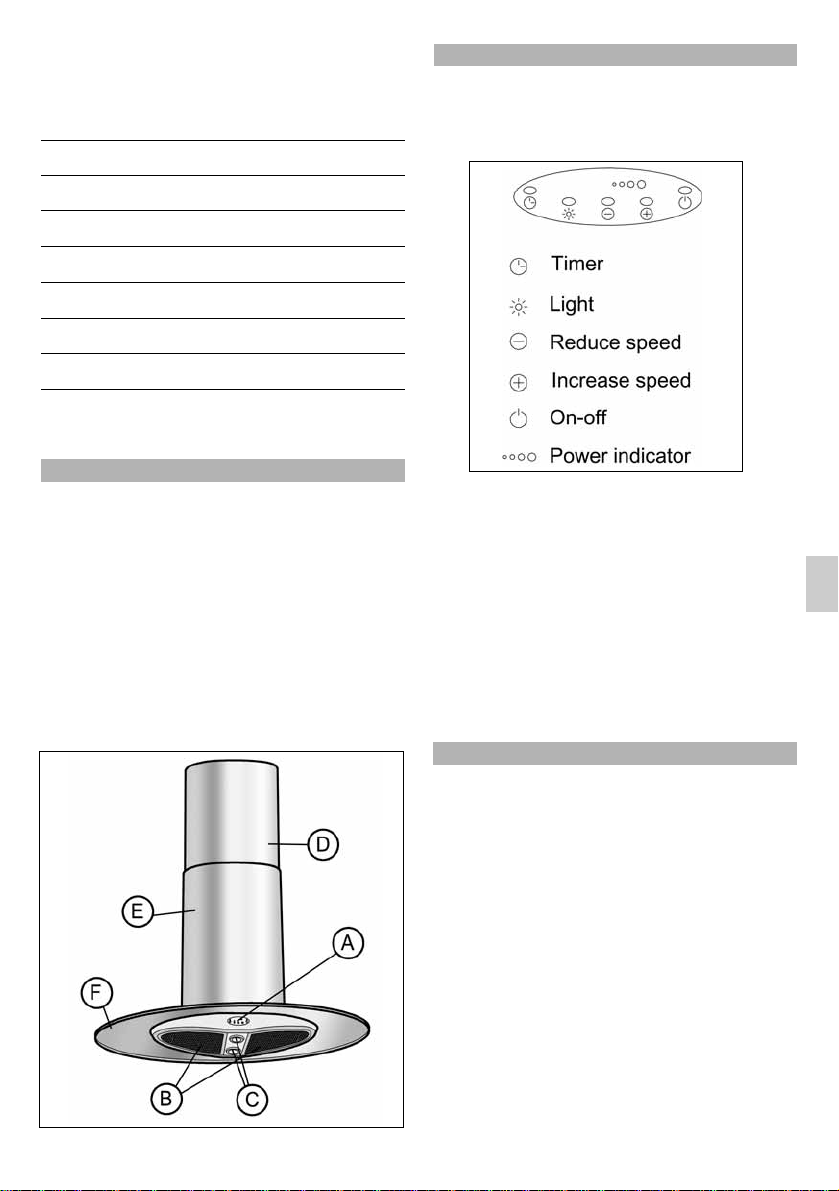

A Electronic programmer control box

with TOUCH CONTROL technology to

control speed, light and power in use

indicators.

B Metal filters.

C Lamps - 20 W (G-4).

D, E Vertically adjustable tubecovers.

F Decorative part (Not incluided).

Switch on the extractor fan a few minutes

before you start to cook in order to ensure that

a steady air flow has been established before

fumes appear.

Allow the extractor fan to run for several

minutes after you have finished cooking

(between 3 to 5 minutes) in order to expel all

the grease from the outlet duct. This prevents

the return of grease, smoke and smells.

Proceed as follows:

1) Turn the kitchen hood on and choose the

required speed.

2) Press "timer".The "power indicator" will

flash.

3) Select the required time by pressing the

increase and decrease speed selectors.

There is a variation of 5 in 5 minutes.

(Min.= 5 min.; Max.= 20 min.).

4) Once the required time has been selected,

press "timer" again to memorise the

program.

5) The kitchen hood will turn itself off once the

programed time has finished.

Instructions for use

Description of the appliance

You may control the kitchen hood by

operating the controls as shown in the

diagram.

Programming timer

Page 4

12

ENG

TEKA INDUSTRIAL S.A. reserves the right to make changes and corrections to its products as

it deems necessary, without altering their basic characteristics.

During cleaning and maintenance work,

make sure the safety instructions set out

on page 10 are complied with.

• If your kitchen hood is made from stainless

steel, use proprietary cleaners mentioned

in the product instructions.

• Never use metallic scourers, nor abrasive

or corrosive products.

• Dry the kitchen hood using a cloth that

does not produce fibres.

Extract the filters from their housings using

the handles specially designed for this

purpose.

The metal filters can be cleaned by soaking

them in hot water with neutral detergent until

the fat dissolves and then rinsing them under

the tap or using special anti-grease products.

They can also be washed in a dishwasher. In

this case, it is advisable to stack them

vertically to avoid food residues to stick to

them.

Cleaning in a dishwasher may damage the

metallic surface (blackening it), although this

will not affect its fat retention capacity.

Once clean, leave them to dry off and then fit

them onto the kitchen hood.

Fig. 2 (Page 31)

Proceed as follows:

• Remove the metal filters. Loosen the

screws (without unscrewing them) of the

EASYCLEAN panels (A), move the panels

aside carefully and take them off.

• Dismount the supports (C) by loosening

the screws (B).

• Change the broken/burnt out lamp (D).

Maximum lamp power is 20 W (G-4).

• Mount the supports again (C).

• Mount the EASYCLEAN panel again (A).

Fit the metal filters.

Cleaning the metal filters

Cleaning the hood body

Cleaning and maintenance

_________________________________________________________

Problem solving

Proceed with the following checks before calling the Technical Service:

Changing light bulbs

Sizes and specifications

See page 30.

Page 5

1 150/ 120 mm reduction.

6 Lock screws (M8 x 45).

Fig. 1 (Page 31)

On installing the kitchen hood make sure

that the Safety Instructions set out on page

10 are complied with.

To obtain optimum performance, the external

conduct must not be more than FOUR

METRES long, have no more than two 90°

angles and its diameter must be at least Ø120.

1) Using the support (O) trace and drill the

where the screw-fittings will sit onto the roof (S)

(Ø8 x 45).

2) Screw the support (O) into the roof with the

screw-fittings (S) (Ø8 x 45).

3) Mount the upper chassis (A6) onto the

support (O) using the screws (Q) (M6 x 16).

4) Adjust the decorative part (U), fixing it softly

to the body of the bell using the screws (V)

(M4) provided with the decorative part.

5) Fit the part (B) if the inner tube (not supplied)

is Ø120.

6) Attach the inner tube with a clamp (not

supplied) to (B) or on to the motor's air outlet

vent as the case may be.

7) Introduce the upper tubecover (A8) into the

lower tubecover (A9).

8) Fit the lower (A9) and upper (A8) tubecover

units onto the lower body (A7) and the

decorative parts (U).

9) Mount the whole lower unit to the upper

section, attaching it to the roof using the

screws (A10) (M4 x 12) at the required height.

10) Connect the upper part of the inner tube

(not supplied) to the exit.

11) Raise the upper tubecover (A8) and attach

it to the upper unit with the screws (G) (M4 x 12

flat head).

12) Adjust the decorative part (U), fixing it

tightly to the body of the bell using the screws

(V) (M4) provided with the decorative part.

When exterior gas extraction is not possible,

then the kitchen hood may be set to purify the

air by recycling it through active charcoal

filters.

The active charcoal filters have an active life of

between three to six months, depending on

the individual conditions of use. These filters

cannot be washed nor regenerated. They must

be replaced once their useful life comes to an

end.

Fig. 1 (Page 31)

1) Using the support (O) trace and drill the

where the screw-fittings will sit onto the roof (S)

(Ø8 x 45).

2) Screw the support (O) into the roof with the

screw-fittings (S) (Ø8 x 45).

3) Mount the diffuser (A5) with the screws (A4)

(M4 x 12) on to the side rectangles of the upper

body (A6).

4) Mount the upper chassis (A6) onto the

support (O) using the screws (Q) (M6 x 16).

5) Adjust the decorative part (U), fixing it softly

to the body of the bell using the screws (V)

(M4) provided with the decorative part.

6) Fit the part (B) if the inner tube (not supplied)

is Ø120.

7) Attach the inner tube with a clamp (not

supplied) to (B) or on to the motor's air outlet

vent as the case may be.

8) Introduce the upper tubecover (A8) into the

lower tubecover (A9).

9) Fit the lower (A9) and upper (A8) tubecover

units onto the lower body (A7) and the

decorative parts (U).

10) Mount the whole lower unit to the upper

section, attaching it to the roof using the

screws (A10) (M4 x 12) at the required height.

11) Connect the upper part of the inner tube

(not supplied) to the exit.

12) Raise the upper tubecover (A8) and attach

it to the upper unit with the screws (G) (M4 x 12

flat head).

13) Adjust the decorative part (U), fixing it

tightly to the body of the bell using the screws

(V) (M4) provided with the decorative part.

14) Remove the metal filters. Loosen the

screws (without unscrewing them) of the

EASYCLEAN panels (A19), move the panels

aside carefully and take them off.

15) Put the filters into the lateral draught

section of the motor making the holes in the

filters match up (A11) with the pivots (A12) of

the motor carcass.

16) Mount the EASYCLEAN panel again (A19).

Fit the metal filters.

Active charcoal filters (Optional)

Installation

13

ENG

Accesories supplied

Page 6

30

Page 7

31

2

1

Page 8

Mod. 0.000 - Gráficas Alhambra

TEKA GROUP

COUNTRY CITY COMPANY CC PHONE FAX

Austria Wien KÜPPERSBUSCH GES.M.B.H. 43 1 - 86680-0 1 - 86680-72

Belgium Zellik B.V.B.A. KÜPPERSBUSCH S.P.R.L. 32 2466-8740 2466-7687

Chile Santiago de Chile TEKA CHILE S.A. 56 2-273.19.45 2-273.10.88

China Shanghai TEKA CHINA LTD. 86 21 - 6236 - 2375 21 - 6236 - 2379

Czech Republic Brno TEKA-CZ, S.R.O. 42 05-4921 - 0478 05 - 4921 - 0479

France Saint Ouen l’Aumône TEKAFRANCE SAS 33 0820 07 27 47 01 34 30 15 96

Greece Athens TEKAHELLAS A.E. 30 210-9760283 210-9712725

Hungary Budapest TEKAHUNGARY KFT. 36 1-354-21-10 1-354-21-15

Indonesia Jakarta P.T. TEKABUANA 62 21 - 39052 - 74 21 - 39052 - 79

Malaysia Kuala Lumpur TEKA KÜCHENTECHNIK

(MALAYSIA) SDN. BHD. 60 3 - 762.01.600 3 - 762.01.626

Mexico Mexico D.F. TEKA MEXICANA S.A. DE C.V. 52 555 - 762.04.90 555 - 762.05.17

Poland Pruszków TEKA POLSKA SP. ZO.O. 48 22 - 738.32.80 22 - 738.32.89

Portugal Ilhavo TEKAPORTUGUESALTDA. 351 234 - 32.95.00 234 - 32.54.57

Russia Moscow TEKA RUS LLC 7 095-737-4689 095-737-4690

Singapore Singapore TEKA SINGAPORE PTE LTD. 65 6-73-42415 6-73-46881

Thailand Bangkok TEKA (THAILAND) CO. LTD. 66 2 - 5164954 2 - 9021484

The Netherlands Zoetermeer TEKA B.V. 31 79-345.15.89 79-345.15.84

Turkey Istanbul TEKATEKNIK MUTFAK A.S. 90 212 - 274.61.04 212 - 274.56.86

U. K. Abingdon TEKA PRODUCTS (UK) LTD. 44 1235 - 86.19.16 1235 - 83.51.07

U.S.A. Tampa TEKA USA, INC. 1 800-419-9344 813-228-8604

Venezuela Caracas TEKAANDINA, S.A. 58 212 - 291.28.21 212 - 291.28.25

Teka Industrial, S.A.

Cajo, 17

39011 Santander (Spain)

Tel.: 34 - 942 - 35 50 50

Fax: 34 - 942 - 34 76 94

http://www.teka.net

Teka Küchentechnik GmbH

Sechsheldener Str. 122

35708 Haiger (Germany)

Tel.: 49 - 2771 - 8141-0

Fax: 49 - 2771 - 8141-10

http://www.teka.net

JKP 06/03

Loading...

Loading...