Teka COOKING HOBS EM-60 3G 1P AI AL TR, COOKING HOBS EM-60 3G 1P AI AL TR TV, COOKING HOBS EM-60 3G 1P AI TR, COOKING HOBS EM-60 4G AI AL TR, COOKING HOBS EM-60 4G AI AL TR TV User Manual

...Page 1

INSTALLATION INSTRUCTIONS

AND RECOMMENDATIONS FOR USE AND MAINTENANCE

COOKING HOBS

EINBAU-ANLEITUNG UND EMPFEHLUNGEN

FÜR GEBRAUCH UND INSTANDHALTUNG

KOCHFELDER

INSTRUCTIONS POUR L’INSTALLATION

ET RECOMMANDATIONS D’UTILISATION ET D’ENTRETIEN

PLAQUES DE CUISSON

ISTRUZIONI PER L’INSTALLAZIONE

E RACCOMANDAZIONI D’USO E MANUTENZIONE

PIANI COTTURA

EM/60 4G AI TR TV - EM/60 4G AI AL TR TV

EM/60 4G AI TR - EM/60 4G AI AL TR

EM/60 3G 1P AI TR TV - EM/60 3G 1P AI AL TR TV

EM/60 3G 1P AI TR - EM/60 3G 1P AI AL TR

EM/60 4G AI TR TV (FUND) - EM/60 4G AI AL TR TV (FUND)

EM/60 4G AI TR (FUND) - EM/60 4G AI AL TR (FUND)

EM/60 3G 1P AI TR TV (FUND) - EM/60 3G 1P AI AL TR TV (FUND)

EM/60 3G 1P AI TR (FUND) - EM/60 3G 1P AI AL TR (FUND)

Page 2

Index

Inhaltsverzeichnis

GB DE

Introduction

User Guide

Installation

Positioning the hobs

Positioning the fan-assisted oven

Fastening the hob

Connecting the gas

Connecting the electricity

Gas conversion

Technical information

Dimensions and power

Technical details

Use and Maintenance

Before starting for the first time

Igniting the burners

Protection mechanism against

inadvertently turning the gas controls

Components of an appliance

with built-in safety

Suggestions for effective use

of the burners

Cleaning and care the burners

Maintaining the burners

Operation of models

with electric hotplates

Suggestions for effective use

of the electric hotplates

Cleaning and care of the hotplates

Using the cover

If something doesn’t work

Page 4

11

11

12

13

13

13

14

14

15

15

16

16

17

17

18

19

Präsentation

6

Hinweise zum Gebrauch

7

Einbau

7

Einbauort für die Kochfelder

8

Einbauort für den Umluftofen

8

Verankerung des Kochfelds

8

Gasanschluss

9

Elektrischer Anschluss

9

Umstellung auf andere Gasart

Technische Angaben

Abmessungen und Leistungsmerkmale

Technische Daten

Gebrauch und Instandhaltung

Besondere Vorbedingungen für

die Inbetriebnahme

Zünden der Gasbrenner

Schutz gegen versehentliches

Drehen der Gashähne

Bestandteile eines Systems

für sicheren Gebrauch

Tipps für den korrekten Gebrauch

der Gasbrenner

Reinigung und Konservierung

der Gasbrenner

Wartung der Gaskochplatten

Funktionsweise der Modelle

mit elektrischen Kochzonen

Tipps für den korrekten Gebrauch

der elektrischen Kochzonen

Reinigung und Pflege der

Kochzonen

Gebrauch des Deckels

Seite 4

20

21

21

22

22

22

23

23

25

25

26

27

27

27

28

28

29

29

30

30

31

31

32

Im Störungsfall

2

33

Page 3

Table des matiéres

Indice

FR

Présentation

Guide d’utilisation

Installation

Logement des tables

de cuisson

Logement du four

Encrage de la table de cuisson

Raccordement au gaz

Branchement électrique

Adaptation du gaz

Caractéristiques techniques

Dimensions et puissances

Caractéristiques techniques

Utilisation et entretien

Conditions spéciales avant la

mise en marche

Allumage des brûleurs

Système de blocage des

commandes de gaz

Composants d’un système

de sécurité

Recommandations pour une

bonne utilisation des brûleurs

Nettoyage et stockage

des brûleurs

Entretien des brûleurs

Fonctionnement des modèles

avec plaques électriques

Recommandations pour une bonne

utilisation des plaques électriques

Nettoyage et entretien des

plaques

Utilisation du couvercle

Si quelque chose ne fonctionne pas

Page 4

IT

Presentazione

34

Guida per l’uso

35

Installazione

Alloggiamento dei piani cottura

35

Alloggiamento del forno

36

Ancoraggio del piano cottura

36

Collegamento del gas

36

Collegamento elettrico

37

Trasformazione del gas

37

Informazioni tecniche

39

Dimensioni e potenze

39

Dati tecnici

40

Uso e manutenzione

41

Requisiti speciali prima della

messa in servizio

41

Accensione dei bruciatori

41

Sistema anti-apertura accidentale

dei comandi del gas

42

Componenti di un sistema

con dispositivo di sicurezza

42

Consigli per un uso corretto

dei bruciatori

43

Pulizia e conservazione

dei bruciatori

43

Manutenzione dei bruciatori

44

Funzionamento dei modelli

con piastre elettriche

44

Consigli per un uso corretto

delle piastre elettriche

45

Pulizia e conservazione

delle piastre

45

Utilizzo del coperchio

46

Se qualcosa non funziona

47

Pagina 4

48

49

49

50

50

50

51

51

53

53

54

55

55

55

56

56

57

57

58

58

59

59

60

61

3

Page 4

Introduction/Präsentation/Présentation/Presentazione

1

2

5

3

GB

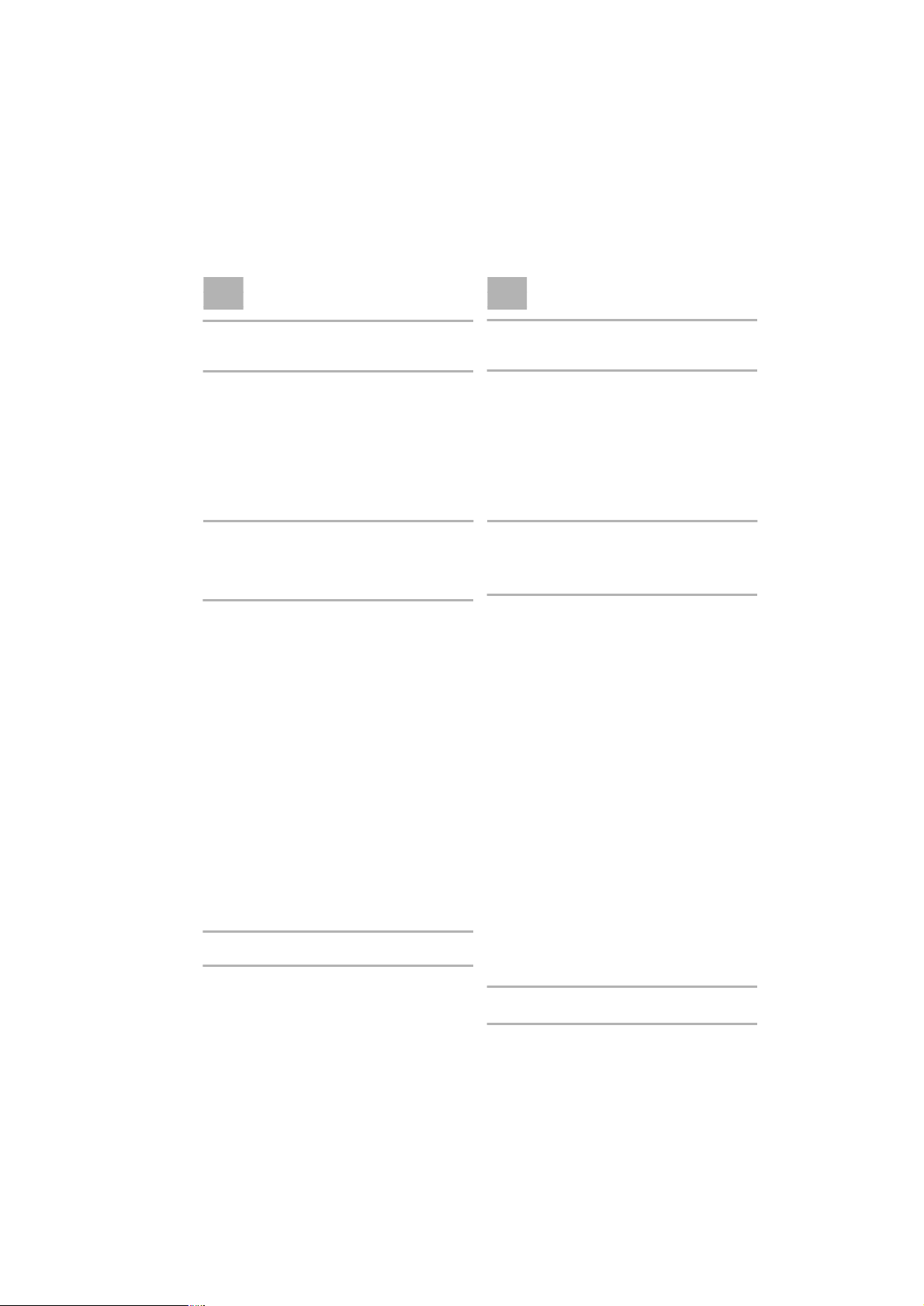

Models EM/60 4G AI AL TR (FUND) and EM/60 4G

AI TR (FUND)

1 Rapid burner 2,580 Kcal/h - 3 kW.

2 Triple crown burner 3,268 Kcal/h -3.8 kW.

3 Semi-rapid burner 1,500 Kcal/h -1.75 kW.

4 Auxiliary burner 860 Kcal/h - 1 kW.

5 Grid.

* Maximum calorific power: 8,208 Kcal/h -9.55 kW.

DE

Modelle EM/60 4G AI AL TR (FUND) und EM/60 4G

AI TR (FUND)

1 Stark-Brenner mit 2580 kcal/h - 3 kW

2 Brenner mit Dreifachkranz 3268 kcal/h -3,8 kW

3 Mittelbrenner mit 1500 kcal/h -1,75 kW

4 Hilfsbrenner mit 860 kcal/h - 1 kW

5 Stellrost

* Maximale Wärmeleistung: 8208 Kcal/h - 9,55 kW.

FR

Modèles EM/60 4G AI AL TR (FUND) et EM/60 4G

AI TR (FUND)

1 Brûleur rapide de 2.580 Kcal/h - 3 kW.

2 Brûleur triple couronne de 3.268 Kcal/h -3,8 kW.

3 Brûleur semi-rapide de 1.500 Kcal/h -1,75 kW.

4 Brûleur auxiliaire de 860 Kcal/h - 1 kW.

5 Grille.

* Puissance calorifique maximale: 8.208 Kcal/h -

9,55 kW.

IT

Modelli EM/60 4G AI AL TR (FUND) e EM/60 4G AI

TR (FUND)

1 Bruciatore rapido da 2.580 Kcal/h - 3 kW.

2 Bruciatore a tripla corona da 3.268 Kcal/h - 3,8 kW.

3 Bruciatore semirapido da 1.500 Kcal/h - 1,75 kW.

4 Bruciatore ausiliario da 860 Kcal/h - 1 kW.

5 Griglia.

* Potenza calorifica massima: 8.208 Kcal/h - 9,55 kW.

4

1

5

3

GB

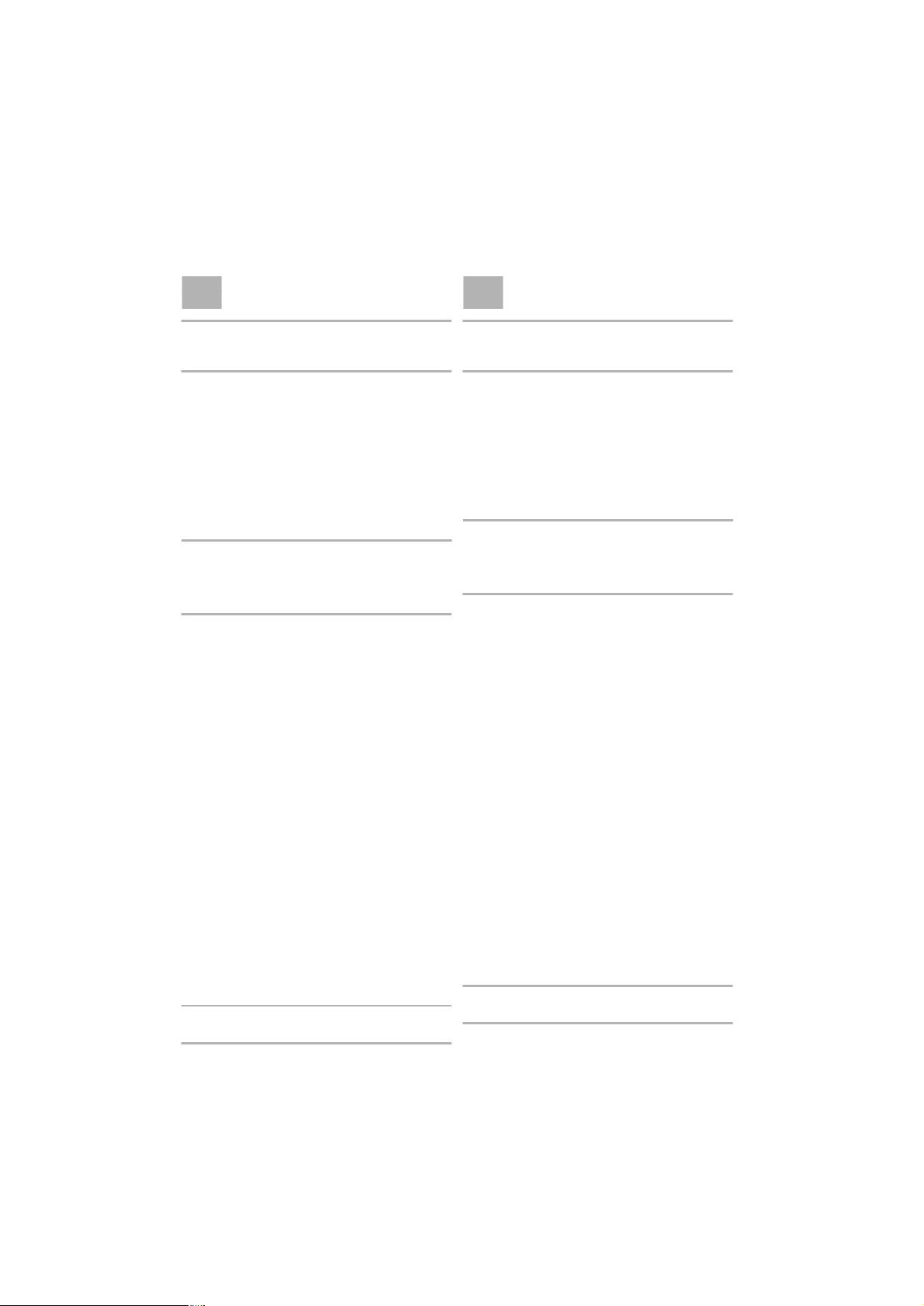

Models EM/60 3G 1P AI AL TR (FUND) and EM/60

3G 1P AI TR (FUND)

1 Electric hotplate Ø 145 mm, 1500 W.

2 Triple crown burner 3,268 Kcal/h - 3.8 kW.

3 Semi-rapid burner 1,500 Kcal/h -1.75 kW.

4 Auxiliary burner 860 Kcal/h - 1 kW.

5 Grid.

* Maximum calorific power: 5,628 Kcal/h -6.55 kW.

DE

Modelle EM/60 3G 1P AI AL TR (FUND) und EM/60

3G 1P AI TR (FUND)

1 Elektro-Kochzone mit Ø 145 mm, 1500 W

2 Brenner mit Dreifachkranz 3268 kcal/h - 3,8 kW

3 Mittelbrenner mit 1500 kcal/h -1,75 kW

4 Hilfsbrenner mit 860 kcal/h - 1 kW

5 Stellrost

* Maximale Wärmeleistung: 5.628 Kcal/h -6,55 kW.

FR

Modèles EM/60 3G 1P AI AL TR (FUND) et EM/60

3G 1P AI TR (FUND)

1 Plaque électrique Ø 145 mm., 1.500 W.

2 Brûleur triple couronne 3.268 Kcal/h -3,8 kW.

3 Brûleur semi-rapide de 1.500 Kcal/h -1,75 kW.

4 Brûleur auxiliaire de 860 Kcal/h - 1 kW.

5 Grille.

* Puissance calorifique maximale: 5.628 Kcal/h -

6,55 kW.

Modelli EM/60 3G 1P AI AL TR (FUND) e EM/60 3G

IT

1P AI TR (FUND)

1 Piastra elettrica Ø 145 mm, 1.500 W.

2 Bruciatore a tripla corona 3.268 Kcal/h - 3,8 kW.

3 Bruciatore semirapido da 1.500 Kcal/h - 1,75 kW.

4 Bruciatore ausiliario da 860 Kcal/h - 1 kW.

5 Griglia.

* Potenza calorifica massima: 5.628 Kcal/h -

6,55 kW.

2

4

4

Page 5

1

6

5

2

6

1

5

2

3

GB

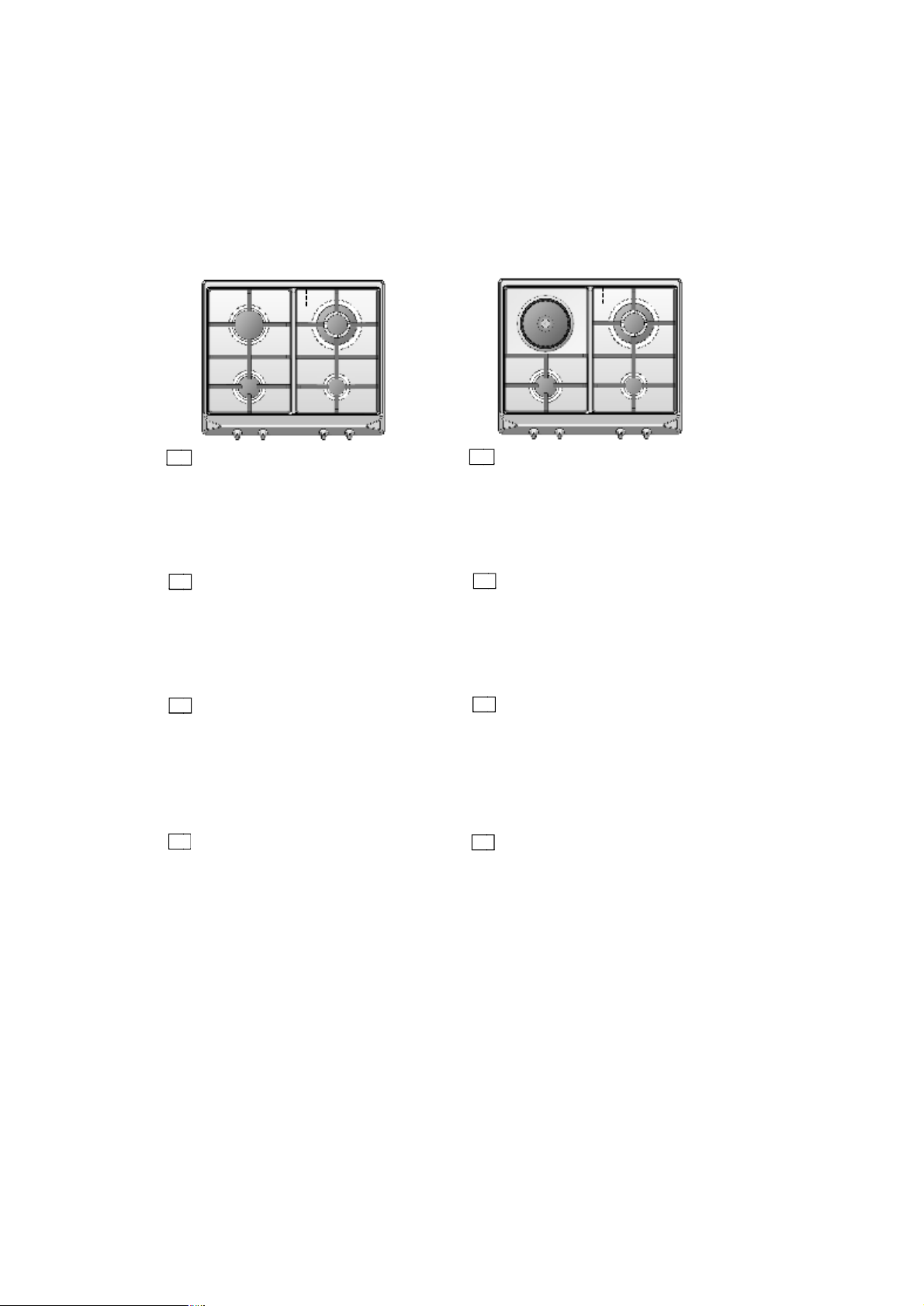

Models EM/60 4G AI TR TV, EM/60 4G AI AL TR

TV, EM/60 4G AI TR TV (FUND) and EM/60 4G AI

AL TR TV (FUND)

1 Rapid burner 2,580 Kcal/h - 3 kW.

2 Triple crown burner 3,268 Kcal/h - 3.8 kW.

3 Semi-rapid burner 1,500 Kcal/h -1.75 kW.

4 Auxiliary burner 860 Kcal/h - 1 kW.

5 Grid.

6 Cover support.

* Maximum calorific power: 8,208 Kcal/h -9.55 kW.

Modelle EM/60 4G AI TR TV, EM/60 4G AI AL TR

DE

TV, EM/60 4G AI TR TV (FUND) und EM/60 4G AI

AL TR TV (FUND)

1 Stark-Brenner mit 2580 kcal/h - 3 kW

2 Brenner mit Dreifachkranz mit 3268 kcal/h - 3,8 kW

3 Mittelbrenner mit 1500 kcal/h - 1,75 kW

4 Hilfsbrenner mit 860 kcal/h - 1 kW

5 Stellrost

6 Halterung für Deckel

* Maximale Wärmeleistung: 8208 Kcal/h - 9,55 kW.

FR

Modèles EM/60 4G AI TR TV, EM/60 4G AI AL TR

TV, EM/60 4G AI TR TV (FUND) et EM/60 4G AI AL

TR TV (FUND)

1 Brûleur rapide de 2.580 Kcal/h - 3 kW.

2 Brûleur triple couronne de 3.268 Kcal/h - 3,8 kW.

3 Brûleur semi-rapide de 1.500 Kcal/h - 1,75 kW.

4 Brûleur auxiliaire de 860 Kcal/h - 1 kW.

5 Grille.

6 Support couvercle.

* Puissance calorifique maximale: 8.208 Kcal/h -

9,55 kW.

IT

Modelli EM/60 4G AI TR TV, EM/60 4G AI AL TR

TV, EM/60 4G AI TR TV (FUND) e EM/60 4G AI AL

TR TV (FUND)

1 Bruciatore rapido da 2.580 Kcal/h - 3 kW.

2 Bruciatore a tripla corona da 3.268 Kcal/h - 3,8 kW.

3 Bruciatore semirapido da 1.500 Kcal/h - 1,75 kW.

4 Bruciatore ausiliario da 860 Kcal/h - 1 kW.

5 Griglia.

6 Supporto coperchio.

* Potenza calorifica massima: 8.208 Kcal/h - 9,55 kW.

4

3

GB

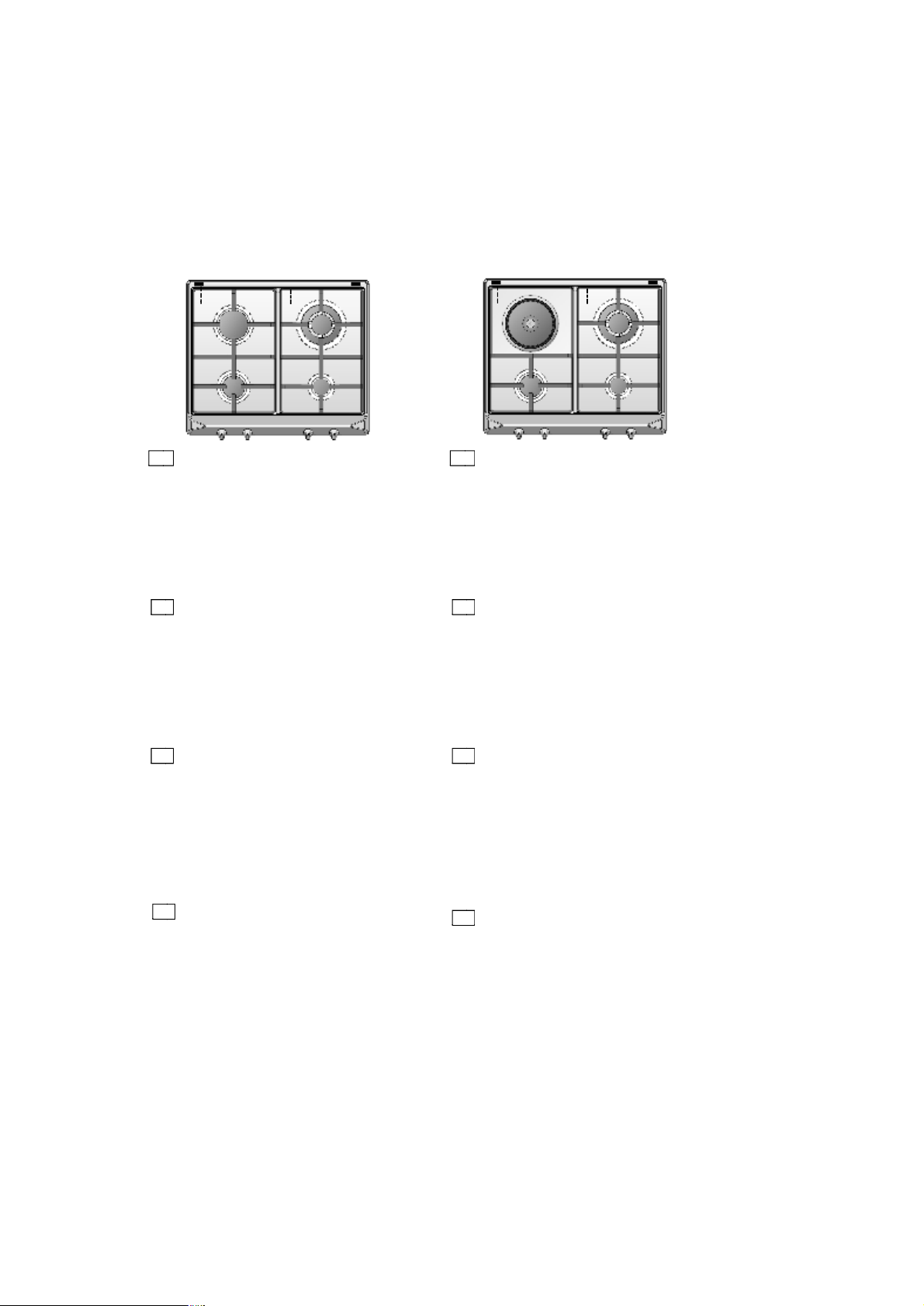

Models EM/60 3G 1P AI TR TV, EM/60 3G 1P AI AL

TR TV, EM/60 3G 1P AI TR TV (FUND) and EM/60

3G 1P AI AL TR TV (FUND)

1 Electric hotplate Ø 145 mm, 1500 W.

2 Triple crown burner 3,268 Kcal/h - 3.8 kW.

3 Semi-rapid burner 1,500 Kcal/h -1.75 kW.

4 Auxiliary burner 860 Kcal/h - 1 kW.

5 Grid.

6 Cover support.

* Maximum calorific power: 5,628 Kcal/h -6.55 kW.

DE

Modelle EM/60 3G 1P AI TR TV, EM/60 3G 1P AI

AL TR TV, EM/60 3G 1P AI TR TV (FUND) und

EM/60 3G 1P AI AL TR TV (FUND)

1 Elektro-Kochzone mit Ø 145 mm, 1500 W

2 Brenner mit Dreifachkranz 3268 kcal/h - 3,8 kW

3 Mittelbrenner mit 1500 kcal/h -1,75 kW

4 Hilfsbrenner mit 860 kcal/h - 1 kW

5 Stellrost

6 Halterung für Deckel

* Maximale Wärmeleistung: 5.628 Kcal/h -6,55 kW.

FR

Modèles EM/60 3G 1P AI TR TV, EM/60 3G 1P AI

AL TR TV, EM/60 3G 1P AI TR TV (FUND) et EM/60

3G 1P AI AL TR TV (FUND)

1 Plaque électrique Ø 145 mm, 1.500 W.

2 Brûleur à triple couronne 3.268 Kcal/h - 3,8 kW.

3 Brûleur semi-rapide de 1.500 Kcal/h -1,75 kW.

4 Brûleur auxiliaire de 860 Kcal/h - 1 kW.

5 Grille.

6 Support couvercle.

* Puissance calorifique maximale: 5.628

Kcal/h - 6,55 kW.

Modelli EM/60 3G 1P AI TR TV, EM/60 3G 1P AI AL

IT

TR TV, EM/60 3G 1P AI TR TV (FUND) e EM/60 3G

1P AI AL TR TV (FUND)

1 Piastra elettrica Ø 145 mm, 1.500 W.

2 Bruciatore a tripla corona 3.268 Kcal/h - 3,8 kW.

3 Bruciatore semirapido da 1.500 Kcal/h - 1,75 kW.

4 Bruciatore ausiliario da 860 Kcal/h - 1 kW.

5 Griglia.

6 Supporto coperchio.

* Potenza calorifica massima: 5.628 Kcal/h - 6,55 kW.

4

5

Page 6

GB

How to use the instruction manual

Dear customer,

Safety instructions

We are delighted that you have put your

trust in us.

We are confident that the new hob that you

have purchased will fully satisfy your

needs.

This modern, functional and practical

model has been manufactured using topquality materials that have undergone

strict quality controls throughout the manufacturing process.

Before installing and using it, please read

this Manual carefully and follow the instructions closely, as this will guarantee better results when using the appliance.

Keep this Instruction Manual in a safe

place so that you can refer to it easily and

thus comply with the terms and conditions

of the guarantee.

In order to make a claim on this Guarantee, it is essential that you submit the purchase receipt together with the guarantee

certificate.

Before using for the first time, you should

carefully read the installation and connection instructions.

These hob models may be installed in the

same kitchen furniture units as TEKA

ovens.

For your safety, installation should be

carried out by an authorised technician

and should comply with existing installation standards. Likewise, any internal work

on the hob should only be done by TEKA’s

technical staff.

Please note:

When the hotplates are in operation or have recently been in operation,

some areas will be hot and can burn.

Children should be kept well away.

You should keep the Guarantee

Certificate or, where relevant, the technical datasheet, together with the Instruction Manual for the duration of the

service life of the appliance. It has

important technical information about

the appliance.

6

Page 7

Installation

Important

INSTALLATION AND SETUP SHOULD

BE CARRIED OUT BY AN AUTHORISED

TECHNICIAN IN LINE WITH CURRENT

INSTALLATION STANDARDS.

Positioning the hobs

A gap with the dimensions shown in figure

1 will be cut into the worktop or stove.

The system for fixing the hob is intended

for use with kitchen units with a thickness

of 20, 30 or 40 mm.

In free-standing models, a shelf should be

placed inside the unit. The minimum distance between the lower part of the hob

and the upper part of the shelf should be

20 mm.

The hobs described in this manual can

only be installed with TEKA ovens.

The minimum distance between the surface supporting the cooking pans and the

lower part of the kitchen unit or the hood

located above the hob should be 650 mm.

If the hood’s installation instructions recom-

mend that the gap is greater than this, you

should follow this advice.

The unit where the hob and oven will be

located will be suitably fixed.

Minimum distances

to walls

Minimum ventilation

distances

40 mm minimum

40 mm minimum

Installation

space

m

u

m

i

x

a

m

GB

fig. 1

OVEN

When hobs are handled before

being installed, care should be taken in

case there is any protruding part or

sharp edge which could cause injury.

TEKA does not accept liability for

any malfunction or damage that may be

caused by faulty installation.

The glues used in manufacturing

the kitchen unit and in the adhesive on

the decorative laminate of the worktop

surface should be made to tolerate temperatures of up to 100ºC.

7

Page 8

GB

The glass covers can shatter when

they heat up. Turn off the burners before

closing the cover.

Positioning the oven

See the corresponding manual.

Fixing the hob

When the gap has been properly sized,

the sealing washer (J) should be put on

the part of the cooker.

Position the clips (K) as shown in figure 2,

fastening them to the openings in the

lower part of the body using the metal threaded screws provided (Ø 4.2 mm).

The clips (K) and the sealing washer (J)

are provided, and can be found in the packaging.

For worktop thicknesses of less than 30

mm., use the self-tapping screws (M) that

are provided as a fastening accessory - put

them into the clip’s round hole. This hole will

be threaded as the screw is inserted into it,

and this should be done before fixing the

clip to the worktop.

Connecting the gas

Connecting the hob to the gas mains

should be done in compliance with the

current installation standards and regulations.

Ventilation slots should also be made at

the site in compliance with current norms.

The hob is provided with a threaded connection 1/2” in diameter, in line with ISO

228-1. A Ø 10/12 mm copper pipe is provided as an accessory for welding the gas

inlet pipe.

fig. 2

40 mm

30 mm

20 mm

Whenever the gas connection nut is removed, its washer should be changed.

In order that the hob is not damaged by

tightening the nut on the gas connection

pipe, a maximum torque of 350 cm * Kgf

should be applied.

When the gas connection has been made,

the installation should be checked to ensure that it is completely sealed. If the check

is done using air, care should be taken that

the test pressure is no more than 200

gr./cm2. Where air is not available, soapy

water should be applied to ensure that

there are no leaks in the connections. Tes-

ting should never be done using a

flame.

When the hob has been installed, check

that the burner minimums are properly

8

Page 9

adjusted. To do this, light the burners and

check that they do not go out if you switch

quickly from the maximum to the minimum.

Connecting the electricity

Before connecting the hob to the electric

mains, check that the voltage and frequency of the mains matches that shown

on the hob’s rating plate, which is located

lower down, and on the guarantee certificate or, where appropriate, the technical

datasheet supplied, which should be kept

together with this manual.

The connection is made via an omnipolar

switch or plug where accessible, which is

suitable for the intensity to be tolerated

and which has a minimum gap of 3 mm

between its contacts, which will ensure

disconnection in case of emergency or

when cleaning the hob.

GB

Gas conversion

Important!

Any alteration that is to be made to the

appliance to convert it to a different

type of gas should only be carried out

by an authorised person and should

comply with current standards.

Information for Technical Assis-

tance: whenever the type of gas or the

appliance’s pressure is changed, the new

regulation plate should be placed on top of

the old one so that the new features can

be seen after the change.

The tasks involved in conversion are:

* Replace the injectors.

* Adjust the taps’ minimums.

The connection should include correct earthing, in compliance with current norms.

If the flexible supply cable fitted to these

appliances ever needs to be changed, it

should be replaced by TEKA’s official SAT

cable, which requires special tools.

The input cable should not be in contact

either with the body of the hob or with the

body of the oven, if the oven is installed in

the same unit.

The injectors required for each gas type

are shown in table 1.

To replace the injectors, follow these instructions:

1 Remove the grids and upper parts of the

burner so that the injector can be seen.

2 Using a number 7 pipe spanner, remove

the injectors and replace them with the

new ones. Ensure that the injector is

properly tightened and so avoid gas

escaping.

3 Replace the grid and burners that were

previously removed.

When the injectors have been changed,

adjust the minimums as follows:

1 Turn the burners on to their minimum.

9

Page 10

GB

2 Remove the cooker’s controls in order to

be able to access the gas taps.

3 Use a slim, grooved screwdriver to turn

the screw located to the left or in the

centre of the gas tap’s shaft (the flame

increases when you turn to the left and

decreases when you turn to the right).

4 When properly adjusted, check that the

flame does not go out when you turn the

knob quickly from maximum to minimum.

TEKA INDUSTRIAL, S.A. does not accept

liability for any hob malfunction if the gas

conversion or the adjustment of the burners’ minimums has not been carried out

by TEKA’s official personnel.

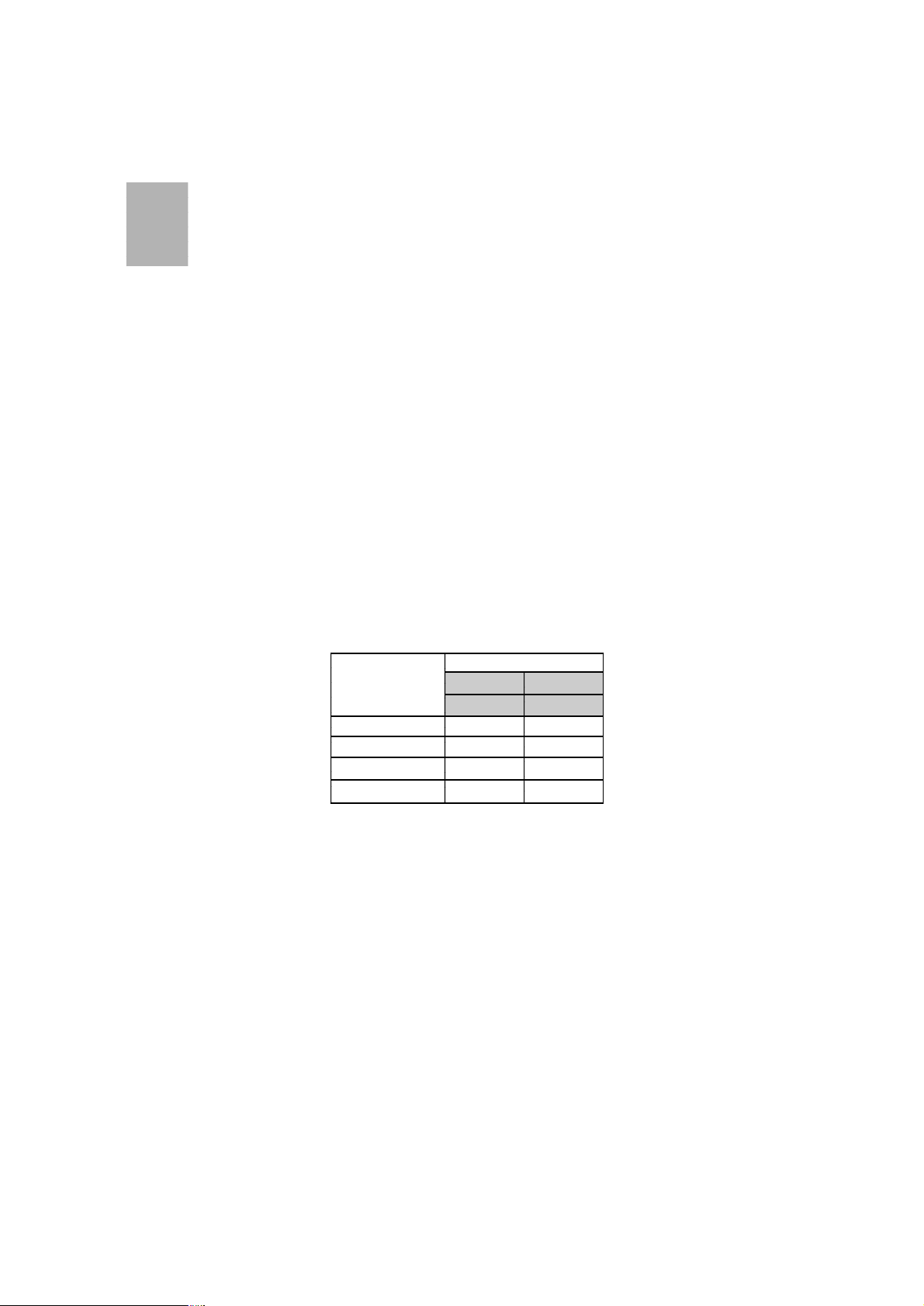

Table 1

Burner Family

Second Third

Group H Group 3+

Triple crown 130 97

Rapid 116 85

Semi-rapid 97 66

Auxiliary 72 50

Ø injector expressed in 1/100 mm.

10

Page 11

Technical Information

Dimensions and power

GB

Models

Hob dimensions

Height (mm) 90 90 90 90

Length (mm) 600 600 600 600

Width (mm) 510 510 510 510

Dimensions of the positioning in the unit

Length (mm) 560 560 560 560

Width (mm) 480 480 480 480

Depth (mm) 40 40 40 40

Power per burner and hotplate

Rapid gas

burner 3 kW. 1

Semi-rapid gas

burner 1.75 kW. 1

Auxiliary gas

burner 1 kW. 1

Triple crown gas

burner 3.8 kW. 1 1 1 1

Electric hotplate

Ø 145 mm, 1

1,500 W

Electric:

Nominal Power

(W) for 230V* 0.6 1,500 0.6 1,500

Supply

voltage (V)

Frequency (Hz) 50 - 60 50 - 60 50 - 60 50 - 60

Gas:

Maximum power kW 9.55 6.55 9.55 6.55

* For voltages other than 230 V please consult the rating plate

on the appliance.

EM/60

4G AI AL TR

(FUND)

SEE THE APPLIANCE’S RATING PLATE

EM/60

3G 1P AI AL

TR (FUND)

1 1 1

1 1 1

EM/60

4G AI TR

(FUND)

1

EM/60

3G 1P AI TR

(FUND)

1

11

Page 12

GB

Technical details

COMMON FEATURES FOR ALL MODELS

WITH ELECTRIC HOTPLATES AND AUTOMATIC IGNITION

The supply voltage and frequency will be

as shown on the rating plate.

If an electric hotplate gets cracked, the

hob should be disconnected from the electricity supply.

COMMON FEATURES FOR ALL

MODELS WITH GAS BURNERS

Warnings:

a) Before installation, make sure that the

local supply conditions (the gas type and

pressure) are compatible with the appliance’s setup.

b) The setup conditions for this appliance

are written on the label (or the rating

plate).

c) This appliance should not be connected

to a device for removing combustion products. It should be installed and connected

in compliance with the current installation

standards. Special attention should be paid

to the regulations applying to ventilation.

A gas cooking appliance produces

heat and moisture at the site where it is

installed. The kitchen should be provided with suitable ventilation: natural

ventilation sources should be kept

Table 3

Burner

Nominal Calorific Consumption

Nominal consumption*

Reduced calorific consumption

Performance

* Consumption over Gross Calorific Value (H )

kW

G-20 (Nm3/h)

G-30 (Kg/h)

G-31 (Kg/h)

kW

%

s

clear, a window opened, or an effective

mechical ventilation system device,

such as a hood, installed.

The intense and prolonged use of

the appliance may call for complementary ventilation, such as opening a window, or more efficient ventilation such

as increasing the power of the mechanical ventilation if this exists.

Class 3 hob.

You should keep the Guarantee Certificate or, where relevant, the

technical datasheet, together with

the Instruction Manual for the duration of the service life of the appliance. It has important technical information about the appliance.

Table 2

Country

Spain

Portugal

United Kingdom

Switzerland

Ireland

Chez Republic

Greece

Hungary

Denmark

Norway

Finland

Sweden

Triple crown

mbar

20

29

37

3.8

0.36

0.28

0.27

1.55

>52

Rapid

3

0.29

0.22

0.21

0.77

>52

Category

II2H3+

II2H3+

II2H3+

II2H3+

II2H3+

II2H3+

I3+

I2H

I2H

I2H

I2H

I2H

Semi-rapid

1.75

0.17

0.13

0.13

0.47

>52

Auxiliary

1

0.10

0.07

0.07

0.33

-

12

Page 13

Use and Maintenance

GB

Special measures before

using for the first time

Before connecting the hob to the electric

mains, check that the voltage and frequency of the mains matches that shown

on the hob’s rating plate, which is located

lower down, and on the guarantee or,

where appropriate, the technical datasheet supplied, which should be kept together

with this manual.

Remember that you may have to remove

the protective plastic cover that is stuck to

the hob.

Igniting the burners

* Make sure that the knobs are in their

correct position.

* Turn on the gas at the mains or turn the

gas cylinder tap.

* Put a flame or spark to the burner if you

do not have automatic ignition.

Press the control knob and at the same

time turn it anti-clockwise to the maximum

position (the big flame, “C” in figure 3). The

burner will now come on at full power;

then, if you wish, you can turn the knob to

the minimum position (the small flame,

“D”).

With hob models that have automatic ignition and the safety feature, proceed as

follows:

1.Press down the burner control.

2.Keeping the burner control pressed

down, turn it all the way till the gas ignites, and keep it pressed down for at

least 2 seconds so that the safety thermocouple can take effect.

fig. 3

‘Burner in operation’ indicator

Knob position when not in use

Maximum gas position

Minimum gas position

3.Set the control to the position required.

In order for the automatic ignition system

to work properly, it is vital that the ignition

(the ceramic and the electrode) is cleaned

regularly and carefully - this will avoid ignition problems. Check, too, that the grooves in the burners have not become obstructed.

On the control panel, areas are marked (A)

that show the control for each burner.

If a gas smell is detected, the gas intake to

the hob should be shut off and the room

ventilated. The gas installation and the hob

should also be checked by a specialised

technician.

Use flat-bottomed pans and check that

they sit squarely on the grid, so that when

food boils the pan does not slip (do not use

pans with a concave or convex base).

13

Page 14

GB

Only pans with a minimum diameter of 140

mm. should be used. If you wish to use a

smaller pan, always use the auxiliary burner.

Please note:

When the burners are in operation

or have recently been in operation, the

hob will be hot in places and this can

lead to burns. Children should be kept

well away.

For safety reasons, we advise that

the instructions provided by the gas

supply company are followed and that

the supply tap is turned off when the

hob is not in use.

The glass covers can shatter when

they heat up. Turn off the burners before

closing the cover.

Protection mechanism against

inad-vertently turning the

gas controls

Safety system

components

On hobs with the safety feature (those

models which have the letters AL), the gas

cut-off device is made up of these elements below:

* The safety tap

* The safety thermocouple, next to the

burner

* The thermocouple-tap connection

The thermocouple sends an electric signal

to the tap which identifies whether the burner has a flame. During ignition, the tap

should be held down for around two

seconds, until the thermocouple has heated up and can send a satisfactory electric

signal to the tap. Should the burner go out,

the absence of a flame is detected by the

thermocouple, which makes the safety tap

cut off the flow of gas.

fig. 4

On models without the safety

system (without the gas cut-off device),

the gas taps are equipped with a mechanical system that prevents the controls from

being freely turned from the off position to

the on position (and, therefore, prevents

any accidental escape of gas from the burners) if the control has not previously

been pressed down.

If at any time while using the hob

you notice that a control can be turned

from the off position without it needing

to be pressed down beforehand (for

example: because of dirt which may

have got into and accumulated in the

gas taps) you should, for your own

safety, quickly notify the technical service so that the problem can be rectified.

14

Safety thermocouple

Thermocouple-tap connection

Spark generation connection

Ignition spark plug

Safety tap

Page 15

Suggestions for using the

burners effectively

* Rapid burners should not be used with

pans that have a small diameter, because part of the flame will spread away from

the pan, thus reducing performance significantly (see figure 5).

Right

fig. 5

Wrong

* The burners should not be operated

without there being a pan on them, or gas

will be wasted and the grid will heat up

excessively. The pan should be covered

up, in order to save energy.

* When the burners are in operation, they

ought not to be exposed to strong

draughts, because as well as losing

calorific power, there is the danger of the

flame going out, which would lead to gas

escaping - except on hobs with the

safety feature - and could cause an accident. This point is particularly important

when the burners are operating at their

minimum power.

GB

* Cast iron plates should not be used on

the grid, because they reflect too much

heat onto the hob.

* Pans placed on the burners should not jut

out past the edge of the hob, because the

effect of the flame being reflected from the

pan can damage hobs whose surfaces

are not resistent to high temperatures.

Cleaning and care

of the burners

* The grids should be cleaned with a non-

abrasive scourer when they have cooled

down.

* The burners - the grooves in particular -

should be cleaned at regular intervals;

they should be put into warm, soapy

water and cleaned with a scourer or a

stiff brush.

* Do not clean the enamel diffusing

covers while they are still hot. Abrasive

products can cause damage: vinegar,

coffee, milk, salt water and tomato juice

that remain on the enamel surfaces for a

long period of time.

fig. 6

* If the burner makes the pans smoky, or

if the tip of the flame is yellow, the burner should be cleaned. If this anomaly

persists, you should contact the Technical Assistance Service.

* Griddles and grills should not be used to

cook on a low heat - they can damage

the hob.

Diffusing cover

Diffusing crown

Injector

Injector holder

15

Page 16

GB

* The stainless steel should be washed in

soapy water using a soft cloth. If the

metal is yellowish after washing, we

recommend that you use: lemon, vinegar, dilute amonia or a cleaning product

that contains dilute amonia.

* When cleaning the appliance with the

burners removed, care should be taken

not to allow liquid or other objects to get

into the injector openings.

* When cleaning, do not use products that

can harm aluminium, such as soda, oil,

etc.

*The ignition unit (ceramic part and elec-

trode) must be periodically cleaned with

care in order to prevent ignition problems. A check should also be made

that the burner slots are not obstructed.

Note: Whenever you replace a burner,

you should check that all of the parts

are properly in place. A part that is not

in the right place can cause poor combustion and/or overheating.

ded by the appliance should be made

by authorised technical personnel.

Operation of models with

electric hotplates

The electric hotplates are controlled by a

switch with seven positions. To get different levels of power, all you need to do is

to turn the appropriate knob and set it to

the position you want. On the control

panel, areas are marked (A) that show

(with a circle) the control for each hotplate.

fig. 7

Maintaining

the burners

Whenever the gas taps are removed, you

should change the washer that is between

the taps and the supply pipe. The burners

are working properly when their flame is

stable and a greeny-blue colour. If the tip

of the flame is yellow, the burners need to

be cleaned; if the problem persists, contact

the Technical Service.

In order to guarantee that the gas installation is properly sealed and that the burners

are working properly, the hob needs to be

inspected by specialised Technical Service

personnel at least once every 4 years.

Note: Any alteration or adjustment nee-

16

‘Hotplate in operation’ indicator

Control index

The pan should be placed on the hotplate

before ignition.

The power corresponding to each of the

switch’s positions is as follows:

Page 17

GB

Control set to

0

1

2

3

4

5

6

The Ø 145 mm 1500 W hotplate (the one

with the red dot) heats up rapidly and

achieves its maximum during around the

first five minutes, after which its power

decreases to 750 W, at which point the

temperature becomes constant.

When first connecting, or if the hotplate

has not been used for some time, the

moisture absorbed by the insulation needs

to be eliminated. To carry out this drying

process, turn the hotplate on - with no pan

on it - for five minutes at switch position 2.

The smell and smoke that are emitted,

while unpleasant, present no risk, and you

should assist ventilation by opening doors

and windows to let the outside air in.

Hotplate Ø 145 -1500 W.

Power

Switched off

135 W.

165 W.

250 W.

500 W.

750 W.

1500 W.

Suggestions for effective

use of the electric hotplates

To ensure maximum performance from

your hob, follow these guidelines:

* Use pans with a flat base, as the greater

the surface contact between the pan

and the hotplate, the greater will be the

heat transmission. We recommend the

use of heavy pans so that the base is

more difficult to dent. The picture shows

how pans with battered or dented bases

have less surface contact. (see fig.8)

Right Wrong Wrong

fig. 8

* Do not use pans with a diameter that is

smaller than that of the hotplate, in order

to avoid boiling foods spilling over onto

the hotplates.

* Dry the bottom of your pans before put-

ting them on the hotplates.

* When you are almost finished cooking, it

is a good idea to set the hotplate to the

minimum or to turn it off just before

removing the pan, in order to make use

of the energy that has been stored and

to avoid the hotplate operating while it is

empty.

Never use the electric hotplate

without a pan on it.

Cleaning and care

of the hotplates

* Disconnect the appliance from the elec-

tric mains before cleaning it.

* Do not use cleaning products that can

harm aluminium, such as soda, acids, etc.

* The electric hotplates should be cleaned

using soapy water and a non-abrasive

scourer. If, after cooking, you notice that

the hotplate’s or hob’s stainless steel rim

are yellowing slightly, you can counter

this by using lemon, vinegar, dilute amonia or any product containing dilute

amonia.

17

Page 18

GB

* If liquids spill onto the hotplate, they

should be quickly removed using a

cloth. Never leave them to be burned on

the hotplate, for this will reduce heat

transmission considerably.

* If the hotplate is not going to be used for

some time, it should be oiled so that the

surface shines and rusting is avoided.

* Remember that the hotplate will have a

longer life if, where possible, moisture

and excessive temperatures are avoided.

Using the cover

Models that have a glass cover should be

cleaned with warm water, without using

rough cloths or abrasive substances. To

make it easier to clean the rear part of the

hob, the cover can be taken off by lifting it up.

After cleaning, the cover should be carefully replaced.

Before the cover is opened, any liquids that

have been spilled should be cleaned up.

* Steam-based appliances should not be

used to clean the hob.

Do not clean the hotplates while

they are still hot.

Do not close the cover when

the burners or the electric hotplate are ON or are still hot.

TEKA INDUSTRIAL S.A. reserves the

right to alter its appliances in any way it

deems necessary or useful while not altering its basic characteristics.

18

Page 19

If something doesn’t work

Before calling the Technical Service, please

make the following checks:

Fault Possible cause Possible solution

Neither the hotplates nor the pilot lights are working

GB

The cable is not con-

nected to the mains

There is no spark when the

automatic ignitiion control is pressed

There is no current at

the plug

There is a spark but the burner does not ignite

The spark plug and the part

of the burner where the

spark should be is soiled or

greasy

The gas burners do not light

Gas is not coming through

to the hob

The burner ignites, however, when you release the knob

activating the safety feature, it goes out again

The flame does not appear

in the area heated by the

thermocouple

Connect the cable

to the mains

Check/repair the electri-

city at the mains

Clean the end of the

spark plug and the

burner

Check that the gas

cylinder tap is properly

open

If it is piped gas, open

the gas tap

Clean the burner’s

openings

The gas burners are making the pans dirty

The burner openings

are dirty

The injector or injector

holder is dirty

Clean the burner

openings

Clean the porta-injector

and injector without

using anything which

could damage or alter

the diameter of the gas

outlet opening

19

Loading...

Loading...