Page 1

OPERATORS MANUAL &

FITTING INSTRUCTIONS

FOR THE

LH 865 CAPACITY INDICATOR

LH No. 020-865-UK Version 2.00

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tel. +45 9696 2500

Fax. +45 9696 2501

Internet: http://www.lh-agro.com/

Page 2

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

We have endeavoured to deliver a fault free product. To ensure optimal use of the

equipment we ask that great attention be paid when reading the manual. We are

more than happy to help should any queries arise, both when the product is used

for the first time and at any later date. Regarding responsibility for use of the

product we refer to our sales and delivery terms especially paragraph 7, which

follows:

7. Product usage.

7.1 Any use of the product is at the sole risk of the buyer. The

buyer is therefore not entitled to any form for compensation

caused by, for example, any of the following:

Disturbance to/from any electronic services or products that

do not confirm to the standards for CE marking,

Missing or poor signal coverage or a succession hereof from

external transmitters/receivers, used by the buyer,

Functional faults, which apply to or from a PC-program or

PC-equipment, not delivered by the seller,

Faults that may arise from the buyers negligence to react to

warnings and fault messages from the product, or which can

be traced to negligence and/or absent constant control of

the work carried out in comparison to the planned job.

7.2 When implementing any new equipment the buyer must take great

care and pay attention. Any doubts as to correct operation/use

should result in contacting the sellers service department.

This manual may not be altered, copied or manipulated in any way. Unoriginal

manuals can lead to operational faults damaging machines or crops as a

consequence thereof. LH Agro can therefore not be held responsible for damages

incurred, which can be traced to the use of unoriginal or manipulated manuals.

Original manuals can be requisitioned at any time from LH Agro.

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tel. +45 9696 2500

Fax. +45 9696 2501

Internet: http://www.lh-agro.com/

2 LH A

GRO

Page 3

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

Contents

THE LH 865 SYSTEM .........................................................................................................4

GENERAL OVERVIEW...............................................................................................4

OPERATING........................................................................................................................6

DISPLAY INDICATIONS .............................................................................................6

CALCULATION OF GRAIN LOSS ..............................................................................7

RULE OF THUMB .......................................................................................................8

SETTING UP THE CAPACITY INDICATOR........................................................................9

FITTING INSTRUCTIONS FOR LH 865............................................................................ 10

FITTING AF MONITOR BOX ....................................................................................10

FITTING OF CONNECTING BOX 1 ..........................................................................10

FITTING OF CONNECTING BOX 2 ..........................................................................10

FITTING OF SUN SENSOR...................................................................................... 10

SUPPLY VOLTAGE .................................................................................................. 11

MOUNTING OF WHEEL SENSOR...........................................................................11

FITTING THE WALKER PADS..........................................................................................12

LEADING THE CABLES FROM THE WALKER PADS............................................. 13

FITTING THE SIEVE SENSOR .........................................................................................15

POSITION .................................................................................................................15

SHORTENING THE SENSOR ..................................................................................16

LEADING THE CABLE FROM THE SIEVE SENSOR ..............................................17

NOTES ..............................................................................................................................18

LH A

3

GRO

Page 4

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

THE LH 865 SYSTEM

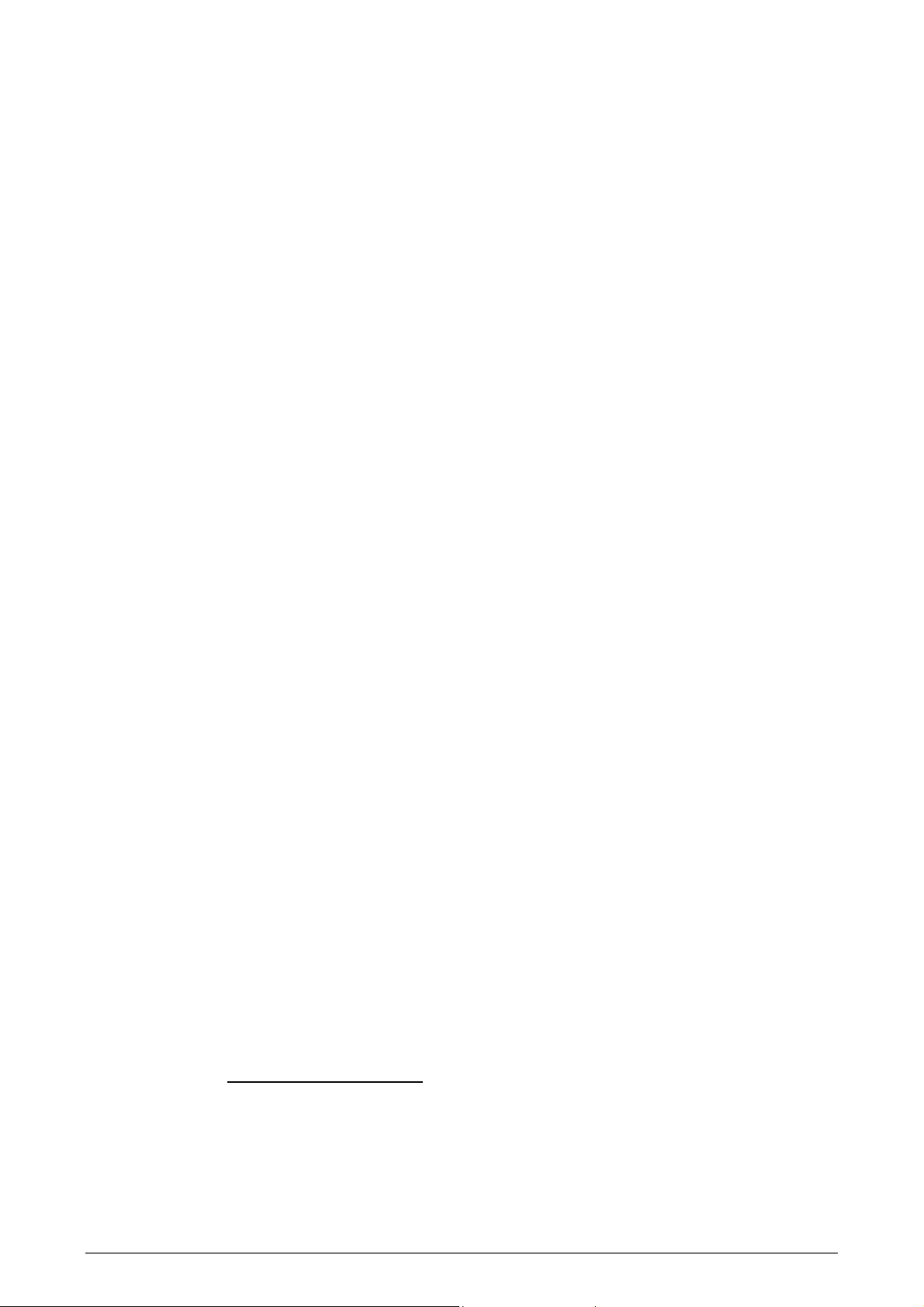

GENERAL OVERVIEW

11

1

ITTING INSTRUCTION

& F

22

21

23

10

4

12

24

6

25

3

2

7

8

26

5

9

27

4 LH A

GRO

Page 5

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

Pos.: LH-part no.: Text:

1 908-865 LH 865 grain loss monitor with foot

2 906-865 Connection box 1 for LH 865 system

ITTING INSTRUCTION

& F

3

866-012 Connection box 2 for LH 865 system

900-013 Print for Connection box 2

4 907-012 Straw walker sensor set (2 integration sensors)

5 927-021 Sieve sensor

6 905-865 LH 865 main cable

7 900-708 Sun sensor

8 900-753 Power supply cable

9 900-982 Wheel sensor

10 198-312 Cable for sieve sensor

Can be purchased separately:

11 915-865 LH 865 box (without foot)

12 903-865 Foot for LH 865 box

Extension possibilities:

Pos.: LH-part no.: Text:

21 a 901-102 Mounting set for LH 1000.

21 b 901-122 Mounting set for LH 1200.

22 a 843-102 Mounting bracket for LH 1000

22 b 843-122 Mounting bracket for LH 1200

23 a 900-100 Multi plug monitor part for LH 1000

23 b 900-121 Multi plug monitor part for LH 1200

24 a 900-101 Multi plug implement part for LH 1000

24 b 900-120 Multi plug implement part for LH 1200

25 955-122 Multi cable (5m 5 x 0,5 mm2)

26 900-982 2 core sensor (area breaker)

27 a 930-983 3 core revolution sensor 5 m with accessories

27 b 931-983 3 core revolution sensor 10 m with accessories

LH A

5

GRO

Page 6

LH 865 C

APACITY INDICATOR

OPERATING

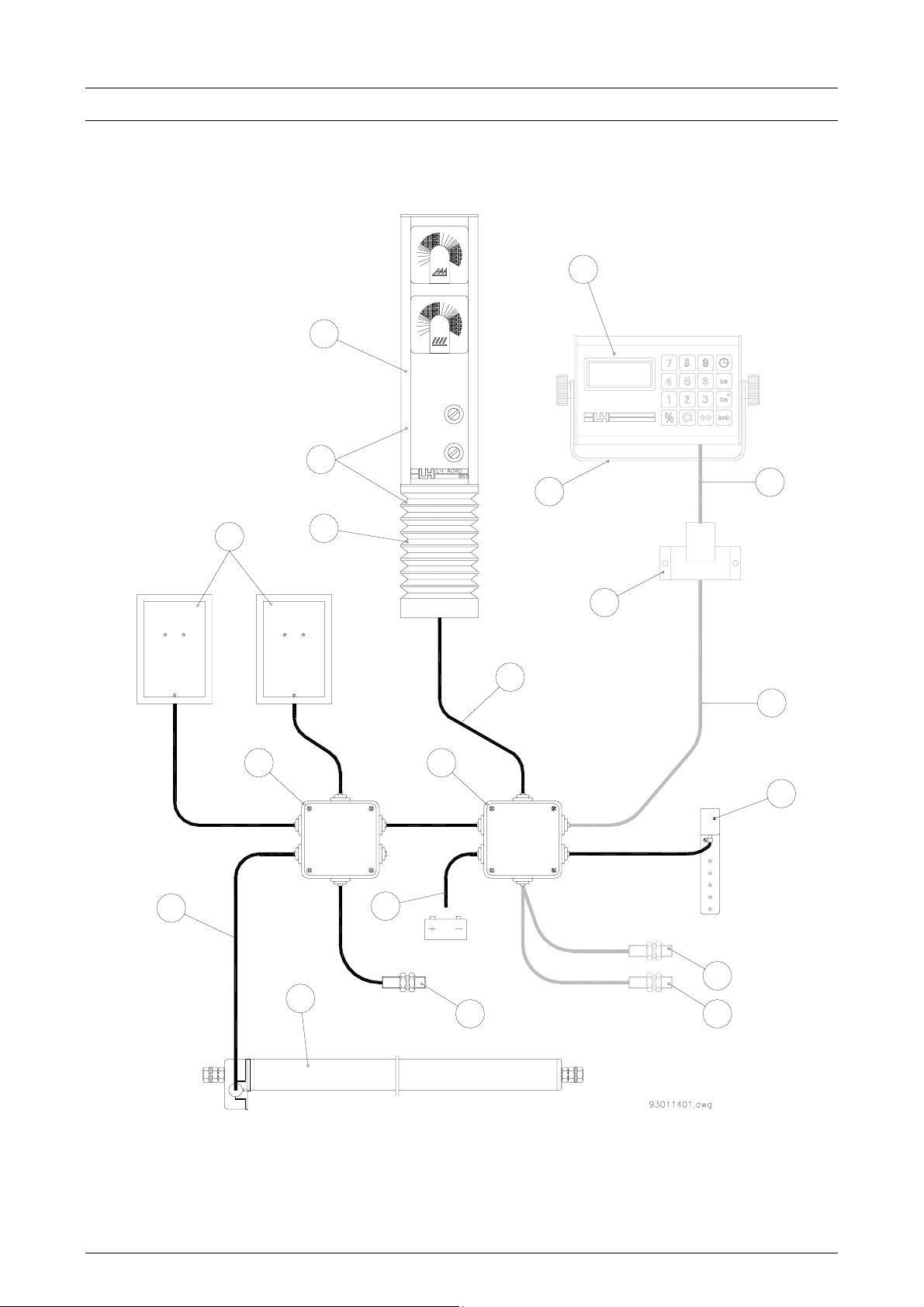

DISPLAY INDICATIONS

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

Both needles in white field

at the same time.

No loss.

You can speed up.

(Higher capacity)

Loss over the sieves.

Too much air or blocking.

No or intermittent loss over

the sieves.

Too little air under the

sieves.

Both needles in red field at

the same time.

Too much loss.

Slow down.

Loss over the straw

walkers.

Straw walkers overloaded.

Slow down.

6 LH A

GRO

Page 7

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

CALCULATION OF GRAIN LOSS

The figures in the below table states the number of seeds per current metre of

straw behind the combine harvester when the loss is 1% in a field where the yield

is 400 kg/ha.

Width of cut Barley Oats Wheat Rye

Foot Cm 25 seeds=1 g 28 seeds=1 g 21 seeds=1 g 25 seeds=1 g

100 100 112 84 100

6’ 180 180 201 161 180

8’ 240 240 268 201 240

8½’ 265 265 296 222 265

10’ 300 300 336 252 300

12’ 360 360 403 302 360

14’ 420 420 470 352 420

15’ 450 450 504 378 450

17’ 510 510 571 428 510

18’ 570 570 638 478 570

In the table we assume that the yield is 4000 kg/ha. Considerable deviation from

this requires correction.

Collect the lost seeds on a piece of canvas placed under the sieves. The length of

it in the drive direction must be known exactly.

Examples:

Barley 12’ width of cut, 220 seeds (yield 4000 kg/ha).

1.

220

Loss =

= 0,6%

360

Barley 12’ width of cut, 220 seeds (yield 4800 kg/ha).

2.

LH A

Loss =

360

x

4800

= 0,5 %

220 4000

Wheat 8½’ width of cut, 200 seeds (yield 5000 kg/ha).

3.

200 4000

Loss =

265

x

5000

= 0,6 %

Seeds that are lying on the field before the harvest shall of course not be included

in the calculation.

7

GRO

Page 8

LH 865 C

APACITY INDICATOR

RULE OF THUMB

From the above table it can be concluded that per 1 cm width of cut there may be

1 seed per driven metre.

As the loss usually lays in a 1 metre wide track behind the harvester the lost seeds

cover app. 1 m2.

A normal hand is about 1/100 m2. Acceptable loss therefore will be 1/100 of the

loss stated in the table.

Example:

A combine harvester of 17’ is used in a barley field yielding as stated above.

From the table it appears that acceptable loss (1%) is 510 seeds per metre.

Under the palm of a hand the accepted volume of seeds then will be:

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

510

= 5,1 seeds

100

8 LH A

GRO

Page 9

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

SETTING UP THE CAPACITY INDICATOR

Before putting the monitor into use, it is very important to realise, that not even the

best capacity indicator can prevent grain from being lost.

The purpose of the monitor is to inform the operator about the amount of grain

being lost.

Therefore the monitor must be adjusted as follows:

Adjust the combine harvester as usual to an acceptable loss (without using

1.

the capacity indicator).

NOTE! See the table calculation of grain loss on page 7

After control of the loss, proceed at the same speed.

2.

Adjust the reading of the meters, under the driving, so that the needles are

3.

in the middle of the green area. Use a coin or a screwdriver for the adjusting

screws for sieve and straw walker meters.

ITTING INSTRUCTION

& F

NOTE! The adjusting screws can only be turned 270 degrees. Do not use too

much force, or the instrument may be damaged.

OBS! Under very favourable harvest conditions it can occur, that almost no loss is

registered on one or both sensors. Under such conditions the reading of the

meters cannot be adjusted into the green area.

The sensitivity adjustment on the straw walker sensor(s) – NORM-MAX-MIN –shall

only be moved from the NORM position under very special conditions. Only in

cases (special years or crops) where adjustment on the instrument is impossible,

the sensor adjustment can be altered as follows:

NORM

MAX

MIN

= normal sensitivity

= maximum sensitivity (small seeds)

= minimum sensitivity (big seeds)

NOTE! The sieve sensor can be moved in the three slots in the brackets, so that it

is always positioned correct in the loss stream.

To obtain the optimum profit by having a correct adjustment of the capacity

indicator, it is recommended to repeat the above setting up every time you change

field or crop.

LH A

After being correctly adjusted the capacity indicator informs the operator, not only

about the amount of loss but also whether the capacity of the combine is fully

utilized or not.

It is recommended to control if the reading of the monitor is in accordance with the

actual loss frequently. Especially when harvesting green and moist crops, as this

may cause the sensors to be coated with a layer of dirt.

This layer must be removed as often as required. Hand cleaner is good for this

purpose.

9

GRO

Page 10

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

FITTING INSTRUCTIONS FOR LH 865

NOTE! See description of the system page 4

FITTING AF MONITOR BOX

Normally the grain loss monitor (the instrument box) is to place on the ground in

the right corner of the driver's cab. This is the most practical place when the

operator is to read the display.

When the mounting place is located this should be marked. The holes for

1.

the fixing and for the cables are drilled using the supplied drill gauge.

Put the cable through the hole and fix the foot.

2.

Adjust the tilt position of the monitor. Raise the sleeve and the screws for

3.

the tilt adjustment to be tightened. Can the upper screws not be reached by

raising the sleeve this can carefully be pulled down.

FITTING OF CONNECTING BOX 1

Connection box 1 should be mounted under the floor of the driver's cab where it

will be well protected and where it at the same time is most suitable as regards

connecting of power and possible extra equipment.

The cable from the instrument box is lead through the cable lead in and connected

on the circuit board in accordance with the directions.

NB! When the cable leads in are adjusted it is most important that exact amount is

cut off so that the lead in is tight around the cable.

FITTING OF CONNECTING BOX 2

Connection box 2 is mounted at the rear end of the combine harvester, normally

on the right side. The box should be situated where it will be best possible

protected and most suitable as regards the later cabling on the combine.

The cable connecting the two connecting boxes is mounted as instructed.

Lead the cable along the existing supply mains, alongside hydraulic tubes etc. to

the connecting box 1. Attach it with the supplied cable clamps.

OBS: Beware of rotating parts, sharp edges and high temperatures (exhaust etc.).

FITTING OF SUN SENSOR

The sun sensor is mounted on the driver's cab or on the grain tank. It must be

situated so that shadows will never fall on it.

Lead the cable to connecting box 1 where it is connected as shown. Where

impossible to fasten the cable to wires, tubes, etc. the supplied cable brackets can

be used.

10 LH A

GRO

Page 11

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

SUPPLY VOLTAGE

The supply voltage is 12 Volt.

Connect the supply cable to 12 V in a way that the supply is switched off. When

the ignition is switched off.

OBS: Blue cable to +

Brown cable to

–

Lead the cable to the connection box and connect as shown on the circuit board.

MOUNTING OF WHEEL SENSOR

Mount the sensor on one of the steering wheels.

The magnet is to mount direct on hub or rim. The supplied 20 mm collar must be

used as support.

Mount as follows:

Mount the bracket for the censor. (Screw or weld).

1.

Mount the sensor in the bracket.

2.

Mount the sensor as illustrated below (cut 4 mm thread).

3.

M4

5-8 mm

Magnet can be painted

Washer

Turn the wheel and check the distance between sensor and magnet (5-8mm).

4.

Lead the cable to connecting box 2 and connect it as described.

5.

Fix the cable and control that it will not be squeezed or worn.

6.

LH A

11

GRO

Page 12

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

FITTING THE WALKER PADS

The two walker pads must be fitted at the rear of the two outside straw walkers.

Stick the supplied adhesive template on the underside of the walkers with the

arrow pointing to the rear of the walkers

template.

ITTING INSTRUCTION

& F

and drill the holes as shown on the

NOTE!

Remember to take any reinforcements and walker extensions into

consideration when positioning the walker pads.

12 LH A

GRO

Page 13

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

LEADING THE CABLES FROM THE WALKER PADS

ITTING INSTRUCTION

& F

There

be a loop in the cable between the walker and the machine side as

must

shown on the following diagram. This loop must be large enough to "capture" the

circular movement of the straw walkers, without affecting the cable too much

(pull/push) when fixing the cable:

Do as follows to determine a suitable loop size:

Attach the cable on the underside of the walker approx. 20 cm from the

1.

point at which the cable comes through the walker, as shown hereunder. Be

careful when attaching the cable fastener as this is important for the life of

the cable (see diagram):

LH A

20 cm

13

GRO

Page 14

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

Turn the walker to the

2.

lowest

position and make a mark (A) on the side of

the machine at a right angle to the fitted cable fastener.

Turn the walker to the

highest

position and make a mark (B) on the side of the

machine.

The length of cable needed to make the "loop" is determined by measuring the

distance (L) between the two marks (A & B) and multiplying this by 3.

Make a loop from the calculated cable length and attach the cable fastener 20 mm

under

the lower mark.

L

B

B

L

A

A

Use this procedure for both walker pads.

Lead the cable hereafter to the junction box. Lead the cable avoiding any sources

that might damage the cable and fasten the cable with the supplied fastener/cable

ties where possible to existing cables, hydraulic pipes, etc.

Connect the wires to the terminals as shown on the junction box PCB.

14 LH A

GRO

Page 15

LH 865 C

APACITY INDICATOR

FITTING THE SIEVE SENSOR

POSITION

The sieve sensor must be fitted so that it can measure the grain loss behind the

sieves over the whole width of the sieves. The best position for normal grain types

is 120 mm behind the rear edge of the sieves and 50 mm under the sieves

(measured from the centre of the tube).

120 mm

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

50 mm

The supplied brackets have three slits, when fitting measure from the middle slit.

This allows the sensor to be moved closer to the sieves when harvesting a crop

where not much air is blown under the sieves, i.e. oil seed rape. If the crop being

harvested needs a lot of air to be blown under the sieves the sensor can be moved

further away.

On some machines it might not be possible to fit the sensor in the recommended

position due to, e.g. the adjustment handle. In such cases it may be necessary to

fit the sensor higher or lower than the height given in the above. The centre of the

sensor must not be higher than the sieves or lower than 100 mm under the sieves.

0 mm

100 mm

LH A

Once the correct position has been found the brackets can welded or bolted to the

sieves. The point at which the brackets are attached must be stable so that the

sensor does not shake.

15

GRO

Page 16

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

SHORTENING THE SENSOR

The steel tube can be shortened to the length between the two brackets thus:

Remove the rubber bung (opposite the plug) by loosening all nuts. Remove

a.

the plastic spacer in the tube by loosening the allen screw.

Measure the distance (x) between the brackets exactly; reduce this length

b.

by 22 mm. This measurement (L) should be measured from in between the

two washers as shown below. Cut the tube with a hacksaw. As the tube can

be damaged easily avoid using a vice when cutting the tube.

ITTING INSTRUCTION

& F

NOTE!

Remember to remove all of the cuttings from the tube before fitting the

rubber bung.

c.

Position the plastic spacer again so that it is approx. 5 mm from the end of

the bolt in the rubber bung. Re-fit the rubber bung so that approx. 5 mm of

the bung is outside the tube. Tighten the nuts so that the rubber swells

slightly

.

22 mmL

x

NOTE!

16 LH A

The bolts in the bung

must not

touch the plastic spacer.

5 mm

GRO

Page 17

LH 865 C

APACITY INDICATOR

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

LEADING THE CABLE FROM THE SIEVE SENSOR

Connect the plug to the sensor and fit the cable fasten to the bracket as shown

below. This fastener is important for the life of the cable.

Make a bend in the cable that is large enough to "capture" the movement of the

sieves. Fit another cable fastener on the side of the machine.

Lead the cable hereafter to the junction box. Lead the cable avoiding any sources

that might damage the cable and fasten the cable with the supplied fastener/cable

ties where possible to existing cables, hydraulic pipes, etc.

LH A

Connect the wires to the terminals as shown on the junction box PCB.

17

GRO

Page 18

LH 865 C

APACITY INDICATOR

NOTES

PERATORS MANUAL

– O

ITTING INSTRUCTION

& F

18 LH A

GRO

Loading...

Loading...