Page 1

OPERATORS MANUAL

FOR THE

LH 85 – SPRAY CONTROLLER

LH. No. 020-851-UK Version 1.00

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tlf. +45 9696 2500

Fax. +45 9696 2501

Internet: http://www.lh-agro.com/

Page 2

Page 3

Introduction

INTRODUCTION ..............................................................................................................1.3

Page 4

I

NTRODUCTION

We have endeavoured to deliver a fault free product. To ensure optimal use of the

equipment we ask that great attention be paid when reading the manual. We are

more than happy to help should any queries arise, both when the product is used

for the first time and at any later date. Regarding responsibility for use of the

product, we refer to our sales and delivery terms especially paragraph 7, which

follows:

7. Product usage.

7.1 Any use of the product is at the sole risk of the buyer. The buyer is

7.2 When implementing any new equipment the buyer must take great care and pay

O

therefore not entitled to any form for compensation caused by, for example,

any of the following:

Disturbance to/from any electronic services or products that do not

confirm to the standards for CE marking,

Missing or poor signal coverage or a succession hereof from external

transmitters/receivers, used by the buyer,

Functional faults, which apply to or from a PC-program or PC-equipment,

not delivered by the seller,

Faults that may arise from the buyers negligence to react to warnings

and fault messages from the product, or which can be traced to

negligence and/or absent constant control of the work carried out in

comparison to the planned job.

attention. Any doubts as to correct operation/use should result in

contacting the sellers service department.

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

This manual may not be altered, copied or manipulated in any way. Unoriginal

manuals can lead to operational faults damaging machines or crops as a

consequence thereof. LH Technologies Denmark ApS can therefore not be held

responsible for damages incurred, which can be traced to the use of unoriginal or

manipulated manuals. Original manuals can be requisitioned at any time from your

dealer.

With regards

LH Technologies Denmark ApS

Mølhavevej 2

9440 Aabybro

Denmark

Tel. +45 96 96 25 00

Fax. +45 96 96 25 01

Internet: http://www.lh-agro.com/

1.2 LH

AGRO

Page 5

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

INTRODUCTION

The LH 85 Spray Controller is not only a powerful spray rate controller, but also a

command centre for the whole sprayer!

Whilst designing this unit we have tried hard to ensure that operation is as simple

as possible, the ergonomically designed housing and the menu based operating

system ensure that the unit will be a pleasure to use for many years.

A large amount of the system is built up around easily understood icons and

instructions on the display in clear text make this operator's manual almost

redundant, however we recommend that this manual be used as a reference for

the many functions available.

Despite the fact that this manual is large and may, upon first impressions, seem to

be too much to read, we ask you to study at least chapter 2 where the basic

functions of the system are explained.

I

NTRODUCTION

Examples are used throughout this manual to ensure that finding a solution to any

problems that might arise can be solved simply by changing the values in the

examples with the values required for the task in hand.

Our experience tells us that it is a good idea to familiarise yourself with the system

before the first day of use thus avoiding delays in getting the job done!

Please keep this operator's manual within easy reach and together with the LH 85.

LH

AGRO

1.3

Page 6

I

NTRODUCTION

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

1.4 LH

AGRO

Page 7

General operation

OPERATING THE LH 85 SPRAY CONTROLLER ...........................................................2.2

THE SPRAY CONTROLLER SYSTEM OUTLINE ...................................................2.2

CONTROLLER SECTION (A) .............................................................................. 2.3

SWITCH SECTION (B) ........................................................................................2.3

SWITCH SECTION OVERVIEW .............................................................................. 2.4

POWER ON/OFF SWITCH (POS. B1)................................................................. 2.4

AGITATION SWITCH (POS.B2) ..........................................................................2.4

FILL FUNCTION SWITCH (POS. B3) .................................................................. 2.4

AUTOMATIC/MANUAL FUNCTION SWITCHES (POS. B4 & B5).......................2.4

MAIN ON/OFF SWITCH (POS. B6) .....................................................................2.4

SWITCHES C1 TO C9 ......................................................................................... 2.4

SWITCHES D1 TO D9 ......................................................................................... 2.4

CONTROLLER OVERVIEW ............................................................................................. 2.5

DISPLAY (POS. A1)............................................................................................. 2.5

SETUP KEY (POS. A2)........................................................................................ 2.6

INFO KEY (POS. A3) ........................................................................................... 2.6

JOB KEY (POS. A4)............................................................................................. 2.7

ESCAPE KEY (POS. A5) .....................................................................................2.7

ARROW KEYS (POS. A6, A8, A9, A10) ..............................................................2.7

ENTER KEY (POS. A7) .......................................................................................2.7

CLEAR KEY (POS. 11) ........................................................................................ 2.7

FUNCTION KEY 1 (POS. A12) ............................................................................2.7

FUNCTION KEYS 2 & 3 (POS. A13 & A14)......................................................... 2.8

FUNCTION KEY 4 (POS. A15) ............................................................................2.8

NAVIGATING THROUGH THE MENUS...........................................................................2.9

SELECTING AN ITEM FROM A MENU AND ALTERING A VALUE........................ 2.9

SELECTING A VALUE FROM A LIST (CHECKBOXES) .......................................2.12

Page 8

G

ENERAL OPERATION

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

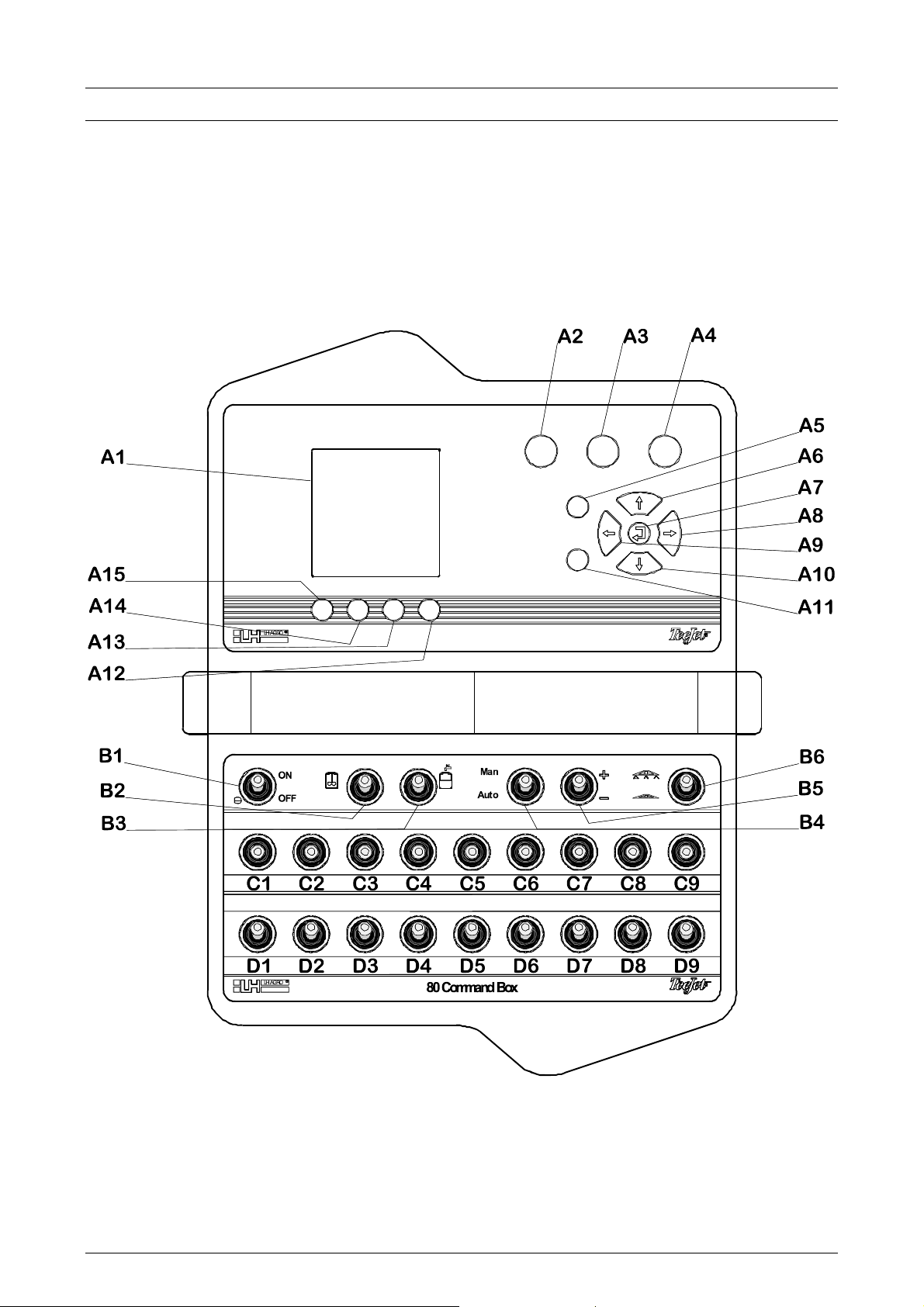

OPERATING THE LH 85 SPRAY CONTROLLER

The LH 85 spray controller system can be split into two sections:

The controller section (A)

The switch section (B, C & D)

THE SPRAY CONTROLLER SYSTEM OUTLINE

2.2 LH

AGRO

Page 9

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

CONTROLLER SECTION (A)

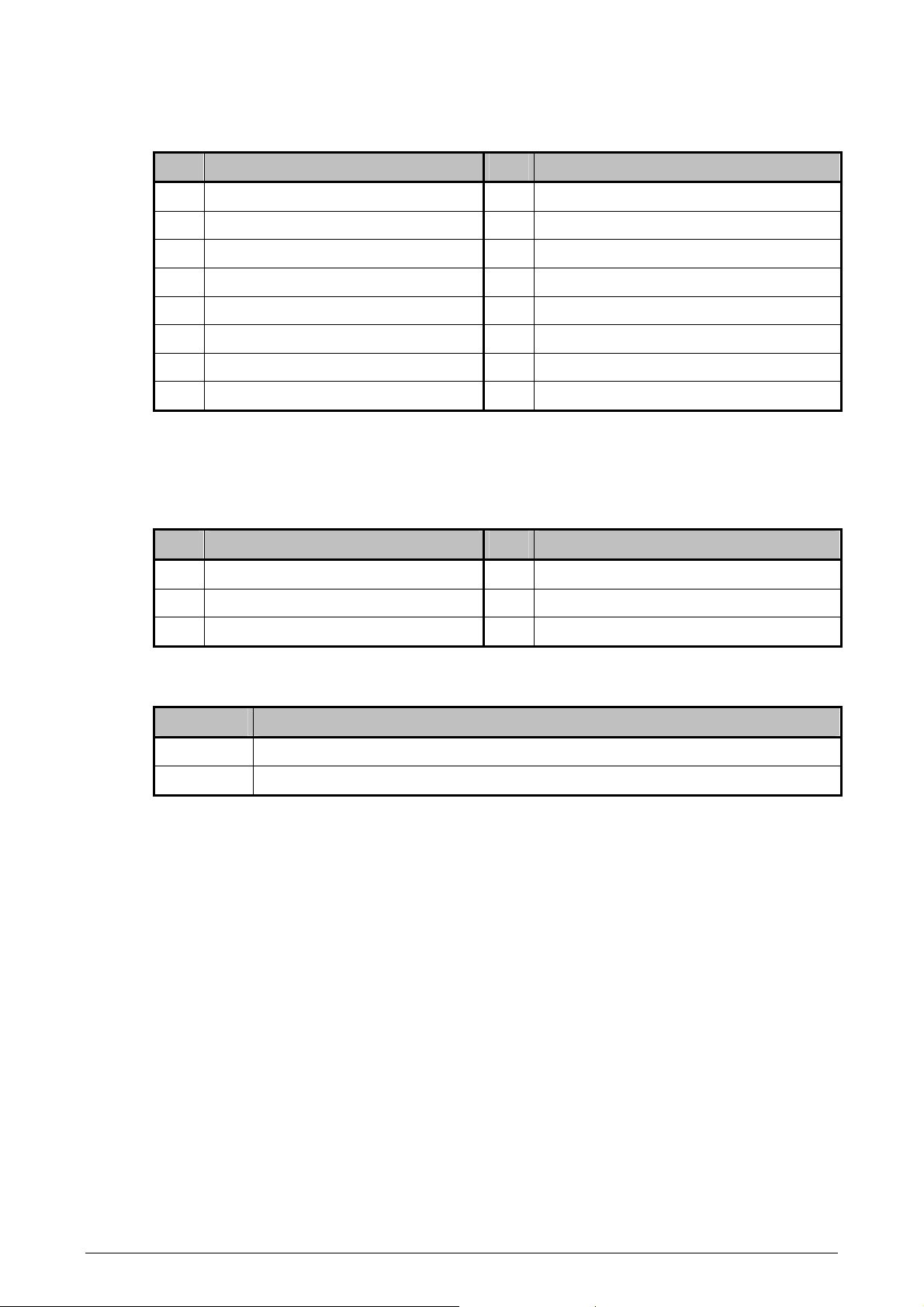

Pos. Description Pos. Description

A1 Display A9 Left function key

A2 Setup key A10 Down function key

A3 Info key A11 Clear key

A4 Job key A12 Function key 1

A5 Escape key A13 Function key 2

A6 Up function key A14 Function key 3

A7 Enter key A15 Function key 4

A8 Right function key

SWITCH SECTION (B)

G

ENERAL OPERATION

Pos. Description Pos. Description

B1 Power on/off switch B4 Auto/man function switch

B2 Agitation switch B5 Rate increase/decrease

B3 Fill function switch B6 Main on/off

Pos. Description

C1 – C9 Switch row C (functions depend on model)

D1 – D9 Switch row D (functions depend on model)

LH

AGRO

2.3

Page 10

G

ENERAL OPERATION

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

SWITCH SECTION OVERVIEW

POWER ON/OFF SWITCH (POS. B1)

This switch is used to switch the system on and off.

AGITATION SWITCH (POS.B2)

This switch is used to switch the tank agitation on and off (if tank agitation is fitted).

FILL FUNCTION SWITCH (POS. B3)

At present this switch has no function.

AUTOMATIC/MANUAL FUNCTION SWITCHES (POS. B4 & B5)

The AUTO/MAN switch is used to change between automatic and manual spray

rate control.

When this switch is in the "MAN" position (up) the spray rate can be controlled

thus:

• The spray rate is increased by holding the RATE INCREASE/DECREASE

switch up.

• The spray rate is decreased by holding the RATE INCREASE/DECREASE

switch down.

When this switch is in the "AUTO" position (down) the spray rate is controlled

automatically by the computer.

MAIN ON/OFF SWITCH (POS. B6)

The main on/off switch is used to switch the main boom on & off.

• When the switch is in the up position the sprayer is on.

• When the switch is in the down position the sprayer is off.

The individual boom sections are typically switched on and off with the switches

D1 to D9 depending on the LH 85 spray controller model.

SWITCHES C1 TO C9

The function for the switches in this row depends on the sprayer.

SWITCHES D1 TO D9

The function for the switches in this row depends on the sprayer.

2.4 LH

AGRO

Page 11

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

CONTROLLER OVERVIEW

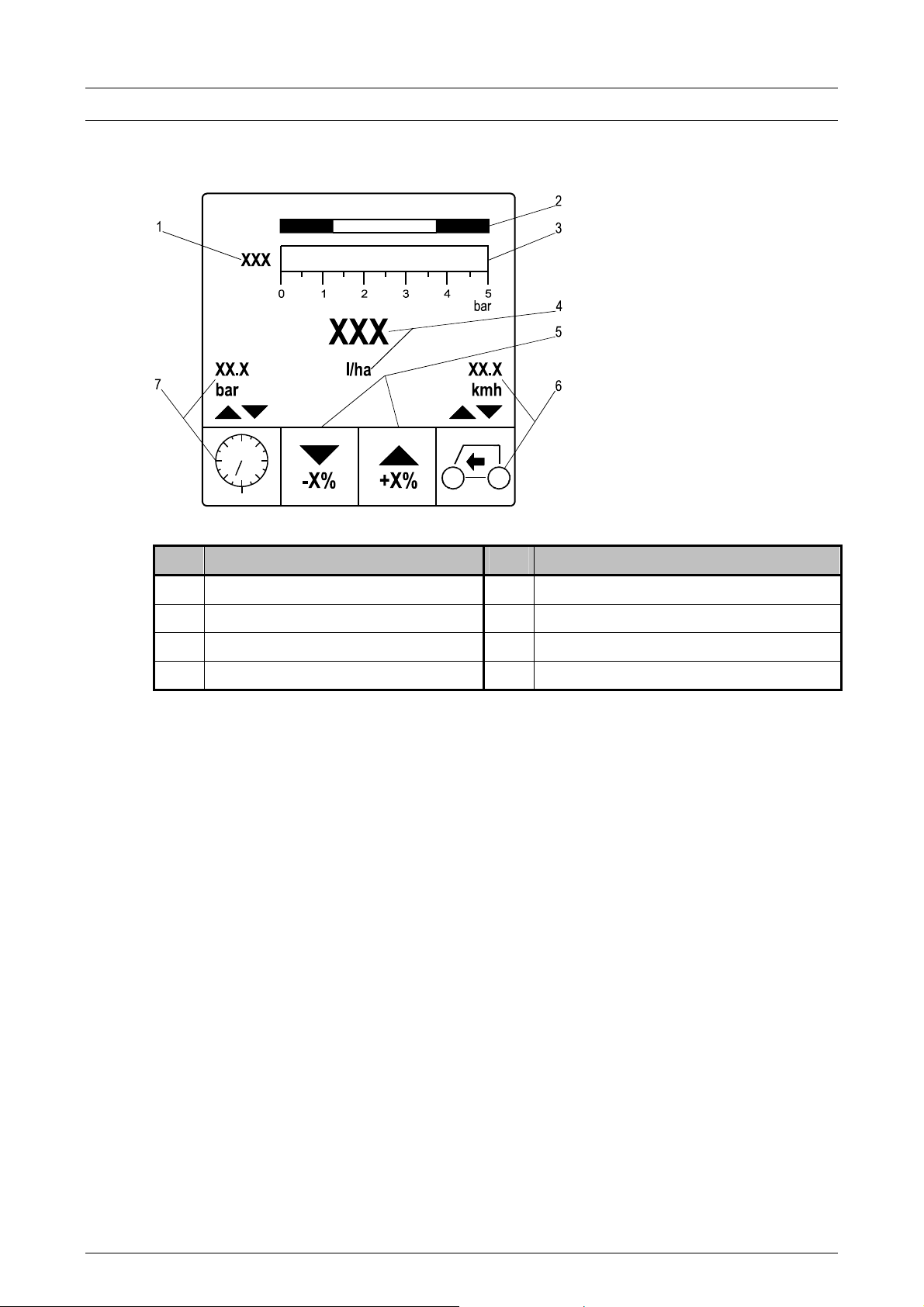

DISPLAY (POS. A1)

G

ENERAL OPERATION

Pos. Description Pos. Description

1 Selected nozzle type 5 Boost or manual +/-

2 Optimum pressure range 6 User selectable work information

3 Working pressure indicator 7 User selectable spray information

4 Application rate

Selected nozzle type (pos. 1):

The nozzle type selected is displayed here.

Optimum pressure range (pos. 2):

The optimum working pressure range for the selected nozzle type is shown here.

Working pressure indicator (pos. 3):

The current working pressure is shown. The range of the pressure indicator

changes to suit, e.g. the selected nozzle type, working speed range, etc.

LH

Application rate (pos. 4):

The actual application rate shown in litres per hectare. The target rate is shown

when the main on/off switch (B6) is in the off position.

AGRO

2.5

Page 12

G

ENERAL OPERATION

Boost or manual +/- (pos. 5):

The function of these keys may change depending on whether automatic or

manual rate control is selected in the "Fast setup" menu. See page 3.4

Increase or decrease the required application rate in steps using the function keys

(A13 & A14). See page 2.8.

The size of the steps (percent of current rate) is encoded under MACHINE SETUP

under "Boost" (see page 4.11).

When manual rate control has been selected from the "Fast setup" menu the

function of the keys changes to manual rate increase (+) and manual rate

decrease (-).

User selectable work information (pos. 6):

It is possible to select which work related information is displayed by pressing

function key 1 (A12).

A description of the work related information that can be displayed can be seen on

page 3.2.

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

User selectable spray information (pos. 7):

It is possible to select which spray related information is displayed by pressing

function key 4 (A15).

A description of the spray related information that can be displayed can be seen

on page 3.2.

SETUP KEY (POS. A2)

Key Description

The SETUP key is used to enter the setup menus.

Setup

If the main on/off switch (B6) is in the on position the "Fast setup"

menu is displayed (see page 3.4).

If the main on/off switch (B6) is in the off position the main setup

menu is shown. A description of the available settings can be seen

in the "Encode" chapter of this operators manual.

INFO KEY (POS. A3)

Key Description

Pressing the INFO key displays the following information (use the

Info

up & down arrow keys (A6 & A10) to highlight and the ENTER key

(A7) to select. A detailed description of each function can be seen

on page 3.3:

• Controller • Counters • Export/Import

• Diagnostics • Alarm log • Active alarms

2.6 LH

AGRO

Page 13

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

JOB KEY (POS. A4)

Key Description

The JOB key is used for the task function. A description of the task

Job

function can be seen on page 5.1.

ESCAPE KEY (POS. A5)

Key Description

G

ENERAL OPERATION

Esc

saving any alterations.

ARROW KEYS (POS. A6, A8, A9, A10)

Key Description

The ESCAPE key is used to return to the previous menu without

The arrow keys are used to select and alter an encodement.

When encoding a value the arrow keys are used to select and

adjust the digit that needs changing.

Each digit can be set from 0 to 9 with the ARROW UP/DOWN keys.

The ARROW RIGHT/LEFT keys are used to select the digit to be

altered.

ENTER KEY (POS. A7)

Key Description

The enter key is used to accept settings and to return to the

previous screen.

CLEAR KEY (POS. 11)

Key Description

The clear key is used to reset settings/counters and to accept

C

warnings.

FUNCTION KEY 1 (POS. A12)

Key Description

Key 1

Pressing this key during operation pages through and selects the

user selectable work related information to be shown on the display.

A description of the work related information that can be displayed

can be seen on page 3.2.

LH

AGRO

2.7

Page 14

G

ENERAL OPERATION

O

FUNCTION KEYS 2 & 3 (POS. A13 & A14)

Key Description

The function of these keys may change depending on whether

automatic or manual rate control is selected in the "Fast setup"

Keys 2 & 3

menu. See page 3.4

Increase or decrease the required application rate in steps using

these function keys.

When manual rate control has been selected from the "Fast setup"

menu the function of the keys changes to manual rate increase (+)

and manual rate decrease (-).

FUNCTION KEY 4 (POS. A15)

Key Description

Pressing this key during operation pages through and selects the

Key 4

user selectable spray related information to be shown on the

display.

A description of the spray related information that can be displayed

can be seen on page 3.2.

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

2.8 LH

AGRO

Page 15

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

G

NAVIGATING THROUGH THE MENUS

The LH 85 Spray controller uses a menu based structure for most functions.

Navigation through the menus is simple and unified throughout the whole

programme.

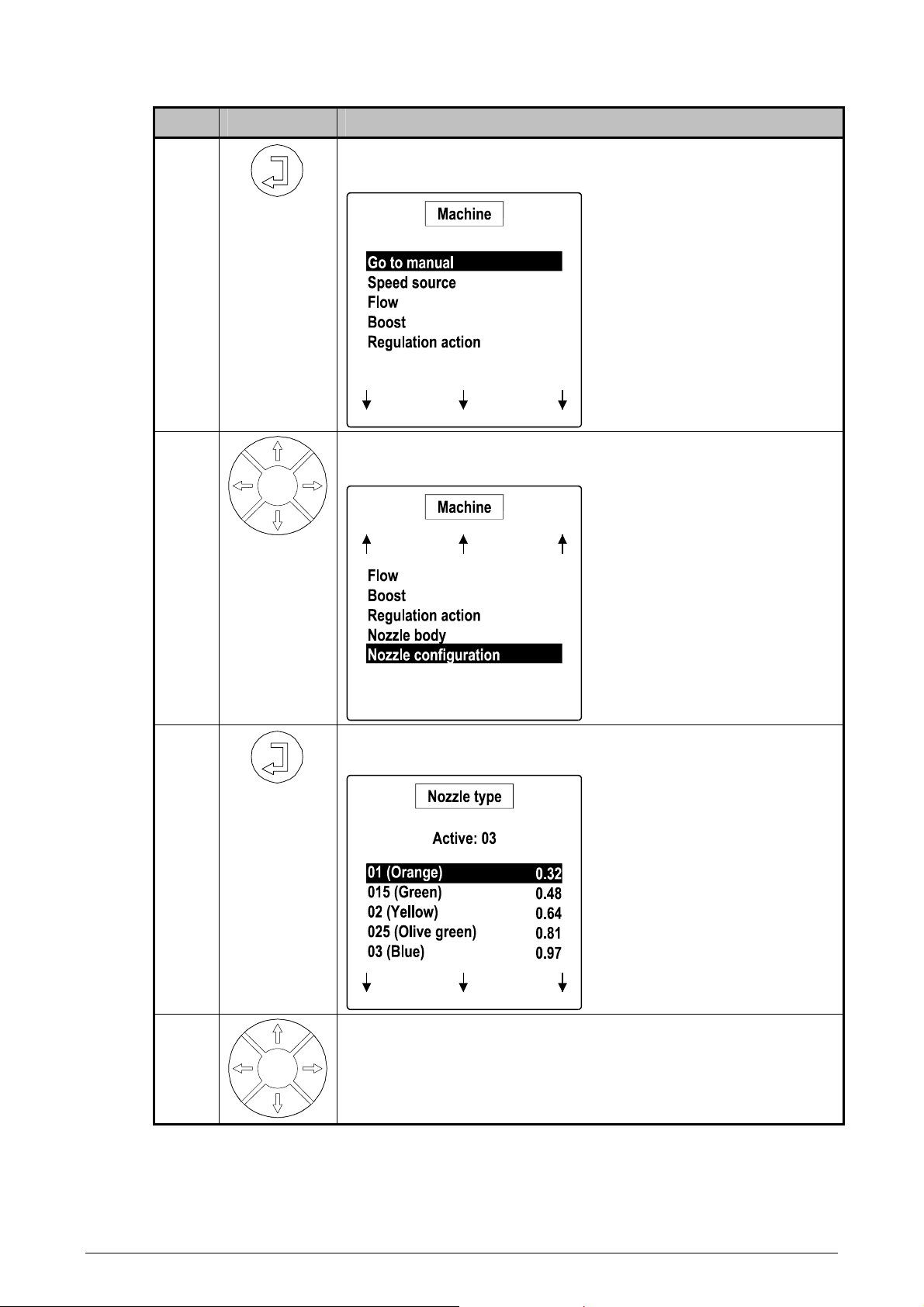

SELECTING AN ITEM FROM A MENU AND ALTERING A VALUE

The procedure to select and alter a setting in the LH 85 Spray controller is simple

and requires very little practice.

The procedure to navigate, select and alter a setting is best illustrated with an

example, which follows:

Step Key Action

To alter the nozzle configuration for a programmable nozzle (P1).

ENERAL OPERATION

1 Switch the main on/off switch (pos. B6) to the OFF position (down).

2

Setup

Press the SETUP key and the following is shown in the

display:

3

Press the ARROW DOWN key to move the cursor to

"Machine"

LH

AGRO

2.9

Page 16

G

ENERAL OPERATION

Step Key Action

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

4

5

Press the ENTER key to select "Machine" and the first 5

available settings are shown in the display.

Notice the 3 arrows pointing

down at the bottom of the

display.

This indicates that further

menu items are available on

another page.

Press the ARROW DOWN key 6 times to highlight "Nozzle

configuration".

Notice the 3 arrows pointing

up at the top of the display.

This indicates that further

menu items are available on

another page.

6

7

Press the ENTER key to select "Nozzle configuration" and

the available settings are shown:

Repeatedly press the ARROW DOWN key until "P1" is

highlighted.

2.10 LH

AGRO

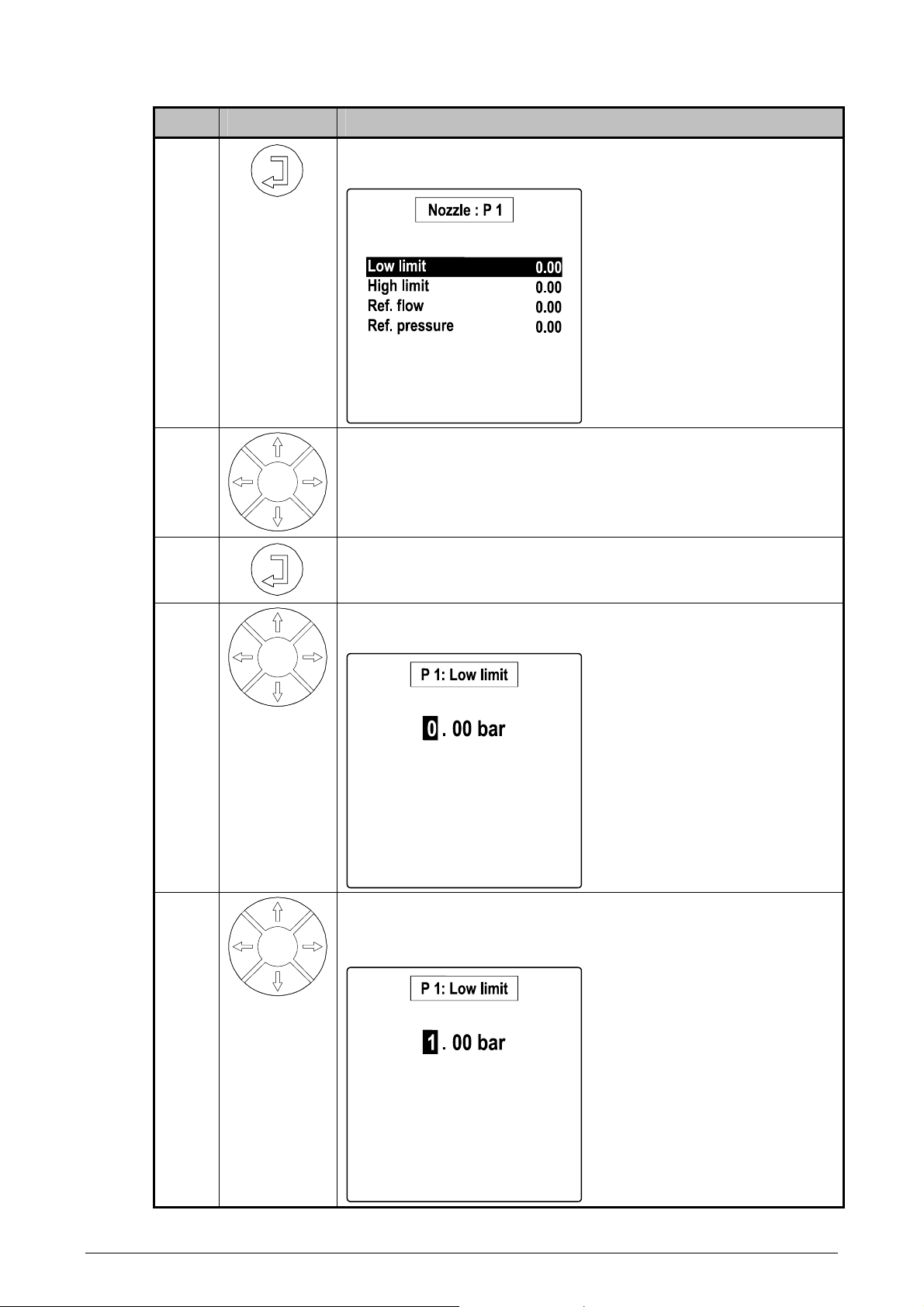

Page 17

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Step Key Action

G

ENERAL OPERATION

8

9

10

11

Press the ENTER key to select the configuration menu for

the selected nozzle.

Highlight the setting to be altered using the ARROW UP

and DOWN keys.

Press the ENTER key when the setting to be altered is

highlighted.

Highlight the digit to be altered by using the ARROW LEFT

and RIGHT keys.

12

Using the ARROW UP and DOWN keys change the digit to

the required value.

To reset a value simply press the C key.

LH

AGRO

2.11

Page 18

G

ENERAL OPERATION

Step Key Action

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

13

Press the ENTER key to store the value and return to the

previous screen.

14

Esc

or

Repeat steps 9 to 13 until all of the required changes have

been made.

Then press the ESCAPE key to return to the previous

menu or press the SETUP key to return to the main menu

Setup

or press the JOB key to return directly to the main

operating screen.

or

Job

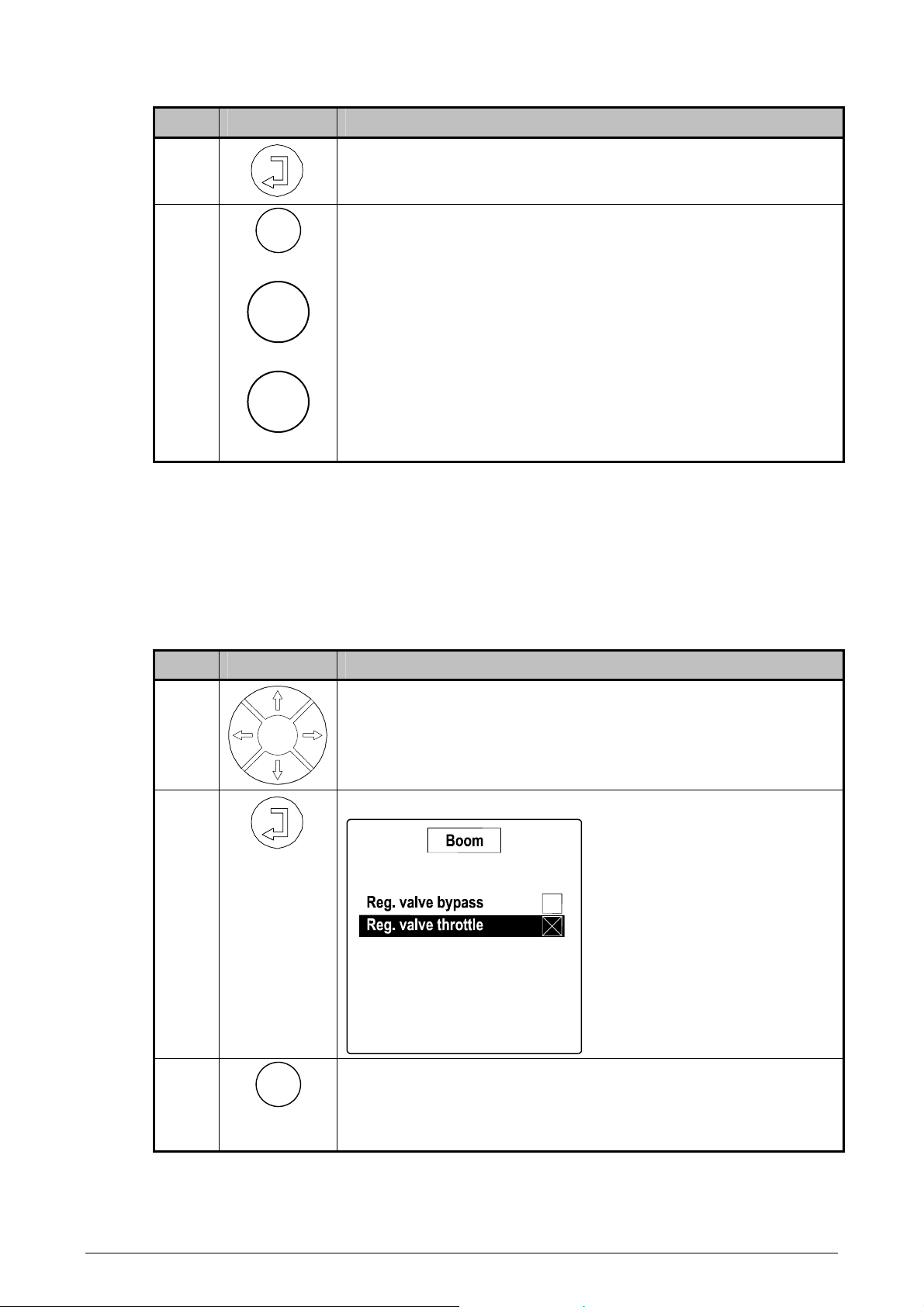

SELECTING A VALUE FROM A LIST (CHECKBOXES)

Some settings have a list of options to select from. The procedure for selecting the

required setting is similar to the above; a checkbox is used instead of a numerical

value.

An example follows:

Step Key Action

1

Highlight the setting to be selected using the ARROW UP

and DOWN keys.

2

Press the ENTER key to select the option.

3

Esc

Then press the ESCAPE key to return to the previous

menu or press the SETUP key to return to the main menu

or press the JOB key to return directly to the main

operating screen.

2.12 LH

AGRO

Page 19

Operation

OPERATION.....................................................................................................................3.2

USER SELECTABLE SPRAY RELATED INFORMATION.......................................3.2

USER SELECTABLE WORK RELATED INFORMATION........................................3.2

INFO MENU .............................................................................................................3.3

FAST SETUP MENU................................................................................................ 3.4

GO TO MANUAL..................................................................................................3.5

SPEED SOURCE................................................................................................. 3.5

REGULATION BASE ...........................................................................................3.6

BACKLIGHT.........................................................................................................3.6

Page 20

O

PERATION

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

OPERATION

All settings should be encoded/checked before any spray work commences.

Please refer to the SETTINGS section of this manual for a description of the

available settings.

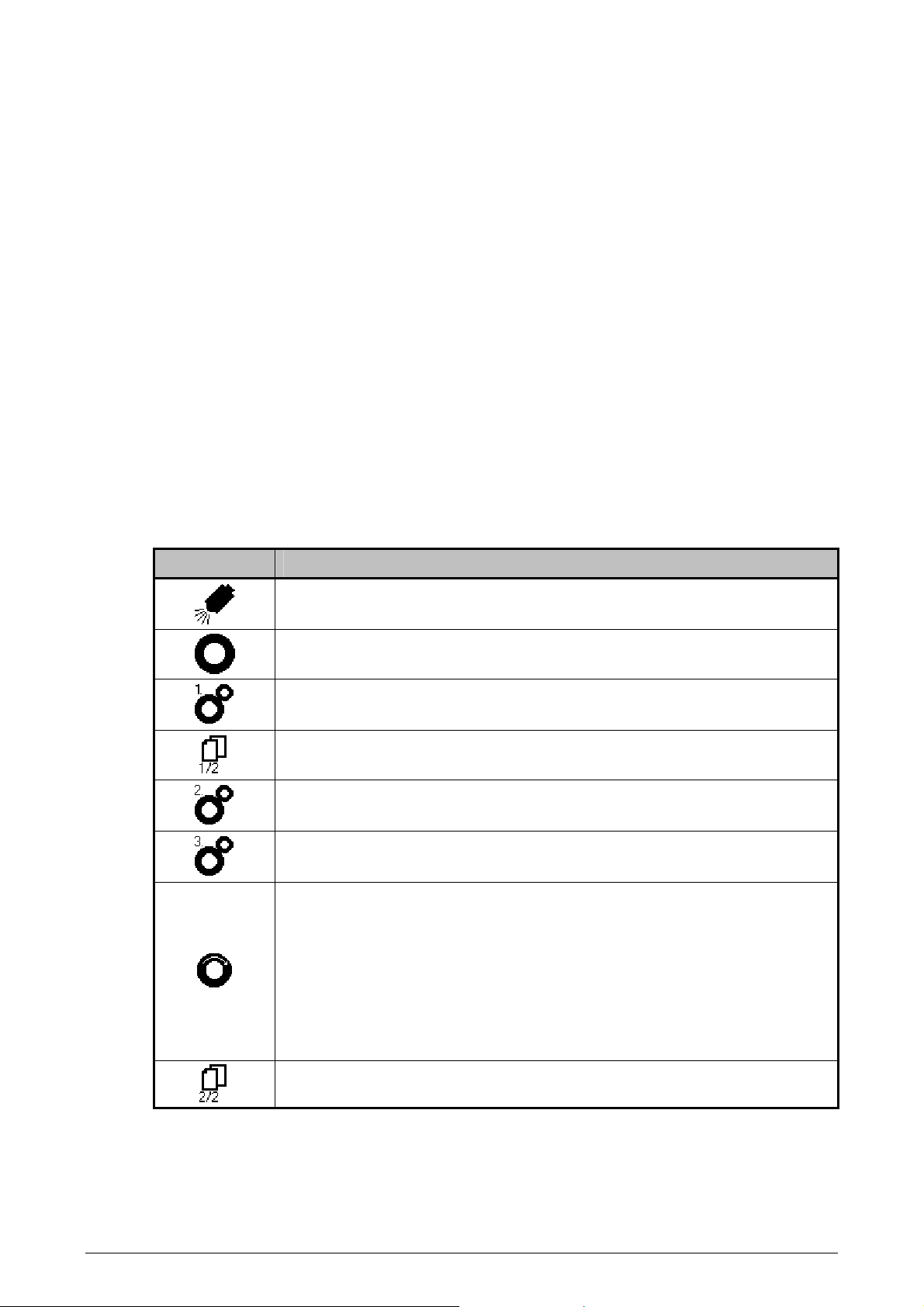

USER SELECTABLE SPRAY RELATED INFORMATION

Symbol Description

Working pressure: The current working pressure shown as bar.

Flow rate: The present flow rate shown in litres per

Sprayed volume: The amount sprayed since the task was

Volume left: The amount remaining for the present field

Density: The density of the liquid being used.

hour.

started or since the counter was reset.

or task.

USER SELECTABLE WORK RELATED INFORMATION

Symbol Description

Forward speed: The present forward speed shown as

Working width: The present working width shown as

Area covered: The total area covered shown as hectares

Area left: The area that can be covered with the

Work efficiency: The present work efficiency shown as

kilometres per hour.

metres.

with 2 decimals since the task was started

or since the counter was reset.

Area is only measured when the sprayer is

in work.

current tank content.

This calculated figure is based on the

present volume in the tank, the actual

application rate and the current working

width.

hectares per hour.

This calculated value is based on the actual

forward speed and the present working

width.

3.2 LH

AGRO

Page 21

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Symbol Description

Distance covered: The distance covered shown as metres

Distance left: The distance that can be covered with the

Elapsed time: The time passed since the task was started

Wind speed: The current wind speed shown in metres

O

PERATION

since the task was started or since the

counter was reset.

Distance is only measured when the sprayer

is in work.

current tank content.

This calculated figure is based on the

present volume in the tank, the actual

application rate and the current working

width

or since the counter was reset.

Time is only measured when the sprayer is

in work.

per second.

This function is only possible when the main

on/off switch is in the off position and the

forward speed = 0 and if the system is fitted

with an anemometer.

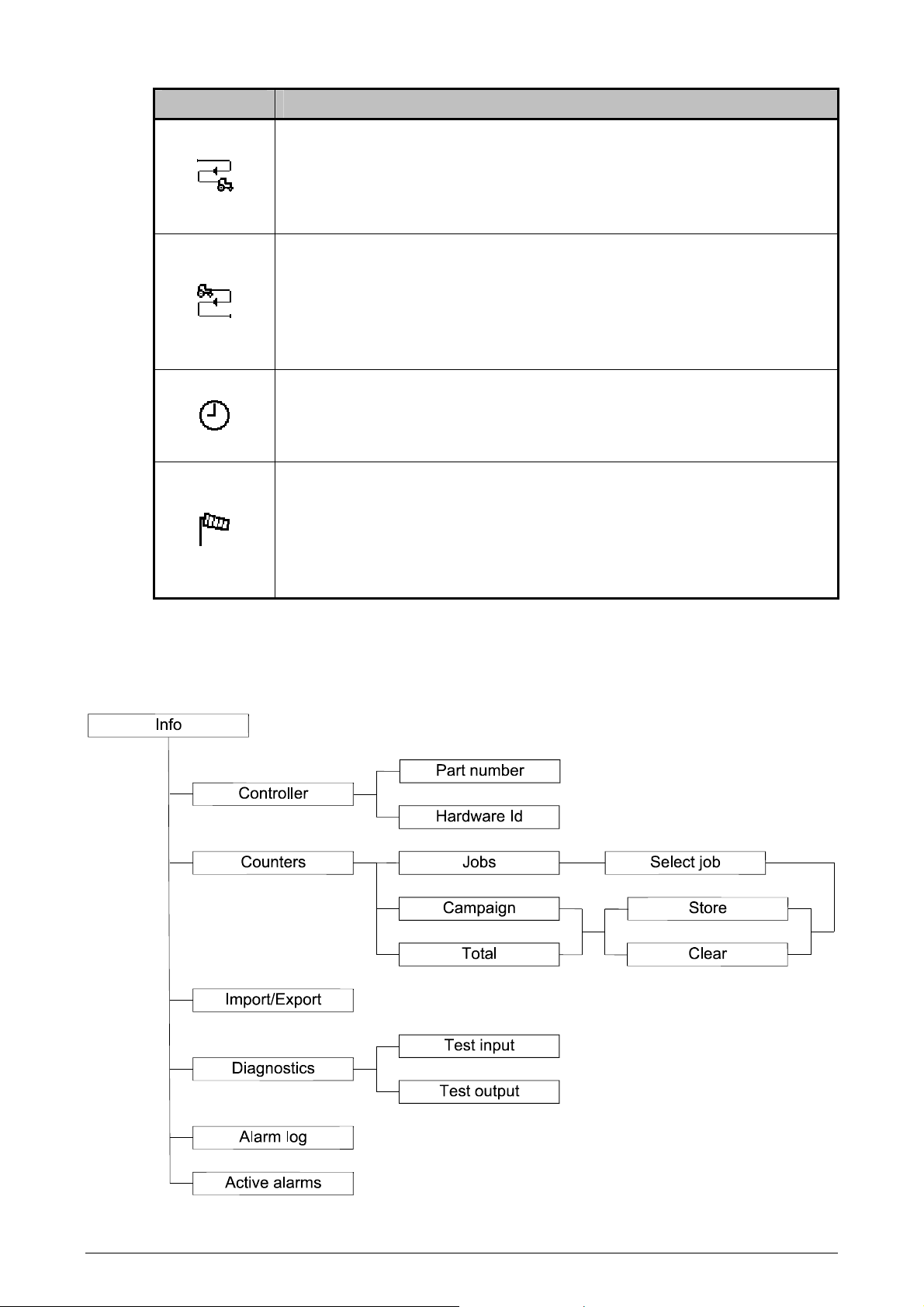

INFO MENU

Pressing the INFO key displays the following menu structure.

Each item in the menu is described in the following:

LH

AGRO

3.3

Page 22

O

PERATION

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Controller:

Selecting controller displays the hardware Id and part number of the LH 85 Spray

controller.

Counters:

There are three counter sets available in the LH 85 Spray controller. A brief

description can be seen in the following, for a more detailed description please see

the "Job Function" section of this manual (page 5.1):

Jobs: Each of the 16 jobs can be viewed, stored or cleared

individually.

Campaign: A total counter for, e.g. the season. The campaign counters

can be viewed, stored or cleared. A password is required to

clear the campaign counter.

Total: Data is constantly added to the total counter. The total

counter can be viewed, stored or cleared. A password is

required to reset the total counter.

Import/Export:

This menu item currently has no function.

Diagnostics:

Should problems arise with the system the inputs and outputs of the LH 85 Spray

controller can be tested using this menu item.

Please refer to the "System" section of this manual (page 6.1) for a description of

the various inputs and outputs.

Alarm log:

This menu item currently has no function.

Active alarms:

This menu item currently has no function.

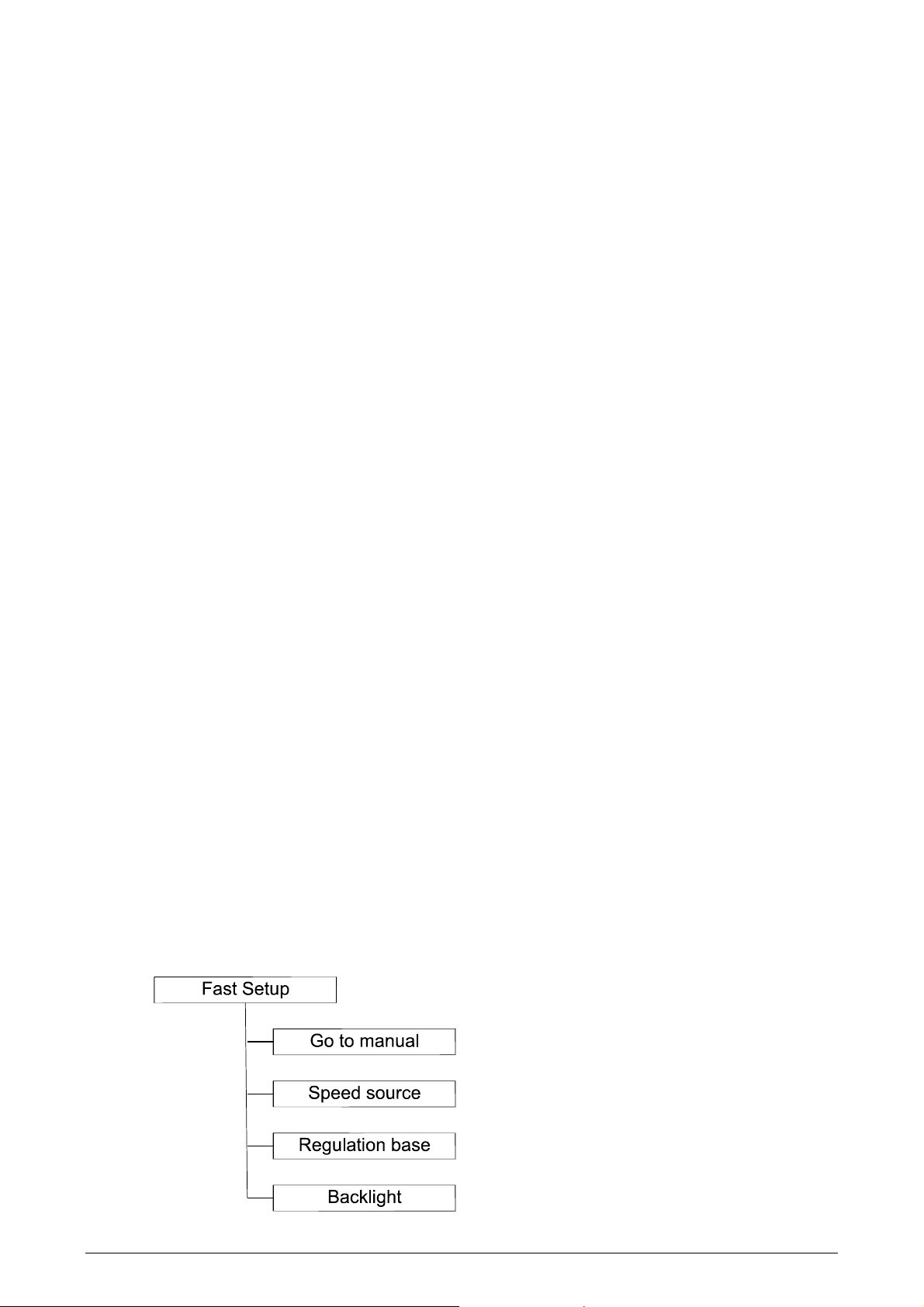

FAST SETUP MENU

When the system is in work (spraying) pressing the SETUP key selects the "Fast

Setup" menu.

The settings in this menu are directly related to spray work and allow the available

settings to be altered whilst spraying.

Each item in the menu is described in the following:

3.4 LH

AGRO

Page 23

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

GO TO MANUAL

Using this function it is possible to change from automatic rate control to manual

rate control and back to automatic rate control again.

The function of the boost keys (pos. A13 & A14) changes to manual

increase/decrease when manual rate control is selected and the rate can be

altered using these keys.

• Pressing the + key increases the rate.

• Pressing the – key decreases the rate.

To return to automatic rate control again simply press the SETUP key and select

"Go to automatic"

SPEED SOURCE

It is possible to change the sensor, from which the forward speed signal is

received and used for regulation, during operation by using this function.

This function can be used when, e.g. different wheels are used on the implement.

O

PERATION

A description of the available forward speed inputs can be seen in the following:

Symbol Description

Radar Pressing this key selects a signal from a

radar sensor.

Tractor wheel Pressing this key selects a signal from a

sensor fitted to the tractor.

Implement wheel 1 Pressing this key selects a signal from a

sensor fitted to the implement.

Pressing this key will show the next page and display the

following

Implement wheel 2 Pressing this key selects a signal from a

sensor fitted to the implement.

Implement wheel 3 Pressing this key selects a signal from a

sensor fitted to the implement

Simulated speed Pressing this key selects simulated forward

speed. When simulated speed has been

selected function keys 2 & 3 (pos. A13 &

A14) will allow the speed to be increased or

decreased.

The speed to be simulated is encoded in the

"Machine setup" menu under "Speed

source" (page 4.8).

LH

Pressing this key will show the first page

For correct operation the speed signal sources to be used must be

calibrated accurately. The procedure for forward speed calibration can be

seen on page 4.5.

AGRO

3.5

Page 24

O

PERATION

O

REGULATION BASE

This menu item might not appear depending on model/settings.

If the system is fitted with a pressure senor and a flowmeter it is possible to select

which sensor should be used for measuring flow (and thus for rate control).

The following options are available:

Symbol Description

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Flowmeter Pressing this key selects flow based

regulation.

Pressure sensor Pressing this key selects pressure based

regulation.

Auto When this key is pressed the LH 85 Spray

controller selects which flow input to be

used based on the minimum flow setting for

the flowmeter.

BACKLIGHT

The contrast and backlight settings for the display can be adjusted during

operation. Please refer to "Contrast/Light" on page 4.24 in the SETTINGS section

of this manual for detailed information.

3.6 LH

AGRO

Page 25

Settings

USER SETUP...................................................................................................................4.3

JOB ..........................................................................................................................4.4

TANK FILLING .........................................................................................................4.4

TANK LEVEL .......................................................................................................4.4

TRANSMIT...........................................................................................................4.4

MACHINE SETUP ............................................................................................................4.4

GO TO MANUAL......................................................................................................4.5

SPEED SOURCE.....................................................................................................4.5

SPEED SENSOR SELECTION AND CALIBRATION ..........................................4.6

SIMULATED SPEED ...........................................................................................4.8

FLOW.......................................................................................................................4.9

AUTOMATIC FLOWMETER CORRECTION .....................................................4.10

MANUAL FLOWMETER CORRECTION ...........................................................4.11

BOOST................................................................................................................... 4.11

REGULATION ACTION .........................................................................................4.11

FAST REGULATION VALUE ............................................................................. 4.11

PRECISE REGULATION VALUE ......................................................................4.12

NOZZLE BODY ...................................................................................................... 4.12

NOZZLE CONFIGURATION ..................................................................................4.13

OEM SETUP................................................................................................................... 4.15

UNIT.......................................................................................................................4.16

SENSORS..............................................................................................................4.16

PRESENCE .......................................................................................................4.16

CALIBRATION ...................................................................................................4.16

BOOM ....................................................................................................................4.19

BOOM SECTIONS.............................................................................................4.19

NOZZLES PER SECTION .................................................................................4.19

NOZZLE SPACING............................................................................................4.20

REGULATION VALVES.....................................................................................4.20

SECTION VALVES ............................................................................................4.20

REGULATION DETAILS....................................................................................4.20

TANK...................................................................................................................... 4.22

MAXIMUM TANK CONTENT ............................................................................. 4.22

AUTO FILLING...................................................................................................4.22

ELECTRIC AGITATION .....................................................................................4.22

MINIMUM TANK VOLUME ................................................................................4.22

AUTO FILLING OFFSET ...................................................................................4.22

ALARM CONFIGURATION.................................................................................... 4.22

MINIMUM TANK CONTENT ALARM.................................................................4.22

FLOW/PRESSURE CROSS-CHECK................................................................. 4.23

COMMUNICATION ................................................................................................ 4.23

MOTOR MANAGEMENT .......................................................................................4.23

Page 26

S

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

CONSOLE SETUP .........................................................................................................4.23

CONTRAST/LIGHT ................................................................................................ 4.24

LANGUAGE ...........................................................................................................4.24

DATE/TIME ............................................................................................................ 4.24

BUZZER................................................................................................................. 4.25

FILE SYSTEM ........................................................................................................ 4.25

4.2 LH

AGRO

Page 27

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

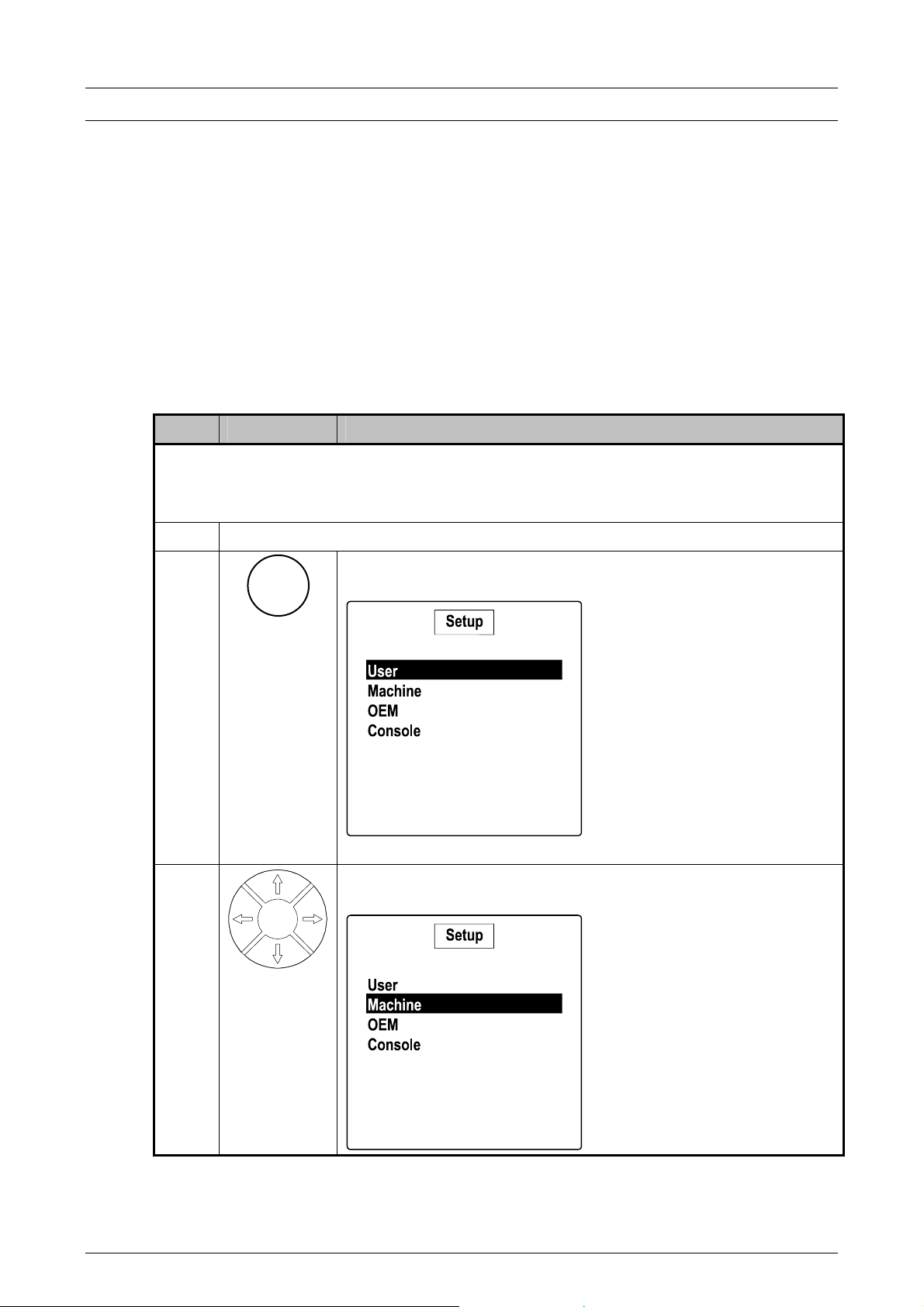

USER SETUP

The settings in the USER setup menu are related to daily work. The procedure to

access the "User setup" menu is thus:

Step Key Action

1 Switch the main on/off switch (B6) to the off position.

S

ETTINGS

2

Setup

Press the SETUP key.

3

Highlight the "User" menu item using the ARROW UP and

DOWN keys.

4

Press the ENTER key to select.

The following diagram shows the menu structure of the "User" setup menu:

A description of each setting is described in the following:

LH

AGRO

4.3

Page 28

S

ETTINGS

O

JOB

For a detailed description of the "Job" menu item please see the JOB FUNCTION

section of this manual.

TANK FILLING

TANK LEVEL

Encode the actual tank content in litres.

This value is used for the following calculated information:

• Volume left.

• Area left.

• Distance left.

TRANSMIT

This menu item currently has no function.

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

MACHINE SETUP

The "Machine" settings relate directly to settings that can differ from machine to

machine. The procedure to access the "Machine setup" menu is similar to the

procedure for accessing the "User setup" menu however the procedure is

described below:

Step Key Action

1 Switch the main on/off switch (B6) to the OFF position.

2

Setup

3

Press the SETUP key.

Highlight the "Machine" menu item using the ARROW UP

and DOWN keys.

4

Press the ENTER key to select.

4.4 LH

AGRO

Page 29

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Once selected, the following menu structure is available, a detailed description of

each setting can be seen after the diagram:

S

ETTINGS

Setup

Machine

OEM

Console

Go to manual

Speed source

Flow

Boost

Regulation action

Nozzle body

Nozzle configuration

Speed source

Simulated speedUser

Flow corr. automatic

Flow corr. manual

Boost percentage

Fast

Precise

Select nozzle body Select nozzle type

Select nozzle type

Select/Calibrate

On/Off - High/Low

Sprayed volume

Vol. From controller

Ta nk lev e l

Regulation value

Low limit

High limit

Ref. flow

Ref. pressure

GO TO MANUAL

This function is described under the "Fast setup" section on page 3.4.

SPEED SOURCE

The sensor to be used for forward speed and thus regulation can be selected and

calibrated here. It is also possible to simulate forward speed with the LH 85 Spray

controller, which is useful for, e.g. flowmeter calibration.

LH

AGRO

4.5

Page 30

S

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

SPEED SENSOR SELECTION AND CALIBRATION

Upon selecting this menu the following is displayed:

Pos. Description Pos. Description

1 Current calibration figure 4 Page key

2 Currently selected sensor 5 Function key 4 (select sensor)

3 Calibrate key 6 Function key 3 (select sensor)

The forward speed sensors available can be seen in the following:

Symbol Description

Radar Pressing this key selects a signal from a

radar sensor.

Tractor wheel Pressing this key selects a signal from a

sensor fitted to the tractor.

Pressing this key will show the next page and display the

following

Implement wheel 1 Pressing this key selects a signal from a

sensor fitted to the implement.

Implement wheel 2 Pressing this key selects a signal from a

sensor fitted to the implement.

Pressing this key will show the next page and display the

following

Implement wheel 3 Pressing this key selects a signal from a

sensor fitted to the implement

Pressing this key will show the first page

4.6 LH

AGRO

Page 31

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Automatic speed sensor calibration:

The procedure to calibrate the forward speed sensor follows:

Step Key Action

1 Measure and mark a 100 metre stretch in the field. Drive to

the start mark and stop.

When calibrating the forward speed sensor we recommend

doing so in the field with ½ the total volume in the tank to

ensure conditions as close to spray work as possible.

2 From the "Machine" setup menu select "Speed source".

3 From the "Speed source" menu select "Speed source" this

screen is shown in the display.

S

ETTINGS

4

Keys 3 & 4

Select the speed sensor to be calibrated by using function

keys 3 & 4 (pos. 5 & 6 in the above).

Use the page key (pos. 4 in the above) to view/select other

sensors.

5

Press the CALIBRATE key once.

6 Drive the 100 metre stretch – the controller will count the

number of pulses received whilst driving.

7 Stop exactly at the stop mark of the 100 metre stretch.

8

Press the ENTER key and the forward speed sensor has

been calibrated.

LH

AGRO

4.7

Page 32

S

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Manual speed sensor calibration:

If the number of pulses received per driven 100 metres is known then this can be

encoded directly thus:

Step Key Action

1 From the "Machine" setup menu select "Speed source".

2 From the "Speed source" menu select "Speed source".

3

Keys 3 & 4

Select the speed sensor to be calibrated by using function

keys 3 & 4 (pos. 5 & 6 in the above).

Use the page key (pos. 4 in the above) to view/select other

sensors.

4

Encode the number of pulses per 100 metres using the

ARROW keys.

5

Press the ENTER key and the forward speed sensor has

been calibrated.

SIMULATED SPEED

To use simulated forward speed in the LH 85 Spray controller do as follows:

Step Key Action

1 From the "Machine" setup menu select "Speed source".

2 From the "Speed source" menu select "Simulated speed".

3

Press the "Low" speed key and enter the lowest speed to

be simulated in kilometres per hour with 1 decimal.

4

Press the ENTER key.

5

4.8 LH

Press the "High" speed key and encode the highest speed

to be simulated in kilometres per hour with 1 decimal.

AGRO

Page 33

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Step Key Action

S

ETTINGS

6

7

8

Press the ENTER key.

Press the "Simulate On" key to switch speed simulation on.

Press the JOB key to return to the main operation screen.

Job

9

10

Press the "High speed" key to set the simulated speed to

the above encoded speed.

Press the "Low speed" key to set the simulated speed to

the above encoded speed.

To switch simulated speed off return to the "Simulated Speed" menu and switch

simulated speed off, or select a different speed source.

FLOW

This menu is for "tweaking" the flowmeter calibration figure. There are two

methods for correcting the flowmeter calibration from this menu:

• Automatic flowmeter correction

• Manual flowmeter correction

This "fine tuning" should not be confused with the initial flowmeter calibration

which is described on page 4.16.

LH

AGRO

4.9

Page 34

S

ETTINGS

O

AUTOMATIC FLOWMETER CORRECTION

The procedure for automatically adjusting the flow meter calibration is as follows:

Step Key Action

1 Reset the litre counter as described in the JOB FUNCTION

section in this manual.

2 Spray a known amount from the tank, e.g.500 litres.

3 Make a note of the amount the controller shows as

sprayed.

4 From the "Machine" setup menu select "Flow".

5 From the "Flow" menu select "Flow corr. automatic".

The current flow meter correction value is shown at the

bottom of the screen.

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

6

7

8

9

10

11

Esc

Select "Sprayed volume" from the menu and encode the

actual amount sprayed, e.g. 500 litres using the ARROW

keys.

Press the ENTER key.

Select "Vol. from controller" from the menu and encode

the volume noted in step 3 using the ARROW keys.

Press the ENTER key.

Highlight "Calc. new flow corr." from the menu and press

the ENTER key – the new flow meter correction value is

displayed at the bottom of the screen.

Press the ESCAPE key and a prompt will appear asking to

accept the new factor or to continue using the existing

factor.

12

Press the ENTER key to accept the new factor.

To continue using the old factor press the CLEAR key.

4.10 LH

AGRO

Page 35

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

MANUAL FLOWMETER CORRECTION

The flowmeter correction factor can be encoded manually. To calculate the

flowmeter correction factor the following formula can be used.

S

ETTINGS

Flow correction factor =

Sprayed volume

Volume from controller

The procedure to encode the calculated flow correction factor is as follows:

Step Key Action

1 From the "Machine" setup menu select "Flow".

2 From the "Flow" menu select "Flow corr. manual".

3

Encode the new flow correction factor using the ARROW

keys.

Use this formula to calculate the new flow factor

4

Press the ENTER key and the new value is stored.

BOOST

The size of the steps which the rate will increase or decrease with when the boost

function is used.

The percentile value encoded is used for both "Boost increase" (+) and "Boost

decrease" (-).

• Minimum value = 1%

• Maximum value 20%

REGULATION ACTION

The regulation action values are used to adjust the "speed" at which the system

adjusts the regulation valve.

The fast regulation action value brings the actual rate quickly towards the required

rate. As the actual rate gets closer to the required rate the precise regulation

action value takes over and controls the valve in smaller "steps".

The two different values used (fast & precise) are explained in the following:

FAST REGULATION VALUE

The fast regulation action value affects regulation when the actual rate is far from

the required rate.

If the system is too slow to find the correct rate then the values should be

increased.

LH

If the system is too unstable then the values should be decreased.

AGRO

4.11

Page 36

S

ETTINGS

O

PRECISE REGULATION VALUE

The precise regulation action value affects regulation when the actual rate is close

to the required rate

If the system is too slow to find the correct rate then the values should be

increased.

If the system is too unstable then the values should be decreased.

NOZZLE BODY

This menu allows the nozzle body to be configured with up to five different

commonly used nozzle types, which can then be selected easily for the sprayer

task (JOB FUNCTION).

Each nozzle type can be configured under "Nozzle configuration" (page 4.13).

The procedure to configure the nozzle body is as follows:

Step Key Action

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

1 From the "Machine" setup menu select "Nozzle body" and

this is shown in the display.

2 Highlight one of the nozzle types (1 to 5) using the

ARROW KEYS

3

Press the ENTER key to select the nozzle body spray

outlet and the following is shown:

4.12 LH

AGRO

Page 37

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Step Key Action

S

ETTINGS

4

Using the ARROW keys highlight the required nozzle type.

5

Press the ENTER key.

6 Repeat steps 2 to 5 for each of the 5 spray outlets.

NOZZLE CONFIGURATION

The configuration for each of the 16 different nozzle types stored in the system

can be altered.

The 11 pre-programmed nozzle types correspond to the ISO colouring system and

we recommend that the configuration for these nozzles is not altered.

There are 5 programmable nozzle types for nozzles that are not colour coded (P1

to P5) and the following settings can be altered:

Low limit:

High limit:

Reference flow:

Reference pressure:

The lowest operating pressure of the nozzle.

The highest operating pressure of the nozzle.

The reference flow in litres per minute for the nozzle.

The pressure at which the above flow rate is true

(ISO = 2 bar).

The procedure for altering the nozzle type configuration is as follows:

LH

AGRO

4.13

Page 38

S

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Step Key Action

1 From the "Machine setup" menu select "Nozzle

configuration".

2

3

4

5

6

Using the ARROW keys highlight the nozzle type to be

altered.

Press the ENTER key to select the configuration menu for

the selected nozzle.

Using the ARROW keys highlight the setting to be

adjusted.

Press the ENTER key when the setting to be altered is

highlighted.

Alter the value using the ARROW keys.

7

Press the ENTER key to store the value.

8 Repeat steps 4 to 7 for each of the settings

9 Repeat steps 3 to 8 for each of the nozzle types to be

altered.

4.14 LH

AGRO

Page 39

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

OEM SETUP

The OEM setup menu is password protected as the settings in this menu are

directly related to the equipment fitted to the sprayer. All of the settings in

the OEM setup menu are normally encoded when the LH 85 controller

system is fitted to the machine and should not need altering thereafter.

For work and machine related settings please refer to the respective

sections in this manual.

The OEM menu structure is as follows:

S

Select unitUnit

ETTINGS

Setup

User

Machine

OEM

Console

Sensors

Boom

Ta nk

Presence

Calibration Calibrate sensors

Boom sections

Nozzles per section

Nozzle spacing

Regulation values Select valve type

Section valves Select valve type

Regulation details

Max tank content

Auto filling on/off

Elec. Agitation on/off

Min. tank volume

Select sensors

Number of sections

Section 1 - 9

Min. Reg pressure

Max. Reg pressure

Regulation valve time

Min. voltage

Reg. dead band

LH

Regulation backlash

Anticipation factor

Default valve position

Reg. valve capacity

Regulation start delay

Min. speed

Manual reg. speed

Alarm config

Communication

Motor management

Auto filling offset

Min. tank content

Flow/press. check

Printer

RS-232

Motor man. on/off

AGRO

4.15

Page 40

S

ETTINGS

UNIT

SENSORS

PRESENCE

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Encode the units with which the system should operate, the following units are

available:

• SI (metric)

• US

• UK (imperial)

In this menu the sensors found on the machine are selected and calibrated.

Select which of the following sensors are fitted to the machine:

• Wheel sensor

• Pressure sensor

• Flowmeter

• GPS

• Tank sensor

CALIBRATION

Pressure sensor:

To calibrate the pressure sensor the ADC values for no pressure and for maximum

pressure must be found.

No Pressure: The minimum ADC value is measured when there is no

pressure in the system.

Pressure max: The maximum working pressure, in bar, of the pressure

sensor calculated from the ADC value for a reference

pressure.

Cal pressure: A reference pressure used to calculate the maximum working

pressure of the pressure sensor.

An automatic pressure sensor calibration procedure is available for calibrating the

pressure sensor and the procedure is as follows:

4.16 LH

AGRO

Page 41

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

As there will almost always be a pressure drop between the pressure sensor

and the nozzles we recommend measuring the actual pressure with a

manometer fitted as close to the nozzles as possible during pressure sensor

calibration.

1. From "OEM setup" select "Sensors".

2. From "Sensors" select "Calibration".

3. From "Calibration" select "Pressure sensor".

4. Highlight "No pressure".

5. With NO pressure in the system press the AUTO key.

6. Confirm that there is no pressure in the system by pressing the ENTER key.

7. Highlight "Cal pressure" press the ENTER key.

8. Encode the reference pressure (standard = 5.0 bar) and press the ENTER

key.

9. Highlight "Pressure max".

S

ETTINGS

10. Press the AUTO key.

11. Increase the pressure on the sprayer until the manometer measures the

encoded reference pressure (see step 8 in the above).

12. Press the ENTER key to complete pressure sensor calibration.

Flow meter:

The LH 85 Spray controller can be fitted with a spray flow meter and a fill flow

meter.

The following must be encoded for each of the flow meters fitted on the sprayer:

• The minimum amount that the flow meter can measure in litres per minute.

• The maximum amount that the flow meter can measure in litres per minute.

• The number of pulses transmitted per litre by the flow meter.

The number of pulses per litre for the flow meter can be encoded directly from the

flow meter calibration menu as follows:

1. From "OEM setup" select "Sensors".

LH

2. From "Sensors" select "Calibration".

3. From "Calibration" select "Flow meter".

4. Select the flow meter for which the minimum and maximum flow rates are to

be encoded by pressing the FLOW INPUT key. The text directly above the

function keys shows which flow meter is being encoded.

5. Encode the number of pulses per litre for the flow meter.

The procedure to encode the minimum & maximum flow rates for the required flow

meter plus an overview of the function keys follow:

AGRO

4.17

Page 42

S

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Key Description Key Description

MIN FLOW key

MAX FLOW key

FLOW INPUT key

CALIBRATE key

1. From "OEM setup" select "Sensors".

2. From "Sensors" select "Calibration".

3. From "Calibration" select "Flow meter".

4. Select the flow meter for which the minimum and maximum flow rates are to

be encoded by pressing the FLOW INPUT key. The text directly above the

function keys shows which flow meter is being encoded.

5. Press the MIN FLOW key.

6. Encode the minimum flow rate of the flow meter in litres per minute.

7. Press the ENTER key.

8. Press the MAX FLOW key.

9. Encode the maximum flow rate of the flow meter in litres per minute.

10. Press the ENTER key.

If the number of pulses per litre for the flow meter is not known or to make sure

that the value is correct an automatic calibration function is available. A description

of how to use the automatic calibration follows:

Automatic flow meter calibration:

1. From "OEM setup" select "Sensors".

2. From "Sensors" select "Calibration".

3. From "Calibration" select "Flow meter".

4. Select the flow meter for which the minimum and maximum flow rates are to

be encoded by pressing the FLOW INPUT key. The text directly above the

function keys shows which flow meter is being encoded.

5. Press the CALIBRATE key.

6. Press the ENTER key.

7. Press the START key and start spraying.

8. When minimum 100 litres has been sprayed stop spraying.

9. Press the STOP key and encode the actual amount sprayed.

10. Press the ENTER key and the flow meter is calibrated.

4.18 LH

AGRO

Page 43

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Tank sensor:

If the sprayer is fitted with a tank sensor this must be calibrated. The procedure for

tank sensor calibration is as follows:

1. From "OEM setup" select "Sensors".

2. From "Sensors" select "Calibration".

3. From "Calibration" select "Tank sensor".

4. With an empty tank select "Empty".

5. Press the AUTO key then the ENTER key to confirm that there is no liquid

on the tank sensor.

6. Press the ESCAPE key when calibration has finished.

7. Fill the tank to the encoded minimum tank level (see page 4.22) and select

"Min level".

8. Press the AUTO key and then the ENTER key to confirm that the tank

contains the number of litres encoded.

S

ETTINGS

9. Press the ESCAPE key when calibration has finished.

10. Fill the tank completely and select "Max level".

11. Press the AUTO key and then the ENTER key to confirm that the tank is

full.

12. Press the ESCAPE key when calibration has finished.

13. Select "Tank shape" and start emptying the tank by spraying with a

constant flow between 60 – 120 litres per minute.

14. When the tank is empty tank sensor calibration is finished.

BOOM

All boom related settings are configured in the boom menu.

BOOM SECTIONS

Encode the number of boom sections on the sprayer.

NOZZLES PER SECTION

To encode the number of nozzles for each individual boom section do thus:

LH

Step Key Action

1 From the "OEM" setup menu select "Boom".

2 From the "Boom" menu select "Nozzles per section".

3

Encode the number of nozzles on boom section 1 (starting

from left using the ARROW UP and DOWN keys.

AGRO

4.19

Page 44

S

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Step Key Action

4

Press the ENTER key.

5

Press the BOOM SECTION UP key to select the next

boom section.

Pressing the BOOM SECTION DOWN key selects the

previous boom section.

6 Repeat steps 3 to 5 for each existing boom section.

NOZZLE SPACING

Encode the distance between the nozzles in centimetres.

REGULATION VALVES

If the regulation valve fitted to the sprayer bypasses the flow to the boom select

"Reg. valve bypass".

If the regulation valve fitted to the sprayer throttles the flow select

"Reg valve throttle".

SECTION VALVES

Select whether the boom section valves are 2-way or 3-way.

REGULATION DETAILS

The following settings determine the regulation process of the LH 85 Spray

controller:

Minimum regulation pressure:

Encode the pressure, in bar, that the sprayer may not go under.

The working pressure will not go lower than this encoded level even if a lower

pressure is required by the regulation system (the controller).

Should the actual pressure on the sprayer be lower than this encoded value the

regulating system will continue to increase the pressure until the minimum

pressure level has been reached.

Maximum regulation pressure:

Encode the pressure, in bar, that the sprayer may not go over.

The working pressure will not go higher than this encoded level even if a higher

pressure is required by the regulation system (the controller).

Should the actual pressure on the sprayer be higher than this encoded value the

regulating system will continue to decrease the pressure until the maximum

pressure level has been reached.

4.20 LH

AGRO

Page 45

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Regulation valve time:

Encode the time, in seconds, that the regulation valve takes from fully closed to

fully open (or fully open to fully closed).

This value should found by measuring the actual time the valve takes from fully

closed to fully open (or the opposite) when the system is supplied with 12V.

Minimum voltage:

Encode the lowest voltage at which the regulation valve starts to move.

The controller uses variable voltage to control the valve; the closer the actual rate

is to the target rate, the lower the voltage sent to the valve is. The minimum

voltage must therefore be found when the valve is under pressure as this affects

the force required to move the valve.

Regulation dead band:

Encode an acceptable regulation dead band in percent.

S

ETTINGS

Regulation will stop when the difference between the target rate and the actual

rate is lower than the encoded dead band (percent of the target rate). This is to

prevent the valve from oscillating when the actual rate is near the target rate.

Regulation backlash:

Encode the time in seconds it takes before the valve starts moving after a direction

change.

Anticipation factor:

Encode the anticipation factor to ensure that the regulation valve is in a suitable

position when switching the main valve on when, e.g. turning on the headland.

0 = OFF The reg. valve remains stationary at the position when the main

valve was switched off.

100 = FULL The reg. valve will move completely to the calculated position.

The number of boom sections open, the target rate, the average forward speed,

the regulation valve time and the maximum reg. valve capacity are used to

calculate a theoretical position of the regulation valve when the main valve is OFF,

e.g. when turning on the headland.

LH

The anticipation factor expresses how much of the time needed to reach the

theoretical valve position will actually be used to drive the valve.

Example: The calculated position will take 1 second to reach; setting the

anticipation factor to 50% will result in the valve moving for ½

second instead of 1 second.

Default valve position:

Encode the required position of the regulation valve in percent of fully open.

When the main valve has been switched off for 10 minutes the reg. valve will move

to this position.

AGRO

4.21

Page 46

S

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Regulation valve capacity:

Encode the capacity of the regulation valve in litres per minute.

Regulation start delay:

Encode the delay in seconds from when the main valve is switched on until

regulation starts.

Minimum forward speed:

Encode the forward speed in kilometres per hour at which the system should

automatically switch the main valve OFF.

Manual regulation speed:

Encode in percent of the regulation valve time how fast the regulation valve should

move in manual operation.

TANK

Settings related to the main sprayer tank are encoded her. A description of the

available settings follow:

MAXIMUM TANK CONTENT

Encode the maximum possible tank content in litres.

AUTO FILLING

Pressing the ENTER when this setting is highlighted switches automatic tank filling

on and off.

ELECTRIC AGITATION

Pressing the ENTER key toggles between switching the automatic tank agitation

start/stop function on and off.

MINIMUM TANK VOLUME

Encode the tank content at which tank agitation should automatically be switched

off.

AUTO FILLING OFFSET

Encode the volume in litres that will still run into the tank after the fill valve has

started shutting.

ALARM CONFIGURATION

The different warnings available are configured in this menu. The available

warnings are described in the following:

MINIMUM TANK CONTENT ALARM

Encode the tank level, in litres, at which the tank content warning should be given.

4.22 LH

AGRO

Page 47

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

FLOW/PRESSURE CROSS-CHECK

Encode the maximum permissible error in percent between the flow measured by

the flow meter and the flow calculated from the pressure and nozzle

characteristics.

COMMUNICATION

Select whether the communications port protocol is for a printer or for, e.g. a

terminal for variable rate control (RS-232).

MOTOR MANAGEMENT

This function is not currently available.

Select whether the integrated motor management function is on or off.

S

ETTINGS

CONSOLE SETUP

The "Console" settings relate directly to settings that alter the user interface of the

console. The procedure to access the "Console" menu is similar to the procedure

for accessing the other setup menus however the procedure is described below:

Step Key Action

1 Switch the main on/off switch (B6) to the OFF position.

2

Setup

3

Press the SETUP key.

Highlight the "Console" menu item using the ARROW UP

and DOWN keys.

LH

4

Press the ENTER key to select.

AGRO

4.23

Page 48

S

A

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Once selected, the following menu structure is available, a detailed description of

each setting can be seen after the diagram:

Setup

User

Machine

OEM

Console

Contrast/Light

Language Select language

Regulation action

File System

Contrast +/-

uto light

Light on/off

Date encode

Time encode

Buzzer on/offBuzzer

Delete

Transfer

Memory status

CONTRAST/LIGHT

Key Description

Pressing this program key will make the screen lighter.

Pressing this program key will make the screen darker.

Pressing this program key will activate the auto-light function.

The backlight is switched off until a key is pressed, the backlight will

be switched on automatically.

The display’s backlight is turned on and off with this program key.

LANGUAGE

Select the language of the LH 85 Spray controller.

DATE/TIME

Encode the current date and time.

4.24 LH

AGRO

Page 49

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

BUZZER

Select whether the system sounds or not when a key is pressed.

FILE SYSTEM

This menu allows the files stored in the system to be transferred & deleted.

The current memory status can also be seen.

For further information regarding transferring and deleting files please see the job

function section of this manual (page 5.1).

S

ETTINGS

LH

AGRO

4.25

Page 50

S

ETTINGS

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

4.26 LH

AGRO

Page 51

Job function

GENERAL JOB & COUNTER INFORMATION................................................................. 5.2

JOB MENU OVERVIEW ................................................................................................... 5.3

STARTING A JOB ............................................................................................................ 5.4

THE NOZZLE CALCULATOR ..........................................................................................5.5

USING THE NOZZLE CALCULATOR...................................................................... 5.5

NOZZLE CALCULATOR EXAMPLE 1 ................................................................. 5.5

NOZZLE CALCULATOR EXAMPLE 2 ................................................................. 5.7

JOB AND COUNTER DATA MANAGEMENT ..................................................................5.9

VIEWING JOBS AND COUNTER DATA.................................................................. 5.9

PRINTING JOBS AND COUNTER DATA ..............................................................5.10

STORING JOBS AND COUNTER DATA...............................................................5.10

CLEARING JOB AND COUNTER DATA ...............................................................5.11

TRANSFERRING JOB AND COUNTER DATA TO AN EXTERNAL DEVICE................5.11

CONNECTING THE LH 85 TO AN EXTERNAL DEVICE ......................................5.11

VIEWING DATA TRANSFERRED FROM THE LH 85 SPRAY CONTROLLER.....5.13

DELETING STORED FILES FROM THE LH 85 SPRAY CONTROLLER..............5.13

Page 52

J

OB FUNCTION

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

GENERAL JOB & COUNTER INFORMATION

There are 3 different counter sets in the LH 85 Spray Controller. Each job and

counter set can be stored as a file on the system for retrieval at a later date.

Jobs:

Up to 16 different jobs are available.

Each job can be started and stopped independently of the other

jobs.

Each individual job can be viewed, printed, stored or cleared.

Each job stores the following information:

Nozzle:

Application rate:

Start:

Stop:

Spray area:

Spray distance:

Spray time:

Spray volume:

Campaign:

A total counter for e.g. the season.

The nozzle type for the job.

The required application rate for the job.

The date & time that the job was started.

The date & time that the job was stopped.

The area sprayed for the job.

The distance covered for the job.

The time the job took in hours &minutes.

The amount sprayed

Data is constantly added to the campaign counter as work

proceeds.

The campaign counter can be viewed, printed, stored or

cleared.

A password is required to clear the campaign counter.

The campaign counter stores the following information:

Area:

The area sprayed since the counter was

cleared.

Volume:

The volume sprayed since the counter

was cleared.

Time:

The time in hours & minutes for which the

sprayer has been spraying.

Max. speed:

The maximum forward speed registered

by the system.

5.2 LH

AGRO

Page 53

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

J

OB FUNCTION

Total:

A total counter for, e.g. the year.

Data is constantly added to the total counter as work proceeds.

The total counter can be viewed, printed, stored or cleared.

A password is required to clear the total counter.

The total counter stores the following information:

Area:

Volume:

Time:

Max. speed:

JOB MENU OVERVIEW

The area sprayed since the counter was

cleared.

The volume sprayed since the counter

was cleared.

The time in hours & minutes for which the

sprayer has been spraying.

The maximum forward speed registered

by the system.

Job

Job number

Nozzle

Application rate

Density

If fertiliser

Density factor

Nozzle calculator

Select job 1 - 16

Select nozzle 1 - 5

Encode rate

Water

Fertiliser

Nozzle

Application rate

Desired speed

Desired pressure

Select nozzle 1 - 5

Encode rate

Encode speed

Encode pressure

LH

Flow rate

AGRO

5.3

Page 54

J

OB FUNCTION

O

STARTING A JOB

The procedure to start a job is as follows:

Step Key Action

1 Switch the main on/off switch (B6) to the off position.

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

2

3

Job

Press the JOB key and the following is displayed:

To select which job is to be active highlight "Job number"

and press the ENTER key.

Select the job number using the ARROW UP and DOWN

keys and press the ENTER key.

Highlight "Nozzle" using the ARROW UP and DOWN keys

and select which nozzle type is to be used for the job.

The nozzle types shown here are the nozzle types

encoded for the "Nozzle body" under "Machine setup"

(page 4.12).

The nozzle/rate/speed/pressure combination can be

checked using the "Nozzle calculator" which is described

on page 5.5.

4

Press the ENTER key to select the required nozzle type.

5 Highlight "Application rate" using the ARROW UP and

DOWN keys, then press the ENTER key.

The nozzle/rate/speed/pressure combination can be

checked using the "Nozzle calculator" which is described

on page 5.5.

6 Encode the required application (target) rate for the job,

then press the ENTER key.

Only if the density of the liquid to be used is not the same as water (1.00 kg/L)

7 Highlight "Density" and press the ENTER key.

8 Highlight "Fertiliser" and press the ENTER key.

9 Highlight "Density factor" and press the ENTER key.

10 Encode the density of the liquid to be used, then press the

ENTER key.

5.4 LH

AGRO

Page 55

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

THE NOZZLE CALCULATOR

The nozzle calculator is a useful tool for deciding the following spray parameters:

• Nozzle type

• Application rate (target rate)

• Desired forward speed

• Desired spraying pressure

USING THE NOZZLE CALCULATOR

The best way to describe how to use the nozzle calculator is to use examples,

which follow:

NOZZLE CALCULATOR EXAMPLE 1

J

OB FUNCTION

In this example the following parameters are required:

Application rate = 150 L/ha Nozzle type = 02 (Yellow) Desired speed = 6.0 km/h

Step Key Action

1 Switch the main on/off switch (B6) to the off position.

2

Job

Press the JOB key and a screen with similar values to the

following is displayed:

Job number 1

Nozzle 015

Application rate 96

Density Water

Nozzle calculator

Job

LH

3

Highlight "Nozzle calculator" using the ARROW UP and

DOWN keys.

4

Press the ENTER key to select nozzle calculator and a

screen with similar values to the following is displayed:

AGRO

5.5

Page 56

J

OB FUNCTION

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Step Key Action

Nozzle calculator

Nozzle 015

Appl. rate 96

Desired speed 6.0

Desired pressure 2.0

Flow rate 0.48

5

With "Nozzle" highlighted press the ENTER key.

6

Highlight the required nozzle type from the list using the

ARROW UP and DOWN keys.

7

Press the ENTER key to select the nozzle type and the

display changes to display the following:

Nozzle calculator

Nozzle 02

Appl. rate 150

Desired speed 6.0

Desired pressure 2.8

Flow rate 0.75

As can be seen from the above, the nozzle type, the

application rate and the desired speed have changed to the

required values.

The pressure required for the nozzle/rate/speed

combination is shown as is the required flow rate for each

nozzle (for calibration purposes).

5.6 LH

AGRO

Page 57

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

NOZZLE CALCULATOR EXAMPLE 2

In this example the following parameters are required:

Application rate = 150 L/ha Nozzle type = 02 (Yellow) Desired pressure = 3.0 bar

Step Key Action

1 Switch the main on/off switch (B6) to the off position.

J

OB FUNCTION

2

3

4

Job

Press the JOB key and a screen with similar values to the

following is displayed:

Job number 1

Nozzle 015

Application rate 96

Density Water

Nozzle calculator

Job

Highlight "Nozzle calculator" using the ARROW UP and

DOWN keys.

Press the ENTER key to select nozzle calculator and a

screen with similar values to the following is displayed:

Nozzle calculator

LH

Nozzle 015

Appl. rate 96

Desired speed 6.0

Desired pressure 2.0

Flow rate 0.48

5

With "Nozzle" highlighted press the ENTER key.

6

Highlight the required nozzle type from the list using the

ARROW UP and DOWN keys.

AGRO

5.7

Page 58

J

OB FUNCTION

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

Step Key Action

7

8

9

Press the ENTER key to select the nozzle type and the

display changes to display the following:

Nozzle calculator

Nozzle 02

Appl. rate 150

Desired speed 6.0

Desired pressure 2.8

Flow rate 0.75

Highlight "Desired pressure" using the ARROW UP and

DOWN keys.

Press the ENTER key and encode the required pressure,

then press the ENTER key to accept this value.

The following is shown in the display:

Nozzle calculator

Nozzle 02

Appl. rate 150

Desired speed 6.2

Desired pressure 3.0

Flow rate 0.78

As can be seen in the above, the nozzle type, the

application rate and the required pressure have been

changed to the required values.

The required speed for the nozzle/rate/pressure

combination is shown as is the required flow rate for each

nozzle (for calibration purposes).

5.8 LH

AGRO

Page 59

O

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

J

JOB AND COUNTER DATA MANAGEMENT

As mentioned before each individual job plus the campaign and total counters can

be viewed, printed, stored and cleared.

The procedure for each function is described in the following:

VIEWING JOBS AND COUNTER DATA

The procedure to view job and counter data is as follows:

Step Key Action

1 Switch the main on/off switch (B6) to the off position.

OB FUNCTION

2

Info

Press the INFO key and the following is displayed:

Jobs

Campaign

Tot al

Counters

To select which counter is to be viewed highlight "Job",

"Campaign" or "Total" and press the ENTER key.

If "Job" is selected then the job to be viewed must be

selected before job data can be viewed.

3

The job or counter data, which is described on page 5.2,

are displayed.

Job data is displayed on two screens. Use the ARROW UP

and DOWN keys to alternate between these pages.

LH

AGRO

5.9

Page 60

J

OB FUNCTION

O

PRINTING JOBS AND COUNTER DATA

It is only possible to print job and counter data if the system is fitted with a

compatible printer and that the "Communication" menu item is set to

"Printer" under console setup (see page 4.23).

The procedure for printing job and counter data is as follows:

Step Key Action

1 Follow steps 1 and 2 as for viewing job and counter data.

PERATORS MANUAL FOR THE LH 85 SPRAY CONTROLLER

2

Press the PRINT key and the selected job or counter will

be printed.

STORING JOBS AND COUNTER DATA

Job and counter data can be stored in the system for later retrieval.