Page 1

F I E L D P I L O T®

U S E R M A N U A L

Assisted Steering Hydraulic Installation Manual for

Vehicle Kit Number 91-02336

Fits Only AGCO Gleaner A75/6 & A85/6, Massey Ferguson

9x95 or Challenger 670/B & 680B

Page 2

FieldPilot

®

FIELDPILOT®

Copyrights

© 2010 TeeJet Technologies. All rights reserved. No part of this document or the computer programs

described in it may be reproduced, copied, photocopied, translated, or reduced in any form or by any

means, electronic or machine readable, recording or otherwise, without prior written consent from TeeJet

Technologies.

Trademarks

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their

respective companies or organizations.

Limitation of Liability

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND,

EITHER EXPRESSED OR IMPLIED. NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO

EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR ANY LOSS OF BUSINESS, LOSS OF PROFIT,

LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT, SPECIAL, INCIDENTAL,

OR CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN

ADVISED OF SUCH DAMAGES ARISING FROM TEEJET TECHNOLOGIES SOFTWARE.

2

www.teejet.com

Page 3

FieldPilot

®

PREPARATION

1. Before beginning the installation, thoroughly clean the vehicle to remove dirt and contaminants that might

get into the hydraulic circuit.

2. Park the vehicle on a clean, level oor with adequate clearance to work around.

3. Do not attempt to loosen any hydraulic ttings while the engine is running.

4. Allow the motor and the hydraulics to cool until it is no more than warm to the touch before proceeding.

5. Prior to loosening any hydraulic ttings, be sure to have the appropriate plugs and caps available in order

to limit loss of hydraulic uid from the open ttings.

PREVENT HYDRAULIC SYSTEM CONTAMINATION. It is essential to thoroughly clean hydraulic

system ttings and hose connections prior to disconnecting or removing them. Use a spray

cleaner such as “Brake Clean” to prevent hydraulic system contamination. Note that o-rings used

on ORB and ORFF type ttings may be damaged by solvent cleaners such as “Brake Clean”. If a tting is to

be cleaned internally, the o-ring should rst be removed and cleaned with a berless cloth.

TO AVOID EXCESS LEAKAGE, DO NOT TURN THE STEERING WHEEL WHILE THE

FITTINGS ON THE MANUAL STEERING VALVE ARE DISCONNECTED.

WARNING: HOT, HIGH PRESSURE FLUID HAZARD. Hydraulic oil may be hot and under

extreme pressure. To prevent serious injury or death, relieve system pressure and allow the

system to cool before repairing or disconnecting. Wear proper hand and eye protection when

searching for leaks, using wood or cardboard instead of hands. Keep all hydraulic components in good repair.

WARNING: PINCH POINT HAZARD! To prevent serious injury or death, avoid unsafe practice

while manually operating hydraulic steering circuits. Keep others away and stay clear of

mechanical steering linkages.

www.teejet.com

1

Page 4

FieldPilot

®

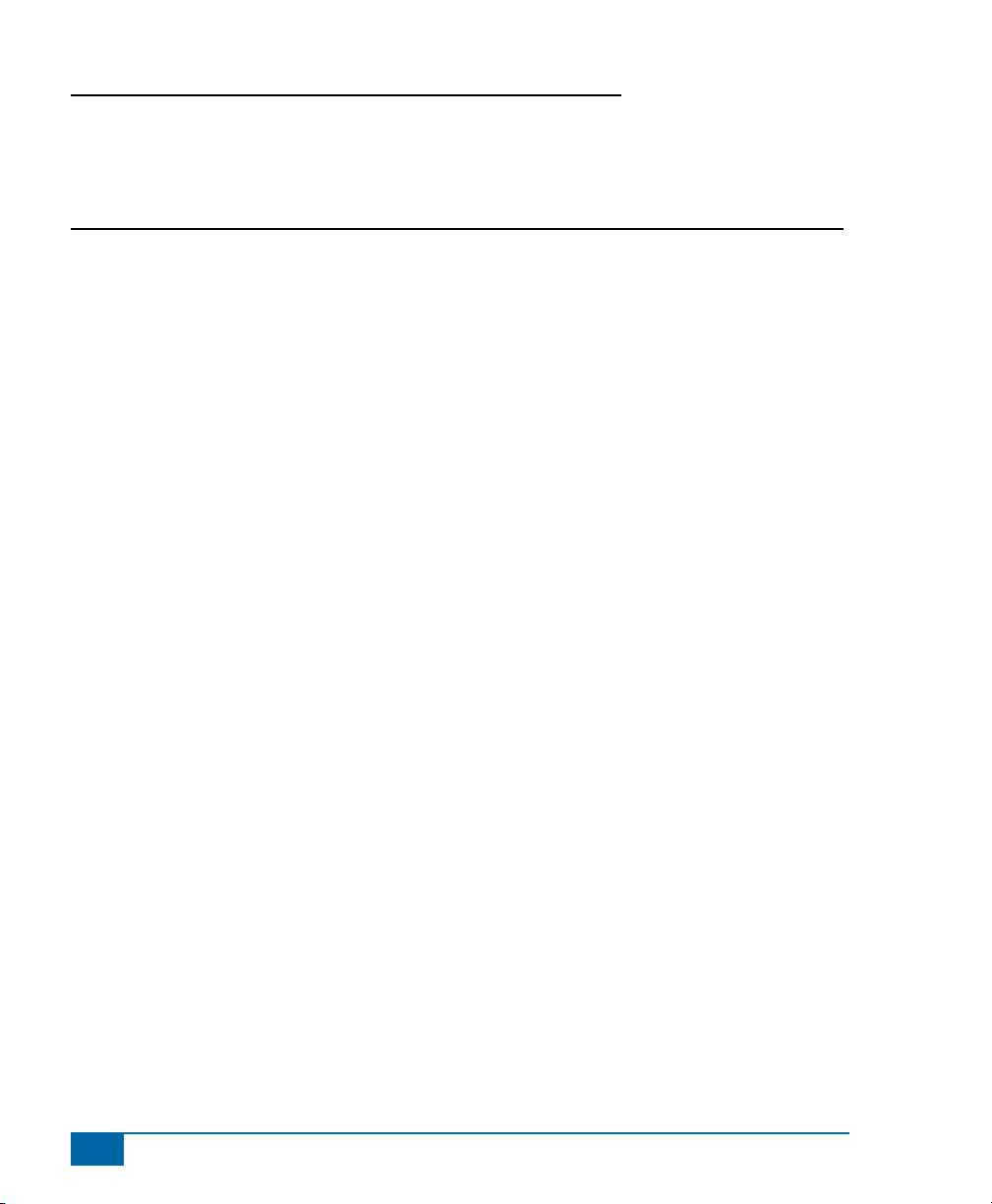

KIT CONTENTS

Unpack the installation kit and identify the required parts.

Item Part Number Description Quantity

A 32-04040 Switch, Engage/Disengage ......................................................................................1

B 350-0037 Washer, Flat - 3/8” SST ...........................................................................................2

C 35-02188 Valve, FieldPilot PWM, CC, LS, 3.2GPM .................................................................1

D 45-07703 Harness, SCM .........................................................................................................1

E 45-10103 Harness, Valve .........................................................................................................1

F 60-04087 Bolt, Hex- 3/8-16 x 3-3/4” SST .................................................................................2

G 60-07027 Nut, NyLock 3/8-16, SST .........................................................................................2

H 68-01033 Hose, Hyd. - 3/8” x 14”, #6FJIC Both Ends ............................................................1

I 68-01100 Hose, Hyd. - 3/8” x 18”, #6FJIC x #6FJIC ...............................................................2

J 68-01258 Hose, Hyd. - 1/2” x 132”, #8FJIC x #12FJIC 90º ....................................................1

K 68-01259 Hose, Hyd. - 1/4” x 132”, #4FJIC x #4FJIC 90º ......................................................1

L 68-02010 Adapter, Hyd. - #4MJIC x #6MORB .........................................................................3

M 68-02011 Adapter, Hyd. Run Tee - #12 JIC .............................................................................1

N 68-02012 Shuttle TEE - #6FORB.............................................................................................1

O 68-02022 Adapter, Hyd. Run Tee - #6 JIC ...............................................................................3

P 68-02051 Adapter, Hyd. 90º - #12MJIC x #12FJIC ..................................................................1

Q 68-02058 Adapter, Hyd. - #4FJIC x #6MJIC ............................................................................1

R 68-02066 Adapter, Hyd. - #6MORB x #6FJIC ..........................................................................1

S 68-02078 Adapter, Hyd. 90º - #6MJIC x #6FJIC ......................................................................2

T 68-02080 Adapter, Hyd. 90º - #6MJIC x #6MORB ...................................................................3

U 68-02090 Adapter, Hyd. 90º - #8MJIC x #6MORB ...................................................................1

V 68-02184 Adapter, Hyd. 90º - #4MJIC x #4FJIC ......................................................................2

W 90-50013 Cable Tie Kit, 15 ......................................................................................................1

X 91-07011 Steering Wheel Switch Kit .......................................................................................1

Z 98-05224 Installation Manual AGCO GLNR A75/6,A85/6, MF 9X95, CHNGR 670/B,680B ...1

2

www.teejet.com

Page 5

Item Part # Description Illustration

A 32-04040 Switch, Engage/Disengage,

Momentary

B 350-0037 Washer, Flat - 3/8" SST

C 35-02188 Valve, FieldPilot PWM, CC,

LS, 3.2GPM

FieldPilot

®

D 45-07703 Harness, SCM

E 45-10103 Harness, Valve

F 60-04087 Bolt, Hex- 3/8-16 x 3-3/4"

SST

G 60-07027 Nut, NyLock 3/8-16, SST

H 68-01033 Hose, Hyd. - 3/8" x 14",

#6FJIC Both Ends

I 68-01100 Hose, Hyd. - 3/8" x 18",

#6FJIC x #6FJIC

J 68-01258 Hose, Hyd. - 1/2" x 132",

#8FJIC x #12FJIC 90º

45-10103

DC:xx/xx

SCM Power I/O

45-07703

DC: xx/xx

Power

Valve Output

A

B

www.teejet.com

3

Page 6

FieldPilot

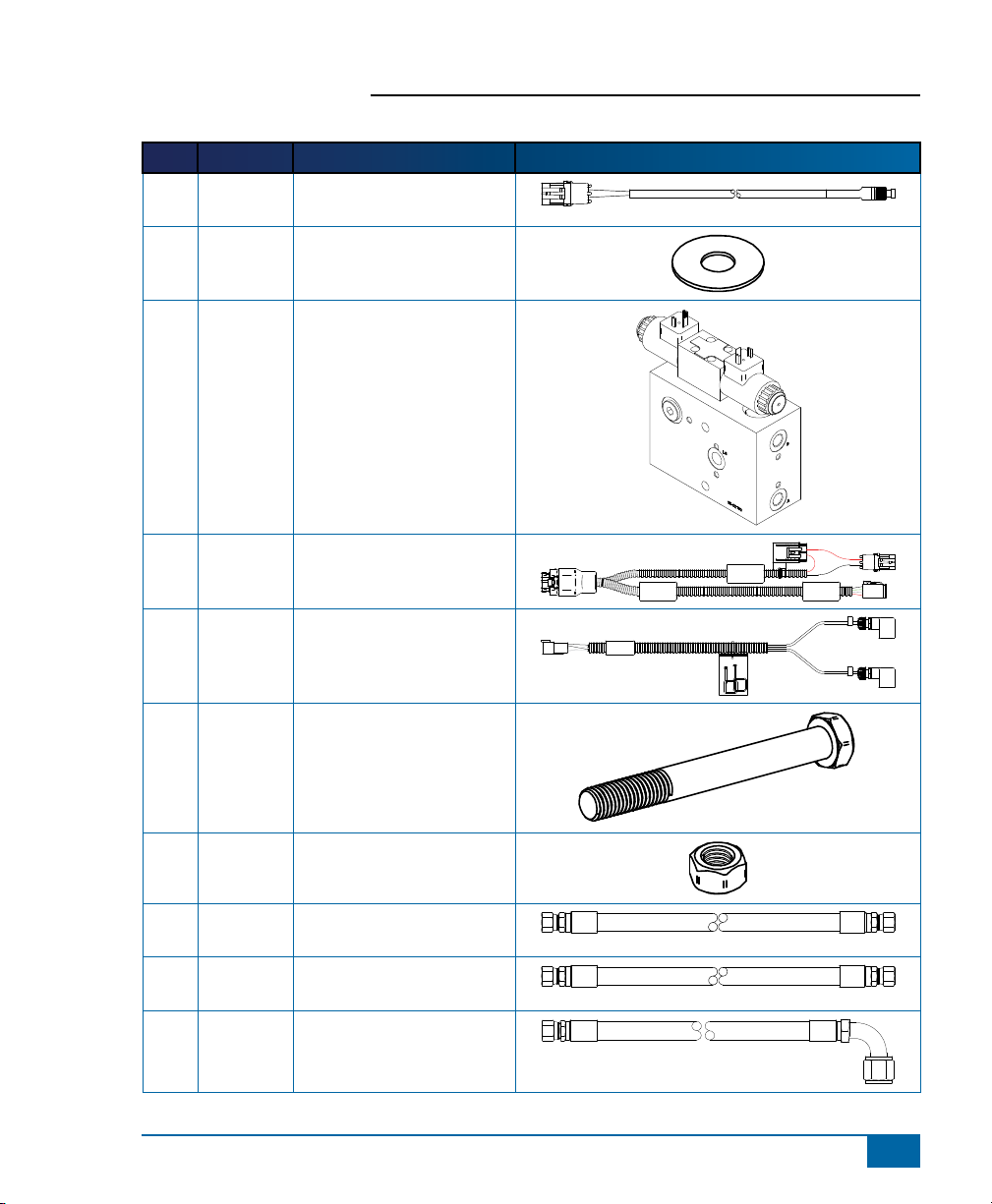

Item Part # Description Illustration

K 68-01259 Hose, Hyd. - 1/4" x 132",

L 68-02010 Adapter, Hyd. - #4MJIC x

M 68-02011 Adapter, Hyd. Run Tee - #12

N 68-02012 Shuttle TEE - #6FORB

®

#4FJIC x #4FJIC 90º

#6MORB

JIC

O 68-02022 Adapter, Hyd. Run Tee - #6

JIC

P 68-02051 Adapter, Hyd. 90º - #12MJIC

x #12FJIC

Q 68-02058 Adapter, Hyd. - #4FJIC x

#6MJIC

4

www.teejet.com

Page 7

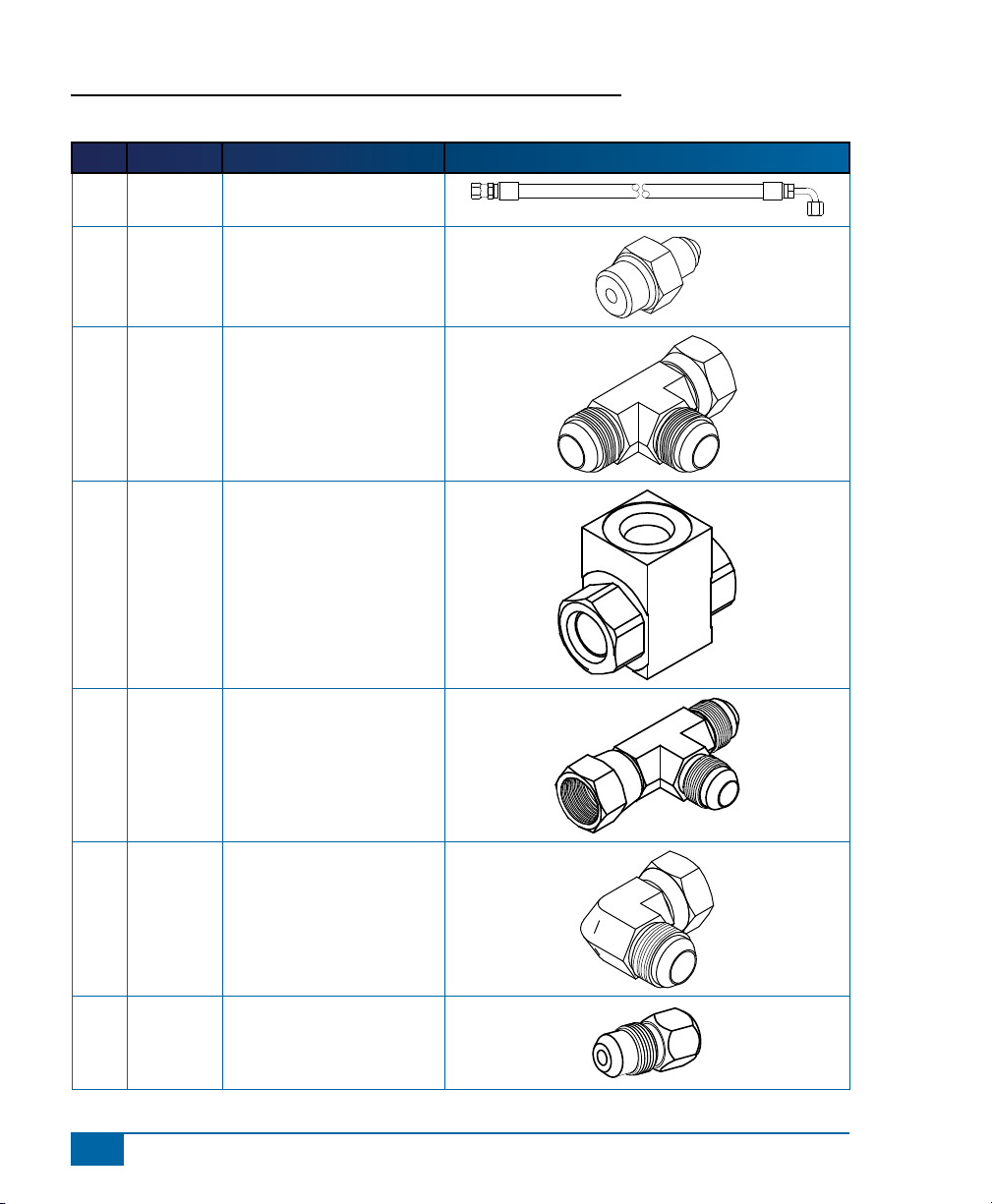

Item Part # Description Illustration

R 68-02066 Adapter, Hyd. - #6MORB x

#6FJIC

S 68-02078 Adapter, Hyd. 90º - #6MJIC

x #6FJIC

T 68-02080 Adapter, Hyd. 90º - #6MJIC

x #6MORB

U 68-02090 Adapter, Hyd. 90º - #8MJIC

x #6MORB

FieldPilot

®

V 68-02184 Adapter, Hyd. 90º - #4MJIC

x #4FJIC

W 90-50013 Cable Tie Kit, 15

X 91-07011 Steering Wheel Switch Kit

Z 98-05224 Installation Manual AGCO GLNR A75/6,A85/6, MF 9X95, CHNGR 670/B,680B

www.teejet.com

5

Page 8

FieldPilot

®

Figure 1-1: Hydraulic Diagram

Tank

R

L

Orbital

I

A

LS

I

B

T

P

Priority Valve

N

Shuttle

K

H

T

J

P

Tee

LS

Main Hydraulic

Auxiliary

Pump

PEF

CFLS

P

Block

Existing Hoses

Hoses From Kit

6

www.teejet.com

FieldPilot Valve

Page 9

FieldPilot

INSTALLATION

If there are questions concerning the installation of the FieldPilot system on this vehicle, or due to

the changes in component specications the parts supplied in the kit are not exactly as presented

in this document, please contact your dealer or TeeJet Customer service representative for

clarication before installation. TeeJet Technologies is not responsible for misuse or incorrect installation of

the system.

NOTE: BE VERY CAREFUL TO ABSOLUTELY SECURE ALL CABLES AND HOSES SO THAT THEY

DON’T INTERFERE WITH THE MANY MOVING PARTS OF THE MACHINE!

Overview of the Machine

• The FieldPilot valve will mount underneath the cab.

• The Tank and Steering lines will tee in at the orbital.

• The Pressure and LS lines will tee in at the main hydraulic block located on the right side of the

machine.

• The GPS should mount at the front edge of the cab.

NOTE: All references to left and right are stated as if the user is seated in the driver’s seat.

Figure 1-2: Overview of the Machine

®

GPS

FieldPilot

Valve

Hydraulic Block

and P & LS

Connections

www.teejet.com

7

Page 10

FieldPilot

1. PREPARE THE FIELDPILOT VALVE

Install adapters (T) in the A, B, & T ports of the FieldPilot valve, Install adapter (U) in the P port of the

FieldPilot valve. Then install adapter (L) in the LS port of the FieldPilot valve.

Figure 1-3: Prepare the FieldPilot Valve

®

U

T

T

L

T

8

www.teejet.com

Page 11

FieldPilot

®

2. MOUNT THE FIELDPILOT VALVE

The FieldPilot valve will mount to the bottom side of the oor of the cab. Use the FieldPilot valve to mark the

location for drilling the two 7/16” mounting holes. The distance between the holes should be 2.9”. Once the

holes are drilled use parts (B, F, & G) to mount the FieldPilot valve. The valve will mount with the solenoids

facing the left side of the machine and the P & T ports facing forward.

Figure 1-4: Mount the FieldPilot Valve

F

Remove oor mat

View from left side

looking to the right side

B, F & G

www.teejet.com

9

Page 12

FieldPilot

3. PREPARE THE ORBITAL

Disconnect the Tank, Left, & Right hoses from the orbital and install run tees (O) on the orbital. Connect the

original hoses the runs of the appropriate tee.

Figure 1-5: Prepare the Orbital

®

L

R

Tank port with O

installed

Left port with O

installed

Right port with O

installed

10

www.teejet.com

Page 13

FieldPilot

4. INSTALL THE STEERING HOSES

Connect hoses (I) from the A & B ports of the FieldPilot valve to the branches of run tees (O) on the L & R

ports of the orbital.

Figure 1-6: Install the Steering Hoses

®

I

I

5. INSTALL THE TANK HOSE

Connect hose (H) from the T port of the FieldPilot valve to the T port of the Orbital.

Figure 1-7: Install the Tank Hose

H

H

www.teejet.com

11

Page 14

FieldPilot

®

6. INSTALL THE PRESSURE HOSE AND ADAPTER

Locate the pressure port on the hydraulic block as indicated. Disconnect the machine’s hose and install run

tee (M). Reconnect the original hose to the run of the tee. Then connect and route hose (J) from the P

port of the FieldPilot valve to the branch of the run tee (M). Adapter (P) can be used as needed to make

your installation easier.

Figure 1-8: Install the Pressure Hose and Adapter

Pressure port

M

Pressure port

J

M

J

P

12

www.teejet.com

Page 15

FieldPilot

7. PREPARE THE SHUTTLE TEE

Install adapters (L & R) in the shuttle tee (N) as shown. Then install adapter (Q) onto adapter (R) as

shown.

Figure 1-9: Prepare the Shuttle Tee

L

N

R

L

8. INSTALL THE SHUTTLE TEE & LOAD SENSE HOSE

Disconnect the machine’s LS hose and install the prepared shuttle tee. Adapters (S & V) can be used as

needed to orient the shuttle tee the best for your installation. Attach original LS hose to shuttle tee and then

route and connect hose (K) from the LS port of the FieldPilot valve to the other side of the shuttle tee as

shown.

Q

®

Figure 1-10: Mount the FieldPilot Valve

Original LS Hose

K

S or V

www.teejet.com

13

Page 16

FieldPilot

®

9. INSTALL THE VALVE CONTROL CABLE

Connect the valve control cable (E) to the FieldPilot valve and route it into the cab.

Figure 1-11: Install the Valve Control Cable

Connect E here

14

www.teejet.com

Page 17

FieldPilot

®

10. INSTALL STEERING DISENGAGE SWITCH KIT 9107011

The steering disengage kit (X) is used to automatically disengage FieldPilot when the steering wheel is

turned. The sensor must be mounted so that it has a 1/8” clearance from the magnets. Remove the shrouds

around the steering base. Locate the steering shaft and attach 3 magnets to the shaft, then install the bracket

and sensor as shown so that there is a clearance of 1/8” between the magnets and sensor. Route the cable

and ensure it will not get tangled in any moving components. Connect the sensor to the SCM harness (D).

Figure 1-12: Install Steering Disengage Switch (Kit 91-07011)

Magnets

Sensor

www.teejet.com

15

Page 18

FieldPilot

®

11. INSTALLATION OF ENGAGE/DISENGAGE SWITCH

Connect item (A) to the connector on the SCM harness labeled Remote Engage/Disengage. Install the push

button in a location that is easily accessible during operation of the machine. This switch (A) is not required

if the optional foot switch 32-04020 is used.

Figure 1-13: Engage/Disengage Switch

12. RECOMMENDED ELECTRONICS INSTALLATION

The Steering Control Module (SCM) should be mounted securely to the oor of the cab as far forward in the

cab as possible. The control console can be mounted to the operator’s preference. The GPS antenna should

be mounted at the front edge of the cab on a metal surface of at least 4” square.

Figure 1-14: Recommended Electronics Installation

SCM

16

www.teejet.com

GPS

Page 19

FieldPilot

®

13. VERIFY OPERATION OF HYDRAULICS

AND SET THE STEERING CONTROL RATE

Clean and pick up the area around the vehicle and make certain that it is safe to operate. Start the engine

and check hydraulic connections for leaks. Rotate the steering wheel from one extreme to the other and back

to center, check for leaks. While steering through the extremes of movement, check the cables and hoses for

wear points and strain, adjust as necessary.

The nal oil ow rate adjustment is accomplished through the Matrix console. The

target lock to lock time is 8 seconds and the valve frequency is 110. Refer to the

Matrix manual for further instructions.

NOTE: To activate the manual overrides, a tool such as a small screwdriver or allen wrench must be inserted

into the end of the coil to depress the override button.

WARNING: PINCH POINT HAZARD! To prevent serious injury or death, avoid unsafe practice

while manually operating hydraulic steering circuits. Keep others away and stay clear of

mechanical steering linkages.

14. COMPLETE ELECTRONIC INSTALLATION

Refer to the owner’s manual supplied with the automated steering system to complete the electronic

installation and setup.

www.teejet.com

17

Page 20

F I E L D P I L O T®

U S E R M A N U A L

A series of equipment-specic hydraulic installation kits have been

developed to work in conjunction with your assisted steering system.

This kit contains the necessary components and instructions to install

assisted steering hydraulics on the AGCO Gleaner A75/6 & A85/6, Massey

Ferguson 9x95 or Challenger 670/B & 680B. Please review this manual

thoroughly before beginning the installation process.

1801 Business Park Drive

Springeld, Illinois 62703 USA

Tel: (217) 747-0235 • Fax: (217) 753-8426

www.teejet.com

98-05224 R0

© TeeJet Technologies 2010

Loading...

Loading...