Page 1

BOOMPILOT®

JOB COMPUTER

USER MANUAL

Software version 0.00

Page 2

COPYRIGHTS

© 2011 TeeJet Technologies. All rights reserved. No part of this document or the computer programs described in it may be reproduced,

copied, photocopied, translated, or reduced in any form or by any means, electronic or machine readable, recording or otherwise, without

prior written consent from TeeJet Technologies.

TRADEMARKS

Unless otherwise noted, all other brand or product names are trademarks or registered trademarks of their respective companies or

organizations.

LIMITATION OF LIABILITY

TEEJET TECHNOLOGIES PROVIDES THIS MATERIAL “AS IS” WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESSED OR

IMPLIED. NO COPYRIGHT LIABILITY OR PATENT IS ASSUMED. IN NO EVENT SHALL TEEJET TECHNOLOGIES BE LIABLE FOR

ANY LOSS OF BUSINESS, LOSS OF PROFIT, LOSS OF USE OR DATA, INTERRUPTION OF BUSINESS, OR FOR INDIRECT,

SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OF ANY KIND, EVEN IF TEEJET TECHNOLOGIES HAS BEEN ADVISED OF

SUCH DAMAGES ARISING FROM TEEJET TECHNOLOGIES SOFTWARE.

To ensure optimal use of the equipment, please read this manual thoroughly. Please contact TeeJet Technologies Customer Support or an

authorized TeeJet Technologies dealer if additional support is required.

RESPONSIBILITY FOR USE OF THIS PRODUCT

Regarding responsibility for use of this product, we refer to our sales and delivery terms which states:

Product Usage

Any use of the product is at the sole risk of the buyer. The buyer is therefore not entitled to any form for compensation caused by, for

example, any of the following:

►Disturbance to/from any electronic services or products that do not conform to the standards for CE marketing;

►Missing or poor signal coverage or a succession hereof from external transmitters/receivers used by the buyer; Functional faults which

apply to or from a PC-program or PC equipment not delivered by the seller;

►Faults that may arise from the buyers’ negligence to react to warnings and fault messages from the product or that can be traced to

negligence and/or absent constant control of the work carried out in comparison to the planned job.

When implementing any new equipment the buyer must take great care and pay attention. Any doubts as to the correct operation/use

should result in contacting the seller’s service department.

Page 3

ISOBUS Job Computer : BoomPilot

Table of Contents

CHAPTER 1– PRODUCT OVERVIEW 1

OPTIONAL SYSTEM COMPONENTS 1

CHAPTER 2 – GETTING STARTED 2

START UP 2

PAGE LAYOUT AND NAVIGATION 2

Home Screen ...................................................................................................................................................................2

Operation Mode ...............................................................................................................................................................3

Main Setup Mode .............................................................................................................................................................3

Main Setup Menu Icons and Section Overviews ...................................................................................................4

CHAPTER 3 – MAIN SETUP 5

Main Setup Screen ................................................................................................................................................................................ 5

Master Screen ......................................................................................................................................................................................... 6

Home Screen ........................................................................................................................................................................................... 6

SETUP 6

GPS Setup ................................................................................................................................................................................................. 7

Overlapping............................................................................................................................................................7

GPS Alarm .............................................................................................................................................................7

GPS Input ..............................................................................................................................................................7

Machine Setup ........................................................................................................................................................................................ 7

Delay Off ................................................................................................................................................................7

Delay On ................................................................................................................................................................7

Front or Back Mounted Implement.........................................................................................................................7

Distance from Boom to Mount Point ......................................................................................................................7

Distance from Antenna to Mount Point ..................................................................................................................7

OEM 8

Antenna Machine Mounted ....................................................................................................................................8

Distance from Hitch to Antenna .............................................................................................................................8

USER INTERFACE 9

Use Preferred VT ...................................................................................................................................................9

Show Number on Soft Key.....................................................................................................................................9

BoomPilot ECU Number (FI) ..................................................................................................................................9

COMMUNICATION 9

®

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

HELP 10

Diagnostic ..............................................................................................................................................................................................10

BoomPilot Protocol ........................................................................................................................................................10

VT Data ..........................................................................................................................................................................11

TECU ............................................................................................................................................................................. 11

About .......................................................................................................................................................................................................11

CHAPTER 4 – OPERATION MODE 12

OPERATION MODE OVERVIEW 12

Keys Descriptions ..........................................................................................................................................................12

Section and Icon Descriptions .......................................................................................................................................12

Master Screen .......................................................................................................................................................................................13

Home Screen .........................................................................................................................................................................................13

APPLICATION BOUNDARY 14

98-05210 R0 UK

i

Page 4

ISOBUS Job Computer : BoomPilot

Bounded Area Coverage Status......................................................................................................................................................14

AUTOMATIC OR MANUAL SECTION CONTROL 14

ALL SECTIONS ON 15

BOOM SECTIONS 15

APPENDIX A - FACTORY SETTINGS & RANGES 16

APPENDIX B - UNIT SPECIFICATIONS 16

®

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

ii

www.teejet.com

Page 5

ISOBUS Job Computer : BoomPilot

®

CHAPTER 1– PRODUCT OVERVIEW

BoomPilot (automatic boom section control) is possible in combination with software built into the IC18 Sprayer/NH3 Electronic Control Unit

(ECU). The ECU should be combined with the appropriate cable to interface with your BoomPilot system, spray controller and/or spraying

machine for quick and easy installation. Electronic Control Units and their related cables are designed to control as many boom sections as

the spray controller to which they are connect, up to a maximum of 9 boom sections.

Figure 1-1: BoomPilot Electronic Control Unit

OPTIONAL SYSTEM COMPONENTS

Matrix 570VT

The Matrix 570VT is a simple to operate, ISOBUS-certied 5.7″

color touch screen display suitable for bright daylight and nighttime

operation

Figure 1-2: Matrix 570VT

Switchbox

Manual section control with remote master capibility. The

switchboxs are available in:

►9 section output or 8 sections and a master output.

►6 section output or 5 sections and a master output.

Figure 1-3: Switchboxes

IC18 Sprayer/NH3 ECU

Use with your existing VT or Matrix® 570VT

• Works seamlessly and displays on any ISOBUS VT

• Easy navigation menu and data rich display

• IC18 Sprayer ECU suitable for use with NH3 and liquid

fertilizer

• Automatic boom section control upgrade option

• Variable rate control available providing your VT has GPS and

task control capability

• Add additional ISOBUS ECUs as your needs change

• Provides basic rate control

• Standardized plugs, cables and software simplify installation

and connectivity and result in true “plug and play” technology.

IC18 ECU resides on the implement, reducing hardware in the

cab

Figure 1-4: IC18 Job Computer

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

98-05210 R0 UK

1

Page 6

ISOBUS Job Computer : BoomPilot

®

CHAPTER 2 – GETTING STARTED

• A rm touch is required when selecting a screen icon.

• Settings are NOT automatically saved when selected. The ACCEPT KEY must be selected to save the setting. Select the

ESCAPE KEY to escape without saving settings and return to the previous menu.

• The menu structure on your display might vary from the one displayed in this User Manual depending on the virtual terminal being

used.

START UP

Power is continuously supplied to the job computer. The virtual terminal will give access to the job computer options and operation.

Figure 2-1: Master Screen

Matrix VT Setup Key

BoomPilot

Other options as available on

ISOBUS system

Master Screen Key

PAGE LAYOUT AND NAVIGATION

The Master Screen gives access to the systems currently available on your VT. From the Master Screen, the Home Screen gives access

to the BoomPilot ECU’s available functions.

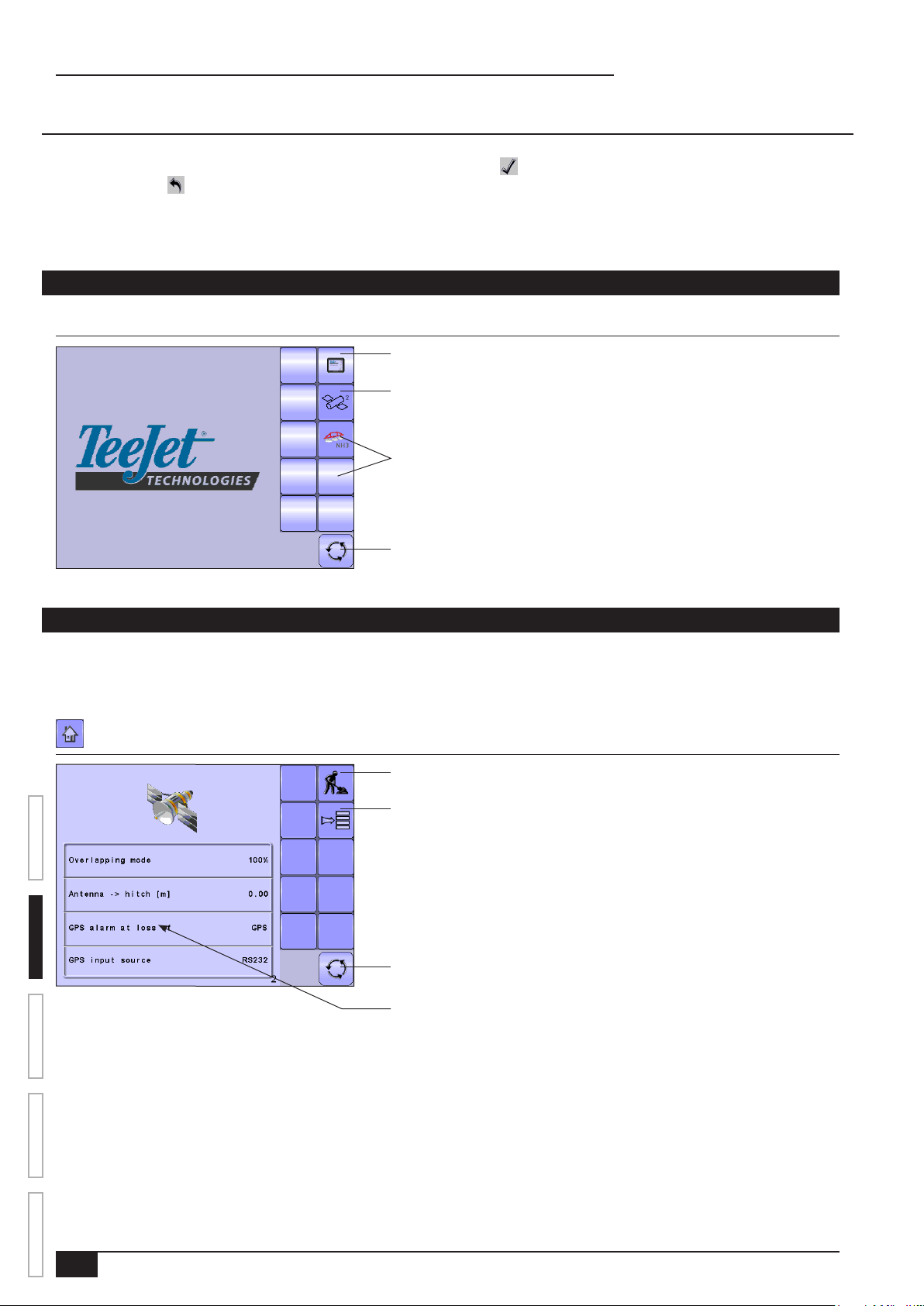

Home Screen

The Home Screen gives access to the BoomPIlot ECU’s available functions: Operation Mode and Main Setup.

Figure 2-2: Home Screen - BoomPilot Mode

Operation Mode

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

Main Setup Mode

Master Screen Key

2

www.teejet.com

Quick View

Information Based on Current Active Trip

Page 7

ISOBUS Job Computer : BoomPilot

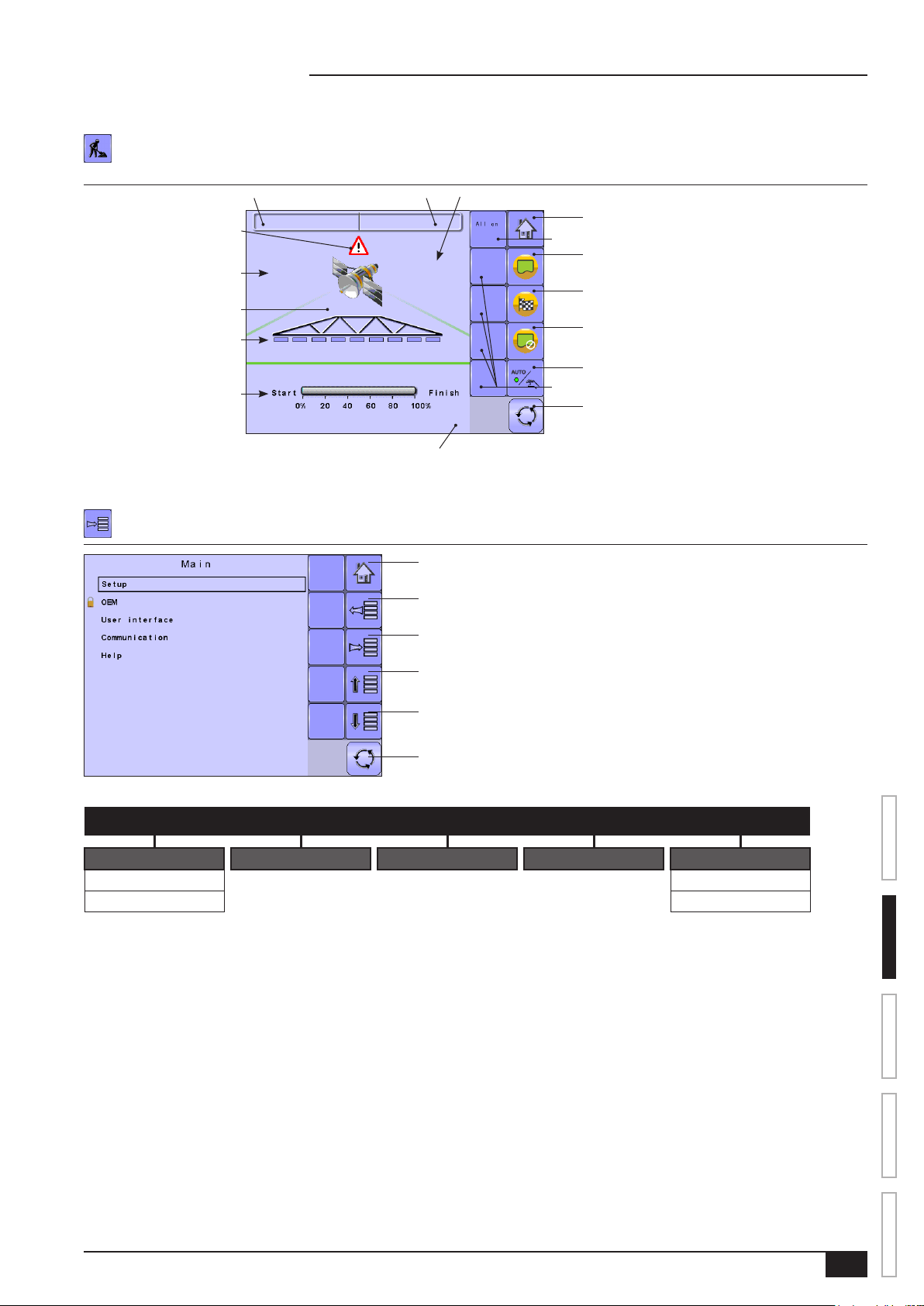

Operation Mode

Information on the Operation screen will vary depending on the parameters set by the user and the OEM.

Figure 2-3: Operation Mode

Total Area Bounded

Alert Warning

Speed

GPS Information

Boom Sections

Bounded Area Application Status

Main Setup Mode

The main setup menu contains ve options. Each of these options either directly access settings or additional menus.

Figure 2-4: Main Setup Screen

Remaining Application Time

1.77 B.area

0:00 hh:mm

5.2 0.0

km/h

No GPS

ECU ID Number

ha

Home Key

Applied Area

Home Key

All Sections On Key

Start Boundary Key

Finish Boundary Key

No Boundary Key

Auto/Manual Mode Key

Extra Key Spaces

Master Screen Key

2

®

Back One Screen

Forward One Screen

Up One Selection

Down One Selection

Master Screen Key

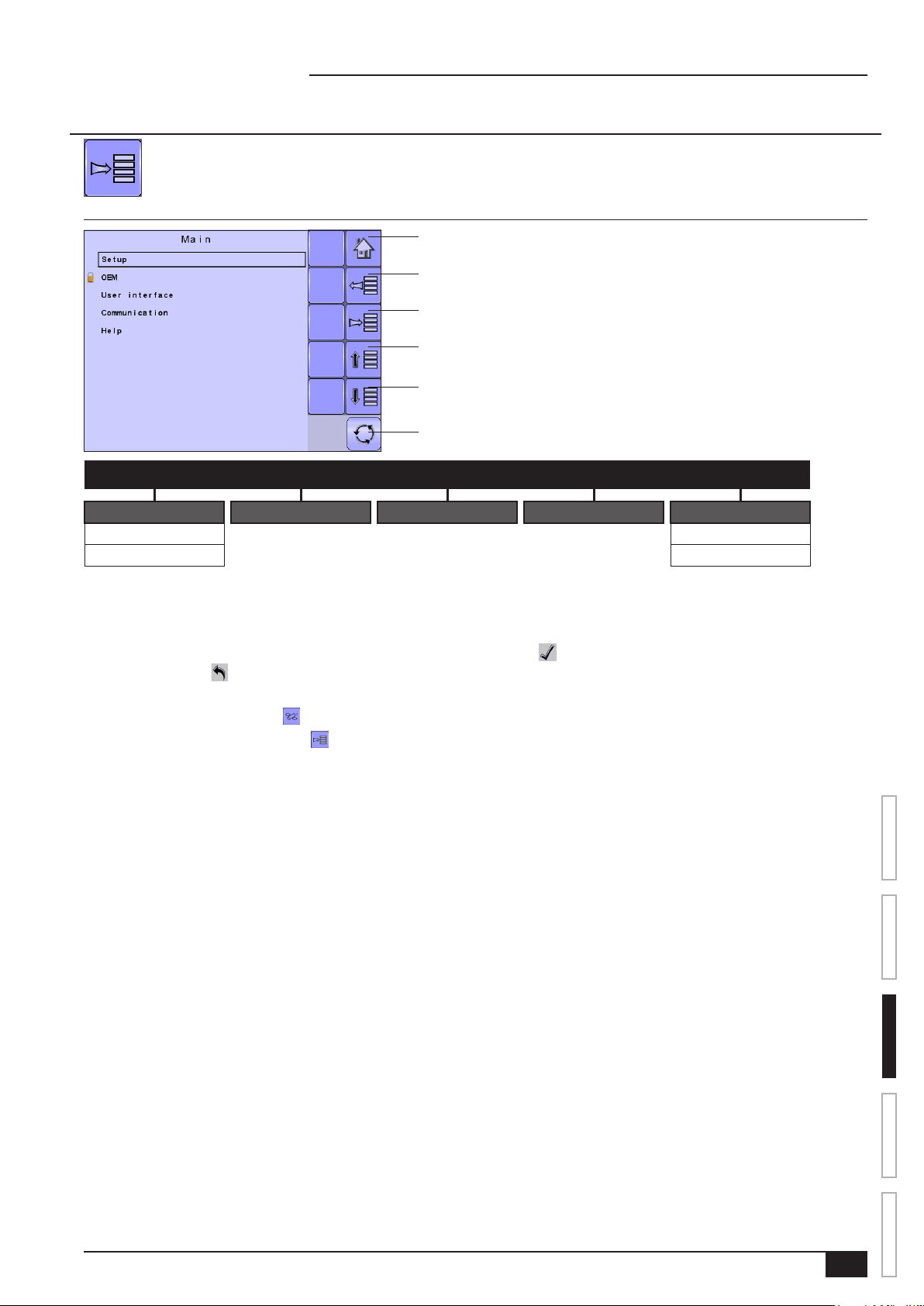

The table below outlines the additional menus.

MAIN SETUP MODE MENU STRUCTURE

| | | | |

Setup OEM User Interface Communication Help

GPS Setup Diagnostic

Machine Setup The OEM setup menu is password protected and the

settings in this menu are directly related to the tted OEM

equipment.

NOTE: Select functions may not be visible due to OEM settings, available equipment or sensors.

About

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

98-05210 R0 UK

3

Page 8

ISOBUS Job Computer : BoomPilot

Main Setup Menu Icons and Section Overviews

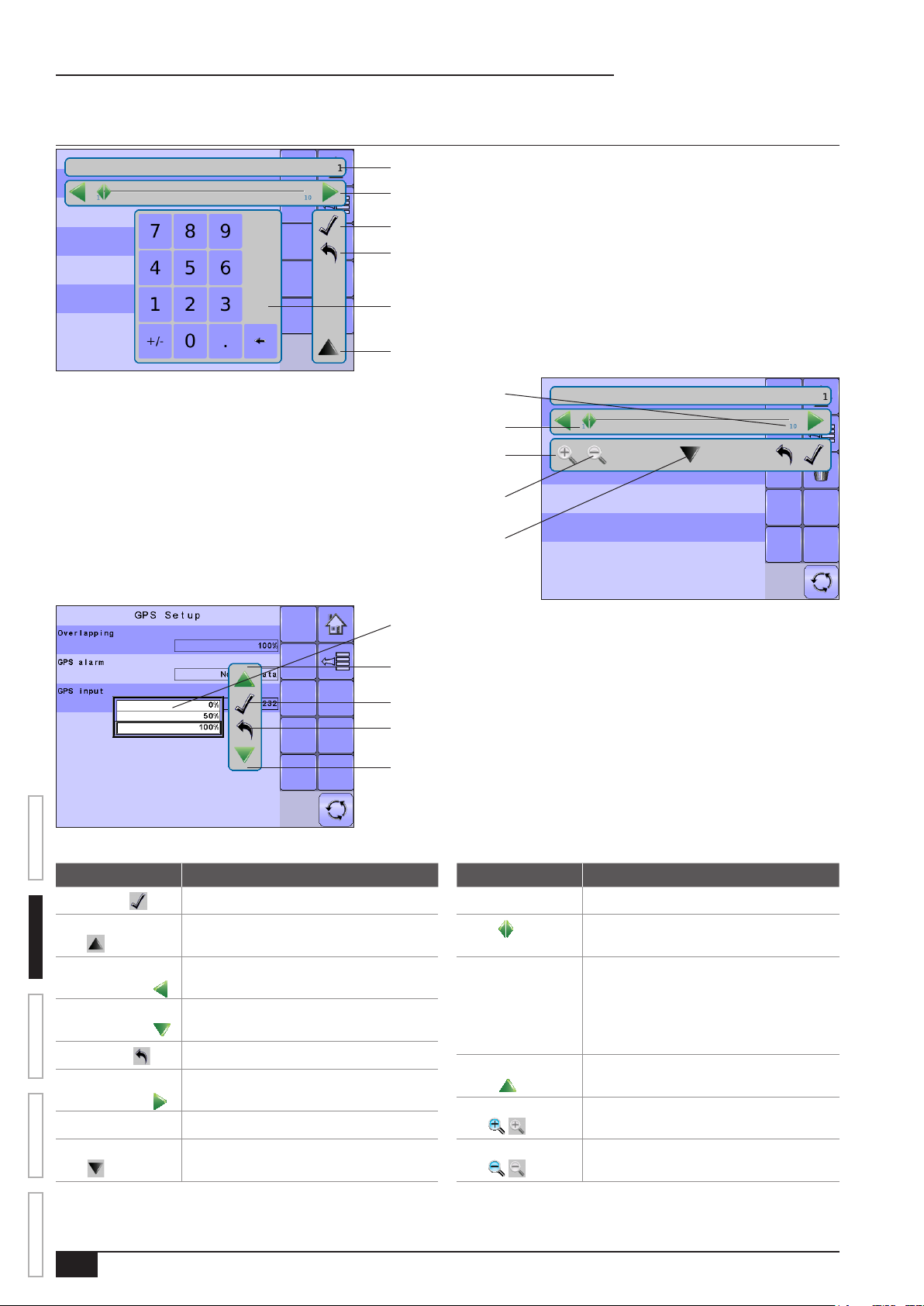

Figure 2-5: Enter Selection Screens

Selection

Slide Bar with Decrease One Selection

and Increase One Selection Arrows

Accept Key

Escape Key

Number Pad

Close Number Pad Key

®

Range Maximum

Range Minimum

Zoom In Key

Zoom Out Key

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

Section or Icon Description

Accept Key

Close Number Pad

Accepts the new selection

Minimizes the number pad

Key

Decrease One

Decreases the setting

Selection Arrow

Down One

Highlights the selection below

Selection Arrow

Escape Key

Increase One

Escapes without saving changes

Increases the setting

Selection Arrow

Number Pad Use the numbers to set the selection value

Open Number Pad

Maximizes the number pad

Key

Open Number Pad Key

Available Selections

Up One Selection

Accept Key

Escape Key

Down One Selection

Section or Icon Description

Selection Displays the current or new selection

Slider

Slide Bar Selects the setting by pressing and

Up One Selection

Arrow

Zoom In

Key

Zoom Out

Key

Slide to the left to decrease or right to

increase the selection

releasing on the slide bar or pressing and

dragging the Slider to a designated value.

Range for a specic setting is displayed on

the slide bar.

Highlights the selection above

Narrows slide bar range. Gray = maximum

zoom level.

Expands slide bar range. Gray = minimum

zoom level.

4

www.teejet.com

Page 9

CHAPTER 3 – MAIN SETUP

Main Setup Mode congures the Setup, OEM, User Interface, Communication and Help options.

NOTE: The menu structure on your display might vary from the one displayed in this User Manual depending on the virtual

terminal being used.

Figure 3-1: Main Setup Screen

ISOBUS Job Computer : BoomPilot

Home Key

Back One Screen

Forward One Screen

Up One Option

Down One Option

Master Screen Key

®

| | | | |

MAIN SETUP MODE MENU STRUCTURE

Setup OEM User Interface Communication Help

GPS Setup Diagnostic

Machine Setup About

The OEM setup menu is password protected and the settings in this menu are directly related to the tted OEM equipment.

Main Setup Screen

NOTE: Settings are NOT automatically saved when selected. The ACCEPT KEY must be selected to save the setting. Select the

ESCAPE KEY to escape without saving settings and return to the previous menu.

To access the Main Setup screens:

1. Select BOOMPILOT ECU KEY from the Master Screen.

2. Select MAIN SETUP SCREEN KEY from the Home Screen.

3. Select from:

►Setup – used to congure the GPS settings and Machine settings

◄ GPS Setup – used to establish the Overlapping percentage, GPS Alarm and GPS Input

◄ Machine Setup – used to establish the delay off and delay on time; front or back implement mounting position; and distance

from the boom and the antenna to the mounting point

►OEM – used to establish if the antenna is machine mounted and its associated distance from the hitch

►User Interface – used to allow the operator to select the system virtual terminal (VT) and ECU identication number

►Communication – used to establish the BoomPilot ECU's ability to communicate with an external computer

►Help – allows the operator to choose between Diagnostics and the About screen

◄ Diagnostic – used to provide information regarding the BoomPilot protocol, VT and TECU.

◄ About – used to provide information on the console such as software version, build number, etc

NOTE: The menu structure on your display might vary from the one displayed in this User Guide depending on the virtual terminal being

used. This User Guide will display all possible options.

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

98-05210 R0 UK

5

Page 10

ISOBUS Job Computer : BoomPilot

®

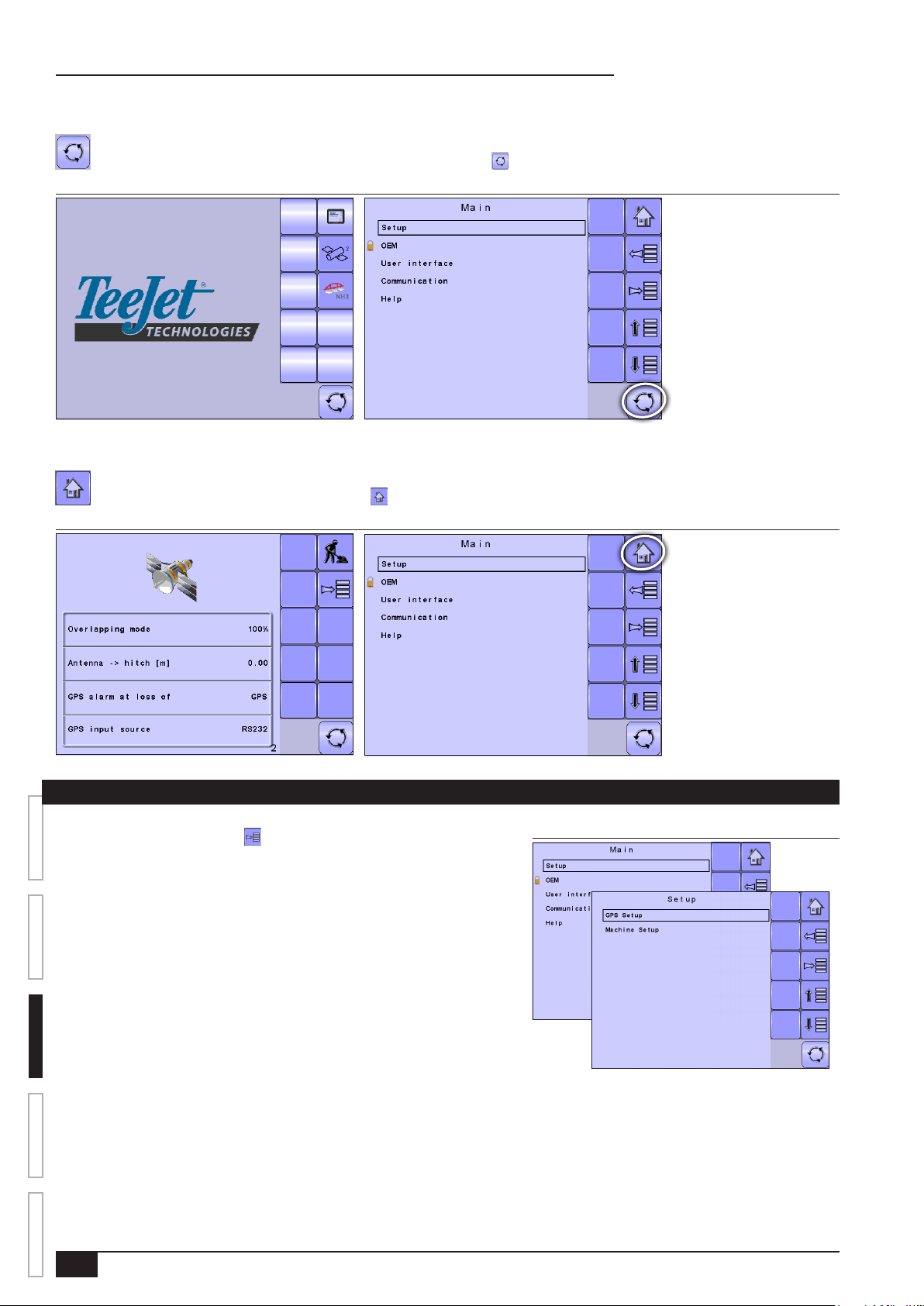

Master Screen

The Master Screen gives access to the systems currently available on your VT.

• To view the Master Screen options, select MASTER SCREEN KEY in bottom right corner of any screen.

Figure 3-2: Master Screen Master Screen Key on Main Setup Screen

Home Screen

The Home Screen gives access to the BoomPilot ECU’s available functions: Operation Mode and Main Setup.

• To view the Home Screen, select HOME KEY in the top right corner of any screen.

Figure 3-3: Home Screen Home Key on Main Setup Screen

SETUP

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

Setup congures the GPS settings and Machine settings.

1. From the Main Setup Screen , select SETUP.

2. Select from:

►GPS Setup – used to establish the Overlapping percentage, GPS Alarm and

GPS Input

►Machine Setup – used to establish the delay off and delay on time; front

or back implement mounting position; and distance from the boom and the

antenna to the mounting point

Figure 3-4: Setup

6

www.teejet.com

Page 11

ISOBUS Job Computer : BoomPilot

®

GPS Setup

GPS setup establishes the Overlapping percentage, GPS Alarm and GPS Input.

Overlapping

Overlapping determines the amount of overlap allowed when each boom section is

turned on and off using Automatic Boom Section Control. Select from 0%, 50% or

100%.

• To select the Overlapping percentage, select an option from the drop down

menu or use the UP/DOWN ARROWS to highlight the option.

GPS Alarm

GPS Alarm determine if an alarm sounds when GPS or DGPS is lost or if there are

no GPS alarms.

• To select the GPS alarm type, select an option from the drop down menu or

use the UP/DOWN ARROWS to highlight the option.

GPS Input

GPS Input determines if the GPS signal is through the internal GPS or an external

RS232 port.

• To select the GPS input type, select an option from the drop down menu or

use the UP/DOWN ARROWS to highlight the option.

Machine Setup

Machine Setup establishes the delay off and delay on time; front or back implement

mounting position; and distance from the boom and the antenna to the mounting

point.

Delay Off

Delay Off functions as a “look ahead” for establishing the timing for the boom

section valves to switch off exactly when entering an area that has been applied. If

the boom turns off too soon when entering an applied area, decrease the Delay Off

setting. If the boom turns off too late when entering an applied area, increase the

Delay Off setting. Range is 0.0 - 10.0 seconds.

• To select the delay off time, use the number pad or slide bar.

Figure 3-5: GPS Setup

Figure 3-6: Overlapping

0 %

50 %

100 %

Figure 3-7: Machine Setup

Delay On

Delay On functions as a “look ahead” for establishing the timing for the boom

section valves to switch on exactly when entering an area that has not been

applied. If the boom turns on too soon when entering a non-applied area, decrease

the Delay On setting. If the boom turns on too late when entering a non-applied

area, increase the Delay On setting. Range is 0.0 - 10.0 seconds.

Figure 3-8: Distance to Mount Point

• To select the delay on time, use the number pad or slide bar.

Front or Back Mounted Implement

Direction to Boom sets whether the boom is located behind or in front of the GPS

antenna as the vehicle moves in a forward direction.

• To select the mounting placement, select an option from the drop down menu

or use the UP/DOWN ARROWS to highlight the option.

Distance from Boom to Mount Point

Hitch/Mount Point

GPS Antenna

Boom

Distance to Boom denes the distance from the hitch or mount point to the boom.

Range is 0.00 - 50.00 meters.

• To select the distance, use the number pad or slide bar.

Distance from Antenna to Mount Point

Distance from Antenna denes the distance from the hitch or mount point to the antenna. The antenna should be behind the mount point

(machine mounting is set in OEM options). Range is 0.00 - 200.00 meters.

• To select the distance, use the number pad or slide bar.

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

98-05210 R0 UK

7

Page 12

ISOBUS Job Computer : BoomPilot

®

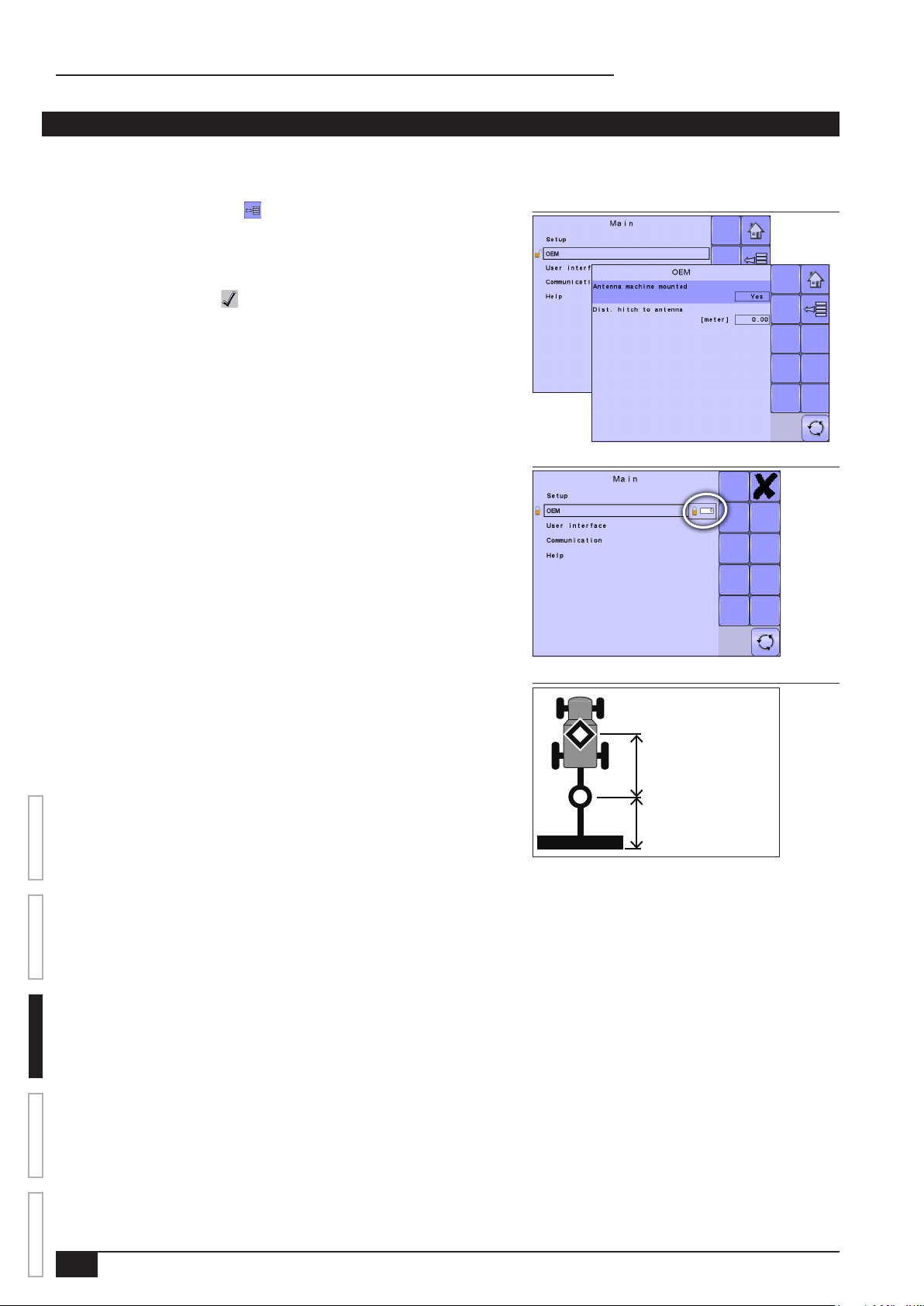

OEM

The OEM setup menu is password protected and the settings in this menu are directly related to the tted OEM equipment. To obtain an

access code, contact your local dealer or TeeJet Technologies Customer Service.

To access the OEM screens:

1. From the Main Setup Screen , select OEM.

2. Select OEM.

3. Select the Access Code Entry Box to the right of the menu option.

4. Use the number pad or slide bar to enter the access code.

5. Select the ACCEPT KEY to complete the unlock process

Antenna Machine Mounted

Antenna Machine Mounted sets if the antenna is mounted on the machine, not the

implement/boom. Range is 0.00 - 200.00 meters.

• To set if the antenna is machine mounted, select an option from the drop down

menu or use the UP/DOWN ARROWS to highlight the option.

Figure 3-9: OEM

Distance from Hitch to Antenna

Distance from Antenna denes the distance from the hitch or mount point to the

antenna. This option is only available if the antenna is machine mounted and the

"Antenna Machine Mounted" options is "Yes". Range is 0.00 - 200.00 meters.

• To set the distance, use the number pad or slide bar.

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

Figure 3-10: OEM Unlock

Figure 3-11: Distance from Hitch to Antenna

GPS Antenna

Hitch/Mount Point

Boom

8

www.teejet.com

Page 13

ISOBUS Job Computer : BoomPilot

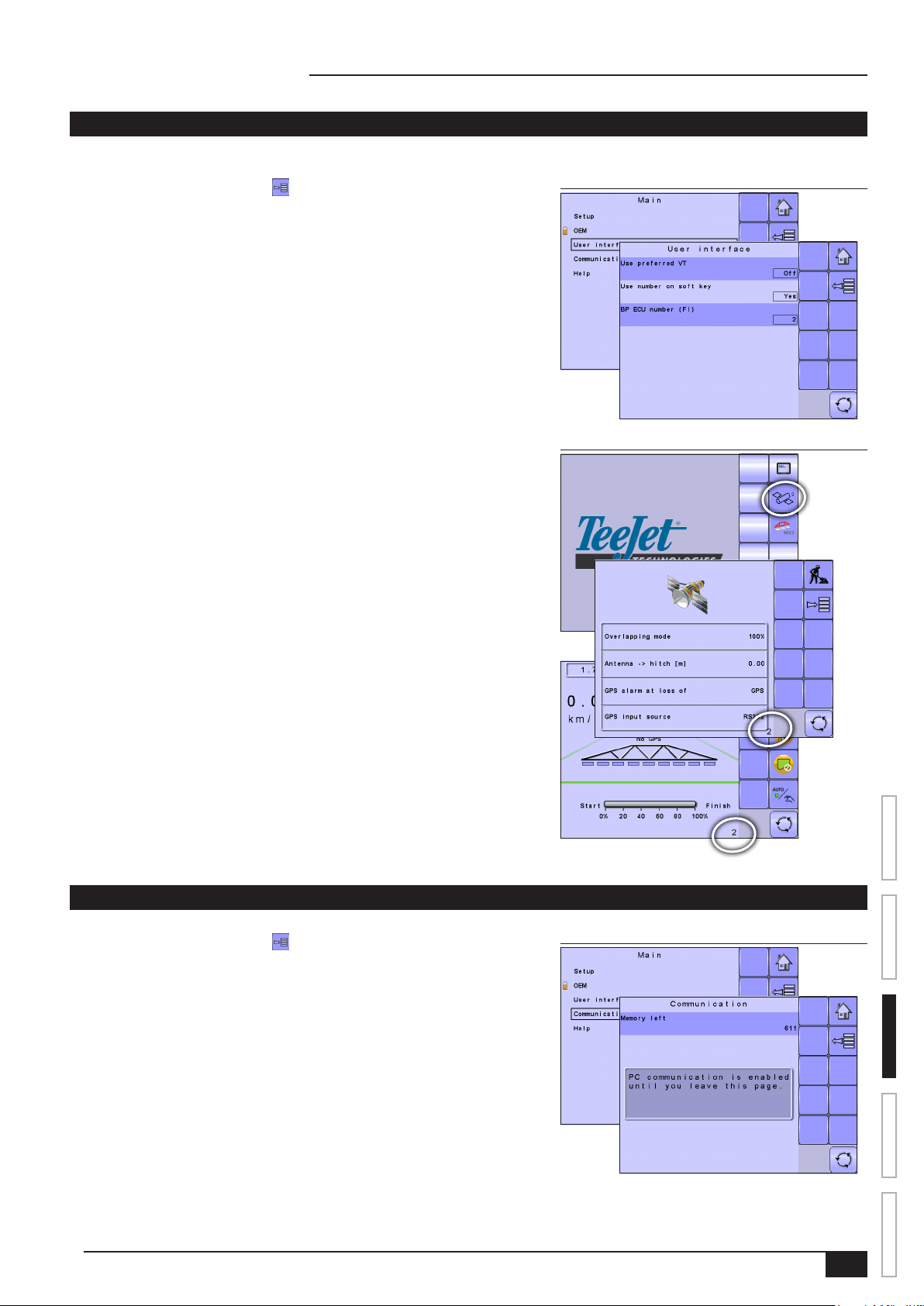

USER INTERFACE

User Interface allows the operator to select the system virtual terminal (VT) and

ECU identication number.

1. From the Main Setup Screen , select USER INTERFACE.

Use Preferred VT

Use Preferred VT sets the virtual terminal preference to either on or off. If “On” is

selected, the preferred VT will be used. If “Off” is selected, the system will arbitrarily

select which VT to use (if more than one VT is available on the ISOBUS CAN).

• To set the Use Preferred VT mode, select an option from the drop down menu

or use the UP/DOWN ARROWS to highlight the option.

NOTE: This should always be set to "off" unless another VT is on the CAN bus.

Show Number on Soft Key

Show Number on Soft Key establishes if a user assigned identication number will

be visible on the Master Screen, Home Screen and Operation Screen.

• To set the Soft Key Number mode, select an option from the drop down menu

or use the UP/DOWN ARROWS to highlight the option.

NOTE: Typically used only if more than one (1) BoomPilot ECU is on the CAN bus.

®

Figure 3-12: User Interface

Figure 3-13: BoomPilot ECU Number

BoomPilot ECU Number (FI)

BP ECU Number is the identication number referring specically to the BoomPilot

ECU.

• To set the BoomPilot ECU Number, use the number pad or slide bar.

COMMUNICATION

Communication establishes the BoomPilot ECU's ability to communicate with an external computer.

1. From the Main Setup Screen , select COMMUNICATION.

Figure 3-14: Communication

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

98-05210 R0 UK

9

Page 14

ISOBUS Job Computer : BoomPilot

®

HELP

The Help menu allows the operator to choose between Diagnostics and the

display of information about serial number, CAN BUS information, etc. These

menus are typically accessed upon Customer Service personnel request only.

1. From the Main Setup Screen , select HELP.

2. Select from:

►Diagnostic – used to provide information regarding the BoomPilot protocol,

VT and TECU.

►About – provides information on the console such as software version, build

number, etc.

Diagnostic

Diagnostic is used to provide information regarding the BoomPilot protocol, VT and

TECU.

►BoomPilot Protocol – provides information regarding the IC18 pairing and the

pair's associated boom sections.

►VT – provides information regarding the virtual terminal controller.

►TECU – provides information regarding the TECU.

Figure 3-15: Help

Figure 3-16: Diagnostic

BoomPilot Protocol

BoomPilot Protocol provides information regarding to which IC18 ECU (per IC18

identication number) the BoomPilot ECU is paired, and the pair's associated boom

sections.

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

Figure 3-17: BoomPilot Protocol

10

www.teejet.com

Page 15

ISOBUS Job Computer : BoomPilot

®

VT Data

The Virtual Terminal (VT) menu provides information regarding the virtual terminal

controller (i.e., address version, etc.).

• If more terminals/controllers are used, switch between these by pressing the

GO TO NEXT VT KEY .

• Press the DELETE OBJECT POOL KEY to upload information from the

IC18 Job Computer to the Virtual Terminal.

NOTE: Restart the IC18 Job Computer to implement and display changes.

TECU

The TECU is a control unit, residing on the tractor, that performs basic functions

such as power handling, speed info, etc. The TECU data are displayed on this

page.

Figure 3-18: VT Data

Figure 3-19: TECU

About

The About screen provides information on the ECU such as software version, build

number, etc. This information may become useful in case of technical support.

Figure 3-20: About

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

98-05210 R0 UK

11

Page 16

ISOBUS Job Computer : BoomPilot

®

CHAPTER 4 – OPERATION MODE

The Operation Screen accesses the working aspects of the BoomPilot ECU including boom section control and trip/application

information.

NOTE: Settings are automatically saved when selected.

NOTE: The menu structure on your display might vary from the one displayed in this User Manual depending on the virtual

terminal being used.

OPERATION MODE OVERVIEW

Information on the Operation screen will vary depending on the parameters set by the user and the OEM.

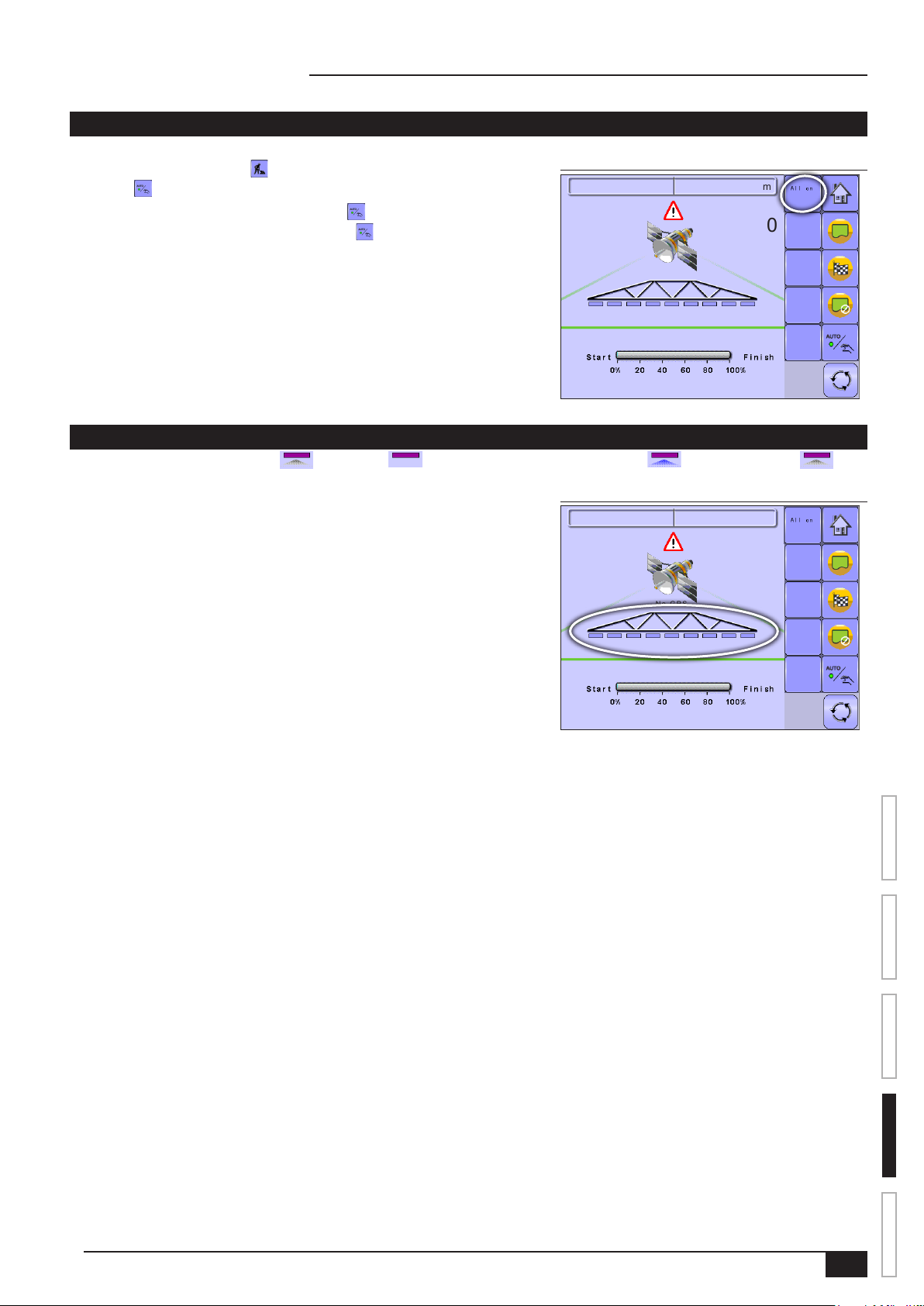

Figure 4-1: Operation Mode Screen Overview

Total Area Bounded

Alert Warning

Speed

GPS Information

Boom Sections

Remaining Application Time

1.77 B.area

0:00 hh:mm

5.2 0.0

km/h

No GPS

Applied Area

ha

Home Key

All Sections On Key

Start Boundary Key

Finish Boundary Key

No Boundary Key

Bounded Area Status

Keys Descriptions

Icon Description

Home Key Press to return to the Home Screen

Start Boundary

Key

Finish Boundary

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

Key

No Boundary

Key

Auto/Manual

Key

All Sections On

Key

Auto/Manual Mode Key

Extra Key Spaces

Master Screen Key

2

ECU ID Number

Press to start a new boundary

Press to nish the boundary. A straight line will complete the boundary between your current location and the

starting point

Press to apply without using a boundary

Press to toggle between automatic and manual application modes

• Automatic mode will turn on ABSC (automatic boom section control)

• Manual mode will turn off ABSC.

Press to turn on all sections whether or not you are in an applied or not applied area

Section and Icon Descriptions

Section or Icon Description

Job Information This information bar displays the total area bounded and remaining

application time

Total Area

Bounded

Remaining

Application Time

Speed Displays vehicle speed

12

www.teejet.com

Displays the total area bounded in current boundary

Displays the amount of time remaining to completely cover the area bounded based on the current speed and

rate of application

1.77 B.area 0:00 hh:mm

Page 17

Section or Icon Description

Applied Area Displays the actual application per hectare/acre

ISOBUS Job Computer : BoomPilot

®

Alarm

Displayed if an alarm condition is active

GPS Information Displays the current GPS status or mode

Boom Sections

Displays the active and inactive boom sections as well as if

they are on (spray is blue) or off (spray is gray).

Sprayer ID Number Displays the soft key number assigned to the displayed IC18 ECU.

Bounded Area Status This information section displays the current or applicaion boundary status

Bounded Area

Coverage Status

Boundary In

Displays the amount of the bounded area that has had application

applied to it

Displays when a boundary is being created

Progress

No Boundary Displays when no boundary is available

Master Screen

The Master Screen gives access to the systems currently available on your VT.

• To view the Master Screen options, select MASTER SCREEN KEY in bottom right corner of any screen.

Figure 4-2: Master Screen Master Screen Key on Operation Mode Screen

1.77 B.area

5.2 0.0

km/h

No GPS

0:00 hh:mm

ha

2

Home Screen

The Home Screen gives access to the BoomPilot ECU’s available functions: Operation Mode and Main Setup.

• To view the Home Screen, select HOME KEY in the top right corner of any screen.

Figure 4-3: Home Screen Home Key on Operation Mode Screen

1.77 B.area

5.2 0.0

km/h

No GPS

0:00 hh:mm

ha

2

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

98-05210 R0 UK

13

Page 18

ISOBUS Job Computer : BoomPilot

®

APPLICATION BOUNDARY

Application boundaries establish areas where application is and is not applied while using ABSC or BoomPilot.

To establish an application boundary:

1. Drive to a desired location at the perimeter of the field/application area.

2. Press START BOUNDARY KEY .

3. Travel the perimeter of the eld/area.

4. Finish boundary:

►Travel to within one swath width of the starting point. The boundary will close

automatically (the operations screen will begin showing the Bounded Area

Coverage Status in the Bounded Area Status section).

►Press BOUNDARY FINISH KEY . A straight line will complete the

boundary between your current location and the starting point

NOTE: The boundary will not be available if the minimum distance is not travelled

(five-times the swath width).

Figure 4-4: Boundary in Progress

To apply without a boundary:

Figure 4-5: Bounded Area Coverage Status

1. Drive to a desired location at the perimeter of the field/application area.

2. Press NO BOUNDARY KEY .

3. Begin application.

Bounded Area Coverage Status

Bounded Area Coverage Status displays the amount of the bounded area that has

had application applied to it.

AUTOMATIC OR MANUAL SECTION CONTROL

Automatic mode will turn on ABSC (automatic boom section control).

• Automatically control when boom sections are turned on/off as an applied area is entered/exited.

Manual mode will turn off ABSC. Section control will be controlled by the associated IC18.

1. On the Operation Screen , establish Automatic Operation Mode or Manual

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

Operation Mode by pressing the AUTO/MANUAL KEY so that the green dot

is on AUTO (automatic) or the hand (manual) accordingly.

Figure 4-6: Auto/Manual Key

1.77 B.area

0:00 hh:mm

5.2 0.0

km/h

No GPS

1.77 B.area

0:00 hh:mm

5.2 0.0

km/h

No GPS

ha

2

ha

14

www.teejet.com

2

Page 19

ISOBUS Job Computer : BoomPilot

ALL SECTIONS ON

All Sections On will turn all sections on whether you are in an applied area or not.

1. On the Operation Screen , turn all sections on by pressing the ALL ON

KEY .

NOTE: Pressing and holding the ALL ON KEY will force all sections to remain

on. When you release the ALL ON KEY , the sections will go back to the

previous mode (auto/manual).

BOOM SECTIONS

Boom Sections displays the active and inactive boom sections as well as if they are on (spray is blue) or off

(spray is gray).

Figure 4-7: All On Key

1.77 B.area

5.2 0.0

km/h

No GPS

Figure 4-8: Boom Sections

1.77 B.area

0:00 hh:mm

ha

2

0:00 hh:mm

®

5.2 0.0

km/h

No GPS

ha

2

OVERVIEWSETUPAPPENDIX GETTING STARTEDOPERATION

98-05210 R0 UK

15

Page 20

ISOBUS Job Computer : BoomPilot

®

APPENDIX A - FACTORY SETTINGS & RANGES

SETUP

GPS Setup

Description Factory Setting Range/Options User Setting

Overlapping 100% 0%, 50%, 100%

GPS Alarm No GPS Data No GPS Data

No DGPS Data

No GPS Alarms

GPS Input Internal Internal

RS232

Machine Setup

Description Factory Setting Range/Options User Setting

Delay Off 0.0 0.0 - 10.0 sec

Delay On 0.0 0.0 - 10.0 sec

Front or Back Mounted Implement Back Front

Back

Distance from Boom to Mount Point 0.00 0.00 - 50.00 m

Distance from Antenna to Mount

Point

0.00 0.00 - 200.00 m

OEM

Description Factory Setting Range/Options User Setting

Antenna Machine Mounted No Yes

No

Distance from Hitch to Antenna 0.00 0.00 - 500.00 m

USER INTERFACE

Description Factory Setting Range/Options User Setting

OVERVIEW SETUP APPENDIXGETTING STARTED OPERATION

Use Perferred VT Off Off

On

Show Number on Soft Key No No

Yes

BoomPilot ECU Number (FI) 1 1 - 9

APPENDIX B - UNIT SPECIFICATIONS

Dimensions 19.05 x 18.42 x 6.03 cm

Weight 0.644kg

Connector 30 position Cinch pins. A1-K3

30 position Cinch pins. L1-Y3

Environmental Operating -40 to +85°C

Humidity 90% non-condensing

Input/Output ISO 11783 (ISOBUS)

Power Requirement <9 watts @12 VDC

16

www.teejet.com

Page 21

BOOMPILOT®

JOB COMPUTER

USER MANUAL

Software Version 0.00

TeeJet Technologies

1801 Business Park Drive

Springeld, Illinois 62703 USA

Tel: (217) 747-0235 • Fax: (217) 753-8426

www.teejet.com

98-05210 R0 UK

© TeeJet Technologies 2011

TeeJet Aabybro

Mølhavevej 2

DK 9440 Aabybro

Denmark

Loading...

Loading...