Page 1

MID-TECH

MIDWEST TECHNOLOGIES, INC.

ARC-6000

LIQUID/GRANULAR

APPLICATION CONTROL SYSTEM

USER GUIDE

PN - 98-05017

Rev . - 1

®

CE & STANDARD VERSION

Flow

RATE

.

Gal./

MID-TECH

MIDWEST TECHNOLOGIES, INC.

®

-Ac

ARC-6000

Automatic

Rate Controller

12345 67 89

BOOMS

ON OPERATE INC.

OFF SET- UP DEC.

%Rate

Product Vol.

Total Area

Field Area

Speed

Scan

Test

Speed

DISPLAY SELECTOR

Application Rate

Total Applied

Impl.Width

Distance

Prime

Midwest Technologies, Inc. of Illinois

Springfield, IL 62703

Page 2

ARC 6000

CHANGE LOG

98-05017

DATE: DATE CODE: PAGES AFFECTED: SW VERSION

05/15/00 00136 New Manual - CE Certified Console 2.03

Rev.- 1

Mid-T ech, Auto-Range, & T ASC ar e all registered trademarks of Midwest Technologies, Inc.

II

CE & STANDARDVERSION

Page 3

ARC 6000

98-05017

Rev.- 1

TABLE OF CONTENTS

CHANGE LOG ..................................................................................................................................................................... II

TABLE OF CONTENTS ...................................................................................................................................................... III

1.0. SWITCHES AND CONTROLS ................................................................................................................................... 1-1

1.1. POWER SWITCH ................................................................................................................................................ 1-1

1.2. MODE SELECTOR “OPERATE / SETUP” SWITCH ......................................................................................... 1-1

1.3. INC / DEC SWITCH ............................................................................................................................................ 1-1

1.4. DISPLAY SELECTOR......................................................................................................................................... 1-2

1.4.1. DISPLAY SELECTOR FUNCTIONS -OPERATE MODE (LIQUID APPLICATION) ............................... 1-2

1.4.2. DISPLAY SELECTOR FUNCTIONS -SET UP MODE (LIQUID APPLICATION) .................................... 1-3

1.4.3. DISPLAY SELECTOR FUNCTIONS-OPERATE MODE (GRANULAR APPLICATION) ........................ 1-4

1.4.4. DISPLAY SELECTOR FUNCTIONS-SET UP MODE (GRANULAR APPLICATION) ............................ 1-5

1.5. BOOM SECTION “ON/OFF” INDICATORS ...................................................................................................... 1-6

1.6. NOT USED ........................................................................................................................................................... 1-6

1.7.--STATUS SWITCH .............................................................................................................................................. 1-6

1.8. GROUND SPEED OVERRIDE (GSO) SWITCH .................................................................................................. 1-6

2.0. CALIBRATION AND SET UP .................................................................................................................................... 2-1

2.1. CHANGING THE APPLICATION PROGRAM ................................................................................................... 2-1

2.2. ENGLISH, METRIC OR METRISH UNITS ........................................................................................................ 2-1

2.2.1. UNITS FOR EACH POSITION (LIQUID APPLICATOR ONLY) .............................................................. 2-1

2.2.2. CHANGING UNITS (LIQUID APPLICATOR ONLY) .............................................................................. 2-2

2.3. SETTING APPLICATION RATE ......................................................................................................................... 2-2

2.4. SETTING THE % RATE CHANGE ..................................................................................................................... 2-2

2.5. SETTING BOOM WIDTHS ................................................................................................................................. 2-2

2.6. APPLICATION RATE SENSOR CALIBRATION ................................................................................................ 2-3

2.6.1. CALIBRATING THE LIQUID APPLICATION .......................................................................................... 2-3

2.6.1.1. DETERMINING THE FLOWMETER INITIAL CALIBRATION NUMBER ................................. 2-3

2.6.1.2. DETERMINING THE PRESSURE SENSOR INITIAL CALIBRATION NUMBER ....................... 2-4

2.6.1.3. PRESSURE SENSOR HIGH/LOW CALIBRATION ....................................................................... 2-4

2.6.1.4. FINE TUNING THE FLOW SENSOR CALIBRATION NUMBER ................................................. 2-5

2.6.1.5. SETTING THE CORRECTION FACTOR (Psi Mode) .................................................................... 2-7

2.6.2. CALIBRATING THE GRANULAR APPLICATION ................................................................................. 2-7

2.6.2.1. SETTING THE PRODUCT DENSITY............................................................................................. 2-7

2.6.2.2. CALCULATING THE INITIAL CALIBRATION NUMBER .......................................................... 2-7

2.6.2.3. RATE SENSOR CALIBRATION .................................................................................................... 2-8

2.7. DISTANCE CALIBRATION, GROUND SPEED SENSOR .................................................................................. 2-9

2.7.1. GENERAL CONSIDERATIONS AND INITIAL CALIBRATION NUMBERS ......................................... 2-9

2.7.2. DISTANCE CALIBRATION PROCEDURE .............................................................................................. 2-9

2.8. SETTING THE "HOLD/CLOSE" RESPONSE OF THE FLOW CONTROL VALVE ......................................... 2-10

2.8.1. STATUS SWITCH ................................................................................................................................... 2-10

2.8.2. ALL BOOMS "OFF" ................................................................................................................................ 2-10

2.9. SETTING THE GROUND SPEED OVERRIDE (GSO) VALUE. ......................................................................... 2-11

2.10. SETTING THE FIELD AREA ALARM ........................................................................................................... 2-11

2.11. PRODUCT VOLUME (FULL LOAD CAPACITY) ........................................................................................... 2-11

2.11.1. SETTING THE FULL LOAD CAPACITY ............................................................................................. 2-11

2.11.2. RECALLING THE FULL LOAD CAPACITY ....................................................................................... 2-12

2.11.3. SETTING A LOAD CAPACITY LESS THAN FULL LOAD ................................................................. 2-12

2.12. SETTING AUTO POWER DOWN TIME ......................................................................................................... 2-12

3.0. OPERATION ............................................................................................................................................................... 3-1

3.1. NORMAL START UP AND OPERATION ........................................................................................................... 3-1

3.2. CHANGING ACTIVE BOOM SECTIONS ........................................................................................................... 3-1

3.3. CHANGING APPLICATION RATE ..................................................................................................................... 3-2

3.4. PRIMING THE MAIN PUMP AND BOOM (LIQUID APPLICATION) .............................................................. 3-2

3.5. RAPID UNLOAD USING THE CONVEYOR (GRANULAR APPLICATION) ................................................... 3-3

3.6. GROUND SPEED OVERRIDE (GSO) .................................................................................................................. 3-3

III

CE & S

TANDARD VERSION

Page 4

98-05017

ARC 6000

Rev.- 1

4.0. MAINTENANCE ........................................................................................................................................................ 4-1

4.1. FLUSHING AND CLEANING ............................................................................................................................. 4-1

4.2. CONTROL CONSOLE ........................................................................................................................................ 4-1

4.3. GROUND SPEED SENSOR ................................................................................................................................. 4-1

4.4. FLOW SENSOR (LIQUID APPLICATION) ........................................................................................................ 4-2

4.5. CONVEYOR RATE SENSOR (GRANULAR APPLICATION) ........................................................................... 4-2

4.6. FLOW CONTROL VALVE (LIQUID APPLICATION) ........................................................................................ 4-2

4.7. WIRING HARNESS ............................................................................................................................................. 4-2

5.0. TROUBLE SHOOTING THE ARC SYSTEM ............................................................................................................. 5-1

5.1. ERROR MESSAGE “Err.”, INVALID SETUP PROCEDURE ............................................................................... 5-1

5.2. ERROR MESSAGE “Err E”, INVALID MEMORY .............................................................................................. 5-1

5.3. ERROR MESSAGE “Err 0”, INVALID CONSTANT SET TO ZERO .................................................................. 5-1

5.4. ERROR MESSAGE “Err-1, 2, 3, 4, & 5,” INVALID OPERATION ....................................................................... 5-2

5.4.1. ERROR MESSAGE “Err-1”....................................................................................................................... 5-2

5.4.2. ERROR MESSAGE “Err-2”....................................................................................................................... 5-2

5.4.3. ERROR MESSAGE “Err-3”....................................................................................................................... 5-2

5.4.4. ERROR MESSAGE “Err 4” ....................................................................................................................... 5-2

5.4.5. ERROR MESSAGE "Err 5" ........................................................................................................................ 5-3

5.5. ERROR MESSAGE “OFLO”, NUMERIC OVERFLOW ..................................................................................... 5-3

5.6. ERROR MESSAGE “Err L”, LOW VOLTAGE ..................................................................................................... 5-3

5.7. ERROR MESSAGES “Err C, n, hook (backward 7)”, INTERNAL DIAGNOSTICS............................................ 5-3

6.0. EMERGENCY OPERATIONS.................................................................................................................................... 6-1

6.1. GROUND SPEED SENSOR FAILURE ................................................................................................................ 6-1

6.2. FLOW CONTROL VALVE FAILURE (LIQUID APPLICATOR) .......................................................................... 6-1

6.3. FLOWMETER FAILURE (LIQUID APPLICATOR) ............................................................................................ 6-2

A-0. APPENDIX A - DRAWINGS .......................................................................................................................................A-1

A-1 ARC FLOW/PRESSURE BASED - WIRING DIAGRAM ....................................................................................A-2

A-2 ARC FLOW/PRESSURE BASED - PLUMBING DIAGRAM ..............................................................................A-3

A-3 ARC SERVICE FORM ........................................................................................................... .............................A-4

B.0. INTRODUCTION .......................................................................................................................................................B-2

B.1. HOW THE ARC CONTROLS APPLICATION RATE ......................................................................................... B-2

B.2. ARC SYSTEM COMPONENT PARTS ............................................................................................................... B-3

B.2.1. THE ARC SYSTEM CONTROL CONSOLE ...........................................................................................B-3

B.2.2. APPLICATION RATE SENSOR ...............................................................................................................B-3

B.2.2.1. LIQUID APPLICATION ..................................................................................................................B-3

B.2.2.2. LIQUID OR GRANULAR APPLICATION ..................................................................................... B-4

B.2.3. FLOW CONTROL VALVE ........................................................................................................................B-4

B.2.4. GROUND SPEED SENSOR ...................................................................................................................... B-4

B.2.5. BOOM INTERFACE .................................................................................................................................B-4

C.0. INSTALLATION .........................................................................................................................................................C-2

C.1. CONTROL CONSOLE INSTALLATION ............................................................................................................ C-2

C.1.1. CONSOLE MOUNTING ...........................................................................................................................C-2

C.1.2. CONSOLE CABLE ROUTING .................................................................................................................C-3

C.2. INSTALLING APPLICATION RATE SENSORS ................................................................................................C-4

C.2.1. FLOWMETER/PRESSURE SENSOR (FLOW SENSOR) INSTALLATION ............................................C-4

C.2.2. RATE SENSOR INSTALLATION .............................................................................................................C-5

C.3. FLOW CONTROL VALVE INSTALLATION ...................................................................................................... C-5

C.4. GROUND SPEED SENSOR INSTALLATION .................................................................................................... C-5

C.5. BOOM CONTROL SWITCHES AND INTERFACE ...........................................................................................C-6

C.5.1. BOOM INTERFACE CABLE ................................................................................................................... C-6

C.5.2. BOOM CONTROL SWITCHES AND INTERFACE .................................................................................C-6

SHADED TOPICS RELATE TO GRANULAR APPLICATION ONLY!

CE & STANDARD VERSION

IV

Page 5

ARC 6000

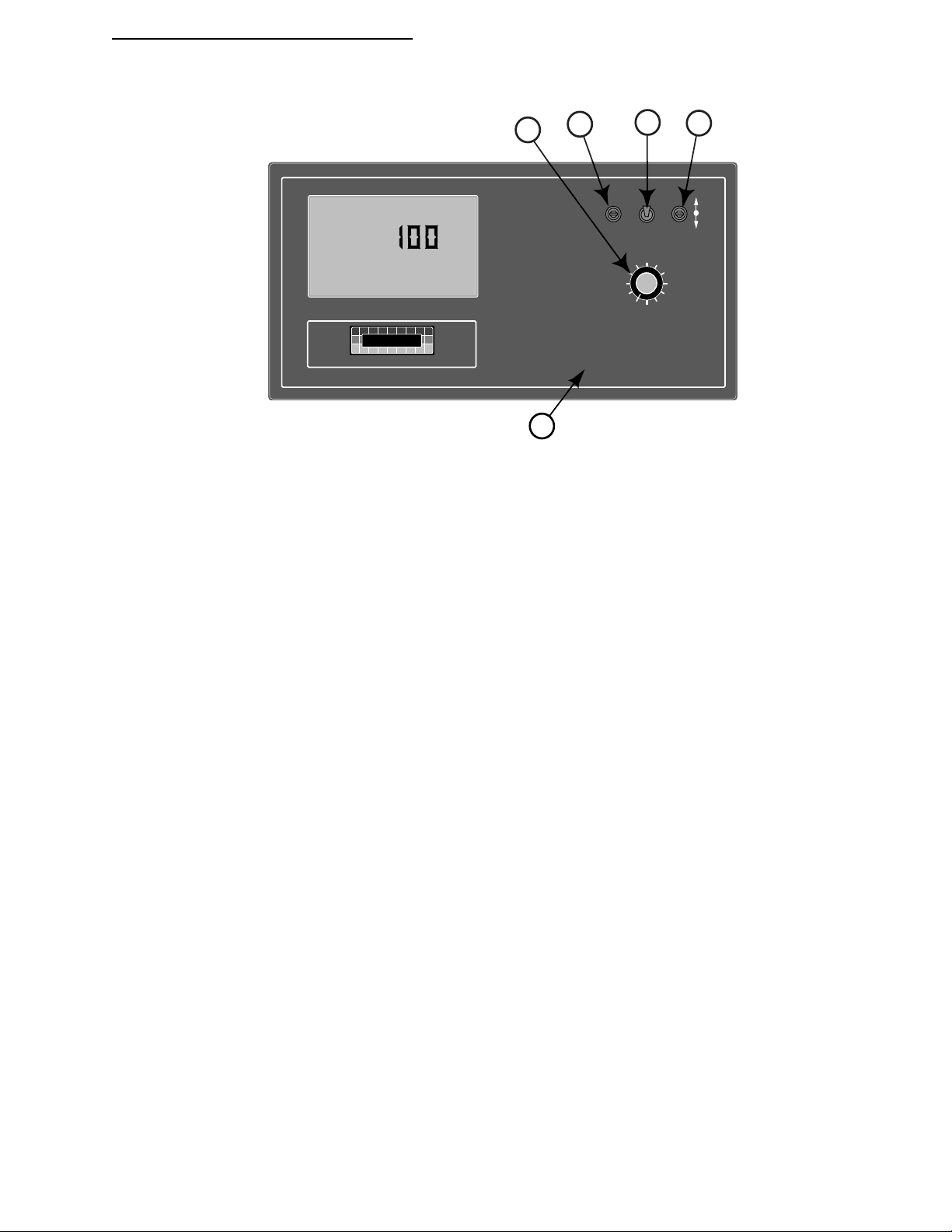

1.0. SWITCHES AND CONTROLS

98-05017

Rev.- 1

Flow

RATE

.

Gal./

MID-TECH

MIDWEST TECHNOLOGIES, INC.

4

ARC-6000

-Ac

¨

Automatic

Rate Controller

1

123456789

BOOMS

2

ON OPERATE INC.

OFF SET- UP DEC.

%Rate

Product Vol.

Total Area

Field Area Impl.Width

Speed

Scan

Test

Speed

DISPLAY SELECTOR

3

Application Rate

Total Applied

Distance

Prime

5

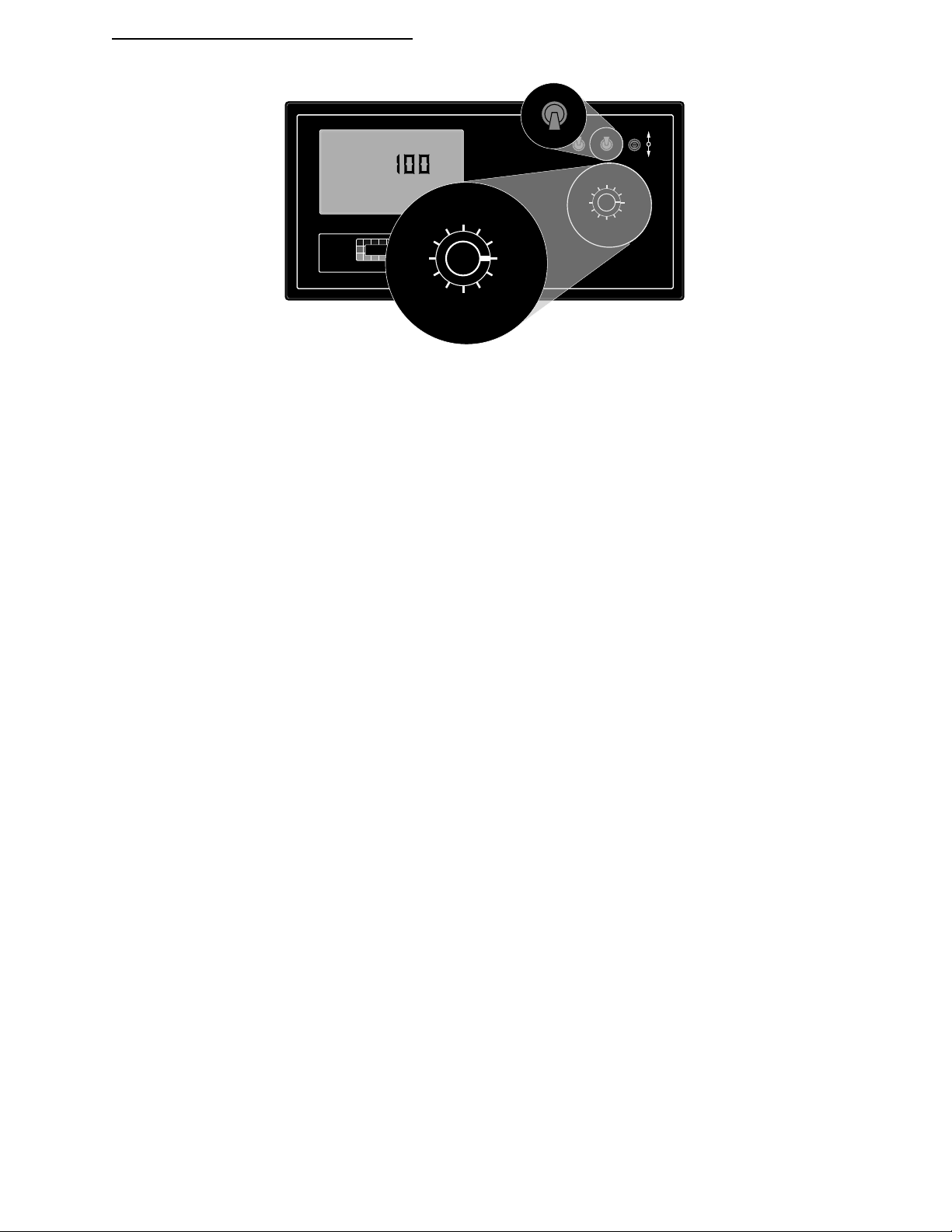

1.1. POWER SWITCH

The power switch controls power to the console. The console has an "Auto Power Down" feature which powers the console

off after an operator selectable time (default is 30 min) has elapsed. The console has a nonvolatile memory so it "remembers"

the constants and data previously entered, even if the power is removed.

NOTE: The “Auto Power Down Feature is only available on the CE version of the console (CE designation label on back of

console).

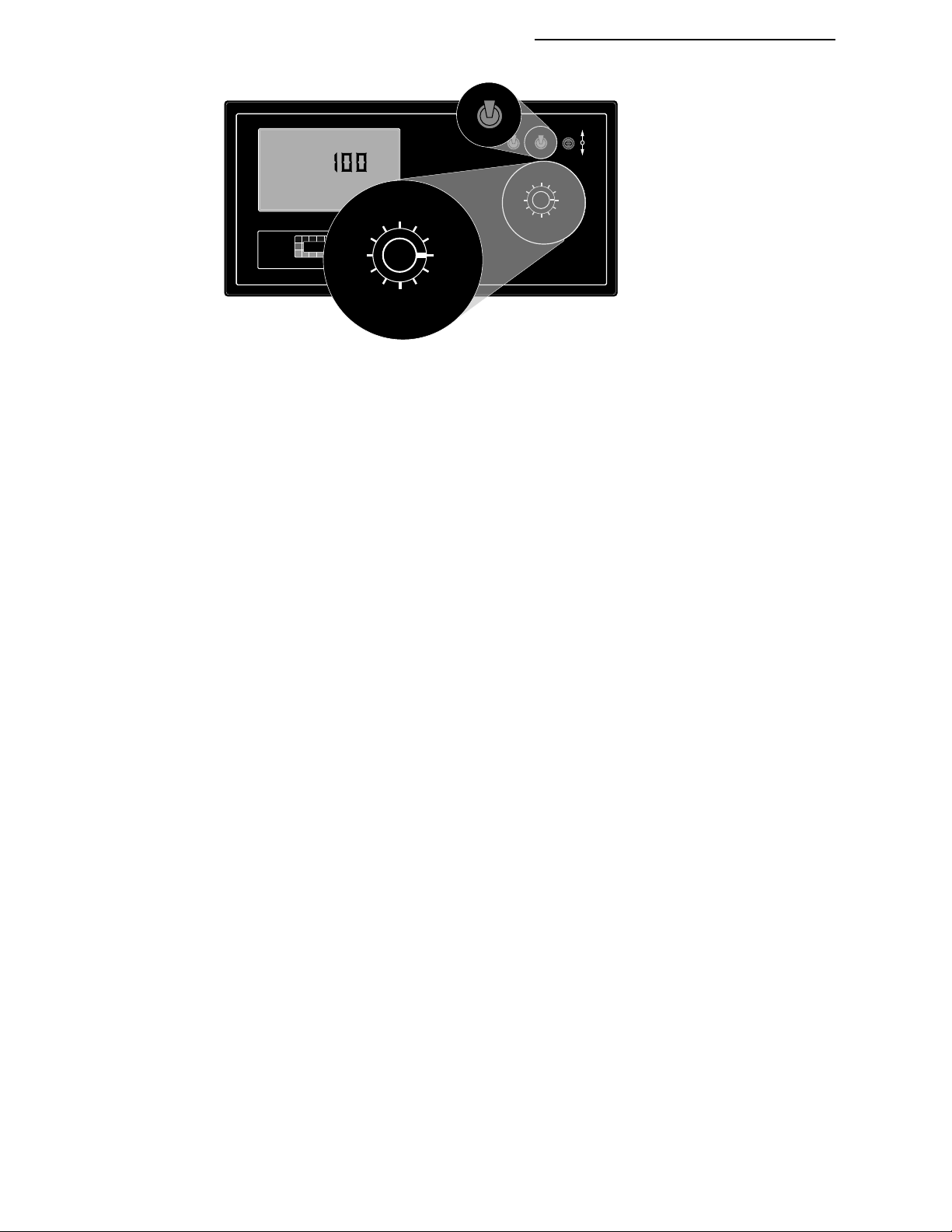

1.2. MODE SELECTOR “OPERATE / SETUP” SWITCH

The Mode Selector switch (upper right center) is used to switch between the OPERATE and SETUP modes of the control

console. When applying materials, this switch must be in the “OPERATE” position. The “SET- UP” position is used for

entering information into the console. In the SETUP Mode an “Err” message will appear if a position which can not be

programmed has been selected.

1.3. INC / DEC SWITCH

The INC/DEC switch (upper right corner) is used to change the values appearing in the display. The INC/DEC switch is

usable in either the OPERATE or SETUP Mode.

This switch is also used to zero the accumulated areas, distance, and total applied by selecting the desired display and

holding this switch in the “DEC” position until the display resets to zero, (approximately 3 sec.).

Use this switch to reset the full load condition while displaying Product Vol. in the operate mode. Holding the switch in the

"INC" position until the display shows the programmed, full load value.

1-1

CE & S

TANDARD VERSION

Page 6

98-05017

123456789

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

BOOMS

OFF SET- UP

ON OPERATE

Rev.- 1

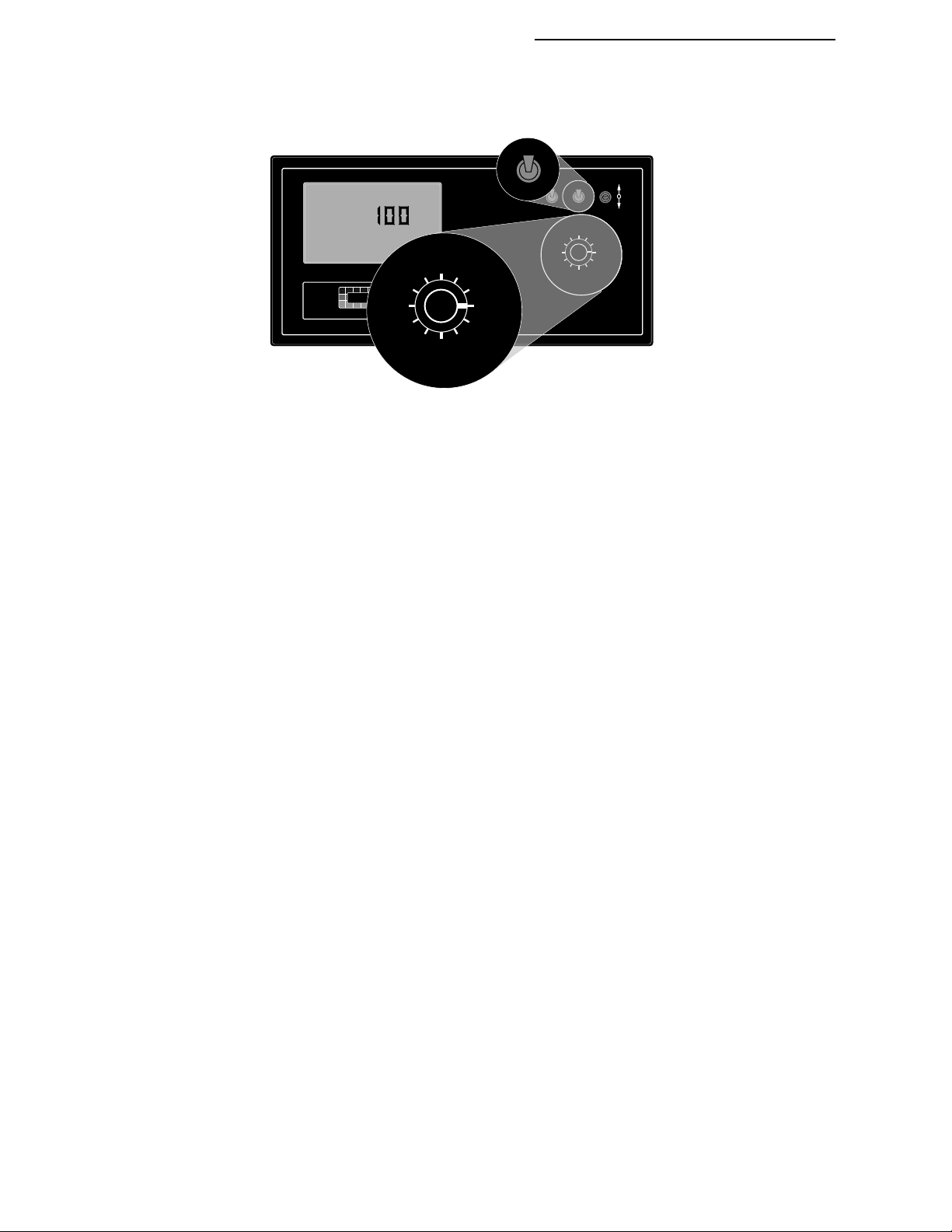

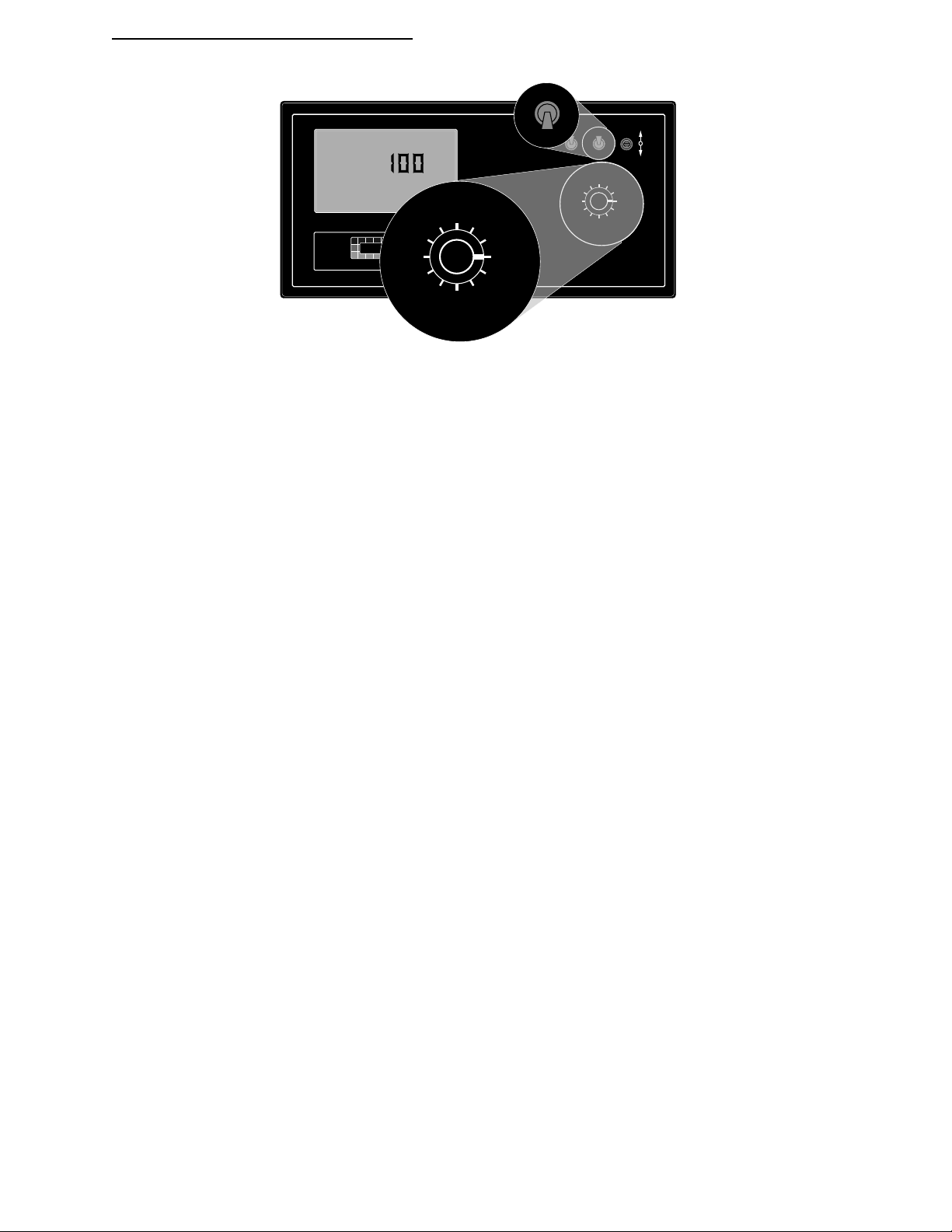

1.4. DISPLAY SELECTOR

The Display Selector (right center) is used to select and display the various console functions.

OPERATE

ARC 6000

Flow

RATE

.

Gal./

Product Vol.

Total Area

MID-TECH

Field Area Impl.Width

MIDWEST TECHNOLOGIES, INC.

Speed

DISPLAY SELECTOR

¨

Scan

-Ac

%Rate

Test

Speed

ARC-6000

Automatic

Rate Controller

Application Rate

Total Applied

Distance

Prime

ON OPERATE INC.

SET- UP

OFF SET- UP DEC.

%Rate

Product Vol.

Application Rate

Total Area

Field Area Impl.Width

Speed

Scan

Prime

Test

Speed

DISPLAY SELECTOR

123456789

BOOMS

Total Applied

Distance

1.4.1. DISPLAY SELECTOR FUNCTIONS -OPERATE MODE (LIQUID APPLICATION)

SPEED: The current vehicle speed in tenths of a Mile per Hour.

FIELD AREA: Accumulated Area, in hundredths of an Acre.*

TOTAL AREA: Accumulated Area, in Acres.*

PRODUCT V OL.: Amount of product aboard the vehicle. Resets to a pre-programmed, full load by holding the INC

switch up with ground speed zero. Ground speed zero also allows setting any value using the INC/DEC switch. Value

counts down as the product is applied, an alarm sounds with ten percent left aboard.**

% RATE: The percent of programmed application rate at which the product is being applied. This percentage can be

changed up or down a preset amount by operating the INC/DEC switch.***

APPLICATION RATE: The desired application rate can be set with the INC/DEC switch when the ground speed is zero

or all booms are OFF.** Once application has commenced, and metered discharge is established, the actual measured

application rate will be displayed here. Also used to set the controlvalve to manual operation.

TOTAL APPLIED: The actual volume applied, as measured by the flowmeter or pressure sensor.*

IMPL. WIDTH: The active boom width in tenths of Feet. Depends on the actual boom sections selected “ON”.

DISTANCE: The accumulated distance in Feet, Miles after 5,280 Ft.*

PRIME: This position is used to lock the control valve open during main pump priming on a liquid system. Initially the

display will show a series of five dashes. Hold INC switch up for three seconds to lock the control valve fully open. The

display will read OPEN. Switching away from PRIME will cause the control valve to drive CLOSED. When operating

in the pressure based (Psi) mode, the current boom pressure is displayed here.

TEST SPEED: The speed the console will use for stationary tests of the sprayer. Use the INC/DEC switch to change this

value.**

SCAN: The display will scan SPEED, FIELD AREA, PRODUCT VOLUME, APPLICATION RATE, TOTAL APPLIED,

and, if in pressure based mode, BOOM PRESSURE. The display will hold at each position for approximately two

seconds before automatically cycling to the next.

NOTES: * Totals can be zeroed in this mode.

** Values are programmable in this mode.

CE & STANDARD VERSION

***Values changeable by a % increase or decrease.

1-2

Page 7

ARC 6000

12345678

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

BOOMS

OFF SET- UP

ON OPERATE

98-05017

Rev.- 1

OPERATE

Flow

RATE

Gal./

Product Vol.

Total Area

MID-TECH

Field Area Impl.Width

MIDWEST TECHNOLOGIES, INC.

Speed

ARC-6000

Automatic

-Ac

Rate Controller

.

%Rate

Test

Speed

Application Rate

Total Applied

Distance

Prime

¨

Scan

ON OPERATE INC.

SET- UP

OFF SET- UP DEC.

%Rate

Application Rate

Product Vol.

Total Area

Field Area Impl.Width

Speed

Prime

Scan

Test

Speed

DISPLAY SELECTOR

123456789

BOOMS

Total Applied

Distance

DISPLAY SELECTOR

1.4.2. DISPLAY SELECTOR FUNCTIONS -SET UP MODE (LIQUID APPLICATION)

SPEED: Ground Speed Override Value (GSO), in tenths of a MPH. Use the INC/DEC switch to change.**

FIELD AREA: Select area alarm. For example; if the alarm is set (using the INC/DEC switch) to 10.00, then

the display will flash and the console will beep when each increment of ten acres is reached. The display will

react for about three seconds and then stop until the next increment is reached.**

TOTAL AREA: Err, No function in the SETUP mode.

PRODUCT V OLUME: Use the INC/DEC switch to set the full tank capacity of the vehicle.**

% RATE: The percent of change in the application rate for each actuation of the INC/DEC switch, when

application operations are underway. Use the INC/DEC switch to change.**

APPLICATION RATE: A pressure sensor correction factor which is used when applying products with a specific

gravity different from that of water (see chart on page 2-7). The correction factor is only visible in Psi mode. Reads ERR

when in STnrd L or rEFLO L modes. Use the INC/DEC switch to change. Maximum is 1.50, minimum is 0.50**

TOTAL APPLIED: This is the pressure sensor or flowmeter calibration number. Use the INC/DEC switch to

change. Note: Must have all booms ON when in the REFLOW Mode.**

WIDTH: Individual boom section widths in inches. The display will cycle through the individual boom sections in

order, unless a particular boom switch is activated while the boom master switch is ON. Use the INC/DEC switch to

change.**

DISTANCE: The current Distance Calibration Number. Use the INC/DEC switch to change.**

PRIME: Holding the INC switch up for over ten seconds establishes LIQUID operation, either STnrd (standard), PSi

(Pressure) or rEFLO (reflow). Holding the DEC switch down for over ten seconds establishes GRANULAR operation,

either STnrd (standard) or SPLit (split drive). Current setting is shown in the display, Pump L is liquid, Pump C is

granular.

TEST SPEED: The current Test Speed in tenths of a Miles per Hour. Use the INC/DEC switch to change this value.**

SCAN: Err, No function in the SETUP mode.

NOTES: * Totals can be zeroed in this mode.

** Values are programmable in this mode.

***Values changeable by a % increase or decrease.

1-3

CE & S

TANDARD VERSION

Page 8

98-05017

123456789

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

BOOMS

OFF SET- UP

ON OPERATE

Rev.- 1

ARC 6000

OPERATE

Flow

RATE

.

Gal./

Product Vol.

Total Area

MID-TECH

Field Area Impl.Width

MIDWEST TECHNOLOGIES, INC.

Speed

DISPLAY SELECTOR

¨

Scan

-Ac

%Rate

Test

Speed

ARC-6000

Automatic

Rate Controller

Application Rate

Total Applied

Distance

Prime

ON OPERATE INC.

SET- UP

OFF SET- UP DEC.

%Rate

Application Rate

Product Vol.

Speed

Scan

Test

Speed

DISPLAY SELECTOR

Prime

Total Applied

Distance

Total Area

Field Area Impl.Width

123456789

BOOMS

1.4.3. DISPLAY SELECTOR FUNCTIONS-OPERATE MODE (GRANULAR APPLICATION)

SPEED: The current vehicle speed in tenths of a Mile per Hour.

FIELD AREA: Accumulated Area, in hundredths of an Acre.*

TOTAL AREA: Accumulated Area, in tenths of an Acre.*

PRODUCT V OL.: Amount of product aboard the vehicle. Resets to a pre-programmed, full load by holding theINC

switch up with ground speed zero. Also allows setting any value using the INC/DEC switch. Value counts down as the

product is applied, an alarm sounds with ten percent left aboard.**

% RATE: The percent of programmed application rate at which the product is being applied. This percentage can be

changed up or down a preset amount by operating the INC/DEC switch.***

APPLICATION RATE: The desired application rate can be set with the INC/DEC switch when the ground speed is zero

or all booms are OFF.** Once application has commenced, and metered discharge is established, the actual measured

application rate will be displayed here. Also used to set the control valve to manual operation.

TOTAL APPLIED: The actual volume applied, as measured by the rate sensor. Rounds to tons after accumulating

19,999 pounds.*

IMPL. WIDTH: The active boom width in tenths of Feet. Depends on the actual boom sections selected “ON”.

DISTANCE: The accumulated distance in Feet, Miles after 5,280 Ft. (Accumulates only when selector switch is in this

position or when applying product)*

PRIME: This position is used to lock the control valve open. It can be used in a granular application to unload the

vehicle at its maximum discharge rate. Initially the display will show a series of five dashes. Hold INC switch up for

three seconds to lock the control valve fully open. The display will read OPEN. Switching away or toggling the DEC

switch will cause the valve to CLOSE.

TEST SPEED: The speed the console will use for stationary tests of the sprayer. Use the INC/DEC switch to change this

value.**

SCAN: The display will scan SPEED, FIELD AREA, PRODUCT VOLUME, APPLICATION RATE and TOTAL

APPLIED. The display will hold at each position for approximately two seconds before automatically cycling to the

next.

NOTES: * Totals can be zeroed in this mode.

CE & STANDARD VERSION

** Values are programmable in this mode.

***Values changeable by a % increase or decrease.

1-4

Page 9

ARC 6000

12345678

%Rate

DISPLAY SELECTOR

Speed

Field Area Impl.Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

Scan

Total Area

Product Vol.

BOOMS

OFF SET- UP

ON OPERATE

98-05017

Rev.- 1

OPERATE

Flow

RATE

.

Gal./

Product Vol.

Total Area

MID-TECH

Field Area Impl.Width

MIDWEST TECHNOLOGIES, INC.

Speed

¨

Scan

-Ac

%Rate

Test

Speed

ARC-6000

Automatic

Rate Controller

Application Rate

Total Applied

Distance

Prime

ON OPERATE INC.

SET- UP

OFF SET- UP DEC.

%Rate

Application Rate

Product Vol.

Speed

Scan

Test

Speed

DISPLAY SELECTOR

Total Applied

Prime

Total Area

Field Area Impl.Width

123456789

BOOMS

Distance

DISPLAY SELECTOR

1.4.4. DISPLAY SELECTOR FUNCTIONS-SET UP MODE (GRANULAR APPLICATION)

SPEED: Ground Speed Override (GSO) Value, in tenths of a MPH, INC/DEC switch changes.**

FIELD AREA: Select area alarm. For example; if the alarm is set (using the INC/DEC switch) to 10.00, then the display

will flash "FIELD AREA" and the console will beep when each increment of ten acres is reached. The display will

react for about three seconds and then stop until the next increment is reached.**

TOTAL AREA: Err, No function in the SETUP mode.

PRODUCT V OLUME: Use the INC/DEC switch to set the full load capacity of the vehicle.**

% RATE: The percent of change in the application rate for each actuation of the INC/DEC switch, when application

operations are underway. Use the INC/DEC switch to change the value.**

APPLICATION RATE: Product density. The default value is 65.0. Use the INC/DEC switch to set the measured

product density.**

TOTAL APPLIED: This is the rate sensor calibration number. Calculate and use the number of sensor pulses per cubic

foot as the initial setting. Use the INC/DEC switch to change. Must have all booms ON when in the SPLIT Drive

Mode**

WIDTH: Individual boom section widths in inches. The display will cycle through the individual boom sections in

order, unless a particular boom solenoid switch is activated. Use the INC/DEC switch to change.**

DISTANCE: The current Distance Calibration Number. Use the INC/DEC switch to change.**

PRIME: Holding the DEC switch down for over ten seconds establishes GRANULAR operation, either STnrd (standard)

or SPLit (split drive). Holding the INC switch up for over ten seconds establishes LIQUID operation, either STnrd

(standard) or rEFLO (reflow). Current setting is shown in the display, Pump L is liquid, Pump C is granular.

TEST SPEED: The current Test Speed in tenths of a Mile per Hour. Use the INC/DEC switch to change this value.**

SCAN: Err, No function in the SETUP mode.

** Values are programmable in this mode.

***Values changeable by a % increase or decrease.

NOTES: * Totals can be zeroed in this mode.

1-5

CE & S

TANDARD VERSION

Page 10

98-05017

ARC 6000

Rev.- 1

1.5. BOOM SECTION “ON/OFF” INDICATORS

The boom section on/off indicators (lower right, labeled “BOOMS”), indicate which boom sections have been selected by

the operator. When a boom has been selected, its indicator will light. Boom position number 1 is to the left. There is a

maximum of nine boom sections available.

1.6. NOT USED

1.7.--STATUS SWITCH

A status switch can be used to override the ARC control. The switch must present a positive voltage (+12.0 VDC) status on

the green (or white) wire of the Boom Interface Cable. So long as this condition is present, the control console will operate

normally. If the voltage is interrupted, the control console will automatically stop controlling. At the same time, the control

console will either "HOLD" or "CLOSE" the control valve, depending on the response selected by the operator. (See Section

2.9.1).

The intent of this feature is to allow the operator to control the operation of the control valve through the normal operation of

the vehicle. The Status switch input may be used to sense the "ON"/"OFF" condition of the main vehicle pump switch, a

separate Status switch, or, an external switch may sense an implement "UP"/"DOWN" condition. The Status switch can

often be used to lessen the operator's work load.

1.8. GROUND SPEED OVERRIDE (GSO) SWITCH

If the ARC system was purchased with an optional MID-TECH boom switch box, the Ground Speed Override switch is

already installed. If a MID-TECH switch box is not used to control the booms, an optional externally mounted Ground

Speed Override switch can be used to temporarily operate the sprayer (or spreader) using a pre-selected Minimum "(GSO)

Speed" rather than the actual speed registered by the Ground Speed Sensor. The override feature is used to bring the

applicator on line quickly when starting from a dead stop or to maintain an adequate application pattern when the vehicle is

maneuvering at very low ground speeds. It can also be used to allow the operator to flush or empty the vehicle from the cab,

while stopped.

The control console operates normally so long as the Ground Speed Override switch condition is open (OFF). Whenever the

Override switch is closed (ON) and the actual ground speed is less than "GSO Speed", the control console automatically

selects the "GSO Speed" value to control application rate. As soon as the switch reverts to its normally open (OFF) condition, or the actual ground speed increases above the preset "GSO Speed", the control console will adjust the rate on the basis

of the actual ground speed.

CAUTION: Controlling application rates based on "GSO Speed" is not as accurate as using the actual ground speed.

When Ground Speed Override is being used and the true ground speed is less than the "GSO Speed", the console will

sound a warning beep and the display will flash a "Too Slow" message to warn the operator of over application.

CE & STANDARD VERSION

1-6

Page 11

ARC 6000

2.0. CALIBRATION AND SET UP

NOTE: PLEASE READ THROUGH THE FOLLOWING SECTIONS COMPLETELY BEFORE YOU BEGIN

CALIBRATION!

The control console needs to be calibrated and programmed with certain information before it is ready to be used. First, the console

needs to be programmed with the specific details of your applicator (i.e. Application Rates, Boom Widths, Test Speed, etc.). Next,

the rate sensor (flowmeter) and ground speed sensors both need to be calibrated. The calibration and set up processes are not

difficult, however; they must be followed precisely in order to get the maximum available accuracy out of the system.

First, BE SURE THE CONSOLE IS SELECTED TO THE APPLICATION PROGRAM YOU WANT. The Choices are;

Liquid Pressure, Liquid standard, Liquid reflow, Granular standard, and Granular split drive.

2.1. CHANGING THE APPLICATION PROGRAM

To view the program currently selected, set the Mode switch to "SETUP" and the Display Selector to "PRIME".

Pump L PSi is LIQUID PRESSURE application (normal pressure based spraying)

Pump L STnrd is STANDARD LIQUID application (normal flow based spraying)

Pump L rEFLO is LIQUID REFLOW application (for use on some European sprayers)

Pump C STnrd is standard GRANULAR application (single conveyor spreaders)

Pump C SPLit is GRANULAR SPLIT DRIVE application (dual conveyor spreaders, air delivery spreaders)

98-0501

Rev.- 1

To change programs, hold the INC switch up to set LIQUID and cycle between standard, reflow, and pressure. Hold the DEC

switch down to set GRANULAR and cycle between standard and split drive. The application remaining in the display when the

INC/DEC switch is released is the program selected. If you have a question about which application to use, check with your

supplier or call MID-TECH Customer Service.

2.2. ENGLISH, METRIC OR METRISH UNITS

When operating as a LIQUID applicator the control console is capable of displaying three separate units of measure, English,

Metric and Metrish. Metrish is the same as Metric, except area is measured in Acres, thus the term Metrish. Operating as a

granular applicator, the display is limited to English units of measurement.

2.2.1. UNITS FOR EACH POSITION (LIQUID APPLICATOR ONLY)

POSITION ENGLISH (US) METRIC METRISH

Speed Miles/Hour (MPH) Kilometers/Hour (KPH) Kilometers/Hour(KPH)

Field Area Acres ( Ac) Hectares ( Ha) Acres ( Ac)

Total Area Acres ( Ac Hectares ( Ha) Acres ( Ac

Product Vol. Gallons (Gal.) Liters Liters

Appl. Rate Gallons/Acre(Gal.-Ac) Liters/Hectare (Liters-Ha) Liters/Acre (Liters-Ac)

Total Applied Gallons (Gal.) Liters Liters

Impl. Width Inches - Feet (In., Ft.) Meters Meters

Distance Feet - Miles (Ft.)* Meters - Kilometers* Meters - Kilometers*

Test Speed Miles/Hour (MPH) Kilometers/Hour (KPH) Kilometers/Hour(KPH)

* No units displayed after roll over of feet to miles or meters to kilometers

2-1

CE & STANDARD VERSION

Page 12

98-05017

ARC 6000

Rev.- 1

2.2.2. CHANGING UNITS (LIQUID APPLICATOR ONLY)

To change units, set the Mode switch to “OPERATE” and the Display Selector to “SPEED”. The current speed units will be

displayed. Holding the INC/DEC switch up or down (see chart) until the display changes (approximately 5 sec.) will set the units

accordingly.

UNITS INC./DEC. Switch

English to Metric DOWN

Metric to English DOWN

English to Metrish UP

Metrish to English DOWN

NOTE: Metric to Metrish is not allowed. Convert to English first and then to Metrish.

2.3. SETTING APPLICATION RATE

The ARC system is designed to maintain a constant, pre-selected application rate. In order for the control console to do this, the

operator must enter the desired application rate.

A. Set the console switches to the following positions:

Power ON

Mode Selector OPERATE (Application rate is set in the Operate Mode!!!)

Display Selector APPLICATION RATE

Ground Speed ZERO

All Booms OFF

The display will show the current application rate.

B. Use the INC/DEC switch to set the value displayed to the desired rate.

C. Setting the APPLICATION RATE to 0.0 will shut off the flow control function.

2.4. SETTING THE % RATE CHANGE

This feature allows the operator to change the application rate “On The Go”. Application rate is changed with a simple

actuation of the INC/DEC switch. The amount of change each switch actuation makes is proportional to the value programmed into this position, (e.g. 20 =20% change in the target rate). For example, if the liquid application rate is set at 10.0

gallons per acre, a single actuation of the INC switch will cause the valve to control flow at the rate of 12.0 gallons per acre

(10.0 + 20% = 12.0).

A. Set the console switches to the following positions:

Power ON

Mode Selector SETUP

Display Selector % RATE

The display will show the current % change value.

B. Use the INC/DEC switch to set this number to the desired % change value.

2.5. SETTING BOOM WIDTHS

The MIDWEST TECHNOLOGIES control console is designed to automatically compensate for changes in the swath width,

caused by turning on or off boom sections. For the console to automatically respond to changes in swath width, it needs to

know the size of each boom section. Use the following procedure to set boom section widths.

CE & STANDARD VERSION

2-2

Page 13

ARC 6000

A. Set the console to the following positions;

Power ON

Mode Selector SET- UP

Display Selector IMPL. WIDTH

All Boom Solenoid Switches (external) OFF

The display will cycle through each boom position (1 through 9) and display its current width in inches.

B. As each boom position appears on the display, use the INC/DEC switch to set the display to the number of inches

covered by that boom. Repeat for each section.

NOTE: Individual boom widths are entered in inches. For example; for a liquid boom with 7 nozzles on

30" spacings, enter 180 for that boom. There is no need to convert to feet, the control console does that

automatically when it is switched back to the OPERATE MODE.

C. Set all unused boom sections to a width of zero “0” inches. This will insure that an accidental boom switch ON will not

affect the control console.

D. The boom width is now set. Turn all boom switches to the ON position and return to the OPERATE Mode, the new

total boom width will be displayed in feet. If this does not agree with your total applicator width, check the individual

boom widths, (steps B and C).

98-0501

Rev.- 1

2.6. APPLICATION RATE SENSOR CALIBRATION

The control console must be calibrated for the flowmeter, pressure sensor, or rate sensor being used. The calibration number

required by the control console is the actual number of electrical pulses per unit volume generated by the sensor, or, for the pressure

sensor, the gallons per acre rating of the nozzles being used. If you have any doubts as to the accuracy of the flow sensor

readings, a field calibration/catch test should be performed using the actual product solution. (see section 2.6.1.4)

2.6.1. CALIBRATING THE LIQUID APPLICATION

Verify that the correct application program has been selected (see section 2.1.)!

If in the Psi mode, check the correction factor. It should be set to 1.0 during the calibration routine. To check the correction

factor, set the Display Selector to APPLICATION RATE, set the Mode Selector switch to SETUP. Use the INC/DEC

switch to set the correction factor if necessary.

2.6.1.1. DETERMINING THE FLOWMETER INITIAL CALIBRATION NUMBER

FLOWMETERS are calibrated for water at the factory. This number is accurate enough for most applications. However, the

actual flow characteristics may differ due to plumbing or other factors.

Standard Flowmeters

SIZE SUPPLIER CAL.# SIZE SUPPLIER CAL.#

.75 inch (Mid-Tech) 396.9 3.00 inch (Mid-Tech) 5.0

1.00 inch (Mid-Tech) 153.1

1.50 inch (Mid-Tech) 38.8 1.25 inch (Raven) 75.0*

2.00 inch (Mid-Tech) 23.8 3.00 inch (Raven) 16.4*

Mid-Tech Rapid Check Flowmeters

SIZE RANGE CAL# SIZE RANGE CAL#

1.00 inch 0.75 - 5 gpm 3200 1.50 inch 2.5 - 25 gpm 612.4

1.00 inch 2.5 - 16 gpm 800 1.50 inch 2.6 - 53 gpm 361.9

2.00 inch 20.0 - 195 gpm 94.5

* Raven flow meters, use the factory calibration number divided by 10. All other flowmeters use the manufacturers'

supplied information regarding the pulses per gallon (usually provided on a tag on the flowmeter).

2-3

CE & STANDARD VERSION

Page 14

98-05017

ARC 6000

Rev.- 1

Once the initial calibration number has been entered into the console, proceed to section 2.6.1.4 to fine tune the flowmeter

for maximum accuracy.

2.6.1.2. DETERMINING THE PRESSURE SENSOR INITIAL CALIBRATION NUMBER

The Pressure Sensor Calibration Number can be found by determining the "Gallons per Acre" rating for the type of nozzles

being used. First find the chart that represents the nozzle series you will use and the nozzle spacing of your boom. Then find

the nozzle size needed for the range of speeds and the rate needed. When the nozzle has been selected find the column of

nozzle ratings in "Gallons per Acre" at 10 MPH. Then, on the left of the chart, find the horizontal line representing the

ratings at 30 PSI. Where the column and row intersect you will find the "Gallons per Acre" rating of your nozzles at 10

MPH and 30 PSI. This is the value to enter into the console as the pressure sensor Cal. #. For example, in the following chart,

for a floodjet K-SS10 nozzle, the row for 30 PSI and column for 10 MPH cross at 26.0 gallons per acre, the pressure sensor

cal. number for this particular nozzle.

NOTE: We recommend that these tests be done using water, and only after neutralizing the tank and system.

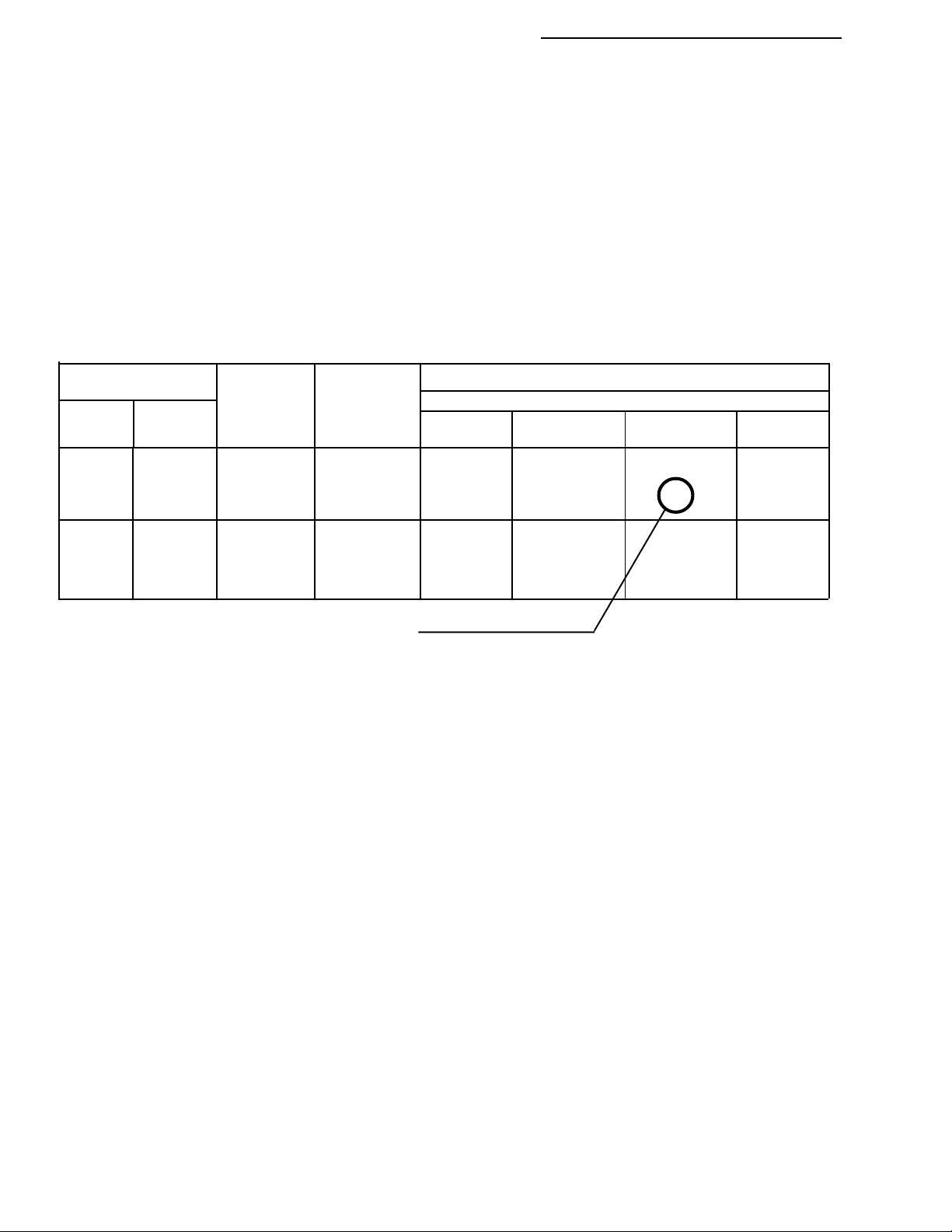

Gallons per AcreType

Liquid Capacity 40" Spacing

Floodjet

Tip No.

TK-SS10

4

TK-SS15

Floodjet Pressure in 6 8 10 12

Nozzle in PSI GPM MPH MPH MPH MPH

10 1.0 25.0 16.6 14.9 12.4

K-SS10 20 1.4 35.0 26.0 21.0 17.5

30

40

10 1.5 37.0 28.0 22.0 18.6

K-SS15 20 2.1 53.0 39.0 32.0 26.0

30 2.6 64.0 48.0 39.0 32.0

40 3.0 74.0 56.0 45.0 37.0

1.7

2.0

43.0 32.0 26.0 21.0

50.0 37.0 30.0 25.0

Use this number as the cal. number in this example.

Use the following procedure to enter the flow sensor calibration number.

A. Set the console to the following positions;

Power ON

Mode Selector SET- UP

Master Switch OFF

Display Selector TOTAL APPLIED

B. Use the INC/DEC switch to select the desired flow sensor calibration number.

2.6.1.3. PRESSURE SENSOR HIGH/LOW CALIBRATION

The pressure sensor's low and high values must be set to match the readings from your pressure gauge following the procedure below.

SETTING THE LOW SIDE:

A. Set the console to the following positions;

Power Switch ON

Setup/Operate Switch OPERATE

Display Selector Switch PRIME

Master Switch ON

At least one Boom Switch ON (to release any trapped pressure)

(May have to remove nozzle if it has a check valve)

Ground speed 0 (zero)

GSO Switch OFF

CE & STANDARD VERSION

2-4

Page 15

ARC 6000

B. Hold INC/DEC switch to DEC until console reads PSi 0

Note: A display reading of "PSi - -" indicates that the pressure sensor is not connected. A reading of "PSi - 0" indicates a reading of less than 0 PSI. This suggests that the sensor may need to be recalibrated to 0 pressure.

SETTING THE HIGH SIDE:

A. Set the console to the following positions;

Power Switch ON

Setup/Operate Switch OPERATE

Display Selector Switch PRIME

Master Switch ON

Supply Pump ON

Ground speed 0 (zero)

B. Hold the INC/DEC switch to INC for about 3 seconds. The display will read "OPEN". Release the INC switch. Push

the INC switch again and hold it for about 3 seconds. The display will read "PSi xxx". The xxx is a pressure. The INC/

DEC switch can now be used to adjust the pressure reading on the console to match the reading on the pressure gauge. If

no switch changes are detected after 3 seconds, the console will read "OPEN" again. Actuating the DEC switch when the

console reads "OPEN" will cause the console to read "CLOSE" and the valve will close.

2.6.1.4. FINE TUNING THE FLOW SENSOR CALIBRATION NUMBER

98-0501

Rev.- 1

NOTE: We recommend that these tests be done using water, and only after neutralizing the tank and system.

Once the initial calibration number has been determined and entered into the console, a calibration run should be made to adjust

the number for maximum accuracy. The hardest part of the calibration procedure will be accurately measuring the actual discharge

of large volumes of liquid. The more accurately the discharge is measured, the more accurate the calibration will be. Since each

operator's facilities are different, it is not possible to prescribe a standard method of measuring discharge. Operators have

successfully performed the task using a second, calibrated flow meter, using a truck scale and calculating volumes based on weight

and density of the liquid discharged, and by discharging into a marked, calibrated tank.

It is necessary to pump and measure at least 100 gallons, and as much as 300 gallons, depending on the accuracy required. For

example: if the actual measurement is accurate to within 3 gallons, using 300 gallons will yield an accuracy of 1 %.

If only 100 gallons are pumped and measured, the calibration can be off as much as 3%. The better the measurement accuracy

of actual discharge and the more material pumped, the more accurate will be the resulting calibration.

A method similar to the following is recommended.

1. If using Psi mode, enter the appropriate Correction Factor for the material that you will be using for the test (Not

applicable for rEFLO or STnrd applications) (see section 2.4.1).

2. Turn the Mode Switch to "OPERATE", the Display Selector to "APPLICATION RATE". Enter the desired

application rate.

3. Verify that the boom switches are "OFF", select the "SETUP" mode; rotate the display selector switch to

"TOTAL APPLIED".

4. For Psi mode applications, the current pressure sensor calibration number will be displayed. Verify that it is the

recommended initial calibration number for the nozzles installed in the system. For rEFLO or STnrd applications,

the flowmeter calibration number will be displayed (rEFLO mode requires all booms be on to view cal. #.) Use the

INC/DEC switch to adjust as necessary.

5. Select "OPERATE" with the mode selector switch. Hold the DEC switch down for three to five seconds to zero

the accumulated gallons.

6. Make sure there is enough liquid in the main tank to do the test. Weigh the sprayer and load of water. Position

the sprayer in an appropriate area to do the calibration test.

2-5

CE & STANDARD VERSION

Page 16

98-05017

Rev.- 1

7. Start the main carrier pump, Rotate the display selector switch to "TEST SPEED". Turn "ON" the Master Switch

and the Boom Switches. The sprayer will start to spray. Allow the sprayer to discharge until the desired amount has

been pumped. Turn "OFF" the Master Switch.

8. Weigh the sprayer again and calculate the amount of water discharged.

9. Turn the display selector switch to "TOTAL APPLIED" and select "OPERATE" with the Mode Switch. If the

total shown on the console agrees with the total amount actually discharged, no further action is necessary. The

pressure sensor, or flowmeter, is now calibrated.

10. If the indicated volume pumped does not agree with the actual volume pumped, calculate a new calibration # as

follows:

PRESSURE SENSOR: New Cal. # =(MEASURED AMOUNT / INDICATED AMOUNT) X Old Cal. #

If the measured amount is more than the indicated amount, the new cal# should be larger.

If the measured amount is less than the indicated amount, the new cal# should be smaller.

FLOW METER: New Cal. # =(INDICATED AMOUNT/ MEASURED AMOUNT) X Old Cal.#

If the measured amount is more than the indicated amount, the new cal. # should be smaller.

If the measured amount is less than the indicated amount, the new cal# should be larger.

10. Set the mode selector to "SETUP" and select "TOTAL APPLIED". Change the cal. # using the INC/DEC

switch. Return the mode selector to "OPERATE". The amount displayed will now match the amount measured.

The flow sensor is now calibrated.

ARC 6000

10a. An alternate method, of correcting the cal. #, at this point, is to switch back and forth, between "OPERATE/

TOTAL APPLIED AND SETUP/ TOTAL APPLIED", changing the cal. # until the Total Applied display, in

operate mode, equals the amount actually dispensed.

11. Write this number down for future reference. This will be the number to use for these specific conditions

(material and applicator configuration).

Another Method of fine tuning the sensor cal. # would be to weigh the sprayer with a full tank of water, zero out the "Total Applied",

set the GSO speed to 10 MPH, and start spraying while watching the "Total Applied" accumulate. When the "Total Applied" has

reached at least 100 gallons, re-weigh the sprayer and determine the actual amount applied as compared to that indicated by the

console. Use the method described in step 9 and 10 above to correct the Cal. #.

Fine tuning of the calibration number can also be done based on field experience.

L Psi (bAr) Mode - Material left over - Adj. Cal. # down slightly

- Short of material - Ad1j. Cal. # up slightly

L STnrd and - Material left over - Adj. Cal. # up slightly

rEFLO Modes - Short of material - Adj. Cal. # down slightly

CE & STANDARD VERSION

2-6

Page 17

ARC 6000

98-0501

Rev.- 1

2.6.1.5. SETTING THE CORRECTION FACTOR (Psi Mode)

If you will be spraying water solutions, the correction factor should be set to 1.00. If you will be spraying a solution with a specific

gravity different than that of water, adjust the correction factor according to the following chart.

Weight of Solution Correction Factor

7.0 lbs/gal .92

8.0 lbs/gal .98

8.34 lbs/gal - Water 1.00

9.0 lbs/gal 1.04

10.0 lbs/gal 1.10

10.65 lbs/gal - 28% Nitrogen 1.13

11.0 lbs/gal 1.15

12.0 lbs/gal 1.20

14.0 lbs/gal 1.30

To enter the correction factor, go to APPLICATION RATE and SETUP mode. Use the

INC/DEC switch to adjust the correction factor.

2.6.2. CALIBRATING THE GRANULAR APPLICATION

Check to be sure the correct application program has been selected (see section 2.1.)!

2.6.2.1. SETTING THE PRODUCT DENSITY

ARC needs to know the product density in order to control the application rate. IF PRODUCT DENSITY IS NOT CORRECT, THE APPLICATION RATE WILL NOT BE CORRECT. Product density is entered as pounds per cubic foot.

Product density should be measured and entered with each load of product.

A. Set the console switches to the following positions:

Power ON

Mode Selector SETUP

Display Selector APPLICATION RATE

The display will show the current product density.

B. Use the INC/DEC switch to set the display to the desired density.

2.6.2.2. CALCULATING THE INITIAL CALIBRATION NUMBER

It is necessary to enter a spreader constant in ARC to ensure an accurate output from the conveyor. The spreader constant is

the number of sensor pulses per cubic foot of material discharged. The constant is different for different gate height settings

on adjustable spreaders. Constants relating to particular gate height settings should be calibrated and recorded for the

spreader.

Calculation of the initial spreader constant requires the following information; 1) Gate height (H) and width (W), in inches,

2) Number of sensor pulses for each revolution of the spreader rate sensor (P), 3) The distance the conveyor moves during

one revolution of the spreader rate sensor (D), in inches.

Calculate the initial spreader constant as follows:

Where; Ft

3

is the volume discharged during each revolution of the spreader rate sensor, in Cubic Feet.

r

Continue as follows:

3

P / Ft

= Initial Calibration Number (Spreader Constant)

r

( D x W x H ) / 1728 = Ft

2-7

3

r

CE & STANDARD VERSION

Page 18

98-05017

ARC 6000

Rev.- 1

Enter this calibration number into the console memory using the procedure that follows.

A. Set the console switches to the following positions:

Power ON

Mode Selector SETUP

Display Selector TOTAL APPLIED

Boom Switches ON (If Split Drive mode is active)

The current Spreader Constant will be displayed.

B. Use the INC/DEC switch to set the display to the calculated Spreader Constant. Remember, the number

cannot be changed when the console is in the Split Drive mode, unless all booms are turned on.

2.6.2.3. RATE SENSOR CALIBRATION

The accuracy of the Spreader Constant should be verified, and adjusted as necessary. The following procedure is suggested

as a relatively simple means of testing the calibration of the spreader constant. BE SURE THE PROPER PRODUCT

DENSITY HAS BEEN ENTERED BEFORE PERFORMING THE CALIBRATION OR THE RESULTS WILL BE

INACCURATE.

A. Set the console switches to the following positions:

Power ON

Mode Selector SETUP

Display Selector TOTAL APPLIED

Boom Switches ON (If Split Drive mode is active)

The display will show the Current Spreader Constant. Record this number for reference.

Turn all booms OFF.

B. Load the vehicle with product of known density. Be sure the density is properly entered in the ARC (Section 2.6.2.1.).

C. Weigh the truck and load and record this weight. Back up to a location where you can safely unload the material

through the conveyor. Be sure the hydraulics are engaged so that there is pressure to the conveyor control valve.

D. Switch the Mode Selector to OPERATE and hold the DEC switch down until the display resets to zero.

E. Rotate the Display Selector to TEST SPEED (be sure an appropriate speed is entered using the INC/DEC switch).

Turn the booms ON and the conveyor will begin to discharge.

F. Discharge enough material to get an accurate measurement but be careful to keep the conveyor running full. As an

example: if the truck scale reads in 20 lb. increments, at least 1000 lbs. must be discharged to be able to calibrate within

1%.

G. When sufficient material has been discharged, turn the booms OFF and rotate the Display Selector to TO T AL AP-

PLIED. ARC displays the Indicated Amount discharged by the conveyor in lbs (or tons over 20,000 lbs.).

H. Weigh the truck and load (be sure the driver's weight is included if he was on the truck when it was weighed the first

time). The difference between the starting weight and the ending weight is the Actual Amount discharged by the

conveyor. (This procedure assumes fuel use is minimal during the test).

I. To adjust the Spreader Constant, use the following formula:

(INDICATED AMOUNT / MEASURED AMOUNT) X CURRENT SPREADER CONSTANT = NEW SPREADER CONSTANT

If the weight read from the console is greater than the weight actually measured, the calibration number will increase.

J. Put the Mode Selector to SETUP and use the INC/DEC switch to change the Spreader Constant. (REMEMBER, IF

SPLIT DRIVE IS ACTIVE, THE BOOM SWITCHES MUST BE ON.) Turn the booms OFF and switch the Mode

CE & STANDARD VERSION

2-8

Page 19

ARC 6000

Selector switch back to OPERATE, the corrected Indicated Amount will be displayed. If this number does not match

the Actual Amount, check the calculation.

NOTE: Write down the spreader constants for different gate settings. Use these numbers whenever that gate setting is

selected.

If it is not convenient to conduct an actual test, field experience will allow fine tuning of the spreader constant. If the

spreader is applying too much, decrease the spreader constant by the same percentage as the over application. If too

little material is being applied, increase the spreader constant by the same percentage as the under application.

2.7. DISTANCE CALIBRATION, GROUND SPEED SENSOR

2.7.1. GENERAL CONSIDERATIONS AND INITIAL CALIBRATION NUMBERS

The control console must be calibrated for the ground speed sensor installation to ensure accurate application rates. The procedure

involves physically measuring an accurate distance along a road or field, driving the vehicle through that distance, and

mathematically comparing the distance computed by the control console to the actual measured distance. If the two distances

compare exactly, no change is necessary. If the distances do not compare exactly, the console can be calibrated by changing the

distance calibration number a proportionate amount. Following the recommended procedure below will ensure accuracy of

operation.

The distance calibration must be periodically checked. This is especially important if the sensor has come loose or been

repositioned, or if the tires have been changed.

98-0501

Rev.- 1

Use the following initial calibration settings to get started. For the radar this number will be pretty close. For the wheel speed

sensor and the speedometer sensor the adjustment to this initial calibration number may be very large, depending on the

configuration of the vehicle. It is important to field calibrate the distance sensor to insure optimum accuracy!

RADAR - 1000 WHEEL SENSOR - 3500 SPEEDOMETER SENSOR - 3500

A. Set the control console switches to the following settings:

Power ON

Mode Selector SETUP

Display Selector DISTANCE

The display will now show the current distance calibration value.

B. Use the INC/DEC switch to select the initial distance calibration value suggested.

You are now ready to perform the distance calibration.

2.7.2. DISTANCE CALIBRATION PROCEDURE

The following procedure is recommended by MIDWEST TECHNOLOGIES for establishing an accurate distance calibration.

NOTE: All boom switches should remain OFF during the entire procedure.

1. Fill the vehicle 1/2 full of material, to approximate actual load conditions. This will minimize the effect on the radar

mounting angle and/or actual working diameter of the tires as the load empties.

2. Measure out a known distance of 400 ft. or more in a field or roadway. The longer the distance, the more accurately the

test can be performed, but keep it in even hundreds of feet and the calculations will be easier.

3. Drive the vehicle to the starting point of the distance range and stop.

4. Turn the Display Selector to the DISTANCE position and the Mode Select switch to the SET- UP mode. The console

will display the current Distance Calibration Number. Record this number for future reference. As an example, assume

this number is 1000.

2-9

CE & STANDARD VERSION

Page 20

98-05017

ARC 6000

Rev.- 1

5. Return the Mode Select switch to the OPERATE position and check to see that the accumulated distance is set at zero.

If not, reset it to zero using the INC/DEC switch.

6. Start driving. Drive the vehicle at a speed of between five and ten miles per hour. Distance measurements will start to

accumulate in the display.

7. Stop the vehicle at the end marker. The display will show the accumulated distance. Compare this distance to the actual

measured distance, to determine how much of a correction is necessary. For example, if an accumulated distance of 396

Ft. is shown after driving over a 400 foot range, the error in the distance calibration is 1.0%.

8. Calculate the new Distance Calibration Number using the following formula:

(Measured distance/Accumulated distance) x Old DC# = New DC#

Example: (400 / 396) x 1000 = 1010, the New DC#

NOTE: The same procedure is used, regardless of the type of distance sensor .

RECORD THE DISTANCE CALIBRATION NUMBER HERE: ______________

2.8. SETTING THE "HOLD/CLOSE" RESPONSE OF THE FLOW CONTROL VALVE

The operator can select a "Hold" or "Close" response of the Flow Control valve to both the Status switch and to an "All Booms

OFF" condition. These responses are independent of each other, allowing the operator to select a "Hold" condition for one and

a "Close" for the other. Careful consideration should be given to both conditions and the response selected for your application.

2.8.1. STATUS SWITCH

When the "Hold" condition is selected, turning off the Status switch will hold the Flow Control valve in its current position. The

valve will not close even though the vehicle speed may drop to zero. Then, when the Status switch is turned on the Flow Control

valve is already open and product flow is instantaneous. This response assumes that some other device has stopped the product

flow.

When the "Close" condition is selected, turning off the Status switch will automatically cause the Flow Control valve to close.

This response would be preferred when it is necessary to use the Flow Control valve to stop the product flow.

To select the desired response:

A. Set the console switches to the following positions:

Power ON

Mode Selector OPERATE

Display Selector TOTAL APPLIED

Boom Switches OFF

B. Hold the INC switch up to display the current response selected.

C. Continuing to hold the INC switch up causes the display to cycle between "Hold" and "Close" at about three second

intervals. The last option appearing in the display when the INC switch is released will be the response selected.

2.8.2. ALL BOOMS "OFF"

When the "Hold" condition is selected, all booms OFF will hold the Flow Control valve in its current position. The valve will

not close even though the vehicle speed may drop to zero. Then, when the booms are selected ON again the Flow Control valve

is already open and product flow is instantaneous.

When the "Close" condition is selected, all booms OFF will automatically cause the Flow Control valve to close. This response

would be preferred when it is necessary to use the Flow Control valve to positively stop the product flow.

CE & STANDARD VERSION

2-10

Page 21

ARC 6000

To select the desired response:

A. Set the console switches to the following positions:

Power ON

Mode Selector OPERATE

Display Selector IMPL WIDTH

Boom Switches OFF

B. Hold the INC switch up to display the current response selected.

C. Continuing to hold the INC switch up causes the display to cycle between "Hold" and "Close" at about three second

intervals. The last option appearing in the display when the INC switch is released will be the response selected.

2.9. SETTING THE GROUND SPEED OVERRIDE (GSO) VALUE.

With the Display Selector set to the Speed position in the SETUP Mode, the console will display the current Ground Speed

Override value. This value can be changed using the INC/DEC switch. If you intend to use this feature, set the value to the

minimum Ground Speed you want to control to when the GSO switch is activated. This should be the lowest speed at which the

sprayer will operate smoothly and provide a good nozzle pattern. If you do not intend to use this feature, set this value to zero (0.0).

CAUTION: This feature causes the product to be applied at a rate consistent with the GSO speed, not the true ground

speed. Serious over application can occur, if not used properly.

98-0501

Rev.- 1

2.10. SETTING THE FIELD AREA ALARM

Use the field area alarm to alert the operator as he accumulates specific area amounts. The console will flash and beep as each

area increment is accumulated.

An operator may use this feature to remind him to check his load to be certain it is disappearing at the correct rate. He also could

use this feature to double check acreage estimates.

A. Make sure all booms are OFF. Set the control console to the following switch settings:

Power ON

Mode Selector SETUP

Display Selector FIELD AREA

The display will now show the current selected acreage increments.

B. Use the INC/DEC switch to set the desired acreage increments.

C. Return the Mode Selector switch to OPERATE to apply.

2.11. PRODUCT VOLUME (FULL LOAD CAPACITY)

2.11.1. SETTING THE FULL LOAD CAPACITY

The full load capacity of the vehicle can be preset in the control console so that it can be recalled as the vehicle is reloaded.

A. Make sure all booms are OFF. Set the control console to the following switch settings:

Power ON

Mode Selector SETUP

Display Selector PRODUCT VOL.

The display will now show the current selected full load capacity.

2-11

CE & STANDARD VERSION

Page 22

98-05017

ARC 6000

Rev.- 1

B. Use the INC/DEC switch to set the desired full load capacity.

C. Return the Mode Selector switch to OPERATE to apply.

2.11.2. RECALLING THE FULL LOAD CAPACITY

Whenever PRODUCT VOL. is displayed in the OPERATE mode, the full load capacity of the vehicle can be recalled by

holding the INC switch up for at least three seconds.

2.11.3. SETTING A LOAD CAPACITY LESS THAN FULL LOAD

If a full load is not taken aboard the vehicle, the actual amount loaded can be set when PRODUCT VOL. is displayed in the

OPERATE mode by holding the DEC switch down (about three seconds) until the Product Vol. values start to decrease. Once

the numbers start to change, they can be set up or down using the INC/DEC switch until the actual load is displayed. Switching

out of the PRODUCT VOL. display will bring the control console back to normal operation.

2.12. SETTING AUTO POWER DOWN TIME

The console has an "Auto Power Down" feature which powers the console off after an operator selectable period (default is

30 min) has elapsed. If no input is received from the speed sensor or any console switch during this time the APD feature is

activated. The APD time can be set from 15 to 60 minutes. Selecting a period less than 15 minutes disables the APD feature.

A. Use the following switch settings to adjust the Auto Power down time:

Power OFF

Mode selector SET-UP

Display selector % Rate

Hold the INC switch UP while turning the power on

The display will show the current Auto Power Down time.

B. Select the desired time using the INC/DEC switch.

C. Exit this set-up mode by moving the Display Selector to another position, the Mode Selector to OPERATE, or

turning the console OFF and back ON.

NOTE: The “Auto Power Down Feature is only available on the CE version of the console (CE designation label on back of

console). If you have the standard console model always turn the console power off when not in use to prevent unnecessary

drain on the battery.

CE & STANDARD VERSION

2-12

Page 23

ARC 6000

3.0. OPERATION

Under normal operating conditions, the MIDWEST TECHNOLOGIES control system is automatic. The system will perform

precisely, according to the information and directions it has received from the operator. It is important to verify that the

control console has the proper instructions before beginning operations each day. It is also important that the switches are

operated properly to ensure accurate application of chemical.

3.1. NORMAL START UP AND OPERATION

A. CONSTANTS: With all external boom switches in the OFF position, check to ensure the proper constants are still

entered in the console. Refer to section 2.0. of this manual to review the procedure for entering these constants. It is a

good idea to write the constants down in a convenient location.

B. APPLICATION RATES: With all Boom switches in the OFF position and the Mode Selector switch in the OPERATE

position, review the application rate by selecting APPLICATION RATE on the display selector.

C. ACCUMULATED AREA: The accumulated acres can be reset to zero by selecting FIELD AREA or TO T AL AREA,

in the OPERATE mode, and holding the INC/DEC switch down until the display resets to zero. The area accumulators

can be zeroed independently to keep track of two separate areas.

D. ACCUMULATED VOLUME: Accumulated volume can be reset to zero by selecting TOTAL APPLIED while in the

OPERATE mode and using the DEC switch to reset. PRODUCT V OL. (the count down register) can be set for the

load aboard by using the procedures in section 2.12.

98-05017

Rev.- 1

E. Now, the Control System is ready to begin automated application. Set the Mode Selector switch to the OPERATE

position. Select an appropriate display using the Display Selector, “SCAN” for example.

F. Be sure the pumps and/or hydraulics are fully engaged.

G. Drive toward the area to be covered. Reaching that position, continue to drive in the direction of the first swath and

turn the desired Boom switches ON. The ARC will control application.

H. Upon reaching the end of the swath, turn the Boom switches to the OFF position to temporarily stop application.

When the vehicle has been turned and is ready to start applying on the next swath, turn the Boom switches to the ON

position and the controlled application will resume.

3.2. CHANGING ACTIVE BOOM SECTIONS

The active boom sections can be changed at any time by turning the appropriate Boom switches ON or OFF. The control

system, will automatically adjust flow rate as individual boom sections are activated or deactivated. When all the Boom

Section switches are OFF, the application will be stopped. This allows the operator to select active boom sections “On The

Go”, while depending on the control system to apply the proper rate on the area being covered.

3-1

CE & STANDARD VERSION

Page 24

98-05017

Rev.- 1

3.3. CHANGING APPLICATION RATE

The operator has chosen a desired application rate and entered this value into the control console using the procedure

outlined in Section 2.2. of this manual. Anticipating the need to increase or decrease the application rate, the operator has

also established a % rate change using the procedure described in Section 2.4. of the manual. As an example, assume the

control console has been set up to apply 10.0 gallons per acre with a % rate change set at 20%

During normal spraying, the control console will maintain the application rate at 10.0 gallons per acre. However, let’s

suppose the operator is spraying an aqueous fertilizer. A soil type change in the middle of the field requires a 40% higher

application in order to reach desired fertility levels. As the sprayer crosses into the new soil type, the operator selects %

RATE with the Display Selector. The display will show the percentage of the programmed application rate, in this case

100%. Pushing the INC/DEC switch up twice will increase the application rate by 2 X 20% or 40%. The display will show

140. The flow control valve will open until the flowmeter records 14.0 gallons per acre. None of the other control functions

of the console will be affected.

The new application rate will be maintained until a further movement of the INC/DEC switch commands additional change,

or a different position is selected with the Display Selector. When the Display Selector is turned to any other normal

position, the control console will control application rate according to the target rate established by the procedure in Section

2.3. of the manual. The % RATE will remain at the last setting so that the operator can switch back to % RATE and change

to the previously set changed rate without holding the INC/DEC switch. There is an approximate two second delay in initial

valve response after the operator has switched to % RATE so the rates don't change by mistake as the Display Selector is

turned through % RATE.

ARC 6000

Operation at a changed application rate is not a normal condition. The control console will only control at the

changed rate as long as the Display Selector is turned to % RATE.

3.4. PRIMING THE MAIN PUMP AND BOOM (LIQUID APPLICATION)

Use the following procedure to PRIME the main pump and boom lines prior to spraying (instructions unique to Pressure

Based operation are so noted).

A. Set the console switches to the following positions:

Power ON

Mode Selector OPERATE

Display Selector PRIME

B. A series of five dashes (- - - - - ) will appear on the display. If in Pressure Based mode the display will read "PSi" and

the current operating pressure.

C. Hold the INC/DEC switch up for about three seconds. The main control valve will open and remain in this position.

While operating in this mode, there will be no accumulation of area, distance or carrier.

D. The main pump can be run, with the booms or handgun open, to prime the sprayer. ARC will not try to shut down the

sprayer because it doesn't see any flow. The control valve will remain open.

E. Select any normal position of the Display Selector switch and the ARC system is ready to begin normal spraying. If in

Pressure Based mode, hold the DECREASE switch down for three to five seconds. The display should read "CLOSE"

and the valve will return to the position it was in before it was driven open. The console will resume reading "PSi".

CE & STANDARD VERSION

3-2

Page 25

ARC 6000

3.5. RAPID UNLOAD USING THE CONVEYOR (GRANULAR APPLICATION)

Use the following procedure to operate the spreader conveyor at maximum speed.