Page 1

854 Sprayer Control

USER MANUAL

Page 2

854 Sprayer Control

COPYRIGHTS

© 2010 TeeJet Technologies. All rights reserved.

No part of this document or the computer programs

described in it may be reproduced, copied,

photocopied, translated, or reduced in any form

or by any means, electronic or machine readable,

recording or otherwise, without prior written consent

from TeeJet Technologies.

TRADEMARKS

Unless otherwise noted, all other brand or product

names are trademarks or registered trademarks of

their respective companies or organizations.

LIMITATION OF LIABILITY

TEEJET TECHNOLOGIES PROVIDES THIS

MATERIAL “AS IS” WITHOUT WARRANTY OF

ANY KIND, EITHER EXPRESSED OR IMPLIED.

NO COPYRIGHT LIABILITY OR PATENT IS

ASSUMED. IN NO EVENT SHALL TEEJET

TECHNOLOGIES BE LIABLE FOR ANY LOSS

OF BUSINESS, LOSS OF PROFIT, LOSS OF

USE OR DATA, INTERRUPTION OF BUSINESS,

OR FOR INDIRECT, SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES OF ANY KIND,

EVEN IF TEEJET TECHNOLOGIES HAS BEEN

ADVISED OF SUCH DAMAGES ARISING FROM

TEEJET TECHNOLOGIES SOFTWARE

Table of Contents

COPYRIGHTS ..........................................................................................................................................................I

TRADEMARKS ........................................................................................................................................................I

LIMITATION OF LIABILITY ................................................................................................................................. I

CHAPTER 1 - INTRODUCTION ....................................................................1

Power On the Console _______________________________________________ 2

Power O the Console _______________________________________________ 2

CHAPTER 2 - OEM PROGRAM MODE .........................................................3

Number of Boom Section Switches On the Console ________________________ 3

Lane Width (GLM Working Units) _______________________________________ 3

Regulation Parameters _______________________________________________ 4

Minimum Regulating Valve Voltage _______________________________________ 4

Regulation Stop Band ________________________________________________ 4

Rotation Time of Regulating Valve ______________________________________ 5

Display Stabilization _________________________________________________ 6

Data Display Screen Options __________________________________________ 6

Calibrate Tip Level Percent ____________________________________________ 6

Digital Output #2 ____________________________________________________ 7

Dual Boom Regulation Mode __________________________________________ 8

Fill Valve Default ____________________________________________________ 8

Auto Power Down ___________________________________________________ 9

www.teejet.com

i

Page 3

854 Sprayer Control

TEEJET COMMUNICATION SYSTEM TCS CONFIGURATION ............................................................9

Job Operating System _______________________________________________ 9

Console Identication Number _______________________________________ 10

Maximum Speed Achieved ___________________________________________ 10

Hidden Area Counter _______________________________________________ 10

Hidden Volume Counter _____________________________________________ 10

PRESSURE TRANSDUCER CALIBRATION P HI ..................................................................................... 11

Memory Save Function ______________________________________________ 12

CHAPTER 3 - SYSTEM SETUP MODE ....................................................... 13

Selection of Working Units ___________________________________________ 13

Reset to Defaults ___________________________________________________ 13

Speed Sensor Calibration ____________________________________________ 14

Proximity/Magnetic Pulses _____________________________________________ 14

Automatic Calibration _________________________________________________ 14

Distance Counter ___________________________________________________ 15

Pressure Hold______________________________________________________ 15

Pressure Sensor Installed ____________________________________________ 16

Pressure Transducer Low Pressure Calibration (P Ref) ______________________ 16

Automatic Calibration _________________________________________________ 16

Pressure Transducer Maximum Rating (P HI) _____________________________ 17

Flow Meter Installed ________________________________________________ 17

Flow Meter Pulses __________________________________________________ 18

Manual Entry ________________________________________________________ 18

Automatic Calibration _________________________________________________ 18

Flow Sensor Minimum Flow Capacity __________________________________ 19

Sensor Selection ___________________________________________________ 20

Section Valve Type __________________________________________________ 20

Pressure Regulating Mode ___________________________________________ 21

Regulating Valve Capacity ___________________________________________ 22

Regulating Valve Speed - Coarse Adjustment ____________________________ 22

Regulating Valve Speed - Fine Adjustment ______________________________ 23

Tank Volume ______________________________________________________ 23

Low Tank Volume Alarm _____________________________________________ 24

Fill Flow Meter Calibration ___________________________________________ 24

Manual Entry ________________________________________________________ 24

Automatic Calibration _________________________________________________ 24

Communications ___________________________________________________ 26

Printing Memory Contents _____________________________________________ 26

Using GPS __________________________________________________________ 27

ii

www.teejet.com

Page 4

854 Sprayer Control

Communicating With a Laptop Running Fieldware Software _________________ 27

Logging Information to a Laptop running Logging Software _________________ 28

GPS Speed ________________________________________________________ 28

Use External Rate __________________________________________________ 28

Simulated Ground Speed ____________________________________________ 29

Low Speed __________________________________________________________ 29

High Speed __________________________________________________________ 29

Auto Master O - Speed _____________________________________________ 30

Minimum Pressure Setting ___________________________________________ 30

Maximum Pressure Setting ___________________________________________ 30

Audible Alarm _____________________________________________________ 31

Dual Boom On Setting ______________________________________________ 31

Memory Reload Function ____________________________________________ 32

CHAPTER 4 - APPLICATION PRESET SETUP MODE ............................... 33

Tip Spacing _______________________________________________________ 33

Number of Tips Per Boom Section _____________________________________ 34

Density ___________________________________________________________ 34

Alternate Density Used ________________________________________________ 34

Density Value ________________________________________________________ 34

Tip Selection ______________________________________________________ 35

Target Application Rate _____________________________________________ 35

Calculation Steps ___________________________________________________ 36

Known Pressure Calculation ___________________________________________ 36

Known Speed Calculation ______________________________________________ 36

CHAPTER 5 - OPERATIONS ...................................................................... 37

Sprayer Evaluation _________________________________________________ 37

Spraying __________________________________________________________ 38

CHAPTER 6 - FEATURES ........................................................................... 39

Area/Volume Display________________________________________________ 39

Memory Feature ___________________________________________________ 40

Viewing Memory Information ___________________________________________ 40

Clearing Memory Locations ____________________________________________ 40

Saving Information to Memory __________________________________________ 40

Tank Feature ______________________________________________________ 41

Auto Tank Filling _____________________________________________________ 41

Tank Volume Feature __________________________________________________ 42

Viewing Remaining Tank Volume ______________________________________ 42

Resetting Tank Volume _____________________________________________ 42

www.teejet.com

iii

Page 5

854 Sprayer Control

Application Alarm __________________________________________________ 42

Sensor LED Alarms _________________________________________________ 43

No Speed Alarm ______________________________________________________ 43

No Flow Alarm _______________________________________________________ 43

No Pressure Alarm____________________________________________________ 44

Flow/Pressure Discrepancy Alarm _______________________________________ 44

Boost Mode _______________________________________________________ 44

Boost Up ____________________________________________________________ 44

Boost Down _________________________________________________________ 45

Auto Power Down __________________________________________________ 45

Smart Sensing _____________________________________________________ 45

iv

www.teejet.com

Page 6

854 Sprayer Control

CHAPTER 1 - INTRODUCTION

This User Guide provides information for software version 1.20.

Make sure that all hardware components are properly installed and tested. Before starting the programming

process, conrm that the console and all sensors are working properly.

IMPORTANT! Before beginning, review the

following Program Guidelines that control the

programming process.

To exit any Setup Mode, press and hold the

PROGRAM key for 3 seconds. The inputs are

stored and the computer will exit Program Mode.

To increase the value of a programmable digit, press

the PLUS key. To decrease the value, press the

MINUS key. These keys are located directly to

the right of the display. For some program steps,

press and hold the PLUS and MINUS keys to

quickly change the values. Press the PLUS and

MINUS keys once to increment/decrement the

values by one unit.

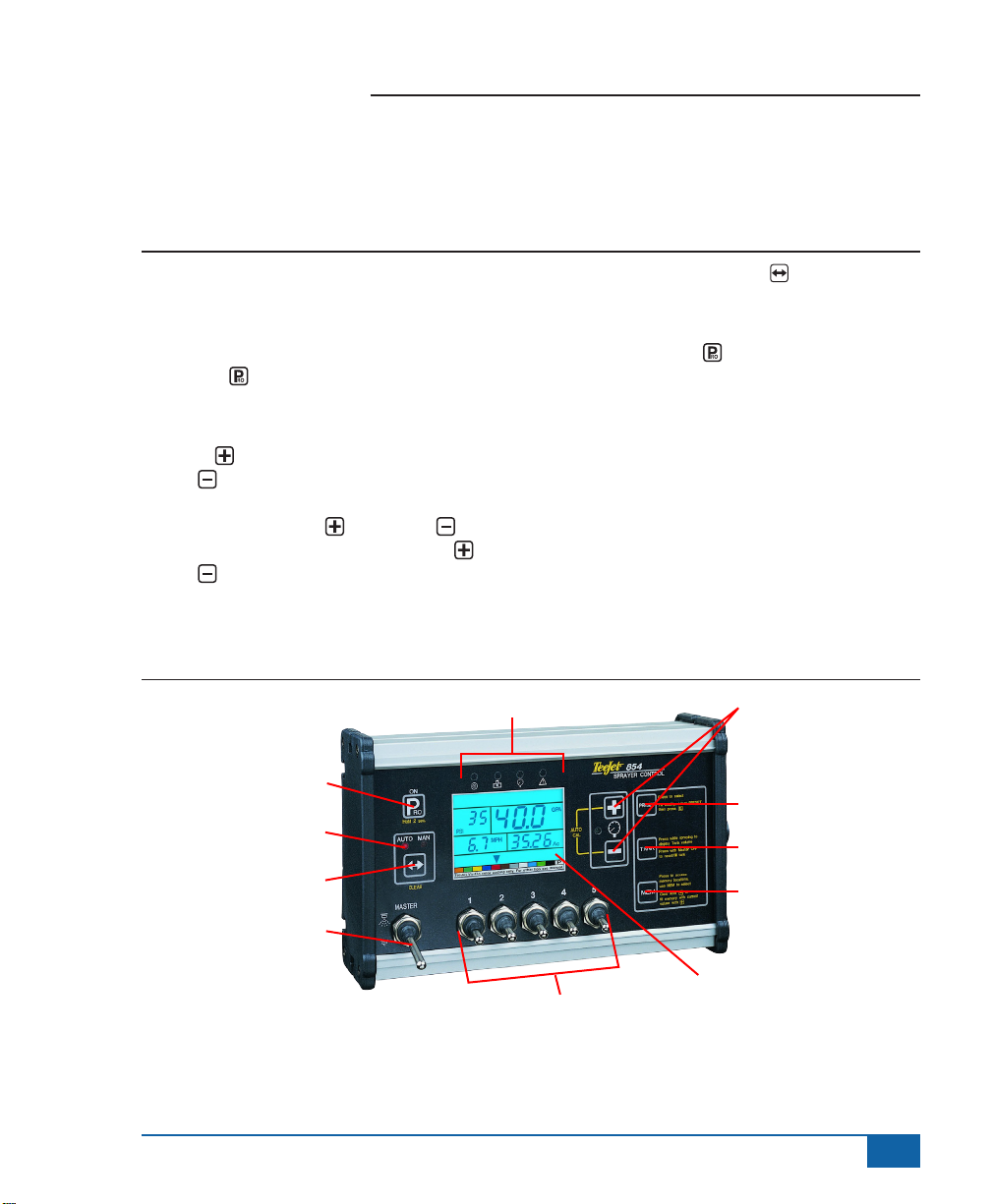

Figure 2-1: 854 Console

Sensor LED Alarms

On/Program button

Auto/Manual mode indicator

Auto/Man key

Press and hold the AUTO/MAN key to reset the

value to “0” or restore factory default settings during

some steps.

Press the PROGRAM key to advance the system

to the next program step. After the nal program step

is complete, the console will nish the programming

loop and return to the initial programming step.

System Setup mode contains the options that

customize the controller to the sprayer or sprayer

components. These include calibration steps and

parameters that seldom change once programmed.

Application Setup mode contains settings that are

frequently changed (tip spacing, number of tips per

boom section, density, nozzles used, and target

application rate).

Plus and Minus keys

Preset key

Tank key

Memory key

Master Switch

Boom Section Controls

Display

www.teejet.com

1

Page 7

854 Sprayer Control

Power On the Console

The 854 console can be powered on by pressing

the PROGRAM key one time. The console will

initially display the software version at the top of

the screen and the serial number of the console

at the bottom of the screen. After approximately

5 seconds, the console will enter into swath width

view.

Press the PROGRAM key to advance to normal

Operations mode.

Figure 2-2: Power On the Console

SFt

H28

1.20

0008

Power O the Console

To power off the 854 console, press and release the

MINUS and PROGRAM keys simultaneously.

The console will save new information (area and

volume counters) to memory before it powers down.

The console also has an automatic power down

feature. This is described in further detail in the

Features section of this User Guide.

Figure 2-3: Power Off the Console

2

www.teejet.com

Page 8

854 Sprayer Control

CHAPTER 2 - OEM PROGRAM MODE

The OEM Program Mode contains conguration steps for the console. The console is typically pre-congured

before being shipped. Changing the congurations is not recommended unless instructed to do so as it may

adversely affect the performance of the controller.

• To enter the OEM Program Mode:

• Begin with the console powered “Off”.

• Press the MINUS key and the PROGRAM

key simultaneously to turn the console “Off”

if required.

• Press and hold the PLUS and MINUS

keys. While still holding them, press the

PROGRAM key 4 times.

• Release all keys.

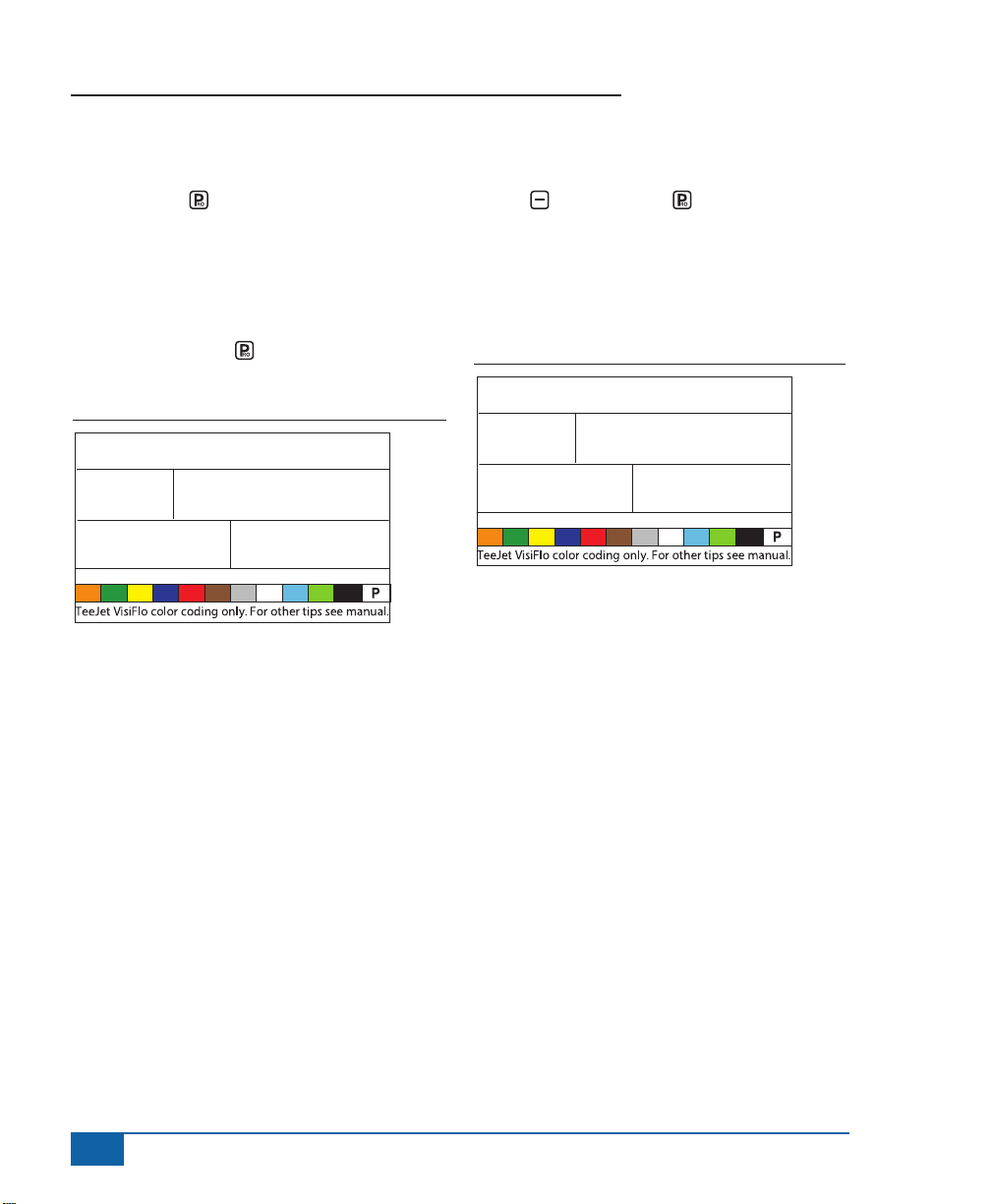

Figure 3-1: Entering OEM Program Mode

nr

5

• Press and hold the AUTO/MAN key for 3

seconds to set the value to “1”.

• Press the AUTO/MAN key once to reset the

value to the default value of “5”.

• Press the PROGRAM key to accept the

value and advance to the next program step.

Lane Width (GLM Working Units)

When Gallons per Lane Mile “GLM” is selected as

the working units, this screen will allow the operator

to enter the lane width in inches.

• Use the PLUS or MINUS keys to modify

the value.

• Press the Program key to accept the value

and advance to the next program step.

SEC

Number of Boom Section

Switches On the Console

The number of individual boom section switches

actually present on the control console (regardless

of the number of boom sections that are on the

sprayer) can be programmed.

• Use the PLUS or MINUS keys to modify

the value.

• 1 to 11 switches can be programmed.

• This number will determine the number of spray

tips per boom section during the System Setup

Mode.

Figure 3-2:

Lane Width (GLM Working Units) Window

144

www.teejet.com

3

Page 9

854 Sprayer Control

Regulation Parameters

The regulation algorithm is congured with the next

three parameters:

1. Minimum Regulating Valve Voltage: the

minimum voltage that can drive the regulating

valve.

2. Regulation Stop Band: the maximum allowed

application error rate.

3. Rotation Time of Regulating Valve: the total

time required to close the regulating valve at

maximum speed.

These three OEM parameters depend on the

regulating valve used.

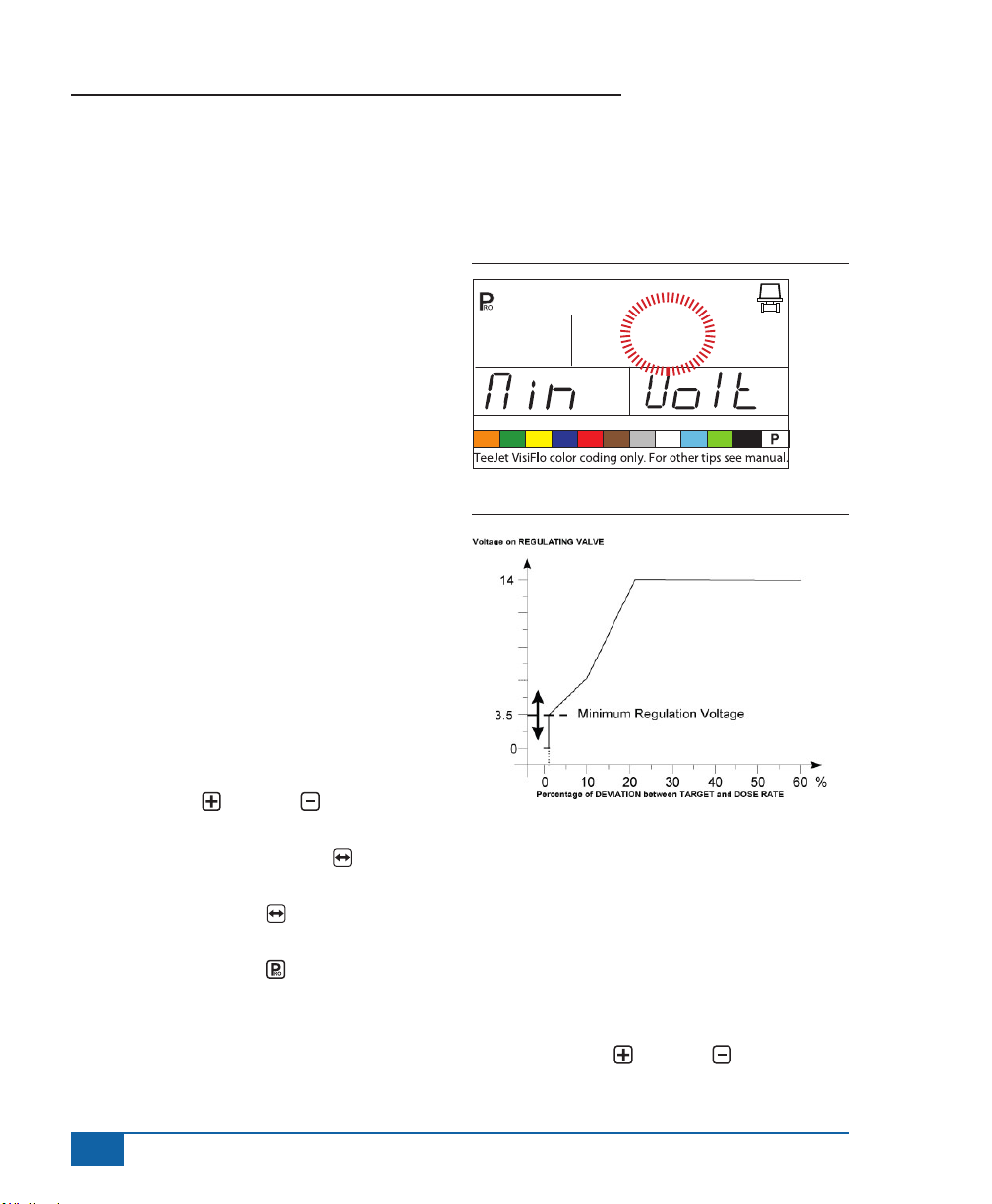

Minimum Regulating Valve Voltage

The console uses variable voltages to drive the

regulating valve. Select the minimum voltage that

the regulating valve needs to make it turn at its

slowest rotation speed (i.e., if the motor of the

regulating valve turns with a minimum of 3.5v, the

number should be used in this location).

The affect of this parameter on the regulation

behavior is illustrated in Figure 2-4. This value must

match the actual operation of the regulating valve

used. Check with the valve manufacturer for the

value.

• Use the Plus or MINUS keys to change

the voltage.

• Press and hold the AUTO/MAN key for 3

seconds to set the value to “0.0”.

• Press the AUTO/MAN key once to set to the

default value of 3.5v.

• Press the PROGRAM key to accept the

value and advance to the next program step.

NOTE: Standard TeeJet Technologies regulating

valve minimum voltage is 3.5v.

If 12v is selected as a minimum voltage, no variable

voltage regulation occurs. Instead, a pulse regulation

occurs. This is necessary when using solenoid

operated regulating valves (i.e., a Ramsay valve).

Figure 3-3: Minimum Regulating Valve Voltage

rE6

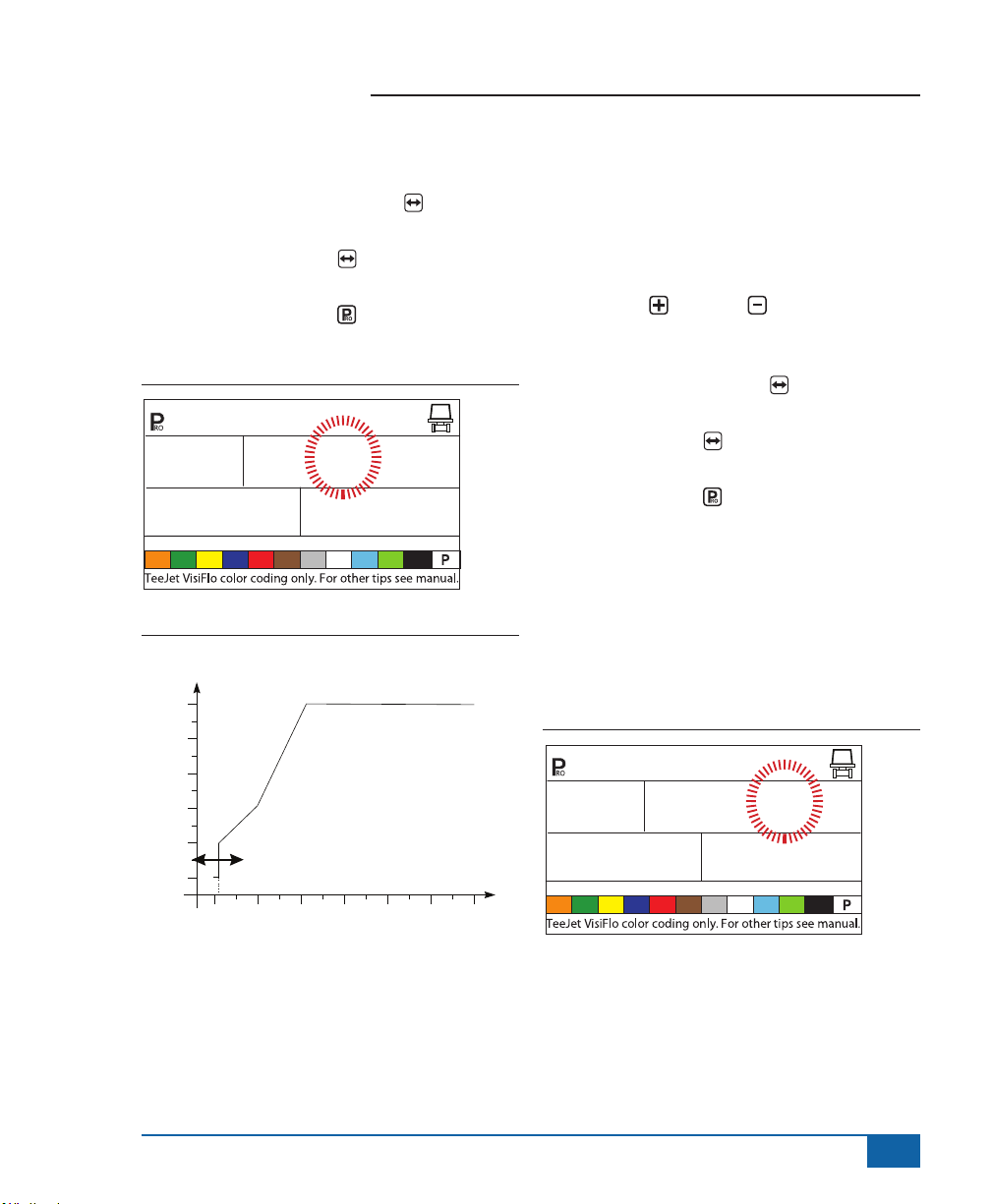

Figure 3-4: Voltage Comparison

3.5

Regulation Stop Band

The Regulation Stop Band is the maximum error

percentage allowed on the application rate before

the regulating valve reacts (i.e., if a stop band of

1.5% is selected, there is no action on the regulating

valve if the actual application rate is within 1.5% of

the target rate). This minimum percentage prevents

the regulating valve from oscillating in a narrow band

around the target point.

• Use the PLUS or MINUS keys to change

the regulation stop band (value is expressed

4

www.teejet.com

Page 10

854 Sprayer Control

0102030405060 %

V

in error percentage). The maximum value is

10.0%.

• Press and hold the AUTO/MAN key for 3

seconds to set the value to “0.0”.

• Press the AUTO/MAN key once to set the

value to the default setting of “1.5%”.

• Press the PROGRAM key to accept the

value and advance to the next program step.

Figure 3-5: Regulation Stop Band

rE6

STP

Figure 3-6: Effects of Parameters

oltage on REGULATING VALVE

14

1.5

BAnd

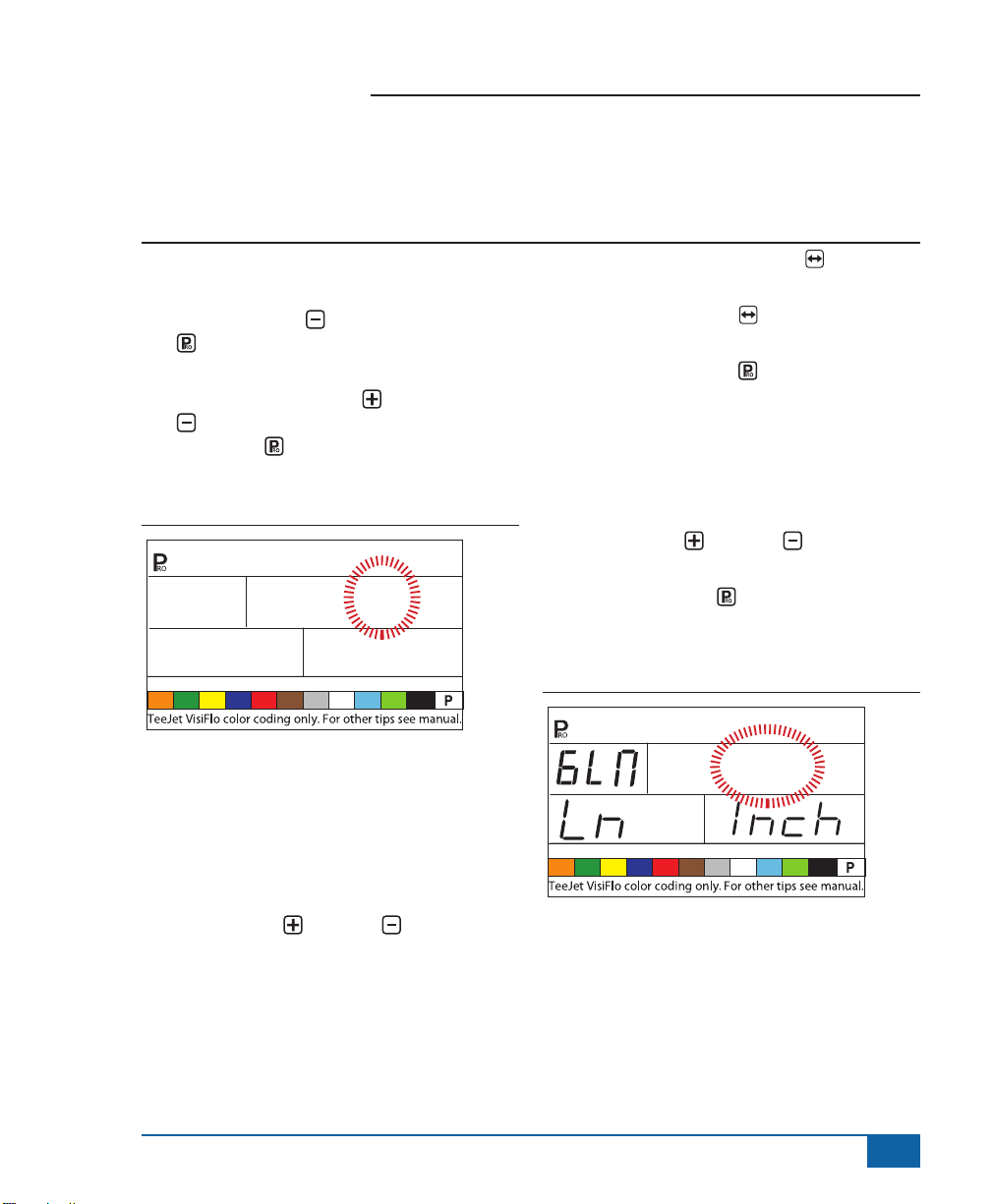

Rotation Time of Regulating

Valve

The Rotation Time of Regulating Valve is the number

of seconds the regulating valve needs to turn from

the complete closed position to the complete open

position at the nominal voltage (i.e., 14v).

Use the PLUS or MINUS keys to change

the rotating time of the regulating valve in seconds

(minimum “0’s”, maximum “50’s”).

Press and hold the AUTO/MAN key for 3 seconds

to set the value to “0.0”.

Press the AUTO/MAN key once to set the value

to the default setting of “6 seconds”.

Press the PROGRAM key to accept the value

and advance to the next program step.

NOTE: Standard TeeJet regulating valve rotation

time is 6 seconds.

The console uses this parameter to control the

regulation speed. The value must match the actual

operation of the regulating valve used. Check with

the valve manufacturer for this value.

Figure 3-7: Rotation Time of Regulating Valve

0

Regulation Stop Band

Percentage of DEVIATION between TARGET and DOSE RATE

rE6

SPd

6

SEC

www.teejet.com

5

Page 11

854 Sprayer Control

Display Stabilization

Display Stabilization establishes the stabilization

rate that steadies the Application Rate displayed

during minor adjustments of the control system.

The controller will continue to make the required

adjustments at all times. Enter the percentage of

allowable change from the target rate in this step.

For example, the system has a target rate of 20 GPA

with 5% programmed for Display Stabilization. The

display will indicate 20 GPA at any time the actual

rate is +/- 5%, or:

• Use the PLUS or MINUS keys to change

the value.

• Press and hold the AUTO/MAN key for 3

seconds to set the value to “0.0”.

• Press the AUTO/MAN key once to set the

value to the default setting of “5%”.

• Press the PROGRAM key to accept the

value and advance to the next program step.

NOTE: The Display Stabilization value is limited to

20%. A value of 0% will disable the setting.

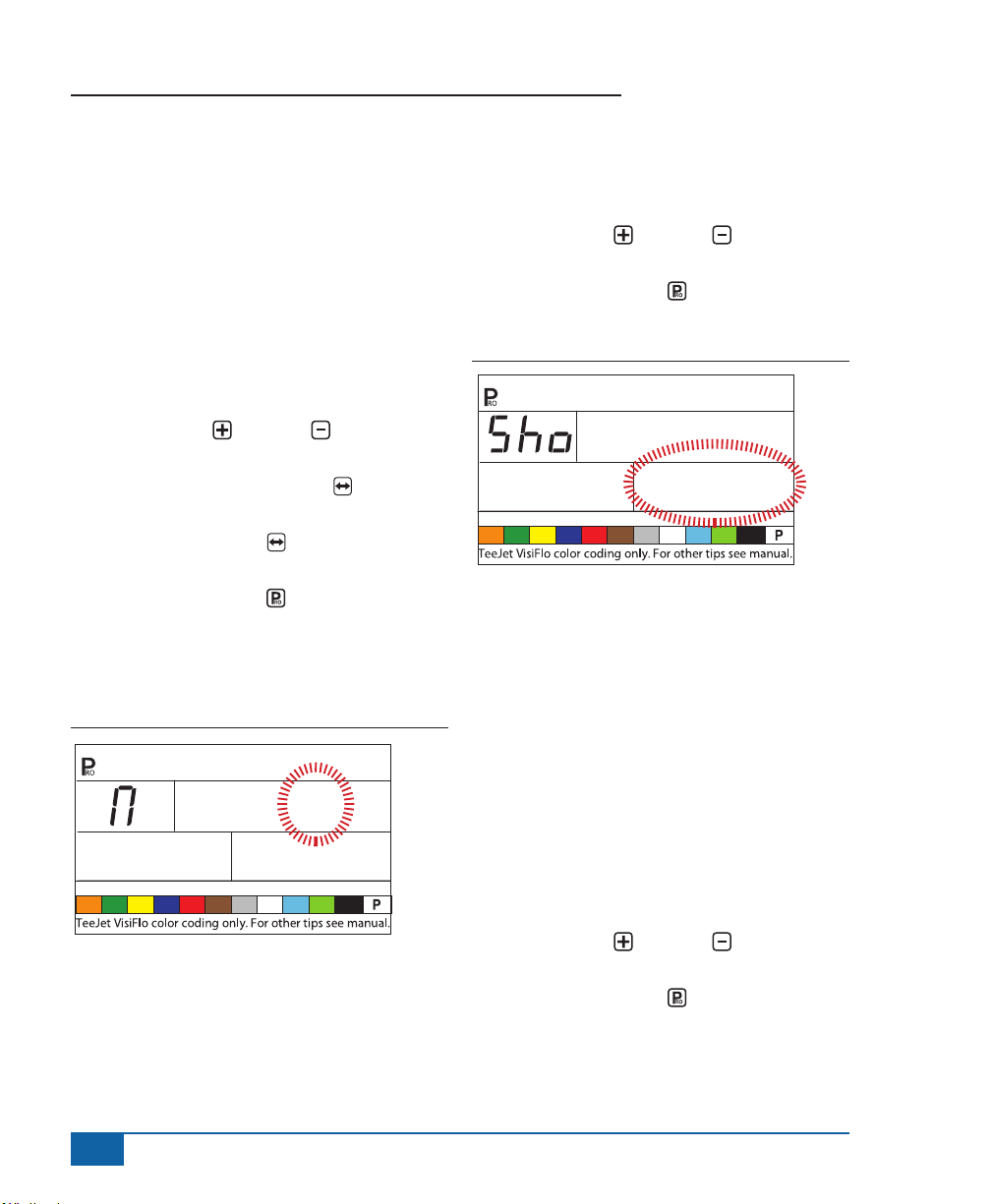

Figure 3-8: Display Stabilization

s O

diS

5

rAtE

Data Display Screen Options

The lower right hand display used during normal

operations mode can be customized to display:

• volume sprayed

• area covered

• both volume sprayed and area covered

(alternating every 3 seconds)

To customize the data display options:

• Use the PLUS or MINUS keys to change

the data to be displayed.

• Press the PROGRAM key to accept the

value and advance to the next program step.

Figure 3-9: Data Display Screen

dAt bOth

Calibrate Tip Level Percent

If both a pressure sensor and a ow meter are

installed and being used, the 854 uses one sensor to

cross check the other for system errors.

Select the primary sensor (used for regulation) in

the Sensor Select step of System Setup Mode. The

opposite sensor will automatically perform the crosschecking function.

The Calibrate Tip Level % will establish the % of

allowable error between the sensors before an

alarm is activated. All sprayer systems have some

discrepancy between pressure and ow due to

pressure drops and positioning of sensors.

• Use the PLUS or MINUS keys to change

the % of allowable error.

• Press the PROGRAM key to accept the

value and advance to the next program step.

NOTE: It is recommended that this value remain at

50% unless instructed otherwise.

6

www.teejet.com

Page 12

854 Sprayer Control

Figure 3-10: Calibrate Tip Level %

CAL

50

tIP LEv

Digital Output #2

The primary output from the console computer

drives the pressure regulating valve. A second

output is available and can be congured for the

following uses:

• Not Used - the second digital output is not used

• Dual Boom - used to control a shutoff valve

on a second boom line that is automatically

activated based on speed and pressure

• Fill Valve - used to automatically shut off a

valve or switch during a tank lling operation

when used with a tank ll ow meter

To establish the Digital Output settings:

• Use the PLUS or MINUS keys to change

the value.

• Press the PROGRAM key to accept the

value and advance to the next program step.

Figure 3-11: Digital Output # 2a

Out

nOT

Out

dUA

Out

FiL

2

USEd

2

bOOn

2

vALV

www.teejet.com

7

Page 13

854 Sprayer Control

db

SPd

re6

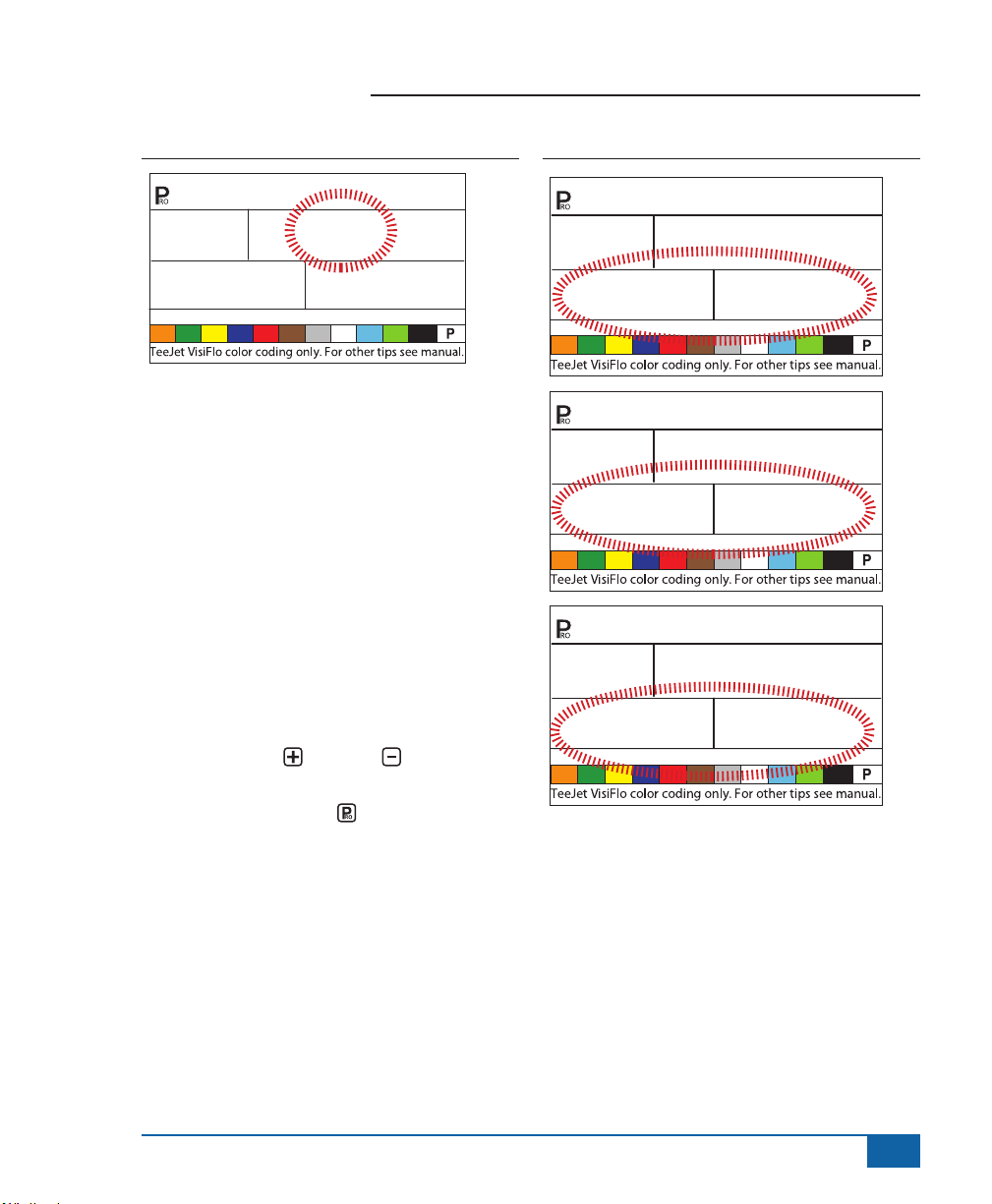

Dual Boom Regulation Mode

NOTE: This step will only be displayed if “Dual

Boom” was selected during the DIGITAL

OUTPUT #2 step.

Dual Boom Regulation Mode is used to regulate

the dual boom feature by either speed (SPD) or

pressure (PRS).

If speed is used to regulate the mode, when the

vehicle reaches the designated speed, the second

boom line will turn On/Off.

If pressure is used to regulate the mode, when

the pressure reaches the designated amount, the

second boom line will turn On/Off.

• Use the PLUS or MINUS keys to change

the value.

• Press the PROGRAM key to accept the

value and advance to the next program step.

The value selected will determine how programming

steps appear during System Setup Mode. Specic

speed or pressure values to be used during

operation are selected during the System Setup

Mode.

Figure 3-12: Dual Boom Regulation Mode - Speed

Figure 3-13: Dual Boom Regulation Mode - Pressure

db

PrS

re6

Fill Valve Default

NOTE: This step will only be displayed if “Dual

Boom” was selected during the DIGITAL

OUTPUT #2 step.

The Fill Valve Default establishes the normal

operating state of the ll valve being used. If the ll

valve requires a +12v signal during the spraying

operation, the valve default is “On”. If the ll valve

requires a +12v signal during the lling operation,

the valve default is “Off”.

• Use the PLUS or MINUS keys to change

the value.

• Press the PROGRAM key to accept the

value and advance to the next program step.

8

db

re6

www.teejet.com

SPd

Figure 3-14: Fill Valve Default

FiL

OFF

OUt

dFLt

Page 14

854 Sprayer Control

Auto Power Down

The 854 console is designed to automatically power

down after 10 minutes of inactivity from the sensor

or operator. To adjust the length of time:

• Use the PLUS or MINUS keys to change

the value of the power down time.

• Press the PROGRAM key to accept the

value and advance to the next program step.

NOTE: If the Power Down Time is set to “0”, the

Auto Power Down feature will be disabled.

Figure 3-15: Auto Power Down

Pur

10

Off

TEEJET COMMUNICATION

SYSTEM TCS CONFIGURATION

NOTE: If the TeeJet Communication System (TCS)

package was not purchased for this console,

the next 2 programming steps DO NOT

pertain to your spraying operation. IF THIS

IS THE CASE, THESE VALUES SHOULD

BE LEFT AT THE DEFAULT SETTINGS.

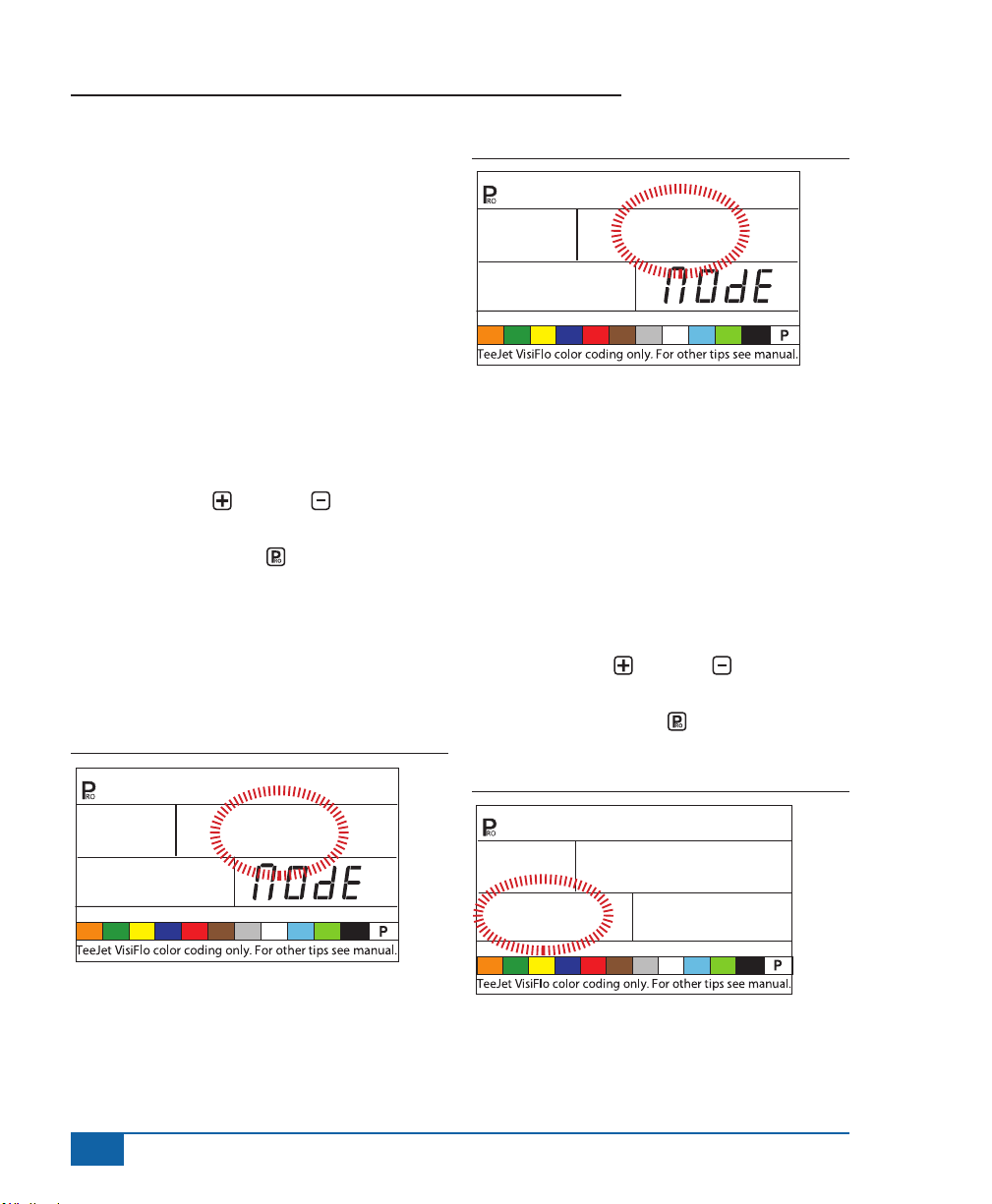

Job Operating System

• Job No (Default) - the console uses application

parameters entered by the operator only

• Job Only - the console uses application

parameters entered from the TeeJet

Communication System only

• Job Both - the console accepts application

parameters for both the operator and the TeeJet

Communication System

To establish the Job Operating System settings:

• Use the PLUS or MINUS keys to change

the value.

• Press the PROGRAM key to accept the

value and advance to the next program step.

Figure 3-16: Job Operating System

JOb

www.teejet.com

9

Page 15

854 Sprayer Control

Console Identication Number

The TeeJet Communications System (TCS) is

capable of monitoring and communicating with

several consoles at one time. Therefore each

console communicating with a single TCS must

be assigned a unique identication number. THE

DEFAULT NUMBER IS “1”.

• Use the PLUS or MINUS keys to change

the value.

• Press the PROGRAM key to accept the

value and advance to the next step.

Figure 3-17: Console Identification Number

1

Id

Maximum Speed Achieved

The Maximum Speed Achieved feature records the

maximum speed achieved by the sprayer. This value

can only be cleared by an authorized TeeJet Dealer,

Distributor, or Representative.

• Press the PROGRAM key to advance to the

next step.

Figure 3-18: Maximum Speed Achieved

Hidden Area Counter

The Hidden Area Counter can only be viewed and

cleared during this step. This value can only be

cleared by an authorized TeeJet Dealer, Distributor,

or Representative.

• Press the PROGRAM key to advance to the

next step.

Figure 3-19: Hidden Area Counter

Ar

1480

Hidden Volume Counter

The Hidden Volume Counter can only be viewed

and cleared during this step. This value can only be

cleared by an authorized TeeJet Dealer, Distributor,

or Representative.

• Press the PROGRAM key to advance to the

next step.

Figure 3-20: Hidden Volume Counter

Ac

uOL

Vol

4630

5.3

10

SPd

MPH

High

www.teejet.com

Page 16

854 Sprayer Control

PRESSURE TRANSDUCER

CALIBRATION P HI

NOTE: This step may not appear if the console has

not been programmed during System Setup

Mode for use with a pressure sensor.

WARNING! It is not recommended that this

calibration procedure be initially performed.

It should ONLY be performed if a known

pressure drop exists between the Pressure

Transducer and the spray tips and if a TeeJet

representative recommends performing it.

The pressure sensor can be automatically calibrated

to compensate for pressure loss between the

pressure transducer and the spray tips.

• Press and hold the PLUS and MINUS

keys to start the Auto Calibration process. The

lower left hand screen will go blank.

• Place an accurate manual pressure gauge in

the spray line, as close to the spray tips as

possible.

• Activate the pump and boom sections to be

used for calibration.

• Turn the Master Switch to the “On” position.

• Press the PLUS or MINUS keys to adjust

the pressure on the manual pressure gauge

near the tips to the desired pressure to be used

for the calibration. The higher the pressure the

better.

• Turn the Master Switch to the “Off” position.

• Use the PLUS or MINUS keys to adjust

the displayed pressure to match the actual

calibration pressure.

• Activate the pump and boom sections to be

used for calibration.

• Conrm that the actual pressure matches the

displayed pressure.

• Press the PROGRAM key to begin

calibration.

• The console will display “0-10” during the

calibration process.

• The new Pressure Transducer Maximum Rating

will be displayed. The value is automatically

carried over to the System Setup Mode.

• Press the PROGRAM key to advance to the

next step.

Figure 3-21: Pressure Transducer Calibration

145

PSI

PrS

75

PSI

PHi

SenS

16.2

206

www.teejet.com

11

Page 17

854 Sprayer Control

Figure 3-22: Memory Save Function

112

PSI

1-10

112

PSI

PrS

Memory Save Function

The Memory Save Function allows for a custom

set of programming parameters. Typically, this is

performed after all three programming sections have

been completed for the console.

Select “Yes” to save all program settings to memory.

These settings can be recalled in the System Setup

Mode during the Mem Load function.

This function is typically used to get the console

back to the starting point after unknown changes

have been made to the program modes.

• Use the PLUS or MINUS keys to select

either “Yes” or “No”.

• Press the PROGRAM key to accept the

value and advance to the next step.

PHi

SenS

PHi

SEnS

SAvE

yes

SAvE

The OEM Programming Mode of the 854 is now

complete. Press the PROGRAM key to return to

the beginning step of the process. Press and hold

the PROGRAM key to exit and save the OEM

Setup Mode. This can be performed at any time

during OEM programming. The console will exit the

OEM programming and return to normal operations.

12

www.teejet.com

Page 18

854 Sprayer Control

CHAPTER 3 - SYSTEM SETUP MODE

The System Setup Mode contains the programming steps that customize the controller to the sprayer

components. These include the calibration steps and parameters that seldom change once programmed.

To enter into System Setup Mode, power on the unit. Press and hold the PROGRAM key for 3 seconds

while in operating mode.

Selection of Working Units

The 854 is capable of working in units of:

• US (US Gallons Per Acre)

• TRF (Turf) (US Gallons/1000 ft2)

• IMP (Imperial Gallons Per Acre)

• NH3 (Pounds of N per Acre)

• GLM (US Gallons Per Lane Mile)

• SI (Metric Liters Per Hectare)

To establish the selection of working units:

• Press the PLUS or MINUS keys to select

the appropriate units.

• Press the PROGRAM key to accept the

value and advance to the next program step.

Figure 4-1: Selection of Working Units

US

vnit

Reset to Defaults

NOTE: If no changes were made to the units, this

step is skipped and setup will automatically

advance to the Speed Sensor Calibration

Step.

If changes have been made to the units during the

rst programing step, the console will inquire if all

the program parameters should be reset to the

defaults specied for the units chosen.

• Press the PLUS or MINUS keys to select

either “Yes” or “No”.

• Press the PROGRAM key to accept the

value and advance to the next program step.

Figure 4-2: Reset Defaults

res

uS

YES

dFLt

www.teejet.com

13

Page 19

854 Sprayer Control

Speed Sensor Calibration

NOTE: During Speed Sensor Calibration, the 854

automatically senses whether a Wheel

Speed or Radar Speed Sensor is being

used.

Proximity/Magnetic Pulses

The speed sensor must be calibrated to provide the

proper speed and area readings. The value for this

step is the number of pulses generated by the speed

sensor in 300 feet (100 meters).

Figure 4-3: Proximity/Magnetic Pulses

Spd

CAL

250

Automatic Calibration

NOTES: When the Automatic Calibration Mode is

activated, “CAL” is displayed on the lower

right of the display.

It is best to perform the automatic speed

calibration process at least twice and use the

average of the speed calibration numbers.

The auto speed calibration process should

take place with the sprayer tank 1/2 full.

• Mark off a distance of exactly 300 feet (100

meters).

• Press and hold the PLUS and MINUS

keys simultaneously for 3 seconds to activate

the auto calibration mode.

• Start driving toward the start point of the 300

feet (100 meter) course.

• As the starting point is crossed, press the PLUS

keys once to begin the calibration process.

• The 854 will count the pulses generated while

the course is driven.

• As the ending point is crossed, press the PLUS

key once. The number displayed on the

screen is the speed calibration number.

• If the console determines that a radar speed

sensor is connected, it will display “rAd” on the

lower left part of the display.

Figure 4-4: Automatic Calibration

CAl

Once the calibration number has been determined, it

must be entered into the console.

• Press the PROGRAM and PLUS keys

simultaneously to put the console into Radar

Mode. When the control console is in Radar

Mode, it will display “rAd” in the lower part of

the console display.

• Use the PLUS or MINUS keys to adjust

the value.

• Pressing the AUTO/MAN key will reset the

speed calibration to the default value.

• Once the correct vale has been entered, press

the PROGRAM key to validate the value and

advance to the next step.

14

www.teejet.com

Page 20

854 Sprayer Control

NOTE: When the Automatic Calibration Mode is

activated, no other functions are possible

until the console receives pulses for

calibration. To deactivate the Automatic

Calibration Mode, press the Plus key

until a number is displayed.

Figure 4-5: Radar Calibration

SPd CAL

rAd

Distance Counter

The Distance Counter feature is not a calibration

step. No specic value must be entered here for

the controller to operate correctly. This feature

measures distance in feet (meters). It can be used

to conrm Automatic Speed Calibration.

• To activate the counter, turn the Master Boom

Switch “On”.

NOTE: To avoid spraying during this process,

toggle the individual boom sections “Off”.

• To stop the counter, turn the Master Boom

Switch “Off”.

• To clear an existing distance value, press and

hold the AUTO/MAN key for 3 seconds.

1000

at the finish point. The distance measured

should be 300 feet (100 meters) (+/- 6 feet)

(+/- 1.8 meters).

Figure 4-6: Distance Counter

dst

Ctr

ft

456

Pressure Hold

NOTE: This step will appear if “GLN” was selected

for Working Units instead of Pressure

Sensor.

The Pressure Hold setting will determine whether

the sprayer will hold a constant pressure, regardless

of ground speed, or adjust to pressure according to

ground speed.

• Use the PLUS or MINUS keys to select

“Off” or “On”.

• Select “Off” to have the sprayer hold a constant

pressure.

• Select “On” to have the sprayer adjust the

pressure according to ground speed.

• Press the PROGRAM key to accept the

value and advance to the next step.

NOTE: To confirm Automatic Speed Calibration,

first complete the calibration procedure.

Advance to the Distance Counter step.

Drive the vehicle across the same 300 feet

(100 meters) course, turning the Master

Switch “On” at the starting point and “Off”

www.teejet.com

15

Page 21

854 Sprayer Control

Figure 4-7: Pressure Hold

Off

PrS

Pressure Sensor Installed

NOTE: If “No” is selected in this step, the next

two screens/steps in this User Guide will

not be displayed on the console during

programming.

The Pressure Sensor Installed step indicates to the

console whether or not a pressure sensor has been

installed on the sprayer.

• Use the PLUS or MINUS keys to select

“Yes” or “No”.

• Select “Yes” if a pressure transducer is

installed.

• Select “No” if a pressure transducer is not being

used.

• Press the PROGRAM key to accept the

value and advance to the next step.

Figure 4-8: Pressure Sensor Installed

YES

PrS

SEnS

Pressure Transducer Low

Pressure Calibration (P Ref)

This function is used to calibrate the Zero Pressure

setting of the pressure transducer installed on the

system. The pressure transducer used with the 854

is a current type transducer and uses a 4-20 mA

reading. “4.0 mA” represents “Zero” pressure.

Figure 4-9: Pressure Transducer

0

PSI

rEF

Automatic Calibration

• Make sure that the sprayer pump is turned off

and that there is absolutely no pressure in the

system (release pressure held by boom control

valves and nozzle body check valves).

• In some cases it may be best to remove the

sensor from the plumbing system to complete

the calibration.

• Press and hold the PLUS and MINUS

keys simultaneously for 3 seconds to activate

the automatic calibration feature.

• The lower left portion of the display will count

from 1 - 10 during the calibration.

• Once the display nishes counting, it should

display a number close to 4.0 (+/- 0.2).

• The low pressure value of the transducer has

been calibrated.

• Press the PROGRAM key to advance to the

next step.

4.00

nA

16

www.teejet.com

Page 22

854 Sprayer Control

Figure 4-10: Automatic Calibration

0

PSI

1-10

0

PSI

REF

Pressure Transducer Maximum

Rating (P HI)

The Pressure Transducer Maximum Rating is used

to establish the maximum rating of the pressure

transducer in the system. This number can be found

stamped on the pressure transducer itself.

• If the transducer has a maximum rating of 145

psi (10 bar) and the number is shown on the

display, advance to the next step by pressing

the PROGRAM key.

• If the maximum rating is 363 psi (25 bar), use

the PLUS or MINUS keys to change the

value.

• Press the PROGRAM key to advance to the

next step.

4.00

88

4.13

nA

The Maximum Pressure cannot be set lower

than the Minimum Pressure.

Figure 4-11: Pressure Transducer Maximum Rating

145

PSI

PHi

PrS SEnS

Flow Meter Installed

NOTE: This step may not appear if other

programming steps have indicated that a

flow sensor is present.

The Flow Meter Installed step indicates to the

console whether a ow meter has been installed on

the sprayer.

• Use the PLUS or MINUS keys to adjust

the value.

• Select “Yes” if a ow meter is installed. Select

“No” if a ow meter has not been used.

• Press the PROGRAM key to advance to the

next step.

Figure 4-12: Flow Meter Installed

YES

FLO

SEnS

NOTES: Do not change the value to “0” even if

there is no pressure sensor installed.

www.teejet.com

17

Page 23

854 Sprayer Control

Flow Meter Pulses

NOTE: This step may not appear. It only appears if

the Flow Meter Installed step is set to “Yes”.

In the Flow Meter Pulses step, the ow meter

calibration number can be manually entered from

the factory calibrated tag, or an automatic calibration

procedure can be started to determine the ow

meter pulses based on a known volume of uid.

NOTE: The automatic calibration procedure is

recommended for maximum accuracy.

Manual Entry

• Locate the factory-calibrated ow meter pulse

rate tag on the ow meter.

• If this varies from the default value of the

console (it typically does), use the PLUS or

MINUS keys to modify the value.

• Press the PROGRAM key to advance to the

next step.

Figure 4-13: Manual Entry

Automatic Calibration

To complete an automatic calibration of the ow

meter:

• Press and hold the PLUS and MINUS

keys simultaneously for 3 SECONDS. This

will clear the existing value and initiate the

calibration procedure.

• “CAL” will be displayed on the screen. This

indicates that the controller is ready to begin

the calibration process.

• Engage the sprayer pump.

• Press the PLUS key to activate the

calibration.

Figure 4-14: Automatic Calibration

CAL

FLO

PLS

18

www.teejet.com

CAL

650.0

CAL

0

• Turn the boom sections on and begin spraying

a known volume of uid (i.e., 100 gallons)

(378.5 liters).

• As the known amount is sprayed, the console

will count the pulses.

Page 24

854 Sprayer Control

• After the known volume has been sprayed, turn

the Master Switch “Off” to stop counting pulses.

Figure 4-15: Automatic Calibration (continued)

CAL

56

• Press the PROGRAM key. The console will

request what volume was sprayed.

• Use the PLUS and MINUS keys to adjust

the value to match the volume sprayed in

gallons/liters.

• Press the PROGRAM key to return to the

programming mode.

• The console will display the new ow meter

calibration number.

• To accept the value, press the PROGRAM

key to advance to the next step.

• To repeat the calibration procedure, refer to the

previous steps.

NOTE: A volume of at least 50 gallons (200 liters)

should be sprayed during the calibration.

The more volume used for calibration, the

more accurate the flow meter will be.

3856

Figure 4-16: Automatic Calibration (continued)

Vol

6AL

1000

Flow Sensor Minimum Flow

Capacity

NOTE: This step may not appear if the console was

not previously programmed for use with a

pressure sensor.

When both a pressure sensor and ow sensor are

installed, the 854 determines when the ow rate has

dropped below the capacity of the ow meter being

used and automatically switches to pressure-based

regulation. When the ow rate once again reaches

an acceptable level for the ow meter to regulate,

the 854 automatically switches back to ow-based

regulation.

• Use the PLUS or MINUS keys to enter

the minimum recommended ow mater, in

GPM or LPM, of the ow meter installed on the

sprayer.

• This information can be located in the ow

meter manufacturer’s literature.

• Minimum ow rates for TeeJet ow meters are

listed in the following table.

• Press the PROGRAM key to return to

accept the value and advance to the next step.

www.teejet.com

19

Page 25

854 Sprayer Control

Figure 4-17: Flow Sensor Minimum Flow Capacity

FLO

LO

Flow Meter Rates:

Nominal Flow Meter Size Minimum Flow Rate in GPM (l/min)

1/2” 0.79 GPM (3 l/min)

3/4” 1.9 GPM (7 l/min)

1” 2.6 GPM (10 l/min)

801-PP-RUB 2.5 GPM (9.5 l/min)

1 1/2” 9.2 GPM (35 l/min)

2” 19 GPM (72 l/min)

5.0

SEnS

Sensor Selection

NOTE: This step may not appear. It will only

appear if both sensors (pressure sensor

and flow sensor) have been installed and

programmed.

The 854 system can be used with either a ow

meter, pressure transducer, or both. The Sense

Selection step instructs the console which type(s) of

sensor is/are being used to control the regulation.

• Use the PLUS or MINUS keys to

select either “Flo” for Flow Meter or “PRS” for

Pressure Sensor.

• Press the PROGRAM key to advance to the

next step.

If both sensors are installed on the sprayer, this

process will determine which sensor is used as

the primary one for regulation. If “Flo” is selected,

the Flow Meter will be used to control ow and the

pressure transducer will be used only to display the

actual pressure. If “PRS” is selected, the pressure

transducer will be used to control the ow and

display the actual pressure.

Figure 4-18: Sensor Selection

Re6

FLO

Section Valve Type

The Section Valve Type distinguishes the type of On/

Off boom control valves installed on the machine.

There are 2 types of valves that can be used:

• 2-way valves

• 3-way valves

A 2-way control valve is simply an On/Off valve.

Flow is either directed to the boom section(s) or it is

blocked.

A 3-way control valve is known as a Bypass valve.

Flow continuously passes through this valve. When

the valve is activated (on), ow is directed to the

boom section(s). When the valve is not activated

(off), ow is directed through a bypass port back to

the supply tank.

• Change the value if required by pressing the

PLUS or MINUS keys.

• Press the PROGRAM key to accept the

value and advance to the next step.

20

www.teejet.com

Page 26

854 Sprayer Control

Figure 4-19: Section Valve Type

2

SEC

Pressure Regulating Mode

The Pressure Regulating Mode instructs the 854

where the regulating valve is plumbed into the

system. Once congured correctly, this value should

not change unless the regulating valve is physically

moved to a new point in the plumbing.

• The default value is “BYP” which indicates that

the pressure regulating valve is plumbed in a

bypass line.

• If the setting is correct, press the PROGRAM

key to accept the value and advance to the

next step.

When programmed in the Bypass Mode, with the

controller in Manual Mode “Man”, the pressure

regulating valve should:

• Close when the PLUS key is pressed.

• Open when the MINUS key is pressed.

tYPE

Figure 4-20: Pressure Regulating Mode

re6

If the pressure regulating valve is plumbed in a

supply line to the booms, it is considered in the

“throttling” position.

• Use the PLUS or MINUS keys to adjust

the value to “thr” (throttling mode). The polarity

that the console uses to control the regulating

valve will be reversed.

• Press the PROGRAM key to accept the

value and advance to the next step.

When programmed in the Throttling Mode, with

the controller in Manual Mode “Man”, the pressure

regulating valve should:

• Open when the PLUS key is pressed.

• Close when the MINUS key is pressed

Figure 4-21: Pressure Regulating Mode

bYP

re6

THr

www.teejet.com

21

Page 27

854 Sprayer Control

Regulating Valve Capacity

Enter the maximum ow capacity of the regulating

valve in Gallons Per Minute (GPM). The valve

parameters needed to drive the regulating valve

smoothly depend on the size of the valve.

• Use the PLUS or MINUS keys to adjust

the valve so that it matches the maximum ow

capacity (GPM) of the regulating valve being

used.

• Press the PROGRAM key to advance to the

next step.

Figure 4-22: Regulating Valve Capacity

re6

CAp

Common Regulating Valves:

Valve GPM

344AE-2RL 27 GPM

344AE-2RB 30 GPM

344AE-2PR 12 GPM

AA346ZR 85 GPM

AA346ZRB 85 GPM

6PM

32

Regulating Valve Speed - Coarse

Adjustment

This step allows for the adjustment of the pressure

regulating valve speed to accommodate different

application needs. Operating conditions may

necessitate a higher or lower response speed for the

regulating valve.

The coarse adjustment controls the speed of the

valve when large adjustments in ow are required by

the controller.

• Use the PLUS or MINUS keys to

increase or decrease the response time.

Any number between 0 - 19 can be selected.

0 = slow

19 = fast

If the regulating valve is plumbed in a bypass line,

the valve speed coarse adjustment number of “15”

works well in most applications.

If the regulating valve is plumed in the Throttling

position (supply line) start with a coarse adjustment

speed number of “5” and adjust the number

according to application requirements.

• Press the PROGRAM key to accept the

value and advance to the next step.

Figure 4-23: Coarse Adjustment

22

www.teejet.com

re6

spd

10

COAr

Page 28

854 Sprayer Control

Regulating Valve Speed - Fine

Adjustment

The ne adjustment controls the speed of the valve

when small adjustments in ow are required by the

controller.

• Use the PLUS or MINUS keys to

increase or decrease the response time.

Any number between 0 - 9 can be selected.

0 = slow

9 = fast

Start with a ne adjustment speed of “2”. This works

well in most situations. The number may need to be

optimized during the spraying operation.

• Press the PROGRAM key to accept the

value and advance to the next step.

Figure 4-24: Fine Adjustment

re6

spd

2

FIme

Tank Volume

In addition to accumulating the total volume applied,

the 854 tracks the volume down from the maximum

tank content to 0 gallons (liters). This allows for the

monitoring of remaining tank volume.

• Use the PLUS or MINUS keys to enter

the maximum volume of the sprayer tank in

gallons (liters).

• Press the PROGRAM key to accept the

value and advance to the next step

Figure 4-25: Tank Volume

0

NOTES: Adjusting agitation volumes can assist the

regulating valve operation.

The speed value can be adjusted to

optimize system performance. If the valve

searches for the programmed application

rate by cycling the pressure up and down

continuously, reduce the number until

the searching is minimized or eliminated.

A higher number will increase the valve

response speed and increase the rate of

adjustment.

www.teejet.com

23

Page 29

854 Sprayer Control

Low Tank Volume Alarm

The 854 console alerts the operator when nearing

the end of a tank.

• Use the PLUS or MINUS keys to enter

the volume at which the console should display

the alert. A value of “0” will disable the feature.

A visual alarm will be displayed when the low tank

level warning is reached.

Figure 4-26: Low Tank Volume Alarm

LO

25

Fill Flow Meter Calibration

NOTE: This step will not be displayed unless the

console has been programmed for use with

a fill flow meter.

The 854 console has the capability of reading

signals from a second ow meter for tank lling

purposes. This feature must be activated by the

organization selling the console kit and requires

an additional ow meter. The 854 can also be

connected to a valve or switch for automatic shutoff

of the lling operation.

Manual Entry

• Locate the factory calibrated tag on the ow

meter.

• If this varies from the default value (it usually

does) use the PLUS or MINUS keys to

modify the value.

• Press the PROGRAM key to advance to the

next step.

Figure 4-27: Manual Entry

FLO

PLS

Automatic Calibration

NOTE: To achieve an accurate flow meter

calibration, a volume of at least 50 gallons

(200 liters) should be pumped during

calibration. The more volume used for

calibration, the more accurate the flow meter

will be.

• Press and hold the PLUS and MINUS

keys simultaneously for 3 seconds. This

will clear the existing value and initiate the

calibration procedure.

• “CAL” will be displayed on the screen. This

indicates that the controller is ready to begin the

calibration procedure.

• Press the PLUS key to activate the

calibration.

• Pump a known volume of uid (i.e., 100 gallons/

liters) through the ow meter in the tank.

FLO

65.00

24

www.teejet.com

Page 30

854 Sprayer Control

Figure 4-28: Automatic Calibration

CAL

CAL

0

As the known volume is pumped, the console will

count the pulses.

• Once the volume has been pumped, turn the

pump (or ow) off to stop counting pulses.

Figure 4-29: Automatic Calibration (continued)

• Use the PLUS and MINUS keys to adjust

the value to match the volume pumped (in

gallons/liters).

Figure 4-30: Automatic Calibration (continued)

6AL

• Press the PROGRAM key to return to

programming mode.

• The new ow meter calibration will be

displayed.

• Press the PROGRAM key to accept the

value and advance to the next step.

• Follow the same procedures to repeat the

calibration process.

Figure 4-31: Automatic Calibration (continued)

1000

CAL

56

• Press the PROGRAM key. The console will

ask what volume was pumped.

3856

FIL

PLS

FLO

67.00

www.teejet.com

25

Page 31

854 Sprayer Control

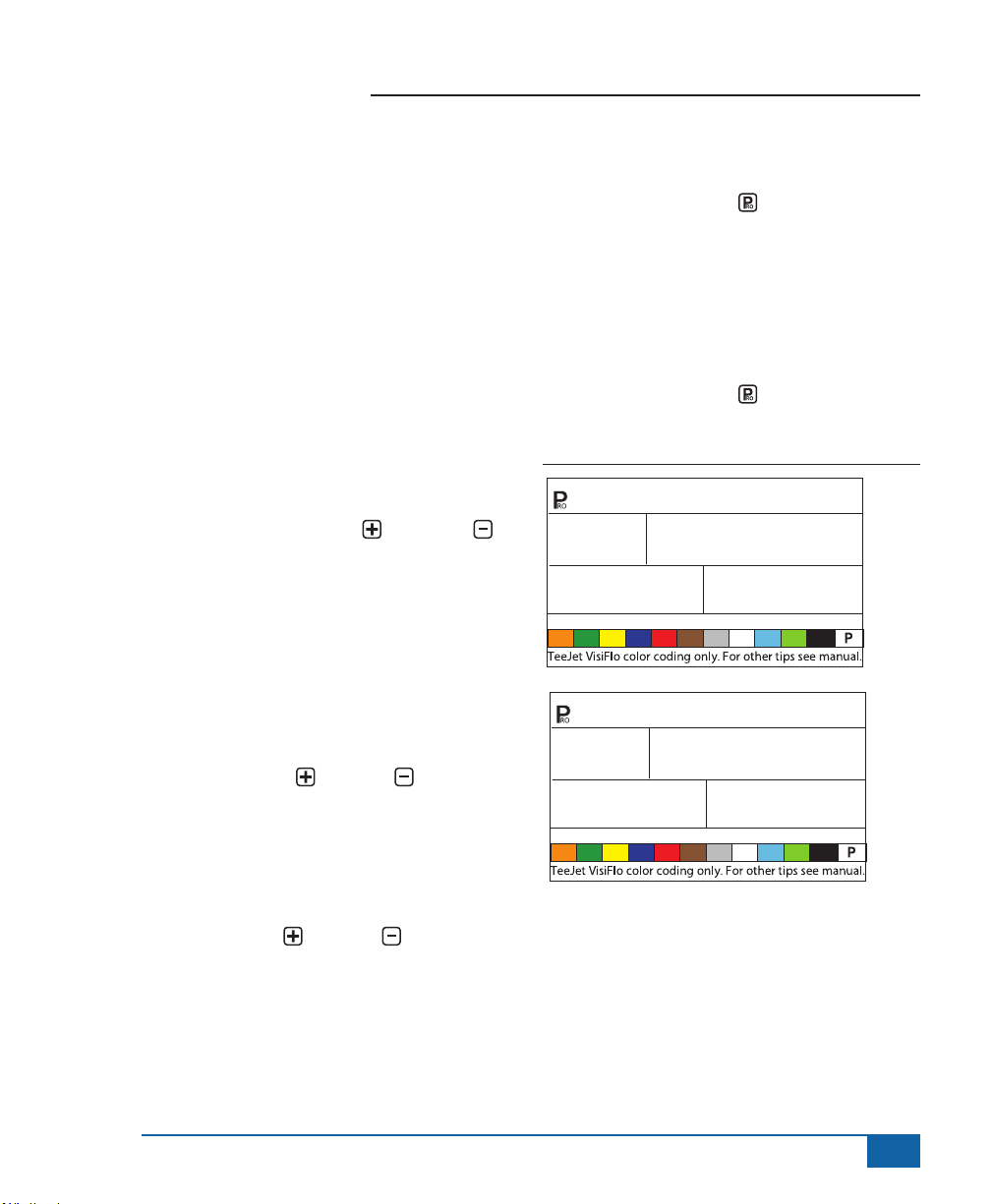

Communications

The Communications step allows for the selection of

the type of communications (if any) used.

Available choices include:

• NO CON - no external communications

• PRT - memory printing

• GPS - global positioning satellite system/

variable rate communication capability

• LOG - downloading to a PC with on-the-go

capabilities

• PC - PC link

• Use the PLUS and MINUS keys select

the type of communications being used.

• Press the PROGRAM key to advance to the

next step.

Figure 4-32: Communications

prt

Figure 4-33: Printing Memory Contents

MeM

• Only information stored in the memory locations

can be printed.

• Press the MEMORY key to launch the PRN

TOT screen, which will allow for the printing of

contents of the Total Memory locations and any

individual memory locations (1-9) that contain

data.

Figure 4-34: Printing Memory Totals

MeM

prt

TOT

Printing Memory Contents

• Connect the 854 console to the 78-20002

printer using a 45-2004 printer cable.

• Select PRT in the Communications Setup step.

• The Boom Master Switch must be set to “Off”.

• Press the MEMORY key. The rst screen

displayed will be the MEM PRN Screen.

• Press the PROGRAM key to advance to the

next step.

26

www.teejet.com

• Continue pressing the MEMORY key to

display screens 1-9, which represent memory

locations 1-9.

• When the desired location is displayed, press

the PROGRAM key to print the report.

• To exit from the Print Menu, press and hold

either the MEMORY key or the PROGRAM

key to return to the Memory Menu.

Page 32

854 Sprayer Control

Figure 4-35: Printed Report

PRN

3

----------------------

tropeR yrammuS

----------------------

12:10 80-20-70 :etaD

----------------------

total yromeM

LAG 06.71 : emuloV

CA 01.61 : aerA

APG 00.0 :etaR naeM

-----------------------

999 tropeR gniyarpS

-----------------------

12:10 80-20-70 :etaD

________________ :dleiF

_____________ :rotarepO

-----------------------

APG 0.02 : tegraT

4 : piT

-----------------------

LAG 00.8 : emuloV

CA 06.0 : aerA

APG 03.31 :etaR naeM

HPM 04.01 :deepS .vA

-----------------------

____________ :1 mehC

___

_______________ :2 mehC

aeM

_______________ :3 mehC

_______________ :4 mehC

_______________ :5 mehC

-----------------------

________:rid/deeps dniW

________: erutarepmeT

________: ytidimuH

-----------------------

______________ :skrameR

emuloV

_______________________

aerA

_______________________

HPM 00.71 :deepS .vA

----------------------

1 yromeM

LAG 08.1 : emuloV

CA 06.0 : aerA

APG 03.3 :etaR naeM

HPM 04.7 :deepS .vA

----------------------

2 yromeM

LAG 04.3 : emuloV

CA 04.3 : aerA

APG 00.1 :etaR naeM

HPM 08.6 :deepS .vA

----------------------

3 yromeM

LAG 05.5 : emuloV

CA 06.4 : aerA

APG 02.1 :etaR n

HPM 02.6 :deepS .vA

----------------------

4 yromeM

LAG 05.2 : emuloV

CA 01.3 : aerA

APG 08.0 :etaR naeM

HPM 01.7 :deepS .vA

----------------------

5 yromeM

LAG 04.4 :

CA 94.4 :

APG 00 .1

:etaR naeM

HPM 00.7

:deepS .vA

----------------------

Using GPS

• The GPS receiver must be sending the GPVTG

string at 9600 Baud with a sampling rate of 1

Hz. Additional strings may also be sent.

• Connect the GPS receiver to the 854 console

using a 45-20063 serial cable.

• Select “GPS” in the Communications Setup

step.

• When the 854 console starts receiving speed

information from the GPS receiver, it uses that

information for determining vehicle speed. If

the 854 console loses communications with the

GPS receiver for more than 5 seconds, it will

revert back to other sources of speed input.

Figure 4-36: Using GPS Speed

6PS

Communicating With a Laptop Running

Fieldware Software

• Connect the laptop to the 854 console using a

45-20063 serial cable.

• Select “PC” in the Communications Setup step.

• Press the PROGRAM key to advance to the

next step.

• The message “GPS SPEED” will appear only

if “PC” was selected in the Communications

Setup step. Select “ON” to receiving GPS

speed through the laptop. Select “OFF” to use

the regular radar or speed sensor input.

• Follow the instructions if the Fieldware manual

to set up and run the ARM function. In System/

SystemSetup/Control, select the TeeJet854.

DRV driver.

www.teejet.com

27

Page 33

854 Sprayer Control

Figure 4-37: Communicating with Laptop/Fieldware

PC

Logging Information to a Laptop running

Logging Software

• Connect the laptop to the 854 console using a

45-20063 serial cable.

• Select “LOG” in the Communications Setup

step.

• The LOG mode is an advanced data transfer

tool used with specially congured hardware

devices only. This mode is not used during

normal applications.

Figure 4-38: Log Mode

LO6

GPS Speed

NOTE: The GPS Speed option is only available

when “PC” is selected during the

Communications Setup.

GPS Speed allows the 854 to accept speed data

from an external GPS source. Select either “On” to

use the external GPS Speed input, or “Off” to ignore

external speed input.

• Use the PLUS or MINUS keys to adjust

the value to either “On” or “Off”.

• Press the PROGRAM key to advance to the

Use External Rate step.

Figure 4-39: GPS Speed Simulation

On

6PS

Use External Rate

NOTE: The External Rate option is only

available when “PC” is selected during

the Communications Setup. This option

is typically used with an external GIS

computer, such as the Legacy 6000.

External Rate is used to indicate whether local

control rates are to be used or ignored. When set

to “Off”, the 854 console will ignore the rate coming

from the external computer and use its own preset

rate. When set to “On”, the 854 will use the rate

determined by the external computer (Legacy 6000),

usually as determined from a prescription map.

• Use the PLUS or MINUS keys to adjust

the value to either “On” or “Off”.

• Press the PROGRAM key to advance to the

Simulated Ground Speed step.

SPed

28

www.teejet.com

Page 34

854 Sprayer Control

Figure 4-40: External Rate

USe

EXT

Simulated Ground Speed

Simulated ground speed allows the verication of

console functions and the sprayer without actually

moving the sprayer. This should be tested prior to all

spraying activity.

The 854 has a low and high simulated ground speed

that allows for switching between the two to simulate

a speed change. This will ensure that the console is

regulating properly during sprayer checkout.

To activate the simulated speed, while in the normal

operating mode with the Master Switch “On”:

• Press the PROGRAM and MINUS keys

for low simulated speed.

• Press the PROGRAM and PLUS keys for

high simulated speed.

Low Speed

• Use the PLUS or MINUS keys to adjust

value.

• Press the PROGRAM key to advance to the

High Simulated Speed step.

ON

rate

Figure 4-41: Low Speed Simulation

SIM

6.0

High Speed

• Use the PLUS or MINUS keys to adjust

value.

• Press the PROGRAM key to advance to

High Simulated Speed step.

Figure 4-42: High Speed Simulation

SIM

9.0

NOTE: Once the sprayer begins moving and the

854 receives actual speed pulses, simulated

speed is deactivated. If a Radar Speed

Sensor is being used, disconnect the Radar

from the main console. Due to the sensitivity

of this speed sensor, any movement can

disable simulated speed.

SPd

MPH

LO

SPd

MPH

High

www.teejet.com

29

Page 35

854 Sprayer Control

Auto Master O - Speed

The TeeJet 854 automatically shuts the boom

sections off at the programmed speed to eliminate

an operator function when slowing to stop or turn

around.

• Use PLUS or MINUS keys to adjust

speed value.

• Press the PROGRAM key to advance to

next step.

When the sprayer speed exceeds the established

Auto Master Off Speed, the boom sections turn back

on. Set this value to “0” to disable. This feature is

disabled when operating in Manual Mode.

Figure 4-43: Auto Master Off - Speed

MIM

SPd

MPH

0.0

Minimum Pressure Setting

Set the minimum pressure to which the sprayer

is allowed to regulate. It is possible that when

the sprayer slows down, the control system will

regulate the pressure so low that it falls below the

manufacturer’s recommended pressure for the spray

tip or reduces system ow to the point where the

ow meter stalls.

Set the pressure setting to the minimum

recommended pressure range for the spray tips

being used. (For example, if this is set to 15 psi/10

bar, the console, in automatic mode, does not

regulate pressure below 15 psi/10 bar.)

• Use the PLUS or MINUS keys to adjust

the minimum pressure value.

• Press the Program key to advance to the

next step.

NOTE: An audible alarm is activated when this

feature is enabled. It will provide a steady

beep, indicating Medium Priority.

Figure 4-44: Minimum Pressure Setting

10

re6

PrS

Maximum Pressure Setting

Set the maximum pressure to which the sprayer

is allowed to regulate. This will help ensure

that the spraying pressure does not exceed the

recommended pressure range of the spray tips

being used. This step can be used to help prevent

spraying applications that contribute to drift.

• Use the PLUS or MINUS keys to adjust

the maximum pressure value.

• Press the PROGRAM key to advance to the

next step.

NOTE: An audible alarm is activated when this

feature is enabled. It will provide a steady

beep, indicating Medium Priority.

30

www.teejet.com

Page 36

854 Sprayer Control

Figure 4-45: Maximum Pressure Setting

145

Hi

Audible Alarm

The audible alarm is used to alert the operator to

problems with the sprayer control system. It is used

in addition to visual alarms on the LCD display and

LED sensor alarms above the screen.

• Use the PLUS or MINUS keys to select

“YES” to activate the audible alarm.

• Use the PLUS or MINUS keys to select

“NO” to deactivate the audible alarm.

• Press the PROGRAM key to advance to the

next step.

Audible alarms are divided into three priorities:

• Low - a long beep

• Medium - a steady beep

• High - three short beeps

Figure 4-46: Audible Alarm

re6

PrS

Dual Boom On Setting

NOTE: This step will not be displayed unless the

dual boom option was selected in the OEM

Programming Mode.

The dual boom option is the speed or pressure

at which the second boom is SHUT OFF. As the

vehicle slows, the system pressure will begin to

drop, eventually to a point where the spray tips are

no longer able to develop a pattern. The Dual Boom

On setting should be adjusted to shut off the second

boom line before this condition occurs.

• Use the PLUS or MINUS keys to adjust

the setting.

• Press the PROGRAM key to advance to the

next step

Figure 4-47: Regulating Mode - Speed

DB

Spd

OFF6.0

Figure 4-48: Regulating Mode - Pressure

Aud

YES

ALrM

15

PRs

Db

www.teejet.com

31

Page 37

854 Sprayer Control

Memory Reload Function

The memory reload function is used to restore all

programming values that were previously set. A

sprayer manufacturer can pre-program the console

for specic parameters on a sprayer and save the

values internally. This step will allow for the return to

those pre-programmed values if required.

WARNING! It is recommended that this setting be

set to “NO” unless otherwise instructed by

an authorized TeeJet representative.

Notes: For protection, the 854 console does not

automatically power down while in Program

Mode. Exit properly as described below

to enable the console’s auto power down

feature.

Cutting the power to the controller while in

Program Mode will not save any changes in

the computer’s memory.

• Use the PLUS or MINUS keys to select

either “YES” or “NO”.

• The default of “NO” indicates that programming

values are saved as entered.

• Selecting “YES” will change the program

values to those programmed and saved by the

manufacturer.

• Press the PROGRAM key to advance to

the next step. The screen should return to the

beginning of Program Mode.

• Press and hold the PROGRAM key for

three seconds to exit Program Mode and save

the programming information to the console’s

memory.

Figure 4-49: Memory Reload Function

MEM

LOADrE

32

www.teejet.com

Page 38

854 Sprayer Control

CHAPTER 4 - APPLICATION PRESET SETUP MODE

To access the Application Preset Setup Mode, the

Master Switch must be in the “Off” position.

• Press the PRESET key to display the

current presets being used.

• Press the PRESET key again within 3

seconds to advance to the next preset. This

process can be continued throughout all 5

presets.

• To program a particular preset, press the

PROGRAM key while that preset is

displayed.

Tip Spacing

Enter the spacing between the spray nozzles in

inches (cm).

• Use the PLUS or MINUS keys to adjust

the value.

• Press the PROGRAM key to advance to the

next step

Figure 5-2: Tip Spacing

Figure 5-1: Application Preset Setup

PST

15.0

-2-

EXAMPLE: To program present #2, press the

PRESET key until “PST - 2 - “ is

displayed. Press the PROGRAM key to

program the value.

20

-2-

www.teejet.com

33

Page 39

854 Sprayer Control

Number of Tips Per Boom

Section

Enter the number of tips on the boom section

corresponding to boom Section 1. The number of

tips entered here is specic to the preset being used

(in the following example, preset 2 is being used).

• Use the PLUS or MINUS keys to adjust

value.

• Press the PROGRAM key to advance to

next step

Once the PROGRAM key has been pressed,

pressing the PROGRAM key again will advance

the console to Section 2. Continue programming

the number of tips for each boom section until all 5

possible boom sections have been programmed. If

a particular boom section switch is not used, set the

value to “0”.

Figure 5-3: Number of Tips

SeC

1

6

-2-

Density

Alternate Density Used

If a product carrier other than water will be used,

change this value to “YES”. Otherwise, leave at

“NO”.

• Use the PLUS or MINUS keys to select

“YES” or “NO”.

• Press the PROGRAM key to advance to the

next step

Figure 5-4: Alternate Density

dEns

Density Value

NOTE: This screen will only be displayed if

Alternate Density Used was set to “YES”.

If a carrier other than water (i.e., liquid fertilizer) is

being used, enter the density value.

• Use the PLUS or MINUS keys to change

the value.

• Press the PROGRAM key to advance to the

next step

34

www.teejet.com

Page 40

854 Sprayer Control

Figure 5-5: Density Value

1.28

DenS

Tip Selection

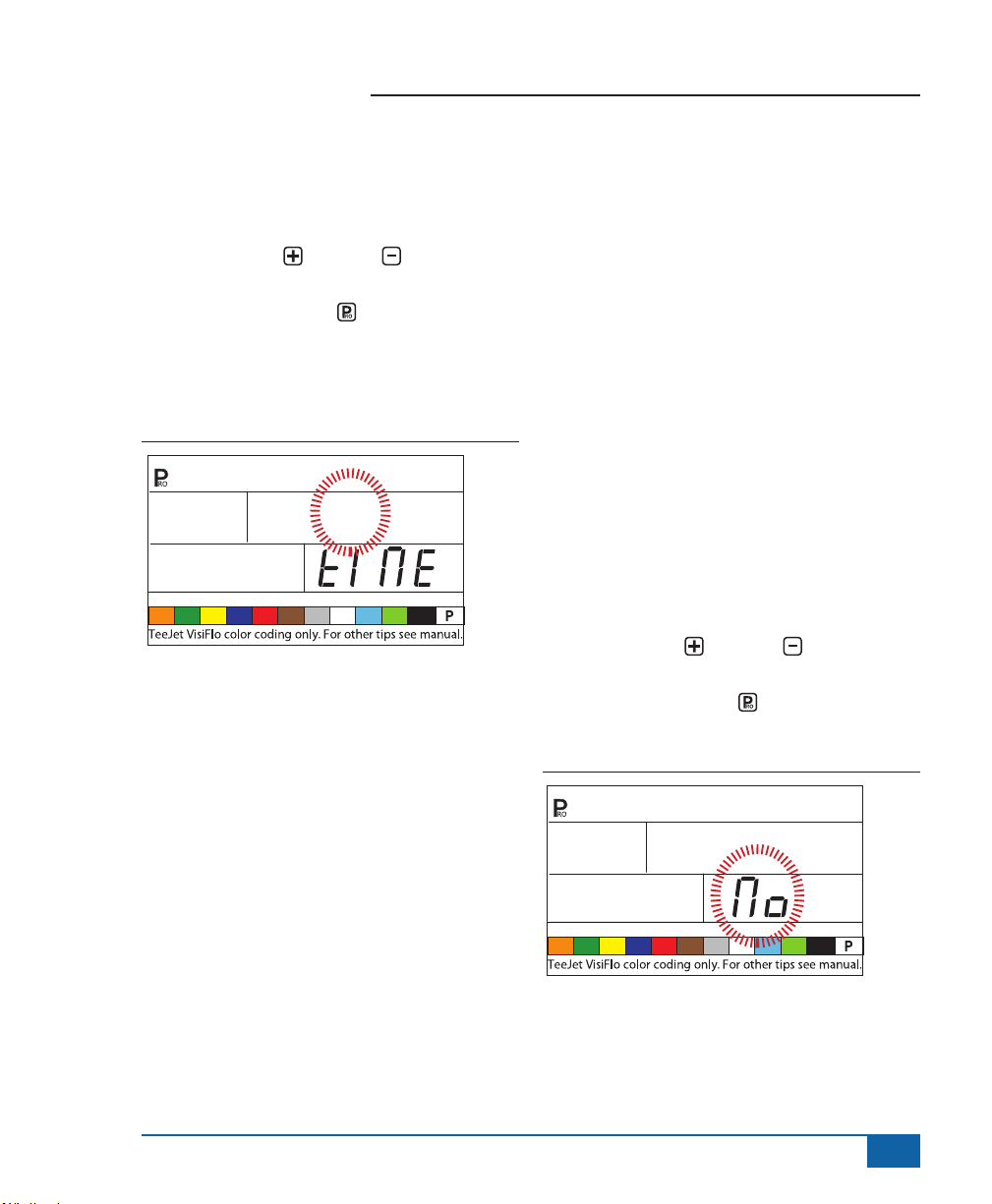

Select the appropriate color of the spray tip being

used.

• Use the PLUS or MINUS keys to move

the ashing arrow to the tip’s corresponding

color tab.

The arrow should be located over the matching

color of the tips being used (tips must be ISO color

coded). The ow rate of the tip in GLM (LPM) at 40

psi/2 bar will be displayed on the lower right corner

of the screen. Press the PROGRAM key to select

the color tab and advance to the next step.

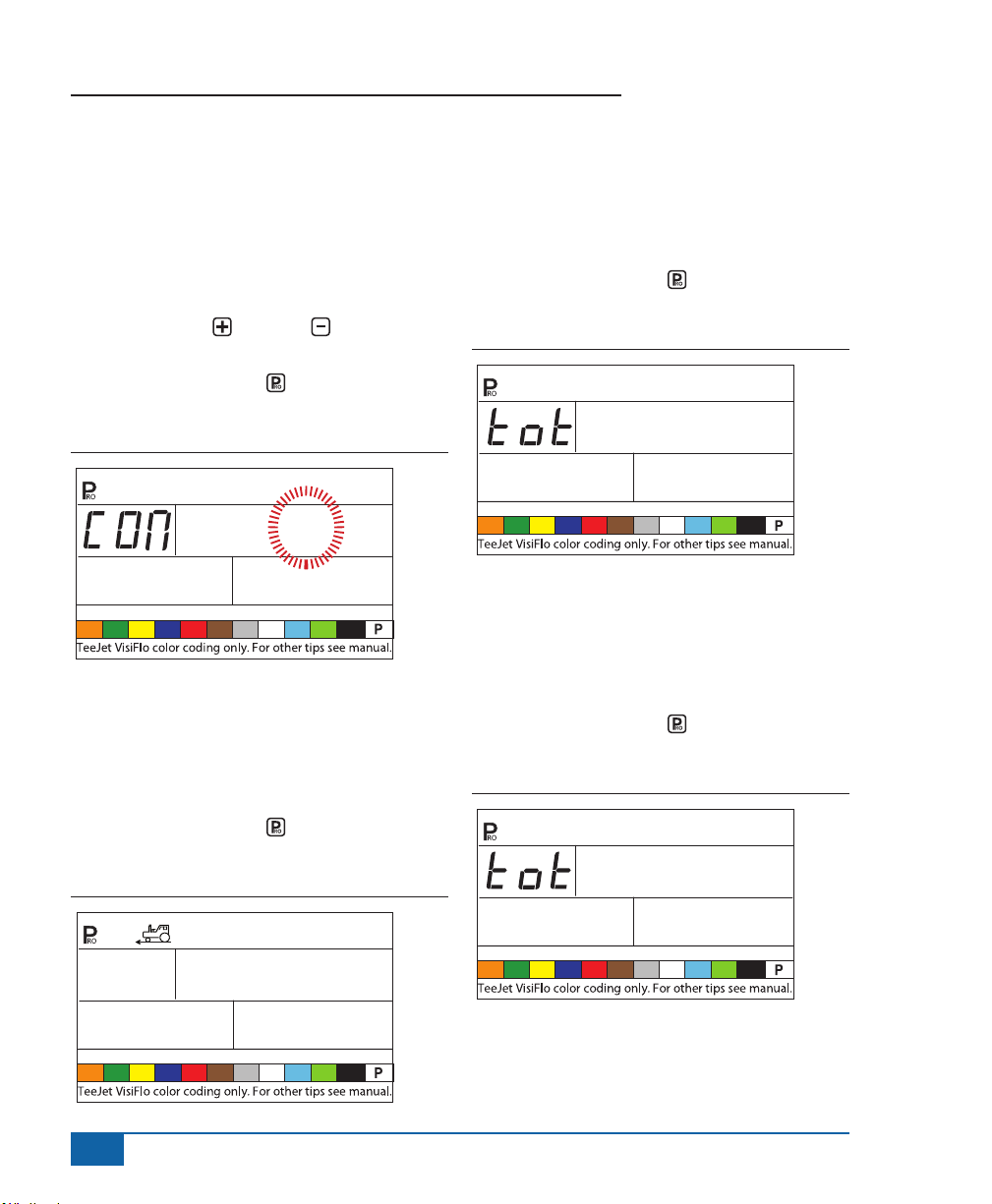

Target Application Rate

Once the tip has been selected, the Target

Application Rate display will be ashing. If the

display rate is not ashing, press the PROGRAM

key three or four times until the Target Application

display starts to ash.

• Use the PLUS or MINUS keys to adjust

the target rate.

• Press the PROGRAM key to advance to the

next step.

Figure 5-7: Target Application Rate

40

6.0

20.0

0.40

Figure 5-6: Tip Selection

40

20.0

6.0

0.40

www.teejet.com

35

Page 41

854 Sprayer Control

Calculation Steps

Known Pressure Calculation

If the approximate operating pressure is known:

• Use the PLUS or MINUS keys to adjust

the value.

The 854 will determine what the operating speed

must be to achieve the target application rate that

the entered pressure. If the indicated speed is too

high, a set of smaller nozzles is required. If the

indicated speed is too low, a set of larger nozzles is

required.

Press the PROGRAM key to advance to the next

step.

Figure 5-8: Known Pressure Calculation

40

6.0

20.0

0.40

Known Speed Calculation

• Use the PLUS or MINUS keys to adjust

the indicated speed to the intended speed.

The 854 will calculate what the pressure must be to

maintain the target application rate at the entered

speed. If the pressure is too high, a set of larger

nozzles or a slower speed is necessary. If the

pressure is too low, a set of smaller nozzles or a

faster speed is necessary.

Continue trying different speed, pressure, and tip

combinations until the desired combination is found.

NOTE: In Application Preset Mode, the tip color tab

must match the actual tips being used.

• Press the PROGRAM key to save the

changes and return to the Tip Selection Step.

• Press and hold the PROGRAM key for 2

seconds to exit Application Preset Mode.

Figure 5-9: Known Speed Calculation

40

20.0

36

www.teejet.com

6.0

0.40

Page 42

CHAPTER 5 - OPERATIONS

Sprayer Evaluation

Before spraying, check all connections related to the

Sprayer Control System. Particular attention should

be given to the sensors to ensure the console

received strong, uninterrupted signals. Make sure

connections are made and the sensors are working

properly.

IMPORTANT! When working around a sprayer or

chemicals, always wear protective clothing

and eye wear.

NOTE: It is recommended that the entire sprayer

be calibrated to prepare the machine for

operation and to diagnose spray tip wear.

Worn tips can contribute to costly chemical

waste and inaccurate spraying, regardless

of the use of a sprayer control. Calibration is

necessary to obtain the benefits associated

with a computerized sprayer control.

Partially ll the sprayer tank with water to ush the

system. Perform a visual inspection of the spray

tips to ensure all tips are delivering a good spray

pattern.

• Set the Master Boom Switch to the “Off”

position.

• Make sure the tank shutoff valve is open.

• Start the vehicle’s engine, engage the pump,

and set the RPM to that being used when

spraying.

• Turn the 854 on by pressing the

PROGRAM key.

• Ensure that the preset reference ow arrow

matches the set of tips being used.

• Verify that the 854 recognizes the simulated

speed. If the simulated speed has been

854 Sprayer Control

disabled (due to vehicle movement)

activate the simulated speed by turning the

Master Boom Switch “On” and pressing

the PROGRAM and MINUS keys

simultaneously for a Low simulated speed,

or by pressing the PROGRAM and

PLUS keys simultaneously for a High

simulated speed.

• Turn each individual spray boom section “On”.

Figure 6-1: Sprayer Evaluation

40.0

6.0

• Press the AUTO/MAN key so that the red

LED indicates “MAN” mode.

• Toggle the Master Boom Switch to the “On”

position.

• Adjust the pressure with the PLUS or

MINUS keys. The pressure should increase

when the PLUS key is pressed and

decrease when the MINUS is pressed.

Check the sprayer to ensure it is activated. Visually

ensure spray tip performance.

• Press the AUTO/MAN key so that the

red LED indicates “AUTO” mode. The

control console should regulate to the target

application rate for the simulated speed.

• While spraying, press the PROGRAM

and PLUS keys simultaneously for a High

simulated speed. The 854 should increase

20.0

MPH

76