Page 1

844-R

Speed Compensated

Application Control

User Guide

98-05047

R0

Page 2

Table Of Contents

TABLE OF CONTENTS ............................................................................................................................. 2

INSTALLING THE SPEED SENSOR ASSEMBLY ................................................................................ 4

TEP

S

TEP

S

TEP

S

TEP

S

POWERING CONSOLE ON/OFF............................................................................................................. 7

OWER ON

P

OWER OFF

P

OPERATING INSTRUCTIONS................................................................................................................. 8

PPLICATOR CHECKOUT

A

HE SPRAYING OPERATION

T

FEATURES................................................................................................................................................. 10

REA/VOLUME DISPLAY

A

PPLICATION ALARM

A

NO F

LOW RATE FEATURE

F

OOST MODE

B

UTO POWER DOWN

A

OCATION

1 - L

Proximity Sensor (optional).................................................................................................................. 4

NSTALLING THE WHEEL MAGNETS

2 - I

NSTALLING THE MAGNETIC SENSOR

3 - I

ONFIRMING SPEED SENSOR INSTALLATION

4 - C

Magnetic Wheel Sensor......................................................................................................................... 6

Radar .................................................................................................................................................... 6

.................................................................................................................................................. 7

................................................................................................................................................ 7

LOW ALARM

Boost Up ............................................................................................................................................. 12

Boost Down......................................................................................................................................... 12

.................................................................................................................................... 4

.............................................................................................. 5

........................................................................................... 5

................................................................................ 6

............................................................................................................................ 8

........................................................................................................................ 9

.......................................................................................................................... 10

............................................................................................................................... 10

..................................................................................................................................... 11

............................................................................................................................... 11

........................................................................................................................................... 12

................................................................................................................................13

PROGRAMMING GUIDELINES............................................................................................................ 14

MPORTANT PRELIMINARY INFORMATION

I

SYSTEM SETUP MODE – TEEJET 844-R CONTROLLER............................................................... 14

ELECTION OF WORKING UNITS

S

ESET TO DEFAULTS

R

LOW METER PULSES

F

IP SPACING

T

# OF T

PEED SENSOR CALIBRATION

S

Proximity/Magnetic Pulses ................................................................................................................. 17

FLOW METER CALIBRATION............................................................................................................. 19

ETHOD

M

Step 1 – Known Value......................................................................................................................... 19

Step 2 – Programming Calibration Number....................................................................................... 19

Step 3 – Resetting Volume Counter..................................................................................................... 19

Step 4 – Spraying Known Volume....................................................................................................... 19

Step 5 – Entering a New Flow Meter Calibration Number................................................................. 20

Step 6 – Double-checking the New Value ........................................................................................... 20

ETHOD

M

Step 1 – Check Tip Size....................................................................................................................... 20

Step 2 – Count Tips............................................................................................................................. 20

Step 3 – Calculated Flow.................................................................................................................... 21

............................................................................................................................................. 16

IPS

.................................................................................................................................................. 16

1 – K

2 – K

................................................................................................................................15

............................................................................................................................... 16

NOWN VOLUME

NOWN TIP SIZE METHOD

.............................................................................................................. 15

................................................................................................................... 17

................................................................................................................ 19

................................................................................................ 14

.................................................................................................. 20

2 98-05047

R0

Page 3

Step 4 – Measure................................................................................................................................. 21

Step 5 – Adjustments ........................................................................................................................... 21

ISTANCE COUNTER

D

IMULATED GROUND SPEED

S

How To Use ........................................................................................................................................ 23

OMMUNICATIONS

C

INIMUM PRESSURE SETTING

M

................................................................................................................................22

.................................................................................................................... 22

................................................................................................................................... 23

.................................................................................................................. 24

APPLICATION SETUP MODE............................................................................................................... 24

ARGET APPLICATION RATE

T

LOW RATE SELECTION

F

ALCULATION STEPS

C

Known Speed Calculation................................................................................................................... 25

Known Pressure Calculation .............................................................................................................. 26

DAILY FLOW METER MAINTENANCE............................................................................................. 26

TROUBLESHOOTING GUIDE............................................................................................................... 27

QUICK REFERENCE GUIDE................................................................................................................. 29

YSTEM SETUP MODE

S

PPLICATION SETUP MODE

A

EATURES

F

................................................................................................................................................. 30

................................................................................................................................25

.................................................................................................................... 24

........................................................................................................................... 25

.............................................................................................................................. 29

...................................................................................................................... 30

98-05047 3

R0

Page 4

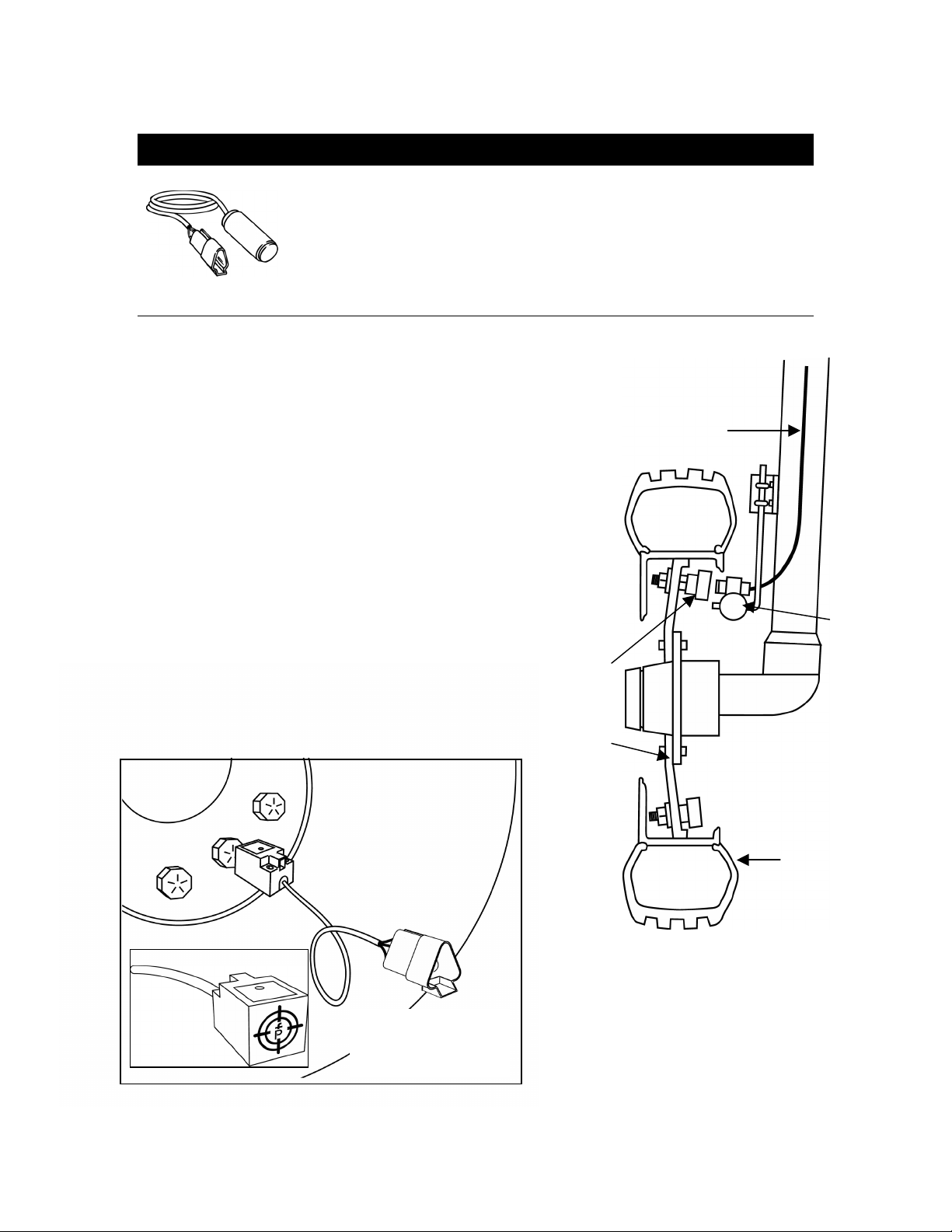

Installing the Speed Sensor Assembly

Components: Two magnets, Sensor with attached connector

cable, and mounting hardware.

If you are installing a radar ground speed sensor, follow the

instructions supplied with that unit.

S

TEP

1 - L

OCATION

The speed sensor assembly should be installed on a

non-driven wheel to avoid potential errors that are likely

to occur from a slipping drive wheel.

(Refer to Figure 1)

Proximity Sensor (optional)

An optional proximity sensor is available to use in cases

where space is limited or for drive shaft mounting. The

proximity sensor works by sensing any metal object.

Mount the proximity sensor so that the sensor face is

within 1/8 to 3/8 inch of the metal object being read.

(Refer to Figure 2)

MAGNET

RIM

CABLE

SENSOR

Figure 1

Wheel Mounting

of Magnetic

Speed sensor

TIRE

NOTE:

TARGET FACES TIRE

LUGS

4 98-05047

Figure 2

R0

Page 5

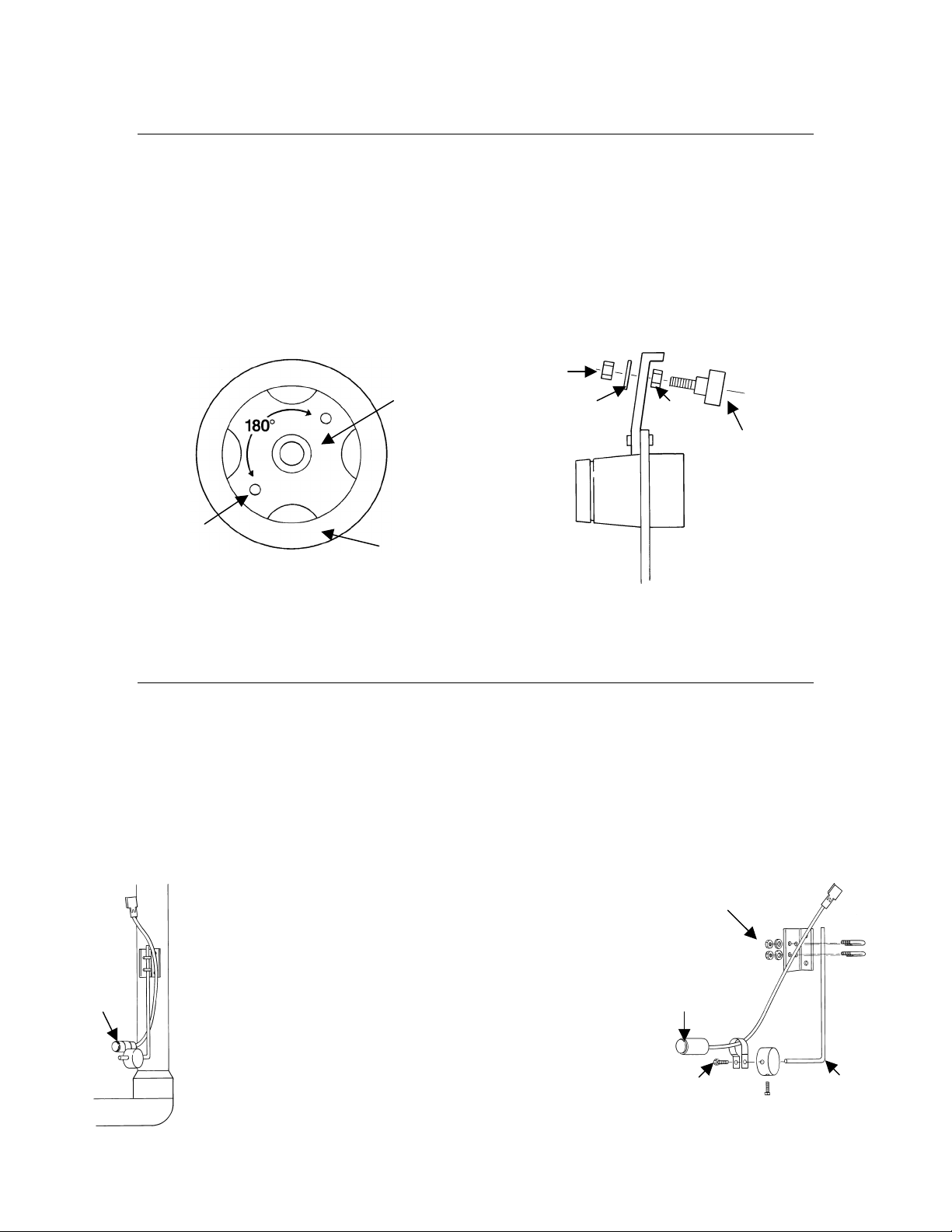

S

TEP

NSTALLING THE WHEEL MAGNETS

2 - I

Check for pre-drilled holes in the wheel rim. If pre-drilled holes are not available,

layout a pattern as shown in figure 3 and drill two 3/8 inch holes, locating them

near the outer rim, if possible, and 180° from each other.

Place the magnets into each of the two holes on the inside rim and securely

fasten using the nuts and washers provided. (See Figure 4)

3/8” (10 mm)

HOLE FOR

MAGNET

WHEEL

TIRE

Figure 3

Magnet Locations

NUT

WASHER

NUT

MAGNET

Figure 4

Magnet Assembly

Sensor

S

TEP

NSTALLING THE MAGNETIC SENSOR

3 - I

Secure the flat, pressed L bracket of the wheel speed sensor kit to a vertical

member near the non-driven wheel. Then secure the round, right angle steel

bracket to the flat bracket with the two U-bolts and necessary hardware provided.

Use the round, right angle bracket to secure the magnetic sensor mounting

clamp. (See Figure 5)

Insert the magnetic sensor into the mounting clamp and

position it to within 1/8 to 3/8 inch of the wheel magnet.

Tighten the sensor clamp using the clamp screw per

Figure 5A.

Figure 5

Sensor Mounting

98-05047 5

R0

Figure 5A

Sensor Assembly

Sensor

Clamp

Screw

Flat

L Bracket

Bracket

Page 6

Your installation will likely vary from the example. It may be necessary to

customize the installation to accommodate your specific machine. Keep in

mind that the two magnets must be spaced an equal distance around the

wheel. The magnetic sensor must be mounted in-line with the magnets and

positioned within 1/8 inch to 3/8 inch from each magnet as they pass the

sensor assembly.

S

TEP

4 - C

ONFIRMING SPEED SENSOR INSTALLATION

Magnetic Wheel Sensor

After the wheel or proximity sensor is installed and the 844-R console is mounted

and powered up test the speed sensor installation. Connect the wheel speed or

proximity sensor to the sensor cable and in turn connect the sensor cable to the

844-R console. When the connections are made, rotate the wheel on which the

magnets are installed. If using a proximity sensor, you will be sensing metal

objects and not magnets. Each time a magnet (metal object for proximity sensor)

passes the sensor a red LED (orange LED for proximity sensor) on the back of

the sensor will light. The LCD display on the console will also indicate a speed as

the sensor receives and sends electronic pulses.

Radar

If a radar speed sensor is used, connect it to the speed sensor connector on the

sensor end cable. An adapter cable will be necessary when using most radars

and are available through your TeeJet 844-R dealer. The 844-R will automatically

sense if the speed sensor is a wheel speed, proximity type, or radar type sensor

during calibration. The 844-R is automatically adapted to most brands of radar

speed sensors, provided that the appropriate adapter cable is used. If using a

radar sensor, the 844-R will display rAd during the calibration procedure.

6 98-05047

R0

Page 7

Powering Console On/Off

OWER ON

P

To power the 844-R on press the

P

RO

Initially the console displays the

software version in the top

display.

After 5 seconds the display shows

the normal operating view.

OWER OFF

P

To manually power the console

off, press the and

simultaneously.

The console saves any new

information (area and volume

counters) to memory and powers

off.

key once.

P

RO

keys

SFt

1.04

OFF

Ha

The console also has an Auto Power Down feature. When the master

switch is “off”, and no buttons are pressed for approximately

10 minutes, the 844-R will automatically power down.

Note: Both “Delivery” and “Agitation” switches still power either pump

even if console is “off”.

98-05047 7

R0

Page 8

Operating Instructions

PPLICATOR CHECKOUT

A

Before spraying, check all connections related to the Control System. Be sure

connections are made and the sensors and cabling are properly secured.

Very Important: Whenever working around chemicals, be sure to wear

protective clothing and eyewear.

Partially fill the applicator tank with water to purge the system of air and to make

a visual check of the liquid outlets to be sure liquid is exiting each outlet as

intended.

Follow these steps, in sequence, being sure the Delivery Switch is in the “OFF”

position:

Be sure the tank shut-off valve is open.

Switch the computer on by pressing the

Press the Auto/Man key so that the red LED light indicates “MAN”

mode.

Now, toggle the Delivery switch to “ON”.

Adjust the pressure with the + and keys. The pressure should

increase when you press the + key and decrease when you press the

key.

At this point, the applicator is activated and each micro-tube or orifice can be

checked.

Now press the Auto/Man key so that the red LED light indicates “Auto”

mode. The control console should regulate to the target application rate

for the simulated speed indicated. See “Simulated Ground Speed” in the

System Setup section of this manual for instructions on using simulated

speed.

To stop applying, toggle the Delivery switch to “OFF”.

The above steps provide a quick way to check out your applicator and control

system.

P

RO

key.

8 98-05047

R0

Page 9

HE SPRAYING OPERATION

T

The sprayer tank is filled and the solution thoroughly mixed. The application rate

and proper nozzles have been determined. The controller has been

programmed with the sprayer and application information.

P

Turn the control console on by pressing the

RO

key.

The Auto/Man key should be switched to “AUTO”.

In the Auto mode, when the Delivery switch is “OFF”, the target application

rate as well as the target symbol is displayed on the console display.

When the Master boom switch is “ON”, the actual rate is displayed and the

target symbol no longer appears.

While spraying with the Delivery switch “ON”, the display always displays

the actual application rate, vehicle speed, application area covered/total

volume applied and calculated pressure. Note: If the application system is

equipped with pressure gauge, the pressure gauge may read differently

than the calculated pressure shown on the console. This does not

necessarily indicate a problem.

As you get to the point where application will begin, turn the Delivery

switch to the “ON” position. This activates the delivery pump. Moderate

changes in vehicle speed don’t affect your application rate, because such

changes are compensated for with automatic pressure adjustments by the

controller.

If it is necessary to stop, turn the Delivery switch to “OFF”.

Alarm warnings may occur momentarily while the pressure regulating valve is

searching for a new setting after a significant speed or rate change. However, if

the alarm stays on for a longer time, the valve may have reached its limit and

your system is unable to regulate flow beyond the limit.

98-05047 9

R0

Page 10

Features

REA/VOLUME DISPLAY

A

The 844-R Sprayer Control counts application area and measures the total

volume applied while the master boom switch is in the “ON” position.

The area counter measures treated acres and is dependent on the values

programmed for the # of outlets and the tip spacing.

The volume measure is dependent on the signal from the flow meter.

The lower right of the display window shows:

Volume Sprayed and Area

Covered (alternating every 3

seconds).

To clear the area counter/volume

measure:

Be sure the Delivery switch is in

the “OFF” position

Press and hold the + or

keys for 3 seconds.

Note: The area/volume measure can only be cleared with Delivery switch

turned “OFF”.

15

PSI

0.0

MPH

2.0

56.25

GPA

Ac

PPLICATION ALARM

A

If the 844-R senses a continuous

discrepancy of 10% or more between

the Target Application Rate and the

Actual Application Rate:

The application rate units flash.

This alerts the operator to a

problem with the applicator,

plumbing, operation or

programming.

10 98-05047

30

PSI

7.0

MPH

2.5

530

GPA

R0

Vol

Page 11

NO F

If the 844-R stops receiving pulses from the flow meter

This alarm indicates that there is a

problem with the flow meter or cabling.

F

The 844-R Sprayer Control measures a flow rate moving through the flow meter

in GPM {Imp GPM}. This feature is activated by pressing and holding the key

while spraying in the normal operating mode. The flow rate display replaces the

area/volume display in the lower right portion of the display.

LOW ALARM

The turbine symbol flashes at the

top of the display.

This alarm occurs only when the

Master boom switch is “ON”.

LOW RATE FEATURE

0

PSI

4.8

0.0

MPH

32.50

GPA

Ac

Any time the key is pressed while

spraying in the normal mode the flow

rate is displayed. Releasing the key

causes the display to return to

area/volume.

This feature can be used for tip

calibration or for calibrating the flow

meter. Refer to page 19 of this manual

for the flow meter calibration

procedures.

15

PSI

0.0

2.0

MPH

8.7

GPA

98-05047 11

R0

Page 12

OOST MODE

B

The 844-R is capable of boosting the target application rate either up or down in

10% increments.

Boost Up

To activate the boost up mode:

Press the + key.

Each subsequent pressing of the

+

key boosts the target rate up

10%.

The amount boosted up is shown

on the display temporarily (approx.

2 seconds).

The target symbol flashes anytime that you are in the boost mode to alert

the operator of the “off target” condition.

To return to the target application rate:

The operator can use the key to get back in 10% increments

The operator can push the + and keys simultaneously to get back to

the target in one step.

Boost Down

To activate the boost down mode:

Press the key.

Each subsequent pressing of the

key boosts the target rate

down 10%.

The amount boosted down is

recorded on the display.

The target symbol flashes

anytime that you are in the boost

mode to alert the operator of the

“off target” condition

To return to the target application rate:

Up

20

D n

30

2.4

1.4

39.50

877

GPA

GPA

Vol

Ac

12 98-05047

R0

Page 13

The operator can either use the + key to get back in 10% increments

The operator can push the + and keys simultaneously to get back to

the target in one step.

UTO POWER DOWN

A

The 844-R console is designed to power

itself off after 10 minutes of no inputs.

This feature keeps the console from

draining the battery on the sprayer if the

operator inadvertently leaves the

console powered on for an extended

period. This only occurs when the

Master boom switch is turned OFF and

the console is not receiving inputs from

any of the sensors (the sprayer is

inactive).

To manually power the console off, refer to the Powering Console On/Off section

of this manual.

Note: When the console display power is “off”, the “Delivery” and

“Agitation” switches can still be operated.

Note: When in the user setup mode, the automatic power down feature is

disabled. However, after 10 minutes without keyboard activity, the console

automatically saves all program changes and exits the program mode. At

this time, the automatic power down feature begins counting and will shut

the console off after 10 minutes.

The programming of the 844-R is divided into two programming categories;

System Setup Mode and User Setup Mode.

The System Setup Mode contains the programming steps that customize

the controller to the applicator or it’s components. These include

calibration steps and parameters that, once programmed, rarely change.

The Application Preset Setup Mode contains target application rate and

orifice or micro tube capacity settings, which are more frequently changed.

OFF

98-05047 13

R0

Page 14

Programming Guidelines

Make sure that all hardware components are properly installed and tested.

Before the programming process starts, confirm that the console and all sensors

are working properly.

MPORTANT PRELIMINARY INFORMATION

I

Before starting, we recommend that you review the following Programming

Guidelines that control the programming process:

To enter the program mode, see the appropriate program section you wish

to enter in this manual. The delivery switch must be in the “off” position to

enter any program mode.

To exit any program mode press and hold the

changes are stored and the computer exits the program mode. This action

can be done at any time during the program process.

To increase the value of a programmable digit, press the + key. To

decrease the value, press the key. These keys are located directly to

the right of the display. For some programming steps, pressing and

holding the + or key changes the programmable value rapidly.

Pressing the + or key once changes the value by one increment.

P

Pressing the

last programming step, the console completes the program loop and

returns to the first programming step.

RO

key advances you to the next programming step. After the

P

RO

key for 3 seconds, your

Due to differences in fonts, some letters on the displays shown in

this manual are not identical with the corresponding letters on the

display of the controller.

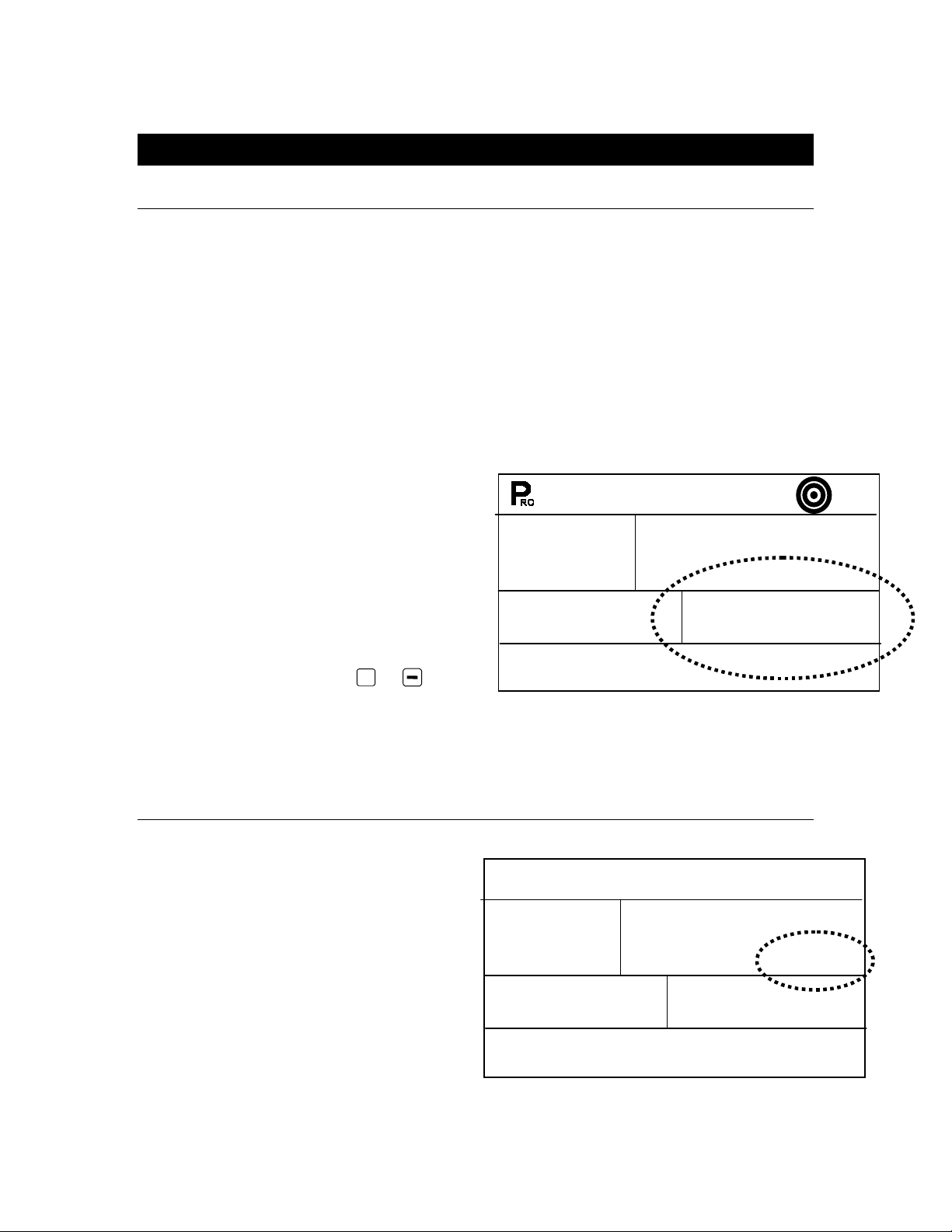

System Setup Mode – TeeJet 844-R Controller

The System Setup Mode contains the programming steps that customize the

controller to the applicator or its components. These include calibration steps and

parameters that, once programmed, rarely change.

To enter the Program Mode, starting from the normal operating mode, press and

P

hold the + and keys and tap the

programming step should appear on the display.

14 98-05047

RO

key twice. Release all keys. The first

R0

Page 15

ELECTION OF WORKING UNITS

S

In this step select the units you will be using.

The 844-R is capable of working in:

GPA (US Gallons Per Acre)

IMP (Imperial Gallons Per

Acre),

Use the + and keys to

select the appropriate units.

P

Press the

value and advance to the next

program step.

ESET TO DEFAULTS

R

RO

key to accept the

US

***********

If you did NOT make any changes to the units, this step is skipped and you are

automatically advanced to the Speed Sensor Calibration Step.

If a change is made to the units in the first programming step, before advancing

to the next step the console asks if you want to reset all the program parameters

to defaults specified for the units chosen.

Use the + or key to select

either yes or no.

P

Press the

or advance to the next step.

RO

key to begin resetting

THIS STEP MAY NOT APPEAR

rES

dEF

***********

YES

98-05047 15

R0

Page 16

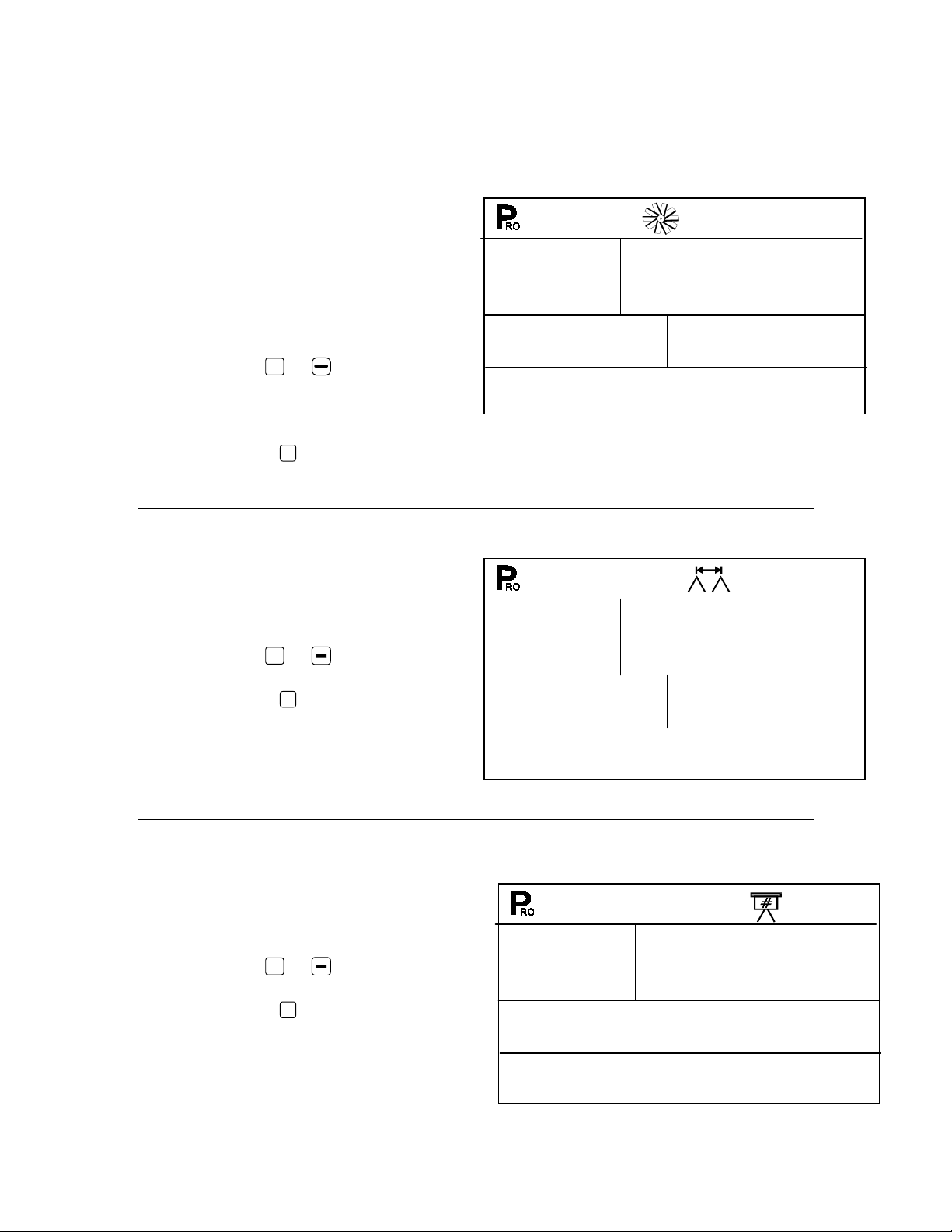

LOW METER PULSES

F

In this step the flow meter calibration

number can be entered manually from

the factory calibrated meter. Your

controller is preset to match the flow

meter installed on the Redball pump

unit. If changes are necessary:

Use the + or keys to modify

the value on the display to

match the tag on your flow

meter.

P

Press the

IP SPACING

T

Enter the spacing between the spray

nozzles or micro tubes in Inches

Use the + or keys to adjust

the value.

Press the

the next step

RO

key to advance to the next step.

P

RO

key to advance to

C a l

4000

30

# OF T

Enter the number of individual micro

tubes or orifices on the applicator.

16 98-05047

IPS

Use the + or keys to adjust

value.

P

Press the

next step

RO

key to advance to the

S e c

1

12

R0

Page 17

PEED SENSOR CALIBRATION

S

During Speed Calibration, the 844-R automatically senses if a Wheel Speed

or Radar Speed Sensor is being used.

Proximity/Magnetic Pulses

The speed sensor must be calibrated in

order to provide the proper speed and

area readings. The value for this step is

the number of pulses generated by the

speed sensor in 300 ft.

Automatic Calibration:

Mark off a distance of exactly 300

ft.

Press and hold the + and

keys simultaneously to activate

the auto calibration mode.

When the auto calibration mode is

been activated, “CAL” is displayed at

the lower right of the display.

Now start driving toward the start point of the of 300 ft. course.

As you cross the start point press

the + key once to begin the

calibration process.

Continue across the course as the

844-R counts the pulses created

by the speed sensor.

As the end point is crossed, press the + key once. The number displayed

is your speed calibration number.

If the console determines that a radar speed sensor is connected, “rAd”

will be displayed in the lower left quadrant of the display.

250

The speed at which you drive over

the course is not important.

cal

98-05047 17

R0

Page 18

It is best to repeat the automatic speed calibration process at least twice and

use the average of the speed calibration numbers.

To manually enter the radar calibration value, first press the Auto/Man key to

put the console into radar mode. When the control console is in the radar

mode, “RAD” is displayed in the lower left of the console display. Now use

the + or keys to adjust the value.

P

Once the correct value is been entered, press the

RO

key to validate this

value and advance to the next step.

If the auto calibration mode is been activated, no other functions are

possible until the console receives speed pulses for calibration. To

deactivate the auto calibration mode, press the + key until a number is

displayed.

18 98-05047

R0

Page 19

Flow Meter calibration

The flow meter supplied with your system has been calibrated at the factory and

under normal circumstances there may be no need to re-calibrate it. However,

the factory calibration setup may not reflect specific sprayer plumbing. Before

spraying actual chemicals, the flow meter should be checked for proper

calibration. To do so, use either of the following methods:

ETHOD

M

1 – K

NOWN VOLUME

Step 1 – Known Value

Select a known volume of water (n) to be pumped through the flow meter. In

these steps, 10 US gallons {8 Imperial gallons} will be used as an example. The

specific volume you use is not important, although larger volumes generally

produce more accurate results.

Step 2 – Programming Calibration Number

Go into the System Setup Mode and advance to the Flow Meter Calibration step

(flashing turbine at the top of the display). In this programming step, enter (n) 10

US gallons {8 Imperial gallons} as the calibration number. Exit the System Setup

mode by pressing and holding the key for five seconds.

Step 3 – Resetting Volume Counter

Reset the total volume number that is displayed in the lower right portion of the

display. (Display alternates between Ac covered and the volume sprayed through

the flow meter). To reset this number, press the and keys simultaneously

for three seconds or until you see the values reset to zero.

Step 4 – Spraying Known Volume

Engage the pump on the sprayer, flip the Master Boom Section of the 844-R to

“ON” (make sure at least one boom section switch is on), and pump exactly (n)

10 US gallons {83 Imperial gallons} through the flow meter. When the known

volume is reached, shut the Master Boom Switch “OFF”.

98-05047 19

R0

Page 20

Step 5 – Entering a New Flow Meter Calibration Number

The number displayed in the lower left hand corner of the display is the new flow

meter calibration number. Record this number, enter the System Setup Mode

and advance to the Flow Meter Calibration Number step. Enter the new value

from the test into this step and exit the System Setup Mode.

Step 6 – Double-checking the New Value

Double-check the new value by spraying a larger volume of water, such as 100

US gallons {83 Imperial gallons} through the flow meter. Before spraying the

larger volume, reset the memory counters by depressing and holding the and

keys simultaneously for three seconds.

NOTE: After double-checking the new calibration number, if the volume

shown is more than +/- 3% in error, change the flow meter calibration

number in the system Setup Mode by the % difference it is in error.

Example: If the volume displayed is 5% too high, then increase the flow

meter calibration number by 5%. Example: If the volume displayed is 5%

too low, then decrease the flow meter calibration number by 5%.

ETHOD

M

2 – K

NOWN TIP SIZE METHOD

Step 1 – Check Tip Size

Determine the size tip on the sprayer. An actual flow collection should be done

on a representative sample to ensure the tips are not worn. To do this, set the

boom at 40psi. This must be pressure at the tips (i.e. use manual pressure gauge

mounted on the boom). Collect flow for 1 minute from 1 tip.

Example: XR8004 tip should spray 0.4 gallons in 1 minute {0.32 Imp Gal}

Step 2 – Count Tips

Count the total number of tips to be used for measure. You can use 1 boom

section, 2 boom sections, etc.

Example: Boom Section 1 has 10 tips

20 98-05047

R0

Page 21

Step 3 – Calculated Flow

Multiply the number of tips to be measured by the size (or individual flow rate) of

each tip.

Example: 10 tips x 0.4 GPM {0.32 Imp GPM} = 4GPM {3.2 Imp GPM}

Step 4 – Measure

Turn the controller on to activate pump. Toggle on the Master Boom Switch and

the number of sections to be measured. Insure that the pressure at the boom is

maintained at 40PSI. While spraying, press and hold the key in. Look at the

lower right display to see if the measured flow matches the calculated flow.

Step 5 – Adjustments

If the measured flow is higher than the calculated flow, the flow meter calibration

number needs to be decreased.

If the measured flow is lower than the calculated flow, the flow meter calibration

number needs to be increased.

Example: Calculate flow is 4.00 GPM {3.20 Imp GPM};

measured flow is 3.6 GPM {2.88 Imp GPM}

4.0 GPM – 3.6 GPM = 0.4 GPM = 0.1 x 100 = 10%

3.2 Imp. GPM – 2.88 Imp GPM = 0.32 Imp GPM = 0.1 x 100 = 10%

Decrease the flow meter calibration number by 10%.

If original number was 650, enter 585 for this programming value.

0.4 GPM

4.00 GPM

0.32 Imp GPM

3.2 Imp GPM

98-05047 21

R0

Page 22

ISTANCE COUNTER

D

This step is a feature, not a calibration step. No specific value needs to be

entered here for the controller to operate correctly.

This feature measures distance in

feet.

It can be used to confirm

Automatic Speed Calibration (see

note below).

To activate the counter, press the

+

key.

To stop the counter, press the +

key again.

To clear an existing distance,

press and the + and keys

simultaneously.

Ft

4 5

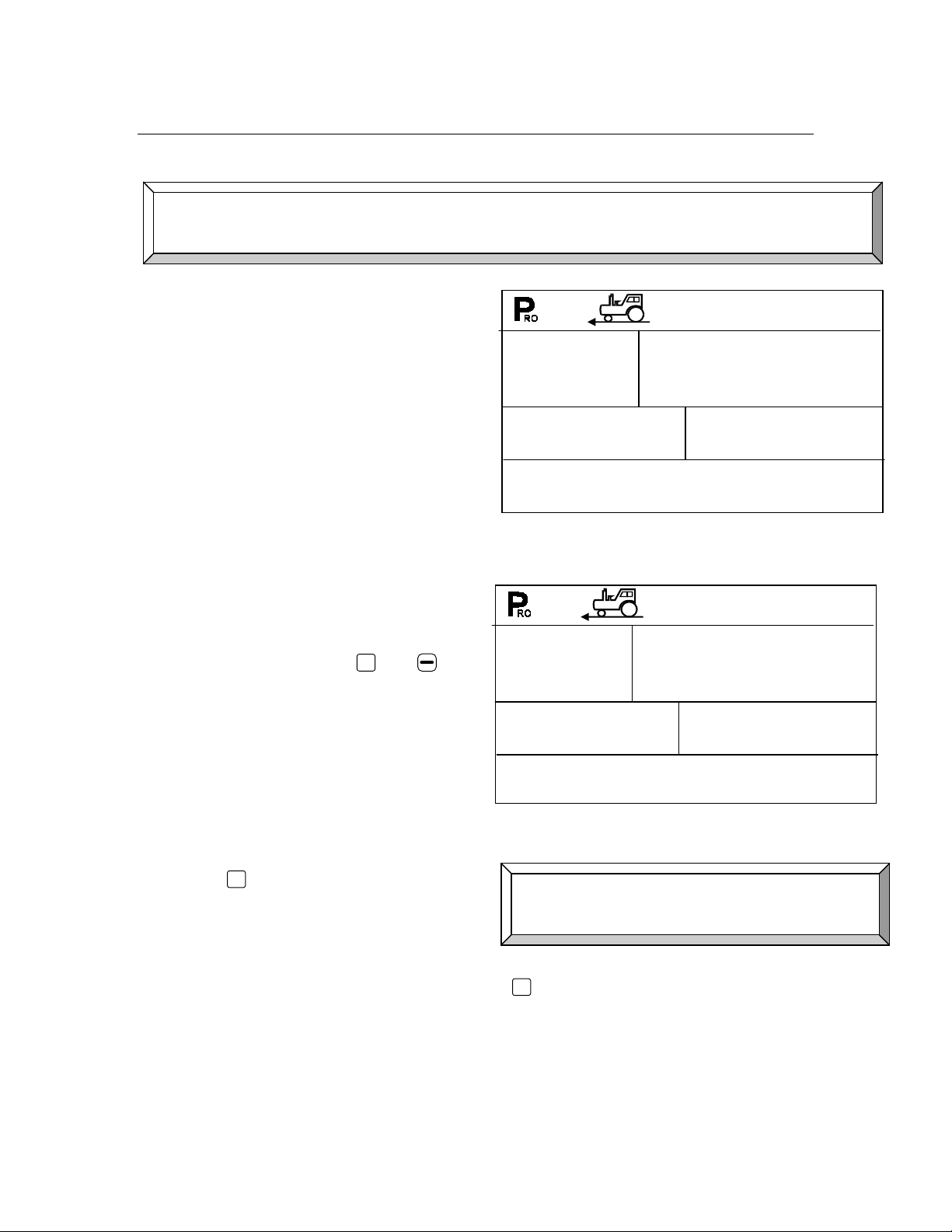

IMULATED GROUND SPEED

S

To confirm Automatic Speed Calibration, first complete the calibration

procedure. Advance to Distance Counter step. Drive across the same 300

feet course. Begin counting at the start point and end at the finish point.

Distance measured should be 300 feet (+/- 6 feet).

Simulated ground speed allows you to check out the functions and operations of

the console and of the pump unit, spraying water, without actually moving the

applicator. This can and should be done prior to any actual application activity.

Use the + and keys to adjust

the value.

P

Press the

High Simulated Speed step.

RO

key to advance to the

SIm

SP

0.0

22 98-05047

R0

Page 23

How To Use

To activate the simulated speed, set a value other than zero in the Simulated

Ground Speed step as indicated above. Upon exiting the programming mode,

the simulated ground speed is in effect, and appears in the speed area of the

display (lower left quadrant). The tractor symbol flashes when a simulated speed

is in effect.

Once the sprayer begins moving and the 844-R receives actual speed pulses, the

simulated speed feature is deactivated. If you are using a Radar Speed Sensor,

disconnect the Radar connection from the main console. Because of the

sensitivity of this speed sensor, any movement can disable simulated speed.

OMMUNICATIONS

C

This step lets you select what type of communication to use (if any).

The choices available are:

“no com” (no communications)

“log” (Downloading to a PC on the

go capability)

“gps” (Global Positioning System /

Variable Rate communication

capability)

”Prt” (printing),

Use the + and keys to select

the type of communication you are

using.

Press the

P

N o

RO

key to advance to the next step.

C o m

98-05047 23

R0

Page 24

INIMUM PRESSURE SETTING

M

Set the minimum pressure that the controller will be allowed to regulate to.

Sometimes when the applicator speed slows down, the control system will

regulate the pressure so low that it falls below the pressure required to open the

check valves on the individual nozzle bodies.

This is typically set to the minimum

recommended pressure nozzle body

check valves.

Use the + or keys to adjust

the minimum pressure.

P

Press the

the next step.

I.e. If this step is set to 15 psi the

console, in automatic mode, will not

regulate pressure below 15 psi.

RO

key to advance to

10

PSI

Min

PrS

Application Setup Mode

P

To access the Application Preset Setup Mode, press the

(Master switch must be OFF)

ARGET APPLICATION RATE

T

After entering the Application Setup Mode, the Target symbol should be flashing.

P

If it is not, press the

indicating that the target rate is ready to be changed.

Press the + key to increase the

target rate or key to decrease

the target rate.

Press the

value and advance to the next

step.

RO

key 3 or 4 times until the Target symbol is flashing,

P

RO

key to accept the

15

PSI

6.0

RO

key two times.

2.0

MPH

0.40

GPA

24 98-05047

R0

Page 25

LOW RATE SELECTION

F

Next, the tip icon in the top section of the display starts flashing. This value

represents the flow capacity of a single orifice or Micro Tube in Gallons Per

Minute (GPM) at 12 PSI. Using flow capacity information from the manufacturers

documentation, set this to the correct value.

Use the + or keys to change

the value.

P

Press the

next step

RO

key to advance to the

12

PSI

6.0

MPH

2.0

0.019

GPA

ALCULATION STEPS

C

The following two steps are calculation or informational steps only. They have no effect

on the application or operation of the console.

Known Speed Calculation

Adjust the speed value to the desired application speed. The pressure value

automatically adjusts to the approximate pressure required to apply the desired

application rate at the speed selected. This allows the opportunity to be sure the

application values are in the range expected prior to the actual application.

Use the + or keys to adjust

the indicated speed to a value

that you will be traveling at.

The console immediately

calculates what the pressure

should be to maintain the target

application rate at this speed.

If the pressure is too high,

substitute a larger set of orifices

or Micro-Tubes, or slow down.

If the pressure is too low, substitute a smaller set of orifices or Micro-

Tubes, or speed up.

PSI

12

6.0

MPH

2.0

0.019

GPA

98-05047 25

R0

Page 26

P

Pressing the

RO

key again will take you back to the pressure calculation step.

Known Pressure Calculation

Adjust the pressure value to the desired operating pressure and the speed value will

automatically change to reflect the approximate speed required to achieve the

programmed target rate at the pressure selected. This gives an indication of the speed

range expected at the desired operating pressure range.

Use the + or keys to adjust this

value.

The console immediately determines

what the operating speed should be to

achieve the target application rate at this

pressure.

If the speed indicated is too high, a set

of smaller orifices or Micro-Tubes is

needed.

If the speed indicated is too low, a set of

larger orifices or Micro-Tubes is needed.

P

Press the

Continue to try different speed, pressure and tip combinations. Once the correct

setting is determined:

Exit the Application Preset Mode by pressing and holding the

seconds.

RO

key to advance to the speed calculation step.

12

PSI

6.0

MPH

2 0.0

0.019

P

RO

key for 2

GPA

Daily Flow Meter Maintenance

√ Remove flow meter from the system

√ Use a soft bristle brush to scrub the tube clean

√ Use clean water to wash any impurities out of the flow meter

√ Reinstall flow meter

26 98-05047

R0

Page 27

Troubleshooting Guide

CONDITION POSSIBLE CAUSES SOLUTION

1.

Application Rate Units (GPA)

continually flash on/off.

2.

Application Rate Units continually

flash on/off.

3.

Flow meter turbine signal

continually flashes on/off.

4.

Actual total volume applied, in GPA,

does not match the total area

covered

Continued on next page

A.

Continuous discrepancy of 10% or

more between Target Application

Rate and Actual Application Rate.

PROGRAMMING

B.

Flow meter pulses

C.

Nozzle Setup

D.

Number of spray tips

A.

Continuous discrepancy of 10% or

more between Target Application

Rate and Actual Application Rate

b.

Plugged Tubes

C.

Wrong capacity tubes

D.

Flow meter plumbed incorrectly

A.

No flow meter pulses

A.

Speed sensor not calibrated

correctly

B.

Incorrect nozzle spacing

MECHANICAL

Check all components and

programming steps related to flow.

In the System Setup Mode, move to

the Flow Meter Pulses section on

page 16. Enter the factory calibrated

flow meter pulse rate located on the

tag accompanying the flow meter.

In the Application Setup Mode, move

to the Flow Rate Selection section on

page 25. Enter the flow rate in GPM at

12 psi of the tips.

If the tips have been used and

possibly worn, measure the flow in

Gallons Per Minute at 12 psi and enter

that value in the step above.

In the System Setup Mode, move to

the # of Tips step on page 16. You

must enter the correct number of

spray tips or micro tubes.

Check all components and

programming steps related to flow.

In the event of plugged tubes, remove

and clean with water and compressed

air.

All tubes should be of the same

capacity (Flow Rate).

A flow directional arrow is located on

the body of the flow meter. Plumb the

arrow in the direction of the flow.

The flow meter must be mounted 10’

to 12’ from other pipe fittings.

Generally, the flow meter works better

when mounted in a vertical position

with the flow being directed up.

Check to ensure that the delivery

pump has been engaged while trying

to spray.

Check cabling for any loose

connections.

Recalibrate the magnetic or radar

speed pulses in the Speed Sensor

Calibration section on page 17.

Check the Tip Spacing section in the

System Setup Mode on page 16 to

ensure the correct nozzle spacing has

been entered. This number should

reflect the distance between nozzles,

in inches.

98-05047 27

R0

Page 28

Troubleshooting Guide

C.

5.

No regulation in Auto mode

Flow meter pulses incorrect

D.

Speed sensor installed incorrectly

E.

Radar incorrectly installed

A.

No speed sensing

B.

Regulating valve malfunction

(Cont.)

In the System Setup Mode, move to

the Flow Meter Pulses section on

page 16. Enter the factory flow meter

pulse rate located on the tag

accompanying the flow meter.

One or more of the wheel sensor

magnets are not consistently sending

a pulse to the monitor.

The distance between the sensor and

the magnets is incorrect. Ground

debris can accidentally move the

sensor out of position. The red LED

on the back side of the sensor should

be lit when placed within the correct

distance from the magnets.

(See Installing the Speed Sensor on

page 4)

A proximity sensor has an orange

LED on the top of the sensor that

should be lit when placed within the

correct distance from the sensing

surface.

Precise installation of the radar is

critical to its working correctly.

Thoroughly review the manual

provided with the radar sensor you are

using.

Check speed sensor to ensure it is

sending pulses to the controller.

Check the Speed Sensor Calibration

section in the System Setup section

on page 17 to ensure speed sensor is

correctly calibrated.

Check wiring from controller to the

regulating valve. Make sure there is

voltage to the regulating valve.

Both wires leading to the regulating

valve are 12V (+). With the Master

Switch on, and the console set to

MAN mode when either the

key is pushed, the appropriate wire

goes to ground (-) to complete the

circuit.

or

28 98-05047

R0

Page 29

Quick Reference Guide

YSTEM SETUP MODE

S

• The Delivery switch must be off. Press

P

pressing the

Step Display Description My Values

RO

key. Press the

+

or keys

P

RO

key again to enter the System Setup Mode.

while simultaneously

Select US or Imperial gallons for your

Units

Flow Meter

Pulses

Nozzle Spacing

Tips per boom

section

Speed

Calibration

Distance

Counter

Simulated Speed

Communications

Minimum

Pressure

US, INP

SEC

1

Ft

No con

Min prs

application units by using

Proceed to next step with

Flow Meter Pulses;

Value from flow meter label. Adjust by

using

Proceed to next step with

Nozzle (or row) spacing;

Distance between spray nozzles or micro

tubes in inches.

Proceed to next step with

# of tips or micro tubes on the machine.

Adjust with

Proceed to next step with

Speed Calibration. Change with + and -, or

to auto calibrate press + and simultaneously to clear value, then drive

300 feet and press

Not a calibration step, but allows you to

measure distance in feet. Press

start counting, press

counting.

Proceed to next step with

Enter the desired simulated ground speed

using

Proceed to next step with

Select the communications mode.

Proceed to next step with

Sets the minimum pressure to which the

controller will regulate. The controller will

not regulate below this pressure.

+

or keys.

+

or keys.

+

or keys.

• To exit the System Setup mode, press and hold

programming process.

+

or keys.

P

RO

key.

P

RO

key.

P

RO

key.

P

RO

key.

P

RO

.

+

key to

+

key again to stop

P

RO

key.

P

RO

key.

P

RO

key.

P

RO

for 3 seconds at any point in

98-05047 29

R0

Page 30

PPLICATION SETUP MODE

A

P

• The Master boom switch must be off. Press the

RO

key twice to enter the

Application Setup Mode.

Step

Target

Application

Rate

Calculation

Step

• To exit the Application Setup Mode, press and hold the

Display Description My Values

All operating

information

displayed

with Pressure

or Speed

values

flashing

Target application rate (GPA).

Use the + and - keys to adjust the value.

P

Go to next step with

Diagnostic tool only. Use the

adjust the flashing values (pressure or speed).

Changes to spraying parameters will be

calculated immediately. To change adjustable

value (flashing value) depress the

RO

button.

+

or keys to

P

RO

key.

P

RO

key for 3 seconds

at any point in the programming process.

EATURES

F

Following are useful features of the 844-R Sprayer Control and how to use them.

Features Description

Percentage increase or decrease in chemical application. Activated

Boost Mode

by depressing either

the + or keys

Each subsequent depression of the + key will increase the

while applying in Auto Mode by.

application rate by 10%. Each subsequent depression of the key

will decrease the application rate by 10%.

Application area (Ac) and total volume (Gal.) applied will be

Area/Volume

Display

alternately displayed at the lower left of the display. To clear these

values (both are cleared together) the master boom switch must be

“off”, then simultaneously depress the

+

or keys

and hold for three

seconds.

Instantaneous

Flow Rate

The instantaneous system flow rate can be measured and displayed.

P

While applying (Delivery switch in ‘on’ position), press the

RO

key

30 98-05047

R0

Page 31

NOTES

98-05047 31

R0

Page 32

Midwest Technologies Illinois, LLC

2864 Old Rochester Road

Springfield IL 62703 USA

217-753-8424

98-05047

R0

Loading...

Loading...